Page 1

DCF6201

Page 2

English (original instructions) 3

B

Copyright DEWALT

Page 3

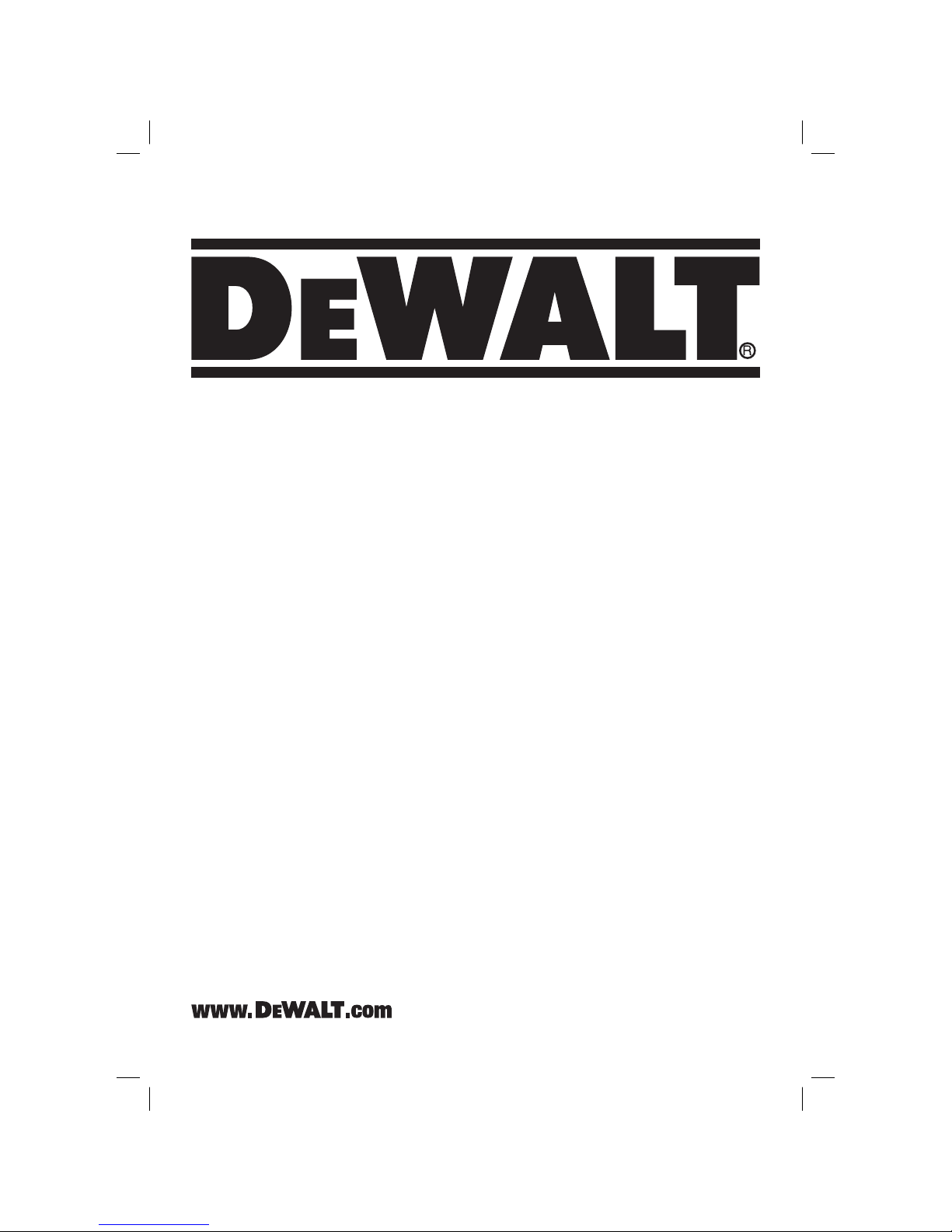

Figure 1

b

e

f

g

c

a

d

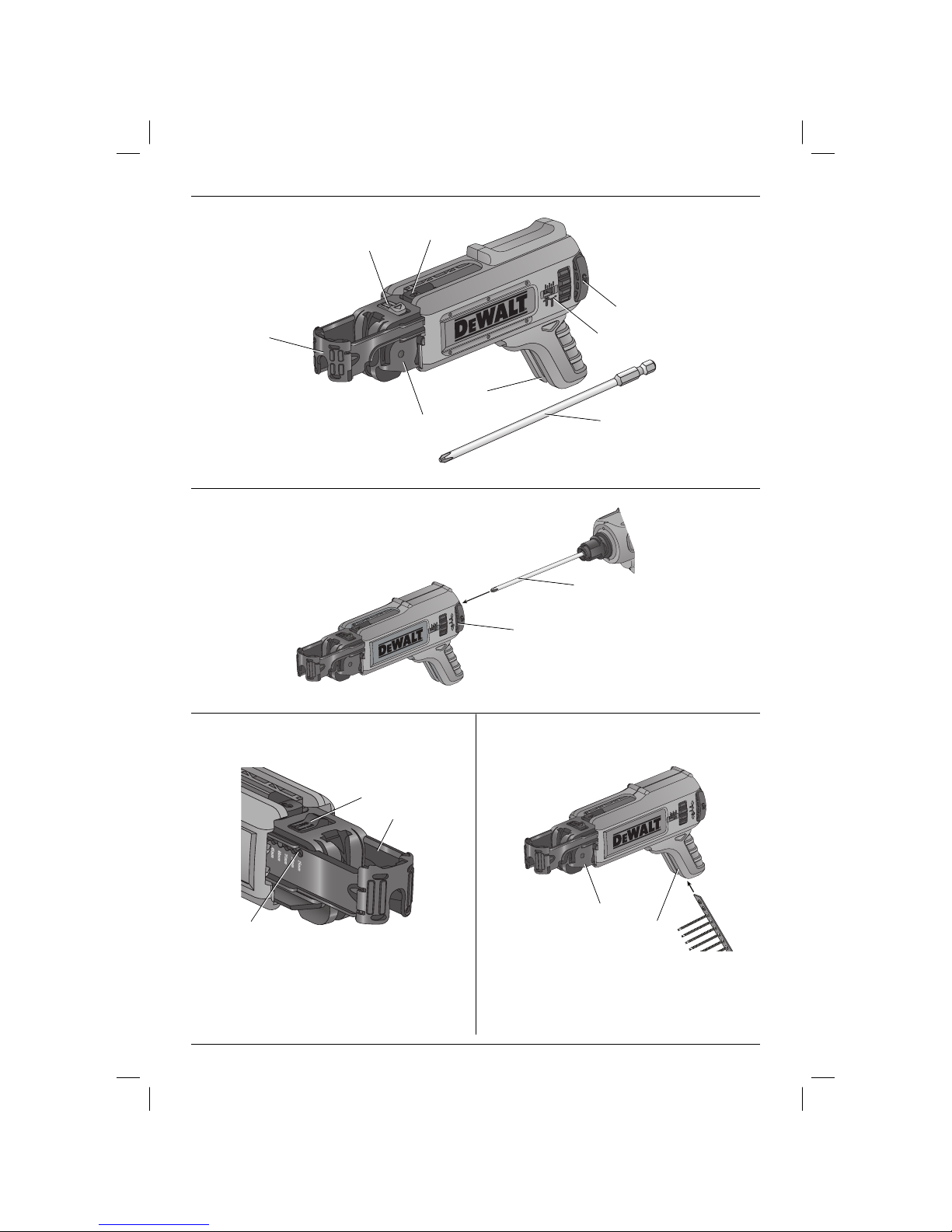

Figure 2

g

Figure 3 Figure 4

b

e

h

h

l

d

a

1

Page 4

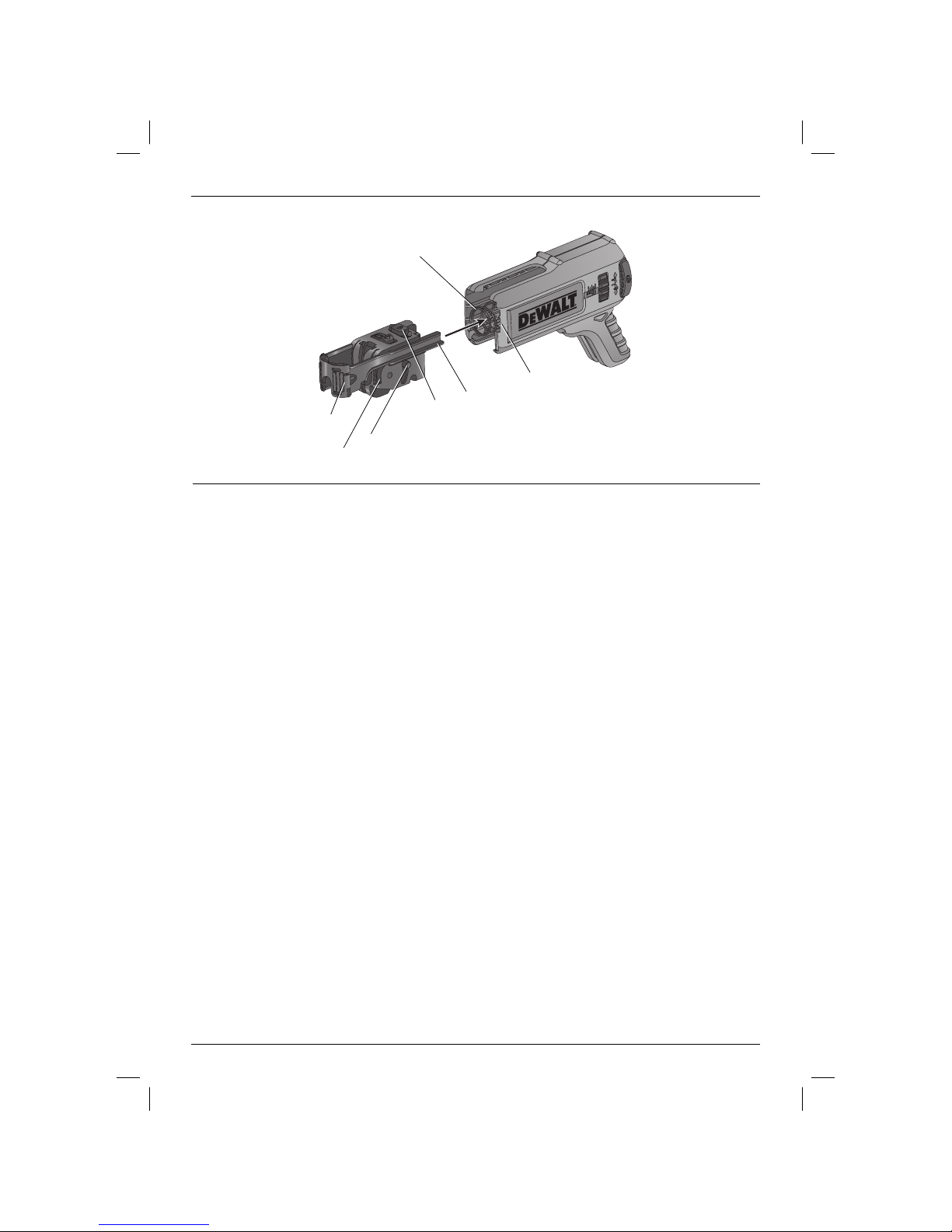

Figure 5

k

j

i

f

e

l

d

2

Page 5

COLLATED MAGAZINE ATTACHMENT

DCF6201

ENGLISH

Congratulations

You have chosen a DEWALT tool. Years of

experience, thorough product development and

innovation make DEWALT one of the most reliable

partners for professional power tool users.

Technical Data

DCF6201

Screw length suitability mm 25 - 57

Weight kg 0.36

Defi nitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and

pay attention to these symbols.

DANGER: Indicates an imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING: Indicates a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

NOTICE: Indicates a practice not

related to personal injury which, if

not avoided, may result in property

damage.

Denotes risk of electric shock.

Denotes risk of fire.

WARNING: To reduce the risk of injury,

read the instruction manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings

and all instructions. Failure to follow

the warnings and instructions may result

in electric shock, fire and/or serious

injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

WARNING! Read all safety warnings

and all instructions provided with your

screwdriver (DFC620 or DCF621).

Failure to follow the warnings and

instructions may result in electric shock,

fire and/ or serious injury.

Additional Specifi c Safety Rules for

Collated Magazine Attachment

• The collated magazine is to only be used with

the DEWALT DCF620 or DCF621 screwdriver.

• Observe all operating instructions and safety

regulations contained in the manual for the

screwdriver the magazine accessory is used

with.

• Before use, ensure that the magazine accessory

is properly attached to the tool.

• Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

• Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

• When driving screws, never reach into the

magazine accessory. Keep hands clear of the

advancing mechanism and the spot where the

screw is being driven.

• Do not use the magazine accessory as a

gripping surface.

• Hold power tool by insulated gripping surfaces,

when performing an operation where the

fastener may contact hidden wiring. Fasteners

contacting a “live” wire may make exposed

metal parts of the power tool “live” and could

give the operator an electric shock.

• Use only screw strips that are suitable to this

magazine. Only insert screw strips when the

screwdriver power is off and the trigger is

locked.

3

Page 6

ENGLISH

Residual Risks

In spite of the application of the relevant safety

regulations and the implementation of safety

devices, certain residual risks cannot be avoided.

These are:

– Impairment of hearing.

– Risk of personal injury due to flying particles.

– Risk of burns due to accessories becoming hot

during operation.

– Risk of personal injury due to prolonged use.

Markings on Tool

The following pictograms are shown on the tool:

Read instruction manual before use.

Wear ear protection.

Wear eye protection.

DATE CODE POSITION

The date code, which also includes the year of

manufacture, is printed into the housing.

Example:

2015 XX XX

Year of Manufacture

Package Contents

The package contains:

1 Collated magazine attachment

1 PR2 collated screwdriver bit (DT7205-QZ)

1 Instruction manual

• Check for damage to the attachment, parts or

accessories which may have occurred

during transport.

• Take the time to thoroughly read and

understand this manual prior to operation.

Description (fi g. 1)

WARNING: Never modify the

attachment or any part of it. Damage or

personal injury could result.

a. Screw guide

b. Screw length adjustment

c. Fine depth adjustment

d. Advancing mechanism

e. Shoe

f. Advancing mechanism removal button

g. Release buttons

h. Collated screwdriver bit

INTENDED USE

This collated drywall magazine is a professional

attachment designed to be used with the DCF620

or DCF621 DEWALT screwdriver for professional

driving of collated screws.

DO NOT use under wet conditions or in the

presence of flammable liquids or gases.

DO NOT let children come into contact with the

tool. Supervision is required when inexperienced

operators use this tool.

• Young children and the infirm. This appliance

is not intended for use by young children or

infirm persons without supervision.

• This product is not intended for use by persons

(including children) suffering from diminished

physical, sensory or mental abilities; lack of

experience, knowledge or skills unless they are

supervised by a person responsible for their

safety. Children should never be left alone with

this product.

ASSEMBLY AND ADJUSTMENTS

WARNING: Prior to assembly and

adjustment, always remove the battery

pack. Always switch off the tool before

inserting or removing the battery pack.

WARNING: Use only DEWALT battery

packs and chargers.

Fitting the Collated Screwdriver Bit

(fi g. 1 & 2)

NOTICE: For proper operation only use

a DEWALT collated screwdriver bit.

1. Remove the nose cone from the screwdriver.

2. Remove the mounted bit and bit holder from

the screw driver.

NOTE: Refer to and follow all instructions on

changing bits and holders in your screw driver

manual.

3. Insert the provided collated screwdriving bit (h)

into the bit holder until it clicks into place.

4

Page 7

ENGLISH

Installing and Removing the

Magazine from the Screwdriver

(fi g.2)

With the the nose cone removed and provided driver

bit (h) installed, push the magazine over the bit onto

the screw driver until the magazine clicks into place

and ensure that it does not disengage.

NOTE: If necessary - rotate the attachment to locate

properly on mount.

NOTE: Make sure the screw driver control lever is

set to forward rotation before use.

To remove the magazine, press and hold the release

buttons (g) on both sides of the accessory and pull

accessory off the screwdriver.

OPERATION

Instructions for Use

WARNING: Always observe the safety

instructions and applicable regulations.

WARNING: To reduce the risk of

serious personal injury, turn tool

off and disconnect battery pack

before making any adjustments or

removing/installing attachments or

accessories. An accidental start-up

can cause injury.

Setting Magazine Screw Length

(fi g.3)

This magazine is designed for 25– 57mm (1"– 2¼")

screw lengths. Failure to set the correct screw

length can cause screws to not be driven accurately

which can result in the failure to advance to the next

screw or screws not being driven properly. The shoe

has marked specific slots (l) for each of the most

common screws, however this attachment can still

drive any size screw between 25– 57mm (1"– 2¼").

To accommodate for less common screws adjust to

the next longest slot.

CAUTION: Do not adjust while a screw

strip is in the magazine.

1. Slide screw length adjustment tab(b) to the left.

2. Holding the screw length adjustment tab in

place, adjust the shoe(e) to the desired length.

3. Release the screw length adjustment tab. Make

sure that the locking pin has fully returned and

is in the correct position.

Inserting Collated Screw Strips

(fi g.4)

NOTICE: Use only screw strips that are

suitable to this magazine. Only insert

screw strips when the screwdriver

power is off and the trigger is locked.

Proper use of collated strips will reduce the risk

of injury, reduce jams and prevents screws from

damaging work piece. For best performance use

new, undamaged strips free of debris.

1. Take a collated strip, holding the plastic portion,

and feed from the bottom of the screw guide

(a) and into the bottom of the advancing

mechanism(d).

2. Continue feeding the strip until the first screw is

one slot below the driver bit.

Setting Screw Depth (fi g. 1)

Turn fine depth adjustment (c) anti-clockwise (as

viewed from behind the tool) to make the screw

head stop raised from the work piece.

Turn fine depth adjustment (c) clockwise to make the

screw head stop deeper into the work piece.

There is a window to show where in the adjustment

range the tool is. When the slider is furthest from

the tool the screw head will stop in the most raised

position. When the slider is closest to the screw

driver tool the screw head will stop in its deepest

position.

Driving Screws (fi g. 1)

1. Before driving screws, ensure screwdriver drive

direction is switched to forward position.

NOTE: Always hold the screwdriver

perpendicular to work piece.

2. With the magazine installed on the screwdriver,

position shoe (e) on work piece in location

where screw is to be driven.

3. Switch the screwdriver on by holding the trigger

in the on position. Continue to hold trigger or

engage the trigger lock-on.

4. Apply pressure against work piece. This will

advance screw into alignment with screwdriver

bit.

5. Continue to apply consistent pressure until

screw is driven in completely and screwdriver

clutches disengage.

6. Lift screwdriver from workpiece.

5

Page 8

ENGLISH

The magazine is designed to drive screws

completely into work piece only. Once screwdriver

is lifted, adjustments to screw must be made by first

removing magazine.

Rotating the Collated Attachment

This attachment has the ability to rotate without

being taken off the drywall screwdriver. To rotate,

grip the top portion with one hand, while holding

the drywall screwdriver with the other then rotate. An

audible "click" indicates the magazine is in each of

the available positions.

MAINTENANCE

Your DEWALT power tool has been designed to

operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation

depends upon proper tool care and regular cleaning.

WARNING: To reduce the risk of

serious personal injury, turn tool

off and disconnect battery pack

before making any adjustments or

removing/installing attachments or

accessories. An accidental start-up

can cause injury.

Lubrication

Your power tool requires no additional lubrication.

Cleaning

WARNING: Blow dirt and dust out of

the main housing with dry air as often

as dirt is seen collecting in and around

the air vents and housing tracks. Wear

approved eye protection and approved

dust mask when performing this

procedure.

WARNING: Never use solvents or

other harsh chemicals for cleaning the

non-metallic parts of the tool. These

chemicals may weaken the materials

used in these parts. Use a cloth

dampened only with water and mild

soap.

For best performance clean magazine by:

1. Remove advancing mechanism from collated

magazine (see Removing and Installing the

Advancing Mechanism instructions).

2. Remove shoe from advancing mechanism.

3. Remove return spring from magazine.

4. Submerge parts in soapy water for 10 minutes.

5. Remove and thoroughly rinse parts.

6. Allow parts to air dry.

7. Reassemble and continue use.

REMOVING AND INSTALLING THE ADVANCING

MECHANISM (FIG. 5)

To remove advancing mechanism:

1. Remove collated magazine attachment from

2. Slightly depress advancing mechanism (d) by

3. Keeping pressure on the shoe (e) with the other

4. Slowly release pressure from the shoe (e) until

To install advancing mechanism:

1. With the collated magazine attachment

2. Push in slightly, then align the spring (k) with the

3. Push advancing mechanism in until you hear

NOTE: The lever arm (l) should be in the up

4. Cycle the advancing mechanism several times

CAUTION: The advancing mechanism

is spring loaded. Two hands must

be used to remove the advancing

mechanism. The spring may eject from

the mechanism.

screwdriver.

pushing on the shoe (e) with one hand.

hand depress advancing mechanism removal

button (f).

the advancing mechanism is out of the collated

magazine.

removed from screwdriver, align the tabs (i)

on the shoe with the slots (j) in the collated

housing.

pocket in the advancing mechanism.

the “click” of the shoe removal button (f).

position (as shown in figure 5) before the

advancing mechanism is installed. If in the down

position, the advancing mechanism will be

locked in place.

by hand to ensure proper function before

installing it onto your screwdriver for use.

6

Page 9

Optional Accessories

WARNING: Since accessories, other

Consult your dealer for further information on the

appropriate accessories.

PR2 Extended Bit x 1 - DT7205-QZ

PR2 Extended Bit x 5 - DT7206-QZ

PR2 Extended Bit x 20 - DT7207-QZ

than those offered by DEWALT, have

not been tested with this product, use

of such accessories with this tool could

be hazardous. To reduce the risk of

injury, only D

accessories should be used with this

product.

EWALT recommended

Protecting the Environment

Separate collection. This product must

not be disposed of with normal

household waste.

Should you find one day that your DEWALT product

needs replacement, or if it is of no further use to you,

do not dispose of it with household waste. Make this

product available for separate collection.

Separate collection of used products

and packaging allows materials to be

recycled and used again. Re-use of

recycled materials helps prevent

environmental pollution and reduces

the demand for raw materials.

Local regulations may provide for separate collection

of electrical products from the household, at

municipal waste sites or by the retailer when you

purchase a new product.

DEWALT provides a facility for the collection and

recycling of DEWALT products once they have

reached the end of their working life. To take

advantage of this service please return your product

to any authorised repair agent who will collect them

on our behalf.

You can check the location of your nearest

authorised repair agent by contacting your local

DEWALT office at the address indicated in this

manual. Alternatively, a list of authorised DEWALT

repair agents and full details of our after-sales

service and contacts are available on the Internet at:

www.2helpU.com.

ENGLISH

7

Page 10

8

Page 11

9

Page 12

Belgique et

Luxembourg België

en Luxemburg

Danmark D

Deutschland D

Ελλάς D

España D

France D

Schweiz

Suisse

Svizzera

Ireland D

Italia D

Nederlands D

Norge D

Österreich D

Portugal D

Suomi D

Sverige D

Türkiye

United

Kingdom

Australia D

Middle East Africa D

DEWALT - Belgium BVBA

Egide Walschaertsstraat 16

2800 Mechelen

EWALT

Roskildevej 22

2620 Albertslund

EWALT

Richard Klinger Str. 11

65510 Idstein

EWALT (Ελλάς) Α.Ε.

EΔΡΑ-ΓΡΑΦΕΙΑ : Στράβωνος 7

& Λ. Βουλιαγμένης, Γλυφάδα 166 74, Αθήνα

SERVICE : Ημερος Τόπος 2 (Χάνι Αδάμ) –

193 00 Ασπρόπυργος

EWALT Ibérica, S.C.A.

Parc de Negocios “Mas Blau”

Edificio Muntadas, c/Bergadá, 1, Of. A6

08820 El Prat de Llobregat (Barcelona)

EWALT

5, allée des Hêtres

BP 30084, 69579 Limonest Cedex

D

EWALT

In der Luberzen 42

8902 Urdorf

EWALT

Calpe House Rock Hill

Black Rock, Co. Dublin

EWALT

via Energypark

20871 Vimercate (MB), IT

EWALT Netherlands BV

Holtum Noordweg 35

6121 RE BORN, Postbus 83, 6120 AB BORN

EWALT

Postboks 4613, Nydalen

0405 Oslo

EWALT

Werkzeug Vertriebsges m.b.H

Oberlaaerstrasse 248, A-1230 Wien

EWALT Limited, SARL

Centro de Escritórios de Sintra Avenida

Almirante Gago Coutinho, 132/134, Edifício 14

2710-418 Sintra

EWALT

PL 47

00521 Helsinki

EWALT

Box 94

431 22 Mölndal

KALE Hırdavat ve Makina A.Ş.

Defterdar Mah. Savaklar Cad. No:15

Edirnekapı / Eyüp / İSTANBUL 34050

TÜRKİYE

D

EWALT, 210 Bath Road;

Slough, Berks SL1 3YD

EWALT

82 Taryn Drive, Epping

VIC 3076 Australia

EWALT

P.O. Box - 17164,

Jebel Ali Free Zone (South), Dubai, UAE

Tel: NL 32 15 47 37 63

Tel: FR 32 15 47 37 64

Fax: 32 15 47 37 99

Tel: 70 20 15 10

Fax: 70 22 49 10

Tel: 06126-21-1

Fax: 06126-21-2770

Τηλ : 00302108981616

Φαξ: 00302108983570

Tel: 934 797 400

Fax: 934 797 419

Tel: 04 72 20 39 20

Fax: 04 72 20 39 00

Tel: 044 - 755 60 70

Fax: 044 - 730 70 67

Tel: 00353-2781800

Fax: 00353-2781811

Tel: 800-014353

39 039 9590200

Fax: 39 039 9590313

Tel: 31 164 283 063

Fax: 31 164 283 200

Tel: 45 25 13 00

Fax: 45 25 08 00

Tel: 01 - 66116 - 0

Fax: 01 - 66116 - 614

Tel: 214 66 75 00

Fax: 214 66 75 80

Puh: 010 400 4333

Faksi: 0800 411 340

Tel: 031 68 61 60

Fax: 031 68 60 08

Tel: 0212 533 52 55

Faks: 0212 533 10 05

Tel: 01753-567055

Fax: 01753-572112

Tel: Aust 1800 338 002

Tel: NZ 0800 339 258

Tel: 971 4 812 7400

Fax: 971 4 2822765

www.dewalt.be

enduser.BE@SBDinc.com

www.dewalt.dk

kundeservice.dk@sbdinc.com

www.dewalt.de

infodwge@sbdinc.com

www.dewalt.gr

Greece.Service@sbdinc.com

www.dewalt.es

respuesta.postventa@sbdinc.com

www.dewalt.fr

scufr@sbdinc.com

www.dewalt.ch

service@rofoag.ch

www.dewalt.ie

www.dewalt.it

www.dewalt.nl

www.dewalt.no

kundeservice.no@sbdinc.com

www.dewalt.at

service.austria@sbdinc.com

www.dewalt.pt

resposta.posvenda@sbdinc.com

www.dewalt.fi

asiakaspalvelu.fi@sbdinc.com

www.dewalt.se

kundservice.se@sbdinc.com

www.dewalt.com.tr

www.dewalt.co.uk

emeaservice@sbdinc.com

www.dewalt.com.au

www.dewalt.co.nz

www.dewalt.ae

Service.MEA@sbdinc.com

N433179 03/15

Loading...

Loading...