Page 1

DEWALT Industrial Tool Company, P.O. Box 158, 626 Hanover Pike, Hampstead, MD 21074 Printed in Italy (MAY96-1) Form No. 154716

Copyright © 1996

Page 2

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW621

Plunge 2 HP Router

Toupie à course plongeante de 2 HP

Rebajadora de columnas de 2 HP

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTIA. ADVERTENCIA: LEASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO. SI TIENE DUDAS, POR FAVOR LLAME.

Page 3

English

General Safety Rules

WARNING! Read and understand all instructions. Failure to follow

all instructions listed below may result in electric shock, fire and/or

serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while operating

a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Double insulated tools are equipped with a polarized plug

(one blade is wider than the other.) This plug will fit in a

polarized outlet only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install a polarized outlet. Do not

change the plug in any way. Double insulation eliminates the

need for the three wire grounded power cord and grounded power

supply system.

• Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of

electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools

or pull the plug from an outlet. Keep cord away from heat, oil,

sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor

extension cord marked “W-A” or “W.” These cords are rated

0.8

0.6

5/8

1

/2

3/4

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

Page 4

for outdoor use and reduce the risk of electric shock. When using

an extension cord, be sure to use one heavy enough to carry the

current your product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and overheating.

The following table shows the correct size to use depending on

cord length and nameplate ampere rating. If in doubt, use the next

heavier gage. The smaller the gage number, the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0- 6 18 161614

6- 10 18 16 14 12

10 - 12 16161412

12 - 16 14 12 Not Recommended

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or medication. A moment

of inattention while operating power tools may result in serious

personal injury,

• Dress properly. Do not wear loose clothing or jewelry. Contain

long hair. Keep your hair, clothing, and gloves away from

moving parts. Loose clothing, jewelry, or long hair can be caught

in moving parts.

• Avoid accidental starting. Be sure switch is off before

plugging in. Carrying tools with your finger on the switch or

plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or switches before turning the tool on.

A wrench or key that is left attached to a rotating part of the tool may

result in personal injury.

• Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control of the tool

in unexpected situations.

1

English

• Use safety equipment. Always wear eye protection. Dust mask,

non-skid safety shoes, hard hat, or hearing protection must be used

for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the

workpiece to a stable platform. Holding the work by hand or

against your body is unstable and may lead to a loss of control.

• Do not force tool. Use the correct tool for your application. The

correct tool will do the job better and safer and the rate for which it

is designed.

• Do not use tool if switch does not turn it on or off. Any tool that

cannot be controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source before making any

adjustments, changing accessories, or storing the tool. Such

preventative safety measures reduce the risk of starting the tool

accidentally.

• Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools, with sharp cutting edges are less likely to

bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage

of parts, and any other condition that may affect the tools

operation. If damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the

manufacturer for your model. Accessories that may be suitable

for one tool, may become hazardous when used on another tool.

Page 5

2

SERVICE

• Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this manual.

Use of unauthorized parts or failure to follow Maintenance

Instructions may create a risk of electric shock or injury.

Additional Safety Rules

• Hold tool by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring or

its own cord. Contact with a “live” wire will make exposed metal

parts of the tool “live” and shock the operator.

• Keep handles dry, clean, free from oil and grease. It is

recommended to use rubber gloves. This will enable better control

of the tool.

• The label on your tool may include the following symbols.

• The label on your tool may include the following symbols.

V ............................volts

A ............................amperes

Hz ..........................hertz

W ..........................watts

min ........................minutes

..........................alternating current

......................direct current

n

o ..........................no load speed

..........................

Class II Construction

…/min ....................revolutions or reciprocation per minute

..........................earthing terminal

..........................safety alert symbol

Motor

Be sure your power supply agrees with nameplate marking.

120 AC means your tool may be operated only with alternating

current and never with direct current.

Voltage decrease of more than 10% will cause loss of power and

overheating. All tools are factory tested; if this tool does not operate,

check the power supply.

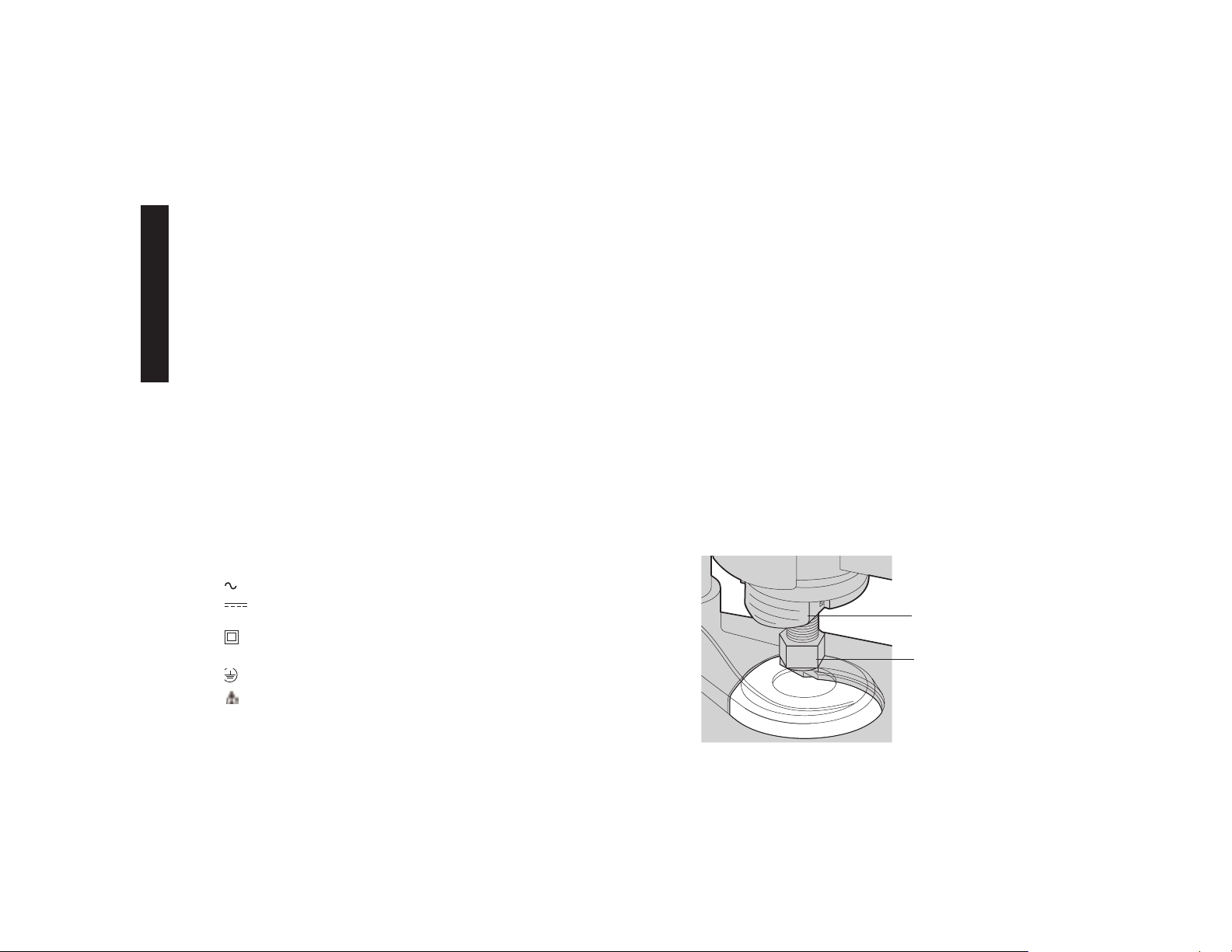

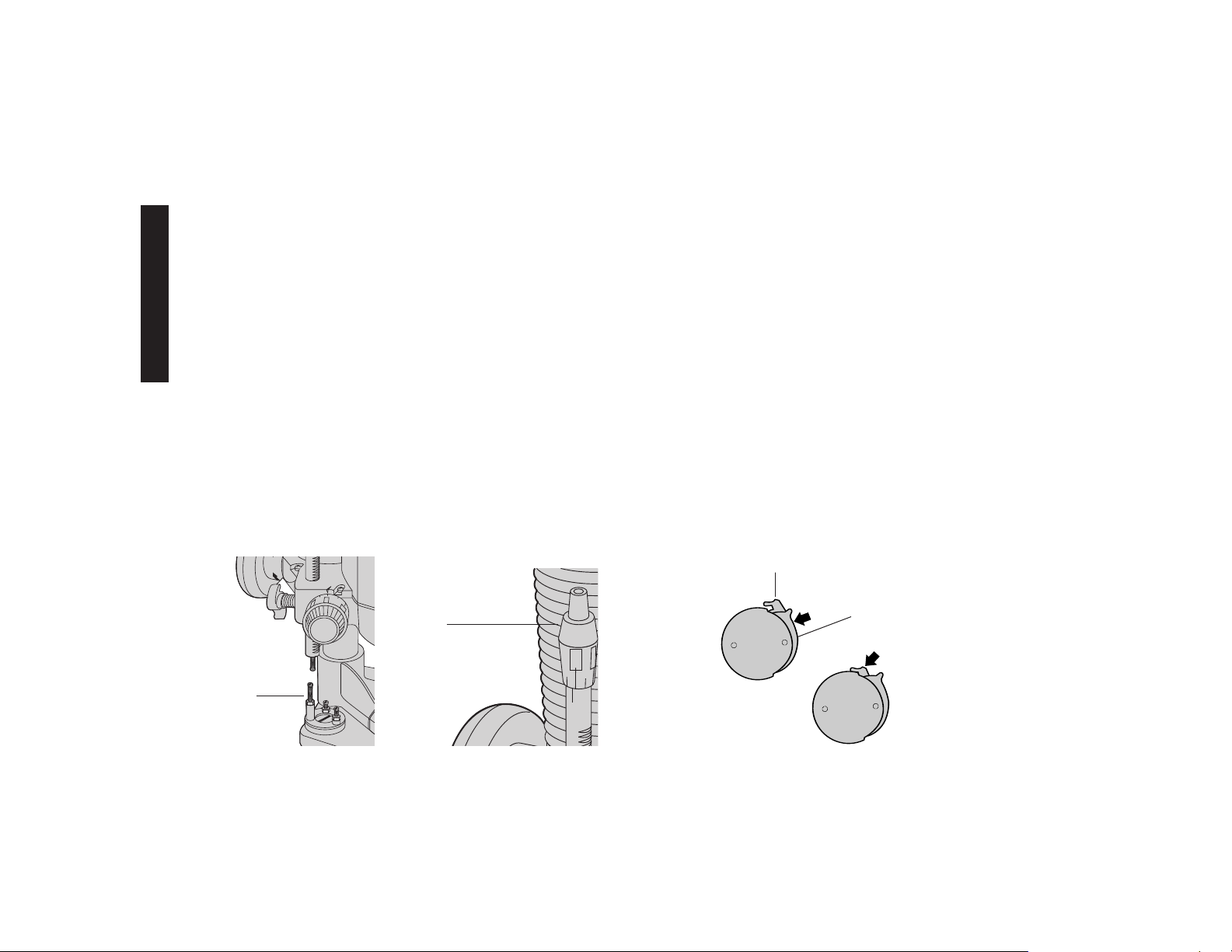

Bit Installation and Removal

TURN OFF AND UNPLUG ROUTER

NOTE: Always snap the collet firmly into the collet nut, (past the

retainer spring) before installing a bit.

Use the supplied wrench and the spindle lock as necessary to loosen

(counterclockwise) the collet nut, (Fig. 1).

Insert the round shank of the desired router bit into the loosened

collet as far as it will go and then pull it out about 1/16". Hold the

spindle shaft by depressing the spindle lock button, while firmly

tightening the collet nut with the wrench provided.

Your router has a unique locking system for retaining the bit. When

removing a bit, the collet nut must be loosened with the wrench. The

English

FIG. 1

SPINDLE LOCK

COLLET NUT

Page 6

collet nut will turn approximately 3/4 of a turn and then become tight

again. At this point the bit can’t be removed. Using the same

procedure, loosen the nut a second time.This lifts the collet and

makes it easy to remove the bit.

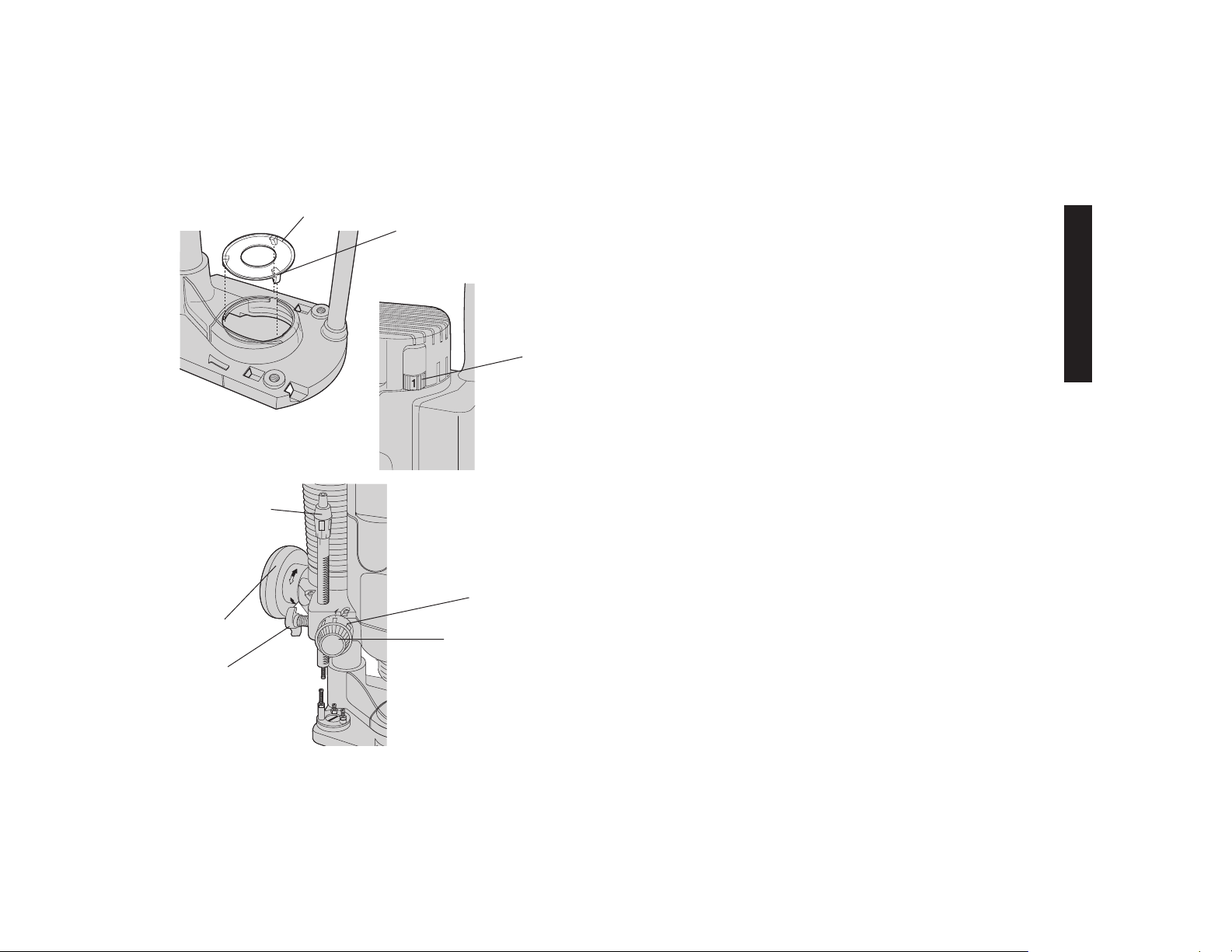

NOTE: Your router is equipped with a clear plastic cap over the

cutting area. This cap assists with dust extraction. When installing a

router bit over 1-1/8" in diameter, ensure the plastic cap is removed

or positioned above the cutting portion of the bit (Fig. 2).To remove

the cap, push it from the bottom of the router. To re-install the cap,

align the tabs (Fig. 2) and snap it into place.

Collets

NEVER TIGHTEN THE COLLET ON THIS TOOL WITHOUT FIRST

INSTALLING A ROUTER BIT IN IT. TIGHTENING AN EMPTY

COLLET CAN DAMAGE THE COLLET.

To change collet sizes, unscrew the collet assembly, as described

above. The collet and the collet nut are connected. Do not attempt to

remove the collet from the collet nut.

Controls

ELECTRONIC SPEED CONTROL DIAL

The speed of your router is variable. Use the electronic speed control

(Fig. 3) dial to produce uniform cutting results in wood, plastics and

aluminum. Use the lower settings (1-3) for large diameter cutters and

the higher settings for small diameter cutters. See Table A for more

information.

Adjusting the Depth of Cut

QUICK ADJUSTMENT USING RACK AND PINION HEIGHT

ADJUSTMENT (FIG. 4)

1) UNPLUG THE ROUTER. It may be necessary to remove the

plastic cap before making adjustments.

3

English

0.

0.6

5/8

1/2

3/4

FIG. 4

FIG. 3

SPEED CONTROL

DIAL

FIG. 2

PLASTIC CAP

FINE

ADJUSTMENT

KNOB

PLUNGE LOCK

HANDLE

HEIGHT

ADJUSTMENT KNOB

QUICK ADJUSTER

DEPTH STOP

LOCKING

BOLT

TABS

Page 7

4

FINE ADJUSTMENT (FIG. 6)

Use the fine adjuster when not using a depth template, or if the depth

of cut needs readjustment.

1) Adjust the depth of cut as described above.

2) Set the fine adjuster to zero using the inner ring. Hold the top

portion while setting the lower ring to zero.

3) Rotate the fine adjuster to the required position. Graduations are

on the top of the fine adjustment knob.

Lock-On/Lock-Off Switch (Fig. 7)

The lock-on/lock-off switch is located in the handle on the right side.

The router is normally locked-off.

To start the router, press the thumb lock and squeeze the trigger. To

lock the switch on, squeeze the trigger, press the thumb lock forward

and release the trigger. To turn the router off, release the switch. If the

tool is locked-on, press the trigger again and release the switch.

NOTE: Loosen the plunge limiter and allow the router carriage to

return to its rest position before switching off.

English

0.

0.6

FIG. 6

FIG. 7

2) Unlock the plunge lock handle.

3) Lower the router carriage until the cutter is in contact with the

workpiece

4) Tighten the plunge lock handle by turning it clockwise.

5) Turn the height adjustment knob counterclockwise until it hits the

revolver depth stop (Fig. 5).

6) Set the quick adjuster to zero, by turning the inner ring knob

clockwise.

7) Adjust the depth of cut by rotating the height adjust knob clockwise

to the desired depth of cut. The adjustment range is indicated by

the arrow.

8) Tighten the plunge limiter by turning the depth stop bolt clockwise.

TRIPLE DEPTH ADJUSTMENT USING THE REVOLVER DEPTH

STOP (FIG. 5)

The revolver depth stop can be used to set three different depths. This

is useful for deep cuts, performed in steps.

1) Place a depth template between the depth stop and the revolver

depth stop to adjust the exact cutting depth.

2) If required, set all three screws.

5/8

1/2

3/4

REVOLVER DEPTH

STOP

FINE

ADJUSTMENT

KNOB

FIG. 5

TRIGGER

PRESS TO LOCK ON

THUMB LOCK

Page 8

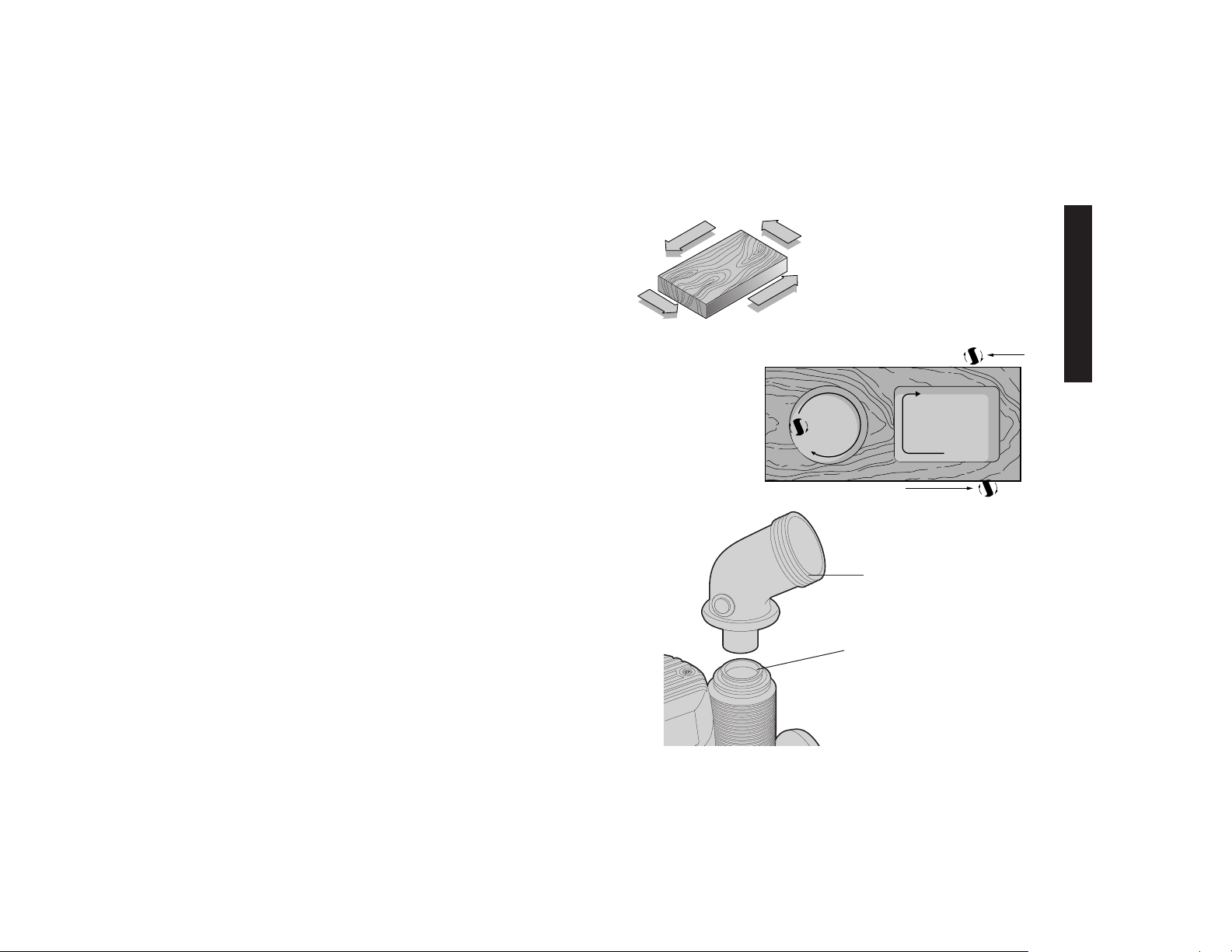

Operation

After setting the cutting depth as described, locate the router such

that the bit is directly over the place you will be cutting. With the

router running, lower the unit smoothly down into the workpiece.

(DO NOT JAM THE ROUTER DOWN). When the tool reaches the

pre-set depth, tighten the plunge lock. When you have finished

routing, loosen the plunge lock and let the spring lift the router directly

out of the workpiece.

NOTE: Always feed the router opposite to the direction in which the cutter

is rotating.

Direction Of Feed

Figs. 8 and 9 show proper direction of feed for some typical cuts.

Mold the outside edge of a piece of stock by a) mold the end grain,

left to right, b) do the straight grain side moving left to right, c) finish

the other end grain side, and d) do the remaining straight grain edge.

The direction of feed is important in router usage. Be sure the cutter

is rotating into the stock by moving left to right on outside edges and

clockwise on inside cuts.

Dust Collection and Extraction

TO SET THE ROUTER FOR DUST EXTRACTION:

1. Unplug router from power supply.

2. If required, insert the dust extraction hose adapter into the dust

extraction port (Fig. 10).

2. Slip the end of any standard vacuum cleaner tube into the hose

adapter.

3. When using dust extraction, be sure that the vacuum cleaner is out

of the way and secure so that it will not tip over or interfere with the

router or workpiece. The vacuum hose and power cord must also

be positioned so that they don't interfere with the router or

5

English

A

D

C

B

FIG. 9

FIG. 8

FIG. 10

DUST EXTRACTION

HOSE ADAPTER

EXTRACTION

PORT

Page 9

6

workpiece. If the vacuum cleaner or vacuum hose cannot be

positioned properly, it should be removed.

4. Turn on vacuum cleaner before router.

5. Empty the vacuum cleaner as necessary.

NOTE: The router comes with a clear plastic removable guard over

the cutting area. Do not attempt to plunge cut through the plastic

guard. The guard is used to assist the dust collection.

Your router includes a dust extraction cap. Be sure it is in place over

the dust extraction port if you are not using a vacuum.

Maintenance

CLEANING & LUBRICATION

Use only mild soap and damp cloth to clean the tool. Never let any

liquid get inside the tool; never immerse any part of the tool into a

liquid.

NOTE: Use only a DRY cloth to wipe the plunge rods. These rods

require no lubrication. Lubricants attract dust, reducing the

performance of your tool.

Accessories

Use only accessories that are recommended by the manufacturer for

your model. Accessories that may be suitable for one tool, may

become hazardous when used on another tool. Recommended

accessories for use with your tool are available at extra cost from

your local dealer or authorized service center. If you need assistance

in locating any accessory for your tool, contact:

D

EWALT Industrial Tool Company

626 Hanover Pike, P.O. Box 158

Hampstead, MD. 21074-0158

1-800-4-DEWALT (1-800-433-9258)

CAUTION: The use of any other accessory not recommended for

use with this tool could be hazardous.

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment should be performed by authorized service centers

or other qualified service organizations, always using identical

replacement parts

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. Arrangements have been made

with the Industrial Tool Division of Black & Decker to provide warranty

repairs for D

EWALT tools. Please return the complete unit,

transportation prepaid, to any Black & Decker Industrial Service

Center or Authorized Service Station listed under “Tools, Electric” in

the yellow pages. This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may

have other rights which vary in certain states or provinces.

In addition to the warranty, DeWalt tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALT heavy duty industrial tool, simply return it to the participating

seller within 30 days for a full refund. Please return the complete unit,

transportation prepaid. Proof of purchase may be required.

English

See ‘Tools-Electric’

–Yellow Pages–

for Service & Sales

Page 10

7

English

Your router is equipped with constant speed cutting—as you load the router, the selected cutting speed

does not slow down during normal use. The electronic control governs the motor and gives you a

consistent finish to your work. Only under very heavy loading will the speed of the unit fall below the

governed speed.

To set the router speed (from 8,000 rpm to 24,000 rpm) rotate the speed control wheel shown in

Fig. 3. The higher the number the higher the speed. Consult the table below to help select the proper

speed for your application.

Table A

SPEED SELECTION CHART

Material Cutter Diam. Electronic Control Settings

Setting 1 Setting 2 Setting 3 Setting 4 Setting 5 Setting 6

Model # DW621 8,000 rpm 12,000 rpm 14,000 rpm 18,000 rpm 21,000 rpm 24,000 rpm

Hardwood, e.g., oak Small (1/2") – – O X XX X

Medium (1/2"-1 1/8") – – O XX X -

Large (over-1 1/8") X XX O – – -

Softwood, e.g., pine Small (1/2") – – O X XX XX

Medium (1/2"-1 1/8") – O X XX XX XX

Large (over-1 1/8") X XX O – – -

Plastic-laminated chipboard Small (1/2") – – O X XX XX

Medium (1/2"-1 1/8") – O X XX XX XX

Large (over-1 1/8") O XX X – – -

Plastics/ Solid Surface Small (1/2") – O X X XX XX

Medium (1/2"-1 1/8") – O XX XX X X

Large (over-1 1/8") X XX O – – -

This table can serve only as a guide, since wood was a living material. Within the same species of timber hardness and density vary.

Speed settings are approximate.

KEY: XX very good X good O Satisfactory – not recommended

Page 11

8

RÈGLES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT! Vous devez lire et comprendre toutes les

instructions. Le non-respect, même partiel, des instructions ci-après

entraîne un risque de choc électrique, d’incendie et/ou de blessures

graves.

CONSERVEZ CES INSTRUCTIONS.

AIRE DE TRAVAIL

• Veillez à ce que l’aire de travail soit propre et bien éclairée. Le

désordre et le manque de lumière favorisent les accidents.

• N’utilisez pas d’outils électriques dans une atmosphère

explosive, par exemple en présence de liquides, de gaz ou de

poussières inflammables. Les outils électriques créent des

étincelles qui pourraient enflammer les poussières ou les vapeurs.

• Tenez à distance les curieux, les enfants et les visiteurs

pendant que vous travaillez avec un outil électrique. Ils

pourraient vous distraire et vous faire faire une fausse manoeuvre.

SÉCURITÉ ÉLECTRIQUE

• Les outils à double isolation sont équipés d’une fiche

polarisée (une des lames est plus large que l’autre), qui ne

peut se brancher que d’une seule façon dans une prise

polarisée Ne modifiez pas la fiche de l’outil. La double

isolation élimine le besoin d’un cordon d’alimentation à trois fils

avec mise à la terre ainsi que d’une prise de courant mise à la

terre.

• Évitez tout contact corporel avec des surfaces mises à la terre

(tuyauterie, radiateurs, cuisinières, réfrigérateurs, etc.). Le

risque de choc électrique est plus grand si votre corps est en

contact avec la terre.

• N’exposez pas les outils électriques à la pluie ou à l’eau. La

présence d’eau dans un outil électrique augmente le risque de

choc électrique.

• Ne maltraitez pas le cordon. Ne transportez pas l’outil par

son cordon et ne débranchez pas la fiche en tirant sur le

Français

0.8

0.6

5/8

1

/2

3/4

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET

OUTIL OU TOUT AUTRE OUTIL D

EWALT, COMPOSER SANS

FRAIS LE NUMÉRO :

1 800 4-DEWALT (1 800 433-9258)

Page 12

cordon. N’exposez pas le cordon à la chaleur, à des huiles, à

des arêtes vives ou à des pièces en mouvement. Remplacez

immédiatement un cordon endommagé. Un cordon

endommagé augmente le risque de choc électrique.

• Lorsque vous utilisez un outil électrique à l’extérieur,

employez un prolongateur pour l’extérieur marqué «W-A» ou

«W». Ces cordons sont faits pour être utilisés à l’extérieur et

réduisent le risque de choc électrique. S’assurer que le cordon de

rallonge est en bon état. Lorsqu’on se sert d’un cordon de rallonge,

s’assurer qu’il est de calibre approprié pour la tension nécessaire

au fonctionnement de l’outil. L’utilisation d’un cordon de calibre

inférieur occasionne une baisse de tension entraînant une perte de

puissance et la surchauffe. Le tableau suivant indique le calibre

approprié selon la longueur du cordon et les mentions de la plaque

signalétique de l’outil. En cas de doute, utiliser un cordon de calibre

supérieur. Le chiffre indiquant le calibre est inversement

proportionnel au calibre du cordon.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0- 6 18 161614

6- 10 18 16 14 12

10 - 12 16161412

12 - 16 14 12 Non recommandé

SÉCURITÉ DES PERSONNES

• Restez alerte, concentrez-vous sur votre travail et faites

preuve de jugement. N’utilisez pas un outil électrique si vous

êtes fatigué ou sous l’influence de drogues, d’alcool ou de

médicaments. Un instant d’inattention suffit pour entraîner des

blessures graves.

• Habillez-vous convenablement. Ne portez ni vêtements

flottants ni bijoux. Confinez les cheveux longs. N’approchez

jamais les cheveux, les vêtements ou les gants des pièces en

mouvement. Des vêtements flottants, des bijoux ou des cheveux

longs risquent d’être happés par des pièces en mouvement.

• Méfiez-vous d’un démarrage accidentel. Avant de brancher

l’outil, assurez-vous que son interrupteur est sur ARRÊT. Le

fait de transporter un outil avec le doigt sur la détente ou de

brancher un outil dont l’interrupteur est en position MARCHE peut

mener tout droit à un accident.

• Enlevez les clés de réglage ou de serrage avant de démarrer

l’outil. Une clé laissée dans un pièce tournante de l’outil peut

provoquer des blessures.

• Ne vous penchez pas trop en avant. Maintenez un bon appui et

restez en équilibre en tout temps. Un bonne stabilité vous permet

de mieux réagir à une situation inattendue.

• Utilisez des accessoires de sécurité. Portez toujours des

lunettes ou une visière. Selon les conditions, portez aussi un

masque antipoussière, des bottes de sécurité antidérapantes, un

casque protecteur et/ou un appareil antibruit.

UTILISATION ET ENTRETIEN DES OUTILS

• Immobilisez le matériau sur une surface stable au moyen de

brides ou de toute autre façon adéquate. Le fait de tenir la pièce

avec la main ou contre votre corps offre un stabilité insuffisante et

peut amener un dérapage de l’outil.

• Ne forcez pas l’outil. Utilisez l’outil approprié à la tâche. L’outil

correct fonctionne mieux et de façon plus sécuritaire. Respectez

aussi la vitesse de travail qui lui est propre.

• N’utilisez pas un outil si son interrupteur est bloqué. Un outil

que vous ne pouvez pas commander par son interrupteur est

dangereux et droit être réparé.

• Débranchez la fiche de l’outil avant d’effectuer un réglage, de

changer d’accessoire ou de ranger l’outil. De telles mesures

préventives de sécurité réduisent le risque de démarrage

accidentel de l’outil.

• Rangez les outils hors de la portée des enfantes et d’autres

personnes inexpérimentées. Les outils sont dangereux dans les

mains d’utilisateurs novices.

9

Français

Page 13

10

• Prenez soin de bien entretenir les outils. Les outils de coupe

doivent être toujours bien affûtés et propres. Des outils bien

entretenus, dont les arêtes sont bien tranchantes, sont moins

susceptibles de coincer et plus faciles à diriger.

• Soyez attentif à tout désalignement ou coincement des pièces

en mouvement, à tout bris ou à toute autre condition

préjudiciable au bon fonctionnement de l’outil. Si vous

constatez qu’un outil est endommagé, faites-le réparer avant

de vous en servir. De nombreux accidents sont causés par des

outils en mauvais état.

• N’utilisez que des accessoires que le fabricant recommande

pour votre modèle d’outil. Certains accessoires peuvent

convenir à un outil, mais être dangereux avec autre.

RÉPARATION

• La réparation des outils électriques doit être confiée à un

réparateur qualifié. L’entretien ou la réparation d’un outil

électrique par un amateur peut avoir des conséquences graves.

• Pour la réparation d’un outil, n’employez que des pièces de

rechange d’origine. Suivez les directives données à la section

«Réparation» de ce manuel. L’emploi de pièces non autorisées

ou le non-respect des instructions d’entretien peut créer un risque

de choc électrique ou de blessures.

• Tenez l’outil par ses surfaces de prise isolées pendant toute

opération où l’outil de coupe portrait venir en contact avec

un câblage dissimulé ou avec son propre cordon. En cas de

contact avec un conducteur sous tension, les pièces métalliques

à découvert de l’outil transmettraient un choc électrique à

l’utilisateur.

Mesures de sécurité additionnelles

• Ne le saisir que par ses poignées en plastique afin de se protéger

des secousses électriques que provoqueraient le contact de la

lame avec un fil sous tension.Lorsqu’on scie dans les murs, les

planchers ou tout autre endroit où peuvent se trouver des fils sous

tension, ne pas toucher à tout composant métallique de l’outil.

• S’assurer que les poignées sont toujours propres, sèches et

libres de toute tache d’huile ou de graisse. Il est recommandé

de porter des gants de caoutchouc. On améliore de la sorte la

maîtrise de l’outil.

• Les symboles suivants peuvent se trouver sur l’étiquette de l’outil.

V ........................volts

A ........................ampères

Hz ........................hertz

W ........................watts

min ........................minutes

........................courant alternatif

........................courant continu

n

o ........................ sous vide

........................construction de classe II

…/min ........................tours ou courses à la minute

........................borne de mise à la terre

Français

FIG. 1

DISPOSITIF DE

VERROUILLAGE DE

L’ARBRE

ÉCROU DE LA PINCE

DE SERRAGE

Page 14

Moteur

Veiller à ce que la tension d’alimentation soit conforme aux exigences

de la plaque signalétique de l’outil.

La mention 120 volts c.a. signifie que l’outil fonctionne seulement sur

une alimentation en courant alternatif et jamais en courant continu.

Une baisse de tension de plus de 10 p. 100 entraîne une perte de

puissance et la surchauffe. Tous les outils sont essayés avant de

quitter l’usine. Lorsque celui-ci refuse de fonctionner, vérifier la source

de courant électrique.

Installation et retrait des fraises

METTRE LA TOUPIE HORS TENSION ET LA DÉBRANCHER.

NOTE : Toujours enclencher la pince de serrage fermement dans

l’écrou (au-delà du ressort de retenue) avant d’installer une fraise.

Se servir au besoin de la clé fournie et du dispositif de verrouillage

pour desserrer (dans le sens antihoraire) l’écrou de la pince de

serrage (fig. 1).

Insérer à fond la tige ronde de la fraise voulue dans la pince de

serrage, puis la retirer d’environ 1.5 mm (1/16 po). Retenir l’arbre de

l’outil en enfonçant le bouton de verrouillage de l’arbre, tout en

serrant fermement l’écrou de la pince de serrage avec la clé fournie.

La toupie comporte un système de verrouillage unique afin de retenir

la fraise. Lorsqu’on retire cette dernière, il faut desserrer l’écrou de la

pince de serrage à l’aide de la clé. L’écrou de la pince de serrage

tourne d’environ 3/4 de tour, puis il se resserre. On ne peut alors plus

retirer la fraise. Procéder de la même façon et desserrer l’écrou une

deuxième fois. On soulève alors la pince de serrage, ce qui facilite

le retrait de la fraise.

NOTE : Il y a un couvercle en plastique transparent au-dessus de la

zone de coupe de la toupie. Celui-ci facilite le dépoussiérage.

Lorsqu’on installe une fraise d’un diamètre de plus de 28 mm

(1 1/8 po), s’assurer de retirer au préalable le couvercle ou de placer

11

Français

0.

0.6

5/8

1

/2

3/4

FIG. 4

FIG. 3

RÉGULATEUR DE

VITESSE

FIG. 2

COUVERCLE EN PLASTIQUE

LEVIER DE

VERROUILLAGE

DE LA COURSE

PLONGEANTE

BOUTON DE

RÉGLAGE DE LA

HAUTER

COMMANDE DE

RÉGLAGE RAPIDE

BOULON DE

BLOCAGE DU

LIMITEUR DE

PROFONDEUR

LANGUETTES

BOUTON DE

RÉGLAGE DE

PRÉCISION

Page 15

12

ce dernier au-dessus de la section tranchante de la fraise (fig. 2).

Pour enlever le couvercle, le pousser hors du dessous de la toupie.

Pour le remettre en place, aligner les languettes (fig. 2) et

l’enclencher en place.

Pinces de serrage

NE JAMAIS SERRER LA PINCE DE L’OUTIL AVANT D’Y AVOIR

INSTALLÉ UNE FRAISE AU PRÉALABLE. LE SERRAGE D’UNE

PINCE VIDE RISQUE DE L’ENDOMMAGER.

Lors qu’on installe une fraise de dimension différente, desserrer la

pince de la façon décrite précédemment. La pince de serrage et

l’écrou sont reliés. Ne pas tenter de retirer la pince de l’écrou.

Commandes

RÉGULATEUR DE VITESSE ÉLECTRONIQUE

La toupie est munie d’un régulateur de vitesse (fig. 3). S’en servir pour

couper uniformément le bois, les plastiques et l’aluminium. Se servir

des basses vitesses (de 1 à 3) avec les grosses fraises et des

vitesses élevées, avec les petites fraises. Consulter le tableau A.

Réglage de la profondeur de coupe

RÉGLAGE RAPIDE À L’AIDE DE LA COMMANDE DE RÉGLAGE

DE LA HAUTEUR À PIGNON ET CRÉMAILLERE (FIG. 4)

1) DÉBRANCHER LA TOUPIE. Il peut être nécessaire de retirer le

couvercle en plastique avant de régler la profondeur de coupe.

2) Déverrouiller le levier de verrouillage de la course plongeante.

3) Abaisser le chariot de la toupie jusqu’à ce que la fraise entre en

contact avec la surface à ouvrer.

4) Serrer le limiteur de la course plongeante en le faisant tourner

dans le sens horaire.

5) Faire tourner le bouton de rélage de la hauter dans le sens

Français

0.

0.6

FIG. 6

5/8

1/2

3/4

LIMITEUR DE

PROFONDEUR

À TOURELLE

BOUTON DE

RÉGLAGE DE

PRÉCISION

FIG. 5

antihoraire jus qu’à ce qu’il frappe le limiteur de profondeur a’

tourelle (fig. 5).

6) Régler la commande de réglage rapide à zéro en faisant tourner le

bouton à bague intérieure dans le sens horaire.

7) Régler la profondeur de coupe en faisant tourner le bouton de

réglage de la hauteur dans le sens horaire jusqu’à la profondeur

voulue. La flèche indique la plage de réglage.

8) Serrer le limiteur de la course plongeante, en faisànt tourner dans

le sens antihoraire le boulon du limiteur de profondeur.

TRIPLE RÉGLAGE DE LA PROFONDEUR À L’AIDE DU

LIMITEUR DE PROFONDEUR À TOURELLE (FIG. 5)

Le limiteur de profondeur à tourelle permet de régler trois profondeurs

de coupe différentes. Il s’agit d’une fonction des plus pratiques pour

effectuer des coupes profondes en plusieurs étapes.

1) Placer un modèle de la profondeur entre le limiteur et le limiteur de

profondeur à tourelle afin de régler la profondeur de coupe exacte.

2) Le cas échéant, régler les trois vis.

Page 16

RÉGLAGE DE PRÉCISION (FIG. 6)

Se servir du réglage de précision lorsqu’on n’utilise pas de modèle de

profondeur ou lorsqu’il faut régler de nouveau la profondeur de coupe.

1) Régler la profondeur de coupe de la manière décrite

précédemment.

2) Régler la commande de précision à zéro à l’aide de la bague

intérieure. Retenir la portion extérieure tout en réglant la portion

intérieure à zéro.

3) Faire tourner la commande de précision à la position requise. Les

calibres se trouvent sur la portion extérieure du bouton de réglage

de précision.

Interrupteur verrouillable (fig. 7)

L’interrupteur verrouillable en mode de fonctionnement ou d’arrêt se

trouve dans la poignée du côté droit de l’outil. La toupie est

normalement verrouillée en position d’arrêt.

Pour actionner la toupie, enfoncer le dispositif de verrouillage au

pouce et la détente. Pour verrouiller l’outil en mode de

fonctionnement, pousser le dispositif de verrouillage vers l’avant et

relâcher la détente. Pour arrêter la toupie, relâcher l’interrupteur.

Lorsque l’outil est verrouillé en mode de fonctionnement, appuyer de

nouveau sur la détente et relâcher l’interrupteur.

NOTE : Desserrer le limiteur de la course plongeante et attendre que

le chariot de la toupie retourne à sa position de repos avant d’arrêter

la toupie.

Fonctionnement

Après avoir réglé la profondeur de coupe, placer la toupie de sorte

que la fraise se trouve directement au-dessus de la surface à ouvrer.

Lorsque la toupie fonctionne, l’abaisser doucement sur la surface.

(NE PAS ABAISSER RAPIDEMENT LA TOUPIE.) Lorsque la toupie

atteint la profondeur de coupe prédéterminée, serrer le dispositif de

verrouillage de la course plongeante. À la fin des travaux, desserrer le

13

Français

FIG. 7

DÉTENTE

ENFONCER POUR

VERROUILLER EN MODE

DE FONCTIONNEMENT

DISPOSITIF DE VERROUILLAGE

AU POUCE

A

D

C

B

FIG. 9

FIG. 8

Page 17

14

dispositif de verrouillage de la course plongeante et laisser le ressort

remonter la toupie directement hors de la pièce.

NOTE : Toujours faire avancer la toupie dans le sens opposé à celui de

rotation de la fraise.

Sens d’alimentation

Les figures 8 et 9 montrent le sens approprié d’alimentation pour des

coupes typiques.

Ouvrer le rebord extérieur d’une pièce en a) ouvrant le grain du bout

de gauche à droite, b) ouvrant le grain droit latéral de gauche à droite,

c) en finissant l’autre grain du bout et d) en ouvrant le grain latéral qui

reste.

le sens d’alimentation est important lorsqu’on se sert d’une toupie.

s’assurer que la fraise tourne dans la pièce en se déplaçant de

gauche à droite sur les rebords extérieurs et dans le sens horaire,

sur les rebords intérieurs.

Dépoussiérage

PRÉPARATION DE LA TOUPIE POUR LE DÉPOUSSIÉRAGE

1. Débrancher la toupie de la source d’alimentation électrique.

2. Le cas échéant, insérer l’adaptateur pour boyau dans l’orifice de

dépoussiérage (fig. 10).

2. Insérer l’extrémité d’un boyau d’aspirateur standard dans

l’adaptateur.

3. Lorsqu’on utilise le système de dépoussiérage, s’assurer que

l’aspirateur ne nuit pas et qu’il ne présente aucun risque de chute.

Il faut également placer le boyau et le cordon de l’aspirateur de

sorte qu’ils ne nuisent pas au bon fonctionnement de la toupie.

Lorsque l’aspirateur ou le boyau nuisent au bon fonctionnement

de la toupie, il vaut mieux ne pas s’en servir.

4. Mettre l’aspirateur en marche avant d’actionner la toupie.

5. Vider l’aspirateur au besoin.

NOTE : La toupie comporte un couvercle amovible en plastique

transparent au-dessus de la zone de coupe. Ne pas effectuer de

coupe en course plongeante à travers le couvercle. Ce protecteur

facilite le dépoussiérage.

La toupie comprend un couvercle pour l’orifice de dépoussiérage.

S’assurer qu’il est en place lorsqu’on ne se sert pas de l’orifice.

Accessoires

On peut se procurer les accessoires recommandés chez les

détaillants et aux centres de service de la région. Pour trouver un

accessoire, communiquer à l’adresse suivante.

D

EWALT Industrial Tool Company

626 Hanover Pike, P.O. Box 158

Hampstead, MD. 21074-0158

É.-U.

MISE EN GARDE : L’utilisation de tout accessoire non

recommandé peut être dangereuse.

Français

FIG. 10

ADAPTATEUR POUR

BOYAU

ORIFICE DE

DÉPOUSSIÉRAGE

Page 18

Nettoyage et lubrification

Utiliser seulement du savon doux et un chiffon humide pour nettoyer

l’outil. Ne laisser aucun liquide s’infiltrer dans l’outil et ne jamais

immerger ce dernier.

NOTE : Utiliser seulement un chiffon SEC pour essuyer les tiges de

plongée. Il n’est pas nécessaire de les lubrifier. Les lubrifiants attirent

la poussière, ce qui risque de minimiser le rendement de l’outil.

Important

Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil, n’en

confier la réparation et les rajustements qu’à un centre de service ou

à un atelier d’entretien autorisé n’utilisant que les seules pièces de

rechange identiques.

Garantie complète

Les outils industriels de service intensif DeWalt sont garantis pendant

un an à partir de la date d’achat. Toute pièce d’un outil DeWalt qui

s’avérait défectueuse en raison d’un vice de matière ou de fabrication

sera réparée ou remplacée sans frais. Selon une entente convenue

entre DeWalt et Black & Decker Canada Inc., la Division des outils

industriels de Black & Decker Canada Inc. s’engage à effectuer les

réparations couvertes par la présente garantie. Il suffit de retourner

l’outil port payé à l’un des centres de service d’outils industriels

Black & Decker ou à tout autre atelier d’entretien d’outils industriels

accrédité, inscrits à la rubrique «Outils électriques» des Pages

Jaunes. DeWalt n’assume aucune responsabilité pour les avaries

dues au mauvais usage, à une manoeuvre négligente, ou aux

réparations tentées ou effectuées par des tiers. Les modalités de la

présente garantie donnent des droits légaux spécifiques. L’utilisateur

peut également se prévaloir d’autres droits selon l’état ou la province

qu’il habite.

En outre, les produits DeWalt sont couverts par la garantie suivante.

GARANTIE DE SATISFACTION DE 30 JOURS

OU ARGENT REMIS

Si, pour quelque raison que ce soit, l’outil industriel de service intensif

DeWalt ne donne pas entière satisfaction, il suffit de le retourner port

payé, avec tous les accessoires, dans les 30 jours au vendeur

participant. On peut exiger une preuve d’achat pour recevoir un

remboursement.

15

Français

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

Page 19

16

Français

La toupie comporte un régulateur de vitesse. Ainsi, la charge sur la toupie ne ralentit pas la vitesse

choisie dans des conditions d'utilisation normales. Le régulateur de vitesse agit sur le moteur afin de

procurer un fini uniforme à la surface ouvrée. Seule une charge très lourde ralentira la vitesse de l'outil.

Pour régler la vitesse de la toupie (de 8 000 à 24 000 trs/min), faire tourner le régulateur de vitesse

illustré à la figure 3. Plus le chiffre choisi est élevé, plus la vitesse l'est. Consulter le tableau plus bas

pour déterminer la vitesse appropriée à la tâche.

tableau A

TABLEAU DE SÉLECTION DES VITESSES

Material Diam. (outil de coupe) Réglages électroniques

Réglage 1 Réglage 2 Réglage 3 Réglage 4 Réglage 5 Réglage 6

Model # DW621 8 000

tr/min 12,000 tr/min 14,000 tr/min 18,000 tr/min 21,000 tr/min 24,000 tr/min

Bois dur (p. ex., le chêne) Petit* – – O X XX X

Moyen** – – O XX X -

Grand*** X XX O – – -

Bois mou (p. ex., le pin) Petit* – – O X XX XX

Moyen** – O X XX XX XX

Grand*** X XX O – – -

Aggloméré plastifié Petit* – – O X XX XX

Moyen** – O X XX XX XX

Grand*** O XX X – – -

Plastique/surface solide Petit(1/2") – O X X XX XX

Moyen** – O XX XX X X

Grand*** X XX O – – -

Ce tableau n’est offert qu’à titre indicatif, puisque le bois est une matière vivante. Puisque la dureté et la densité de divers bois de même

espèce peut varier, les réglages de vitesses sont approximatifs.

LÉGENDE : XX – très bon; X = bon; 0 = satisfaisant; - = non recommandé

*Petit : 12,7 mm (1/2 po)

**Moyen : 12,7 à 3,2 mm (_ à 1-1/8 po)

***Grand : plus de 3,2 mm (1-1/8 po)

Page 20

Reglas generales de seguridad

¡ADVERTENCIA! Lea y comprenda todas las instrucciones. No

hacerlo puede originar riesgos de choque eléctrico, incendio y

lesiones personales de gravedad.

CONSERVE ESTAS INSTRUCCIONES

AREA DE TRABAJO

• Conserve su área de trabajo limpia y bien iluminada. Las

bancas amontonadas y las zonas oscuras propician los

accidentes.

• No opere herramientas eléctricas en atmósferas explosivas,

como en presencia de líquidos, gases o polvos inflamables.

Las herramientas eléctricas producen chispas que pueden originar

la ignición de los polvos o los vapores.

• Conserve a observadores, niños y visitantes alejados

mientras opera una herramienta eléctrica. Las distracciones

pueden ocasionar que pierda el control.

SEGURIDAD ELECTRICA

• Las herramientas con doble aislamiento están equipadas con

una clavija polarizada (con una pata más ancha que la otra.)

Esta clavija se acoplará únicamente en una toma de corriente

polarizada de una manera. Si la clavija no se acopla al

contacto, inviértala. Si aún así no se ajusta, comuníquese con

un electricista calificado para que le instalen una toma de

corriente polarizada apropiada. El doble aislamiento elimina la

necesidad de cables con tres hilos y sistemas de alimentación con

conexión a tierra.

• Evite el contacto corporal con superficies aterrizadas tales

como tuberías, radiadores, hornos y refrigeradores. Hay un

gran riesgo de choque eléctrico si su cuerpo hace tierra.

• No exponga las herramientas eléctricas a la lluvia o a

condiciones de mucha humedad. El agua que se introduce en

17

Español

0.8

0.6

5/8

1

/2

3/4

Page 21

18

las herramientas aumenta el riesgo de descargas eléctricas.

• No maltrate el cable. Nunca tome el cable para transportar

una herramienta ni para desconectarla de la toma de

corriente. Consérvelo alejado de calor aceite, bordes afilados

o piezas móviles. Cambie inmediatamente los cables

dañados. Los cables dañados aumentan el riego de choque

eléctrico.

• Cuando opere una herramienta eléctrica a la intemperie,

utilice una extensión marcada “W-A” o “W”. Estas extensiones

están clasificadas para uso a la intemperie y para reducir el riesgo

de choques eléctricos.

• Cuando utilice una extensión, asegúrese de emplear una con

el calibre suficiente para soportar la corriente necesaria para

su herramienta. Una extensión con calibre inadecuado causará

una caída en el voltaje de la línea resultando en pérdida de

potencia y sobrecalentamiento. La tabla siguiente muestra el

calibre correcto para usarse, relativo a la longitud de la extensión

y el amperaje mencionado en la placa de identificación. Si tiene

dudas, utilice el calibre siguiente. Mientras más pequeño sea el

número del calibre, mayor será su capacidad.

CCalibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7,6 7,6-15,2 15,2-30,4 30,4-45,7

240V 0-15,2 15,2-30,4 30,4-60,9 60,9-91,4

AMPERAJE

Más No más Calibre del cordón AWG

de de

0- 6 18 161614

6- 10 18 16 14 12

10 - 12 16161412

12 - 16- 14 12 No recomendado

SEGURIDAD PERSONAL

• Esté alerta concéntrese en lo que está haciendo. Recurra al

sentido común cuando opere una herramienta eléctrica. No

opere ninguna herramienta si se encuentra fatigado o bajo la

influencia de drogas, alcohol o medicamentos. Un momento

de desatención mientras se operan herramientas eléctricas puede

ocasionar lesiones graves.

• Vístase de manera adecuada. No tenga puestas ropas o

artículos de joyería flojos. Cubra su cabello si lo tiene largo.

Conserve su cabello, sus ropas y guantes alejados de las

piezas móviles. Las piezas de vestir flojas, las joyas y el cabello

largo pueden resultar atrapados por las piezas móviles.

• Evite el encendido accidental. Asegúrese que el interruptor

esté en posición de apagado antes de conectar. Sostener una

herramienta con el dedo en el interruptor o conectarla sin fijarse si

el interruptor está en posición de encendido propicia los

accidentes.

• Retire las llaves de ajuste antes de encender la herramienta.

Una llave que se deja en una pieza giratoria puede ocasionar

lesiones personales.

• No se sobreextienda. Conserve siempre los pies bien

apoyados, al igual que el equilibrio. La posición correcta de los

pies y el equilibrio permiten controlar mejor la herramienta en

situaciones inesperadas.

• Utilice equipo de seguridad. Siempre utilice protección en

los ojos. Se deben utilizar mascarillas contra polvo, zapatos

antiderrapantes, casco o protectores para los oídos para tener las

condiciones apropiadas.

USO Y CUIDADOS DE LA HERRAMIENTA

• Conserve los mangos secos, limpios y libres de aceite y

grasa. Es recomendable utilizar guantes de goma, esto le

permitirá controlar mejor la herramienta.

• Utilice prensas u otros medios prácticos para asegurar y

apoyar la pieza de trabajo en una plataforma estable. Sujetar

las piezas con la mano o contra su cuerpo es inestable y puede

originar la pérdida de control.

• No utilice la herramienta si el interruptor no enciende y apaga.

Cualquier herramienta que no pueda controlarse por medio del

Español

Page 22

interruptores peligrosa y debe reemplazarse.

• Desconecte la clavija de la toma de corriente antes de hacer

cualquier ajuste, cambio de accesorios o de guardar la

herramienta. Ta les medidas de seguridad preventivas reducirán

el riesgo de que la herramienta se encienda accidentalmente.

• Guarde las herramientas fuera del alcance de los niños y de

otras personas no capacitadas. Las herramientas son

peligrosas en manos de personas no capacitadas.

• Cuide sus herramientas. Conserve las herramientas de corte

afiladas y limpias. Las herramientas que reciben un

mantenimiento adecuado, con piezas de corte afiladas,

difícilmente se atascan y son más fáciles de controlar.

• Verifique la alineación de las piezas móviles, busque fracturas

en las piezas y cualesquiera otras condiciones que puedan

afectar la operación de las herramientas. Si está dañada, lleve

su herramienta a servicio antes de usarla de nuevo. Muchos

accidentes se deben a herramientas con mantenimiento pobre.

• Solamente use accesorios que el fabricante recomiende para

su modelo de herramienta. Los accesorios que estén diseñados

para una herramienta, pueden volverse peligrosos cuando se

emplean con otra.

SERVICIO

• El servicio a las herramientas lo debe efectuar únicamente

personal calificado. El servicio o mantenimiento realizado por

personal no calificado puede originar riesgos de lesiones.

• Cuando efectúe servicio a una herramienta, utilice

únicamente refacciones idénticas. Siga las instrucciones de

la sección de Mantenimiento de este manual. El empleo de

piezas no autorizadas o no seguir las instrucciones de

mantenimiento puede originar riegos de choque eléctrico o

lesiones.

• Tome la herramienta por las superficies aislantes de sujeción

cuando realice una operación en que la herramienta de corte

pueda hacer contacto con cables ocultos o con su propia

extensión. El contacto con un cable “vivo” hará que las partes

metálicas de la herramienta queden “vivas” y descarguen hacia el

operador.

Reglas adicionales de seguridad

• Sujétela solamente por las superficies aislantes para evitar el

choque eléctrico si corta un cable vivo. Cuando corte en muros,

pisos o dondequiera que pueda encontrarse con cables eléctricos

vivos, ¡NO TOQUE NINGUNA PARTE METALICA DE LA

HERRAMIENTA!

• Conserve los mangos secos, limpios y libres de aceite y

grasa. Se recomienda emplear guantes de goma. Esto le

brindará mayor control sobre la herramienta.

• La etiqueta de su herramienta debe incluir los siguientes símbolos.

V ........................volts

A ........................amperes

Hz ........................hertz

W ........................watts

min ........................minutos

........................corriente alterna

........................corriente directa

n

o ........................velocidad sin carga

........................construcción Clase II

…/min ........................revoluciones o reciprocaciones por minuto

........................terminales de conexión a tierra

Motor

Asegúrese que su alimentación de corriente concuerde con la

marcada en la placa de identificación.

120 volts AC, significa que su herramienta está diseñada para operar

con corriente alterna, nunca con corriente directa.

Disminuciones en el voltaje mayores al 10% causarán pérdida de

19

Español

Page 23

20

potencia y sobrecalentamiento. Todas las herramientas se prueban

en la fábrica. Si esta herramienta no funciona, revise la alimentación

de corriente.

Instalación y remoción de cuchillas

APAGUE Y DESCONECTE LA REBAJADORA.

NOTA: Siempre coloque firmemente la boquilla en la tuerca de la

boquilla (más allá del resorte de retén) antes de instalar una cuchilla.

Utilice la llave suministrada y oprima el botón de seguro de la flecha

para aflojar (en sentido contrario a las manecillas del reloj) la tuerca

de la boquilla, como se muestra en la figura 1.

Inserte el vástago cilíndrico de la cuchilla que desee tanto como sea

posible en la boquilla una vez aflojada, a continuación tire de la

cuchilla aproximadamente 1,5 mm (1/16”). Sujete la flecha mientras

oprime el seguro al tiempo que aprieta firmemente tuerca de la

boquilla con la llave.

Su rebajadora cuenta con un sistema único que le permite

asegurarla para retener la cuchilla. Cuando quite una cuchilla, la

tuerca de la boquilla debe aflojarse con la llave. La tuerca de la

boquilla girará aproximadamente 3/4 de vuelta y se apretará otra

Español

FIG. 1

SEGURO DE LA FLECHA

0.

0.6

5/8

1

/2

3/4

FIG. 4

FIG. 3

CONTROL DE

VELOCIDAD

TUERCA DE LA BOQUILLA

FIG. 2

TAPA DE PLASTICO

PERILLA DE

AJUSTE FINO

ASA DEL SEGURO DE

PENETRACION

PERILLA DE AJUSTE

DE ALTURA

AJUSTE RAPIDO

TORNILLO DE

SEGURIDAD

DEL TOPE DE

PROFUNDIDAD

OREJAS

Page 24

Controles

CONTROL ELECTRONICO DE VELOCIDAD

Su rebajadora tiene velocidad variable. utilice el control electrónico

de velocidad (fig. 3) para producir cortes uniformes en madera,

plásticos y aluminio. Utilice las posiciones bajas (1-3) para cuchillas

de diámetros grandes y las posiciones altas para cuchillas de

diámetro pequeño. Consulte el cuadro A para obtener mayor

información.

Ajuste de la profundidad de corte

AJUSTE RAPIDO UTILIZANDO EL AJUSTE DE ALTURA DE

PIÑON Y CREMALLERA (FIG. 4)

1) DESCONECTE LA REBAJADORA. Puede ser necesario quitar

la tapa de plástico antes de hacer ajustes.

2) Quite el seguro del mango de penetración

3) Baje el carro de la rebajadora hasta que la cuchilla haga contacto

con la pieza de trabajo.

4) Apriete el limitador de penetración girándolo en sentido a las

manecillas del reloj.

5) Gire la perilla de ajuste de altura en sentido contrario a las

manecillas del reloj hasta que haga contacto con el tope de

profundidad de revólver (fig. 5).

6) Coloque el ajuste rápido en cero, girando la perilla del aro interior

en el sentido de las manecillas del reloj.

7) Ajuste la profundidad de corte girando la perilla de ajuste de altura

en el sentido de las manecillas del reloj hasta que obtenga la

profundidad deseada. El rango de ajuste se indica con la flecha.

8) Apriete el limitador de penetración girando el tornillo del tope de

profundidad en el sentido de las manecillas del reloj.

21

Español

0.

0.6

FIG. 6

5/8

1/2

3/4

TOPE DE

PROFUNDIDAD DE

REVOLVER

PERILLA DE

AJUSTE FINO

FIG. 5

vez. En este punto la cuchilla no puede removerse. Con el mismo

procedimiento, afloje la tuerca por segunda vez. Esto levantará la

boquilla y hará muy fácil la remoción de la cuchilla.

NOTA: Su rebajadora está equipada con una tapa de plástico

transparente sobre el área de corte. Esta tapa le asiste para la

extracción de polvo. Cuando instale una cuchilla de más de 28 mm

(1-1/8”) de diámetro, asegúrese de quitar la tapa de plástico o

colóquela por arriba de la porción afilada de la cuchilla (fig. 2). Para

quitar la tapa, empújela desde abajo de la rebajadora. Para instalarla

de nuevo, haga coincidir las orejas (fig. 2) y presiónelas en su sitio.

Boquillas

NUNCA APRIETE LA BOQUILLA DE ESTA HERRAMIENTA SIN

ANTES HABER INSTALADO UNA CUCHILLA. APRETAR UNA

BOQUILLA VACIA PUEDE DAÑARLA

Para cambiar tamaños de boquilla, destornille el montaje de la

boquilla, como se describió anteriormente. La boquilla y la tuerca de

la boquilla están conectadas. No intente separar la boquilla de la

tuerca.

Page 25

22

Español

FIG. 7

GATILLO

OPRIMA PARA ACTIVAR EL

SEGURO DE ENCENDIDO

PERMANENTE

SEGURO

AJUSTE TRIPLE DE PROFUNDIDAD CON EL TOPE DE

PROFUNDIDAD DE REVOLVER (FIG. 5)

El tope de profundidad de revólver se puede emplear para ajustar

tres profundidades diferentes, realizando los pasos.

1) Coloque una plantilla entre el tope de profundidad y el tope de

profundidad de revólver para ajustar la profundidad de corte

exacta.

2) En caso que se requiera, ajuste los tres tornillos.

AJUSTE FINO (FIG. 6)

Utilice el ajuste fino cuando no emplee una plantilla de profundidad,

o si necesita reajustar la profundidad de corte.

1) Ajuste la profundidad de corte como se describió anteriormente.

2) Coloque el ajuste fino en cero con el aro interior. sujete la porción

superior mientras coloca el aro interior en cero.

3) Gire el ajuste fino a la posición requerida. Las graduaciones están

en la parte superior de la perilla de ajuste fino.

A

D

C

B

FIG. 9

FIG. 8

FIG. 10

ADAPTADOR DE

MANGUERA PARA

EXTRACCION DE POLVO

PUERTO DE

EXTRACCION

Page 26

Interruptor con seguro de

encendido/seguro de apagado (Fig. 7)

El interruptor con seguro de encendido/seguro de apagado se

encuentra en el mango hacia el lado derecho. La rebajadora

normalmente se encuentra con el seguro de apagado activado.

Para encender la rebajadora, presione el botón con el pulgar y oprima

el gatillo. Para asegurar la herramienta en posición de encendido,

oprima el gatillo, presione el botón hacia adelante y suelte el gatillo.

Para apagar la rebajadora, libere el interruptor. Si la herramienta se

encuentra asegurada en posición de encendido, oprima de nuevo el

gatillo y suelte el interruptor.

NOTA: Afloje el limitador de penetración y permita que el carro de la

rebajadora regrese a su posición de descanso antes de apagar el

interruptor.

Operación

Después de fijar la profundidad de corte como se describió, coloque

la rebajadora de modo que la cuchilla quede exactamente arriba del

sitio en que desea cortar. Con la rebajadora en funcionamiento, baje

lentamente la unidad hacia la pieza de trabajo. (NO ATORE LA

REBAJADORA ABAJO.) Cuando la herramienta alcance la

profundidad preseleccionada, apriete el seguro de penetración.

Cuando haya terminado de rebajar, afloje el seguro de penetración

y permita que el resorte levante la rebajadora directamente hacia

afuera de la pieza de trabajo.

NOTA: Siempre alimente la rebajadora en dirección opuesta al

movimiento de rotación de la cuchilla.

Dirección de alimentación

Las figuras 8 y 9 muestran la dirección de alimentación apropiada

para algunos tipos de corte básicos.

Recorte el borde exterior de una pieza de desperdicio de la siguiente

manera: (a), rebaje un extremo a contrahilo, de izquierda a derecha,

(b) recorte al hilo de izquierda a derecha; (c) rebaje el extremo

contrario a contra hilo, y (d) rebaje el lado restante al hilo.

El sentido de alimentación es muy importante en el manejo de las

rebajadoras. Asegúrese que la cuchilla esté girando en contacto

con la pieza moviendo de izquierda a derecha en los bordes

exteriores y en el sentido de las manecillas del reloj en el caso de

cortes interiores.

Recolección y extracción de polvo

PARA AJUSTAR LA REBAJADORA PARA EXTRACCION DE

POLVO:

1. Desconecte la rebajadora de la toma de corriente.

2. Si se requiere, inserte el adaptador de manguera para extracción

de polvo en el puerto de extracción de polvo (fig. 10).

3. Deslice el extremo de cualquier tubo de aspiradora estándar en el

adaptador para manguera.

4. Cuando utilice la extracción de polvo, asegúrese que la

aspiradora esté fuera del camino y que usted no tropezará con

ella ni interferirá con la rebajadora o la pieza de trabajo. La

manguera de la aspiradora y el cable eléctrico deben colocarse

de manera que igual no interfieran. Si la aspiradora o la manguera

no se pueden colocar correctamente, deben retirarse.

5. Encienda la aspiradora antes que la rebajadora.

6. Vacíe la aspiradora con la frecuencia necesaria.

NOTA: la rebajadora viene con una guarda de plástico transparente

desmontable sobre la zona de corte. No intente cortar a través de la

guarda de plástico. Es útil para la recolección de polvo.

Su rebajadora incluye una tapa para extracción de polvo. Asegúrese

que esté colocada sobre el puerto de extracción de polvo si no utiliza

una aspiradora.

23

Español

Page 27

24

Accesorios

Dispone usted de los accesorios recomendados para su herramienta

con cargo adicional con su distribuidor local o en los centros de

servicio autorizado. Si necesita usted ayuda para encontrar algún

accesorio, haga por favor contacto con:

DeWalt Industrial Tool Company

626 Hanover Pike, P.O. Box 158

Hampstead, MD 21074-0158

PRECAUCION: El uso de cualquier accesorio no recomendado para

emplearse con esta herramienta puede ser peligroso.

Limpieza y lubricación

Utilice únicamente jabón suave y un trapo húmedo para limpiar la

herramienta. Nunca permita que ningún líquido se introduzca en la

herramienta; nunca sumerja ninguna parte de la herramienta en

ningún líquido.

NOTA: Utilice únicamente un trapo SECO para limpiar las columnas.

Estas columnas no requieren lubricación. los lubricantes atraen

polvo, afectando el funcionamiento de su herramienta.

Importante

Para garantizar la SEGURIDAD y la CONFIABILIDAD del producto,

las reparaciones, el mantenimiento y los ajustes deberán ser

realizados en los centros de servicio autorizado u otras

organizaciones calificadas de servicio, que empleen siempre

refacciones idénticas.

Garantía Completa

Las herramientas industriales DeWalt están garantizadas durante un

año a partir de la fecha de compra. Repararemos, sin cargos,

cualquier falla debida a material o mano de obra defectuosos.

Hemos hecho arreglos con la División de Herramientas Industriales

de Black & Decker para que hagan las reparaciones en garantía a

las herramientas DeWalt. Por favor regrese la unidad completa, con

el transporte pagado, a cualquier Centro de Servicio para

Herramientas Industriales de Black & Decker o a las estaciones de

servicio autorizado enlistadas bajo “Herramientas Eléctricas” en la

Sección Amarilla. Esta garantía no se aplica a los accesorios ni a

daños causados por reparaciones efectuadas por terceras personas.

Esta garantía le otorga derechos legales específicos, y usted puede

tener otros derechos que pueden variar de estado a estado.

En adición a la garantía, las herramientas DeWalt están amparadas

por nuestra:

GARANTIA DE SATISFACCION SIN RIESGO POR 30 DIAS

Si usted no se encuentra completamente satisfecho con el

desempeño de su herramienta industrial DeWalt, sencillamente

devuélvala a los vendedores participantes durante los primeros 30

días después de la fecha de compra para que le efectúen un

reembolso completo. Por favor regrese la unidad completa, con el

transporte pagado. Se puede requerir prueba de compra.

Español

IMPORTADOR: BLACK & DECKER S.A. DE C.V.

BOSQUES DE RADIATAS NO. 42

BOSQUES DE LAS LOMAS, 05120 MEXICO,

D.F.

TEL 326-7100

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

Page 28

25

Español

Su rebajadora está equipada con velocidad de corte constante, al aumentar la carga, la velocidad

seleccionada no disminuye bajo condiciones normales de uso. El control electrónico gobierna al motor

y le proporciona un acabado consistente para su trabajo. Solamente bajo cargas muy pesadas la

velocidad de la unidad puede disminuir.

Para ajustar la velocidad de la rebajadora (de 8,000 rpm a 24,000 rpm) gire la perilla de control de

velocidad mostrado en la figura 3. Mientras mayor sea el número, mayor será la velocidad. Consulte

la tabla que sigue para ayudarse a seleccionar la velocidad apropiada para su aplicación.

Table A

TABLA DE SELECCIÓN DE VELOCIDADES

Material Diámetro de cuchilla Ajuste de control electrónico

Posición 1 Posición 2 Posición 3 Posición 4 Posición 5 Posición 6

Modelo # DW621 8 000

rpm 12,000 rpm 14,000 rpm 18,000 rpm 21,000 rpm 24,000 rpm

Madera dura, pe. encino Pequeña (1/2") – – O X XX X

Mediana (1/2"-11/8") – – O XX X -

Grande (más de 1 1/8") X XX O – – -

Madera suave, pe. pino Pequeña (1/2") – – O X XX XX

Mediana (1/2"-11/8") – O X XX XX XX

Grande (más de 1 1/8") X XX O – – -

Aglomerado c/laminado plástico Pequeña (1/2") – – O X XX XX

Mediana (1/2"-11/8") – O X XX XX XX

Grande (más de 1 1/8") O XX X – – -

Plástico/superficie sólida Pequeña (1/2") – O X X XX XX

Mediana (1/2"-11/8") – O XX XX X X

Grande (más de 1 1/8") X XX O – – -

Este vector puede servir solamente como guía, puesto que la madera era un material vivo. Dentro de la misma especie de la dureza y de

la densidad de la madera varíe. Las configuraciones de la velocidad son aproximadas.

Llave : XX – muy bueno; X = bon; 0 = satisfactorio; - =No recomendado

Loading...

Loading...