Page 1

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW999

18 Volt 7/8" Cordless Rotary Hammer

Perceuse à percussion sans fil á 18 volt 22 mm (7/8 po)

Rotomartillos inalámbricas 18 volt 22 mm (7/8")

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

Questions? See us on the World Wide Web at www.dewalt.com

Page 2

1

English

F YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

General Safety Rules – For All Battery

Operated Tools

WARNING! Read and understand all instructions. Failure to

follow all instructions listed below may result in electric shock, fire

and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while operating

a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Do not abuse the cord. Never use the cord to carry the tool.

Keep cord away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Damaged cords may create

a fire.

• A battery operated tool with integral batteries or a separate

battery pack must be recharged only with the specified charger

for the battery. A charger that may be suitable for one type of

battery may create a risk of fire when used with another battery.

• Use battery operated tool only with the specifically

designated battery pack. Use of any other batteries may create a

risk of fire.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or medication. A

moment of inattention while operating power tools may result in

serious personal injury,

• Dress properly. Do not wear loose clothing or jewelry. Contain

long hair. Keep your hair, clothing, and gloves away from

moving parts. Loose clothing, jewelry, or long hair can be caught

in moving parts. Air vents often cover moving parts and should also

be avoided.

• Avoid accidental starting. Be sure switch is in the locked or

off position before inserting battery pack. Carrying tools with

your finger on the switch or inserting the battery pack into a tool

with the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool

on. A wrench or a key that is left attached to a rotating part of the

tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control of the tool

in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask,

non-skid safety shoes, hard hat, or hearing protection must be

used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the

workpiece to a stable platform. Holding the work by hand or

against your body is unstable and may lead to a loss of control.

• Do not force tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate for which

it is designed.

• Do not use tool if switch does not turn it on or off. A tool that

cannot be controlled with the switch is dangerous and must be

repaired.

• Disconnect battery pack from tool or place the switch in the

locked or off position before making any adjustments,

changing accessories, or storing the tool. Such preventative

safety measures reduce the risk of starting the tool accidentally.

Page 3

• Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

• When battery pack is not in use, keep it away from other metal

objects like: paper clips, coins, keys, nails, screws, or other

small metal objects that can make a connection from one

terminal to another. Shorting the battery terminals together may

cause sparks, burns, or a fire.

• Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools, with sharp cutting edges are less likely

to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage

of parts, and any other condition that may affect the tools

operation. If damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the

manufacturer for your model. Accessories that may be suitable

for one tool, may create a risk of injury when used on another tool.

SERVICE

• Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

personnel may result in a risk of injury.

• When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this manual.

Use of unauthorized parts or failure to follow Maintenance

Instructions may create a risk of shock or injury.

Additional Specific Safety Rules for

Rotary Hammers

• Hold tools by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring.

Contact with a “live” wire will make exposed metal parts of the tool

“live” and shock the operator.

• Wear safety goggles or other eye protection. Hammering and

drilling operations cause chips to fly. Flying particles can cause

permanent eye damage.

2

English

• Always use the side handle supplied with the tool. Keep a firm

grip on the tool at all times. Do not attempt to operate this tool

without holding it with both hands. Operating this tool with one

hand will result in a loss of control.

• Do not use chisels in any of the rotation modes. Chisel may

jam causing loss of control.

• Wear gloves when handling hammer bits and tools. Hammer

bits and tools get hot during operation.

CAUTION: Wear appropriate personal hearing protection during

use. Under some conditions and duration of use, noise from this

product may contribute to hearing loss.

CAUTION: Some tools with large battery packs will stand upright

on the battery pack but may be easily knocked over. When not in use,

place tool on its side on a stable surface where it will not cause a

tripping or falling hazard.

CAUTION: DO NOT TOUCH ANY METAL PARTS OF THE TOOL

when drilling or driving into walls, floors or wherever live electrical wires

may be encountered! Hold the tool only by insulated grasping surfaces

to prevent electric shock if you drill or drive into a live wire.

WARNING: Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do

this type of work. To reduce your exposure to these chemicals: work in

a well ventilated area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with soap

Page 4

3

and water. Allowing dust to get into your mouth, eyes, or lay on the

skin may promote absorption of harmful chemicals.

• The label on your tool may include the following symbols.

V..............volts A ............amperes

Hz............hertz W ..........watts

min ..........minutes ..........alternating current

........direct current no..........no load speed

............Class II Construction ..........earthing terminal

..........safety alert symbol .../min ....revolutions per minute

Important Safety Instructions for

Battery Packs

The battery pack is not fully charged out of the carton! First read the

safety instructions below. Then follow charging notes and procedures.

• Do not incinerate the battery pack even if it is severely

damaged or is completely worn out. The battery pack can

explode in a fire.

• A small leakage of liquid from the battery pack cells may

occur under extreme usage or temperature conditions. This

does not indicate a failure. However, if the outer seal is broken

and this leakage gets on your skin:

a. Wash quickly with soap and water.

b. Neutralize with a mild acid such as lemon juice or vinegar.

c. If battery liquid gets into your eyes, flush them with clean water for

a minimum of 10 minutes and seek immediate medical attention.

(Medical note: The liquid is 25-35% solution of potassium

hydroxide.)

• Do not carry extra battery packs in aprons, pockets, or tool

boxes along with other metal objects. Battery pack could be

short circuited causing damage to the battery pack and possibly

causing severe burns or fire.

• Charge the battery packs only in D

EWALT chargers.

• NOTE: The batteries in your battery pack are the nickel–cadmium

type. Cadmium is considered to be a toxic material by the Environmental Protection Agency. Before disposing of damaged or worn

out Nickel–Cadmium battery packs, check with your state

Environmental Protection Agency to find out about special

restrictions on the disposal of these battery packs or return them to

a D

EWALT certified service center for recycling.

•

DO NOT store or use the tool and battery pack in locations where

the temperature may reach or exceed 105°F (such as outside

sheds or metal buildings in summer).

DANGER: Never attempt to open the battery pack for any reason.

If battery pack case is cracked or damaged, do not insert into

charger. Danger of electric shock or electrocution. Damaged

battery packs should be returned to service center for recycling.

NOTE: Battery storage and carrying caps are provided for use

whenever the battery is out of the tool or charger. Remove cap before

placing battery in charger or tool.

WARNING: Do not store or carry battery so that

metal objects can contact exposed battery terminals.

For example, do not place battery in aprons, pockets, tool

boxes, product kit boxes, drawers, etc. with loose nails,

screws, keys, etc. without battery cap. Without cap in

place, battery could short circuit causing fire or burns or

damage to battery.

The RBRC™ Seal

The RBRC™ (Rechargeable Battery Recycling Corpora

tion) Seal on the nickel-cadmium battery (or battery pack)

indicates that the costs to recycle the battery (or battery

pack) at the end of its useful life have already been paid

by D

EWALT. In some areas, it is illegal to place spent

nickel-cadmium batteries in the trash or municipal solid

waste stream and the RBRC program provides an environmentally

conscious alternative.

RBRC in cooperation with D

EWALT and other battery users, has

established programs in the United States to facilitate the collection of

spent nickel-cadmium batteries. Help protect our environment and

conserve natural resources by returning the spent nickel-cadmium

battery to an authorized D

EWALT service center or to your local retailer

English

Page 5

WARNING: Don’t allow any liquid to get inside charger. Electric

shock may result.

• The charger and battery pack are specifically designed to

work together. DO NOT attempt to charge the battery pack with

any chargers other than the ones in this manual.

• These chargers are not intended for any uses other than charging

D

EWALT rechargeable batteries. Any other uses may result in risk

of fire, electric shock or electrocution.

• To reduce risk of damage to electric plug and cord, pull by plug

rather than cord when disconnecting charger.

• Make sure cord is located so that it will not be stepped on, tripped

over, or otherwise subjected to damage or stress.

• An extension cord should not be used unless absolutely necessary.

Use of improper extension cord could result in risk of fire, electric

shock, or electrocution.

• An extension cord must have adequate wire size (AWG or

American Wire Gauge) for safety. The smaller the gauge number of

the wire, the greater the capacity of the cable, that is 16 gauge has

more capacity than 18 gauge. When using more than one

extension to make up the total length, be sure each individual

extension contains at least the minimum wire size.

Recommended Minimum AWG Size for Extension Cords

Total Extension Cord Length (feet)

25 50 75 100 125 150 175

Wire Gauge

18 18 16 16 14 14 12

• The charger is ventilated through slots in the top and the bottom of

the housing. Do not place any object on top of charger or place the

charger on a soft surface that might block the ventilation slots and

result in excessive internal heat. Place the charger in a position

away from any heat source.

• Do not operate charger with damaged cord or plug — have them

replaced immediately.

• Do not operate charger if it has received a sharp blow, been

dropped, or otherwise damaged in any way; take it to an authorized

service center.

4

English

for recycling. You may also contact your local recycling center for

information on where to drop off the spent battery.

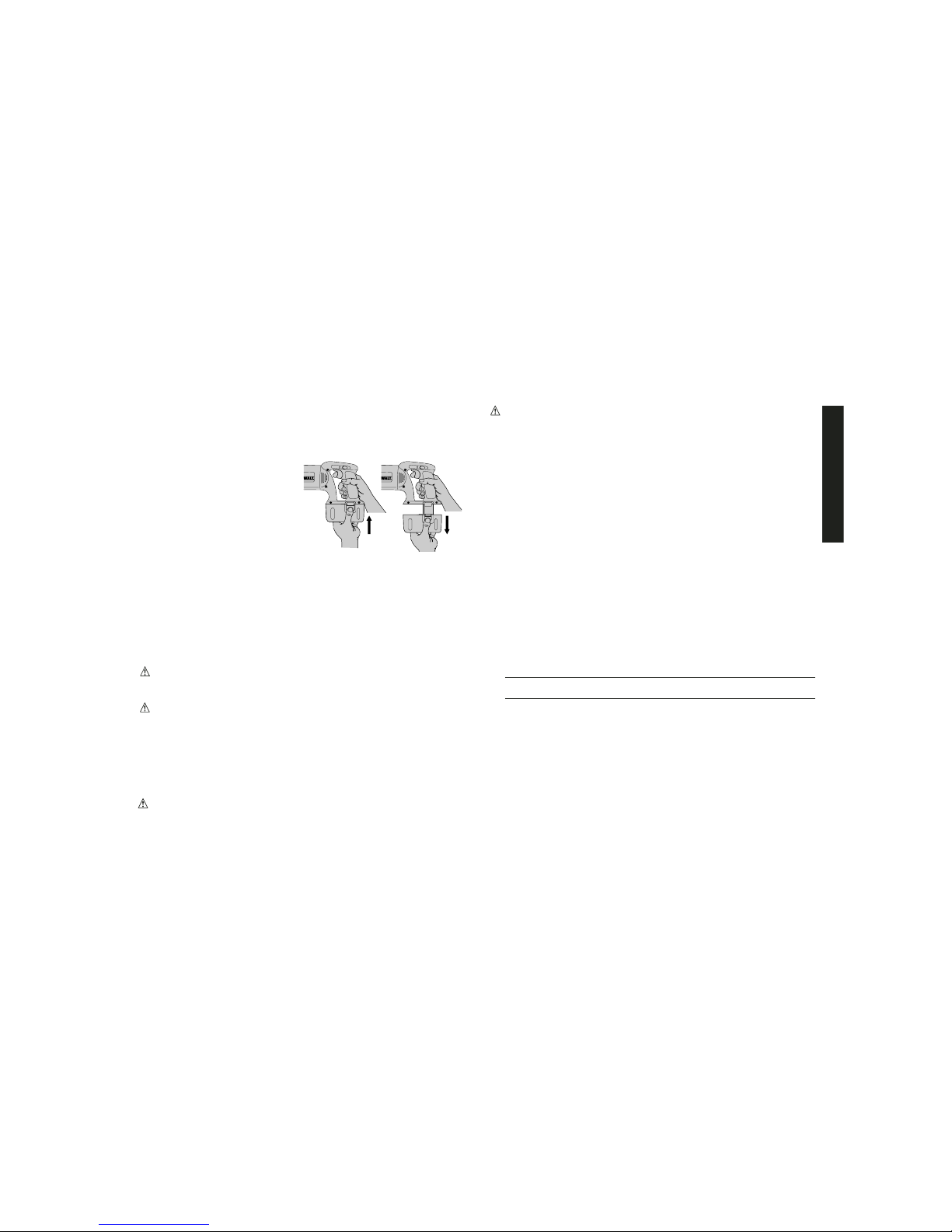

Installing and Removing the Battery

Pack (Fig. 1)

NOTE: Make sure your battery

pack is fully charged. To install

the battery pack into the tool

handle, align the base of the tool

with the notch inside the tool’s

handle and slide the battery pack

firmly into the handle until you

hear the lock snap into place.

To remove the battery pack from the tool, press the release buttons

and firmly pull the battery pack out of the tool handle. Insert it into the

charger as described in the Charging Procedures section.

Important Safety Instructions for Battery

Chargers

SAVE THESE INSTRUCTIONS - This manual contains important

safety instructions for D

EWALT battery chargers.

• Before using battery charger, read all instructions and cautionary

markings on battery charger, battery and product using battery.

CAUTION:To reduce the risk of injury, charge only D

EWALT nickel

cadmium rechargeable batteries. Other types of batteries may

burst causing personal injury and damage.

CAUTION: Under certain conditions, with the charger plugged in to

the power supply, the exposed charging contacts inside the charger

can be shorted by foreign material. Foreign materials of a

conductive nature such as, but not limited to, steel wool, aluminum

foil, or any buildup of metallic particles should be kept away from

charger cavities. Always unplug the charger from the power supply

when there is no battery pack in the cavity. Unplug charger before

attempting to clean.

DANGER: 120 volts present at charging terminals. Do not probe

with conductive objects. Danger of electric shock or electrocution.

FIG. 1

Page 6

5

English

• Do not disassemble charger; take it to an authorized service center

when service or repair is required. Incorrect reassembly may result

in a risk of electric shock, electrocution or fire.

• To reduce risk of electric shock, unplug charger from outlet before

attempting any cleaning. Removing the battery pack will not reduce

this risk.

• NEVER attempt to connect 2 chargers together.

• The charger is designed to operate on standard household electrical

power (120 Volts AC). Do not attempt to use it on any other voltage!

This does not apply to vehicular charger.

Chargers

Your battery can be charged in DEWALT 1 Hour Chargers, 15 Minute

Chargers or Vehicular 12 volt charger. Be sure to read all safety

instructions before using your charger.

Consult chart on back cover for compatibility of chargers and battery

packs.

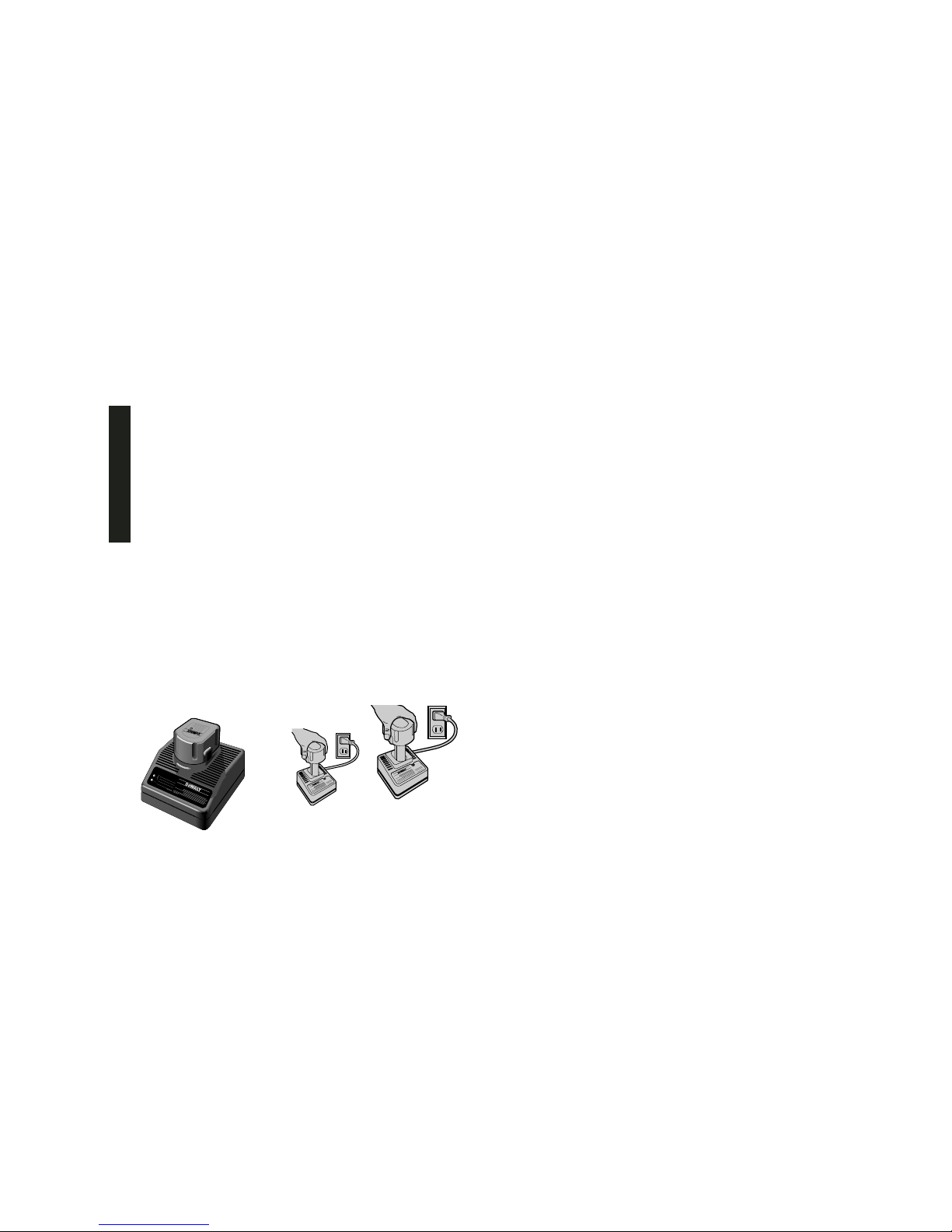

Charging Procedure

1 HOUR CHARGERS

1. Plug the charger into an appropriate power outlet.

2. Insert the battery pack into the charger, as shown in FIG.2, making

sure the pack is fully seated in the charger. The red (charging) light

will blink continuously indicating that the charging process has

started.

3. The battery pack will be fully charged in about 1 hour. The

completion of charge will be indicated by the red light remaining ON

continuously. The pack is fully charged and may be used at this time

or left in the charger.

TROUBLE INDICATORS: These chargers are designed to detect

certain problems that can arise with battery packs which would be

indicated by the red light flashing at a fast rate (and continuous beeping

for 15 Minute Chargers). If this occurs, re-insert battery pack. If

problem persists, try a different battery pack to determine if the charger

is OK. If the new pack charges correctly, then the original pack is

defective and should be returned to a service center for recycling. If the

new battery pack elicits the same trouble indication as the original,

have charger tested at an authorized service center.

PROBLEM POWER LINE

If your charger has a Problem Power Line indicator: When the charger

‘is used with some portable power sources such as generators or

sources that convert DC to AC, the charger may temporarily suspend

operation, flashing the red light with two fast blinks followed by a

pause. This indicates the power source is out of limits.

HOT PACK DELAY

If your charger has a Hot Pack Delay feature: When the charger detects

a battery that is hot, it automatically starts a Hot Pack Delay, suspending

charging until the battery has cooled. After the battery has cooled, the

charger automatically switches to the Pack Charging mode. This

feature ensures maximum battery life. The red light flashes long, then

short while in the Hot Pack Delay mode.

15 MINUTE CHARGERS

1. Plug the charger into an appropriate power outlet. The charger will

beep twice, the red light will blink and go off.

2. Insert the battery pack into the charger, as shown in FIG. 2, making

sure the pack is fully seated in the charger. The red light will blink

and the charger will beep once indicating the charging process has

started.

¥

C

H

A

R

G

I

N

G

¥

C

H

A

R

G

E

D

¥

D

E

L

A

Y

DW9115

DAN

GER:

W

A

RNIN

G:

15 M

IN

UT

E CHARG

ER

F

L

A

S

H

I

N

G

O

N

F

A

S

T

F

L

A

S

H

¥

D

E

F

E

C

T

I

V

E

P

A

C

K

O

N

9.0v

E

X

T

E

N

D

E

D R

U

N

TIM

E

R

R

15 MINUTE CHARGER

1 HOUR CHARGERS

¥

C

H

A

R

G

I

N

G

¥ C

H

A

R

G

E

D

¥ D

E

L

AY

1

5

M

I

N

U

T

E

C

H

A

R

G

E

R

F

LA

S

H

IN

G

O

N

F

A

S

T

F

LA

S

H

¥

D

E

FE

C

T

IV

E

P

A

C

K

O

N

D

W

9115

D

A

N

G

E

R

:

W

A

R

N

I

N

G

:

¥

C

H

A

R

G

I

N

G

¥

C

H

A

R

G

E

D

¥

D

E

L

A

Y

15 MINUTE CHARGER

F

L

A

S

H

I

N

G

O

N

F

A

S

T

F

L

A

S

H

¥

D

E

F

E

C

T

I

V

E

P

A

C

K

O

N

D

W

9

1

1

5

DANGER:

WARNING:

FIG. 2

Page 7

6

English

when you turn out the lights. (3) Move charger and battery pack to a

location where the surrounding air temperature is approximately

65°F - 75°F (18°- 24°C). (4) If charging problems persist, take or

send the tool, battery pack and charger to your local service center.

4. The battery pack should be recharged when it fails to produce

sufficient power on jobs which were easily done previously. DO NOT

CONTINUE to use under these conditions. Follow the charging

procedure. You may also charge a partially used pack whenever you

desire with no adverse affect on the battery pack.

5. Under certain conditions, with the charger plugged into the power

supply, the exposed charging contacts inside the charger can be

shorted by foreign material. Foreign materials of a conductive nature

such as, but not limited to, steel wool, aluminum foil, or any buildup

of metallic particles should be kept away from charger cavities.

Always unplug the charger from the power supply when there is no

battery pack in the cavity. Unplug charger before attempting to clean.

6. Do not immerse charger in water or any other liquid.

WARNING: Don't allow any liquid to get inside charger. Electric

shock may result. To facilitate the cooling of the battery pack after

use, avoid placing the charger or battery pack in a warm environment such as in a metal shed, or an uninsulated trailer.

CAUTION: Never attempt to open the battery pack for any reason.

If the plastic housing of the battery pack breaks or cracks, return to

a service center for recycling.

BATTERY PERFORMANCE

Some chargers have a tune-up feature optimizes battery pack

performance. Your charger may provide Automatic Tune-Up™ Mode

or manual (i.e. push button) Tune-Up™ mode. For information on this

feature, please see the appropriate section below. Because batteries

slowly lose their charge when they are not on the charger, the best

place to keep your battery pack is on the charger at all times.

Using Automatic Tune-Up™ Mode

The Automatic Tune-Up™ Mode equalizes or balances the individual

cells in the battery pack allowing it to function at peak capacity.

3. The battery pack will be fully charged in less than 15 minutes under

most conditions. This will be indicated by the red light remaining ON

and 3 beeps. The pack is fully charged and may be used at this time

or left in the charger.

WEAK BATTERY PACKS: The charger can also detect a weak

battery. Such batteries are still usable but should not be expected to

perform as much work. In such cases, about 10 seconds after battery

insertion, the charger will beep rapidly 8 times to indicate a weak

battery condition. The charger will then go on to charge the battery to

the highest capacity possible.

ALL CHARGERS

Leaving the battery pack in the charger: When the red light remains

ON, the charger has switched to its "equalize charge" mode which

lasts approximately 4 hours, after which the charger will switch to

"maintenance charge" mode. The battery pack can be removed at

any time during these charge cycles, but will only be fully charged if the

red light is continuously ON. The charger and battery pack can be left

connected with the red light glowing indefinitely. The charger will keep

the battery pack fresh and fully charged. A battery pack will slowly

lose its charge when kept out of the charger. If the battery pack has not

been kept on maintenance charge, it may need to be recharged before

use. A battery pack may also slowly lose its charge if left in a charger

that is not plugged into an appropriate AC source.

Important Charging Notes

1. Longest life and best performance can be obtained if the battery

pack is charged when the air temperature is between 65°F and 75°F

(18°- 24°C). DO NOT charge the battery pack in an air temperature

below +40°F(+4.5°C), or above +105°F (+40.5°C). This is important

and will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to touch while

charging. This is a normal condition, and does not indicate a

problem.

3. If the battery pack does not charge properly — (1) Check current at

receptacle by plugging in a lamp or other appliance, (2) Check to see

if receptacle is connected to a light switch which turns power off

Page 8

7

English

hours to complete. Battery packs should be tuned up weekly or after

10 to 20 charge/discharge cycles or whenever the pack no longer

delivers the same amount of work.

1. To tune up your battery pack, place the battery in the charger as

usual. The red light will blink continuously indicating that the

charge cycle has started.

2. Press the Tune-Up™ Mode button any time after the charge cycle

has started. The red light will stop blinking momentarily, blink

quickly 3 times, and then resume blinking continuously. The

charger is now tuning up the cells in your battery.

3. When the Tune-Up™ mode cycle is complete, the light will stay on

continuously. The pack is fully charged and may be used at this

time or left in the charger.

4. If you select Tune-Up™ Mode and then change your mind,

remove the battery from the charger. After 5 seconds, insert the

battery into the charger. The normal charge cycle will begin.

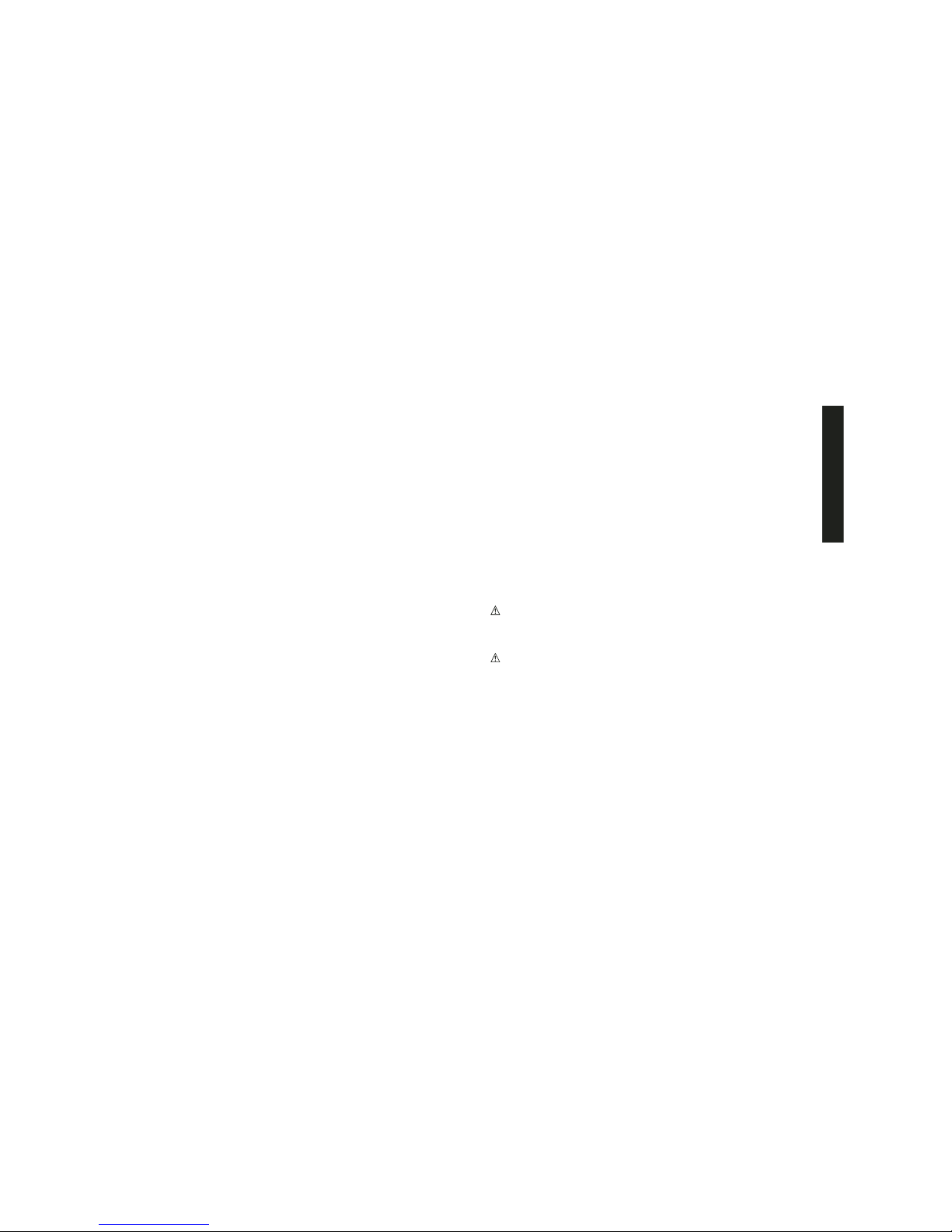

Side Handle (Fig. 3)

A side handle (A) is supplied with this hammer. It clamps to the front of

the gear case as shown and can be rotated 360˚ to permit right or left

hand use.

CAUTION: Always use the side handle supplied with the tool.

Keep a firm grip on the tool at all times. Do not attempt to operate this

tool without holding it with both hands. Operating this tool with one

hand will result in loss of control. Breaking through or encountering

hard materials such as re-bar may be be hazardous as well.

Variable Speed Switch (Fig. 3-B)

To turn the tool on, squeeze the trigger switch. To turn the tool off,

release the trigger switch. Your tool is equipped with a brake. The

chuck will stop as soon as the trigger switch is fully released.

The variable speed switch enables you to select the best speed for a

particular application. The farther you squeeze the trigger, the faster

the tool will operate. Use lower speeds for starting holes without a

center punch, drilling in metals or plastics, driving screws and drilling

ceramics. For maximum tool life, use variable speed only for starting

holes or fasteners.

Battery packs should be tuned up after every 10th charge/ discharge

cycle or whenever the pack no longer delivers the same amount of

work. To use the automatic tune-up mode, simply place the battery

pack in the charger and leave it for at least eight hours. The charger

will cycle through the following modes.

1. The red light will blink continuously indicating that the 1-hour

charge cycle has started.

2. When the 1-hour charge cycle is complete, the light will stay on

continuously and will no longer blink. This indicates that the pack

is fully charged and can be used at this time.

3. Whenever the pack is left in the charger after the initial 1-hour

charge, the charger will begin the Automatic Tune-Up™ Mode.

This mode continues up to 8 hours or until the individual cells in

the battery pack are equalized. The battery pack is ready for use

and can be removed at any time during the Tune-Up™ Mode.

4. Once the Automatic Tune-Up™ Mode is complete the charger

will transition to a maintenance charge; no indicator light shows

the completion of the Automatic Tune-Up™ Mode.

Using the Manual Tune-Up™ Mode

The manual Tune-up™ mode equalizes or balances the individual

cells in the battery pack at its peak capacity. This mode takes up to 8

FIG. 3

A

C

B

D

Page 9

8

English

Operation

DRILLING

1. Always unplug the drill when attaching or changing bits or

accessories.

2. Be sure the material to be drilled is anchored or clamped firmly. If

drilling thin material, use a wood “back-up” block to prevent damage

to the material.

3. Always apply pressure in a straight line with the bit. Use enough

pressure to keep drill biting, but do not push hard enough to stall the

motor or deflect the bit.

4. Hold tool firmly to control the twisting action of the drill.

5. IF DRILL STALLS, it is usually because it is being overloaded or

improperly used. RELEASE TRIGGER IMMEDIATELY, remove drill

bit from work, and determine cause of stalling. DO NOT CLICK

TRIGGER OFF AND ON IN AN ATTEMPT TO START A STALLED

DRILL — THIS CAN DAMAGE THE DRILL.

6. To minimize stalling or breaking through the material, reduce

pressure on drill and ease the bit through the last fractional part of

the hole.

7. Keep the motor running when pulling the bit back out of a drilled

hole. This will help prevent jamming.

8. With variable speed drills there is no need to center punch the point

to be drilled. Use a slow speed to start the hole and accelerate by

squeezing the trigger harder when the hole is deep enough to drill

without the bit skipping out.

DRILLING IN METAL

An ‘SDS shank to round shank’ adapter chuck is required. Ensure

that tool is in rotation only mode. Start drilling with slow speed and

increase to full power while applying firm pressure on the tool. A smooth

even flow of metal chips indicates the proper drilling rate. Use a cutting

lubricant when drilling metals. The exceptions are cast iron and brass

which should be drilled dry. The cutting lubricants that work best are

sulphurized cutting oil or lard oil; bacon-grease will also serve the

purpose.

NOTE: Continuous use in variable speed range is not recommended.

It may damage the switch and should be avoided.

Forward/Reverse Control Button (3-C)

A forward/reverse control button determines the direction and also

serves as a lock off button. To select forward rotation, release the

trigger switch and depress the forward/reverse control button on the

right side of the tool.To select reverse, depress the forward/reverse

control button on the left side of the tool. The center position of the

control button locks the tool in the off position. When changing the

position of the control button, be sure the trigger is released. NOTE:

The first time the tool is run after changing the direction of rotation,

you may hear a click on start up. This is normal and does not indicate

a problem.

SDS Chuck (Fig. 3-D)

To insert bit,

insert shank of bit about 3/4” into chuck. Push and rotate

bit until it locks into place. The bit will be securely held.

To release bit,

pull the collar back and remove the bit.

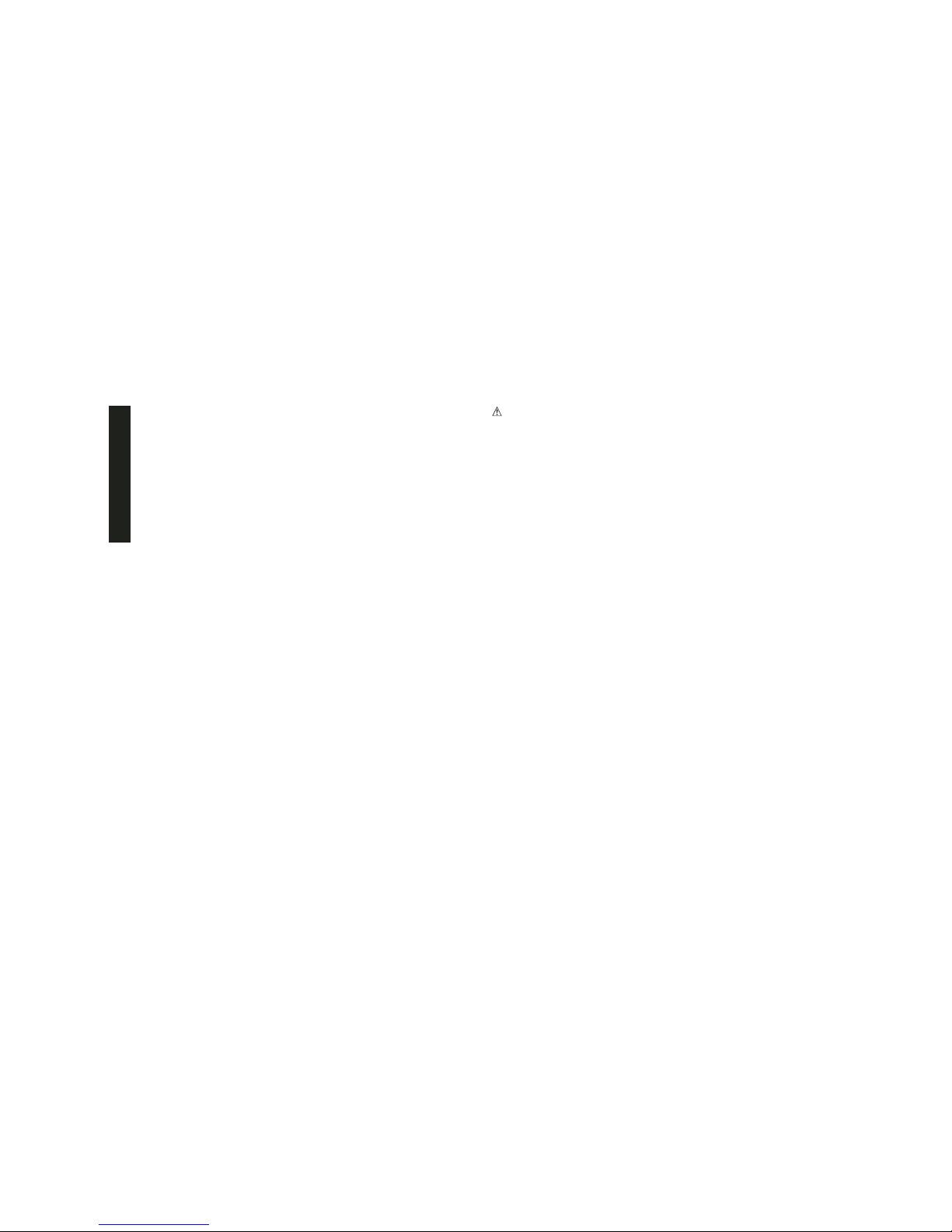

Hammer/Drill Selector (Fig. 4)

To switch the tool from the drilling mode to the hammering mode (or

vice-versa) rotate the dial (A) to the applicable symbol shown. For

straight drilling, align the dial with the drill bit symbol (B) as shown. For

hammering, align the dial with the hammer symbol (C). NOTE: The

selector must be in either drill, or hammer/drill mode at all times. There

are no operable positions between the two.

FIG. 4

A

B

C

Page 10

9

English

NOTE: Large (5/16” to 1/2”) holes in steel can be made easier if a pilot

hole (5/32” to 3/16”) is drilled first.

DRILLING IN WOOD

An ‘SDS shank to round shank’ adapter chuck is required. Ensure

that tool is in rotation only mode. Start drilling with slow speed and

increase to full power while applying firm pressure on the tool. Holes in

wood can be made with the same twist drills used for metal. These bits

may overheat unless pulled out frequently to clear chips from the flutes.

Work that is apt to splinter should be backed up with a block of wood.

DRILLING IN MASONRY

When drilling in masonry, use carbide tipped bits rated for percussion

drilling and be certain that the bit has adequate carbide on the tip.

Ensure that the rotary hammer mode is selected. Use a constant and

firm force on the tool to drill most effectively. A smooth, even flow of

dust indicates the proper drilling rate.

Depth Rod

To adjust the depth rod, loosen the handle and move rod so that the

distance between the end of the rod and the end of the bit equals the

desired drilling depth. When drilling with depth rod, stop when end of

rod reaches surface of material.

Maintenance

CLEANING & LUBRICATION

Use only mild soap and damp cloth to clean the tool. Never let any liquid

get inside the tool; never immerse any part of the tool into a liquid.

Self-lubricating bearings are used in the tool and periodic relubrication

is not required. If service is needed, take your tool to an authorized

service location.

Accessories

Recommended accessories for use with your tool are available for

purchase from your retailer or local service center.

CAUTION: The use of any non-recommended accessory may be

hazardous.

MAXIMUM RECOMMENDED CAPACITY - DW999

RPM 0 - 1,100

BPM 0 - 4900

BITS, METAL DRILLING 1/2”

BITS, FLAT BORING 1”

BITS, MASONRY 7/8” BIT - CONCRETE, BRICK, BLOCK

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information, call

1-800-4-D

EWALT. This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may have

other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALT heavy duty industrial tool, simply return it to the participating

seller within 30 days for a full refund. Please return the complete unit,

transportation prepaid. Proof of purchase may be required.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DEWALT for a free

replacement.

Page 11

SI VOUS AVEZ DES QUESTIONS OU VOULEZ NOUS FAIRE

PART DE VOS COMMENTAIRES CONCERNANT CET OUTIL OU

TOUT AUTRE OUTIL DeWALT, COMPOSEZ SANS FRAIS LE : 1

800 433-9258.

Règles générales de sécurité - Outils à

piles

AVERTISSEMENT! Lire et comprendre toutes les directives, car

le non-respect des directives suivantes peut entraîner un choc

électrique, un incendie ou des blessures graves.

CONSERVER CES DIRECTIVES

ZONE DE TRAVAIL

• Garder la zone de travail propre et bien éclairée; les établis

encombrés et les endroits sombres sont propices aux accidents.

• Ne pas utiliser les outils électriques dans une atmosphère

explosive, comme à proximité de liquides, de gaz ou de

poussières inflammables; le moteur peut créer des étincelles et

enflammer les vapeurs ou les poussières environnantes.

• Tenir les enfants, les visiteurs ou toute autre personne à

l’écart lorsqu’on utilise un outil électrique; les distractions

peuvent faire perdre la maîtrise de ce dernier.

MESURES DE SÉCURITÉ : ÉLECTRICITÉ

• Ne pas utiliser le cordon de manière abusive; on ne doit pas

transporter l’outil en le tenant par le cordon. On doit tenir le cordon

à l’écart des sources de chaleur, de l’huile, des bords tranchants

ou des pièces mobiles. Remplacer immédiatement les cordons

endommagés, car ces derniers augmentent les risques d’incendie.

• Un outil à piles intégrées ou à bloc-piles externe doit être

rechargé seulement au moyen du chargeur approprié, car un

chargeur destiné à une pile particulière peut entraîner un risque

d’incendie lorsqu’il est utilisé avec une autre.

• N’utiliser l’outil à piles qu’avec le bloc-piles désigné, car

l’utilisation d’un autre type de piles peut entraîner un risque

d’incendie.

SÉCURITÉ PERSONNELLE

• Rester vigilant en tout temps et faire preuve de jugement

lorsqu’on utilise un outil électrique; ne pas utiliser l’outil

lorsqu’on est fatigué ou sous l’influence de drogues, d’alcool ou

de médicaments, car un moment d’inattention peut entraîner des

blessures graves.

• Porter des vêtements appropriés; ne pas porter de vêtements

amples ni de bijoux. Couvrir ou attacher les cheveux longs. Garder

les cheveux, les vêtements, les bijoux et les gants éloignés des

pièces mobiles, car ceux-ci peuvent s’y coincer. Se tenir éloigné

des évents puisque ces derniers pourraient camoufler des pièces

mobiles.

• Éviter les démarrages accidentels; s’assurer que l’interrupteur

soit placé en position de verrouillage ou d’arrêt avant d’insérer le

bloc-piles. Ne pas transporter l’outil en laissant le doigt sur

l’interrupteur ni insérer le bloc-piles lorsque l’outil est en position de

marche, car cela pourrait causer un accident.

• Retirer les clés de réglage avant de démarrer l’outil; une clé

laissée sur une pièce rotative peut entraîner des blessures.

• Ne pas trop étendre les bras; les pieds doivent rester ancrés

fermement sur le sol afin de maintenir son équilibre en tout temps

et de mieux maîtriser l’outil dans des situations imprévues.

• Utiliser le matériel de sécurité approprié; toujours porter des

lunettes de protection. Porter un masque anti-poussières, des

chaussures antidérapantes, un casque de sécurité ou des

protecteurs auditifs lorsque la situation le requiert.

UTILISATION ET ENTRETIEN DE L’OUTIL

• Fixer et soutenir l’ouvrage sur une plate-forme stable au

moyen d’un étau ou de tout autre dispositif semblable;

l’ouvrage est instable lorsqu’on le retient manuellement ou qu’on

l’appuie contre le corps, ce qui peut faire perdre la maîtrise de

10

Français

Page 12

11

l’outil.

• Ne pas forcer l’outil ni l’utiliser pour des travaux autres que

ceux pour lesquels il a été conçu. Pour obtenir de meilleurs

résultats et prévenir les risques de blessure, laisser l’outil couper

à la vitesse pour laquelle il a été conçu.

• Ne pas utiliser l’outil lorsque l’interrupteur de marche-arrêt ne

fonctionne pas; tout outil qui ne peut être commandé au moyen

de l’interrupteur est dangereux et doit être réparé.

• Débrancher le bloc-piles de l’outil ou mettre l’interrupteur en

position de verrouillage ou d’arrêt avant d’effectuer un

réglage, de changer les accessoires ou de ranger l’outil; ces

mesures de sécurité préventives réduisent les risques de

démarrage accidentel.

• Lorsqu’on n’utilise pas l’outil, le ranger hors de la portée des

enfants ou des personnes non qualifiées; les outils sont

dangereux entre les mains de personnes inexpérimentées.

• Lorsqu’on n’utilise pas le bloc-piles, le ranger à l’écart des

objets métalliques tels que les trombones, les pièces de

monnaie, les clés, les clous, les vis ou autres petits objets

susceptibles de conduire l’électricité entre les bornes et

d’occasionner ainsi des étincelles, des brûlures ou un incendie.

• Bien entretenir l’outil; s’assurer qu’il soit toujours bien propre et

aiguisé. Les outils bien entretenus et dont les bords sont bien

tranchants sont moins susceptibles de rester coincés et sont plus

faciles à maîtriser.

• Vérifier les pièces mobiles afin de s’assurer qu’elles soient

bien alignées et qu’elles ne restent pas coincées; vérifier

également les pièces afin de s’assurer qu’il n’y ait aucun bris ni

aucune autre condition susceptible de nuire au bon

fonctionnement de l’outil. Faire réparer l’outil si ce dernier est

endommagé avant de s’en servir à nouveau, car les accidents sont

souvent causés par des outils mal entretenus.

•

N’utiliser que les accessoires recommandés par le fabricant

pour le modèle concerné;

un accessoire destiné à un outil

particulier peut devenir dangereux lorsqu’il est utilisé avec un

autre.

ENTRETIEN

• L’outil doit être entretenu ou réparé par le personnel qualifié

seulement; toute maintenance effectuée par une personne non

qualifiée peut entraîner des risques de blessure.

• Lors de l’entretien, n’utiliser que des pièces de rechange

identiques et suivre les directives de la section «Entretien» du

présent manuel afin de prévenir les risques de choc électrique ou

de blessure.

Mesures de sécurité additionnelles

relatives aux perceuses rotatives

MISE EN GARDE : Lorsqu’on perce dans les murs, les planchers

ou tout autre endroit o

∫

peuvent se trouver des fils sous tension, ne pas

toucher aux composants mêtalliques de l’outil. Ne le saisir que par ses

surfaces en plastique afin de se protéger des secousses électriques

si on entre en contact avec un fil sous tension.

Porter des protège-tympans lorsqu’on utilise l’outil pendant de longues

périodes.

MISE EN GARDE : porter un dispositif de protection

personnel anti-bruit approprié durant l’utilisation. Sous certaines

conditions et pendant toute la durée de l’utilisation, le bruit émanant

de ce produit pourrait contribuer à la perte d’audition.

ATTENTION: Quelques outils avec de grands paquets de batterie

se tiendront droits sur le paquet de batterie mais peuvent être

facilement frappés plus de. Quand pas en service, placez l'outil de son

côté sur une surface stable où il ne causera pas un risque de

déclenchement ou en chute.

AVERTISSEMENT : Certains outils, tels que les sableuses

électriques, les scies, les meules, les perceuses ou certains autres

outils de construction, peuvent soulever de la poussière contenant des

produits chimiques susceptibles d’entraîner le cancer, des

malformations congénitales ou pouvant être nocifs pour le système

reproductif. Parmi ces produits chimiques, on retrouve :

Français

Page 13

• le plomb dans les peintures à base de plomb;

• la silice cristalline dans les briques et le ciment et autres produits de

maçonnerie;

• l’arsenic et le chrome dans le bois de sciage ayant subi un

traitement chimique (CCA).

Le risque associé à de telles expositions peut varier selon la fréquence

avec laquelle on effectue ces travaux. Pour réduire l’exposition à de

tels produits, il faut travailler dans un endroit bien ventilé et utiliser

l’équipement de sécurité approprié tel un masque anti-poussières

spécialement conçu pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par

cet outil ou autres outils électriques. Porter des vêtements

de protection et nettoyer les parties exposées du corps avec

de l’eau savonneuse. S’assurer de bien se protéger afin d’éviter

d’absorber par la bouche, les yeux ou la peau des produits

chimiques nocifs.

• L’étiquette de l’outil peut comporter les symboles suivants.

V ........volts A ..........ampères

Hz ......hertz W..........watts

min......minutes ........courant alternatif

....courant continu no ........sous vide

........Construction de classe II ..........borne de mise à la

............ ............minute

......symbole d´avertissement .../min ..tours à la minute

Importantes consignes de sécurité

concernant les bloc-piles

Les piles ne sont pas complètement chargées au moment de leur

livraison! Avant de les charger, lire attentivement toutes les

consignes de sécurité énumérées ci-dessous, ainsi que les

remarques, les notes et les méthodes de chargement.

LIRE TOUTES LES DIRECTIVES

• Ne pas incinérer les bloc-piles, même s’ils ont subi des

dommages importants ou ils sont usés complètement, car ils

peuvent exploser en présence de flammes.

• Les cellules des bloc-piles peuvent subir une fuite légère par

suite d’un usage extrême ou d’une exposition à certaines

températures; ceci n’indique pas un problème. Cependant, si le

scellant externe est percé et le liquide entre en contact avec la

peau, on doit :

a) se laver rapidement la partie du corps touchée avec de l’eau

savonneuse;

b) neutraliser l’effet au moyen d’un acide doux tel que du jus de

citron ou du vinaigre;

c) si les yeux sont touchés, les rincer à fond avec de l’eau propre

pendant au moins 10 minutes et consulter immédiatement un

médecin. (Remarque aux fins médicales : ce liquide contient

une solution composée de 25 à 35 % d’hydroxyde de

potassium.)

• Ne pas transporter des bloc-piles supplémentaires dans un tablier,

une poche ou une boîte à outils contenant des objets métalliques,

car le bloc-pile pourrait causer un court-circuit et s’endommager,

ou risquer de provoquer de graves brûlures ou un incendie.

• Ne charger les bloc-piles qu’au moyen des chargeurs D

EWALT.

• REMARQUE : le bloc-piles contient des piles au nickel-cadmium.

Le cadmium est considéré comme une substance toxique par les

agences de protection de l’environnement, dont le ministère de

l’Environnement; on recommande donc de vérifier auprès de

l’agence concernée avant de mettre au rebut des bloc-piles au

nickel-cadmium usés ou endommagés afin de se renseigner sur les

dispositions particulières qui s’appliquent dans votre région à ce

sujet, ou de retourner les bloc-piles usés ou endommagés à un

centre de service qualifié D

EWALT afin qu’ils puissent être recyclés.

•

NE PAS

ranger ni utiliser l’outil ou le bloc-piles dans des endroits

où la température peut atteindre ou dépasser 40,5 ºC (105 ºF),

comme les cabanons ou les bâtiments en revêtement métallique

durant l’été.

12

Français

Page 14

13

• DANGER : Ne jamais tenter d’ouvrir le bloc-piles pour quelle que

raison que ce soit. Si le compartiment se rupture ou subit des

dommages, ne pas l’insérer dans le chargeur afin

d’éviter les risques de choc électrique ou

d’électrocution. On doit retourner les bloc-piles

endommagés à un centre de service afin qu’ils

puissent être recyclés.

REMARQUE : un capuchon est fourni avec la pile en vue

d’être utilisé chaque fois qu’on retire cette dernière de l’outil ou du

chargeur en vue de la ranger ou de la transporter; enlever le capuchon

avant de remettre la pile dans le chargeur ou dans l’outil.

AVERTISSEMENT : s’assurer, au moment de ranger ou de

transporter la pile, qu’aucun objet métallique n’entre en contact

avec les bornes à découvert de la pile.

Par exemple, il faut éviter de

placer une pile sans capuchon dans un tablier, une poche, une boîte à

outils ou un tiroir (etc.) contenant des objets tels que des clous, des vis

ou des clés, car la pile pourrait causer un court-circuit et

s’endommager, ou risquer de provoquer des brûlures ou un incendie.

Bloc-piles

L'outil fonctionne sur un bloc-piles DEWALT de 18 volts. Lorsqu’on

commande des bloc-piles de rechange, on doit indiquer le numéro de

catalogue et la tension requise. Les bloc-piles à durée prolongée

durent 25 % plus longtemps que les bloc-piles standard.

REMARQUE : bien que l’outil puisse fonctionner au moyen de l’un ou

l’autre des deux types de bloc-piles, on doit s’assurer d’en choisir un

de tension appropriée.

Sceau RBRC

MC

Le sceau RBRCMC de la Rechargeable Battery Recyc

ling Corporation apposé sur la pile au nickel-cadmium (ou

le bloc-piles) indique que les coûts de recyclage de ce

dernier à la fin de sa vie utile ont déjà été payés par

D

EWALT. En certains endroits, la mise au rebut ou aux

ordures municipales des piles au nickel-cadmium est illégale; le

programme de «RBRC» constitue donc une solution des plus

pratiques et écologiques.

La «RBRC», en collaboration avec D

EWALT et d’autres utilisateurs de

piles, a mis sur pied des programmes aux États-Unis dans le but de

faciliter la collecte des piles déchargées. D

EWALT encourage ses

utilisateurs à participer à son programme de protection de l'environnement et de conservation des ressources naturelles en retournant les

piles usagées à un centre de service D

EWALT ou chez un dépositaire

local afin qu’elles puissent être recyclées. On peut en outre se

renseigner auprès d’un centre de recyclage local pour connaître

d'autres sites les acceptant.

Retrait et installation de l’ensemble de

piles (Fig. 1)

NOTE : S’ASSURER QUE

L’ENSEMBLE DE PILES EST

COMPLÈTEMENT CHARGÉ.

Pour installer l’ensemble de piles

dans la poignée de l’outil, aligner le

socle de l’outil sur l’encoche à

l’intérieur de la poignée de l’outil et

faire glisser l’ensemble de piles fermement dans la poignée jusqu’à

ce qu’un déclic se fasse entendre.

Pour retirer l’ensemble de piles de l’outil, il suffit d’appuyer sur les

boutons de dégagement et de tirer fermement l’ensemble de piles hors

de la poignée de l’outil. L’insérer dans le chargeur de la façon décrite

précédemment.

Importantes consignes de sécurité

concernant les chargeurs

CONSERVER CES DIRECTIVES – Le présent manuel contient

d’importantes consignes de sécurité concernant les chargeurs

D

EWALT.

Français

FIG. 1

Page 15

• Avant d’utiliser le chargeur, lire toutes les directives et étiquettes de

mise en garde apposées sur le chargeur, la pile et le produit utilisant

la pile.

• Ne pas utiliser les outils électriques dans une atmosphère

explosive, comme à proximité de liquides, de gaz ou de poussières

inflammables; le moteur peut créer des étincelles et enflammer les

vapeurs ou les poussières environnantes.

• MISE EN GARDE : afin de réduire les risques de blessure, ne

charger que des piles au nickel-cadmium rechargeables D

EWALT,

car les autres peuvent éclater et entraîner des blessures ou des

dommages matériels.

• MISE EN GARDE : dans certaines conditions, lorsque le

chargeur est enfiché, les raccords de charge à nu situés à l’intérieur

du chargeur peuvent subir un court-circuit lorsqu’ils entrent en

contact avec une matière étrangère. Les matières conductives

comme la laine d’acier, la feuille d’aluminium ou les particules

métalliques, mais sans toutefois s’y limiter, doivent être tenus à

l’écart des cavités du chargeur. Toujours débrancher celui-ci

lorsque le bloc-piles n’y est pas inséré ou avant de le nettoyer.

• DANGER : les bornes du chargeur conduisent une haute

tension; on ne doit pas les toucher au moyen d’objets conducteurs

afin d’éviter les risques de choc électrique ou d’électrocution.

• AVERTISSEMENT : ne jamais laisser de liquide s’infiltrer à

l’intérieur du chargeur ni l’exposer à la pluie ou à la neige afin

d’éviter les risques de choc électrique.

• Le chargeur et le bloc-piles sont conçus spécialement pour être

utilisés ensemble; NE PAS charger le bloc-piles au moyen d’un

chargeur autre que ceux décrits dans le présent manuel.

• N’utiliser ces derniers que pour charger les piles rechargeables

D

EWALT; tout autre usage peut entraîner des risques d’incendie, de

choc électrique ou d’électrocution.

• Afin de réduire les risques de dommage à la fiche ou au cordon

électrique, débrancher le chargeur en saisissant la fiche, non le

cordon.

• S’assurer que le cordon soit placé de manière à éviter qu’il ne

subisse des dommages ou des contraintes ou que les personnes

s’y prennent les pieds et trébuchent.

• Ne pas utiliser de rallonge à moins que cela ne soit absolument

nécessaire, car l’usage d’une rallonge ayant une puissance

inadéquate pourrait causer des risques d’incendie, de choc

électrique ou d’électrocution.

• Afin d’assurer la sécurité de l’utilisateur, la rallonge doit être de

calibre AWG approprié. Plus le calibre est petit, plus la capacité est

grande; autrement dit, une rallonge de calibre 16 est plus puissante

qu’une rallonge de calibre 18. Lorsqu’on utilise plusieurs rallonges

pour obtenir la longueur voulue, s’assurer que chacune d’elles

présente les valeurs minimales requises.

Calibre minimal recommandé des rallonges

Longueur totale de la rallonge (en pieds)

25 50 75 100 125 150 175

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Calibre AWG

18 18 16 16 14 14 12

• Le chargeur s’aère par l’entremise de fentes situées sur le dessus

et le dessous du logement; ne jamais mettre un objet sur le dessus

du chargeur ni placer celui-ci sur une surface molle risquant

d’obstruer les fentes de ventilation, ce qui pourrait causer une

chaleur interne excessive. Tenir le chargeur éloigné de toute

source de chaleur.

• Ne pas faire fonctionner le chargeur lorsque le cordon ou la fiche

est endommagé. Si tel est le cas, les remplacer immédiatement.

• Ne pas faire fonctionner le chargeur s’il a subi un coup important,

une chute ou des dommages quelconques. Si cela se produit,

l’emporter à un centre de service autorisé.

• Ne pas démonter le chargeur, car un mauvais assemblage pourrait

occasionner des risques de choc électrique, d’électrocution ou

d’incendie. Le chargeur doit être retourné à un centre de service

autorisé aux fins d’une réparation ou d’un entretien, le cas échéant.

14

Français

Page 16

15

• Afin de réduire les risques de choc électrique, débrancher le

chargeur de la prise murale avant de procéder au nettoyage; le

seul fait d’enlever le bloc-piles ne réduit pas ce risque.

•

Ne JAMAIS

brancher deux chargeurs ensemble.

• Ne pas alimenter le chargeur au moyen d’une source autre que

celles indiquées sur la plaque signalétique.

Chargeurs

Les piles DEWALT peuvent être chargées au moyen d’un chargeur

D

EWALT d’une heure ou de 15 minutes, ou d’un chargeur pour

véhicules de 12 volts. S’assurer de lire toutes les consignes de

sécurité avant d’utiliser le chargeur.

Consulter le diagramme apparaissant sur le couvercle arrière afin

de vérifier la compatibilité du chargeur avec le bloc-piles.

Méthode de chargement

CHARGEURS D’UNE HEURE

1. Enficher le chargeur dans une prise appropriée.

2. Insérer le bloc-piles dans le chargeur, tel qu’illustré à la FIG. 1, en

s’assurant de bien l’enfoncer. Le voyant (de charge) rouge clignotera

continuellement, indiquant que le cycle de charge est amorcé.

3. Le bloc-piles est complètement chargé après environ une heure.

Le voyant rouge restera allumé, indiquant que le bloc-piles est

complètement rechargé; on peut alors le réutiliser ou le laisser

dans le chargeur.

PROBLÈMES RELIÉS À LA SOURCE DE COURANT : les chargeurs

munis d’un voyant d’indication de problème au niveau de la source de

courant peuvent suspendre temporairement le chargement s’il est

branché dans une source d’alimentation portative, comme une

génératrice ou un convertisseur de courant continu en courant

alternatif. En présence d’un tel problème, le voyant rouge émet

deux clignotements rapides, suivis d’une pause, indiquant que le

problème se situe au niveau de la source de courant.

DISPOSITIF DE DÉTECTION DE PILES CHAUDES : si le chargeur

est muni d’un dispositif visant à détecter les piles chaudes, le

chargement sera retardé jusqu’à ce que la pile se soit refroidie et le

chargeur se placera automatiquement en position de chargement; ce

dispositif sert à maximiser la durée de vie des piles. Le voyant rouge

s’allume longuement, et ensuite brièvement lorsque ce dispositif est en

marche.

CHARGEURS DE 15 MINUTES

1. Enficher le chargeur dans une prise appropriée; une fois alimenté,

il émet deux signaux sonores et le voyant rouge clignote puis

s’éteint.

2. Insérer le bloc-piles dans le chargeur, tel qu’illustré à la FIG. 1, en

s’assurant de bien l’enfoncer. Le voyant rouge clignotera

continuellement et le chargeur émettra un seul signal sonore pour

indiquer que le cycle de charge est amorcé.

3. Dans la plupart des cas, le bloc-piles requiert moins de 15 minutes

pour se charger complètement. Le voyant rouge reste allumé et le

chargeur émet trois signaux sonores pour indiquer que le blocpiles est complètement rechargé; on peut alors le réutiliser ou le

laisser dans le chargeur.

4. BLOC-PILES FAIBLE : on peut aussi utiliser le chargeur de 15

minutes pour déterminer si une pile est faible. Bien qu’on puisse

continuer à utiliser une pile faible, elle ne procurera pas un plein

rendement. Si tel est le cas, 10 secondes après l’insertion de la pile,

le chargeur émettra rapidement huit signaux sonores pour indiquer

qu’il s’agit d’une pile faible, puis chargera la pile jusqu’à sa pleine

capacité.

Français

¥

C

H

A

R

G

I

N

G

¥

C

H

A

R

G

E

D

¥

D

E

L

A

Y

15 MINUTE CHARGER

F

L

A

S

H

I

N

G

O

N

F

A

S

T

F

L

A

S

H

¥

D

E

F

E

C

T

I

V

E

P

A

C

K

O

N

D

W

9

1

1

5

DANGER:

WARNING:

¥ C

H

AR

G

IN

G

¥

C

H

A

R

GE

D

¥

D

E

L

A

Y

D

W

9

1

1

5

DANGER:

WARNING:

15 M

IN

U

TE C

H

A

RG

ER

F

L

A

SH

IN

G

O

N

F

AS

T

FLA

SH

¥

D

E

FEC

T

IV

E PA

CK

O

N

9

.0

v

E

X

T

E

N

D

E

D

R

U

N

T

I

M

E

R

R

CHARGEUR

DE 15 MINUTE

¥ C

H

A

R

GI

N

G

¥

CH

A

R

G

E

D

¥

D

E

L

A

Y

1

5

M

I

N

U

T

E

C

H

A

R

G

E

R

FL

A

S

H

IN

G

O

N

F

A

S

T

FL

A

S

H

¥

D

E

FE

CT

IV

E

P

A

C

K

O

N

D

W

9115

D

A

N

G

E

R

:

W

A

R

N

I

N

G

:

CHARGEURS

D’ 1 HEUR E

FIG. 2

Page 17

CHARGEURS DE TOUT TYPE

Bloc-piles laissé dans le chargeur. Lorsque le voyant rouge reste

allumé, cela signifie que le chargeur s’est placé en mode d’égalisation

de charge, lequel peut rester ainsi pendant environ 4 heures. Après

ce délai, le chargeur se placera en mode de tenue de charge. Bien que

le bloc-piles puisse être retiré pendant n’importe quel de ces cycles, il

n’est complètement chargé que lorsque le voyant rouge reste allumé

continuellement. On peut laisser le chargeur (avec un bloc-piles

inséré) raccordé à une prise tant que le voyant rouge reste allumé; le

chargeur maintient alors la charge du bloc-piles afin que ce dernier soit

prêt à être utilisé. Un bloc-piles perd graduellement sa charge s’il n’est

pas gardé dans le chargeur. Un bloc-piles n’étant pas maintenu en

mode de tenue de charge devra être rechargé avant son utilisation. Un

bloc-piles peut graduellement perdre sa charge s’il est laissé dans un

chargeur qui n’est pas enfiché dans une source d’alimentation à

courant alternatif appropriée.

INDICATEURS D’ANOMALIE : les chargeurs sont conçus pour

détecter certains problèmes pouvant être reliés aux bloc-piles. Ces

problèmes sont indiqués par le clignotement rapide du voyant rouge et,

dans le cas des chargeurs de 15 minutes, par un signal sonore

continu. Si un tel problème survient, réinsérer le bloc-piles dans le

chargeur. Si le problème persiste, remplacer le bloc-piles afin de

déterminer si le chargeur fonctionne bien. Si le bloc-piles de rechange

se charge correctement, cela signifie que le bloc initial est défectueux

et qu’on doit le retourner à un centre de service afin qu’il puisse être

recyclé. Si le bloc neuf affiche le même problème que le bloc initial, on

doit faire vérifier le chargeur à un centre de service autorisé.

Notes importantes concernant le

chargement

1. Afin de maximiser la durée de vie du bloc-piles et d’assurer son

rendement optimal, le charger à la température ambiante, soit

entre 18 et 24 °C (65 et 75 °F). Afin d’éviter d’endommager le

bloc-piles, il est important de NE PAS le charger à des

températures inférieures à +4,5 °C (+40 °F) ou supérieures à

+40,5 °C (105 °F).

2. Le chargeur et le bloc-piles peuvent devenir chauds au toucher

lors du chargement. Ceci est normal et n’indique pas la présence

d’un problème.

3. Si le bloc-piles ne se charge pas normalement, il faut : (1) vérifier

l’alimentation de la prise en y enfichant une lampe ou un appareil,

(2) s’assurer que la prise ne soit pas raccordée à un interrupteur qui

coupe le courant lorsqu’on éteint les lumières, (3) placer le chargeur

et le bloc-piles dans un endroit où la température ambiante est

environ 18 à 24 °C (65 et 75 °F) ou, si le problème persiste, (4)

retourner l’outil, le bloc-piles et le chargeur au centre de service de

sa région.

4. Le bloc-piles doit être rechargé lorsqu’il ne produit pas

suffisamment de courant pour permettre à l’utilisateur de travailler

normalement. On doit CESSER de l’utiliser dans de telles

conditions et suivre la méthode de chargement. On peut aussi

charger en tout temps un bloc-piles partiellement déchargé sans

nuire à son fonctionnement.

5. Dans certaines conditions, lorsque le chargeur est enfiché, les

raccords de charge à nu situés à l’intérieur du chargeur peuvent

subir un court-circuit lorsqu’ils entrent en contact avec une matière

étrangère. Les matières conductives comme la laine d’acier, la

feuille d’aluminium ou les particules métalliques, mais sans

toutefois s’y limiter, doivent être tenus à l’écart des cavités du

chargeur. Toujours débrancher celui-ci lorsque le bloc-piles n’y est

pas inséré ou avant de le nettoyer.

6. Ne pas congeler le chargeur ni l’immerger.

AVERTISSEMENT : ne jamais laisser de liquide s’infiltrer à

l’intérieur du chargeur afin d’éviter les risques de choc électrique. Pour

faciliter le refroidissement du bloc-piles après son utilisation, éviter de

placer ce dernier ou le chargeur dans un environnement chaud comme

un cabanon en métal ou une remorque non isolée.

MISE EN GARDE : Ne jamais ouvrir le bloc-piles pour quelle que

raison que ce soit. Si le compartiment en plastique se rupture ou se

fissure, le retourner au centre de service afin qu’il puisse être recyclé.

16

Français

Page 18

17

L'EXÉCUTION de BATTERIE

L'EXÉCUTION de BATTERIE que quelques chargeurs ont un

dispositif de mise au point optimalise l'exécution de paquet de

batterie. Votre chargeur peut fournir automatique Accordent-Up™

le mode ou manuel (c.-à-d. bouton de poussée) Accordez-Up™ le

mode. Pour l'information sur ce dispositif, voir s'il vous plaît la

section appropriée ci-dessous. Puisque les batteries détruisent

lentement leur charge quand elles ne sont pas sur le chargeur, le

meilleur endroit pour garder votre paquet de batterie est sur le

chargeur à tous les temps.

L'utilisation automatique Accordent-Up™

L'utilisation automatique Accordent-Up™ le mode que les

automatiques Accordent-Vers le haut le mode égalisent ou

équilibrent les différentes cellules dans le paquet de batterie lui

permettant de fonctionner à la capacité maximale. Des paquets de

batterie devraient être accordés vers le haut après que chaque

10ème cycle de charge/décharge ou toutes les fois que le paquet ne

fournit plus la même quantité de travail. Pour utiliser le mode

automatique de mise au point, placez simplement le paquet de

batterie dans le chargeur et laissez-le pendant au moins huit heures.

Le chargeur fera un cycle par les modes suivants.

1. La lumière rouge clignotera sans interruption indiquant que le

cycle d'une heure de charge a commencé.

2. Quand le cycle d'une heure de charge est complet, la lumière

restera en fonction sans interruption et ne clignotera plus. Ceci

indique que le paquet est entièrement chargé et peut être utilisé

à ce moment.

3. Toutes les fois que le paquet est laissé dans le chargeur après que

la charge d'une heure initiale, le chargeur commence l'automatique

Accordez-Vers le haut le mode. Ce mode continue jusqu'à 8

heures ou jusqu'aux différentes cellules dans le paquet de batterie

sont égalisés. Le paquet de batterie est opérationnel et peut être

retiré à tout moment pendant Accordent-Vers le haut le mode.

4. Une fois les automatiques Accordent-Vers le haut le mode sont

complets la transition de volonté de chargeur à une charge

d'entretien ; aucun voyant de signalisation ne montre

l'accomplissement de l'Autom.

Mode rechargement (Tune-UpMC)

Le mode rechargement (Tune-UpMC) sert à égaliser ou à équilibrer

chaque cellule du bloc-piles lors de son cycle de capacité limite; le

cycle total dure 8 heures. Le bloc-piles doit être rechargé chaque

semaine, après 10 ou 20 cycles de charge / de décharge ou lorsque

la capacité du bloc-piles commence à diminuer.

1. Pour recharger le bloc-piles, placer les piles dans le chargeur de

la manière habituelle. Le voyant rouge clignotera continuellement,

indiquant que le cycle de charge est amorçé.

2. On peut enfoncer le bouton Tune-Up

MC

à n’importe quel moment

une fois la charge amorçée. Le voyant rouge s’éteindra

momentanément, clignotera trois fois brièvement puis restera

allumé, indiquant que le chargeur est en mode rechargement.

3. Une fois le cycle de rechargement terminé, le voyant restera

allumé, indiquant que le bloc-piles est complètement rechargé; on

peut alors le réutiliser ou le laisser dans le chargeur.

4. Si on sélectionne le mode de rechargement mais qu’on change

d’idée par la suite, retirer les piles du chargeur. Attendre 5

secondes, puis réinsérer la pile afin d’amorcer le cycle de charge

normal.

CONSERVER CES MESURES

Poignée latérale (Fig. 3)

Toujours utiliser la poignée latérale fournie avec l’outil et toujours le

tenir fermement; toujours faire fonctionner l’outil en le tenant avec les

deux mains afin de ne pas perdre la maîtrise. Éviter de percer les

matériaux durs tels que les barres d’armature ou de mettre la mèche

en contact avec ceux-ci afin d’éviter les risques de blessure.

Français

Page 19

Interrupteur (Fig. 3-B)

Enfoncer l’interrupteur à détente pour mettre l’outil en marche (B).

Pour l’arrêter, il suffit de relâcher l’interrupteur. Pour assurer le

fonctionnement continu de l’outil, il suffit d’enfoncer la détente et de

pousser le bouton de verrouillage vers le haut. L’outil continue alors

de fonctionner. Pour arrêter l’outil lorsqu’il est en mode de

fonctionnement continu, enfoncer l’interrupteur à fond et le relâcher.

Toujours s’assurer que le bouton de verrouillage fonctionne bien

avant d’utiliser l’outil (chaque fois).

Ne pas verrouiller l’interrupteur lorsqu’on effectue des travaux de

perçage manuels de manière à relâcher instantanément l’interrupteur

si le foret reste coincé. Il faut seulement utiliser le bouton de

verrouillage lorsque la perceuse est installée sur un établi ou fixée de

toute autre façon. Veiller à ce que le bouton de verrouillage soit

dégagé avant de débrancher l’outil, sinon celui-ci se remettra

immédiatement en marche la prochaine fois qu’on s’en servira et cela

présente des risques de dommages et de blessures.

Le régulateur de vitesse permet de contrôler la vitesse de l’outil. Plus

on enfonce l’interrupteur à détente, plus l’outil fonctionne rapidement.

NOTE : Afin de maximiser la durée de l’outil, se servir des basses

vitesses uniquement pour l’amorçage de trous sans utiliser un

poinçon au préalable, pour percer les métaux, les plastiques et la

céramique ou pour enfoncer des vis. Les vitesses élevées

conviennent mieux au perçage du bois et des panneaux ainsi que

pour utiliser des accessoires de ponçage et de polissage.

L’inverseur de marche sert à sortir les vis ou les forets bloqués. Il se

trouve au-dessus de l’interrupteur à détente, comme le montre la

figure 2. Pour actionner la marche arrière, il faut mettre l’outil hors

tension et faire glisser l’inverseur de marche vers la gauche (lorsqu’on

regarde le mandrin). Remettre l’inverseur à la marche avant en

arrêtant d’abord l’outil et en faisant glisser l’inverseur vers la droite.

Fonctionnement à vitesses basses ou

élevées (Fig. 3-C)

Les deux gammes de vitesses de la perceuse rotatives procurent un

fonctionnement efficace pour une gamme complète d’utilisations

avec un grand choix d’accessoires.

Pour utiliser les VITESSES BASSES, faire tourner le cadran de

sélection qui se trouve sous la perceuse rotatives de sorte que le

symbole des vitesses basses se trouve à l’avant de l’outil.

Pour utiliser les VITESSES ÉLEVÉES, faire tourner le cadran de

sélection de sorte que le symbole des vitesses élevées se trouve à

l’avant de l’outil.

On peut seulement modifier la position des engrenages lorsque l’outil

est hors tension. Il peut toutefois être nécessaire de faire tourner le

mandrin légèrement à la main afin d’aligner les engrenages lorsqu’on

fait tourner le cadran de sélection. NE PAS TENTER DE MODIFIER

LE RÉGIME DE L’OUTIL en actionnant le cadran de sélection lorsque

l’outil fonctionne au risque d’endommager les engrenages.

Mandrin SDS (Fig. 3-D)

Pour insérer un foret, ouvrir les mâchoires du mandrin en faisant

tourner la bague à la main et y insérer environ 3/4 po de l’arbre du

foret. Resserrer la bague du mandrin à la main. Placer la clé du

18

Français

FIG. 3

A

C

B

D

Page 20

19

mandrin dans chacun des trois trous et serrer dans le sens horaire. Il

estessentiel de bien serrer les trois trous du mandrin afin de prévenir

le glissement du foret. Pour dégager le foret, il suffit de faire tourner la

clé du mandrin dans le sens antihoraire dans l’un des trous, puis de

desserrer le mandrin à la main.

Sélecteur du mode de fonctionnement

(Fig.4)

Pour passer du mode de perçage à celui de perçage rotaives (ou vice

versa), faire tourner le cadran qui se trouve sur le dessus de l’outil en

choisissant le symbole approprié. Pour percer, aligner le symbole du

foret sur le mandrin. Pour percer rotative, aligner celui du marteau sur

le mandrin (voir la figure).

NOTE : Le sélecteur doit être dans l’une ou l’autre de ces positions en

tout temps. Il n’y a aucun mode de fonctionnement entre ces deux

positions.

Fonctionnement

PERÇAGE

1. Toujours débrancher l’outil lorsqu’on en change les forets ou les

accessoires.

2. N’utiliser que des forets bien affûtés. Pour le BOIS : utiliser les

vitesses basses et des forets hélicoïdaux, à langue d’aspic, de

tarière ou des emporte-pièce; pour le MÉTAL : utiliser les vitesses

basses et des forets hélicoïdaux en acier de coupe rapide ou des

emporte-pièce; pour la MAÇONNERIE (brique, ciment et béton,

etc.) : forets au carbure pour le perçage à percussion. Utiliser les

vitesses basses pour les forets de plus de 3/8 po de diamètre.

3. Veiller à ce que la pièce à percer soit solidement retenue ou fixée

en place. Afin d’éviter les avaries aux matériaux minces, les

adosser à un bloc de bois épais.

4. Toujours exercer la pression en ligne directe avec le foret. N’user

que de la force qu’il faut pour que le foret continue de percer; éviter

de trop forcer, ce qui pourrait faire caler le moteur ou dévier le foret.

5. Saisir fermement la perceuse afin de contrer l’effet de torsion de

l’outil en marche.

6. LA PERCEUSE S’ÉTOUFFE habituellement lorsqu’elle est

surchargée ou utilisée de façon inappropriée. RELÂCHER

IMMÉDIATEMENT L’INTERRUPTEUR À DÉTENTE, retirer le

foret du matériau et déterminer la cause du blocage. ÉVITER DE

METTRE EN MARCHE ET HORS CIRCUIT L’OUTIL À L’AIDE

DE L’INTERRUPTEUR À DÉTENTE DANS LE BUT DE FAIRE

DÉMARRER LA PERCEUSE BLOQUÉE, CELA POURRAIT

L’ENDOMMAGER.

7. Afin de minimiser l’étouffement du moteur ou le défoncement de

la pièce, réduire la pression et faire avancer plus doucement le

foret vers la fin de sa course.

8. Laisser le moteur en marche lorsqu’on retire le foret d’un trou afin

d’éviter qu’il se coince.

9. Il n’est pas nécessaire de pratiquer un creux de guidage avec les

perceuses à régulateur de vitesse. Utiliser plutôt une basse

vitesse pour commencer le trou, puis accélérer en enfonçant plus

profondément l’interrupteur à détente lorsque le foret est

suffisamment inséré dans la pièce.

PERÇAGE DANS LE MÉTAL

UTILISER SEULEMENT à la gamme de vitesses basses.

Commencer à percer à basse vitesse et augmenter jusqu’à la pleine

puissance tout en exerçant une pression ferme sur l’outil. Une

Français

FIG. 4

A

B