Page 1

NW

-71-

---F

oo

@

&

r.D_

,,,_z

C3W

(D I---

Z(D

O'.d

"___

Oz

0.-w_

o>cl

LUaO

C3'_ rr

©,< a_

_z m

O,_rr

rr_

O3 W

E

_ ._ .N_

m

DEWALT Industrial Tool Co., 701 Joppa Road, Baltimore, MD 21286

(JUN10) Part No. N073473 DWC860W Copyright © 2010 DEWALT

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme; the

"D" shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of

lozenge-shaped humps on the surface of the tool.

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

_&DANGER: Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

AWARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

ACAUTION: Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury which, ff not avoided, may

result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258).

_ WARNING: To reduce the risk of read the instruction manual.

General Power Tool Safety Warnings

_ ARNING! Read all safety warnings and instructions Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury,

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or

fumes.

• Keep bystanders, children, and visitors away while operating a power tool Distractions

can cause you to lose control.

ELECTRICAL SAFETY

• Double insulated tools are equipped with a polarized plug (one blade is wider than the

other.) This plug will fit in a polarized outlet only one way. If the plug does not fit fully

in the outlet, reverse the plug. If it still does not fit, contact a quafified electrician to

install a polarized outlet. Do not change the plug in any way. Double insulation []

eliminates the need for the three wire grounded power cord and grounded power supply

system.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

• Don't expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged

cords immediately. Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension cord marked "W-A"

or "W." These cords are rated for outdoor use and reduce the risk of electric shock. When

using an extension cord, be sure to use one heavy enough to carry the current your product

will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and

overheating. The following table shows the correct size to use depending on cord length

and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gage

number, the heavier the cord.

Minimum Gauge for Cord Sets

Ampere Rating

MoreThan

0

6

10

12

Not More Than

6

10

12

16

injury,

Volts Total Length of Cord in Feet

120V 25 (7.6) 50 (15.2) 100 (30.5)

240V 50 (15.2) 100 (30.5) 200 (61.0)

18

18

16

14

AWG

16

16

16

12

16 14

14 12

14 12

Not Recommended

(meters)

O

"_- u) 0

='9_E

150 (45.7)

300 (91.4)

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a power

tool Do not use tool while tired or under the influence of drugs, alcohol, or medication.

A moment of inattention while operating power tools may result in serious personal injury,

• Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts. Loose clothing, jewelry, or long hair can be

caught in moving parts. Air vents often cover moving parts and should also be avoided.

• Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with

your finger on the switch or plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that

is left attached to a rotating part of the tool may result in personal injury,

• Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss of

control

• Do not force tool Use the correct tool for your application. The correct tool will do the job

better and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled with

the switch is dangerous and must be repaired.

• Disconnect the plug from the power source before making any adjustments, changing

accessories, or storing the tool Such preventative safety measures reduce the risk of

starting the tool accidentally,

• Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools,

with sharp cutting edges are less likely to bind and are easier to control

• Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tool's operation, ff damaged, have the tool serviced before

using. Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your modeL

Accessories that may be suitable for one tool, may become hazardous when used on

another tool.

SERVICE

• Tool service must be performed only by qualified repair personneL Service or

maintenance performed by unqualified personnel could result in a risk of injury,

• When servicing a tool use only identical replacement parts. Follow instructions in

the Maintenance section of this manual Use of unauthorized parts or failure to follow

maintenance instructions may create a risk of electric shock or injury,

Additional Specific Safety Instructions for Masonry Saws

• DANGER! Keep hands away from cutting area and blade. Keep your second hand on

auxiliary handle or motor housing./f both hands are holding the saw, they cannot be cut

by the blade.

• Do not reach underneath the workpiece. The guard cannot protect you from the blade

below the workpiece

• Never hold piece being cut in your hands or across your leg. Secure the workpiece to

a stable platform. It is important to support the work properly to minimize body exposure,

blade binding, or loss of control.

• Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a "five" wire will also

make exposed metal parts of the power tool "live" and shock the operator.

• Always use blades with correct size and shape (diamond versus round) of arbor holes.

Blades that do not match the mounting hardware of the saw will run eccentrically, causing

loss of control.

• Never use damaged or incorrect blade washers or bolt. The blade washers and bolt were

specially designed for your saw, for optimum performance and safety of operation.

• Keep your body positioned to either side of the blade, but not in line with the saw

blade.

• Blades coast after turn off. Serious personal injury may result.

• Don't unplug if plug or receptacle is wet. Disconnect the fuse or circuit breaker that supplies

power to the tool. Then unplug and examine for presence of water in the receptacle.

• Wait for the saw to come to a complete stop. An unprotected, coasting blade will cause

the saw to walk backwards, cutting whatever is in its path. Be aware of the time it takes for the

blade to stop after switch is released.

• Do not use to cut wood or metal.

• Never use toothed blades. This tool is not equipped with a

lower guard.

A DANGER: Keep hands away from cutting area and blade.

Personal injury may result.

WARNING: Always plug extension cord into a GFCI protected outlet.

WARNING: To reduce the risk of electrocution, keep all connections

dry and off the ground. Do not touch plug with wet hands.

_)_WARNING: A Ground Fault Circuit Interrupter (GFCI) is provided on the cord set. Receptacles

are available having built in GFCI protection and may be used for an added measure of safety,

When using an extension cord, always plug into a GFCI protected receptacle or outlet.

WARNING: Test GFCI before each use:

1. Plug GFCI into power outlet. Indicator should turn red.

2. Press test button. Red indicator should disappear.

3. Press reset button for use. Do not use if above test fails.

WARNING: Never use saw with salt water or a conductive fluid.

_&WARNING: DO NOT use wet cutting when using bonded abrasive blades. Wheel rupture and

personal injury may result.

iiWARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known in the state of California to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed

areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the

skin may promote absorption of harmful chemicals.

iiWARNING: Use of this tool can generate and/or disburse dust, which may cause serious

and permanent respiratory or other injury, Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure. Direct particles away from face and body, Always

operate tool in well-ventilated area and provide for proper dust removal. Use dust collection

system wherever possible.

_ WARNING: ALWAYS wear proper personal hearing protection during use. Under some

conditions and duration of use, noise from this product may contribute to hearing loss.

WARNING: ALWAYS use eye protection. All users and bystanders must wear eye

protection that conforms to ANSI Z87.1.

• The label on your tool may include the following symbols. The symbols and their definitions

are as follows:

V................... volts

Hz................. hertz

min ............... minutes

--- ............ direct current

@ ................. Class I Construction

(grounded)

[] ................. Class II Construction

(double insulated)

BPM ............. beats per minute

RPM ............. revolutions per minute

A .................... amperes

W................... watts

'_ .................. alternating current

.................. alternating or direct current

no .................. no load speed

................... earthing terminal

_, .................. safety alert symbol

.../min ............ per minute

IPM ................ impacts per minute

Page 2

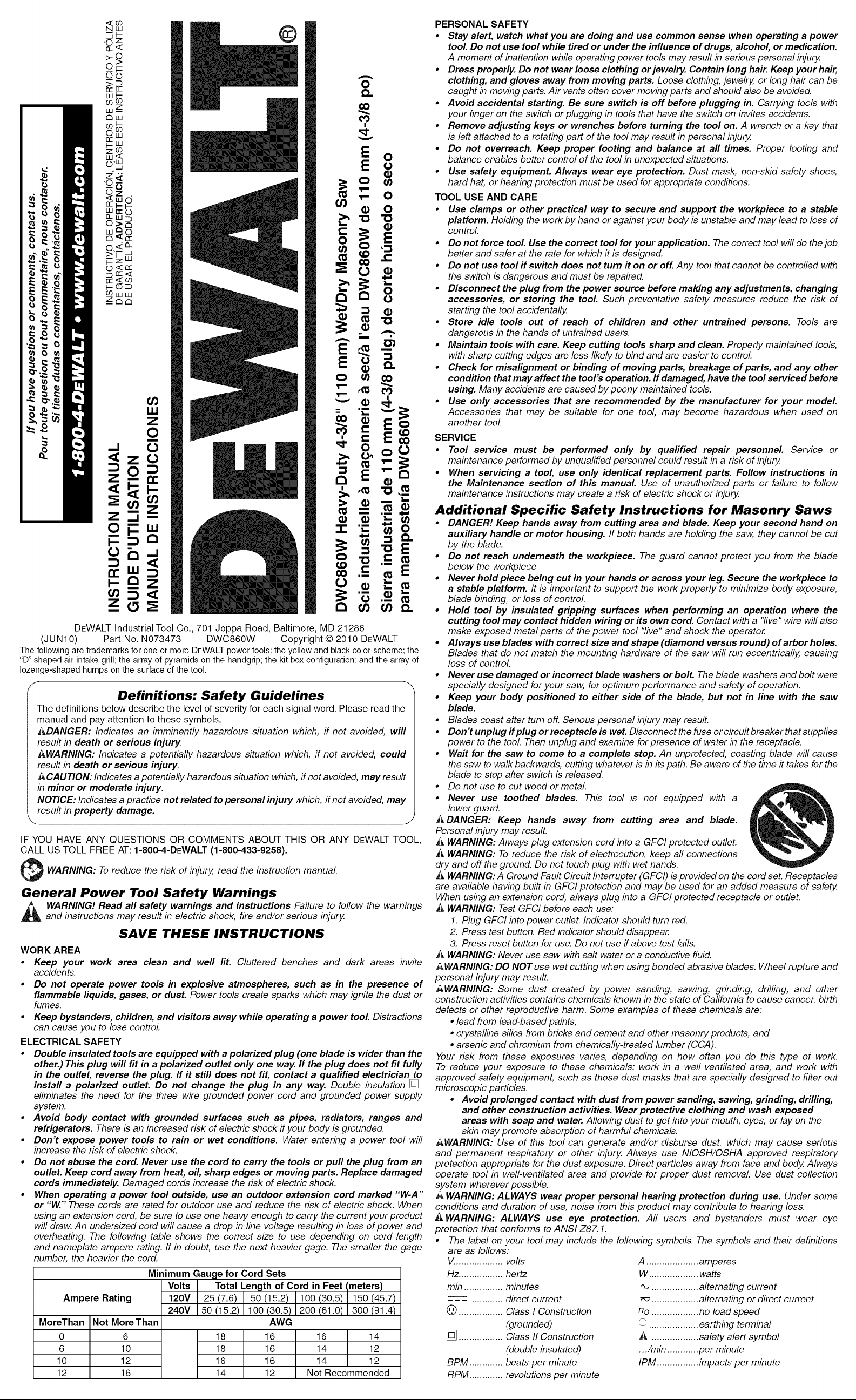

COMPONENTS (Fig. 1)

A. GFCI on cord set

B. On/Off Switch

C. Lock-On button

D. Diamond blade

E. External flange

R Clamping screw

G. Water tubing

H. Tool inlet

I. Water tubing adapter

J. Water pressure regulator (5 psi)

K. Screw

L. Water nozzle

M. Depth adjustment knob

N. Shoe

O. Water valve lever

P. Cutting guide

Q. Bevel adjustment knob

R. Brush covers

S. Brush assembly

T. Front handle

U. Main handle

V. flange wrench

W. T-handle wrench

ASSEMBLY

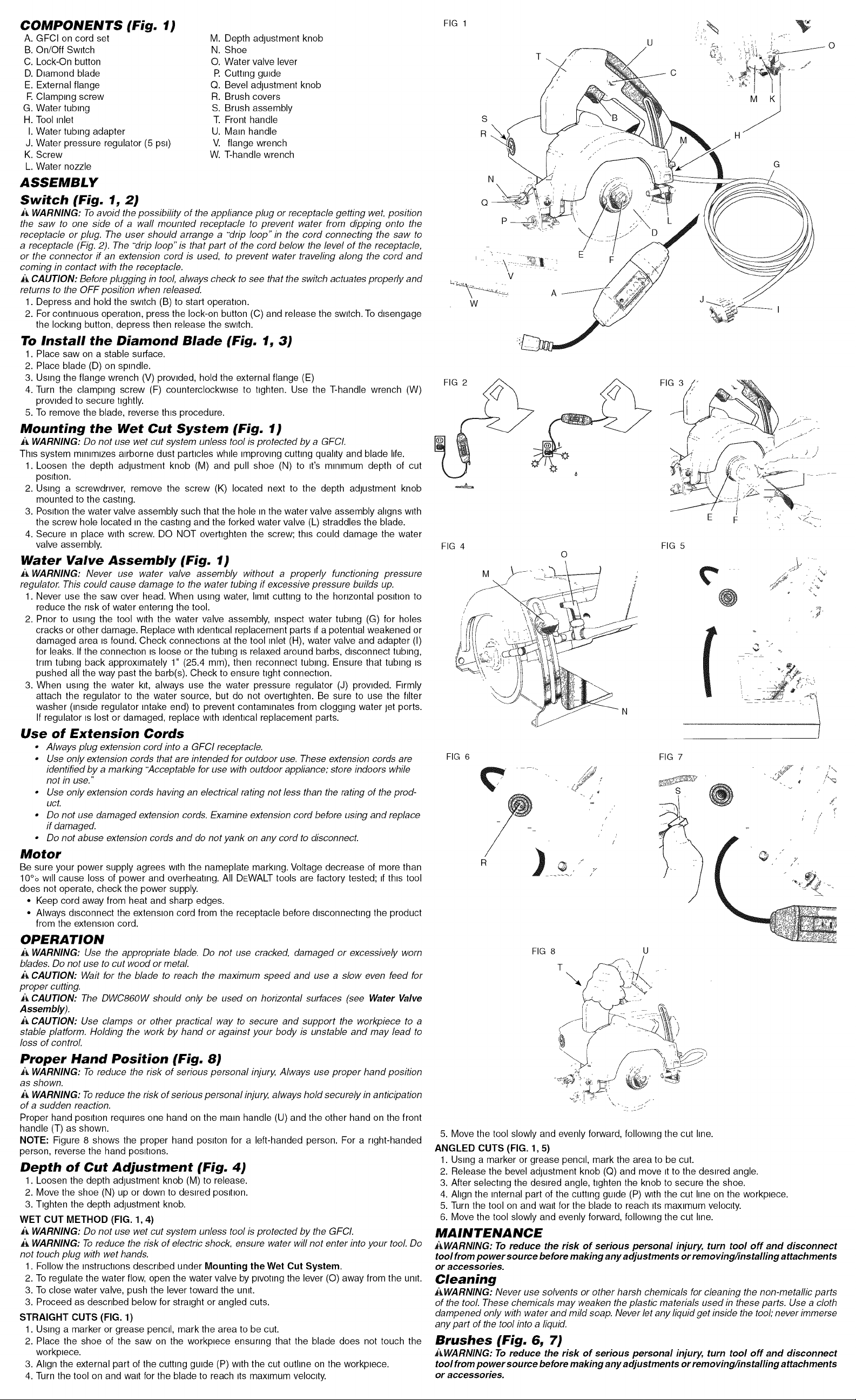

Switch (Fig. 1, 2)

i_,WARNING: Toavoid the possibility of the appliance plug or receptacle getting wet, position

the saw to one side of a wall mounted receptacle to prevent water from dipping onto the

receptacle or plug. The user should arrange a "'drip loop" in the cord connecting the saw to

a receptacle (Fig. 2). The "'drip loop" is that part of the cord below the level of the receptacle,

or the connector ff an extension cord is used, to prevent water traveling along the cord and

coming in contact with the receptacle.

,_ CAUTION: Before plugging in tool, always check to see that the switch actuates properly and

returns to the OFF position when released.

1. Depress and hold the switch (B) to start operation.

2. For continuous operation, press the lock-on button (C) and release the switch. To disengage

the locking button, depress then release the switch.

To Install the Diamond Blade (Fig. 1, 3)

1. Place saw on a stable surface.

2. Place blade (D) on spindle.

3. Using the flange wrench (V) provided, hold the external flange (E)

4. Turn the clamping screw (F) counterclockwise to tighten. Use the T-handle wrench (W)

provided to secure tightly.

5. To remove the blade, reverse this procedure•

Mounting the Wet Cut System (Fig. 1)

WARNING: Do not use wet cut system unless tool is protected by a GFCl.

This system minimizes airborne dust particles while improving cutting quality and blade life.

1. Loosen the depth adjustment knob (M) and pull shoe (N) to it's minimum depth of cut

pos_hon.

2. Using a screwdriver, remove the screw (K) located next to the depth adjustment knob

mounted to the casting.

3. Position the water valve assembly such that the hole inthe water valve assembly aligns with

the screw hole located in the casting and the forked water valve (L) straddles the blade.

4. Secure in place with screw. DO NOT overtlghten the screw; this could damage the water

valve assembly.

Water Valve Assembly (Fig. 1)

WARNING: Never use water valve assembly without a properly functioning pressure

regulator. This could cause damage to the water tubing ff excessive pressure builds up.

1. Never use the saw over head. When using water, limit cutting to the horizontal position to

reduce the risk of water entering the tool.

2. Prior to using the tool with the water valve assembly, inspect water tubing (G) for holes

cracks or other damage. Replace with identical replacement parts if a potential weakened or

damaged area is found. Check connections at the tool inlet (H), water valve and adapter (I)

for leaks. If the connection is loose or the tubing is relaxed around barbs, disconnect tubing,

trim tubing back approximately 1" (25.4 mm), then reconnect tubing. Ensure that tubing is

pushed all the way past the barb(s). Check to ensure tight connection.

3. When using the water kit, always use the water pressure regulator (J) provided. Firmly

attach the regulator to the water source, but do not overtlghten. Be sure to use the filter

washer (inside regulator intake end) to prevent contaminates from clogging water jet ports•

If regulator is lost or damaged, replace with identical replacement parts•

Use of Extension Cords

• Always plug extension cord into a GFCl receptacle.

• Use only extension cords that are intended for outdoor use. These extension cords are

identified by a marking "'Acceptable for use with outdoor appliance: store indoors while

not in use."

• Use only extension cords having an electrical rating not less than the rating of the prod-

uct.

• Do not use damaged extension cords. Examine extension cord before using and replace

ff damaged.

• Do not abuse extension cords and do not yank on any cord to disconnect.

Motor

Be sure your power supply agrees with the nameplate marking. Voltage decrease of more than

10°5 will cause loss of power and overheating. All DEWALT tools are factory tested; if this tool

does not operate, check the power supply•

• Keep cord away from heat and sharp edges•

• Always disconnect the extension cord from the receptacle before disconnecting the product

from the extension cord.

OPERATION

WARNING: Use the appropriate blade. Do not use cracked, damaged or excessively worn

blades. Do not use to cut wood or metal

,& CAUTION: Wait for the blade to reach the maximum speed and use a slow even feed for

proper cutting.

i_,CAUTION: The DWC860W should only be used on horizontal surfaces (see Water Valve

Assembly).

_ CAUTION: Use clamps or other practical way to secure and support the workpiece to a

stable platform. Holding the work by hand or against your body is unstable and may lead to

loss of control

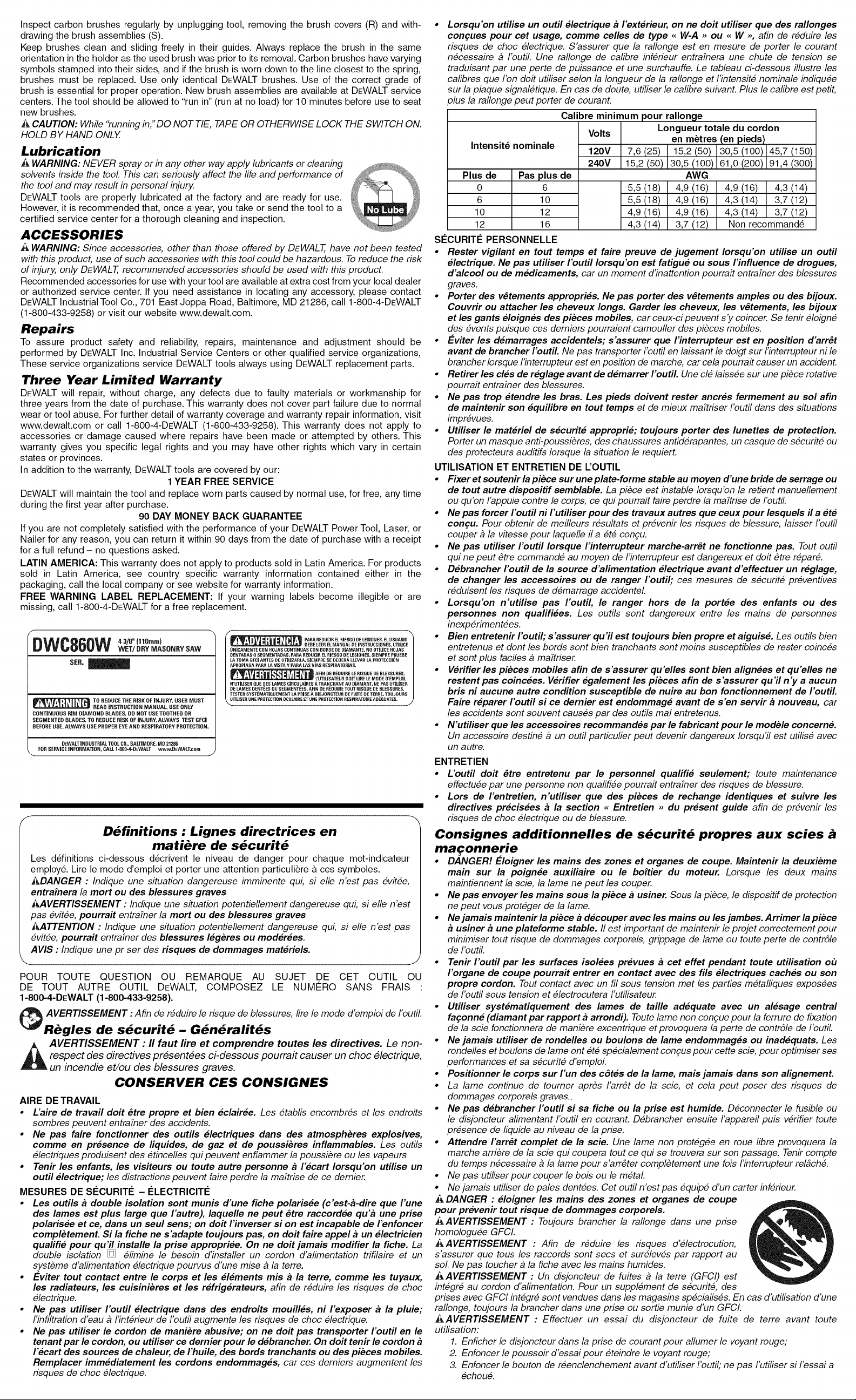

Proper Hand Position (Fig. 8)

i_ WARNING: To reduce the risk of serious personal injury, Always use proper hand position

as shown.

i_,WARNING: Toreduce the risk of serious personal injury, always hold securely in anticipation

of a sudden reaction.

Proper hand position requires one hand on the main handle (U) and the other hand on the front

handle (T) as shown.

NOTE: Figure 8 shows the proper hand poslton for a left-handed person. For a right-handed

person, reverse the hand positions.

Depth of Cut Adjustment (Fig. 4)

1. Loosen the depth adjustment knob (M) to release.

2. Move the shoe (N) up or down to desired position.

3. Tighten the depth adjustment knob.

WET CUT METHOD (FIG. 1,4)

_LWARNING: Do not use wet cut system unless tool is protected by the GFCI.

,& WARNING: To reduce the risk of electric shock, ensure water will not enter into your tooL Do

not touch plug with wet hands.

1. Follow the instructions described under Mounting the Wet Cut System.

2. To regulate the water flow, open the water valve by pivoting the lever (0) away from the unit.

3. To close water valve, push the lever toward the unit.

3. Proceed as described below for straight or angled cuts.

STRAIGHT CUTS (FIG. 1)

1. Using a marker or grease pencil, mark the area to be cut.

2. Place the shoe of the saw on the workplece ensuring that the blade does not touch the

workplece.

3. Align the external part of the cutting guide (P) with the cut outline on the workplece.

4. Turn the tool on and wait for the blade to reach its maximum velocity.

FIG 1

T

S

R

G

N

D

E

F

v

w

FIG 2

FIG 4

0

FIG 5

@

_, "'/

N

!

1

FIG 6

FIG 7

- ._7 #

@

/

R

FIG 8

T

\

5. Move the tool slowly and evenly forward, following the cut line.

ANGLED CUTS (FIG. 1, 5)

1. Using a marker or grease pencil, mark the area to be cut.

2. Release the bevel adjustment knob (Q) and move itto the desired angle•

3. After selecting the desired angle, tighten the knob to secure the shoe.

4. Align the internal part of the cutting guide (P) with the cut line on the workplece.

5. Turn the tool on and wait for the blade to reach its maximum velocity.

6. Move the tool slowly and evenly forward, following the cut line.

MAINTENANCE

_WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing attachments

or accessories.

Cleaning

Z_WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tooL These chemicals may weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse

any part of the tool into a liquid.

Brushes (Fig. 6, 7)

J_WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing attachments

or accessories.

0

,<Y"

Page 3

Inspect carbon brushes regularly by unplugging tool, removing the brush covers (R) and with-

drawing the brush assemblies (S).

Keep brushes clean and sliding freely in their guides. Always replace the brush in the same

orientation in the holder as the used brush was prior to its removal. Carbon brushes have varying

symbols stamped into their sides, and ifthe brush is worn down to the line closest to the spring,

brushes must be replaced. Use only identical DEWALT brushes. Use of the correct grade of

brush is essential for proper operation. New brush assemblies are available at DEWALT service

centers. The tool should be allowed to "run in" (run at no load) for 10 minutes before use to seat

new brushes.

CAUTION: While "running in," DO NOT TIE, TAPE OR OTHERWISE LOCK THE SWITCH ON.

HOLD BY HAND ONLY.

Lubrication

WARNING: NEVER spray or in any other way apply lubricants or cleaning

solvents inside the tool This can seriously affect the life and performance of

the tool and may result in personal injury.

DEWALT tools are properly lubricated at the factory and are ready for use.

However, it is recommended that, once a year, you take or send the tool to a

certified service center for a thorough cleaning and inspection.

ACCESSORIES

WARNING: Since accessories, other than those offered by DEWALT, have not been tested

with this product, use of such accessories with this tool could be hazardous. To reduce the risk

of injury, only DEWALT, recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at extra cost from your local dealer

or authorized service center. If you need assistance in locating any accessory, please contact

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-DEWALT

(1-800-433-9258) or visit our website www.dewalt.com.

Repairs

To assure product safety and reliability, repairs, maintenance and adjustment should be

performed by DEWALT Inc. Industrial Service Centers or other qualified service organizations,

These service organizations service DEWALT tools always using DEWALT replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for

three years from the date of purchase. This warranty does not cover part failure due to normal

wear or tool abuse. For further detail of warranty coverage and warranty repair information, visit

www.dewalt.com or call 1-800-4-DEWALT (1-800-433-9258). This warranty does not apply to

accessories or damage caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights which vary in certain

states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your DEWALT Power Tool, Laser, or

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt

for a full refund - no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products

sold in Latin America, see country specific warranty information contained either in the

packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-4-DEWALT for a free replacement.

f

DWC86OW''""'°°°'

SER. _

CONTINUOUS RiM DIAMOND BLADES. DO NOT USE TOOTHED OR

SEGMENTED BLADES. TO REDUCE RiSK OF iNJURY, ALWAYS TEST GFCJ

BEFORE USE. ALWAYS USE PROPER EYE AND RESPIRATORY PROTECTION.

DEWALTiNDUSTRiALTOOL CO., OALTiMORE, MD 21286

FORSERVICE iNFORMATiON, CALL1-800..,4-DEWALT www.DEWALT.com

%. J

WET/DRY MASONRY SAW

TU REDUCE THE RISK OF iNJURY, USER MUST

READ iNSTRUCTiON MANUAL. USE ONW

f__'_ PARA flEDUCIR EL RIESGO OE LESiONES, EL USPARIO /

0NMAMENTE CON NOJAS CONTiNUAS CON BORDE DE DJAMANTE. NO UTJLJCE HOJAS

RENTABAS 0 SEGMENTAOAS. PARA REDUCJR EL MESOO DE LEMONES, MEMPRE PROERE

LA TOMA GFCJ ANTES DE UTJLJZARLA, SJEMPRE SEDEBER._ LLEVAR LA PROTECCi(}N

APROPJAOA PARA LA VISTA Y PAPA LAS ViAS RESPIRATORIAS.

_J_r_=__ _ UTlU SATEO RDOlT URE LE MODE B'EMPLOL

N'UTJUSER ODE OES LAMES CJRCOLAMES A TRANURANT AN RJAMANT. NE PAS NTJLMER/

OE LAMES OENT_ES OO SEGMENTEES. AFJN DE REOUME TOOT MSQUE DE BLESSURES,

TESTER SYSTEMATJQUEMENT LA PRISE A DJSJONCTEOR DE FUiTE DE TEflRE. TOUJOURS

_ .UTILISER ONE PROTECTION OCULAJRE ET UNE PROTECTION RESPIRATOiflE AOEOUATES.

DERE LEER EL MANUAL DE JNSTRUCCIONES. UTiUCE I

ARM DE REBUIRE LE RISQUE BE BLESSURES,

/

J

Ddfinitions : Lignes directrices en

matidre de sdcuritd

Les dOfinitions ci-dessous dOcrivent le niveau de danger pour chaque mot-indicateur

employ& Lire le mode d'emploi et porter une attention particuli_re & ces symboles.

_,DANGER : Indique une situation dangereuse imminente qui, si elle n'est pas evitOe,

entrainera la mort ou des blessures graves

AAVERTISSEMENT : Indique une s#uation potentiellement dangereuse qui, si elle n'est

pas evitOe, pourra# entrafner la mort ou des blessures graves

i_4TTENTION : Indique une situation potentiellement dangereuse qui, si elle n'est pas

evitOe, pourrait entrafner des blessures legeres ou moderees.

AVIS : Indique une pr ser des risques de dommages materiels.

J

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET OUTIL OU

DE TOUT AUTRE OUTIL DEWALT, COMPOSEZ LE NUMg:RO SANS FRAIS :

1-800-4-DEWALT (1-800-433-9258).

(_ AVERTISSEMENT : Afin de reduire le risque de blessures, lire le mode d'emploi de I'outil.

R_gles de s_curit_ - G_n_ralit_s

_ AVERTISSEMENT : II faut lire et comprendre toutes les directives. Le non-

respect des directives pr#sent#es ci-dessous pourrait causer un choc #lectrique,

un incendie et/ou des blessures graves.

CONSERVER CES CONSIGNES

AIRE DE TRAVAIL

• L'aire de travail doff 6tre propre et bien eclairee. Les etablis encombres et les endroits

sombres peuvent entrMner des accidents.

• Ne pas faire fonctionner des outils electriques clans des atmospheres explosives,

comme en presence de liquides, de gaz et de poussieres inflammables. Les outils

electriques produisent des etincelles qui peuvent enflammer la poussiere ou les vapeurs

• Tenir les enfants, les visiteurs ou toute autre personne a I'ecart Iorsqu'on utilise un

outil electrique; les distractions peuvent faire perdre la maftrise de ce dernier.

MESURES DE SI_CURITI_ - I_LECTRICITI_

• Les outils a double isolation sont munis d'une fiche polarisee (c'est-a-dire que I'une

des lames est plus large que I'autre), laqueile ne peut 6tre raccordee qu'a une prise

polarisee et ce, clans un seul sens; on dolt I'inverser si on est incapable de I'enfoncer

completement. Si la fiche ne s'adapte toujours pas, on dolt faire appel a un electricien

qualifie pour qu'il instaile la prise appropriee. On ne dolt jamais modifier la fiche. La

double isolation [] elimine le besoin d'installer un cordon d'alimentation trifilaire et un

systeme d'alimentation electrique pourvus d'une mise a la terre.

• _:viter tout contact entre le corps et les elements mis a la terre, comme les tuyaux,

les radiateurs, les cuisinieres et les refrigerateurs, afin de reduire les risques de choc

electrique.

• Ne pas utiliser I'outil electrique clans des endroits mouilles, ni I'exposer a la pluie;

I'infiltration d'eau a I'interieur de I'outil augmente les risques de choc electrique.

• Ne pas utiliser le cordon de maniere abusive; on ne dolt pas transporter I'outil en le

tenant par le cordon, ou utiliser ce dernier pour le debrancher. On doit tenir le cordon

I'ecart des sources de chaleur, de I'huile, des bords tranchants ou des pieces mobiles.

Remplacer immediatement les cordons endommages, car ces derniers augmentent les

risques de choc electrique.

Lorsqu'on utilise un outil electrique a I'exterieur, on ne doff utiliser que des rallonges

con_ues pour cet usage, comme celles de type ,, W-A _,ou ,, W _,, afin de reduire /es

risques de choc electrique. S'assurer que la rallonge est en mesure de porter le courant

necessaire a Ibutil. Une rallonge de calibre inferieur entrafnera une chute de tension se

traduisant par une perte de puissance et une surchauffe. Le tableau ci-dessous illustre les

calibres que I'on doff utiliser selon la Iongueur de la rallonge et I'intensite nominale indiquee

sur la plaque signaletique. En cas de doute, utiliser le calibre suivant. Plus le calibre est petit,

olus la rallonge peut porter de courant.

Calibre minimum pour rallonge

Volts Longueur totale du cordon

Intensit6 nominale

Plus de

0

6

10

12

Pas plus de

10

12

16

120V 7,6 (25)

240V 15,2 (50)

6

5,5(18)

5,5(18)

4,9 (16)

4,3 (14)

en m_tres (en pieds)

15,2 (50)

30,5 (100)

30,5 (100) 45,7 (150)

61,0 (200) 91,4 (300)

AWG

4,9 (16)

4,9 (16)

4,9 (16)

3,7 (12)

4,9 (16) 4,3 (14)

4,3 (14) 3,7 (12)

4,3 (14) 3,7 (12)

Non recommand6

SECURITI_ PERSONNELLE

Rester vigilant en tout temps et faire preuve de jugement Iorsqu'on utilise un outil

electrique. Ne pas utiliser I'outil Iorsqu'on est fatigue ou sous I'influence de drogues,

d'alcool ou de medicaments, car un moment d'inattention pourrait entrMner des blessures

graves.

• Porter des vOtements appropries. Ne pas porter des vOtements amples ou des bijoux.

Couvrir ou attacher les cheveux longs. Carder les cheveux, les vOtements, les bijoux

et les Rants eloignes des pieces mobiles, car ceux-ci peuvent s'y coincer. Se tenir eloigne

des events puisque ces derniers pourraient camoufler des pieces mobiles.

• _:viter les demarrages accidentels; s'assurer que I'interrupteur est en position d'arrOt

avant de brancher I'outil. Ne pas transporter I'outil en laissant le doigt sur I'interrupteur nile

brancher Iorsque I'interrupteur est en position de marche, car cela pourrait causer un accident.

• Retirer les cles de reglage avant de demarrer I'outil. Une cle laissee sur une piece rotative

pourrait entrafner des blessures.

• Ne pas trop etendre les bras. Les pieds doivent rester ancres fermement au sol afin

de maintenir son equilibre en tout temps et de mieux maftriser I'outil dans des situations

imprevues.

• Utiliser le materiel de securite approprie; toujours porter des lunettes de protection.

Porter un masque anti-poussieres, des chaussures antiderapantes, un casque de securite ou

des protecteurs auditifs Iorsque la situation le requiert.

UTILISATION ET ENTRETIEN DE L'OUTIL

• Fixer et soutenir la piece sur une plate-forme stable au moyen d'une bride de serrage ou

de tout autre dispositif semblable. La piece est instable Iorsqu'on la retient manuellement

ou qu'on I'appuie contre le corps, ce qui pourrait faire perdre la maftrise de I'outil.

• Ne pas forcer I'outil ni I'utiliser pour des travaux autres que ceux pour lesquels il a ete

con_u. Pour obtenir de meilleurs resultats et prevenir les risques de blessure, laisser I'outil

couper a la vitesse pour laquelle il a ete con_u.

• Ne pas utiliser I'outil Iorsque I'interrupteur marche-arrOt ne fonctionne pas. Tout outil

qui ne peut 6tre commande au moyen de I'interrupteur est dangereux et doit 6tre repare.

• Debrancher I'outil de la source d'alimentation electrique avant d'effectuer un reglage,

de changer les accessoires ou de ranger I'outil; ces mesures de securite preventives

reduisent les risques de demarrage accidenteL

• Lorsqu'on n'utilise pas I'outil, le ranger hors de la portee des enfants ou des

personnes non qualifiees. Les outils sont dangereux entre les mains de personnes

inexperimentees.

• Bien entretenir I'outil; s'assurer qu'il est toujours bien propre et aiguise. Les outils bien

entretenus et dont les bords sont bien tranchants sont moins susceptibles de rester coinces

et sont plus faciles a maftriser.

• Wrifier les pieces mobiles afin de s'assurer qu'elles sont bien alignees et qu'eiles ne

restent pas coincees. Wrifier egalement les pieces afin de s'assurer qu'il n'y a aucun

bris ni aucune autre condition susceptible de nuire au bun fonctionnement de I'outil.

Faire reparer I'outil si ce dernier est endommage avant de s'en servir a nouveau, car

les accidents sont souvent causes par des outils mal entretenus.

• N'utiliser que les accessoires recommandes par le fabricant pour le modele concerne.

Un accessoire destine a un outil particulier peut devenir dangereux Iorsqu'il est utilise avec

un autre.

ENTRETIEN

• L'outil dolt 6tre entretenu par le personnel qualifie seulement; toute maintenance

effectuee par une personne non qualifiee pourrait entrafner des risques de blessure.

• Lors de I'entretien, n'utiliser que des pieces de rechange identiques et suivre les

directives precisees a la section ,, Entretien _, du present guide afin de prevenir les

risques de choc electrique ou de blessure.

Consignes additionnelles de s_curit_ propres aux scies

mar:onnerie

• DANGER! Eloigner les mains des zones et organes de coupe. Maintenir la deuxieme

main sur la poignee auxiliaire ou le boitier du moteur. Lorsque /es deux mains

maintiennent la scie, la lame ne peut les couper.

• Ne pas envoyer les mains sous la piece a usiner. Sous la piece, le dispositif de protection

ne peut vous proteger de la lame.

• Ne jamais maintenir la piece a decouper avec les mains ou les jambes. Arrimer la piece

usiner a une plateforme stable. II est important de maintenir le projet correctement pour

minimiser tout risque de dommages corporels, grippage de lame ou toute perte de contr&le

de I'outil.

• Tenir I'outil par les surfaces isolees prevues a cet effet pendant toute utilisation ob

I'organe de coupe pourrait entrer en contact avec des ills electriques caches ou son

propre cordon. Tout contact avec un fil sous tension met les parties metalliques exposees

de I'outil sous tension et electrocutera I'utilisateur.

• Utiliser systematiquement des lames de taille adequate avec un alesage central

fa_onne (diamant par rapport a arrondi). Toute lame non con_ue pour la ferrure de fixation

de la scie fonctionnera de maniere excentrique et provoquera la perte de contrOle de I'outil.

• Ne jamais utiliser de rondeiles ou boulons de lame endommages ou inadequats. Les

rondelles et boulons de lame ont ete specialement con_us pour cette scie, pour optimiser ses

performances et sa securite d'emploL

• Positionner le corps sur I'un des cotes de la lame, mais jamais clans son alignement.

• La lame continue de tourner apres I'arrOt de la scie, et cela peut poser des risques de

dommages corporels graves..

• Ne pas debrancher I'outil si sa fiche ou la prise est humide. Deconnecter le fusible ou

le disjoncteur alimentant I'outil en courant. Debrancher ensuite I'appareil puis verifier toute

presence de liquide au niveau de la prise.

• Attendre I'arrOt complet de la scie. Une lame non protegee en roue libre provoquera la

marche arriere de la scie qui coupera tout ce qui se trouvera sur son passage. Tenir compte

du temps necessaire a la lame pour s'arrOter completement une fois I'interrupteur rel&che.

• Ne pas utiliser pour couper le bois ou le metal

• Nejamais utiliser de pales dentees. Cet outil n'estpas equipe d'un carter inferieur.

DANGER : eloigner les mains des zones et organes de coupe

pour prevenir tout risque de dommages corporels.

J_,AVERTISSEMENT : Toujours brancher la rallonge dans une prise

homologuee GFCI.

AAVERTISSEMENT : Afin de reduire les risques d'electrocution,

s'assurer que tousles raccords sont secs et sureleves par rapport au

sol Ne pas toucher a la fiche avec les mains humides.

J_AVERTISSEMENT : Un disjoncteur de fuites a la terre (GFCI) est

integre au cordon d'alimentation. Pour un supplement de securite, des

prises avec GFCI integre sont vendues dans les magasins specialises. En cas d'utilisation d'une

rallonge, toujours la brancher clans une prise ou sortie munie d'un GFCI.

_AVERTISSEMENT : Effectuer un essai du disjoncteur de fuite de terre avant toute

utilisation:

1. Enficher le disjoncteur dans la prise de courant pour allumer le voyant rouge;

2. Enfoncer le poussoir d'essai pour eteindre le voyant rouge;

3. Enfoncer le bouton de reenclenchement avant d'utiliser I'outil; ne pas I'utiliser si I'essai a

echoue.

Page 4

J_AVERTISSEMENT : Alejamais utiliser la scie avec de I'eau salee ou un fluide conducteur.

_AVERTISSEMENT : NE PAS effectuer de decoupes a I'eau avec des lames abrasives

composites pour prevenir tout risque de brisure et de dommages corporels.

i_,AVERTISSEMENT : Certaines poussieres creees par le pon_age, le sciage, le meulage et

le forage mecaniques ainsi que d'autres activites de construction contiennent des produits

chimiques reconnus pour causer le cancer, des anomalies congenitales ou d'autres anomalies

liees a la reproduction. Parmi ces produits chimiques, citons notamment :

• le plomb provenant des peintures au plomb ;

• la silice cristalline provenant des briques, du beton et d'autres materiaux de

ma_onnerie ;

• I'arsenic et le chrome provenant du bois traite (arseniate de cuivre et de chrome).

Le risque associe aces expositions varie selon la frequence de ces types de travaux. Pour

reduire I'exposition aux produits chimiques : travailler dans un local bien ventile et utiliser du

materiel de securite approuve, comme les masques antipoussieres specialement congus pour

filtrer les particules microscopiques.

• Eviter le contact prolonge avec la poussiere provenant du pon_age, du sciage,

du meulage et du forage mecanique ainsi que d'autres activites de construction.

Porter des v_tements de protection et laver les parties exposees au savon et

I'eau. La poussiere qui pourrait penetrer clans la bouche et les yeux ou se deposer sur

la peau peut favoriser I'absorption de produits chimiques nocifs.

Z&AVERTISSEMENT : Cet outil peut produire et repandre de la poussiere susceptible de

causer des dommages serieux et permanents au systeme respiratoire. Toujours utiliser un

appareil respiratoire anti-poussieres approuve par le NIOSH ou I'OSHA. Diriger les particules

dans le sens oppose du visage et du corps.

AAVERTISSEMENT : porter SYSTEMATIQUEMENT une protection auditive appropriee

durant I'utilisation. Sous certaines conditions et suivant la duree d'utilisation, le bruit emanant

de ce produit pourrait contribuer a une perte de I'acuite auditive.

_AVERTISSEMENT : porter SYSTEMATIOUEMENT une protection oculaire. Tout utilisateur

ou individu present doit porter une protection oculaire homologuee ANSI Z87.1.

• L'etiquette apposee sur votre outil peut comprendre les symboles suivants. Les symboles et

leurs definitions sont indiques ci-apres :

V............. volts

Hz........... hertz

min ......... minutes

- -- ......courant continu

@ ........... Construction de classe I (mis

[] ........... Construction de classe II

(a double isolation)

BPM .......coups par minute

.../min ....par minute

IPM ......... impacts par minute

a la terre)

A .......... amperes

W......... watts

"_ ........courant alternatif

........courant alternatif ou continu

no ........ vitesse a vide

......... borne de terre

,& ........symbole d'alerte a la securite

RPM ....rotations ou alternance par

minute

DESCRIPTION (Fig. 1)

A. DDFT int6gr6 au cordon

B. Interrupteur marche/arr6t

C. Bouton de verrouillage en position

D. Disque diamant

E. Bride externe

E Vis de serrage

G. Tubage

H. Arriv6e d'eau

I. Raccord de tubage

J. R6gulateur de pression d'eau (5 psi)

K. Vis

L. Gicleur

de marche

M. Bouton de r6glage de profondeur

N. Patin

O. Robinet & levier

P. Guide de coupe

Q. Bouton de r6glage de chanfrein

R. Protege balai

S. Module balai

T Poign6e avant

U Poign6e principale

V. CI6 &bride

W. CI6 &poign6e en T

MONTAGE

Interrupteur (Fig. 1, 2)

,& AVERTISSEMENT : pour eviter que la fiche de I'appareil ou la prise murale ne soit mouillee,

positionner la scie sur le c6te d'une prise murale pour eviter que I'eau ne s'ecoule sur la

prise ou la fiche. II est aussi recommande de faire un , anneau d'ecoulement _, sur le cordon

connectant la scie a la prise (fig. 2)., L'anneau d'ecoulement _ est represente par la partie du

cordon au-dessous du niveau de la prise, ou du connecteur si une rallonge est utilisee, pour

eviter que I'eau ne s'ecoule le long du cordon et n'entre en contact avec la prise.

_,A TTENTION :avant de brancher lbutil, verifier syst6matiquement que I'interrupteur fonctionne

correctement et retourne en position d'ARRET une fois rel&che.

1. Maintenez I'interrupteur (B) appuy6 pour commencer & travailler.

2. Pour un travail continu, enfoncez le bouton de verrouillage (C) puis rel&chez I'interrupteur.

Pour d6sactiver le bouton de verrouillage, appuyez puis rel&chez I'interrupteur.

Installation du disque diamant (Fig. 1, 3)

1. Posez la scie sur une surface stable.

2. Installez le disque (D) sur la broche.

3. A I'aide de la cl6 &bride (V) fournie & cet effet, immobilisez la bride externe (E).

4. Vissez la vis de serrage (F) vers la gauche pour la serrer. Utilisez la cl6 & poign6e en T (W)

fournie & cet effet pour serrer & fond.

5. Pour retirer le disque, suivez la proc6dure en sens inverse.

Installation du syst_me de d_coupe a I'eau (Fig. 1)

_AVERTISSEMENT : ne pas utiliser le systeme de decoupe a I'eau si I'outil n'est pas protege

par un DDFT.

Ce syst_me minimise les poussi_res volantes tout en am61iorant la qualit6 de la coupe et en

augmentant la dur6e de vie des organes de coupe.

1. D6vissez le bouton de r6glage de profondeur (M) et tirez le patin (N) sur sa position de

profondeur de coupe minimale..

2. A I'aide d'un tournevis, retirez la vis (K) situ6e & c6t6 du bouton de r6glage de profondeur

sur le moulage.

3. Installez le module du robinet d'adduction d'eau de fagon & ce que le trou du module

du robinet s'aligne sur I'orifice de la vis sur le moulage et que le robinet en fourche (L)

chevauche le disque.

4. Serrez I'ensemble avec lavis. Attention & NE PAS trop serrer la vis, cela pourrait endommager

le module du robinet d'adduction d'eau.

Module du robinet d'adduction d'eau (Fig. 1)

I&AVERTISSEMENT : ne jamais utiliser le module du robinet d'adduction d'eau sans un

regulateur de pression en bon etat de marche. Une pression excessive pourrait endommager

le tubage.

1. N'utilisez jamais la scie pour d6couper au-dessus de votre t_te. En cas de d6coupe & I'eau,

d6coupez uniquement & rhorizontale pour prot6ger I'outil de toute infiltration d'eau.

2. Avant d'utiliser I'outil avec le module du robinet d'adduction d'eau, v6rifiez que le tubage (G)

ne comporte nitrous ni entailles ou tout autre dommage. Remplacez-le par une piece de

rechange identique en cas de dommages ou d6gradation. V6rifiez qu'il n'y a aucune fuite au

niveau de I'arriv6e d'eau (H), du robinet d'adduction d'eau et du raccord (I). Si la connexion

est I&che ou le tubage est desserr6 au niveau des raccords, d6connectez le tubage, coupez-

en environ 25,4 mm (1 pc.), puis reconnectez-le.. Assurez-vous que le tubage est pouss6 &

fond au-del& du/des raccord(s). V6rifiez que la connexion est bien 6tanche..

3. En cas de d6coupe & I'eau, utilisez syst6matiquement le r6gulateur de pression d'eau (J)

fourni & cet effet. Fixez solidement le r6gulateur & la source d'eau, en faisant attention & ne

pas trop serrer. Assurez-vous de bien ins6rer la rondelle filtre (& I'int6rieur de I'entr6e d'eau

du r6gulateur) pour pr6venir le colmatage des orifices de passage. En cas de perte ou de

dommages, remplacez le r6gulateur par une piece identique.

Rallonges

• Brancher systematiquement la rallonge dans une prise DDFT.

• Utiliser exclusivement des rallonges con_ues pour I'exterieur. Ces rallonges comportent

I'inscription _ Utilisation acceptable avec des appareils congus pour I'exterieur ; stocker

I'interieur apres utilisation. _

• Utiliser exclusivement des rallonges dont les caracteristiques electriques sont au moins

equivalentes a I'intensite nominale du produit.

• Ne pas utiliser de rallonges endommagees. Verifier la rallonge avant toute utilisation et la

remplacer si elle est endommagee.

• Ne pas traiter la rallonge de fagon abusive, et ne pas tirer sur le cordon pour le

debrancher.

Moteur

S'assurer que le courant utilis6 correspond & celui recommand6 sur la plaque signal6tique. Une

baisse de tension de plus de 10 % causera perte de puissance et surchauffe. Tousles outils

DEWALT sont soumis & des essais en usine ; si cet outil ne fonctionne pas, v6rifier le secteur.

• Prot6ger le cordon de la chaleur, et de tout bord ac6r6.

• D6connecter syst6matiquement la rallonge de la prise avant de d6brancher I'appareil de la

rallonge.

UTILISATION

AVERTISSEMENT : utiliser un organe de coupe adequat. Ne pas utiliser d'organes de coupe

fissures, endommages ou excessivement uses. Ne pas utiliser pour couper le bois ou le metal

_ATTENTION : pour une decoupe adequate, attendre que I'organe de coupe atteigne sa

vitesse maximale et alimenter lentement et uniformement la coupe.

ATTENTION: la DWC860W ne doit 6tre utilisee que sur des surfaces horizontales (se reporter

la rubrique Module du robinet d'adduction d'eau).

_ATTENTION : utiliser des serre-joints ou tout autre moyen pour fixer et immobiliser le

materiau sur une surface stable. Tenir la piece a la main ou contre son corps offre une stabilite

insuffisante qui pourrait vous en faire perdre le contr61e.

Position correcte des mains (Fig. 8)

,&AVERTISSEMENT : pour reduire tout risque de dommages corporels graves, adopter

syst#matiquement la position des mains illustr#e.

_AVERTISSEMENT : pour reduire tout risque de dommages corporels graves, maintenir

systematiquement I'outil fermement pour anticiper toute reaction soudaine.

La position correcte des mains requiert une main sur la poign6e principale (U), et I'autre sur la

poign6e avant (T), comme illustr6.

REMARQUE : la figure 8 illustre la position correcte des mains pour un gaucher. Pour les

droitiers, inverser la position des mains.

R_glage de la profondeur de coupe (Fig. 4)

1. Desserrez le bouton de r6glage de profondeur (M) pour le lib6rer.

2. D6placez le patin (N) vers le haut ou le bas selon la position d6sir6e.

3. Resserrez le bouton de r6glage de profondeur.

MC'THODE DE De'COUPE ._.L'EAU (FIG. 1,4)

J_AVERTISSEMENT : ne pas utiliser le systeme de decoupe a I'eau si I'outil n'est pas protege

par un DDFT.

I&AVERTISSEMENT : pour reduire tout risque de chocs electriques, proteger I'outil de toute

penetration d'eau. Ne pas toucher la fiche avec des mains humides.

1. Suivez les instructions d6crites dans la section Installation du syst_me de d6coupe h

I'eau.

2. Pour r6guler le flot d'eau, ouvrez le robinet d'adduction d'eau en 61oignant le levier (O) de

I'appareil.

3. Pour fermer le robinet d'adduction d'eau, repoussez le levier vers I'appareil.

3. Proc6dez comme d6crit ci-dessous pour toute coupe droite ou angulaire.

COUPES DROITES (FIG. 1)

1. ,&,I'aide d'un marqueur ou d'un crayon gras, tracez la ligne & d6couper.

2. Placez le patin de la scie sur la piece & travailler en vous assurant que le disque ne touchera

pas cette derni_re.

3. Alignez la partie externe du guide de coupe (P) sur le trac6 de coupe sur la piece &

travailler.

4. Mettez I'outil en marche et attendez que le disque atteigne sa vitesse maximale.

5. Faites avancer I'outil lentement et uniform6ment, en suivant le trac6 de coupe.

COUPES ANGULAIRES (FIG. 1,5)

1. A I'aide d'un marqueur ou d'un crayon gras, tracez la ligne & d6couper.

2. Rel&chez I'bouton d'ajustement du chanfrein (Q) et placez-le sur I'angle d6sir6.

3. Une fois I'angle d6sir6 choisi, resserrez I'bouton pour fixer le patin.

4. Alignez la partie interne du guide de coupe (P) sur le trac6 de coupe sur la piece &

travailler.

5. Mettez I'outil en marche et attendez que le disque atteigne sa vitesse maximale.

6. Faites avancer I'outil lentement et uniform6ment, en suivant le trac6 de coupe.

ENTRETIEN

_,AVERTISSEMENT : Pour reduire le risque de blessures corporelles graves, eteindre

I'outil et le debrancher avant d'effectuer tout reglage, ou d'enlever ou d'installer des

accessoires.

Nettoyage

_AVERTISSEMENT : Ne jamais utiliser de solvants ni d'autres produits chimiques puissants

pour nettoyer les pieces non metalliques de I'outiL Ces produits chimiques peuvent affaiblir les

materiaux de plastique utilises dans ces pieces. Utiliser un chiffon humecte uniquement d'eau

et de savon doux. Ne jamais laisser de liquide penetrer clans I'outil et n'immerger aucune partie

de I'outil dans un liquide.

Balais (fig. 6, 7)

_,AVERTISSEMENT : Pour reduire le risque de blessures corporelles graves, eteindre

I'outil et le debrancher avant d'effectuer tout reglage, ou d'enlever ou d'installer des

accessoires.

Inspecter les balais de charbon r6guli_rement en d6branchant I'outil, en retirant les proteges

balai (R) et en retirant les modules de balais (S).

Maintenir les balais propres et v6rifier qu'ils glissent librement dans leurs supports. Toujours

remettre un nouveau balai dans son support en suivant la m_me orientation que celle de rancien

balai. Les balais de charbon comportent des symboles vari6s imprim6s sur leurs c6t6s, et si le

balai est us6 au niveau de la ligne la plus proche du ressort, le balai doit _tre chang& N'utiliser

que des balais de rechange DEWALT identiques. Le fait d'utiliser un balai de bon calibre est

essentiel pour le bon fonctionnement de I'outil. Des modules de balai sont disponibles dans

les centres de service autoris6s DEWALT. Faire tourner I'outil & vide pendant 10 minutes avant

d'installer de nouveaux balais.

AATTENTION : Pendant le fonctionnement a vide, NE PAS ATTACHER, COLLER

OU VERROUILLER L'INTERRUPTEUR EN POSITION DE MARCHE. LE MAINTENIR

MANUELLEMENT SEULEMENT.

Lubrification

maniere que ce soit, un lubrifiant ou un solvant de nettoyage a I'interieur de

_AVERTISSEMENT : NE JAMAIS pulveriser, ni appliquer de quelque

I'outil, car cela pourrait reduire serieusement la duree de vie et nuire au

rendement de I'outil et entra_ner des risques de blessure. _,,,= _

Les outils DEWALT sont lubrifi6s en usine et sont donc pr_ts & rutilisation.

Cependant, il est recommand6 d"apporter ou d'envoyer I'outil une fois par

an dans un centre de service qualifi6 afin qu'il puisse y _tre compl_tement

nettoy6 et inspect&

ACCESSOIRES

_AVERTISSEMENT : Puisque les accessoires autres que ceux offerts par DEWALT n'ont pas

ete testes avec ce produit, leur utilisation pourrait s'averer dangereuse. Pour reduire le risque

de blessures, utiliser exclusivement les accessoires DEWALT recommandes avec le present

produit.

Les accessoires recommand6s pour votre outil peuvent _tre achet6s aupr_s du distributeur local

ou d'un centre de r6paration agr66. Si vous avez besoin d'assistance pour trouver un accessoire

pour votre outil, veuillez contacter DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore,

MD 21286, €:tats-Unis, composer le 1(800) 4-DEWALT (1-800-433-9258) ou visiter notre site Web

&www.dewalt.com.

Reparations

Pour assurer la SI2CURITI2 et la FIABILITI2 de cet outil, toutes les op6rations de r6paration,

d'entretien et de r6glage doivent _tre effectu6es dans un centre de service autoris6 ou par du

personnel qualifi6 (cela comprend I'inspection et le remplacement du balai); on ne doit utiliser

que des pi_ces de rechange identiques.

Garantie limit_e trois ans

DEWALT r6parera gratuitement tousles probl_mes dus & des d6fauts de mat6riau ou de

fabrication pendant trois ans & compter de la date d'achat. Cette garantie ne couvre pas des

d6faillances de piece dues & une usure normale ou & une mauvaise utilisation de I'outil. Pour

Page 5

plusdedBtailsrelatifsAlacouverturedelagarantieetauxrBparationssousgarantie,visiterle

siteWebwww.dewalt.comoucomposerle1(800)4-DEWALT(1(800)433-9258).Cettegarantie

nes'appliquepasauxaccessoiresniauxdommagescausBspardesrBparationsrBalisBesou

tentBespardestiers.Cettegarantievousaccordedesdroits16gauxspBcifiquesetilestpossible

quevousayezd'autresdroitsquivarientd'un€:tat ou d'une province A I'autre.

En plus de la garantie, les outils DEWALT sont couverts par notre :

SERVICE D'ENTRETIEN GRATUlT DE 1 AN

DEWALT entretiendra I'outil et remplacera les pi_ces usBes par une utilisation normale et ce,

gratuitement, A tout instant pendant la premiere annBe Acompter de la date d'achat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si vous n'Btes pas enti_rement satisfait des performances de votre outil 61ectrique, laser ou de

votre cloueuse DEWALT pour quelque raison que ce soit, vous pouvez le retourner accompagn6

d'un re£u dans les 90 jours suivant la date d'achat et nous vous rembourserons enti_rement -

sans poser de questions.

AMI_RIQUE LATINE : cette garantie ne s'applique pas aux produits vendus en AmBrique latine.

Pour ceux-ci, veuillez consulter les informations relatives A la garantie spBcifique prBsente dans

I'emballage, appeler I'entreprise locale ou consulter le site Web pour les informations relatives

Acette garantie.

REMPLAOEMENT GRATUlT DES #TIQUETTES D'AVERTISSEMENT : si les 6tiquettes

d'avertissement deviennent illisibles ou sont manquantes, composer le 1 (800) 4-DEWALT pour

en obtenir le remplacement gratuit.

PARA REDUCM EL RIESSO DE LESIONES, EL USUARI

DWC86OW'""'°°°'

SER.

CONTINUOUS RiM DIAMOND BLADES. DO NOT USE TOOTHED OR

SEGMENTED BLADES. TO REDUCE RiSE OF iNJURY, ALWAYS TEST GFCJ

BEFORE USE. ALWAYS USE PROPER EYE AND RESPIRATORY PROTECTION.

DEWALTiNDUSTRiALTOOL CO., BALTIMORE, MD 2_28fi

FORSERVICE iNFORMATION, CALL 1-800-4-DEWALT www.DEWALT.com j

WET/DRY MASONRY SAW

TO REDUCE THE RiSK OF iNJURY, USER MUST

READ iNSTRUCTiON MANUAL. USE 0NW

LIN[CAMENTE CON HOJAS CBNTJNUAS CON BORUE DE UJAMANTE. NO OTJLiCE HBJAS

DENTABAS 0 SOMENTADAS. PARA REBBCIB EL BJEBGO BE LESJONES, SJEMPRE PRUEBE

LA TOMA GECi ANTES BE UTILiZABLA. SiEMPRE SE UEBERA LLEVAR LA PROTECCiON

APBOPJADA PABA LA VISTA Y PARA LAB VJA$ BESPMATORiAS.

N'U_[1LJSER QUE DES LAMES CJRCULAJRES ._ TBANCHANT AU DJAMANT, NE PAS UTJL]SEB I

DE LAMES DENTEES OU SEGMENTEES. AF|N DE REBUiRE TOUT RISQUE DE BLESSBRES,

TESTER SYSTEMATIQUEMENT LA PRISE A BiSJONCTEUR BE FUiTE DE TEBRE. TOUJOURS

,,UTILiSER UNE PBOTECTiBN OCULAME ET UNE PROTECTION BESPiRATOME ABEBDATES.

Definiciones: Normas de seguridad

Las siguientes definiciones describen el nivel de gravedad de cada palabra de sepal. Lea el

manual y preste atenci6n a estos simbolos.

i_PELIGRO: Indica una situaci6n de peligro inminente que, si no se evita, provocara la

muerte o lesiones graves.

AADVERTENClA: Indica una situaci6n de peligro potencial que, si no se evita, podria

provocar la muerte o lesiones graves.

i_ATENClBN: Indica una situacidn de peligro potencial que, si no se evita, posiblemente

provocarfa lesiones leves o moderadas.

AVlSO: Se refiere a una practica no relacionada a lesiones corporales que de no evitarse

puede resultar en daUBs a la propiedad.

SI TIENE ALGUNA DUDA O ALGON COMENTARIO SOBRE €:STAU OTRA HERRAMIENTA

DEWALT, LL,_MENOS AL NOMERO GRATUITO: 1-800-4-DEWALT (1-800-433-9258).

_ ADVERTENClA: Para reducir el riesgo de lesiones, lea el manual de instrucciones.

Instrucciones de seguridad generales

_ ADVERTENCIA: Lea todas las instrucciones hasta comprenderlas. No

ajustarse a las instrucciones siguientes puede ser causa de cheque el_ctrico,

incendio o lesiones graves.

CONSERVE ESTAS INSTRUCCIONES

AREA DE TRABAJO

• Mantenga el Urea de trabajo limpia y bien iluminada. Las bancadas desordenadas y las

zonas oscuras propician los accidentes.

• No opere herramientas electricas en atmosferas explosivas, comB en presencia de

liquidos, gases o polvos inflamables. Las herramientas electricas producen chispas que

pueden originar la ignici6n del polvo o los vapores.

• Mientras opere una herramienta electrica, mantenga lejos a los observadores, ni_os y

visitantes. Las distracciones pueden ocasionar que pierda el control

SEGURIDAD ELI_CTRICA

• Las herramientas con doble aislamiento estan equipadas con una clavija polarizada

(una pata es mas ancha que la otra). Esta clavija se acoplara a un enchufe polarizado

de una sola manera. Si la clavija no se acopla al contacto, inviertala. Si aOn as( no se

ajusta, comuniquese con un electricista cualificado para que instale un enchufe

polarizado apropiado. Nunca cambie la clavija. Eldoble aislamiento [] elimina la necesidad

de cables con tres hilos y sistemas de suministro electrico con conexi6n a tierra.

• Evite el contacto del cuerpo con superficies conectadas a tierra, tales comb tuberias,

radiadores, registros y refrigeradores. El riesgo de choque electrico aumenta si su cuerpo

hace tierra.

• No exponga las herramientas electricas a la Iluvia o a condiciones de mucha humedad.

Si entra agua en una herramienta electrica, aumenta el riesgo de choque electrico.

• No maltrate el cable. Nunca tome el cable para transportar la herramienta ni para

desconectarla del enchufe. Mantenga el cable alejado de las fuentes de calor, el ace#e,

las orillas afiladas o las piezas en movimiento. Cambie inmediatamente los cables

da_ados. Los cables dahados aumentan el peligro de choque electrico.

• Cuando opere una maquina herramienta a la intemperie, utilice un alargador

marcado "W-A" o "W'. Estos alargadores estan clasificados para ser usados a la

intemperie y reducen el riesgo de descarga electrica. AI usar un alargador, aseg_rese

de que tenga el calibre necesario para Ilevar la corriente que su producto requerira. Un

alargador de un calibre insuficiente causara una ca[da en la tensi6n de la I[nea dando

por resultado la perdida de energ[a y sobrecalentamiento. La tabla siguiente muestra el

tamaho correcto para utifizar dependiendo de la Iongitud del alargador y del amperaje

nominal de la placa de identificaci6n. En caso de duda, utifice el de mayor calibre. Cuanto

mas pequeho es el n_mero del calibre, mas resistente es el alargador.

Calibre minimo para juegos de cables

Capacidad nominal

en amperios

Desde Hasta

0 6

6 10

10 12

12 16

SEGURIDAD PERSONAL

• AI utilizar una herramienta electrica, este atento, concentrese en Io que hace y aplique

el sentido comOn. No utilice la herramienta si se encuentra fatigado o bajo la influencia

de drogas, alcohol o farmacos. Mientras se uti/izan herramientas e/ectricas, basta un

instante de distraccidn para sufrir lesiones graves.

• Lleve ropa adecuada. No utilice ropa suelta ni joyas. Recojase el cabello largo.

Mantenga el cabello, la ropa y los guantes apartados de las piezas en movimiento.

Las partes mdviles pueden atrapar las prendas de vestir sueltas, las joyas y el cabello. Los

orificios de ventilacidn suelen cubrir piezas en movimiento, por Io que tambien se deben

evitar.

• Evite puestas en marcha accidentales. Aseg_rese de que el interruptor este apagado

antes de enchufar la maquina. Transportar las herramientas con el dedo sobre el interruptor

o enchufarlas con el interruptor encendido favorece los accidentes.

• Antes de poner en marcha la herramienta, retire las Ilaves de ajuste. Una Ilave que se

deje en una pieza giratoria de la herramienta puede provocar lesiones.

• No ponga en peligro su estabilidad. Mantengase siempre bien apoyado y equilibrado.

Un buen apoyo y equilibrio permiten controlar mejor la herramienta si se produce alden

imprevisto.

Voltios Largo total del cable en metros (en pies)

120V 7,6 (25) 30,5 (100) 45,7 (150)

240V 15,2 (50) 61,0 (200) 91,4 (300)

18

18

16

14

15,2 (50)

30,5 (100)

AWG

16

16

16

12

DEBE LEER EL MANUAL BE JNSTRUCCiONES. BTILiCE I

AFJN DE REDUJBE LE BISQUE DE BLESSUBES,

L'UTJLiSATEUR BOlT URE LE MODE D'EMPLBL

16 14

14 12

14 12

No recomendado

• Utilice el equipo de seguridad. Lleve siempre lentes protectores. Cuando sea adecuado,

tambien se debe usar mascarilla antipolvo, zapatos de suela antideslizante, casco o

protectores auditivos.

USO Y CUlDADOS DE LA HERRAMIENTA

• Utilice abrazaderas u otro elemento adecuado para sujetar y apoyar la pieza de trabajo

en una plataforma estable. Sujetar la pieza con la mano o contra el cuerpo es inestable y

facifita la perdida de control

• No fuerce la herramienta. Emplee la herramienta correcta para cada aplicacion. La

herramienta correcta hace el trabajo mejor y mas seguro dentro del rango para el que ha

sido disehada.

• No utilice la herramienta si el interruptor no la enciende y apaga. Cualquier herramienta

que no pueda controlarse con el interruptor es pefigrosa y se debe reparar.

• Desconecte la clavija del enchufe antes de proceder a cualquier ajuste, cambiar un

accesorio o guardar la herramienta. Estas medidas de seguridad preventiva reducen el

riesgo de poner en marcha la herramienta accidentalmente.

• Cuando no las utifice, guarde las herramientas fuera del alcance de los ni#os o de

cualquier persona no capacitada. Las herramientas son peligrosas en manos de usuarios

no capacitados.

• Cuide las herramientas. Conserve las herramientas de corte afiladas y limpias. Unas

herramientas adecuadamente cuidadas y con los bordes de corte afilados se atascan menDs

y son mas faciles de controlar.

• Compruebe si las piezas moviles se desalinean o atascan, si hay alguna pieza rota

o cualquier otra circunstancia que pueda afectar la operacion de la herramienta. Si

la herramienta esta da#ada, hagala reparar antes de usarla. Muchos accidentes los

provocan unas herramientas mal cuidadas.

• Utilice Onicamente los accesorios recomendados por el fabricante para su modelo. Un

mismo accesorio puede ser adecuado para una herramienta, pero peligroso si se usa en otra.

SERVIClO

• El servicio a la herramienta solo debe realizarlo personal cualificado. El servicio o

mantenimiento reafizados por personal no cafificado puede dar comB resultado un riesgo de

lesiones.

• AI proceder al mantenimiento de una herramienta, utilice Onicamente refacciones

identicas. Siga las instrucciones de la seccion "Mantenimiento" de este manual La

utilizaci6n de piezas no autorizadas, o no respetar las instrucciones de mantenimiento,

puede suponer un peligro de choque electrico o de lesiones.

Instrucciones de seguridad adicionales especificas para

sierras de mamposteria

• iPELIGRO! Mantenga las manos alejadas del area de corte y de la hoja. Mantenga su

segunda mano sobre la agarradera auxiliar o la carcasa del motor. Si ambas manos

estan sosteniendo la sierra, no pueden ser cortadas por la hoja.

• No trate de alcanzar algo por debajo de la pieza de trabajo. Por debajo de la pieza de

trabajo la guarda no puede protegerlo de la hoja

• Nunca sostenga la pieza siendo cortada en sus manos o cruzada sobre su pierna.

Asegure la pieza de trabajo a una plataforma estable. Es importante apoyar el trabajo

correctamente para minimizar la exposicidn del cuerpo, el agarrotamiento de la hoja o la

perdida de control.

• Sostenga la herramienta por sus superficies de empu_adura aisladas cuando realice

una operacion en la cual la herramienta para cortar pudiera entrar en contacto con

instalaciones electricas ocultas o con su propio cable. El contacto con un conductor

activo tambien provocara que las piezas metalicas de la herramienta conduzcan

electricidad y que el operador reciba una descarga electrica.

• Utilice siempre hojas con el tama#o y la forma correctos para los orificios de mandril

(romboide vs. redondo). Las hojas que no coincidan con los accesorios de montaje de la

sierra correran en forma excentrica, causando la perdida del control

• Nunca use arandelas o pernos para la hoja da#ados o incorrectos. Las arandelas

y perno para la hoja fueron especialmente disehados para su sierra, en busca de un

desempeho dptimo y seguridad en la operacidn.

• Mantenga su cuerpo colocado a cualquier lado de la hoja, pero no en linea con la hoja

de la sierra.

• Las hojas giran por inercia despues del apagado. Puede resultar en lesiones corporales

serias.

• No desconecte si el enchufe o la toma estan mojados. Desconecte el fusible o interruptor

de circuito que abastece electricidad a la herramienta. Luego desench#fela y examine la

toma para verificar que no contenga agua.

• Espere a que la hoja se detenga completamente. Una hoja girando por inercia, sin

protecci6n, hara que la sierra camine hacia atras, cortando Io que este en su camino.

Sea consciente del tiempo necesario para que la hoja se detenga despues de soltar el

interruptor.

• No la utilice para cortar madera o metal

• Nunca use hojas dentadas. Esta herramienta no esta equipada

con una guarda inferior.

PELIGRO: Mantenga las manos alejadas del area de corte y de

la hoja. Podria resultar en lesiones corporales.

_,ADVERTENClA: Siempre enchufe alargadores en tomas protegidas

por interruptores accionados por corriente de perdida a tierra (GFCI).

_},ADVERTENClA: Para reducir el riesgo de electrocuci6n, mantenga

todas las conexiones secas y no las deje en el suelo. No toque el

enchufe si tiene las manos mojadas.

_,ADVERTENClA: El cable viene con un interruptor accionado por corriente de perdida a

tierra (GFCI). Algunas tomas de corriente vienen con protecci6n GFCI incorporada y pueden

ser utifizadas comB medida adicional de seguridad. Cuando utilice un alargador, ench#felo

siempre en una toma protegida por GFCI.

_ADVERTENClA: Pruebe el GFCI antes de cada uso:

1. Enchufe el GFCI a la toma de corriente. El indicador deberfa ponerse rojo.

2. Presione el bot6n de prueba. El indicador rojo deberfa apagarse.

3. Presione el bot6n de reposici6n para utifizar el GFCI. Si laprueba anterior fall& no Io

use.

_ADVERTENClA: Nunca use la sierra con agua salada oun ffquido conductor.

,&ADVERTENClA: NO utilice corte en h#medo cuando use hojas con abrasivo pegado. Podrfa

tener comB resultado la ruptura del disco y lesiones corporales.

_ADVERTENClA: Parte del polvo generado al lijar, serrar, esmerilar o taladrar, asi comB al

realizar otras actividades del sector de la construcci6n, contienen productos quimicos que

pueden producir cancer, defectos congBnitos u otras afecciones reproductivas. Ejemplos de

esas substancias quimicas son:

• plomo procedente de pinturas basadas en plomo,

• 6xido de sificio cristafino procedente de ladrillos, cemento y otros productos de

mamposterfa, y

• arsenico y cromo procedentes de madera tratada qufmicamente (CCA).

El peligro derivado de estas exposiciones que usted enfrente varfa en funci6n de la frecuencia

con que se realice este tipo de trabajo. Para reducir la exposici6n a esas sustancias qufmicas:

trabaje en una zona bien ventilada y flevando equipos de seguridad aprobados, comB

mascarillas antipolvo especialmente disei_adas para filtrar partfculas microsc6picas.

• Evite el contacto prolongado con el polvo procedente del lijado, serrado,

esmerilado y taladrado electricos, as(comB de otras actividades del sector de la

construccion. Lleve ropa protectora y lave con agua y jabon las zonas expuestas.

Si permite que el polvo se introduzca en la boca u BiDSo quede sobre la piel, puede

favorecer la absorci6n de productos qufmicos peligrosos.

_,ADVERTENClA: Toda persona que entre al area de trabajo debera usar una mascara

antipolvo o protecci6n respiratoria. El filtro deberfa ser reemplazado a diario o cuando el

usuario tenga dificultad para respirar. Puede encontrar la mascara antipolvo apropiada

aprobada por NIOSH/OSHA en su ferreterfa local

_ADVERTENClA: UTILICE SIEMPRE proteccion auditiva personal apropiada al usar

esta herramienta. Bajo algunas condiciones y duraciones de uso, el ruido producido por este

producto puede contribuir a la perdida auditiva.

_,ADVERTENClA: SIEMPRE utilice proteccion ocular. Todos los usuarios y personas

circunstantes deben Ilevar protecci6n ocular en conformidad con ANSI Z87.1.

• La etiqueta de su herramienta puede incluir los siguientes sfmbolos. Los sfmbolos y sus

definiciones son los siguientes:

V............ voltios A ........... amperios

Hz.......... hertz W.......... vatios

Page 6

min........ minutes

---. ....... corriente directa

@ .......... Construccidn Clase I

(con conexidn a tierra)

[] .......... Construccidn Clase II

(con aislamiento doble)

i_, .......... sfmbolo de alerta de seguridad

IPM ........ impactos per minute

........ corriente alterna

........ corriente alterna o directa

no ......... velocidad sin carga

@ .......... terminal a tierra

.../min... per minute

RPM ..... revoluciones o reciprocidad per minute

BPM ......golpes per minute

COMPONENTES (FIG. 1)

A. GFCI sobre el juego del cord6n

B. Conmutador de encendido y apagado

C. Bot6n de bloqueo en encendido

D. Hoja de diamante

E. Brida externa

E Tornillo de sujeci6n

G. Tuberia del agua

H. Admisi6n de la herramienta

I. Adaptador para tuberia del agua

J Regulador de presi6n del agua (5 psi)

K. Tornillo

L. Boquilla del agua

M. Perilla de ajuste de la profundidad

N. Zapata

O. Palanca de la valvula del agua

R Guia de corte

Q. Perilla para ajuste del bisel

R. Cubiertas de las escobillas

S. Unidad de escobillas

T. Agarradera frontal

U. Agarradera principal

V. Llave para brida

W. Llave con agarradera en "T"

MONTAJE

Interruptor (Fig. 1, 2)

_ADVERTENClA: Para evitar la posibilidad que se moje el enchufe del aparato o la toma

de corriente, coloque la sierra al cestado de una tema de corriente montada en la pared para

evitar que caiga agua al enchufe e la toma de corriente. El usuarie deberfa crear un daze de

goteo_ en el cable que conecta la sierra a la toma de corriente (Fig. 2). El "lazo de goteo" es

aquella parte del cable que se encuentra a una altura menor que la de la tema de corriente

e del conector, si se utiliza un alargader, utilizade para evitar que el agua viaje per el cable y

entre en contacte con la tema de corriente.

AATENCl6N: Antes de enchufar la herramienta, siempre verifique que el interrupter actEla

correctamente y vuelve a la posici6n de APAGADO cuande se suelta.

1. Presione y sostenga el interrupter (B) para iniciar la operaci6n.

2. Para un funcionamiento continue, presione el bot6n de bloqueo en encendido (C) y suelte

el interrupter. Para desengranar el bot6n del seguro, oprima y luego suelte el interrupter.

Para instalar la hoja adiamantada (Fig. 1, 3)

1. Coloque la sierra sobre una superficie estable.

2. Coloque la hoja (D) sobre el husillo.

3. Utilizando la Ilave para brida (V) provista, sostenga la brida externa (E)

4. Para apretar gire el tornillo de sujeci6n (F) en sentido antihorario. Utilice la Ilave con

agarradera en ,,T,, (W) suministrada para apretar en forma segura.

5. Para retirar la hoja, invierta el procedimiento.

Para montar el Sistema de corte h_medo (Fig. 1)

_ADVERTENClA: No utilizar el sistema de corte h_medo a menos que la herramienta esta

pretegida per un GFCI.

Este sistema minimiza las particulas de polvo en el aire, al mismo tiempo que mejora la calidad

del corte y alarga la vida t_tilde la hoja.

1. Afloje la perilla de ajuste de la profundidad (M) y hale la zapata (N) hasta su posici6n de

minima profundidad de corte.

2. Utilizando un destornillador, retire el tornillo (K) ubicado cerca a la perilla de ajuste de la

profundidad montada en la carcasa.

3. Coloque el conjunto de la valvula de agua de tal manera que el orificio del conjunto de la

valvula de agua quede alineado con el orificio del tornillo situado en la carcasa y la valvula

de agua ahorquillada (L) quede a ambos lades de la hoja.

4. Asegure en su lugar con tornillo. NO apriete excesivamente el tornillo; esto podria daSar el

conjunto de la valvula de agua.

Conjunto de la v_lvula de agua (Fig. 1)

,_ADVERTENClA : Nunca use el conjunto de la valvula de agua sin un regulador de presidn

que funcione correctamente. Esto pedrfa causar dahes a la tuberfa del agua si se acumula

presidn excesiva.

1. No utilice nunca la sierra per encima de la cabeza. AI utilizar agua, limite el corte a la

posici6n horizontal para reducir el riesgo de que entre agua a la herramienta.

2. Antes de utilizar la herramienta con el conjunto de la valvula de agua, revise la tuberia del

agua (G) en busca de orificios, grietas u otro tipo de deterioro. Reemplace con repuestos

id_nticos si se encuentra un Area potencialmente debilitada o daSada. Inspeccione las

conexiones en la admisi6n de la herramienta (H), la valvula de agua y el adaptador (I)

en busca de fugas. Si la conexi6n esta suelta o la tuberia esta relajada alrededor de las

leng(Jetas, desconecte la tuberia, recorte la tuberia hacia atras aproximadamente 25,4 mm

(1 pulg.), y a continuaci6n vuelva a conectar la tuberia. Asegt_rese de que la tuberia sea

empujada mas alia de la(s) leng(Jeta(s). Compruebe para garantizar que la conexi6n quede