Page 1

Final Page size: A5 (148mm x 210mm)

DWD010

DWD014

DWD014S

Page 2

DeWALT

English (original instructions) 4

Copyright

B

Page 3

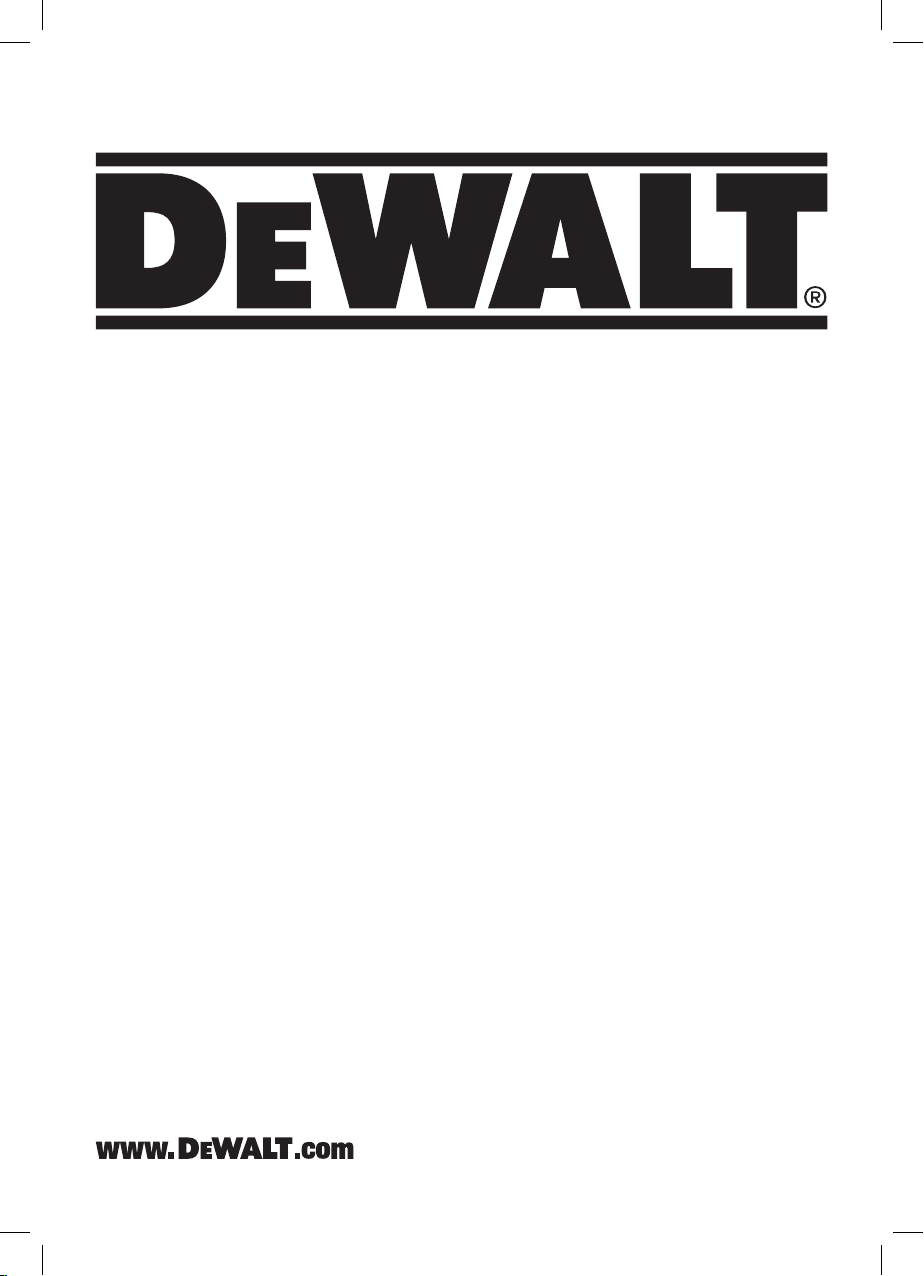

Figure 1

DWD010

C

DWD014

H

D

A

B

D

E

A

B

E

F

H

F

A

DWD014S, DWD014S-XE

DWD014, DWD014S

C

G

A

I

DWD014S-XE

C

A

1

Page 4

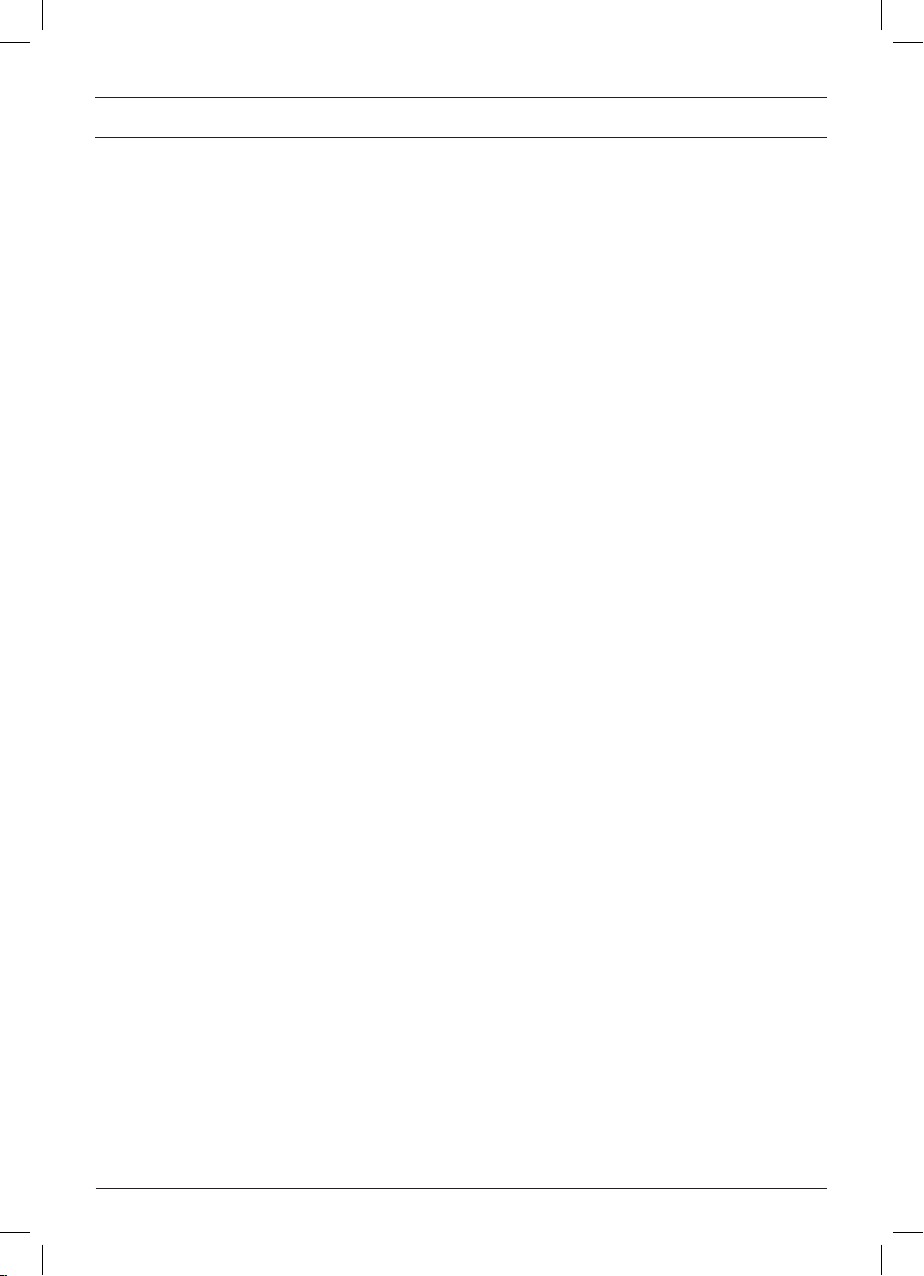

Figure 2 Figure 3

Figure 4

D

Figure 5 Figure 6

2

Page 5

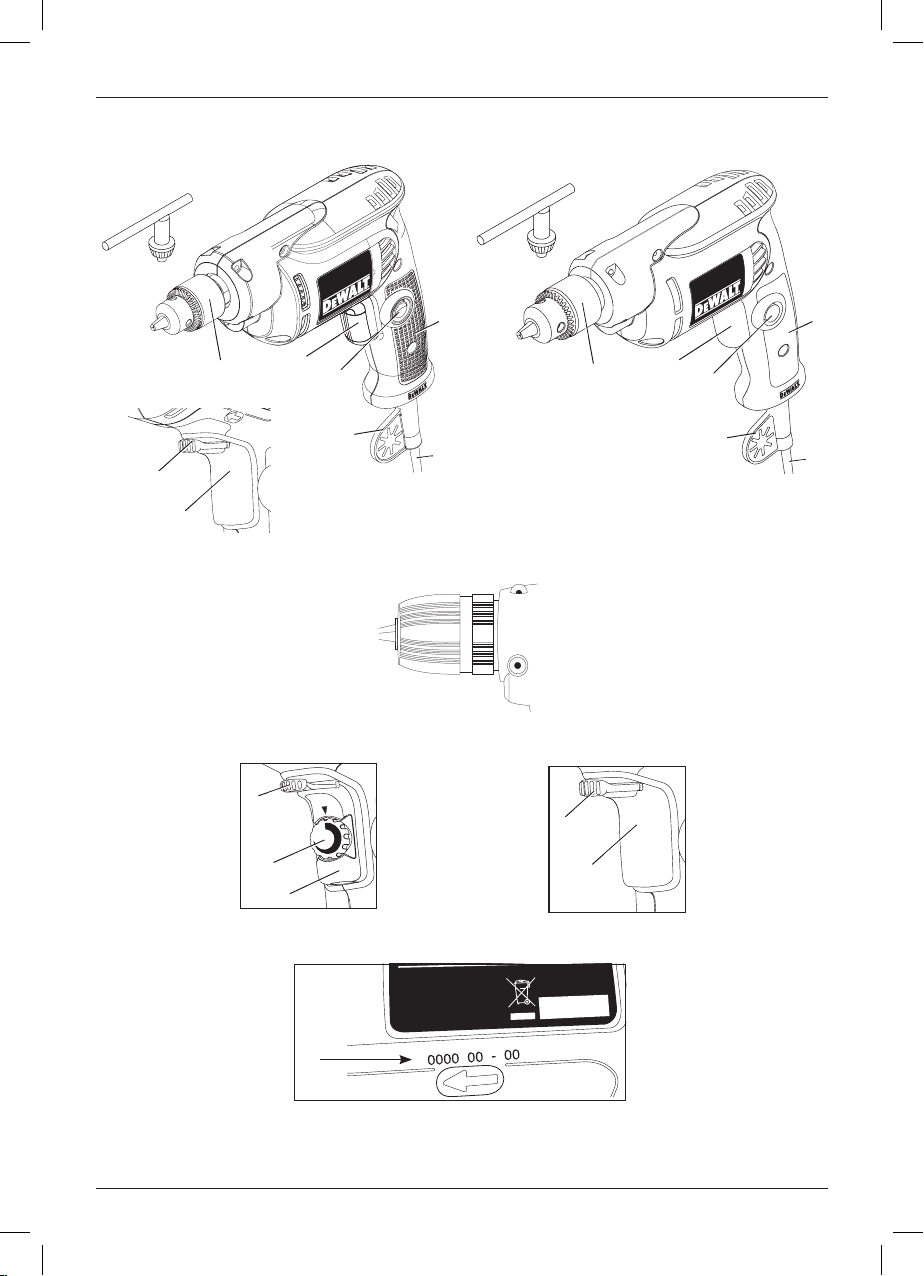

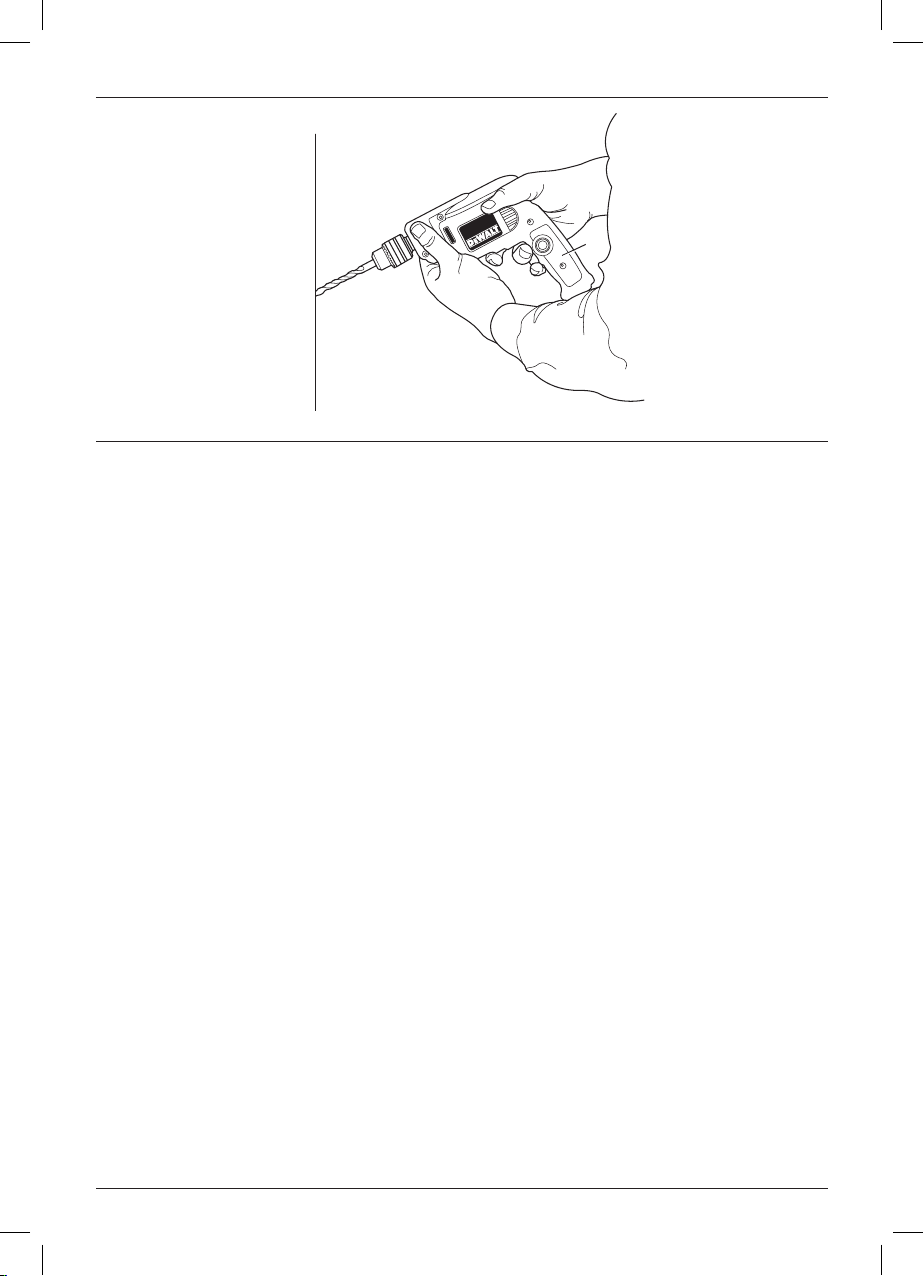

Figure 7

H

3

Page 6

English

DeWALT

VARIABLE SPEED REVERSIBLE DRILL

DWD010, DWD014, DWD014S, DWD014S-XE

Congratulations!

You have chosen a

DeWALT one of the most reliable partners for professional power tool users.

Technical Data

DWD010 DWD014 DWD014S DWD014S-XE

Voltage VAC 220–240 230 230 230

Type 1 1 1 1

Power input W 380 550 550 550

No load speed /min 0–3600 0–2800 0–2800 0–2800

Maximum drilling range: steel/wood mm 6.5/15 10/25 10/25 10/25

Torque Nm 3.9 7.9 7.9 7.9

Chuck spindle thread size UNF 3/8" x 24 1/2" x 20 1/2" x 20 1/2" x 20

Maximum chuck capacity mm 6.5 10 10 10

Weight kg 1.16 1.3 1.3 1.3

Noise values and vibration values (triax vector sum) according to EN60745-2-1:

LPA (emission sound pressure level) dB(A)

LWA (sound power level) dB(A)

K (uncertainty for the given sound level) dB(A)

tool. Years of experience, thorough product development and innovation make

81 82 82 82

92 92 92 92

3 2.9 2.9 2.9

Vibration emission value ah =

Uncertainty K = m/s²

The vibration emission level given in this information

sheet has been measured in accordance with a

standardised test given in EN60745 and may be

used to compare one tool with another. It may be

used for a preliminary assessment of exposure.

WARNING: The declared vibration

emission level represents the main

applications of the tool. However if the

tool is used for different applications,

with different accessories or poorly

maintained, the vibration emission

may differ. This may significantly

increase the exposure level over the

total working period.

An estimation of the level of exposure to

vibration should also take into account

the times when the tool is switched off

or when it is running but not actually

doing the job. This may significantly

reduce the exposure level over the total

working period.

4

m/s²

9.0 8.5 8.5 8.5

1.5 1.5 1.5 1.5

Identify additional safety measures to

Fuses:

Europe 230 V tools 10 Amperes, mains

U.K. & Ireland 230 V tools 13 Amperes, mains

protect the operator from the effects of

vibration such as: maintain the tool and

the accessories, keep the hands warm,

organisation of work patterns.

Definitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and

pay attention to these symbols.

DANGER: Indicates an imminently

WARNING: Indicates a potentially

hazardous situation which, if not avoided,

will result in death or serious injury.

hazardous situation which, if not

avoided, could result in death or

serious injury.

Page 7

English

DeWALT

DeWALT

DeWALT

DeWALT

CAUTION: Indicates a potentially

NOTICE: Indicates a practice not

Denotes risk of electric shock.

Denotes risk of fire.

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

related to personal injury which, if

not avoided, may result in property

damage.

EC-Declaration of Conformity

MACHINERY DIRECTIVE

VARIABLE SPEED REVERSIBLE DRILL

DWD010, DWD014, DWD014S, DWD014S-XE

declares that these products described

under Technical Data are in compliance with:

2006/42/EC, EN60745-1:2009+A11:2010,

EN60745-2-1:2010.

These products also comply with Directive

2004/108/EC (until 19.04.2016), 2014/30/EU (from

20.04.2016) and 2011/65/EU. For more information,

please contact

refer to the back of the manual.

The undersigned is responsible for compilation of the

technical file and makes this declaration on behalf of

Markus Rompel

Director Engineering

D-65510, Idstein, Germany

24.10.2016

WARNING: To reduce the risk of injury,

.

, Richard-Klinger-Straße 11,

read the instruction manual.

at the following address or

General Power Tool Safety Warnings

WARNING! Read all safety warnings

and all instructions. Failure to follow

the warnings and instructions may result

in electric shock, fire and/or serious

injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to

your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of

electric shock.

b) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators. There

is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the

risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric

shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

5

Page 8

English

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure

the switch is in the off position before

connecting to power source and/or

battery pack, picking up or carrying the

tool. Carrying power tools with your finger

on the switch or energising power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating

part of the power tool may result in personal

injury.

e) Do not overreach. Keep proper

footing and balance at all times. This

enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce

dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

b) Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the switch

is dangerous and must be repaired.

c) Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories, or

storing power tools. Such preventive safety

measures reduce the risk of starting the

power tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tool’s operation.

If damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and

tool bits etc., in accordance with these

instructions taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a

qualified repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

Additional Specific Safety Rules

for Drills

• Wear ear protectors. Exposure to noise can

cause hearing loss.

• Hold power tool by insulated gripping

surfaces only when performing an

operation where the cutting accessory

may contact hidden wiring or its own

cord. Cutting accessory contacting a “live”

wire may make exposed metal parts of the

power tool “live” and shock the operator

• Use clamps or other practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand

or against your body is unstable and may

lead to loss of control.

• Wear safety goggles or other eye

protection. Drilling operations cause chips to

fly. Flying particles can cause permanent eye

damage.

• Bits and tools get hot during operation.

Wear gloves when touching them.

• Keep handles dry, clean, free from oil and

grease. it is recommended to use rubber

gloves. This will enable better control of the

tool.

• Use auxiliary handle(S), if supplied with

the tool. Loss of control can cause personal

injury.

WARNING: We recommend the use of

a residual current device with a residual

current rating of 30mA or less.

6

Page 9

English

DeWALT

Residual Risks

The following risks are inherent to the use of drills:

– Injuries caused by touching the rotating parts or

hot parts of the tool.

In spite of the application of the relevant safety

regulations and the implementation of safety

devices, certain residual risks cannot be avoided.

These are:

– Impairment of hearing.

– Risk of squeezing fingers when changing

accessories.

– Health hazards caused by breathing dust

developed when working in wood.

– Risk of personal injury due to flying particles.

– Risk of personal injury due to prolonged use.

Markings on Tool

The following pictograms are shown on the tool:

Read instruction manual

before use.

Wear ear protection.

Wear eye protection.

DATE CODE POSITION (FIG. 1)

The Date Code (I), which also includes the year of

manufacture, is printed into the housing.

Example:

2016 XX XX

Year of Manufacture

Package Contents

The package contains:

1 Drill

1 Chuck key (DWD010, DWD014)

1 Instruction manual

• Check for damage to the tool, parts or

accessories which may have occurred during

transport.

• Take the time to thoroughly read and

understand this manual prior to operation.

Description (fig. 1)

WARNING: Never modify the power

A. Variable speed trigger switch

B. Lock-on button

C. Forward/reverse lever

D. Chuck

E. Cord protector

F. Cord set

G. Speed dial (DWD014, DWD014S)

H. Main handle

I. Date code position

INTENDED USE

These heavy-duty V.S.R. drills are designed for

professional drilling.

DO NOT use under wet conditions or in presence of

flammable liquids or gases.

These heavy-duty drills are professional power tools.

DO NOT let children come into contact with the

tool. Supervision is required when inexperienced

operators use this tool.

• Young children and the infirm. This appliance

• This product is not intended for use by persons

tool or any part of it. Damage or

personal injury could result.

is not intended for use by young children or

infirm persons without supervision.

(including children) suffering from diminished

physical, sensory or mental abilities; lack of

experience, knowledge or skills unless they are

supervised by a person responsible for their

safety. Children should never be left alone with

this product.

Electrical Safety

The electric motor has been designed for one

voltage only. Always check that the power supply

corresponds to the voltage on the rating plate.

Your DeWALT tool is double insulated in

accordance with EN60745; therefore no

earth wire is required.

If the supply cord is damaged, it must be replaced

by a specially prepared cord available through the

service organization.

Mains Plug Replacement

(U.K. & Ireland Only)

If a new mains plug needs to be fitted:

• Safely dispose of the old plug.

7

Page 10

English

• Connect the brown lead to the live terminal in

the plug.

• Connect the blue lead to the neutral terminal.

WARNING: No connection is to be

made to the earth terminal.

Follow the fitting instructions supplied with good

quality plugs. Recommended fuse: 13 A.

Using an Extension Cable

If an extension cable is required, use an approved

extension cable suitable for the power input of this

tool (see technical data).

The minimum conductor size is 1.5 mm2.

When using a cable reel, always unwind the cable

completely.

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of

injury, turn unit off and disconnect

machine from power source before

installing and removing accessories,

before adjusting or changing setups or when making repairs. Be sure

the trigger switch is in the OFF position.

An accidental start-up can cause injury.

Forward/Reverse Lever (fig. 1)

The forward/reverse lever (C) is used for withdrawing

bits from tight holes and removing screws. It is

located above the trigger switch.

To reverse the motor, release the trigger switch

FIRST and then push the lever to the right (viewed

when holding the drill in the operating position).

After any reversing operations, return lever to

forward position.

Keyed Chuck (fig. 1, 2, 3)

DWD010, DWD014

The DWD010 and the DWD014 feature a keyed

chuck (D).

TO INSERT A DRILL BIT OR OTHER ACCESSORY

1. Open the chuck jaws by turning collar by hand

and insert the shank of the bit about 19 mm

(3/4") into chuck. Tighten the chuck collar by

hand.

2. Place chuck key in each of the three holes, and

tighten in clockwise direction. It’s important to

tighten chuck with all three holes.

To release the bit, turn the chuck counterclockwise

in just one hole, then loosen the chuck by hand.

REMOVAL OF KEYED CHUCK (FIG. 2)

Tighten the chuck around the shorter end of a hex

key. Using a soft hammer, strike the key sharply in

the counterclockwise direction when viewed from

the front of the tool. This will loosen the chuck so

that it can be removed by hand.

KEYED CHUCK INSTALLATION (FIG. 3)

Screw the chuck on by hand as far as it will go.

Insert the shorter end of a hex key and strike it in the

clockwise direction with a soft hammer.

Keyless Chuck (fig. 1, 4–6)

DWD014S, DWD014S-XE

The DWD014S, DWD014S-XE features a keyless

chuck (D) for greater convenience.

TO INSERT A DRILL BIT OR OTHER ACCESSORY

1. Grasp the rear half of the chuck with one hand

and use your other hand to rotate the front half

counterclockwise, as shown in Figure 4. Rotate

far enough so that the chuck opens sufficiently

to accept the desired accessory.

2. Insert the bit or other accessory about 19 mm

(3/4") into the chuck and tighten securely by

holding the rear half of the chuck and rotating

the front portion in the clockwise direction.

When the chuck is nearly tightened, you

will hear a clicking sound. After 4–6 clicks,

the chuck is securely tightened around the

accessory.

3. To release the accessory, repeat step 1 listed

above.

WARNING: Do not attempt to tighten

drill bits (or any other accessory) by

gripping the front part of the chuck

and turning the tool on. Damage to the

chuck and personal injury may result.

KEYLESS CHUCK REMOVAL (FIG. 5)

Tighten the chuck around the shorter end of a hex

key (not supplied). Using a soft hammer or piece of

wood, strike the longer end in the counterclockwise

direction. This will loosen the chuck so that it can be

unscrewed by hand.

KEYLESS CHUCK INSTALLATION (FIG. 6)

Screw the chuck on by hand as far as it will go.

Tighten the chuck around the shorter end of a hex

key (not supplied) and strike the longer end in the

clockwise direction with a soft hammer.

8

Page 11

English

OPERATION

Instructions for Use

WARNING: Always observe the safety

instructions and applicable regulations.

WARNING: To reduce the risk of

injury, turn unit off and disconnect

machine from power source before

installing and removing accessories,

before adjusting or changing setups or when making repairs. Be sure

the trigger switch is in the OFF position.

An accidental start-up can cause injury.

Trigger Switch (fig. 1)

To start the drill, depress the trigger switch; to stop

the drill, release the trigger switch.

NOTE: Use lower speeds for starting holes without

a center punch, drilling in metal or plastics, driving

screws or drilling ceramics. Higher speeds are better

for drilling wood and composition boards and using

abrasive and polishing accessories.

VARIABLE SPEED

A variable speed trigger switch (A) permits speed

control—the farther the trigger is depressed, the

higher the speed of the drill.

For continuous operation, press and hold the

variable speed switch, move the lock-on button (B)

up, then release the switch.

To stop continuous operation, press the switch

briefly and release it. Always switch the tool off when

work is finished and before unplugging.

Speed Dial (fig. 1)

DWD014, DWD014S

To reduce the speed, turn the speed dial (G)

counterclockwise. To increase speed, turn the dial

clockwise.

Proper Hand Position (fig. 7)

WARNING: To reduce the risk of

serious personal injury, ALWAYS

use proper hand position as shown

in figure 7.

WARNING: To reduce the risk of

serious personal injury, ALWAYS hold

securely in anticipation of a sudden

reaction.

Proper hand position requires one hand under the

the housing, with the other hand on the main handle

(H).

Drilling

WARNING: To reduce the risk of

personal injury, ALWAYS ensure

workpiece is anchored or clamped

firmly. If drilling thin material, use a wood

“back-up” block to prevent damage to

the material.

1. Use sharp drill bits only. For WOOD, use the

low speed setting and twist drill bits, spade bits,

power auger bits, or hole saws. For METAL, use

the low speed setting and steel twist drill bits or

hole saws.

2. Always apply pressure in a straight line with the

bit. Use enough pressure to keep drill biting, but

do not push hard enough to stall the motor or

deflect the bit.

3. Hold tool firmly with both hands to control the

twisting action of the drill.

CAUTION: Drill may stall if overloaded

causing a sudden twist. Always expect

the stall. Grip the drill firmly to control

the twisting action and avoid injury.

4. IF DRILL STALLS, it is usually because

it is being overloaded or improperly used.

RELEASE TRIGGER IMMEDIATELY, remove

drill bit from work, and determine cause of

stalling. DO NOT CLICK TRIGGER ON

AND OFF IN AN ATTEMPT TO START A

STALLED DRILL — THIS CAN DAMAGE

THE DRILL.

5. To minimize stalling or breaking through the

material, reduce pressure on drill and ease the

bit through the last fractional part of the hole.

6. Keep the motor running when pulling the bit

back out of a drilled hole. This will help prevent

jamming.

7. With variable speed drills there is no need to

center punch the point to be drilled. Use a

slow speed to start the hole and accelerate by

squeezing the trigger harder when the hole is

deep enough to drill without the bit skipping

out.

DRILLING IN METAL

Start drilling with slow speed and increase to full

power while applying firm pressure on the tool.

A smooth even flow of metal chips indicates the

proper drilling rate. Use a cutting lubricant when

drilling metals. The exceptions are cast iron and

brass which should be drilled dry.

NOTE: Large [5/16" (8 mm) to 1/2" (13 mm)] holes

in steel can be made easier if a pilot hole [5/32"

(4 mm) to 3/16" (5 mm)] is drilled first.

9

Page 12

English

DeWALT

DeWALT

DRILLING IN WOOD

Start drilling with slow speed and increase to full

power while applying firm pressure on the tool.

Holes in wood can be made with the same twist

drills used for metal. These bits may overheat unless

pulled out frequently to clear chips from the flutes.

Work that is apt to splinter should be backed up

with a block of wood.

MAINTENANCE

Your DeWALT power tool has been designed to

operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation

depends upon proper tool care and regular cleaning.

WARNING: To reduce the risk of

injury, turn unit off and disconnect

machine from power source before

installing and removing accessories,

before adjusting or changing setups or when making repairs. Be sure

the trigger switch is in the OFF position.

An accidental start-up can cause injury.

Motor Brushes

automatically stops the drill when the brushes wear

out. This prevents serious damage to the motor.

New brush assemblies are available at authorized

replacement parts.

uses an advanced brush system which

service centers. Always use identical

Lubrication

Your power tool requires no additional lubrication.

WARNING: Never use solvents or

other harsh chemicals for cleaning the

non-metallic parts of the tool. These

chemicals may weaken the materials

used in these parts. Use a cloth

dampened only with water and mild

soap. Never let any liquid get inside the

tool; never immerse any part of the tool

into a liquid.

Optional Accessories

WARNING: Since accessories, other

than those offered by DeWALT, have

not been tested with this product, use

of such accessories with this tool could

be hazardous. To reduce the risk of

injury, only DeWALT, recommended

accessories should be used with this

product.

CAUTION: To reduce the risk of injury,

accessories should be used only in

sizes up to the maximums shown in the

Technical Data.

Consult your dealer for further information on the

appropriate accessories.

Protecting the Environment

Separate collection. Products and

batteries marked with this symbol

must not be disposed of with normal

household waste.

Products and batteries contain materials that can

be recovered or recycled reducing the demand for

raw materials. Please recycle electrical products

and batteries according to local provisions. Further

information is available at www.2helpU.com.

Cleaning

WARNING: Blow dirt and dust out of

10

the main housing with dry air as often as

dirt is seen collecting in and around the

air vents. Wear approved eye protection

and approved dust mask when

performing this procedure.

Page 13

111213

Page 14

Page 15

Page 16

Belgique et

Luxembourg België

en Luxemburg

DeWALT - Belgium BVBA

Egide Walschaertsstraat 16

2800 Mechelen

Tel: NL 32 15 47 37 63

Tel: FR 32 15 47 37 64

Fax: 32 15 47 37 99

www.dewalt.be

enduser.BE@SBDinc.com

Danmark DeWA LT

Roskildevej 22

2620 Albertslund

Tel: 70 20 15 10

Fax: 70 22 49 10

www.dewalt.dk

kundeservice.dk@sbdinc.com

Deutschland DeWA LT

Richard Klinger Str. 11

65510 Idstein

Tel: 06126-21-1

Fax: 06126-21-2770

www.dewalt.de

infodwge@sbdinc.com

Ελλάς DeWALT (Ελλάς) Α.Ε.

EΔΡΑ-ΓΡΑΦΕΙΑ : Στράβωνος 7

& Λ. Βουλιαγμένης, Γλυφάδα 166 74, Αθήνα

SERVICE : Ημερος Τόπος 2 (Χάνι Αδάμ) –

193 00 Ασπρόπυργος

Τηλ: 00302108981616

Φαξ: 00302108983570

www.dewalt.gr

Greece.Service@sbdinc.com

España DeWALT Ibérica, S.C.A.

Parc de Negocios “Mas Blau”

Edificio Muntadas, c/Bergadá, 1, Of. A6

08820 El Prat de Llobregat (Barcelona)

Tel: 934 797 400

Fax: 934 797 419

www.dewalt.es

respuesta.postventa@sbdinc.com

France DeWALT

5, allée des Hêtres

BP 30084, 69579 Limonest Cedex

Tel: 04 72 20 39 20

Fax: 04 72 20 39 00

www.dewalt.fr

scufr@sbdinc.com

Schweiz

Suisse

Svizzera

DeWA LT

In der Luberzen 42

8902 Urdorf

Tel: 044 - 755 60 70

Fax: 044 - 730 70 67

www.dewalt.ch

service@rofoag.ch

Ireland DeWALT

Calpe House Rock Hill

Black Rock, Co. Dublin

Tel: 00353-2781800

Fax: 00353-2781811

www.dewalt.ie

Italia DeWA LT

via Energypark

20871 Vimercate (MB), IT

Tel: 800-014353

39 039 9590200

Fax: 39 039 9590313

www.dewalt.it

Nederlands DeWALT Netherlands BV

Holtum Noordweg 35

6121 RE BORN, Postbus 83, 6120 AB BORN

Tel: 31 164 283 063

Fax: 31 164 283 200

www.dewalt.nl

Norge DeWALT

Postboks 4613, Nydalen

0405 Oslo

Tel: 45 25 13 00

Fax: 45 25 08 00

www.dewalt.no

kundeservice.no@sbdinc.com

Österreich DeWALT

Werkzeug Vertriebsges m.b.H

Oberlaaerstrasse 248, A-1230 Wien

Tel: 01 - 66116 - 0

Fax: 01 - 66116 - 614

www.dewalt.at

service.austria@sbdinc.com

Portugal DeWALT Limited, SARL

Centro de Escritórios de Sintra Avenida

Almirante Gago Coutinho, 132/134, Edifício 14

2710-418 Sintra

Tel: 214 66 75 00

Fax: 214 66 75 80

www.dewalt.pt

resposta.posvenda@sbdinc.com

Suomi DeWALT

PL 47

00521 Helsinki

Puh: 010 400 4333

Faksi: 0800 411 340

www.dewalt.fi

asiakaspalvelu.fi@sbdinc.com

Sverige DeWALT

Box 94

431 22 Mölndal

Tel: 031 68 61 60

Fax: 031 68 60 08

www.dewalt.se

kundservice.se@sbdinc.com

Türkiye

KALE Hırdavat ve Makina A.Ş.

Defterdar Mah. Savaklar Cad. No:15

Edirnekapı / Eyüp / İSTANBUL 34050

TÜRKİYE

Tel: 0212 533 52 55

Faks: 0212 533 10 05

www.dewalt.com.tr

United

Kingdom

DeWALT, 210 Bath Road;

Slough, Berks SL1 3YD

Tel: 01753-567055

Fax: 01753-572112

www.dewalt.co.uk

emeaservice@sbdinc.com

Australia DeWALT

82 Taryn Drive, Epping

VIC 3076 Australia

Tel: Aust 1800 338 002

Tel: NZ 0800 339 258

www.dewalt.com.au

www.dewalt.co.nz

Middle East Africa DeWALT

P.O. Box - 17164,

Jebel Ali Free Zone (South), Dubai, UAE

Tel: 971 4 812 7400

Fax: 971 4 2822765

www.dewalt.ae

Service.MEA@sbdinc.com

N500969 10/16

14

Loading...

Loading...