Page 1

INSTRUCTION

MANUAL

-.D364-O4

W

Circular

Saw

with Electric

Brake

J384-O4

8-114"

Gircular

Saw with Electric Brake

Page 2

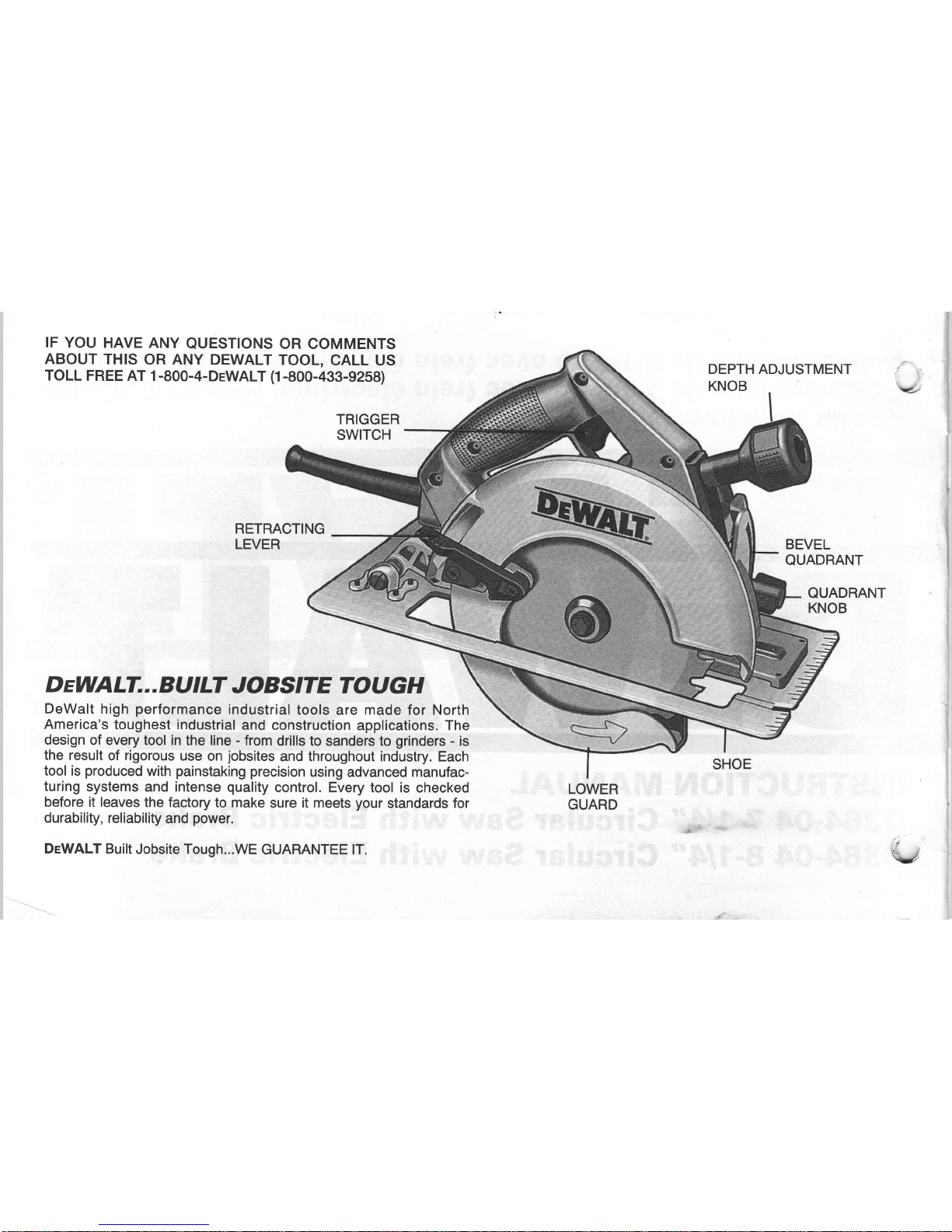

IF YOU

HAVE ANY

QUESTIONS OR COMMENTS

ABOUT

THIS

OR ANY DEWALT

TOOL,

CALL US

TOLL

FREE AT 1-800-4-DTWALT

(1-800-433-9258)

TRIGGER

SWITCH

RETRACTING

LEVER

D aWALT...

BU tLT

JO

BS7TE

TOU

cH

DeWalt high

performance

industrial

tools are made for North

America's

toughest

industrial

and construction

applications. The

design

of every tool in

the line - from

drills to

sanders

to

grinders

-

is

the result

of rigorous

use

on

jobsites

and throughout industry. Each

tool

is

produced

with

painstaking

precision

using advanced manufac-

turing

systems and intense

quality

control.

Every tool is

checked

before it leaves

the factory

to

make

sure it meets

your

standards for

durabiliÿ,

reliabiliÿ

and

power.

DeWALT

Built Jobsite Tough...WE

GUABANTEE lT.

DEPTH ADJUSTMENT

KNOB

BEVEL

QUADRANT

QUADRANT

KNOB

LOWER

GUARD

\U

Page 3

I

m

porta

nt S afeÿ

I nstru cti o

ns

*

WARNING:

When using Electric

Tools, basic safeÿ

precautions

should always

be followed

to reduce the

risk of fire, electric

shock and

personal

injury, including the

following:

*

Read all

lnstructions.

*

KEEP

WORK AREA CLEAN.

Cluttered areas

and benches invite

injuries.

*

CONSIDER

WORKAREA

ENVIRONMENT.

Don't expose

power

tools

to rain.

Don't use

power

tools

in damp or

wet locations.

Keep

work

area

well lit.

*

GUARD

AGAINST ELECTRIC SHOCK.

Prevent body

contact

with

grounded

sufaces.

For example:

pipes,

radiators,

ranges,

refrigerator

enclosures.

*

KEEP CHILDREN

AWAY. All visitors should

be kept away

from

work area.

Do not

let visitors contact tool or extension

cord.

*

STORE

IDLE TOOLS.

When not in use, tools should be stored

in dry,

and

high

or

locked-up

place -

out of

reach of children.

*

DON'T

FORCE

TOOL. lt will do the

job

better and

safer

at

the

rate for which

it was intended.

*

USE

RIGHT

TOOL. Don't

force

small tool or

attachment to do

the

job

of

a

heavy-duty

tool. Don't use tool for

purpose

not

intended, for example,

don't use circular saw

for cutting tree

limbs

or logs.

*

DRESS

PROPERLY.

Do not wear

loose

clothing or

jewelry.

They can be caught

in moving

parts.

Rubber

gloves

and

non-

skid footwear are

recommended

when working outdoors. Wear

protective

hair

covering

to contain

long hair.

*

USE

SAFETY

GLASSES.

Also

use

face or

dustmask

if opera-

tion

is dusÿ.

*

DON'T

ABUSE CORD.

Never carry

tool by cord

or

yank

it to dis-

connect

from receptacle.

Keep cord

from

heat, oil and

sharp

edges.

*

SECURE

WORK. Use

clamps or a

vise to

hold

work. lt's safer

than

using

your

hand and

it frees both

hands

to

operate

tool'

*

DON'T OVERREACH.

Keep

proper

footing

and balance

at all

times.

*

MAINTAIN

TOOLS

WITH CARE.

Keep tools

sharp and

clean

for

better

and safe

performance.

Follow instructions

for

lubricating

and

changing

accessories.

lnspect tool cords

periodically

and

if

damaged

have

repaired by authorized

service

faciliÿ.

lnspect

extension

cords

periodically

and replace

if damaged.

Keep

han:

dles dry,

clean and

free from

oil

and

grease.

*

DISCONNECT

TOOLS.

When not

in

use,

before

servicing

and

when changing

accessories,

such as

blades,

bits, cutters.

*

REMOVE

ADJUSTING

KEYS

AND WRENCHES.

FOTM

hAbit

Of

checking

to see that

keys and adiusting

wrenches are

removed

from tool

before turning

it

on.

*

AVOID UNINTENTIONAL

STARTING.

DON'I CArry

PIUggEd.iN

tool with

finger on switch.

Be sure switch

is off when

plugging

in.

*

OUTDOOR

USE

EXTENSION

CORDS.

When tool

is

used

out-

doors, use

only extension

cords

intended

for use outdoors

and

so

marked.

Page 4

lmporta

nt

Safeÿ

lnstructions

(Continued)

*

STAY ALERT.

Watch

what

you

are doing.

Use common

sense.

Do not

operate

tool when

you

are tired.

*

CHECK DAMAGED

PARTS.

Before

further

use of the

tool,

a

guard

or

other

part

that

is

damaged

should

be carefully

checked

to determine

that it

will

operate

properly

and

perform

ité

intended

function.

Check

for

alignment

of moving

parts,

binding

of moving

parts,

breakage

of

parts,

mounting

and any

other

coÀditions

thàt

Circular

Saw

Safeÿ

lnstructions

1. Disconnect plug

from

power

supply

before

changing

blades, mak-

ing

cutting

depth

or cutting

angle

adjustments,

inspecting,

clean-

ing

or when

saw is not

being used.

2. Keep

guards

in

place

and in working

order.

Never

wedge

or tie

lower

guard

open.

Check

operation

of

lower guard

before

each

use. Do

not

use if

lower

guard

does

not

close

briskly

and com-

pletely

over

saw

blades.

CAUTION:

lf

saw is

dropped, lower

guard

may

be

bent

restricting

full return.

Do

not

usè

saw until

_ loyel0yard

is

returned

to the

proper

working

order.

3.

KEEP

BI-ADES

CLEAN

AND

SHARP.

Shàrp

btades

minimize

stalling,

overload,

kickback

and

give

a cleaner

cut.

4. DANGER:

KEEP

HANDS

AWAY

FROM

CUTTING

AREA.

Keep

hands

away from

blades.

Do

not reach

underneath

work whilê

blade

is rotating.

Do

not

attempt

to remove

cut material

when

blade

is moving.

CAUTION:

Blades

continue

to

coast

after

releas-

ing trigger.

Never

place

your

hand

on

the work

surface

in front

of

or

behind

the saw.

manual.

Have

defective

switches

replaced

by

authorized

service

centre.

Do

not

use tool

if

switch

does not

turn

it

on and

off.

*

DO

NOT

OPERATE

portable

electric

tools near

flammable

liquids

or in

gaseous

or explosive

atmospheres.

Motors

in

these

iools

normally

spark

and the

sparks

might

ignite

fumes.

SAVE

THESE

INSTRUCTIONS

FOR

FUTURE

USE.

5.

SUPPORT

LARGE

PANELS.

Large

panels

must

be supported

as

shown

in FIGURE

14

to minimize

the

risk

of overload'

ând kick_

back

from

blade

pinching.

When

cutting

operation

requires

the

resting

of the

saw

on the

workpiece,

the

saw

should

be iested

on

the larger portion

and the

smaller

piece

cut

off.

6.

USE

RIP

FENCE.

Always

use

a fence

or straight

edge

guide

when

ripping.

7.

GUARD

AGAINST

K|CKBACK.

Kickback

occurs

when

the

saw

begins

to stall

rapidly

and is

driven

back

towards

the

operator.

Release

switch

immediately

if

blade

binds

or

saw

stallô.

Keep

blades

sharp.

Support

large

panels

as shown

in FIGURE

t+.

Usb

fence

or straight

edge

guide

when

ripping.

Don,t

force

tool.

Stay

alert,

exercise

control.

Don't

remove

saw-from

work

during

a

crit

while

the

blade

is moving.

A more

detailed

explanation

àt t<ick_

back

follows

the

"Operation"

section

of

this manual.

8. LOWER

GUARD.

When

necessary

for

accurate

starts

or

when

-

qgclelgyïIg,

laise

lower guard

wirh

the retracring

tever.

9.

ADJUSTMENTS.

Before

cutting

be sure

depth

aÀd bevet

adjust_

ments

are tight.

v

Page 5

10. USE

ONLY

BLADES

WITH

5/8"

DIAMETER

ARBOR. Do not

ft

use

blades

with incorrect size

holes. Never use defective or

'

incorrect blade washers or

bolts.

11.

AVOID

CUTTING

NAILS. lnspect for and

remove all

nails

from lumber before

cutting.

CAUTION:

When sawing

into walls, floors or

wherever

"live"

electrical

wires may be encountered,

DO

NOT TOUCH ANY

METAL PARTS OF

THE TOOL! Hold the Saw

only by its

plas-

tic

handles to

prevent

electric shock

if

you

saw into a

"live"

wire.

SAVE

THESE

INSTRUCTIONS

Motor

Your DeWalt

tool is

powered

by a DeWalt-built

motor.

Be

sure

your

power

supply

agrees

with nameplate

marking.

120 Volts

AC/DC means

your

saw

will

operate

on alternating

or direct cur-

rent. Lower

voltage

will

cause

loss of

power

and

can

result in

over-heating.

All DeWalt

tools

are

factory-tested;

if this tool does

not operate,

check

the

power

supply.

Double lnsulation

Your

unit

is DOUBLE

INSUI-ATED.

This means that

it is

con-

structed

throughout

with TWO separate

"layers"

of electrical

insu-

lation or one

DOUBLE thickness

of insulation between

you

and

the tool's electrical

system.

Tools

built

with this

insulation system are

not intended to be

grounded.

As a result,

your

tool

is equipped

with

a two-prong

plug

which

permits

you

to

use extension cords

without concern for

maintaining a

ground

connection.

NOTE: DOUBLE

INSULATION does

not take the

place

of

normal

safeÿ

precautions

when

operating

this tool.

This insulation sys-

tem is for

added

protection

againt

injury

resulting

from a

possible

,r{Bctrical

insulation failure within

the tool.

-

l,UTION:

When

servicing

all tools, USE ONLY

IDENTICAL

nEPIâCEMENT

PARTS. Repair or

replace damaged cords.

Electric

Brake

Your saw

has an automatic

electric brake

which is designed

to

stop

the blade

from

coasting

in

about

two seconds after

you

release

the trigger switch.

lt is

useful

when making certain

cuts

in

wood

where a coasting

blade

would result

in a

wide, imprecise

cut.

Occasionally,

under

certain

conditions,

the brake

will not function

properly

and

won't stop

the saw

in the 2 seconds

discussed

above.

lf this condition

persists,

turn the saw

on and off

four or

five times.

lf the brake still

does

not stop the blade

in about

2 sec-

onds,

the

problem

may be

worn brushes.

Replace the brushes as

described

below and

try

the saw again.

lf the

problem

still

per-

sists,

have the tool

seruiced at a

service

center or authorized

ser-

vice facility.

DeWalt tools are

serviced

by the

lndustrial

Tool

Division

of Black &

Decker

Canada

lnc.

Brushes

DISCONNECT

PLUG

FROM

POWER SUPPLY

lnspect

carbon brushes

regularly by

unplugging

tool,

removing

the'Brush

lnspection Cap

(Figure

2) and

withdrawing

the

brush

assembly.

Keep brushes

clean and

sliding

freely

in their

guides.

Always

replace a used

brush

in the same

orientation

in the

holder

as

it was

prior

to removal.

Carbon

brushes

have

varying symbols

stamped

into their sides, and

if

the

brushes

are

worn down to

the

line closest

to the spring,

they

must be

replaced. Use

only

identi-

cal

DeWalt brushes.

Always

replace

both brushes.

Use

of the

correct

grade

of

brush

is essential

for

proper

operation

of

electric

brakes.

New brush assemblies

are

available

at

your

local service

center.

The tool should

be allowed

to

"run

in"

(run

at

no load with-

out blade)

for 10

minutes before

use to

seat new brushes.

This is

especially

important

for saws equipped

with electric brakes,

which

may

be

erratic

in operation

until the brushes

are

properly

seated

(worn

in).

While

"running

in"

DO NOT

TlE,

TAPE, OR OTHERWISE

LOCK

THE TRIGGER SWITCH

ON.

HOLD

BY HAND ONLY.

Page 6

Adjustments

and

Setup

ATTACHING

AND REMOVING

BLADES

DISCONNECT

PLUG FROM

POWER

SUPPLY.

To attach

the blade, retract

lower

blade

guard

and

place

inner

clamp

washer

and blade on

saw spindle with

printed

side

of blade

out

(teeth

at bottom

ol blade

pointing

forward)

(Figure

1). lnstall

outer clamp washer.

The larger

sufaces of

both washers must

face the

blade. Thread

on blade clamping

screw firmly

by

hand

to

hold

washers in

position.

Lightly

depress

the blade lock

(Figure

2) while

turning the

spindle

until the blade stops

rotating. Tighten

blade

clamping

screw

(clockwise)

firmly with

the blade wrench

(Figure

3).

NEVER ENGAGE

BLADE

LOCK WHILE

SAW IS RUNNING,

OR

ENGAGE IN

AN EFFORT

TO STOP THE

TOOL. NEVER

TURN

SWITCH

ON

WHEN

BLADE LOCK

IS ENGAGED.

When removing

the

blade, first

unplug the

saw.

Engage

the blade

lock

and unscrew the blade

clamping

screw by turning it

counter-

clockwise with the

blade wrench.

CUTTING DEPTH ADJUSTMENT

DISCONNECT

PLUG FROM POWER

SUPPLY.

Loosen

(counterclockwise)

the Cutting

Depth Adjustment

Knob,

shown in

(Figure

4).

Lift the

saw handle,

as shown in the figure,

to

adjust

it

to the desired height.

Tighten

the knob

to secure it in

place.

lf depth

of cut cannot

be adjusted, inspect

parts

for

dam-

age

and service as required

before

use. A scale

and

pointer

is

provided

to

enable

you

to

select a specific

depth of cut.

Simply

align the

pointer,

shown in

(Figure

5), to

the desired depth

of cut.

FIG.1

INNER

CLAMP

WASHER

OUTER

CLAMP

WASHER

BLADE

CLAMPING

SCREW

LOOSEN

Y.'

BRUSH INSPECTION

CAP

Page 7

->

PO|NTER

SCALE

NOTE: To adjust the depth of cut

pointer

for various

blade diame-

ters,

loosen

the Cutting

Depth Adjustment Knob

and

raise the

saw

until the blade

just

touches the workpiece and tighten

the

knob.

This is

the

zero

depth of cut

position.

lf required, loosen the

screw

that holds the

pointer

and

adjust

to the

zero indicator mark.

The saw is now

adjusted

to

accurately

indicate the depth of cut

for the blade used.

For the most efficient cutting

action

using a carbide tipped saw

blade, set the Depth Adjustment so that about one half of a tooth

projects

below the surface of the

wood

to be cut.

The height

of a

whole tooth is the distance from the tip of the tooth to the boüom

of the

gullet

in

front of

it.

Study

Figures

5A and 58

to

determine

what

one

half tooth means.

(5A

shows

one half tooth

projecting

below

the surface

and

figure

58

shows a whole tooth

projecting

below the sufface).

Setting the saw

at the

proper

cutting depth

keeps

blade

friction

to

a

minimum, removes sawdust from between the blade teeth,

results in cooler, faster sawing and reduces the chance

of kick-

back.

A

method of checking for the correct cutting depth

is

shown in

Figure 6. Lay a

piece

of the

material

you plan

to

cut along

the

side of the blade, as shown

in

the figure, and observe

how much

tooth

projects

beyond

the material.

NOTE: When

using a

non carbide tipped blade, make an excep-

tion to the above

procedure

and allow a

full tooth to

project

below

the

material,

as shown

in Figure

58.

BEVEL ANGLE ADJUSTMENT

DISCONNECT THE

SAW

FROM THE POWER

SUPPLY.

The full range of the Bevel Adjustment is from

0

to 50 DEGREES.

ïhe

quadrant

is

graduated

in increments of 1 degree.

On the

front

of the saw

is

a bevel angle adjustment

mechanism

(Figure

8) consisting of a calibrated

quadrant

and a

knob. To

set

the saw

for

a bevel cut,

loosen

(counterclockwise)

the

quadrant

knob

and

tilt

shoe

to the

desired angle by aligning

the

pointer

with

the desired angle

mark. Retighten knob firmly

(clockwise).

FIG.5A

RIP FENCE

FIG.58

Page 8

KERF INDICATOR

The front

of

the

saw shoe

has

a

kerf indicator

(Figure

8)

for verti-

cal and bevel cutting.

This indicator

enables

you

to

guide

the saw

along

cutting lines

penciled

on the

material

being cut.

The indica-

tor

lines

up with the left

(inner)

side of

the

saw blade,

which

makes

the slot or

"kef'

cut by the moving

blade

fall to the right of

the

indicator.

Guide along the

penciled

cutting line so that

the kerf

falls

into

the waste or

surplus

material

-

See

Figure

9.

Figure 9

shows the dimensions of the shoe. Note

that

the left side is 5

1/2"

between the lefi side

of

the

blade and the

left

edge

of the shoe

(standard

6x lumber). The right

dimension

is 1 112"

(standard

2x

lumber).

SHOE

ALIGNMENT

Your saw has

been set at the factory

for

accurate

vertical

cuts

(a

90 degree angle between the bottom of the shoe and

the blade).

The edge of the

shoe

has

also

been

set

parallel

to the blade

so

that it will not bind when using an edge

guide,

lf

the saw should

ever need adjustment, it may be done as follows:

ADJUSTING FOR

90" CUTS

1. DISCONNECT PLUG FROM POWER

SUPPLY.

2. Adjust the saw to 0" bevel.

3.

Place saw on blade

side

(Figure

10). Retract

blade

guard.

4. Loosen

quadrant

knob.

(Figure

10). Place

a

square against

the blade

and

shoe to

adjust the

g0'

setting.

5. Loosen the

hex nut

and move the

adjustment

screw so that

the shoe

will

stop at the

proper

angle

as shown

in Figure 11.

Lock the screw in

place

by tightening the hex nut.

6.

lt may

be

necessary

to

adjust

the

quadrant

angle

pointer

to

line up on

"O"

after shoe has been

adjusted.

Yk

FIG.9

GUIDE

ALONG WASTE

PENCILED CUTTING OR

LINE

SO

KERF FALLS SURPLUS

IN WASTE STOCK STOCK

Allrn

btt side

ot

Atign

E{t

sidê

ôfr.

saw blade with

"+5'

sEw blade wilh

mark,

as shofln,

{or

',0"

mark for

45c kr€l eutùr!g

.'r::

§treiâlil

cuitinû.

OUADRANT

u

Page 9

HEX NUT

ADJUSTING THE

SHOE

PRALLEL TO THE BLADE

1. DISCONNECT

PLUG FROM POWER

SUPPLY.

2. Loosen the hex nut shown in

(Figure

12) and then

turn the

adjustment

screw in or out

as

needed to adjust for

parallelism.

3.

Adjust the

shoe

until it is

parallel

to the blade by

measuring

from the edge of the shoe to the blade, front & rear.

You

can

measure from the outside edge of the blade to the shoe as

shown in

(Figure

12) or from the

inner

edge of the blade to the

wider

part

of

the shoe.

(Do

not measure from the tips of

any

saw blade

teeth.)

4. When the shoe and blade are

parallel,

hold the

adjusting

screw

in

place

and

tighten the hex nut firmly.

Operation

SWITCH

Pull the trigger switch to turn the

motor

"ON".

Releasing the trig-

ger

turns

the motor.OFF".

Releasing the trigger

also automatical-

ly

actuates

the electric brake.

This tool has no

provision

to lock

the switch

in

the

"ON" position,

and

should never be

locked

"ON"

by any other

means.

WORKPIECE SUPPORT

Figure 13 shows

proper

sawing

position.

Note

that

hands

are

kept away from cutting area, and

power

cord

is

positioned

clear

of the cutting area so that

it will not

get

caught or hung up on the

work.

To

avoid

kickback, DO support

board

of

panel

NEAR the cut

and

on both sides of the cut,

(Figure

14). DON'T support board or

panel

away

from the

cut,

(Figure

15). When ripping long narrow

strips,

support cut-otf waste material.

When operating the saw, keep the cord

away

from the cutting

area and

prevent

it

from becoming

hung

up on the

workpiece.

Note that

a special Cord

Keeper has

been

provided

on

the

tool's

handle,

as shown

in Figure 4.

Simply

press

the cord

into

the

keeper

to

keep it in

sight and out of the

way.

QUADRANT HEX

POINTER

NUT

SCREW

FtG. 12

FtG. 13

Page 10

WARNING:

lt is important

to support the work

properly

and to hold

the saw firmly

to

prevent

loss

of control which

could cause

personal

injury; Figure 13

illustrates

ÿpical

hand

support of the saw.

ALWAYS

DISCONNECT

SAW

BEFORE

MAKING ANY ADJUST-

MENTS!

Place the work

with its

"good"

side

-

the

one on

which

appearance is most important

-

down. The

saw cuts upward,

so any

splintering will

be on the work face

that is up when

you

saw

it.

Support the work

so that the cut will

be on

your

right. Place the wider

portion

of the saw shoe

on that

part

of the workpiece which

is solidly

supported,

not on the

section that will fall

off

when

the cut is made. As

examples, Figure

16 illustrates

the RIGHT way

to cut off the end of a

board,

and Figure 17 the

WRONG way. Always

clamp work. Don't try

to hold

short

pieces

by hand!

Remember to

support cantilevered and

overhanging material.

Use caution when sawing material

from below.

CUTTING

Be

sure saw is up to

full speed before

blade contacts material to be

cut.

Starting saw with

blade against material to

be

cut

or

pushed

for-

ward into kerf

can result in kickback.

Push

the

saw

forward

at

a

speed which

allows the blade

to cut

with-

out laboring. Hardness

and toughness

can vary even in the same

piece

of material,

and knotty or

damp sections can

put

a

heavy load

on

the saw. When

this happens,

push

the saw more slowly, but hard

enough

to keep it working without

much

decrease

in

speed.

Forcing

the

saw can cause rough

cuts, inaccuracy, kickback

and over-heating

of the motor.

Should

your

cut begin to

go

off the line,

don't try to force it back on.

Release

the

switch and

allow blade to come to

a complete stop.

Then

you

can withdraw

the saw,

sight anew,

and start a

new

cut slightly

inside

the

wrong

one. ln

any event, withdraw

the saw

if

you

must

shift

the

cut.

Forcing

a

correction

inside

the cut can stall the saw and

lead

to kickback. lF

SAW STALLS, RELEASE THE TRIGGER

AND BACK

THE

SAW

UNTIL

IT IS LOOSE.

BE

SURE

BI.ADE IS

STRAIGHT

IN

THE

CUT AND

CLEAR

OF

THE

CUTTING EDGE BEFORE

RESTARTING.

FtG.

15

WRONG

MATERIAL

BENDS

ON

BLADE

CAUSING HEAVY

LOADS

OR KICKBACK.

SUPPORT

WORK

NEAR

CUT

WRONG

Page 11

rl§s

you

finish a

cut, release

the trigger and

allow

the blade

to stop

ftfore

lifting the saw

from the

work.

As

you

lift

the saw, the

spring-tensioned

telescoping

guard

will

automatically

close under

the blade.

Remember the

blade

is exposed until

this

occurs,

never reach under

the

work for any

reason

whatsoever.

When

you

have to

retract the

telescoping

guard

manually

(as

is neces-

sary for starting

pocket

cuts) always

use

the retracting

lever.

NOTE: When cutting

thin strips,

be

careful to ensure

that small

cutoff

pieces

don't

hang up

on

inside of

lower

guard.

Always use a

fence or

straight

edge

guide

when

ripping'

POCKET

CUTTING

DISCONNECT

PLUG

FROM POWER

SUPPLY.

Adjust

saw

shoe

so blade

cuts at

desired depth.

Tilt

saw

forward

and

rest front of

the shoe on

material

to be cut.

Using

the

retracting

lever, relract

blade

guard

to an

upward

position.

Lower rear

of shoe until

blade

teeth almost

touch

cutting

line. Now

release the

blade

guard

and

its

contact

with the

work will

keep it in

position

to open

freely as

you

startthe

cut

(Figure

18).

Start

the

motor

and

gradually

lower

the saw

until

its shoe

rests

flat on

the

material

to be

cut.

Advance

saw along

the

cutting

line

until

cut

is completed.

Release trigger

and

allow

blade

to stop

completely

before

withdrawing

the

blade

from the

material'

When

starting

eàch

new

cut, repeat

as above.

Never tie

the blade

guard

in a

raised

position.

Kickback

When the

saw

blade becomes

pinched

or

twisted

in the

cut,

kick-

back

can

occur.

The

saw is thrust

rapidly

back

toward

the

opera-

tor.

When

the blade

is

pinched

or

bound

tightly

by the

kerf

closing

down,

the

blade

stalls

and the

motor

reaction

drives

the unit

backward.

When

the

blade becomes

twisted

or misaligned

in the

cut,

the

teeth at

the

back edge

of

the blade

can

dig

into the

top

surface

of

the

wood

causing

the blade

to climb

out

of

the

kerf and

jump

back

toward

the

oPerator.

kictiOack

is

more

likely to

occur

when any

of the

following

condi-

tions

exist.

1. IMPROPER

WORKPIECE

SUPPORT

A. Sagging

or

improper

litting of

the cut

off

piece

causing

pinching

of

the blade.

B. ôutting

through

material

supported

at

the

outer

ends

only

(see

Figure

15).

As the

material

weakens

it

sags,

closing

down

the

kerf and

pinching

the blade.

C.

Cutting

of

a cantilevered

or

overhanging

piece

oJ

material

from the

bottom

up

in a vertical

direction.

The falling

cut off

piece

can

pinch

the

blade.

D. Ôutting

off long

narrow

strips

(as

in

ripping).

The cut

off

strip

can sag

or twist

closing

the

kerf and

pinching

the

blade.

E. Snagging

the

lower

guard

on a surface

below

the

material

being

cut

momentarily

reducing operator

control'

The saw

can

lift

partially

out

of the

cut

increasing

the

chance

of

blade

twist.

Page 12

2. IMPROPER

DEPTH

OF CUT

SETTING

ON

SAW

Using the

saw with

an

excessive

depth

cut setting

increases

loading

on

the unit

and susceptibility

to

twisting

of the blade in

the kerf.

lt

also increases

the

surface

area of the

blade avail-

able for

pinching

under

conditions

of kerf close

down.

3. B|-ADE

TWIST|NG

(M|SALIGNMENT

tN

CUT)

A. Pushing

harder

to

cut through

a

knot,

nail,

or a hard

grain

area

can cause

the

blade to twist.

B. Trying

to turn

the

saw in the

cut

(trying

to

get

back

on the

marked

line)

can cause

blade

twist.

C. Extended

reach

or

operating

saw with

poor

body

control

(out

of

balance),

can result

in

twisting

the

blade.

D.

Changing

hand

grip

or body

position

white

cutting

can

result

in

blade

twist.

E. Backing

unit up to

clear

blade

can lead

to twist if not

done

carefully.

4.

MATERIALS

THAT

REQUIRE

EXTRA

ATTENTION

A. Wet

lumber

B.

Green lumber

(materialfreshly

cut

or not kiln

dried)

C. Pressure

treated

lumber

(material

treated with

preserva-

tives

or anti-rot

chemicals)

5.

USE OF DULL

OR DIRTY

BI.ADES

Dull

or dirÿ blades

cause increased

loading

of the

saw, To

compensate,

an operator

will

usually

push

harder

which

fur-

ther loads

the

unit

and

promotes

twisting

of the

blade in

the

kerf.

Worn

blades

may

also

have

reduced

body

clearance

which

increases

the chance

of

binding

and increased

loading.

6. LIFTING

THE

SAW WHEN

MAKING

BEVEL

CUTS

Bevel_

cuts

require

special

operator

attention

to

proper

cutting

techniques -

especially

guidance

of the

saw. Both

blade

anglé

to the

shoe

and

greater

blade

surface in

the material

increale

the chance

for

binding

and misalignment (twist)

to

occur.

7.

RESTARTING

A

CUT

WITH THE

BLADE

TEETH

JAMMED."

AGAINSTTHE

MATERIAL

I

The

saw

should

be

brought

up to full

operating

speed

beforèÿ

starting

a cut

or

restarting

a cut

after the

unit has

been

stopped

with

the blade

in

the kerf. Failure

to do

so can

cause

stalling

and kickback.

Any

other

conditions

which

could result

in

pinching,

binding,

twisÈ

ing,

or misalignment

of

the blade

could

cause kickback.

Èefer

to

the

sections

on

'Adjustments

And

SetUp"

and

"Operation',

for

procedures

and

techniques

that will

minimize

the occurrence

of

kickback.

Blades

A

dull blade

will

cause

slow, inefficient

cutting

overload

on the

saw motor,

excessive

splintering

and could increase

the

possibili-

ÿ

of kickback.

lt is

a

good practice

to keep

extra

blades'on

hand

so that

sharp

blades

are

available while

the dull ones

are

being

sharpened

(See "SAWS-SHARPEN|NG"

in

the

ye[ow pages).

tn

fact,

many

lower

priced

blades

can

be replaced

with new

ônes

at

very

little

cost

over the

sharpening

price.

Hardened

gum

on the

blade

will

slow down

the cutting.

This

gum

can best

be removed

with

kerosene,

turpentine

or

oven cleanôr.

DeWalt

manufactures

a complete

line

of saw

blades

and the fol-

lowing

ÿpes

of blades

are available

from

your

service

center.

VISUALLY

EXAMINE

CARBIDE

BLADES

BEFORE

USE.

REPLACE

IF DAMAGED.

10

\,

Page 13

FLADETYPE

COMBINATION

-

For

general purpose

ripping and

cutting

CROSS-CUT

-

For smoother,

faster

cross cutting

RIPPING

-

For fast rip cuts

PLYWOOD

-

For smooth

cuts in

plywood.

Reduce splintering.

FRAMING/RIP

-

For facing,

roofing, siding, sub-flooring,

fram-

ing, form cutting.

PLANER

-

For

very smooth ripping and

cross-cutting.

FRICTION

-

For cutting

corrugated,

galvanized

sheets.

METAL-CUTTING

-

For cutting aluminum,

copper

and other

soft

metals.

FLOORING

-

For sawing

where

nails may be occasionally

encountered.

CARBIDE-TIPPED

-

For longest sawing

without blade sharp-

ening.

Cuts

wood,

Transite, Cemesto

board,

Formica,

Masonite, and

similar

materials.

Accessories

lf

you

need assistance

in locating any accessory,

please

contact:

DeWALT

lndustrial

Tool

ComPanY

Consumer

Service

DePartment

100 CentralAve.

P.O. Box 618

Brockville,

Ont.

K6V 5W6

Every

DeWalt tool

is of

the

highest

quality.

A.

RIP

FENCE...

Attaches

to top of Saw

shoe.

Permits

rip cuts

without

penciled

guide

line.

B. SAW

PhOTRACTOR...

Guides

Saw

for accurate

cut-off

work.

Adjusts

from 0

to

70

degrees.

C.

CUT-OFF

GUIDE...

For 90

degree or

45 degree

cuts.

D. CARRYING

CASE...

Protects

your

Saw.

Keeps

blades'

extension

cords,

etc.

handy on

the

job.

E. SAFETY

SPECTACLES...

Designed to

fit over

standard

glasses.

F. FILTER

MASK

CAUTION:

Recommended

accessories

and

saw blades

for

your

Saw are

listed

in this manual.

The

use of any

other

accessory

or

attachment

may be

hazardous.

The

accessories

listed in this

manual are available

at eltra cost.

.A

complete

listinq of

service centres

is included on the depot

list-

ft

."ro

packed

üith

your

tool.

1't

Page 14

Extension

Cords

Double-insulated

tools have

2-wire

cords and

can be

used with 2-

wire

or 3-wire

extension

cords.

Only round-jacketed

extension

cords should

be used. lf

the extension

will

be used

outside, the

cord must

be suitable for

outdoor

use. Any

cord marked

as out-

door

can be used for

indoor work.

The letter

"W'on

the cord

jack-

et

indicates

that the cord is

suitable for

outdoor

use.

An

extension cord

must have

adequate

wire

size

(AWG

or

American

Wire

Gauge) for

safety,

and to

prevent

loss

of

power

and overheating.

The

smaller the

gauge

number

of

the

wire,

the

greater

the capacity

of the cable,

that is 16

gauge

has more

capacity

than

18

gauge.

When using

more

than one extension

to

make

up

the total length,

be sure

each individual

extension

con-

tains

at

least

the minimum

wire

size.

To determine

the minimum

wire

size

required,

refer

to the

chart

below.

oHART FOR MTN|MUM

WIRE

S|ZE

(AWG)

OF

EXTENSION

CORDS

NAMEPLATE

TOTALEXTENSIONCORDLENGTH-METRES

RATTNG-AMPS

10 15

20

30 40 45

50 60

0-10.0

10.1-13.0

13.1-15.0

Before

using

an extension

cord, inspect

it for

loose

or exposed

wires,

damaged insulation,

and defective

fittings. Make

any need-

ed repairs

or replace

the cord if

necessary.

lmpohant!

To

assure

product

SAFETY

and RELIABILITY,

particutarty

for

Double-lnsulated

tools, repairs,

maintenance

and adjustment

(excluding

maintenance

described in

this manual)

should

be

per-

formed

by BLACK

& DECKER

Service

Centres

or other

qualified

service

organizations,

always using

the identical

DEWALT

replacement

parts.

ONE.YEAR

WARRANTY

DeWalt

Heavy

Duÿ Tools

are warranted

for

one

year

from

datei"-

purchases

to

correct

by repair

or

parts

replâcement

withoLÉ

ghargq,

any

product

defect

due

to faulÿ

material

or workmanship

for

tools used

in

commercial

or rental

sérvice. Arrangements

havb

been

made

with

the lndustrial

Tool

Division

of Blàck & Decker

Canada Inc.

to

provide

warranÿ

repairs

for

DeWalt

Tools.

piTply.

retqrn

the complele

unit'transportation prepaid

to

any

lndustrial

Black

& Decker

Service

Centè

or

lndudtriai

Authorizeâ

Service

Centre. DeWalt

assumes

no responsibility

for

damage

or

faulÿ

performance

caused

by misuse,

careless hàndling

or rihere

repairs

have

been made,

or attempted

by others.

No ôther

war-

ranties,

written

or verbal,

are authorized.

Note:

This

warranÿ

and

related

provisions

set

out above

may not

be

applicable in

certain

provinces.

30 DAY NO

RISK

SATISFACTION

GUARANTEE

II

y9y.rl"

not

completely

satisfied

with

the

performance

of

your

DeWalt

heavy

duÿ industrial

tool,

simply return

the

complete irnit,

including

all accessory

items,

to

the

pariicipating

seller

dr direcfly,

transportation

prepaid,

to:

DeWalt

lndustrial

Tool

Company,

100

Central Avenue,

Brockville,

Ontario

K6V 5W6

Attention:

Satisfaction

Guarantee

Department

Proof

of

purchase

is required

to receive

your

refund.

DEWALT

INDUSTRIAL

TOOL

COMPANY,

1OO

CENTRAL

AVE.

BROCKVILLE,

ONTARIO

K6V

5W6

16

16 16

16

14 14 12

12

16

16 14

14 14

12 12

12

14

14

12 12

12 12

12

v

Printed in

U.S.A.

Form

263582-01

(JULeS-CD-2)

Loading...

Loading...