Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DEWALT • www.dewalt.com

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DC300 36V Cordless Circular Saw

DC310 28V Cordless Circular Saw

DC300 Scie circulaire sans fil de 36 volts

DC310 Scie circulaire sans fil de 28 volts

DC300 Sierra circular inalámbrica de 36 V

DC310 Sierra circular inalámbrica de 28 V

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

Page 2

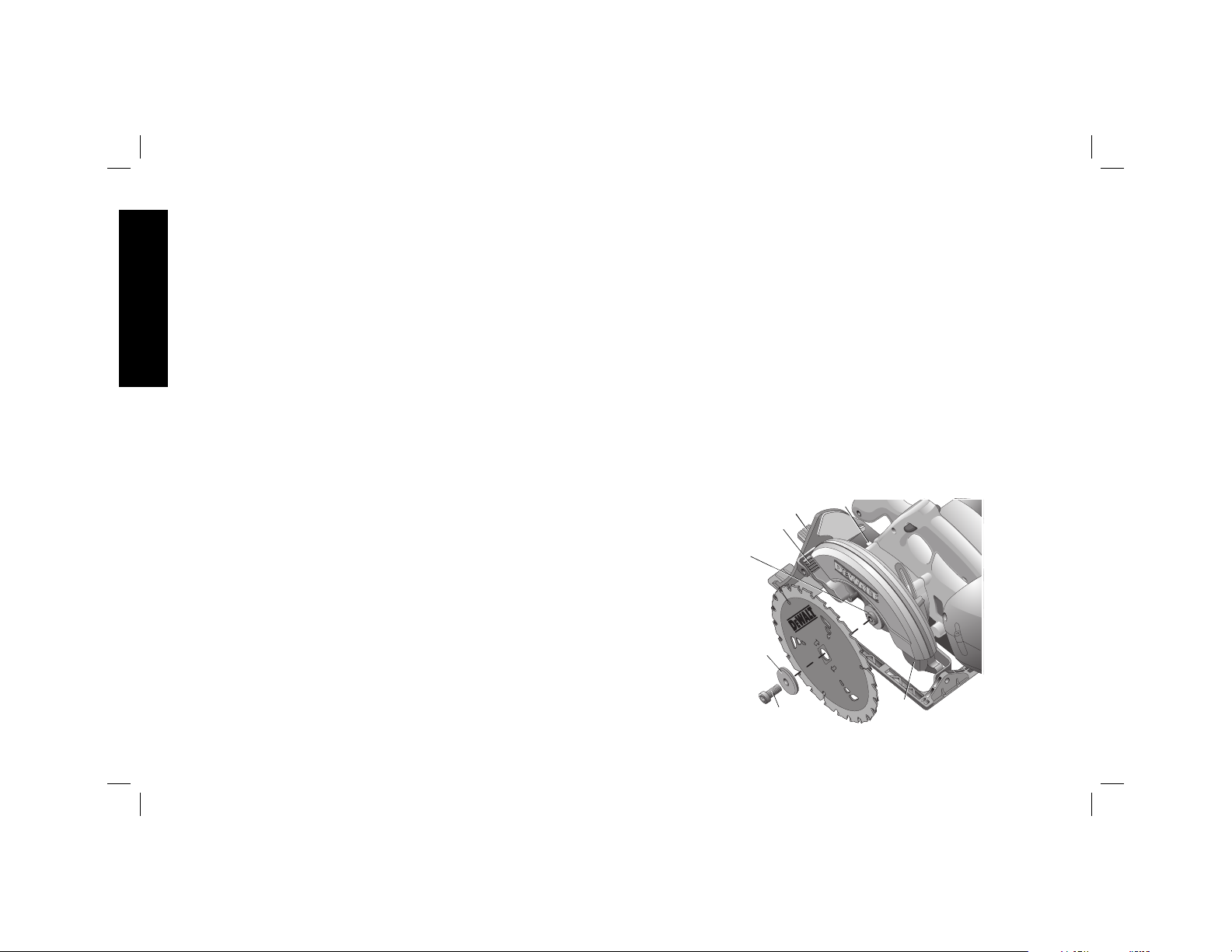

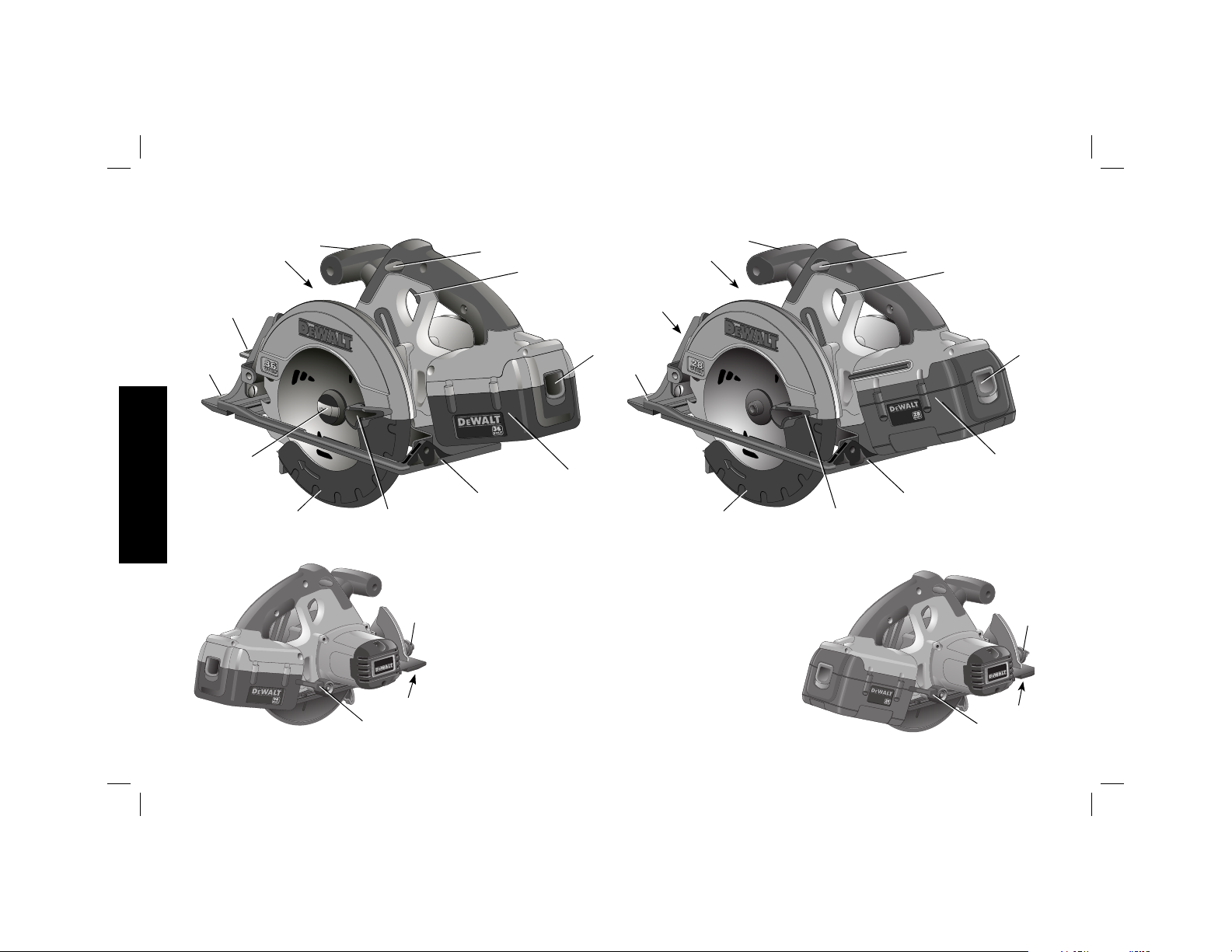

FIG. 1

DC300, 36 Volt 4000 RPM

M

L

DC310, 28 Volt 3800 RPM

A

B

M

L

A

B

J

English

I

J

N

I

H

E

G

F

A. SWITCH LOCK-OFF

BUTTON

B. TRIGGER SWITCH

C. BATTERY PACK

D. DEPTH ADJUSTMENT

J J

K

D

LEVER

E. SHOE

F. LOWER GUARD

RETRACTING LEVER

G. LOWER GUARD

H. KEYLESS BLADE

CLAMP (DC300 ONLY)

C

E

G

I. KERF INDICATOR

J. BEVEL ADJUSTMENT

LEVER (DC300)

OR KNOB (DC310)

K. ADJUSTMENT SCREW

L. BLADE LOCK BUTTON

(not shown)

M. AUXILARY HANDLE

N. BATTERY RELEASE

BUTTON

F

N

C

K

D

1

Page 3

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

D

EWALT (1-800-433-9258)

EWALT TOOL, CALL US TOLL FREE AT: 1-800-4-

General Safety Rules

WARNING! Read all instructions. Failure to follow all

instructions listed below may result in electric shock, fire

and/or serious injury. The term “power tool” in all of the

warnings listed below refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock. Replace

or repair damaged cords. Make sure your extension cord is

in good condition. Use only 3-wire extension cords that have

3-prong grounding-type plugs and 3-pole receptacles that

accept the tool’s plug.

e) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock. When using

an extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord will

cause a drop in line voltage resulting in loss of power and

overheating. The following table shows the correct size to

use depending on cord length and nameplate ampere rating.

If in doubt, use the next heavier gage. The smaller the gage

number, the heavier the cord.

Recommended Minimum Wire Size

for Extension Cords

Total Length of Cord

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Wire Size AWG

18 18 16 16 14 14 12

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use safety equipment. Always wear eye protection. Safety

equipment such as dust mask, non-skid safety shoes, hard

English

2

Page 4

hat, or hearing protection used for appropriate conditions will

reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is in the

off-position before plugging in. Carrying power tools with

your finger on the switch or plugging in power tools that have

the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the

English

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair can be caught in

moving parts. Air vents often cover moving parts and should

also be avoided.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of these devices can

reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do

not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding

of moving parts, breakage of parts and any other condition

that may affect the power tools operation. If damaged,

have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

g) Use the power tool, accessories and tool bits etc., in

accordance with these instructions and in the manner

intended for the particular type of power tool, taking

into account the working conditions and the work to be

performed. Use of the power tool for operations different from

those intended could result in a hazardous situation.

5) BATTERY TOOL USE AND CARE

a) Ensure the switch is in the off position before inserting

battery pack. Inserting the battery pack into power tools that

have the switch on invites accidents.

b) Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type of

battery pack may create a risk of fire when used with another

battery pack.

c) Use power tools only with specifically designated battery

packs. Use of any other battery packs may create a risk of

injury and fire.

d) When battery pack is not in use, keep it away from other

metal objects like paper clips, coins, keys, nails, screws,

or other small metal objects that can make a connection

from one terminal to another. Shorting the battery terminals

together may cause burns or a fire.

3

Page 5

e) Under abusive conditions, liquid may be ejected from

the battery, avoid contact. If contact accidentally occurs,

flush with water. If liquid contacts eyes, additionally seek

medical help. Liquid ejected from the battery may cause

irritation or burns.

6) SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

Additional Safety Rules for

Circular Saws

DANGER: Keep hands away from cutting area and blade. Keep

your second hand on auxiliary handle or motor housing. If both

hands are holding the saw, they cannot be cut by the blade.

• Keep your body positioned to either side of the blade, but

not in line with the saw blade. KICKBACK could cause the

saw to jump backwards (see KICKBACK).

• Do not reach underneath the work. The guard can not protect

you from the blade below the work.

• Adjust the cutting depth to the thickness of the workpiece.

Less than a full tooth of the blade teeth should be visible below

the workpiece.

• Never hold piece being cut in your hands or across your

leg. Secure the workpiece to a stable platform. It is important

to support the work properly to minimize body exposure, blade

binding, or loss of control.

• Check lower guard for proper closing before use. Do not

operate saw if lower guard does not move freely and close

instantly. Never clamp or tie the lower guard into the open

position. If saw is accidentally dropped, lower guard may be

bent. Raise the lower guard with the Retracting Handle and

make sure it moves freely and does not touch the blade or any

other part, in all angles and depths of cut.

• Check the operation and condition of the lower guard

spring. If the guard and the spring are not operating properly,

they must be serviced before use. Lower guard may operate

sluggishly due to damaged parts, gummy deposits, or a buildup of

debris.

• Lower guard should be retracted manually only for special

cuts such as “Pocket Cuts” and “Compound Cuts.” Raise

lower guard by Retracting Handle. As soon as blade enters

the material, lower guard must be released. For all other

sawing, the lower guard should operate automatically.

• Always observe that the lower guard is covering the blade

before placing saw down on bench or floor. An unprotected,

coasting blade will cause the saw to walk backwards, cutting

whatever is in its path. Be aware of the time it takes for the blade

to stop after switch is released.

• Hold tool by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring.

Contact with a “live” wire will make exposed metal parts of the tool

“live” and shock the operator.

• When ripping always use a rip fence or straight edge guide.

This improves the accuracy of cut and reduces the chance for

blade binding.

• Always use blades with correct size and shape (diamond

vs. round) arbor holes. Blades that do not match the mounting

hardware of the saw will run eccentrically, causing loss of control.

• Never use damaged or incorrect blade washers or bolts. The

blade washers and bolt were specially designed for your saw, for

optimum performance and safety of operation.

• Avoid cutting nails. Inspect for and remove all nails from

lumber before cutting.

CAUSES AND OPERATOR PREVENTION OF KICKBACK

• Kickback is a sudden reaction to a pinched, bound or misaligned

saw blade, causing an uncontrolled saw to lift up and out of the

workpiece toward the operator.

English

4

Page 6

• When the blade is pinched or bound tightly by the kerf closing

down, the blade stalls and the motor reaction drives the unit

rapidly back toward the operator.

• If the blade becomes twisted or misaligned in the cut, the teeth

at the back edge of the blade can dig into the top surface of the

wood causing the blade to climb out of the kerf and jump back

toward operator.

• Kickback is the result of tool misuse and/or incorrect operating

English

procedures or conditions and can be avoided by taking proper

precautions as given below:

• Maintain a firm grip with both hands on the saw and

position your body and arm to allow you to resist kickback

forces. Kickback forces can be controlled by the operator, if

proper precautions are taken.

• When blade is binding, or when interrupting a cut for any

reason, release the trigger and hold the saw motionless

in the material until the blade comes to a complete stop.

Never attempt to remove the saw from the work or pull the

saw backward while the blade is in motion or kickback may

occur. Investigate and take corrective actions to eliminate the

cause of blade binding.

• When restarting a saw in the workpiece, center the saw

blade in the kerf and check that the saw teeth are not

engaged into the material. If saw blade is binding, it may walk

up or kickback from the workpiece as the saw is restarted.

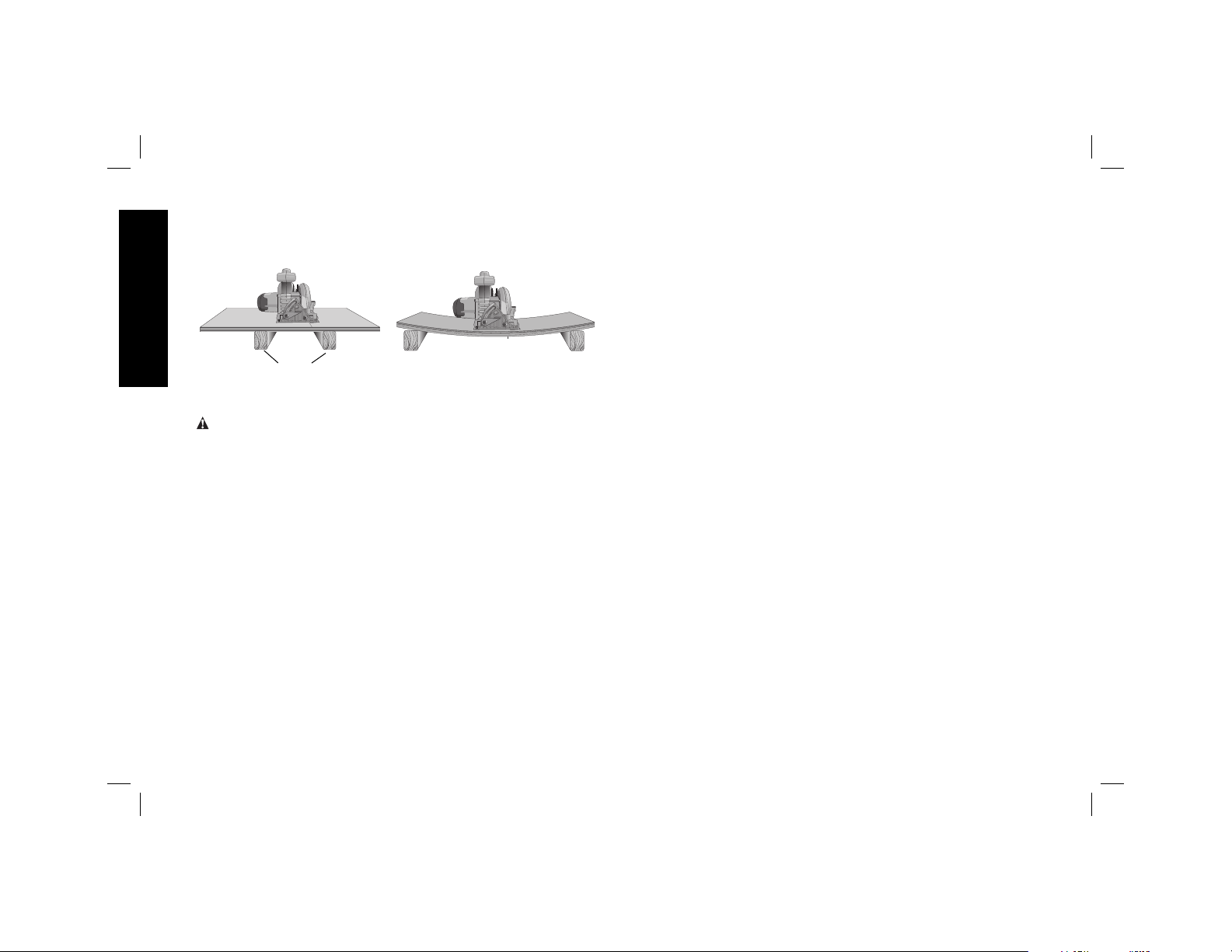

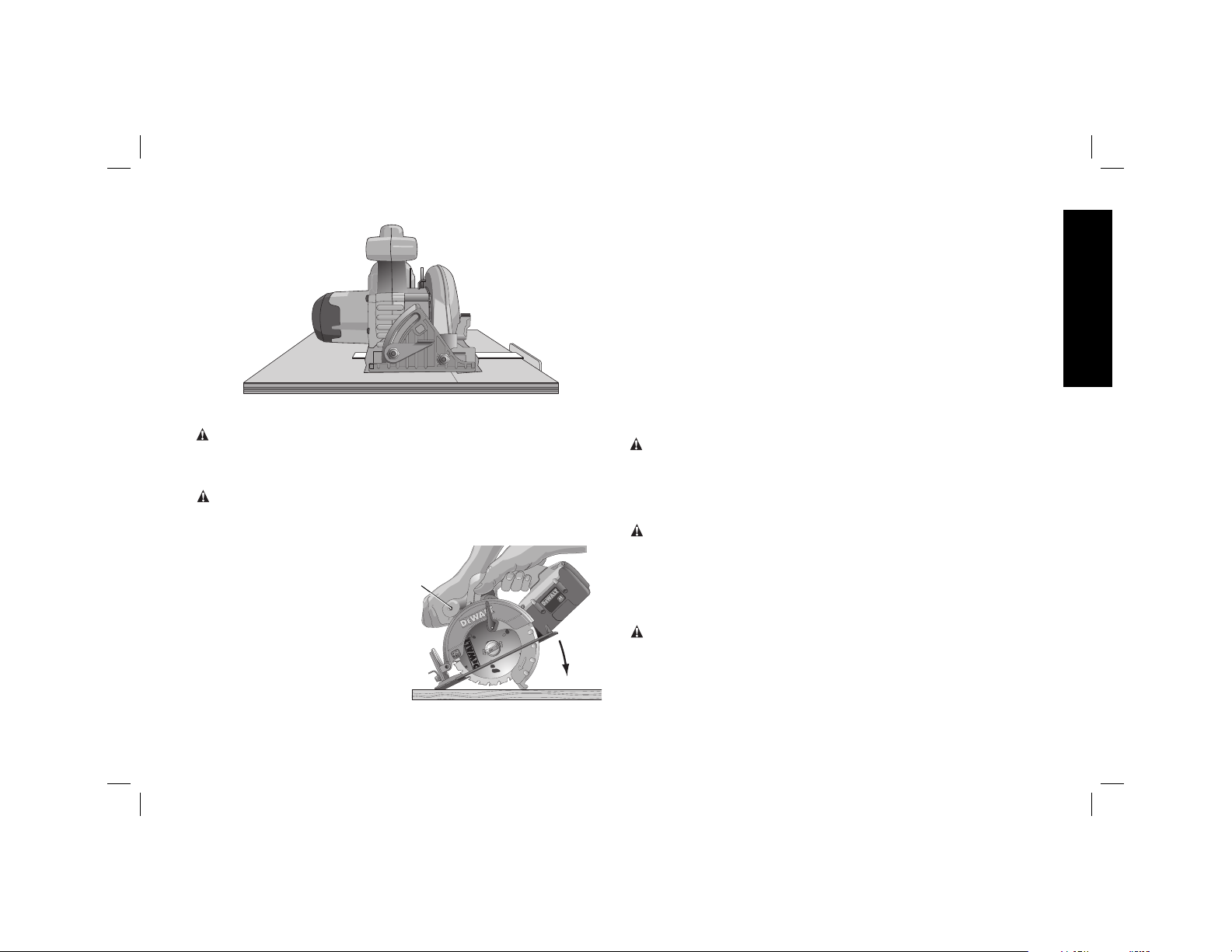

• Support large panels to minimize the risk of blade pinching

and kickback. Large panels tend to sag under their own weight.

Support must be placed under the panel on both sides, near the

line of cut and near the edge of the panel.

• Do not use dull or damaged blade. Unsharpened or improperly

set blades produce narrow kerf causing excessive friction, blade

binding, and kickback.

• Blade depth and bevel adjusting locking levers must be

tight and secure before making cut. If blade adjustment shifts

while cutting, it may cause binding and KICKBACK.

• Use extra caution when making a “Pocket Cut” into existing

walls or other blind areas. The protruding blade may cut

objects that can cause kickback.

WARNING: ALWAYS use safety glasses. Everyday eyeglasses

are NOT safety glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber

(CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed

to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust,

which may cause serious and permanent respiratory or other

injury. Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face

and body.

5

Page 7

WARNING: Always use eye protection. All users and bystanders

must wear eye protection that conforms to ANSI Z87.1.

WARNING: Always wear proper personal hearing protection

that conforms to ANSI S12.6 (S3.19) during use. Under some

conditions and duration of use, noise from this product may

contribute to hearing loss.

CAUTION: When not in use, place circular saw on a stable

surface, shoe side down, where it will not cause a tripping

or falling hazard. Some tools with large battery packs will stand

upright on the battery pack but may be easily knocked over.

• The label on your tool may include the following symbols. The

symbols and their definitions are as follows:

V ........... volts A ............. amperes

Hz ......... hertz W ............ watts

min ....... minutes

.... direct current

......... Class I Construction ............ ear thing terminal

............. (grounded) ........... safety alert symbol

......... Class II Construction …/min ..... revolutions or

............. (double insulated) ................reciprocation

BPM ..... beats per minute ................per minute

........... alternating current

n

o ...........no load speed

Important Safety Instructions for

Battery Chargers

SAVE THESE INSTRUCTIONS: This manual contains important

safety instructions for battery chargers.

• Before using charger, read all instructions and cautionary

markings on charger, battery pack, and product using battery

pack.

WARNING: Shock hazard. Do not allow any liquid to get inside

charger.

CAUTION: Burn hazard. To reduce the risk of injury, charge

only D

EWALT batteries. Other types of batteries may burst causing

personal injury and damage.

CAUTION: Under certain conditions, with the charger plugged in

to the power supply, the charger can be shorted by foreign material.

Foreign materials of a conductive nature such as, but not limited to,

steel wool, aluminum foil, or any buildup of metallic particles should

be kept away from charger cavities. Always unplug the charger from

the power supply when there is no battery pack in the cavity. Unplug

charger before attempting to clean.

• DO NOT attempt to charge the battery pack with any

chargers other than the ones in this manual. The charger

and battery pack are specifically designed to work together.

• These chargers are not intended for any uses other than

charging D

may result in risk of fire, electric shock or electrocution.

• Do not expose charger to rain or snow.

• Pull by plug rather than cord when disconnecting charger.

This will reduce risk of damage to electric plug and cord.

• Make sure that cord is located so that it will not be stepped

on, tripped over, or otherwise subjected to damage or

stress.

• Do not use an extension cord unless it is absolutely

necessary. Use of improper extension cord could result in risk

of fire, electric shock, or electrocution.

• An extension cord must have adequate wire size (AWG

or American Wire Gauge) for safety. The smaller the gauge

number of the wire, the greater the capacity of the cable, that is

16 gauge has more capacity than 18 gauge. When using more

than one extension to make up the total length, be sure each

individual extension contains at least the minimum wire size.

• Do not place any object on top of charger or place the

charger on a soft surface that might block the ventilation

EWALT rechargeable batteries. Any other uses

English

6

Page 8

slots and result in excessive internal heat. Place the charger

in a position away from any heat source. The charger is ventilated

through slots in the top and the bottom of the housing.

• Do not mount charger on wall or permanently affix charger

to any surface. The charger is intended to use on a flat, stable

surface (i.e., table top, bench top).

• Do not operate charger with damaged cord or plug — have

English

them replaced immediately.

• Do not operate charger if it has received a sharp blow, been

dropped, or otherwise damaged in any way. Take it to an

authorized service center.

• Do not disassemble charger; take it to an authorized

service center when service or repair is required. Incorrect

reassembly may result in a risk of electric shock, electrocution

or fire.

• Disconnect the charger from the outlet before attempting

any cleaning. This will reduce the risk of electric shock.

Removing the battery pack will not reduce this risk.

• NEVER attempt to connect 2 chargers together.

• The charger is designed to operate on standard household

electrical power (120 Volts). Do not attempt to use it on

any other voltage.

SAVE THESE INSTRUCTIONS

Introduction

The DC9000 charger is designed to charge DEWALT battery packs

in approximately 1 hour. This charger requires no adjustment and

is designed to be as easy as possible to operate. Simply place your

battery pack into the receptacle of a plugged in charger and it will

automatically charge the pack.

Important Safety Instruction for

Battery Packs

WARNING: For safe operation, read this manual and manuals

originally supplied with tool before using the charger.

When ordering replacement battery packs, be sure to include

catalog number and voltage. Consult the chart on the last page of

this manual for compatibility of chargers and battery packs.

The battery pack is not fully charged out of the carton. Before using

the battery pack and charger, read the safety instructions below.

Then follow charging procedures outlined.

READ ALL INSTRUCTIONS

• Do not incinerate the battery pack even if it is severely

damaged or is completely worn out. The battery pack can

explode in a fire. Toxic fumes and materials are created when

lithium ion battery packs are burned.

• Do not charge or use battery in explosive atmospheres,

such as in the presence of flammable liquids, gases or dust.

Inserting or removing the battery from the charger may ignite the

dust or fumes.

• If battery contents come into contact with the skin,

immediately wash area with mild soap and water. If battery

liquid gets into the eye, rinse water over the open eye for 15

minutes or until irritation ceases. If medical attention is needed,

the battery electrolyte is composed of a mixture of liquid organic

carbonates and lithium salts.

• Contents of opened battery cells may cause respiratory

irritation. Provide fresh air. If symptoms persists, seek medical

attention

WARNING: Burn hazard. Battery liquid may be flammable if

exposed to spark or flame.

• Charge the battery packs only in D

EWALT chargers.

7

Page 9

• DO NOT splash or immerse in water or other liquids.

• Do not store or use the tool and battery pack in locations

where the temperature may reach or exceed 105°F (40˚)

(such as outside sheds or metal buildings in summer).

WARNING: Never attempt to open the battery pack for any

reason. If battery pack case is cracked or damaged, do not insert

into charger. Do not crush, drop or damage battery pack. Do not

use a battery pack or charger that has received a sharp blow, been

dropped, run over or damaged in any way (i.e., pierced with a nail,

hit with a hammer, stepped on). Damaged battery packs should be

returned to service center for recycling.

WARNING: Fire hazard. Do not store or carry battery so

that metal objects can contact exposed battery terminals.

For example, do not place battery in aprons, pockets, tool boxes,

product kit boxes, drawers, etc., with loose nails, screws, keys, etc.

Transporting batteries can possibly cause fires if the battery

terminals inadvertently come in contact with conductive

materials such as keys, coins, hand tools and the like. The

US Department of Transportation Hazardous Material Regulations

(HMR) actually prohibit transporting batteries in commerce or

on airplanes (i.e., packed in suitcases and carry-on luggage)

UNLESS they are properly protected from short circuits. So

when transporting individual batteries, make sure that the battery

terminals are protected and well insulated from materials that could

contact them and cause a short circuit.

The RBRC™ Seal

The RBRC™ (Rechargeable Battery Recycling

Corporation) Seal on the lithium ion battery (or battery

pack) indicates that the costs to recycle the battery (or

battery pack) at the end of its useful life have already

been paid by D

RBRC™ in cooperation with D

established programs in the United States to facilitate the collection

EWALT.

EWALT and other battery users, has

of spent lithium ion batteries. Help protect our environment and

conserve natural resources by returning the spent lithium ion

battery to an authorized D

EWALT service center or to your local

retailer for recycling. You may also contact your local recycling

center for information on where to drop off the spent battery.

RBRC™ is a registered trademark of the Rechargeable Battery Recycling

Corporation.

Storage Recommendations

1. The best storage place is one that is cool and dry away from

direct sunlight and excess heat or cold.

2. Long storage will not harm the battery pack or charger. Under

proper conditions, they can be stored for 5 years or more.

Charger

Your battery pack requires a 1 hour DEWALT charger. Be sure

to read all safety instructions before using your charger. Consult

the chart on the back of this manual for compatibility of chargers

and battery packs.

Charging Procedure

1. Plug the charger into an appropriate outlet before inserting the

battery pack.

2. Insert the battery pack into the charger. The charger is equipped

with a three-light fuel gauge that will blink according to the state

of charge of the battery pack.

3. The completion of charge is indicated by the three red lights

remaining ON continuously. The pack is fully charged and may

be used at this time or left on the charger.

0% - 33% 1st light blinks

st

33% - 66% 1

66% - 99% 1

100% 1

light on, 2nd light blinks

st

, 2nd lights on, 3rd light blinks

st

, 2nd, 3rd lights on

English

8

Page 10

Charger Diagnostics

This charger is designed to detect certain problems that can arise

with the battery packs or the charger. Problems are indicated by the

three red lights flashing together in different patterns.

PROBLEM POWERLINE

When the charger is used with some portable power sources

such as generators or sources that convert DC to AC, the charger

English

may temporarily suspend operation. The three red lights will flash

together with two fast blinks followed by a pause. This indicates

that the power souce is out of limits.

BAD BATTERY

The charger can detect a weak or damaged battery. The three

red lights will flash together with rapid blinking. The battery will

no longer charge and should be returned to a service center or a

collection site for recycling.

BAD CHARGER

The charger will detect if it is not functioning properly. The three red

lights will flash together with one fast blink followed by a long

blink. The charger will no longer work and should be returned to an

authorized service center or replaced.

LEAVING THE BATTERY IN THE CHARGER

The charger and battery pack can be left connected with the red

lights glowing indefinitely. The charger will keep the battery pack

fresh and fully charged. This charger features an automatic tune-up

mode which equals or balances the individual cells in the battery

pack to allow it to function at peak capacity. Battery packs should

be tuned up weekly or whenever the battery no longer delivers the

same amount of work. To use the automatic tune-up mode, place

the battery pack in the charger and leave it for at least 8 hours.

Important Charging Notes

1. Longest life and best performance can be obtained if the battery

pack is charged when the air temperature is between 65°F and

75°F (18°- 24°C). DO NOT charge the battery pack in an air

temperature below +40°F (+4.5°C), or above +105°F (+40.5°C).

This is important and will prevent serious damage to the battery

pack.

2. The charger and battery pack may become warm to touch while

charging. This is a normal condition, and does not indicate a

problem. To facilitate the cooling of the battery pack after use,

avoid placing the charger or battery pack in a warm environment

such as in a metal shed, or an uninsulated trailer.

3. If the battery pack does not charge properly:

a. Check current at receptacle by plugging in a lamp or other

appliance

b. Check to see if receptacle is connected to a light switch

which turns power off when you turn out the lights.

c. Move charger and battery pack to a location where the

surrounding air temperature is approximately 65°F - 75°F

(18°- 24°C).

d. If charging problems persist, take the tool, battery pack and

charger to your local service center.

4. The battery pack should be recharged when it fails to produce

sufficient power on jobs which were easily done previously.

DO NOT CONTINUE to use under these conditions. Follow

the charging procedure. You may also charge a partially used

pack whenever you desire with no adverse affect on the battery

pack.

5. Foreign materials of a conductive nature such as, but not limited

to, steel wool, aluminum foil, or any buildup of metallic particles

should be kept away from charger cavities. Always unplug the

charger from the power supply when there is no battery pack in

the cavity. Unplug charger before attempting to clean.

6. Do not freeze or immerse charger in water or any other liquid.

WARNING: Shock hazard. Do not allow any liquid to get inside

charger.

9

Page 11

CAUTION: Never attempt to open the battery pack for any

reason. If the plastic housing of the battery pack breaks or cracks,

return to a service center for recycling.

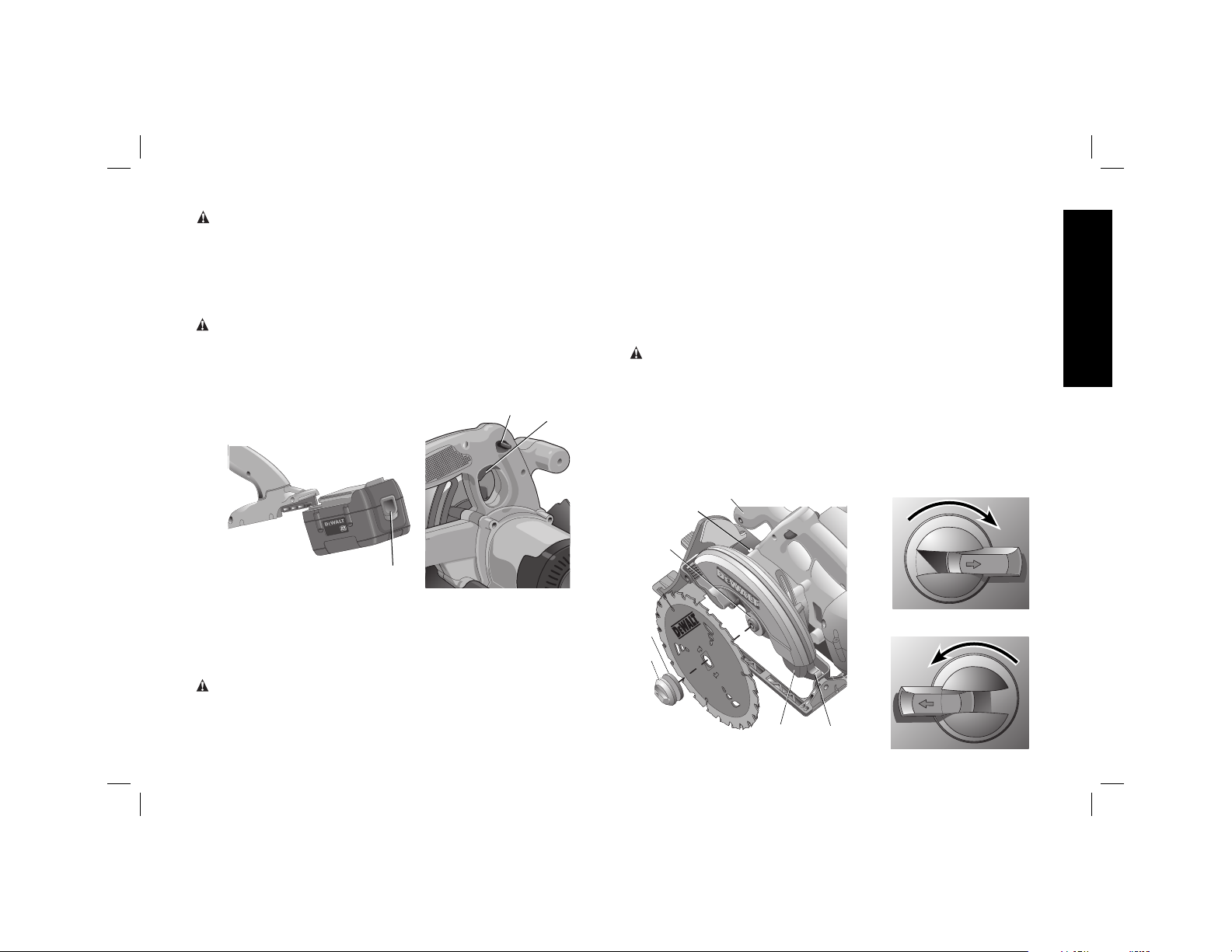

Installing and Removing the

Battery Pack (Fig. 2, 3)

NOTE: Make sure your battery pack is fully charged.

WARNING: Make certain the switch lock-off button (A) is engaged

to prevent switch actuation before removing or installing battery.

To install the battery pack into the tool handle, align the base of

the tool with the rails inside the tool’s handle and slide the battery

pack firmly into the handle until you hear the lock snap into place.

FIG. 2

FIG. 3

N

A

B

Switch

Release switch lock-off button (A) by pressing button as shown (Fig.

3). Pull the trigger switch (B) to turn the motor ON. Releasing the

trigger switch turns the motor OFF. Releasing the trigger switch

also automatically actuates lock-off button.

NOTE: This tool has no provision to lock the switch in the ON

position, and should never be locked ON by any other means.

Changing Blades

WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from battery pack before

making any adjustments or removing/installing attachments

or accessories.

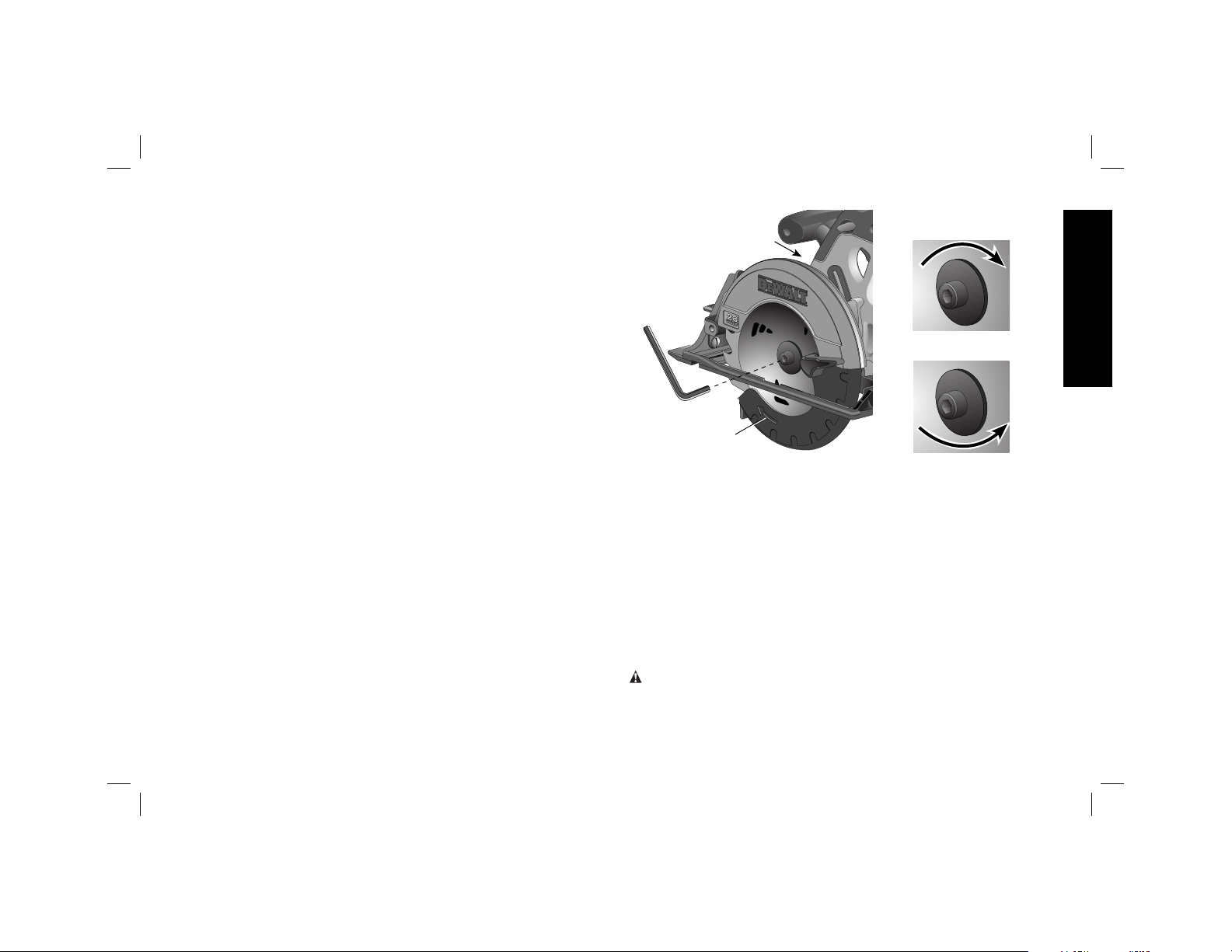

DC300 ONLY (FIG. 4, 5)

The DC300 is equipped with a keyless blade clamp (H) and is

designed to be tightened by hand. The use of external tools may

cause damage to this blade clamp.

FIG. 4

O

M

L

FIG. 5

LOOSEN (clockwise)

English

To remove the battery pack from the tool, press the release

button (N) and firmly pull the battery pack out of the tool handle.

Insert it into the charger as described in the charger section of this

manual.

OPERATION

WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from battery pack before

making any adjustments or removing/installing attachments

or accessories.

10

TIGHTEN

P

H

G

F

(counterclockwise)

Page 12

To Install the Blade:

1. Place inner clamp washer (O) on saw spindle with the large flat

surface facing out toward the blade (Fig. 4).

2. Retract the lower blade guard (G) and place blade on saw spindle

against the inner clamp washer, making sure that the blade will

rotate in the proper direction (the direction of the rotation arrow

on the saw blade and the teeth must point in the same direction

English

as the direction of rotation arrow on the lower guard). Do not

assume that the printing on the blade will always be facing you

when properly installed. When retracting the lower blade guard

to install the blade, check the condition and operation of the

lower blade guard to assure that it is working properly. Make

sure it moves freely and does not touch the blade or any other

part, in all angles and depths of cut.

3. Place outer clamp washer (P) on saw spindle with the large flat

surface against the blade and the side with ratchet teeth facing

out.

4. Thread the keyless blade clamp (H) into saw spindle by

hand (clamp has left-hand threads and must be turned

counterclockwise to tighten, as shown in Figure 5).

5. Depress the blade lock button (L) while turning the saw spindle

by hand until the blade lock engages and the blade stops

rotating.

6. Extend the lever on the keyless blade clamp (H) and hand

tighten firmly (Fig. 5).

CAUTION: Never engage the blade lock while saw is running or

engage in an effort to stop the tool. Never turn the saw on while the

blade lock is engaged. Serious damage to your saw will result.

To Replace the Blade (Fig. 4):

1. Depress the blade lock button (L) and turn the saw spindle

until the blade lock engages and the blade stops rotating. With

the blade lock engaged, extend the lever on the keyless blade

clamp and turn clockwise (clamp has left-hand threads and

must be turned clockwise to loosen, as shown in Figure 5).

2. Remove the keyless blade clamp (H) and outer clamp washer

(P) only. Remove old blade.

3. Clean any sawdust that may have accumulated in the guard or

clamp washer area and check the condition and operation of the

lower blade guard as previously outlined. Do not lubricate this

area.

4. Select the proper blade for the application (see Blades). Always

use blades that are the correct size (diameter) with the proper size

and shape center hole for mounting on the saw spindle. Always

assure that the maximum recommended speed (rpm) on the saw

blade meets or exceeds the speed (rpm) of the saw.

5. Follow steps 2 through 6 under To Install the Blade, making

sure that the blade will rotate in the proper direction.

DC310 ONLY (FIG. 6, 7)

To Install the Blade:

1. Place inner clamp washer (Q) on saw spindle with the large flat

surface facing out toward the blade (Fig. 6).

FIG. 6

J

F

Q

R

S

L

G

11

Page 13

2. Retract the lower blade guard (G) and place blade on saw

spindle against the inner clamp washer, making sure that

the blade will rotate in the proper direction (the direction of

the rotation arrow on the saw blade and the teeth must point

in the same direction as the direction of rotation arrow on the

saw). Do not assume that the printing on the blade will always

be facing you when properly installed. When retracting the

lower blade guard to install the blade, check the condition and

operation of the lower blade guard to assure that it is working

properly. Make sure it moves freely and does not touch the

blade or any other part, in all angles and depths of cut.

3. Place outer clamp washer (R) on saw spindle with the large flat

surface against the blade with beveled side facing out.

4. Thread blade clamping screw (S) into saw spindle by hand

(screw has left-hand threads and must be turned counterclockwise

to tighten, as shown in Figure 8).

5. Depress the blade lock (L) while turning the saw spindle with

the blade wrench until the blade lock engages and the blade

stops rotating (Fig. 7).

6. Tighten the blade clamping screw firmly with the blade wrench.

CAUTION: Never engage the blade lock while saw is running or

engage in an effort to stop the tool. Never turn the saw on while the

blade lock is engaged. Serious damage to your saw will result.

To Replace the Blade (Fig. 7):

1. To loosen the blade clamping screw (S), depress the blade lock

button (L) and turn the saw spindle with the blade wrench until

the blade lock engages and the blade stops rotating. With the

blade lock engaged, turn the blade clamping screw clockwise

with the blade wrench (screw has left-hand threads and must

be turned clockwise to loosen).

2. Remove the blade clamping screw (S) and outer clamp washer

(R) only. Remove old blade.

FIG. 7

FIG. 8

L

G

LOOSEN

(clockwise)

TIGHTEN

(counterclockwise)

3. Clean any sawdust that may have accumulated in the guard or

clamp washer area and check the condition and operation of the

lower blade guard as previously outlined. Do not lubricate this

area.

4. Select the proper blade for the application (see Blades). Always

use blades that are the correct size (diameter) with the proper

size and shape center hole for mounting on the saw spindle.

Always assure that the maximum recommended speed (rpm)

on the saw blade meets or exceeds the speed (rpm) of the

saw.

5. Follow steps 2 through 6 under To Install the Blade, making

sure that the blade will rotate in the proper direction.

LOWER BLADE GUARD (DC300 and DC310)

WARNING: The lower blade guard is a safety feature which

reduces the risk of serious personal injury. Never use the

saw if the lower guard is missing, damaged, misassembled or

not working properly. Do not rely on the lower blade guard to

English

12

Page 14

protect you under all circumstances. Your safety depends

on following all warnings and precautions as well as proper

operation of the saw. Check lower guard for proper closing

before each use as outlined in Additional Safety Rules

for Circular Saws. If the lower blade guard is missing or not

working properly, have the saw serviced before using. To

assure product safety and reliability, repair, maintenance and

adjustment should be performed by an authorized service

English

center or other qualified service organization, always using

identical replacement parts.

Blades

WARNING: To minimize the risk of eye injury, always use eye

protection. Carbide is a hard but brittle material. Foreign objects in

the workpiece such as wire or nails can cause tips to crack or break.

Only operate saw when proper saw blade guard is in place. Mount

blade securely in proper rotation before using, and always use a

clean, sharp blade.

CAUTION: Do not cut ferrous metals (steel), masonry, glass,

Hardiplank® (or similar masonry-type planking), cement board or

tile with this saw.

Do not use abrasive wheels or blades. A dull blade will cause slow,

inefficient cutting, overload on the saw motor, excessive splintering,

and could increase the possibility of kickback. Please refer to the

following table to determine the correct size replacement blade for

your model saw.

Model Diameter Arbor

DC300 7-1/4" 5/8"

DC310 6-1/2" 5/8"

Use only D

or non-carbide plywood/vinyl cutting blades.

If you need assistance regarding blades, please call 1-800-4D

EWALT (1-800-433-9258).

EWALT general purpose cutting, smooth wood cutting,

Cutting Depth

FIG. 9

Adjustment

WARNING: To reduce the risk of

serious personal injury, turn tool off

and disconnect tool from battery

pack before making any adjustments

or removing/installing attachments

or accessories.

1. Hold the saw firmly and loosen

(clockwise) the depth adjustment lever (Fig. 9, D) and move

shoe to obtain the desired depth of cut.

2. Make sure the depth adjustment lever has been retightened

(counterclockwise) before operating saw.

For the most efficient cutting action,

set the depth adjustment so that one

tooth of the blade will project below the

material to be cut. This distance is from

the tip of the tooth to the bottom of the

gullet in front of it. This keeps blade

friction at a minimum, removes sawdust

from the cut, results in cooler, faster

sawing and reduces the chance of

kickback. A method for checking for

correct cutting depth is shown in

Figure 10. Lay a piece of the material

you plan to cut along the side of the blade, as shown, and observe

how much tooth projects beyond the material.

NOTE: When using carbide-tipped blades, make an exception to

the above rule and allow only one-half of a tooth to project below

the material to be cut.

FIG. 10

D

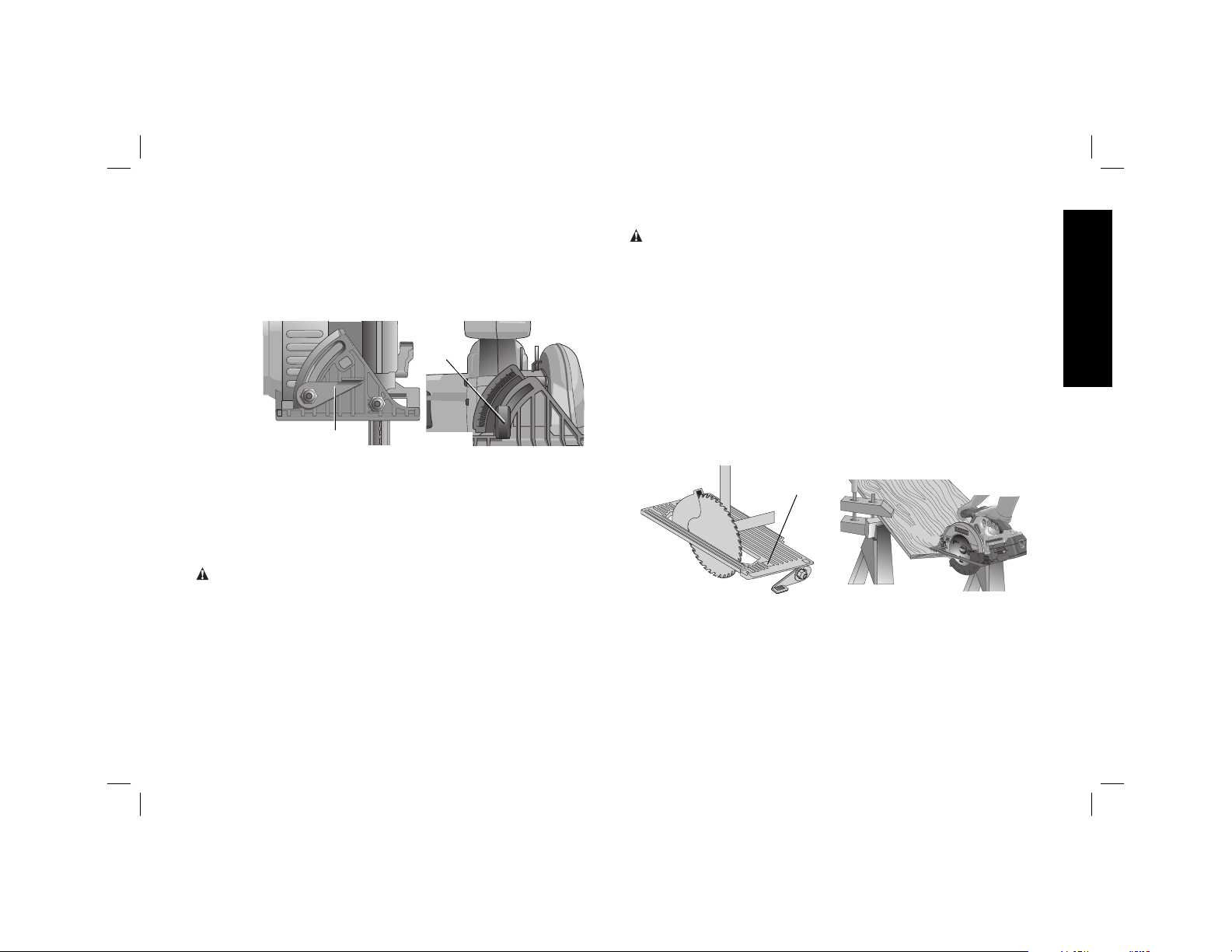

Bevel Angle Adjustment (Fig. 11)

WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from battery pack before

13

Page 15

making any adjustments or removing/installing attachments

or accessories.

The full range of the bevel adjustment is from 0˚ to 50˚.

The pivot bracket is graduated in increments of 1˚. On the

front of the saw is a bevel angle adjustment mechanism

(Fig. 11) consisting of a calibrated pivot bracket and a bevel

adjustment lever (DC300) or knob (DC310).

FIG. 11

J

DC300

TO SET THE SAW FOR A BEVEL CUT (FIG.11)

1. Raise the lever or knob (J) to loosen the bevel adjustment and

tilt shoe to the desired angle by aligning the pointer with the

desired angle mark.

2. Retighten the bevel adjustment by lowering the lever.

J

DC310

Bevel Detent (DC300 only)

WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from battery pack before

making any adjustments or removing/installing attachments

or accessories.

The saw is equipped with a bevel detent feature. As you tilt the

shoe you will hear a click and feel the shoe stop at both 22.5 and

45 degrees. If either of these is the desired angle, retighten the

lever (J) by lowering it. If you desire another angle, continue tilting

the shoe until the pointer aligns with the desired mark. Retighten

lever (J) by lowering it.

Shoe Adjustment for 90˚ Cuts

WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from battery pack before

making any adjustments or removing/installing attachments

or accessories.

IF ADDITIONAL ADJUSTMENT IS NEEDED (FIG. 12)

1. Adjust the saw to 0˚ bevel.

2. Retract blade guard. Place the saw on blade side.

3. Loosen bevel adjustment lever or knob (J). Place a square

against the blade and shoe to adjust the 90˚ setting.

4. Turn the adjustment screw (K) on the underside of the shoe

until the blade and the shoe are both in flush contact with the

square. Retighten the bevel adjust lever or knob.

5. Confirm the accuracy of the setting by checking the squareness

of an actual cut on a scrap piece of material.

FIG. 13

FIG. 12

K

Kerf Indicator

The front of the saw shoe has a kerf indicator for vertical and bevel

cutting. This indicator enables you to guide the saw along cutting

lines penciled on the material being cut. The indicator lines up

with the left (outer) side of the saw blade, which makes the slot or

“kerf” cut by the moving blade fall to the right of the indicator. Guide

along the penciled cutting line so that the kerf falls into the waste

or surplus material.

English

14

Page 16

FIG. 14

DO support board or

panel NEAR the cut.

FIG. 15

DON’T support board or

panel AWAY from the cut.

English

SUPPORT

Workpiece Support

WARNING: It is important to support the work properly and to

hold the saw firmly to prevent loss of control which could cause

personal injury. Figure 13 illustrates proper hand support of the saw.

Maintain a firm grip with both hands on the saw and position your

body and arm to allow you to resist kickback if it occurs.

Figure 13 shows proper sawing position. Note that hands are kept

away from cutting area. To avoid kickback, DO support board or

panel NEAR the cut (Fig. 14). DON’T support board or panel away

from the cut (Fig. 15).

Place the work with its “good” side – the one on which appearance

is most important – down. The saw cuts upward, so any splintering

will be on the work face that is up when you cut it.

Cutting

Place the wider portion of the saw shoe on that part of the

workpiece which is solidly supported, not on the section that will

fall off when the cut is made. As examples, Figure 13 illustrates the

RIGHT way to cut off the end of a board. Always clamp work. Don’t

try to hold short pieces by hand! Remember to support cantilevered

and overhanging material. Use caution when sawing material from

below.

Be sure saw is up to full speed before blade contacts material to

be cut. Starting saw with blade against material to be cut or pushed

forward into kerf can result in kickback. Push the saw forward at

a speed which allows the blade to cut without laboring. Hardness

and toughness can vary even in the same piece of material, and

knotty or damp sections can put a heavy load on the saw. When

this happens, push the saw more slowly, but hard enough to keep

working without much decrease in speed. Forcing the saw can

cause rough cuts, inaccuracy, kickback, and over-heating of the

motor. Should your cut begin to go off the line, don’t try to force it

back on. Release the switch and allow blade to come to a complete

stop. Then you can withdraw the saw, sight anew, and start a new

cut slightly inside the wrong one. In any event, withdraw the saw if

you must shift the cut. Forcing a correction inside the cut can stall

the saw and lead to kickback.

IF SAW STALLS, RELEASE THE TRIGGER AND BACK THE

SAW UNTIL IT IS LOOSE. BE SURE BLADE IS STRAIGHT

IN THE CUT AND CLEAR OF THE CUTTING EDGE BEFORE

RESTARTING.

As you finish a cut, release the trigger and allow the blade to

stop before lifting the saw from the work. As you lift the saw, the

spring-tensioned telescoping guard will automatically close under

the blade. Remember the blade is exposed until this occurs. Never

reach under the work for any reason. When you have to retract the

telescoping guard manually (as is necessary for starting pocket

cuts) always use the retracting lever.

NOTE: When cutting thin strips, be careful to ensure that small

cutoff pieces don’t hang up on inside of lower guard.

RIPPING (FIG. 16)

Ripping is the process of cutting wider boards into narrower strips

– cutting grain lengthwise. Hand guiding is more difficult for this type

of sawing and the use of a rip fence is recommended.

15

Page 17

FIG. 16

POCKET CUTTING (FIG. 17)

WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from battery pack before

making any adjustments or removing/installing attachments

or accessories.

WARNING: Never tie the blade guard in a raised position. Never

move the saw backwards when pocket cutting. This may cause the

unit to raise up off the work surface which could cause injury.

A pocket cut is one that is made in

a floor, wall, or other flat surface.

1. Adjust the saw shoe so the

blade cuts at desired depth.

2. Tilt the saw forward and rest

front of the shoe on material

to be cut.

3. Using the retracting lever,

retract lower blade guard to

an upward position. Lower

rear of shoe until blade teeth

almost touch cutting line.

FIG. 17

M

INSTALL

RIP FENCE

IN THIS

DIRECTION

4. Release the blade guard(its contact with the work will keep it

in position to open freely as you start the cut). Remove hand

from guard lever and firmly grip auxilary handle, (M) as shown

in Figure 17. Position your body and arm to allow you to resist

kickback if it occurs.

5. Make sure blade is not in contact with cutting surface before

starting saw.

6. Start the motor and gradually lower the saw until its shoe rests

flat on the material to be cut. Advance saw along the cutting line

until cut is completed.

7. Release trigger and allow blade to stop completely before

withdrawing the blade from the material.

8. When starting each new cut, repeat as above.

MAINTENANCE

WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from battery pack before

making any adjustments or removing/installing attachments

or accessories.

Cleaning

WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool. These chemicals may

weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get

inside the tool; never immerse any part of the tool into a liquid.

CHARGER CLEANING INSTRUCTIONS

WARNING: Shock hazard. Disconnect the charger from the AC

outlet before cleaning. Dirt and grease may be removed from the

exterior of the charger using a cloth or soft non-metallic brush. Do

not use water or any cleaning solutions.

Lubrication

Self lubricating ball and roller bearings are used in the tool and

relubrication is not required. However, it is recommended that, once

16

English

Page 18

a year, you take or send the tool to a certified service center for a

thorough cleaning, inspection, and lubrication of the gear case.

Repairs

To assure product SAFETY and RELIABILITY, repairs,

maintenance and adjustments (including brush inspection and

replacement) should be performed by a D

center, a D

English

service personnel. Always use identical replacement parts.

EWALT authorized service center or other qualified

EWALT factory service

Accessories

WARNING: Since accessories, other than those offered by

D

EWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the risk of

injury, only D

EWALT, recommended accessories should be used

with this product.

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If

you need assistance in locating any accessory for your tool, please

contact D

Baltimore, MD 21286, call 1-800-4-D

EWALT Industrial Tool Co., 701 East Joppa Road,

EWALT (1-800-433-9258) or

visit our website www.dewalt.com.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty

materials or workmanship for three years from the date of purchase.

This warranty does not cover part failure due to normal wear or tool

abuse. For further detail of warranty coverage and warranty repair

information, visit www.dewalt.com or call 1-800-4-D

433-9258). This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other

rights which vary in certain states or provinces.

EWALT (1-800-

In addition to the warranty, D

EWALT tools are covered by our:

1 YEAR FREE SERVICE

EWALT will maintain the tool and replace worn parts caused by

D

normal use, for free, any time during the first year after purchase.

2 YEARS FREE SERVICE ON D

EWALT BATTERY PACKS

DC9096, DC9091, DC9071, DC9360 and DC9280

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

DEWALT Power Tool, Laser, or Nailer for any reason, you can return

it within 90 days from the date of purchase with a receipt for a full

refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold

in Latin America. For products sold in Latin America, see country

specific warranty information contained either in the packaging, call

the local company or see the website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-D

EWALT for a free

replacement.

17

Page 19

Patent Notification

Manufactured under one or more of

the following U.S. patents:

6859013

6329788

6175211

Other patents pending.

6133713

6057608

6653815

English

18

Page 20

FIG. 1

DC300, 36 Volt 4000 tr/min

M

L

DC310, 28 Volt 3800 tr/min

A

B

M

L

A

B

J

I

Français

J

N

I

H

E

G

F

A. Bouton de verrouillage

de la gâchette

B. Gâchette

C. Bloc-piles

D. Levier de réglage de la

J J

K

D

profondeur

E. Semelle

F. Levier d’escamotage du

protège-lame inférieur

G. Protège-lame inférieur

H. Bride de lame sans clé

(DC300 seulement)

C

E

G

I. Indicateur de trait de

scie

J. Levier de réglage

d’angle de biseau

(DC300) or bouton de

réglage d’angle

de biseau (DC310)

K. Vis de réglage

l. Bouton de verrouillage

de la lame (non illustré)

M. Poignée auxiliaire

N. Bouton de dégagement

du bloc-piles

F

N

C

K

D

19

Page 21

SI VOUS AVEZ DES QUESTIONS OU VOULEZ NOUS FAIRE

PART DE VOS COMMENTAIRES CONCERNANT CET OUTIL OU

TOUT AUTRE OUTIL D

1 800 433-9258.

EWALT, COMPOSEZ SANS FRAIS LE :

Règles de sécurité – Généralités

AVERTISSEMENT : Lire toutes ces directives. Tout

manquement aux directives suivantes pose des risques

de choc électrique, d’incendie et/ou de blessure grave. Le

terme « outil électrique » dans tous les avertissements ciaprès se rapporte à votre outil électrique à alimentation sur

secteur (avec fil) ou par piles (sans fil).

CONSERVER CES DIRECTIVES

1) SÉCURITÉ - AIRE DE TRAVAIL

a) Maintenir l’aire de travail propre et bien éclairée. Les lieux

encombrés ou sombres sont propices aux accidents.

b) Ne pas faire fonctionner un outil électrique dans une

atmosphère explosive, en présence par exemple de

poussières, gaz ou liquides inflammables. Les outils

électriques peuvent engendrer des étincelles qui pourraient

enflammer toute émanation ou poussière ambiante.

c) Tenir les enfants, ou toute autre personne, éloignés

pendant l’utilisation d’un outil électrique. Toute distraction

pourrait vous faire perdre la maîtrise de ce dernier.

2) SÉCURITÉ – ÉLECTRICITÉ

a) La fiche électrique de l’outil doit correspondre à la prise

murale. Ne jamais modifier la fiche en aucune façon. Ne

jamais utiliser de fiche d’adaptation avec un outil électrique mis à la terre. L’utilisation de fiches d’origine et de

prises appropriées réduira les risques de choc électrique.

b) Éviter tout contact corporel avec des éléments mis à la

terre comme tuyaux, radiateurs, cuisinières ou réfrigéra-

teurs. Les risques de choc électrique augmentent lorsque le

corps est mis à la terre.

c) Ne pas exposer les outils électriques à la pluie ou à

l’humidité. Toute pénétration d’un outil électrique par un

liquide augmente les risques de choc électrique.

d) Ne pas utiliser le cordon de façon abusive. Ne jamais

utiliser le cordon pour transporter, tirer ou débrancher

un outil électrique. Protéger le cordon de la chaleur, de

l’huile et de tout bord tranchant ou pièce mobile. Les

cordons endommagés ou emmêlés augmentent les risques

de choc électrique.

e) Lors de l’utilisation d’un outil électrique à l’extérieur,

n’utiliser que des rallonges conçues pour l’extérieur.

L’utilisation d’une rallonge conçue pour l’extérieur réduit les

risques de choc électrique. En cas d’utilisation d’une rallonge,

s’assurer que les valeurs nominales de la rallonge utilisée

correspondent bien à celles de l’outil alimenté. L’usage d’une

rallonge de calibre insuffisant causera une chute de tension

entraînant perte de puissance et surchauffe. Le tableau

ci-dessous illustre les calibres à utiliser selon la longueur de

rallonge et l’intensité nominale indiquée sur la plaque signalétique. En cas de doutes, utiliser le calibre suivant. Plus le

calibre est petit, plus la rallonge peut supporter de courant.

Calibre de fil minimum recommandé pour les rallonges

Longueur totale de la rallonge

25 pi 50 pi 75 pi 100 pi 125 pi 150 pi 175 pi

7,6 m 15,2 m 22,9 m 30,5 m 38,1 m 45,7 m 53,3 m

Calibre AWG

18 18 16 16 14 14 12

3) SÉCURITÉ PERSONNELLE

a) Rester vigilant en tout temps et faire preuve de jugement

pendant l’utilisation d’un outil électrique. Ne pas utiliser

d’outil électrique en cas de fatigue ou sous l’influence

Français

20

Page 22

de drogues, d’alcool ou de médicaments. Tout moment

d’inattention pendant l’utilisation d’un outil électrique pose des

risques de blessure grave.

b) Utiliser le matériel de sécurité approprié. Toujours porter

des lunettes de protection. Le fait de porter un masque

anti-poussières, des chaussures antidérapantes, un casque

de sécurité ou des protecteurs auditifs lorsque la situation le

requiert réduira les risques de blessure.

c) Éviter tout démarrage accidentel. S’assurer que

l’interrupteur est en position d’arrêt avant tout branchement. Transporter un outil le doigt sur l’interrupteur ou

brancher un outil électrique alors que l’interrupteur est en

position de marche invite les accidents.

d) Retirer toute clé de réglage avant de démarrer l’outil. Une

clé laissée sur une pièce rotative d’un outil électrique pose

des risques de blessure.

e) Ne pas effectuer de travaux hors de portée. Les pieds

doivent rester bien ancrés au sol afin de maintenir son

Français

équilibre en tout temps. Cela permet de mieux maîtriser

l’outil électrique dans les situations imprévues.

f) Porter des vêtements appropriés. Ne pas porter de v

êtements amples ni de bijoux. Maintenir cheveux,

vêtements et gants éloignés des pièces mobiles.

Vêtements amples, bijoux ou cheveux longs risquent

de rester coincés dans ces pièces mobiles. Prendre des

précautions autour des évents car ils recouvrent des pièces

mobiles.

g) Lorsque un dispositif de connexion à un système de

dépoussiérage ou d’élimination est fourni, s’assurer

qu’il est connecté et utilisé correctement. L’utilisation de

ces dispositifs peut réduire les risques engendrés par les

poussières.

4) UTILISATION ET ENTRETIEN DES OUTILS ÉLECTRIQUES

a) Ne pas forcer un outil électrique. Utiliser l’outil approprié

au travail en cours. L’outil approprié effectuera un meilleur

travail, de façon plus sûre et à la vitesse pour laquelle il a été

conçu.

b) Ne pas utiliser un outil électrique dont l’interrupteur est

défectueux. Tout appareil dont l’interrupteur est défectueux

est dangereux et doit être réparé.

c) Débrancher la fiche du secteur et/ou le bloc-piles de

l’outil électrique avant de faire tout réglage ou changement d’accessoire, ou avant de ranger ce dernier. Ces

mesures préventives réduisent les risques de démarrage

accidentel de l’appareil.

d) Après usage, ranger les outils électriques hors de la

portée des enfants, et ne permettre à aucune personne

n’étant pas familière avec un outil électrique (ou son

manuel d’instruction) d’utiliser ce dernier. Les outils

peuvent être dangereux entre les mains des novices.

e) Entretenir les outils électriques. Vérifier les pièces

mobiles pour s’assurer qu’elles sont bien alignées et

tournent librement, qu’elles sont en bon état et ne sont

affectées d’aucune condition susceptible de nuire au

bon fonctionnement de l’outil. En cas de dommage, faire

réparer l’outil électrique avant toute nouvelle utilisation.

Bien des accidents sont causés par des outils mal entretenus.

f) Maintenir tout outil de coupe bien aiguisé et propre. Les

outils de coupe bien entretenus et affûtés sont moins susceptibles de se coincer et sont plus faciles à contrôler.

g) Utiliser un outil électrique, ses accessoires, mèches,

etc., conformément aux présentes directives et suivant

la manière prévue pour ce type particulier d’outil électrique, en tenant compte des conditions de travail et du

21

Page 23

travail à effectuer. L’utilisation d’un outil électrique pour toute

opération autre que celle pour laquelle il a été conçu est

dangereuse.

5) UTILISATION ET ENTRETIEN DE L'OUTIL ALIMENTÉ PAR

PILE

a) S’assurer que l’interrupteur se trouve à la position

d'arrêt avant d’insérer le bloc-piles. Insérer un bloc-piles

dans un outil électrique dont l’interrupteur est à la position de

marche risque de provoquer un accident.

b) Ne recharger l'outil qu'au moyen du chargeur précisé par

le fabricant. L’utilisation d’un chargeur qui convient à un type

de bloc-piles risque de provoquer un incendie s’il est utilisé

avec un autre type de bloc-piles.

c) Utiliser les outils électriques uniquement avec les blocs-

piles conçus à cet effet. L’utilisation de tout autre bloc-piles

risque de causer des blessures ou un incendie.

d) Lorsque le bloc-piles n’est pas utilisé, le tenir éloigné

des objets métalliques, notamment des trombones, de la

monnaie, des clés, des clous, des vis, etc., qui peuvent

établir une connexion entre les deux bornes. Mettre en

court-circuit les bornes du bloc-piles peut provoquer des

brûlures ou un incendie.

e) En cas d’utilisation abusive, un liquide peut gicler hors

du bloc-piles, éviter tout contact. Si un contact accidentel se produit, laver à grande eau. Si le liquide entre en

contact avec les yeux, obtenir des soins médicaux. Le

liquide qui gicle hors du bloc-piles peut provoquer des

irritations ou des brûlures.

6) SERVICE

a) Faire entretenir les outils électriques par un répara-

teur qualifié en n’utilisant que des pièces de rechange

identiques. Cela permettra d’assurer l’intégrité de l’outil

électrique et la sécurité de l’utilisateur.

Règles de sécurité supplémentaires

pour scies circulaires

DANGER : Garder les mains éloignées des zones de coupe

et de la lame. Toujours tenir l’outil en plaçant une main sur la

poignée auxiliaire ou le carter du moteur. On protège ses mains

en les utilisant toutes les deux pour tenir l’outil.

• Toujours se placer d’un côté ou de l’autre de la lame en

évitant de se tenir dans son trajet, car la scie pourrait

reculer brusquement par suite d’un REBOND. (Voir la section

« REBOND » du présent guide.)

• Ne pas mettre les mains sous la pièce car il n’y a aucune

protection contre la lame à cet endroit.

• Vérifier le protège-lame inférieur afin de s’assurer qu’il est

bien fermé avant d’utiliser l’outil; ne pas faire fonctionner ce dernier si le protège-lame ne se déplace pas librement ou s’il ne se ferme pas instantanément. Ne jamais le

bloquer ou le fixer en position ouverte. Si on échappe la

scie, soulever le protège-lame inférieur au moyen du levier

d’escamotage et le vérifier afin de s’assurer qu’il n’y a aucun

dommage, qu’il se déplace librement et qu’il n’entre pas en

contact avec la lame ou toute autre pièce de l’outil, quel que soit

l’angle et la profondeur de coupe.

• S’assurer que le ressort du protège-lame inférieur est en

bon état de fonctionnement; sinon, on doit lui faire subir

un entretien avant d’utiliser l’outil. Le protège-lame peut être

difficile à déplacer en présence de pièces endommagées, de

dépôts gommeux ou de débris accumulés.

• On ne doit escamoter manuellement le protège-lame inféri-

eur que pour réaliser une coupe spéciale, complexe ou

interne. Pour ce faire, on doit le soulever au moyen du levier

d’escamotage, relâchant ce dernier dès que la lame mord

dans la pièce. Le protège-lame s’escamote automatiquement

pour tous les autres types de coupe.

Français

22

Page 24

• Toujours s’assurer que le protège-lame inférieur recouvre

la lame avant de déposer la scie sur le plancher ou sur un

établi, car, sans protection, une lame qui tourne encore fait

reculer la scie, coupant tout ce qui se trouve sur son passage. Il

est en outre bon de savoir combien de temps la lame prend pour

s’arrêter une fois l’interrupteur relâché.

• Ne JAMAIS tenir la pièce dans ses mains ou la placer

de travers sur ses jambes pour la couper. Il est important

de soutenir la pièce correctement afin d’éviter d’exposer des

parties du corps à la lame, de coincer cette dernière ou encore,

de perdre la maîtrise de l’outil.

• Tenir l’outil par les surfaces isolées prévues à cette fin

lorsqu’il risque d’entrer en contact avec des fils cachés, car

de tels contacts peuvent mettre les pièces métalliques de l’outil

sous tension, engendrant des risques de choc électrique.

• Toujours utiliser un guide de refend ou de bord droit

lorsqu’on effectue une coupe en long afin d’assurer la précision de cette dernière et d’éviter de coincer la lame.

• Toujours utiliser une lame munie d’un arbre dont les

Français

orifices sont de dimension et de forme appropriées (en

losanges vs ronds); les lames qui ne correspondent pas

aux éléments de fixation de la scie tourneront de manière excentrique, faisant perdre la maîtrise de l’outil.

• Ne jamais utiliser de rondelles ou de boulons endommagés

ou autres que ceux qui ont été conçus pour la scie, afin

d’obtenir un rendement optimal et de travailler en toute sécurité.

• Éviter de passer la lame sur des clous; vérifier le bois de

sciage afin de s’assurer qu’il n’y en a aucun; les retirer, le cas

échéant, avant d’effectuer la coupe.

CAUSES DU REBOND ET MESURES PRÉVENTIVES

• Le rebond est une réaction soudaine de l’outil causée par une

lame pincée, bloquée ou mal alignée, occasionnant la perte de

maîtrise de la scie, qui se soulève et se détache de la pièce en

direction de l’opérateur.

• Lorsque la lame reste coincée ou qu’elle est immobilisée par

une entaille qui se referme, l’arrêt de la lame et la réaction du

moteur entraîne un recul brusque de l’outil vers l’opérateur.

• Si la lame se tord ou est mal alignée, les dents arrière peuvent

s’engager sur le dessus de la pièce, faisant grimper la lame hors

de l’entaille et rebondir l’outil en direction de l’opérateur.

• Le rebond découle d’une mauvaise utilisation ou du mauvais

fonctionnement de l’outil; on peut l’éviter en prenant les précautions suivantes.

• Tenir fermement l’outil des deux mains et placer le corps

et les bras de manière à pouvoir maîtriser les effets du

rebond; le rebond peut être maîtrisé si l’opérateur prend les

précautions nécessaires.

• Lorsque la lame se coince ou qu’on veut interrompre

une coupe pour quelque raison que ce soit, relâcher

l’interrupteur à gâchette et maintenir la scie immobile dans

la pièce, jusqu’à ce que la lame s’arrête complètement.

Ne jamais tenter de sortir la scie hors de l’entaille ou de

la tirer vers soi avant que la lame ne se soit immobilisée

complètement afin d’éviter le rebond. Vérifier la pièce afin de

déterminer la cause du coincement et de prendre les mesures

correctives qui s’imposent.

• Lorsqu’on remet la scie en marche, centrer la lame dans

l’entaille et s’assurer que les dents ne sont pas engagées

dans le matériau. Si la lame se coince, la scie peut grimper

hors de l’entaille ou faire un rebond lorsqu’on la redémarre.

• Soutenir les grands panneaux afin d’éviter autant que

possible de coincer la lame et d’engendrer un rebond. Les

grands panneaux tendent à s’affaisser sous leur poids et doivent

être soutenus de chaque côté, près de la ligne de coupe et du

bord du panneau.

23

Page 25

• Ne pas utiliser de lames usées ou endommagées, car celles-

ci produisent des entailles plus étroites, ce qui peut causer une

friction excessive, coincer la lame et engendrer un rebond.

• Bien verrouiller les leviers de réglage de profondeur et

d’angle de biseau avant d’amorcer une coupe; si ces leviers se déplacent durant la coupe, la lame peut se coincer et

entraîner un REBOND.

• On doit faire particulièrement attention lorsqu’on effectue

une coupe interne dans un mur ou un endroit difficile à

voir, car la lame peut couper des objets cachés qui risquent

d’occasionner un rebond.

AVERTISSEMENT : TOUJOURS porter des lunettes de

sécurité. Les lunettes de vue ne constituent PAS des lunettes

de sécurité. Utiliser également un masque facial ou antipoussière si l’opération de découpe génère de la poussière.

TOUJOURS PORTER UN ÉQUIPEMENT DE PROTECTION

HOMOLOGUÉ :

• protection oculaire conforme à la norme ANSI Z87.1 (CAN/

CSA Z94.3),

• protection auditive conforme à la norme ANSI S12.6 (S3.19)

et

• protection des voies respiratoires conformes aux normes

NIOSH/OSHA/MSHA.

AVERTISSEMENT : Certaines poussières créées par le pon-

çage, le sciage, le meulage et le forage mécaniques ainsi que

d’autres activités de construction contiennent des produits chimiques reconnus pour causer le cancer, des anomalies congénitales ou d’autres anomalies liées à la reproduction. Parmi ces

produits chimiques, citons notamment :

• le plomb provenant des peintures au plomb ;

• la silice cristalline provenant des briques, du béton et d’autres

matériaux de maçonnerie ;

• l’arsenic et le chrome provenant du bois traité (arséniate de

cuivre et de chrome).

Le risque associé à ces expositions varie selon la fréquence de ces

types de travaux. Pour réduire l’exposition aux produits chimiques :

travailler dans un local bien ventilé et utiliser du matériel de sécurité

approuvé, comme les masques antipoussières spécialement conçus

pour filtrer les particules microscopiques.

• Éviter le contact prolongé avec la poussière provenant du

ponçage, du sciage, du meulage et du forage mécanique

ainsi que d’autres activités de construction. Porter des

vêtements de protection et laver les parties exposées au

savon et à l’eau. La poussière qui pourrait pénétrer dans la

bouche et les yeux ou se déposer sur la peau peut favoriser

l’absorption de produits chimiques nocifs.

AVERTISSEMENT : Cet outil peut produire et répandre de la

poussière susceptible de causer des dommages sérieux et permanents au système respiratoire. Toujours utiliser un appareil respiratoire anti-poussières approuvé par le NIOSH ou l’OSHA. Diriger les

particules dans le sens opposé du visage et du corps

AVERTISSEMENT : Toujours porter des lunettes de sécurité.

L’utilisateur et toute autre personne se trouvant à proximité de la

zone de coupe doit porter des lunettes de sécurité conformes à la

norme ANSI Z87.1.

AVERTISSEMENT : TOUJOURS porter une protection auditive

appropriée conformément à la norme ANSI S12.6 (S3.19) lors

de l’utilisation du produit. Dans certaines conditions et selon la

durée d’utilisation, le bruit émis par ce produit peut contribuer à

une perte auditive.

MISE EN GARDE : Lorsque l'outil n'est pas utilisé, placez la

scie circulaire sur une surface stable, semelle de chaussure

vers le bas, de manière à ne faire trébucher ou tomber personne. Certains outils présentant un gros bloc-piles reposeront sur

ce dernier, à la verticale, mais risque d'être facilement renversés.

.

Français

24

Page 26

• L'étiquette apposée sur votre outil peut comprendre les

symboles suivants. Les symboles et leurs définitions sont

indiqués ci-après :

V ..........volts A ............ ampères

Hz ........hertz W ........... watts

min ...... minutes

...courant continu

........Construction de classe I ........... borne de terre

............ (mis à la terre)

........ Constr uction de .............. à la sécurité

............ classe II …/min ....rotations ou

............ (à double isolation) .............. alternance par

BPM ....coups par minute minute

......... courant alternatif

n

o .......... vitesse à vide

.......... symbole d'alerte

Directives de sécurité importantes pour

les chargeurs de piles

CONSERVER CES DIRECTIVES : Ce manuel contient des directives de sécurité importantes sur les chargeurs de piles.

Français

• Avant d’utiliser le chargeur, lire toutes les directives et les indications d'avertissement figurant sur le chargeur, le bloc-piles et le

produit utilisé avec le bloc-piles.

AVERTISSEMENT : Risque de choc. Éviter la pénétration de tout

liquide dans le chargeur.

MISE EN GARDE : Risque de brûlure. Pour réduire le risque de

blessures, charger seulement les piles D

piles peuvent exploser et causer des blessures corporelles et des

dommages.

MISE EN GARDE : Sous certaines conditions, lorsque le

chargeur est branché au bloc d’alimentation, le chargeur peut

être court-circuité par des corps étrangers. Tout corps étranger

conducteur, tel que, mais sans s'y limiter, la laine d'acier, le papier

d'aluminium, ou toute accumulation de particules métalliques, doit

être maintenu à distance des ouvertures du chargeur. Débrancher

EWALT. D’autres types de

systématiquement le chargeur si aucun bloc-piles n’y est inséré.

Débrancher le chargeur avant tout nettoyage.

• NE PAS charger le bloc-piles au moyen de tout autre

chargeur que ceux mentionnés dans le présent manuel. Le

chargeur et le bloc-piles sont spécialement conçus pour être

utilisés ensemble.

• Ces chargeurs ne sont pas prévus pour être utilisés à

d’autres fins que celles de charger les piles rechargeables

EWALT. Toute autre utilisation risque de provoquer un incend-

D

ie, un choc électrique ou une électrocution

• Ne pas exposer le chargeur à la pluie ou à la neige.

• Tirer sur la fiche plutôt que sur le cordon pour débrancher

le chargeur. Cela permet de réduire le risque d’endommager

la fiche ou le cordon d’alimentation.

• S’assurer que le cordon est situé en lieu sûr de manière à

ce que personne ne marche ni ne trébuche dessus ou à ce

qu’il ne soit pas endommagé ni soumis à une tension.

• Ne pas utiliser de rallonge à moins que cela ne soit absolument nécessaire. L’utilisation d’une rallonge inadéquate

risque d’entraîner un incendie, un choc électrique ou une électrocution.

• La rallonge utilisée doit présenter un calibre adéquat (AWG