Page 1

Questions? See us on the World Wide Web at www.dewalt.com

¿Dudas? Visítenos en Internet: www.dewalt.com

Dúvidas? Visite-nos na Internet em www.dewalt.com.br

INSTRUCTION MANUAL

MANUAL DE INSTRUCCIONES

MANUAL DE INSTRUÇÕES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR

EL PRODUCTO.

INSTRUÇÕES DE OPERAÇÃO, CENTRO DE SERVIÇOS E CERTIFICADO

DE GARANTIA. ADVERTÊNCIA: LEIA ESTAS INSTRUÇÕES ANTES DE

UTILIZAR O PRODUTO.

DW341

VS Orbital Jig Saw 3/4" (20 mm) Stroke

Sierra Caladora Orbital VV 20 mm (3/4") CPM

Serra Tico-Tico VV e Ação Orbital Comprimeto do Golpe 20 mm (3/4")

Page 2

Definitions: Safety Guidelines

The definitions below describe the level of severity for each

signal word. Please read the manual and pay attention to

these symbols.

DANGER: Indicates an imminently hazardous situa-

tion which, if not avoided, will result in death or serious

English

injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

CAUTION: Used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided, may

result in property damage.

General Safety Instructions

WARNING! Read and understand all instructions. Failure to

follow all instructions listed below, may result in electric shock,

fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust.

Power tools create sparks which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while operating

a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Grounded tools must be plugged into an outlet properly

installed and grounded in accordance with all codes and

ordinances. Never remove the grounding prong or modify

the plug in any way. Do not use any adaptor plugs. Check

with a qualified electrician if you are in doubt as to whether

the outlet is properly grounded. If the tools should electrically

malfunction or break down, grounding provides a low resistance

path to carry electricity away from the user. Applicable only to

Class I (grounded) tools.

• Double insulated tools are equipped with a polarized plug

(one blade is wider than the other.) This plug will fit in a

polarized outlet only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install a polarized outlet. Do not

change the plug in any way. Double insulation

the need for the three wire grounded power cord and grounded

power supply system. Applicable only to Class II (double

insulated) tools.

• Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk

of electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the

tools or pull the plug from an outlet. Keep cord away from

heat, oil, sharp edges or moving parts. Replace damaged

cords immediately. Damaged cords increase the risk of electric

shock.

• When operating a power tool outside, use an outdoor

extension cord marked “W-A” or “W.” These cords are rated

for outdoor use and reduce the risk of electric shock. When using

an extension cord, be sure to use one heavy enough to carry the

eliminates

1

1

Page 3

current your product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and overheating.

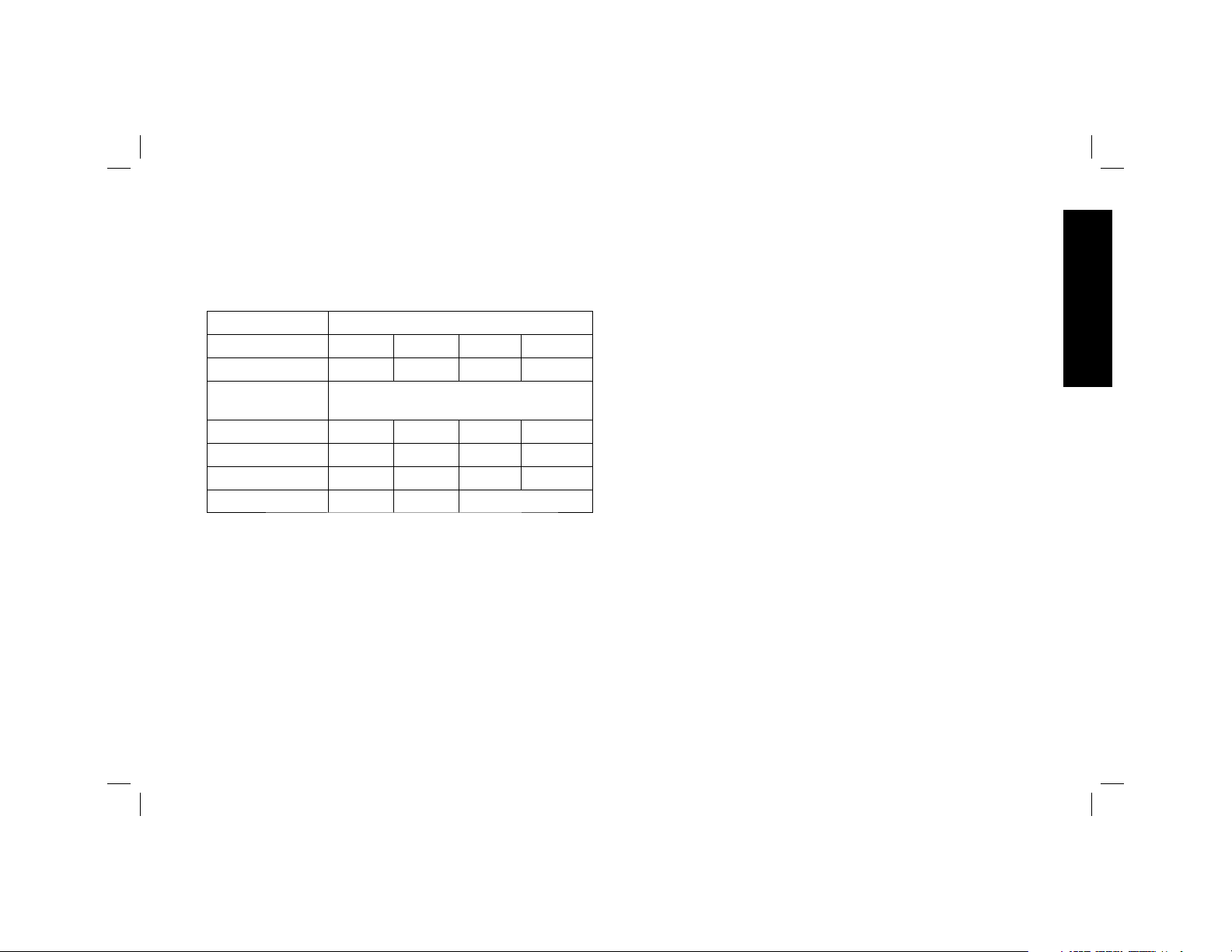

The following table shows the correct size to use depending on

cord length and nameplate ampere rating. If in doubt, use the

next heavier gauge. The smaller the gauge number, the heavier

the cord.

Voltage (Volts)

120 0 - 7 7 - 15 15 - 30 30 - 50

220 - 240V 0 - 15 15 - 30 30 - 60 60 - 100

Rated Ampere

range

0 - 6A 1.0 1.5 1.5 2.5

6 - 10A 1.0 1.5 2.5 4.0

10 - 12A 1.5 1.5 2.5 4.0

12 - 16A 2.5 4.0 Not Recommended

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use tool

while tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating power

tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves

away from moving parts. Loose clothing, jewelry, or long hair

can be caught in moving parts. Air vents often cover moving

parts and should also be avoided.

• Avoid accidental starting. Be sure switch is off before

plugging in. Carrying tools with your finger on the switch or

plugging in tools that have the switch on invites accidents.

Total length of cord in meters (m)

Minimal cross-sectional area of the

cord in meters (mm2 )

• Remove adjusting keys or wrenches before turning the tool

on. A wrench or a key that is left attached to a rotating part of

the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control of the

tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust

mask, non-skid safety shoes, hard hat, or hearing protection

must be used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support

the workpiece to a stable platform. Holding the work by

hand or against your body is unstable and may lead to loss of

control.

• Do not force tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate for

which it is designed.

• Do not use tool if switch does not turn it on or off. Any tool

that cannot be controlled with the switch is dangerous and must

be repaired.

• Disconnect the plug from the power source before making

any adjustments, changing accessories, or storing the tool.

Such preventative safety measures reduce the risk of starting

the tool accidentally.

• Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and

clean. Properly maintained tools, with sharp cutting edges are

less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage

of parts, and any other condition that may affect the tool’s

operation. If damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained tools.

English

2

2

Page 4

• Use only accessories that are recommended by the

manufacturer for your model. Accessories that may be

suitable for one tool, may become hazardous when used on

another tool.

SERVICE

• Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

English

personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement

parts. Follow instructions in the Maintenance section of

this manual. Use of unauthorized parts or failure to follow

maintenance instructions may create a risk of electric shock or

injury.

Additional Specific Safety Instructions

for Jig Saws

• Hold tool by insulated gripping surfaces when performing

an operation where the cutting tool may contact hidden

wiring or its own cord. Contact with a “live” wire will make

exposed metal parts of the tool “live” and shock the operator.

• Allow the motor to come to a complete stop before

withdrawing the blade from the kerf (the slot created by

cutting). A moving blade may impact the workpiece causing a

broken blade, workpiece damage or loss of control and possible

personal injury.

• Keep handles dry, clean, free from oil and grease. This will

enable better control of the tool.

• Keep blades sharp. Dull blades may cause the saw to swerve

or stall under pressure.

• Clean out your tool often, especially after heavy use. Dust

and grit containing metal particles often accumulate on interior

surfaces and could create an electric shock hazard.

• Do not operate this tool for long periods of time. Vibration

caused by the operating action of this tool may cause permanent

injury to fingers, hands, and arms. Use gloves to provide extra

cushion, take frequent rest periods, and limit daily time of use.

WARNING: Always wear eye protection while operating this

power tool.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber

(CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed

to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with soap

and water. Allowing dust to get into your mouth, eyes, or lay on

the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust,

which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face

and body.

WARNING: ALWAYS USE SAFETY GLASSES. Everyday

eyeglasses are NOT safety glasses. Also use face or dust mask if

cutting operation is dusty. All users and bystanders MUST ALWAYS

wear certified safety equipment:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

3

3

Page 5

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

CAUTION: Wear appropriate hearing protection during use.

Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

• The label on your tool may include the following symbols. The

symbols and their definitions are as follows:

V ............ volts A ............ amperes

Hz .......... hertz W ........... watts

min ......... m inutes

.......direct current

........... Class I Construction ........... earthing terminal

............... (grounded) ...........safety alert symbol

............Class II Construction …/min .... revolutions or

............... (double insulated) ..............reciprocation

BPM....... beats per minute

sfpm ...... surface feet

..............

per minute (sfpm) ..............

..........alternating current

n

o ........... no load speed

............... per minute

...............

SAVE THESE INSTRUCTIONS

Checking and changing the saw blade

• Only use saw blades conforming to the specifications contained

in these operating instructions.

• Only sharp saw blades in perfect working condition should be

used; cracked or bent saw blades should be discarded and

replaced at once.

• Ensure that the saw blade is securely fixed.

• The saw blade could be hot due to the work process. So when

changing the blade make sure that it is chilled, cooled off or

wear protective gloves when touching the blade.

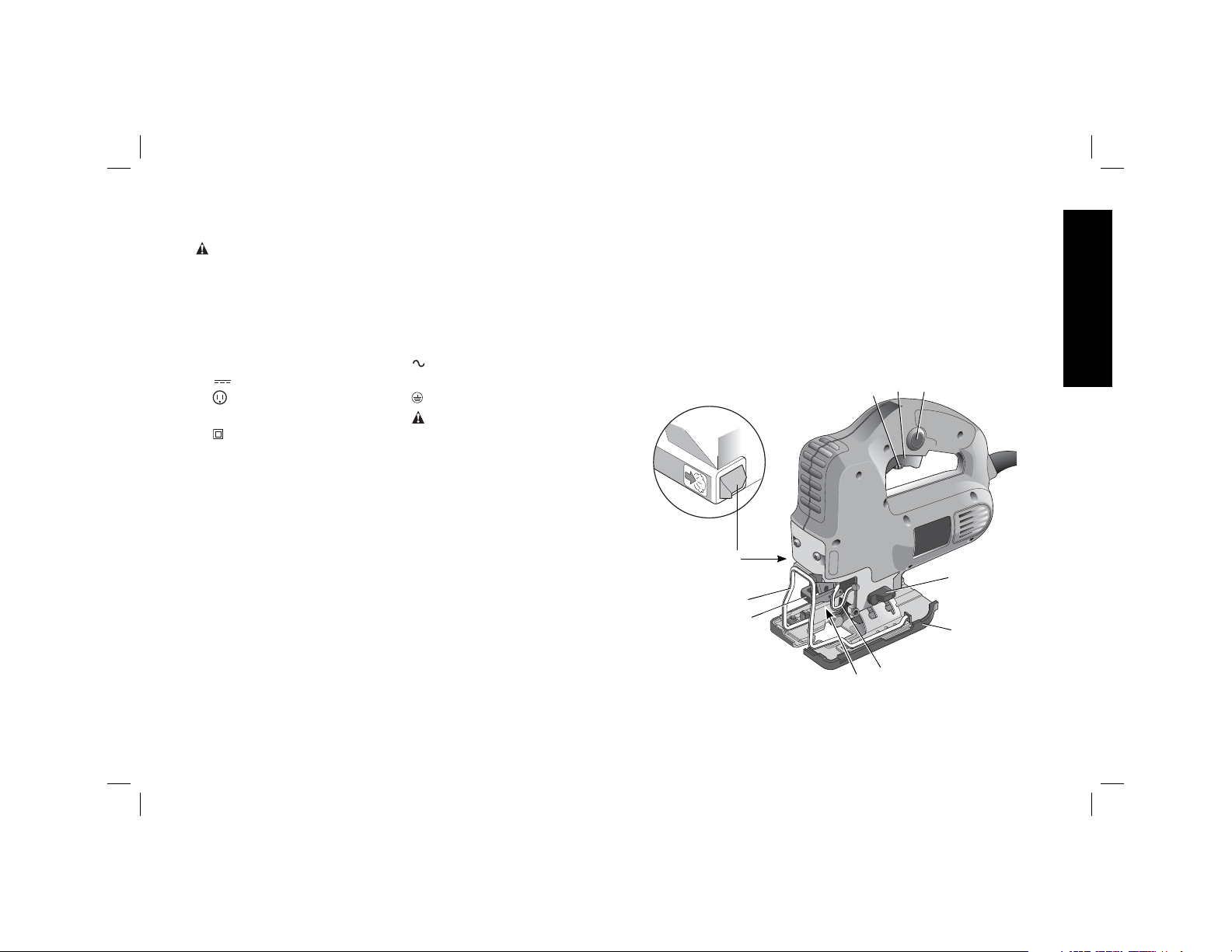

Description (fig. A)

Your jigsaw DW341

wood, steel, aluminium, plastic and ceramic material.

1 On/off switch 7 Blade holder

2 Lock-on button 8 Guide roller

3 Speed control dial 9 Shoe

4 Sawdust blower 10 Pendulum stroke selector

5 Blade latch

6 Finger guard

FIG. A

has been designed for professional cutting of

1

3

4

6

5

7

2

10

9

8

English

4

4

Page 6

Assembly and Adjustment

WARNING: Prior to assembly and adjustment always unplug the

tool.

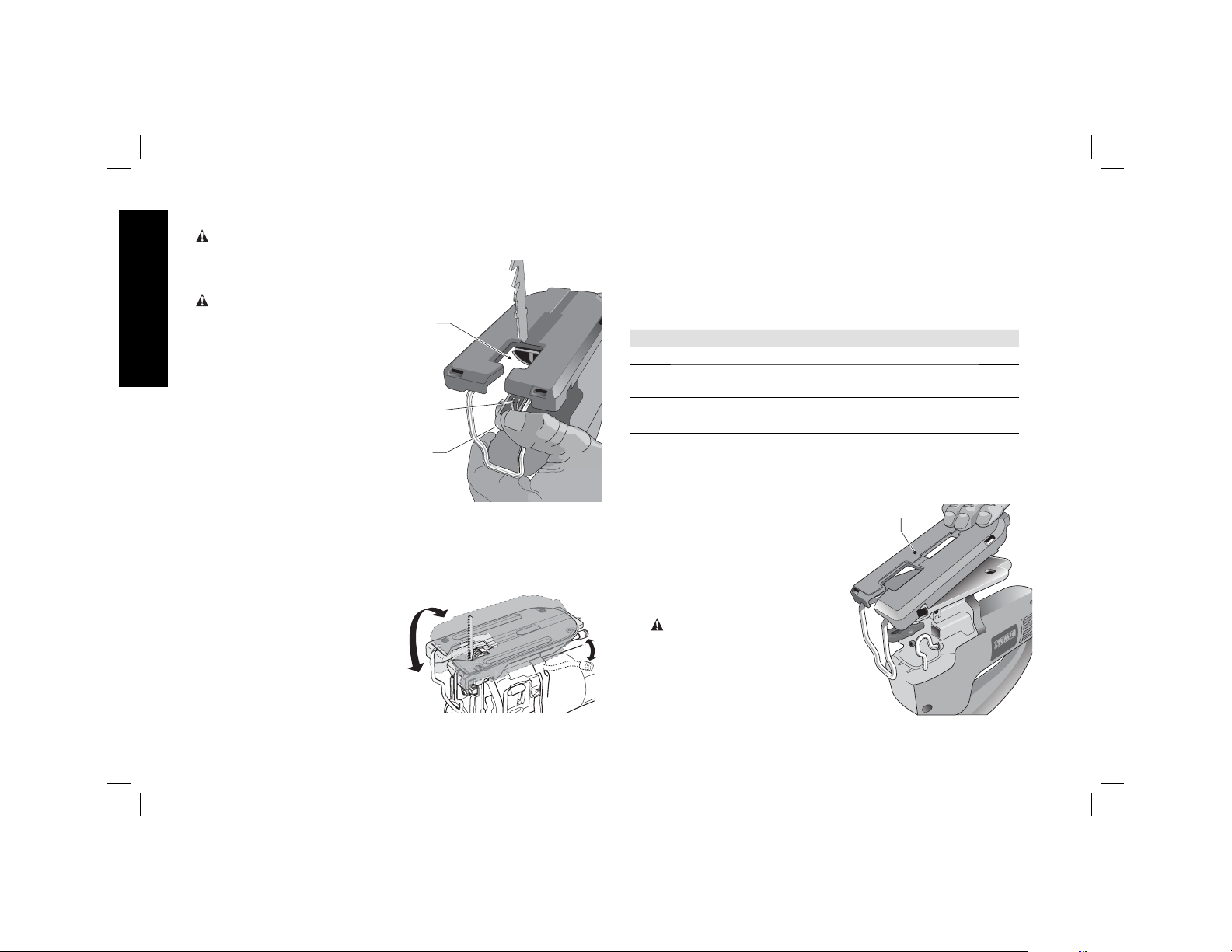

FITTING AND REMOVING A

SAW BLADE (FIG. B)

WARNING:The saw blade could

be hot due to the work process. So

English

when changing the saw blade

make sure that it is chilled cooled

off or wear protetive gloves when

touching the blade.

• The tool-free blade exchange

system ensures quick and

easy changing of saw blades.

• Open the blade holder (7) by

fully retracting the blade latch

(5).

• Insert the saw blade into the

blade holder (7) guiding the

back of the blade into the groove of the guide roller (8).

• Release the blade latch (5).

• To remove the saw blade, fully retract the blade latch and pull

the blade out of the holder.

SETTING THE BEVEL ANGLE

(FIG. C)

The adjustable shoe (9) allows

cutting of LH and RH bevel

angles up to 45°. The bevel scale

has preset positions at 0° and

45°.

• Slacken the screws (11) using

the supplied Torx wrench.

• Slide the shoe (9) toward the saw blade.

FIG. B

8

7

5

FIG. C

• Tilt the shoe and set the desired bevel angle using the scale.

• Tighten the screws.

SETTING THE PENDULUM STROKE (FIG. A)

The adjustable pendulum stroke guarantees a perfect cutting stroke

for different materials.

• Slide the selector (10) to the desired position referring to the

table below. The selector can be manipulated during operation.

Pos. Wood Metal Plastics

2 Fast cuts – PVC

2 Thick workpieces – Fibreglass

1 Plywood Aluminium –

Chipboard Non-ferrous –

0 Thin workpieces

Fine cuts

MOUNTING THE PLASTIC

ANTI-SCRATCH SHOE COVER

(FIG. D)

The anti-scratch shoe cover (12)

reduces damage to the surface of

(sensitive) workpieces.

• Click the cover onto the shoe

as shown.

Sheet metal –

FIG. D

12

Acrylic

Instructions for use

WARNING:

• Always observe the safety

instructions and applicable

regulations.

• Make sure your workpiece is

well secured. Remove nails,

screws and other fasteners

that may damage the blade.

5

5

Page 7

• Check that there is sufficient space for the blade underneath

the workpiece. Do not cut materials that exceed the maximum

cutting depth of the blade.

• Use sharp saw blades only. Damaged or bent saw blades

must be removed immediately.

• Do not use the tool for sawing pipes or tubes.

• Never run your tool without a saw blade.

• For optimal results, move the tool smoothly and constantly over

the workpiece. Do not exert lateral pressure on the saw blade.

Keep the shoe flat on the workpiece and lead the cord away

in line with the tool. When sawing curves, circles or other

round shapes, push the tool gently forward.

• Wait until the tool has come to a standstill before removing the

saw blade from the workpiece. After sawing the blade may be

very hot. Do not touch.

SWITCHING ON AND OFF (FIG. A)

• To run the tool, press the on/off switch (1).

• For continuous operation, press and hold down the switch (1),

press the lock-on button (2) and release the switch.

• To stop the tool, release the switch.

• To stop the tool in continuous operation, press the switch briefly

and release it. Always switch off the tool when work is finished

and before unplugging.

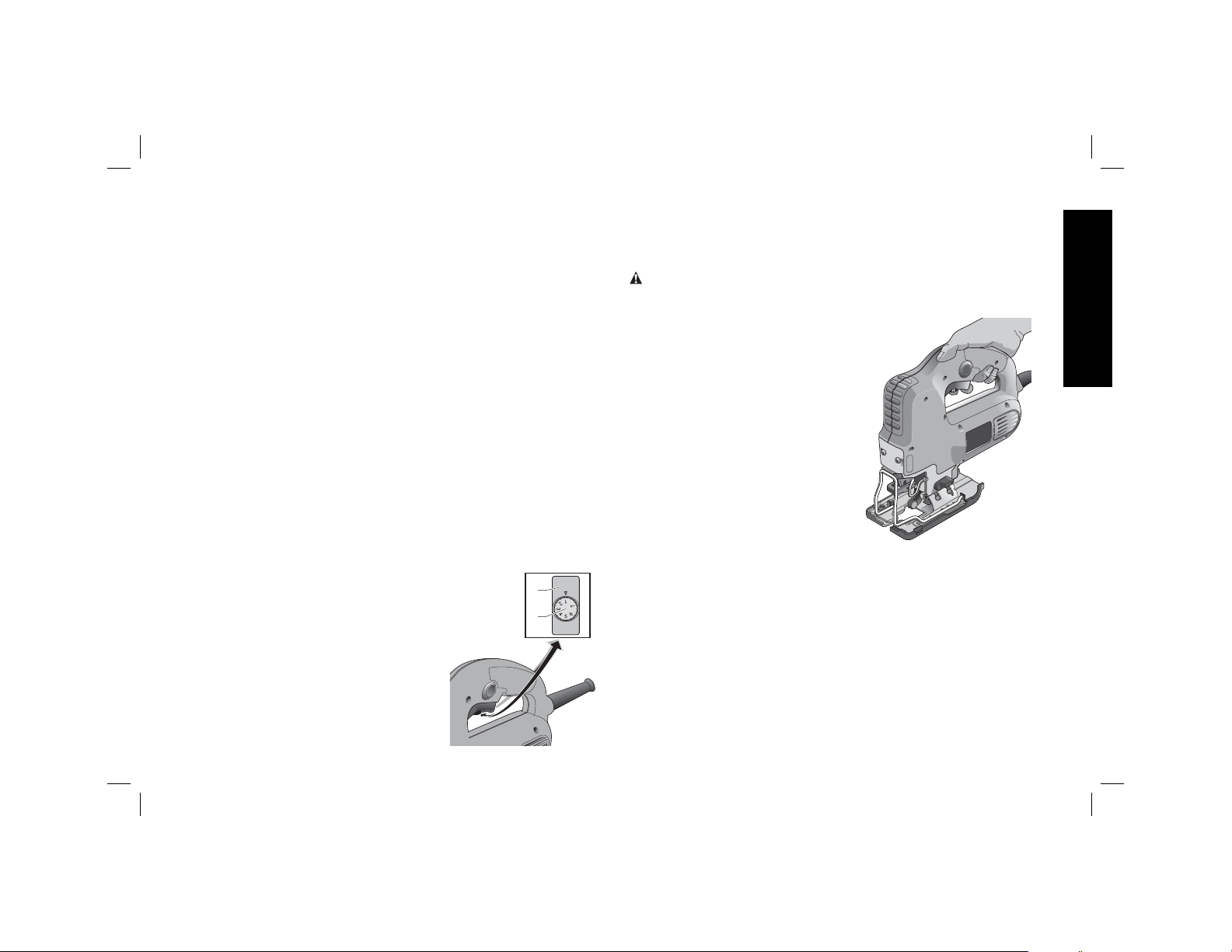

SETTING THE ELECTRONIC

SAWING SPEED (FIG. E)

FIG. E

1

3

The sawing speed varies with the

pressure exerted on the on/off switch

(1).

• To preset the sawing speed, turn the

control dial (3) to the desired level.

The higher the rate, the higher the

sawing speed. The required setting depends on the thickness

and kind of material.

• Use high speeds for sawing soft materials such as wood. Use

low speeds for sawing metal.

WARNING: After using the tool for an extended period on low

speed settings, run it for approx. 3 minutes on maximum no-load

speed.

HOLDING THE TOOL (FIG. F)

FIG. F

• Hold the tool as shown.

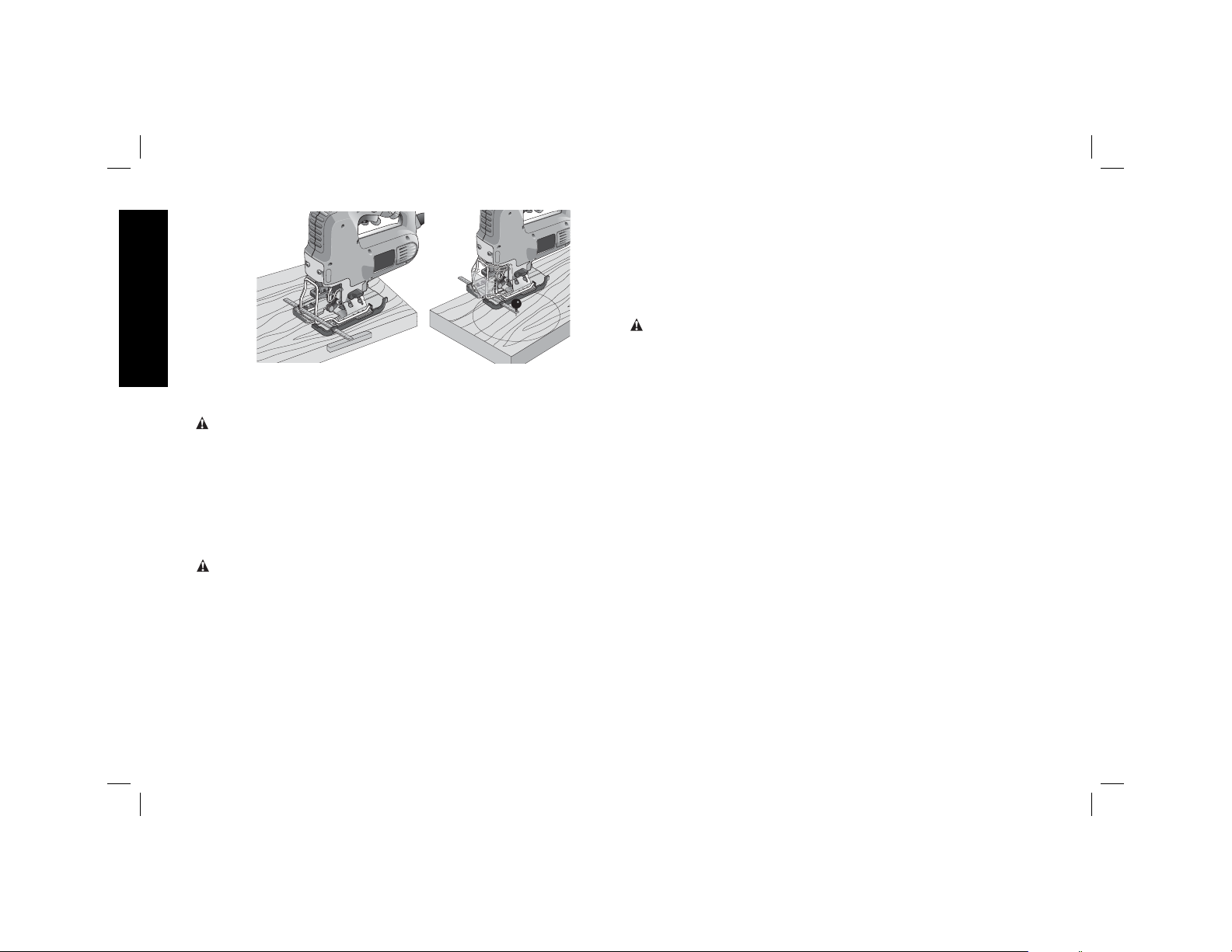

SAWING IN WOOD

• If necessary, draw a cutting line.

• Switch the tool on.

• Hold the tool against the

workpiece and follow the line.

• For sawing parallel to the edge

of your workpiece, install the

parallel fence and guide your

jigsaw along the workpiece a

shown in figure G.

SAWING IN WOOD USING A

PILOT HOLE

• If necessary, draw a cutting line.

• Drill a hole (ø min. 12 mm) and introduce the saw blade.

• Switch the tool on.

• Follow the line.

• For cutting perfectly round shapes, install the trammel bar and

set it to the required radius (fig. H).

English

6

6

Page 8

FIG. G

FIG. H

English

SAWING IN METAL

• Mount an appropriate saw blade.

• Proceed as described above.

WARNING: Use a cooling lubricant (cutting oil) to prevent

overheating of the saw blade or the workpiece.

MAINTENANCE

Your D E WALT power tool has been designed to operate over a

long period of time with a minimum of maintenance. Continuous

satisfactory operation depends upon proper tool care and regular

cleaning.

Cleaning

CAUTION: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool. These chemicals may

weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap.

Do not use gasoline, turpentine, lacquer or paint thinner, dry

cleaning fluids or similar products. Never let any liquid get inside the

tool; never immerse any part of the tool into a liquid.

Lubrication

LUBRICATING THE GUIDE ROLLER (FIG. B)

• Apply a drop of oil to the guide roller (8) at regular intervals to

prevent jamming.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement)

should be performed by authorized service centers or other qualified

service personnel, always using identical replacement parts.

ACCESSORIES

WARNING: Since accessories, other than those offered by

D

EWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the risk

of injury, only D

with this product.

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center.

OPTIONAL ACCESSORIES

Consult your dealer for further information on the appropriate

accessories.

These include:

DE3241 Parallel guide

DE3242 Trammel bar

DT2048 Fine toothed cutting blade

DT2075 Coarse toothed cutting blade

DT2160 Metal cutting blade

DT2074 Flush cutting blade

7

7

EWALT, recommended accessories should be used

Page 9

Definiciones: Normas de

seguridad

Las siguientes definiciones describen el nivel de gravedad de

cada advertencia. Lea el manual y preste atención a estos

símbolos.

PELIGRO:

si no se evita,

ADVERTENCIA:

que, si no se evita,

graves

PRECAUCIÓN:

que, si no se evita,

moderadas.

PRECAUCIÓN:

seguridad indica una situación de peligro potencial que, si no

se evita,

indica una situación de peligro inminente que,

provocará

Utilizado sin el símbolo de alerta de

puede provocar

la

muerte o lesiones graves.

Indica una situación de peligro potencial

podría

Indica una situación de peligro potencial

provocar la

puede

provocar

daños en la

muerte o lesiones

lesiones leves o

propiedad

.

Instrucciones de seguridad generales

¡ADVERTENCIA! Lea todas las instrucciones hasta

comprenderlas. No ajustarse a las instrucciones

siguientes puede ser causa de choque eléctrico, incendio o

lesiones graves.

CONSERVE ESTAS INSTRUCCIONES

ÁREA DE TRABAJO

• Mantenga el área de trabajo limpia y bien iluminada. Las

bancadas desordenadas y las zonas oscuras propician los

accidentes.

• No opere herramientas eléctricas en atmósferas explosivas,

como en presencia de líquidos, gases o polvos inflamables.

Las herramientas eléctricas producen chispas que pueden

originar la ignición del polvo o los vapores.

• Mientras opere una herramienta eléctrica, mantenga lejos

a los observadores, niños y visitantes. Las distracciones

pueden ocasionar que pierda el control.

SEGURIDAD ELÉCTRICA

• Las herramientas con conexión a tierra deben conectarse a

una toma de corriente debidamente instalada y con conexión

a tierra, de acuerdo con todos los códigos y ordenanzas

aplicables. Nunca quite la pata de conexión a tierra ni

modifique el enchufe en ninguna manera. No emplee ningún

adaptador para enchufes. Si tiene alguna duda acerca de si

la toma de corriente está debidamente conectada a tierra,

consulte a un electricista calificado. Si las herramientas

presentasen fallas eléctricas o averías, la conexión a tierra ofrece

una vía de baja resistencia para alejar la corriente eléctrica del

usuario. Sólo es aplicable a las herramientas de Clase I (con

conexión a tierra).

• Las herramientas con doble aislamiento están equipadas

con una clavija polarizada (una pata es más ancha que

la otra). Esta clavija se acoplará a un enchufe polarizado

de una sola manera. Si la clavija no se acopla al contacto,

inviértala. Si aún así no se ajusta, comuníquese con

un electricista cualificado para que instale un enchufe

polarizado apropiado. Nunca cambie la clavija. El doble

aislamiento

sistemas de suministro eléctrico con conexión a tierra. Sólo es

aplicable a las herramientas de Clase II.

• Evite el contacto del cuerpo con superficies conectadas

a tierra, tales como tuberías, radiadores, registros y

refrigeradores. El riesgo de choque eléctrico aumenta si su

cuerpo hace tierra.

elimina la necesidad de cables con tres hilos y

Español

8

8

Page 10

• No exponga las herramientas eléctricas a la lluvia o a

condiciones de mucha humedad. Si entra agua en una

herramienta eléctrica, aumenta el riesgo de choque eléctrico.

• No maltrate el cable. Nunca tome el cable para transportar

la herramienta ni para desconectarla del enchufe. Mantenga

el cable alejado de las fuentes de calor, el aceite, las orillas

afiladas o las piezas en movimiento. Cambie inmediatamente

los cables dañados. Los cables dañados aumentan el peligro

de choque eléctrico.

• Cuando opere una máquina herramienta a la intemperie,

utilice un alargador marcado “W-A” o “W”. Estos alargadores

están clasificados para ser usados a la intemperie y reducen

el riesgo de descarga eléctrica. Al usar un alargador,

asegúrese de que tenga el calibre necesario para llevar la

corriente que su producto requerirá. Un alargador de un

calibre insuficiente causará una caída en la tensión de la línea

dando por resultado la pérdida de energía y sobrecalentamiento.

La tabla siguiente muestra el tamaño correcto para utilizar

dependiendo de la longitud del alargador y del amperaje

Español

nominal de la placa de identificación. En caso de duda, utilice

el de mayor calibre. Cuanto más pequeño es el número del

calibre, más resistente es el alargador.

Ténsion (Volts) Longitud del cable in metros (m)

120 0 - 7 7 - 15 15 - 30 30 - 50

220 - 240V 0 - 15 15 - 30 30 - 60 60 - 100

Corriente nominal

(Ampéres)

0 - 6A 1.0 1.5 1.5 2.5

6 - 10A 1.0 1.5 2.5 4.0

10 - 12A 1.5 1.5 2.5 4.0

12 - 16A 2.5 4.0 No recomendado

Sección nominal mínima del cable in

milímetros quadrados (mm2 )

SEGURIDAD PERSONAL

• Al utilizar una herramienta eléctrica, esté atento, concéntrese

en lo que hace y aplique el sentido común. No utilice la

herramienta si se encuentra fatigado o bajo la influencia de

drogas, alcohol o fármacos. Mientras se utilizan herramientas

eléctricas, basta un instante de distracción para sufrir lesiones

graves.

• Lleve ropa adecuada. No utilice ropa suelta ni joyas.

Recójase el cabello largo. Mantenga el cabello, la ropa y los

guantes apartados de las piezas en movimiento. Las partes

móviles pueden atrapar las prendas de vestir sueltas, las joyas

y el cabello. Los orificios de ventilación suelen cubrir piezas en

movimiento, por lo que también se deben evitar.

• Evite puestas en marcha accidentales. Asegúrese de que

el interruptor esté apagado antes de enchufar la máquina.

Transportar las herramientas con el dedo sobre el interruptor

o enchufarlas con el interruptor encendido favorece los

accidentes.

• Antes de poner en marcha la herramienta, retire las llaves

de ajuste. Una llave que se deje en una pieza giratoria de la

herramienta puede provocar lesiones.

• No ponga en peligro su estabilidad. Manténgase siempre

bien apoyado y equilibrado. Un buen apoyo y equilibrio

permiten controlar mejor la herramienta si se produce algún

imprevisto.

• Utilice el equipo de seguridad. Lleve siempre lentes

protectores. Cuando sea adecuado, también se debe usar

mascarilla antipolvo, zapatos de suela antideslizante, casco o

protectores auditivos.

USO Y CUIDADOS DE LA HERRAMIENTA

• Utilice abrazaderas u otro elemento adecuado para sujetar

y apoyar la pieza de trabajo en una plataforma estable.

Sujetar la pieza con la mano o contra el cuerpo es inestable y

facilita la pérdida de control.

9

9

Page 11

• No fuerce la herramienta. Emplee la herramienta correcta

para cada aplicación. La herramienta correcta hace el trabajo

mejor y más seguro dentro del rango para el que ha sido

diseñada.

• No utilice la herramienta si el interruptor no la enciende y

apaga. Cualquier herramienta que no pueda controlarse con el

interruptor es peligrosa y se debe reparar.

• Desconecte la clavija del enchufe antes de proceder

a cualquier ajuste, cambiar un accesorio o guardar la

herramienta. Estas medidas de seguridad preventiva reducen

el riesgo de poner en marcha la herramienta accidentalmente.

• Cuando no las utilice, guarde las herramientas fuera del

alcance de los niños o de cualquier persona no capacitada.

Las herramientas son peligrosas en manos de usuarios no

capacitados.

• Cuide las herramientas. Conserve las herramientas de

corte afiladas y limpias. Unas herramientas adecuadamente

cuidadas y con los bordes de corte afilados se atascan menos

y son más fáciles de controlar.

• Compruebe si las piezas móviles se desalinean o atascan,

si hay alguna pieza rota o cualquier otra circunstancia

que pueda afectar la operación de la herramienta. Si la

herramienta está dañada, hágala reparar antes de usarla.

Muchos accidentes los provocan unas herramientas mal

cuidadas.

• Utilice únicamente los accesorios recomendados por el

fabricante para su modelo. Un mismo accesorio puede ser

adecuado para una herramienta, pero peligroso si se usa en

otra.

SERVICIO

• El servicio a la herramienta sólo debe realizarlo personal

cualificado. El servicio o mantenimiento realizados por personal

no calificado puede dar como resultado un riesgo de lesiones.

• Al proceder al mantenimiento de una herramienta, utilice

únicamente refacciones idénticas. Siga las instrucciones

de la sección “Mantenimiento” de este manual. La utilización

de piezas no autorizadas, o no respetar las instrucciones de

mantenimiento, puede suponer un peligro de choque eléctrico o

de lesiones.

Normas específicas de seguridad

adicionales para sierra caladora

• Sujete la herramienta por las superficies aislantes si lleva

a cabo una operación en que la herramienta pueda tocar

un conductor oculto. El contacto con un conductor activo

provocará que las piezas metálicas de la herramienta conduzcan

electricidad y que el operador reciba una descarga eléctrica.

• Permita que el motor se detenga por completo antes de

retirar la hoja de la línea de corte. Las hojas en movimiento

pueden impactar la pieza de trabajo y romperse, dañar la pieza

de trabajo o causar la pérdida de control de la herramienta y

posibles lesiones corporales.

• Mantenga las empuñaduras secas, limpias, libres de aceite

y grasa. Esto permitirá un mejor control de la herramienta.

• Mantenga las hojas afiladas. Las hojas romas pueden hacer

que la sierra se desvíe o estanque bajo presión.

• Limpie su herramienta con frecuencia, especialmente

después de usos prolongados. El polvo y la arenilla que

contienen partículas metálicas se acumulan con frecuencia

en las superficies interiores y podrían ocasionar peligro de

descarga eléctrica.

• No opere esta herramienta durante períodos largos de

tiempo. La vibración causada por la acción de operación de

esta herramienta puede causar lesiones permanentes a los

dedos, las manos y los brazos. Utilice guantes para una mayor

amortiguación, tome descansos frecuentes y limite el tiempo de

uso diario.

Español

10

10

Page 12

ADVERTENCIA: Siempre utilice protección ocular cuando opere

...........

...............

...........

esta máquina herramienta.

ADVERTENCIA: Parte del polvo generado al lijar, serrar,

esmerilar y taladrar con máquinas herramienta, así como al realizar

otras actividades del sector de la construcción, contienen productos

químicos que pueden producir cáncer, defectos congénitos u otras

afecciones reproductivas. Ejemplos de esas substancias químicas

son:

• plomo procedente de pinturas a base de plomo,

• óxido de silicio cristalino procedente de ladrillos, cemento y

otros productos de mampostería y

• arsénico y cromo procedentes de madera tratada

químicamente (CCA).

El peligro derivado de estas exposiciones que usted enfrente

varía en función de la frecuencia con que se realice este tipo de

trabajo. Para reducir la exposición a esas sustancias químicas:

trabaje en una zona bien ventilada y llevando equipos de seguridad

aprobados, como mascarillas antipolvo especialmente diseñadas

para filtrar partículas microscópicas.

Español

• Evite el contacto prolongado con el polvo procedente

del lijado, serrado, esmerilado y taladrado eléctricos, así

como de otras actividades del sector de la construcción.

Lleve ropa protectora y lave con agua y jabón las zonas

expuestas. Si permite que el polvo se introduzca en la boca o

los ojos o quede sobre la piel, puede favorecer la absorción de

productos químicos peligrosos.

ADVERTENCIA: El uso de esta herramienta puede generar o

dispersar polvo lo cual puede causar lesiones respiratorias serias y

permanentes y otros tipos de lesión. Siempre use protección

respiratoria aprobada por NIOSH/OSHA para la exposición al polvo.

Dirija las partículas en dirección opuesta a su cara y cuerpo.

PRECAUCIÓN: Utilice una protección auditiva apropiada

durante el uso. En determinadas condiciones y con

utilizaciones prolongadas, el ruido generado por este producto

puede favorecer la pérdida de audición.

• La etiqueta de su herramienta puede incluir los siguientes

símbolos. Los símbolos y sus definiciones son los siguientes:

V ......... voltios A.............amperes

Hz ....... hertz W ........... watts

min ..... minutos

.. corriente directa

....... Construcción Clase I ........... terminal a tierra

........... (con conexión a tierra) ........... símbolo de alerta

....... Construcción Clase II ............... de seguridad

........... (con aislamiento doble) …/min ....revoluciones o

BPM ... golpes por minuto

sfpm ... pies de superficie por minuto

......... corriente alterna

n

o ........... velocidad sin carga

............... reciprocidad

........... por minuto

CONSERVE ESTAS INSTRUCCIONES

COMPROBACIÓN Y CAMBIO DE LA HOJA DE SIERRA

• Use sólo hojas de sierra que cumplan las especificaciones

indicadas en estas instrucciones de uso.

• Sólo deben usarse hojas de sierra afiladas y en perfecto estado;

las hojas de sierra con grietas o dobladas deben desecharse y

cambiarse inmediatamente.

• Compruebe que la hoja de la sierra está bien sujeta.

• La hoja de sierra puede calentarse al trabajar. Por ello, cuando

cambie la hoja compruebe que ya está fría, déjela enfriar o lleve

guantes protectores si toca la hoja.

Descripción (fig. A)

La sierra caladora DW341

de madera, acero, aluminio, plástico y material cerámico.

1 Interruptor de marcha/parada

2 Botón de funcionamiento continuo

11

ha sido diseñada para el corte profesional

Page 13

3 Control de velocidad

4 Soplador de serrín

5 Cierre de la hoja

6 Protector de los dedos

7 Portahojas

8 Rodillo de guía

9 Zapata

10 Selector de la carrera del péndulo

1

FIG. A

3

4

6

5

7

2

10

9

8

Montaje y ajustes

ADVERTENCIA: Desenchufe la herramienta antes de proceder

con el montaje y los ajustes.

AJUSTE Y RETIRADA DE LA HOJA DE SIERRA (FIG. B)

ATENCIÓN: La hoja de sierra puede calentarse cuando se está

utilizando. Por ello, cuando cambie la hoja compruebe que ya está

fría, déjela enfriar o lleve guantes protectores si toca la hoja.

• El sistema de cambio de hojas independiente de la herramienta

garantiza un cambio rápido y fácil de las hojas de sierra.

• Abra el portahojas (7)

retirando totalmente el cierre

FIG. B

de la hoja (5).

• Inserte la hoja de sierra en el

portahojas (7) guiando la parte

8

posterior de la hoja hacia la

ranura del rodillo guía (8).

• Suelte el cierre de la hoja (5).

• Para sacar la hoja de sierra,

retire totalmente el cierre de la

7

hoja y sáquela del portahojas.

AJUSTE DEL ÁNGULO DE

BISEL (FIG. C)

5

La zapata ajustable (9) permite el

corte de ángulos oblicuos a

izquierda y derecha hasta 45°. La

escala de bisel tiene posiciones

preajustadas de 0° y 45°.

• Afloje los tornillos (11) con la

FIG. C

llave Torx suministrada.

• Deslice la zapata (9) hacia la

hoja de sierra.

• Incline la zapata y ajuste el

ángulo de bisel deseado

utilizando la escala.

• Apriete los tornillos.

Español

12

Page 14

AJUSTE DE LA CARRERA DEL PÉNDULO (FIG. A)

La carrera ajustable del péndulo garantiza una carrera de corte

perfecta para distintos materiales.

• Deslice el selector (10) hasta la posición deseada según la

siguiente tabla. Puede manipularse el selector durante el

funcionamiento.

Pos. Madera Meta Plásticos

2 Cortes rápidos – PVC

2 Piezas de trabajo – Fibra de

1 Contrachapado Aluminio –

Aglomerado No ferroso –

0 Piezas de trabajo finas

Cortes finos

MONTAJE DE LA CUBIERTA PLÁSTICA ANTIARAÑAZOS

DE LA ZAPATA (FIG. D)

La cubierta antiarañazos de

Español

lazapata (12) reduce los daños

a la superficie de las piezas de

trabajo (delicadas).

• Encaje la cubierta sobre la

zapata como se muestra.

Instrucciones para

Chapa de metal –

FIG. D

12

el uso

ADVERTENCIA:

• Respete siempre las

instrucciones de seguridad

y las normas de aplicación.

vidrio gruesas Acrílico

• Compruebe que el material esté bien sujeto. Retire clavos,

tornillos u otros objetos que podrían dañar la hoja.

• Compruebe que hay espacio suficiente para la hoja debajo

de la pieza de trabajo. No corte materiales que excedan la

profundidad de corte máxima de la hoja.

• Utilice sólo hojas afiladas. Descarte de inmediato las hojas

dañadas o dobladas.

• No use la herramienta para cortar tubos o cañerías.

• Nunca ponga en marcha la herramienta sin la hoja

correspondiente.

• Para obtener los mejores resultados, mueva la herramienta

sobre el material de manera suave y constante. No ejerza

presión lateral sobre la hoja de la sierra. Mantenga la zapata

de la sierra apoyada sobre el material y aleje el cable,

sosteniéndolo en línea con la herramienta. Cuando corte

curvas, círculos u otras formas redondeadas, empuje la

herramienta hacia adelante con suavidad.

• Espere hasta que la herramienta se detenga por completo

antes de retirar la hoja de la pieza con la que trabaja.

Después de efectuar un corte es posible que la hoja se

encuentre muy caliente. No la toque.

ENCENDIDO Y APAGADO (FIG. A)

• Para poner en marcha la herramienta, presione el interruptor de

encendido/apagado (1).

• Para funcionamiento continuo, pulse el interruptor (1) y

manténgalo en esta posición. Pulse el botón de bloqueo (2) y

suelte el interruptor.

• Para parar la herramienta, suelte el interruptor.

• Para parar la herramienta en modo de funcionamiento continuo,

pulse brevemente el interruptor y suéltelo. Siempre se debe

13

13

Page 15

apagar la herramienta al acabar de trabajar y antes

de desconectarla de la red.

AJUSTE DEL CONTROL

ELECTRÓNICO DE VELOCIDAD

DE SERRADO (FIG. E)

FIG. E

1

3

La velocidad de serrado varía en función

de la presión ejercida sobre el interruptor

de encendido/apagado (1).

• Para preajustar la velocidad de

serrado, gire el control (3) hasta el

nivel deseado. Cuanto más alto sea

el nivel, más alta será la velocidad

de serrado. El ajuste depende del

espesor y la clase de material.

• Use las velocidades altas para serrar materiales blandos como

la madera. Use las velocidades bajas para serrar metal.

ADVERTENCIA: Después de utilizar la herramienta durante un

período prolongado con ajustes a baja velocidad, hágala funcionar

aproximadamente 3 minutos a velocidad máxima sin carga.

CÓMO SUJETAR LA HERRAMIENTA (FIG. F)

• Sujete la herramienta como se

muestra.

CORTE DE MADERA

FIG. F

• Si es necesario, trace una línea

de referencia.

• Encienda la herramienta.

• Presione la herramienta contra el

material y siga la línea trazada.

• Para cortar en línea paralela

al borde de la pieza en la que

trabaja, instale la guía paralela y

dirija la sierra de calar a lo largo de la pieza, tal como se indica

en la figura G.

FIG. G

FIG. H

CORTE DE MADERA CON UN ORIFICIO DE REFERENCIA

• Si es necesario, trace una línea para el corte.

• Perfore un orificio (ø mín. 12 mm) e introduzca la hoja de la

sierra.

• Encienda la herramienta.

• Siga la línea trazada.

• Para cortar formas perfectamente redondas, instale el compás

de barra y ajústelo con el radio que desee (fig. H).

CORTE DE METAL

• Monte una hoja de sierra adecuada.

• Proceda de la manera antes descrita.

ADVERTENCIA: Utilice un lubricante refrigerante (aceite para

cuchillas) para evitar el sobrecalentamiento de la hoja de la sierra

o del material con que trabaja.

MANTENIMIENTO

Limpieza

PRECAUCIÓN: Sólo use una tela húmeda para limpiar las

partes plásticas. Muchos limpiadores para uso doméstico pueden

contener sustancias químicas que podrían dañar el plástico

Español

14

14

Page 16

considerablemente. Tampoco utilice gasolina, aguarrás, disolvente

para barniz o pintura, líquidos para lavado en seco o productos

similares que podrían dañar las partes plásticas considerablemente.

Nunca permita que penetre líquido dentro de la herramienta ni

sumerja ninguna de las piezas en un líquido.

Lubricación

LUBRICACIÓN DEL RODILLO GUÍA (FIG. B)

• Aplique una gota de aceite al rodillo guía (8) a intervalos

regulares para evitar que se atasque.

Reparaciones

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán

hacerse reparaciones, mantenimiento y ajustes de esta

herramienta en los centros autorizados de servicio D

organizaciones autorizadas. Estas organizaciones prestan servicio

a las herramientas D

legitimas D

EWALT.

EWALT y emplean siempre refacciones

EWALT u otras

ACCESORIOS

Español

ADVERTENCIA: Debido a que no se han probado con este

producto otros accesorios que no sean los que ofrece D

uso de dichos accesorios podría ser peligroso. Para reducir el

riesgo de lesiones, con este producto deben usarse sólo los

accesorios D

Los accesorios recomendados para su herramienta están

disponibles por un cargo adicional en su distribuidor o centro de

servicio autorizado local.

ACCESORIOS OPCIONALES

Consulte a su proveedor si desea información más detallada sobre

los accesorios apropiados.

EWALT recomendados.

EWALT, el

Éstos incluyen:

DE3241 Guía paralela

DE3242 Barra de compás

DT2048 Hoja de corte de dientes finos

DT2075 Hoja de corte de dientes gruesos

DT2160 Hoja de corte para metal

DT2074 Hoja de corte para acabado

Especificaciones

DW341

Tensión de alimentación: 120 V~/220 V

Frecuencia de operación: 50-60 Hz

Potencia nominal: 550 W

Rotación sin carga: 0-3 100/min

15

Page 17

Definições: Diretrizes de

Segurança

As definições a seguir descrevem o nível de gravidade para

cada palavra sinalizadora. Leia o manual e preste atenção

a estes símbolos.

PERIGO: Indica uma situação de risco iminente que, se

não for evitada, resultará em morte ou ferimentos graves.

AVISO: Indica uma situação de risco potencial que,

se não evitada, poderá resultar em morte ou ferimentos

graves.

CUIDADO: Indica uma situação de risco potencial que,

se não evitada, poderá resultar em ferimentos leves ou

moderados.

CUIDADO: Usado sem o símbolo de alerta de segurança

indica uma situação de risco potencial que, se não evitada,

poderá resultar em danos à propriedade.

Instruções gerais de segurança

AVISO! Leia e compreenda todas as instruções. O não

cumprimento de todas as instruções listadas abaixo pode

resultar em choque elétrico, incêndio e/ou ferimentos graves

GUARDE ESTAS INSTRUÇÕES

ÁREA DE TRABALHO

• Mantenha sua área de trabalho limpa e bem iluminada.

Bancadas desorganizadas e áreas escuras são um convite para

acidentes.

• Não opere ferramentas elétricas em ambientes explosivos,

como na presença de líquidos, gases ou pós inflamáveis. As

ferramentas elétricas produzem fagulhas que podem incendiar o

pó ou os vapores.

• Mantenha visitantes, crianças e curiosos afastados durante

a operação de uma ferramenta elétrica. Distrações podem

fazer com que você perca o controle.

SEGURANÇA ELÉTRICA

• Não modifique o plugue de forma alguma. O isolamento

duplo elimina a necessidade de cabos de energia de três

fios aterrados e sistema de fornecimento de energia aterrado.

Aplicável somente a ferramentas de Classe II (isolamento

duplo).

• Evite que o corpo entre em contato com superfícies

aterradas tais como canos, radiadores, fogões e

refrigeradores. O risco de choque elétrico é maior se o seu

corpo estiver aterrado.

• Não exponha ferramentas elétricas a condições de chuva

ou umidade. A água que entrar em uma ferramenta elétrica

aumentará o risco de choque elétrico.

• Não force o fio. Nunca utilize o fio para transportar ou

desconectar a ferramenta da tomada. Mantenha o fio longe

de calor, óleo, bordas afiadas ou partes móveis. Substitua

os fios danificados imediatamente. Fios danificados aumentam

o risco de choque elétrico.

• Ao operar uma ferramenta em local externo, utilize uma

extensão para ambientes externos com marca “W-A” ou

“W”. Estes cabos são classificados para utilização em ambientes

externos e reduzem o risco de choque elétrico. Ao utilizar uma

extensão, assegure-se de usar uma suficientemente resistente

para suportar a corrente elétrica que o seu produto demandará.

Um cabo subdimensionado causa queda na voltagem,

resultando em perda de potência e superaquecimento. A tabela

a seguir exibe o tamanho correto a ser utilizado dependendo da

extensão do cabo e da indicação da amperagem nominal. Em

caso de dúvida, use o calibre imediatamente superior.

Português

16

Page 18

Tensão

(Volts)

120 - 127V 0 - 7 7 - 15 15 - 30 30 - 50

220 - 240V 0 - 15 15 - 30 30 - 60 60 - 100

Faixa de

Corrente

nominal

(Ampéres)

0 - 6A 1.0 1.5 1.5 2.5

6 - 10A 1.0 1.5 2.5 4.0

10 - 12A 1.5 1.5 2.5 4.0

12 - 16A 2.5 4.0 Não Recomendado

Comprimento do cabo de extensão

em Metros (m)

Secção minima do cabo de extensão em

milimetros quadrados (mm2)

SEGURANÇA PESSOAL

• Permaneça alerta, observe com atenção o que você está

fazendo e use o bom senso ao operar uma ferramenta

elétrica. Não use a ferramenta quando estiver cansado

ou sob o efeito de drogas, álcool ou medicamentos. Um

momento de desatenção durante a operação de ferramentas

elétricas pode resultar em ferimentos graves.

• Vista-se adequadamente. Não use roupas muito folgadas

ou jóias. Prenda os cabelos longos. Mantenha os cabelos,

as roupas e as luvas longe das partes móveis. Roupas

muito folgadas, jóias ou cabelos longos podem ficar presos nas

partes móveis. Saídas de ar geralmente cobrem peças móveis

e também devem ser evitadas.

• Certifique-se de que a ferramenta esteja desligada antes

de conectá-la. Carregar ferramentas elétricas com o dedo no

Português

interruptor ou conectar ferramentas elétricas na tomada com o

interruptor ligado é um convite para acidentes.

• Remova as chaves ajustáveis ou chaves inglesas antes

de ligar a ferramenta. Uma chave inglesa ou uma chave

deixada em uma parte giratória da ferramenta pode resultar em

ferimentos.

• Não se incline muito. Mantenha uma posição adequada

dos pés e o equilíbrio durante o tempo inteiro. Uma

posição adequada e equilíbrio permitem um melhor controle da

ferramenta em situações inesperadas.

• Utilize equipamento de segurança. Sempre use proteção

para os olhos. Máscara contra poeira, sapatos de segurança

antiderrapantes, capacete ou proteção auricular devem ser

usados para condições apropriadas.

UTILIZAÇÃO E CUIDADOS COM A FERRAMENTA

• Use braçadeiras ou outra maneira prática para prender e

apoiar a peça a uma plataforma estável. Segurar o trabalho

com as mãos ou contra o corpo é instável e pode levar a perda

de controle.

• Não force a ferramenta. Use a ferramenta adequada à sua

aplicação. A ferramenta adequada fará o trabalho melhor e com

mais segurança, na faixa para a qual foi projetada.

• Não utilize a ferramenta se o interruptor não estiver ligando

ou desligando. Uma ferramenta que não pode ser controlada

pelo interruptor é perigosa e deverá ser consertada.

• Desconecte o plugue da fonte de alimentação antes de fazer

qualquer ajuste, trocar acessórios ou guardar a ferramenta.

Estas medidas de segurança preventivas reduzem o risco de

ativar a ferramenta de forma acidental.

• Guarde as ferramentas inativas fora do alcance das

crianças e de outras pessoas não treinadas. Ferramentas

são perigosas nas mãos de usuários sem treinamento.

• Preserve as ferramentas com cuidado. Mantenha as

ferramentas de corte afiadas e limpas. Ferramentas de corte

e pontas afiadas com manutenção apropriada têm menos

probabilidade de emperrar e são mais fáceis de controlar.

17

Page 19

• Verifique se há partes móveis desalinhadas ou emperradas,

peças quebradas e qualquer outra condição que possa

afetar o funcionamento da ferramenta. Se danificada, leve

a ferramenta a uma assistência técnica antes de usá-la.

Muitos acidentes são causados por manutenção deficiente das

ferramentas elétricas.

• Utilize somente acessórios que sejam recomendados pelo

fabricante para o modelo de sua ferramenta. Acessórios

que podem ser apropriados para uma ferramenta, podem ser

perigosos quando usados em outras.

ASSISTÊNCIA TÉCNICA

• O conserto da ferramenta somente deve ser realizado por

pessoal de reparo qualificado. O conserto ou manutenção

realizado por pessoal não qualificado pode resultar em risco de

ferimentos.

• Ao consertar uma ferramenta, use somente peças de

substituição idênticas. Siga as instruções na seção de

manutenção deste manual. O uso de peças não autorizadas

ou a falha em seguir as instruções de manutenção podem

causar risco de choque ou ferimentos.

Instruções de segurança específicas

adicionais para serras tico tico

• Segure a ferramenta pelas superfícies isoladas ao executar

uma atividade na qual a ferramenta de corte possa entrar

em contato com cabos escondidos ou seu próprio cabo.

O contato com um cabo “energizado” fará com que as partes

metálicas expostas da ferramenta fiquem “energizadas” e

causarão um choque elétrico no operador.

• Deixe que o motor pare completamente antes de remover

a lâmina do entalho (a abertura criada pelo corte). Uma

lâmina em movimento pode golpear a peça causando quebra

da lâmina, danos à peça ou perda de controle e possíveis

ferimentos.

• Mantenha as mãos secas, limpas e sem óleo ou graxa. Isto

permitirá um melhor controle da ferramenta.

• Mantenha as lâminas afiadas. Lâminas sem corte podem

fazer com que serra dê uma guinada ou emperre sob pressão.

• Limpe a sua ferramenta com freqüência, especialmente

após o uso prolongado. Sujeira e areia contendo partículas

de metal geralmente se acumulam nas superfícies internas e

podem criar risco de choque elétrico.

• Não opere esta ferramenta por longos períodos de tempo.

As vibrações causadas pela operação desta ferramenta podem

causar ferimentos permanentes nos dedos, mãos e braços.

Use luvas para fornecer amortecimento extra, faça períodos de

descanso freqüentes e limite o tempo de uso diário.

AVISO: utilize sempre proteção para os olhos quando operar

esta ferramenta.

AVISO: a poeira criada pela ação de lixar, cortar, triturar e

perfurar com ferramentas elétricas e outras atividades de construção

contém produtos químicos conhecidos por causar câncer, defeitos

congênitos ou outros problemas reprodutivos. Alguns exemplos

destes produtos químicos são:

• chumbo de tintas à base de chumbo,

• sílica cristalina de tijolos e de cimento e outros produtos de

alvenaria e

• arsênico e cromo de madeiras tratadas quimicamente

(CCA).

O risco a estas exposições varia, dependendo da freqüência com

que você faz este tipo de trabalho. Para reduzir a exposição a

estes produtos químicos: trabalhe em uma área bem ventilada e

com o equipamento de segurança aprovado, como máscaras para

pó que sejam especialmente desenvolvidas para filtrar partículas

microscópicas.

• Evite o contato prolongado com a poeira da atividade de

lixar, cortar, triturar e perfurar com ferramentas elétricas e

outras atividades de construção. Use roupas de proteção e

Português

18

Page 20

lave as áreas expostas com água e sabão. Permitir que o pó

entre na sua boca, olhos ou que permaneça na sua pele poderá

facilitar a absorção de produtos químicos nocivos.

AVISO: o uso desta ferramenta pode gerar e/ou desprender pó,

o que pode causar problemas respiratórios graves e permanentes

ou outros ferimentos. Use sempre proteção respiratória aprovada

pelo NIOSH/OSHA e apropriada para a exposição ao pó. Direcione

as partículas para longe da face e do corpo.

AVISO: utilize equipamento de proteção auricular apropriado

durante o uso. Sob algumas condições e duração do uso, o ruído

deste produto pode contribuir para a perda de audição.

• A etiqueta na sua ferramenta pode incluir os seguintes símbolos.

Os símbolos e suas definições são as seguintes:

V .......... volts A ............ amperes

Hz ........ hertz W ........... watts

min ....... minutos

..... corrente contínua

......... Construção Classe I ........... terminal de

............. (aterrado) ............... aterramento

......... Construção Classe II .......... símbolo de alerta de

............. (isolamento duplo) ............... segurança

GPM .... golpes por minuto …/min .... revoluções ou

............. ............... alternações por minuto

.......... corrente alternada

n

o ........... velocidade sem carga

imediato.

• Certifique-se de que a lâmina da serra está fixa de forma

segura.

• A lâmina da serra pode estar quente devido ao processo de

trabalho. Por isso, quando mudar a lâmina, certifique-se de

que está fria ou de que arrefeceu o suficiente, ou use luvas de

proteção ao tocar na lâmina.

1

FIG. A

3

4

6

5

2

10

9

GUARDE ESTAS INSTRUÇÕES

VERIFICAR E MUDAR A LÂMINA DA SERRA

• Utilize apenas lâminas de serra que estejam em conformidade

com as especificações contidas nestas instruções de

funcionamento.

• Apenas devem ser utilizadas lâminas de serra afiadas em

Português

perfeitas condições de funcionamento; lâminas de serra

fendidas ou dobradas devem ser eliminadas e substituídas de

8

7

Descrição (fig. A)

A sua serra tico-tico DW341

de produtos de madeira, aço, alumínio, plástico e cerâmica.

1 Interruptor on/off

2 Botão de bloqueio do interruptor

3 Controle de velocidade

19

19

foi concebida para o corte profissional

Page 21

4 Soprador

5 Fecho da lâmina

6 Proteção para os dedos

7 Suporte da lâmina

8 Rolo guia

9 Pé

10 Seletor de curso do pêndulo

Montagem e

afinação

AVISO: Antes da montagem

de acessórios e da afinação

retire sempre a ficha da

tomada.

COLOCAÇÃO E REMOÇÃO

DA LÂMINA DA SERRA

(FIG. B)

AVISO:A lâmina da serra pode

estar quente devido ao processo

de trabalho. Por isso, quando

mudar a lâmina da serra,

certifique-se de que está fria ou

de que arrefeceu o suficiente, ou

use luvas de proteção ao tocar

na lâmina.

• O sistema de substituição de lâmina sem ferramenta garante a

substituição rápida e fácil das lâminas da serra.

• Abra o suporte da lâmina (7) retraindo totalmente o fecho da

lâmina (5).

• Insira a lâmina da serra no suporte da lâmina (7) guiando a

parte de trás da lâmina para a ranhura no rolo guia (8).

• Solte o fecho da lâmina (5).

FIG. B

8

7

5

• Para retirar a lâmina da serra, retraia totalmente o fecho da

lâmina e puxe a lâmina para fora do suporte da lâmina.

AJUSTE DO ÂNGULO DE CORTE (FIG. C)

A sapata ajustável (9) permite o

corte em ângulos de corte à

direita e à esquerda até 45°. A

escala angular tem posições

pré-determinadas para 0° e 45°.

• Desaperte os parafusos

(11) utilizando a chave Torx

fornecida.

• Faça deslizar o pé (9) na direcção da lâmina da serra.

• Incline o pé e defina o ângulo de corte desejado, utilizando a

escala.

• Aperte os parafusos.

AJUSTE DO DA AÇÃO PENDULAR (FIG. A)

Da ação pendular garante um curso de corte perfeito para

materiais diferentes.

• Faça deslizar o selector (10) para a posição desejada

consultando a tabela abaixo. O selector pode ser manipulado

durante o funcionamento.

Pos. Madeira Metal Plásticos

2 Cortes rápidos – PVC

2 Peças de trabalho – Fibra de vidro

1 Prancha Alumínio –

Aglomerado Não ferroso –

0 Peças de trabalho finas

Cortes de precisão

FIG. C

espessas

Acrílico

Metal branco –

Português

20

20

Page 22

MONTAGEM DA PROTEÇÃO SAPATA (FIG. D)

Proteção sapata (12) reduz os danos

na superfície de peças de trabalho

(sensíveis).

• Encaixe a tampa no pé,

conforme mostrado.

Modo de emprego

AVISO:

• Cumpra sempre as

instruções de segurança e

os regulamentos aplicáveis.

• Assegure-se que a peça

a cortar está bem presa.

Remova pregos, parafusos e outros dispositivos de bloqueio

que possam danificar a lâmina.

• Verifique se há espaço suficiente para a lâmina por baixo

da peça de trabalho. Não corte os materiais que excedam a

profundidade máxima de corte da lâmina.

• Use sómente lâminas afiadas. Lâminas danificadas ou

dobradas devem ser substituídas imediatamente.

• Não utilize a ferramenta para cortar canos ou tubos.

• Nunca coloque em funcionamento a ferramenta sem a

lâmina.

• Para optimizar os resultados, acione a ferramenta

gradualmente e constantemente sobre a peça. Não efectue

pressões laterais na lâmina. Mantenha a base sobre a peça

ser cortada e afaste o cabo de alimentação mantendo-o

alinhado com o lado posterior da ferramenta. Para o corte

de curvas, círculos ou outras superfícies arredondadas,

Português

empurre a ferramenta ligeiramente para frente.

• Espere até que a ferramenta tenha parado de funcionar

antes de remover a lâmina da peça trabalhada. Depois de

cortar a lâmina pode estar quente. Não toque.

FIG. D

12

LIGAR E DESLIGAR (FIG. A)

• Para ligar a máquina pressione o interruptor (1).

• Para funcionamento contínuo, pressione continuamente o

interruptor (1). Pressione o botão de bloqueio (2) e libere o

interruptor.

• Para desligar a máquina, liberte o interruptor.

• Para parar a ferramenta quando esta se encontrar em operação

contínua, pressione levemente o interruptor "on/off" e volte

a soltá-lo. Desligue sempre a ferramenta quando acabar de

trabalhar e antes de desligar da rede.

REGULAGEM ELECTRÓNICA DE VELOCIDADE

DE CORTE (FIG. E)

A velocidade de corte varia com a

pressão exercida sobre o interruptor on/

FIG. E

1

3

off (1).

• Para predefinir a velocidade de

serragem, rode o controle (3) para

o nível desejado. Quanto maior o

número, mais alta a velocidade

de corte. A regulação necessária

depende da espessura e do tipo de

material.

• Utilize velocidades elevadas para cortar materiais moles como

madeira. Utilize velocidades baixas para cortar metais.

AVISO: Após utilizar a ferramenta durante um longo período de

tempo a regulações de velocidade baixas, deixe-a a funcionar

durante aproximadamente 3 minutos na velocidade máxima sem

carga.

MANUSEAMENTO DA FERRAMENTA (FIG. F)

• Segure na ferramenta como mostrado.

21

21

Page 23

PARA CORTAR MADEIRA

• Se for necessário, desenhe uma

linha de corte para referência na

peça a trabalhar.

• Ligue a ferramenta.

• Segure a ferramenta contra a

peça e siga a linha de corte

desenhada anteriormente.

PARA CORTAR MADEIRA

UTILIZANDO UM ORIFÍCIO

PILOTO

• Se for necessário, desenhe uma

linha de corte para referência na

peça a trabalhar.

• Faça um orifício (ø mín. 12 mm)

e introduza a lâmina.

• Siga a linha de corte desenhada anteriormente.

• Para cortar formas perfeitamente redondas, instale a guia de

corte em circulo e regule-a no raio que for requerido (fig. H).

FIG. G

FIG. F

FIG. H

PARA CORTAR METAIS

• Monte uma lâmina apropriada.

• Proceda como descrito anteriormente.

AVISO: Utilize um lubrificante de refrigeração (óleo para corte)

para evitar o sobreaquecimento da lâmina ou da peça.

MANUTENÇÃO

Limpeza

AVISO: ao limpar, use apenas pano úmido em peças plásticas.

Diversos limpadores domésticos contêm produtos químicos que

podem danificar gravemente o plástico. Além disso, não use

gasolina, laca ou solvente de tintas, fluidos para limpeza a seco ou

produtos semelhantes que podem danificar seriamente as peças

plásticas. Nunca deixe que nenhum líquido penetre na ferramenta;

nunca mergulhe nenhuma peça da ferramenta em líquidos.

Lubrificação

LUBRIFICAR O ROLO GUIA (FIG. B)

• Aplique uma gota de óleo no rolo guia (8) a intervalos regulares

para evitar que encrave.

Reparos

Para assegurar a SEGURANÇA e a CONFIABILIDADE da

ferramenta, os reparos, a manutenção e os ajustes (incluindo

inspeção e substituição da escova) devem ser realizados por um

centro de assistência técnica autorizado da D

equipe técnica qualificada. Use sempre peças de reposição

originais.

EWALT ou outra

Português

22

22

Page 24

SOLAMENTE PARA PROPÓSITO DE MÉXICO:

IMPORTADO POR: BLACK & DECKER S.A. DE C.V.

BOSQUES DE CIDROS, ACCESO RADIATAS NO. 42

3A. SECCIÓN DE BOSQUES DE LAS LOMAS

DELEGACIÓN CUAJIMALPA,

05120, MÉXICO, D.F.

TEL. (52) 555-326-7100

R.F.C.: BDE810626-1W7

IMPORTED BY/IMPORTADO POR:

BLACK & DECKER DO BRASIL LTDA.

ROD. BR 050, S/N° - KM 167

DIST. INDUSTRIAL II

UBERABA – MG – CEP: 38064-750

CNPJ: 53.296.273/0001-91

INSC. EST.: 701.948.711.00-98

S.A.C.: 0800-703-4644

MAQUINAS Y HERRAMIENTAS BLACK & DECKER CHILE S.A.

AVDA. EDUARDO FREI M. #6001 EDIFICIO 67

CONCHALI-SANTIAGO

CHILE

SOLAMENTE PARA PROPÓSITO DE ARGENTINA:

IMPORTADO POR: BLACK & DECKER ARGENTINA S.A.

PACHECO TRADE CENTER

COLECTORA ESTE DE RUTA PANAMERICANA

KM. 32.0 EL TALAR DE PACHECO

PARTIDO DE TIGRE

BUENOS AIRES (B1618FBQ)

REPÚBLICA DE ARGENTINA

NO. DE IMPORTADOR: 1146/66

TEL. (011) 4726-4400

HECHO EN CHINA

FABRICADO NA CHINA

MADE IN CHINA

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 (DEC08) Part No. 1009194-00 DW341

Copyright © 2008 DEWALT

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme; the “D” shaped air intake grill; the array of pyramids

on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

Loading...

Loading...