Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, cont_ctenos.

iNSTRUCTiON MANUAL

GUIDE D'UTILISATION

INSTRUCTIVO DE OPERACION, CENTROS DE SERVICIO Y P©LIZA DE

GARANT[A. ADVERTENCIA: LEASE ESTE INSTRUCTIVO ANTES DE

USAR EL PRODUCTO.

MANUAL DE INSTRUCCIONES

DCF680, DCF682

8V Max* Cordless Gyroscopic Screwdriver/Tournevis gyroscopique sans fil de 8 V max*/Atornillador

girosc6pico inalambrico de 8 V Max*

DCF681

8V Max* Cordless Gyroscopic Electrician's Screwdriver/Tournevis d'electricien gyroscopique, sans fil,

de 8 v max*/Atornillador girosc6pico inalambrico de 8 V Max*

®

Page 2

f

Definitions: Safety Guidelines

The definitions below describe the level of severity for each

signal word. Please read the manual and pay attention to these

symbols.

J_DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

A CAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury

which, if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY DEWALT TOOL, CALL US TOLL FREE AT: 1-800-4-DEWALT

(1-800-433-9258}.

WARNING: To reduce the risk of injury, read the instruction

manual.

General Power Tool Safety Warnings

_ WARNING! Read all safety warnh_gs and all h_structions.

Failure to follow the warnings and instructions may result in

electric shock, fire and/or serious injury,

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term "power tool" in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool

1} WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a

power tooL Distractions can cause you to lose control

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tooL Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

If operating apowertool in a damp location is unavoidable,

use a ground fault circuff interrupter (GFCI) protected

supply. Use of a GFC/ reduces the risk of electric shock.

Page 3

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common

sense when operating a power tool Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, non-

skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in

the off position before connecting to power source and/

or battery pack, picking up or carrying the tool Carrying

power tools with your finger on the switch or energizing power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool Use the correct power tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn ff

on and off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool Power tools

are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding

of moving parts, breakage of parts and any other

condition that may affect the power tool:s operation. If

damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind and

are easier to control

g) Use the power tool, accessories and tool bits, etc. in

accordance with these instructions, taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

Page 4

5} BATTERY TOOL USE AND CARE

a) Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type of

battery pack may create a risk of fire when used with another

battery pack.

b) Use power tools only with specifically designated battery

packs. Use of any other battery packs may create a risk of

injury and fire.

c) When battery pack is not in use, keep it away from

other metal objects, like paper clips, coins, keys, nails,

screws, or other small metal objects, that can make a

connection from one terminal to another. Shorting the

battery terminals together may cause bums or a fire.

d) Under abusive conditions, liquid may be ejected from

the battery; avoid contact. If contact accidentally occurs,

flush with water. If liquid contacts eyes, additionally seek

medical help. Liquid ejected from the battery may cause

irritation or bums.

6} SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power too/is maintained.

Additional Safety Rules for Screwdriver

• Hold power tool by insulated gripping surfaces, when

performing an operation where the fastener may contact

hidden wiring. Fasteners contacting a "live" wire may make

exposed metal parts of the power tool "live" and could give the

operator an electric shock.

, Use clamps or another practical way to secure and support

the workpiece to a stable platform. Holding the work by hand

or against your body leaves it unstable and may lead to loss of

control.

• Air vents often cover moving parts and should be avoided.

Loose clothes, jewelry or long hair can be caught in moving parts.

_ WARNING: ALWAYS use safety glasses. Everyday eyeglasses are

NOT safety glasses. Also use face or dust mask if cutting operation is

dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT_

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

ANSI $12.6 ($3.19) hearing protection,

NIOSH/OSHA/MSHA respiratory protection.

_kWARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to the State of Califomia to cause canced birth defects or other

reproductive harm. Some examples of these chemicals are:

lead from lead-based paints,

crystalline silica from bricks and cement and other masonry

products, and

arsenic and chromium from chemically-treated lumbe_

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to

filter out microscopic particles.

Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

Page 5

WARNING: Use of this too/can generate and/or disperse dust,

which may cause serious and permanent respiratory or other

injury. Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face

and body.

A CAUTION: When not in use, place tool on its side on a stable

surface where it will not cause a tripping or falling hazard.

i_,WARNING: To reduce the risk of injury do not carry this tool in

your pocket.

Some tools with large battery packs will stand upright on the battery

pack but may be easily knocked ove_

• The label on your tool may include the following symbols. The

symbols and their definitions are as follows:

V................... volts A...................... amperes

Hz................. hertz

min ............... minutes

--- or DC... direct current

(_)................. Class I Construction

(grounded)

[] ................. Class II Construction

(double insulated)

.../min ........... per minute

BPM ............. beats per minute

IPM............... impacts per minute

RPM ............. revolutions per

minute

sfpm ............. surface feet

per minute

SPM ............... strokes per minute

W..................... watts

,x_or AC.......... alternating

current

_-_or AC/DC... alternating

or direct

current

no .................... no load

speed

n...................... rated

speed

G ..................... earthing

terminal

A ..................... safety alert

symbol

Important Safety Instructions for All

Battery Packs

When ordering replacement battery packs, be sure to include the

catalog number and voltage. Consult the chart at the end of this

manual for compatibility of chargers and battery packs.

The battery pack is not fully charged out of the carton. Before using

the battery pack and charger, read the safety instructions below and

then follow charging procedures outlined.

READ ALL INSTRUCTIONS

• Do not charge or use the battery pack in explosive

atmospheres, such as in the presence of flammable liquids,

gases or dust, Inserting or removing the battery pack from the

charger may ignite the dust or fumes.

• NEVER force the battery pack into the charger. DO NOT

modify the battery pack in any way to fit into a non=

compatible charger as battery pack may rupture causing

serious personal injury. Consult the chart at the end of this

manual for compatibility of batteries and chargers.

• Charge the battery packs only in designated D,_-:WALTchargers.

• DO NOT splash or immerse in water or other liquids.

• Do not store or use the tool and battery pack in locations

where the temperature may reach or exceed 105 °F (40 °C)

(such as outside sheds or metal buildings in summer). For

best fife store battery packs in a coo/, dry location.

NOTE: Do not store the battery packs in a tool with the

trigger switch locked on. Never tape the trigger switch in

the ON position.

,_ WARNING: Fire hazard, Never attempt to open the battery pack

for any reason. If the battery pack case is cracked or damaged, do

Page 6

notinsertintothecharge_Donotcrush,dropordamagethebattery

pack.Donotuseabatterypackorchargerthathasreceivedasharp

blow,beendropped,runoverordamagedinanyway(e.g.,piemed

withanail,hitwithahammedsteppedon).Damagedbatterypacks

shouldberetumedtotheservicecenterforrecycling.

NOTE: Battery storage and carrying caps are provided for

use whenever the battery is out of the tool or charger.

Remove cap before placing battery in charger or tool.

WARNING." Fire hazard. Do not store or carry the

battery pack so that metal objects can contact

exposed battery terminals. For example, do not place

the battery pack in aprons, pockets, tool boxes, product

kit boxes, drawers, etc., with loose nails, screws, keys, etc.

Transporting batteries can possibly cause fires if the battery

terminals inadvertently come in contact with conductive

materials such as keys, coins, hand tools and the like. The

US Department of Transportation Hazardous Material Regulations

(HMR) actually prohibit transporting batteries in commeme or on

airplanes (e.g., packed in suitcases and carry-on luggage) UNLESS

they are properly protected from short circuits. So when transporting

individual battery packs, make sure that the battery terminals are

protected and well insulated from materials that could contact them

and cause a short circuit.

SPECiFiC SAFETY INSTRUCTIONS FOR LITHIUM ION (Li=lon)

• Do not incinerate the battery pack even if it is severely

damaged or is completely worn out. The battery pack can

explode in a fire. Toxic fumes and materials are created when

lithium ion battery packs are burned.

• If battery contents come into contact with the skin,

immediately wash area with mild soap and water, if battery

liquid gets into the eye, rinse water over the open eye for 15

minutes or until irritation ceases. If medical attention is needed,

the battery electrolyte is composed of a mixture of liquid organic

carbonates and lithium salts.

• Contents of opened battery cells may cause respiratory

irritation. Provide fresh ai_ If symptoms persist, seek medical

attention.

i_,WARNING: Burn hazard. Battery liquid may be flammable if

exposed to spark or flame.

The RBRC TM Seal

The RBRCTM (Rechargeable Battery Recycling Corp-

oration) Seal on the nickel cadmium, nickel metal

hydride or lithium ion batteries (or battery packs)

indicate that the costs to recycle these batteries

(or battery packs) at the end of their useful life have

already been paid by DEWALT. In some areas, it is

illegal to place spent nickel cadmium, nickel metal hydride or lithium

ion batteries in the trash or municipal solid waste stream and the

RBRC program provides an environmentally conscious alternative.

RBRCTM, in cooperation with DEWALTand other battery users, has

established programs in the United States and Canada to facilitate

the collection of spent nickel cadmium, nickel metal hydride or lithium

ion batteries. Help protect our environment and conserve natural

resources by returning the spent nickel cadmium, nickel metal

hydride or lithium ion batteries to an authorized DE,WALT service

center or to your local retailer for recycling. You may also contact

your local recycling center for information on where to drop off the

spent battery.

RBRCTM is a registered trademark of the Rechargeable Battery

Recycling Corporation.

Page 7

Important Safety Instructions for All

Battery Chargers

SAVE THESE INSTRUCTIONS." This manual contains important

safety and operating instructions for battery chargers.

• Before using the charged read all instructions and cautionary

markings on the charged battery pack and product using the

battery pack.

i_ WARNING: Shock hazard. Do not allow any liquid to get inside the

charge_ Electric shock may result.

i_,OAUTION: Bum hazard. Toreduce the risk of injury, charge only

DE:WALTrechargeable battery packs. Other types of batteries may

overheat and burst resulting in personal injury and property damage.

NOTICE: Under certain conditions, with the charger plugged into

the power supply, the charger can be shorted by foreign material

Foreign materials of a conductive nature, such as, but not limited to,

grinding dust, metal chips, steel wool, aluminum foil or any buildup

of metallic particles should be kept away from the charger cavities.

Always unplug the charger from the power supply when there is no

battery pack in the cavity, Unplug the charger before attempting to

clean.

• DO NOT attempt to charge the battery pack with any

chargers other than the ones in this manual The charger and

battery pack are specifically designed to work togethe_

• These chargers are not intended for any uses other than

charging DEWALT rechargeable batteries. Any other uses

may result in risk of fire, electric shock or electrocution.

• Do not expose the charger to rain or snow.

• Pull by the plug rather than the cord when disconnecting

the charger. This will reduce the risk of damage to the electric

plug and cord.

Make sure that the cord is located so that it will not be

stepped on, tripped over or otherwise subjected to damage

or stress.

Do not use an extension cord unless it is absolutely

necessary. Use of improper extension cord could result in risk of

fire, electric shock or electrocution.

When operating a charger outdoors, always provide a dry

location and use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric

shock.

An extension cord must have adequate wire size (AWG or

American Wire Gauge) for safety. The smaller the gauge number

of the wire, the greater the capacity of the cable, that is, 16 gauge

has more capacity than 18 gauge. An undersized cord will cause a

drop inline voltage resulting in loss ofpower and overheating. When

using more than one extension to make up the total length, be sure

each individual extension c)ontains at least the minimum wire size.

The following table shows the correct size to use depending on

cord length and nameplate ampere rating. If in doubt, use the next

heavier gauge. The lower the gauge numbed the heavier the cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord

in Feet (meters}

Ampere Rating 120V 25 (7.6) 50 (15.2)1100(30.5) 150 (45.7)

240V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

More Not

Than More AWG

Than

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

Page 8

• Do not place any object on top of the charger or place the

charger on a soft surface that might block the ventilation

slots and result in excessive internal heat. Place the charger

in a position away from any heat source. The charger is ventilated

through slots in the top and the bottom of the housing.

Do not operate the charger with a damaged cord or plug.

, Do not operate the charger if it has received a sharp blow,

been dropped or otherwise damaged in any way. Take it to

an authorized service cente_

Do not disassemble the charger, take it to an authorized

service center when service or repair is required. /ncorrect

reassemb/y may result in arisk of electric shock, electrocution or fire.

Disconnect the charger from the outlet before attempting

any cleaning. This will reduce the risk of electric shock.

Removing the battery pack will not reduce this risk.

NEVER attempt to connect 2 chargers togethe_

The charger is designed to operate on standard 120V

household electrical power. Do not attempt to use it on any

other voltage. Thisdoes not apply to the vehicular charge_

Chargers

Your tool uses a DEWALT charger. Be sure to read all safety

instructionsbefore using your charger. Consult the chart at the end of

this manual for compatibility of chargers and battery packs.

Charging Procedure (Fig. 1)

1. Plug the charger into an appropriate outlet before insertingthe

battery pack.

2. Insert the battery pack (G) into the charger, as shown in Figure 1,

making sure the pack is fullyseated in charger. The red (charging)

light will blink continuously, indicating that the charging process

has started.

3. The completion of charge will be

indicated by the red light remaining

ON continuously. The pack is fully

FIG. 1

G--

charged and may be used at this

time or left in the charger.

Indicator Light

Operation

_] ACKCHARGING

PACKCHARGED

t_)_HO_COLD DELAY

_l_ PRODLEMPACKORCHARGER

m 0 m 0 m 0 m® m®

O@Q®®®@Q®O

Charge Indicators

This charger is designed to detect certain problems that can arise.

Problems are indicated by the red light flashing at a fast rate. If this

occurs, re-insert the battery pack into the charger. If the problem

persists, try a different battery pack to determine if the charger is

working properly. If the new pack charges correctly, then the original

pack is defective and should be returned to a service center or other

collection site for recycling. If the new battery pack elicits the same

trouble indication as the original, have the charger and the battery

pack tested at an authorized service center.

HOT/COLD DELAY

This charger hasa hot/cold delay feature: when the charger detects a

battery that is hot, it automatically starts a delay,suspending charging

until the battery has cooled. After the battery has cooled, the charger

Page 9

automaticallyswitchestothepackchargingmode.Thisfeature

ensuresmaximumbatterylife.Theredlightflasheslong,thenshort

whileinthehot/colddelaymode.

LEAVING THE BATTERY PACK IN THE CHARGER

The charger and battery pack can be left connected with the charge

indicator showing Pack Charged.

WEAK BATTERY PACKS: Weak batteries will continue to function

but should not be expected to perform as much work.

FAULTY BATTERY PACKS: This charger will not charge a faulty

battery pack. The charger will indicate faulty battery pack by refusing

to light or by displaying problem pack or charger.

NOTE: This could also mean a problem with a charger.

imporltant Charging Notes

1. Longest life and best performance can be obtained if the battery

pack is charged when the air temperature is between 65 °F

and 75 °F (18-24 °C). DO NOT charge the battery pack in air

temperature below +40 °F (+4.5 °C), or above +105 °F (+40.5 °C).

This is important and will prevent serious damage to the battery

pack.

2. The charger and battery pack may become warm to touch while

charging. This is a normal condition, and does not indicate a

problem. To facilitate the cooling of the battery pack after use,

avoid placing the charger or battery pack in a warm environment

such as in a metal shed, or an uninsulated trailer.

3. If the battery pack does not charge properly:

a. Check operation of receptacle by plugging in a lamp or other

appliance;

b. Check to see if receptacle is connected to a light switch which

turns power off when you turn out the lights;

c. Move charger and battery pack to a location where the

surrounding air temperature is approximately 65 °F-75 °F

(18-24 °C);

d. If charging problems persist, take the tool, battery pack and

charger to your local service center.

4. The battery pack should be recharged when it fails to produce

sufficient power on jobs which were easily done previously. DO

NOT CONTINUE to use under these conditions. Follow the

charging procedure. You may also charge a partially used pack

whenever you desire with no adverse affect on the battery pack.

5. Foreign materials of a conductive nature such as, but not limited

to, grinding dust, metal chips, steel wool, aluminum foil, or any

buildup of metallic particles should be kept away from charger

cavities. Always unplug the charger from the power supply when

there is no battery pack in the cavity. Unplug charger before

attempting to clean.

6. Do not freeze or immerse charger in water or any other liquid.

WARNING: Shock hazard. Don't allow any liquid to get inside

charge_ Electric shock may result.

i_ CAUTION: Never attempt to open the battery pack for any reason.

If the plastic housing of the battery pack breaks or cracks, retum to a

service center for recycling.

Storage Recommendations

1. The best storage place is one that is cool and dry, away from

direct sunlight and excess heat or cold.

2. For long storage, it is recommended to store a fully charged

battery pack in a cool dry place out of the charger for optimal

results.

NOTE: Battery packs should not be stored completely depleted of

charge. The battery pack will need to be recharged before use.

SAVE THESE iNSTRUCTiONS

FOR FUTURE USE

Page 10

FIG.2

DCF681

c

[

DOF682

DCF680

I

G K

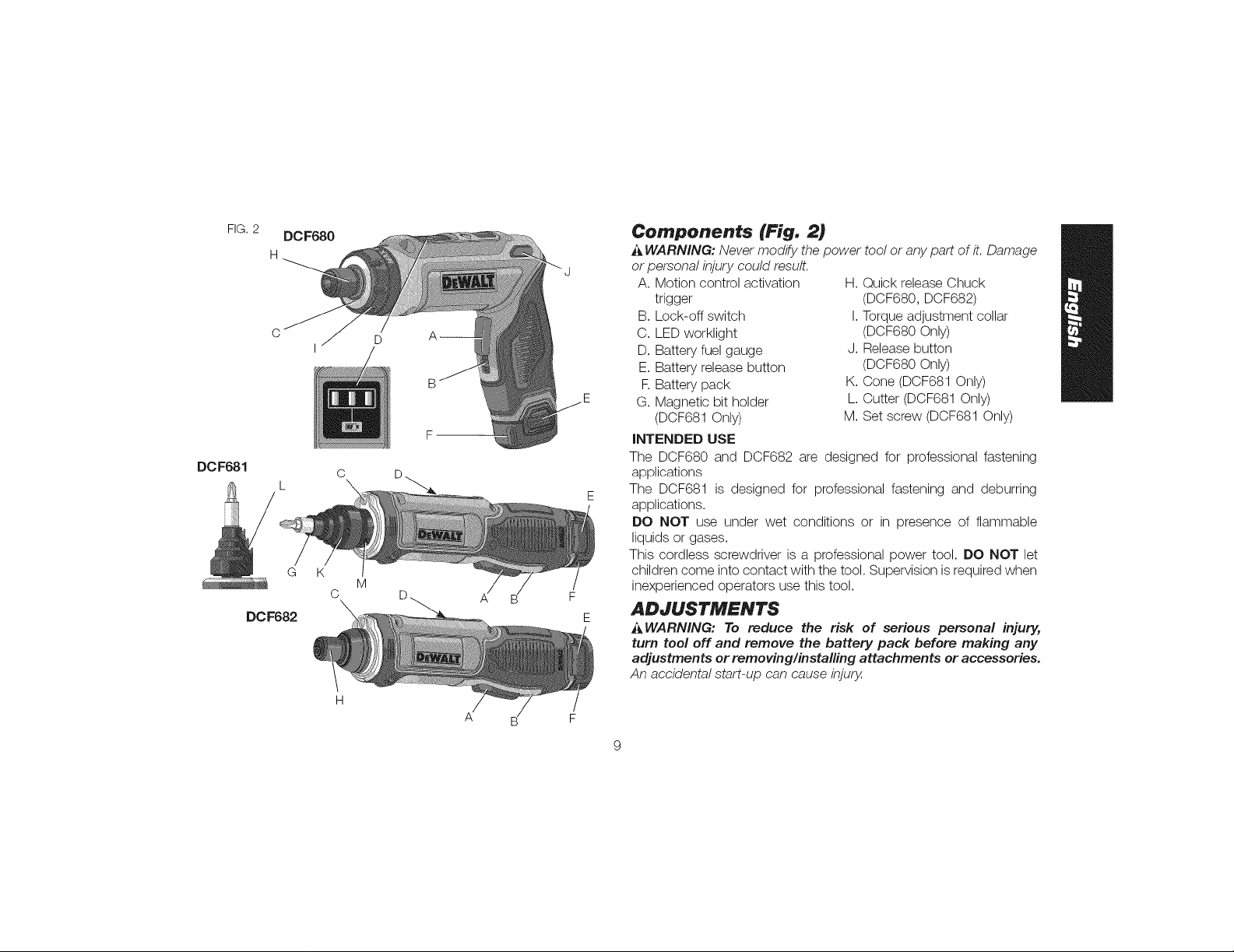

Components (Fig. 2)

WARNING: Never modify the power

or personal injury could result.

A. Motion control activation H.

trigger

B. Lock-off switch I.

C. LED worklight

D. Battery fuel gauge J.

E. Battery release button

R Battery pack K.

G. Magnetic bit holder L.

(DCF681 Only) M.

INTENDED USE

c

M

C

F

\

The DCF680 and DCF682 are designed for professional fastening

applications

The DCF681 is designed for professional fastening and deburring

applications.

DO NOT use under wet conditions or in presence of flammable

liquids or gases.

This cordless screwdriver is a professional power tool. DO NOT let

children come into contact with the tool. Supervision is required when

inexperienced operators use this tool.

ADJUSTMENTS

E

_WARNING: To reduce the risk of serious personal injury,

turn tool off and remove the battery pack before making any

adjustments or removing/installing attachments or accessories.

An accidental start-up can cause injury.

too/or any part of it. Damage

Quick release Chuck

(DCF680, DCF682)

Torque adjustment collar

(DCF680 Only)

Release button

(DCF680 Only)

Cone (DCF681 Only)

Cutter (DCF681 Only)

Set screw (DCF681 Only)

Page 11

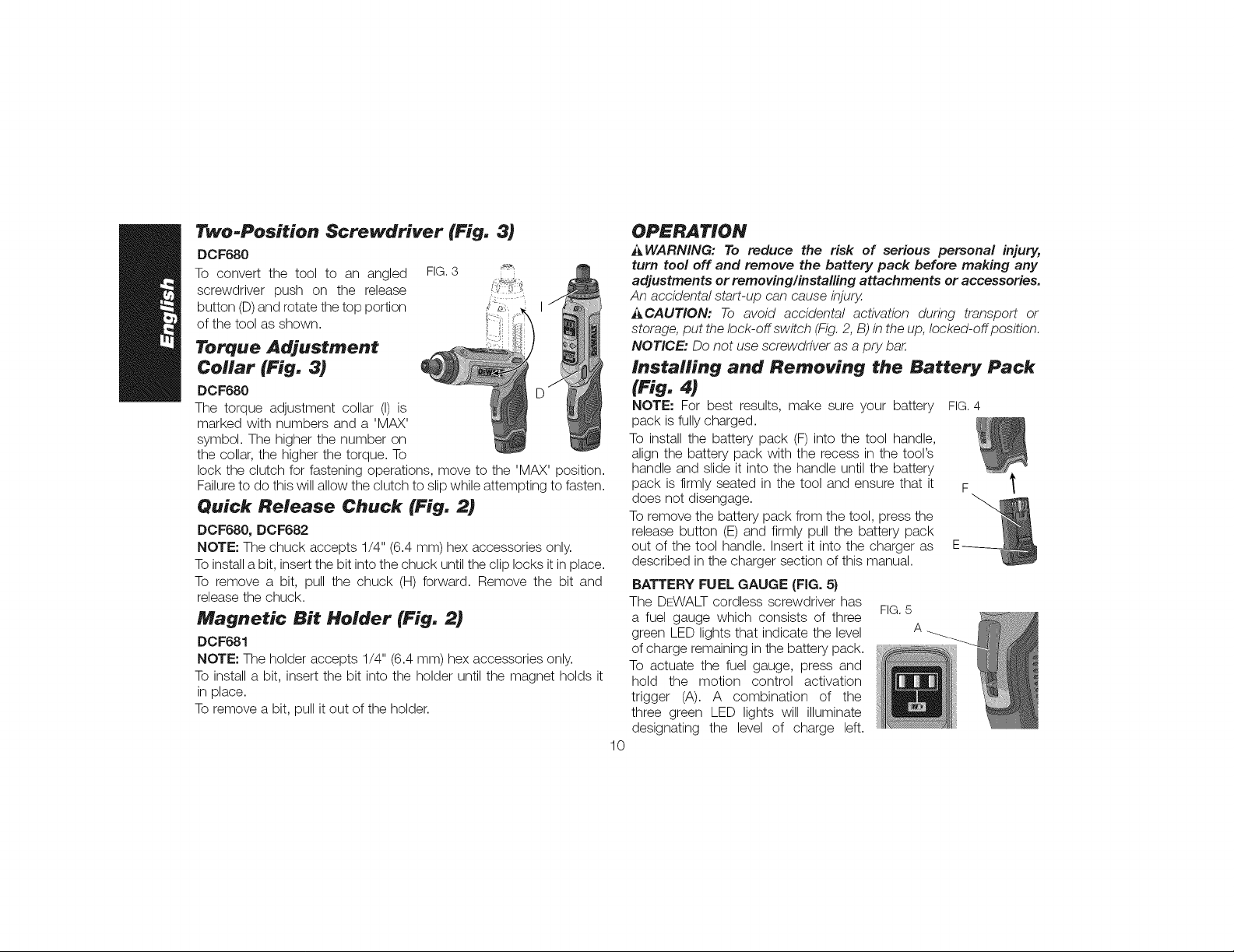

Two-Position Screwdriver (Fig. 3)

DCF680

To convert the tool to an angled FIG.3 _;_

screwdriver push on the release

button (D)and rotate the top portion

of the tool as shown.

Torque Adjustment

Collar (Fig. 3)

DCF680 D

The torque adjustment collar (I) is

marked with numbers and a 'MAX'

symbol. The higher the number on

the collar, the higher the torque. To

lock the clutch for fastening operations, move to the 'MAX' position.

Failure to do this will allow the clutch to slip while attempting to fasten.

Quick Release Chuck (Fig. 2)

DCF680, DCF682

NOTE: The chuck accepts 1/4" (6.4 mm) hex accessories only.

Toinstall a bit, insert the bit into the chuck until the clip locks it in place.

To remove a bit, pull the chuck (H) forward. Remove the bit and

release the chuck.

Magnetic Bit Holder (Fig. 2)

DCF681

NOTE: The holder accepts 1/4" (6.4 mm) hex accessories only.

To install a bit, insert the bit into the holder until the magnet holds it

in place.

To remove a bit, pull it out of the holder.

OPERATION

_WARNING: To reduce the risk of serious personal injury,

turn tool off and remove the battery pack before making any

adjustments or removing/installing attachments or accessories.

An accidental start-up can cause injury.

AOAUTION: To avoid accidental activation during transport or

storage, put the lock-off switch (Fig.2, B) inthe up, locked-off position.

NOTICE: Do not use screwdriver as a pry ba_

installing and Removing the Battery Pack

(Fig. 4)

NOTE: For best results, make sure your battery FIG.4

pack is fully charged.

To install the battery pack (F)into the tool handle,

align the battery pack with the recess in the tool's

handle and slide it into the handle until the battery

pack

is firmly seated in the tool and ensure that it F "_

does not disengage.

To remove the battery pack from the tool, press the

release button (E) and firmly pull the battery pack

out of the tool handle. Insert it into the charger as

described in the charger section of this manual.

BATTERY FUEL GAUGE (FIG. 5)

The DEWALT cordless screwdriver has

a fuel gauge which consists of three

green LED lights that indicate the level A

of charge remaining in the battery pack.

To actuate the fuel gauge, press and

hold the motion control activation

trigger (A). A combination of the

three green LED lights will illuminate

designating the level of charge left.

10

FIG.5

A

!

Page 12

Vdrl_tLIOr] r.Pdsec! or] [oroc!UCL corn[oor]er]LS, Lsrn[o_r_tLur8 _tr]c! _no-user

application.

For more information regarding the battery fuel gauge, please call

1-800-4-DEWALT (1-800-433-9258) or visit our website www.dewalt.

com.

To Operate

Your screwdriver uses gyroscopic technology to sense your hand

motion. To operate, press in the motion control activation trigger

and turn your hand in the direction that you want the screwdriver to

operate.

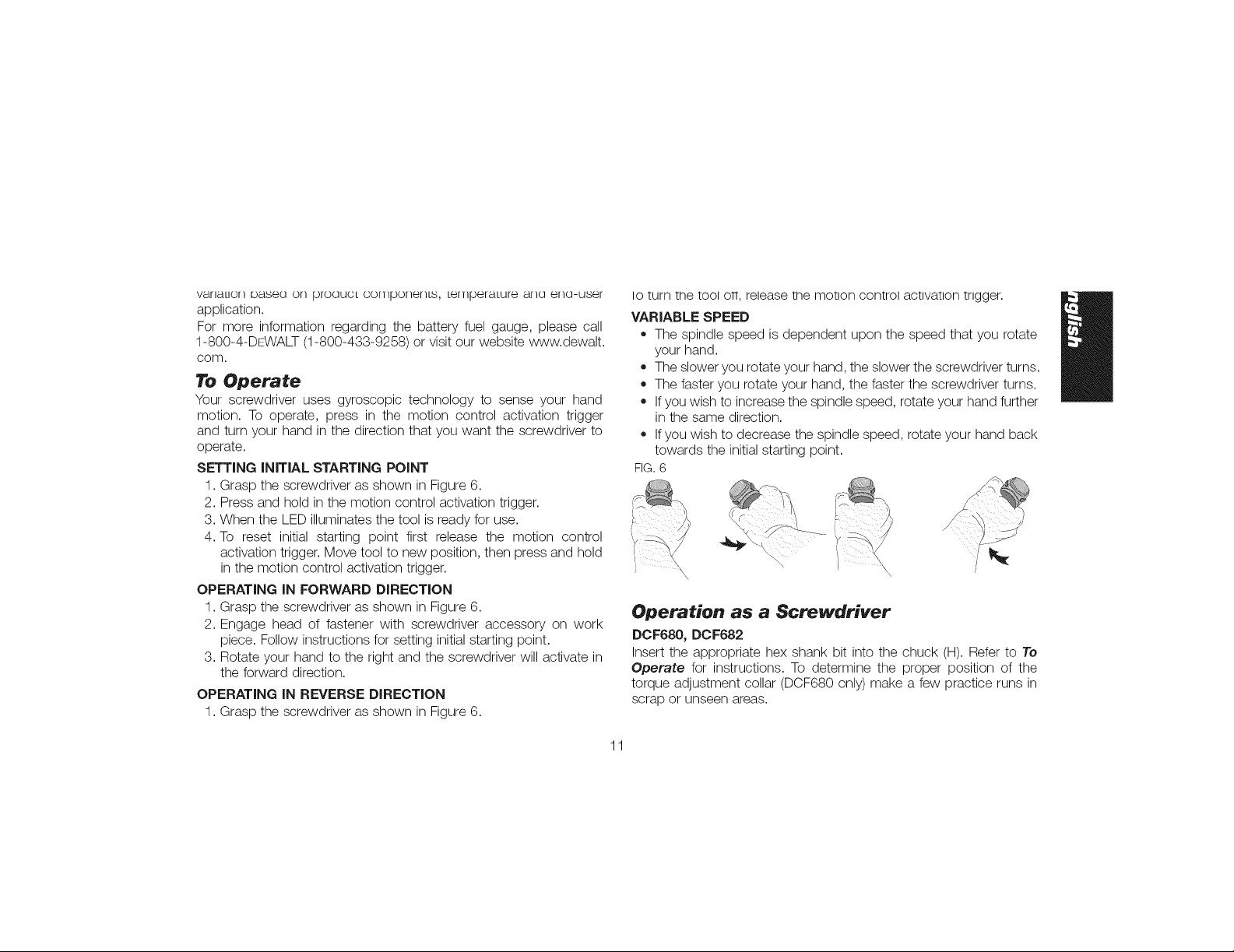

SETTING INITIAL STARTING POINT

1. Grasp the screwdriver as shown in Figure 6.

2. Press and hold in the motion control activation trigger.

3. When the LED illuminates the tool is ready for use.

4. To reset initial starting point first release the motion control

activation trigger. Move tool to new position, then press and hold

in the motion control activation trigger.

OPERATING IN FORWARD DIRECTION

1. Grasp the screwdriver as shown in Figure 6.

2. Engage head of fastener with screwdriver accessory on work

piece. Follow instructions for setting initial starting point.

3. Rotate your hand to the right and the screwdriver will activate in

the forward direction.

OPERATING IN REVERSE DIRECTION

1. Grasp the screwdriver as shown in Figure 6.

IO turn 1:he 1:OOloH, release 1:he tool:ion control ac1:lva1:lon 1:rigger.

VARIABLE SPEED

• The spindle speed is dependent upon the speed that you rotate

your hand.

• The slower you rotate your hand, the slower the screwdriver turns.

The faster you rotate your hand, the faster the screwdriver turns.

Ifyou wish to increase the spindle speed, rotate your hand further

in the same direction.

Ifyou wish to decrease the spindle speed, rotate your hand back

towards the initial starting point.

FIG. 6

Operation as a Screwdriver

DCF680, DCF682

Insertthe appropriate hex shank bit into the chuck (H). Refer to To

Operate for instructions.To determine the proper position of the

torque adjustment collar (DCF680 only) make a few practice runs in

scrap or unseen areas.

11

Page 13

DCF681

Insert the appropriate hex shank bit into the magnetic bit holder (G).

Refer to To Operate for instructions.

Operation as a Deburring Tool (Fig. 2, 7)

DCF681

WARNING: Always keep hands and clothing away from the cutting

area of the tool

i_ WARNING: Only retract the cone by pressing against a pipe end.

Do not lock the cone in the retracted position.

NOTICE: When deburring it is recommended to leavea hex bit in the

magnetic holde_ Metal chips and shavings caused by deburring can

be picked up by the magnet in the holde_

1. Activate the tool by the pressing the trigger and rotating the tool

in the desired direction.

2. Slowly feed into pipe and press cone against burred pipe end.

NOTE: Tool should be active before engaging with the pipe.

3. With tool activley rotating, firmly depress cone against the pipe,

engaging the cutter with pipe end. Allow multiple rotations to fully

deburr the pipe end.

i_WARNING: Tool can stall, causing a sudden twist. To reduce the

risk of injury, always use proper hand position as shown, and always

hold securely in anticipation of the tool cutter binding.

4. Once pipe end is deburred, pull the tool out of pipe and then

release the trigger.

_, WARNING: Before and after each use, inspect the cone for proper

closing. Do not operate the tool if the cone does not move freely and

close instantly,

FIG, 7

MAINTENANCE

_WARNING: To reduce the risk of serious personal injury,

turn tool off and remove the battery pack before making any

adjustments or removing/installing attachments or accessories.

An accidental start-up can cause injury,

Cleaning

_ WARNING: Blow dirt and dust off of too/and cone/cutter area

(DCF681) with clean, dry air at least once a week. To minimize the

risk of eye injury, always wear ANSI Z87.1 approved eye protection

when performing this.

_WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool These chemicals may

weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get

inside the tool,"never immerse any part of the tool into a liquid.

CHARGER CLEANING INSTRUCTIONS

WARNING: Shock hazard. Disconnect the charger from the AC

outlet before cleaning. Dirt and grease may be removed from the

exterior of the charger using a cloth orsoft non-metallic brash. Do not

use water or any cleaning solutions.

12

Page 14

Accessories

AWARNING: Since accessories, other than those offered by

DEWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the risk of

injury, only D,_-;WALTrecommended accessories should be used with

this product.

Recommended accessories for use with your tool are available

at extra cost from your local dealer or authorized service center. If

you need assistance in locating any accessory, please contact

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD

21286, call 1-800-4-DE.:.WALT(1-800-433-9258) or visit our website:

www.dewalt.com.

Repairs

The charger and battery pack are not serviceable.

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by a DEWALT factory service center, a DEWALT

authorized service center or other qualified service personnel. Always

use identical replacement parts.

When deburring becomes difficult a new cutter may be required.

INSTALLING REPLACEMENT CUTTER ACCESSORY DWA26011R

(FIG. 8)

i_,WARN/NG: To reduce the risk of serious persona/ injury,

turn tool off and remove the battery pack before making any

adjustments or removing/insta//ing attachments or accessories.

An accidental start-up can cause injury,

1. Use a 5/64 hex key to loosen and remove set screw (M).

2. Retract cone and tip cutter up and remove.

3. With the slot (N)in the magnetic bit holder and the slot (O) inthe

cone aligned, insert new cutter (L)sliding the tip under the round

wire ring (P) first. Then seat cutter. When seated correctly the

cutter should be flush with cone when in forward position.

4. Replace set screw. Align the tip with the hole in the cutter. Tighten

firmly.

i_,CAUTION: If the set screw is lost or damaged do not replace with

anything but an exact replacement part.

FIG.8 M

N

O

Register Online

Thank you for your purchase. Register your product now for:

• WARRANTY SERVICE: Registering your product will help you

obtain more efficient warranty service in case there is a problem

with your product.

• CONFIRMATION OF OWNERSHIP: In case of an insurance

loss, such as fire, flood or theft, your registration of ownership will

serve as your proof of purchase.

13

Page 15

• FOR YOUR SAFETY: Registering your product will allow us to

contact you in the unlikely event a safety notification is required

under the Federal Consumer Safety Act.

Register online at www.dewalt.com/register.

Three Year Limited Warranty

DE.:.WALTwill repair,without charge, any defects due to faulty materials

or workmanship for three years from the date of purchase. This

warranty does not cover part failure due to normal wear or tool

abuse. For further detail of warranty coverage and warranty repair

information, visit www.dewalt.com or call 1-800-4-DE.:.WALT(1-800-

433-9258). This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights

which vary in certain states or provinces.

In addition to the warranty, DE.:.WALTtools are covered by our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by

normal use, for free, any time during the first year after purchase.

2 YEARS FREE SERVICE ON DEWALT BATTERY PACKS

D09071, D09091, D09096, DC9280, DC9360, DC9180, DCB120,

DCB201, DCB203, DCB207 and DCB127

3 YEARS FREE SERVICE ON DEWALT BATTERY PACKS

DCB200, DCB204

DEWALT BATTERY PACKS

Product warranty voided if the battery pack is tampered with in any

way. DEWALT is not responsible for any injury caused by tampering

and may prosecute warranty fraud to the fullest extent permitted by

law.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

DEWALTPower Tool, Laser, or Nailer for any reason, you can return

it within 90 days from the date of purchase with a receipt for a full

refund - no questions asked.

LATIN AMERICA: This warranty does not apply to products sold

in Latin America. For products sold in Latin America, see country

specific warranty information contained in the packaging, call the

local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DEWALT (1-800-433-

9258) for a free replacement.

/ SV= (Max) /

! no 0-'_30/mi, (RPM} $ER. |

_ INSTRUCTION_NUaL. USEp_0PEr_ EVEAN_

_._vemreNcl_: pAPAELMANEJOS_GUH0LEAELmANUAl.0E

INS'T_UCCl0_ES._tPRODUCT0SE0EBE_A_PLE._ S0L_,MEr_TEC0NBATEF_i._s

DrWALT,$1_MP'_: SEI_E_EI_.LLEV,_RI_ PROT[CClO_ e,p_0pP_0APA_,IA VlSr,_ y

I_ARALASVIAS R_SPIRA_0_gAS.,_.AVE_Hss_r_t ENlr= A _ITR_PREV_NIIFr LI_E

L_GOID_ UTILISE_S_ULEN_NT AV_COESPIL_SD_WAL_ ILFAUTT0UJOURS

P0_TER DE L'EQUiPEMENT _E PROTEC_0N 0CUtAJRE IT RESNRATOINE APPROP_iE,

SCREWDRIVER

R[SPIRATOR'_ pROTECTiON. USE DEWALT BATTERIES.

FOR S_RV J_ JNFO RMAT_O_, CA LL 1_g-4-OEWALT www.O EWALT.com

14

Page 16

D_finitions : iignes directrices en

mati_re de s_curit_

Les definitions ci-dessous decrivent le niveau de danger pour

chaque mot-indicateur employe. LiFele mode d'emploi et porter

une attention particuliere _.ces symboles.

_DANGER : indique une situation dangereuse imminente qui,

si elle n'est pas evitee, entrainera la mort ou des blessures

graves.

h_AVERTISSEMENT : indique une situation potentie//ement

dangereuse qui, si e//e n'est pas evitee, pourraff entra?ner /a

mort ou des blessures graves.

AATTENTION : indique une situation potentie//ement

dangereuse qui, si e//en'est pas evitee, pourraff entra?ner des

blessures I_g_res ou mod_r6es.

AVIS : indique une pratique ne posant aucun risque de

dommages corporels mais qui par contre, si rien n'est fait

pour I'evited pourrait poser des risques de dommages

materiels.

J

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE OET

OUTIL OU DE TOUT AUTRE OUTIL DE.-:WALT,COMPOSEZ LE

NUMC:RO SANS FRAIS : 1-800-4-DEWALT (1-800-433-9258}.

@ VERTISSEMENT : afin de reduire le risque de blessures, life

le mode d'emploi de I'outil.

Avertissernents de s_curit_ g_n_raux

pour les outils _lectriques

s6curit_ et toutes les directives. Le non-respect des

_ AVERTISSEMENT! life tousles avertissements de

avertissements et des directives pourrait se solder par un

choc dectrique, un incendie et/ou une blessure grave.

CONSERVER TOUSLES AVERTISSEMENTS

ET TOUTES LES DIRECTIVES POUR UN

USAGE ULTERIEUR

Le terme _ outil dectrique _ cite clans les avertissements se rapporte

votre outil dectrique a alimentation sur secteur (avec ill) ou par piles

(sans fil).

1} S#CURIT# DU LIEU DE TRAVAIL

a) Tenir I'aire de travail propre et bien 6clair6e. Les /ieux

encombres ou sombres sont propices aux accidents.

b) Ne pas faire fonctionner d'outils 61ectriques clans un

milieu d_flagrant, tel qu'en pr6sence de liquides, de

gaz ou de poussi_res inflammables. Les outi/s dectriques

produisent des etincelles qui pourraient enflammer lapoussiere

ou les vapeurs.

c) Eloigner les enfants et les personnes bproximit6 pendant

I'utilisation d'un outi! 61ectrique. Une distraction pourrait en

faire perdre la ma?trisea I'utilisateu_

2) SECURITE EN MATIERE D'#LECTRICIT#

a) Les fiches des outils _lectriques doivent correspondre

& la prise. Ne jamais modifier la fiche d'aucune faqon.

Ne jamais utiliser de fiche d'adaptation avec un outil

61ectrique mis & la terre. Le risque de choc dectrique sera

reduit par/'uti/isation de fiches non modifiees correspondant

la prise.

15

Page 17

b)Evitertoutcontactphysiqueavecdessurfacesmisesbla

tortecommedestuyaux,desradiateurs,descuisini_res

etdesr6frig6rateurs.Lerisquedechocdectriqueestp/us

devesivotrecorpsestmisalaterre.

c)Nepasexposerlosoutils61ectriques b la pluie ou b

I'humidit_. La penetration de /'eau dans un outi/ dectrique

augmente le risque de choc dectrique.

d) Ne pas utiliser le cordon de faqon abusive. Ne jamais

utiliser le cordon pour transporter, tirer ou d_brancher

un outil 61ectrique. Tenir le cordon 61oign_ de la chaleur,

de I'huile, des bords tranchants et des pi_ces mobiles.

Les cordons endommages ou enchev6tres augmentent /es

risques de choc dectrique.

e) Pour I'utilisation d'un outil 61ectrique b I'ext_rieur, se

servir d'une rallonge convenant _ cette application.

L'utilisation d'une rallonge conque pour I'exterieur reduira les

risques de choc dectrique.

f) S'il est impossible d'6viter I'utilisation d'un outil

61ectrique clans un endroit humide, brancher I'outil clans

une prise ou sur un circuit d'alimentation dot6s d'un

disjoncteur de fuite _ la torte (GFCI). L'uti/isation de ce type

de disjoncteur reduit /es risques de choc dectrique.

3} SC:CURITi_ PERSONNELLE

a) Etre vigilant, surveiller le travail effectu6 et faire preuve

de jugement Iorsqu'un outil 61ectrique est utilis6. Ne

pas utiliser d'outil 61ectrique en cas de fatigue ou sous

I'influence de drogues, d'alcool ou de m_dicaments. Un

simple moment d'inattention en uti/isant un outi/ dectrique pout

entra?ner des blessures corpore//es graves.

b) Utiliser des 6quipements de protection individuelle.

Toujours porter une protection oculaire. L'uti/isation

d' equipements de protection comme un masque antipoussiere,

des chaussures antiderapantes, un casque de securite ou des

protecteurs auditifs Iorsque la situation le requiert reduira les

risques de blessures corporelles.

c) Emp@cher los d_marrages intempestifs. S'assurer que

I'interrupteur se trouve _ la position d'arr@t avant de

relier I'outil _ une source d'alimentation et/ou d'ins6rer

un bloc-piles, de ramasser ou de transporter I'outiL

Transporter un outi/ e/ectrique a/ors que /e doigt repose sur

I'interrupteur ou brancher un outil dectrique dont I'interrupteur

est a la position de mamhe risque de provoquer un accident.

d) Retirer toute cl_ de r6glage ou cl_ avant de d_marrer

I'outiL Une cle ou une cle de reglage attachee a une pattie

pivotante de I'outil dectrique peut pmvoquer des blessures

corporelles.

e) Ne pas trop tendre los bras. Conserver son 6quilibre en

tout temps. Ce/apermet de mieux ma_triser /'outi/ dectrique

dans les situations imprevues.

S'habiller de mani_re appropri6e. Ne pas porter de

v@tements amples ni de bijoux. Garder los cheveux, los

v@tements et los gants b 1'6cart des pi_ces mobiles. Les

v6tements amples, les bijoux ou les cheveux longs risquent de

rester coinces clans les pieces mobiles.

g) Si des composants sont fournis pour le raccordement de

dispositifs de d_poussi6rage et de ramassage, s'assurer

que ceux-ci sont bien raccord_s et utilis6s. L'uti/isation

d'un dispositif de depoussierage peut reduire /es dangers

engendres par les poussieres.

16

Page 18

4)UTILISATION ET ENTRETIEN D'UN OUTIL leLECTRIQUE

a) Ne pas forcer un outil 61ectrique. Utiliser I'outil 61ectrique

appropri6 _ I'application. L'outi/ e/ectrique approprie

effectuem un meilleur travail, de faqon plus sore eta la vitesse

pour laquelle il a ere conqu.

b) Ne pas utiliser un outil 61ectrique dent I'interrupteur

est d_fectueux. Tout outi/ dectrique dent /'interrupteur est

defectueux est dangereux et doit 6tre repare.

c) D6brancher la fiche de la source d'alimentation et/ou du

bloc-piles de I'outil 61ectrique avant de faire tout r6glage

ou changement d'accessoire ou avant de ranger I'outil.

Ces mesures preventives reduisent /es risques de demarrage

accidentel de I'outil dectrique.

d) Ranger les outils 61ectriques hers de la pottle des

enfants et ne permettre _ aucune personne n'6tant

pas famili_re avec un outil 61ectrique ou son mode

d'emploi d'utiliser cet outil. Les outi/s dectriques deviennent

dangereux entre/es mains d'uti/isateurs inexperimentes.

e) Entretien des outils 61ectriques. V_rifier si les pi_ces

mobiles sent mal align6es ou coinc6es, si des pi_ces sent

bris6es ou pr6sentent toute autre condition susceptible

de nuire au ben fonctionnement de I'outil 61ectrique.

En cas de dommage, faire r_parer I'outil 61ectrique

avant toute nouvelle utilisation. Beaucoup d'accidents sent

causes par des outils dectriques mal entretenus.

f) S'assurer que les outils de coupe sent aiguis6s et

propres. Les outi/s de coupe bien entretenus et affOtes sent

moins susceptibles de se coincer et sent plus faciles a ma?trise_

g) Utiliser I'outil 61ectrique, les accessoires, les forets,

etc. conform6ment aux pr_sentes directives en tenant

compte des conditions de travail et du travail _ effectuer.

L'utilisation d'un outil dectrique pour toute operation autre que

celle pour laquelle ila ere conqu est dangereuse.

5} UTILISATION ET ENTRETIEN DU BLOC-PILES

a) Ne recharger I'outil qu'au moyen du chargeur pr6cis6

par le fabricant. L'uti/isation d'un chargeur qui convient

un type de bloc-piles risque de pmvoquer un incendie s'il est

utilise avec un autre type de b Ioc-piles.

b) Utiliser les outils 61ectriques uniquement avec les blocs=

piles conqus & cet effet. L'uti/isation de tout autre bloc-piles

risque de causer des b/essures ou un incendie.

c) Lorsque le bloc-piles n'est pas utilis_, le tenir 61o_gn_

des objets m6tailiques, notamment des trombones, de

la monnaie, des cl_s, des clous, des vis ou autres petits

objets m_tailiques qui peuvent 6tablir Line connexion

entre les deux homes. Le court-circuit des bomes du bloc-

piles risque de provoquer des brO/uresou un incendie.

d) En cas d'utilisation abusive, le liquide peut gicler hers

du bloc-piles; 6viter tout contact avec ce liquide. Si

un contact accidentel se produit, laver _ grande eau.

Si le liquide entre en contact avec les yeux, obtenir

6galement des soins m_dicaux. Le /iquide qui gic/e hers du

bloc-piles peut provoquer des irritations ou des brOlures.

6) RF:PARATION

a) Faire r6parer I'outil 61ectrique par un r6parateur

professionnel en n'utilisant que des pi_ces de rechange

identiques. Ce/a permettra de maintenir une uti/isation

securitaire de/'outi/dectrique.

17

Page 19

R_gles additionnelles de s_curit_ propres

aux tournevis

, Saisir I'outil 61ectrique par ses surfaces de prises isol6es

Iorsque I'outil peut entrer en contact avec des fils cach6s

ou son cordon. En cas de contact avec un fil sous tension, les

pieces metalliques de I'outil semnt sous tension et I'utilisateur

subira des secousses dectriques.

• Utiliser des brides de fixation ou un autre dispositif de

fixation permettant de fixer solidement et de soutenir la

piece sur une plateforme stable. Tenir /apiece avec /a main ou

contre son corps/a rend instab/e et risque de provoquer une perte

de ma_trisede I'outil.

• Prendre des pr6cautions _ proximit_ des 6vents, car ils

cachent des pi_ces mobiles. V6tements amp/es, bijoux ou

cheveux longs risquent derester coinces clansces pieces mobiles.

J_,AVERTISSEMENT : porter SYSTEMATIQUEMENT des lunettes

de protection. Les lunettes courantes NE sont PAS des lunettes de

protection. Utiliser aussi un masque antipoussieres si la decoupe

doit en pmduire beaucoup. PORTER SYSTEMATIQUEMENT UN

EQUIPEMENT DE SECURITE HOMOL OGUE :

• Protection oculaire ANSI Z87.1 (CAN/CSA Z94.3) ;

Protection auditive ANSI S12.6 ($3.19) ;

Protection des voies respiratoires NIOSH/OSHA/MSHA.

J_,AVEFtTISSEMENT :les scies, meules, ponceuses, pemeuses

ou autres outils de construction peuvent produire des poussieres

contenant des pmduits chimiques reconnus par I'Etat califomien

pour causer cancers, malformations congenitales ou 6tre nocifs au

systeme repmducteu_ Parmi ces pmduits chimiques, on retrouve :

Le plomb clans les peintures a base de plomb ;

• La silice cristallisee clans les briques et le ciment, ou autres

produits de maqonnerie ;et

L'arsenic et le chrome clans le bois ayant subi un traitement

chimique.

Le risque associe a de telles expositions varie selon la frequence

laquelle on effectue ces travaux. Pour reduire toute exposition aces

produits : travailler clans un endroit bien aere, en utilisant du materiel

de securite homologue, tel un masque antipoussieres specialement

conqu pour filtrer les particules micmscopiques.

• Limiter toute exposition prolong6e avec los poussi_res

provenant du ponqage, sciage, meulage, perqage ou toute

autre activit6 de construction. Porter des v_tements de

protection et nettoyer _ I'eau savonneuse los parties du

corps expos_es. Le fait de/aisser/a poussiere penetrer clans/a

bouche, /es yeux ou /apeau peut favoriser /'absorption de produits

chimiques dangereux.

_AVERTISSEMENT :cet outil peut pmduire et/ou repandre

de la poussiere susceptible de causer des dommages serieux et

permanents au systeme respiratoire. Utiliser systematiquement un

appareil de protection des voies respiratoires homologue par le

NIOSH ou I'OSHA. Diriger les particules clans le sens oppose au

visage et au corps.

_ATTENTION : apr_s utilisation, ranger I'outil sur son c6t_,

sur une surface stable, 14 ob il ne pourra ni faire tr6bucher

ni faire chuter quelqu'un. Certains outi/s equipes d'un large bloc-

piles peuvent tenir a la verticale sur celui-ci, mais manquent alors de

stabilite.

18

Page 20

L'etiquette apposee sur votre outil peut inclure les symboles

suivants. Les symboles et leur definition sont indiques ci-apres :

V................... volts A....................... amperes

Hz................. hertz W...................... watts

min ............... minutes _ ou AC .......... courant altematif

--- ou DC... courant continu _ ou AC/DC... courant altematif

(_)................. classe I fabrication ou continu

(mis a la terre) no ..................... vitesse a vide

[] ................. fabrication n ....................... vitesse nominale

classe II (double G ...................... borne de terre

isolation) A ...................... symbole

.../min ........... par minute d'avertissement

IPM............... impacts par SPM (FPM) ....... frequence par

minute minute

BPM ............. battements par r/min ................. tours par

minute minute

sfpm ............. pieds lineaires

par minute (plpm)

Consignes irnportantes de s_curit_

propres _ tous les blocs=piles

Pour commander un bloc-piles de rechange, s'assurer d'inclure son

numero de catalogue et sa tension. Consulter letableau en derniere

page de ce manuel pour connaTtreles compatibilites entre chargeurs

et blocs-piles.

Le bloc-piles n'est pas totalement charge d'usine. Avant d'utiliser le

bloc-piles et le chargeur, life les consignes de securite ci-dessous.

Puis suivre la procedure de charge indiquee.

I-IFtE TOUTES L£S CONSIGNES

• Ne pas recharger ou utiliser un bloc-piles en milieu

d_flagrant, en pr6sence, par exemple, de poussi_res, gaz

ou liquides inflammables. Le fair d'inserer ou retirer un bloc-

piles de son chargeur pourrait causer I'inflammation de poussieres

ou d' emanations.

• NE JAMAIS forcer I'insertion d'un bloc-piles clans un

chargeur. NE modifier un bloc-piles d'AUCUNE fagon

pour le faire rentrer clans un chargeur incompatible, car

il pourraff se briser et causer des dommages corporels

graves. Consulter/e tableau en demiere page de ce manuel pour

conna_tre les compatibilites entre chargeurs et blocs-piles.

• Recharger les blocs-piles exclusivement clans des chargeurs

DEWALT.

• NE PAS eclabousser le bloc-piles ou I'immerger clans I'eau ou

clans tout autre Iiquide.

• Ne pas entreposer ou utiliser I'appareil et le bloc-piles en

presence de temp6ratures ambiantes pouvant exc_der

40 °C (105 °F) (comme clans des hangars ou des b&timents

m6talliques 1'6t6), Pour preserver/eur duree de vie, entreposer

les blocs-piles dans un endroit frais et sec.

REMARQUE : ne pas mettre un bloc-piles clans un outil

dont la g&chette est verrouill_e en position de marche. Ne

jamais bloquer I'interrupteur en position de MARCHE.

AAVERTISSEMENT : risques d'incendie. Ne jamais tenter

d'ouvrir /e bloc-piles pour que/que raison que ce soit. Si /e bo_tier

du bloc-piles est fissure ou endommage, ne pas I'inserer dans un

chargeur Ne pas ecrased laisser tombed ou endommager les blocs-

piles. Ne pas utiliser un bloc-piles ou un chargeur qui a regu unchoc

violent, ou si I'appareil est tombe, a ere ecrase ou endommage de

quelque fagon que ce soit (p. ex. peme par un clou, frappe d'un

coup demarteau, pietine). Les blocs-piles endommages doivent 6tre

renvoyes a un centre de reparation pour y 6tre recycles.

19

Page 21

REMARQUE: un bottler special et des capuchons de

securite sont fournis avec le bloc-piles pour utilisation

chaque fois qu'on le retire de I'outil ou du chargeur pour le

ranger ou le transporter. Enlever le capuchon avant de

remettre le bloc-piles dans lechargeur ou I'outil.

_VERTiSSEMENT : risques d'incendie. Au moment

de ranger ou transporter le bloc-piles, s'assurer

qu'aucun objet m_tallique n'entre en contact avec

los homes _ d6couvert du bloc-piles. Par exemp/e, eviter de

placer un bloc-piles dans un tab/ie_ une poche, une bore a outi/s ou

un tiroid etc. contenant des objets tels que des clous, des vis, des

cles, etc. Le fair de transporter des bloc-piles comporte des

risques d'incendie, car les homes des piles pourraient entrer,

par inadvertance, en contact avec des objets conducteurs,

tels que : cl_s, pi_ces de monnaie, outils ou autres. La

reglementation sur les produits dangereux (Hazardous Material

Regulations) du departement americain des transports interdit, en

faR, le transport des piles pour le commeme ou clans les avions

(ex :dans les bagages enregistres ou a main) A MOINS qu'elles ne

soient correctement protegees contre tout court-circuit. Aussi lot's du

transport individuel de blocs-piles, s'assurer que leurs bomes sont

ben protegees et isolees de tout materiau pouvant entrer en contact

avec elles et provoquer un court-circuit.

CONSIGNES DE SI_CURIT# PROPRES AUX PILES AU

LITHIUM-ION (Li=lon}

, Ne pas incin_rer le bloc-piles m@me s'il est s6v_rement

endommag_ ou compl_tement usag6, car il pourrait

exploser et causer un incendie. Pendant /'incineration des

blocs-piles au lithium-ion, des vapeurs et matieres toxiques sont

degagees.

• En cas de contact du liquide de la pile avec la peau, rincer

imm6diatement au savon doux et _ I'eau. En cas de contact

ocu/aire, rincer /'ceil ouvert a/'eau claire une quinzaine de minutes

ou jusqu'a ce que I'irritation cesse. Si des soins medicaux

s'averaient necessaires, noter que I'dectrolyte de la pile est

compose d'un mdange de carbonates organiques Iiquides et de

sels de lithium.

, Le contenu des cellules d'une pile ouverte peut causer une

irritation respiratoire. En cas d'inha/ation, exposer/'individu

Fairlibre. Siles sympt6mes persistent, consulter un medecin.

JAAVERTISSEMENT : risques de brOlure. Le Iiquide de la pile peut

s'enflammer s'il est expose a des etincelles ou a une flamme.

Le sceau SRPRC Mc

Le seeau SRPRCMc ($oeiete de recyclage des piles

rechargeables au Ganada)appose sur une pile au

nickel-cadmium, a hydrure metallique de nickel ou au

lithium-ion (ou un bloc-piles) indique que les coots de

recyclage de ces derniers en fin d'utilisation ont dej_.

ete regles par DEWALT. Dans certaines regions, la mise au rebut ou

aux ordures municipales des piles au nickel-cadmium, _. I'hydrure

metallique de nickel ou au lithium-ion, est illegale ; le programme de

SRPRC constitue donc une solution pratique et ecologique.

La SRPRCMe,en collaboration avec DEWALT et d'autres utilisateurs

de piles, a mis sur pied des programmes aux Etats-Unis et au

Canada pour faciliter la collecte des piles au nickel-cadmium, _.

I'hydrure metallique de nickel ou au lithium-ion usagees. Aidez-nous

_.proteger I'environnement et _.conserver nos ressources naturelles

en renvoyant les piles au nickel-cadmium, _.I'hydrure metallique de

nickel ou au lithium-ion usagees _.un centre de reparation autorise

DEWALTou chez votre detaillant afin qu'elles y soient recyclees. On

peut en outre se renseigner aupres d'un centre de recyclage local

pour connaTtre d'autres sites les acceptant.

2O

Page 22

SRPRCMCestunemarquedeposeedelaSociete de recyclage des

piles rechargeables au Canada.

Directives de s_curit_ irnpo_antes

propres _ tous les chargeurs de piles

CONSERVER CES INSTRUCTIONS : ce manuel contient des

directives de securite et d'utilisation importantes propres aux

chargeurs de piles.

• Avant d'utiliser le chargeud life route consigne et tout avertissement

apposes sur le chargeud le bloc-piles et le produit utilisant le bloc-

piles.

_VERTISSEMENT : risques de chocs dectriques. Ne laisser aucun

Iiquide penetrer clans le chargeud des chocs dectriques pourraient en

resulte_

ATTENTION : risques de brOlure. Pour reduire tout risque de

dommages corporels, ne recharger que des blocs-piles rechargeables

DEWALT. Tout autre type de piles pourrait exploser et causer des

dommages corporels et materiels.

AVIS : sous certaines conditions, Iorsque le chargeur est connecte au

bloc d'alimentation, des materiaux etrangers pourraient court-circuiter

le chargeu_ Los corps etrangers conducteurs tels que (mais pas

limite a) poussieres de rectification, debris metalliques, laine d'acied

feuilles d'aluminlum, ou toute accumulation de particules metalliques

doivent 6tre maintenus a distance des orifices du chargeu_ Debrancher

systematiquement le chargeur Iorsque le bloc-piles n'y est pas insere.

Debrancher systematiquement le chargeur avant tout entretien.

• NE PAS tenter de charger de bloc-piles avec des chargeurs

autres que ceux d_crits clans ce manuel Le chargeur et son

bloc-piles ont ere conqus tout specialement pour fonctionner

ensemble.

, Cos chargeurs n'ont pas _t_ conqus pour une utilisation

autre que recharger los blocs-piles rechargeables DEWALT.

Toute autre uti/isation comporte des risques d'incendie, de chocs

dectriques ou d'dectrocution.

• Prot6ger le chargeur de la pluie ou de la neige.

• Tirer sur la fiche plut6t que sur le cordon pour d6brancher

le chargeur. Ce/a permet de reduire /es risques d'endommager

la fiche ou le cordon d'alimentation.

• S'assurer que le cordon est prot_g6 de mani_re _ ce que

personne ne marche ni ne tr6buche dessus, ou _ ce qu'il

ne soit ni endommag6 ni soumis _ aucune tension.

• N'utiliser une rallonge qu'en cas de n6cessit_ absolue.

L'uti/isation d'une ra//onge inadequate comporte des risques

d'incendie, de chocs dectriques ou d'dectrocution.

• Pour utiliser un chargeur _ I'ext_rieur, le placer clans un

endroit sec et utiliser une rallonge conque pour I'ext6rieur.

L'utilisation d'une rallonge conque pour I'exterieur reduit los

risques de chocs dectriques.

• Pour la s_curit_ de I'utilisateur, utiliser une rallonge de

calibre ad_quat (AWG, American Wire Gauge [calibrage

am_ricain normalis_ des fils _lectriques]). Plus/e calibre est

petit, et plus sa capacite est grande. Un calibre 16, par exemple,

a une capacite superieure a un calibre 18. L'usage d'une rallonge

de calibre insuffisant causera une chute de tension qui entra?nera

porte de puissance et surchauffe. Si plus d'une rallonge est utilisee

pour obtenir une certaine Iongueud s'assurer que chaque rallonge

presente au moins le calibre de filminimum. Le tableau ci-dessous

illustre los calibres a utiliser solon la Iongueur de rallonge et

I'intensite nominale indiquee sur la plaque signaletique. En cas

de doute, utiliser le calibre suivant. Plus le calibre est petit, plus la

rallonge pout supporter de courant.

21

Page 23

Calibres minimau× des rallonges

volts Longueur totale de

Intensit_ (en

amperes}

Sup_rieur Inf_rieur

0 6

6 10

10 12

12 16 14 12

• Ne poser aucun objet sur le chargeur. Ne pas mettre le

chargeur sur une surface molle qui pourrait en bloquer la

ventilation et provoquer une surchauffe interne. E/oigner

/e chargeur de route source de cha/eu_ Le chargeur dispose

d'orifices d'aeration sur le dessus et le dessous du bo_tie_

• Ne pas le faire fonctionner avec un cordon d'alimentation

ou une fiche endommag6e.

• Ne pas utiliser le chargeur s'il a requ un coup, fait une chute

ou a 6t_ endommag_ de quelque faqon que ce soit. Le

ramener clans un centre de reparation agree.

• Ne pas d_monter le chargeur. Pour tout service ou r6paration,

le rapporter clans un centre de r6paration agr_. Le fair de/e

reassemb/er de faqon incorrecte comporte des risques de chocs

dectriques, d'dectrocution et d'incendie.

120V 7,6 15,2 30,5

(25) (50) (100)

240V 15,2 30,5 61,0

(50) (100)(200)

18 16 16

18 16 14

16 16 14

cordon

en m_tres (pieds)

45,7

(150)

91,4

(300)

AW6

14

12

12

Non

recommande

• D_brancher le chargeur du secteur avant tout entretien.

Cela r6duira tout risque de chocs 61ectriques. Le fair de retirer

/e bloc-piles ne reduira pas ces risques.

• NE JAMAIS tenter de connecter 2 chargeurs ensemble.

• Le chargeur a 6t6 con_u pour @tre aliment_ en courant

61ectrique domestique standard de 120 volts. Ne pas tenter

de I'utiliser avec toute autre tension. Ce/a ne s'app/ique pas

aux chargeurs de postes mobiles.

Chargeurs

L'outil utilise un chargeur DEWALT. S'assurer de bien life toutes

les directives de securite avant d'utiliser le chargeur. Consulter le

tableau figurant _.la fin du present mode d'emploi pour connaTtre la

compatibilite des chargeurs et des blocs-piles.

Procedure de charge (Fig. 1)

1. Branchez le chargeur dans FIG.1

la prise appropriee avant d'y

inserer le bloc-piles. G --

2. Inserez le bloc-piles (G) dans

le chargeur, comme illustre en

Figure 1, en vous assurant qu'il

y est correctement cale. Le

voyant rouge (charge) clignotera

de fagon continue indiquant

que le cycle de chargement a

commence.

3. En fin de charge, le voyant rouge restera ALLUME de fagon

continue. Le bloc-piles est alors compl_tement charge et peut

_tre utilise ou laisse dans le chargeur.

22

Page 24

Fonctionnernent du voyant

BLOC-PILESEN

COURSDECHARGEMENT

BLOC=PiLESCHARGe:

= USPENSIONDECHARGE

CONTRELECHAUD/EROJD

BLOC-PILESOU

CHARGEURD_:FECTUEUX

0000000000000000

Voyants de charge

Ce chargeur a ete con_u pour detecter les probl@_es pouvant

survenir. Un voyant rouge clignotant rapidement indique qu'il y a

un probleme. Dans cette eventualite, reinserez le bloc-piles dans le

chargeur. Si le probleme persiste, essayez un autre bloc-piles pour

determiner si le chargeur fonctionne. Si le nouveau bloc-piles se

recharge correctement, le bloc-piles initial est endommage et doit

_tre retourne dans un centre de reparation ou tout autre site de

recuperation pour y _tre recycle. Si I'on obtient le m_me resultat avec

le nouveau bloc-piles, faites verifier lechargeur et le bloc-piles chez un

centre de reparation agree.

FONCTION DE SUSPENSION DE CHARGE CONTRE LE

CHAUD/FROiD

Ce chargeur est equipe d'une fonction de suspension de charge

contre le chaud/froid. Lorsque le chargeur detecte un bloc-piles

chaud, il d@_arre automatiquement la fonction de suspension de

charge contre le chaud, en suspendant le chargement jusqu'au

refroidissement de ce dernier. Une fois le bloc-piles refroidi, le

chargeur se met automatiquement en mode de chargement. Cette

caracteristique assure aux blocs-piles une duree de vie maximale.

Le voyant rouge clignote Ionguement, puis rapidement en mode de

suspension de charge contre le chaud/froid.

LAISSER LE BLOC=PILES DANS LE CHARGEUR

Le chargeur et son bloc-piles peuvent rester connectes, le voyant du

chargeur affichant alors Bloc-piles charge.

BLOCS=PILES FAIBLES : les blocs-piles fables continueront de

fonctionner, mais il faudra s'attendre _,un rendement moindre.

BLOCS=PILES DI'-=FECTUEUX : ce chargeur ne pourra recharger

un bloc-piles defectueux. Le chargeur indiquera qu'un bloc-piles est

defectueux en refusant de s'allumer ou en affichant bloc-piles ou

chargeur defectueux.

REMARQUE : cela pourra aussi indiquer un probleme avec le

chargeur.

Remarques importantes concernant le

chargernent

1. Pour augmenter la duree de vie du bloc-piles et optimiser

son rendement, le recharger _,une temperature ambiante de

18 ° _,24 °C (65 °F _,75 °F). NE PAS recharger le bloc-piles _,

une temperature inferieure _,+ 4,5 °C (+ 40 °F) ou superieure

_, + 40,5 °C (+ 105 °F). C'est important pour prevenir tout

dommage serieux au bloc-piles.

2. Le chargeur et son bloc-piles peuvent devenir chauds au

toucher pendant la charge. C'est normal et ne represente

en aucun cas une defaillance du produit. Pour faciliter le

refroidissement du bloc-piles apres utilisation, eviter de laisser

le chargeur ou le bloc-piles dans un local o8 la temperature

ambiante est elevee comme dans un hangar metallique ou une

remorque non isolee.

23

Page 25

3.Silebloc-pilesneserechargepascorrectement:

a.Wrifierlebonfonctionnementdelapriseenybranchantune

lampeoutoutautreappareilelectrique.

b.Wrifierquelaprisen'estpascontrOleeparuninterrupteur

quicoupelecourantIorsqu'oneteintleslumi_res.

c.Deplacerlechargeuret lebloc-pilesdansunlocalcOla

temperatureambiantesetrouveentreenviron18°et24°C

(65°Fet75°F).

d.Sileprobl_mepersiste,amenerI'outil,lebloc-pilesetson

chargeurdansuncentredereparationlocal.

4.Rechargerle bloc-pilesIorsqu'ilne produitplusassezde

puissancepoureffectuerun travailqu'ilfaisaitfacilement

auparavant.NEPASCONTINUER_,I'utiliserdansces

conditions.Suivrelaproceduredecharge.Sinecessaire,il

estaussipossiblederechargerunbloc-pilespartiellement

dechargesanseffetnuisiblesurlebloc-piles.

5.Lescorpsetrangersconducteurstelsque(maispaslimite_,)

poussi_resderectification,debrismetalliques,lained'acier,

feuillesd'aluminium,ou touteaccumulationde particules

metalliquesdoivent_tremaintenus_,distancedesorificesdu

chargeur.DebranchersystematiquementlechargeurIorsquele

bloc-pilesn'yestpasinsere.Debranchersystematiquementle

chargeuravanttoutentretien.

6.NepascongelerouimmergerlechargeurdansI'eauoutout

autreliquide.

_AVERTISSEMENT: risques de chocs electriques. Ne laisser

aucun Iiquide penetrer dans le chargeuc des chocs electriques

pourraient en resulte_

_ATTENTION : ne jamais tenter d'ouvrir le bloc-piles pour

quelque raison que ce soit. Si le bo_tier plastique du bloc-piles est

brise ou fissure, le retoumer dans un centre de reparation pour y

6tre recycle.

Recomrnandations de stockage

1. Le lieu ideal de rangement est un lieufrais et sec, _,I'abri de toute

lumiere solaire directe et de toute temperature excessive.

2. Pour un stockage prolonge, il est recommande d'entreposer le

bloc-piles pleinement charge dans un lieu frais et sec, hors du

chargeur pour optimiser les resultats.

REMARQUE : les blocs-piles ne devraient pas _tre entreposes

compl_tement decharges. II sera necessaire de recharger le bloc-

piles avant reutilisation.

CONSERVER CES CONSIGNES POUR

UTILISATION ULTERIEURE

24

Page 26

FIG.2

DCF681

c

[

DOF682

DCF680

I

G K

DESCRIPTION (Fig. 2)

i_,AVERTISSEMENT : ne jamais modifier I'outil dectrique ni aucun

de ses composants, car il y a risques de dommages corporels ou

materiels.)

A. G_,chette automatique H. Mandrin automatique

actionnee par le mouvement (DCF680, DCF682)

B. Interrupteur de verrouillage I. Bague de reglage de couple

C. Lampe DEL (DCF680 seulement)

D. Bouton de liberation J. Bouton de liberation

E. Temoin de charge du (DCF680 seulement)

bloc-piles K. C6ne (DCF681 seulement)

F.Bouton de liberation du bloc- L. Organe de coupe

piles (DCF681 seulement)

G. Porte-embout magnetique M. Vis de pression

c

M

C

\

F

E

(DCF681 seulement) (DCF681 seulement)

USAGE PR#VU

Les modeles DCF680 et DCF682 ont ete con_us pour le vissage

professionnel.

Le modele DCF681 a ete con_u pour le vissage et I'ebarbage

professionnels.

NE PAS I'utiliser en milieu ambiant humide ou en presence de

liquides ou de gaz inflammables.

Ce tournevis sans fil est un outil electrique de professionnels. NE

PAS le laisser _, la portee des enfants. Une supervision est necessaire

aupres de tout utilisateur non experimente.

AJUST£MENTS

_AVERTISSEMENT : pour r6duire le risque de blessures graves,

6teindre I'outil et retirer le bloc-piles avant d'effectuer tout

r6glage et d'enlever ou d'installer tout accessoire. Un demarrage

accidente/ peut provoquer des b/essures.

25

Page 27

Tournevis _ deux positions (Fig. 3)

DCF680

Pour convertir I'outil en un tournevis FIG.3 _!

angulaire, tirer sur le bouton de

degagement (D) et faire pivoter la I

pattie superieure de I'outil, tel

qu'illustre.

Bague de r_glage de

couple (Fig. 3)

DCF680 D

Sur la bague de reglage de couple (I)

se trouvent inscrits des numeros et

le symbole _,MAX ,,. Plus le numero

sur la bague est eleve, plus le couple est eleve. Pour verrouiller

I'embrayage lots du vissage, selectionnez la position _,MAX ,,. Dans

le cas contraire, I'embrayage pourrait patiner au cours du vissage.

Liberation instantan_e du mandrin (Fig. 2)

DCF680, DCF682

REMARQUE : le mandrin accepte uniquement des accessoires

hexagonaux de 6,4 mm (1/4 pc).

Pour installer un embout, inserez I'embout dans le mandrin jusqu'_, ce

que le clip le verrouille en place.

Pour retirer I'embout, tirez le mandrin (H)vers I'avant. Retirez I'embout

puis relS.chezle mandrin.

Porte-embout magn_tique (Fig. 2)

DCF681

REMARQUE : leporte-embout accepte uniquement des accessoires

hexagonaux de 6,4 mm (1/4 pc).

Pour installer un embout, poussez I'embout dans le porte-embout

jusqu'_ ce que I'aimant le maintienne en place.

Pour retirer I'embout, tirez-le hors du porte-embout.

UTILISA TION

i_AVERTISSEMENT : pour r6duire le risque de blessures graves,

6teindre I'outil et retirer le bloc-piles avant d'effectuer tout

r6glage et d'enlever ou d'installer tout accessoire. Un demarrage

accidente/ peut provoquer des b/essures.

i_,ATTENTION : pour eviter toute activation accidentelle /ors du

transport ou du stockage, pousser I'interrupteur de verrouillage

(fig. 2, B) vers le haut, sur sa position de verrouillage.

AVIS : ne pas se servir du toumevis comme levie_

C6mo instalar y retirar la unidad de

bateria (Fig. 4) FIG.4

NOTA: Para mejores resultados, verifique que su

unidad de bater[a este completamente cargada.

Pour installer le bloc-piles (F) dans la poignee de

I'outil, inserez le bloc-piles dans la cavite de la

poignee de I'outil et faites-le glisser fermement en F

place puis verifiez qu'il ne s'en detachera pas.

Pour retirer le bloc-piles de I'outil, poussez sur

le bouton de liberation (E) et tirez fermement le

bloc-piles hors de la poignee de I'outil. Inserez-le

dans son chargeur comme decrit dans la section

appropriee de ce guide d'utilisation.

!

26

Page 28