Page 1

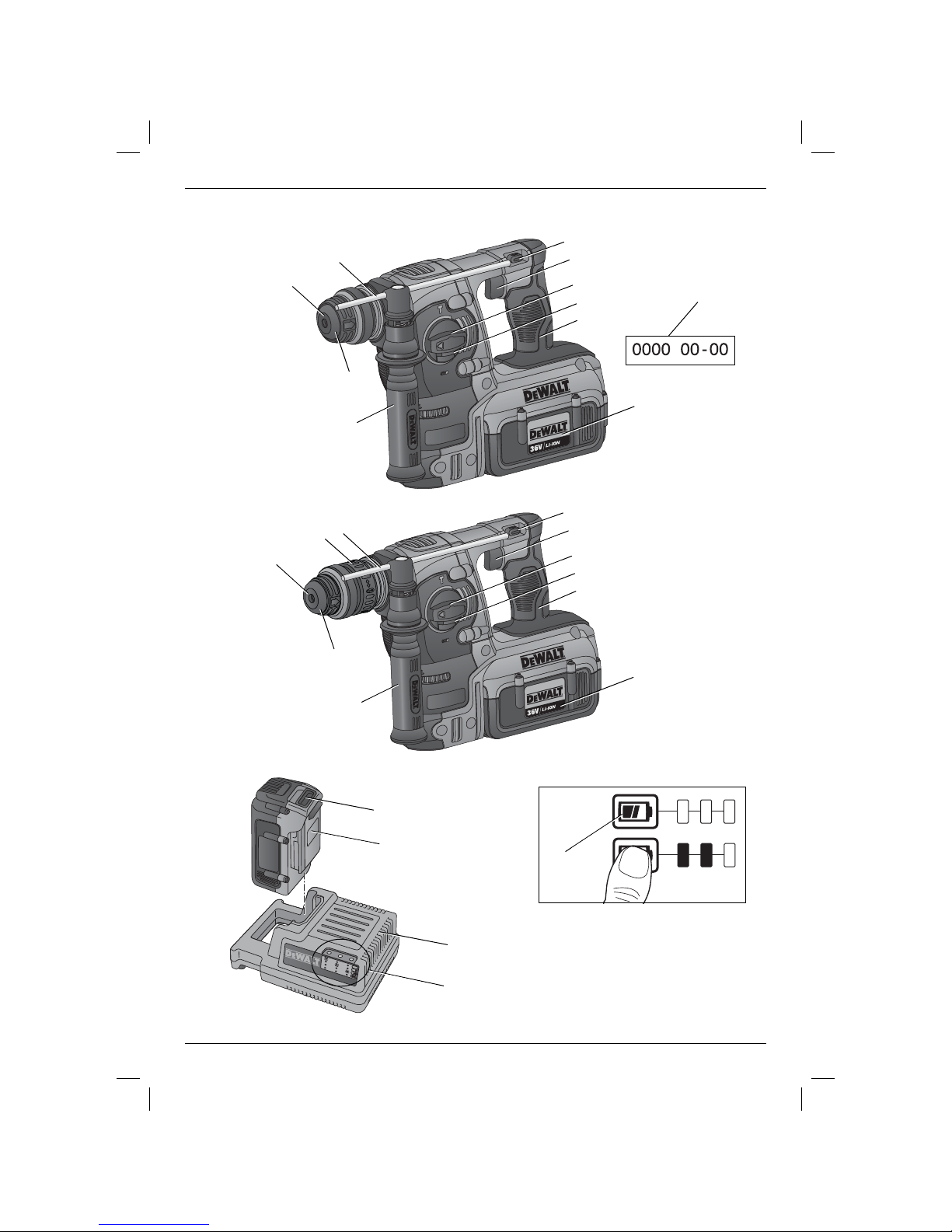

DCH363

DCH364

Page 2

Dansk (oversat fra original brugsvejledning) 4

Deutsch (übersetzt von den Originalanweisungen) 19

English (original instructions) 34

Español (traducido de las instrucciones originales) 47

Français (traduction de la notice d’instructions originale) 63

Italiano (tradotto dalle istruzioni originali) 77

Nederlands (vertaald vanuit de originele instructies) 92

Norsk (oversatt fra de originale instruksjonene) 107

Português (traduzido das instruções originais) 121

Suomi (käännetty alkuperäisestä käyttöohjeesta) 137

Svenska (översatt från de ursprungliga instruktionerna) 150

Türkçe (orijinal talimatlardan çevrilmiştir) 164

Ελληνικά (μετάφραση από τις πρωτότυπες οδηγίες) 179

2

Copyright DEWALT

Page 3

2

8

7

5

9

8

6

7

1

3

4

10

11

2

1

3

4

10

20

A

5

9

12

11

13

14

21

11

1

Page 4

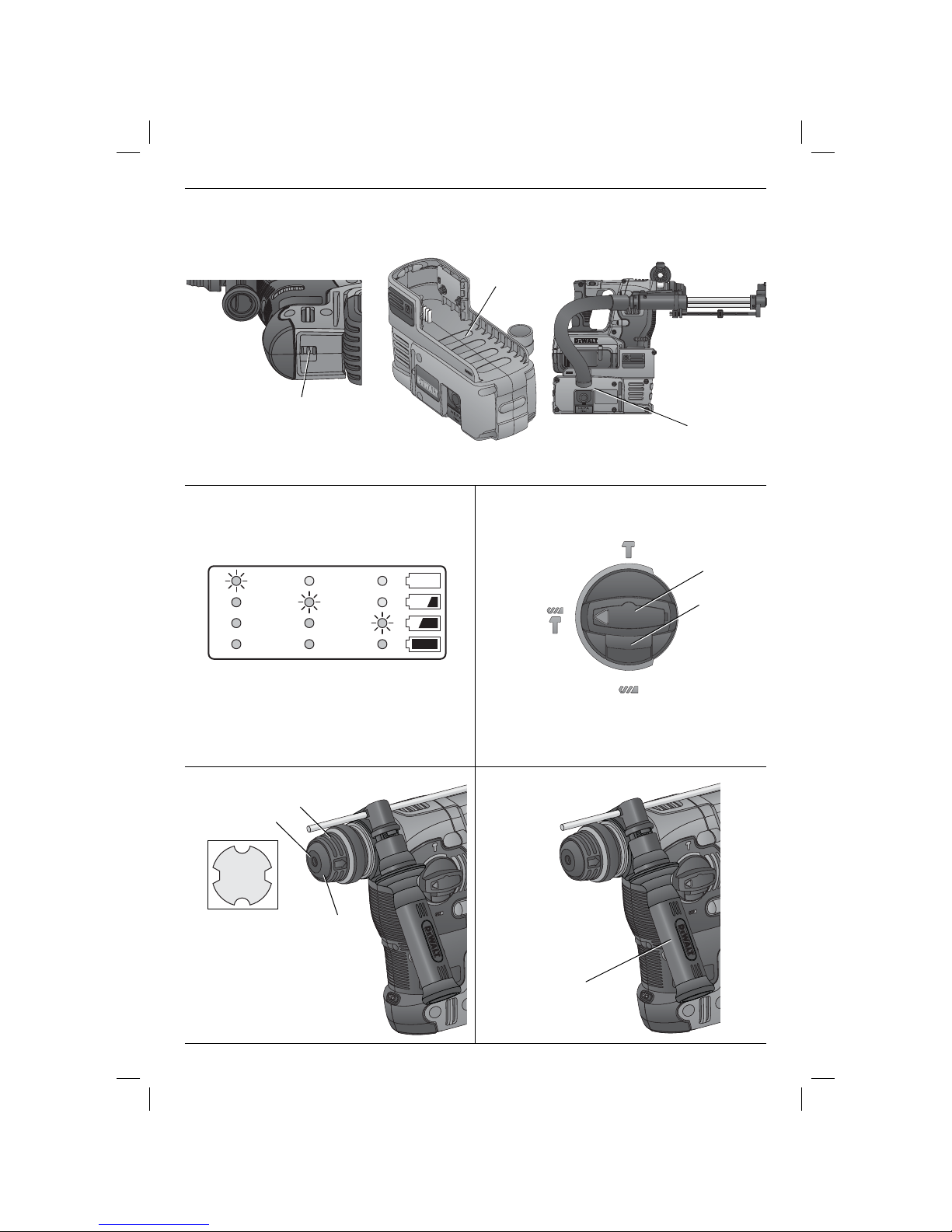

A1

18

17

19

3

4

B

D

2

C

15

7

5

9

E

Page 5

2

8

9

F

5

6

16

G

HI

3

Page 6

ENGLISH

CORDLESS ROTARY HAMMERDRILL

DCH363, DCH364

Congratulations!

You have chosen a DEWALT tool. Years of experience, thorough product development and innovation make

DEWALT one of the most reliable partners for professional power tool users.

Technical Data

DCH363 DCH364

Voltage V 36 36

Type 1 1

No-load speed min-1 0–1100 0–1100

Power output W 600 600

Impact energy (EPTA 05/2009) J 2.3 2.3

Maximum drilling range in

steel/wood/concrete mm 13/30/26 13/30/26

Tool holder SDS Plus® SDS Plus

Impacts per minute 4500 4500

Weight (without battery pack) kg 2.6 2.8

LPA (sound pressure) dB(A) 86 86

KPA (sound pressure uncertainty) dB(A) 3 3

LWA (sound power) dB(A) 97 97

KWA (sound power uncertainty) dB(A) 3 3

®

Vibration total values (triax vector sum) determined according to EN 60745:

Vibration emission value a

Drilling into metal

a

h,D

Uncertainty K = m/s²

Vibration emission value a

Drilling into concrete

a

h,HD

Uncertainty K = m/s²

Vibration emission value a

Chiselling

a

h,Cheq

Uncertainty K = m/s²

Vibration emission value a

Screwdriving without impact

ah

Uncertainty K = m/s²

h

=

m/s²

<2.5 <2.5

1.5 1.5

h

=

m/s²

7.1 7.1

1.5 1.5

h

=

m/s²

5.5 5.5

1.5 1.5

h

=

m/s²

<2.5 <2.5

1.5 1.5

The vibration emission level given in this information sheet has been measured in accordance with a

standardised test given in EN 60745 and may be used to compare one tool with another. It may be used for a

preliminary assessment of exposure.

4

Page 7

ENGLISH

WARNING: The declared vibration

An estimation of the level of exposure to

Identify additional safety measures to

Battery pack DE9360/DC9360 DCB360 DCB361

Voltage V

Capacity Ah 2.0 4.0 2.0

Weight kg 0.9 1.3 0.9

Charger DE9000/DC9000

Mains voltage V

Approx. charging time min 90 45

(4.0 Ah) (2.0 Ah)

Weight kg 0.9

Fuses:

Europe 230 V tools 10 Amperes, mains

U.K. & Ireland 230 V tools 3 Amperes, in plugs

emission level represents the main

applications of the tool. However if the

tool is used for different applications,

with different accessories or poorly

maintained, the vibration emission may

differ. This may significantly increase the

exposure level over the total working

period.

vibration should also take into account

the times when the tool is switched off or

when it is running but not actually doing

the job. This may significantly reduce

the exposure level over the total working

period.

protect the operator from the effects of

vibration such as: maintain the tool and

the accessories, keep the hands warm,

organisation of work patterns.

36 36 36

DC

230

AC

Defi nitions: Safety Guidelines

The definitions below describe the level of severity for

each signal word. Please read the manual and pay

attention to these symbols.

DANGER: Indicates an imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING: Indicates a potentially

hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION: Indicates a potentially

hazardous situation which, if not avoided,

may result in minor or moderate

injury.

NOTICE: indicates a practice not

related to personal injury which, if

not avoided, may result in property

damage.

Denotes risk of electric shock.

Denotes risk of risk of fire.

EC-Declaration of Conformity

MACHINERY DIRECTIVE

CORDLESS ROTARY HAMMERDRILL

DCH363, DCH364

DEWALT declares that these products described

under Technical Data are in compliance with:

2006/42/EC, EN 60745-1, EN 60745-2-6.

These products also comply with Directive

2014/30/EU and 2011/65/EU. For more information,

please contact DEWALT at the following address or

refer to the back of the manual.

The undersigned is responsible for compilation of the

technical file and makes this declaration on behalf of

D

EWALT.

Horst Grossmann

Vice President Engineering

DEWALT, Richard-Klinger-Straße 11,

D-65510, Idstein, Germany

30.01.2014

WARNING: To reduce the risk of injury,

read the instruction manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or batteryoperated (cordless) power tool.

and all instructions. Failure to follow the

warnings and instructions may result in

electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

5

Page 8

ENGLISH

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric

shock.

b) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is

an increased risk of electric shock if your body

is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric

shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply. Use

of an RCD reduces the risk of electric shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes,

hard hat, or hearing protection used for

appropriate conditions will reduce personal

injuries.

c) Prevent unintentional starting. Ensure

the switch is in the off position before

connecting to power source and/or battery

pack, picking up or carrying the tool.

Carrying power tools with your finger on the

switch or energising power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A wrench

or a key left attached to a rotating part of the

power tool may result in personal injury.

e) Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in unexpected

situations.

f) Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the

correct power tool for your application. The

correct power tool will do the job

better and safer at the rate for which it

was designed.

b) Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the switch

is dangerous and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power

tool before making any adjustments,

changing accessories, or storing power

tools. Such preventive safety measures

reduce the risk of starting the power tool

accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tool’s operation.

If damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

6

Page 9

ENGLISH

g) Use the power tool, accessories and

tool bits etc., in accordance with these

instructions taking into account the working

conditions and the work to be performed.

Use of the power tool for operations different

from those intended could result in a

hazardous situation.

5) BATTERY TOOL USE AND CARE

a) Recharge only with the charger specified

by the manufacturer. A charger that is

suitable for one type of battery pack may

create a risk of fire when used with another

battery pack.

b) Use power tools only with specifically

designated battery packs. Use of any

other battery packs may create a risk of

injury and fire.

c) When battery pack is not in use, keep it

away from other metal objects like paper

clips, coins, keys, nails, screws or other

small metal objects that can make a

connection from one terminal to another.

Shorting the battery terminals together may

cause burns or a fire.

d) Under abusive conditions, liquid may be

ejected from the battery; avoid contact.

If contact accidentally occurs, flush with

water. If liquid contacts eyes, additionally

seek medical help. Liquid ejected from the

battery may cause irritation or burns.

6) SERVICE

a) Have your power tool serviced by a

qualified repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

Additional Specifi c Safety Rules for

Rotary Hammers

• Wear ear protectors. Exposure to noise can

cause hearing loss.

• Use auxiliary handle(s) if supplied with the

tool. Loss of control can cause personal injury.

• Hold the power tool by insulated gripping

surfaces when performing an operation where

the cutting accessory may contact hidden

wiring. Cutting accessory contacting a “live” wire

will make exposed metal parts of the tool “live”

and could give the operator an electric shock.

• Use clamps or other practical way to secure

and support the workpiece to a stable

platform. Holding the work by hand or against

your body is unstable and may lead to loss of

control.

• Wear safety goggles or other eye protection.

Hammering operations cause chips to fly. Flying

particles can cause permanent eye damage.

Wear a dust mask or respirator for applications

that generate dust. Ear protection may be

required for most applications.

• Keep a firm grip on the tool at all times.

Do not attempt to operate this tool without

holding it with both hands. It is recommended

that the side handle be used at all times.

Operating this tool with one hand will result in

loss of control. Breaking through or encountering

hard materials such as re-bar may be hazardous

as well. Tighten the side handle securely before

use.

• Do not operate this tool for long periods of

time. Vibration caused by hammer action may

be harmful to your hands and arms. Use gloves

to provide extra cushion and limit exposure by

taking frequent rest periods.

• Do not recondition bits yourself. Chisel

reconditioning should be done by an authorized

specialist. Improperly reconditioned chisels could

cause injury.

• Wear gloves when operating tool or changing

bits. Accessible metal parts on the tool and bits

may get extremely hot during operation. Small

bits of broken material may damage bare hands.

• Never lay the tool down until the bit has come

to a complete stop. Moving bits could cause

injury.

• Do not strike jammed bits with a hammer to

dislodge them. Fragments of metal or material

chips could dislodge and cause injury.

• Slightly worn chisels can be resharpened by

grinding.

• Keep the power cord away from the rotating

bit. Do not wrap the cord around any part of

your body. An electric cord wrapped around a

spinning bit may cause personal injury and loss

of control.

Residual Risks

The following risks are inherent to the use of rotary

hammers:

- Injuries caused by touching the rotating parts or

hot parts of the tool.

In spite of the application of the relevant safety

regulations and the implementation of safety devices,

certain residual risks cannot be avoided. These are:

- Impairment of hearing.

- Risk of squeezing fingers when changing the

accessory.

7

Page 10

ENGLISH

- Health hazards caused by breathing dust

developed when working in concrete and/or

masonry.

Markings on Tool

The following pictograms are shown on the tool:

Read instruction manual before use.

Wear ear protection.

Wear eye protection.

DATE CODE POSITION (FIG. A)

The Date Code (20) which also includes the year of

manufacture, is printed into the housing surface that

forms the mounting joint between tool and battery.

Example:

2014 XX XX

Year of Manufacture

Important Safety Instructions for All

Battery Chargers

SAVE THESE INSTRUCTIONS: This manual

contains important safety and operating instruc tions

for the DE9000/DC9000 battery charger.

• Before using charger, read all instructions and

cautionary markings on charger, battery pack,

and product using battery pack.

DANGER: Electrocution hazard.

230 volts are present at charging

terminals. Do not probe with conductive

objects. Electric shock or electrocution

may result.

WARNING: Shock hazard. Do not allow

any liquid to get inside charger. Electric

shock may result.

CAUTION: Burn hazard. To reduce

the risk of injury, charge only DEWALT

rechargeable batteries. Other types of

batteries may burst causing personal

injury and damage.

CAUTION: Under certain conditions,

with the charger plugged in to the power

supply, the exposed charging contacts

inside the charger can be shorted by

foreign material. Foreign materials of

a conductive nature such as, but not

limited to, steel wool, aluminum foil, or

any buildup of metallic particles should

be kept away from charger cavities.

Always unplug the charger from the

power supply when there is no battery

pack in the cavity. Unplug charger before

attempting to clean.

• DO NOT attempt to charge the battery pack

with any chargers other than the ones in

this manual. The charger and battery pack are

specifically designed to work together.

• These chargers are not intended for any uses

other than charging D

batteries. Any other uses may result in risk of

fire, electric shock or electrocution.

• Do not expose charger to rain or snow.

• Pull by plug rather than cord when

disconnecting charger. This will reduce risk

of damage to electric plug and cord.

• Make sure that cord is located so that it will

not be stepped on, tripped over, or otherwise

subjected to damage or stress.

• Do not use an extension cord unless it

is absolutely necessary. Use of improper

extension cord could result in risk of fire,

electric shock, or electrocution.

• Do not place any object on top of charger

or place the charger on a soft surface that

might block the ventilation slots and result in

excessive internal heat. Place the charger in a

position away from any heat source. The charger

is ventilated through slots in the top and the

bottom of the housing.

• Do not operate charger with damaged cord

or plug — have them replaced immediately.

• Do not operate charger if it has received

a sharp blow, been dropped, or otherwise

damaged in any way. Take it to an authorised

service center.

• Do not disassemble charger; take it to an

authorized service center when service or

repair is required. Incorrect reassembly may

result in a risk of electric shock, electrocution or

fire.

• Disconnect the charger from the outlet before

attempting any cleaning. This will reduce the

risk of electric shock. Removing the battery

pack will not reduce this risk.

• NEVER attempt to connect 2 chargers together.

• The charger is designed to operate on

standard 230V household electrical power.

Do not attempt to use it on any other voltage.

This does not apply to the vehicular charger.

EWALT rechargeable

8

Page 11

ENGLISH

SAVE THESE INSTRUCTIONS

Chargers

The DE9000/DC9000 chargers accept 36 V Li-Ion

batteries only.

This charger requires no adjustment and is designed

to be as easy as possible to operate.

Charging Procedure (fi g. A, B)

DANGER: Electrocution hazard.

230 volts present at charging terminals.

Do not probe with conductive objects.

Danger of electric shock or electrocution.

1. Plug the charger (13) into an appropriate outlet

before inserting battery pack.

2. Insert the battery pack into the charger. The

charger is equipped with a three-light fuel gauge

that will blink according to the state of charge of

the battery pack.

3. The completion of charge will be indicated by the

red light remaining ON continuously. The pack is

fully charged and may be used at this time or left

in the charger.

NOTE: To ensure maximum performance and life of

Li-Ion batteries, charge the battery pack fully before

first use.

Charging Process

Refer the table below for the state of charge of the

battery pack.

State of charge

1 light blinking < 33%

1 light blinking, 1 light on 33–66%

1 light blinking, 2 lights on 66–99%

3 lights on 100%

Automatic Refresh

The automatic refresh mode will equalise or balance

the individual cells in the battery pack at its peak

capacity. Battery packs should be refreshed weekly

or whenever the pack no longer delivers the same

amount of work.

To refresh your battery pack, place the battery in the

charger as usual. Leave the battery pack for at least

10 hours in the charger.

Hot/Cold Pack Delay

When the charger detects a battery that is too hot

or too cold, it automatically starts a Hot/Cold Pack

Delay, suspending charging until the battery has

reached an appropriate temperature. The charger

then automatically switches to the pack charging

mode. This feature ensures maximum battery life.

LI-ION BATTERY PACKS ONLY

Li-Ion batteries are designed with an Electronic

Protection System that will protect the battery against

overloading, overheating or deep discharge.

The tool will automatically turn off if the Electronic

Protection System engages. If this occurs, place the

Li-Ion battery on the charger until it is fully charged.

Important Safety Instructions for All

Battery Packs

When ordering replacement battery packs, be sure to

include catalogue number, voltage and amp hour.

The battery pack is not fully charged out of the

carton. Before using the battery pack and charger,

read the safety instructions below. Then follow

charging procedures outlined.

READ ALL INSTRUCTIONS

• Do not charge or use battery in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Inserting or

removing the battery from the charger may ignite

the dust or fumes.

• Charge the battery packs only in DEWALT

chargers.

• DO NOT splash or immerse in water or other

liquids.

• Do not store or use the tool and battery pack

in locations where the temperature may reach

or exceed 40˚C (such as outside sheds or

metal buildings in summer).

DANGER: Never attempt to open the

battery pack for any reason. If battery

pack case is cracked or damaged, do not

insert into charger. Do not crush, drop

or damage battery pack. Do not use a

battery pack or charger that has received

a sharp blow, been dropped, run over or

damaged in any way (i.e., pierced with

a nail, hit with a hammer, stepped on).

Electric shock or electrocution may result.

Damaged battery packs should be

returned to service center for recycling.

CAUTION: When not in use, place

tool on its side on a stable surface

where it will not cause a tripping or

falling hazard. Some tools with large

battery packs will stand upright on the

battery pack but may be easily knocked

over.

9

Page 12

ENGLISH

SPECIFIC SAFETY INSTRUCTIONS FOR LITHIUM ION

(Li Ion)

• Do not incinerate the battery pack even if it

is severely damaged or is completely worn

out. The battery pack can explode in a fire. Toxic

fumes and materials are created when lithium ion

battery packs are burned.

• If battery contents come into contact with the

skin, immediately wash area with mild soap

and water. If battery liquid gets into the eye, rinse

water over the open eye for 15 minutes or until

irritation ceases. If medical attention is needed,

the battery electrolyte is composed of a mixture

of liquid organic carbonates and lithium salts.

• Contents of opened battery cells may cause

respiratory irritation. Provide fresh air. If

symptoms persists, seek medical attention.

WARNING: Burn hazard. Battery liquid

may be flammable if exposed to spark or

flame.

Transportation

DEWALT batteries comply with all applicable shipping

regulations as prescribed by industry and legal

standards which include UN Recommendations on

the Transport of Dangerous Goods; International

Air Transport Association (IATA) Dangerous Goods

Regulations, International Maritime Dangerous Goods

(IMDG) Regulations, and the European Agreement

Concerning The International Carriage of Dangerous

Goods by Road (ADR). Lithium-ion cells and

batteries have been tested to section 38.3 of the UN

Recommendations on the Transport of Dangerous

Goods Manual of Tests and Criteria.

In most instances, shipping a DEWALT battery pack

will be excepted from being classified as a fully

regulated Class 9 Hazardous material. In general, the

two instances that require shipping Class 9 are:

1. Air shipping more than two DEWALT lithium-ion

battery packs when the package contains only

battery packs (no tools), and

2. Any shipment containing a lithium-ion battery

with an energy rating greater than 100 watt hours

(Wh). All lithium-ion batteries have the watt hour

rating marked on the pack.

Regardless of whether a shipment is considered

excepted or fully regulated, it is the shipper's

responsibility to consult the latest regulations for

packaging, labeling/marking and documentation

requirements.

Transporting batteries can possibly cause fire if the

battery terminals inadvertently come in contact with

conductive materials. When transporting batteries,

make sure that the battery terminals are protected

and well insulated from materials that could contact

them and cause a short circuit.

The information provided in this section of the manual

is provided in good faith and believed to be accurate

at the time the document was created. However,

no warranty, expressed or implied, is given. It is

the buyer’s responsibility to ensure that its activities

comply with the applicable regulations.

Battery Pack

BATTERY TYPE

The DCH363 and DCH364 operate on 36volt Li-Ion

battery packs.

Storage Recommendations

1. The best storage place is one that is cool and

dry away from direct sunlight and excess heat or

cold. For optimum battery performance and life,

store battery packs at room temperature when

not in use.

NOTE: Li-Ion battery packs should be fully

charged when stored.

2. Long storage will not harm the battery pack or

charger. Under proper conditions, they can be

stored for up to 5 years.

Labels on Charger and Battery Pack

In addition to the pictographs used in this manual, the

labels on the charger and the battery pack show the

following pictographs:

Read instruction manual before use.

See Technical Data for charging time

Do not expose to water

Do not probe with conductive objects

Do not charge damaged battery packs

Do not use damaged chargers

Charge only between 4°C and 40°C

10

Page 13

ENGLISH

Have defective cords replaced immediately

Charger problem

Battery problem

Discard the battery pack with due care for

the environment

Do not incinerate the battery pack

Charge DEWALT battery packs only with

designated DEWALT chargers. Charging

battery packs other than the designated

DEWALT batteries with a DEWALT charger

may make them burst or lead to other

dangerous situations.

Package Contents

The package contains:

1 Cordless rotary hammerdrill

1 Side handle

1 Depth adjustment rod

1 Keyless chuck (DCH364)

2 Battery packs (D2, M2)

1 Battery pack (D1, M1)

1 Charger

1 Kitbox

1 Instruction manual

NOTE: Battery packs and chargers are not included

with N-models.

• Check for damage to the tool, parts or

accessories which may have occurred during

transport.

• Take the time to thoroughly read and understand

this manual prior to operation.

Description (fi g. A, A1, D, H)

WARNING: Never modify the power tool

1 Variable speed switch

2 Forward/reverse slider

3 Mode selector

4 Safety lock

5 SDS Plus

or any part of it. Damage or personal

injury could result.

®

tool holder

6 Locking collar

7 Dust cover

8 Depth adjustment rod

9 Side handle

10 Main handle

11 Battery pack

12 Release button

13 Charger

14 Charging indicators (red)

15 Tool holder locking sleeve

16 Keyless chuck

INTENDED USE

Your cordless rotary hammerdrills have been

designed for professional drilling, hammerdrilling and

screwdriving applications as well as for light chipping.

DO NOT use under wet conditions or in presence of

flammable liquids or gases.

These heavy-duty rotary hammerdrills are professional

power tools. DO NOT let children come into

contact with the tool. Supervision is required when

inexperienced operators use this tool.

• Young children and the infirm. This appliance

is not intended for use by young children or infirm

persons without supervision.

• This product is not intended for use by persons

(including children) suffering from diminished

physical, sensory or mental abilities; lack of

experience, knowledge or skills unless they are

supervised by a person responsible for their

safety. Children should never be left alone with

this product.

DUST EXTRACTION SYSTEM (FIG. A1)

17 Electrical pins for dust extraction system

18 Dust extraction system (D25302DH)*

19 Dust extraction system attached to rotary

hammerdrill

*The dust extraction system (D25302DH) can be

purchased separately from your nearest authorised

DEWALT dealer at additional cost.

OVERLOAD CLUTCH

In case of jamming of a drill bit, the drive to the drill

spindle is interrupted. Because of the resulting forces,

always hold the tool with both hands and take a firm

stance.

BRAKE MECHANISM

When the variable speed switch is released,

the spindle will stop rotating instantly.

11

Page 14

ENGLISH

ACTIVE VIBRATION CONTROL

The active vibration control neutralises rebound

vibration from the hammer mechanism. Lowering

hand and arm vibration, it allows more comfortable

use for longer periods of time and extends the life of

the unit. In operation, a spring loaded mechanism

counterbalances the vibration forces. This can be

sensed by the cushioning effect when pressure is

applied to the tool. Make sure the spring is engaged

but not too firmly. The mechanism should be allowed

to "float."

Electrical Safety

The electric motor has been designed for one voltage

only. Always check that the battery pack voltage

corresponds to the voltage on the rating plate.

Also make sure that the voltage of your charger

corresponds to that of your mains.

Your DEWALT charger is double insulated

in accordance with EN 60335; therefore no

earth wire is required.

If the supply cord is damaged, it must be replaced

by a specially prepared cord available through the

DEWALT service organization.

Mains Plug Replacement

(U.K. & Ireland Only)

If a new mains plug needs to be fitted:

• Safely dispose of the old plug.

• Connect the brown lead to the live terminal in the

plug.

• Connect the blue lead to the neutral terminal.

Follow the fitting instructions supplied with good

quality plugs. Recommended fuse: 3 A.

WARNING: No connection is to be made

to the earth terminal.

Using an Extension Cable

An extension cord should not be used unless

absolutely necessary. Use an approved extension

cable suitable for the power input of your charger

(see technical data). The minimum conductor size is

1mm2; the maximum length is 30 m.

When using a cable reel, always unwind the cable

completely.

ASSEMBLY AND ADJUSTMENT

WARNING: Prior to assembly and

adjustment, always remove the

battery pack. Always switch off the

tool before inserting or removing the

battery pack.

WARNING: Use only DEWALT battery

packs and chargers.

Fitting and Removing the Battery

Pack (fi g. A)

• To fit the battery pack (11), line it up with the

receptacle on the tool. Slide the battery pack into

the receptacle and push until the battery snaps

into place.

• To remove the battery pack, push the release

button (12) while at the same time pulling the

battery pack out of the receptacle.

FUEL GAUGE BATTERY PACKS (FIG. A)

Some DEWALT battery packs include a fuel gauge

which consists of three green LED lights that indicate

the level of charge remaining in the battery pack.

To actuate the fuel gauge, press and hold the fuel

gauge button (21). A combination of the three green

LED lights will illuminate designating the level of

charge left. When the level of charge in the battery

is below the usable limit, the fuel gauge will not

illuminate and the battery will need to be recharged.

NOTE: The fuel gauge is only an indication of the

charge left on the battery pack. It does not indicate

tool functionality and is subject to variation based

on product components, temperature and end-user

application.

Selecting the Operating Mode (fi g. C)

The tool can be used in the following operating

modes:

Rotary drilling: for screwdriving and for

drilling into steel, wood and plastics

Hammer drilling: for concrete and

masonry drilling

Hammering only: for light chipping

• To select the operating mode, press the safety

lock (4) and rotate the mode selector switch (3)

until it points to the symbol of the required mode.

• Release the safety lock and check that the mode

selector switch is locked in place.

WARNING: Do not select the operating

mode when the tool is running.

12

Page 15

ENGLISH

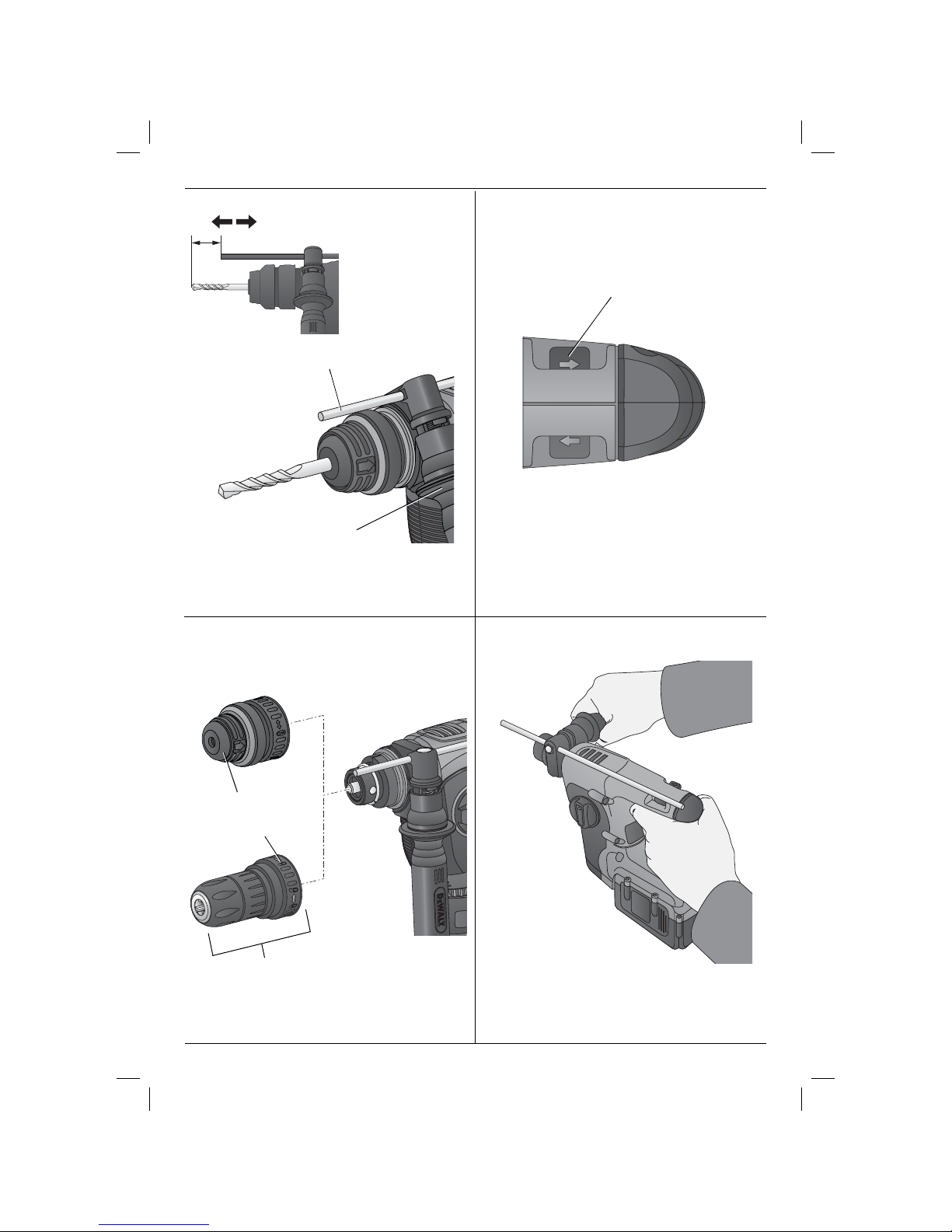

Inserting and Removing SDS Plus®

Accessories (fi g. D)

Your rotary hammerdrill uses SDS Plus® accessories

(refer to the inset in fig. D for a cross-section of an

SDS Plus

• Clean and grease the SDS Plus

• Insert the SDS Plus

• Push the bit down and turn it slightly until it fits

• Pull on the bit to check if it is properly locked.

• To remove a bit, pull back the SDS Plus® tool

®

bit shank).

®

tool holder (5).

into the slots.

The hammering function requires the bit to be

able to move axially several centimetres when

locked in the SDS Plus

holder locking sleeve (15) and pull out the bit.

bit shank into the SDS Plus

®

tool holder.

®

bit shank.

Fitting the Side Handle (fi g. E)

The side handle (9) can be fitted to suit both

right-hand and left-hand users.

WARNING: Do not use the tool without

• Loosen the side handle.

• For RH-users, slide the side handle clamp over

• For LH-users, slide the side handle clamp over

• Rotate the side handle to the desired position

the side handle properly assembled.

the collar behind the tool holder, handle at the

left.

the collar behind the tool holder, handle at the

right.

and tighten the handle.

Setting the Drilling Depth (fi g. F)

• Insert the required drill bit.

• Slacken the side handle (9).

• Fit the depth adjustment rod (8) through the hole

in the side handle clamp.

• Adjust the drilling depth as shown.

• Tighten the side handle.

Forward/Reverse Slider (fi g. G)

• Push the forward/reverse slider (2) to the LH-side

for forward (RH) rotation. See arrows on tool.

• Push the forward/reverse slider (2) to the RH-side

for reverse (LH) rotation.

CAUTION: Always wait until the motor

has come to a complete standstill before

changing the direction of rotation.

Replacing the SDS Plus® Tool Holder

with the Keyless Chuck (fi g. H)

DCH364

• Turn the locking collar (6) into the unlocked

position and pull the SDS Plus® tool holder (5) off.

• Push the keyless chuck (16) onto the spindle and

®

turn the locking collar into the locked position.

• To replace the keyless chuck with the SDS Plus

tool holder, first remove the keyless chuck the

same way as the SDS Plus® tool holder was

removed. Then place the SDS Plus® tool holder

the same way as the keyless chuck was placed.

CAUTION: Never use the keyless chuck

(16) in the hammerdrilling mode. Only the

SDS Plus® toolholder should be used for

hammerdrilling.

Replacing the Dust Cover (fi g. D)

The dust cover (7) prevents dust ingress into the

mechanism. Replace a worn dust cover immediately.

• Pull back the SDS Plus® tool holder locking

sleeve (15) and pull the dust cover (7) off.

• Fit the new dust cover.

• Release the SDS Plus® tool holder locking sleeve.

OPERATION

Instructions for Use

WARNING: To reduce the risk of

WARNING:

• Always observe the safety instructions and

• Be aware of the location of pipework and wiring.

• Apply only a gentle pressure to the tool (approx.

• Do not drill or drive too deep to prevent damage

• Always hold the tool firmly with both hands and

• Always operate the tool with the side handle

serious personal injury, turn tool

off and disconnect battery pack

before making any adjustments or

removing/installing attachments or

accessories. An accidental start-up can

cause injury.

applicable regulations.

5 kg). Excessive force does not speed up drilling

but decreases tool performance and may shorten

tool life.

to the dust cover.

ensure a secure stance.

properly mounted.

®

13

Page 16

ENGLISH

• If the cutting tool is no longer sharp, replace with

a new cutting tool.

Prior to Operation:

• Make sure your battery pack is (fully) charged.

• Make sure the battery pack is properly seated.

Proper Hand Position (fi g. A, I)

WARNING: To reduce the risk of serious

WARNING: To reduce the risk of serious

Proper hand position requires one hand on the

side handle (9), with the other hand on the main

handle(10).

personal injury, ALWAYS use proper

hand position as shown.

personal injury, ALWAYS hold securely in

anticipation of a sudden reaction.

Switching On and Off (fi g. A)

• To run the tool, press the variable speed switch

(1). The pressure exerted on the variable speed

switch determines the tool speed.

• To stop the tool, release the switch.

• To lock the tool in off position, move the forward/

reverse slider (2) to the central position.

Hammerdrilling (fi g. A)

• Set the mode selector switch (3) to the

"hammerdrilling" position.

• Insert the appropriate drill bit. For best results use

high quality carbide-tipped bits.

• Adjust the side handle (9) as required.

• If necessary, set the drilling depth.

• Mark the spot where the hole is to be drilled.

• Place the drill bit on the spot and switch on the

tool.

Rotary Drilling (fi g. A, H)

• Set the mode selector switch (3) to the "rotary

drilling" position.

• Depending on your tool, follow either of the

following instructions:

- Fit a chuck adaptor/chuck assembly (DCH363).

Keyed and keyless chucks and chuck adaptors

can be purchased separately. Special SDS

®

Plus

adaptors with threaded sections are

available for use with standard 10 or 13 mm

chucks to enable straight shank bits to be

used.

- Replace the SDS Plus

keyless chuck (16) (DCH364).

®

tool holder with the

• Proceed as described for hammerdrilling.

CAUTION: Never use the keyless chuck

(16) in the hammerdrilling mode. Only the

SDS Plus® toolholder should be used for

hammerdrilling.

Screwdriving (fi g. A, H)

• Set the mode selector switch (3) to the "rotary

drilling" position.

• Select the direction of rotation.

• Depending on your tool, follow either of the

following instructions:

- Insert a special SDS Plus® screwdriving adaptor

for use with hexagonal screwdriver bits which

can be purchased separately (DCH363).

- Replace the SDS Plus® tool holder (5) with the

keyless chuck (16) (DCH364).

• Insert the appropriate screwdriver bit. When

driving slotted head screws, always use bits with

a finder sleeve.

• Gently press the variable speed switch (1) to

prevent damage to the screw head. In reverse

(LH) rotation the tool speed is automatically

reduced for easy screw removal.

• When the screw is flush with the workpiece,

release the variable speed switch to prevent the

screw head from penetrating into the workpiece.

Chipping (fi g. A)

DCH363, DCH364

• Set the mode selector switch (3) to the

"hammering only" position.

• Insert the appropriate chisel and check if it is

properly locked.

• Adjust the side handle (9) as required.

• Switch on the tool and start working.

It may be necessary to briefly run the motor after

having changed from chiselling to rotary modes in

order to align the gears.

WARNING:

• Do not use this tool to mix or pump easily

combustible or explosive fluids (benzine, alcohol,

etc.).

• Do not mix or stir inflammable liquids labelled

accordingly.

MAINTENANCE

Your DEWALT power tool has been designed to

operate over a long period of time with a minimum

14

Page 17

ENGLISH

of maintenance. Continuous satisfactory operation

depends upon proper tool care and regular cleaning.

WARNING: To reduce the risk of

serious personal injury, turn tool

off and disconnect battery pack

before making any adjustments or

removing/installing attachments or

accessories. An accidental start-up can

cause injury.

The charger and battery pack are not serviceable.

There are no serviceable parts inside.

Lubrication

Your power tool requires no additional lubrication.

Accessories and attachments used must be regularly

lubricated around the SDS Plus® fitment.

Cleaning

WARNING: Blow dirt and dust out of the

main housing with dry air as often as dirt

is seen collecting in and around the air

vents. Wear approved eye protection and

approved dust mask when performing

this procedure.

WARNING: Never use solvents or other

harsh chemicals for cleaning the nonmetallic parts of the tool. These chemicals

may weaken the materials used in these

parts. Use a cloth dampened only with

water and mild soap. Never let any liquid

get inside the tool; never immerse any

part of the tool into a liquid.

CHARGER CLEANING INSTRUCTIONS

WARNING: Shock hazard. Disconnect

the charger from the AC outlet before

cleaning. Dirt and grease may be

removed from the exterior of the charger

using a cloth or soft non-metallic brush.

Do not use water or any cleaning

solutions.

Optional Accessories

WARNING: Since accessories, other

than those offered by DEWALT, have not

been tested with this product, use of

such accessories with this tool could be

hazardous. To reduce the risk of injury,

only DEWALT recommended accessories

should be used with this product.

®

Various types of SDS Plus

available as an option.

Consult your dealer for further information on the

appropriate accessories.

drill bits and chisels are

Protecting the Environment

Separate collection. This product must

not be disposed of with normal household

waste.

Should you find one day that your DEWALT product

needs replacement, or if it is of no further use to you,

do not dispose of it with household waste. Make this

product available for separate collection.

Separate collection of used products and

packaging allows materials to be

recycled and used again. Re-use of

recycled materials helps prevent

environmental pollution and reduces

the demand for raw materials.

Local regulations may provide for separate collection

of electrical products from the household, at municipal

waste sites or by the retailer when you purchase a

new product.

DEWALT provides a facility for the collection and

recycling of DEWALT products once they have

reached the end of their working life. To take

advantage of this service please return your product

to any authorised repair agent who will collect them

on our behalf.

You can check the location of your nearest authorised

repair agent by contacting your local DEWALT office

at the address indicated in this manual. Alternatively, a

list of authorised DEWALT repair agents and full details

of our after-sales service and contacts are available

on the Internet at: www.2helpU.com.

Battery Pack

The long life battery pack must be recharged when it

fails to produce sufficient power on jobs which were

easily done before. At the end of its technical life,

discard it with due care for our environment:

• Run the battery pack down completely, then

remove it from the tool.

• Li-Ion cells are recyclable. Take them to your

dealer or a local recycling station. The collected

battery packs will be recycled or disposed of

properly.

15

Page 18

ENGLISH

GUARANTEE

DEWALT is confident of the quality of its

products and offers an outstanding guarantee

for professional users of the product. This

guarantee statement is in addition to and in

no way prejudices your contractual rights as a

professional user or your statutory rights as a

private non-professional user. The guarantee

is valid within the territories of the Member

States of the European Union and the

European Free Trade Area.

• 30 DAY NO RISK SATISFACTION GUARANTEE •

If you are not completely satisfied with the

performance of your D

return it within 30 days, complete with all

original components, as purchased, to

the point of purchase, for a full refund or

exchange. The product must have been

subject to fair wear and tear and proof of

purchase must be produced.

• ONE YEAR FREE SERVICE CONTRACT •

If you need maintenance or service for your

EWALT tool, in the 12 months following

D

purchase, you are entitled to one service free

of charge. It will be undertaken free of charge

at an authorised DEWALT repair agent. Proof

of purchase must be produced. Includes

labour. Excludes accessories and spare parts

unless failed under warranty.

• ONE YEAR FULL WARRANTY •

EWALT product becomes defective

If your D

due to faulty materials or workmanship

within 12 months from the date of purchase,

EWALT guarantees to replace all defective

D

parts free of charge or – at our discretion –

replace the unit free of charge provided that:

• The product has not been misused;

• The product has been subject to fair

wear and tear;

• Repairs have not been attempted by

unauthorised persons;

• Proof of purchase is produced;

• The product is returned complete with all

original components.

If you wish to make a claim, contact your

seller or check the location of your nearest

authorised D

EWALT catalogue or contact your DEWALT

D

EWALT repair agent in the

office at the address indicated in this manual.

A list of authorised DEWALT repair agents and

full details of our after-sales service is available

on the Internet at: www.2helpU.com.

EWALT tool, simply

16

Page 19

17

Page 20

Belgique et

Luxembourg België

en Luxemburg

Danmark D

Deutschland D

Ελλάς D

España D

France D

Schweiz

Suisse

Svizzera

Ireland D

Italia D

Nederlands D

Norge D

Österreich D

Portugal D

Suomi D

Sverige D

Türkiye

United

Kingdom

Australia D

Middle East Africa D

DEWALT - Belgium BVBA

Egide Walschaertsstraat 16

2800 Mechelen

EWALT

Roskildevej 22

2620 Albertslund

EWALT

Richard Klinger Str. 11

65510 Idstein

EWALT (Ελλάς) Α.Ε.

EΔΡΑ-ΓΡΑΦΕΙΑ : Στράβωνος 7

& Λ. Βουλιαγμένης, Γλυφάδα 166 74, Αθήνα

SERVICE : Ημερος Τόπος 2 (Χάνι Αδάμ) –

193 00 Ασπρόπυργος

EWALT Ibérica, S.C.A.

Parc de Negocios “Mas Blau”

Edificio Muntadas, c/Bergadá, 1, Of. A6

08820 El Prat de Llobregat (Barcelona)

EWALT

5, allée des Hêtres

BP 30084, 69579 Limonest Cedex

D

EWALT

In der Luberzen 42

8902 Urdorf

EWALT

Calpe House Rock Hill

Black Rock, Co. Dublin

EWALT

via Energypark

20871 Vimercate (MB), IT

EWALT Netherlands BV

Holtum Noordweg 35

6121 RE BORN, Postbus 83, 6120 AB BORN

EWALT

Postboks 4613, Nydalen

0405 Oslo

EWALT

Werkzeug Vertriebsges m.b.H

Oberlaaerstrasse 248, A-1230 Wien

EWALT Limited, SARL

Centro de Escritórios de Sintra Avenida

Almirante Gago Coutinho, 132/134, Edifício 14

2710-418 Sintra

EWALT

Tekniikantie 12, 02150 Espoo

02150 Espoo, Finland

EWALT

Box 94

431 22 Mölndal

KALE Hırdavat ve Makina A.Ş.

Defterdar Mah. Savaklar Cad. No:15

Edirnekapı / Eyüp / İSTANBUL 34050

TÜRKİYE

D

EWALT, 210 Bath Road;

Slough, Berks SL1 3YD

EWALT

82 Taryn Drive, Epping

VIC 3076 Australia

EWALT

P.O. Box - 17164,

Jebel Ali Free Zone (South), Dubai, UAE

Tel: NL 32 15 47 37 63

Tel: FR 32 15 47 37 64

Fax: 32 15 47 37 99

Tel: 70 20 15 11

Fax: 70 22 49 10

Tel: 06126-21-1

Fax: 06126-21-2770

Τηλ : 00302108981616

Φαξ: 00302108983570

Tel: 934 797 400

Fax: 934 797 419

Tel: 04 72 20 39 20

Fax: 04 72 20 39 00

Tel: 044 - 755 60 70

Fax: 044 - 730 70 67

Tel: 00353-2781800

Fax: 00353-2781811

Tel: 800-014353

39 039 9590200

Fax: 39 039 9590313

Tel: 31 164 283 063

Fax: 31 164 283 200

Tel: 22 90 99 10

Fax: 45 25 08 00

Tel: 01 - 66116 - 0

Fax: 01 - 66116 - 614

Tel: 214 66 75 00

Fax: 214 66 75 80

Puh: 010 400 43 33

Faksi: 0800 411 340

Tel: 031 68 60 60

Fax: 031 68 60 08

Tel: 0212 533 52 55

Faks: 0212 533 10 05

Tel: 01753-567055

Fax: 01753-572112

Tel: Aust 1800 338 002

Tel: NZ 0800 339 258

Tel: 971 4 812 7400

Fax: 971 4 2822765

www.dewalt.be

enduser.BE@SBDinc.com

www.dewalt.dk

kundeservice.dk@sbdinc.com

www.dewalt.de

infobfge@sbdinc.com

www.dewalt.gr

Greece.Service@sbdinc.com

www.dewalt.es

respuesta.postventa@sbdinc.com

www.dewalt.fr

scufr@sbdinc.com

www.dewalt.ch

service@rofoag.ch

www.dewalt.ie

www.dewalt.it

www.dewalt.nl

www.dewalt.no

kundeservice.no@sbdinc.com

www.dewalt.at

service.austria@sbdinc.com

www.dewalt.pt

resposta.posvenda@sbdinc.com

www.dewalt.fi

asiakaspalvelu.fi@sbdinc.com

www.dewalt.se

kundservice.se@sbdinc.com

www.dewalt.com.tr

www.dewalt.co.uk

emeaservice@sbdinc.com

www.dewalt.com.au

www.dewalt.co.nz

www.dewalt.ae

Service.MEA@sbdinc.com

N404990 06/14

Loading...

Loading...