Page 1

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 Printed in Italy (NOV00-1) Form No. 329785-01

DW567, DW567-220 Copyright © 1997

DW567/329785-01 10/1/02 9:56 AM Page 2

Page 2

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW565, DW567, DW567-220

1”Heavy Duty SDS Rotary Hammers

Perceuses rotatives SDS 26mm (1 po) de service intensif

Rotomartillos SDS 26mm (1”) para trabajo pesado

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

Questions? See us in the World Wide Web at www.dewalt.com

DW567/329785-01 10/1/02 9:56 AM Page 3

Page 3

General Safety Rules

WARNING! READ AND UNDERSTAND ALL INSTRUCTIONS.

Failure to follow all instructions listed below may result in electric

shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and dark

areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in

the presence of flammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while operating a

power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Grounded tools must be plugged into an outlet properly installed

and grounded in accordance with all codes and ordinances.

Never remove the grounding prong or modify the plug in any way.

Do not use any adapter plugs. Check with a qualified electrician if

you are in doubt as to whether the outlet is properly grounded. If the

tools should electrically malfunction or break down, grounding provides

a low resistance path to carry electricity away from the user.

Applicable only to Class I (grounded) tools.

• Double insulated tools are equipped with a polarized plug (one

blade is wider than the other.) This plug will fit in a polarized outlet

only one way. If the plug does not fit fully in the outlet, reverse the

plug. If it still does not fit, contact a qualified electrician to install a

polarized outlet. Do not change the plug in any way. Double insulation

1

English

eliminates the need for the three wire grounded power cord and

grounded power supply system. Applicable only to Class II (double

insulated) tools.

• Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of

electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water entering

a power tool will increase the risk of electric shock. Other liquids, such

as perspiration present the same hazard.

• Do not abuse the cord. Never use the cord to carry the tools or

pull the plug from an outlet. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged cords immediately.

Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension

cord marked “W-A” or “W.” These cords are rated for outdoor use

and reduce the risk of electric shock. When using an extension cord,

be sure to use one heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line voltage resulting in

loss of power and overheating. The following table shows the correct

size to use depending on cord length and nameplate ampere rating. If

in doubt, use the next heavier gage. The smaller the gage number, the

heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0-6 18161614

6 - 10 18 16 14 12

10-1216161412

12 - 16 14 12 Not Recommended

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

DW567/329785-01 10/1/02 9:56 AM Page 1

Page 4

preventative safety measures reduce the risk of starting the tool

accidentally.

• Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools, with sharp cutting edges are less likely to

bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage of

parts, and any other condition that may affect the tools operation.

If damaged, have the tool serviced before using. Many accidents

are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer

for your model. Accessories that may be suitable for one tool, may

become hazardous when used on another tool.

SERVICE

• Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this manual.

Use of unauthorized parts or failure to follow Maintenance Instructions

may create a risk of electric shock or injury.

Additional Specific Safety Rules for

Rotary Hammers

• Hold tool by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring or its

own cord. Contact with a “live” wire will make exposed metal parts of

the tool “live” and shock the operator.

• Wear ear protectors when hammering for extended periods of

time. Prolonged exposure to high intensity noise can cause hearing

loss.

• Wear safety goggles or other eye protection. Hammering and

drilling operations cause chips to fly. Flying particles can cause

permanent eye damage.

2

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use tool while tired or under

the influence of drugs, alcohol, or medication. A moment of

inattention while operating power tools may result in serious personal

injury,

• Dress properly. Do not wear loose clothing or jewelry. Contain

long hair. Keep your hair, clothing, and gloves away from moving

parts. Loose clothing, jewelry, or long hair can be caught in

moving parts. Air vents often cover moving parts and should also be

avoided.

• Avoid accidental starting. Be sure switch is off before plugging in.

Carrying tools with your finger on the switch or plugging in tools that

have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. A

wrench or key that is left attached to a rotating part of the tool may

result in personal injury.

• Do not overreach. Keep proper footing and balance at all times.

Proper footing and balance enables better control of the tool in

unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask,

non-skid safety shoes, hard hat, or hearing protection must be used for

appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the

workpiece to a stable platform. Holding the work by hand or against

your body is unstable and may lead to a loss of control.

• Do not force tool. Use the correct tool for your application. The

correct tool will do the job better and safer and the rate for which it is

designed.

• Do not use tool if switch does not turn it on or off. Any tool that

cannot be controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source before making any

adjustments, changing accessories, or storing the tool. Such

English

DW567/329785-01 10/1/02 9:56 AM Page 2

Page 5

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals: work

in a well ventilated area, and work with approved safety equipment,

such as those dust masks that are specially designed to filter out

microscopic particles.

• The label on your tool may include the following symbols.

V ........................volts

A ........................amperes

Hz ........................hertz

W ........................watts

min ........................minutes

........................alternating current

........................direct current

n

o ........................no load speed

........................Class II Construction

…/min ......................revolutions per minute

BPM ........................beats per minute

............................safety alert symbol

3

English

R

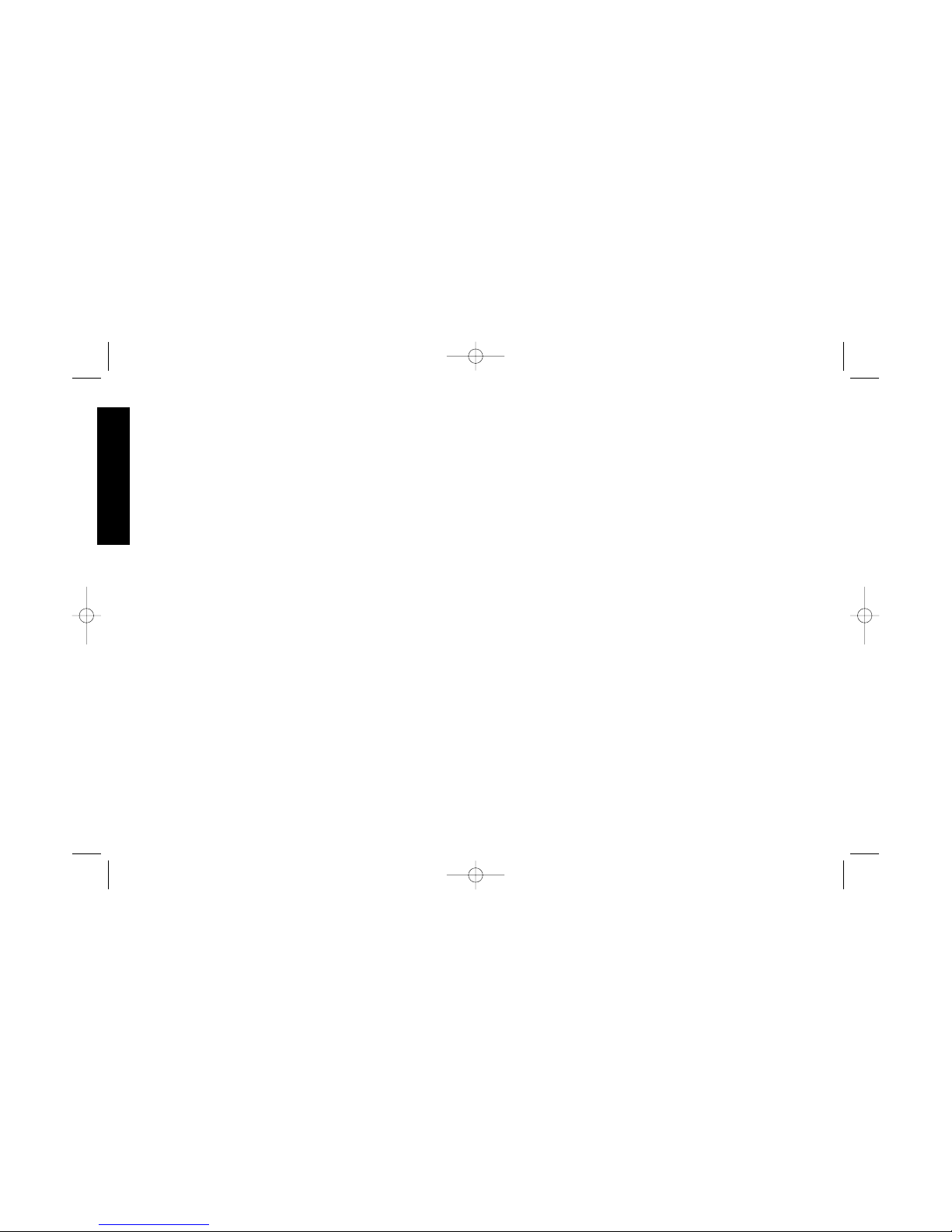

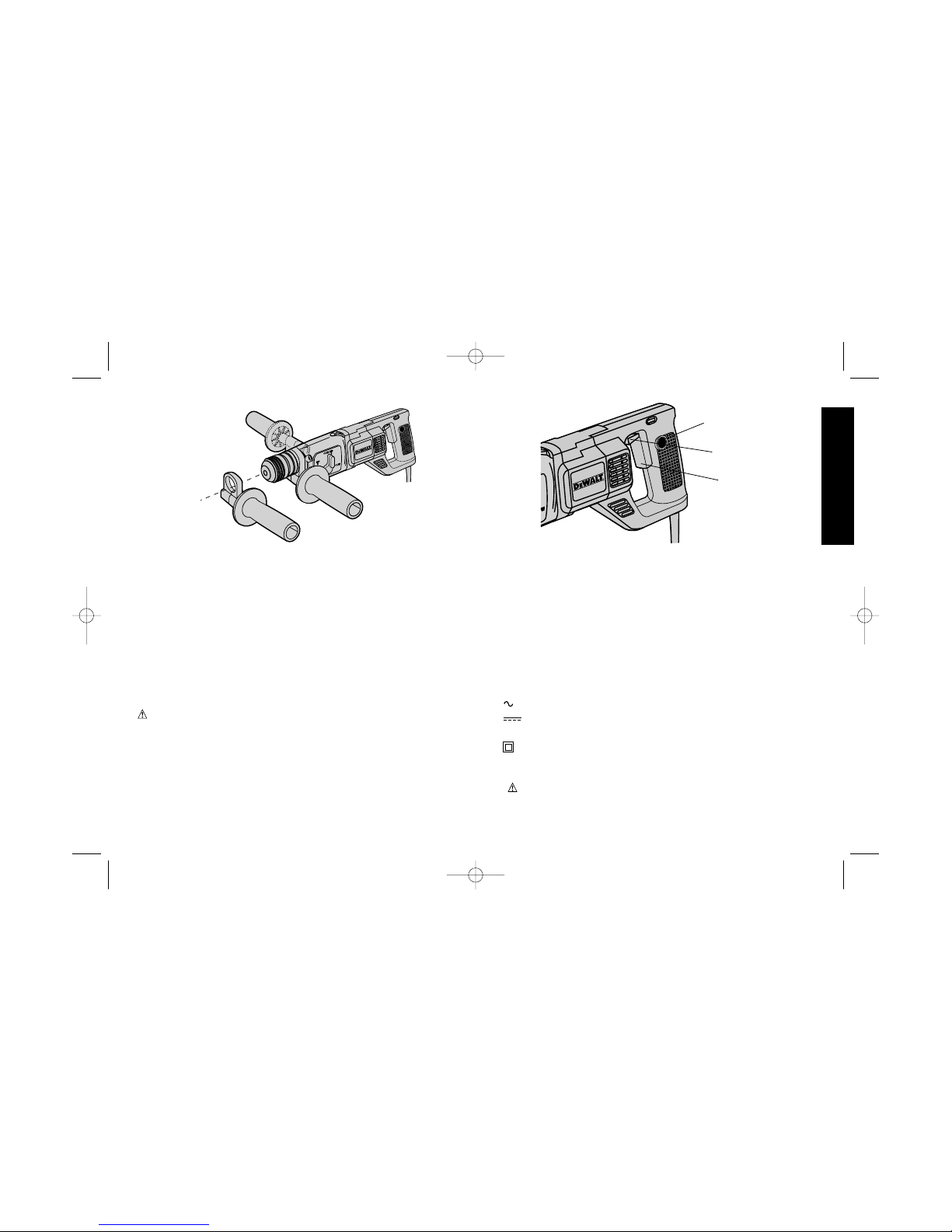

FIGURE 1

R

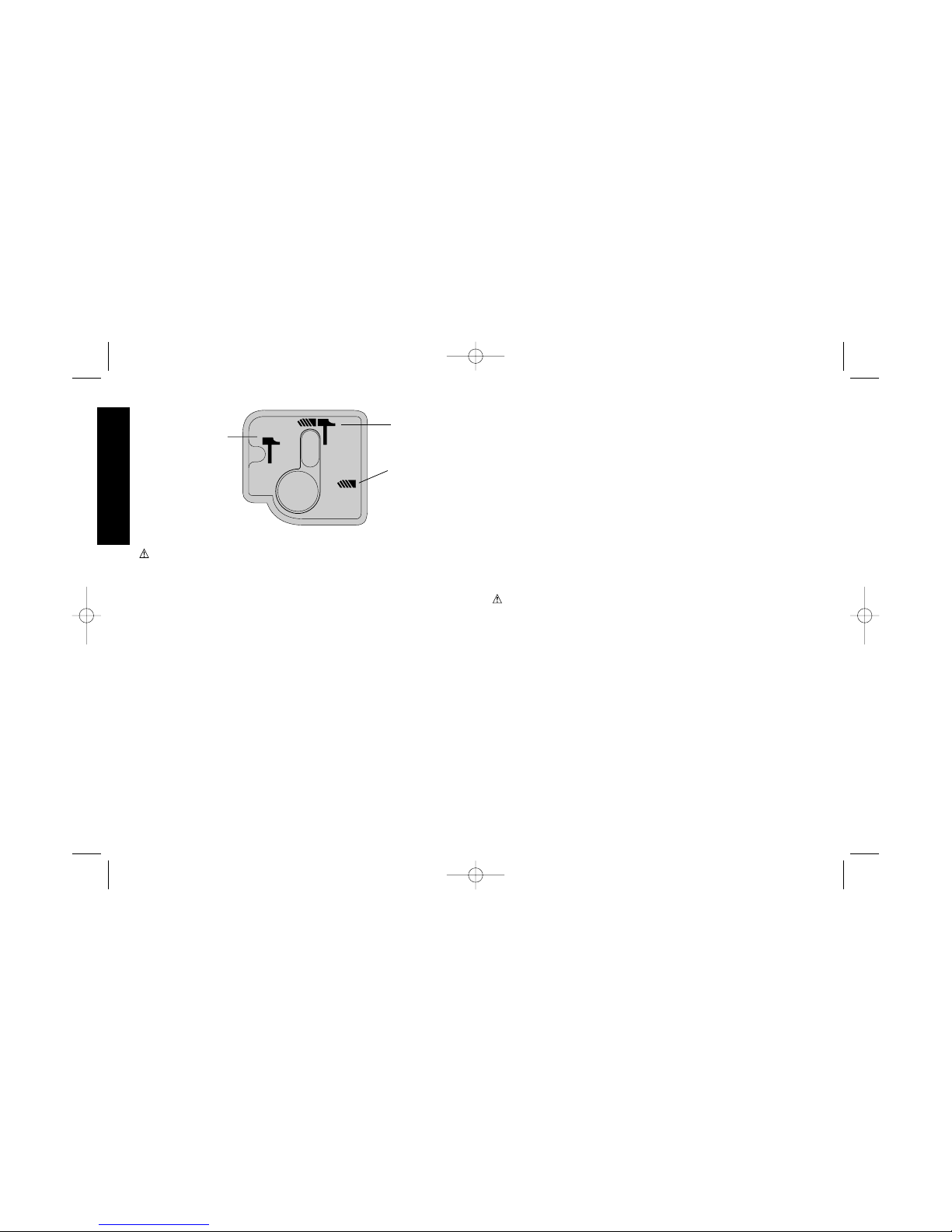

REVERSING

LEVER

TRIGGER

SWITCH

LOCKING

BUTTON

FIGURE 2

• Always use the side handle supplied with the tool. Keep a firm

grip on the tool at all times. Do not attempt to operate this tool without

holding it with both hands. Operating this tool with one hand will result

in loss of control. Breaking through or encountering hard materials

such as re-bar may be be hazardous as well.

• Do not use chisels in any of the rotation modes. Chisels may jam

causing loss of control.

• Wear gloves when handling hammer bits and tools. Hammer bits

and tools get hot during operation. Gloves and frequent rest periods

will reduce the risk of vibration damage to hands and arms.

• Keep hands and body from between the tool and wall or post, etc.,

to avoid being crushed by the tool should it twist unexpectedly if the bit

binds.

WARNING: Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber (CCA).

DW567/329785-01 10/1/02 9:56 AM Page 3

Page 6

4

immediately the next time it is plugged in. Damage or injury could

result.

The variable speed trigger switch permits speed control. The

farther the trigger switch is depressed, the higher the speed of the

hammerdrill.

NOTE: Use lower speeds for starting holes without a centerpunch,

drilling in metal, plastics or ceramics, or driving screws. Higher

speeds are better for drilling in wood and composition board and for

using abrasive and polishing accessories.

The reversing lever is used to reverse the rotary hammer for

backing out screws or jammed bits. It is located above the trigger,

shown in Figure 2. To reverse the rotary hammer, turn it OFF and

push the reversing lever to the left (when viewed from the chuck end).

To position the lever for forward operation, turn the rotary hammer

OFF and push the lever to the right.

CAUTION: When reversing to clear jammed bits, be ready for

strong reactive torque.

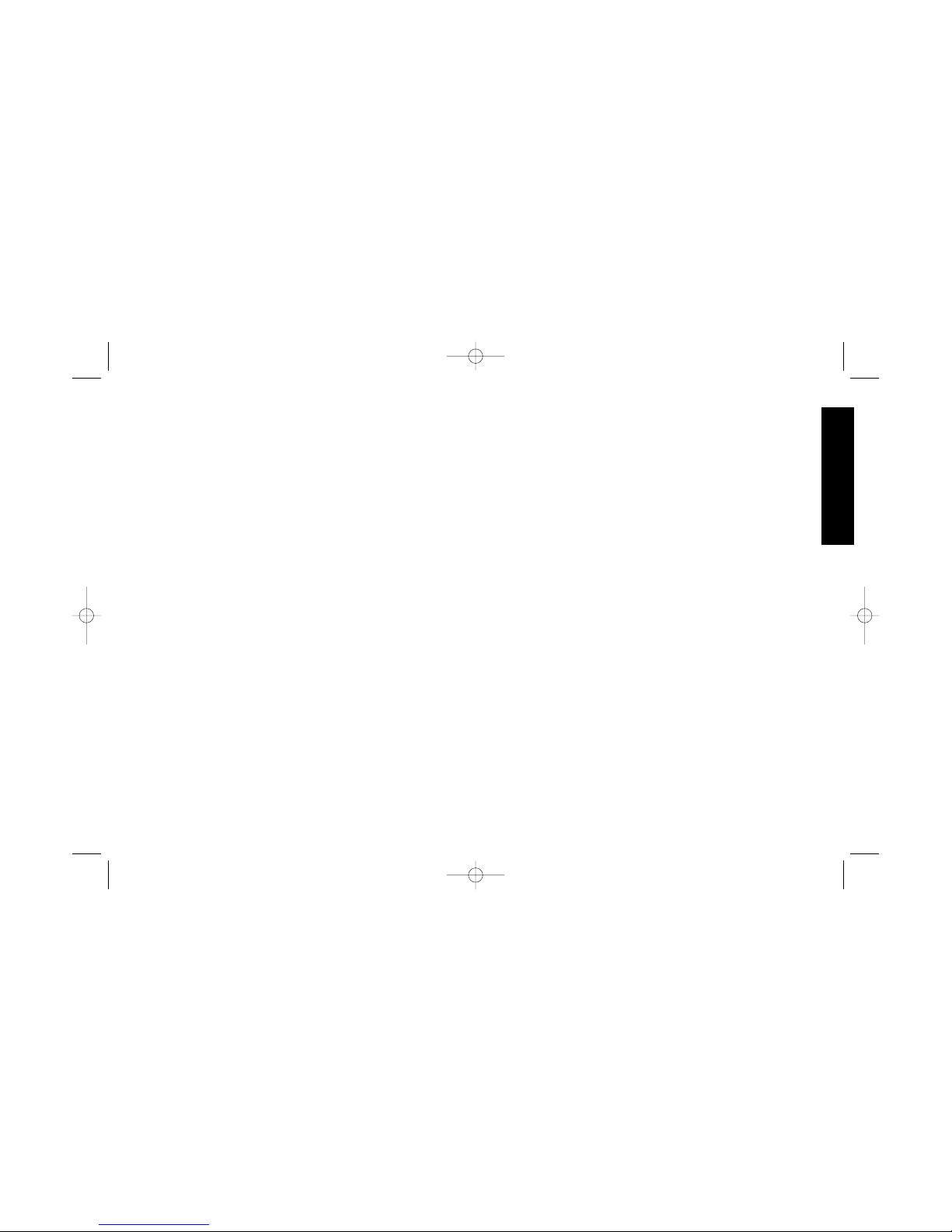

Hammer/Drill Selector (DW567)

To switch tool from the drill only mode to the rotary hammer or

hammer only mode rotate the dial on the applicable symbol shown in

Figure 3.

NOTE: The selector must be in either drill, rotary hammer or hammer

mode at all times. There are no operable positions between the

positions.

SDS Chuck

To insert bit, insert shank of bit about 3/4” into chuck. Push and

rotate bit until it locks in place. The bit will be securely held.

To release bit, pull the collar back and remove the bit.

English

FIGURE 3

Side Handle

CAUTION: Always hold rotary hammer with both hands. A side

handle is supplied with this rotary hammer. It clamps to the front of

the gear case as shown in Figure 1 and can be rotated 360˚ to permit

right or left hand use. The side handle can be tightened by rotating

the black plastic portion of the side handle clockwise and loosened by

rotating it counterclockwise.

Switch

To start rotary hammer, depress the trigger switch (Figure 2). To

stop rotary hammer, release the switch. To lock the trigger switch in

the ON position for continuous operation, depress the trigger switch

and push in the locking button. The tool will continue to run. To turn

the tool OFF, from a locked ON condition, squeeze and release the

trigger once. Before using the tool (each time), be sure that the

locking button release mechanism is working freely. Do not lock the

switch in the “ON” position when driling by hand so that you can

instantly release the trigger whitch if the bit binds in the hole.

Do not lock the switch ON when drilling by hand so that you can

instantly release the trigger switch if the bit binds in the hole. The

locking button is for use only when the rotary hammer is mounted in

a drill press stand or other wise held stationary. Be sure to release

the locking mechanism before disconnecting the plug from the power

supply. Failure to do so will cause the rotary hammer to start

DRILL

SETTING

HAMMER

SETTING

ROTARY

HAMMER -

SETTING

DW567/329785-01 10/1/02 9:56 AM Page 4

Page 7

Operation

DRILLING

1. Always unplug the drill when attaching or changing bits or

accessories.

2. Use sharp drill bits only. For WOOD, use twist drill bits, spade bits,

power auger bits, or hole saws. For METAL, use steel twist drill bits

or hole saws. For MASONRY, such as brick, cement, cinder block,

etc., use carbide-tipped bits rated for percussion drilling. Be sure

the material to be drilled is anchored or clamped firmly. If drilling

thin material, use a wood “back-up” block to prevent damage to the

material.

3. Always apply pressure in a straight line with the bit. Use enough

pressure to keep drill biting, but do not push hard enough to stall

the motor or deflect the bit.

4. Hold tool firmly to control the twisting action of the drill.

5. IF DRILL STALLS, it is usually because it is being overloaded or

improperly used. RELEASE TRIGGER IMMEDIATELY, remove

drill bit from work, and determine cause of stalling. DO NOT

CLICK TRIGGER ON AND OFF IN AN ATTEMPT TO START A

STALLED DRILL — THIS CAN DAMAGE THE DRILL.

6. To minimize stalling or breaking through the material, reduce

pressure on drill and ease the bit through the last fractional part of

the hole.

7. Keep the motor running when pulling the bit back out of a drilled

hole. This will help prevent jamming.

8. With variable speed drills there is no need to center punch the

point to be drilled. Use a slow speed to start the hole and

accelerate by squeezing the trigger harder when the hole is deep

enough to drill without the bit skipping out.

DRILLING IN METAL

An SDS to round shank adaptor chuck is required. Ensure that

tool is in “rotation only” mode. (DW567 only. The DW565 has no

“rotation only” mode). Start drilling with slow speed and increase to full

5

English

power while applying firm pressure on the tool. A smooth even flow of

metal chips indicates the proper drilling rate. Use a cutting lubricant

when drilling metals. The exceptions are cast iron and brass which

should be drilled dry. The cutting lubricants that work best are

sulphurized cutting oil or lard oil; bacon-grease will also serve the

purpose.

NOTE: Large (5/16” to 1/2”) holes in steel can be made easier if a

pilot hole (5/32” to 3/16”) is drilled first.

DRILLING IN WOOD

An SDS to round shank adaptor chuck is required. Ensure that

tool is in “rotation only” mode. (DW567 only. The DW565 has no

“rotation only” mode). Start drilling with slow speed and increase to full

power while applying firm pressure on the tool. Holes in wood can be

made with the same twist drills used for metal. These bits may

overheat unless pulled out frequently to clear chips from the flutes. For

larger holes, use spade bits, power auger bits, or hole saws. Work that

is apt to splinter should be backed up with a block of wood.

DRILLING IN MASONRY

When drilling in masonry, use carbide tipped bits rated for percussion

drilling and be certain that the bit is sharp. Use a constant and firm

force on the tool to drill most effectively. A smooth, even flow of dust

indicates the proper drilling rate.

Depth Rod

To adjust the depth rod, loosen the handle and move rod so that the

distance between the end of the rod and the end of the bit equals

the desired drilling depth. When drilling with depth rod, stop when

end of rod reaches surface of material.

DW567/329785-01 10/1/02 9:56 AM Page 5

Page 8

6

Maintenance

CLEANING & LUBRICATION

Use only mild soap and damp cloth to clean the tool. Never let any liquid

get inside the tool; never immerse any part of the tool into a liquid.

Self-lubricating bearings are used in the tool and periodic relubrication is not required. In the unlikely event that service is ever

needed, take your tool to an authorized service location.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your distributor or local service center.

CAUTION: The use of any non-recommended accessory may be

hazardous.

MAXIMUM RECOMMENDED CAPACITIES

DW565, DW567 DW567-220

MAXIMUM CAPACITY

MASONRY 1" 1" 1"

STEEL N/A 1/2" 1/2"

WOOD N/A 1 1/2" 1 1/2"

OPTIMUM CAPACITY

MASONRY 5/32"-5/8" 5/32"-5/8" 5/32"-5/8"

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information,

call 1-800-4-D

EWALT. This warranty does not apply to accessories

or damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may

have other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALT heavy duty industrial tool, simply return it to the participating

seller within 30 days for a full refund. Please return the complete unit,

transportation prepaid. Proof of purchase may be required.

English

DW567/329785-01 10/1/02 9:56 AM Page 6

Page 9

SI VOUS AVEZ DES QUESTIONS OU VOULEZ NOUS FAIRE PART

DE VOS COMMENTAIRES CONCERNANT CET OUTIL OU TOUT

AUTRE OUTIL DEWALT, COMPOSEZ SANS FRAIS LE :

1 800 433-9258.

Règles de sécurité – Généralités

AVERTISSEMENT! LIRE ET COMPRENDRE TOUTES LES

DIRECTIVES; le non-respect des directives suivantes peut entraîner

un choc électrique, un incendie ou des blessures graves.

CONSERVER CES DIRECTIVES

ZONE DE TRAVAIL

· Garder la zone de travail propre et bien éclairée; les établis

encombrés et les endroits sombres sont propices aux accidents.

· Ne pas utiliser les outils électriques dans une atmosphère

explosive, comme à proximité de liquides, de gaz ou de

poussières inflammables; le moteur peut créer des étincelles et

enflammer les vapeurs ou les poussières environnantes.

· Tenir les enfants, les visiteurs ou toute autre personne à l’écart

lorsqu’on utilise un outil électrique; les distractions peuvent faire

perdre la maîtrise de ce dernier.

MESURES DE SÉCURITÉ - ÉLECTRICITÉ

· Les outils mis à la terre doivent être branchés dans une prise bien

installée et mise à la terre conformément à tous les codes et

règlements en vigueur. Ne jamais retirer la broche de terre ni

modifier la fiche. Ne pas utiliser d'adaptateur. Vérifier auprès d'un

électricien qualifié en cas de doute quant à la mise à la terre de la

prise. En cas de défaillance électrique ou de bris de l'outil, la mise à la

terre procure un chemin de faible résistance au courant qui autrement

traverserait l'utilisateur. Cette protection ne s’applique qu’aux outils

de classe I (mis à la terre).

· Les outils à double isolation sont munis d’une fiche polarisée

(c’est-à-dire que l’une des lames est plus large que l’autre),

laquelle ne peut être raccordée qu’à une prise polarisée et ce,

dans un seul sens; on doit l’inverser si on est incapable de l’enfoncer

complètement. Si la fiche ne s’adapte toujours pas, on doit demander

à un électricien qualifié d’installer la prise appropriée. On ne doit

jamais modifier la fiche. La double isolation élimine le besoin d’installer

un cordon d’alimentation trifilaire et un système d’alimentation

électrique pourvus d’une mise à la terre; seuls les outils de classe II

(à double isolation) sont munis d’une telle protection.

· Éviter tout contact entre le corps et les éléments mis à la terre,

comme les tuyaux, les radiateurs, les cuisinières et les

réfrigérateurs, afin de réduire les risques de choc électrique.

· Ne pas utiliser l’outil électrique dans des endroits mouillés, ni

l’exposer à la pluie; l’infiltration d’eau – ou de tout autre liquide,

comme la sueur – à l’intérieur de l’outil augmente les risques de choc

électrique.

· Ne pas utiliser le cordon de manière abusive; on ne doit pas

transporter l’outil en le tenant par le cordon, ou utiliser ce dernier pour

le débrancher. On doit tenir le cordon à l’écart des sources de chaleur,

de l’huile, des bords tranchants ou des pièces mobiles. Remplacer

immédiatement les cordons endommagés, car ces derniers

augmentent les risques de choc électrique.

· Lorsqu’on utilise un outil électrique à l’extérieur, on ne doit

utiliser que des rallonges conçues pour cet usage, comme celles

de type W-A ou W, afin de réduire les risques de choc électrique. Si

on utilise une rallonge, s’assurer d’en choisir une de calibre approprié

aux valeurs nominales de l’outil, sans quoi on risque de causer une

chute de tension et par conséquent, une perte de puissance et une

surchauffe. Le tableau suivant indique le calibre recommandé selon la

longueur de la rallonge et l’intensité nominale indiquée sur la plaque

signalétique. En cas de doute, toujours opter pour un cordon de calibre

supérieur; plus le chiffre désignant le calibre est petit, plus ce dernier

est fort.

Calibre minimal des cordons de rallonge

Longueur totale du cordon

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7

Français

DW567/329785-01 10/1/02 9:56 AM Page 7

Page 10

8

7,6 m 15,2 m 22,9 m 30,5 m 38,1 m 45,7 m 53,3 m

Intensité

18 AWG 18 AWG 16 AWG 16 AWG 14 AWG 14 AWG 12 AWG

SÉCURITÉ PERSONNELLE

· Rester vigilant en tout temps et faire preuve de jugement

lorsqu’on utilise un outil électrique; ne pas utiliser l’outil lorsqu’on

est fatigué ou sous l’influence de drogues, d’alcool ou de médicaments

– un moment d’inattention peut entraîner des blessures graves.

· Porter des vêtements appropriés; ne pas porter de vêtements

amples ni de bijoux. Couvrir ou attacher les cheveux longs.

Garder les cheveux, les vêtements, les bijoux et les gants éloignés des

pièces mobiles, car ceux-ci peuvent s’y coincer. Éviter également

d’entrer en contact avec les évents, lesquels recouvrent habituellement

des pièces mobiles.

· Éviter les démarrages accidentels; s’assurer que l’interrupteur soit

en position d’arrêt avant de brancher l’outil. Ne pas transporter l’outil

en laissant le doigt sur l’interrupteur ni le brancher lorsque l’interrupteur

est en position de marche, car cela pourrait causer un accident.

· Retirer les clés de réglage avant de démarrer l’outil; une clé laissée

sur une pièce rotative peut entraîner des blessures.

· Ne pas trop étendre les bras; les pieds doivent rester ancrés

fermement sur le sol afin de maintenir son équilibre en tout temps et de

mieux maîtriser l’outil dans des situations imprévues.

· Utiliser le matériel de sécurité approprié; toujours porter des

lunettes de protection. Porter un masque anti-poussières, des

chaussures antidérapantes, un casque de sécurité ou des protecteurs

auditifs lorsque la situation le requiert.

UTILISATION ET ENTRETIEN DE L’OUTIL

· Fixer et soutenir l’ouvrage sur une plate-forme stable au moyen

d’un étau ou de tout autre dispositif semblable; l’ouvrage est

instable lorsqu’on le retient manuellement ou qu’on l’appuie contre le

corps, ce qui peut faire perdre la maîtrise de l’outil.

· Ne pas forcer l’outil ni l’utiliser pour des travaux autres que ceux

pour lesquels il a été conçu. Pour obtenir de meilleurs résultats et

prévenir les risques de blessure, laisser l’outil couper à la vitesse pour

laquelle il a été conçu.

· Ne pas utiliser l’outil lorsque l’interrupteur marche-arrêt ne

fonctionne pas; tout outil qui ne peut être commandé au moyen de

l’interrupteur est dangereux et doit être réparé.

· Débrancher l’outil avant d’effectuer un réglage, de changer les

accessoires ou de ranger l’outil; ces mesures de sécurité

préventives réduisent les risques de démarrage accidentel.

· Lorsqu’on n’utilise pas l’outil, le ranger hors de la portée des

enfants ou des personnes non qualifiées; les outils sont dangereux

entre les mains de personnes inexpérimentées.

· Bien entretenir l’outil; s’assurer qu’il soit toujours bien propre et

aiguisé; les outils bien entretenus et dont les pièces coupantes sont

bien tranchantes sont moins susceptibles de rester coincés et sont

plus faciles à maîtriser.

· Vérifier les pièces mobiles afin de s’assurer qu’elles soient bien

alignées et qu’elles ne restent pas coincées; vérifier également les

pièces afin de s’assurer qu’il n’y ait ni bris ni aucune autre condition

susceptible de nuire au bon fonctionnement de l’outil; faire réparer

l’outil si ce dernier est endommagé avant de s’en servir de nouveau –

les accidents sont souvent causés par des outils mal entretenus.

· N’utiliser que les accessoires recommandés par le fabricant pour

le modèle concerné; un accessoire destiné à un outil particulier peut

devenir dangereux lorsqu’il est utilisé avec un autre.

ENTRETIEN

· L’outil doit être entretenu par du personnel qualifié seulement;

toute maintenance effectuée par une personne non qualifiée peut

entraîner des risques de blessure.

· Lors de l’entretien, n’utiliser que des pièces de rechange

identiques et suivre les directives de la section «Entretien» du

Français

DW567/329785-01 10/1/02 9:56 AM Page 8

Page 11

présent manuel afin de prévenir les risques de choc électrique ou de

blessure.

Règles de sécurité additionnelles

relatives aux perceuses à percussion

· Tenir l’outil par les surfaces isolées prévues à cette fin lorsque

l’outil risque d’entrer en contact avec des fils cachés ou le

cordon; de tels contacts peuvent mettre les pièces métalliques de

l’outil sous tension, engendrant des risques de choc électrique.

· Porter des protège-oreilles lorsqu’on effectue le martelage pour

des périodes prolongées; une exposition prolongée à des niveaux

acoustiques élevés peut causer une perte d’audition temporaire.

· Porter des lunettes de sécurité ou autre dispositif de protection

oculaire car le martelage et le perçage peuvent faire projeter des

particules en l’air et entraîner des dommages irréversibles aux yeux.

· Toujours utiliser la poignée latérale fournie avec l’outil et tenir

fermement ce dernier. Toujours le faire fonctionner en le tenant avec

les deux mains, sans quoi on risque d’en perdre la maîtrise (à une

main, le fait de traverser l’ouvrage ou de rencontrer des matériaux durs

comme des barres d’armature peut s’avérer dangereux).

· Ne jamais utiliser de burins lorsque l’outil est en mode de

rotation; ces derniers risquent de se coincer et entraîner une perte

de maîtrise.

· Porter des gants pour manipuler les mèches et les accessoires de

l’outil, lesquels peuvent devenir chauds après leur utilisation. Le

port de gants et des arrêts fréquents permettront de réduire les risques

de blessures liées à la vibration aux mains et aux bras.

· S’assurer qu’aucune partie du corps ne se trouve entre l’outil et le

mur ou l’ouvrage à travailler afin d’éviter de rester coincé contre l’outil

si ce dernier devait soudainement faire un mouvement de torsion en

raison du blocage de la mèche.

AVERTISSEMENT : certains outils électriques, comme les

sableuses, les scies, les meules, les perceuses ou certains autres

outils de construction, peuvent soulever de la poussière contenant

des produits chimiques susceptibles d’entraîner le cancer, des

malformations congénitales ou pouvant être nocifs pour le système

reproductif. Parmi ces produits chimiques, on retrouve :

· le plomb dans les peintures à base de plomb;

· la silice cristalline dans les briques et le ciment et autres produits de

maçonnerie;

· l’arsenic et le chrome dans le bois de sciage ayant subi un traitement

chimique.

Le risque associé à de telles expositions peut varier selon la fréquence

avec laquelle on effectue ces travaux. Pour réduire l’exposition à de tels

produits, il faut travailler dans un endroit bien ventilé et utiliser

l’équipement de sécurité approprié tel un masque anti-poussières

spécialement conçu pour filtrer les particules microscopiques.

· L’étiquette apposée sur l’outil peut afficher les symboles suivants :

V ..................volts

A ..................ampères

Hz ................hertz

W..................watts

min ..............minutes

................courant alternatif

............courant continu

n o................aucune option à vide

................construction de classe II

…/min ..........tours ou mouvements alternatifs par minute

BPM ............battement par minute

................symbole d´avertissement

Poignée latérale

MISE EN GARDE : toujours tenir la perceuse à percussion avec les

deux mains. La poignée latérale fournie avec l’outil se fixe sur la partie

antérieure du carter d’engrenages, tel qu’illustré à la figure 1; on peut

la tourner complètement dans un sens ou dans l’autre afin de l’utiliser

à gauche ou à droite, selon le cas. Pour serrer la poignée, tourner la

partie en plastique noir vers la droite; pour la desserrer, la tourner vers

9

Français

DW567/329785-01 10/1/02 9:56 AM Page 9

Page 12

10

la gauche.

Interrupteur

Enfoncer l’interrupteur à gâchette (figure 2) pour faire démarrer la

perceuse à percussion; le relâcher pour l’arrêter. Pour un

fonctionnement continu, enfoncer la gâchette et la bloquer en appuyant

sur le bouton de verrouillage. Pour arrêter l’outil lorsqu’il est verrouillé

en position de marche, enfoncer et relâcher la gâchette. Avant de

mettre l’outil en marche (et ce, à chaque utilisation), s’assurer que le

mécanisme de déverrouillage du bouton fonctionne correctement.

Ne pas verrouiller l’interrupteur en position de marche lorsqu’on utilise

l’outil en mode manuel afin de pouvoir l’arrêter instantanément (si la

mèche reste coincée dans le trou, par exemple). Le bouton de

verrouillage ne doit être utilisé que lorsque la perceuse à percussion

est maintenue immobile au moyen d’un support pour perceuse ou

autrement. S’assurer de relâcher le bouton de verrouillage avant de

débrancher la fiche de la prise murale, à défaut de quoi l’outil se mettra

en marche dès qu’on le branchera de nouveau, ce qui pourrait causer

des dommages matériels ou des blessures corporelles.

L’interrupteur de variation de vitesse permet de choisir la vitesse de

fonctionnement; plus on l’enfonce, plus la vitesse est élevée.

REMARQUE : utiliser les basses vitesses pour amorcer un trou sans

pointeau, pour percer le métal, le plastique ou la céramique, ou pour

enfoncer une vis. On recommande d’utiliser les vitesses plus élevées

pour percer le bois et les panneaux d’agglomérés, ou lorsqu’on utilise

des accessoires d’abrasion ou de polissage.

Le levier de commande de marche arrière sert à mettre la perceuse à

percussion en marche arrière, pour retirer une vis ou une mèche

coincée. Il est situé au-dessus de la gâchette, tel qu’illustré à la figure

2. Pour mettre l’outil en marche arrière, l’arrêter et pousser le levier

vers la gauche (lorsqu’on le regarde du côté du mandrin). Pour le

remettre en position de marche avant, arrêter la perceuse à percussion

et pousser le levier vers la droite.

MISE EN GARDE : lorsqu’on utilise l’outil en marche arrière pour

libérer une mèche coincée, on doit s’attendre à ressentir un brusque

couple de rotation.

Sélecteur de modes martelage/perçage

(DW567)

Pour sélectionner les modes de perçage, de perçage à percussion ou de

martelage, tourner le bouton rotatif vers le symbole approprié (figure 3).

REMARQUE : le sélecteur doit toujours être placé soit en mode de

perçage, de perçage à percussion ou de martelage; l’outil ne

fonctionnera pas si le sélecteur est placé entre deux positions.

Français

R

R

LEVIER DE

COMMANDE DE

MARCHE

ARRIÈRE

INTERRUPTEU

R À GÂCHETTE

BOUTON DE

VERROUILLAGE

FIGURE 2

FIGURE 1

DW567/329785-01 10/1/02 9:56 AM Page 10

Page 13

Mandrin SDS

Pour insérer la mèche, enfoncer la tige de la mèche d’environ 19 mm

(3/4 po) dans le mandrin; la mèche y restera solidement fixée.

Pour retirer la mèche, repousser le collier et enlever la mèche.

Fonctionnement

PERÇAGE

1. Toujours débrancher la perceuse avant de fixer ou de remplacer

les mèches ou les accessoires.

2. Utiliser des mèches aiguisées seulement. Pour percer le BOIS,

utiliser une mèche hélicoïdale, de vrille ou de tarière à moteur ou

encore, une scie à trous; pour le MÉTAL, utiliser une mèche

hélicoïdale ou une scie à trous. Quant aux matériaux de

MAÇONNERIE comme la brique, le ciment, les blocs en béton de

laitier, etc., choisir des mèches à pointe carburée destinées au

forage par percussion. Bien fixer et soutenir l’ouvrage. Dans le cas

de matériaux minces, utiliser des blocs de remplissage en bois afin

de ne pas l’endommager.

3. Appliquer une pression en ligne droite au moyen de la mèche en

exerçant juste assez de pression pour permettre à la mèche de

mordre dans l’ouvrage, en évitant de caler le moteur ou de faire

dévier la mèche.

4. Saisir fermement la perceuse afin de maîtriser la torsion.

5. LE CALAGE DE LA PERCEUSE découle généralement d’une

surcharge ou d’une mauvaise utilisation. Lorsque cela se produit,

RELÂCHER LA GÂCHETTE IMMÉDIATEMENT, retirer la mèche

de l’ouvrage et déterminer la cause du calage. NE PAS

ENFONCER ET RELÂCHER LA GÂCHETTE À PLUSIEURS

REPRISES POUR ESSAYER DE REDÉMARRER LA PERCEUSE

AFIN D’ÉVITER DE L’ENDOMMAGER.

6. Pour réduire les risques de calage et de bris de matériaux, ne pas

exercer trop de pression sur l’outil et percer lentement jusqu’au bout

du trou.

7. Maintenir le moteur en marche lorsqu’on retire la mèche du trou

percé afin d’éviter qu’elle ne reste coincée.

8. Lorsqu’on utilise une perceuse à vitesse variable, il n’est pas

nécessaire de marquer l’emplacement prévu du trou au moyen d’un

pointeau. Faire fonctionner la perceuse à basse vitesse et

augmenter celle-ci en enfonçant davantage la gâchette lorsque le

trou est suffisamment profond pour empêcher la mèche d’en sortir.

PERÇAGE DU MÉTAL

Un mandrin d’adaptation «tige SDS–tige arrondie» est requis pour ce

type de perçage. Mettre l’outil en mode de perçage seulement (modèle

DW567 seulement – le modèle DW565 n’offre pas ce mode). Faire

fonctionner la perceuse très lentement et augmenter la vitesse jusqu’à

ce qu’on obtienne la vitesse maximale, tout en appuyant fermement

sur l’outil; la vitesse choisie est appropriée lorsque les éclats de

métaux sont projetés uniformément et régulièrement. Utiliser une huile

de coupe lorsqu’on perce des métaux, à l’exception de la fonte et du

laiton, car des derniers doivent être percés à sec. Les meilleurs

lubrifiants sont l’huile sulfurée et l’huile de lard; on peut aussi utiliser de

la graisse de bacon.

REMARQUE : il est plus facile de percer de larges trous (c.-à-d., de

7,94 à 12,7 mm ou de 5/16 à 1/2 po) dans l’acier si on perce d’abord

un trou de guidage de 3,97 à 4,76 mm ou de 5/32 à 3/16 po.

11

Français

FIGURE 3

RÉGLAGE DE

PERÇAGE

RÉGLAGE DE

MARTELAGE

RÉGLAGE DE

PERÇAGE À

PERCUSSION

DW567/329785-01 10/1/02 9:56 AM Page 11

Page 14

12

PERÇAGE DU BOIS

Un mandrin d’adaptation «tige SDS–tige arrondie» est requis pour ce

type de perçage. Mettre l’outil en mode de perçage seulement (modèle

DW567 seulement – le modèle DW565 n’offre pas ce mode). Faire

fonctionner la perceuse très lentement et augmenter la vitesse jusqu’à

ce qu’on obtienne la vitesse maximale, tout en appuyant fermement

sur l’outil. On peut percer le bois au moyen des mèches hélicoïdales

qu’on utilise pour le métal. Ces mèches peuvent surchauffer si on ne

les sort pas fréquemment pour enlever les copeaux restés coincés

dans les goujures. Pour réaliser des trous plus grands, utiliser des

mèches de vrille ou de tarière à moteur ou encore, une scie à trous.

Les ouvrages susceptibles de se fractionner doivent être calés au

moyen d’un bloc de bois.

PERÇAGE DE LA MAÇONNERIE

Lorsqu’on perce de la maçonnerie, utiliser des mèches à pointe

carburée destinées au forage par percussion, en s’assurant qu’elles

soient bien aiguisées. Appuyer constamment et fermement sur l’outil

pour assurer un perçage efficace. La vitesse choisie est appropriée

lorsque la poussière est soulevée uniformément et régulièrement.

Tige de profondeur

Pour régler la tige de profondeur, desserrer la poignée et déplacer la

tige de manière à ce que la distance entre son extrémité et celle de la

mèche corresponde à la profondeur de perçage voulue. Lorsqu’on

perce au moyen d’une tige de profondeur, on doit s’arrêter dès que

l’extrémité de la tige atteint la surface de l’ouvrage.

Entretien

NETTOYAGE ET LUBRIFICATION

Nettoyer l’outil seulement au moyen d’un linge humide et d’un savon

doux. Ne jamais laisser de liquide s’infiltrer à l’intérieur de l’outil, et ne

jamais immerger ce dernier dans quelque liquide que ce soit. Comme

les roulements sont autolubrifiants, il n’est pas nécessaire de les

lubrifier manuellement. Dans l’éventualité peu probable qu’un entretien

s’avère nécessaire, on doit apporter l’outil à un centre de service

autorisé.

Accessoires

Les accessoires recommandés pour cet outil sont vendus séparément

chez les distributeurs ou les centres de service locaux.

MISE EN GARDE : l’usage d’un accessoire non recommandé peut

présenter un danger.

CAPACITÉS MAXIMALES RECOMMANDÉES (en pouces)

DW565 DW567 DW567-220

CAPACITÉ MAXIMALE

MAÇONNERIE 1 po 1 po 1 po

ACIER s/o 1/2 po 1/2 po

BOIS s/o 1 1/2 po 1 1/2 po

CAPACITÉ OPTIMALE

MAÇONNERIE 5/32 à 5/8 po 5/32 à 5/8 po 5/32 à 5/8 po

Important

Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil, n’en

confier la réparation, l’entretien et les rajustements (y compris

l’inspection et le remplacement des balais) qu’au personnel d’un

centre de service D

EWALT ou d’un atelier d’entretien autorisé

n’utilisant que des pièces de rechange identiques.

Garantie complète

Les outils industriels de service intensif DEWALT sont garantis

pendant un an à partir de la date d’achat. Toute pièce d’un outil

D

EWALT qui s’avérait défectueuse en raison d’un vice de matière ou

de fabrication sera réparée ou remplacée sans frais. Pour obtenir

de plus amples renseignements sur les réparations couvertes par la

garantie, composer le 1 (800) 4-D

EWALT (! (800) 433-9258). La ga

rantie ne couvre pas les accessories ni les réparations tentées ou

effectuées par des tiers. Les modalités de la présente garantie

donnent des droits légaux spécifiques. L’utilisateur peut également

Français

DW567/329785-01 10/1/02 9:56 AM Page 12

Page 15

se prévaloir d’autres droits selon l’état ou la province qu’il habite.

En outre, la garantie suivante couvre les outils D

EWALT.

GARANTIE DE SATISFACTION DE 30 JOURS OU ARGENT REMIS

Si, pour quelque raison que ce soit, l’outil industriel de service

intensif DEWALT ne donne pas entière satisfaction, il suffit de le

retourner chez le marchand participant dans les 30 jours suivant la

date d’achat afin d’obtenir un remboursement complet. Il faut

retourner, port payé, l’outil complet. On peut exiger une preuve

d’achat.

o tuberías, radiadores, cocinas, y refrigeradoras. Existe un mayor riesgo

13

Français

DW567/329785-01 10/1/02 9:56 AM Page 13

Page 16

14

SI TIENE PREGUNTAS O COMENTARIOS SOBRE ESTA U OTRA

HERRAMIENTA DeWALT, LLÁMENOS GRATIS AL

1-800-433-9258

Reglas generales de seguridad

[symbol] ¡ADVERTENCIA! LEA Y ENTIENDA TODO EL INSTRUCTIVO.

El no seguir todas las instrucciones enumeradas a continuación puede

resultar en electrochoque, fuego y/o seria lesión personal.

GUARDE ESTAS INSTRUCCIONES

ÁREA DE TRABAJO

· Mantenga su área de trabajo limpio y bien iluminado. Bancos de

trabajo abarrotados de cosas y áreas oscuras son una invitación a los

accidentes.

· No opere herramientas eléctricas en atmósferas explosivas,

donde hay presencia de líquidos, gases, o polvos inflamables.

Las herramientas eléctricas crean chispas que podrían encender el

polvo o los gases.

· Mantenga a los transeúntes, niños, y visitantes alejados mientras

opera una herramienta eléctrica. Las distracciones podrían causar

la pérdida de control.

SEGURIDAD ELÉCTRICA

· Las herramientas a tierra deberán conectarse a un tomacorriente

instalado correctamente y puesto a tierra de acuerdo con todos

los códigos y ordenanzas. Nunca debe quitar el clavijero de tierra o

modificar el enchufe de algún modo. No usar enchufes adaptadores.

Infórmese con un electricista competente si duda que el tomacorriente

esté adecuadamente puesto a tierra. Si las herramientas funcionan

mal eléctricamente, o fallan, la puesta a tierra provee una vía de

resistencia baja que aparta del usuario la electricidad extraída.

Sólo aplica a la Clase I herramientas (a tierra).

· Las herramientas con doble aislamiento están equipadas con un

enchufe polarizado (una clavija es más ancha que la otra.) Este

enchufe encajará en un tomacorriente polarizado de una sola

manera. Si el enchufe no encaja bien en el tomacorriente, invierta el

enchufe. Si todavía no encaja, contacte a un electricista competente

para que instale un tomacorriente polarizado. No cambie el enchufe. El

aislamiento doble elimina la necesidad de un cable eléctrico a tierra de

tres alambres y un sistema de alimentación eléctrica puesto a tierra.

Sólo aplica a la Clase II herramientas (aislamiento doble).

· Evite que su cuerpo haga contacto con superficies a tierra tales

como tuberías, radiadores, cocinas, y refrigeradoras. Existe un

mayor riesgo de electrochoque si su cuerpo está a tierra

· No exponga las herramientas eléctricas a la lluvia o condiciones

húmedas. La penetración de agua a una herramienta eléctrica

incrementará el riesgo de electrochoque. Otros líquidos, como el

sudor, presentan el mismo riesgo.

· No maltrate el cable. No lo use nunca para acarrear las herramientas

o halar el enchufe de un tomacorriente. Mantenga el cable alejado del

calor, aceite, bordes afilados o partes en movimiento. Reemplace

inmediatamente los cables dañados. Los cables dañados incrementan el riesgo de electrochoque.

· Al operar una herramienta eléctrica a la intemperie, use un cable

de extensión para exteriores marcado “W-A” o “W.” Estos cables

están hechos para uso exterior y reducen el riesgo de electrochoque.

Cuando utiliza un cable de extensión, asegúrese de que sea lo

suficientemente “pesado” para transportar la corriente que su producto

va a extraer. Un cable de tamaño insuficiente causará una caída en la

línea de voltaje resultando en pérdida de energía y recalentamiento.

La siguiente tabla muestra el tamaño correcto que debe usar

dependiendo del largo del cable y la potencia de amperaje nominal.

Si tiene dudas, use el calibre de mayor peso que le sigue. Cuanto

más reducido sea el calibre, más pesado será el cable.

Calibre mínimo requerido (AWG) para cables de extensión

Español

DW567/329785-01 10/1/02 9:56 AM Page 14

Page 17

Longitud total del cable de extensión

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.,6 m 15,2 m 22,9 m 30,5 m 38,1 m 45,7 m 53,3 m

Calibre promedio del alambre

18 AWG 18 AWG 16 AWG 16 AWG 14 AWG 14 AWG 12 AWG

SEGURIDAD PERSONAL

· Manténgase alerta, observe lo que está haciendo y use sentido

común al usar una herramienta eléctrica. No la use cuando esté

cansado o bajo la influencia de drogas, alcohol, o medicinas. Un

instante de inatención mientras opera herramientas eléctricas puede

resultar en serias lesiones personales.

· Vístase adecuadamente. No use vestimenta suelta o joyas.

Mantenga el cabello largo sujeto. Mantenga su cabello, vestimenta y

guantes apartados de piezas en movimiento. La vestimenta suelta, las

joyas o el cabello largo podrían quedar atrapados en las partes en

movimiento. A menudo las ventosas de aire cubren las partes en

movimiento, y éstas también se deben evitar.

· Evite un arranque accidental. Asegúrese de apagar la herramienta

antes de enchufarla. El cargar las herramientas con el dedo en el

interruptor o enchufar herramientas que tienen el interruptor activado

es una invitación a los accidentes.

· Quite las llaves de ajuste antes de activar la herramienta. Una llave

que se deja anexada a una parte giratoria de la herramienta puede

resultar en lesión personal.

· No se extralimite. Mantenga la pisada firme y el balance apropiado

todo el tiempo.

El pie bien afincado y el balance apropiado permite un mejor control

de la herramienta en situaciones inesperadas.

· Utilice equipo de seguridad. Use siempre protección para los

ojos. Se deberá usar máscara contra el polvo, calzado protector

antirresbalante, casco, o protector de oído en las condiciones que los

justifican.

USO Y CUIDADO DE HERRAMIENTAS

· Utilice tornillos de banco u otra forma práctica para sujetar y

apoyar la pieza de trabajo a una plataforma estable. Sujetar la

pieza manualmente o contra su cuerpo es inestable y puede llevar a

la pérdida de control.

· No fuerce la herramienta. Use la herramienta correcta para la

aplicación. La herramienta correcta hará una labor mejor y más

segura, con la energía nominal para la cual fue diseñada.

· No use la herramienta si el interruptor no prende y apaga. La

herramienta que no se puede controlar con el interruptor es peligrosa

y debe ser reparada.

· Desconecte el enchufe de la fuente de energía antes de efectuar

cualquier ajuste, cambio de accesorios, o guardar la herramienta.

Estas medidas de seguridad preventivas reducen el riesgo a que la

herramienta arranque accidentalmente.

· Mantenga herramientas que no estén en uso fuera del alcance

de los niños y otras personas no entrenadas. Las herramientas

son peligrosas en manos de usuarios no entrenados.

· Las herramientas deben recibir un mantenimiento cuidadoso.

Mantenga las herramientas para corte afiladas y limpias. Las

herramientas bien cuidadas con bordes de corte afilados son menos

susceptibles a trabarse y más fáciles de controlar.

· Revise si hay desalineamiento o traba en las partes movibles,

partes rotas u otra condición que pueda afectar la operación de la

herramienta. De estar dañada, dar servicio a la misma antes de

utilizarla. Muchas veces la causa de accidentes se debe a herramientas con poco mantenimiento.

· Use solamente los accesorios que el fabricante recomienda para

su modelo. Los accesorios adecuados para una herramienta, pueden

resultar peligrosos cuando se usa en otra.

SERVICIO

· El servicio a la herramienta debe ser hecho por personal de

reparación calificado únicamente. El servicio o mantenimiento

hecho por personal no calificado puede entrañar un riesgo o lesión.

15

Español

DW567/329785-01 10/1/02 9:56 AM Page 15

Page 18

16

· Al dar servicio a la herramienta, use sólo piezas de repuesto

idénticas. Siga las instrucciones contenidas en la sección

Mantenimiento de este manual. El uso de repuestos no autorizados o

el no cumplir con las instrucciones de Mantenimiento puede crear el

riesgo de electrochoque o lesión.

Reglas de seguridad específicas

adicionales para rotomartillos

· Usted debe asir la herramienta por las superficies de agarre con

aislamiento, al ejecutar una operación donde la herramienta para

corte pueda hacer contacto con el cableado oculto o el cable de

la misma. El contacto con un cable con corriente hará que las partes

expuestas de la herramienta que sean de metal, tengan corriente y

proporcionen un electrochoque al operador.

· Use protectores de oído cuando debe martillear por tiempo

prolongado. La exposición prolongada a ruidos de alta intensidad

puede causar pérdida auditiva.

· Use gafas de seguridad u otra protección ocular. Las operaciones

de martilleo y taladrado hacen que las astillas vuelen. Las partículas

volantes pueden causar daño ocular permanente.

· Utilice siempre la manija lateral de la herramienta. Sujete siempre

la herramienta de manera firme. No trate de operar esta herramienta

sin asirla con las dos manos. El operar esta herramienta con una mano

resultará en pérdida de control. Atravesar o encontrarse con

materiales duros como barras de refuerzo, también puede ser

peligroso.

· No usar cinceles en ninguna de las modalidades de rotación. Los

cinceles pueden trabarse y causar pérdida de control.

· Use guantes al manejar brocas de martillo y herramientas. Estas

se recalientan durante su funcionamiento. Los guantes y períodos

frecuentes de descanso reducirán el riesgo de daño por vibración a las

manos y brazos.

· No deje que las manos y el cuerpo queden entre la herramienta y

la pared o el poste, etc., para evitar ser estrujado por la herramienta

si ésta se retuerce inesperadamente al trabarse la broca.

[symbol] ADVERTENCIA: Ciertos polvos creados por el lijado, aserrado,

trituración, taladrado y otras actividades de construcción contienen

químicos causantes de cáncer, defectos de nacimiento u otros daños

en la reproducción. Algunos ejemplos de estos químicos son:

· el plomo de las pinturas a base de plomo,

· la sílice cristalina de los ladrillos y cemento y otros productos de

albañilería, y

· el arsénico y el cromo de las maderas tratadas con químicos (CCA).

El riesgo a la exposición varía, dependiendo de cuán a menudo usted

ejecuta este tipo de trabajo. Para reducir la exposición a estos

químicos: trabaje en un área bien ventilada y hágalo con equipos de

seguridad aprobados, tales como las máscaras de polvo que están

especialmente diseñadas para filtrar las partículas microscópicas.

· La etiqueta puesta en su herramienta podría incluir los símbolos

siguientes.

V ....................voltios

A ....................amperios

Hz ..................hertz

W ....................vatios

min..................minutos

..................corriente alterna

................corriente directa

n o ..................velocidad sin carga

....................Construcción Clase II

…/min ............revoluciones por minuto

BPM................golpes por minuto

................símbolo de alerta de seguridad

Manija lateral

ATENCIÓN:Siempre sujete el rotomartillo con ambas manos. Este

rotomartillo viene con una manija lateral. La manija se fija en la parte

frontal de la caja de engranajes como lo demuestra la Figura 1 y puede

girarse 360˚ para permitir el uso de la mano derecha o izquierda. La

Español

DW567/329785-01 10/1/02 9:56 AM Page 16

Page 19

manija lateral se puede apretar girando la porción negra de plástico de

la manija en sentido horario y aflojarse girándola en sentido

antihorario.

Interruptor

Para operar el rotomartillo, oprima el interruptor de disparo (Figura 2). Para

pararlo, suelte el interruptor. Para cerrar el interruptor de disparo en la

posición ON para operación continua, oprima el interruptor de disparo y

empuje el botón de cierre hacia adentro. La herramienta continuará

funcionando. Para apagar el martillo (OFF), desde la posición cerrada ON,

apriete y suelte el interruptor de disparo una vez. Antes de usar la

herramienta (cada vez), asegúrese de que el mecanismo de liberación del

botón de cierre trabaja con soltura.

No cierre el interruptor en la posición “ON” mientras taladra manualmente, a

fin de que pueda soltar el interruptor de disparo instantáneamente si la broca

se traba en el hueco. El botón de cierre se debe usar sólo cuando el

rotomartillo está montado en una prensa de taladrar o se mantenga

estacionario por algún otro medio. Asegúrese de liberar el mecanismo de

cierre antes de desconectar el enchufe del tomacorriente. El no hacerlo

podría resultar en que el rotomartillo arranque inmediatamente la próxima vez

que se enchufe, ocasionando daños o lesiones.

El interruptor de disparo de velocidad variable permite el control de la

velocidad. Cuanto más se oprima el interruptor, mayor será la velocidad del

rotomartillo.

NOTA: Use velocidades más bajas para comenzar huecos sin granetazo,

taladrado en metal, plástico o cerámica, o apretar tuercas. Las velocidades

más altas son más aptas para taladrar madera y tablas de material

compuesto y para usar accesorios de lijar y pulir.

La palanca de inversión se utiliza para reversar el rotomartillo a fin de botar

tornillos o brocas trabadas. Está ubicada encima del disparador, como se

demuestra en la Figura 2. Para reversar el rotomartillo, apague (OFF) y

empuje la palanca de inversión hacia la izquierda (visto desde el extremo del

portabroca ). Para posicionar la palanca en operación de avance, apague el

rotomartillo (OFF) y empuje la palanca hacia la derecha.

ATENCIÓN:Cuando lo ponga en reverso para destrabar un brocas,

prepárese para un momento de torsión fuerte y reactivo.

Selector de Martillo/Taladro (DW567)

Para cambiar la herramienta de la modalidad de taladrado solamente a la de

rotomartillo o sólo martillo, gire el cuadrante al símbolo que aplica como se

demuestra en la Figura 3.

NOTA: El selector debe estar en la modalidad de taladro, rotomartillo o

martillo en todo momento. No hay otras posiciones de operación entre éstas.

Portabroca SDS

Para insertar la broca, inserte la espiga de la broca aprox. 3/4” dentro del

portabrocas. Empuje y gire la broca hasta que encaje bien. La broca quedará

afianzada en forma segura.

Para liberar la broca, empuje el collar hacia atrás y saque la broca.

17

Español

R

FIG. 1

R

PALANCA

INVERSORA

INTERRUPTOR

BOTÓN DE

CIERRE

FIG. 2

DW567/329785-01 10/1/02 9:56 AM Page 17

Page 20

18

Operación

TALADRADO

1. Siempre desenchufe el taladro al cambiar brocas o accesorios.

2. Use sólo brocas afiladas. Use las brocas helicoidales, las de gran

diámetro, de berbiquí, o de perforación para MADERA. Para

METAL, use brocas helicoidales de acero o brocas de perforación.

Para la ALBAÑILERÍA, como por ej. ladrillos, cemento, bloques de

hormigón, etc. use brocas con puntas de carburo, apropiadas para

taladrado de percusión. Cerciórese de que el material a taladrar

esté bien fijado o atornillado. De taladrar un material delgado, utilice

un bloque de madera como soporte para prevenir que el material se

dañe.

3. Aplique siempre presión en línea recta con la broca. Usar suficiente

presión para mantener el taladro mordiendo, pero no empujarlo

tan fuerte que atasque al motor o desvíe la broca.

4. Mantenga la herramienta firme para controlar la acción de

torcionamiento del taladro.

5. SI EL TALADRO SE ATASCA, se debe generalmente a que está

sobrecargado o utilizado incorrectamente. SUELTE EL

INTERRUPTOR DE DISPARO INMEDIATAMENTE, quite la broca

de la pieza de trabajo y determine la causa del atascamiento. NO

ACTIVAR Y DESACTIVAR EL INTERRUPTOR PARA INTENTAR

EL ARRANQUE DE UN TALADRO ATASCADO – ESTO PUEDE

DAÑARLO.

6. Para minimizar que la herramienta se atasque o atraviese el

material, reduzca la presión sobre el taladro y saque la broca

suavemente a través de la última parte fraccionada del hueco.

7. Mantenga el motor en marcha al sacar la broca de un hueco

taladrado. Esto ayudará a que no se trabe.

8. Con taladros de velocidad variable no hay necesidad de centrar el

punto a taladrar con punzón. Use una velocidad baja para

comenzar el hueco y acelere apretando el interruptor de disparo

más fuertemente cuando el hueco sea lo bastante profundo para

taladrar sin que la broca salte hacia afuera.

TALADRADO EN METAL

Se requiere un adaptador de ‘espiga SDS a una espiga redonda’. Cerciórese

de que la herramienta esté en modalidad de “sólo rotación”. (DW567

solamente. El modelo DW565 no tiene la modalidad de “sólo rotación”).

Comience a taladrar a baja velocidad y aumente a velocidad plena mientras

presiona la herramienta firmemente. Un flujo de viruta uniforme indica que la

velocidad del taladro es adecuada. Use un lubricante para corte al taladrar

metales. Las excepciones son hierro forjado y bronce, estos deben taladrarse

en seco. Los lubricantes para corte que mejor funcionan son aceites

sulfurizados para corte o manteca de cerdo; la grasa de tocino también sirve.

NOTA: Huecos grandes (5/16” a 1/2”) en acero se ejecutan más fácilmente

si primero se taladra un hueco piloto (5/32” a 3/16”).

TALADRADO EN MADERA

Se requiere un adaptador de ‘espiga SDS a una espiga redonda’. Cerciórese

de que la herramienta esté en modalidad de “sólo rotación”. (DW567

solamente, el modelo DW565 no tiene la modalidad de “sólo rotación”).

Comience a taladrar a baja velocidad y aumente a velocidad plena mientras

presiona la herramienta firmemente. Los huecos en madera pueden hacerse

con las mismas brocas helicoidales que se utilizan para el metal. Estas

brocas pueden recalentarse si no se sacan frecuentemente para quitar las

virutas de las ranuras. Para huecos más grandes, utilice brocas de gran

diámetro, de berbiquí o de perforación. Las piezas de trabajo que tienden a

Español

FIG. 3

REGLAJE DEL

TALADRO

REGLAJE DEL

MARTILLO

ROTOMARTILLO

- REGLAJE

DW567/329785-01 10/1/02 9:56 AM Page 18

Page 21

astillarse, deberán afincarse con un bloque madera.

TALADRADO EN ALBAÑILERÍA

Cuando se taladra en material de albañilería, use brocas con puntas de

carburo para taladrado de percusión y cerciórese de que la broca esté afilada.

Ejerza una fuerza constante y firme sobre la herramienta para un taladrado

eficaz. Un flujo uniforme de polvo indica que la velocidad del taladro es

adecuada.

Varilla de profundidad

Para ajustar la varilla de profundidad, afloje la manija y mueva la varilla de tal

forma que la distancia entre el extremo de la varilla y el extremo de la broca

iguala la profundidad de taladrado deseada. Cuando se taladra con varilla

de profundidad, parar el taladrado cuando ésta alcanza la superficie del

material.

Mantenimiento

LIMPIEZA Y LUBRICACIÓN

Utilice únicamente un jabón suave y paño húmedo para limpiar la

herramienta. Nunca debe permitir que algún líquido penetre la herramienta;

no sumerja nunca la herramienta o parte de ella en algún líquido.

La herramienta utiliza cojinetes auto-lubricantes y no requiere relubricación

periódica. En caso (poco probable) de necesitar servicio, lleve su herramienta

a un centro de servicio autorizado.

Accesorios

Los accesorios que se recomiendan usar con su herramienta están

disponibles a un costo adicional donde su distribuidor o centro de servicios

local.

ATENCIÓN: Puede ser peligroso usar cualquier accesorio no

recomendado.

CAPACIDAD MÁXIMA RECOMENDADA

DW565, DW567 DW567-220

CAPACIDAD MÁXIMA

ALBAÑILERÍA 1" 1" 1"

ACERO N/A 1/2" 1/2"

MADERA N/A 1 1/2" 1 1/2"

CAPACIDAD ÓPTIMA

ALBAÑILERÍA 5/32"-5/8" 5/32"-5/8" 5/32"-5/8"

Importante

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán

hacerse reparaciones, mantenimiento y ajustes de esta herramienta

en los centros autorizados de servicio D

EWALT u otras organizaciones

autorizadas. Estas organizaciones prestan servicio a las herramientas

DeWALT y emplean siempre refacciones legitimas D

EWALT.

PARA REPARACION Y SERVICIO DE SUS HERRAMIENTAS

ELECTRICAS FAVOR DE DIRIGIRSE AL CENTRO DE SERVICIO MAS

CERCANO

CULIACAN

Av. Nicolas Bravo #1063 Sur (91 671) 242 10

GAUDALAJARA

Av. La Paz #1779 (91 3) 826 69 78.

MEXICO

Eje Lázaro Cárdenas No. 18 Local D, Col. Obrera 588-9377

MERIDA

Calle 63 #459-A (91 99) 23 54 90

MONTERREY

Av. Francisco I. Madero Pte. 1820-A (91 83) 72 11 25

PUEBLA

17 Norte #205 (91 22) 46 37 14

QUERETARO

Av. Madero 139 Pte. (91 42) 14 16 60

SAN LOUIS POTOSI

Pedro Moreno #100 Centro (91 48) 14 25 67

TORREON

Blvd. Independencia, 96 pte. (91 17) 16 52 65

VERACRUZ

Prolongación Diaz Miron #4280 (91 29) 21 70 16

VILLAHERMOSA

Constitucion 516-A (91 93) 12 53 17

PARA OTRAS LOCALIDADES LLAME AL: 326 7100

19

Español

DW567/329785-01 10/1/02 9:56 AM Page 19

Page 22

20

Póliza de GarantÍía

IDENTIFICACIÓN DEL PRODUCTO:

Sello o firma del Distribuidor.

Nombre del producto: __________ Mod./Cat.: _____________

Marca: _____________________ Núm. de serie:__________

(Datos para ser llenados por el distribuidor)

Fecha de compra y/o entrega del producto: __________________

Nombre y domicilio del distribuidor donde se adquirió el producto:

_____________________________________________________

Este producto está garantizado por un año a partir de la fecha de

entrega, contra cualquier defecto en su funcionamiento, así como en

materiales y mano de obra empleados para su fabricación. Nuestra

garantía incluye la reparación o reposición del producto y/o

componentes sin cargo alguno para el cliente, incluyendo mano de

obra, así como los gastos de transportación razonablemente erogados

derivados del cumplimiento de este certificado.

Para hacer efectiva esta garantía deberá presentar su herramienta y

esta póliza sellada por el establecimiento comercial donde se adquirió

el producto, de no contar con ésta, bastará la factura de compra.

EXCEPCIONES.

Esta garantía no será válida en los siguientes casos:

• Cuando el producto se hubiese utilizado en condiciones distintas a

las normales;

• Cuando el producto no hubiese sido operado de acuerdo con el

instructivo de uso que se acompaña;

• Cuando el producto hubiese sido alterado o reparado por personas

distintas a las enlistadas al final de este certificado.

Anexo encontrará una relación de sucursales de servicio de fábrica,

centros de servicio autorizados y franquiciados en la República

Mexicana, donde podrá hacer efectiva su garantía y adquirir partes,

refacciones y accesorios originales.

Garantía Completa

Las herramientas industriales DEWALT están garantizadas durante un

año a partir de la fecha de compra. Repararemos, sin cargos, cualquier

falla debida a material o mano de obra defectuosos. Por favor regrese

la unidad completa, con el transporte pagado, a cualquier Centro de

Servicio para Herramientas Industriales de D

EWALT o a las estaciones

de servicio autorizado enlistadas bajo "Herramientas Eléctricas" en la

Sección Amarilla. Esta garantía no se aplica a los accesorios ni a

daños causados por reparaciones efectuadas por terceras personas.

Esta garantía le otorga derechos legales específicos, y usted puede

tener otros derechos que pueden variar de estado a estado.

En adición a la garantía, las herramientas D

EWALT están amparadas

por nuestra:

GARANTÍA DE SATISFACCIÓN SIN RIESGO POR 30 DÍAS

Si usted no se encuentra completamente satisfecho con el desempeño

de su herramienta industrial D

EWALT, sencillamente devuélvala a los

vendedores participantes durante los primeros 30 días después de la

fecha de compra para que le efectúen un reembolso completo. Por

favor regrese la unidad completa, con el transporte pagado. Se puede

requerir prueba de compra.

Español

Epecificaciones DW565, DW567,DW567-220

Tensión de alimentación 120 v c.a.~

Potencia nominal: 828 W

Frecuencia de operación: 50/60 Hz

Consumo de corriente: 6,9 A

IMPORTADO: DEWALT S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. 326-7100

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

DW567/329785-01 10/1/02 9:56 AM Page 20

Loading...

Loading...