Page 1

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 Printed in Italy (SEP02-CD-1) Form No. 154728-01

DW530/DW531/DW532/DW533/DW540/DW541/DW545 Copyright © 2002

154728-01 rev 9/10/02 2:23 PM Page 2

Page 2

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW530/DW531/DW532/DW533/DW540/DW541/DW545

Rotary Hammers

Perceuses rotatives

Rotomartillos

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

154728-01 rev 9/10/02 2:23 PM Page 3

Page 3

Important Safety Instructions

WARNING: When using electric tools, basic safety precautions

should always be followed to reduce risk of fire, electric shock, and

personal injury, including the following:

READ ALL INSTRUCTIONS

Grounding Instructions

This tool should be grounded while in use to protect the operator from

electric shock. The tool is equipped with a 3-conductor cord and 3prong grounding type plug to fit the proper grounding type receptacle.

The green (or green and yellow) conductor in the cord is the

grounding wire. Never connect the green (or green and yellow) wire

to a live terminal. If your unit is intended for use on less than 150 V, it

has a plug that looks like that shown in sketch A. If it is for use on

150 to 250 V, it has a plug that looks like that shown in sketch D. An

adapter, sketches B and C, is available for connecting sketch A type

plugs to 2-prong receptacles. The green-colored rigid ear, lug, or the

like, extending from the adapter must be connected to a permanent

ground, such as a properly grounded outlet box. No adapter is

available for a plug as shown in sketch D. ADAPTER SHOWN IN

FIGURES B and C IS NOT FOR USE IN CANADA.

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

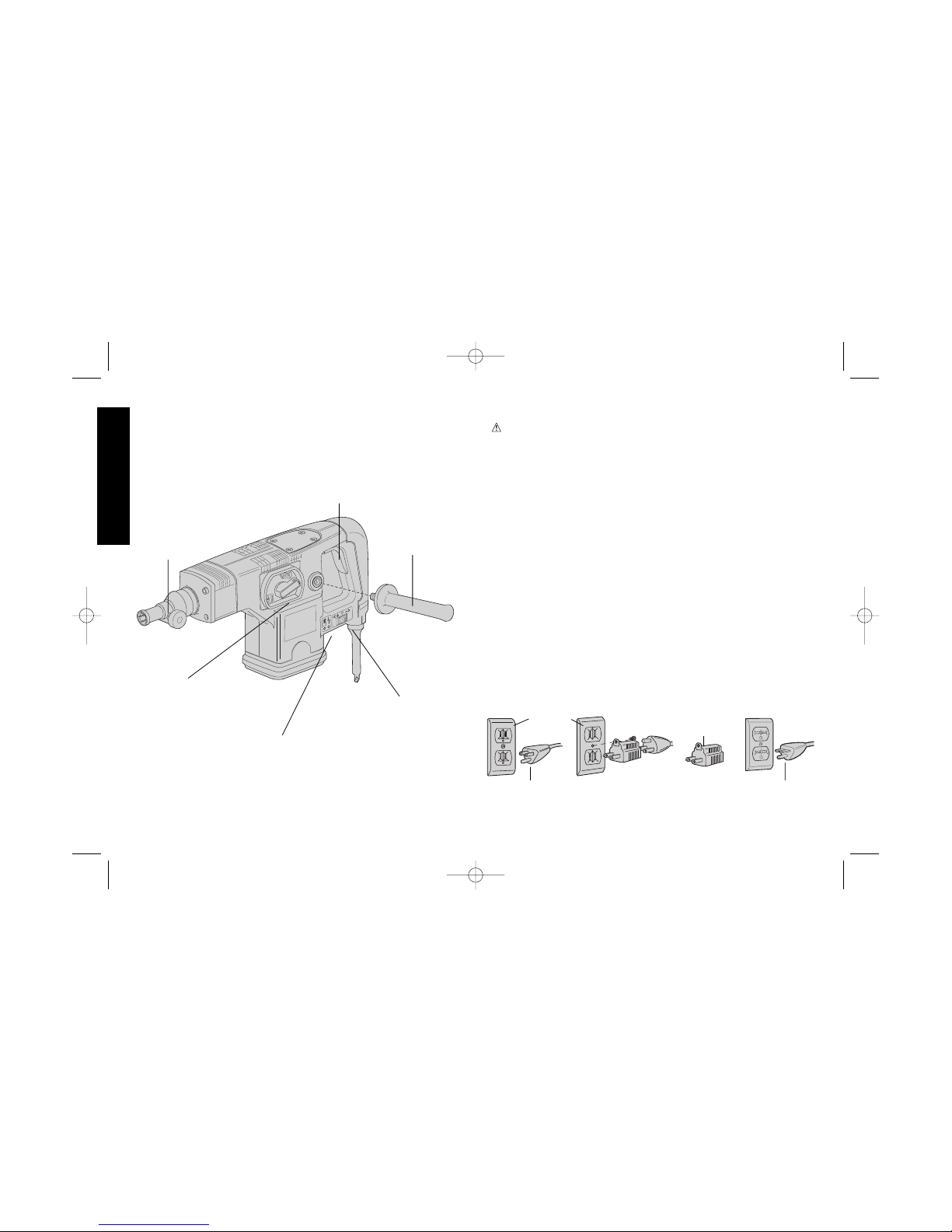

ON/OFF SWITCH

SPEED AND IMPACT

CONTROL DIAL (DW541,

DW532, DW533, DW545)

SERVICE AND POWERS INDICATORS

(DW541, DW532, DW533, DW540, DW545)

TOOL HOLDER

SIDE HANDLE

MODE SELECTOR

(ALL UNITS

EXCEPT DW530)

AB CD

GROUNDING PIN

GROUNDED

OUTLET

BOX

GROUNDING

MEANS

GROUNDING PIN

ADAPTER

154728-01 rev 9/10/02 2:23 PM Page 4

Page 4

Safety Instructions For All Tools

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite

injuries.

• CONSIDER WORK AREA ENVIRONMENT. Don’t expose power

tools to rain. Don’t use power tools in damp or wet locations. Keep

work area well lit. Do not use tool in presence of flammable liquids

or gases.

• GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with

grounded surfaces. For example; pipes, radiators, ranges, and

refrigerator enclosures.

• KEEP CHILDREN AWAY. Do not let visitors contact tool or

extension cord. All visitors should be kept away from work area.

• STORE IDLE TOOLS. When not in use, tools should be stored in

dry, and high or locked-up place — out of reach of children.

• DON’T FORCE TOOL. It will do the job better and safer at the rate

for which it was intended.

• USE RIGHT TOOL. Don’t force small tool or attachment to do the

job of a heavy-duty tool. Don’t use tool for purpose not intended.

• DRESS PROPERLY. Do not wear loose clothing or jewelry. They

can be caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors. Wear

protective hair covering to contain long hair.

• USE SAFETY GLASSES. Also use face or dust mask if operation

is dusty.

• DON’T ABUSE CORD. Never carry tool by cord or yank it to

disconnect from receptacle. Keep cord from heat, oil, and sharp

edges.

• SECURE WORK. Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate tool.

• DON’T OVERREACH. Keep proper footing and balance at all

times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for

better and safer performance. Follow instructions for lubricating

and changing accessories. Inspect tool cords periodically and if

damaged, have repaired by authorized service facility. Inspect

extension cords periodically and replace if damaged. Keep handles

dry, clean, and free from oil and grease.

• DISCONNECT OR LOCK OFF TOOLS when not in use, before

servicing, and when changing accessories, such as blades, bits,

cutters.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed

from tool before turning it on.

• AVOID UNINTENTIONAL STARTING. Don’t carry tool with finger

on switch. Be sure switch is off when plugging in.

• EXTENSION CORDS. Make sure your extension cord is in good

condition. When using an extension cord, be sure to use one heavy

enough to carry the current your product will draw. An undersized

cord will cause a drop in line voltage resulting in loss of power and

overheating. The following table shows the correct size to use

depending on cord length and nameplate ampere rating. If in

doubt, use the next heavier gage. The smaller the gage number,

the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0-6 18161614

6 - 10 18 16 14 12

10-1216161412

12 - 16 14 12 Not Recommended

• OUTDOOR USE EXTENSION CORDS. When tool is used

outdoors, use only extension cords intended for use outdoors and

so marked.

• STAY ALERT. Watch what you are doing. Use common sense. Do

1

English

154728-01 rev 9/10/02 2:23 PM Page 1

Page 5

2

not operate tool when you are tired.

• CHECK DAMAGED PARTS. Before further use of the tool, a guard

or other part that is damaged should be carefully checked to

determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized service

center unless otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by authorized service

center. Do not use tool if switch does not turn it on and off.

Additional Safety Instructions for Rotary

Hammers

• WEAR SAFETY GOGGLES or other eye protection.

• WEAR EAR PROTECTORS when hammering for extended

periods.

• ALWAYS USE THE SIDE HANDLE supplied with the tool. Keep a

firm grip on the hammer when it is operating.

• DON’T OVERREACH. Maintain a firm, balanced working stance.

When necessary, use only properly positioned, safe platforms,

ladders and scaffolds, to do the job safely.

• Hammer bits and tools get hot in operation. Wear gloves when

touching them.

• CAUTION: When drilling or driving into walls, floors or wherever

“live” electrical wires may be encountered, DO NOT TOUCH ANY

FRONT METAL PARTS OF THE TOOL! Hold the tool only by the

plastic handle to prevent shock if you drill or drive into a “live” wire.

SAVE THESE INSTRUCTIONS FOR

FUTURE USE

English

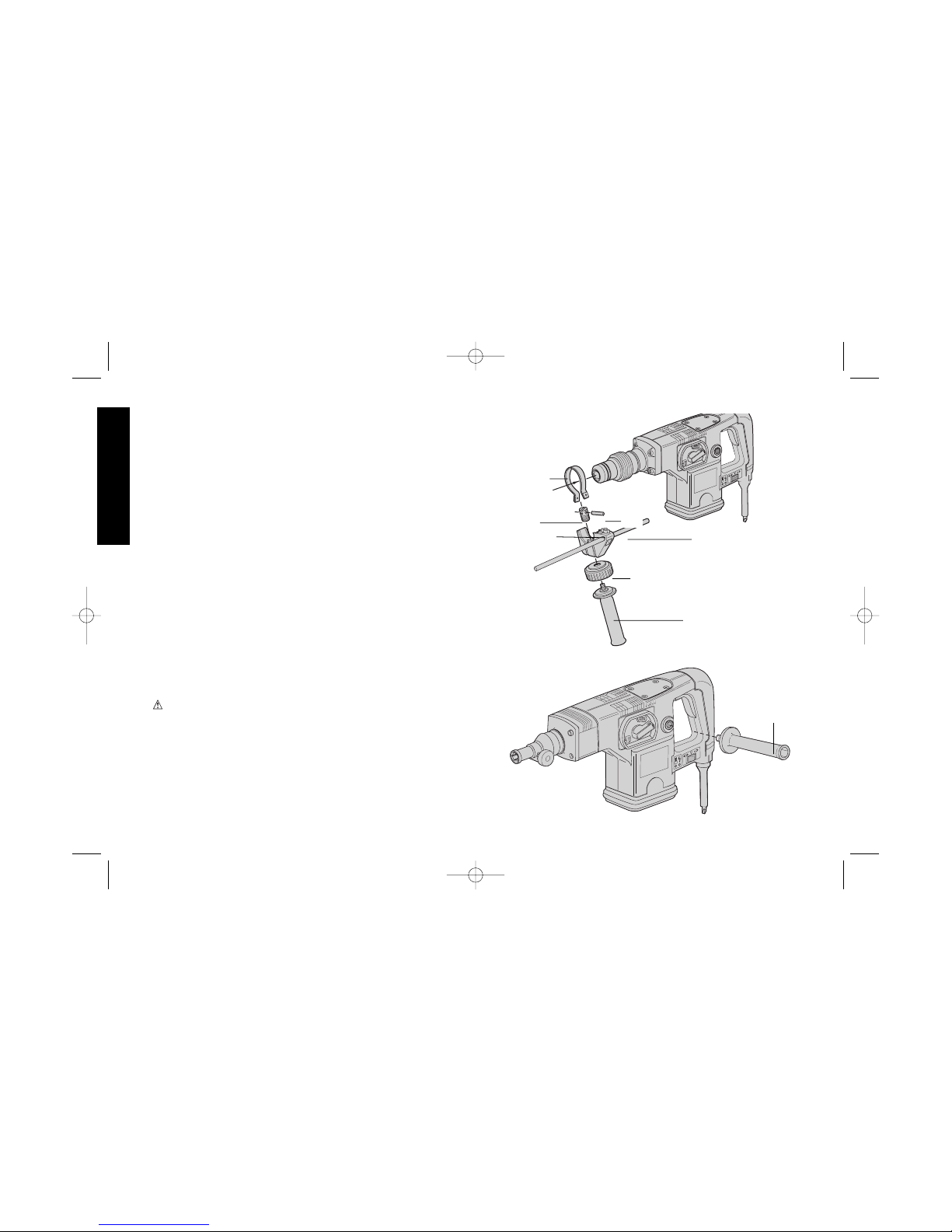

FIG. 1

FIG. 2

STEEL RING

BUSH

PIN

DEPTH ROD

CLAMP NUT

CLAMP KNOB

SIDE HANDLE

SIDE HANDLE

154728-01 rev 9/10/02 2:23 PM Page 2

Page 6

Motor

Your tool is powered by a D

EWALT built motor. Be sure your power

supply agrees with nameplate marking.

Voltage decrease of more than 10% will cause loss of power and

overheating. All D

EWALT tools are factory tested; if this tool does not

operate, check the power supply.

Side Handle and Depth Rod

For operating convenience, the side handle can be installed in front

or rear positions. Always operate the tool with the side handle

properly assembled.

TO MOUNT IN FRONT POSITION (FIG. 1)

1. Unscrew the side handle and disassemble the side handle clamp.

2. Snap the steel ring over the collar behind the tool holder. Squeeze

both ends together, mount the bush and insert the pin.

3. Place the side handle clamp and screw on the clamp knob. Do not

tighten.

4. Insert adjustable depth rod into hole.

5. Screw the side handle into the clamp knob and tighten it.

6. Rotate the side handle mounting assembly to the desired position.

For drilling horizontally with a heavy drill bit, place the side handle

assembly at an angle of approximately 20˚ for optimum control.

7. Lock the side handle mounting assembly in place by tightening the

clamp knob.

TO MOUNT IN REAR POSITION (FIG. 2)

1. Unscrew the side handle and remove it from the front position.

Leave the side handle mounting assembly in front position so that

the depth adjustment rod can still be used.

2. Screw the side handle directly into one of the rear side handle

positions on either side of the tool.

3

English

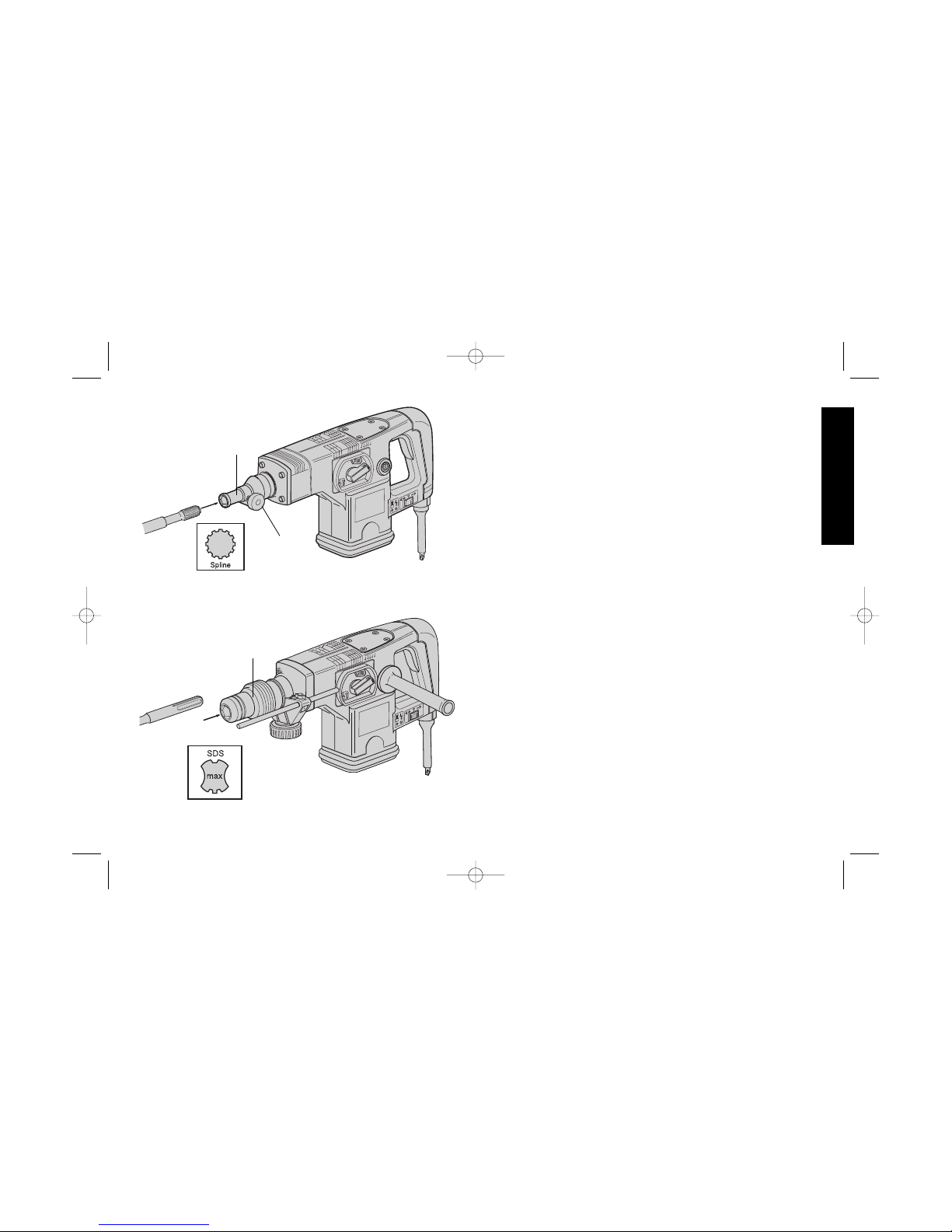

FIG. 3

FIG. 4

TOOL

HOLDER

RETAINING

PIN BUTTON

LOCKING

SLEEVE

154728-01 rev 9/10/02 2:23 PM Page 3

Page 7

4

TO ADJUST THE DEPTH ROD

1. Loosen clamp nut and insert bit into tool holder.

2. Push drill bit into a surface and adjust rod to desired depth of hole

(distance between bit tip and depth rod tip).

3. Tighten clamp nut.

NOTE: This adjustment can be made with or without side handle in

place.

Inserting and Removing Spline Drive

Accessories

FIG. 3: (DW531, DW530, DW532, DW533)

TURN OFF TOOL AND DISCONNECT FROM POWER SUPPLY.

1. Unlock the tool holder by pushing the retaining pin button and holding it

in.

2. Insert the bit shank into the tool holder as far as it will go.

3. Release the retaining pin button.

4. Pull on the bit to check if it is properly locked.

5. To remove a bit unlock the tool holder as described above.

Inserting and Removing SDS-max™

Accessories

FIG. 4: (DW541, DW540 AND DW545)

TURN OFF TOOL AND DISCONNECT FROM POWER SUPPLY.

1. Pull back the tool holder locking sleeve and insert the bit shank.

2. Turn the bit slightly until the sleeve snaps back in position.

3. Pull on the bit to check if it is properly locked. The hammering

function requires the bit to be able to move axially several

centimeters when locked in the tool holder.

4. To remove bit, pull back the tool holder locking sleeve and pull the

bit out of the tool holder.

English

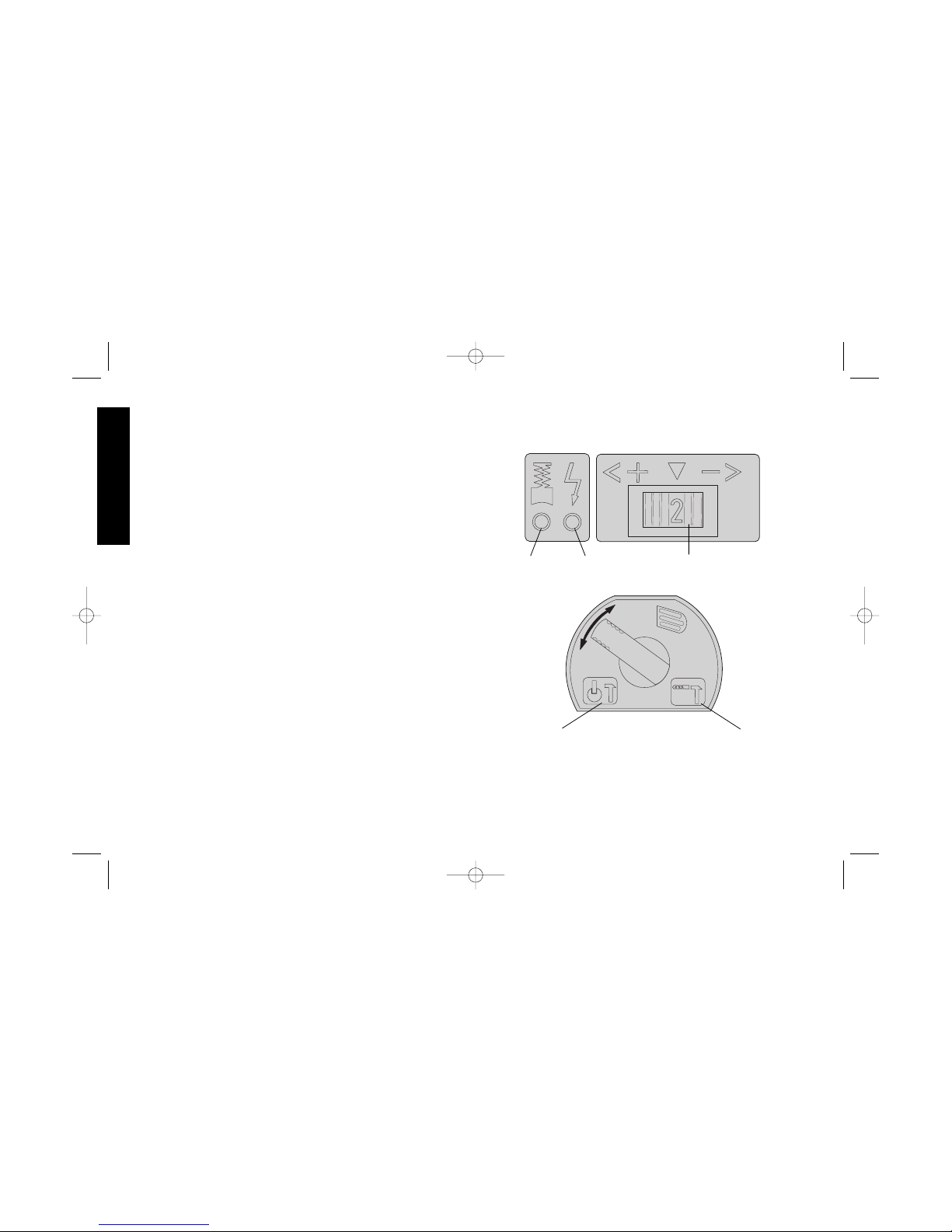

FIG. 5

FIG. 6

RED LED GREEN LED

ELECTRONIC SPEED /

IMPACT CONTROL

DIAL

HAMMER ONLY

WITH SPINDLE

LOCK

HAMMER DRILL

154728-01 rev 9/10/02 2:23 PM Page 4

Page 8

Soft Start Feature (DW541, DW532,

DW533, DW545)

The soft start feature allows you to build up speed slowly, thus

preventing the drill bit from walking off the intended hole position

when starting. The soft start feature also reduces the immediate

torque reaction transmitted to the gearing and the operator if the

hammer is started with the drill bit in an existing hole.

Torque Limiting Clutch

All rotary hammers are equipped with a torque limiting clutch that

reduces the maximum torque reaction transmitted to the operator in

the case of a jamming drill bit. This feature also prevents the gearing

and motor from stalling. The torque limiting clutch has been factory

set and cannot be adjusted.

Electronic Speed and Impact Control

(DW541, DW532, DW533, DW545)

(Fig. 5) The electronic speed and impact control allows the use of

smaller drill bits without the risk of bit breakage, drilling into light and

brittle materials without shattering, and optimal tool control for

precise chiseling. To set the control dial: Turn the dial to the desired

level. The higher the number, the greater the speed and impact

energy. With dial settings from “1” to “5” (full power) the tool is

extremely flexible and adaptable for many different applications. The

required setting depends on the bit size and hardness of material

being drilled.

Mode Selector

(Fig. 6) Your rotary hammer (all units except DW530) can be used in

two operating modes: Hammer drilling (simultaneous rotating and

impacting for all concrete and masonry drilling operations) and

Hammering only with spindle lock (impacting only- for light

chipping, chiseling, and demolition applications. The chisel can be

locked into 8 different positions.

NOTE: Also in this mode, the hammer can also be used as a lever to

free a jammed drill bit.

To select the required operating mode, rotate the selector lever

over the safety lock until it covers the symbol.

SERVICE AND POWER INDICATOR LEDS (DW541, DW532,

DW533, DW545)

(Fig. 5) The RED service indicator LED lights up when the carbon

brushes are nearly worn out to indicate that the tool needs servicing.

After approximately 8 hours of use the motor will automatically be

shut off. Take the tool to a D

EWALT service location for routine

inspection and maintenance.

The GREEN power-ON indicator LED lights up when the tool is

switched ON. If the indicator LED is lit but the tool does not start, this

indicates a motor related problem. If the indicator LED does not light

up and the tool does not start, this indicates an ON/OFF switch or

cord related problem.

DRILLING WITH A SOLID BIT

1. Set the speed and impact control dial (DW541, DW532, DW533,

DW545).

2. Set the model selector to the “hammer drilling” position (for all

units except DW530).

3. Insert the appropriate drill bit.

4. Fit and adjust the side handle.

5. If necessary, set the drilling depth rod.

5

English

154728-01 rev 9/10/02 2:23 PM Page 5

Page 9

6

6. Mark the spot where the hole is to be drilled.

7. Place the drill bit on the spot and press the ON/OFF switch.

8. Push with only enough force until hammer beats smoothly. The

hammer only needs enough pressure or force to engage the

mechanism. Pushing harder will not make the hammer drill faster.

9. To stop the tool, release the ON/OFF switch. Always turn the tool

OFF when work is finished and before unplugging.

DRILLING WITH A CORE BIT

1. Turn the speed and impact control dial to the maximum torque

position. (DW541, DW532, DW533 DW545)

2. Set the model selector to the “hammer drilling” position (for all

units except DW530).

3. Fit and adjust the side handle.

4. Assemble the centering bit and adapter shank into core bit.

5. Place the centering bit on the spot and press the ON/OFF switch.

NOTE: Some core drills require the removal of centering bit after

about 1 cm of penetration. If so, remove and continue drilling.

6. When drilling through a structure thicker than the depth of the core

bit, break away the round cylinder of concrete or core inside the bit

at regular intervals. To avoid unwanted breaking away of concrete

around the hole, first drill a hole the diameter of the centering bit

completely through the structure. Then drill the cored hole halfway

from each side.

7. To stop the tool, release the ON/OFF switch. Always turn the tool

OFF when work is finished and before unplugging.

CHIPPING AND CHISELING

1. Set the model selector to the “hammering only with spindle lock”

position on all models except DW530 in which it is not necessary.

2. Set the impact control dial to desired impact energy.

3. Insert the appropriate chisel and rotate it by hand to lock it into the

desired position. For spline units, use a 3/4” hex x 21/32” round

insert tool and for SDS Max models use SDS Max insert tools.

4. Fit and adjust the side handle.

5. Press the ON/OFF switch and start working.

6. Push with enough force to keep bit from bouncing only. Pushing

harder will not increase chipping speed.

7. To stop the tool, release the ON/OFF switch. Always turn the tool

OFF when work is finished and before unplugging.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your distributor or local service center.

CAUTION: The use of any non-recommended accessory may be

hazardous.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information,

call 1-800-4-D

EWALT. This warranty does not apply to accessories

or damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may

have other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALT heavy duty industrial tool, simply return it to the participating

seller within 30 days for a full refund. Please return the complete unit,

transportation prepaid. Proof of purchase may be required.

English

154728-01 rev 9/10/02 2:23 PM Page 6

Page 10

7

Français

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET

OUTIL OU TOUT AUTRE OUTIL DEWALT, COMPOSER SANS

FRAIS LE NUMÉRO:

1 800 4-DEWALT (1 800 433-9258)

Importantes mesures de sécurité

AVERTISSEMENT : Afin de réduire les risques d’incendie, de

secousses électriques ou de blessures lorsqu’on utilise des outils

électriques, il faut toujours respecter les mesures de sécurité

suivantes.

LIRE TOUTES LES DIRECTIVES.

Mise à la terre

L’outil devrait être mis à la terre lors de son utilisation afin de protéger

l’utilisateur contre les risques de secousses électriques. L’outil est

doté d’un cordon trifilaire et d’une fiche à trois broches de type mis à

la terre qui s’insère dans une prise mise à la terre. Le conducteur vert

(ou vert et jaune) du cordon est le fil de mise à la terre. Ne jamais

raccorder le fil vert (ou vert et jaune) à une borne sous tension.

Lorsque l’outil est conçu pour recevoir une alimentation de moins de

150 volts, il est doté d’une fiche semblable à celle illustrée à la figure

A. Lorsque l’outil est conçu pour recevoir une alimentation variant

entre 150 et 250 volts, il est doté d’une fiche semblable à celle

illustrée à la figure D. On peut se procurer un adaptateur (fig. B et C)

pour brancher une fiche semblable à celle de la figure A dans des

prises à deux orifices. Il faut alors relier la tige, la cosse ou le

dispositif similaire de couleur verte à une mise à la terre permanente

(comme une prise bien mise à la terre). Il n’y a pas d’adaptateur pour

AB CD

BROCHE DE PRISE

MISE À LA TERRE

BROCHE DE PRISE

MISE À LA TERRE

PRISE MISE

À LA TERRE

DISPOSITIF DE

MISE À LA TERRE

ADAPTATEUR

INTERRUPTEUR

RÉGULATEUR DE

VITESSE ET DE FORCE

DE FRAPPE (MODÈLES

DW541, DW532, DW533 ET

DW545)

TÉMOINS D’ENTRETIEN ET DE

FONCTIONNEMENT(MODÈLES

DW541, DW532, DW533, DW540 ET

DW545)

PORTE-EMBOUT

POIGNÉE

LATÉRALE

SÉLECTEUR DE MODE DE

FONCTIONNEMENT

(TOUS LES MODÈLES

SAUF LE MODELE DW530)

154728-01 rev 9/10/02 2:23 PM Page 7

Page 11

8

la fiche illustrée à la figure D. L’ADAPTATEUR ILLUSTRÉ AUX

FIGURES B ET C NE PEUT PAS ETRE UTILISÉ AU CANADA.

Utiliser seulement des cordons de rallonge trifilaires qui acceptent

des fiches à 3 broches et des prises à 3 orifices qui acceptent la fiche

de l’outil. Remplacer ou réparer les cordons endommagés.

Mesures de sécurité pour tous les outils

• BIEN DÉGAGER LA SURFACE DE TRAVAIL. Des surfaces et

des établis encombrés peuvent être la cause de blessures.

• TENIR COMPTE DU MILIEU DE TRAVAIL. Protéger les outils

électriques de la pluie. Ne pas s’en servir dans des endroits

humides ou mouillés. Bien éclairer la surface de travail. Ne pas se

servir de l’outil en présence de liquides ou de vapeurs

inflammables.

• SE PROTÉGER CONTRE LES SECOUSSES ÉLECTRIQUES.

Éviter tout contact avec des objets mis à la terre, comme des

tuyaux, radiateurs, cuisinières, réfrigérateurs et autres objets du

genre.

• ÉLOIGNER LES ENFANTS. Tous les visiteurs doivent être tenus

à l’écart de l’aire de travail et il faut les empêcher de toucher à

l’outil ou au cordon de rallonge.

• RANGER LES OUTILS INUTILISÉS. Il faut ranger les outils dans

un endroit sec, situé en hauteur ou fermé à clé, hors de la portée

des enfants.

• NE JAMAIS FORCER L’OUTIL. Afin d’obtenir un rendement sûr et

efficace, utiliser l’outil à son rendement nominal.

• UTILISER L’OUTIL APPROPRIÉ. Ne jamais exiger d’un petit outil

ou d’un accessoire le rendement d’un outil de fabrication plus

robuste. Se servir de l’outil selon l’usage prévu.

• PORTER DES VÊTEMENTS APPROPRIÉS. Éviter de porter des

vêtements amples et des bijoux qui peuvent être happés par les

pièces en mouvement. Porter des gants de caoutchouc et des

chaussures à semelle antidérapante pour travailler à l’extérieur.

Protéger la chevelure si elle est longue.

• PORTER DES LUNETTES DE SÉCURITÉ. Porter également un

masque respiratoire si le travail de coupe produit de la poussière.

• NE PAS MANIPULER LE CORDON DE FAÇON ABUSIVE. Ne

pas transporter l’outil par le cordon ni tirer sur ce dernier pour le

débrancher de la prise. Éloigner le cordon des sources de chaleur,

des flaques d’huile et des arêtes tranchantes.

• ASSUJETTIR LA PIÈCE. Immobiliser la pièce à l’aide de brides

ou d’un étau. On peut alors se servir des deux mains pour faire

fonctionner l’outil, ce qui est plus sûr.

• NE PAS DÉPASSER SA PORTÉE. Toujours demeurer dans une

position stable et garder son équilibre.

• PRENDRE SOIN DES OUTILS. Conserver les outils propres pour

qu’ils donnent un rendement supérieur et sûr. Suivre les directives

concernant la lubrification et le remplacement des accessoires.

Inspecter régulièrement le cordon de l’outil et le faire réparer au

besoin à un atelier d’entretien autorisé. Inspecter régulièrement les

cordons de rallonge et les remplacer lorsqu’ils sont endommagés.

S’assurer que les poignées sont toujours propres, sèches et libres

de toute tache d’huile ou de graisse.

• DÉBRANCHER OU VERROUILLER EN POSITION HORS

TENSION LES OUTILS NON UTILISÉS. Respecter cette mesure

lorsqu’on ne se sert pas de l’outil, ou qu’on doit le réparer ou en

changer un accessoire (comme une lame, un foret ou un couteau).

• ENLEVER LES CLÉS DE RÉGLAGE. Prendre l’habitude de

vérifier si les clés de réglage ont été retirées avant de faire

démarrer l’outil.

• ÉVITER LES DÉMARRAGES ACCIDENTELS. Ne pas laisser le

doigt sur l’interrupteur lorsqu’on transporte l’outil. S’assurer que

l’interrupteur est à la position hors circuit lorsqu’on branche l’outil.

• CORDONS DE RALLONGE. S’assurer que le cordon de rallonge

est en bon état. Lorsqu’on se sert d’un cordon de rallonge,

s’assurer qu’il est de calibre approprié pour la tension nécessaire

au fonctionnement de l’outil. L’utilisation d’un cordon de calibre

inférieur occasionne une baisse de tension entraînant une perte de

Français

154728-01 rev 9/10/02 2:23 PM Page 8

Page 12

puissance et la surchauffe. Le tableau suivant indique le calibre

approprié selon la longueur du cordon et les mentions de la plaque

signalétique de l’outil. En cas de doute, utiliser un cordon de calibre

supérieur. Le chiffre indiquant le calibre est inversement

proportionnel au calibre du cordon.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0-6 18161614

6 - 10 18 16 14 12

10-1216161412

12 - 16 14 12 Non recommandé

• CORDONS DE RALLONGE PRÉVUS POUR L’EXTÉRIEUR.

Lorsque l’outil est utilisé à l’extérieur, ne se servir que d’un cordon

de rallonge conçu pour l’extérieur et portant la mention appropriée.

• DEMEURER VIGILANT. Travailler avec vigilance et faire preuve

de bon sens. Ne pas se servir de l’outil lorsqu’on est fatigué.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES. Avant de continuer à

utiliser l’outil, il faut vérifier si le protecteur ou toute autre pièce

endommagée remplit bien la fonction pour laquelle il a été prévu.

Vérifier l’alignement et les attaches des pièces mobiles, le degré

d’usure des pièces et leur montage, ainsi que tout autre facteur

susceptible de nuire au bon fonctionnement de l’outil. Faire réparer

ou remplacer tout protecteur ou toute autre pièce endommagée

dans un centre de service autorisé, sauf si le présent guide fait

mention d’un avis contraire. Confier le remplacement de tout

interrupteur défectueux à un centre de service autorisé. Ne jamais

se servir d’un outil dont l’interrupteur est défectueux.

Mesures de sécurité relatives aux

perceuses rotatives

• PORTER DES LUNETTES DE SÉCURITÉ ou tout autre

équipement protecteur pour les yeux.

• PORTER DES PROTEGE-TYMPANS lorsqu’on effectue des

travaux de perçage à percussion sur de longues périodes.

• TOUJOURS UTILISER LA POIGNÉE LATÉRALE fournie avec

l’outil. Saisir fermement l’outil en service.

• NE PAS DÉPASSER SA PORTÉE. Toujours demeurer dans une

position stable et garder son équilibre. Le cas échéant, se servir

uniquement de plates-formes, d’échelles et d’échafauds

sécuritaires afin de travailler en toute sécurité.

• Les outils et les accessoires deviennent chauds au toucher

lorsqu’on s’en sert. Porter des gants pour y toucher.

• MISE EN GARDE : Lorsqu’on perce ou qu’on visse dans les

murs, les planchers ou tout autre endroit où peuvent se trouver des

fils sous tension, NE PAS TOUCHER AUX COMPOSANTS

MÉTALLIQUES À L’AVANT DE L’OUTIL. Ne le saisir que par ses

poignées en plastique afin de se protéger des secousses

électriques que provoqueraient le contact du foret avec un fil sous

tension.

CONSERVER CES MESURES À TITRE

DE RÉFÉRENCE.

Moteur

Un moteur D

EWALT entraîne cet outil D

EWALT. Veiller à ce que la

tension d’alimentation soit conforme aux exigences de la plaque

signalétique de l’outil.

Une baisse de tension de plus de 10 p. 100 peut entraîner une perte

de puissance et la surchauffe. Tous les outils D

EWALT sont essayés

avant de quitter l’usine. Lorsque celui-ci refuse de fonctionner, vérifier

la source de courant électrique.

9

Français

154728-01 rev 9/10/02 2:23 PM Page 9

Page 13

10

Poignée latéral et jauge de profondeur

Par souci de commodité, la poignée latérale s’installe à l’avant ou à

l’arrière de l’outil. Se servir de l’outil seulement lorsque la poignée

latérale est bien installée.

INSTALLATION À L’AVANT (FIG. 1)

1. Dévisser la poignée latérale et en démonter le dispositif de

serrage.

2. Enclencher la bague en acier sur le collet derrière le porteembout. En serrer les extrémités l’une contre l’autre, installer la

douille et y insérer la tige.

3. Installer le dispositif de serrage de la poignée latérale et visser le

bouton de fixation en place. Ne pas serrer.

4. Insérer la jauge de profondeur réglable dans le trou.

5. Visser la poignée latérale dans le bouton de fixation et serrer

celui-ci.

6. Placer la poignée latérale à la position voulue. Pour percer à

l’horizontale à l’aide d’un gros foret, placer la poignée latérale à un

angle d’environ 20° afin d’en optimiser la maîtrise.

7. Verrouiller la poignée latérale en place en serrant le bouton de

fixation.

INSTALLATION À L’ARRIERE (FIG. 2)

1. Dévisser la poignée latérale et la retirer de la position avant.

Laisser le dispositif de montage de la poignée latérale dans la

position avant de façon à pouvoir se servir de la jauge de

profondeur.

2. Visser la poignée latérale directement dans l’une des positions à

l’arrière d’un côté ou de l’autre de l’outil.

RÉGLAGE DE LA JAUGE DE PROFONDEUR

1. Desserrer l’écrou de serrage et insérer le foret dans le porteembout.

2. Pousser le foret dans une surface et régler la jauge de profondeur

Français

FIG. 1

FIG. 2

BAGUE EN

ACIER

DOUILLE

TIGE

JAUGE DE

PROFONDEUR

ÉCROU DE

SERRAGE

BOUTON DE FIXATION

POIGNÉE

LATÉRALE

POIGNÉE

LATÉRALE

154728-01 rev 9/10/02 2:23 PM Page 10

Page 14

à la profondeur voulue pour le trou (la distance entre l’extrémité du

foret et celle de la jauge).

3. Resserrer l’écrou de serrage.

NOTE : Ce réglage peut se faire même si la poignée latérale n’est

pas en place.

Installation et retrait d’accessoires à tige

cannelée

FIG. 3 : (MODELES DW531, DW530, DW532 ET DW533)

METTRE L’OUTIL HORS TENSION ET LE DÉBRANCHER.

1. Déverrouiller le porte-embout en enfonçant le bouton de la tige de

retenue et en le maintenant enfoncé.

2. Insérer à fond la tige du foret.

3. Relâcher le bouton de la tige de retenue.

4. Tirer sur le foret pour s’assurer qu’il est bien bloqué.

5. Pour retirer le foret de l’outil, il suffit de déverrouiller le porteembout de la manière décrite précédemment.

Installation et retrait d’accessoires

SDS-max

FIG. 4 : (MODELES DW540, DW541 ET DW545)

METTRE L’OUTIL HORS TENSION ET LE DÉBRANCHER.

1. Tirer le manchon de verrouillage du porte-embout vers l’arrière et

insérer la tige du foret.

2. Faire tourner le foret légèrement jusqu’à ce que le manchon

s’enclenche en place.

3. Tirer sur le foret pour s’assurer qu’il est bien bloqué. En mode de

perçage à percussion, le foret doit pouvoir se déplacer de

plusieurs centimètres autour de son axe lorsqu’il est bloqué dans

le porte-embout.

11

Français

FIG. 3

FIG. 4

PORTE-EMBOUT

BOUTON DE

LA TIGE DE

RETENUE

MANCHON DE

VERROUILLAGE

154728-01 rev 9/10/02 2:23 PM Page 11

Page 15

12

4. Pour retirer le foret de l’outil, il suffit de tirer le manchon de

verrouillage du porte-embout vers l’arrière et de retirer le foret du

porte-embout.

Caractéristique de démarrage en douceur

(DW541, DW532, DW533 et DW545)

La caractéristique de démarrage en douceur permet à l’outil

d’accélérer graduellement afin d’éviter le déplacement du foret hors

de l’emplacement voulu pour le trou au moment du démarrage. Cette

caractéristique réduit également l’effet du couple immédiat transmis

aux engrenages et à l’utilisateur lorsque le foret se trouve dans un trou

existant au moment du démarrage du perçage à percussion.

Embrayage à limiteur de couple

Toutes les perceuses rotatives sont dotées d’un embrayage à limiteur

de couple afin de minimiser l’effet de couple maximal transmis à

l’utilisateur en cas de blocage du foret. Cette caractéristique prévient

également le calage du moteur et des engrenages. L’embrayage à

limiteur de couple est réglé en usine et on ne peut pas le régler.

Régulateur électronique de vitesse et de

force de frappe (Modèles DW541, DW532,

DW533 et DW545)

(FIG. 5) Le régulateur électronique de vitesse et de force de frappe

permet d’utiliser de petits forets sans risque de les briser, de percer

des matériaux légers et friables sans production d’éclats et de mieux

maîtriser l’outil afin de ciseler avec précision. Faire ce qui suit pour

régler le régulateur: Régler le cadran au niveau voulu. Plus le chiffre

est élevé, plus la vitesse et la force de frappe sont élevées. L’outil est

des pus souples et des plus adaptables pour de nombreuses

utilisations différentes grâce à des réglages variant de «1» à «5»

(pleine puissance). Le réglage varie en fonction de la dimension du

foret et de la dureté du matériau à percer.

Français

FIG. 5

FIG. 6

D.É.L.

ROUGE

D.É.L.

VERTE

RÉGULATEUR

ÉLECTRONIQUE DE VITESSE

ET DE FORCE DE FRAPPE

PERÇAGE À

PERCUSSION

SEULEMENT AVEC

ARBRE DE

VERROUILLAGE

PERCEUSE À

PERCUSSION

154728-01 rev 9/10/02 2:23 PM Page 12

Page 16

Sélecteur de mode de fonctionnement

(FIG. 6) La perceuse rotative (tous les modèles, sauf le

modèle DW530) peut servir en deux modes de fonctionnement : en

perçage à percussion (action simultanée de rotation et de frappe

pour percer le béton et la maçonnerie) et en perçage à percussion

avec l’arbre verrouillé (frappe seulement, pour les travaux légers de

burinage, de ciselage et de démolition). Le ciselage peut se faire en

8 positions différentes.

NOTE : Dans ce dernier mode, la perceuse peut également servir de

levier pour dégager un foret coincé.

Pour choisir le mode de fonctionnement voulu, faire tourner le

levier du sélecteur au-dessus du dispositif de verrouillage de sûreté

jusqu’à ce qu’il couvre le symbole.

TÉMOINS D’ENTRETIEN ET DE FONCTIONNEMENT À D.É.L.

(MODELES DW541, DW532, DW533 ET DW545)

(FIG. 5) Le témoin d’entretien à D.É.L. ROUGE s’allume lorsque les

balais sont presque usés afin d’indiquer qu’il faut les remplacer. Au

bout d’environ 8 heures d’utilisation après que le témoin se soit

allumé, le moteur s’arrête automatiquement. Confier l’outil au

personnel d’un centre de service D

EWALT pour lui faire subir une

inspection et un entretien de routine.

Le témoin de fonctionnement à D.É.L. VERTE s’allume lorsque l’outil

est mis sous tension. Lorsque le témoin s’allume mais que l’outil ne

démarre pas, cela signifie que le moteur est défectueux. Lorsque le

témoin ne s’allume pas et que l’outil ne démarre pas, cela signifie

que l’interrupteur ou le cordon est défectueux.

PERÇAGE À L’AIDE D’UN FORET PLEIN

1. Régler le régulateur de vitesse et de force de frappe (modèles

DW541, DW532, DW533 et DW545).

2. Régler le sélecteur de mode de fonctionnement au mode de

perçage à percussion (tous les modèles sauf le modèle DW530).

3. Insérer le foret approprié.

4. Régler la poignée latérale.

5. Le cas échéant, régler la jauge de profondeur.

6. Marquer l’emplacement du trou à percer.

7. Placer le foret sur l’emplacement et enfoncer l’interrupteur.

8. Pousser avec la force nécessaire jusqu’à ce que la frappe se

fasse en douceur. Il faut exercer seulement la pression nécessaire

pour engager le mécanisme. Une pression excessive n’accélère

pas le processus.

9. Pour arrêter l’outil, relâcher l’interrupteur. Toujours mettre l’outil

HORS TENSION à la fin des travaux et avant de le débrancher.

PERÇAGE À L’AIDE D’UN TRÉPAN CAROTTIER

1. Faire tourner le régulateur jusqu’à la position de couple maximal

(modèles DW541, DW532, DW533 et DW545).

2. Régler le sélecteur de mode de fonctionnement au mode de

perçage à percussion (tous les modèles sauf le modèle DW530).

3. Régler la poignée latérale.

4. Monter le foret de centrage et la tige de l’adaptateur sur le trépan

carottier.

5. Placer le foret de centrage sur la marque de l’emplacement et

enfoncer l’interrupteur.

NOTE : Dans le cas de certains trépans carottiers, il faut retirer le

foret de centrage lorsqu’il est enfoncé à environ 1 cm. Le cas

échéant, le retirer et continuer à percer.

6. Lorsqu’on perce une structure plus épaisse que la longueur du

trépan carottier, il faut briser à intervalles réguliers le cylindre de

béton qui se trouve dans le trépan. Afin d’éviter le bris non voulu

de béton autour du trou, il faut d’abord percer à travers toute la

structure un trou dont le diamètre correspond à celui du foret de

centrage. On perce ensuite la moitié du trou voulu de chaque côté

de la structure.

7. Pour arrêter l’outil, relâcher l’interrupteur. Toujours mettre l’outil

HORS TENSION à la fin des travaux et avant de le débrancher.

13

Français

154728-01 rev 9/10/02 2:23 PM Page 13

Page 17

14

BURINAGE ET CISELAGE

1. Choisir le mode de perçage à percussion avec l'arbre verrouillé

pour tous les modèles sauf le modèle DW530 pour lequel ce n'est

pas nécessaire.

2. Régler le régulateur à la force de frappe voulue.

3. Insérer le ciseau approprié et le faire tourner à la main jusqu'à ce

qu'il s'enclenche dans la position voulue. Dans le cas des forets à

tige cannelée, utiliser un outil d'insertion de 3/4 po hexagonal et

de 21/32 po rond. Dans les cas des modèles SDS Max, utiliser

un outil d'insertion SDS Max.

4. Régler la poignée latérale.

5. Enfoncer l'interrupteur et commencer à travailler.

6. User de la force nécessaire pour empêcher le ciseau de rebondir.

Une pression excessive n'accélère pas le processus.

7. Pour arrêter l'outil, relâcher l'interrupteur. Toujours mettre l'outil

HORS TENSION à la fin des travaux et avant de le débrancher.

Accessoires

Les accessoires recommandés pour l’outil sont vendus séparément

chez le distributeur ou au centre de service de la région.

MISE EN GARDE : L’utilisation de tout accessoire non

recommandé peut être dangereuse.

Reparations

Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil, n’en

confier la réparation, l’entretien et les rajustements (y compris

l’inspection des balais) qu’à un centre de service ou à un atelier

d’entretien autorisé n’utilisant que des pièces de rechange

identiques.

Garantie complète

Les outils industriels de service intensif D

EWALT sont garantis

pendant un an à partir de la date d’achat. Toute pièce d’un outil

D

EWALT qui s’avérait défectueuse en raison d’un vice de matière ou

de fabrication sera réparée sans frais. Pour obtenir de plus amples

renseignements sur les réparations couvertes para garantie,

composer le 1 (800) 4-D

EWALT. Il suffit de retourner l’outil complet à

un centre de service D

EWALT. La présente garantie ne couvre pas les

accessoires ni les avaries dues aux réparations tentées ou

effectuées par des tiers. Les modalités de la présente garantie

donnet des droits légaux spécifiques. L'utilisateur peut également

se prévaloir d'autres droits selon l'état ou la province qu'il habite.

En outre, la garantie suivante couvre les outils D

EWALT.

GARANTIE DE SATISFACTION DE 30 JOURS OU ARGENT

REMIS

Si, pour quelque raison que ce soit, l’outil ne donne pas entière

satisfaction, il suffit de le retourner où il a été acheté dans les 30 jours

suivant la date d’achat afin d’obtenir un remboursement intégral.

Prière de retourner l'outil complet port payé. Une preuve d'achat peut

être requise.

Français

154728-01 rev 9/10/02 2:23 PM Page 14

Page 18

Instrucciones importantes de seguridad

ADVERTENCIA: Es indispensable sujetarse a las precauciones

básicas de seguridad, con la finalidad de reducir el peligro de

incendio, choque eléctrico y lesiones personales, en todas las

ocasiones en que se utilicen herramientas eléctricas. Entre estas

precauciones se incluyen la siguientes:

LEA TODAS LAS INSTRUCCIONES

Instrucciones de aterrizaje

Esta herramienta debe conectarse a tierra para proteger al operador

de choques eléctricos. Esta unidad está equipada con un cordón

eléctrico de tres hilos aprobado y una clavija para aterrizaje de tres

patas para conectarse a la toma de corriente adecuada. El conductor

verde (o verde y amarillo) es el cable de tierra. Nunca conecte el

cable verde (o verde y amarillo) a una terminal viva. Si su unidad está

hecha para funcionar con menos de 150 volts, tiene una clavija

similar a la que se muestra en la figura A. Si es para usarse con

corriente de 150 a 250 volts, tiene una clavija como la que se

muestra en la figura D. Hay adaptadores, figuras B y C, para conectar

clavijas del tipo de la figura A a tomas de corriente para dos patas.

La oreja de color verde deberá conectarse a tierra permanente, tal

como una toma de corriente aterrizada adecuadamente. No hay

adaptadores para clavijas como la de la figura D. EL ADAPTADOR

MOSTRADO EN LAS FIGURAS B Y C NO ESTA HECHO PARA

USARSE EN CANADA.

15

Español

AB CD

PATA DE

CONEXION A

TIERRA

PATA DE

CONEXION A

TIERRA

TOMA DE

CORRIENTE

ATERRIZADA

MEDIO DE

ATERRIZAJE

ADAPTADOR

INTERRUPTOR DE

ENCENDIDO Y APAGADO

CONTROL DE VELOCIDAD

E IMPACTO (DW541,

DW532, DW533, DW545)

INDICADORES DE CORRIENTE Y

SERVICIO

(DW541, DW532, DW533, DW540,

DW545)

PORTA

HERRAMIENTA

MANGO

LATERAL

SELECTOR DE MODO

(TODAS LAS UNIDADES

EXCEPTO DW530)

Epecificaciones

(DW530, DW531, DW532, DW540, DW541)

Tensión de alimentación 120 V CA/CD

Potencia nominal: 1000 W

Consumo de corriente: 9,4 A

Frecuencia de operación: 50-60 Hz

(DW533, DW545)

Tensión de alimentación 120 V CA/CD

Potencia nominal: 1160 W

Consumo de corriente: 10,6 A

Frecuencia de operación: 50-60 Hz

154728-01 rev 9/10/02 2:23 PM Page 15

Page 19

16

Instrucciones de seguridad para todas las

herramientas

• CONSERVE LIMPIA LA ZONA DE TRABAJO. Las superficies y

los bancos con objetos acumulados en desorden propician los

accidentes.

• OTORGUE PRIORIDAD AL AMBIENTE DE TRABAJO. No deje

las herramientas eléctricas expuestas a la lluvia. No las utilice en

lugares inundados o mojados. Conserve bien iluminada la zona de

trabajo. No utilice la herramienta en presencia de líquidos o gases

inflamables.

• PROTEJASE CONTRA EL CHOQUE ELECTRICO. Evite el

contacto corporal con superficies aterrizadas, por ejemplo,

tuberías, radiadores, antenas y gabinetes de refrigeración.

• CONSERVE APARTADOS A LOS NIÑOS. No permita que los

visitantes toquen las herramientas o los cables de extensión. Los

visitantes deben estar alejados del área de trabajo.

• GUARDE LAS HERRAMIENTAS QUE NO EMPLEE. Las

herramientas que no se están utilizando deben guardarse en un

lugar seco y elevado o bajo llave, fuera del alcance de los niños.

• NO FUERCE LA HERRAMIENTA. Esta cumplirá su función mejor

y con más seguridad bajo las especificaciones para las que se

diseñó.

• EMPLEE LA HERRAMIENTA ADECUADA. No fuerce a una

herramienta pequeña o a sus dispositivos de montaje en un trabajo

de tipo pesado. No emplee la herramienta en una tarea para la que

no se diseñó.

• VISTASE DE LA MANERA ADECUADA. No tenga puestas ropas

o artículos de joyería flojos, pues podrían quedar atrapados por las

partes móviles de las herramientas. Se recomienda el empleo de

guantes de caucho y calzado antiderrapante cuando se trabaja al

aire libre. Cúbrase bien la cabeza para sujetarse el pelo si lo tiene

largo.

• COLOQUESE ANTEOJOS DE SEGURIDAD. Póngase también

una mascarilla contra el polvo si lo produce la operación que va a

efectuar.

• NO ABUSE DEL CABLE ELECTRICO. Nunca levante la

herramienta por el cordón ni tire de éste para desconectarlo del

enchufe. Apártelo del calor y los objetos calientes, las sustancias

grasosas y los bordes cortantes.

• SUJETE FIRMEMENTE LOS OBJETOS SOBRE LOS QUE

TRABAJE. Utilice prensas o tornillos de banco para sujetar bien

los objetos sobre los que va a trabajar. Esto ofrece mayor

seguridad que sujetar los objetos con la mano, y además deja

libres ambas manos para operar la herramienta.

• NO SE SOBREEXTIENDA. Conserve en todo momento bien

apoyados los pies, lo mismo que el equilibrio.

• CUIDE SUS HERRAMIENTAS. Conserve sus herramientas bien

afiladas y limpias para que funcionen mejor y con mayor

seguridad. Obedezca las instrucciones de lubricación y cambio

de accesorios. Inspeccione los cordones eléctricos con frecuencia

y, si los encuentra dañados, hágalos cambiar o reparar en un

centro de servicio autorizado. Revise también con frecuencia las

extensiones eléctricas y reemplácelas si están dañadas. Conserve

los mangos secos, limpios y libres de aceites y grasas.

• DESCONECTE LAS HERRAMIENTAS. Hágalo cuando no las

emplee, antes de darles servicio y cuando vaya a cambiarles

accesorios como seguetas, discos, brocas y otros dispositivos de

corte.

• RETIRE LAS LLAVES DE AJUSTE Y DE TUERCAS. Adquiera

el hábito de asegurarse de que se han retirado las llaves de ajuste

de la herramienta antes de accionarla.

• EVITE QUE LA HERRAMIENTA SE ACCIONE

ACCIDENTALMENTE. Nunca sostenga una herramienta con el

dedo en el interruptor si se encuentra conectada a la corriente

eléctrica. Asegúrese que el interruptor está en la posición de

“apagado” antes de conectarla.

• CABLES DE EXTENSION. Asegúrese que su extensión esté en

buenas condiciones. Cuando utilice un cordón de extensión,

asegúrese de emplear uno con el calibre suficiente para soportar

Español

154728-01 rev 9/10/02 2:23 PM Page 16

Page 20

la corriente necesaria para su producto. Una extensión con calibre

menor al necesario causará una caída en el voltaje de la línea,

resultando en pérdida de potencia y sobre calentamiento. El

cuadro siguiente muestra los calibres correctos para usarse de

acuerdo con la longitud de la extensión y el amperaje especificado.

Si tiene dudas, utilice el calibre siguiente, más pesado. Cuanto

más pequeño el número de calibre del alambre, mayor la

capacidad del cable.

Calibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7.62 7.63-15.24 15.25-30.48 30.49-45.72

240V 0-15.24 15.25-30.48 30.49-60.96 60.97-91.44

AMPERAJE

Más No más Calbre del cordón

de de

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No Recomendado

• EXTENSIONES PARA TRABAJOS A LA INTEMPERIE. Cuando

trabaje a la intemperie, utilice siempre cordones de extensión

diseñados exclusivamente para esta finalidad y marcados así.

• NO SE DISTRAIGA. Concéntrese en lo que está haciendo.

Recurra al sentido común. No opere ninguna herramienta si se

encuentra fatigado.

• VERIFIQUE LAS PARTES DAÑADAS. Antes de seguir

empleando cualquier herramienta, es indispensable verificar con

mucho cuidado que las guardas u otras partes dañadas puedan

operar de la manera adecuada para cumplir con su función.

Verifique la alineación de las partes móviles, la firmeza con que

deben encontrarse sujetas en sus montaduras, las partes rotas,

las propias montaduras y cualesquiera otros DETALLES que

pudieran afectar a la operación de la herramienta. Las guardas y

las otras partes que se encuentren dañadas deberán repararse

bien o cambiarse en un centro de servicio autorizado, a menos

que se diga otra cosa en el manual del usuario. Haga que se

cambien los interruptores dañados en un centro de servicio

autorizado. No emplee ninguna herramienta que tenga inutilizado

o estropeado el interruptor.

Instrucciones adicionales de seguridad

para rotomartillos

• UTILICE ANTEOJOS DE SEGURIDAD u otro tipo de protección

para los ojos.

• UTILICE PROTECTORES PARA LOS OIDOS cuando taladre por

periodos prolongados.

• EMPLEE SIEMPRE EL MANGO LATERAL que se le suministró

con la herramienta. Sujete bien la herramienta cuando esté en

operación.

• NO SE EXTIENDA MÁS ALLÁ DE SU PUNTO DE EQUILIBRIO.

Conserve una postura balanceada y firme. Utilice plataformas o

escaleras únicamente cuando sea necesario, para realizar el

trabajo de manera segura.

• Las brocas y otras herramientas de corte se calientan con la

operación. Utilice guantes cuando las toque.

• PRECAUCION: Cuando taladre o atornille en muros, suelos o

cualquier otro sitio en el que puedan encontrarse cables eléctricos

“vivos”, ¡NO TOQUE EL BROQUERO NI. CUALQUIER OTRA

PARTA METALICA FRONTAL DEL TALADRO! Sostenga el taladro

por las superficies aislantes para prevenir las descargas eléctricas

en el caso de hacer contacto con un cable “vivo”.

CONSERVE ESTAS INSTRUCCIONES PARA

REFERENCIAS FUTURAS

Motor

Se herramienta funciona con un motor D

EWALT integrado.

Asegúrese que la alimentación de corriente concuerde con la

marcada en la placa de identificación de la herramienta.

17

Español

154728-01 rev 9/10/02 2:23 PM Page 17

Page 21

18

Disminuciones en el voltaje mayores al 10% causarán pérdida de

potencia y sobre calentamiento. Todas las herramientas se prueban

en la fábrica, si esta herramienta no funciona, verifique la toma de

corriente.

Mango lateral y varilla de profundidad

Para mayor comodidad durante su operación, se puede instalar el

mango lateral en las posiciones delantera o trasera. Nunca opere la

herramienta sin el mango auxiliar instalado.

PARA MONTARLO EN LA POSICION FRONTAL (FIGURA 1)

1. Destornille el mango lateral y desarme el sujetador del mango

lateral.

2. Coloque el aro de acero sobre el collarín detrás del sujetador de

la herramienta. Una ambos extremos, instale el buje e inserte el

perno.

3. Coloque el sujetador del mango lateral y atorníllelo en la perilla.

No apriete.

4. Inserte la varilla de profundidad ajustable en el orificio.

5. Apriete el mango lateral a la perilla.

6. Gire el montaje del mango lateral hasta la posición que desee.

Para taladrar horizontalmente con una broca grande, coloque el

mango lateral a un ángulo aproximado de 20° para máximo

control.

7. Asegure el montaje del mango lateral apretando la perilla de

fijación.

PARA MONTARLO EN LA POSICION TRASERA (FIGURA 2)

1. Destornille el mango lateral y retírelo de la posición frontal. Deje

el montaje del mango en la posición delantera para poder seguir

utilizando la varilla de profundidad.

2. Atornille el mango lateral directamente en una de las posiciones

traseras a cualquiera de los lados de la herramienta.

Español

FIG. 1

FIG. 2

ARO DE

ACERO

BUJE

PERNO

VARILLA DE

PROFUNDIDAD

TUERCA DE

SUJECION

PERILLA DE FIJACION

MANGO

LATERAL

MANGO

LATERAL

154728-01 rev 9/10/02 2:23 PM Page 18

Page 22

PARA AJUSTAR LA VARILLA DE PROFUNDIDAD

1. Afloje la tuerca de seguridad e inserte la broca en el broquero.

2. Empuje la broca en una superficie y ajuste la varilla a la

profundidad que desee (la distancia será la que quede entre la

punta de la broca y la punta de la varilla de profundidad).

3. Apriete la tuerca de seguridad.

NOTA: Este ajuste puede realizarse con el mango lateral en su sitio o

sin él.

Instalación y remoción de accesorios con

cuadro de mando ranurado

FIGURA 3: (DW531, DW530, DW532, DW533)

APAGUE LA HERRAMIENTA Y DESCONECTELA DE LA TOMA

DE CORRIENTE.

1. Quite el seguro al broquero oprimiendo el botón del perno retén y

conservándolo oprimido.

2. Inserte el vástago de la broca en el broquero tanto como sea

posible.

3. Suelte el botón del perno retén.

4. Tire de la broca para verificar que esté asegurada

apropiadamente.

5. Para quitar una broca, quite el seguro del broquero como se

describe anteriormente.

Instalación y remoción de accesorios SDSMax

FIGURA 4: (DW540, DW541 Y DW545)

APAGUE LA HERRAMIENTA Y DESCONECTELA DE LA TOMA

DE CORRIENTE.

1. Tire hacia atrás del mango de seguridad del broquero e inserte el

vástago del accesorio.

19

Español

FIG. 3

FIG. 4

PORTA

HERRAMIENTA

BOTON DEL

PERNO

RETEN

MANGO DE

SEGURIDAD

154728-01 rev 9/10/02 2:23 PM Page 19

Page 23

20

2. Gire ligeramente la broca hasta que el mango de seguridad se

devuelva a su posición natural.

3. Tire de la broca para verificar que esté asegurada

apropiadamente. La función de martillo requiere que la broca

pueda moverse de manera axial varios centímetros cuando esté

asegurada en el broquero.

4. Para sacar el accesorio, tire hacia atrás del mango de seguridad

del broquero y saque la broca del broquero.

Encendido suave (DW541, DW532, DW533,

DW545)

La característica de encendido suave le permite incrementar la

velocidad lentamente, evitando por consiguiente que la broca se

deslice de la posición en que se pretende iniciar un barreno. Esta

característica reduce también la reacción inmediata de torque

transmitido a los engranes y al operador si el rotomartillo se enciende

con la broca dentro de una barreno preexistente.

Embrague de par limitado

Todos los rotomartillos están equipados con un embrague de par

limitado que reduce la reacción máxima de torque transmitida al

operador en caso de que una broca se atasque. esta característica

también evita que el motor y los engranes se atasquen. El embrague

de par limitado se ajusta en la fábrica y no se puede alterar.

Control electrónico de velocidad e impact

(DW541, DW532, DW533, DW545)

(FIGURA 5) El control electrónico de velocidad e impacto permite el

uso de brocas más pequeñas evitando el riesgo de fractura, perforar

materiales ligeros y quebradizos sin astillar, y un control óptimo del

torque para cincelar con precisión. Para ajustar la perilla de

control: Gire la perilla al nivel deseado. Mientras mayor sea el

Español

FIG. 5

FIG. 6

LED

ROJO

LED

VERDE

CONTROL ELECTRONICO

DE VELOCIDAD E

IMPACTO

MARTILLO CON

SEGURO EN LA

FLECHA

ROTOMARTILLO

154728-01 rev 9/10/02 2:23 PM Page 20

Page 24

número, mayores serán la velocidad y el impacto. Con las posiciones

1 a 5 (máximo poder) de la perilla, la herramienta es

extremadamente flexible y adaptable a diversas aplicaciones. El

ajuste requerido depende del tamaño de la broca y de la dureza del

material que se piense barrenar.

Selector de modo

(FIGURA 6) Su rotomartillo (todas las unidades excepto el DW530)

puede utilizarse en dos modos de operación: Rotomartillo (rotación

e impacto simultáneos para todas las operaciones de perforación de

concreto y mampostería) y Acción de martillo con el seguro de la

flecha (solamente impacto- para aplicaciones ligeras de astillado,

cincelado y demolición). El cincel se puede asegurar en 8 posiciones

diferentes.

NOTA: En este modo, el rotomartillo puede utilizarse también como

palanca para liberar una broca atascada.

Para seleccionar el modo de operación gire el selector que se

encuentra sobre el seguro hasta que cubra el símbolo deseado.

LEDs INDICADORES DE SERVICIO Y ALIMENTACION (DW541,

DW532, DW533, DW545)

(FIGURA 5) El LED ROJO de indicación de servicio se enciende

cuando los carbones están cerca de desgastarse por completo para

indicar que la herramienta requiere servicio. Después de

aproximadamente 8 horas de uso, el motor se apagará

automáticamente. Lleve la herramienta a un centro de servicio

D

EWALT para una inspección de rutina y mantenimiento.

El LED VERDE de indicación de alimentación se enciende al

encender la unidad. Si el LED se enciende pero la herramienta no

arranca, se indica un problema relacionado con el motor. Si el LED

no enciende y la herramienta no arranca, se indica un problema

relacionado con el interruptor o el cable.

TALADRADO CON UNA BROCA SOLIDA

1. Ajuste la perilla de control de velocidad e impacto (DW541,

DW532, DW533, DW545).

2. Coloque el selector de modo en la posición de rotomartillo (para

todas las unidades excepto el DW530).

3. Coloque la broca apropiada.

4. Coloque y ajuste el mango lateral.

5. Ajuste la varilla de profundidad en caso necesario.

6. Marque el punto donde hará el barreno.

7. Coloque la broca en el punto y oprima el interruptor.

8. Empuje con fuerza suficiente hasta que el rotomartillo golpee

suavemente. El rotomartillo solamente necesita presión o fuerza

suficientes para activar el mecanismo. Empujar con más fuerza

no hará que el rotomartillo perfore más rápidamente.

9. Para detener la herramienta, suelte el interruptor. Siempre

apague el interruptor al terminar el trabajo y antes de desconectar

el rotomartillo.

TALADRADO CON BROCAS TUBULARES

1. Gire el control de velocidad e impacto a la posición de torque

máximo (DW541, DW532, DW533, DW545).

2. Coloque el selector de modo en la posición de rotomartillo (para

todas las unidades excepto el DW545).

3. Coloque y ajuste el mango lateral.

4. Ensamble el centro y el adaptador de vástago de la broca tubular.

5. Coloque el centro en el punto y oprima el interruptor.

NOTA: Algunas brocas tubulares requieren que se retire el centro

después de haber penetrado aproximadamente 1 cm. En tal caso,

quítelo y continúe perforando.

6. Cuando perfore a través de una estructura con espesor mayor a

la profundidad de la broca tubular, elimine el cilindro de concreto

que se forma dentro de la broca a intervalos regulares. Para evitar

21

Español

154728-01 rev 9/10/02 2:23 PM Page 21

Page 25

22

que el concreto se fracture alrededor del barreno, taladre primero

un orificio con el diámetro del centro que pase a través de la

estructura completa, y a continuación utilice la broca tubular

haciendo la mitad del barreno desde cada lado.

ASTILLADO Y CINCELADO

1. Coloque el selector de modo en la posición de “martillo con

seguro en la flecha” en todos los modelos excepto el DW530, en

el que no es necesario.

2. Ajuste el control de velocidad e impacto en el punto que desee.

3. Inserte el cincel apropiado y gírelo a mano para asegurarlo en la

posición deseada. Para unidades ranuradas, utilice un inserto de

3/4” hexagonal x 21/32” redondo (19 x 16,6 mm) y para los

modelos SDS Max utilice insertos SDS Max.

4. Coloque y ajuste el mango lateral.

5. Oprima el interruptor e inicie el trabajo.

6. Empuje con fuerza suficiente únicamente para evitar que rebote.

Empujar con más fuerza no aumentará la velocidad de astillado.

7. Para detener la herramienta, suelte el interruptor. Siempre

apague el interruptor al terminar el trabajo y antes de desconectar

el rotomartillo.

Accesorios

Dispone usted de los accesorios recomendados para su herramienta

con cargo adicional con su distribuidor local autorizado.

PRECAUCION: El empleo de cualquier accesorio no

recomendado puede ser peligroso.

Reparaciónes

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán

hacerse reparaciones, mantenimiento y ajustes de esta herramienta

en los centros de servicio para herramientas industriales de D

EWALT.

u otras organizaciones calificadas. Estas organizaciones prestan

servicio a las herramientas DEWALT y emplean siempre refacciones

legítimas D

EWALT.

PARA REPARACION Y SERVICIO DE SUS HERRAMIENTAS

ELECTRICAS FAVOR DE DIRIGIRSE AL CENTRO DE SERVICIO MAS

CERCANO

CULIACAN

Av. Nicolas Bravo #1063 Sur (91 671) 242 10

GAUDALAJARA

Av. La Paz #1770 (91 3) 826 69 78.

LEON

Polara #32 (91 471) 314 56

MEXICO

Sonora #134 Hiprodromo Condesa 553-9979

MERIDA

Calle 63 #459 (91 99) 23 54 90

MONTERREY

Av. Francisco I. Madero Pte. 1820-A (91 83) 72 11 25

PUEBLA

17 Norte #2057 (91 22) 46 90 20

QUERETARO

Av. Madero 139 Pte. (91 42) 14 60 60

SAN LOUIS POTOSI

Pedro Moreno #408 Fracc. la Victoria (91 48) 14 25 67

TORREON

Blvd. Independencia, 96 pte. (91 17) 16 52 65

VERACRUZ

Prolongación Diaz Miron #4280 (91 29) 21 70 18

VILLAHERMOSA

Zaragoza #105 (91 93) 12 53 17

PARA OTRAS LOCALIDADES LLAME AL: 326 7100

Español

154728-01 rev 9/10/02 2:23 PM Page 22

Page 26

Garantía Completa

Las herramientas industriales D

EWALT están garantizadas durante un año a

partir de la fecha de compra. Repararemos, sin cargos, cualquier falla debida

a material o mano de obra defectuosos. Por favor regrese la unidad completa,

con el transporte pagado, a cualquier Centro de Servicio para Herramientas

Industriales de DEWALT o a las estaciones de servicio autorizado enlistadas

bajo "Herramientas Eléctricas" en la Sección Amarilla. Esta garantía no se

aplica a los accesorios ni a daños causados por reparaciones efectuadas

por terceras personas. Esta garantía le otorga derechos legales específicos,

y usted puede tener otros derechos que pueden variar de estado a estado.

En adición a la garantía, las herramientas D

EWALT están amparadas por

nuestra:

GARANTÍA DE SATISFACCIÓN SIN RIESGO POR 30 DÍAS

Si usted no se encuentra completamente satisfecho con el desempeño de

su herramienta industrial D

E

WALT, sencillamente devuélvala a los

vendedores participantes durante los primeros 30 días después de la fecha

de compra para que le efectúen un reembolso completo. Por favor regrese la

unidad completa, con el transporte pagado. Se puede requerir prueba de

compra.

23

Español

IMPORTADO: DEWALT S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. 326-7100

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

154728-01 rev 9/10/02 2:23 PM Page 23

Loading...

Loading...