Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contactenos.

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACION, CENTROS DE SERVICIO Y POLIZA DE

GARANT[A. ADVERTENOIA: LEASE ESTE INSTRUCTIVO ANTES DE

USAR EL PRODUCTO.

DCS372

18V 5-1/2" (140 mm) Cordless Metal-Cutting Circular Saw

Scie circulaire & mdtaux sans fil, 140 mm (5-1/2 po) et 18 V

Sierra circular inal&mbrica de 18 V 140 mm (5,5 pulg.) para corte de metal

®

Page 2

Page 3

Definitions: Safety Guidelines

The definitions below describe the level of severity br each

signal word. Please read the manual and pay attention to these

symbols.

_DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

iJ,WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

i_CAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury

which, if not avoided, may result in property damage.

. J

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY DEWALT TOOL, CALL US TOLL FREE AT: 1-800-4-DEWALT

(1-800-433-9258}.

_ ARNING: To reduce the risk of injury, read the instruction

manual.

General Power Tool Safety Warnings

_ WARNING! Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in

electric shock, fire and/or serious injury,

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term "power tool" in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tooL Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

If operating a powertool in a damp location is unavoidable,

use a ground fault circuit interrupter (GFCI) protected

supply. Use of a GFCI reduces the risk of electric shock.

Page 4

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, non-

skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in

the off position before connecting to power source and/

or battery pack, picking up or carrying the tool. Carrying

power tools with your finger on the switch or energizing power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool Use the correct power tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do

not allow persons unfamiliar with the power tool or these

instructions to operate the power tool Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding

ofmoving parts, breakage of parts and any other condition

that may affect the power tool's operation. If damaged,

have the power tool repaired before use. Many accidents

are cau,_ed by poorly maintained power tool,_.

t) Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind and

are easier to control

g) Use the power tool, accessories and tool bits, etc. in

accordance with these instructions, taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

5) BATFERY TOOL USE AND CARE

a) Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type of

battery pack may create a risk of fire when used with another

battery pack.

b) Use power tools only with specifically designated battery

packs. Use of any other battery packs may create a risk of

injury and fire.

Page 5

c) When battery pack is not in use, keep H away from other

metal objects, like paper clips, coins, keys, nails, screws,

or other small metal objects, that can make a connection

from one terminal to another. Shorting the battery terminals

together may cause bums or a fire.

d) Under abusive conditions, liquid may be ejected from

the battery; avoid contact. If contact accidentally occurs,

flush with water. If liquid contacts eyes, additionally seek

medical help. Liquid ejected from the battery may cause

irritation or bums.

6) SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

Safety Instructions for All Saws

a) _DANGER: Keep hands away from cutting area and

the blade. Keep your second hand on auxiliary handle,

or motor housing. If both hands are holding the saw, they

cannot be cut by the blade.

b) Do not reach underneath the workpiece. The guard cannot

protect you from the blade below the workpiece.

c) Adjust the cutting depth to the thickness of the workpiece.

Less than a full tooth of the blade teeth should be visible below

the workpiece.

d) Never hold piece being cut in your hands or across

your leg. Secure the workpiece to a stable platform. /t

is important to support the work properly to minimize body

exposure, blade binding, or loss of control

e) Hold power tool by insulated gripping surfaces when

performing an operation where the cutting tool may

contact hidden wiring. Contact with a "live" wire will also

make exposed metal parts of the power tool "live" and shock

the operator.

When ripping always use a rip fence or straight edge

guide. This improves the accuracy of cut and reduces the

chance of blade binding.

g) Always use blades with correct size and shape (diamond

versus round) of arbor holes. Blades that do not match the

mounting hardware of the saw will run eccentrically, causing

loss of control.

h) Never use damaged or incorrect blade washers or bolt.

The blade washers and bolt were specially designed for your

saw, for optimum performance and safety of operation.

Further Safety Instructions for All Saws

CAUSES AND OPERATOR PREVENTION OF KICKBACK:

• Kickback is a sudden reaction to a pinched, bound or misa/igned

saw blade, causing an uncontrolled saw to rift up and out of the

workpiece toward the operator,"

• When the blade is pinched or bound tightly by the kerr closing

down, the blade stalls and the motor reaction drives the unit rapidly

back toward the operator,"

• If the blade becomes twisted or misaligned in the cut, the teeth at

the back edge of the blade can dig into the top surface of the wood

causing the blade to climb out of the kerf andjump back toward the

operator.

Kickback is the result of saw misuse and/or incorrect operating

procedures or conditions and can be avoided by taking proper

precautions as given below."

a) Maintain a firm grip with both hands on the saw and

position your arms to resist kickback forces. Position

your body to either side of the blade, but not in line with

the blade. Kickback could cause the saw to jump backwards,

Page 6

butkickbackforcescanbecontrolledbytheoperator,ifproper

precautionsaretaken.

b)When blade is binding, or when interrupting a cut for any

reason, release the trigger and hold the saw motionless

in the material until the blade comes to a complete

stop. Never attempt to remove the saw from the work

or pull the saw backward while the blade is in motion or

kickback may occur. Investigate and take corrective actions

to eliminate the cause of blade binding.

c) When restarting a saw in the workpiece, center the

saw blade in the kerf and check that saw teeth are not

engaged into the material. If saw blade is binding, it may

walk up or kickback from the workpiece as the saw is restarted.

d) Support large panels to minimize the risk of blade

pinching and kickback. Large panels tend to sag under their

own weight. Supports must be placed under the panel on both

sides, near the line of cut and near the edge of the panel

e) Do not use dull or damaged blades. Unsharpened or

improperly set blades produce narrow kerr causing excessive

friction, blade binding and kickback.

Blade depth and bevel adjusting locking levers must be

tight and secure before making cut. If blade adjustment

shifts while cutting, it may cause binding and kickback.

g) Use extra caution when sawing into existing walls or

other blind areas. The protruding blade may cut objects that

can cause kickback.

LOWER GUARD SAFETY INSTRUCTIONS

a) Check lower guard for proper closing before each use. Do

not operate the saw if lower guard does not move freely

and close instantly. Never clamp or tie the lower guard

into the open position. If saw is accidentally dropped, lower

guard may be bent. Raise the lower guard with the retracting

handle and make sure it moves freely and does not touch the

blade or any other part, in all angles and depths of cut.

b) Check the operation of the lower guard spring. If the

guard and the spring are not operating properly, they

must be serviced before use. Lower guard may operate

sluggishly due to damaged parts, gummy deposits, or a build-

up of debris.

c) Lower guard should be retracted manually only for

special cuts such as "plunge cuts" and "compound cuts."

Raise lower guard by retracting handle and as soon

as blade enters the material, the lower guard must be

released. For all other sawing, the lower guard should operate

automatically.

d) Always observe that the lower guard is covering the

blade before placing saw down on bench or floor. An

unprotected, coasting blade will cause the saw to walk

backwards, cutting whatever is in its path. Be aware of the time

it takes for the blade to stop after switch is released.

NOTE: Although the above information references wood, this saw is

only to be used to cut metal Kickback can occur when cutting metal

Additional Specific Safety Instructions for

Circular Saws

i_ WARNING: Do not use abrasive wheels or blades.

WARNING: Do not use water feed attachments.

ACAUTION: Do not attempt to cut stainless steel, rebar,

hardened or heat-treated steel, cast iron, masonry or unknown

materials

• Use clamps or another practical way to secure and support

the workpiece to a stable platform. Holding the work by hand

or against your body leaves it unstable and may lead to loss of

control.

Page 7

• Keep your body positioned to either side of the blade, but

not in line with the saw blade. KICKBACK could cause the saw

to jump backwards (see Causes and Operator Prevention of

Kickback and KICKBACK).

• Air vents often cover moving parts and should be avoided.

Loose clothes, jewelry or long hair can be caught in moving parts.

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are

NOTsafety glasses. Also use face or dust mask if cutting operation

is dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT_

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI $12.6 ($3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

A WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to the State of California to cause cancer, birth defects or

other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromMm from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to

filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with soap

and water. Allowing dust to get into your mouth, eyes, or lay on

the skin may promote absorption of harmful chemicals.

A WARNING: Use of this tool can generate and/or disperse dust,

which may cause serious and permanent respiratory or other

injury. Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face

and body.

_ WARNING: Always wear proper personal hearing protection

that conforms to ANSI $12.6 ($3.19) during use. Under some

conditions and duration of use, noise from this product may

contribute to hearing loss.

A CAUTION: When not in use, place circular saw on a stable

surface, shoe side down, where it will not cause a tripping or

falling hazard. Some tools with large battery packs will stand upright

on the battery pack but may be easily knocked over.

• The label on your tool may include the following symbols. The

symbols and their definitions are as follows:

V ................... volts

Hz................. hertz

min ............... minutes

--- or DC... direct current

(_) ................. Class I Construction

(grounded)

[] ................. Class II Construction

(double insulated)

.../min .......... per minute

BPM ............. beats per minute

IPM ............... impacts per minute

RPM ............. revolutions per

minute

sfpm ............. surface feet

per minute

A...................... amperes

W..................... watts

"_ or AC .......... alternating

current

_-_or AC/DC... alternating

or direct

current

no .................... no load

speed

n...................... rated

speed

..................... earthing

terminal

_ ..................... safety alert

symbol

SPM ............. strokes per minute

Page 8

Important Safety Instructions for All

Battery Packs

When ordering replacement battery packs, be sure to include the

catalog number and voltage. Consult the chart at the end of this

manual for compatibility of chargers and battery packs.

The battery pack is not fully charged out of the carton. Before using

the battery pack and charger, read the safety instructions below. Then

follow charging procedures outlined.

READ ALL INSTRUCTIONS

• Do not charge or use battery in explosive atmospheres,

such as in the presence of flammable liquids, gases or dust.

Inserting or removing the battery from the charger may ignite the

dust or fumes.

• NEVER force battery pack into charger. DO NOT modify

battery pack in any way to fit into a non-compatible charger

as battery pack may rupture causing serious personal injury.

Consult the chart at the end of this manual for compatibility of

batteries and chargers.

• Charge the battery packs only in DEWALT chargers.

• DO NOT splash or immerse in water or other liquids.

• Do not store or use the tool and battery pack in locations

where the temperature may reach or exceed 105 °F (40 °C)

(such as outside sheds or metal buildings in summer).

_DANGER: Electrocution hazard. Never attempt to open the battery

pack for any reason. If battery pack case is cracked or damaged, do

not insert into charger. Do not crush, drop or damage battery pack.

Do not use a battery pack or charger that has received a sharp blow,

been dropped, run over or damaged in any way (i.e., pierced with a

nail, hit with a hammer, stepped on). Electric shock or electrocution

may result. Damaged battery packs should be returned to service

center for recycling.

NOTE" Battery storage and carrying caps are

provided for use whenever the battery is out of the

tool or charger. Remove cap before placing battery in

charger or tool.

_ WARNING: Fire hazard. Do not store or carry

battery so that metal objects can contact exposed battery

terminals. For example, do not place battery in aprons, pockets,

tool boxes, product kit boxes, drawers, etc., with loose nails,

screws, keys, etc. without battery cap. Transporting batteries

can possibly cause fires if the battery terminals inadvertently

come in contact with conductive materials such as keys, coins,

hand tools and the like. The U.S. Department of Transportation

Hazardous Material Regulations (HMR) actually prohibit transporting

batteries in commerce or on airplanes (i.e., packed in suitcases and

carry-on luggage) UNLESS they are properly protected from short

circuits. So when transporting individual batteries, make sure that the

battery terminals are protected and well insulated from materials that

could contact them and cause a short circuit.

SPECIFIC SAFETY INSTRUCTIONS FOR NICKEL CADMIUM

(NiCd) OR NICKEL METAL HYDRIDE (NiMH)

• Do not incinerate the battery pack even if it is severely

damaged or is completely worn out. The battery pack can

explode in a fire.

• A small leakage of liquid from the battery pack cells may

occur under extreme usage or temperature conditions. This

does not indicate a failure.

However, if the outer seal is broken:

a. and the battery liquid gets on your skin, immediately wash with

soap and water for several minutes.

b. and the battery liquid gets into your eyes, flush them with

clean water for a minimum of 10 minutes and seek immediate

Page 9

medicalattention.(Medicalnote: The liquid is 25-35%

solution of potassium hydroxide.)

SPECIFIC SAFETY INSTRUCTIONS FOR LITHIUM ION (Li-lon)

• Do not incinerate the battery pack even if it is severely

damaged or is completely worn out. The battery pack can

explode in a fire. Toxic fumes and materials are created when

lithium ion battery packs are burned.

• If battery contents come into contact with the skin,

immediately wash area with mild soap and water. If battery

liquid gets into the eye, rinse water over the open eye for 15

minutes or until irritation ceases. If medical attention is needed,

the battery electrolyte is composed of a mixture of liquid organic

carbonates and lithium salts.

• Contents of opened battery cells may cause respiratory

irritation. Provide fresh air. If symptoms persist, seek medical

attention.

A WARNING: Bum hazard. Battery liquid may be flammable if

exposed to spark or flame.

The RBRC TM Seal

The RBRCTM (Rechargeable Battery Recycling

Corporation) Seal on the nickel cadmium, nickel metal

hydride or lithium ion batteries (or battery packs)indicate

that the costs to recycle these batteries (or battery

packs) at the end of their useful life have already been

paid by DEWALT. In some areas, it is illegal to place

spent nickel cadmium, nickel metal hydride or lithium ion batteries in

the trash or municipal solid waste stream and the RBRC program

provides an environmentally conscious alternative.

RBRCTM in cooperation with DFWALT and other battery users, has

established programs in the United States and Canada to facilitate

the collection of spent nickel cadmium, nickel metal hydride or lithium

ion batteries. Help protect our environment and conserve natural

resources by returning the spent nickel cadmium, nickel metal hydride

or lithium ion batteries to an authorized DEiWALTservice center or

to your local retailer for recycling. You may also contact your local

recycling center for information on where to drop off the spent battery.

RBRC TM is a registered trademark of the Rechargeable Battery

Recycling Corporation.

Important Safety Instructions for All

Battery Chargers

SAVE THESE INSTRUCTIONS: This manual contains important

safety and operating instructions for battery chargers.

• Before using charger, read all instructions and cautionary markings

on charger, battery pack, and product using battery pack.

ADANGER: Electrocution hazard. 120 volts are present at charging

terminals. Do not probe with conductive objects. Electric shock or

electrocution may result.

A WARNING: Shock hazard. Do not allow any liquid to get inside

charger. Electric shock may result.

A CAUTION: Bum hazard. To reduce the risk of injury, charge only

DEWALT rechargeable batteries. Other types of batteries may burst

causing personal injury and damage.

NOTICE: Under certain conditions, with the charger plugged in to

the power supply, the exposed charging contacts inside the charger

can be shorted by foreign material Foreign materials of a conductive

nature such as, but not limited to, grinding dust, metal chips, steel

wool, aluminum foil, or any buildup of metallic particles should be

kept away from charger cavities. Always unplug the charger from

the power supply when there is no battery pack in the cavity, Unplug

charger before attempting to clean.

Page 10

• DO NOT attempt to charge the battery pack with any

chargers other than the ones in this manual The charger and

battery pack are specifically designed to work together.

• These chargers are not intended for any uses other than

charging DEWALT rechargeable batteries. Any other uses may

result in risk of fire, electric shock or electrocution.

• Do not expose charger to rain or snow.

• Puff by plug rather than cord when disconnecting charger.

This will reduce risk of damage to electric plug and cord.

• Make sure that cord is located so that it will not be stepped

on, tripped over, or otherwise subjected to damage or

stress.

• Do not use an extension cord unless it is absolutely

necessary. Use of improper extension cord could result in risk of

fire, electric shock, or electrocution.

• When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for outdoor

use reduces the risk of electric shock.

• An extension cord must have adequate wire size (AWG

or American Wire Gauge) for safety. The smaller the gauge

number of the wire, the greater the capacity of the cable, that is

16 gauge has more capacity than 18 gauge. An undersized cord

will cause a drop in line voltage resulting in loss of power and

overheating. When using more than one extension to make up the

total length, be sure each individual extension contains at least the

minimum wire size. The following table shows the correct size to

use depending on cord length and nameplate ampere rating. If in

doubt, use the next heavier gauge. The smaller the gauge number,

the heavier the cord.

Minimum Gauge for Cord Sets

Not

More

6

10

12

16

Volts Total Length of Cord in Feet (meters)

120V 25 (7.6) 50 (15.2) 100 (30.5)

240V 50 (15.2) 100 (30.5) 200 (61.0)

AWG

150 (45.7)

300 (91.4)

Ampere

Rating

More

Than

Than

0 18 16 16 14

6 18 16 14 12

10 16 16 14 12

12 14 12 Not Recommended

• Do not place any object on top of charger or place the

charger on a soft surface that might block the ventilation

slots and result in excessive internal heat. Place the charger

in a position away from any heat source. The charger is ventilated

through slots in the top and the bottom of the housing.

• Do not operate charger with damaged cord or plug.

• Do not operate charger flit has received a sharp blow, been

dropped, or otherwise damaged in any way. Take it to an

authorized service center.

• Do not disassemble charger; take it to an authorized service

center when service or repair is required. Incorrect reassemb/y

may result in a risk of electric shock, electrocution or fire.

• Disconnect the charger from the outlet before attempting

any cleaning. This will reduce the risk of electric shock.

Removing the battery pack will not reduce this risk.

• NEVER attempt to connect two chargers together.

• The charger is designed to operate on standard 120 volts

household electrical power. Do not attempt to use it on any

other voltage. This does not apply to the vehicular charger.

Page 11

Using Automatic Tune-Up TM Mode

The automatic Tune-Up TM Mode equalizes or balances the

individual cells in the battery pack allowing it to function at peak

capacity. Battery packs should be tuned up weekly or after

10 charge/discharge cycles or whenever the pack no longer delivers

the same amount of work. To use the automatic Tune-Up TM, place

the battery pack in the charger and leave it for at least 8 hours. The

charger will cycle through the following modes.

1. The red light will blink continuously indicating that the 1-hour

charge cycle has started.

2. When the 1-hour charge cycle is complete, the light will stay on

continuously and will no longer blink. This indicates that the pack

is fully charged and can be used at this time.

3. If the pack is left in the charger after the initial 1-hour charge, the

charger will begin the Automatic Tune-Up TM mode. This mode

continues up to 8 hours or until the individual cells in the battery

pack are equalized. The battery pack is ready for use and can be

removed at any time during the Automatic Tune-Up TM mode.

4. Once the Automatic Tune-Up TM mode is complete, the charger will

begin a maintenance charge; the red indicator will remain lit.

Chargers

Your tool uses a DEWALTcharger. Be sure to read all safety instructions

before using your charger. Consult the chart at the end of this manual

for compatibility of chargers and battery packs.

Charging Procedure (Fig. 1)

i_DANGER: Electrocution hazard. 120 volts are present at charging

terminals. Do not probe with conductive objects. Electric shock or

electrocution may result.

1. Plug the charger into an appropriate outlet before inserting battery

pack.

2. Insert the battery pack (I) into the charger, as shown in Figure 1,

making sure the pack is fully seated in charger. The red (charging)

light will blink continuously indicating that the charging process

has started.

3. The completion of charge will be indicated by the red light

remaining on continuously. The pack is fully charged and may be

used at this time or left in the charger.

FIG.1

Indicator Light Operation

PACK CHARGING ................... === =_ =_ =_ =_ =_ =_ === =_

PACK CHARGED .....................

HOT/COLD PACK DELAY ........ _ [] _ [] _ []

REPLACE PACK ...................... ® ®®e®®®®®oo®o®e

PROBLEM POWER LiNE ........ ® ® O [] • ® [] [] [] O

Charge Indicators

Some chargers are designed to detect certain problems that can arise

with battery packs. Problems are indicated by the red light flashing

at a fast rate. If this occurs, re-insert battery pack into the charger. If

the problem persists, try a different battery pack to determine if the

charger is OK. If the new pack charges correctly, then the original

Page 12

packis defectiveandshouldbereturnedto a servicecenteror

othercollectionsiteforrecycling.Ifthenewbatterypackelicitsthe

sametroubleindicationastheoriginal,havethechargertestedatan

authorizedservicecenter.

HOT/COLD PACK DELAY

Some chargers have a Hot/Cold Pack Delay feature: when the charger

detects a battery that is hot, it automatically starts a Hot Pack Delay,

suspending charging until the battery has cooled. After the battery

has cooled, the charger automatically switches to the Pack Charging

mode. This feature ensures maximum battery life. The red light flashes

long, then short while in the Hot Pack Delay mode.

PROBLEM POWER LINE

Some chargers have a Problem Power Line indicator. When the

charger is used with some portable power sources such as generators

or sources that convert DC to AC, the charger may temporarily

suspend operation, flashing the red light with two fast blinks

followed by a pause. This indicates the power source is out of limits.

LEAVING THE BATTERY PACK IN THE CHARGER

The charger and battery pack can be left connected with the red light

glowing indefinitely. The charger will keep the battery pack fresh and

fully charged.

NOTE: A battery pack will slowly lose its charge when kept out of

the charger. If the battery pack has not been kept on maintenance

charge, it may need to be recharged before use. A battery pack may

also slowly lose its charge if left in a charger that is not plugged into an

appropriate AC source.

WEAK BATrERY PACKS: Chargers can also detect a weak battery

pack. Such batteries are still usable but should not be expected to

perform as much work. The charger will indicate to replace battery

pack.

Important Charging Notes

1. Longest life and best performance can be obtained if the battery

pack is charged when the air temperature is between 65 °F and

75 °F (18 °-24 °C). DO NOT charge the battery pack in an air

temperature below +40 °F (+4.5 °C), or above +105 °F (+40.5 °C).

This is important and will prevent serious damage to the battery

pack.

2. The charger and battery pack may become warm to touch while

charging. This is a normal condition, and does not indicate a

problem. To facilitate the cooling of the battery pack after use,

avoid placing the charger or battery pack in a warm environment

such as in a metal shed, or an uninsulated trailer.

3. If the battery pack does not charge properly:

a. Check operation of receptacle by plugging in a lamp or other

appliance;

b. Check to see if receptacle is connected to a light switch which

turns power off when you turn out the lights;

c. Move charger and battery pack to a location where the

surrounding air temperature is approximately 65 °F-75 °F

(18 °-24 °C);

d. If charging problems persist, take the tool, battery pack and

charger to your local service center.

4. The battery pack should be recharged when it fails to produce

sufficient power on jobs which were easily done previously. DO

NOT CONTINUE to use under these conditions. Follow the

charging procedure. You may also charge a partially used pack

whenever you desire with no adverse affect on the battery pack.

5. Under certain conditions, with the charger plugged into the power

supply, the exposed charging contacts inside the charger can

be shorted by foreign material. Foreign materials of a conductive

nature such as, but not limited to, grinding dust, metal chips, steel

wool, aluminum foil, or any buildup of metallic particles should

10

Page 13

be kept away from charger cavities. Always unplug the charger

from the power supply when there is no battery pack in the cavity.

Unplug charger before attempting to clean.

6. Do not freeze or immerse charger in water or any other liquid.

A WARNING: Shock hazard. Don't allow any liquid to get inside

charger. Electric shock may result.

,_,WARNING: Bum hazard. Never attempt to open the battery pack

for any reason. If the plastic housing of the battery pack breaks or

cracks, return to a service center for recycling.

Storage Recommendations

1. The best storage place isone that iscool and dry away from direct

sunlight and excess heat or cold.

2. For long storage, it is recommended to store a fully charged

battery pack in a cool dry place out of the charger for optimal

results.

NOTE" Battery packs should not be stored completely depleted of

charge. The battery pack will need to be recharged before use.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

FIG. 2

B

A

M

E

C

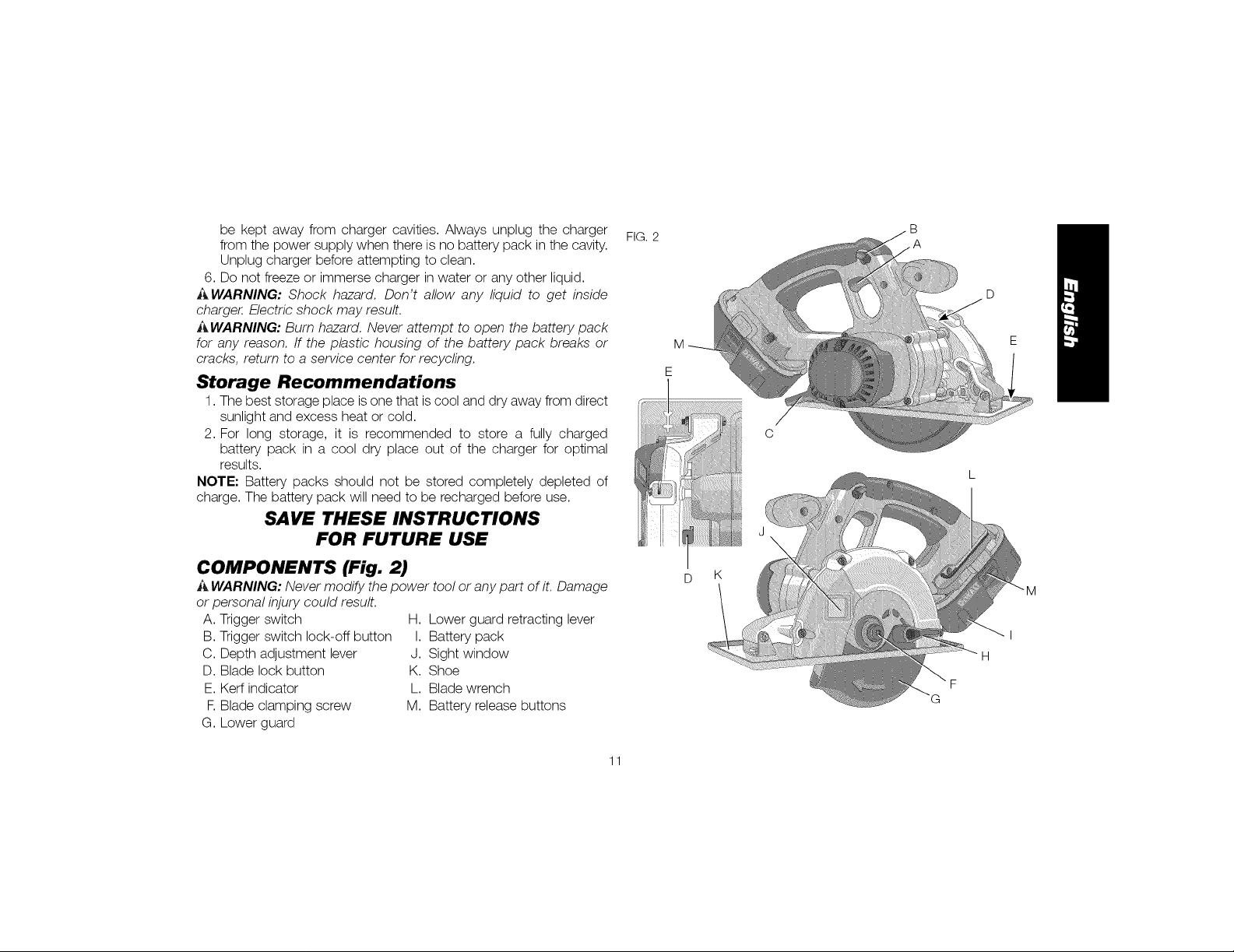

COMPONENTS (Fig. 2)

A WARNING: Never modify the power tool or any part of it. Damage

or personal injury could result.

A. Trigger switch

B. Trigger switch lock-off button

C. Depth adjustment lever

D. Blade lock button

E. Kerf indicator

F.Blade clamping screw

G. Lower guard

H. Lower guard retracting lever

I. Battery pack

J. Sight window

K. Shoe

L. Blade wrench

M. Battery release buttons

D K

11

Page 14

INTENDED USE

This metal cutting circular saw is intended for use by professionals for

cutting light gauge metals and small metal structural shapes.

DO NOT use under wet conditions or in presence of flammable liquids

or gases.

This metal cutting circular saw is a professional power tool. DO NOT

let children come into contact with the tool. Supervision is required

when inexperienced operators use this tool.

i_ WARNING: Do not plunge cut or pocket cut with this saw.

Windows (Fig. 2)

_WARNING: Do not operate the saw with a damaged or

missing sight window. If window is damaged or missing, have

the saw serviced at an authorized service center. If saw is operated

without the window, metal chips could fly through the guard and

cause personal injury.

A CAUTION: Do not use oil or cutting fluids with the metal-

cutting saw. Do not use cleaning fluids to clean window.

Cleaning fluids, cutting fluids or oils could harm the plastic in the

window, interfering with the safe operation of the saw.

The saw is equipped with a sight window (J) on the side of the upper

guard. This window allows the user to see a cutting lineon the material

to be cut.

Saw Shoe (Fig. 2)

The front of the saw shoe (K) has a kerf indicator (E) that allows the

operator to glide the saw along cutting lines. Aligning the cutting line

with the notch on the front of the shoe and centering it using the

modified V-shaped kerf indicator allows the operator to keep the

blade in line with the cutting line. If the cutting line is visible through

the narrowest part of the kerf indicator, the blade will pass directly over

the cutting line.

OPERATION

_ WARNING: To reduce the risk of injury, turn unit off and

disconnect R from power source before installing and removing

accessories, before adjusting or when making repairs. An

accidental start-up can cause injury.

Installing and Removing the Battery Pack

(Fig. 3)

NOTE: For best results, make sure your battery pack is fully charged.

Toinstall the battery pack (I)into the tool handle, align the notch inside

the tool's handle with the battery pack and slide the battery pack firmly

into the handle until you hear the lock snap into place as shown in

Figure 3.

FIG. 3

Toremove the battery pack from the tool, press the release buttons (M)

and firmly pull the battery pack out of the tool handle. Insert it into the

charger as described in the charger section of this manual.

12

Page 15

Switch (Fig. 2)

The saw is controlled by a trigger switch (A) and lock off button (B).

The lock off button must be pressed before the trigger switch will turn

the saw on. Releasing the trigger turns the saw off.

NOTE" This tool has no provision to lock the switch on. The saw

should never be locked on by any means.

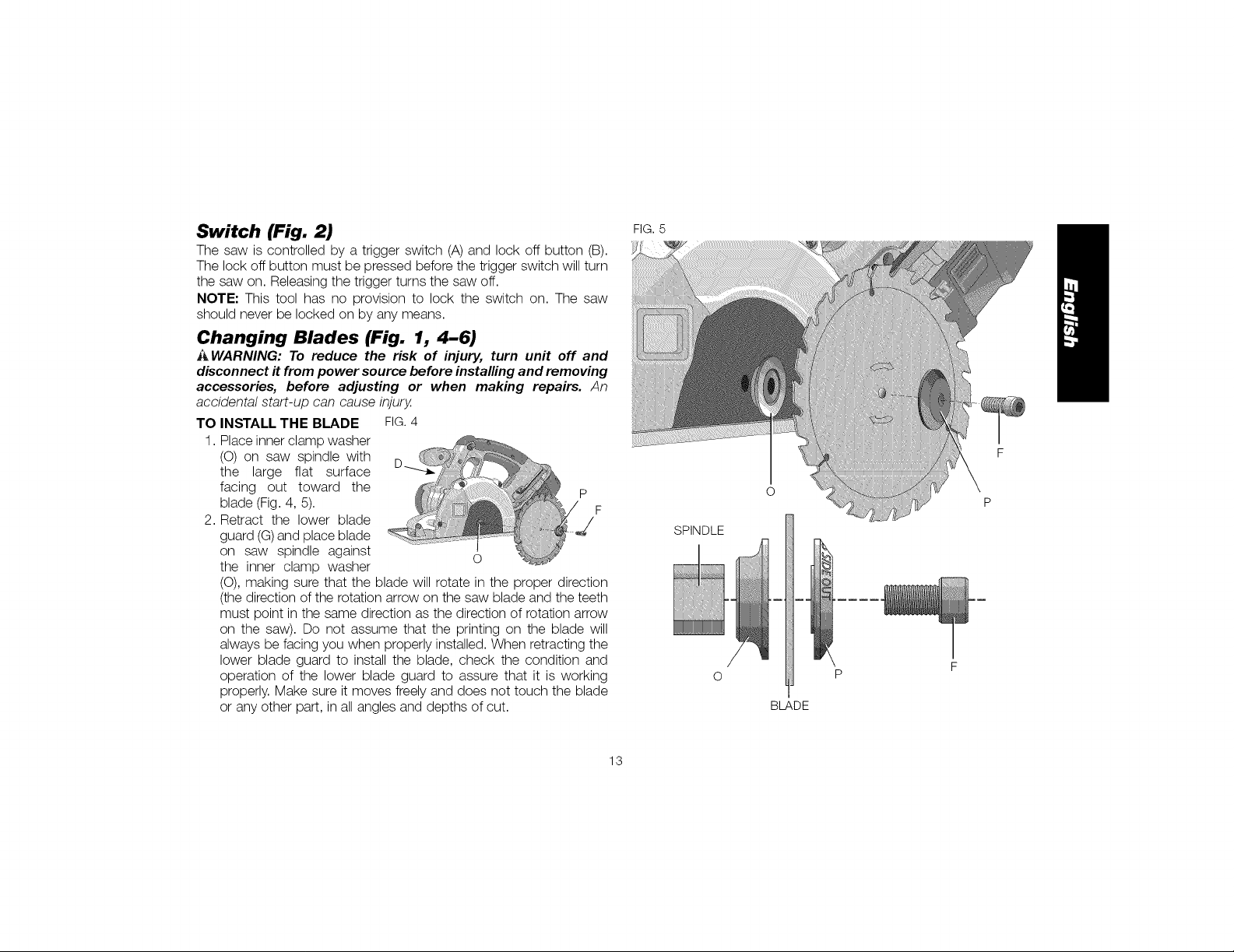

Changing Blades (Fig. 1, 4-6)

WARNING: To reduce the risk of injury, turn unit off and

disconnect it from power source before installing and removing

accessories, before adjusting or when making repairs. An

accidental start-up can cause injury.

TO INSTALL THE BLADE FIG.4

1. Place inner clamp washer

(O) on saw spindle with

the large flat surface

facing out toward the p

blade (Fig. 4, 5). F

2. Retract the lower blade /

guard (G) and place blade

on saw spindle against O

the inner clamp washer

(O), making sure that the blade will rotate in the proper direction

(the direction of the rotation arrow on the saw blade and the teeth

must point in the same direction as the direction of rotation arrow

on the saw). Do not assume that the printing on the blade will

always be facing you when properly installed. When retracting the

lower blade guard to install the blade, check the condition and

operation of the lower blade guard to assure that it is working

properly. Make sure it moves freely and does not touch the blade

or any other part, in all angles and depths of cut.

FIG. 5

SPINDLE

O

BLADE

13

Page 16

3. Place outer clamp washer (P)on FIG.6

saw spindle with the large flat

surface against the blade with

beveled side facing out.

4. Thread blade clamping screw (F)

into saw spindle by hand (screw

has left-hand threads and must

be turned counterclockwise to

tighten) (Fig. 6).

5. Depress the blade lock button

(D)while turning the saw spindle LOOSEN TIGHTEN

with the blade wrench (L, Fig. 1) (clockwise) (countemtockwise)

until the blade lock engages and

the blade stops rotating.

6. Tighten the blade clamping screw firmly with the blade wrench.

NOTICE: Never engage the blade lock while saw is running, or

engage in an effort to stop the tool Never turn the saw on while the

blade lock is engaged. Serious damage to your saw will result.

TO REPLACE THE BLADE

1. To loosen the blade clamping screw (F), depress the blade lock

button (D)and turn the saw spindle with the blade wrench until the

blade lock engages and the blade stops rotating. With the blade

lock engaged, turn the blade clamping screw clockwise with the

blade wrench (screw has left-hand threads and must be turned

clockwise to loosen).

2. Remove the blade clamping screw (F)and outer clamp washer (P)

only. Remove old blade.

3. Clean any metal chips/shavings that may have accumulated in

the guard or clamp washer area and check the condition and

operation of the lower blade guard as previously outlined. Do not

lubricate this area.

4. Select the proper blade for the application (see Blades). Always

use blades that are the correct size (diameter) with the proper size

and shape center hole for mounting on the saw spindle. Always

assure that the maximum recommended speed (rpm) on the saw

blade meets or exceeds the speed (rpm) of the saw.

5. Follow steps 2 through 6 under ToInstall the Blade, making sure

that the blade will rotate in the proper direction.

LOWER BLADE GUARD

WARNING: The lower blade guard is a safety feature which

reduces the risk of serious personal injury. Never use the saw

if the lower guard is missing, damaged, misassembled or not

working properly. Do not rely on the lower blade guard to protect

you under all circumstances. Your safety depends on following

all warnings and precautions as well as proper operation of

the saw. Check lower guard for proper closing before each

use as outlined in Additional Safety Rules for Circular Saws.

If the lower blade guard is missing or not working properly,

have the saw serviced before using. To assure product safety

and reliability, repair, maintenance and adjustment should be

performed by an authorized service center or other qualified

service organization, always using identical replacement parts.

A WARNING: Under certain conditions of use, metal chips may

become imbedded in the surfaces of the lower guard, causing

the lower guard to rub against the upper guard. Check the

operation of the lower guard before each use and remove any

imbedded chips.

Blades

_WARNING: To minimize the risk of eye injury, always use eye

protection. Carbide is a hard but brittle material Foreign objects in

the workpiece such as wire or nails can cause tips to crack or break.

14

Page 17

Only operate saw when proper saw blade guard is in place. Mount

blade securely in proper rotation before using, and always use a

clean, sharp blade.

Blade Diameter Teeth Application

DWA7770 5-1/2" (140 mm) 30 General purpose ferrous

metal cutting

Ifyou need assistance regarding blades, please call 1-800-4-DEWALT

(1-800-433-9258).

KICKBACK

Kickback is a sudden reaction to a pinched, bound or misaligned saw

blade, causing an uncontrolled saw to liftup and out of the workpiece

toward the operator. When the blade is pinched or bound tightly by the

kerf closing down, the blade stalls and the motor reaction drives the

unit rapidly back toward the operator. If the blade becomes twisted or

misaligned in the cut, the teeth at the back edge of the blade can dig

into the top surface of the material causing the blade to climb out of

the kerf and jump back toward the operator.

Kickback is more likely to occur when any of the following conditions

exists.

1. IMPROPER WORKPIECE SUPPORT

A. Sagging or improper lifting of the cut off piece can cause

pinching of the blade and lead to kickback (Fig. 9).

B. Cutting through material supported at the outer ends only can

cause kickback. As the material weakens it sags, closing down

the kerf and pinching the blade (Fig. 9).

C. Cutting off a cantilevered or overhanging piece of material from

the bottom up in a vertical direction can cause kickback. The

falling cut off piece can pinch the blade.

D. Cutting off long narrow strips can cause kickback. The cut off

strip can sag or twist closing the kerf and pinching the blade.

E. Snagging the lower guard on a surface below the material being

cut momentarily reduces operator control. The saw can lift

partially out of the cut increasing the chance of blade twist.

2. IMPROPER DEPTH OF CUT SETTING ON SAW

To make the most efficient cut, the blade should protrude only far

enough to expose a tooth as shown in Figure 8. This allows the

shoe to support the blade and minimizes twisting and pinching in

the material. See the section titled Cutting Depth Adjustment.

3. BLADE TWISTING (MISALIGNMENT IN CUT)

A. Pushing harder to cut can cause the blade to twist.

B.Trying to turn the saw in the cut (trying to get back on the

marked line)can cause blade twist.

C. Overreaching or operating the saw with poor body control (out

of balance), can result in twisting the blade.

D. Changing hand grip or body position while cutting can result in

blade twist.

E. Backing up the saw to clear blade can lead to twist.

4. USE OF DULL OR DIRTY BLADES

Dull blades cause increased loading of the saw. To compensate,

an operator will usually push harder which further loads the unit

and promotes twisting of the blade in the kerf. Worn blades may

also have insufficient body clearance which increases the chance

of binding and increased loading.

5. RESTARTING A CUT WITH THE BLADE TEETH JAMMED

AGAINST THE MATERIAL

The saw should be brought up to full operating speed before

starting a cut or restarting a cut after the unit has been stopped

with the blade in the kerf. Failure to do so can cause stalling and

kickback.

Any other conditions which could result in pinching, binding, twisting,

or misalignment of the blade could cause kickback. Refer to the

sections Further Safety Instructions for All Saws and Blades

15

Page 18

for procedures and techniques that will minimize the occurrence of

kickback.

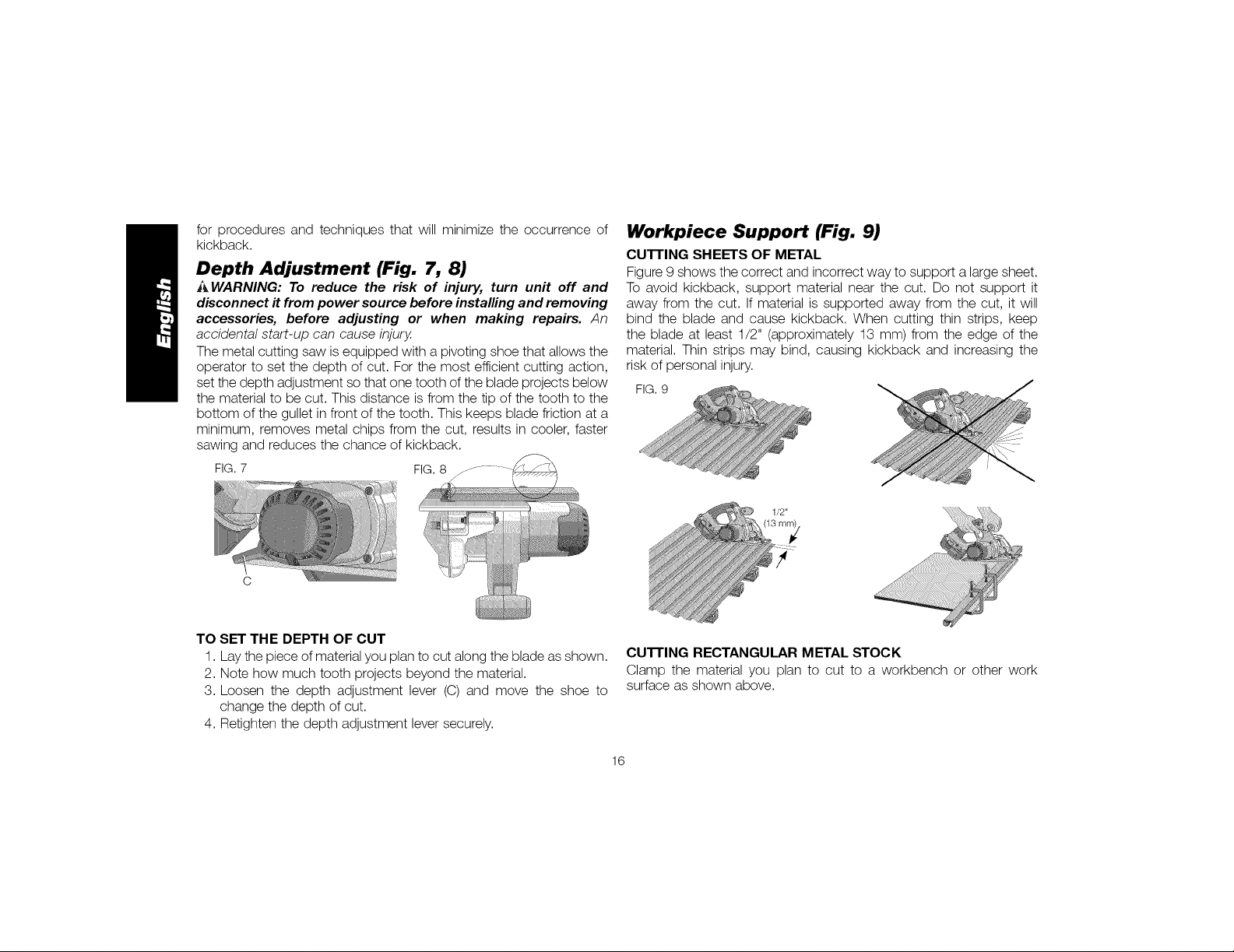

Depth Adjustment (Fig. 7, 8)

_ WARNING: To reduce the risk of injury, turn unit off and

disconnect it from power source before installing and removing

accessories, before adjusting or when making repairs. An

accidental start-up can cause injury.

The metal cutting saw is equipped with a pivoting shoe that allows the

operator to set the depth of cut. For the most efficient cutting action,

set the depth adjustment so that one tooth of the blade projects below

the material to be cut. This distance is from the tip of the tooth to the

bottom of the gullet in front of the tooth. This keeps blade friction at a

minimum, removes metal chips from the cut, results in cooler, faster

sawing and reduces the chance of kickback.

FIG. 7 FIG. 8

Workpiece Support (Fig. 9)

cu'n'ING SHEETS OF METAL

Figure 9 shows the correct and incorrect way to support a large sheet.

To avoid kickback, support material near the cut. Do not support it

away from the cut. If material is supported away from the cut, it will

bind the blade and cause kickback. When cutting thin strips, keep

the blade at least 1/2" (approximately 13 mm) from the edge of the

material. Thin strips may bind, causing kickback and increasing the

risk of personal injury.

FIG. 9

TO SET THE DEPTH OF CUT

1. Lay the piece of material you plan to cut along the blade as shown.

2. Note how much tooth projects beyond the material.

3. Loosen the depth adjustment lever (C) and move the shoe to

change the depth of cut.

4. Retighten the depth adjustment lever securely.

cu'n'ING RECTANGULAR METAL STOCK

Clamp the material you plan to cut to a workbench or other work

surface as shown above.

16

Page 19

Cutting (Fig. 10, 11) FIG,10 X\ _.\ ',.\

1. Hold the saw securely using both

appropriate hand position. Keep

your body to one side of the line

along which you are cutting. This

will protect you from injury related

hands. Figure 10 shows

to kickback.

2. When cutting ends off of

rectangular metal stock, place

the widest part of the shoe on the part of the material that is

clamped to the workbench or other support, not on the part of the

material that will fall when the cut is made.

3. Depress the trigger switch and allow the saw to reach full speed

before the blade contacts the material to be cut (Fig. 11).

FIG. 11

4. Push the saw forward at a speed that allows the blade to cut

without laboring.

5. As you finish a cut, release the trigger and allow the blade to stop

before lifting the saw from the work. As you lift the saw, the guard

will automatically close under the blade.

CORRECTING A CUT

Should your cut begin to leave the cutting line, don't try to force it

back on. Forcing a correction can stall the saw and cause kickback.

Instead, release the switch and allow the blade to come to a complete

stop. Then, back the saw out of the cut. Restart the saw and re-enter

the cut, following the desired cutting line.

A WARNING: Do not stack materials for cutting. Do not cut through

bolts with the saw. Do not touch the blade, workpiece or metal chips

with your bare hand immediately after cutting--they are extremely

hot and may bum your skin.

Maximizing Blade Life

Toextend blade life, follow these practices:

• Do not force the blade through the metal. The saw must cut at its

own pace and at a constant rate.

• Change blades when it is no longer easy to push the saw through

the cut, when the motor isstraining, or when excessive heat is built

up in the blade.

• Keep base of the saw firmly against metal you are cutting.

• If the metal you are cutting is vibrating or shaking, clamp the

material as close to the cut as possible and slow down the cutting

rate.

MAINTENANCE

A WARNING: To reduce the risk of injury, turn unit off and

disconnect it from power source before installing and removing

accessories, before adjusting or when making repairs. An

accidental start-up can cause injury.

Replacing Sight Window (Fig. 1)

,_ WARNING: Do not operate the saw with a damaged or missing

sight window. If window is damaged or missing, have the saw

serviced at an authorized service center. If the saw is operated

without the window, metal chips could fly through the guard and

cause personal injury.

The sight window (J) must be replaced by an authorized DEWALT

service center.

17

Page 20

Cleaning

i_,WARNING: Blow dirt and dust out of all air vents with clean, dry air

at least once a week. To minimize the risk of eye injury, always wear

ANSI Z87.1 approved eye protection when performing this.

_ WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool These chemicals may

weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get

inside the tool,"never immerse any part of the tool into a liquid.

i_ CAUTION: Do not use any cleaning fluids on the sight window to

avoid clouding it and compromising the safe operation of the saw.

Use compressed air to remove accumulated dust from the inside of

the sight window. Wear safety glasses when performing this.

CHARGER CLEANING INSTRUCTIONS

,6,WARNING: Shock hazard. Disconnect the charger from the AC

outlet before cleaning. Dirt and grease may be removed from the

exterior of the charger using a cloth or soft non-metallic brush. Do

not use water or any cleaning solutions.

Lubrication

Self lubricating ball and roller bearings are used in the tool and

relubrication is not required. However, it is recommended that, once

a year, you take or send the tool to a certified service center for a

thorough cleaning, inspection, and lubrication of the gear case.

Accessories

i_WARNING: Since accessories, other than those offered by

DEWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the risk of

injury, only DEWALT recommended accessories should be used with

this product.

Use only 5-1/2" (140 mm) DEWALT metal cutting blades with a 20 mm

arbor.

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory, please contact DEWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call

1-800-4-DEWALT (1-800-433-9258) or visit our website: www.dewalt.

com.

Repairs

The charger and battery pack are not serviceable.

Toassure product SAFETYand RELIABILITY, repairs, maintenance and

adjustment (including brush inspection and replacement) should be

performed by a DEWALTfactory service center, a DEWALT authorized

service center or other qualified service personnel. Always use

identical replacement parts.

Register Online

Thank you for your purchase. Register your product now for:

• WARRANTY SERVICE: Registering your product will help you

obtain more efficient warranty service in case there is a problem

with your product.

• CONFIRMATION OF OWNERSHIP: In case of an insurance

loss, such as fire, flood or theft, your registration of ownership will

serve as your proof of purchase.

• FOR YOUR SAFETY: Registering your product will allow us to

contact you in the unlikely event a safety notification is required

under the Federal Consumer Safety Act.

Register online at www.dewalt.com/register.

18

Page 21

Three Year Limited Warranty

DEWALTwill repair,without charge, any defects due to faulty materials

or workmanship for three years from the date of purchase. This

warranty does not cover part failure due to normal wear or tool abuse.

For further detail of warranty coverage and warranty repair information,

visit www.dewalt.com or call 1-800-4-DEWALT (1-800-433-9258).

This warranty does not apply to accessories or damage caused where

repairs have been made or attempted by others. This warranty gives

you specific legal rights and you may have other rights which vary in

certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by

normal use, for free, any time during the first year after purchase.

2 YEARS FREE SERVICE ON DEWALT BA'rrERY PACKS

DC9071, DC9091, DC9096, DC9280, DC9360, DC9180, DCB120,

DCB201 and DCB203

3 YEARS FREE SERVICE ON DEWALT BA'rI'ERY PACKS

DCB200, DCB204

DEWALT BATTERY PACKS

Product warranty voided if the battery pack is tampered with in any

way. DEWALT is not responsible for any injury caused by tampering

and may prosecute warranty fraud to the fullest extent permitted by

law.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

DE-:WALTPower Tool, Laser, or Nailer for any reason, you can return it

within 90 days from the date of purchase with a receipt for a full refund

- no questions asked.

LATIN AMERICA: This warranty does not apply to products sold

in Latin America. For products sold in Latin America, see country

specific warranty information contained in the packaging, call the local

company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DEWALT (1-800-433-

9258) for a free replacement.

r

DCS37251/2" (140rnm) CORDLESS

SER.

_ KE£PHANDSAflO BODY AWAY _ROMAND

A _Gne_ MAN_NGA L_S M_aOS Y ELCUE_POAL_ADOS O_

t_AHOJAY AUN LADO _IELAMISMA, ELCONYACTOCON LAHO_tA

PeOVOC_ L_SION_S_RAVE_.

I_A_](_E_I: TENIR LESMAINS E¥TOUTEAi_TREPARTIEt)U CORPS

_OIGNE_S DE _ LAU_ ETSUe LECOTEO_CELLE-CLTOUTCO_TAC_

AVECLA LAMEI_JSO_ OE CAUS_ OE GRAVES8L_SSURE5.

_ _o REDtJCETHE_ISK 0F INJU_Y,_$£_MUST_A_ I_UC_ON MA_U_L

M_I_ a_JU_TS. DO _OTUS_ C_TTI_ OIL

LEE_SE_L MANUAL_E INSTRUCCIONES.

_ J

METAL CUTTINGCIRCULARSAW

TOTHESI9E OFTI_E_LADE. COk_A_ WITH

_LAD_ WlL_ _ESUL_ mNsEelous It_JURy.

CH_C__u_l_ SYSTEM. IT_US_

CUBRIRLAHOJAALINSTANTE_S0S_ENGALASIERRACO_AMBASMAN0S,

APOYEYSUJETEELT_ABAJO,USEPROTECClbNOCULAR,USESiEMP_E

PROTECCIO__ESPI_AT0_IAADECUAOA,USARCO_ BATERiADEWAL_,SAQUE

LAUNIDADDEBATERiAAL CAMBIARLASHOJAS0 HACERAJUSTES,NOUSE

ACEITE0EtORTE,

AVERTZSSEMINT: V_RIFIERLEBON_0NCTIO_NEMENTDUCA_ER

O_P_OTECTIO_,ILD01TPOUVOIR_ECOUWlRLALA_ INSTANTA_MEN_

MAINTENIRLASCIEP.DEU×MAINS,SOUTENIRETARRIMERLETRAVAIL,

PORTERUNEPROTECTIONOCULAJ_EP0eTERSYSTEMATIOUEME_TUN

SYSTEMEDE P_OTECTION_S VOLES_ESPI_AT01RESA_EO_ATS,UTILISE_

AVECUNBLOC-PILEDEWALT,_ETIRERLEBLOC-PILESAVANTDECHANGERLA

_/&BVEI_I_IENC|_: COMPRiI_BE EL $1STEMA DE P_0TECCJ0N. iDE_E

LAME0UD'EFFECTUERDESREGLAGES,NE FASUTlUSERD'HUlLEOECOUPE,

D_WALTINDUSTRIALTOOLCO,,_ALIlMO_, _O2128_USA

FO_SERVICEINfOrMATIONCALL:1-e00-_-_WALT _,O_WALT.com

19

Page 22

D_finitions : lignes directrices en

mati_re de s_curit_

Les definitions ci-dessous decrivent le niveau de danger pour

chaque mot-indicateur employe. Lire le mode d'emploi et porter

une attention particuliere a.ces symboles.

_,DANGER : indique une situation dangereuse imminente qui,

si elle n'est pas evitee, entraTnera la mort ou des blessures

graves.

i_AVERTISSEMENT : indique une situation potentie//ement

dangereuse qui, si e//e n'est pas evitee, pourrait entra_ner /a

mort ou des blessures graves.

_ATTENTION : indique une situation potentie//ement

dangereuse qui, si e//e n'est pas evitee, pourrait entra_ner des

blessures I_g_res ou modifies.

AVIS : indique une pratique ne posant aucun risque de

dommages corporels mais qui par contre, si rien n'est fair

pour /'eviter, pourrait poser des risques de dommages

materiels.

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET OUTIL

OU DE TOUT AUTRE OUTIL DEWALT, COMPOSE LE NUMC:RO

SANS FRAIS : 1-800-4-DEWALT (1-800-433-9258).

_ VERTISSEMENT : afin de reduire le risque de blessures, life

le mode d'emploi de I'outil.

Avertissements de s_curit_ g_n_raux pour

les outils _lectriques

s_curit_ et toutes les directives. Le non-respect des

_k AVERTISSEMENT! life tous les avertissements de

avertissements et des directives pourrait se solder par un

choc dectrique, un incendie et/ou une blessure grave.

CONSERVER TOUS LES AVERTISSEMENTS

ET TOUTES LES DIRECTIVES POUR UN

USAGE ULTERIEUR

Le terme _ outil dectrique _cite dans les avertissements se rapporte

votre outil dectrique a alimentation sur secteur (avec ill) ou par piles

(sansfi/).

1) S#CURIT# DU LIEU DE TRAVAIL

a) Ten#" I'aire de travail propre et bien _clair_e. Les Iieux

encombres ou sombres sont propices aux accidents.

b) Ne pas faire fonctionner d'outils _lectriques clans un

milieu d_flagrant, tel qu'en presence de liquides, de

gaz ou de poussi_res inflammables. Les outi/s e/ectriques

produisent des etincelles qui pourraient enflammer la poussiere

ou les vapeurs.

c) E-Ioigner les enfants et les personnes aproximit_ pendant

I'utilisation d'un outil _lectrique. Une distraction pourrait en

faire perdre la ma_trise a I'utilisateur.

2) S#CURIT# EN MATIERE D'#LECTRICIT#

a) Les fiches des outils _lectriques doivent correspondre

la prise. Ne jamais modifier la fiche d'aucune faqon.

Ne jamais utiliser de fiche d'adaptation avec un outil

_lectrique mis a la terre. Le risque de choc electrique sera

reduit par I'utilisation de fiches non modifiees correspondant

la prise.

2O

Page 23

b) Eviter tout contact physique avec des surfaces mises a la

terre comme des tuyaux, des radiateurs, des cuisini_res

et des r_frig_rateurs. Le risque de choc dectrique est plus

deve si votre corps est mis a la terre.

c) Ne pas exposer les outils _lectriques a la pluie ou

I'humidit_. La penetration de /'eau dans un outi/ e/ectrique

augmente le risque de choc dectrique.

d) Ne pas utiliser le cordon de fa_on abusive. Ne jamais

utiliser le cordon pour transporter, tirer ou d_brancher un

outil _lectrique. Tenir le cordon _loign_ de la chaleur, de

I'huile, des bords tranchants et des pi_ces mobiles. Les

cordons endommages ou enchev_tres augmentent les risques

de choc dectrique.

e) Pour I'utilisation d'un outil _lectrique a I'ext_rieur, se

servir d'une rallonge convenant a cette application.

L'utilisation d'une rallonge conque pour I'exterieur reduira les

risques de choc dectrique.

S'il est impossible d'_viter I'utilisation d'un outil _lectrique

dans un endroit humide, brancher I'outil dans une prise

ou sur un circuit d'alimentation dot_s d'un disjoncteur de

fuite a la terre (GFCI). L'utilisation de ce type de disjoncteur

reduit les risques de choc dectrique.

3) SI_CURITI_ PERSONNELLE

a) Etre vigilant, surveiller le travail effectu_ et faire preuve

de jugement Iorsqu'un outil _lectrique est utilis_. Ne

pas utiliser d'outil _lectrique en cas de fatigue ou sous

I'influence de drogues, d'alcool ou de m_dicaments. Un

simple moment d'inattention en utilisant un outil dectrique peut

entra_ner des blessures corporelles graves.

b) Utiliser des _quipements de protection individuelle.

Toujours porter une protection oculaire. L'utilisation

d'equipements de protection comme un masque antipoussiere,

des chaussures antiderapantes, un casque de securite ou des

protecteurs auditifs Iorsque la situation le requiert reduira les

risques de blessures corporelles.

c) Emp_cher les d_marrages intempestifs. S'assurer que

I'interrupteur se trouve a la position d'arr_t avant de

relier I'outil a une source d'alimentation et/ou d'ins_rer

un bloc-piles, de ramasser ou de transporter I'outil.

Transporter un outil dectrique alors que le doigt repose sur

I'interrupteur ou brancher un outil dectrique dont I'interrupteur

est a la position de marche risque de provoquer un accident.

d) Retirer toute cl_ de r_glage ou cl_ avant de d_marrer

I'outil. Une c/e ou une c/e de reg/age attachee a une pattie

pivotante de I'outil dectrique peut provoquer des blessures

corporelles.

e) Ne pas trop tendre les bras. Conserver son _quilibre en

tout temps. Ce/a permet de mieux ma_triser /'outi/ e/ectrique

dans les situations imprevues.

S'habiller de mani_re appropri_e. Ne pas porter de

v_tements amples ni de bijoux. Garder les cheveux, les

v_tements et les gants a I'_cart des pi_ces mobiles. Les

v_tements amp/es, /es bijoux ou /es cheveux longs risquent de

rester coinces dans les pieces mobiles.

g) Si des composants sent fournis pour le raccordement de

dispositifs de d_poussi_rage et de ramassage, s'assurer

que ceux-ci sent bien raccord_s et utilis_s. L'utilisation

d'un dispositif de depoussierage peut reduire les dangers

engendres par les poussieres.

21

Page 24

4) UTILISATION ET ENTRETIEN D'UN OUTIL leLECTRIQUE

a) Ne pas forcer un outil _lectrique. Utiliser I'outil _lectrique

appropri_ a I'application. L'outil electrique approprie

effectuera un mei/leur travail, de faqon plus sore et a la vitesse

pour laquelle il a ete conqu.

b) Ne pas utiliser un outil _lectrique dont I'interrupteur

est d_fectueux. Tout outil dectrique dont I'interrupteur est

defectueux est dangereux et dolt _tre repare.

c) D_brancher la fiche de la source d'alimentation et/ou du

bloc-piles de I'outil _lectrique avant de faire tout r_glage

ou changement d'accessoire ou avant de ranger I'outil.

Ces mesures preventives reduisent les risques de demarrage

accidentel de I'outil dectrique.

d) Ranger les outils _lectriques hors de la pottle des enfants

et ne permettre a aucune personne n'_tant pas famili_re

avec un outil _lectrique ou son mode d'emploi d'utiliser

cet outil. Les out/Is dectr/ques dev/ennent dangereux entre les

mains d' utilisateurs inexperimentes.

e) Entretien des outils _lectriques. V_rifier si les pi_ces

mobiles sont mal align_es ou coinc_es, si des pi_ces sont

bris_es ou pr_sentent toute autre condition susceptible

de nuire au bon fonctionnement de I'outil _lectrique.

En cas de dommage, faire r_parer I'outil _lectrique

avant toute nouvelle utilisation. Beaucoup d'accidents sont

causes par des outils dectriques mal entretenus.

S'assurer que les outils de coupe sont aiguis_s et

propres. Les outils de coupe bien entretenus et affOtes

sont moins susceptibles de se coincer et sont plus faciles

ma_triser.

g) Utiliser I'outil _lectrique, les accessoires, les forets,

etc. conform_ment aux pr_sentes directives en tenant

compte des conditions de travail et du travail a effectuer.

L'utilisation d'un outil dectrique pour toute operation autre que

celle pour laquelle il a ete conquest dangereuse.

5) UTILISATION ET ENTRETIEN DU BLOC-PILES

a) Ne recharger l'outil qu'au moyen du chargeur pr_cis_ par

le fabricant. L'utilisation d'un chargeur qui convient a un type

de bloc-piles risque de provoquer un incendie s'il est utilise

avec un autre type de b Ioc-piles.

b) Utiliser les outils _lectriques uniquement avec les blocs-

piles conqus a cet effet. L'utilisation de tout autre bloc-piles

risque de causer des blessures ou un incendie.

c) Lorsque le bloc-piles n'est pas utilis_, le tenir _loign_

des objets m_talliques, notamment des trombones, de

la monnaie, des cl_s, des clous, des vis ou autres petits

objets m_talliques qui peuvent _tablir une connexion

entre les deux bornes. Le court-circuit des bomes du bloc-

piles risque de provoquer des brOlures ou un incendie.

d) En cas d'utilisation abusive, le liquide peut gicler hors

du bloc-piles; _viter tout contact avec ce liquide. Si un

contact accidentel se produit, laver a grande eau. Si le

liquide entre en contact avec les yeux, obtenir _galement

des soins m_dicaux. Le Iiquide qui gicle hors du bloc-piles

peut provoquer des irritations ou des brOlures.

6) RI_PARATION

a) Faire r_parer I'outil _lectrique par un r_parateur

professionnel en n'utilisant que des pi_ces de rechange

identiques. Cela permettra de maintenir une utilisation

securitaire de I'outil dectrique.

22

Page 25

Consignes de s_curit_ propres _ toutes

les scies

a) _,DANGER : _loigner les mains des zones et organes

de coupe. Maintenir la deuxi_me main sur la poign_e

auxiliaire ou le boftier du moteur. Lorsque /es deux mains

maintiennent lascie, la lame ne peut les couper.

b) N'essayez pas de tenir le dessous de I'ouvrage. Le

protege-lame ne peut pas vous proteger de la lame en

dessous de I'ouvrage.

c) Ajustez la profondeur de coupe a l'_paisseur de l'ouvrage.

Moins d'une dent entiere de lame devrait _tre visible en

dessous de I'ouvrage.

d) Ne tenez jamais clans vos mains ou sur vos genoux un

ouvrage qui est en cours de coupe. Fixez votre ouvrage

sur une plateforme stable. // est important de soutenir

correctement I'ouvrage afin de minimiser I'exposition du corps

la lame, le risque de coincement de la lame ou la perte de

contr61e de I'outil.

e) Tenez I'outil _lectrique par ses surfaces de prehension

isolantes quand vous r_alisez une operation au cours de

laquelle routil de coupe pourraft entrer en contact avec

des c&bles dissimul_s. Le contact avec un fi/ sous tension

mettra ega/ement sous tension toutes /es pieces meta//iques

exposees et donnera un choc dectrique a I'utilisateur de I'outil.

Pendant les coupes de refente, utilisez toujours un

guide de refente ou un guide a bord droit. Ceci augmente

toujours /'exactitude de la coupe et diminue la possibilite de

coincement de la lame.

g) Utilisez toujours des lames dont I'al_sage central est

de la taille et de la forme appropri_es (soft en forme

de diamant, soft en forme de fond). Les lames qui ne

correspondent pas aux pieces de montage de la cie toumeront

de faqon excentrique, ce qui causera une perte de contr61e

de I'outil.

h) Ne vous servez jamais de rondelles ou de boulons

de lames qui sent endommag_s ou inappropri_s. Les

rondelles et le boulon de lame ont ete conqus specifiquement

pour votre scie dans le but d'assurer une performance

optimale et un fonctionnement sans danger.

Consignes additionnelles de s_curit_

propres _ toutes les scies

CAUSES DES REBONDS ET M#THODES DE PR#VENTION

POUVANT I_TRE UTILIS#ES PAR L'UTILISATEUR :

• Le rebond est une reaction subite (causee par une lame de

scie pincee, coincee ou mal alignee) qui peut entra_ner le

soulevement d'une scie non contr61ee, sa sortie de I'ouvrage

et sa projection en direction de I'utilisateur.

• Si la lame est pincee ou coincee fortement pendant

I'abaissement de la scie, la lame se cale et le moteur reagit en

entra_nant rapidement I'outil vers I'arriere dans la direction de

I'operateur.

• Si la lame se tord ou perd son alignement correct au cours

de la coupe, les dents sur le bord arriere de la lame peuvent

entamer la surface superieure du bois, forqant ainsi la lame

sortir du trait de scie eta _sauter _ vers I'arriere en direction

de I'operateur.

Le rebond est la consequence d'une mauvaise utilisation de la scie

et/ou de procedures ou de conditions incorrectes, et il peut _tre evite

en prenant les precautions qui sont decrites ci-dessous :

a) Maintenez fermement la scie avec vos deux mains et

posftionnez vos bras de faqon a r_sister aux forces de

rebond. Les forces de rebond peuvent _tre contr61ees par

I'utilisateur quand les precautions appropriees sont prises.

23

Page 26

b) En cas de coincement de la lame ou d'interruption d'une

coupe pour une raison quelconque, rel&chez la g&chette

et tenez la scie immobile clans I'ouvrage jusqu'a ce que la

lame se soit immobilis_e compl_temenL Ne tentez jamais

de retirer la scie de I'ouvrage ou de la tirer vers I'arri_re

pendant que la lame est en mouvement, car un rebond

risquerait de se produire. Evaluez la situation et prenez les

mesures correctives necessaires pour diminer la cause du

coincement de la lame.

c) Lorsque vous remettez une scie en marche quand

I'ouvrage est present, centrez la lame de scie clans le trait

de scie et v_rifiez que les dents de la lame ne sent pas

engag_es clans le mat_riau de I'ouvrage. Si /a lame de scie

se coince, elle peut grimper hors de I'ouvrage ou rebondir sur

celui-ci quand la scie est remise en marche.

d) Soutenez les panneaux de grande taille de fa_on

minimiser le risque de pincement et de rebond de la

lame. Les panneaux de grande taille ont tendance a s'affaisser

sous leur propre poids. Des supports doivent _tre places des

deux c6tes sous le panneau, a proximite de la ligne de coupe

eta proximite du rebord du panneau.

e) N'utilisez pas de lame _mouss_e ou endommag_e. Des

lames non aiguisees ou mal instal/ees produisent un trait de

scie etroit qui cause une friction excessive, le coincement de la

lame et un effet de rebond.

0 Les leviers de r_glage de la profondeur et de I'angle de

coupe de la lame doivent _tre bien serf, s et assujettis

avant de r_aliser une coupe. Une modification du reglage

de la lame pendant la coupe risque d'entra_ner un coincement

et un rebondissement de la lame.

g) Prendre des precautions suppl_mentaires lots de coupes

clans des murs existants ou clans toute zone a visibilit_

r_duite. La lame sail/ante peut couper des objets, et ceci peut

entra_ner un rebond.

CONSIGNES DE SleCURITle RELATIVES AU PROTI-GE-LAME

INFleRIEUR

a) Inspectez le protege-lame inf_rieur avant chaque

utilisation pour vous assurer qu'il se ferme correctement.

Ne faites pas fonctionner la scie si le protege-lame

inf_rieur ne se d_place pas librement et ne se ferme

pas instantan_menL Ne forcez jamais le protege-lame

inf_rieur clans la position ouverte a I'aide d'un collier de

serrage ou d'une attache. /I est possible que le protege-

lame inferieur se torde en cas de chute accidentelle de la

scie. Soulevez le protege-lame inferieur a I'aide de la poignee

retractable et assurez-vous qu'il se deplace sans probleme et

qu'il ne touche pas la lame ou une autre piece, quel que soit

I'angle ou la profondeur de la coupe.

b) V_rifiez le fonctionnement du ressort du protege-lame

inf_rieur. Si le protege-lame inf_rieur et le ressort ne

fonctionnent pas correctement, ils doivent _tre r_par_s

avant I'emploL Le protege-lame inferieur peut parfois ma/

fonctionner a cause de pieces endommagees, d'accumulation

de resine ou de debris.

c) Le protege-lame inf_rieur dolt _tre r_tract_ a la main

uniquement a I'occasion de coupes sp_ciales telles que

les _ coupes en plong_e _,ou les _ coupes compos_es _,.

Soulevez le protege-lame inf_rieur a I'aide la poign_e

r_tractable et rel&chez-le d_s que la lame p_n_tre clans le

mat_riau de I'ouvrage. Pour toute autre operation de sciage,

le protege-lame inferieur doit fonctionner automatiquement.

d) V_rifiez toujours que le protege-lame inf_rieur couvre la

lame avant de placez la scie sur un banc ou sur le sol.

Une lame non protegee qui toume Iibrement entra_nera le

mouvement de la scie en marche arriere, ce qui provoquera

la coupe de tout se qui se trouve sur sa trajectoire. Soyez

conscient du temps necessaire a la lame pour s'arr_ter une

lois que la gSchette est relSchee.

24

Page 27

REMARQUE : bien que les directives de securite ci-dessus

mentionnent le bois, cette scie ne doit _tre utilisee que pour couper

le metal Lots de la coupe du metal, des rebonds pourraient se

produire.

Consignes sp_cifiques additionnelles de

s_curit_ propres aux scies circulaires

iCAVERTISSEMENT : ne pas utiliser de meules ou de lames

abrasives.

_VERTISSEMENT : ne pas utiliser des dispositifs

d'alimentation en eau.

_ATTENTION : ne pas tenter de couper I'acier inoxydable, les

barres nervur_es, I'acier tremp6 ou trait_ thermiquement, la

fonte, la maqonnerie ou des mat_riaux inconnus.

• Utilisez des serres de fixation ou un autre dispositif de

fixation permettant de soutenir et de retenir la piece sur

une plate-forme stable. Tenir lapiece avec la main ou contre son

corps n'est pas suffisamment stable et risque de provoquer une