Page 1

.<o

@

>--rr

©_-

--(/)

___z

_m

rr W

WW

n

-,LU

_7.-I

III ..

&

€._ z

e=

oo. 0£

DEWALT Industrial Tool Co., 701 Joppa Road, Baltimore, MD 21286

(MAR06) Form No. 637379-00 DC900 Copyright © 2006 DEWALT

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme;

the "D" shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the

array of lozenge-shaped humps on the surface of the tool.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258)

General Safety Rules - For All Battery Operated Tools

_ WARNING! Read all instructions. Failure to follow all instructions listed below

may result in electric shock, fire and/or serious injury. The term "power tool" in all

of the warnings listed below refers to your mains-operated (corded) power tool or bat-

tery-operated (cordless) power tool

SAVE THESE INSTRUCTIONS

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while operating a power tooL Distractions can

cause you to lose control

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tooL Keep cord away from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock. Replace or repair damaged cords.

Make sure your extension cord is in good condition. Use only 3-wire extension cords that

have 3-prong grounding-type plugs and 3-pole receptacles that accept the tool's plug.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock. When using

an extension cord, be sure to use one heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line voltage resulting in loss of power and

overheating. The following table shows the correct size to use depending on cord length

and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gage

number, the heavier the cord.

Recommended Minimum Wire Size for Extension Cords

Total Length of Cord

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Wire Size AWG

18 18 16 16 14 14 12

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tools may

result in serious personal injury

b) Use safety equipment. Always wear eye protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate condi-

tions will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is in the off-position before plugging

in. Carrying power tools with your finger on the switch or plugging in power tools that have

the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or

a key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in

moving parts. Air vents often cover moving parts and should also be avoided.

g) ff devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of these devices can reduce dust-

related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tooL Use the correct power tool for your application. The cor-

rect power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons unfa-

miliar with the power tool or these instructions to operate the power tool Power

tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the power tools operation, ff

damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions and in the manner intended for the particular type of power tool, taking

into account the working conditions and the work to be performed. Use of the power

tool for operations different from those intended could result in a hazardous situation.

5) BATTERY TOOL USE AND CARE

a) Ensure the switch is in the off position before inserting battery pack. Inserting the

battery pack into power tools that have the switch on invites accidents.

b) Recharge only with the charger specified by the manufacturer. A charger that is

suitable for one type of battery pack may create a risk of fire when used with another

battery pack.

c) Use power tools only with specifically designated battery packs. Use of any other

battery packs may create a risk of injury and fire.

d) When battery pack is not in use, keep it away from other metal objects like paper

clips, coins, keys, nails, screws, or other small metal objects that can make a

connection from one terminal to another. Shorting the battery terminals together may

cause bums or a fire.

e) Under abusive conditions, liquid may be ejected from the battery, avoid contact. If

contact accidentally occurs, flush with water. If liquid contacts eyes, additionally

seek medical help. Liquid ejected from the battery may cause irritation or burns.

6) SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Specific Safety Rules for Hammerdrills

• Hold tool by insulated gripping surfaces when performing an operation where the tool

may contact hidden wiring or its own cord. Contact with a "live" wire will also make

exposed metal parts of the tool "live" and shock the operator.

• Wear ear protectors with impact drills. Exposure to noise can cause hearing loss.

• Use auxiliary handles supplied with the tooL Loss of control can cause personal injury.

• Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss of

control

• Wear ear protectors when hammering for extended periods of time. Prolonged expo-

sure to high intensity noise can cause hearing loss. Temporary hearing loss or serious ear

drum damage may result from high sound levels generated by hammerdrilling.

• Wear safety goggles or other eye protection. Hammering and drilling operations cause

chips to fly. Flying particles can cause permanent eye damage.

• Always use the side handle supplied with the tool Keep a firm grip on the tool at all times.

Do not attempt to operate this tool without holding it with both hands.

• Hammer bits and tools get hot during operation. Wear gloves when touching them.

J& WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses.

Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED SAFETY

EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI $12.6 ($3. 19) hearing protection,

• NIOSH/OSHA respiratory protection.

J& WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other con-

struction activities contains chemicals known to cause cancer, birth defects or other reproduc-

tive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

_, WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and

permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face and body.

_, CAUTION: When not in use, place tool on its side on a stable surface where it will not

cause a tripping or falling hazard. Some tools with large battery packs will stand upright on

the battery pack but may be easily knocked over.

CAUTION: Wear appropriate hearing protection during use. Under some conditions

and duration of use, noise from this product may contribute to hearing loss.

• The label on your tool may include the following symbols. The symbols and their definitions

are as follows:

V.................. volts

Hz................ hertz

min .............. minutes

.... ............ direct current

@ ................ Class I Construction

(grounded)

[] ................ Class II Construction

(double insulated)

BPM ............ beats per minute

A .................. amperes

W.................. watts

'_ ................ alternating current

no ................ no load speed

.................. earthing terminal

_ .................. safety alert symbol

.../min .......... revolutions or reciprocation

per minute

Important Safety Instructions for Battery Chargers

SAVE THESE INSTRUCTIONS: This manual contains important safety instructions for battery

chargers.

• Before using charger, read all instructions and cautionary markings on charger, battery pack,

and product using battery pack.

_ WARNING: Shock hazard. Do not allow any liquid to get inside charger.

_,CAUTION: Bum hazard. To reduce the risk of injury, charge only DEWALT batteries. Other

types of batteries may burst causing personal injury and damage.

_CAUTION: Under certain conditions, with the charger plugged in to the power supply, the

charger can be shorted by foreign material Foreign materials of a conductive nature such as,

but not limited to, steel wool, aluminum foil, or any buildup of metallic particles should be kept

away from charger cavities. Always unplug the charger from the power supply when there is no

battery pack in the cavity. Unplug charger before attempting to clean.

• DO NOT attempt to charge the battery pack with any chargers other than the ones in

this manuaL The charger and battery pack are specifically designed to work together.

• These chargers are not intended for any uses other than charging DEWALT recharge-

able batteries. Any other uses may result in risk of fire, electric shock or electrocution.

• Do not expose charger to rain or snow.

• Pull by plug rather than cord when disconnecting charger. This will reduce risk of

damage to electric plug and cord.

• Make sure that cord is located so that it will not be stepped on, tripped over, or other-

wise subjected to damage or stress.

• Do not use an extension cord unless it is absolutely necessary. Use of improper

extension cord could result in risk of fire, electric shock, or electrocution.

• An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that

is 16 gauge has more capacity than 18gauge. When using more than one extension to make

up the total length, be sure each individual extension contains at least the minimum wire size.

• Do not place any object on top of charger or place the charger on a soft surface that

might block the ventilation slots and result in excessive internal heat. Place the charg-

er in a position away from any heat source. The charger is ventilated through slots in the top

and the bottom of the housing.

• Do not mount charger on wall or permanently affix charger to any surface. The

charger is intended to use on a flat, stable surface (i.e., table top, bench top).

• Do not operate charger with damaged cord or plug -- have them replaced immediately.

• Do not operate charger ff it has received a sharp blow, been dropped, or otherwise

damaged in any way. Take it to an authorized service center.

• Do not disassemble charger; take it to an authorized service center when service or

repair is required. Incorrect reassembly may result in a risk of electric shock, electrocution

or fire.

• Disconnect the charger from the outlet before attempting any cleaning. This will

reduce the risk of electric shock. Removing the battery pack will not reduce this risk.

• NEVER attempt to connect 2 chargers together.

• The charger is designed to operate on standard household electrical power (120

Volts). Do not attempt to use it on any other voltage.

SAVE THESE INSTRUCTIONS

Introduction

The DC9000 charger is designed to charge DEWALT battery packs in approximately 1 hour. This

charger requires no adjustment and is designed to be as easy as possible to operate. Simply

place your battery pack into the receptacle of a plugged in charger and it will automatically

charge the pack.

Important Safety Instruction for Battery Packs

_ WARNING: For safe operation, read this manual and manuals originally supplied with tool

before using the charger.

When ordering replacement battery packs, be sure to include catalog number and voltage.

Consult the chart on the last page of this manual for compatibility of chargers and battery packs.

The battery pack is not fully charged out of the carton. Before using the battery pack and

charger, read the safety instructions below. Then follow charging procedures outlined.

READ ALL INSTRUCTIONS

• Do not incinerate the battery pack even if it is severely damaged or is completely

worn ouL The battery pack can explode in a fire. Toxic fumes and materials are created

when lithium ion battery packs are burned.

• Do not charge or use battery in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Inserting or removing the battery from the charger may

ignite the dust or fumes.

• If battery contents come into contact with the skin, immediately wash area with mild

soap and water, ff battery liquid gets into the eye, rinse water over the open eye for 15 min-

utes or until irritation ceases. If medical attention is needed, the battery electrolyte is com-

posed of a mixture of liquid organic carbonates and lithium salts.

• Contents of opened battery cells may cause respiratory irritation. Provide fresh air. If

symptoms persists, seek medical attention.

,&WARNING: Bum hazard. Battery liquid may be flammable if exposed to spark or flame.

• Charge the battery packs only in DEWALT chargers.

• DO NOT splash or immerse in water or other liquids.

• Do not store or use the tool and battery pack in locations where the temperature may

reach or exceed 105°F (40 °)(such as outside sheds or metal buildings in summer).

AWARNING: Never attempt to open the battery pack for any reason. If battery pack case is

cracked or damaged, do not insert into charger. Do not crush, drop or damage battery pack. Do

not use a battery pack or charger that has received a sharp blow, been dropped, run over or

damaged in any way (i.e., pierced with a nail, hit with a hammer, stepped on). Damaged

battery packs should be returned to service center for recycling.

,& WARNING: Fire hazard. Do not store or carry battery so that metal objects can contact

exposed battery terminals. For example, do not place battery in aprons, pockets, tool boxes,

product kit boxes, drawers, etc., with loose nails, screws, keys, etc. Transporting batteries can

possibly cause fires ff the battery terminals inadvertently come in contact with conduc-

tive materials such as keys, coins, hand tools and the like. The US Department of

Transportation Hazardous Material Regulations (HMR) actually prohibit transporting batteries in

commerce or on airplanes (i.e., packed in suitcases and carry-on luggage) UNLESS they are

Page 2

properlyprotectedfromshortcircuits.Sowhentransportingindividualbatteries,makesurethat

thebatteryterminalsareprotectedandwellinsulatedfrommaterialsthatcouldcontactthem

andcauseashortcircuit.

The RBRC TM Seal

The RBRC TM (Rechargeable Battery Recycling Corporation) Seal on the lithium

ion battery (or battery pack) indicates that the costs to recycle the battery (or

battery pack) at the end of its useful life have already been paid by DEWALT.

RBRC TM in cooperation with DEWALT and other battery users, has established

programs in the United States to facilitate the collection of spent lithium ion

batteries. Help protect our environment and conserve natural resources by returning the spent

lithium ion battery to an authorized DEWALT service center or to your local retailer for recycling.

You may also contact your local recycling center for information on where to drop off the spent

battery.

RBRCTM is a registeredtrademark ofthe RechargeableBattery RecyclingCorporation.

Storage Recommendations

1. The best storage place is one that is cool and dry away from direct sunlight and excess heat

or cold.

2. Long storage will not harm the battery pack or charger. Under proper conditions, they can

be stored for 5 years or more.

Charger

Your battery pack requires a 1 hour DEWALT charger Be sure to read all safety instructions

before using your charger. Consult the chart on the back of this manual for compatibility

of chargers and battery packs.

Charging Procedure

1. Plug the charger into an appropriate outlet before inserting the battery pack.

2. Insert the battery pack into the charger. The charger is equipped with a three-light fuel gauge

that will blink according to the state of charge of the battery pack.

3. The completion of charge is indicated by the three red lights remaining ON continuously.

The pack is fully charged and may be used at this time or left on the charger.

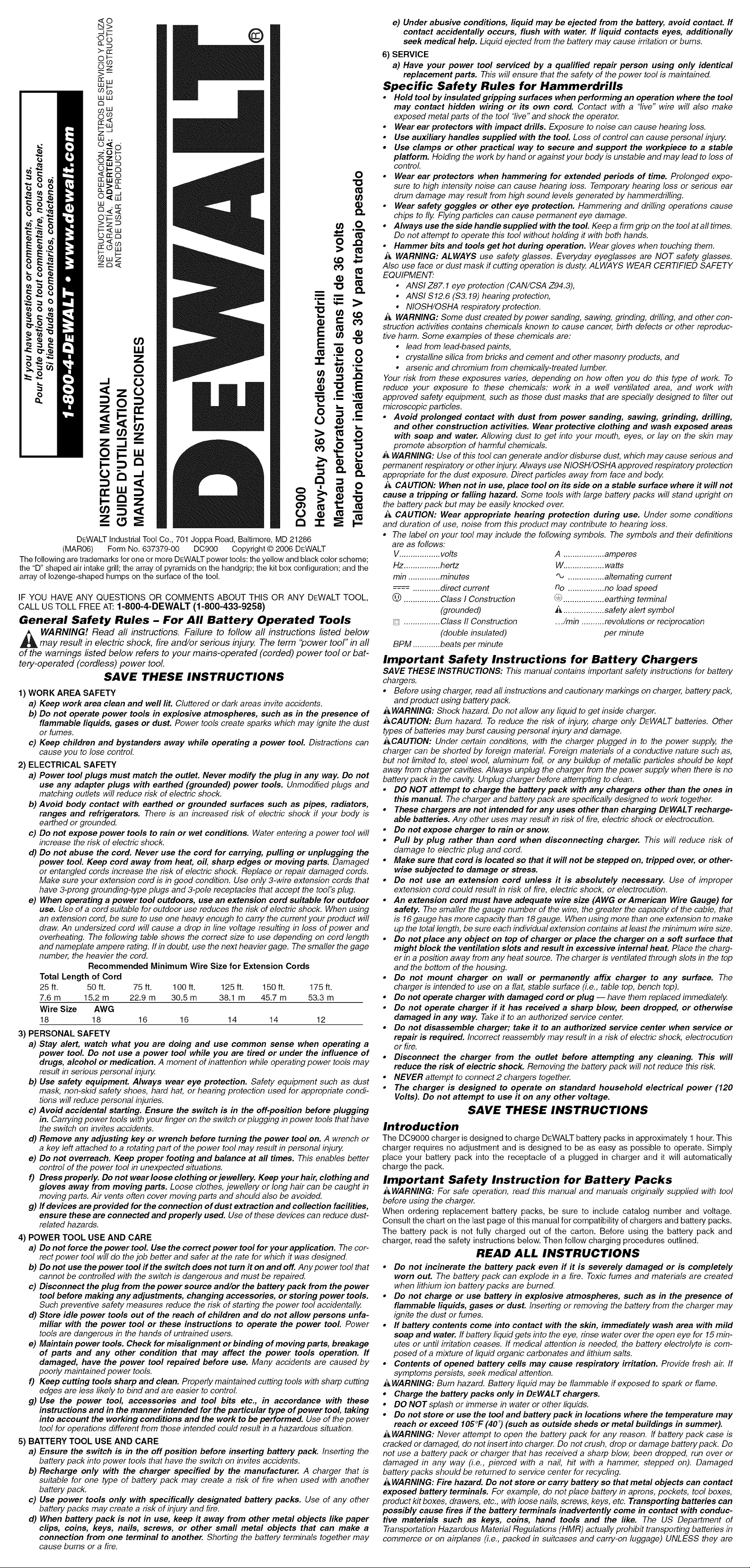

FIG. 1

FIG. 2 FIG. 3

D C

FIG. 4

_e e D 0% - 33% 1st light blinks

®:_e [3 33% - 66% 1st light on, 2nd light blinks

® o_:_ 66% - 99% 1 st, 2 nd lights on, 3 rd light blinks

e ® • _ 100% 1st, 2nd, 3 rd lights on

Charger Diagnostics

This charger is designed to detect certain problems that can arise with the battery packs or the

charger. Problems are indicated by the three red lights flashing together in different patterns.

PROBLEM POWER LINE

When the charger is used with some portable power sources such as generators or sources that

convert DC to AC, the charger may temporarily suspend operation. The three red lights will flash

together with two fast blinks followed by a pause. This indicates that the power source is out

of limits.

BAD BATTERY

The charger can detect a weak or damaged battery. The three red lights will flash together with

rapid blinking. The battery will no longer charge and should be returned to a service center or

a collection site for recycling.

BAD CHARGER

The charger will detect if it is not functioning properly. The three red lights will flash together with

one fast blink followed by a long blink. The charger will no longer work and should be

returned to an authorized service center or replaced.

LEAVING THE BATTERY IN THE CHARGER

The charger and battery pack can be left connected with the red lights glowing indefinitely. The

charger will keep the battery pack fresh and fully charged. This charger features an automatic

tune-up mode which equals or balances the individual cells in the battery pack to allow it to func-

tion at peak capacity. Battery packs should be tuned up weekly or whenever the battery no

longer delivers the same amount of work. To use the automatic tune-up mode, place the battery

pack in the charger and leave it for at least 8 hours.

Important Charging Notes

1. Longest life and best performance can be obtained if the battery pack is charged when the

air temperature is between 65°F and 75°F (18°- 24°C). DO NOT charge the battery pack in

an air temperature below +40°F (+4.5°C), or above +105°F (+40.5°C). This is important and

will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to touch while charging. This is a normal

condition, and does not indicate a problem. To facilitate the cooling of the battery pack after

use, avoid placing the charger or battery pack in a warm environment such as in a metal

shed, or an uninsulated trailer.

3. If the battery pack does not charge properly:

a. Check current at receptacle by plugging in a lamp or other appliance

b. Check to see if receptacle is connected to a light switch which turns power off when you

turn out the lights.

c. Move charger and battery pack to a location where the surrounding air temperature is

approximately 65°F - 75°F (18 °- 24°C).

d. If charging problems persist, take the tool, battery pack and charger to your local

service center.

4. The battery pack should be recharged when it fails to produce sufficient power on jobs which

were easily done previously. DO NOT CONTINUE to use under these conditions. Follow the

charging procedure. You may also charge a partially used pack whenever you desire with no

adverse affect on the battery pack.

5. Foreign materials of a conductive nature such as, but not limited to, steel wool, aluminum

foil, or any buildup of metallic particles should be kept away from charger cavities. Always

unplug the charger from the power supply when there is no battery pack in the cavity.

Unplug charger before attempting to clean.

6. Do not freeze or immerse charger in water or any other liquid.

AWARNING: Shock hazard. Do not allow any liquid to get inside charger.

_CAUTION: Never attempt to open the battery pack for any reason, ff the plastic housing of

the battery pack breaks or cracks, return to a service center for recycling.

KEY FEATURES AND FUNCTIONS

Variable Speed Switch (Fig. 1)

Toturn the tool on, squeeze the trigger switch (A). To turn the tool off, release the trigger switch.

Your tool is equipped with a brake. The chuck will stop as soon as the trigger switch is fully

released.

NOTE: Continuous use in variable speed range is not recommended. It may damage the switch

and should be avoided.

Forward/Reverse Control Button (Fig. 1)

A forward/reverse control button (B) determines the direction the tool will spin and also serves

as a lock-off button.

To select forward rotation, release the trigger switch and depress the forward/reverse control

button on the right side of the tool.

To select reverse, depress the forward/reverse control button on the left side of the tool.

The center position of the control button locks the tool in the OFF position. When changing the

position of the control button, be sure the trigger is released.

NOTE: The first time the tool is run after changing the direction of rotation, you may hear a click

on start up. This is normal and does not indicate a problem.

Mode Control Collar

Your drill is equipped with a separate mode control collar (Fig. 1, C) to switch between drilling

and screwdriving.

SCREWDRIVlNG (FIG. 2)

1. Select the desired speed/torque range using the three-speed gear shifter (E) on the top of

tool to match the speed and torque to the planned application. To set the torque level to the

proper setting on the clutch collar, initially set the clutch collar at a lower setting to ensure

the fastener to be set to your specification.

NOTE: Use the lowest torque setting required to seat the fastener at the desired depth. The

lower the number, the lower the torque output.

2. Rotate the mode control collar (C) so the line on the lever (F) is aligned with the screw

symbol.

3. Set the torque adjustment collar (D) to the appropriate number setting for the torque desired.

NOTE: The torque adjustment collar may be set on any number and change between

screwdriving and drilling modes using the mode control collar.

DRILLING (FIG. 3)

_,CAUTION: When the mode collar is in the drill/hammerdrill mode, the drill will not clutch out

regardless of the position of the torque adjustment collar (D).

Rotate the mode control collar (C) so that the line on the lever (F) is aligned with the drill

symbol.

NOTE: The torque adjustment collar (D) may be set on any number.

HAMMERDRILLING (FIG. 4)

Rotate the mode control collar (C) to align the line on the lever (F) with the hammerdrill

symbol and turn the torque adjustment collar (D) to align the hammer symbol with the line (F).

Torque Adjustment Collar (Fig. 2)

Your tool has an adjustable torque screwdriver mechanism for driving and removing a wide

array of fastener shapes and sizes and a hammer mechanism for drilling into masonry. Circling

the torque adjustment collar (D) are numbers and a hammer symbol. These numbers are used

to set the clutch to deliver a torque range. The higher the number on the collar, the higher the

torque and the larger the fastener which can be driven. To select any of the numbers, rotate until

the desired number aligns with the arrow.

Three-Speed Gearing (Fig. 2)

The three-speed feature of your tool allows you to shift gears for greater versatility To select

speed 1 (highest torque setting), turn the tool off and permit itto stop. Slide the gear shifter (E) all

the way to the left. Speed 2 (middle torque and speed setting) is in the middle position. Speed 3

(highest speed setting) isto the right.

NOTE: Do not change gears when the tool is running. Always allow the drill to come to a complete

stop before changing gears. If you have trouble changing gears, make sure that the gear shifter is

engaged in one of the three speed settings.

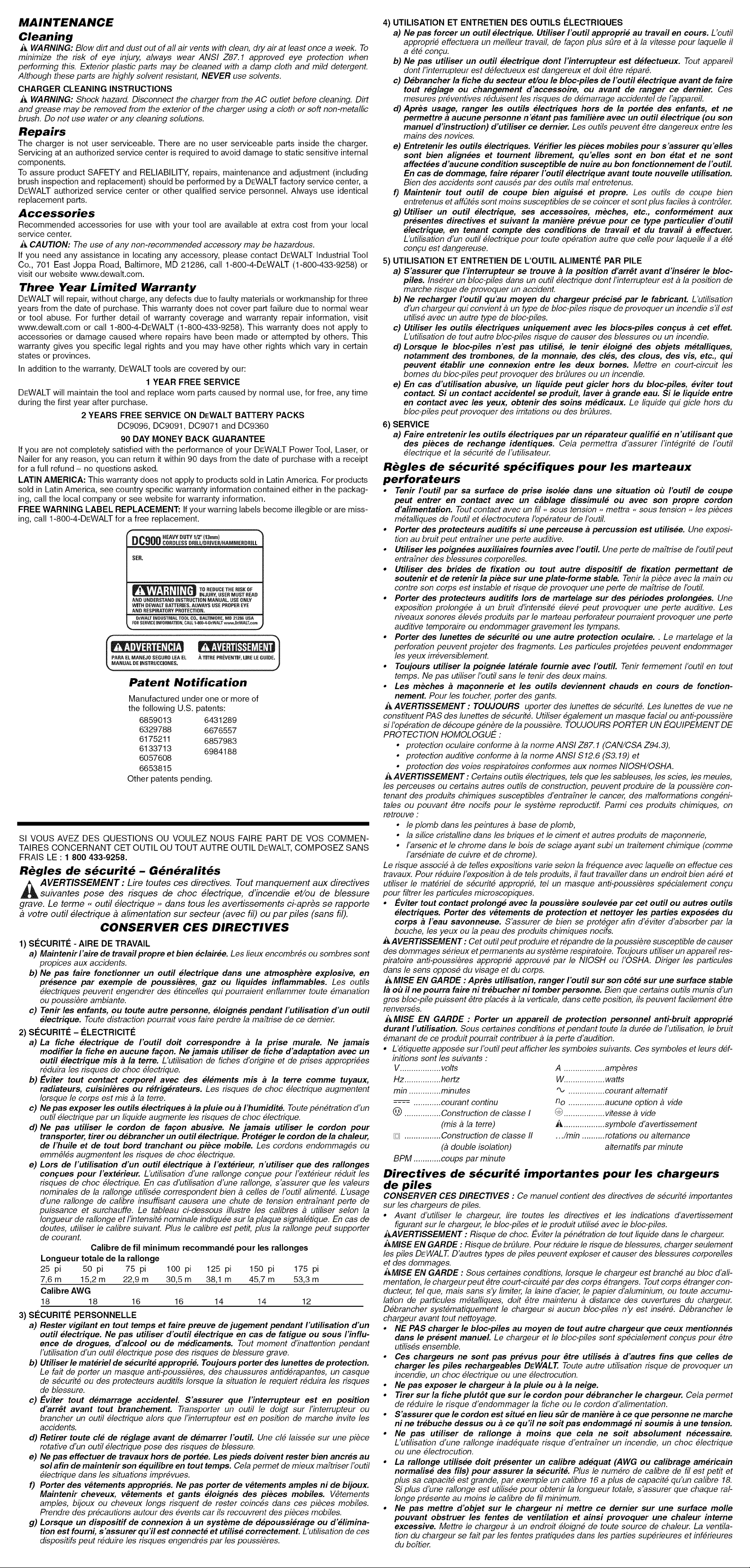

Self-Tightening Chuck Operation (Fig. 5-7)

_ WARNING: Do not attempt to tighten drill bits (or any other accessory) by gripping the front

part of the chuck and turning the tool on. Damage to the chuck and personal injury may result.

Always lock off trigger switch when changing accessories.

D

SCREWDRIVlNG DRILLING

VlSSAGE PER CAGE

DESTORNILLADOR TALADRO

FIG. 5 FIG. 6

G

FIG. 8 FIG. 9

A WARNING: Always ensure the b# is secure before starting the tool. A loose b# may eject

from tool causing possible personal injury.

TO INSERT A DRILL BIT OR OTHER ACCESSORY

1. Lock the trigger in the OFF position.

2. Grasp the chuck sleeve (G) with one hand and use the other hand to secure the tool as

shown in Figure 5. Rotate the sleeve counterclockwise (viewed from the front) far enough

to accept the desired accessory.

3. Insert the bit or other accessory about 3/4" (19mm) into the chuck, as shown in Figure 6.

Grasp the chuck sleeve securely and rotate the sleeve clockwise (viewed from the front)

with one hand while using the other hand to secure the tool. Rotate the sleeve clockwise

until sleeve cannot be rotated any further, as demonstrated in Figure 7. As the drill is being

operated in the forward position, the chuck will continually self-tighten the jaws of the chuck

onto the bit to maximize the bit gripping strength.

To release the accessory, repeat Step 2.

HAMMERDRILLING

MARTEAU PERFORATEUR

TALADRO PERCUTOR

FIG. 7

OPERATION

Installing and Removing the Battery Pack (Fig. 8, 9)

NOTE: Make sure your battery pack is fully charged.

,&CAUTION: Make certain the lock-off button (B), as shown in Figure 1, is engaged to prevent

switch actuation before removing or installing battery.

To install the battery pack into the tool handle, align the base of the tool with the rails inside

the tool's handle and slide the battery pack firmly into the handle until you hear the lock snap

into place (Fig. 8).

To remove the battery pack from the tool, press the release button (H) and firmly pull the

battery pack out of the tool handle. Insert it into the charger (Fig. 9) as described in the charger

section of this manual.

Side Handle

A CAUTION: Always operate the tool with the side handle properly

assembled. Hold tool with both hands to maximize control.

Side handle clamps to the front of the gear case as shown and may be

rotated to permit right- or left-hand use. Side handle must be tightened

sufficiently to resist the twisting action of the tool if the accessory binds or

stalls. Be sure to grip the side handle at the far end to control the tool dur-

ing a stall.

If model is not equipped with side handle, grip drill with one hand on the handle and one hand

on the battery pack.

Drill Operation

1. Select the desired speed/torque range using the gear shifter to match the speed and torque

to the planned operation.

2. For WOOD, use twist bits, spade bits, power auger bits or hole saws. For METAL, use high-

speed steel twist drill bits or hole saws. Use a cutting lubricant when drilling metals. The

exceptions are cast iron and brass which should be drilled dry.

3. Always apply pressure in a straight line with the bit. Use enough pressure to keep the drill

bit biting, but do not push hard enough to stall the motor or deflect the bit.

4. Hold tool firmly with both hands to control the twisting action of the drill.

5. IF DRILL STALLS, it is usually because it is being overloaded. RELEASE TRIGGER

IMMEDIATELY, remove drill bit from work, and determine cause of stalling. DO NOT

CLICK TRIGGER OFF AND ON IN AN ATTEMPT TO START A STALLED DRILL - THIS

CAN DAMAGE THE DRILL.

6. Keep the motor running when pulling the bit back out of a drilled hole. This will help 3revent

jamming.

Hammerdrill Operation

1. When drilling, use just enough force on the hammer to keep it from bouncing excessively or

"rising" off the bit. Too much force will cause slower drilling speeds, overheating, and a lower

drilling rate.

2. Drill straight, keeping the bit at a right angle to the work. Do not exert side pressure on the

bit when drilling as this will cause clogging of the bit flutes and a slower drilling speed.

3. When drilling deep holes, if the hammer speed starts to drop off, pull the bit partially out of

the hole with the tool still running to help clear debris from the hole.

4. For MASONRY, use carbide-tipped bits or masonry bits. A smooth, even flow of dust indi-

cates the proper drilling rate.

Screwdriver Operation

Select the desired speed/torque range using the three-speed gear shift lever on the top of tool

to match the speed and torque to the planned operation. Insert the desired fastener accessory

into the chuck as you would any drill bit. Set the torque adjustment collar (D) to the desired

setting. Make a few practice runs in scrap or unseen areas to determine the proper position of

the clutch collar.

Page 3

MAINTENANCE

Cleaning

_, WARNING: Blow dirt and dust out of all air vents with clean, dry air at least once a week. To

minimize the risk of eye injury, always wear ANSI Z87.1 approved eye protection when

performing this. Exterior plastic parts may be cleaned with a damp cloth and mild detergent.

Although these parts are highly solvent resistant, NEVER use solvents.

CHARGER CLEANING INSTRUCTIONS

,& WARNING: Shock hazard. Disconnect the charger from the AC outlet before cleaning. Dirt

and grease may be removed from the exterior of the charger using a cloth or soft non-metallic

brush. Do not use water or any cleaning solutions.

Repairs

The charger is not user serviceable. There are no user serviceable parts inside the charger.

Servicing at an authorized service center is required to avoid damage to static sensitive internal

components.

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including

brush inspection and replacement) should be performed by a DEWALT factory service center, a

DEWALT authorized service center or other qualified service personnel. Always use identical

replacement parts.

Accessories

Recommended accessories for use with your tool are available at extra cost from your local

service center.

A CAUTION: The use of any non-recommended accessory may be hazardous.

If you need any assistance in locating any accessory, please contact DEWALT Industrial Tool

Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-DEWALT (1-800-433-9258) or

visit our website www.dewalt.com.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for three

years from the date of purchase. This warranty does not cover part failure due to normal wear

or tool abuse. For further detail of warranty coverage and warranty repair information, visit

www.dewalt.com or call 1-800-4-DEWALT (1-800-433-9258). This warranty does not apply to

accessories or damage caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights which vary in certain

states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

2 YEARS FREE SERVICE ON DEWALT BATTERY PACKS

DC9096, DC9091, DC9071 and DC9360

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your DEWALT Power Tool, Laser, or

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt

for a full refund - no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products

sold in Latin America, see country specific warranty information contained either in the packag-

ing, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: Ifyour warning labels become illegible or are miss-

ing, call 1-800-4-DEWALT for a free replacement.

f-_ t'_NA HEAVY DUTY 1/2" (13ram)

U _UU CORDLESSDRiLUDRiVER/HAMMERDRiLL

SER.

TD REDUCETHERISKOF

AND UNDERSTAND INSTRUCTION MANUAL. USE ONLY

WiTH DEWALT BATTERIES. ALWAYS USE PROPER EYE

AND RESPIRATORY PROTECTION.

DEWALT iNDUSTRiAL TOOL CO., BALTIMORE, MO 21286 USA

FORS_EWALT www.DEWALT.cem

L ," J EDUR0 EAEL"TIT.EPRE ENTI..L,RELEOU,°!I

U I S UCCIO S. J

INJURY, USER MUST READ

J

Patent Notification

Manufactured under one or more of

the following U.S. patents:

6859013 6431289

6329788 6676557

6175211 6857983

6133713 6984188

6057608

6653815

Other patents pending.

SI VOUS AVEZ DES QUESTIONS OU VOULEZ NOUS FAIRE PART DE VOS COMMEN-

TAIRES CONCERNANT CET OUTIL OU TOUT AUTRE OUTIL DEWALT, COMPOSEZ SANS

FRAIS LE : 1 800 433-9258.

Rdgles de sdcuritd - Gdndralitds

_ AVERTISSEMENT : Lire toutes ces directives. Tout manquement aux directives

suivantes pose des risques de choc electrique, d'incendie et/ou de blessure

grave. Le terme , outil electrique _ dans tous les avertissements ci-apr#s se rapporte

votre outil electrique _ alimentation sur secteur (avec ill) ou par piles (sans ill).

CONSERVER CES DIRECTIVES

1) SI_CURITI_ -AIRE DE TRAVAIL

a) Maintenir I'aire de travail propre et bien eclairee. Les /ieux encombrCs ou sombres sont

propices aux accidents.

b) Ne pas faire fonctionner un outil electrique clans une atmosphere explosive, en

presence par exemple de poussieres, gaz ou liquides inflammables. Les outils

61ectriques peuvent engendrer des 6tincelles qui pourraient enflammer toute 6manation

ou poussibre ambiante.

c) Tenir les enfants, ou toute autre personne, eloignes pendant I'utilisation d'un outil

electrique. Toute distraction pourrait vous faire perdre la maftrise de ce demier.

2) SI_CURITI_ - I_LECTRICITI_

a) La fiche electrique de I'outil doff correspondre a la prise murale. Ne jamais

modifier la fiche en aucune faFon. Ne jamais utiliser de fiche d'adaptation avec un

outil electrique mis a la terre. L'utilisation de fiches d'origine et de prises appropri6es

r6duira les risques de choc 61ectrique.

b) Eviter tout contact corporel avec des elements mis a la terre comme tuyaux,

radiateurs, cuisinieres ou refrigerateurs. Les risques de choc #/ectrique augmentent

Iorsque le corps est mis a la terre.

c) Ne pas exposer les outils electriques a la pluie ou a I'humidite. Toute p#n#tration d'un

outil #lectrique par un liquide augmente les risques de choc #lectrique.

d) Ne pas utiliser le cordon de faFon abusive. Ne jamais utiliser le cordon pour

transporter, tirer ou debrancher un outil electrique. Proteger le cordon de la chaleur,

de I'huile et de tout bord tranchant ou piece mobile. Les cordons endommag#s ou

emm61#s augmentent les risques de choc #lectrique.

e) Lors de I'utilisation d'un outil electrique a I'exterieur, n'utiliser que des railonges

conFues pour I'exterieur. L'utilisation d'une rallonge conoue pour I'ext#rieur r#du# les

risques de choc #lectrique. En cas d'utilisation d'une rallonge, s'assurer que les valeurs

nominales de la rallonge utilis#e correspondent bien a celles de Ibutil alimentS. L'usage

d'une rallonge de calibre insuffisant causera une chute de tension entrMnant perte de

puissance et surchauffe. Le tableau ci-dessous illustre les calibres a utiliser selon la

Iongueur de rallonge et I'intensit# nominale indiqu#e sur la plaque signal#tique. En cas de

doutes, utiliser le calibre suivant. Plus le calibre est petit, plus la rallonge peut supporter

de courant.

Calibre de fil minimum recommand6 pour les rallonges

Longueur totale de la rallonge

25 pi 50 pi 75 pi 100 pi 125 pi 150 pi 175 pi

7,6 m 15,2 m 22,9 m 30,5 m 38,1 m 45,7 m 53,3 m

Calibre AWG

18 18 16 16 14 14 12

3) SI_CURITI_ PERSoNNELLE

a) Rester vigilant en tout temps et faire preuve de jugement pendant I'utilisation d'un

outil electrique. Ne pas utiliser d'outil electrique en cas de fatigue ou sous I'influ-

ence de drogues, d'alcool ou de medicaments. Tout moment d'inattention pendant

I'utilisation d'un outil _lectrique pose des risques de blessure grave.

b) Utiliser le materiel de securite approprie. Toujours porter des lunettes de protection.

Le fait de porter un masque anti-poussibres, des chaussures antid_rapantes, un casque

de s#curit# ou des protecteurs auditifs Iorsque la situation le requiert r#duira les risques

de blessure.

c) E:viter tout demarrage accidenteL S'assurer que I'interrupteur est en position

d'arr6t avant tout branchement. Transporter un outil le doigt sur I'interrupteur ou

brancher un outil #lectrique alors que I'interrupteur est en position de marche invite les

accidents.

d) Retirer toute cle de reglage avant de demarrer I'outil. Une cl_ laiss_e sur une pibce

rotative d'un outil #lectrique pose des risques de blessure.

e) Ne pas effectuer de travaux hors de portee. Les pieds doivent rester bien ancres au

sol afin de maintenir son equilibre en tout temps. Cela permet de mieux maftriser I'outil

#lectrique dans les situations impr#vues.

f) Porter des vCtements appropries. Ne pas porter de vCtements amples ni de bijoux.

Maintenir cheveux, vCtements et gants eloignes des pieces mobiles. V#tements

amples, bijoux ou cheveux longs risquent de rester coinc_s clans ces pibces mobiles.

Prendre des precautions autour des #vents car ils recouvrent des pibces mobiles.

g) Lorsque un dispositif de connexion a un systeme de depoussierage ou d'elimina-

tion est fourni, s'assurer qu'il est connecte et utilise correctement. L'uti/isationde ces

dispositifs peut r_duire les risques engendr_s par les poussibres.

4) UTILISATION ET ENTRETIEN DES OUTILS I_LECTRIQUES

a) Ne pas forcer un outil electrique. Utiliser I'outil approprie au travail en cours. L'outil

appropri# effectuera un meilleur travail, de fa_on plus s_re eta la vitesse pour laquelle il

a#t# conou.

b) Ne pas utiliser un outil electrique dont I'interrupteur est defectueux. Tout appareil

dont I'interrupteur est d#fectueux est dangereux et doit #tre r#par#.

c) Debrancher la fiche du secteur et/ou le bloc-piles de I'outil electrique avant de faire

tout reglage ou changement d'accessoire, ou avant de ranger ce dernier. Ces

mesures preventives r#duisent les risques de d#marrage accidentel de I'appareil.

d) Apres usage, ranger les outils electriques hors de la portee des enfants, et ne

permettre a aucune personne n'etant pas familiere avec un outil electrique (ou son

manuel d'instruction) d'utiliser ce dernier. Les outils peuvent _tre dangereux entre/es

mains des novices.

e) Entretenir les outils electriques. Verifier les pieces mobiles pour s'assurer qu'elles

sont bien alignees et tournent librement, qu'elles sont en bon etat et ne sont

affectees d'aucune condition susceptible de nuire au bon fonctionnement de I'outil.

En cas de dommage, faire reparer I'outil electrique avant toute nouvelle utilisation.

Bien des accidents sont causes par des outils mal entretenus.

f) Maintenir tout outil de coupe bien aiguise et propre. Les outils de coupe bien

entretenus et affOt#s sont moins susceptibles de se coincer et sont plus faciles a contr61er.

g) Utiliser un outil electrique, ses accessoires, meches, etc., conformement aux

presentes directives et suivant la maniere prevue pour ce type particulier d'outil

electrique, en tenant compte des conditions de travail et du travail a effectuer.

L'utilisation d'un outil #lectrique pour toute operation autre que celle pour laquelle il a#t#

conou est dangereuse.

5) UTILISATION ET ENTRETIEN DE L'OUTIL ALIMENT# PAR PILE

a) S'assurer que I'interrupteur se trouve a la position d'arrCt avant d'inserer le bloc-

piles. InsUrer un bloc-piles dans un outil _lectrique dont I'interrupteur est a la position de

marche risque de provoquer un accident.

b) Ne recharger I'outil qu'au moyen du chargeur precise par le fabricant. L'utilisation

d'un chargeur qui convient a un type de bloc-piles risque de provoquer un incendie s'il est

utilis# avec un autre type de bloc-piles.

c) Utiliser les outils electriques uniquement avec les blocs-piles con_us a cet effet.

L'utilisation de tout autre bloc-piles risque de causer des blessures ou un incendie.

d) Lorsque le bloc-piles n'est pas utilise, le tenir eloigne des objets metalliques,

notamment des trombones, de la monnaie, des cles, des clous, des vis, etc., qui

peuvent etablir une connexion entre les deux bornes. Mettre en court-circuit /es

bornes du bloc-piles peut provoquer des brOlures ou un incendie.

e) En cas d'utilisation abusive, un liquide peut gicler hors du bloc-pile& eviter tout

contact. Si un contact accidentel se produit, laver a grande eau. Si le liquide entre

en contact avec les yeux, obtenir des soins medicaux. Le liquide qui gicle hors du

bloc-piles peut provoquer des irritations ou des brDlures.

6) SERVICE

a) Faire entretenir les outils electriques par un reparateur qualifie en n'utilisant que

des pieces de rechange identiques. Cela permettra d'assurer I'int_grit_ de I'outil

#lectrique et la s#curit# de I'utilisateur.

R_gles de s_curit_ sp_cifiques pour les marteaux

perforateurs

• Tenir I'outil par sa surface de prise isolee clans une situation ob I'outil de coupe

peut entrer en contact avec un c#blage dissimule ou avec son propre cordon

d'alimentation. Tout contact avec un fil _ sous tension _,mettra _ sous tension _,les pibces

m#talliques de I'outil et #lectrocutera I'op#rateur de I'outil.

• Porter des protecteurs auditifs si une perceuse a percussion est utilisee. Une exposi-

tion au bruit peut entrMner une perte auditive.

• Utiliser les poignees auxiliaires fournies avec I'outil. Une perte de maftrise de I'outil peut

entrafner des blessures corporelles.

• Utiliser des brides de fixation ou tout autre dispositif de fixation permettant de

soutenir et de retenir la piece sur une plate-forme stable. Tenir la pibce avec la main ou

contre son corps est instable et risque de provoquer une perte de maftrise de Ibutil.

• Porter des protecteurs auditifs Iors de martelage sur des periodes prolongees. Une

exposition prolong#e a un bruit d'intensit# #lev# peut provoquer une perte auditive. Les

niveaux sonores #lev#s produits par le marteau perforateur pourraient provoquer une perte

auditive temporaire ou endommager gravement les tympans.

• Porter des lunettes de securite ou une autre protection oculaire.. Le martelage et la

perforation peuvent projeter des fragments. Les particules projet#es peuvent endommager

les yeux irr#versiblement.

• Toujours utiliser la poignee laterale fournie avec I'outil. Tenir fermement I'outil en tout

temps. Ne pas utiliser I'outil sans le tenir des deux mains.

• Les meches a maFonnerie et les outils deviennent chauds en cours de fonction-

nement. Pour les toucher, porter des gants.

AVERTISSEMENT : TOUJOURS uporter des lunettes de s#curit#. Les lunettes de vue ne

constituent PAS des lunettes de s#curit#. Utiliser #galement un masque facial ou anti-poussibre

si I'op#ration de d#coupe g#nb[e de la poussibre. TOUJOURS PORTER UN EQUIPEMENT DE

PROTECTION HOMOLOGUE :

• protection oculaire conforme a la norme ANSI Z87.1 (CAN/CSA Z94.3),

• protection auditive conforme a la norme ANSI $12.6 ($3.19) et

• protection des voies respiratoires conformes aux normes NIOSH/OSHA.

_AVERTISSEMENT : Certains outils #lectriques, tels que les sableuses, les scies, les meules,

les perceuses ou certains autres outils de construction, peuvent produire de la poussiere con-

tenant des produits chimiques susceptibles d'entrafner le cancer, des malformations cong#ni-

tales ou pouvant 6tre nocifs pour le systbme reproductif. Parmi ces produits chimiques, on

retrouve :

• le plomb dans les peintures a base de plomb,

• la silice cristalline dans les briques et le ciment et autres produits de maoonnerie,

• I'arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique (comme

I'ars#niate de cuivre et de chrome).

Le risque associ# a de telles expositions varie selon la fr#quence avec laquelle on effectue ces

travaux. Pour r_duire I'exposition a de tels produits, il faut travailler clans un endro# bien a_r_ et

utiliser le materiel de s#curit# appropri#, tel un masque anti-poussibres sp#cialement conou

pour filtrer les particules microscopiques.

• Eviter tout contact prolonge avec la poussiere soulevee par cet outil ou autres outils

electriques. Porter des vCtements de protection et nettoyer les parties exposees du

corps a I'eau savonneuse. S'assurer de bien se prot_ger afin d'_viter d'absorber par la

bouche, les yeux ou la peau des produits chimiques nocifs.

AAVERTISSEMENT : Cet outil peut produire et r#pandre de la poussibre susceptible de causer

des dommages s#rieux et permanents au systbme respiratoire. Toujours utiliser un appareil res-

piratoire anti-poussibres appropri# approuv# par le NIOSH ou I'OSHA. Diriger les particules

dans le sens oppos# du visage et du corps.

•&MISE EN GARDE : Apres utilisation, ranger I'outil sur son c6te sur une surface stable

la ob il ne pourra faire ni trebucher ni tomber personne. Bien que certains outils munis d'un

gros bloc-pile puissent 6tre places a la verticale, dans cette position, ils peuvent facilement 6tre

renvers#s.

i_MISE EN GARDE : Porter un appareil de protection personnel anti-bruit approprie

durant I'utilisation. Sous certaines conditions et pendant toute la dur#e de I'utilisation, le bruit

#manant de ce produit pourrait contribuer a la perte d'audition.

• L'etiquette apposee sur I'outil peut afficher les symboles suivants. Ces symboles et leurs def-

initions sont les suivants :

V.................. volts

Hz ................ hertz

min .............. minutes

.... ............courant continu

@ ................ Construction de classe I

(mis a la terre)

[] ................ Construction de classe II

(a double isolation)

A .................. ampbres

W.................. watts

,x, ................ courant altematif

no ................ aucune option a vide

.................. vitesse a vide

i_,.................. symbole d'avertissement

.../min ..........rotations ou altemance

altematifs par minute

BPM ............coups par minute

Directives de sdcuritd importantes pour les chargeurs

de piles

CONSERVER CES DIRECTIVES : Ce manuel contient des directives de s#curit# importantes

sur les chargeurs de piles.

• Avant d'utiliser le chargeur, lire toutes les directives et les indications d'avertissement

figurant sur le chargeur, le bloc-piles et le produit utilis# avec le bloc-piles.

_AVERTISSEMENT : Risque de choc. E-viter la p#n#tration de tout liquide dans le chargeur.

_,MISE EN GARDE : Risque de brDlure. Pour r#duire le risque de blessures, charger seulement

les piles DEWALT. D'autres types de piles peuvent exploser et causer des blessures corporelles

et des dommages.

,&MISE EN GARDE : Sous certaines conditions, Iorsque le chargeur est branch_ au bloc d'afi-

mentation, le chargeur peut 6tre court-circuit# par des corps #trangers. Tout corps #tranger con-

ducteur, tel que, mais sans s'y limiter, la laine d'acier, le papier d'aluminium, ou toute accumu-

lation de particules m#talliques, doit 6tre maintenu a distance des ouvertures du chargeur.

Debrancher systematiquement le chargeur si aucun bloc-piles n'y est insere. Debrancher le

chargeur avant tout nettoyage.

• NE PAS charger le bloc-piles au moyen de tout autre chargeur que ceux mentionnes

clans le present manuel Le chargeur et le bloc-piles sont sp#cialement conous pour #tre

utilis#s ensemble.

• Ces chargeurs ne sont pas prevus pour 6tre utilises a d'autres fins que celles de

charger les piles rechargeables DEWALT. Toute autre utilisation risque de provoquer un

incendie, un choc #lectrique ou une #lectrocution.

• Ne pas exposer le chargeur a la pluie ou a la neige.

• Tirer sur la fiche plut6t que sur le cordon pour debrancher le chargeur. Cela permet

de r#duire le risque d'endommager la fiche ou le cordon d'alimentation.

• S'assurer que le cordon est situe en lieu sOr de maniere ace que personne ne marche

ni ne trebuche dessus ou ace qu'il ne soit pas endommage ni soumis a une tension.

• Ne pas utiliser de rallonge a moins que cela ne soit absolument necessaire.

L'utilisation d'une rallonge inadequate risque d'entrMner un incendie, un choc #lectrique

ou une #lectrocution.

• La rallonge utilisee dolt presenter un calibre adequat (AWG ou calibrage americain

normalise des ills) pour assurer la securite. Plus le num#ro de calibre de fil est petit et

plus sa capacit# est grande, par exemple un calibre 16 a plus de capacit# qu'un calibre 18.

Si plus d'une rallonge est utilis#e pour obtenir la Iongueur totale, s'assurer que chaque ral-

Ionge pr#sente au moins le calibre de fil minimum.

• Ne pas mettre d'objet sur le chargeur ni mettre ce dernier sur une surface molle

pouvant obstruer les fentes de ventilation et ainsi provoquer une chaleur interne

excessive. Mettre le chargeur a un endroit #loign# de toute source de chaleur. La ventila-

tion du chargeur se fait par les fentes pratiqu#es dans les parties sup#rieures et inf#rieures

du boftier.

Page 4

• Ne pas monter le chargeur sur un mur ni le fixer de maniere permanente sur une

surface quelconque. Le chargeur est destin6 a une utilisation sur une surface plane et

stable (c.-a-d. un dessus de table).

• Ne pas faire fonctionner le chargeur si la fiche ou le cordon est endommage; les

remplacer imm6diatement.

• Ne pas faire fonctionner le chargeur s'il a reFu un choc violent, s'il est tombe ou s'il a

ete endommage de quelque maniere que ce soit. Apporter le chargeur a un centre de

r6paration autoris6.

• Ne pas demonter le chargeur; I'apporter a un centre de reparation autorise Iorsqu'un

entretien ou une reparation est requise. Un chargeur mal r6assembl6 peut causer un choc

61ectrique, une 61ectrocution ou un incendie.

• Debrancher le chargeur avant de le nettoyer. Cela permettra de reduire le risque de

choc electrique. Retirer le bloc-piles ne r6duira pas le risque.

• Ne JAMAIS relier 2 chargeurs ensemble.

• Le chargeur est conFu pour 6tre alimente en courant domestique standard (120 V).

Ne pas utiliser une tension superieure pour le chargeur.

CONSERVER CES DIRECTIVES

Introduction

Le chargeur DC9000 est con_u pour charger le bloc-piles DEWALT en environ une heure. Ce

chargeur n'exige aucun ajustement et est con_u pour _tre aussi facile que possible. Placer tout

simplement votre bloc-piles dans la prise d'un chargeur branch6 et il se chargera automatique-

ment le bloc-piles.

Directives de s_curit_ importantes pour les blocs-piles

_AVERTISSEMENT : Pour un fonctionnement sans danger, lire ce manuel et les manuels

initialement foumis avec I'outil avant d'utiliser le chargeur.

Pour la commande d'un bloc-piles de rechange, s'assurer d'inclure le num6ro de catalogue et

la tension. Consulter le tableau figurant & la derni_re page du pr6sent manuel pour connaftre la

compatibilit6 des chargeurs et des blocs-piles.

Le bloc-piles n'est pas compl_tement charg6 & la sortie de la bofte pliante. Avant d'utiliser

le bloc-piles et le chargeur, lire les directives de s6curit6 ci-apr_s. Suivre les consignes de

chargement d6crites.

LIRE TOUTES LES DIRECTIVES

• Ne pas incinerer le bloc-piles m6me s'il est tres endommage ou completement use. Le

bloc-piles peut exploser dans un feu. Des vapeurs et des matibres toxiques 6manent Iorsque

les blocs-piles au lithium-ion sont br_16s.

• Ne pas charger ou utiliser une pile clans un milieu deflagrant, soit en presence de

liquides inflammables, de gaz ou de poussiere. Ins6rer ou retirer une pile du chargeur

peut enflammer la poussibre ou des 6manations.

• Si le contenu de la pile entre en contact avecla peau, laver immediatement la zone

touchee au savon doux eta I'eau. Si le liquide de la pile entre en contact avec les yeux,

rincer I'oeil ouvert a I'eau pendant 15 minutes ou jusqu'a ce que I'irritation cesse. Si des soins

m6dicaux sont n6cessaires, 1'61ectrolytede la pile est compos6 d'un m61ange de carbonates

organiques liquides et de sels de lithium.

• Le contenu des cellules de pile ouvertes peut provoquer une irritation respiratoire.

Exposer la personne a de I'air frais. Si les sympt6mes persistent, obtenir des soins m6dicaux.

_4VERTISSEMENT : Risque de br_lure. Le liquide de la pile peut s'enflammer s'il est expos6

des 6tincelles ou a une flamme.

• Charger les blocs-piles uniquement au moyen de chargeurs DEWALT.

• NE PAS 6clabousser le bloc-piles ou I'immerger dans I'eau ou tout autre liquide.

• Ne pas ranger ni utiliser I'outil et le bloc-piles a un endroit ob la temperature peut

atteindre ou depasser les 40,5 °C (105 °F) (comme clans les remises exterieures ou les

b#timents metalliques I'ete).

_A VERTISSEMENT : Ne jamais ouvrir le bloc-piles pour quelque raison que ce soit. Si le bofti-

er du bloc-piles est fissur# ou endommag#, ne pas I'ins#rer dans un chargeur. Ne pas broyer,

#chapper ou endommager le bloc-piles. Ne pas utiliser un bloc-piles ou un chargeur qui a re_u

un choc violent, qui est tomb#, #cras# ou qui a #t# endommag# de quelque manibre que ce

soit (p. ex. perc# par un clou, frapp# d'un coup de marteau, march# dessus). Les blocs-piles

endommag#s doivent 6tre envoy#s au centre de r#paration pour 6tre recycles.

_4VERTISSEMENT :Risque d'incendie Ne pas ranger ni transporter les piles de maniere

ce que des objets metalliques puissent entrer en contact avec les bornes exposees des

piles. Par exemple, ne pas mettre les piles dans un tablier, une poche, une bMte a outils, une

bofte de n#cessaire de produit, un tiroir, etc. avec des clous, des vis, des cl#s etc. Le transport

des piles peut causer un incendie si les bornes des piles entrent en contact involon-

tairement avec des matieres conductrices comme des cles, de la monnaie, des outils

manuels et d'autres elements semblables. La Hazardous Material Regulation du d#parte-

ment am#ricain des transports interdit en fait le transport des piles pour le commerce et dans

les avions (ex. : piles emball#es clans des valises et des bagages a main) ,4 MOINS qu'elles

soient bien protegees contre les courts-circuits. Pour le transport des piles individuelles,

s'assurer que les homes sont protegees et bien isol#es contre toute matibre pouvant entrer en

contact avec elles et causer un court-circuit.

Le sceau SRPRC _c

Le sceau SRPRC M°(Soci6t6 de Recyclage des Piles Rechargeables au Canada)

sur la pile au lithium-ion (ou sur le bloc-piles) indique que le cot]t de recyclage de

cette pile (ou bloc-piles) & la fin de sa vie utile a 6t6 pay6 par DEWALT.

SRPRC Mcen collaboration avec DEWALT et d'autres utilisateurs de piles ont 6tabli

aux 12tats-Unis et au Canada des programmes facilitant la cueillette des piles au

lithium-ion d6charg6es. Aidez-nous & prot6ger I'environnement et & conserver nos ressources

naturelles en retournant les piles au lithium-ion 6puis6es & un centre de r6paration DEWALT ou

au d6taillant de votre r6gion pour qu'elles soient recycl6es. II est aussi possible de communi-

quer avec le centre de recyclage de votre r6gion pour obtenir des informations sur les lieux de

d6p6t des piles 6puis6es.

SRPRC Mcest une marque deposee de la Societe de recyclage despiles rechargeablesau Canada,

Recommandations de rangement

1. Le meilleur endroit de rangement est celui qui est frais et sec, loin de toute lumi_re directe

et de temp6rature excessive (chaleur ou froid).

2. Un long entreposage n'endommagera pas le bloc-piles ou le chargeur. Sous de bonnes

conditions, ils peuvent _tre rang6s jusqu'& 5 ans ou plus.

Chargeur

Votre bloc-piles exige un chargeur d'une heure DEWALT. S'assurer de bien lire les direc-

tives de s6curit6 avant d'utiliser le chargeur. Consulter le tableau figurant & I'arri_re de ce

manuel pour connaftre la compatibilit6 des chargeurs et des blocs-piles.

Procedure de charge

1. Brancher le chargeur dans une prise appropri6e avant d'ins6rer le bloc-piles.

2. Ins6rer le bloc-piles dans le chargeur. Le chargeur est dot6 d'une jauge de carburant & trois

lumi_res qui clignotera selon 1'6tatde charge du bloc-piles.

3. La fin de la charge sera indiqu6e par les trois voyants rouges qui demeureront continuelle-

ment allum6s. Le bloc-piles est charg6 & plein et peut _tre utilis6 ou laiss6 dans le chargeur

& ce moment.

@¢ ¢ [] 0 % - 33 % ler voyant clignote

_@e D 33 % - 66 % ler voyant allume, 2_voyant clignote

_@la 66 % - 99 % 1% 28 voyants allumes, 38 voyant clignote

• e | 1O0 % 1 er, 2_, 3_,voyants allumes

Diagnostique de chargeur

Ce chargeur est congu pour d6tecter certains probl_mes pouvant survenir avec les blocs-piles

ou le chargeur. Les probl_mes sont indiqu6s par trois voyants clignotant ensemble dans des

motifs diff6rents.

PROBL#ME AVEC LE SECTEUR

Lorsque le chargeur est utilis6 avec certaines sources d'alimentation portatifs comme des

g6n6ratrices ou des sources qui font la conversion de c.c. & c.a., le chargeur peut suspendre

temporairement son fonctionnement. Les trois voyants rouges clignoteront ensemble avec deux

clignotements rapides suivis par une pause. Cela indique que la source d'alimentation est

hors tol6rance.

PILE EN MAUVAIS I_TAT

Le chargeur peut aussi d6tecter les piles faibles ou endommag6es. Les trois voyants rouges

clignoteront ensemble avec un clignotement rapide. La pile ne se chargera plus et doit _tre

retourn6e & un centre de r6paration ou & un site de collecte pour le recyclage.

CHARGEUR EN MAUVAIS I_TAT

Le chargeur d6tectera s'il ne fonctionne pas correctement. Les trois voyants rouges clignoteront

ensemble avec un clignotement rapide suivi d'un long clignotement. Le chargeur ne fonc-

tionnera plus et doit _tre retourn6 & un centre de r6paration autoris6 ou remplac6.

PILE LAISSI_ DANS LE CHARGEUR

Le chargeur et le bloc-piles peuvent _tre laiss6s branch6s avec les voyants rouges allum6s

ind6finiment. Le chargeur maintiendra le bloc-piles charg6 & plein et en bon 6tat. Ce chargeur

comprend un mode de mise au point automatique qui 6galise ou 6quilibre chaque cellule du

bloc-piles pour lui permettre de fonctionner & son rendement optimum. Les blocs-piles doivent

_tre r6gl6s chaque semaine ou Iorsque la pile ne fonctionne plus de mani_re optimale. Pour

utiliser le mode de mise au point automatique, mettre le bloc-piles dans le chargeur et 'y

laisser pendant au moins 8 heures.

Remarques de chargement importantes

1. Pour augmenter la dur6e de vie du bloc-piles et optimiser son rendement, le charger & une

temp6rature entre 18 -0C et 24 -0C (65 -0F- 75 -0F). NE PAS charger le bloc-piles & des tem-

p6ratures inf6rieures & 4,5 -0C(40-0F) ou sup6rieures & 40,5 -0C(105-0F).Ces consignes sont

importantes et permettent d'6viter d'endommager le bloc-piles.

2. Le chargeur et le bloc-piles peuvent devenir chaud au toucher pendant la charge. II s'agit

d'un 6tat normal et n'indique pas un probl_me. Pour faciliter le refroidissement du bloc-piles

apr_s son utilisation, 6viter de mettre le chargeur ou le bloc-piles dans un endroit chaud

comme dans une remise m6tallique ou une remorque non isol6e.

3. Si le bloc-piles ne se charge pas ad6quatement :

a. V6rifier le courant & la prise en branchant une lampe ou un autre appareil 61ectrique.

b. V6rifier si la prise est reli6e & un interrupteur de lumi_re qui la met hors tension Iorsque

vous 6teignez les lumi_res.

c. D6placer le chargeur et le bloc-piles & un endroit oQ la temp6rature ambiante est entre

18 -0Cet 24 -0C(65 -OF- 75 -OF).

d. Si le probl_me persiste, apporter ou envoyer routil, le bloc-piles et le chargeur au centre

de r6paration de votre r6gion.

4. Le bloc-piles doit _tre recharg6 Iorsqu'il n'arrive pas & produire suffisamment de puissance

pour des travaux qui 6taient facilement r6alis6s pr6c6demment. NE PAS CONTINUER &

utiliser le bloc-piles dans ces conditions. Suivre les proc6dures de charge. Vous pouvez

6galement recharger un bloc-piles partiellement utilis6 chaque fois que vous le souhaitez

sans effet nuisible sur le bloc-piles.

5. Tout corps 6tranger conducteur, tel que, mais sans s'y limiter, la laine d'acier, le papier d'a-

luminium, ou toute accumulation de particules m6talliques, doit _tre maintenu & distance

des ouvertures du chargeur. D6brancher syst6matiquement le chargeur si aucun bloc-piles

n'y est ins6r6. D6brancher le chargeur avant tout nettoyage.

6. Ne pas geler ni immerger le chargeur dans I'eau ou dans tout autre liquide.

i_AVERTISSEMENT : Risque de choc. Eviter la p#n#tration de tout liquide dans le chargeur.

_ MISE EN GARDE : Ne jamais essayer d'ouvrir le bloc-piles pour quelque raison que ce soit.

Si le boftier de plastique du bloc-piles est bris# ou fissure, le retoumer a un centre de r#para-

tion pour _tre recycle.

CARACTERISTIQUES ET FONCTIONNALITES CLES

Ddtente a vitesse variable (fig. 1)

Pour d6marrer I'outil, presser la d6tente (A). Pour 1'6teindre, simplement la rel&cher. L'outil est

dot6 d'un frein, d_s le rel&chement complet de la d6tente, le mandrin s'arr_tera.

REMARQUE : un usage continu dans la plage & vitesse variable n'est pas recommand6. Cette

pratique pourrait endommager la d6tente et devrait _tre 6vit6.

Bouton de commande marche avant/marche arri_re

(fig. 1)

Un bouton de commande marche avant/marche arri_re (B) d6termine le sens de rotation de

I'outil et sert aussi de bouton de verrouillage.

Pour s61ectionner la marche avant, rel&cher la d6tente et enfoncer le bouton de commande

marche avant/marche arri_re vers le c6t6 droit de I'outil.

Pour la marche arri_re, enfoncer le bouton de commande marche avant/marche arri_re vers le

c6t6 gauche de I'outil.

La position du centre du bouton de commande verrouille I'outil en position d'arr6t. Toujours

rel&cher la d6tente avant de changer la position du bouton de commande.

REMARQUE : au premier d6marrage de I'outil, apr_s un changement de direction, il est possi-

ble qu'un d6clic se fasse entendre. Le d6clic est normal et n'indique pas de probl_me.

Bague de commande de mode

La perceuse est munie d'une hague de commande de mode autonome (fig. 1, C) pour passer

entre les modes per£age et vissage.

VISSAGE (FIG. 2)

1. ,&,I'aide du bouton de changement de rapport & trois vitesses (E) sur le dessus de I'outil,

s61ectionner la gamme de vitesse et de couple d6sir6e qui convient & I'application planifi6e.

Pour ajuster le niveau de couple sur la bague d'embrayage, le r6gler & un niveau plus bas

pour s'assurer que la vis sera serr6e au couple voulu.

REMARQUE : utiliser le niveau de couple de serrage le plus bas exig6 pour bien asseoir la

vis & la profondeur d6sir6e. Plus le nombre est petit, plus le couple produit est bas.

2. Tourner la bague de commande de mode (C) de sorte que la ligne de la saillie (F) s'aligne

avec le symbole de la vis.

3. R6gler la bague de r6glage du couple (D) & la valeur appropri6e pour le couple de serrage

recherch6.

REMARQUE : r6gler la bague de r6glage du couple & n'importe quelle valeur et changer

entre les modes vissage et per£age & I'aide de la bague de commande de mode.

PER(_AGE (FIG. 3)

_MISE EN GARDE : peu importe la position de la bague de r_glage du couple, la perceuse

ne se d#brayera pas Iorsque la bague de commande de mode pointe sur le mode

perceuse/marteau perforateur (D).

Tourner la hague de commande de mode (C) de sorte que la ligne de la saillie (F) s'aligne

avec le symbole de la perceuse.

REMARQUE : r6gler la hague de r6glage du couple (D) & n'importe quelle valeur.

MARTEAU PERFORATEUR (FIG. 4)

Tourner la hague de commande de mode (C) de sorte que la ligne de la saillie (F) s'aligne

avec le symbole du marteau perforateur puis tourner la hague de r6glage du couple (D) pour

aligner le symbole du marteau avec la ligne de la saillie (F).

Bague de r_glage du couple (fig. 2)

L'outil est dot6 d'un m6canisme de vissage & couple r6glable pour le vissage et le retrait d'une

vaste gamme de vis de formes et de tailles vari6es de m_me qu'un m6canisme de martelage

pour le per£age de magonnerie. On retrouve des nombres et un symbole de marteau tout

autour de la bague de r6glage du couple (D). L'embrayage se r_gle & I'aide des nombres pour

produire une gamme de couple. Plus le nombre sur la bague est 61ev6 et plus le couple est

61ev6. On peut ainsi visser une plus grande vis. Pour s61ectionner un des nombres, tourner la

bague jusqu'& ce que le nombre voulu s'aligne avec la fl_che.

Embrayage a trois vitesses (fig. 2)

Pour une polyvalence accrue, la fonction & trois vitesses de I'outil vous permet de changer de

vitesse. Pour s61ectionner la vitesse 1 (le couple le plus 61ev6de I'outil), 6teindre routil et le laisser

s'immobiliser compl_tement. Glisser le bouton de changement de rapport (E) compl_tement vers

la gauche. On retrouve la vitesse 2 (vitesse et couple moyen) en position mitoyenne et la vitesse

3 (vitesse la plus 61ev6e)avec le bouton compl_tement & droite.

REMARQUE : ne pas changer de vitesse avec I'outil en fonctionnement. Toujours attendre que

I'outil s'immobilise compl_tement avant de changer I'embrayage. En cas de difficult6 avec le

changement d'embrayage, v6rifier si le bouton de changement de rapport est bien enclench6 &

I'une des trois options de vitesses.

Fonctionnement du mandrin autobloquant (fig. 5 a 7)

AVERTISSEMENT : ne pas essayer de resserrer les meches (ou tout autre accessoire) en

saisissant la partie avant du mandrin et en mettant I'outil en marche. Cette pratique pourrait

endommager le mandrin et provoquer des blessures corporelles. Toujours verrouiller la d#tente

lots du changement d'accessoires.

AVERTISSEMENT : toujours s'assurer que la mbche est bien fix#e avant de d#marrer

I'outil. Une mbche desserr#e peut _tre #ject#e de I'outil et causer des blessures corporelles.

INSERTION D'UNE M#CHE OU AUTRE ACCESSOIRE

1. Verrouiller la d6tente en position d'ARRI_T.

2. Saisir le manchon du mandrin (G) d'une main et utiliser I'autre pour tenir I'outil comme

indiqu6 & la figure 5. Tourner le manchon en sens antihoraire (vue de I'avant) pour ouvrir

suffisamment les m&choires du mandrin.

3. Ins6rer d'environ 19 mm (3/4 po) la m_che voulue ou tout autre accessoire dans le mandrin

comme indiqu6 & la figure 6. Saisir de nouveau le manchon du mandrin fermement d'une

main et le tourner en sens horaire (vue de I'avant) alors que I'autre main tient le corps de

I'outil. Tourner le manchon en sens horaire jusqu'& ce qu'il bloque comme indiqu6 & la fig-

ure 7. D_s la mise en marche de la perceuse en marche avant, les m&choires du mandrin

continueront de se resserrer automatiquement sur la m_che pour maximiser la force de

pr6hension de celles-ci.

Pour d6gager I'accessoire, r6p6ter 1'6tape2.

FONCTIONNEMENT

Installation et retrait du bloc-piles (fig. 8, 9)

REMARQUE : s'assurer que le bloc-piles est enti_rement charg6.

_MISE EN GARDE : s'assurer que le bouton de verrouillage (B) est bien engag# pour

emp6cher I'utilisation de la d#tente Iors de I'installation et du retrait du bloc-piles (fig 1).

Pour rinstaller darts la poign6e de routil, aligner la base de I'outil avec les rails situ6s &

I'int6rieur de la poign6e et glisser le bloc-piles fermement dans la poign6e jusqu'& ce qu'on

entende un d6clic indiquant qu'il est bien enclench6 (fig. 8).

Pour retirer le bloc-piles hors de routil, appuyer sur le bouton de d6gagement et tirer

fermement le bloc-piles hors de la poign6e. L'ins6rer dans le chargeur (fig. 9) comme d6crit &

la rubrique de charge du bloc-piles du pr6sent mode d'emploi.

Poign_e lat_rale

MISE EN GARDE : toujours utiliser I'outil avec la poignee laterale

bien assemblee. Tenir I'outil des deux mains pour obtenir une plus grande

maftrise de I'outil.

La poign6e lat6rale se fixe & I'avant du carter d'engrenages comme illustr6

et peut _tre tourn6e & 360 ° pour permettre une utilisation de la main droite

ou gauche. S'assurer que la poign6e lat6rale soit suffisamment serr6e pour

r6sister &la torsion de I'outil si I'accessoire se coince ou que le moteur cale.

Pour mieux maftriser I'outil si le moteur cale, bien saisir la poign6e lat6rale

par son extr6mit6.

Si le module ne comporte pas de poign6e lat6rale, saisir la poign6e de la perceuse avec une

main et placer rautre sur le bloc-piles.

Fonctionnement en mode perceuse

1. S61ectionner la gamme de vitesses et de couples & I'aide du bouton de changement de

rapport afin de correspondre & la vitesse et au couple requis pour I'op6ration pr6vue.

2. Pour le BOIS, utiliser des m_ches &vrille, des forets &trois pointes, des m_ches &bois pour

outil 61ectrique ou des scies- cloches. Pour le MC:TAL, utiliser des forets h61icofdaux en acier

&coupe rapide ou des scies-cloches. Utiliser un lubrifiant de coupe pour percer les m6taux.

Seuls la fonte et le laiton doivent _tre perc6s & sec.

3. Toujours exercer une pression en ligne droite par rapport au foret. Exercer suffisamment de

pression pour faire mordre le foret mais ne pas appuyer &I'exc_s pour 6viter de bloquer le

moteur ou de faire d6vier le foret.

4. Tenir I'outil fermement des deux mains pour contr61er la torsion de la perceuse.

5. SI LA PERCEUSE SE BLOQUE, le probl_me est g6n6ralement attribuable & une sur-

charge. REL,&,CHER IMMC:DIATEMENT LA DETENTE, retirer la m_che du trou perc6 et

d6terminer la cause du blocage. NE PAS APPUYER DE FA(_ON RI2pI2TI2E SUR LA

DI2TENTE POUR TENTER DE SUPPRIMER LE BLOCAGE CAR CETTE PRATIQUE

PEUT ENDOMMAGER LA PERCEUSE.

6. Faire tourner la perceuse pour retirer la m_che du trou perc6. Cette pratique emp_che la

m_che de se coincer.

Fonctionnement en mode marteau perforateur

1. Pour effectuer le per_age, exercer juste assez de pression sur le marteau pour I'emp_cher

de rebondir excessivement ou pour 6viter que la m_che ne se ,, soul_ve _>au-dessus de la

surface & percer. Une trop grande pression r6duira la vitesse de I'outil, en diminuera le

rendement et pourrait causer une surchauffe.

2. Maintenir I'outil bien droit, en s'assurant que la m_che soit & un angle droit avec la surface

& percer. Ne pas exercer de pression lat6rale sur la m_che en cours de per£age. En effet,

cette pratique bouchera les cannelures de la m_che et diminuera le r6gime de I'outil.

3. Lors de per£age de trous profonds, si la vitesse du marteau commence & chuter, retirer

partiellement la m_che du trou avec le moteur toujours en marche pour d6gager les d6bris

du trou.

4. Pour la MA(_ONNERIE, utiliser des m_ches & pointe carbur6e ou des m_ches & ma_on-

nerie. Une 6vacuation continue de poussi_re indique que votre vitesse de per£age est

ad6quate.

Page 5

Fonctionnement en mode vissage