Page 1

DCD730

DCD735

DCD780

DCD785

Page 2

English (original instructions) 3

15

25

35

DeWALT

Copyright

2

Page 3

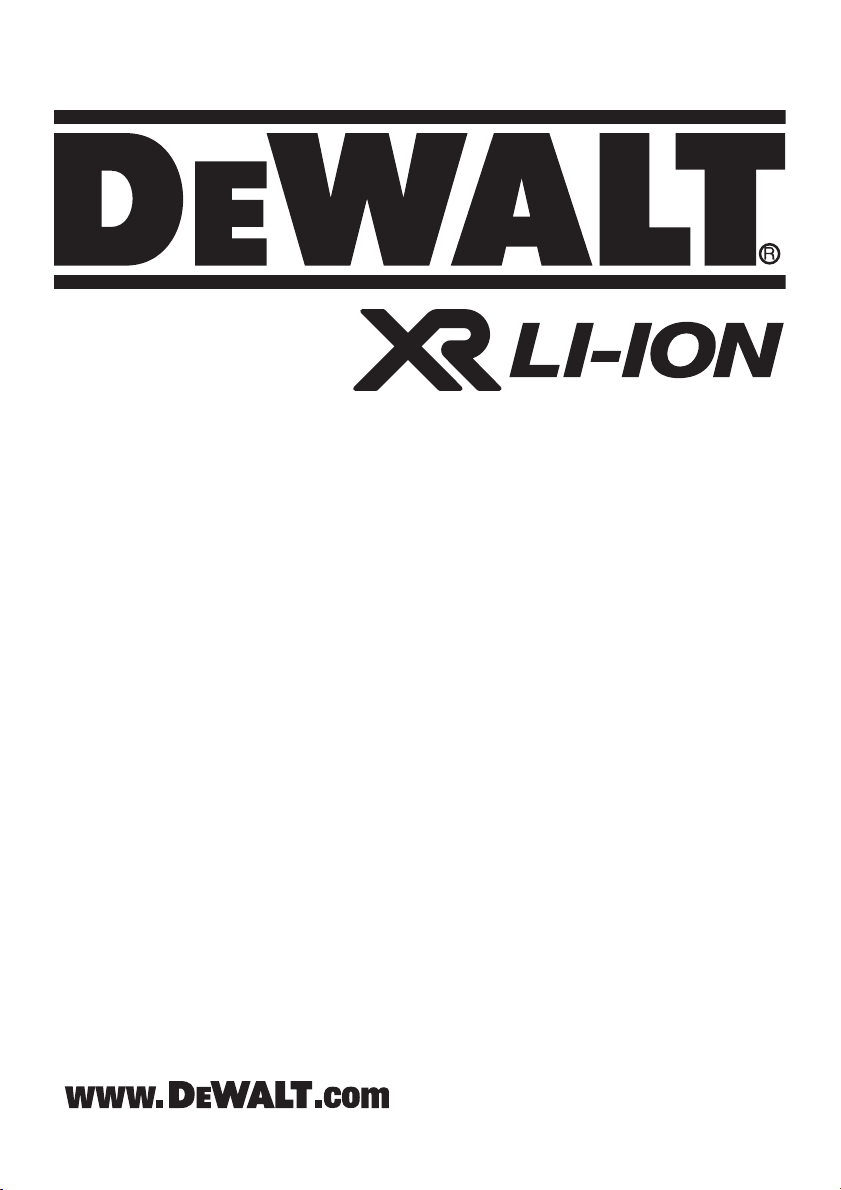

Figure 1

f

c

d

e

b

a

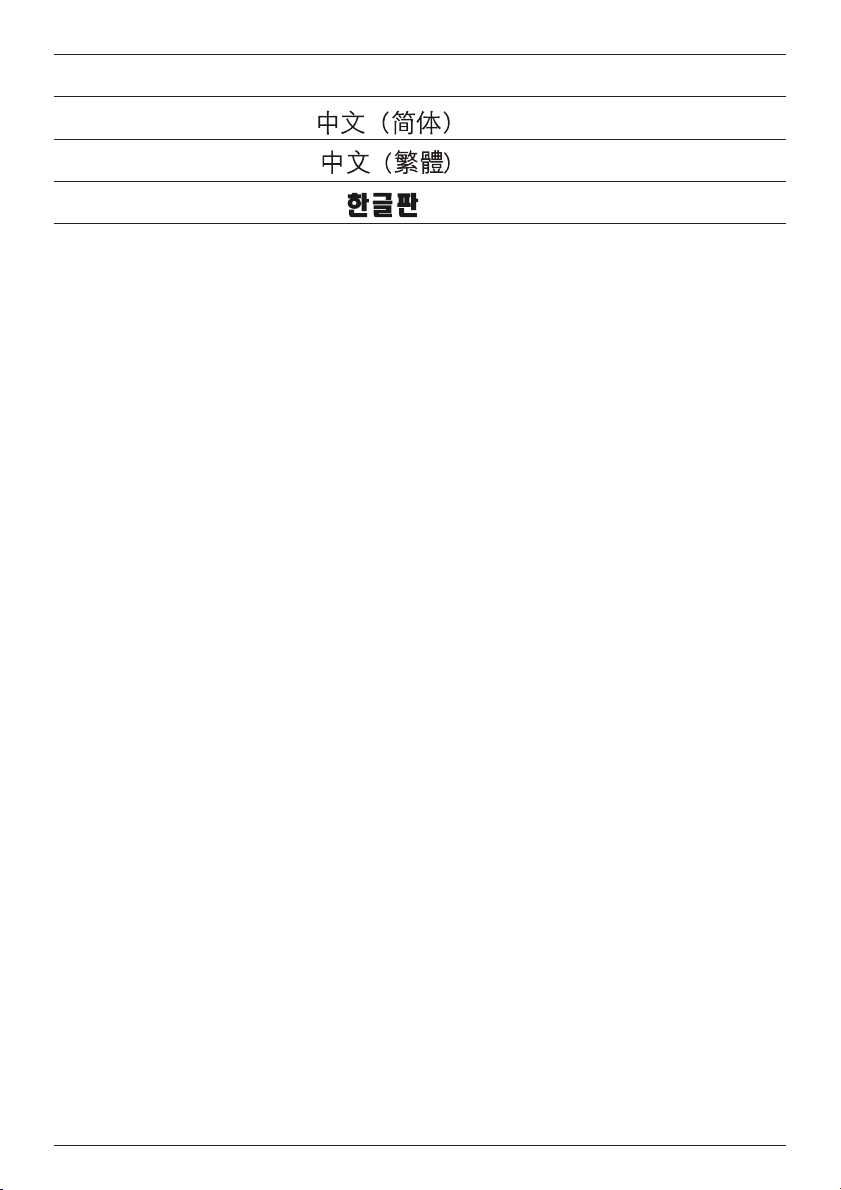

Figure 2

i

k

g

h

h

j

j

k

1

Page 4

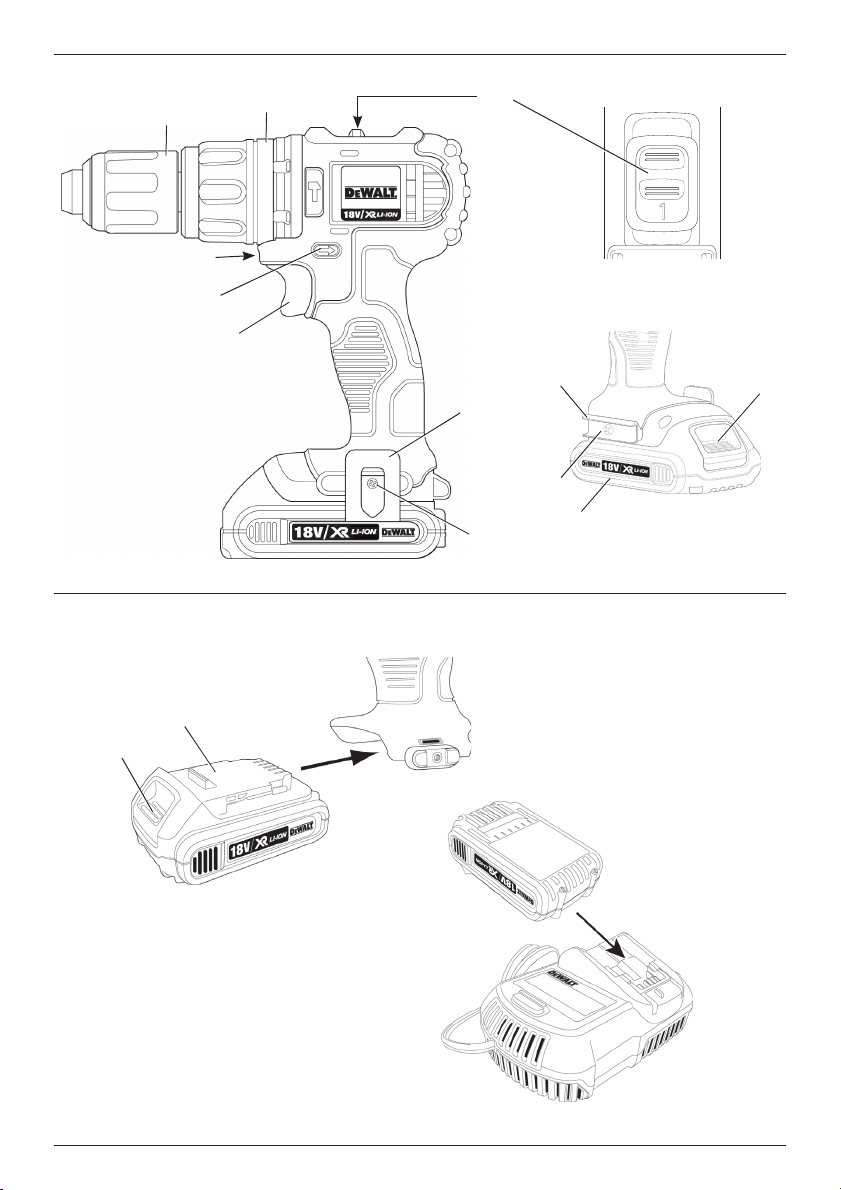

Figure 3

m

Figure 4 Figure 5 Figure 6

c

c

l

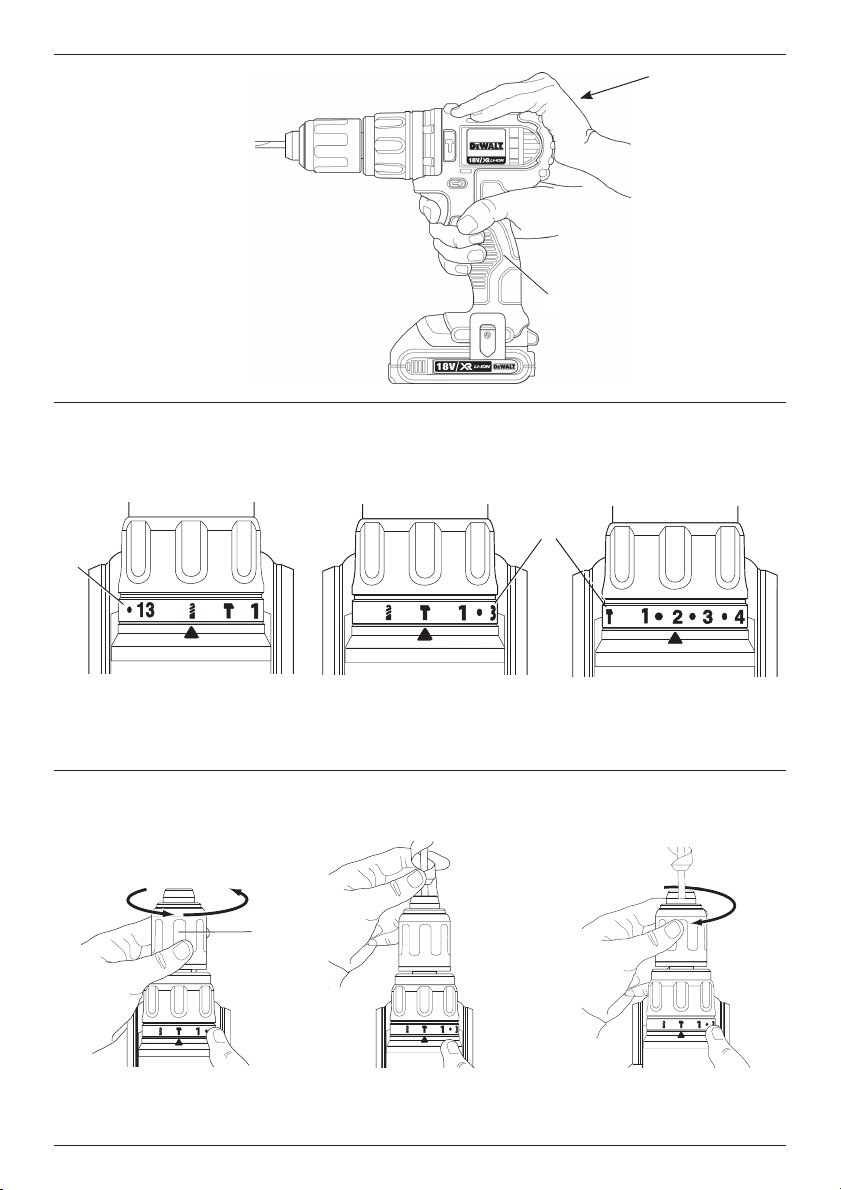

Figure 7

2

Figure 8 Figure 9

f

Page 5

English

CORDLESS COMPACT 13 mm (1/2") DRILL/DRIVER

DCD730, DCD780

CORDLESS COMPACT 13 mm (1/2") DRILL/DRIVER/

HAMMERDRILL

DCD735, DCD785

Congratulations!

You have chosen a DeWALT tool. Years of experience, thorough product development and innovation make

DeWALT one of the most reliable partners for professional power tool users.

Technical Data

DCD730 DCD735 DCD780 DCD785

Voltage V

Type 1 1 1 1

Battery Type Li-Ion Li-Ion Li-Ion Li-Ion

Power output W 300 300 350 350

No-load speed

1st gear min

2nd gear min

Impact rate

1st gear min

2nd gear min

Max. torque Nm 57 57 60 60

Chuck capacity mm 13 13 13 13

Maximum drilling capacity

Wood mm 35 35 38 38

Metal mm 13 13 13 13

Masonry mm – 13 – 13

Weight (without battery pack) kg 1.2 1.24 1.2 1.24

An estimation of the level of exposure to vibration should also take into account the times when the tool is

switched off or when it is running but not actually doing the job. This may significantly reduce the exposure

level over the total working period.

Identify additional safety measures to protect the operator from the effects of vibration such as: maintain the

tool and the accessories, keep the hands warm, organisation of work patterns.

14.4 14.4 18 18

DC

-1

0–550 0–550 0–600 0–600

-1

0–1900 0–1900 0–2000 0–2000

-1

– 0–9350 – 0–10200

-1

– 0–32300 – 0–34000

3

Page 6

English

Battery pack DCB140 DCB141 DCB180 DCB181

Battery type Li-Ion Li-Ion Li-Ion Li-Ion

Voltage V

Capacity A

14.4 14.4 18 18

DC

3.0 1.5 3.0 1.5

h

Weight kg 0.53 0.30 0.64 0.35

Charger DCB105

Mains voltage V

220~240 V

AC

Battery type Li-Ion

Approx. charging time min 30 60

(1.5 Ah battery packs) (3.0 Ah battery packs)

Weight kg 0.49

Definitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and

pay attention to these symbols.

WARNING: Indicates a potentially

CAUTION: Indicates a potentially

NOTICE: Indicates a practice not

DANGER: Indicates an imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

hazardous situation which, if not

avoided, could result in death or

serious injury.

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

related to personal injury which, if

not avoided, may result in property

damage.

Denotes risk of electric shock.

Save all warningS and inStructionS

for future reference

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or batteryoperated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of

Denotes risk of fire.

electric shock.

b) Avoid body contact with earthed or

grounded surfaces such as pipes,

WARNING: To reduce the risk of injury,

read the instruction manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings

and all instructions. Failure to follow

the warnings and instructions may result

in electric shock, fire and/or serious

injury.

radiators, ranges and refrigerators. There

is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the

risk of electric shock.

4

Page 7

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric

shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure

the switch is in the off position before

connecting to power source and/or

battery pack, picking up or carrying the

tool. Carrying power tools with your finger

on the switch or energising power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating

part of the power tool may result in personal

injury.

e) Do not overreach. Keep proper

footing and balance at all times. This

enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce

dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

English

b) Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the switch

is dangerous and must be repaired.

c) Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories, or

storing power tools. Such preventive safety

measures reduce the risk of starting the

power tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tool’s operation.

If damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and

tool bits etc., in accordance with these

instructions taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

5) BATTERY TOOL USE AND CARE

a) Recharge only with the charger specified

by the manufacturer. A charger that is

suitable for one type of battery pack may

create a risk of fire when used with another

battery pack.

b) Use power tools only with specifically

designated battery packs. Use of any

other battery packs may create a risk of

injury and fire.

c) When battery pack is not in use, keep it

away from other metal objects like paper

clips, coins, keys, nails, screws or other

small metal objects that can make a

connection from one terminal to another.

Shorting the battery terminals together may

cause burns or a fire.

d) Under abusive conditions, liquid may be

ejected from the battery, avoid contact.

If contact accidentally occurs, flush with

5

Page 8

English

water. If liquid contacts eyes, additionally

seek medical help. Liquid ejected from the

battery may cause irritation or burns.

6) SERVICE

a) Have your power tool serviced by a

qualified repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

Additional Specific Safety Rules for

Drill/Driver/Hammerdrill

• Wearearprotectorswhen impact drilling.

Exposure to noise can cause hearing loss.

• Useauxiliaryhandle(s),ifsuppliedwiththe

tool. Loss of control can cause personal injury.

• Holdpowertoolbyinsulatedgripping

surfaces, when performing an operation

where the cutting accessory may contact

hidden wiring. Cutting accessory contacting a

“live” wire may make exposed metal parts of the

power tool “live” and could give the operator an

electric shock.

• Useclampsorotherpracticalwaytosecure

and support the workpiece to a stable

platform. Holding the work by hand or against

your body is unstable and may lead to loss of

control.

• Wearsafetygogglesorothereyeprotection.

Hammering and drilling operations cause chips

to fly. Flying particles can cause permanent eye

damage.

• Accessoriesandtoolmaygethotduring

operation. Wear gloves when handling them if

performing heat producing applications such as

hammerdrilling and drilling metals.

• Donotoperatethistoolforlongperiodsof

time. Vibration caused by hammer action may

be harmful to your hands and arms. Use gloves

to provide extra cushion and limit exposure by

taking frequent rest periods.

• Airventsoftencovermovingpartsand

should be avoided. Loose clothes, jewelry or

long hair can be caught in moving parts.

Residual Risks

The following risks are inherent to the use of drills:

– Injuries caused by touching the rotating parts or

hot parts of the tool.

In spite of the application of the relevant safety

regulations and the implementation of safety

devices, certain residual risks cannot be avoided.

These are:

– Impairment of hearing.

– Risk of squeezing fingers when changing

accessories.

– Health hazards caused by breathing dust

developed when working in wood.

– Risk of personal injury due to flying particles.

– Risk of personal injury due to prolonged use.

Markings on Tool

The following pictograms are shown on the tool:

Read instruction manual before use.

DATE CODE POSITION

The Date Code, which also includes the year of

manufacture, is printed into the housing surface that

forms the mounting joint between tool and battery.

Example:

2011 XX XX

Year of Manufacture

Important Safety Instructions for All

Battery Chargers

SAVE THESE INSTRUCTIONS: This manual

contains important safety and operating instruc tions

for the DCB105 battery charger.

• Beforeusingthecharger,readallinstructions

and cautionary markings on charger, battery

pack and product using the battery pack.

WARNING: Shock hazard. Do not allow

CAUTION: Children should be

NOTICE: Under certain conditions, with

any liquid to get inside charger. Electric

shock may result.

CAUTION: Burn hazard. To reduce

the risk of injury, charge only

rechargeable battery packs. Other types

of batteries may overheat and burst

resulting in personal injury and property

damage.

supervised to ensure that they do not

play with the appliance.

the charger plugged in to the power

supply, the exposed charging contacts

inside the charger can be shorted by

foreign material. Foreign materials of

DeWALT

6

Page 9

a conductive nature such as, but not

x

limited to, steel wool, aluminum foil or

any buildup of metallic particles should

be kept away from charger cavities.

Always unplug the charger from the

power supply when there is no battery

pack in the cavity. Unplug charger

before attempting to clean.

• DONOTattempttochargethebatterypack

with any chargers other than the ones in

this manual. The charger and battery pack are

specifically designed to work together.

• Thesechargersarenotintendedfor

any uses other than charging

rechargeable batteries. Any other uses

may result in risk of fire, electric shock or

electrocution.

• Donotexposechargertorainorsnow.

• Pullbyplugratherthancordwhen

disconnecting charger. This will reduce risk

of damage to electric plug and cord.

• Makesurethatcordislocatedsothatitwill

not be stepped on, tripped over or otherwise

subjected to damage or stress.

• Donotuseanextensioncordunlessit

is absolutely necessary. Use of improper

extension cord could result in risk of fire,

electric shock or electrocution.

• Whenoperatingachargeroutdoors,always

provide a dry location and use an extension

cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of

electric shock.

• Donotblocktheventilationslotsonthe

charger.Theventilationslotsarelocated

on the top and sides of the charger. Place

the charger in a position away from any heat

source.

• Donotoperatechargerwithdamagedcord

or plug — have them replaced immediately.

• Do not operate charger if it has received

a sharp blow, been dropped or otherwise

damaged in any way. Take it to an authorised

service centre.

• Donotdisassemblethecharger;takeitto

an authorised service centre when service or

repair is required. Incorrect reassembly may

result in a risk of electric shock, electrocution or

fire.

• Incaseofdamagedpowersupplycordthe

supply cord must be replaced immediately by

the manufacturer, its service agent or similar

DeWALT

English

qualified person to prevent any hazard.

• Disconnectthechargerfromtheoutlet

beforeattemptinganycleaning.Thiswill

reduce the risk of electric shock. Removing

the battery pack will not reduce this risk.

• NEVERattempt to connect 2 chargers together.

• Thechargerisdesignedtooperateon

standard220~240Vhouseholdelectrical

power. Do not attempt to use it on any other

voltage. This does not apply to the vehicular

charger.

Save tHeSe inStructionS

Chargers

The DCB105 charger accepts 10.8 V, 14.4 V and

18 V Li-Ion (DCB121, DCB140, DCB141, DCB180

and DCB181) battery packs.

This charger requires no adjustment and is designed

to be as easy as possible to operate.

Charging Procedure (figure 2)

1. Plug the charger into an appropriate 220~240 V

outlet before inserting the battery pack.

2. Insert the battery pack (j) into the charger,

making sure the pack is fully seated in the

charger. The red (charging) light will blink

continuously indicating that the charging

process has started.

3. The completion of charge will be indicated by

the red light remaining ON continuously. The

pack is fully charged and may be used at this

time or left in the charger.

NOTE: To ensure maximum performance and life of

Li-Ion batteries, charge the battery pack fully before

first use.

Charging Process

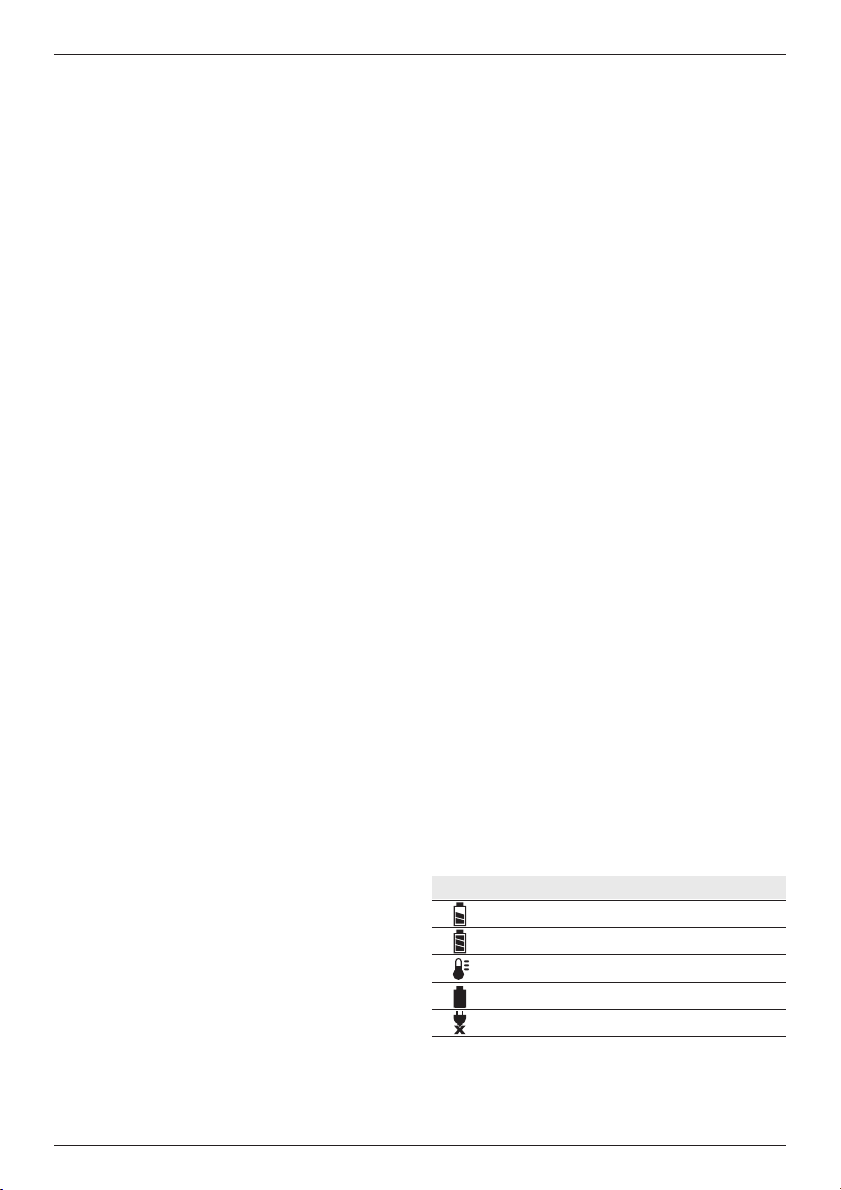

Refer to the table below for the state of charge of

the battery pack.

State of charge

charging –– –– –– ––

fully charged –––––––––––––––––

hot/coldpackdelay ––•––•––• ––•

problempackorcharger ••••••••••••

problempowerline ••••••••••••

7

Page 10

English

This charger will not charge a faulty battery pack.

The charger will indicate faulty battery by refusing to

light or by displaying problem pack or charger blink

pattern.

NOTE: This could also mean a problem with a

charger.

If the charger indicates a problem, take the charger

and battery pack to be tested at an authorised

service centre.

Hot/Cold Pack Delay

When the charger detects a battery that is too hot

or too cold, it automatically starts a hot/cold pack

delay, suspending charging until the battery has

reached an appropriate temperature. The charger

then automatically switches to the pack charging

mode. This feature ensures maximum battery life.

XR Li-Ion tools are designed with an Electronic

Protection System that will protect the battery

against overloading, overheating or deep discharge.

The tool will automatically turn off if the Electronic

Protection System engages. If this occurs, place the

Li-Ion battery on the charger until it is fully charged.

A cold battery pack will charge at about half the rate

of a warm battery pack. The battery pack will charge

at that slower rate throughout the entire charging

cycle and will not return to maximum charge rate

even if the battery warms.

Important Safety Instructions for All

Battery Packs

When ordering replacement battery packs, be sure

to include the catalog number and voltage.

The battery pack is not fully charged out of the

carton. Before using the battery pack and charger,

read the safety instructions below and then follow

the charging procedures outlined.

read all inStructionS

• Donotchargeorusethebatterypack

in explosive atmospheres, such as in the

presence of flammable liquids, gases or

dust. Inserting or removing the battery pack

from the charger may ignite the dust or fumes.

• Never force the battery pack into charger.

Do not modify the battery pack in any way

to fit into a non-compatible charger as

battery pack may rupture causing serious

personal injury.

• Chargethebatterypacksonlyindesignated

DeWALT chargers.

• DONOTsplash or immerse in water or other

liquids.

• Donotstoreorusethetoolandbattery

pack in locations where the temperature

may reach or exceed 40˚ C (105° F) (such as

outside sheds or metal buildings in summer).

• Forbestresults,makesurethebatterypackis

fully charged before use.

CAUTION: When not in use, place

SPECIFIC SAFETY INSTRUCTIONS FOR LITHIUM ION

(Li-Ion)

• Donotincineratethebatterypackevenifit

• Ifbatterycontentscomeintocontactwith

• Contentsofopenedbatterycellsmaycause

WARNING: Burn hazard. Battery liquid

WARNING: Never attempt to open

the battery pack for any reason. If

the battery pack case is cracked or

damaged, do not insert it into the

charger. Do not crush, drop or damage

battery pack. Do not use a battery

pack or charger that has received a

sharp blow, been dropped, run over

or damaged in any way (e.g., pierced

with a nail, hit with a hammer, stepped

on). Electric shock or electrocution may

result. Damaged battery packs should

be returned to the service centre for

recycling.

tool on its side on a stable surface

where it will not cause a tripping or

falling hazard. Some tools with large

battery packs will stand upright on the

battery pack but may be easily knocked

over.

is severely damaged or is completely worn

out. The battery pack can explode in a fire.

Toxic fumes and materials are created when

lithium ion battery packs are burned.

the skin, immediately wash the area with

mild soap and water. If the battery liquid gets

into the eye, rinse water over the open eye for

15 minutes or until irritation ceases. If medical

attention is needed, the battery electrolyte

is composed of a mixture of liquid organic

carbonates and lithium salts.

respiratory irritation. Provide fresh air. If

symptoms persists, seek medical attention.

may be flammable if exposed to spark

or flame.

8

Page 11

English

Battery Pack

BATTERY TYPE

The DCD730 and DCD735 operate on 14.4 volt

battery packs.

The DCD780 and DCD785 operate on 18 volt

battery pack.

The DCB140, DCB141, DCB180 or DCB181 battery

packs may be used. Refer to Technical Data for

more information.

Storage Recommendations

1. The best storage place is one that is cool and

dry away from direct sunlight and excess heat

or cold. For optimum battery performance and

life, store battery packs at room temperature

when not in use.

2. For long storage, it is recommended to store a

fully charged battery pack in a cool, dry place

out of the charger for optimal results.

NOTE: Battery packs should not be stored

completely depleted of charge. The battery pack will

need to be recharged before use.

Labels on Charger and Battery Pack

In addition to the pictographs used in this manual,

the labels on the charger and the battery pack show

the following pictographs:

Read instruction manual before use.

Charging.

Use only with DeWALT battery packs.

Others may burst, causing personal injury

and damage.

Do not expose to water.

Have defective cords replaced

immediately.

Charge only between 4° C and 40° C.

Discard the battery pack with due care for

the environment.

Do not incinerate the battery pack.

Charges Li-Ion battery packs.

See technical data for charging time.

Only for indoor use.

Package Contents

The package contains:

1 Drill/driver or 1 drill/driver/hammerdrill

1

Charger

2 Batteries

1 Kitbox

1 Instruction manual

Fully charged.

Hot/cold pack delay.

Problem pack or charger.

x

Problem powerline.

Do not probe with conductive objects.

Do not charge damaged battery packs.

NOTE: Battery packs, chargers and kitboxes are not

included with N-models.

• Checkfordamagetothetool,partsor

accessories which may have occurred during

transport.

• Takethetimetothoroughlyreadand

understand this manual prior to operation.

Description (figure 1)

WARNING: Never modify the power

tool or any part of it. Damage or

personal injury could result.

a. Trigger switch

9

Page 12

English

b. Forward/reverse control button

c. Torque adjustment collar

d. Gear shifter

e. Worklight

f. Keyless chuck

g. Belt hook

h. Mounting screw

i. Bit clip

j. Battery pack

k. Battery release button

INTENDED USE

These drills/drivers/hammerdrills are designed

for professional drilling, percussion drilling and

screwdriving applications.

DO NOT use under wet conditions or in presence of

flammable liquids or gases.

These drills/drivers/hammerdrills are professional

power tools.

DO NOT let children come into contact with the

tool. Supervision is required when inexperienced

operators use this tool.

• Thisproductisnotintendedforusebypersons

(including children) suffering from diminished

physical, sensory or mental abilities; lack of

experience, knowledge or skills unless they are

supervised by a person responsible for their

safety. Children should never be left alone with

this product.

Electrical Safety

The electric motor has been designed for one

voltage only. Always check that the battery pack

voltage corresponds to the voltage on the rating

plate. Also make sure that the voltage of your

charger corresponds to that of your mains.

Your DeWALT charger is double insulated

in accordance with EN 60335; therefore

no earth wire is required.

If the supply cord is damaged, it must be replaced

by a specially prepared cord available through the

DeWALT service organisation.

Using an Extension Cable

An extension cord should not be used unless

absolutely necessary. Use an approved extension

cable suitable for the power input of your charger

(see Technical Data). The minimum conductor size

is 1 mm2; the maximum length is 30 m.

When using a cable reel, always unwind the cable

completely.

ASSEMBLY AND ADJUSTMENTS

WARNING: Prior to assembly and

adjustment, always remove the battery

pack. Always switch off the tool before

inserting or removing the battery pack.

WARNING: Use only DeWALT battery

packs and chargers.

Inserting and Removing the

Battery Pack from the Tool (figure 2)

NOTE: For best results, make sure your battery

pack is fully charged.

TO INSTALL THE BATTERY PACK INTO THE TOOL HANDLE

1. Align the battery pack (j) with the rails inside the

tool’s handle (figure 2).

2. Slide it into the handle until the battery pack is

firmly seated in the tool and ensure that it does

not disengage.

TO REMOVE THE BATTERY PACK FROM THE TOOL

1. Press the battery release button (k) and firmly

pull the battery pack out of the tool handle.

2. Insert battery pack into the charger as

described in the charger section of this manual.

Variable Speed Trigger Switch

(figure 1)

To turn the tool on, squeeze the trigger switch (a).

To turn the tool off, release the trigger switch. Your

tool is equipped with a brake. The chuck will stop as

soon as the trigger switch is fully released.

NOTE: Continuous use in variable speed range is

not recommended. It may damage the switch and

should be avoided.

Forward/Reverse Control Button

(figure 1)

A forward/reverse control button (b) determines the

direction of the tool and also serves as a lock-off

button.

To select forward rotation, release the trigger switch

and depress the forward/reverse control button on

the right side of the tool.

To select reverse, depress the forward/reverse

control button on the left side of the tool.

10

Page 13

The center position of the control button locks

the tool in the off position. When changing the

position of the control button, be sure the trigger is

released.

NOTE: The first time the tool is run after changing

the direction of rotation, you may hear a click on

start up. This is normal and does not indicate a

problem.

Torque Adjustment Collar (figure 1)

Your tool has an adjustable torque screwdriver

mechanism for driving and removing a wide array of

fastener shapes and sizes and in some models, a

hammer mechanism for drilling into masonry. Circling

the collar (c) are numbers, a drill bit symbol, and in

some models, a hammer symbol. These numbers

are used to set the clutch to deliver a torque range.

The higher the number on the collar, the higher the

torque and the larger the fastener which can be

driven. To select any of the numbers, rotate until the

desired number aligns with the arrow.

Dual Range Gearing (figure 1)

The dual range feature of your drill/driver allows you

to shift gears for greater versatility.

1. To select speed 1 (high torque setting), turn

the tool off and permit it to stop. Slide the gear

shifter (d) forward (towards the chuck).

2. To select speed 2 (low torque setting), turn the

tool off and permit it to stop. Slide the gear

shifter back (away from the chuck).

NOTE: Do not change gears when the tool is

running. Always allow the drill to come to a complete

stop before changing gears. If you are having trouble

changing gears, make sure that the dual range

gear shifter is either completely pushed forward or

completely pushed back.

Worklight (figure 1)

There is a worklight (e) located just above the

trigger switch (a). The worklight is activated when

the trigger switch is depressed. When the trigger is

released the worklight will stay illuminated for up to

20 seconds.

NOTE: The worklight is for lighting the immediate

work surface and is not intended to be used as a

flashlight.

Keyless Single Sleeve Chuck

(figure 7–9)

English

WARNING: Do not attempt to tighten

WARNING: Always ensure the bit

Your tool features a keyless chuck (f) with one

rotating sleeve for one-handed operation of the

chuck. To insert a drill bit or other accessory, follow

these steps.

1. Turn tool off and disconnect tool from power

2. Grasp the black sleeve of the chuck with one

3. Insert the accessory about 19 mm (3/4") into

Be sure to tighten chuck with one hand on the

chuck sleeve and one hand holding the tool for

maximum tightness.

To release the accessory, repeat steps 1 and 2

above.

drill bits (or any other accessory) by

gripping the front part of the chuck

and turning the tool on. Damage to

the chuck and personal injury may

result. Always lock off trigger switch

and disconnect tool from power source

when changing acces sories.

is secure before starting the tool. A

loose bit may eject from tool causing

possible personal injury.

source.

hand and use the other hand to secure the

tool. Rotate the sleeve counterclockwise far

enough to accept the desired accessory.

the chuck and tighten securely by rotating

the chuck sleeve clockwise with one hand

while holding the tool with the other. Your tool

is equipped with an automatic spindle lock

mechanism. This allows you to open and close

the chuck with one hand.

Belt Hook and Bit Clip (figure 1)

WARNING: To reduce the risk of

WARNING: To reduce the risk of

IMPORTANT: When attaching or replacing the

belt hook or bit clip, use only the screw (h) that is

provided. Be sure to securely tighten the screw.

serious personal injury, turn tool

off and disconnect battery pack

before making any adjustments or

removing/installing attachments or

accessories.

serious personal injury, DO NOT

suspend tool overhead or suspend

objects from the belt hook. ONLY hang

tool’s belt hook from a work belt.

WARNING: To reduce the risk of

serious personal injury, ensure the

screw holding the belt hook is secure.

11

Page 14

English

The belt hook (g) and bit clip (i) can be be attached

to either side of the tool using only the screw (h)

provided, to accommodate left- or right- handed

users. If the hook or bit clip is not desired at all, it

can be removed from the tool.

To move belt hook or bit clip, remove the screw

(h) that holds it in place then reassemble on the

opposite side. Be sure to securely tighten the screw.

OPERATION

Instructions for Use

WARNING: Always observe the safety

instructions and applicable regulations.

WARNING: To reduce the risk

of serious personal injury, turn

tool off and disconnect tool from

power source before making any

adjustments or removing/installing

attachments or accessories.

Proper Hand Position (figure 3)

WARNING: To reduce the risk of

WARNING: To reduce the risk of

Proper hand position requires one hand on the top

of the drill (l) as shown, with the other hand on the

main handle (m).

serious personal injury, ALWAYS use

proper hand position as shown.

serious personal injury, ALWAYS hold

securely in anticipation of a sudden

reaction.

Drill Operation (figure 4)

WARNING: To reduce the risk of

WARNING: To reduce the risk of

1. Turn the collar (c) to the drill symbol.

2. Select the desired speed/torque range using the

3. For WOOD, use twist bits, spade bits, power

serious personal injury, turn tool off and

disconnect tool from power source

before making any adjustments or

removing/installing attachments or

accessories.

personal injury, ALWAYS ensure

workpiece is anchored or clamped

firmly. If drilling thin material, use a wood

“back-up” block to prevent damage to

the material.

gear shifter to match the speed and torque to

the planned operation.

auger bits or hole saws. For METAL, use high-

speed steel twist drill bits or hole saws. Use

a cutting lubricant when drilling metals. The

exceptions are cast iron and brass which should

be drilled dry.

4. Always apply pressure in a straight line with the

bit. Use enough pressure to keep drill biting, but

do not push hard enough to stall the motor or

deflect the bit.

5. Hold tool firmly with both hands to control

the twisting action of the drill. If model is not

equipped with side handle, grip drill with one

hand on the handle and one hand on the

battery pack.

6. IF DRILL STALLS, it is usually because

7. To minimize stalling or breaking through the

8. Keep the motor running when pulling the bit

9. With variable speed drills there is no need to

CAUTION: Drill may stall if overloaded

causing a sudden twist. Always expect

the stall. Grip the drill firmly to control

the twisting action and avoid injury.

it is being overloaded or improperly used.

RELEASE TRIGGER IMMEDIATELY, remove

drill bit from work, and determine cause of

stalling. DO NOT CLICK TRIGGER ON AND

OFF IN AN ATTEMPT TO START A STALLED

DRILL — THIS CAN DAMAGE THE DRILL.

material, reduce pressure on drill and ease the

bit through the last fractional part of the hole.

back out of a drilled hole. This will help prevent

jamming.

center punch the point to be drilled. Use a

slow speed to start the hole and accelerate by

squeezing the trigger harder when the hole is

deep enough to drill without the bit skipping

out.

Hammerdrill Operation (figure 5)

1. Turn the collar (c) to the hammerdrill symbol.

2. Select the high speed setting by sliding the

selector back (away from the chuck).

IMPORTANT: Use carbide-tipped or masonry

bits only.

3. Drill with just enough force on the hammer to

keep it from bouncing excessively or “rising” off

the bit. Too much force will cause slower drilling

speeds, overheating and lower drilling rate.

4. Drill straight, keeping the bit at a right angle to

the work. Do not exert side pressure on the bit

when drillling as this will cause clogging of the

bit flutes and a slower drilling speed.

12

Page 15

5. When drilling deep holes, if the hammer speed

starts to drop off, pull the bit partially out of the

hole with tool stil running to help clear debris

from the hole.

NOTE: A smooth, even flow of dust from the hole

indicates proper drilling rate.

Screwdriver Operation (figure 6)

1. Select the desired speed/torque range using the

dual range gear selector to match the speed

and torque of the planned operation.

2. Turn the torque adjustment collar (c) to the

desired position. Lower numbers indicate lower

torque settings; higher numbers indicate higher

torque settings.

3. Insert the desired fastener accessory into the

chuck as you would any drill bit.

4. Make some practice runs in scrap or on unseen

areas to determine the proper position of the

clutch collar.

5. Always start with lower torque settings, then

advance to higher torque settings to avoid

damage to the workpiece or fastener.

MAINTENANCE

Your DeWALT power tool has been designed to

operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation

depends upon proper tool care and regular cleaning.

WARNING: To reduce the risk of

serious personal injury, turn tool

off and disconnect battery pack

before making any adjustments or

removing/installing attachments or

accessories. An accidental start-up

can cause injury.

The charger and battery pack are not serviceable.

There are no serviceable parts inside.

Lubrication

Your power tool requires no additional lubrication.

Cleaning

WARNING: Blow dirt and dust out of

the main housing with dry air as often as

dirt is seen collecting in and around the

English

air vents. Wear approved eye protection

and approved dust mask when

performing this procedure.

CHARGER CLEANING INSTRUCTIONS

WARNING: Shock hazard. Disconnect

WARNING: Never use solvents or

other harsh chemicals for cleaning the

non-metallic parts of the tool. These

chemicals may weaken the materials

used in these parts. Use a cloth

dampened only with water and mild

soap. Never let any liquid get inside the

tool; never immerse any part of the tool

into a liquid.

the charger from the AC outlet before

cleaning. Dirt and grease may be

removed from the exterior of the charger

using a cloth or soft non-metallic brush.

Do not use water or any cleaning

solutions.

Optional Accessories

WARNING: Since accessories, other

Consult your dealer for further information on the

appropriate accessories.

than those offered by D

not been tested with this product, use

of such accessories with this tool could

be hazardous. To reduce the risk of

injury, only D

accessories should be used with this

product.

eWALT, recommended

eWALT, have

Protecting the Environment

Separate collection. This product must

not be disposed of with normal

household waste.

Should you find one day that your D

needs replacement, or if it is of no further use to you,

do not dispose of it with household waste. Make this

product available for separate collection.

Separate collection of used products and

packaging allows materials to be

recycled and used again. Re-use of

recycled materials helps prevent

environmental pollution and reduces

the demand for raw materials.

Local regulations may provide for separate collection

of electrical products from the household, at

municipal waste sites or by the retailer when you

purchase a new product.

eWALT product

13

Page 16

English

DeWALT provides a facility for the collection and

recycling of D

eWALT products once they have

reached the end of their working life. To take

advantage of this service please return your product

to any authorised repair agent who will collect them

on our behalf.

You can check the location of your nearest

authorised repair agent by contacting your local

eWALT office at the address indicated in this

D

manual. Alternatively, a list of authorised D

eWALT

repair agents and full details of our after-sales

service and contacts are available on the Internet at:

www.2helpU.com.

Rechargeable Battery Pack

This long life battery pack must be recharged when

it fails to produce sufficient power on jobs which

were easily done before. At the end of its technical

life, discard it with due care for our environment:

• Runthebatterypackdowncompletely,then

remove it from the tool.

• Li-Ioncellsarerecyclable.Takethemtoyour

dealer or a local recycling station. The collected

battery packs will be recycled or disposed of

properly.

14

Page 17

简体中文

13

毫米

(1/2")

紧凑型充电式电钻/起子

DCD730,DCD780

13

毫米

(1/2")

紧凑型充电式电钻/起子/冲击钻

DCD735, DCD785

恭喜!

E

恭喜您选择了

之一。

技术性数据

电压

型号

电池类型

输出功率

空载转速

1 档

2 档

撞击率

1 档

2 档

最大扭矩

钻头直径

最大钻孔直径

木材

金属

石料

重量(不含电池)

工具。多年的经验和深入的产品开发创新使

WALT

D

V

DC

W

-1

min

-1

min

-1

min

-1

min

Nm

mm

mm

mm

mm

kg

DCD730

14.4

1

锂离子

300

0–550

0–1900

–

–

57

13

35

13

–

1.2

DEWALT

DCD735

14.4

1

锂离子

300

0–550

0–1900

0–9350

0–32300

57

13

35

13

13

1.24

成为专业电动工具使用者最可靠的合作伙伴

DCD780

18

1

锂离子

350

0–600

0–2000

–

–

60

13

38

13

–

1.2

DCD785

18

1

锂离子

350

0–600

0–2000

0–10200

0–34000

60

13

38

13

13

1.24

对机器振动水平的估测应考虑到机器开关的次数以及空载运转时的情况。这可能会显著降低总工作期间的振动暴露水平。

应采取额外的安全措施以保护操作者免受振动影响,如:维护工具及配件,保持双手温暖,针对操作工件适当使用机器。

电池组

电池类型

电压

容量

重量

充电器

电源电压

电池类型

大概充电时间

重量

V

V

min

DC

A

h

kg

AC

kg

DCB140

锂离子

14.4

3.0

0.53

30 60

(1.5

DCB141

锂离子

14.4

1.5

0.30

安培电池组

) (3.0

DCB105

220V~240V

锂离子

0.49

DCB180

锂离子

18

3.0

0.64

安培电池组

DCB181

锂离子

18

1.5

0.35

)

15

Page 18

简体中文

定义:安全方针

下面的定义描述了每个信号词的严重程度。请仔细阅读

说明书,注意这些符号。

危险:

表示存在紧迫的危险情况,如果不

加以避免,则可能导致

警告:

表示存在潜在的危险情况,如果不

加以避免,则可能导致

注意:

表示存在潜在的危险情况,如果不

加以避免,则可能导致

小心:

不避免,可能导致

表示存在触电的危险。

表示存在火灾的危险。

警告:

说明书。

不涉及人身伤害

表示

为了减少受伤的危险,请阅读使用

死亡或严重伤害

死亡或严重伤害

轻微或中等伤害

财产损失

。

。

。

的做法,如果

。

一般电动工具安全规则

警告!请阅读所有安全规则和使用说明书。

如果不遵守这些规则和说明,可能会导致

触电、火灾和/或严重伤害的危险。

请保存全部安全规则和说明文件,以供将来参考。

警告中的术语“电动工具”是指由电源线通电的(有插

电)电动工具或由电池驱动时(无插电)电动工具。

工作场地

1 )

保持工作场地清洁和明亮,

)

a

容易引发事故。

禁止在易爆环境中操作电动工具,如有易燃液

)

b

体、气体或粉尘的环境。

会点燃粉尘或烟雾。

操纵电动工具时禁止儿童和旁观者靠近。

)

c

可能会导致您操作不当。

电器安全

2 )

电动工具插头必须与同规格的插座搭配。禁止

)

a

以任何方式改装插头。需要接地的电动工具不

能使用任何转接插头。

格的插座将减少触电的危险。

避免人体与接地表面接触, 如管道、散热器、炉

)

b

灶、冰箱。

增加。

请勿将电动工具暴露在雨中或潮湿环境中。

)

c

动工具进水将增加触电危险。

如果您的身体接地,触电危险性会

杂乱或阴暗的地方

电动工具产生的火花

干扰

原厂所附的插头与同规

电

切勿滥用电线。切勿使用电源线搬运、拉动或

)

d

拔下电动工具。保持电源线远离热源、油、锐

边或运动部件。

的危险。

在室外操作电动工具时,请使用适合户外使用

)

e

的外接电线。

的危险。

如果必须得在潮湿的地方操作电动工具,请使

)

f

用剩余电流装置(

用减少了触电的危险。

)

人身安全

3

保持警觉,操作电动工具时注意操作,保持清

)

a

醒。切勿在疲倦或治疗时或在药物或酒精的影

响下使用电动工具。

集中可能会导致严重的人身伤害。

使用个人防护装备。始终佩戴护目镜。

)

b

条件下使用防护装备将减少人身伤害,如防尘

口罩、防滑安全鞋、安全帽、听力保护设备。

防止意外启动。在连接电源或电池组之前以及

)

c

拿起或携带工具之前请确保开关处于关闭位

置。

携带电动工具时把手指放在开关上或充电

时开关处于打开位置会造成人身危险。

打开工具前拆下所有调整键或扳手。

)

d

动工具旋转零件上的扳手或调整键可能导致人

身伤害。

禁止手伸得太长,时刻注意脚下和身体平衡。

)

e

这样在意外情况下能更好地控制电动工具。

穿着得当。操作电动工具时切忌穿宽松的衣服

)

f

或佩戴首饰。让您的头发、衣服和手套远离运

动的零件。

入运动零件中。

如果有提供连接排屑集尘设备的装置,请确保

)

g

这些装置连接完好,使用正常。

粉尘有关的危害。

)

电动工具的使用和注意事项

4

禁止强制使用电动工具。根据用途,使用正确

)

a

的电动工具。

率下能更好更安全地完成工作。

禁止使用开关不能打开和关闭的电动工具。

)

b

何不能用开关控制的电动工具都很危险,必须

进行修理。

调整、更换附件或储存电动工具前,请将电动

)

c

工具和电源插头或电池组断开。

全措施能减少意外启动电动工具的风险。

受损或缠绕的电线会增加触电

适合户外使用的电线会减少触电

)保护的电源。

RCD

操作电动工具时注意力不

宽松的衣服、首饰或长发可能会卷

正确的电动工具在设计的额定功

的使

RCD

适当的

连接在电

集尘可减少与

这种预防性安

任

16

Page 19

将电动工具储存在儿童不能够着的地方,禁止

)

d

不熟悉电动工具或本说明书的人操作电动工

具。

让未经训练的用户操作电动工具是很危险

的。

保养电动工具。检查运动部件是否卡住,是否

)

e

对准,零件是否破损,以及是否有其他可能影

响电动工具操作的情况。如有损坏,请在使用

前对电动工具进行维修。

动工具维护不良而发生的。

保持刀具锋利和清洁,

)

f

工具,可使操作是不容易卡住,且更容易控

制。

请根据这些操作指示使用电动工具、配件和切

)

g

割工具等,并且考虑工作条件和要执行的工

作。

将电动工具用于不是预期的操作用途可能

会导致危险情况。

)

电池工具使用和注意事项

5

只使用由制造商指定的充电器充电。

)

a

于其他类型电池组的充电器充电可能会引发火

灾。

只使用带专门指定的电池组。

)

b

池组可能造成伤害,引发火灾。

不使用电池组时,要将电池组储存在远离回形

)

c

针、硬币、钥匙、钉子、螺丝或其他可能使电

池短路的小型金属物体。如果电池短路可能导

致灼伤或火灾。

在恶劣条件下,电池可能会喷射出液体,请避

)

d

免接触该液体。如果不小心接触到液体,请用

清水冲洗。如果液体接触眼睛,请另外寻求医

疗帮助。

从电池喷出的液体可能会引起刺激或

灼伤。

)

服务

6

请让合格的维修人员维修您的工具,维修人员

)

a

只能使用相同的更换零件。

安全性能。

许多事故就是由于电

妥善保养的锋利的切削

使用适用

使用任何其他电

以确保电动工具的

电钻/起子/冲击钻的附加安全规则

在使用冲击钻时请戴耳罩,

●

听力损失。

如果有提供辅助手柄,请使用辅助手柄。

●

可能导致人身伤害。

切割配件可能接触隐藏的电线时,请握住工具的绝

●

缘表面。

切割配件接触带电电线可能使电动工具外

露的金属部件带电,因而导致操作人员触电。

使用夹具或其他切实可行的办法将工件固定,维持

●

在稳定的平台上。

上是不稳定的,并可能失去控制。

暴露于噪声中可能造成

失去控制

手持工件或将工件靠在您的身体

简体中文

佩戴安全护目镜或其他保护眼睛的设备。

●

井作业会导致碎片乱飞。四射的小型物可能会造成

永久性的眼部损伤。

配件和工具可能会在操作过程中变热。

●

和金属钻孔等这些会产生热的作业时,请戴上手

套。

●

禁止长时间操作本工具。

动可能会伤害您的手和胳膊。使用手套会提供额外

的缓冲,频繁的休息也能限制伤害。

●

通风口通常包括运动部件,应尽量避免。

服、首饰或长发可能会卷入运动零件中。

冲击钻的运动所引起的振

锤击和钻

执行冲击钻

宽松的衣

剩余风险

下列风险是操作钻子时固有的:

-

触摸工具的旋转部件或高温部件造成的伤害。

尽管遵守相关的安全法规,应用安全装置,某些剩余风

险仍然是无法避免的。这些风险包括:

-

听力损害。

-

更换配件时挤压手指的危险。

-

钻木材时吸入粉尘而造成的健康损害。

-

四射的物品引起的人身伤害。

-

长时间的使用引起的人身伤害。

工具上的标记

工具上有下列标志:

使用前阅读使用说明书。

日期代码位置

连接工具和电池之间的外壳表面印有日期代码,日期代

码包括制造年份。

例如:

2011 XX XX

制造年份

针对所有电池充电器的

重要安全说明

请保存这些说明:

器安全和操作说明。

使用充电器之前,请阅读所有说明和充电器、电池

●

组和电池组产品上的警示标记。

本手册包含重要的

警告:

触电危险。禁止让任何液体进入充

电器。 否则会引起触电。

注意:

烧伤危险。为了减少受伤的危险,

E

只使用

类型的电池可能会过热爆裂,造成人身伤

害和财产损失。

可充电电池组充电。其它

WALT

D

DCB105

电池充电

17

Page 20

简体中文

注意:

监督儿童以确保他们不把设备当玩

具。

小心:

在某些情况下,充电器连接电源

时,异物可能会连接充电器内的外露充电

接触点而造成短路。请勿让能导电的异物

靠近充电器腔,这些异物包括钢棉、铝箔

或任何金属颗粒的堆积物。充电器腔中没

有电池组时,请断开充电器和电源。清洗

前请拔掉充电器。

●

禁止使用本手册指定的充电器以外的其他任何充电

器为电池组充电。

有兼容性。

●

除了为

E

D

用于其他任何用途。

击或触电的危险。

●

请勿将充电器暴露于雨中或雪中。

●

断开充电器时,拔出插头而不是拔电线。

电源插头和电源线损坏的风险。

●

确保电源线不会被踩到、钩到或以其他方式受到损

坏或压力。

●

非绝对必要条件下禁止使用延长线。

当可能会导致火灾、电击或触电的危险。

●

户外操作充电器时,要保持干燥,使用适合户外使

用的延长线。

险。

●

禁止堵塞充电器上的通风槽。通风槽位于充电器的

顶部和两侧。

●

禁止使用电源线或插头损坏的充电器,

损坏的充电器。

●

禁止使用受过冲击、坠落或以其他方式受损的充电

器。

请将损坏的充电器送到授权的服务中心维修。

●

请勿拆卸充电器,请将需要维修或服务的充电器送

到授权的服务中心。

或火灾。

●

损坏的电源线必须立即由制造商、服务代理或类似

的合格人员进行更换以防止安全隐患。

●

清洁前请将充电器和插座断开以减少触电的危险。

仅取出电池不会减少触电风险。

●

切勿

将两个充电器连接在一起。

●

充电器额定电压是标准

任何其他电压下使用充电器

充电器。

充电器和电池是专门设计的,具

充电电池充电,这些充电器都不能

WALT

其他用途可能会导致火灾、电

使用延长线不

适合户外使用的电线会减少触电的危

充电器应远离所有热源。

不正确的重装可能会引起触电

220~240V

请保存这些说明。

家用电力。禁止在

。

这条规则不适用于车辆

这将减少

请立即更换

充电器

充电器适用于:

DCB105

(

DCB121、DCB140、DCB141、DCB180和

)电池组。

DCB181

该充电器无需调整,设计目的是为了让操作尽可能容易。

充电程序(图

插入电池组前请将充电器插入到合适的

1.

座。

将电池组(j)插入到充电器中,确定电池组完全就

2.

位。红色(充电)指示灯将闪烁不断,表明充电过

程已经开始。

红色灯的常亮表示充电完成。此时电池组已完全充

3.

电,此时您可使用电池组或将电池组留在充电器

上。

注意:

为了确保锂离子电池的最佳性能和寿命,请在第

一次使用前将电池组完全充电。

10.8 V,14.4 V 和 18 V

2)

的锂离子

220~240V

充电过程

关于电池组的充电状态,请参阅下表。

充电状态

充电中

充电完成

热/冷电池延迟

故障电池组或充电器

故障电源线

这个充电器不能为故障电池组充电。充电器指示灯不亮时

或“故障电池组或充电器”指示灯闪烁的话说明电池有故

障。

注意:

这也可能意味着充电器有故障。

如果充电器提示有故障存在,请将充电器和电池组送到授

权的服务中心进行测试。

- - - -

●

-

- ● - ● -

● ● ● ● ● ● ● ● ● ● ●

●● ●● ●● ●● ●● ●●

●

热/冷电池延迟

当充电器检测到电池太热或太冷时,它会自动启动热/冷

电池延迟模式,暂停充电,直到电池达到适当的温度,

然后自动切换到电池组充电模式。此功能可确保电池拥

有最长的寿命。

XR锂离子电池工具的设计带有防止电池超载、过热或深

度放电的电子保护系统。

如果电子保护系统处于运作状态,该工具将自动停止运

转。如果发生这种情况,请将锂离子电池放在充电器上

直到完全充电。

插

18

Page 21

冷电池组充电速率是温热的电池组充电速率的一半左

右。电池组在整个充电周期的充电速度都会较慢,即使

电池升温也不会返回到最高速度。

针对所有电池充电器的

重要安全说明

在要求更换电池组时,请务必附上目录号码和电压。

货箱中的电池组是未完全充电的。在使用电池和充电器

之前,请阅读下面的安全说明,然后按照充电程序进行

操作。

请阅读所有说明。

●

禁止在易爆环境中充电或使用电池组,如有易燃液

体、气体或粉尘的环境。

会点燃粉尘或烟雾。

●

切勿将电池组强行插入充电器。禁止将电池组插入

不兼容的充电器,禁止任何方式改装电池组,这种

操作可能会导致电池组破裂,造成严重的人身伤

害。

●

只使用指定的

●

禁止把电池组浸泡在水或其他液体中,或泼洒水或

其他液体到电池组上。

●

在温度可能达到或超过

禁止

如夏天户外的棚子或金属建筑物中)储存或使用

(

工具和电池组。

●

为达到最佳效果,请确保电池组在使用前完全充

电。

E

D

警告:

组。电池组外壳破裂或损坏时,禁止将电

池组插入充电器。请勿挤压、跌落或损坏

电池组。禁止使用受过强烈冲击、跌落、

碾压或以任何其他方式(如被钉子穿破、

受到锤子的重击)被损坏的电池或充电

器。否则会引起触电。损坏的电池组应交

回服务中心回收。

注意:

引起人摔倒的稳定表面上。

池组的工具会电池端朝下直立,很容易被

撞翻。

锂离子电池的安全说明

即使在电池组严重受损或完全磨损的情况下,也请

●

勿焚烧电池组。

组被烧毁时会产生有毒气体和材料。

插入或取出电池组时可能

充电器为电池组充电。

WALT

40˚C(105°F

无论任何理由,都禁止打开电池

在不使用时,请将工具放置在不会

电池可能在火中爆炸。锂离子电池

)的地方

一些带大型电

简体中文

如果电池里的东西与皮肤接触,请立即用温和肥皂

●

和水冲洗接触的地方。

清洗睁开的眼睛15分钟或直到刺激停止。如果需要

医疗救助,请告知医护人员:电池的电解质是由有

机碳酸盐和锂盐的混合物组成。

电池里的成分可能刺激呼吸道。

●

气。如果症状仍然存在,请就医。

警告:

或火焰可能会燃烧。

如果电池液进入眼睛,用水

此时请提供新鲜空

烧伤危险。电池液如果接触到火花

电池组

电池类型

DCD730 和 DCD735 使用 14.4

DCD780 和 DCD785 使用 18

DCB140、DCB141、DCB180或DCB181

使用。 更多信息,请参阅

伏的电池组。

伏的电池组。

技术性数据

电池组都可以

。

存储建议

1.

最好将电池存放在阴凉、干燥、远离阳光直射、不

会过热或过冷的地方。为了获得最佳的电池性能和

寿命,在不使用时请将电池组存储在室温下。

2.

长期储存时,建议将完全充电的充电器储存在阴

凉、干燥的地方,以达到电池组最佳的效果。

注意:

电池组储存时不能处于电荷完全耗尽的状态。在

使用电池组前需要充电。

充电器和电池上的标签

除了在本手册中使用的标志,充电器和电池组的标签还

包括:

使用前请阅读使用说明书。

充电中。

充电完成。

热/冷电池延迟。

故障电池组或充电器。

故障电源线。

19

Page 22

简体中文

禁止用导电物体碰触。

禁止给损坏的电池组充电。

E

只使用

会爆炸,造成人身伤害和损害。

禁止暴露于水中。

电线故障,请立即更换。

只在4 ℃和40 ℃之间的温度下充电。

废弃电池请回收。

禁止焚烧电池组。

锂离子电池组充电。

充电时间,请参阅技术性数据。

只能在室内使用。

电池组。其他电池组可能

WALT

D

说明(图1)

警告:

禁止改装电动工具或其任何部分。

否则可能导致损失或人身伤害。

触发开关

a.

正转/反转控制按钮

.

b

扭矩调节轴环

.

c

变速杆

.

d

工作灯

e.

无键夹头

f.

皮带扣

g.

安装螺钉

h.

钻头夹具

i.

电池组

j.

电池释放按钮.

k.

预期用途

这些电钻/起子/冲击钻是为专业的钻孔、冲击钻孔、起子

用途而设计的。

请勿

在潮湿环境中或有易燃液体或气体的环境中使用。

该电钻/起子/冲击钻是专业的电动工具。

请勿

让儿童接触工具。缺乏经验的操作员需要在监督下

使用此工具。

本产品不适合身体、感官或心智能力有缺陷以及缺

●

乏经验、知识或技能的人(包括儿童)使用,除非

有人负责他们的安全监督。请勿将儿童单独留在存

放本产品的地方。

套装内容

该产品套装包含:

个电钻/起子或1个电钻/起子/冲击钻

1

个充电器

1

个电池

2

个维修箱

1

份使用说明书

1

注意:

模型不带电池、充电器和维修箱。

N

●

检查工具、零件或配件在运输过程中是否被损坏。

●

操作前花时间仔细阅读和理解本手册。

20

电器安全

电动机只有一个工作电压。请务必检查电池组的电压是

否和铭牌上的电压一致。另外,确保充电器电压和电源

对应。

E

您的

因此无需接地线。

电源线损坏时必须用

更换。

D

WALT

E

D

充电器按

EN60335

服务机构专门制备的电线

WALT

双重绝缘,

使用延长线

除非绝对必要,否则不应使用延长线。请使用适合您的

充电器电源输入的合格延长线(见

的最小尺寸为

当使用电缆卷筒时,请务必完全卷出电缆。

1mm

2

,最大长度为

技术性数据

。

30m

)。导线

Page 23

简体中文

组装和调试

警告:

组装和调试前,请务必拆下电池组。

插入或取出电池之前,务必关掉工具。

只使用

D

E

WALT

电池组和充电器。

警告:

插入/拆除电池组(图2)

注意:

为达到最佳效果,请确保电池组完全充电。

将电池组安装到工具手柄中:

将电池组(j)对齐工具手柄内的轨道(图 2)。

1.

将电池组滑入手柄内,使其牢牢地固定在工具内,

2.

并确保不会脱离。

从工具上移除电池组

按电池释放按钮(k),并用力将电池组从工具手柄

1.

中拉出。

按本手册充电器部分所述将电池组插入充电器中。

2.

变速触发开关(图1)

开启该工具请按下触发开关(a)。关闭工具请释放触发

开关。您的工具配备有制动系统。触发开关完全释放时

钻头夹将停止运作。

注意:

不建议在变速范围内连续使用工具。否则可能会

损坏开关。请尽量避免。

扭矩调节轴环(图

您的工具带有可调扭矩起子功能用于拧紧和拆除不同形

状和大小的紧固件,以及为砖石钻孔的冲击钻功能。轴

环(c)周围有数字和钻头符号,在某些机型上,还有冲

击钻符号。这些数字是用来设置夹具的扭矩范围。轴环

上数字越大,扭矩和可驱动的紧固件就越大。选择任何

一个数字时,旋转轴环直到所需的数字与箭头对齐。

1)

双档调速(图1)

您的起子/电钻的双档调速功能使你能够调档,从而获得

更大的灵活性。

要选择转速1(高扭矩设定)时,关闭工具使其停止运

1.

作。向前滑动变速杆(d)(朝向夹头)。

要选择转速2(高扭矩设定)时,关闭工具使其停止运

2.

作。向后滑动变速杆(远离夹头)。

注意:

工具运行时切勿换挡。换挡前电钻要完全停止运

作。如果换档出现问题,确保双档变速杆要么是彻底推

到前部或完全推到后部。

工作灯(图1)

触发开关(a)的上方有一工作灯。挤压触发开关即可激

活工作灯。

大停留20秒。

注意:

电筒使用。

从触发开关到释放后,工作灯照明状态将最

工作灯是用于照明紧邻的工作表面,不能当作手

正转/反转控制按钮(图1)

正转/反转控制按钮(b)确定工具方向,也有锁止按钮的

功能。

选择向前旋转时,释放触发开关,按下工具右侧的正转

反转控制按钮。

选择反向旋转时,按下工具左侧的正转/反转控制按钮。

控制按钮的中心位置会将工具锁定在关闭状态。改变控

制按钮的位置时,确保触发开关处于释放状态。

注意:

改变旋转方向后第一次运行该工具时,您可能会

在启动时听到“啪嗒”声。这是正常现象,并不代表出

现故障。

无键单套夹头(图

警告:

/

您的工具配有无键夹头(f)。夹头带有一旋转套筒,用

于夹头的单手操作。要插入钻头或其他部件时,请按下列

步骤操作

1.

2.

具来拧紧钻头(或任何其它配件)。这会

损坏夹头并导致人身伤害。更换配件时,

切记锁定触发开关,并将工具和电源断

开。

警告:

的钻头可能从工具上弹出,引起人身伤

害。

:

关闭工具和断开电源。

用一只手抓住夹头的黑色外套,并用另一只手固定

工具。逆时针旋转套筒使其足以容纳所需配件。

)

7-9

禁止通过抓住夹头的前部并启动工

确保启动工具前,紧固钻头。松弛

21

Page 24

简体中文

将配件插入夹头约

3.

住工具,用另一只手顺时针旋转夹头套筒,使其紧

固。您的工具配备自动主轴锁定机制。这可以让你

用一只手打开和关闭夹头。

请务必使用一只手握住夹头套筒,一只手握住工具,紧

固到最大限度。

要释放配件,请重复上述步骤1和步骤

19mm (3/4")

,收紧然后一只手握

2.

皮带扣和钻头夹具(图1)

为了减少严重人身伤害的危险,调整

警告:

或拆卸/安装附件或配件前,请务必关闭工

具,断开电池组。

为了减少严重人身伤害的危险,请勿

警告:

将工具悬挂在头顶上方或用皮带扣悬挂物

只可以

品。

扣。

警告:

保固定皮带扣子的螺钉是牢固的。

重要:

安装或更换皮带扣或钻头夹具时,只可以使用提

供的螺钉(h)。切记要拧紧螺钉。

可使用提供的螺钉(h)将皮带扣(g)和钻头夹具(i)

装到工具的任意一侧,以方便习惯左手操作或习惯右手

操作的用户。无需皮带扣和钻头夹具时,可以从工具上

拆除。

要拆除皮带扣和钻头夹具时,卸下固定它们的螺丝

(h),然后在另一边重新装上。切记要拧紧螺钉。

使用工作皮带悬挂工具的皮带

为了减少严重的人身伤害的风险,

确

操作

使用说明

警告:

请务必遵守安全说明和适用的法

规。

为了减少严重人身伤害的危险,

警告:

调整或拆卸/安装附件或配件前,请务必

关闭工具,断开电源。

正确的手持方式(图3)

警告:

为了减少严重人身伤害的危险,

请务必使用如图所示的正确手持方式。

警告:

为了减少严重人身伤害的风险,

请务必紧握住工具以防突发状况。

正确的手持方式如图所示,一只手在电钻(l)顶部,另

一只手在主手柄(m)上。

钻孔操作(图4)

警告:

为了减少严重人身伤害的危险,

调试或拆卸/安装附件或配件前,请务必

关闭工具电源,断开电源。

为了减少人身伤害的危险,请确

警告:

保

夹紧或固定工件。如果在薄材料上钻

孔,请使用木材“衬垫”以防止材料损

坏。

转动轴环(c)到钻孔标志。

1.

使用变速杆选择所需的转速/转矩范围,以配合计划

2.

的运作速度和转矩。

钻木材时,应使用麻花钻头、扁钻头、电力螺旋钻

3.

头或孔锯。钻金属时,使用高速钢麻花钻头或孔

锯。钻金属时使用切削润滑剂。铸铁和黄铜是例

外,应干钻。

用力方向始终与钻头成直线。施加钻咬所需的压力

4.

不应过大,以免导致马达失速或钻头倾斜。

用双手紧握工具,控制钻头的扭转效应。如果该型

5.

号没有配备侧手柄,请用一只手握住电钻手柄,另

一只手握住电池组。

警告:

电钻过载时会停止运转,并导致

突然扭转。请务必考虑到停转的可能性。

握紧工具,控制扭转效应并避免受伤。

电钻停转通常是因为超载或使用不当。请立即松开

6.

触发开关,取出钻头,并确定停转原因。切勿通过

点动触发开关来启动停转的电钻,这样可能会损坏

电钻。

为了尽量减少停转故障,避免钻头在材料中折断,

7.

请降低对电钻的压力,让钻头在孔的最后部分缓和

下来。

从成孔中拉出钻头时,请保持电机运行。这有助于

8.

防止卡死。

使用变速电钻时,无需中心冲定位。启动时使用较

9.

低速度,当钻孔够深可以防止跳钻时,加力挤压触

发开关进行加速。

冲击钻操作(图5)

转动轴环(c)到冲击钻标志。

1.

向后(远离夹头)滑动选择开关选择高速设置。

2.

重要:

仅可使用硬质合金或砖石钻头。

对冲击钻的用力应刚好防止过度回弹或“跳离”。用

3.

力过猛会导致钻孔速度减慢、过热和降低转速。

22

Page 25

直线钻进,使工件和钻头成直角。钻进时,不得对

4.

钻头施加侧向力,这会堵塞屑槽、降低钻进速度。

钻深孔时,如果冲击钻的速度开始下降了,请把钻

5.

头从孔中拉出一部分,同时保持工具运行,以帮助

钻屑从洞口清除出来。

注意:

如果钻屑平稳均匀地从孔中清除出来,则表示钻

孔速度适当。

螺丝起子操作(图6)

1.

使用双档换档变速杆选择所需的转速/转矩范围,以

配合计划的运作速度和转矩。

2.

转动扭矩调节轴环(c)到所需位置。数字越小表

示扭矩设置越低;数字越大表明转矩设置越高。

3.

把所需的紧固件配件插入夹头,与安装钻头的操作

一样。

4.

在废料上或在不可见的区域做些练习,确定离合器

环的适当位置。

5.

启动时,始终采用较低的扭矩设置,然后升高到较

高的扭矩设置,以避免损坏工件或紧固件。

维护

E

您的

最低限度的维护。连续令人满意的操作取决于适当的工

具护理和定期清洁。

充电器和电池都不能被维修,里面没有可以维修的部

件。

电动工具设计精良,可以长期使用,只需

WALT

D

为了减少严重人身伤害的危险,

警告:

调整或拆卸/安装附件或配件前,请务必

关闭工具,断开电池组。

导致人身伤害。

偶然的启动可能

清洁

警告:

通风口和周围积聚可见的粉尘

时,请用干燥的空气吹走主机外壳内的粉

尘和灰尘。执行此过程时,需戴上经认可

的护目装备和防尘口罩。

警告:

切勿使用溶剂或其他烈性化学制

品来清洁工具的非金属零件。这些化学物

质可能会削弱这些部位使用的材料。请用

布蘸温和的肥皂水擦拭。切勿让任何液体

进入工具,禁止让工具的任何部分在液体

中浸泡。

充电器清洁说明

警告:

触电危险。清洁前,请把充电器

从交流电源插座上断开。可用布或非金属

软刷清除充电器外部的污垢和油脂。禁止

使用水或任何清洁剂。

可选配件

警告:

由于除了

其他配件都未经此产品兼容性测试,本工

具若使用此类配件将存在安全隐患。为了

减少受伤的风险,本产品只可使用

E

推荐的配件。

D

WALT

请向您的经销商咨询更多关于合适配件的信息。

D

E

WALT

提供的配件,

环境保护

简体中文

润滑

您的电动工具无需另行润滑。

分类回收。该产品不能与普通生活垃圾一

起处理。

如果有一天您发现您的

续使用,禁止把它和生活垃圾一起处理。请单独分类回

收。

市政废物处理场或您购买新产品的零售商处,地方性法规

可能要求电器产品和生活垃圾分开回收。

E

产品需要更换,或不能继

D

WALT

使用过的产品和包装的分类回收能够得以

再循环和再利用。再生材料的再利用有助

于防止环境污染,并降低对原材料的需

求。

23

Page 26

简体中文

E

提供设施收集和回收使用寿命到期的

D

WALT

产品。要充分利用这项服务,请将产品返回任何授权的

维修代理,他们将代表我们回收您的产品。

您可以在本手册查找离您最近的授权维修代理的位置,

E

与本手册注明的当地

以登陆以下网址查看授权

及我们的售后服务的详细资料和联系方式:

www.2helpU.com.

办事处联系。另外,也可

WALT

D

E

D

WALT

维修代理商清单,以

DEWALT

可充电电池组

本长寿命电池组不能提供顺利完成工作所需的电力时必

须进行充电。其技术寿命结束时,要谨慎处理,注意保

护环境:

耗尽电池组的电力,然后从工具上拆下。

●

锂离子电池是可回收的。将它们送往您的经销商处

●

或当地的回收站。回收的电池组将被妥善回收或

理。

制造商:百得(苏州)科技有限公司

地址:苏州工业园区苏虹中路200号出口加工区

产地:苏州

处

24

Page 27

繁體中文

鋰電充電式

13mm

電鑽起子機

DCD730,DCD780

鋰電充電式

DCD735, DCD785

13mm

恭喜!

E

WALT

D

恭喜您選擇了

工具。多年的經驗和專業的產品開發創新使

之一。

技術性資料

電壓

型號

電池類型

輸出功率

空載轉速

1檔

2檔

衝擊頻率

1檔

2檔

最大扭矩

鑽頭直徑

最大鑽孔直徑

木材

金屬

石料

重量(不含電池)

估計震動暴露水準應該考慮工具的關閉時間或工具待機但實際未作業的情況。這可能會顯著降低總工作期間的震動暴露

水準。

採取額外的安全措施,以保護受震動影響的操作者,如:維護工具及配件、保持雙手溫暖、組織工作模式。

電池組

電池類型

電壓

容量

重量

充電器

電源電壓

電池類型

大概充電時間

重量

三用震動電鑽起子機

V

min

min

min

min

mm

mm

mm

mm

V

V

min

Nm

DC

W

-1

-1

-1

-1

kg

DC

A

h

kg

AC

kg

DCD730

14.4

1

鋰電池

300

0–550

0–1900

–

–

57

13

35

13

–

1.2

DCB140

鋰電池

14.4

3.0

0.53

30 60

(1.5

DEWALT

DCD735

14.4

1

鋰電池

300

0–550

0–1900

0–9350

0–32300

57

13

35

13

13

1.24

DCB141

鋰電池

14.4

1.5

0.30

) (3.0

安培電池組

成為專業電動工具使用者最可靠的合作夥伴

DCD780

18

1

鋰電池

350

0–600

0–2000

–

–

60

13

38

13

–

1.2

DCB180

鋰電池

18

3.0

0.64

DCB101

120V

鋰電池

安培電池組

0.49

DCD785

18

1

鋰電池

350

0–600

0–2000

0–10200

0–34000

60

13

38

13

13

1.24

DCB181

鋰電池

18

1.5

0.35

)

25

Page 28

繁體中文

定義:安全方針

下面的定義描述了每個信號標示的嚴重程度。請仔細閱

讀說明書,注意這些符號。

表示存在緊急的危險情況,如果不

危險:

加以避免,則可能導致死亡或嚴重傷害。

表示存在潛在的危險情況,如果不

警告:

加以避免,則可能導致死亡或嚴重傷害。

表示存在潛在的危險情況,如果不

注意:

加以避免,則可能導致輕微或中等傷害。

表示不涉及人身傷害的做法,如果

小心:

不避免,可能導致財物損失。

表示存在觸電的危險。

表示存在火災的危險。

為了減少受傷的危險,請閱讀使用

警告:

說明書。

一般電動工具安全規則

警告!請閱讀所有安全規則和使用說明

書。如果不遵守這些規則和說明,可能會

導致觸電、火災和/或嚴重傷害的危險。

請保存全部安全規則和說明文件,以供將來參考。

警告中的術語“電動工具”是指由電源通電時(有插

電)電動工具或由電池驅動時(無插電)電動工具。

1 )

工作场地

)

保持工作場地清潔和明亮,雜亂或陰暗的地方

a

容易引發事故。

)

禁止在易爆環境中操作電動工具,如有易燃液

b

體、氣體或粉塵的環境。電動工具產生的火花

會點燃粉塵或煙霧。

)

操縱電動工具時禁止兒童和旁觀者靠近。

c

可能會導致您操作不當。

2 )

電器安全

電動工具插頭必須與同規格的插座搭配。禁止

)

a

以任何方式改裝插頭。需要接地的電動工具不

能使用任何轉接插頭。原廠所附的插頭與同規

格的插座將減少觸電的危險。

避免人體與接地表面接觸, 如管道、散熱器、爐

)

b

灶、冰箱。如果您的身體接地,觸電危險性會

增加。

請勿將電動工具暴露在雨中或潮濕環境中。

)

c

動工具進水將增加觸電危險。

干擾

電

切勿濫用電線。切勿使用電源線搬運、拉動或

)

d

拔下電動工具。保持電源線遠離熱源、油、銳

邊或運動部件。受損或纏繞的電線會增加觸電

的危險。

在室外操作電動工具時,請使用適合戶外使用

)

e

的外接電線。適合戶外使用的電線會減少觸電

的危險。

如果必須得在潮濕的地方操作電動工具,請使

)

f

(

)

用剩餘電流裝置

用減少了觸電的危險.

)

3

人身安全

保持警覺,操作電動工具時注意操作,保持清

)

a

醒。切勿在疲倦或治療時或在藥物或酒精的影

響下使用電動工具。操作電動工具時注意力不

集中可能會導致嚴重的人身傷害。

使用個人防護裝備。始終佩戴護目鏡。

)

b

條件下使用防護裝備將減少人身傷害,如防塵

口罩、防滑安全鞋、安全帽、聽力保護設備。

防止意外啟動。在連接電源或電池組之前以及

)

c

拿起或攜帶工具之前請確保開關處於關閉位

置。攜帶電動工具時把手指放在開關上或充電

時開關處於打開位置會造成人身危險。

打開工具前拆下所有調整鍵或扳手。連接在電

)

d

動工具旋轉零件上的扳手或調整鍵可能導致人

身傷害。

禁止手伸得太長,時刻注意腳下和身體平衡。

)

e

這樣在意外情況下能更好地控制電動工具。

穿著得當。操作電動工具時切忌穿寬鬆的衣服

)

f

或佩戴首飾。讓您的頭髮、衣服和手套遠離運

動的零件。寬鬆的衣服、首飾或長髮可能會捲

入運動零件中。

如果有提供連接排屑集塵設備的裝置,請確保

)

g

這些裝置連接完好,使用正常。集塵可減少與

粉塵有關的危害。

)

4

電動工具的使用和注意項

禁止強制使用電動工具。根據用途,使用正確

)

a

的電動工具。正確的電動工具在設計的額定功

率下能更好更安全地完成工作。

禁止使用開關不能打開和關閉的電動工具。

)

b

何不能用開關控制的電動工具都很危險,必須

進行修理。

調整、更換附件或儲存電動工具前,請將電動

)

c

工具和電源插頭或電池組斷開。這種預防性安

全措施能減少意外啟動電動工具的風險。

RCD

保護的電源。

RCD

的使

適當的

任

26

Page 29

將電動工具儲存在兒童不能拿到的地方,禁止

)

d

不熟悉電動工具或本說明書的人操作電動工

具。讓未經訓練的用戶操作電動工具是很危險

的。

保養電動工具。檢查運動部件是否卡住,是否

)

e

對準,零件是否破損,以及是否有其他可能影

響電動工具操作的情況。如有損壞,請在使用

前對電動工具進行維修。許多事故就是由於電

動工具維護不良而發生的。

保持刀具鋒利和清潔,

)

f

具,可使操作是不容易卡住,且更容易控制。

請根據這些操作指示使用電動工具、配件和切

)

g

割工具等,並且考慮工作條件和要執行的工

作。將電動工具用於不是預期的操作用途可能

會導致危險情況。

)

5

電池工具使用和注意事項

只使用由製造商指定的充電器充電。使用適用

)

a

於其他類型電池組的充電器充電可能會引發火

災。

只使用專門指定的電池組。

)

b

組可能造成傷害,引發火災。

不使用電池組時,要將電池組儲存在遠離迴紋

)

c

針、硬幣、鑰匙、釘子、螺絲或其他可能使電

池短路的小型金屬物體。如果電池短路可能導

致灼傷或火災。

在惡劣條件下,電池可能會噴射出液體,請避

)

d

免接觸該液體。如果不小心接觸到液體,請用

清水沖洗。如果液體接觸眼睛,請另外尋求醫

療幫助。從電池噴出的液體可能會引起刺激或

灼傷。

)

服务

6

請讓合格的維修人員維修您的工具,維修人員

)

a

只能使用相同的更換零件以確保電動工具的安

全性能。

妥善保養鋒利的切削工

使用任何其他電池

電鑽/起子/錘鑽的附加安全說明

在使用衝擊鑽時請戴耳罩。

●

聽力損失。

如果有提供輔助手柄,請使用輔助手柄。

●

可能導致人身傷害。

切割配件可能接觸隱藏的電線時,請握住工具的絕

●

緣表面。切割配件接觸帶電電線可能使電動工具的

金屬部件帶電,因而導致操作人員觸電。

使用夾具或其他切實可行的辦法將工件固定,維持

●

在穩定的平臺上。手持工件或將工件靠在您的身體

上是不穩定的,並可能失去控制。

暴露於雜訊中可能造成

失去控制

繁體中文

●

佩戴安全護目鏡或其他保護眼睛的設備。

孔作業會導致碎片亂飛。四射的小型物可能會造成

永久性的眼部損傷。

●

配件和工具可能會在操作過程中變熱。

金屬鑽孔等這些會產生熱的作業時,請戴上手套。

●

禁止長時間操作本工具。

可能會傷害您的手和胳膊。使用手套會提供額外的

緩衝,頻繁的休息也能限制傷害。

●

通風口通常包括運動部件,應儘量避免。

服、首飾或長髮可能會捲入運動零件中。

錘鑽的運動所引起的振動

錘擊和鑽

執行錘鑽和

寬鬆的衣

剩餘風險

下列風險是操作鑽子時固有的:

-

觸摸工具的旋轉部件或高溫部件造成的傷害。

儘管遵守相關的安全法規,應用安全裝置,某些剩餘風

險仍然是無法避免的。這些風險包括:

-

聽力損害

-

更換配件時擠壓手指的風險。

-

鑽木材時吸入粉塵的健康損害。

-

四射的物品引起的人身傷害。

-

長時間的使用引起的人身傷害。

工具上的標記

工具上有下列標誌:

使用前閱讀使用說明書。

日期代碼位置

連接工具和電池之間的外殼表面印有日期代碼,日期代

碼包括製造年份。

例如:

2011 XX XX

製造年份

針對所有電池充電器的

重要安全說明

請保存這些說明:

器安全和操作說明。

使用充電器之前,請閱讀所有說明和充電器、電池

●

組和電池組產品上的警示標記。

本手冊包含重要的

觸電危險。禁止讓任何液體進入充

警告:

電器,否則會引起觸電。

燒傷危險。為了減少受傷的危險,

注意:

E

D

WALT

只使用

類型的電池可能會過熱爆裂,造成人身傷

害和財產損失。

DCB101

電池充電

可充電電池組充電。其他

27

Page 30

繁體中文

監督兒童以確保他們不把設備當玩

注意:

具。

在某些情況下,充電器連接電源

小心:

時,異物可能會連接充電器內的外露充電

接觸點而造成短路。請勿讓能導電的異物

靠近充電腔,這些異物包括鋼棉、鋁箔或

任何金屬顆粒的堆積物。充電腔中沒有電

池組時,請斷開充電器和電源。清洗前請

拔掉充電器。

●

禁止使用本手冊指定的充電器以外的其他任何充電

器為電池組充電。充電器和電池是專門設計的,具

有相容性。

●

●

●

●

●

●

●

●

●

●

●

●

●

●

DEWALT

除了為

用於其他任何用途。其他用途可能會導致火災、電

擊或觸電的危險。

請勿將充電器暴露於雨中或雪中。

斷開充電器時,拔出插頭而不是拔電線。這將減少

電源插頭和電源線損壞的風險。

確保電源線不會被踩到、鉤到或以其他方式受到損

壞或壓力。

非絕對必要條件下禁止使用延長線。使用延長線不

當可能會導致火災、電擊或觸電的危險。

戶外操作充電器時,要保持乾燥,使用適合戶外使

用的延長線。適合戶外使用的電線會減少觸電的危

險。

禁止堵塞充電器上的通風槽。通風槽位於充電器的

頂部和兩側。充電器應遠離所有熱源。

禁止使用電源線或插頭損壞的充電器,

損壞的充電器。

禁止使用受過衝擊、墜落或以其他方式受損的充電

器。請將損壞的充電器送到授權的服務中心維修。

請勿拆卸充電器,請將需要維修或服務的充電器送

到授權的服務中心。不正確的重裝可能會引起觸電

或火災。

損壞的電源線必須立即由製造商、服務代理或類似

的合格人員進行更換以防止安全隱患。

清潔前請將充電器和插座斷開以減少觸電的危險。

僅取出電池不會減少觸電風險。

切勿

將兩個充電器連接在一起。

充電器額定電力是標準

任何其他電壓下使用充電器。這條規則不適用於車

輛充電器。

充電電池充電,這些充電器都不能

110~120V

家用電力。禁止在

請保存這些說明。

請立即更換

充電器

DCB101

充電器適用於:

(

DCB121、DCB140、DCB141、DCB180和DCB181

電池組。

該充電器無需調整,設計目的是為了讓操作盡可能容易。

(

充電程式

插入電池組前請將充電器插入到合適的

1.

座。

將電池組

2.

位。紅色(充電)指示燈將閃爍不斷,表明充電過程

已經開始。

紅色燈的持續亮起表示充電完成。此時電池組已完

3.

全充電,此時您可使用電池組或將電池組留在充電

器上。

注意:

使用前將電池組完全充電。

圖

(j)

為了確保鋰電池的最佳性能和壽命,請在第一次

10.8V,14.4V和18V

的鋰電池

2)

110~120V

插入到充電器中,確定電池組完全就

充電過程

關於電池組的充電狀態,請參閱下表。

充電狀態

充電中

充電完成

熱/冷電池延遲

故障電池組或充電器

故障電源線

這個充電器不能為故障電池組充電。充電器指示燈不亮或

“故障電池組或充電器”指示燈閃爍的話說明電池有故

障。

這也可能意味充電器有故障。

注意:

如果充電器提示有故障存在,請將充電器和電池組送到授

權的服務中心進行測試。

- - - -

●

-

- ● - ● -

● ● ● ● ● ● ● ● ● ● ●

●● ●● ●● ●● ●● ●●

●

熱/冷電池延遲

當充電器檢測到電池過熱或過冷時,它會自動啟動過熱/

過冷電池延遲模式,暫停充電,直到電池達到適當的溫

度,然後自動切換到電池組充電模式。此功能可確保電

池擁有最長的壽命。

XR

鋰電池工具的設計帶有防止電池超載、過熱或深度放

電的電子保護系統。

如果電子保護系統處於運作狀態,該工具將自動停止運

轉。如果發生這種情況,請將鋰電池放在充電器上直到

完全充電。

)

插

28

Page 31

冷電池組充電速率是溫熱的電池組充電速率的一半左

右。電池組在整個充電週期的充電速度都會較慢,即使

電池升溫也不會返回到最高速度。

針對所有電池充電器的

重要安全說明

在要求更換電池組時,請務必附上目錄號碼和電壓。

貨箱中的電池組是未完全充電的。在使用電池和充電器

之前,請閱讀下面的安全說明,然後按照充電程式進行

操作。

請閱讀所有說明。

●

禁止在易爆環境中充電或使用電池組,如有易燃液

體、氣體或粉塵的環境。插入或取出電池組時可能

會點燃粉塵或煙霧。

●

切勿將電池組強行插入充電器。禁止將電池組插入

不相容的充電器,禁止任何方式改裝電池組,這種

操作可能會導致電池組破裂,造成嚴重的人身傷

害。

●

只使用指定的

●

禁止把電池組浸泡在水或其他液體中,或潑灑水或

其他液體到電池組上。

●

禁止在溫度可能達到或超過

夏天戶外的棚子或金屬建築物中)儲存或使用工具和

電池組。

●

為達到最佳效果,請確保電池組在使用前完全充

電。

鋰電池的安全說明

●

即使在電池組嚴重受損或完全磨損的情況下,也請

勿焚燒電池組。電池可能在火中爆炸。鋰電池組被

燒毀時會產生有毒氣體和材料。

E

WALT

D

充電器為電池組充電。

40˚C(105°F

無論任何理由,都禁止打開電池

警告:

組。電池組外殼破裂或損壞時,禁止將電

池組插入充電器。請勿擠壓、跌落或損壞

電池組。禁止使用受過強烈衝擊、跌落、

碾壓或以任何其他方式(如被釘子穿破、

受到錘子的重擊)被損壞的電池或充電

器。否則會引起觸電。損壞的電池組應交

回服務中心回收。

在不使用時,請將工具放置在不會

注意:

引起人摔倒的穩定表面上。一些帶大型電

池組的工具會電池端朝下直立,很容易被

撞翻。

)

的地方(如

繁體中文

●

如果電池裏的東西與皮膚接觸,請立即用溫和肥皂

和水沖洗接觸的地方。如果電池液進入眼睛,用水

清洗睜開的眼睛15分鐘或直到刺激感消失。如果需

要醫療救助,請告知醫護人員:電池的電解質是由

有機碳酸鹽和鋰鹽的混合物組成。

●

電池裏的成分可能刺激呼吸道。

氣。如果症狀仍然存在,請就醫。

燒傷危險。電池液如果接觸到火花

警告:

或火焰可能會燃燒。

此時請提供新鮮空

電池組

電池類型

DCD730和DCD735使用14.4

DCD780和DCD785使用18

DCB140、DCB141、DCB180或DCB181

使用。更多資訊,請參閱技術性資料。

伏特的電池組。

伏特的電池組。

電池組都可以

存儲建議

最好將電池存放在陰涼、乾燥、遠離陽光直射、不

1.

會過熱或過冷的地方。為了獲得最佳的電池性能和

壽命,在不使用時請將電池組存儲在室溫下。

長期儲存時,建議將完全充電的充電器儲存在陰

2.

涼、乾燥的地方,以達到電池組最佳的效果。

電池組儲存時不能處於電荷完全耗盡的狀態。在

注意:

使用電池組前需要充電。

充電器和電池上的標籤

除了在本手冊中使用的標誌,充電器和電池組的標籤還

包括:

使用前請閱讀使用說明書。

充電中。

充電完成。

熱/冷電池延遲。

故障電池組或充電器。

故障電源線。

29

Page 32

繁體中文

禁止用導電物體碰觸。

禁止給損壞的電池組充電。

E

WALT

D

只使用

會爆炸,造成人身傷害和損害。

禁止暴露于水中。

電線故障,請立即更換。

4

只在

廢棄電池請回收。

禁止焚燒電池組。

鋰電池組充電。

充電時間,請參閱技術性資料。

只能在室內使用。

電池組。其他電池組可能

℃

℃

40

和

之間的溫度下充電。

說明(圖1)

禁止改裝電動工具或其任何部分,

警告:

否則可能導致損失或人身傷害。

a.

觸發開關

.

正轉/反轉控制按鈕

b

.

扭矩調整卡環

c

.

變速杆

d

e.

工作燈

f.

無鍵夾頭

g.

皮帶扣

h.

安裝螺釘

i.

鑽頭夾具

j.

電池組

k.

電池釋放按鈕.

預期用途

這些電鑽/起子/錘鑽是為專業的鑽孔、衝擊鑽孔、起子用

途而設計的。

在潮濕環境中或有易燃液體或氣體的環境中使用。

請勿

這些電鑽/起子/錘鑽是專業的電動工具。

讓兒童接觸工具。缺乏經驗的操作員需要在監督下

請勿

使用此工具。

本產品不適合身體、感官或心智慧力有缺陷以及缺

●

乏經驗、知識或技能的人(包括兒童)使用,除非有

人負責他們的安全監督。請勿將兒童單獨留在存放

本產品的地方。

套裝內容

該產品套裝包含:

1

個電鑽/起子或1個電鑽/起子/錘鑽

1

個充電器

2

個電池

1

個維修箱

1

份使用說明書

N

模型零件圖不帶電池、充電器和維修箱。

注意:

●

檢查工具、零件或配件在運輸過程中是否被損壞。

●

操作前花時間仔細閱讀和理解本手冊。

30

電器安全

電動機只有一個工作電壓。請務必檢查電池組的電壓是

否和銘牌上的電壓一致。另外,確保充電器電壓和電源

對應。

E

D

您的

因此無需接地線。

電源線損壞時必須用

更換。

WALT

E

D

WALT

EN60335

充電器按

服務機構專門製備的電線

雙重絕緣,

使用延長線

除非絕對必要,否則不應使用延長線。請使用適合您的

充電器電源輸入的合格延長線(見技術性資料

最小尺寸為

當使用電纜捲筒,請務必完全卷出電纜。

1mm

2

,最大長度為

30m

。

)。導線的

Page 33

繁體中文

組裝和調試

組裝和調試前,請務必拆下電池組。

警告:

插入或取出電池之前,務必關掉工具。

警告:

插入/拆除電池組(圖

為達到最佳效果,請確保電池組完全充電。

注意:

將電池組安裝到工具手柄中。

( j )

將電池組

1.

將電池組滑入手柄內,使其牢牢地固定在工具內,

2.

並確保不會脫離。

對齊工具手柄內的軌道(圖

從工具上移除電池組

1.

按電池釋放按鈕

拉出。

2.

按本手冊充電器部分所述將電池組插入充電器中。

變速觸發開關(圖

開啟該工具請按下觸發開關

( a )

關

。您的工具配備有制動系統。觸發開關完全釋放時

鑽頭夾將停止運作。

不建議在變速範圍內連續使用工具。否則可能會

注意:

損壞開關。請儘量避免。

E

WALT

D

只使用

(k)

,並用力將電池組從工具手柄中

電池組和充電器。

2

)

2

1

)

( a )

。關閉工具請釋放觸發開

1

扭矩調整卡環(圖

您的工具帶有可調扭矩起子功能用於鎖和拆除不同形狀

和大小的緊固件,以及為磚石鑽孔的錘鑽功能。扭力環

(c)

周圍有數位和鑽頭符號,在某些機型上,還有錘鑽符

號。這些數字是用來設置夾具的扭矩範圍。扭力環上數

字越大,扭矩和可驅動的緊固件就越大。選擇任何一個

數字時,旋轉扭力環直到所需的數字與箭頭對齊。

二段調速(圖

您的起子/電鑽的二段調速功能使你能夠調速,從而獲

)

。

得更大的靈活性。

要選擇轉速1(高扭矩設定)時,關閉工具使其停止

1.

運作。向前滑動變速杆

要選擇轉速2(高扭矩設定)時,關閉工具使其停止

2.

運作。向後滑動變速杆(遠離夾頭)。

工具運行時切勿換擋。換擋前電鑽要完全停止

注意:

運作。如果換檔出現問題,確保二段調速杆要麼是徹

底推到前部或完全推到後部。

LED

內置工作燈(圖1)

( a )

觸發開關

動工作燈。

最大停留20秒 。

注意:

手電筒使用。

的上方有一工作燈。擠壓觸發開關即可啟

從觸 發 開 關到釋 放 後 ,工作 燈 照 明狀態將

工作燈是用於照明緊鄰的工作表面,不能當做

)

1

)

(d)

(朝向夾頭)。

1

正轉/反轉控制按鈕(圖

正轉/反轉控制按鈕

功能。

選擇向前旋轉時,釋放觸發開關,按下工具右側的正轉/

反轉控制按鈕。

選擇反向旋轉時,按下工具左側的正轉/反轉控制按鈕。

控制按鈕的中心位置會將工具鎖定在關閉狀態。改變控

制按鈕的位置時,確保觸發開關處於釋放狀態。

注意:改變旋轉方向後第一次運行該工具時,您可能會

在啟動時聽到“啪嗒”聲。這是正常現象,並不代表出

現故障。

( b )

確定工具方向,也有鎖止按鈕的

)

7-9

無鑰匙夾頭(圖

警告:

工具來擰緊鑽頭(或任何其他配件)。這

會損壞夾頭並導致人身傷害。更換配件

時,切記鎖定觸發開關,並將工具和電源

斷開。

警告:

弛的鑽頭可能從工具上彈出,引起人身傷

害。

您的工具配有無鑰匙夾頭

用於夾頭的單手操作。要插入鑽頭或其他部件時,請按

下列步驟操作。

關閉工具和斷開電源。

1.

用一隻手抓住夾頭的黑色外套,並用另一隻手固

2.

定工具。逆時針旋轉套筒使其足以容納所需配

件。

)

禁止通過抓住夾頭的前部並啟動

確保啟動工具前,緊固鑽頭。鬆

(f)

。夾頭帶有一個旋轉套筒,

31

Page 34

繁體中文

將配件插入夾頭約

3.

握住工具,用另一隻手順時針旋轉夾頭套筒,使

其緊固。您的工具配備自動主軸鎖定機制。這可

以讓你用一隻手打開和關閉夾頭。

請務必使用一隻手握住夾頭套筒,一隻手握住工具,

緊固到最大限度。

要釋放配件,請重複上述步驟1和步驟2.

皮帶扣和鑽頭夾具(圖

安裝或更換皮帶扣或鑽頭夾具時,只可以使用提

重要:

(h)

供的螺釘

可使用提供的螺釘

的任意一側,以方便習慣左手操作或習慣右手操作的用

戶使用。無需皮帶扣和鑽頭夾具時,可以從工具上拆

除。

要拆除皮帶扣和鑽頭夾具時,卸下固定它們的螺絲

然後在另一邊重新裝上。 切記要擰緊螺釘。

。切記要擰緊螺釘。

19mm(3/4")

為了減少嚴重人身傷害的危險,

警告:

調整或拆卸/安裝附件或配件前,請務必

關閉工具電源,斷開電池組。

為了減少嚴重人身傷害的危險,

警告:

請勿將工具懸掛在頭頂上方或用皮帶扣懸

掛物品。只可以使用工作皮帶懸掛工具的

皮帶扣。

為了減少嚴重的人身傷害的風

警告:

險,確保固定皮帶扣子的螺釘是牢固的。

(h)

將皮帶扣

,收緊然後一隻手

1

)

(g)

和鑽頭夾具

(i)

裝到工具

(h)

操作

使用說明

請務必遵守安全說明和適用的法

警告:

規。

為了減少嚴重人身傷害的危險,

警告:

調整或拆卸/安裝附件或配件前,請務必

關閉工具,斷開電源。

3

正確的手持方式(圖

警告:

使用如圖所示的正確的手持方式。

請務必

警告:

緊握住工具以防突發狀況。

請務必

正確的手持方式如圖所示,一隻手應該放在電鑽

部,另一隻手放在在主手柄

)

為了減少嚴重人身傷害的危險,

為了減少嚴重人身傷害的風險,