Page 1

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW616/DW618

Router System

Système de toupie

Sistema de rebajadora

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO

ANTES DE USAR EL PRODUCTO.

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286

(MAR05) Form No. 631103-00 DW616, DW618 Copyright © 2003, 2005 D

EWALT

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme; the “D” shaped

air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps

on the surface of the tool.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS, OR ANY DEWALT TOOL,

CALL US TOLL FREE AT 1-800-4-D

E

WALT (1-800-433-9258).

SAVE THESE INSTRUCTIONS

General Safety Instructions

WARNING! Read and understand all instructions. Failure to follow all instructions listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Safety Instructions For All Tools

WORK AREA

Keep your work area clean and well lit. Cluttered benches and dark areas invite acci-

dents.

Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust

or fumes.

Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

Grounded tools must be plugged into an outlet properly installed and grounded in

accordance with all codes and ordinances. Never remove the grounding prong or

modify the plug in any way. Do not use any adapter plugs. Check with a qualified

electrician if you are in doubt as to whether the outlet is properly grounded. If the

tool should electrically malfunction or break down, grounding provides a low resistance

path to carry electricity away from the user. This tool uses grounded construction (3 prong

plug) to provide a means to transfer electrical energy safely away from the user in the event

the tool electrically malfunctions, breaks down, or the tool case becomes live. Damage to, or

loss of, one of the 3 plug blades; damage to the plug or cord, or failure to have the tool

plugged into a verified and continuously grounded electrical system, may result in electric

shock, serious injury, or death. To avoid these risks of injury, the tool must, at all times, be

maintained and in proper working order (cord, plug blades) and plugged into a continuously

grounded electrical system. (See also “Cleaning” in the Maintenance section.)

Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord to carry tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric shock.

When operating a power tool outside, use an outdoor extension cord marked “W-A”

or “W.” These cords are rated for outdoor use and reduce the risk of electric shock.

EXTENSION CORDS

Make sure your extension cord is in good condition. When using an extension cord,

be sure to use one heavy enough to carry the current your product will draw. A volt-

age decrease of more than 10% will cause a loss of power and overheating

.

An undersized

cord will cause a drop in line voltage resulting in loss of power and overheating. The following table shows the correct size to use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gage. The smaller the gage number, the heavier the

cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gage

Than Than

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

PERSONAL SAFETY

Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use tool while tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating power tools may result in serious

personal injury.

Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your

hair, clothing , and gloves away from moving parts. Loose clothes, jewelry, or long hair

can be caught in moving parts.

Air vents often cover moving parts and should also be avoided.

Avoid accidental starting. Be sure switch is off before plugging in. Carrying

tools with your finger on the switch or plugging in tools that have the switch on invites

accidents.

Remove adjusting keys or wrenches before turning the tool on. A wrench or key that

is left attached to a rotating part of the tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enables better control of the tool in unexpected situations.

Use safety equipment. Always wear eye protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

Use clamps or other practical ways to secure and support the workpiece to a stable platform. Holding the work by hand or against your body is unstable and may lead

to loss of control.

Do not force tool. Use the correct tool for your application. The correct tool will do

the job better and safer and the rate for which it is designed.

Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled

with the switch is dangerous and must be repaired.

Disconnect the plug from the power source before making any adjustments,

changing accessories, or storing the tool. Such preventative safety measures reduce

the risk of starting the tool accidentally.

Store idle tools out of reach of children and other untrained persons. Tools are dan-

gerous in the hands of untrained users.

Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

tools, with sharp cutting edges are less likely to bind and are easier to control.

Check for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the tools operation. If damaged, have the tool serviced before using. Many accidents are caused by poorly maintained tools.

Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool may become hazardous when used on

another tool.

SERVICE

Tool service must be performed only by qualified repair personnel. Service or main-

tenance performed by unqualified personnel could result in a risk of injury.

When servicing a tool, use only identical replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unauthorized parts or failure to follow main-

tenance instructions may create a risk of electric shock or injury.

Specific Safety Rules for Routers

Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will

make exposed metal parts of the tool “live” and shock the operator.

Metal cutting with router: If using router for metal cutting, clean out tool often. Metal dust

and chips often accumulate on interior surfaces and could create a risk of serious injury,

electrical shock or death.

Never run the motor unit when it is not inserted in one of the router bases. The motor

is not designed to be handheld.

Keep handles dry, clean, and free from oil and grease. This will enable better control of

the tool.

Keep hands away from cutting area. Never reach under the workpiece for any reason.

Keep the router base firmly in contact with the workpiece when cutting. Hold the

router only by the handles. These precautions will reduce the risk of personal injury.

Use sharp cutters. Dull cutters may cause the router to swerve or stall under pressure.

Never touch the bit immediately after use. It may be extremely hot.

Be sure that the motor has stopped completely before you lay the router down. If the

cutter head is still spinning when the tool is laid down, it could cause injury or damage.

Be sure that the router bit is clear of the workpiece before starting the motor. If the bit

is in contact with the workpiece when the motor starts it could make the router jump, causing damage or injury.

CAUTION: Wear appropriate hearing protection during use. Under some conditions and

duration of use, noise from this product may contribute to hearing loss.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other con-

struction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paint.

• crystalline silica from bricks and cement and other masonry products.

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious

and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

• The label on your tool may include the following symbols. The symbols and definitions are

as follows:

V ............volts ........alternating current

A ............amperes ......direct current

Hz ..........hertz

n

o..........no load speed

W ............watts

..........

Class II Construction

min..........minutes

..........earthing terminal

..........safety alert symbol …/min ..revolutions per minute

FAMILIARIZATION

Motor

Your DEWALT tool is powered by a DEWALT-built motor. Be sure your power supply agrees

with the nameplate marking.

“120 V~” means your tool may be operated with alternating current only. Do not connect your

tool to a direct current power supply. All D

EWALT tools are factory tested; if this tool does not

operate, check the power supply.

Switch

To turn the tool on, push the toggle switch to the on position indicated on the tool. To turn the

tool off, push the toggle switch to the off position indicated on the tool.

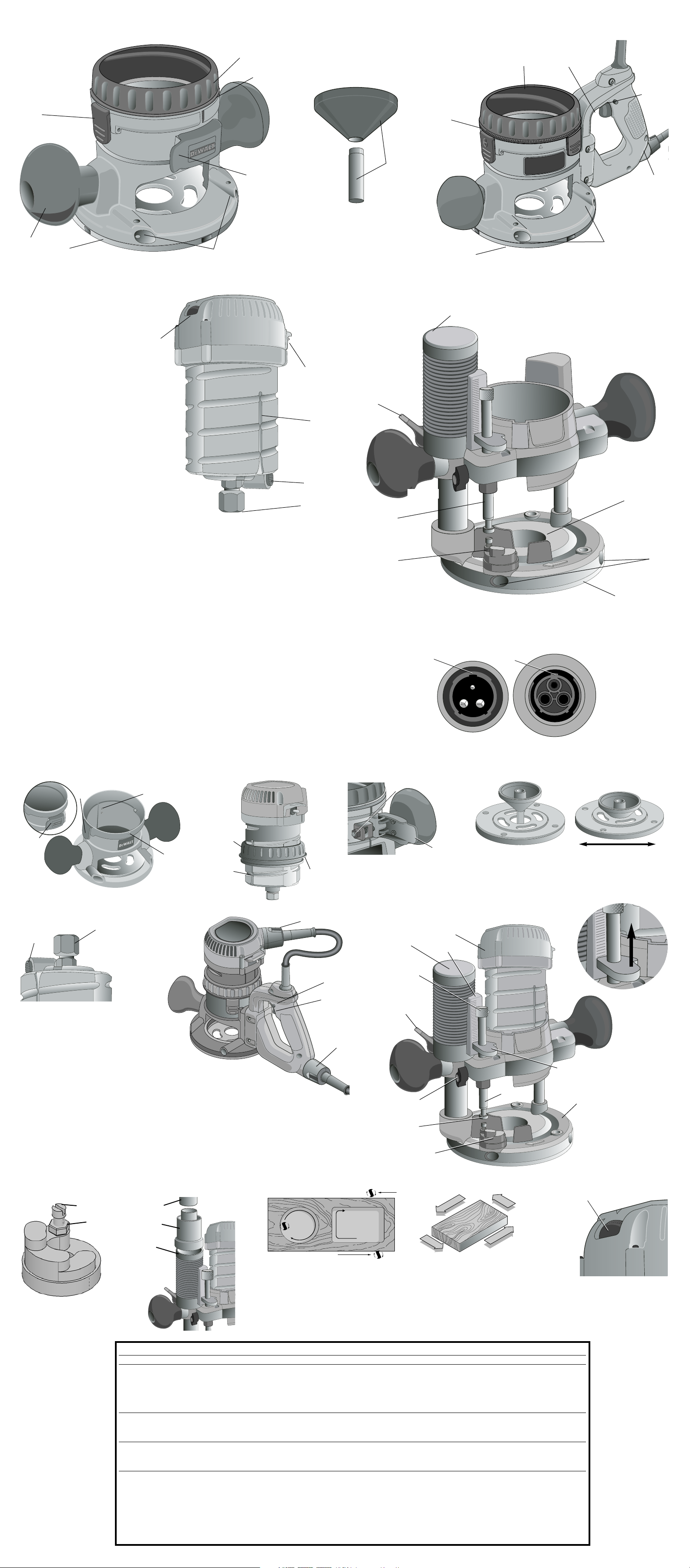

Detachable Cord Set (Fig. 1)

Insert the detachable cordset plug so that the key (W) is aligned with the notch (V) in the

socket. Turn the plug clockwise one quarter turn to lock.

CAUTION: Always turn off the tool and remove the plug from the power supply before

detaching the cordset from the tool.

CAUTION: Always leave the toggle switch in the off position when removing or attaching

the cord from the motor. If the toggle switch is in the on position when the cordset is attached,

the tool will start unexpectedly, causing loss of control, personal injury, and/or damage to the

tool or workpiece.

SET-UP: FIXED BASE

Motor Quick Release (Fig. 2)

CAUTION: Turn the router off and disconnect it from the power supply.

1. Open the locking lever (D) on the base.

2. Grasp the base with one hand, depressing the quick release latches (A).

3. With the other hand, grasp the top of the motor unit and lift it from the base.

Inserting the Motor into the Fixed Base (Fig. 3)

CAUTION: Turn the router off and disconnect it from the power supply.

1. Open the locking lever (D) on the base.

2. If the depth adjustment ring (B) is not on the motor, thread the depth adjustment ring (B)

onto the motor until the ring is about halfway between the top and bottom of the motor as

shown. Insert the motor into the base by aligning the groove on the motor (H) with the

guide pins (X) on the base. Slide the motor down until the Depth Adjustment Ring snaps

into the quick release latches (A).

NOTE: Guide pin grooves are located on either side of the motor so that it can be positioned

in two orientations.

3. Adjust the depth of cut by turning the depth adjustment ring. See the heading Adjusting the

Depth of Cut in the OPERATION: FIXED BASE section of this manual.

4. Close the locking lever (D) when the desired depth is achieved. For information on setting the cutting depth, see the heading Adjusting the Depth of Cut in the OPERATION:

FIXED BASE section of this manual.

Locking Lever Adjustment (Fig. 4)

CAUTION: Turn the router off and disconnect it from the power supply.

You should be able to clamp the locking lever without excessive force. Excessive force may

damage the base.

You should not be able to move the motor in the base when the locking lever is clamped. To

adjust the locking lever’s clamping force, open the locking lever (D) and turn the nut (Y) in

small increments. Turning the nut clockwise tightens the lever, while turning the nut counterclockwise loosens the lever.

Centering the Subbase (Fig. 5)

CAUTION: Turn the router off and disconnect it from the power supply.

If you need to adjust, change, or replace the subbase, a centering tool is provided. The centering tool consists of a cone and a pin. To adjust the subbase, follow the steps below.

1. Loosen but do not remove the subbase screws so that the subbase can move freely.

2. Insert the pin into the collet and tighten the collet nut.

3. Insert the motor into the base and clamp the locking lever on the base.

4. Place the cone on the pin and lightly press down on the cone until it stops as shown. This

will center the subbase.

5. While holding down on the cone, tighten the subbase screws.

OPERATION: FIXED BASE

Bit Installation and Removal (Fig. 6)

CAUTION: Turn the router off and disconnect it from the power supply.

1. To install a bit, insert the round shank of the desired router bit into the loosened collet as

far as it will go and then pull it out about 1/16". Using the wrench(es) provided, turn the collet nut (J) clockwise while holding the spindle shaft with the second wrench. [On the

DW618, depress the spindle lock button (I) to hold the spindle shaft.]

2. To remove a bit, hold the spindle shaft while turning the collet nut (J) counterclockwise

with the wrench provided. [Hold the spindle by depressing the spindle lock button (I) on

the DW618.] The self-releasing collet nut will turn approximately 3/4 of a turn and then

become tight again. At this point the bit cannot be removed. Continue turning the collet

nut counterclockwise. This lifts the collet, allowing the bit’s removal.

Collets

NOTE: Never tighten the collet without first installing a router bit in it. Tightening an empty collet, even by hand, can damage the collet.

Two collets are included with the motor: one 1/4" and one 1/2". To change collet sizes,

unscrew the collet assembly as described above. Install the desired collet by reversing the

procedure. The collet and the collet nut are connected. Do not attempt to remove the collet

from the collet nut.

Adjusting the Depth of Cut (Fig. 2, 3)

CAUTION: Turn the router off and disconnect it from the power supply.

1. Select and install the desired bit. See the heading Bit Installation and Removal.

2. Place the router on its base on the work piece.

3. Open the locking lever (D) and turn the depth adjustment ring (B) until the bit just touches

the work piece. Turning the ring clockwise raises the cutting head while turning it counterclockwise lowers the cutting head.

4. Move the adjustable scale clockwise (C) so that 0 on the scale is located exactly above

the pointer (Z) on the base.

5. Turn the depth adjustment ring along with the adjustable scale to the desired depth. Note

that each mark on the adjustable scale represents a depth change of 1/64" or .015"

(.4mm).

6. Close the locking lever (D).

Using a Parallel Fence

A parallel fence (DW6913) is available from your local retailer or service center at extra cost.

Follow the assembly instructions included with the fence. Insert the two bars through the edge

guide holes in the router base. Adjust as needed for parallel routing.

SET-UP: D-HANDLE BASE

Motor Quick Release

CAUTION: Turn the router off and disconnect it from the power supply.

1. Open the locking lever (D) on the base.

2. Grasp the base with one hand while depressing the quick release latches (A).

3. With the other hand, grasp the top of the motor unit and lift it from the base.

Inserting the Motor into the D-Handle Base (Fig. 7)

CAUTION: Turn the router off and disconnect it from the power supply.

1. Open the locking lever (D) on the base.

2. Thread the depth adjustment ring (B) onto the motor until the ring is about halfway between

the top and bottom of the motor. Insert the motor into the base by aligning the groove on

the motor (H) with the guide pins (X) on the base. Slide the motor down until the depth

adjustment ring snaps into the quick release latches (A).

3. Close the locking lever when the desired depth is achieved. For information on setting cutting depth, see the heading Adjusting the Depth of Cut in the OPERATION: D-HANDLE

BASE section of this manual.

4. Be sure that the trigger switch (N) is released and the trigger lock button (O) is in the

unlocked and off position.

5. Unlock and disconnect the detachable cordset (L) from the motor.

6. Connect the detachable cordset (L) to bottom of D-Handle and lock the cord.

7. Connect the short cord (AA) from top of D-Handle to the motor as shown. Be sure the cord

is locked.

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DEWALT • www.dewalt.com

Page 2

8. Place the toggle switch in the on position. This allows the trigger switch on the D-handle

to control the router.

Locking Lever Adjustment (Fig. 4)

CAUTION: Turn the router off and disconnect it from the power supply.

You should be able to clamp the locking lever without excessive force. Excessive force may

damage the base.

You should not be able to move the motor in the base when the locking lever is clamped. To

adjust the locking lever’s clamping force, open the locking lever (D) and turn the nut (Y) in

small increments. Turning the nut clockwise tightens the lever while turning the nut counterclockwise loosens the lever.

Centering the Subbase (Fig. 5)

CAUTION: Turn the router off and disconnect it from the power supply.

If you need to adjust, change, or replace the subbase, a centering tool is provided. The centering tool consists of a cone and a pin. To adjust the subbase, follow the steps below.

1. Loosen but do not remove the subbase screws so that the subbase can move freely.

2. Insert the pin into the collet and tighten the collet nut.

3. Insert the motor into the base and clamp the locking lever on the base.

4. Place the cone on the pin and lightly press down on cone until it stops as shown. This will

center the subbase.

5. While holding down on the cone, tighten the subbase screws.

OPERATION: D-HANDLE BASE

Knob Locations

Grip the D-Handle with one hand and place the other hand on the the knob. The D-Handle

router base has two positions for the knob to accommodate right or left hand use.

CAUTION: Use both hands at all times to maintain control.

Trigger Lock

To lock the trigger, pull the trigger switch (N) completely, then push the trigger lock button (O).

The router will remain on after you remove your finger from the trigger. To unlock the trigger lock

button, pull the trigger and release. The lock button will pop out and the router will turn off.

Bit Installation and Removal (Fig. 6)

CAUTION: Turn the router off and disconnect it from the power supply.

1. To install a bit, insert the round shank of the desired router bit into the loosened collet as far

as it will go and then pull it out about 1/16". Using the wrench(es) provided, turn the collet

nut (J) clockwise while holding the spindle shaft with the second wrench. [On the DW618,

depress the spindle lock button (I) to hold the spindle shaft.]

2. To remove a bit, hold the spindle shaft while turning the collet nut (J) counterclockwise with

the wrench provided. [Hold the spindle by depressing the spindle lock button (I) on the

DW618.] The self-releasing collet nut will turn approximately 3/4 of a turn and then become

tight again. At this point the bit cannot be removed. Continue turning the collet nut counterclockwise. This lifts the collet, allowing the bit’s removal.

Collets

NOTE: Never tighten the collet without first installing a router bit in it. Tightening an empty collet, even by hand, can damage the collet.

Two collets are included with the motor: one 1/4" and one 1/2". To change collet sizes, unscrew

the collet assembly as described above. Install the desired collet by reversing the

procedure.The collet and the collet nut are connected. Do not attempt to remove the collet from

the collet nut.

Adjusting the Depth of Cut (Fig. 3)

CAUTION: Turn the router off and disconnect it from the power supply.

1. Select and install the desired bit. See the heading Bit Installation and Removal.

2. Place the router on its base on the work piece.

3. Open the locking lever (D) and turn the depth adjustment ring (B) until the bit just touches

the work piece. Turning the ring clockwise raises the cutting head while turning it counterclockwise lowers the cutting head.

4. Move the adjustable scale clockwise so that 0 on the scale is located exactly above the

pointer (Z) on the base.

5. Turn the depth adjustment ring along with the adjustable scale to the desired depth. Note

that each mark on the adjustable scale represents a depth change of 1/64" or .015"

(.4mm).

6. Close the locking lever (D).

Using a Parallel Fence

A parallel fence (DW6913) is available from your local retailer or service center at extra cost.

Follow the assembly instructions included with the fence. Insert the two bars through the holes

in the router base. Adjust as needed for parallel routing.

SET-UP: PLUNGE BASE (Fig. 8)

Motor Quick Release

CAUTION: Turn the router off and disconnect it from the power supply.

1. Open the locking lever (D) on the base.

2. Grasp the top of the motor unit and lift it from the base.

Inserting the Motor into the Plunge Base

CAUTION: Turn the router off and disconnect it from the power supply.

1. Remove the depth adjustment ring from the motor. It is not used with the plunge base.

2. Open the locking lever (D) on the base to ensure that the motor properly seats.

3. Ensure that the plunge lock lever (R) is locked.

4. Align the flat of the motor’s end cap (BB) with pillar (CC) and insert the motor into the

plunge base until it stops.

5. Close the locking lever (D).

Locking Lever Adjustment (Fig. 4)

CAUTION: Turn the router off and disconnect it from the power supply.

You should be able to clamp the locking lever without excessive force. Excessive force may

damage the base.

You should not be able to move the motor in the base when the locking lever is clamped.

To adjust the locking lever’s clamping force, open the locking lever (D) and turn the nut

(Y) in small increments. Turning the nut clockwise tightens the lever, while turning the nut

counterclockwise loosens the lever.

Centering the Subbase (Fig. 5)

CAUTION: Turn the router off and disconnect it from the power supply.

If you need to adjust, change, or replace the subbase, a centering tool is provided. The

centering tool consists of a cone and a pin. To adjust the subbase, follow the steps below.

1. Loosen but do not remove the subbase screws so that the subbase can move freely.

2. Insert the pin into the collet and tighten the collet nut.

3. Insert the motor into the base and clamp the locking lever on the base.

4. Place the cone on the pin and lightly press down on the cone until it stops as shown. This

will center the subbase.

5. While holding down on the cone, tighten the subbase screws.

OPERATION: PLUNGE BASE

Bit Installation and Removal (Fig. 6)

CAUTION: Turn the router off and disconnect it from the power supply.

1. To install a bit, insert the round shank of the desired router bit into the loosened collet as

far as it will go and then pull it out about 1/16". Using the wrench(es) provided, turn the collet nut (J) clockwise while holding the spindle shaft with the second wrench. [On the

DW618, depress the spindle lock button (I) to hold the spindle shaft.]

2. To remove a bit, hold the spindle shaft while turning the collet nut (J) counterclockwise

with the wrench provided. [Hold the spindle by depressing the spindle lock button (I) on

the DW618.] The self-releasing collet nut will turn approximately 3/4 of a turn and then

become tight again. At this point the bit cannot be removed. Continue turning the collet

nut counterclockwise. This lifts the collet, allowing the bit’s removal.

Collets

NOTE: Never tighten the collet without first installing a router bit in it. Tightening an empty collet, even by hand, can damage the collet.

Two collets are included with the motor: one 1/4" and one 1/2". To change collet sizes, unscrew

the collet assembly as described above. Install the desired collet by reversing the

procedure.The collet and the collet nut are connected. Do not attempt to remove the collet from

the collet nut.

Adjusting the Plunge Routing Depth (Fig. 8)

CAUTION: Turn the router off and disconnect it from the power supply.

1. Unlock the plunge mechanism by pushing up the plunge lock lever (R). Plunge the router

down as far as it will go, allowing the bit to just touch the workpiece.

2. Lock the plunge mechanism by pushing the plunge lock lever (R) down.

3. Loosen the depth adjustment rod (Q) by turning the wingscrew (DD) counterclockwise.

4. Slide the depth adjustment rod (Q) down so that it meets the lowest turret stop (P).

5. Slide the tab (EE) on the depth adjustment rod down so that the top of it meets zero on the

pillar scale (FF).

6. Grasping the top, knurled section of the depth adjustment rod (Q), slide it up so that the

tab (EE) aligns with the desired depth of cut on the pillar scale (FF).

7. Tighten the wingscrew (DD) to hold the depth adjustment rod in place.

8. Keeping both hands on the handles, unlock the plunge mechanism by pushing the plunge

lock lever (R) up. The plunge mechanism and the motor will move up. When the router is

plunged, the depth adjustment rod will hit the turet stop, allowing the router to reach exactly the desired depth.

Fine Adjustment of Routing Depth

CAUTION: Turn the router off and disconnect it from the power supply.

The knurled knob (GG) at the bottom end of the depth adjustment rod can be used to make

minor adjustments.

1. To decrease the cutting depth, rotate the knob clockwise (looking down from the top of the

router).

2. To increase the cutting depth, rotate the knob counterclockwise (looking down from the top

of the router).

NOTE: One complete rotation of the knob results in a change of about 5/128" or .04" (1 mm)

in depth.

Using the Rotating Turret Stop (Fig. 9)

The turret depth stop can be used to set 5 different depths. One of the turret stops is adjustable.

To use the adjustable turret stop, loosen the nut (HH), then adjust the screw (II) to the desired

height. Turning the screw counterclockwise will raise the screw which will decrease the cutting

depth. The turret stop is useful for making deep cuts in several passes.

WARNING: Do not change the turret stop while the router is running. This will place your

hands too near the cutter head.

Cutting with the Plunge Base (Fig. 8)

CAUTION: Turn the router on before plunging the cutter head into the workpiece.

1. Unlock the plunge lock lever (R).

2. Plunge the router down until the bit reaches the set depth.

3. Lock the plunge lock lever (R).

4. Perform the cut.

5. Unlock the plunge lock lever. This will allow the router bit to disengage the work.

6. Turn the router off.

Dust Extraction (Fig. 10)

CAUTION: Turn the router off and disconnect it from the power supply.

To connect the router to a vacuum cleaner for dust extraction, follow these steps:

1. Remove the dust cap (T) by pulling straight up.

2. Insert the dust extraction hose adapter (JJ) into the dust extraction port (KK) as shown.

3. Insert the end of a standard vacuum cleaner tube (LL) into the hose adapter.

4. When using dust extraction, be aware of the placement of the vacuum cleaner. Be sure that

the vacuum cleaner is stable and that its hose will not interfere with the work.

OPERATION: ALL BASES

Direction Of Feed (Fig. 11)

The direction of feed is very important when routing and can make the difference between a

successful job and a ruined project. The figures at left show the proper direction of feed for

some typical cuts. A general rule to follow is to move the router in a counterclockwise direction

on an outside cut and a clockwise direction on an inside cut.

Shape the outside edge of a piece of stock by following these steps:

1. Shape the end grain, left to right

2. Shape the straight grain side moving left to right

3. Cut the other end grain side

4. Finish the remaining straight grain edge

Choosing Router Speed (DW618 only) (Fig. 12)

Refer to the chart above to choose a router speed. Turn the speed dial (G) to control router

speed.

MAINTENANCE

Cleaning

WARNING: Blowing dust and chips out of the motor housing using clean, dry compressed

air is a necessary regular maintenance procedure. Dust and chips containing metal particles

often accumulate on interior surfaces and could create an electrical shock or electrocution if

not frequently cleaned out. ALWAYS WEAR SAFETY GLASSES.

CAUTION: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tool. Use a clean, dry rag only.

NOTE FOR PLUNGE BASE ONLY: Use only a DRY cloth to wipe the plunge rods. These

rods require no lubrication. Lubricants attract dust, reducing the performance of your tool.

Accessories

Recommended accessories for use with your tool are available at extra cost from your local

dealer or authorized service center. If you need assistance in locating any accessory for your

tool, call us toll free at: 1-800-4-D

EWALT (1-800-433-9258) or contact DEWALT Industrial Tool

Co., 701 East Joppa Road, Baltimore, MD 21286.

CAUTION: The use of any other accessory not recommended for use with this tool could

be hazardous.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including brush inspection and replacement) should be performed by authorized service centers or

other qualified service personnel, always using identical replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for

three years from the date of purchase. This warranty does not cover part failure due to normal

wear or tool abuse. For further detail of warranty coverage and warranty repair information,

visit www.dewalt.com or call 1-800-4-D

EWALT (1-800-433-9258). This warranty does not apply

to accessories or damage caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights which vary in certain

states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your D

EWALT Power Tool, Laser,

or Nailer for any reason, you can return it within 90 days from the date of purchase with a

receipt for a full refund – no questions asked.

RECONDITIONED PRODUCT: Reconditioned product is covered under the 1 Year Free

Service Warranty. The 90 Day Money Back Guarantee and the Three Year Limited Warranty

do not apply to reconditioned product.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-4-D

EWALT for a free replacement.

SI VOUS AVEZ DES QUESTIONS OU VOUS VOULEZ NOUS FAIRE PART DE VOS COMMENTAIRES CONCERNANT CET OUTIL OU TOUT AUTRE OUTIL DEWALT, COMPOSEZ

SANS FRAIS LE 1 800 433-9258.

CONSERVER CES DIRECTIVES!

MESURES DE SÉCURITÉ – GÉNÉRALITÉS

AVERTISSEMENT! Lire et comprendre toutes les directives, car le nonrespect des directives suivantes pourrait entraîner un risque de choc électrique, d’incendie ou de blessures graves.

CONSERVER CES DIRECTIVES

Consignes de sécurité concernant tous les outils

ZONE DE TRAVAIL

Garder la zone de travail propre et bien éclairée; les établis encombrés et les endroits

sombres sont propices aux accidents.

Ne pas utiliser les outils électriques dans une atmosphère explosive, comme à

proximité de liquides, de gaz ou de poussières inflammables; le moteur peut créer

des étincelles et enflammer les vapeurs ou les poussières environnantes.

Tenir les enfants, les visiteurs ou toute autre personne à l’écart lorsqu’on utilise un

outil électrique; les distractions peuvent faire perdre la maîtrise de ce dernier.

MESURES DE SÉCURITÉ - ÉLECTRICITÉ

Les outils mis à la terre doivent être branchés dans une prise bien installée et mise

à la terre conformément à tous les codes et règlements en vigueur. Ne jamais retirer la broche de terre ni modifier la fiche. Ne pas utiliser d'adaptateur. Vérifier auprès

d'un électricien qualifié en cas de doute quant à la mise à la terre de la prise. En cas

de défaillance électrique ou de bris de l'outil, la mise à la terre procure un chemin de faible

résistance au courant qui autrement traverserait l'utilisateur. Pour éviter que l’utilisateur ne

soit électrocuté en cas de défaillance, de bris ou de conductivité de l’outil, celui-ci est doté

d’une fiche à trois broches afin d’assurer la mise à la terre. Il y a risque d’électrocution, de

blessures graves ou de mort lorsqu’on utilise un outil dont une broche est endommagée ou

absente ou dont la fiche ou le cordon est endommagé ou qui n’est pas branché dans une

prise conforme mise continuellement à la terre. Pour éviter les risques de blessures, l’outil

doit toujours être bien entretenu et en bon état de marche (cordon, broches de la fiche)

et doit être branché dans une prise mise à la terre continuellement. (Voir également la

rubrique « Nettoyage » dans la section Entretien.)

Éviter tout contact entre le corps et les éléments mis à la terre, comme les tuyaux,

les radiateurs, les cuisinières et les réfrigérateurs, afin de réduire les risques de choc

électrique.

Ne pas utiliser l’outil électrique dans des endroits mouillés, ni l’exposer à la pluie;

l’infiltration d’eau à l’intérieur de l’outil augmente les risques de choc électrique.

Ne pas utiliser le cordon de manière abusive; on ne doit pas transporter l’outil en le

tenant par le cordon, ou utiliser ce dernier pour le débrancher. On doit tenir le cordon à l’écart des sources de chaleur, de l’huile, des bords tranchants ou des pièces

mobiles. Remplacer immédiatement les cordons endommagés, car ces derniers aug-

mentent les risques de choc électrique.

Lorsqu’on utilise un outil électrique à l’extérieur, on ne doit utiliser que des rallonges conçues pour cet usage, comme celles de type

«

W-A»ou « W», afin de

réduire les risques de choc électrique.

RALLONGES

S’assurer que la rallonge est en bon état; si on utilise une rallonge, s’assurer d’en

choisir une qui est en mesure de porter le courant nécessaire à l’outil. Une baisse

de tension de plus de 10 p. 100 peut entraîner une perte de puissance et la surchauffe.

Une rallonge de calibre inférieur entraînera une chute de tension se traduisant par une

perte de puissance et une surchauffe. Le tableau ci-dessous illustre les calibres que l’on

doit utiliser selon la longueur de la rallonge et l’intensité nominale indiquée sur la plaque

signalétique. En cas de doute, utiliser le calibre suivant. Plus le calibre est petit, plus la rallonge peut porter de courant.

Calibre minimal des cordons de rallonge

TensionLongueur totale du cordon en meters

120 V De 0 à 7 De 7 à 15 De 15 à 30 De 30 à 45

240 V De 0 à 7 De 7 à 15 De 15 à 39 De 30 à 45

Intensité (A)

Au Au Calibre moyen de fil

moins plus

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

SÉCURITÉ PERSONNELLE

Rester vigilant en tout temps et faire preuve de jugement lorsqu’on utilise un outil

électrique; ne pas utiliser l’outil lorsqu’on est fatigué ou sous l’influence de drogues,

d’alcool ou de médicaments, car un moment d’inattention pourrait entraîner des blessures

graves.

Porter des vêtements appropriés; ne pas porter de vêtements amples ni de bijoux.

Couvrir ou attacher les cheveux longs. Garder les cheveux, les vêtements, les bijoux

et les gants éloignés des pièces mobiles, car ceux-ci peuvent s’y coincer. Se tenir éloigné

des évents puisque ces derniers pourraient camoufler des pièces mobiles.

Éviter les démarrages accidentels; s’assurer que l’interrupteur est en position d’arrêt avant de brancher l’outil. Ne pas transporter l’outil en laissant le doigt sur l’interrup-

teur ni le brancher lorsque l’interrupteur est en position de marche, car cela pourrait causer

un accident.

Retirer les clés de réglage avant de démarrer l’outil; une clé laissée sur une pièce rotative peut entraîner des blessures.

Ne pas trop étendre les bras; les pieds doivent rester ancrés fermement au sol afin

de maintenir son équilibre en tout temps et de mieux maîtriser l’outil dans des situa-

tions imprévues.

Utiliser le matériel de sécurité approprié; toujours porter des lunettes de protection.

Porter un masque anti-poussières, des chaussures antidérapantes, un casque de sécurité

ou des protecteurs auditifs lorsque la situation le requiert.

UTILISATION ET ENTRETIEN DE L’OUTIL

Fixer et soutenir le matériel sur une plate-forme stable au moyen d’une bride de serrage ou de tout autre dispositif semblable; le matériel est instable lorsqu’on le retient

manuellement ou qu’on l’appuie contre le corps, ce qui peut faire perdre la maîtrise de l’outil.

Ne pas forcer l’outil ni l’utiliser pour des travaux autres que ceux pour lesquels il a

été conçu. Pour obtenir de meilleurs résultats et prévenir les risques de blessure, laisser

l’outil couper à la vitesse pour laquelle il a été conçu.

Ne pas utiliser l’outil lorsque l’interrupteur marche-arrêt ne fonctionne pas; tout outil

qui ne peut être commandé au moyen de l’interrupteur est dangereux et doit être réparé.

Page 3

D

A

Z

X

D-Handle Base - Base de la poignée fermée

Base con mango en D

Plunge Base - Base plongeante - Base para penetración

M

N

O

P

Q

R

T

U

L

M

S

F

F

B

C

Centering Tool

Outil de centrage

Herramienta

de centrado

V

W

H

B

C

D

Y

I

J

Fixed Base - Base fixe - Base fija

A. QUICK RELEASE LATCH

B. DEPTH ADJUSTMENT RING

C. ADJUSTABLE SCALE

D. LOCKING LEVER

E. HANDLE

F. SUBBASE

G. SPEED DIAL (618 ONLY)

H. GUIDE PIN GROOVE

I. SPINDLE LOCK BUTTON

(618 ONLY)

J. COLLET NUT

K. TOGGLE SWITCH

L. DETACHABLE CORDSET

M. HOLES FOR UNIVERSAL

EDGE GUIDE

N. TRIGGER SWITCH

O. TRIGGER LOCK BUTTON

P. TURRET STOP

Q. DEPTH ADJUSTMENT ROD

R. PLUNGE LOCK LEVER

S. DUST SHROUD

T. DUST CAP

U. CENTERING TOOL

D

B

A

E

F

H

I

J

M

G

K

C

FIG. 1

FIG. 2

FIG. 3

Motor - Bloc moteur - Unidad del motor

A. VERROU DE DÉBLOCAGE RAPIDE

B. ANNEAU DE RÉGLAGE DE PROFONDEUR

C. ÉCHELLE RÉGLABLE

D. LEVIER DE VERROUILLAGE

E. POIGNÉE

F. SOUS-BASE

G.BOUTON DE RÉGLAGE DES VITESSES

(MODÈLE 618 SEULEMENT)

H. RAINURE DE LA GOUPILLE DE GUIDAGE

I. BOUTON DE VERROUILLAGE DE LA

BROCHE (MODÈLE 618 SEULEMENT)

J. ÉCROU DE LA DOUILLE DE SERRAGE

K. COMMUTATEUR À BASCULE

L. CORDON AMOVIBLE

M. ORIFICES POUR BORD-GUIDE UNIVERSEL

N. INTERRUPTEUR À GÂCHETTE

O. BOUTON DE VERROUILLAGE DE LA

GÂCHETTE

P. BUTÉE DE LA TOURELLE

Q. TIGE DE RÉGLAGE DE PROFONDEUR

R. LEVIER DE VERROUILLAGE DE PLONGÉE

S. ENVELOPPE ANTI-POUSSIÈRE

T. CAPUCHON ANTI-POUSSIÈRE

U. OUTIL DE CENTRAGE

A. SEGURO DE LIBERACIÓN RÁPIDA

B. ANILLO DE AJUSTE DE PROFUNDIDAD

C. ESCALAAJUSTABLE

D. PALANCA DE SEGURIDAD

E. MANGO

F. SUB BASE

G. SELECTOR DE VELOCIDAD

(ÚNICAMENTE 618)

H. CANAL PARA PERNO GUÍA

I. BOTÓN DEL SEGURO DE LA FLECHA

J. TUERCA DE LA MORDAZA

K. INTERRUPTOR DE CAMBIO

L. CABLE DESMONTABLE

M. ORIFICIOS PARA GUÍA UNIVERSAL

PARA BORDES

N. GATILLO INTERRUPTOR

O. BOTÓN DE SEGURO DEL GATILLO

P. TOPE DE TORRETA

Q. VARILLA DE AJUSTE DE PROFUNDIDAD

R. PALANCA DE SEGURO DE PENETRACIÓN

S. CUBIERTA CONTRA POLVO

T. TAPA DE POLVO

U. HERRAMIENTA DE CENTRADO

FIG. 3

FIG. 4

FIG. 5

FIG. 6

AA

L

N

O

K

BB

CC

R

FIG. 7

FIG. 8

FF

EE

DD

GG

Q

F

HH

II

KK

JJ

LL

1

4

3

2

G

FIG. 9

FIG. 10

FIG. 11

FIG. 12

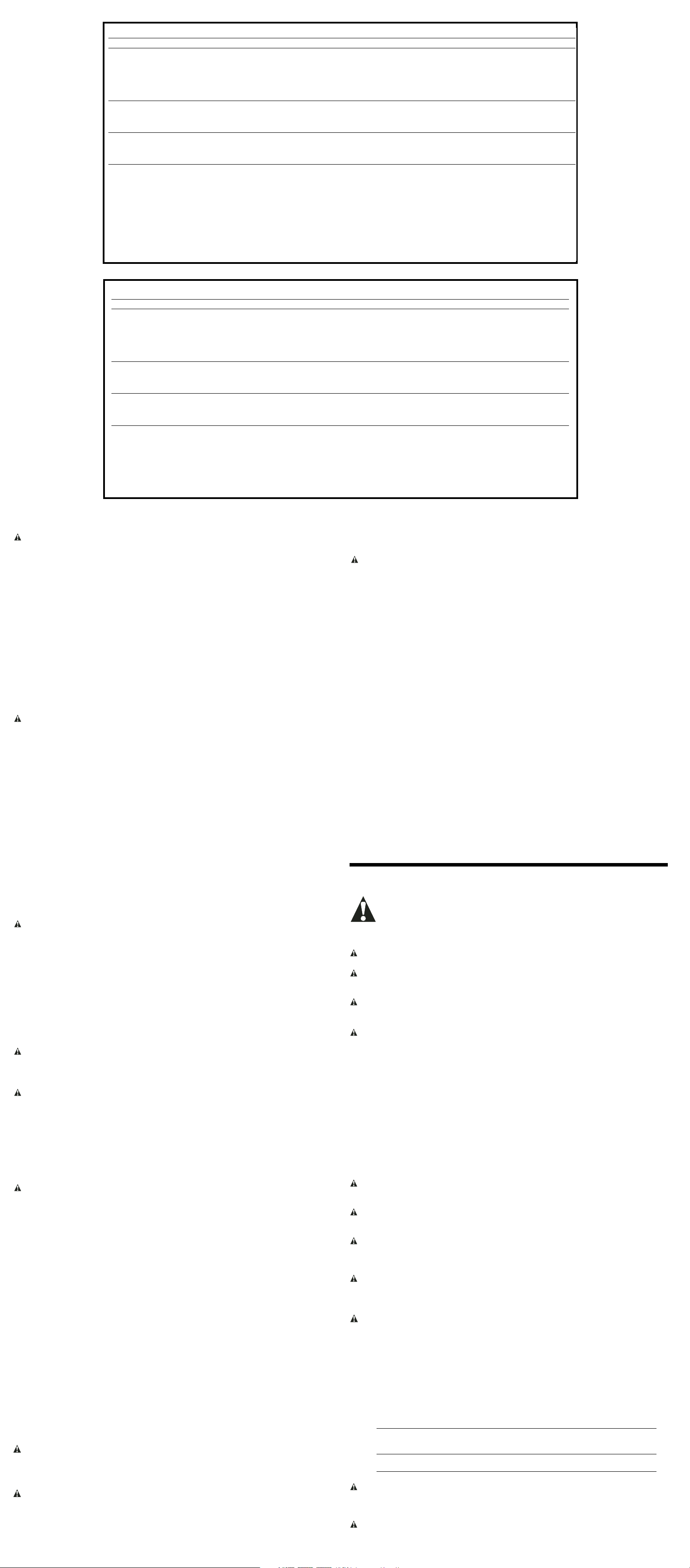

SPEED SELECTION CHART

Material Cutter Diam. Electronic Control Settings

Setting 1 Setting 2 Setting 3 Setting 4 Setting 5 Setting 6

Model # DW618 8,000 rpm 12,000 rpm 14,000 rpm 18,000 rpm 21,000 rpm 24,000 rpm

Hardwood, e.g., oak Small (1/2") – – O X XX X

Medium (1/2"-1 1/8") – – O XX X –

Large (over-1 1/8") X XX O – – –

Softwood, e.g., pine Small (1/2") – – O X XX XX

Medium (1/2"-1 1/8") – O X XX XX XX

Large (over-1 1/8") X XX O – – –

Plastic-laminated chipboard Small (1/2") – – O X XX XX

Medium (1/2"-1 1/8") – O X XX XX XX

Large (over-1 1/8") O XX X – – –

Plastics/Solid Surface Small (1/2") – O X X XX XX

Medium (1/2"-1 1/8") – O XX XX X X

Large (over-1 1/8") X XX O – – –

This table can serve only as a guide, since wood was a living material. Within the same species of timber hardness and density vary.

Speed settings are approximate.

KEY: XX very good X good O Satisfactory – not recommended

T

P

Page 4

Débrancher l’outil avant d’effectuer un réglage, de changer les accessoires ou de

ranger l’outil; ces mesures de sécurité préventives réduisent les risques de démarrage

accidentel.

Lorsqu’on n’utilise pas l’outil, le ranger hors de la portée des enfants ou des personnes non qualifiées; les outils sont dangereux entre les mains de personnes inex-

périmentées.

Bien entretenir l’outil et s’assurer qu’il est toujours bien propre et aiguisé; les outils

bien entretenus et dont les bords sont bien tranchants sont moins susceptibles de rester

coincés et sont plus faciles à maîtriser.

Vérifier les pièces mobiles afin de s’assurer qu’elles sont bien alignées et qu’elles

ne restent pas coincées; vérifier également les pièces afin de s’assurer qu’il n’y a

ni bris ni aucune autre condition susceptible de nuire au bon fonctionnement de

l’outil; faire réparer l’outil si ce dernier est endommagé avant de s’en servir à nouveau,

car les accidents sont souvent causés par des outils mal entretenus.

N’utiliser que les accessoires recommandés par le fabricant pour le modèle concerné; un accessoire destiné à un outil particulier peut devenir dangereux lorsqu’il est util-

isé avec un autre.

ENTRETIEN

L’outil doit être entretenu par le personnel qualifié seulement; toute maintenance

effectuée par une personne non qualifiée peut entraîner des risques de blessure.

Lors de l’entretien, n’utiliser que des pièces de rechange identiques et suivre les

directives de la section «Entretien» du présent guide afin de prévenir les risques de

choc électrique ou de blessure.

Règles de sécurité spécifique concernant les toupies

Tenir l’outil par les surfaces isolées prévues à cette fin lorsque l’outil risque d’entrer en contact avec des fils cachés ou le cordon, car de tels contacts peuvent mettre les

pièces métalliques de l’outil sous tension, engendrant des risques de choc électrique.

Découpage du métal à la toupie : si la toupie sert à découper du métal, il faut la nettoyer

souvent. La poussière de métal s’accumule souvent sur les surfaces intérieures et pourrait

causer des blessures sérieuses, une électrocution ou la mort.

Ne jamais faire fonctionner le bloc moteur lorsqu’il n’est pas inséré dans l’une des

bases de la toupie; le moteur n’est pas conçu pour être tenu à la main.

Maintenir les poignées sèches, propres et exemptes d’huile et de graisse afin de

mieux maîtriser l’outil.

Garder les mains éloignées des zones de coupe; ne pas mettre les mains sous le

matériel pour quelque raison que ce soit. S’assurer de bien maintenir la base de la

toupie en contact avec la pièce lors de la coupe et de toujours tenir l’outil par les

poignées seulement afin de réduire les risques de blessure.

Toujours utiliser une arête bien aiguisée, car les arêtes usées peuvent faire dévier la

toupie ou faire caler le moteur lorsqu’on exerce trop de pression sur l’outil.

Ne jamais toucher à la mèche immédiatement après l’avoir utilisée, car elle peut être

extrêmement chaude.

Attendre que le moteur s’arrête complètement avant de déposer la toupie. Si l’arête

tranchante tourne encore lorsqu’on dépose l’outil, on risque de causer des dommages ou

des blessures.

S’assurer que la mèche n’est pas en contact avec la pièce avant de démarrer le

moteur, afin d’éviter de faire bondir la toupie et de causer des dommages ou des

blessures.

MISE EN GARDE : Porter un dispositif de protection personnel anti-bruit approprié

durant l’utilisation. Sous certaines conditions et pendant toute la durée de l’utilisation, le bruit

émanant de ce produit pourrait contribuer à la perte d’audition.

AVERTISSEMENT : Certains outils électriques, tels que les sableuses, les scies, les

meules, les perceuses ou certains autres outils de construction, peuvent produire de la poussière contenant des produits chimiques susceptibles d’entraîner le cancer, des malformations

congénitales ou pouvant être nocifs pour le système reproductif. Parmi ces produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb,

• la silice cristalline dans les briques et le ciment et autres produits de maçonnerie,

• l’arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique (comme

l’arséniate de cuivre et de chrome).

Le risque associé à de telles expositions varie selon la fréquence avec laquelle on effectue ces

travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un endroit bien aéré

et utiliser le matériel de sécurité approprié, tel un masque anti-poussières spécialement conçu

pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par cet outil ou autres out-

ils électriques. Porter des vêtements de protection et nettoyer les parties exposées

du corps avec de l’eau savonneuse. S’assurer de bien se protéger afin d’éviter d’ab-

sorber par la bouche, les yeux ou la peau des produits chimiques nocifs.

AVERTISSEMENT : Cet outil peut produire et répandre de la poussière susceptible de

causer des dommages sérieux et permanents au système respiratoire. Toujours utiliser un

appareil respiratoire anti-poussières approuvé par le NIOSH ou l’OSHA. Diriger les particules

dans le sens opposé du visage et du corps.

• L’étiquette apposée sur l’outil peut comprendre les symboles suivants. Voici les symboles

et leurs définitions :

V..........volts A............ampères

Hz........hertz W ..........watts

min ......minutes ........courant alternatif

....courant direct

n

o ..........régime sans charge

........construction de classe II ..........borne de mise à la terre

........symbole de risque de choc .../min ....tours par minute

FAMILIARISATION

Moteur

Cet outil est entraîné par un moteur DEWALT. S’assurer que l’intensité nominale du cordon

d’alimentation correspond à celle indiquée sur la plaque signalétique; sur cette dernière, la

mention «120 V ~» signifie que l’outil ne doit être branché que dans une prise de courant alternatif; ne pas brancher l’outil dans une prise de courant continu. Tous les outils D

EWALT sont

soumis à des essais en usine; si cet outil ne fonctionne pas, on doit d’abord vérifier l’intensité

nominale du cordon d’alimentation.

Interrupteur

Pour mettre l’outil en marche, enfoncer le commutateur à bascule jusqu’à la position de marche

(« ON ») indiquée sur l’outil; pour l’arrêter, enfoncer le commutateur jusqu’à la position d’arrêt

(« OFF »), également indiquée sur l’outil.

Cordon amovible (Fig. 1)

Insérer la fiche du cordon amovible de manière à aligner la clé (W) avec l’encoche (V) de la

douille. Tourner la fiche d’un quart de tour vers la droite afin de la verrouiller.

MISE EN GARDE : Toujours arrêter et débrancher l’outil de la source d’alimentation élec-

trique avant de débrancher le cordon de l’outil.

MISE EN GARDE : Toujours régler le commutateur à bascule à la position d’arrêt (« OFF »)

avant de retirer le cordon du moteur ou de le fixer à ce dernier. Si le commutateur est réglé à

la position de marche (« ON ») lorsque le cordon est fixé au moteur, l’outil démarrera accidentellement, ce qui entraînera la perte de maîtrise de l’outil ou des blessures graves, ou endommagera l’outil ou la pièce.

INSTALLATION DE LA BASE FIXE

Verrou de déblocage rapide du moteur (Fig. 2)

MISE EN GARDE : Arrêter et débrancher la toupie de la source d’alimentation électrique.

1. Ouvrier le levier de verrouillage (D) situé sur la base.

2. Saisir la base d’une main et enfoncer les verrous de déblocage rapide (A).

3. Saisir le dessus du bloc moteur de l’autre main et le soulever hors de la base.

Installation du moteur dans la base fixe (Fig. 3)

MISE EN GARDE : Arrêter et débrancher la toupie de la source d’alimentation électrique.

1. Ouvrier le levier de verrouillage (D) situé sur la base.

2. Si l’anneau de réglage de profondeur n’est pas déjà installé sur le moteur, fileter l’anneau

(B) sur ce dernier jusqu’à ce que qu’il se trouve à mi-chemin entre le dessus et le dessous

du moteur (voir l’illustration). Installer le moteur dans la base en alignant la rainure située

sur le moteur (H) avec les goupilles de guidage (X) se trouvant sur la base. Glisser le

moteur vers le bas jusqu’à ce que l’anneau de réglage de profondeur s’enclenche dans les

verrous de déblocage rapide (A).

REMARQUE: Les rainures du moteur sont situées de chaque côté du moteur afin qu’on

puisse l’orienter dans un sens ou dans l’autre.

3. Régler la profondeur de coupe en tournant l’anneau de réglage de profondeur. Consulter

la rubrique « Réglage de la profondeur de coupe » dans la section « FONCTION-

NEMENT DE LA BASE FIXE » du présent guide.

4. Fermer le levier de verrouillage (D) dès qu’on a atteint la profondeur voulue. Pour obtenir

des renseignements sur le réglage de la profondeur de coupe, consulter la rubrique «

Réglage de la profondeur de coupe » dans la section « FONCTIONNEMENT DE LA

BASE FIXE » du présent guide.

Réglage du levier de verrouillage (Fig. 4)

MISE EN GARDE : Arrêter et débrancher la toupie de la source d’alimentation électrique.

On doit pouvoir fixer solidement le levier de verrouillage sans exercer trop de pression; une

pression excessive risque d’endommager la base. Le moteur doit rester immobile dans la base

une fois le levier fixé. Pour régler la force de serrage du levier de verrouillage, ouvrir ce dernier

(D) et tourner l’écrou (Y) par petits échelons; le tourner vers la droite pour serrer le levier, ou

vers la gauche pour le desserrer.

Centrage de la sous-base (Fig. 5)

MISE EN GARDE : Arrêter et débrancher la toupie de la source d’alimentation électrique.

Un outil de centrage est fourni afin de permettre à l’utilisateur de régler, de changer ou de remplacer la sous-base, le cas échéant. L’outil de centrage est doté d’un cône et d’une goupille.

Pour régler la sous-base, suivre les étapes énumérées ci-dessous :

1. Desserrer les vis de la sous-base sans les retirer afin de permettre à la sous-base de se

déplacer librement;

2. Insérer la goupille dans la douille de serrage et serrer l’écrou de la douille;

3. Installer le moteur dans la base et fixer le levier de verrouillage sur la base;

4. Mettre le cône sur la goupille et appuyer légèrement sur le cône jusqu’à ce qu’il s’immobilise (voir la figure), afin de centrer la sous-base;

5. Appuyer sur le cône pour le retenir en place et serrer les vis de la sous-base.

FONCTIONNEMENT DE LA BASE FIXE

Installation et retrait de l’arête tranchante (Fig. 6)

MISE EN GARDE : Arrêter et débrancher la toupie de la source d’alimentation électrique.

1. Pour installer l’arête, insérer sa tige circulaire dans la douille de serrage (celle-ci doit être

desserrée), en l’enfonçant aussi loin que possible, puis la retirer sur environ 1 mm (1/16

po). Tourner l’écrou de la douille de serrage (J) vers la droite au moyen d’une ou de

plusieurs clés fournies, en retenant l’arbre à broche au moyen de la deuxième clé. [Pour

le modèle DW618, retenir l’arbre à broche en enfonçant le bouton de verrouillage de la

broche (I).]

2. Pour retirer l’arête tranchante, retenir l’arbre à broche et tourner l’écrou de la douille de

serrage (J) vers la gauche au moyen de la clé fournie. [Pour le modèle DW618, retenir la

broche en enfonçant son bouton de verrouillage (I).] L’écrou à autodéclenchement de la

douille de serrage tourne sur environ trois-quarts de tour avant de se resserrer; il devient

alors impossible de retirer l’arête. Continuer à tourner l’écrou vers la gauche afin de permettre à la douille de se soulever et de pouvoir ainsi retirer l’arête.

Douilles de serrage

REMARQUE : Ne jamais serrer la douille avant d’y avoir d’abord inséré une arête; on risque

d’endommager une douille sans arête, même lorsqu’on la serre manuellement.

Deux douilles sont fournies avec le moteur : une de 6,4 mm (1/4 po) et l’autre de 13 mm (1/2

po). Pour changer d’une douille à l’autre, dévisser son assemblage tel que décrit précédemment, puis insérer la douille voulue en suivant les étapes en sens inverse. La douille et son

écrou sont rattachés; ne pas tenter de les séparer.

Réglage de la profondeur de coupe (Fig. 2 & 3)

MISE EN GARDE : Arrêter et débrancher la toupie de la source d’alimentation électrique.

1. Installer l’arête voulue. Consulter la rubrique « Installation et retrait de l’arête tranchante»

du présent guide.

2. Mettre la toupie sur sa base et déposer l'ensemble sur la pièce.

3. Ouvrir le levier de verrouillage (D) et tourner l’anneau de réglage de profondeur (B) jusqu’à

ce que l’arête touche à peine la pièce. Tourner l’anneau vers la droite pour soulever l’arête,

ou vers la gauche pour l’abaisser.

4. Déplacer l’échelle réglable (C) de manière à placer la marque « 0 » directement au-dessus

de l’indicateur (Z) situé sur la base.

5. Tourner l’anneau de réglage de profondeur et l’échelle réglable jusqu’à la profondeur

voulue. Il est à noter que chaque marque indiquée sur l’échelle représente un écart de profondeur de 0,4 mm (1/64 po ou 0,015 po).

6. Fermer le levier de verrouillage (D).

Utilisation d’un guide parallèle

Le guide parallèle (modèle DW6913) est vendu séparément chez un dépositaire local ou dans

un centre de service. Pour l’installer, suivre les directives d’assemblage fournies avec le guide

parallèle. Insérer les deux barres dans les orifices du guide-bord situés dans la base de la

toupie; les régler, au besoin, pour effectuer le toupillage parallèle.

INSTALLATION DE LA BASE DE LA POIGNÉE FERMÉE

Verrou de déblocage rapide du moteur

MISE EN GARDE : Arrêter et débrancher la toupie de la source d’alimentation électrique.

1. Ouvrir le levier de verrouillage (D) situé sur la base.

2. Saisir la base d’une main et enfoncer les verrous de déblocage rapide (A).

3. Saisir le dessus du bloc moteur de l’autre main et le soulever hors de la base.

Installation du moteur dans la base de la poignée

fermée (Fig. 7)

MISE EN GARDE : Arrêter et débrancher la toupie de la source d’alimentation électrique.

1. Ouvrir le levier de verrouillage (D) situé sur la base.

2. Fileter l’anneau de réglage de profondeur (B) sur le moteur jusqu’à ce que qu’il se trouve

à mi-chemin entre le dessus et le dessous du moteur. Installer le moteur dans la base en

alignant la rainure située sur le moteur (H) avec les goupilles de guidage (X) se trouvant

sur la base. Glisser le moteur vers le bas jusqu’à ce que l’anneau de réglage de profondeur s’enclenche dans les verrous de déblocage rapide (A).

3. Fermer le levier de verrouillage dès qu’on a atteint la profondeur voulue. Pour obtenir des

renseignements sur le réglage de la profondeur de coupe, consulter la rubrique « Réglage

de la profondeur de coupe » dans la section « FONCTIONNEMENT DE LA BASE DE

LA POIGNÉE FERMÉE » du présent guide.

4. S’assurer que l’interrupteur à gâchette (N) est relâché et que le bouton de verrouillage de

la gâchette (O) est déverrouillé et réglé à la position d’arrêt.

5. Déverrouiller et débrancher le cordon amovible (L) du moteur.

6. Raccorder le cordon amovible (L) à la partie inférieure de la poignée fermée et verrouiller

le cordon.

7. Raccorder le cordon court (AA) situé sur la partie supérieure de la poignée fermée au

moteur, tel qu’illustré; s’assurer que le cordon est bien verrouillé.

8. Régler le commutateur à bascule à la position de marche (« ON ») afin de pouvoir maîtriser la toupie au moyen de l’interrupteur à gâchette situé sur la poignée fermée.

Réglage du levier de verrouillage (Fig. 4)

MISE EN GARDE : Arrêter et débrancher la toupie de la source d’alimentation électrique.

On doit pouvoir fixer solidement le levier de verrouillage sans exercer trop de pression; une

pression excessive risque d’endommager la base. Le moteur doit rester immobile dans la base

une fois le levier fixé. Pour régler la force de serrage du levier de verrouillage, ouvrir ce dernier

(D) et tourner l’écrou (Y) par petits échelons; le tourner vers la droite pour serrer le levier, ou

vers la gauche pour le desserrer.

Centrage de la sous-base (Fig. 5)

MISE EN GARDE : Arrêter et débrancher la toupie de la source d’alimentation électrique.

Un outil de centrage est fourni afin de permettre à l’utilisateur de régler, de changer ou de remplacer la sous-base, le cas échéant. L’outil de centrage est doté d’un cône et d’une goupille.

Pour régler la sous-base, suivre les étapes énumérées ci-dessous :

1. Desserrer les vis de la sous-base sans les retirer afin de permettre à la sous-base de se

déplacer librement;

2. Insérer la goupille dans la douille de serrage et serrer l’écrou de la douille;

3. Installer le moteur dans la base et fixer le levier de verrouillage sur la base;

4. Mettre le cône sur la goupille et appuyer légèrement sur le cône jusqu’à ce qu’il s’immobilise (voir la figure), afin de centrer la sous-base;

5. Asppuyer sur le cône pour le retenir en place et serrer les vis de la sous-base.

FONCTIONNEMENT DE LA BASE DE LA POIGNÉE FERMÉE

Emplacement des boutons

Saisir la poignée fermée d’une main et mettre l’autre main sur la poignée arrondie. Le bouton

de la base de la toupie à poignée fermée comporte deux positions afin d’accommoder les

droitiers et les gauchers.

MISE EN GARDE : Utiliser les deux mains en tout temps afin de bien maîtriser l’outil.

Bouton de verrouillage de la gâchette

Pour verrouiller la gâchette, tirer à fond sur son interrupteur (N), puis enfoncer le bouton de

verrouillage de la gâchette (O). La toupie demeure sous tension lorsqu’on retire le doigt de la

gâchette. Pour déverrouiller le bouton de verrouillage de la gâchette, tirer sur la gâchette et la

relâcher afin de faire ressortir le bouton et d’arrêter la toupie.

Installation et retrait de l’arête tranchante (Fig. 6)

MISE EN GARDE : Arrêter et débrancher la toupie de la source d’alimentation électrique.

1. Pour installer l’arête, insérer sa tige circulaire dans la douille de serrage (celle-ci doit être

desserrée), en l’enfonçant aussi loin que possible, puis la retirer sur environ 1 mm (1/16 po).

Tourner l’écrou de la douille de serrage (J) vers la droite au moyen d’une ou de plusieurs

clés fournies, en retenant l’arbre à broche au moyen de la deuxième clé. [Pour le modèle

DW618, retenir l’arbre à broche en enfonçant le bouton de verrouillage de la broche (I).]

2. Pour retirer l’arête, retenir l’arbre à broche et tourner l’écrou de la douille de serrage (J)

vers la gauche au moyen de la clé fournie. [Pour le modèle DW618, retenir la broche en

enfonçant son bouton de verrouillage (I).] L’écrou à autodéclenchement de la douille de

serrage tourne sur environ trois-quarts de tour avant de se resserrer; il devient alors

impossible de retirer l’arête. Continuer à tourner l’écrou vers la gauche afin de permettre

à la douille de se soulever et de pouvoir ainsi retirer l’arête.

Douilles de serrage

REMARQUE : Ne jamais serrer la douille avant d’y avoir d’abord inséré une arête; on risque

d’endommager une douille sans arête, même lorsqu’on la serre manuellement.

Deux douilles sont fournies avec le moteur : une de 6,4 mm (1/4 po) et l’autre de 13 mm

(1/2 po). Pour changer d’une douille à l’autre, dévisser son assemblage tel que décrit

précédemment, puis insérer la douille voulue en suivant les étapes en sens inverse. La

douille et son écrou sont rattachés; ne pas tenter de les séparer.

Réglage de la profondeur de coupe (Fig. 3)

MISE EN GARDE : Arrêter et débrancher la toupie de la source d’alimentation électrique.

1. Installer l’arête voulue. Consulter la rubrique « Installation et retrait de l’arête tran-

chante » du présent guide.

2. Mettre la toupie sur sa base et déposer l'ensemble sur la pièce.

3. Ouvrir le levier de verrouillage (D) et tourner l’anneau de réglage de profondeur (B)

jusqu’à ce que l’arête touche à peine la pièce. Tourner l’anneau vers la droite pour

soulever l’arête, ou vers la gauche pour l’abaisser.

4. Déplacer l’échelle réglable de manière à placer la marque « 0 » directement au-dessus de

l’indicateur (Z) situé sur la base.

5. Tourner l’anneau de réglage de profondeur et l’échelle réglable jusqu’à la profondeur

voulue. Il est à noter que chaque marque indiquée sur l’échelle représente un écart de profondeur de 0,4 mm (1/64 po ou 0,015 po).

6. Fermer le levier de verrouillage (D).

Utilisation d’un guide parallèle

Un guide parallèle (modèle DW6913) est vendu séparément chez un dépositaire local ou dans

un centre de service. Pour l’installer, suivre les directives d’assemblage fournies avec le guide

parallèle. Insérer les deux barres dans les orifices situés dans la base de la toupie; les régler,

au besoin, pour effectuer le toupillage parallèle.

INSTALLATION DE LA BASE PLONGEANTE (Fig. 8)

Verrou de déblocage rapide du moteur

MISE EN GARDE : Arrêter et débrancher la toupie de la source d’alimentation électrique.

1. Ouvrier le levier de verrouillage (D) situé sur la base.

2. Saisir le dessus du bloc moteur et le soulever hors de la base.

Installation du moteur dans la base plongeante

MISE EN GARDE : arrêter et débrancher la toupie de la source d’alimentation électrique.

1. Retirer l’anneau de réglage de profondeur hors du moteur (celle-ci ne doit pas être utilisée

avec la base plongeante).

2. Ouvrier le levier de verrouillage (D) de la base afin de s’assurer que le moteur est bien en

place.

3. S’assurer que le levier de verrouillage de la base de plongée (R) est verrouillé.

4. Aligner la partie plate du capuchon d’extrémité du moteur (BB) avec la colonne (CC), puis

installer le moteur dans la base plongeante, en le poussant jusqu’au fond.

5. Fermer le levier de verrouillage (D).

Réglage du levier de verrouillage (Fig. 4)

MISE EN GARDE : Arrêter et débrancher la toupie de la source d’alimentation électrique.

On doit pouvoir fixer solidement le levier de verrouillage sans exercer trop de pression; une

pression excessive risque d’endommager la base. Le moteur doit rester immobile dans la base

une fois le levier fixé. Pour régler la force de serrage du levier de verrouillage, ouvrir ce dernier

(D) et tourner l’écrou (Y) par petits échelons; le tourner vers la droite pour serrer le levier, ou

vers la gauche pour le desserrer.

Centrage de la sous-base (Fig. 5)

MISE EN GARDE : Arrêter et débrancher la toupie de la source d’alimentation électrique.

Un outil de centrage est fourni afin de permettre à l’utilisateur de régler, de changer ou de remplacer la sous-base, le cas échéant. L’outil de centrage est doté d’un cône et d’une goupille.

Pour régler la sous-base, suivre les étapes énumérées ci-dessous :

1. Desserrer les vis de la sous-base sans les retirer afin de permettre à la sous-base de se

déplacer librement;

2. Insérer la goupille dans la douille de serrage et serrer l’écrou de la douille;

3. Installer le moteur dans la base et fixer le levier de verrouillage sur la base;

4. Mettre le cône sur la goupille et appuyer légèrement sur le cône jusqu’à ce qu’il s’immobilise (voir la figure), afin de centrer la sous-base;

5. Appuyer sur le cône pour le retenir en place et serrer les vis de la sous-base.

Page 5

¡

CONSERVE ESTAS INSTRUCCIONES!

Instrucciones generales de seguridad

¡ADVERTENCIA! Lea y comprenda todas las instrucciones. El no cumplir

con todas las advertencias a continuación podría resultar en el riesgo de un

choque eléctrico, incendio o de lesiones graves.

CONSERVE ESTAS INSTRUCCIONES

ÁREA DE TRABAJO

Conserve su área de trabajo limpia y bien iluminada. Las bancas amontonadas y las

zonas oscuras propician los accidentes.

No opere herramientas eléctricas en atmósferas explosivas, como en presencia de

líquidos, gases o polvos inflamables. Las herramientas eléctricas producen chispas que

pueden originar la ignición de los polvos o los vapores.

Conserve a observadores, niños y visitantes alejados mientras opera una herramienta eléctrica. Las distracciones pueden ocasionar que pierda el control.

SEGURIDAD ELÉCTRICA

Las herramientas con conexión a tierra deben conectarse a una toma de corriente

instalada y aterrizada correctamente de conformidad con todos los códigos y regulaciones locales. Nunca elimine la pata de conexión a tierra ni modifique la clavija en

ninguna manera. No utilice clavijas adaptadoras. Consulte con un electricista calificado si tiene dudas acerca de la conexión correcta a tierra de su toma de corriente.

En el caso que la herramienta tuviese una falla eléctrica, la puesta a tierra proporciona

una vía de baja resistencia para alejar la electricidad del usuario. Esta herramienta

emplea una clavija con toma de tierra (de tres patas) que ofrece una vía para garantizar la

seguridad del usuario en caso de que la herramienta presentase disfunciones eléctricas o

averías, o si se diera el caso de que la carcasa de la herramienta condujese la electricidad.

El deterioro o la desaparición de alguna de las tres patas de la clavija; el deterioro de la clavija o del cable, o el hecho de enchufar la herramienta a un sistema eléctrico que no esté verificado, ni conectado continuamente a tierra, puede ser causa de electrocución, lesiones

graves o incluso muerte. Para evitar el riesgo de lesiones, la herramienta debe recibir un

mantenimiento adecuado y estar siempre en perfectas condiciones de trabajo (cable, patas

de la clavija), así como enchufada a un sistema eléctrico continuamente conectado a tierra.

(Consulte también el apartado “Limpieza,” en la sección de Mantenimiento)

Evite el contacto corporal con superficies aterrizadas tales como tuberías, radiadores, hornos y refrigeradores. Hay un gran riesgo de choque eléctrico si su cuerpo

hace tierra.

No exponga las herramientas eléctricas a la lluvia o a condiciones de mucha

humedad. El agua que se introduce en las herramientas aumenta el riesgo de descargas

eléctricas.

No maltrate el cable. Nunca tome el cable para transportar una herramienta ni para

desconectarla de la toma de corriente. Consérvelo alejado de calor aceite, bordes afilados o piezas móviles. Cambie inmediatamente los cables dañados. Los cables daña-

dos aumentan el riesgo de choque eléctrico.

Cuando opere una herramienta eléctrica a la intemperie, utilice una extensión marcada “W-A” o “W”. Estas extensiones están clasificadas para uso a la intemperie y para

reducir el riesgo de choques eléctricos.

CABLES DE EXTENSION

Asegúrese que su extensión esté en buenas condiciones. Cuando utilice una extensión, asegúrese de emplear una con el calibre suficiente para soportar la corriente

necesaria para su producto. Disminuciones en el voltaje mayores a 10% provocarán la

pérdida de potencia y sobre calentamiento. Una extensión con calibre menor al necesario

causará una caída en el voltaje de la línea, resultando en pérdida de potencia y sobrecalentamiento. El cuadro siguiente muestra los calibres correctos para usarse de acuerdo con

la longitud de la extensión y el amperaje especificado. Si tiene dudas, utilice el calibre siguiente, más pesado. Cuanto más pequeño el número de calibre del alambre, mayor la

capacidad del cable.

Calibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7,6 7,6-15,2 15,2-30,4 30,4-45,7

240V 0-15,2 15,2-30,4 30,4-60,9 60,9-91,4

AMPERAJE

Más No más Calibre del cordón AWG

de de

10-1216161412

12 - 16 14 12 No recomendado

SEGURIDAD PERSONAL

Esté alerta, concéntrese en lo que está haciendo. Recurra al sentido común cuando opere una herramienta eléctrica. No opere ninguna herramienta si se encuentra

fatigado o bajo la influencia de drogas, alcohol o medicamentos. Un momento de

desatención mientras se operan herramientas eléctricas puede ocasionar lesiones graves.

Vístase de manera adecuada. No tenga puestas ropas o artículos de joyería flojos.

Cubra su cabello si lo tiene largo. Conserve su cabello, sus ropas y guantes aleja-

TABLEAU DE SÉLECTION DES VITESSES

Material Diam. (outil de coupe) Réglages électroniques

Réglage 1 Réglage 2 Réglage 3 Réglage 4 Réglage 5 Réglage 6

Model # DW618 8 000

tr/min 12 000 tr/min 14 000 tr/min 18 000 tr/min 21 000 tr/min 24 000 tr/min

Bois dur (p. ex., le chêne) Petit* – – O X XX X

Moyen** – – O XX X –

Grand*** X XX O – – –

Bois mou (p. ex., le pin) Petit* – – O X XX XX

Moyen** – O X XX XX XX

Grand*** X XX O – – –

Aggloméré plastifié Petit* – – O X XX XX

Moyen** – O X XX XX XX

Grand*** O XX X – – –

Plastique/surface solide Petit* – O X X XX XX

Moyen** – O XX XX X X

Grand*** X XX O – – –

Ce tableau n’est offert qu’à titre indicatif, puisque le bois est une matière vivante. Puisque la dureté et la densité de divers bois de même

espèce peut varier, les réglages de vitesses sont approximatifs.

LÉGENDE : XX = très bon X = bon O = satisfaisant – = non recommandé

*Petit : 12,7 mm (1/2 po)

**Moyen : 12,7 à 3,2 mm (1/2 à 1-1/8 po)

***Grand : plus de 3,2 mm (1-1/8 po)

FONCTIONNEMENT DE LA BASE PLONGEANTE

Installation et retrait de l’arête tranchante (Fig. 6)

MISE EN GARDE : Arrêter et débrancher la toupie de la source d’alimentation électrique.

1. Pour installer l’arête, insérer sa tige circulaire dans la douille de serrage (celle-ci doit être

desserrée), en l’enfonçant aussi loin que possible, puis la retirer sur environ 1 mm (1/16 po).

Tourner l’écrou de la douille de serrage (J) vers la droite au moyen d’une ou de plusieurs

clés fournies, en retenant l’arbre à broche au moyen de la deuxième clé. [Pour le modèle

DW618, retenir l’arbre à broche en enfonçant le bouton de verrouillage de la broche (I).]

2. Pour retirer l’arête, retenir l’arbre à broche et tourner l’écrou de la douille de serrage (J)

vers la gauche au moyen de la clé fournie. [Pour le modèle DW618, retenir la broche en

enfonçant son bouton de verrouillage (I).] L’écrou à autodéclenchement de la douille de

serrage tourne sur environ trois-quarts de tour avant de se resserrer; il devient alors

impossible de retirer l’arête. Continuer à tourner l’écrou vers la gauche afin de permettre

à la douille de se soulever et de pouvoir ainsi retirer l’arête.

Douilles de serrage

REMARQUE : Ne jamais serrer la douille avant d’y avoir d’abord inséré une arête; on risque

d’endommager une douille sans arête, même lorsqu’on la serre manuellement.

Deux douilles sont fournies avec le moteur : une de 6,4 mm (1/4 po) et l’autre de 13 mm

(1/2 po). Pour changer d’une douille à l’autre, dévisser son assemblage tel que décrit

précédemment, puis insérer la douille voulue en suivant les étapes en sens inverse. La

douille et son écrou sont rattachés; ne pas tenter de les séparer.

Réglage de la profondeur de toupillage (Fig. 8)

MISE EN GARDE : Arrêter et débrancher la toupie de la source d’alimentation électrique.

1. Déverrouiller le mécanisme de plongée en poussant le levier de verrouillage de plongée

(R) vers le haut et en poussant la toupie vers le bas, aussi loin que possible, jusqu’à ce

que l’arête tranchante touche à peine la pièce.

2. Verrouiller le mécanisme de plongée en poussant le levier de verrouillage de plongée (R)

vers le bas.

3. Desserrer la tige de réglage de profondeur (Q) en tournant la vis à oreilles (DD) vers la

gauche.

4. Faire glisser la tige de réglage de profondeur (Q) vers le bas, jusqu’à ce qu’elle entre en

contact avec la butée de la tourelle située au point le plus bas (P).

5. Faire glisser la languette (EE) de la tige de réglage de profondeur vers le bas, de manière