Page 1

Instruction Manual

зѬҕєѪѠдѥіѲнҖкѥь

D28810, D28811, D28803

Heavy Duty Small Angle Grinder

ѯзіѪѷѠкѯлѨѕіѯеҖѥєѫєѰээѲнҖкѥьўьѤд

Page 2

ݏ༹ዐ࿔ 13

English 3

Thai 17

Page 3

3

General Safety Rules – For All T

ools

W

ARNING! Read and understand all instructions.

Failure to follow all instructions listed below may

result in electric shock, fire and/or serious personal injury

.

SA

VE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit.

Cluttered benches

and dark areas invite accidents.

•

Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust.

Power tools create sparks which may ignite the dust or fumes.

•

Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL

SAFETY

•

Grounded tools must be plugged into an outlet properly

installed and grounded in accordance with all codes and

ordinances. Never remove the grounding prong or modify

the plug in any way

. Do not use any adaptor plugs. Check

with a qualified electrician if you are in doubt as to whether

the outlet is properly grounded.

If the tools should electrically malfunction or break down, grounding provides a low resistance path to carry electricity away from the user

. Applicable

only to Class I (grounded) tools.

•

Double insulated tools are equipped with a polarized plug

(one blade is wider than the other

.) This plug will fit in a

polarized outlet only one way

. If the plug does not fit fully in

the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install a polarized outlet. Do not

change the plug in any way

.

Double insulation

eliminates

the need for the three wire grounded power cord and grounded

power supply system. Applicable only to Class II (double

insulated) tools.

•

Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk

of electric shock if your body is grounded.

•

Don’

t expose power tools to rain or wet conditions.

Water

entering a power tool will increase the risk of electric shock.

•

Do not abuse the cord. Never use the cord to carry the tools

or pull the plug from an outlet. Keep cord away from heat,

oil, sharp edges or moving parts. Replace damaged cords

immediately.Damaged cords increase the risk of electric shock.

Technical data

Power input W

No Load Speed

/min

Max. Disc Diameter mm

Side handle*

Dust-ejection system

One-piece brush arm

Brushes

Flange

Spindle Thread

W

eight

kg

D28810

680

10000

100

No

No

Yes

Pop off

Anti-Lock

M10

1.80

D28811

720

10000

100

No

No

Yes

Pop off

Anti-Lock

M10

1.80

D28803

850

Rated frequency Hz

50/60

50/60

50/60

Rated voltage V

220-240~

220-240~

220-240~

10000

100

Regular

No

Yes

Pop off

Anti-Lock

M10

1.85

ANGLE GRINDER

Congratulation!

D28810, D28811, D28803

You have chosen a D

E

WALT tool. Years of experience, thorough

product development and innovation make DEWALT one of the

most reliable partners for professional power tool users.

English

*D28803 sold in China does not include side handle.

Page 4

4

Using an extension cable

If an extension cable is required, use and approved extension

cable suitable for the power input of this tool (See technical data).

The minimum conductor size is 1.5 mm2.

When using a cable reel, always unwind the cable completely.

Also refer to the table below.

Conductor size (mm2) Cable rating (Amperes)

0.75

6

1.00

10

1.50

15

2.50

20

4.00 25

Cable length (m)

7.5

15 25

30

45

60

Voltage

Amperes Cable rating (Amperes)

115

0

- 2.0

6 6

6

6

6

10

2.1

-

3.4 6 6

6

6

15

15

3.5

-

5.0 6 6 10

15

20

20

5.1

-

7.0 10 10 15

20

20

25

7.1

-

12.0 15 15 20

25

25

-

12.1

-

20.0 20 20 25 - -

-

230

0

-

2.0 6 6

6

6

6

6

2.1

-

3.4 6 6

6

6

6

6

3.5

-

5.0 6 6

6

6

10

15

5.1

-

7.0 10 10 10

10

15

15

7.1

-

12.0 15 15 15

15

20

20

12.1

-

20.0 20 20 20

20

25

-

PERSONAL SAFETY

•

Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use tool while

tired or under the influence of drugs, alcohol, or medication.

A moment of inattention while operating power tools may

result in serious personal

injury

.

• Dress properly

. Do not wear loose clothing or jewelry

.

Contain long hair

. Keep your hair

, clothing, and gloves away

from moving parts. Loose clothing, jewelry

, or long hair can be

caught in moving parts.

Air vents often cover moving parts and

should also be avoided.

•

Avoid accidental starting. Be sure switch is of

f before plug-

ging in.

Carrying tools with your finger on the switch or plugging

in tools that have the switch on invites accidents.

•

Remove adjusting keys or wrenches before turning the tool

on.

A wrench or a key that is left attached to a rotating part of

the tool may result in personal injury

.

•

Do not overreach. Keep proper footing and balance at all

times.

Proper footing and balance enables better control of the

tool in unexpected situations.

•

Use safety equipment. Always wear eye protection. Dust

mask, non-skid safety shoes, hard hat, or hearing protection

must be used for appropriate conditions.

TOOL USE AND CARE

•

Use clamps or other practical way to secure and support

the workpiece to a stable platform.

Holding the work by hand

or against your body is unstable and may lead to loss of control.

• Do not force tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate for

which it is designed.

• Do not use tool if switch does not turn it on or of

f.

Any tool

that cannot be controlled with the switch is dangerous and must

be repaired.

English

Page 5

5

missing or damaged.

If grinding wheel or accessory loosens,

it may dismount from the machine and may cause serious

personal injury.

•

Always use proper guard with grinding wheel.

A

guard pro-

tects operator from broken wheel fragments and wheel contact.

• Accessories must be rated for at least the speed recommended on the tool warning label. Wheels and other acces-

sories running over rated speed can fly apart and cause injury.

Accessory ratings must be above listed minimum wheel speed

as shown on tool nameplate.

•

Hold tool by insulated gripping surfaces when performing

an operation where the cutting tool may contact hidden

wiring or its own cord.

Contact with a “live” wire will make

exposed metal parts of the tool “live” and shock the operator

.

•

AL

W

AYS WEAR EYE PROTECTION WHEN USING THIS

T

OOL.

•

Use of accessories not specified in this manual is not recommended and may be hazardous.

Use of power boosters

that would cause the tool to be driven at speeds greater than its

rated speed constitutes misuse.

•

Do not use circular saw blades or any other toothed blades

with this tool.

Serious injury may result.

• When starting the tool with a new or replacement wheel, or

a new or replacement wire brush installed, hold the tool in

a well protected area and let it run for one minute.

If the

wheel has an undetected crack or flaw

, it should burst in less

than one minute. If the wire brush has loose wires, they will be

detected. Never start the tool with a person in line with the

wheel. This includes the operator

.

• Avoid bouncing the wheel or giving it rough treatment.

If this

occurs, stop the tool and inspect the wheel for cracks or flaws.

•

Disconnect the plug from the power source before making

any adjustments, changing accessories, or storing the tool.

Such preventative safety measures reduce the risk of starting

the tool accidentally.

•

Store idle tools out of reach of children and other untrained

persons.Tools are dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and

clean.

Properly maintained tools, with sharp cutting edges are

less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts, break-

age of parts, and any other condition that may af

fect the

tool’

s operation. If damaged, have the tool serviced before

using. Many accidents are caused by poorly maintained tools.

•

Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for

one tool, may become hazardous when used on another tool.

SERVICE

• Tool service must be performed only by qualified repair

personnel.

Service or maintenance performed by unqualified

personnel could result in a risk of injury.

•

When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this manual.

Use of unauthorized parts or failure to follow maintenance

instructions may create a risk of electric shock or injury

.

Additional Specific Safety Instructions

for Grinders

•

Check that the grinding wheel backing flange has a yellow

rubber ring (I) installed, see Figure 1. Replace rubber ring if

missing, damaged or worn. See page 9 for details regarding

proper accessory installation.

WARNING:

The grinding wheel or accessory may loosen

during coast-down of the tool when shut off if rubber ring is

English

Page 6

6

•

When the wheel is pinched or bound tightly by the workpiece,

the wheel stalls and the motor reaction drives the unit rapidl

y

back toward or away from the operator

.

•

Kickback is the result of tool misuse and/or incorrect operating

procedures or conditions and can be avoided by taking proper

precautions as given below:

•

Maintain a firm grip with both hands on the unit and position your body and arm to allow you to resist kickback

forces.

Kickback forces can be controlled by the operator, if

proper precautions are taken.

•

When wheel is binding, or when interrupting a cut for any

reason, release the trigger and hold the unit motionless

in the material until the wheel comes to a complete stop.

Never attempt to remove the unit from the work or pull

the unit backward while the wheel is in motion or kickback may occur

.

Investigate and take corrective actions to

eliminate the cause of wheel binding.

•

When restarting a cut-of

f tool in the workpiece, check

that the wheel is not engaged into the material.

If wheel is

binding, it may walk up or kickback from the workpiece as the

tool is restarted.

•

Support large panels to minimize the risk of wheel pinching and kickback.

Large panels tend to sag under their own

weight. Support must be placed under the panel on both

sides, near the line of cut and near the edge of the panel.

W

ARNING:

Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chem-

icals known to cause cancer

, birth defects, or other reproductive

harm. Some examples of these chemicals are:

•

lead from lead-based paints,

•

crystalline silica from bricks and cement and other masonry

products, and

•

arsenic and chromium from chemically-treated lumber (CCA).

•

Direct sparks away from operator

, bystanders or flammable

materials. Sparks may be produced while cutting and/or

grind

ing. Sparks may cause burns or start fires.

•

Always use side handle.Tighten the handle securely

. The

side handle should always be used to maintain control of the tool

at all times.

•

Never cut into area that may contain electrical wiring or

piping. Serious injury may result.

•Clean out your tool often, especially after heavy use. Dust

and grit containing metal particles often accumulate on interior

surfaces and could create an electric shock hazard.

•

Do not operate this tool for long periods of time.

V

ibration

caused by the operating action of this tool may cause permanent

injury to fingers, hands, and arms. Use gloves to provide extra

cushion, take frequent rest periods, and limit daily time of use.

• Direct the Dust Ejection System (DES) away from operator

and coworkers. Serious injury may result (Fig. 1, H).

•

The label on your tool may include the following symbols. The

symbols and their definitions are as follows:

V

..........volts

A..............amperes

Hz

........hertz

W

............watts

min ......minutes

..........alternating current

....direct current

n

o............no load speed

........Class II

Construction ..........safety alert symbol

........earthing terminal

…/min

....revolutions per minute

Causes and Operator Pr

evention

of Kickback

•

Kickback is a sudden reaction to a pinched, bound or misaligned

wheel, wire brush or flap disc causing an uncontrolled cut-off

tool to lift up and out of the workpiece toward the operator.

English

Page 7

7

FIG. 1

Your risk from these exposures varies, depending on how often

you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with

soap and water

.

Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

WARNING:

Use of this tool can generate and/or disburse dust,

which may cause serious and permanent respiratory or other injury

.

Always use NIOSH/OSHA

approved respiratory protection appro-

priate for the dust exposure. Direct particles away from face and

body

.

CAUTION:

Use extra care when working into a corner because

a sudden, sharp movement of the grinder may be experienced

when the wheel or other accessory contacts a secondary surface

or a surface edge.

CAUTION: W

ear appropriate personal hearing protection

during use.

Under some conditions and duration of use, noise

from this product may contribute to hearing loss.

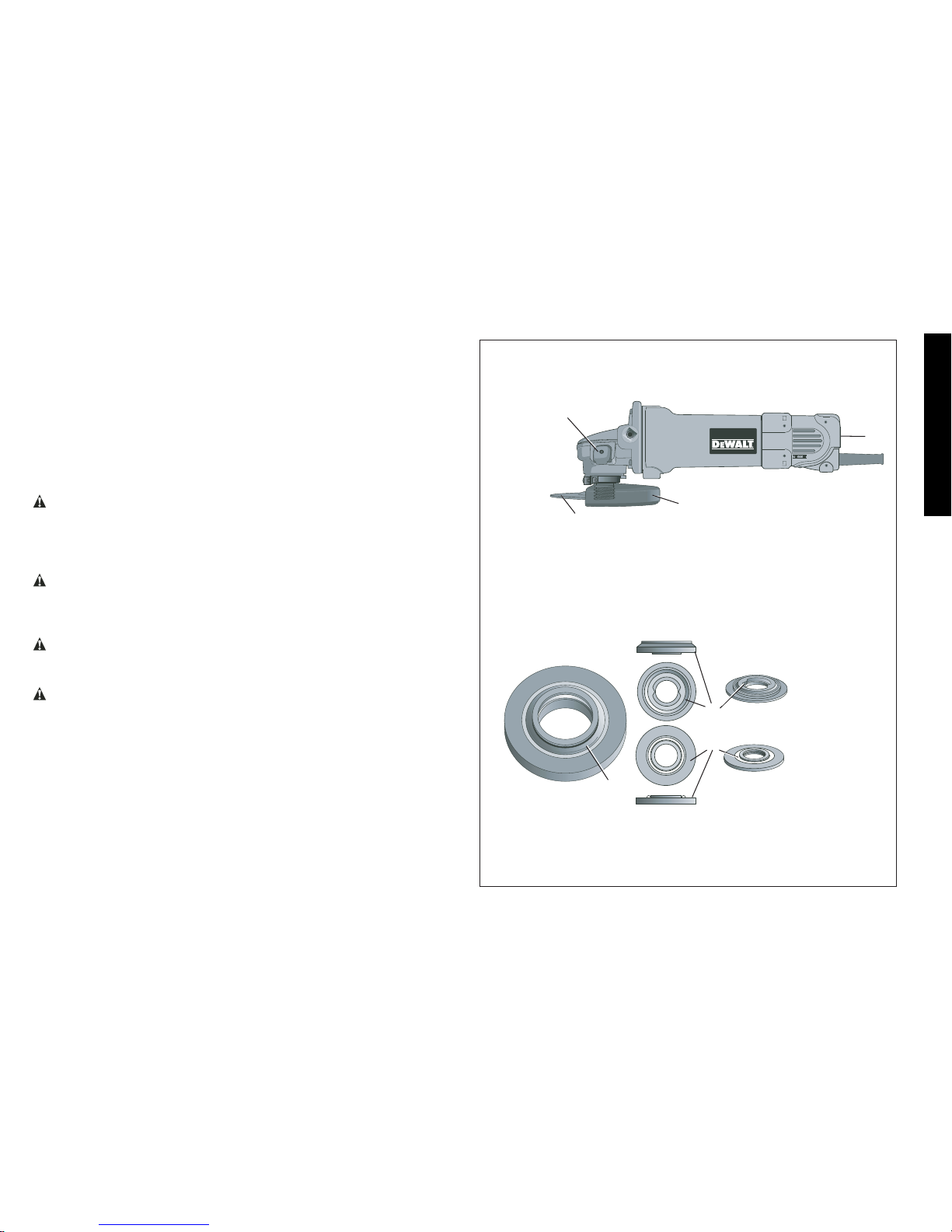

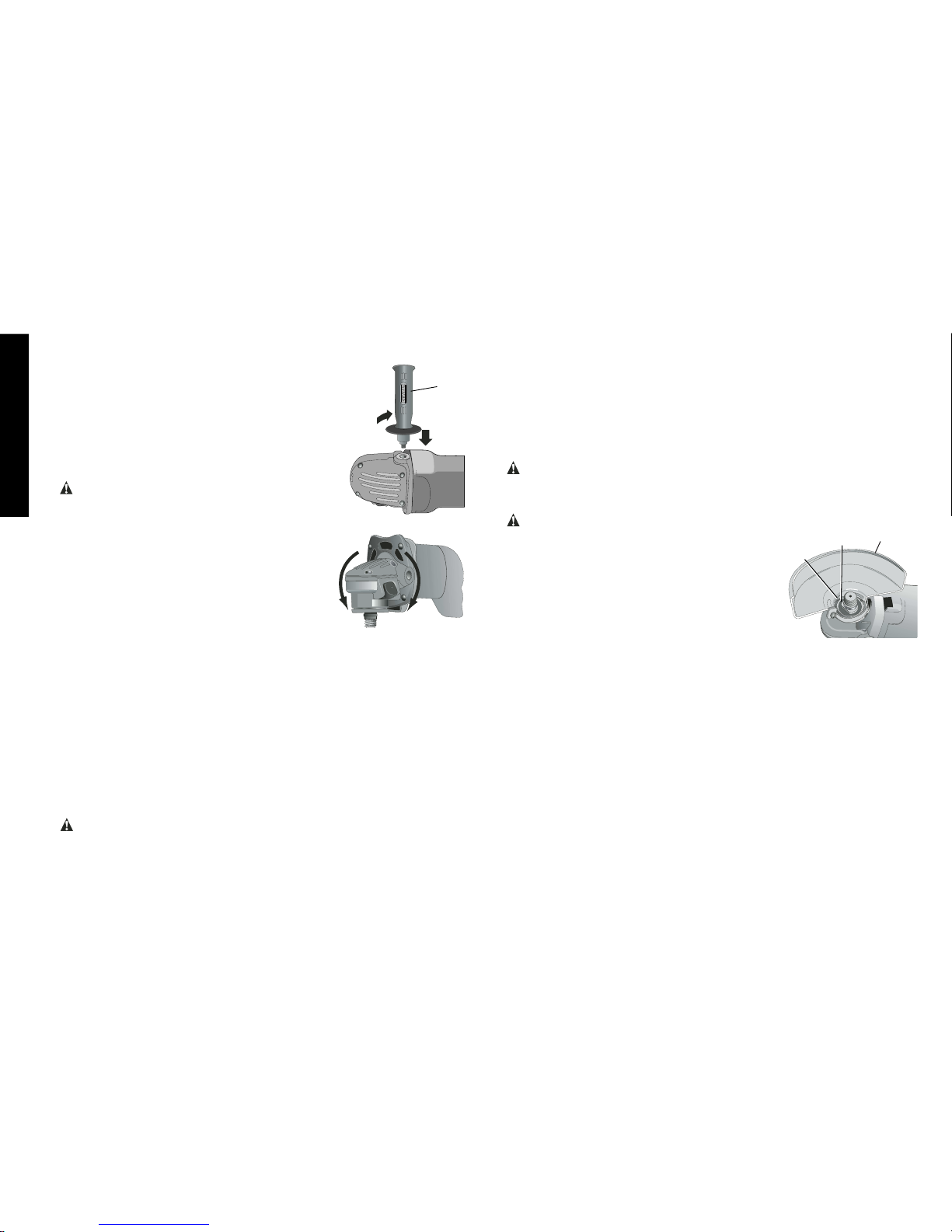

COMPONENTS (Fig. 1)

A. Spindle Lock Button

G.

Threaded Clamp Nut

F. Anti-Lockup Backing Flange

B. Guard

C.

100 mm Grinding Wheel

H. Rubber ring

D.

Switch

E.

Side Handle

WARNING:

Don’t forget to fix all screws on the enclosure.

English

G

F

D28810

D28811

D28803

H

A

C

B

D

Page 8

8

Mounting Guar

d

MOUNTING AND REMOVING GUARD

CAUTION: T

urn of

f and unplug the tool before making any

CAUTION:

adjustments or removing or installing attachments or accessories.

ASSEMBL

Y AND ADJUSTMENTS

ATTACHING SIDE HANDLE

The side handle (E) can be fitted to either

side of the gear case in the threaded holes,

as shown. Before using the tool, check that

the handle is tightened securely. Use a

wrench to firmly tighten the side handle.

Rotating the Gear Case

1.

Remove guard and flanges from tool.

2.

3. Separating the gear case from motor

housing not more than 6.4mm, rotate

the gear case head to desired position.

NOTE: If the gear case and motor housing become separated by

more than 6.4mm, the tool must be serviced and re-assembled by a

D

EW

AL

T

service center

. Failure to have the tool serviced may

cause brush, motor and bearing failure.

3.

Re-install screws to attach the gear case to the motor housing.

Tighten screws to 18 in./lbs. torque. Overtightening could causescrews to strip.

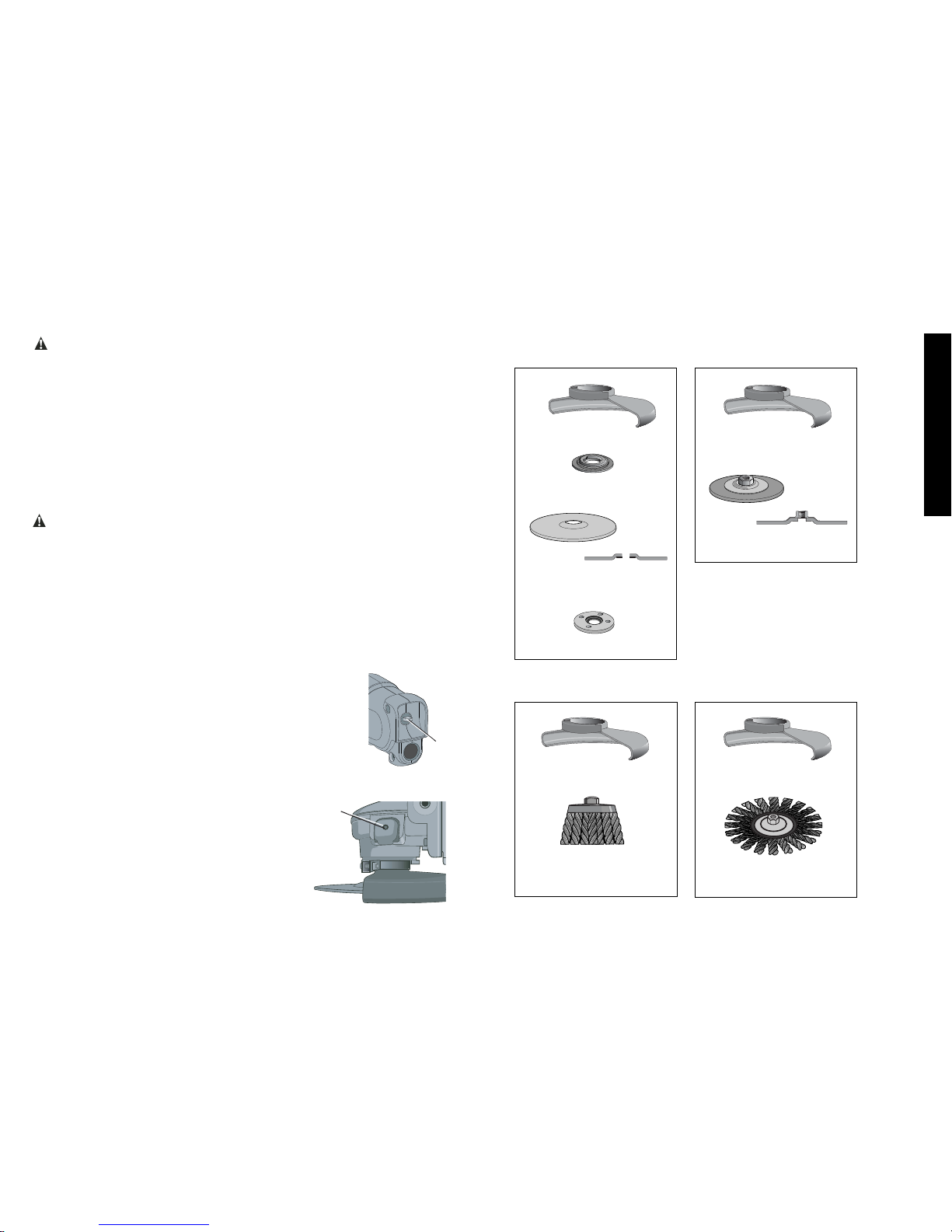

Accessories

It is important to choose the correct guards, backing pads and

flanges to use with grinder accessories.

WARNING:

90˚

90˚

E

R

emove t

h

e

fourco

r

ne

r

s

c

rewsattach

in

g

t

heg

e

a

r caset

o

mo

tor housin

g

.

English

Always make sure the guard is correctly fitted

before and during using the tool.

1.

Loosen screw. Align the lugs (K) on the

guard with slots (L) on the gear case.

2.

Push the guard down until the guard lug

engages and rotates freely in the groove

on the gear case hub.

3.

Rotate guard (B) into desired working position.

The guard body

should be positioned between the spindle and the operator to

provide maximum operator protection.

4.

T

ighten the screw to secure the guard on the gear case cover

.

Y

ou should be unable to rotate the guard by hand. Do not

operate grinder with a loose guard.

5.

T

o remove the guard, loosen screw

, rotate the guard so that the

arrows are aligned and pull up on the guard.

OPERA

TION

Guards and Flanges

It is important to choose the correct guards and flanges to use with

the grinder accessories. See page 6 and this page for the correct

accessories.

NOTE: Edge grinding and cutting can be performed with

T

ype 27

wheels designed and specified for this purpose.

K

L

B

CAUTION:

Tu rn off a nd unplu g the

to ol before making any a dju stm ent s

or removing or installing attachments

or accessories.

100mm abrasive wheels with rated max. speed lower

than 13500RPM can’t be used on this grinder. Accessories must be

rated for at least the speed recommended on the tool warning label.

Wheels and other accessories running over rated accessory speed

may burst and cause injury. Threaded accessories must have a

M10 hub. Every unthreaded accessory must have a 16mm arbor

hole. If it does not, it may have been designed for a circular saw and

should not be used. Use only the accessories shown on pages 9–10

of this manual. Accessory ratings must be above listed minimum

wheel speed as shown on tool nameplate.

Page 9

9

WARNING:

English

Switches

CAUTION:

Hold the side handle and body of the tool firmly to

maintain control of the tool at start up and during use and until the

wheel or accessory stops rotating. Make sure the wheel has come

to a complete stop before laying the tool down.

NOTE: To reduce unexpected tool movement, do not switch the

tool on or off while under load conditions. Allow the grinder to run

up to full speed before touching the work surface. Lift the tool from

the surface before turning the tool off. Allow the tool to stop rotating

before putting it down.

TURN ON & TURN OFF

To turn on the tool, push the toggle switch(N) to ''1"

position, to turn off the tool, push the toggle

switch(N) to "0" position.

SPINDLE LOCK

The spindle lock (A) is provided to prevent the spindle from rotating when installing or removing wheels. Operate the spindle lock

only when the tool is turned off, unplugged

from the power supply, and has come to a

complete stop. Do not engage the spindle

lock while the tool is operating because

damage to the tool will result. To engage the

lock, depress the spindle lock button and

rotate the spindle until you are unable to

rotate the spindle further.

A

A

Type 27 guard

100mm Grinding Wheels

backing flange

threaded clamp nut

Type 27 hubbed wheel

Type 27 guard

Type 27 depressed

center wheel

Wire Wheels

75mm/100mm

wire cupbrush

75mm/100mm

wire wheel

Type 27 guard

Type 27 guard

N

100mm abrasive wheels with rated max. speed lower

than 13500RPM can’t be used on this grinder. Accessories must be

rated for at least the speed recommended on the tool warning label.

Wheels and other accessories running over rated accessory speed

may burst and cause injury. Threaded accessories must have a

M10 hub. Every unthreaded accessory must have a 16mm arbor

hole. If it does not, it may have been designed for a circular saw and

should not be used. Use only the accessories shown on pages

9–10 of this manual. Accessory ratings must be above listed

minimum wheel speed as shown on tool nameplate.

Page 10

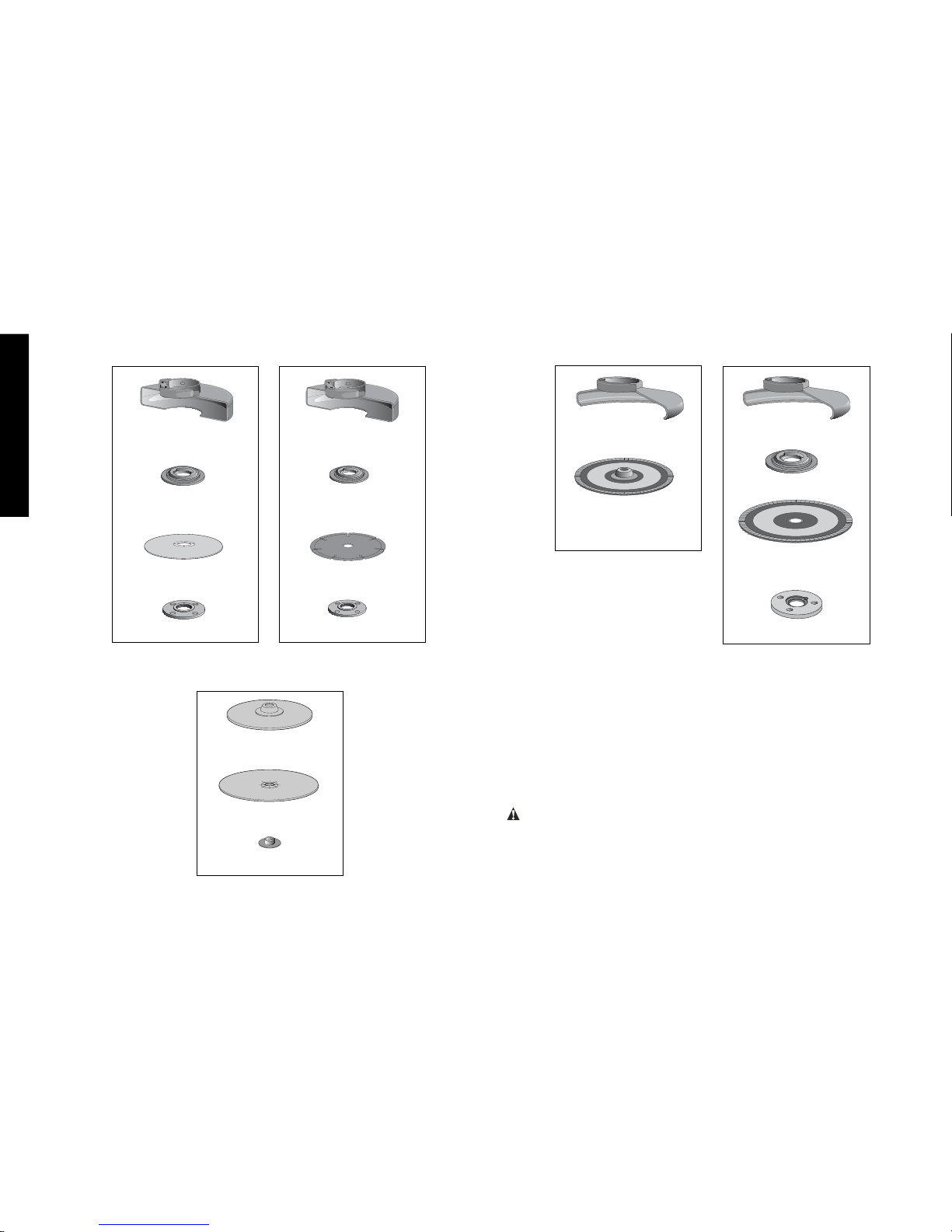

10

English

rubber backing pad

sanding disc

threaded clamp nut

Sanding Discs

100mm Cutting Wheels

Type 1 guard

backing flange

abrasive cutting wheel

clamp nut

Type 1 guard

backing flange

diamond cutting wheel

clamp nut

100mm Sanding Flap Discs

hubbed sanding

flap disc

backing flange

non-hubbed sanding

flap disc

threaded clamp nut

Type 27 guard

Type 27 guard

Mounting and Using Depressed Center

Grinding Wheels and Sanding

Flap Discs

MOUNTING AND REMOVING HUBBED WHEELS

CAUTION: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or accessories. Before reconnecting the tool, depress and release the

paddle switch to ensure that the tool is off.

Hubbed wheels install directly on the M10 threaded spindle.

Thread of accessory must match thread of spindle.

Please use the correct size of accessories according the rated size

in nameplate.

Do not use accessories designed for 125mm grinder on a 100mm

grinder!

Page 11

11

SURFACE GRINDING WITH GRINDING WHEELS

1. Allow the tool to reach full speed before touching the tool to the

work surface.

2. Apply minimum pressure to the work surface, allowing the tool

to operate at high speed. Grinding rate is greatest when the tool

operates at high speed.

3. Maintain a 20˚ to 30˚ angle between the

tool and work surface.

4. Continuously move the tool in a forward

and back motion to avoid crea ting

gouges in the work surface.

5. Remove the tool from work surface before turning tool off. Allow

the tool to stop rotating before laying it down.

EDGE GRINDING WITH GRINDING WHEELS

CAUTION:

Wheels used for cuttingand edge grinding may break

if they bend or twist while the tool is being used to do cut-off work or

deep grinding. T

o

reduce the risk of serious injury

, limit the use of

1. Backing flange is retained to the grinder by an O-ring on the

spindle. Remove backing flange by pulling and twisting flange

away form the machine.

2. Thread the wheel on the spindle by hand.

3. Depress the spindle lock button and use a wrench to tighten the

hub of the wheel.

4. Reverse the above procedure to remove the wheel.

CAUTION:

Failure to properlyseat the wheel before turning the

tool on may resultin damage to the tool or the wheel.

MOUNTING NON-HUBBED WHEELS

CAUTION: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or accessories. Before reconnecting the tool, turn the switch on and off

as previously described to ensure that the tool is off.

Depressed center Type 27 grinding wheels

must be used with included flanges. See

page 6 of this manual for more information.

1. Install the unthreaded backing flange

(G) on spindle (D) with the raised section

(pilot) against the wheel. Be sure the

backing flange recess is seated onto the flats of the spindle by

pushing and twisting the flange before placing wheel.

2. Place wheel against the backing flange,

centering the wheel on the raised section (pilot) of the backing flange.

3. While depressing the spindle lock button, thread the clamp nut (H) on spindle. If the wheel you are installing is

more than 1/8" (3.31mm) thick, place

the threaded clamp nut on the spindle

so that the raised section (pilot) fits into

the center of the wheel. If the wheel you

are installing is 1/8" (3.31mm) thick or

1/4" WHEELS

(6.35mm)

Clamp Nut

less, place the threaded clamp nut on

the spindle so that the raised section

(pilot) is not against the wheel.

4. While depressing the spindle lock button,

tighten the clamp nut with a wrench.

5. To remove the wheel, depress the spindle lock button and loosen the threaded

clamp nut with a wrench.

NOTE: If the wheel spins after the clamp nut

is tightened, check the orientation of the

threaded clamp nut. If a thin wheel is

installed with the pilot on the clamp nut

against the wheel, it will spin because the

height of the pilot prevents the clamp nut

from holding the wheel.

1/8" WHEELS

(3.31mm)

Backing Flange

Backing Flange

Clamp Nut

H

G

D

20°-30°

Englis

h

Page 12

12

English

these wheels with a standard Type 27 guard

to shallow cutting and notching (less than

1/2" in depth). The open side of the guard

must be positioned away from the operator.

For deeper cutting with a Type 1 cut-off

wheel, use a closed, Type 1 guard. Type

1 guards are available at extra cost from

your local dealer or authorized service

center.

1. Allow the tool to reach full speed before

touching the tool to the work surface.

2.

Apply minimum pressure to the work surface, allowing the tool

to operate at high speed. Grinding rate is greatest when the

3.

Position yourself so that the open-under

side of the wheel is

facing away from you.

4.

Once a cut is begun and a notch is established in the workpiece, do not change the angle of the cut. Changing the angle

will cause the wheel to bend and may cause wheel breakage.

Edge grinding wheels are not designed to withstand side pressures caused by bending.

5.

Remove the tool from the work surface before turning the tool

off. Allow the tool to stop rotating before laying it down.

WARNING:

tool operates at high speed.

SURFACE FINISHING WITH SANDING FLAP DISCS

1. Allow the tool to reach full speed before touching the tool to the

work surface.

2. Apply minimum pressure to work surface, allowing the tool to

operate at high speed. Sanding rate is greatest when the tool

operates at high speed.

3. Maintain a 5˚ to 10˚ angle between

the tool and work surface.

4. Continuously move the tool in a

forward and back motion to avoid

creating gouges in the work

surface.

5. Remove the tool from work surface before turning tool off. Allow

the tool to stop rotating before laying it down.

MOUNTING SANDING BACKING PADS

CAUTION: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or accessories. Before reconnecting the tool, turn the switch on and off

as previously described to ensure that the tool is off.

5˚-10˚

CAUTION:

Proper guard must be reinstalled for grinding wheel,

sanding flap disc, wire brush or wire wheel applications after sanding applications are complete.

1. Place or appropriately thread backing

pad (Q) on the spindle.

2. Place the sanding disc (R) on the

backing pad.

3. While depressing spindle lock, thread

clamp nut (H) on spindle, piloting the

raised hub on the clamp nut into the

center of sanding disc and backing

pad.

4. Tighten the clamp nut by hand. Then

depress the spindle lock button while

turning the sanding disc until the sanding disc and clamp nut

are snug.

5. To remove the wheel, grasp and turn the backing pad and

sanding pad while depressing the spindle lock button.

H

Q

R

Do not use edge grinding/cutting wheels for surface

grinding applications because these wheels are not designed for

side pressures encountered with surface grinding. Wheel breakage

and injury may result.

Page 13

13

English

USING SANDING BACKING PADS

Choose the proper grit sandpaper for your application. Sandpaper

is available in various grits. Coarse grits yield faster material

removal rates and a rougher finish. Finer grits yield slower

material

removal and a smoother finish.

Begin with coarse grit discs for fast, rough material removal.

Move to a medium grit paper and finish with a fine grit disc for

optimal finish.

Coarse 16 - 30 grit

Medium 36 - 80 grit

Fine Finishing 100 - 120 grit

Very Fine Finishing 150 - 180 grit

1. Allow the tool to reach full speed before touching tool to the

work surface.

2. Apply minimum pressure to work surface, allowing the tool to

operate at high speed. Sanding rate is greatest when the tool

operates at high speed.

3. Maintain a 5˚ to 15˚ angle between

the tool and work surface. The sanding disc should contact approximately one inch of work surface.

4. Move the tool constantly in a straight

line to prevent burning and swirling

of work surface. Allowing the tool to rest on the work surface

without moving, or moving the tool in a circular motion causes

burning and swirling marks on the work surface.

5. Remove the tool from work surface before turning tool off. Allow

the tool to stop rotating before laying it down.

Mounting and Using Wire Brushes

and Wire Wheels

Wire cup brushes or wire wheels screw directly on the grinder

spindle without the use of flanges. Use only wire brushes or

wheels provided with a M10 threaded hub. A Type 27 guard is

required when using wire brushes and wheels.

CAUTION: Wear work gloves when handling wire brushes

and wheels.

They can become sharp.

CAUTION:

Wheel or brush must not touch guard when mounted

or while in use. Undetectable damage could occur to the accessory,

causing wires to fragment from accessory wheel or cup.

MOUNTING WIRE CUP BRUSHES AND WIRE WHEELS

CAUTION: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or accessories. Before reconnecting the tool, turn the switch on and off

as previously described to ensure that the tool is off.

1. Thread the wheel on the spindle by hand.

2. Depress spindle lock button and use a wrench on the hub of the

wire wheel or brush to tighten the wheel.

3. To remove the wheel, reverse the above procedure.

CAUTION:

Failure to properly seat the wheel hub before turning

the tool on may result in damage to tool or wheel.

USING WIRE CUP BRUSHES AND WIRE WHEELS

Wire wheels and brushes can be used for removing rust, scale and

paint, and for smoothing irregular surfaces.

1. Allow the tool to reach full speed before touching the tool to the

work surface.

2. Apply minimum pressure to work surface, allowing the tool to

operate at high speed. Material removal rate is greatest when

the tool operates at high speed.

3. Maintain a 5˚ to 10˚ angle between the

tool and work surface for wire cup

brushes.

4. Maintain contact between the edge of

the wheel and the work surface with

wire wheels.

5˚-10˚

5˚-15˚

Page 14

14

English

5. Continuously move the tool in a forward

and back motion to avoid creating gouges in

the work surface. Allowing the tool to rest on

the work surface without moving, or moving

the tool in a circular motion causes burning

and swirling marks on the work surface.

6. Remove the tool from the work surface before turning the tool

off. Allow the tool to stop rotating before setting it down.

CAUTION:

Use extra care when working over an edge, as a

sudden sharp movement of grinder may be experienced.

Mounting and Using Cutting Wheels

Cutting wheels include diamond wheels and abrasive discs.

Abrasive cutting wheels for metal and concrete use are available.

Diamond blades for concrete cutting can also be used.

WARNING:

A

closed, 2-sided cutting wheel guard is not include

d

with this tool but is required when using cutting wheels. Failure to

use proper flange and guard can result in injury resulting from wheel

breakage and wheel contact..

MOUNTING CLOSED GUARD

CAUTION: T

urn off and unplug the tool before making any

adjustments or removing or installing attachments or accessories. Before reconnecting the tool, turn the switch on and of

f

as previously described to ensure that the tool is of

f.

1. Open the guard latch (J).

Align

the lugs (K) on the guard with the

slots (L) on the gear case.

2. Push the guard down until the

guard lug engages and rotates

freely in the groove on the gear

case hub.

3. Rotate guard (B) into desired

working position. The guard body

should be positioned between the

spindle and the operator to provide

maximum operator protection.

4. Close the guard latch to secure the guard

on the gear case cover. You should be

unable to rotate the guard by hand when

the latch is in closed position. If rotation is

possible, tighten the adjusting screw (M) with clamp lever in the

closed position. Do not operate grinder with a loose guard or

clamp lever in open position.

B

J

L

K

5. To remove the guard, open the guard latch, rotate the guard so

that the arrows are aligned and pull up on the guard.

NOTE: If, after a period of time, the guard

becomes loose, tighten the adjusting

screw (M) with the clamp lever in the

closed position.

CAUTION:

Do not tighten adjusting

screw with clamp lever in open position.

Undetectable damage to guard or

mounting hub may result.

MOUNTING CUTTING WHEELS

CAUTION: Turn of

f and unplug the tool before making any

adjustments or removing or attachments or accessories.

Before reconnecting the tool, turn the switch on and off as

previously described to ensure that the tool is off.

M

CAUTION:

Matching diameter threaded backing flange and

clamp nut (included with tool) must be used for cutting wheels.

1. Place the unthreaded backing flange on spindle with the raised

section (pilot) facing up.

The raised section (pilot) on the back-

ing flange will be against the wheel when the wheel is installed.

2. Place the wheel on the backing flange, centering the wheel on

the raised section (pilot).

3. Install the threaded clamp nut with the raised section (pilot)

facing away from the wheel.

Page 15

15

English

4. Depress the spindle lock button and tighten clamp nut with

a wrench.

5. To remove the wheel, grasp and turn while depressing the

spindle lock button.

USING CUTTING WHEELS

W

ARNING:

Do not use edge grinding/

cutting wheels for surface grinding applica-

tions because these wheels are not

designed for side pressures encountered

with surface grinding. Wheel breakage and

injury may result.

1. Allow tool to reach full speed before

touching tool to work surface.

2. Apply minimum pressure to work

surface, allowing tool to operate at

high speed. Cutting rate is greatest

when the tool operates at high speed.

3. Once a cut is begun and a notch is established in the work-

piece, do not change the angle of the cut. Changing the angle

will cause the wheel to bend and may cause wheel breakage.

4. Remove the tool from work surface before turning tool of

f.

Allow

the tool to stop rotating before setting it down.

CARBON BRUSH REPLACEMENT

CAUTION:

Turn off and unplug the

tool before making any adjustments or

removing or installing attachments or

accessories. Before reconnecting the

tool, depress and release the paddle

switch to ensure that the tool is off.

CAUTION: Only use the DEWALT

qualified carbon brush designed

for this tool, consult your local dealer or authorized service

1.

2.

3.

4.

center for correct carbon brush. Use of carbon brush not

designed for this tool or not qualified by DEWALT may

damage the tool and may result serious injury!

Loose the screws on brush doors and take out the brush

doors.

Disconnect the brush terminal from connector by pull the

terminal out.

Pull the torsion springs which to hold the brush holder back

and place it to the plastic raised parts on housing, so your

brush arms are free now.

Replace the old carbon brushes by new brush. Reverse

above procedures to finish brush change.

CAUTION: The two brush doors are not interchangeable. There

is a icon of brush on the brush door which underneath of the

housing in order to differentiate from the other one. Make sure each

brush door are fit on the right position before fit and tighten screws.

CAUTION: Make sure all screws are correctly fitted and

tightened before re-connect the tool to power supply.

MAINTENANCE

Cleaning

WARNING:

ALWA

YS WEAR

SAFETY

GLASSES when cleaning or using this tool.

Blowing dust and grit out of motor and switch actuator

using clean, dry compressed air is a necessary regular maintenance

procedure. Dust and grit containing metal particles often accumulate

on interior surfaces and could create an electrical shock or electrocu-

tion if not frequently cleaned out.

It is recommended that a ground

from electric shock resulting from the accumulation of conductive

particles. If the tool is deactivated by the GFCI, unplug the tool and

check and clean the tool before resetting the GFCI.

fault circuit interrupter (GFCI) is utilized to further protect the user

Page 16

16 655601-00

English

CAUTION:

Never use solvents or other harsh chemicals

for cleaning the non-metallic parts of the tool. Use a clean, dry

cloth only.

Lubrication

DEWALT tools are properly lubricated at the factory and are ready

for use.

Repairs

To assure product SAFETY

and RELIABILITY, repairs, mainte-

nance and adjustments should be performed by a D

EWALT factory

service center

, a DEWALT authorized service center or other

qualified service personnel.

Always use identical replacement

parts.

Accessories

extra cost from your local dealer or authorized service center

. If you

need assistance in locating any accessory, please contact local

DEWalt Sales.

CAUTION:

The use of any other accessory not recommended

for use with this tool could be hazardous.

Not all the accessories recommended in this manual are standard

accessories come with tool for selling.

Page 17

Instruction Manual

ืมูค อการใชงาน

D28810, D28811, D28803

Heavy Duty Small Angle Grinder

เครื่องเจียรเขามุมแบบใชงานหนัก

Page 18

13

English 3

ไทย

1

7

Page 19

3

กฎด้านความปลอดภัยทั่วไปสำหรับเครื่องมือทุกประเภท

คำเตือน! อ่านและทำความเข้าใจข้อแนะการใช้งานทุกข้อ

หากไม่ปฏิบัติตามคำเตือนและข้อแนะนำการใช้งานด้านล่าง

rอาจจะก่อให้เกิดไฟฟ้าช็อต ไฟไหม้ หรือบาดเจ็บอย่างรุนแรงได้

กรุณาเก็บคู่มือเล่มนี้ไว้

พื้นที่ทำงาน

• รักษาพื้นที่ทำงานให้สะอาดและมีแสงสว่างเพียงพอ โต๊ะทำงาน

ที่ระเกะระกะและพื้นที่ที่มืดอาจก่อให้เกิดอุบัติเหตุได้

•

ห้ามใช้เครื่องมือไฟฟ้าในพื้นที่ที่มีโอกาสระเบิด เช่น มีของเหลวที่ติดไฟ

แก๊ส หรือผงวัสดุที่ติดไฟได้เครื่องมือไฟฟ้าจะก่อให้เกิดประกายไฟ

ซึ่งอาจทำให้ฝุ่นละอองหรือสารเคมีเหล่านี้ติดไฟได้

•

ระมัดระวังผู้ที่อยู่ข้างเคียง เด็ก และ ผู้ที่เยี่ยมชมขณะที่กำลังใช้งานเครื่องมือ

ไฟฟ้าอย

ู่ การสูญเสียสมาธิอาจทำให้สูญเสียการควบคุมเครื่องมือได้

ความปลอดภัยทางไฟฟ้า

•

เครื่องมือที่มีสายดินจะต้องเสียบปลั๊กเข้ากับเต้ารับที่มีการติดตั้งและมี

การต่อสายดินอย่างถูกต้องตามที่กฏหมายกำหนด ห้ามดึงขากราวด์ทิ้ง

หรือดัดแปลงปลั๊กของเครื่องมือไม่ว่าจะด้วยวิธีใดก็ตาม ห้ามใช้ปลั๊ก

อะแดปเตอร์ใดๆ กับเครื่องมือนี้ หากท่านไม่แน่ใจว่าเต้ารับได้รับการติดตั้ง

สายดินเรียบร้อยหรือไม่ โปรดให้ช่างไฟฟ้าที่มีความรู้ทำการตรวจสอบ

ในกรณีที่เครื่องมือมีปัญหาทางด้านไฟฟ้า หรือมีไฟฟ้าช็อต ระบบสายดิน

ที่มีความต้านทานต่ำจะทำหน้าที่ผ่านกระแสไฟฟ้าจากผู้ใช้ลงสู่พื้นดิน

ใช้เฉพาะกับเครื่องมือที่มีสายดินแบบ Class I (มีสายดิน) เท่านั้น

•

เครื่องมือนี้หุ้มฉนวนสองชั้นพร้อมปลั๊กที่ระบุขั้ว (ขาข้างหนึ่งจะกว้างกว่าอีก

ข้าง) ปลั๊กชนิดนี้จะสามารถเสียบเข้ากับเต้ารับแบบระบุขั้วได้เพียงด้านเดียว

ถ้าไม่สามารถเสียบปลั๊กเข้าเต้ารับได้ ให้กลับด้านปลั๊ก หากยังไม่สามารถ

เสียบปลั๊กได้ให้ติดต่อช่างไฟฟ้าเพื่อติดตั้งเต้ารับแบบระบุขั้ว ห้ามทำการ

เปลี่ยนปลั๊กไฟโดยเด็ดขาด

ฉนวนหุ้มสองชั้นของเครื่อง ช่วยให้ไม่จำเป็น

ต้องใช้สายไฟแบบมีสายดินและระบบจ่ายไฟที่มีระบบสายดิน ใช้เฉพาะกับ

เครื่องมือแบบ Class II (หุ้มฉนวนสองชั้น)

•

หลีกเลี่ยงไม่ให้ร่างกายสัมผัสกับพื้นผิวที่มีการต่อลงดิน เช่น ท่อ

หม้อน้ำ เตา และตู้เย็น หากร่างกายของท่านสัมผัสกับพื้นดินจะมีความเสี่ยง

ต่อไฟฟ้าช็อตเพิ่มมากขึ้น

• อย่าให้เครื่องมือที่ใช้ไฟฟ้าโดนฝนหรือความชื้น หากมีน้ำเข้าไปในเครื่องมือ

ไฟฟ้าจะเพิ่มความเสี่ยงต่อการเกิดไฟฟ้าช็อตได้

•

ห้ามใช้งานสายไฟของเครื่องมืออย่างผิดวิธี ห้ามใช้สายไฟของเครื่องมือในการ

หิ้วเครื่องมือ หรือใช้ถอดปลั๊กเครื่องมือออกจากเต้ารับ เก็บสายไฟให้ห่างจาก

ความร้อน น้ำมัน วัตถุมีคม หรือชิ้นส่วนที่เคลื่อนไหว เปลี่ยนสายไฟที่เสียหาย

ทันทีที่พบ สายไฟที่เสียหายก่อให้เกิดความเสี่ยงต่อไฟฟ้าช็อตเพิ่มมากขึ้น

ข้อมูลทางด้านเทคนิค

กำลังไฟเข้า วัตต์

ความเร็วขณะหมุนเปล่า /นาที

เส้นผ่าศูนย์กลางจานเจียรสูงสุด

มม.

ด้ามจับด้านข้าง*

ระบบกำจัดฝุ่น

ก้านแปรงถ่านแบบชิ้นเดียว

แปรงถ่าน

หน้าแปลน

เกลียวแกนหมุน

น้ำหนัก

กก.

D28810

680

10000

100

ไม่มี

ไม่มี

มี

เปิดเร็ว

ป้องกันล็อก

M10

1.80

D28811

720

10000

100

ไม่มี

ไม่มี

มี

เปิดเร็ว

ป้องกันล็อก

M10

1.80

D28803

850

พิกัดความถี่ เฮิรตซ์ 50/60 50/60 50/60

พิกัดแรงดันไฟ โวลต์ 220-240~ 220-240~ 220-240~

10000

100

ปกติ

ไม่มี

มี

เปิดเร็ว

ป้องกันล็อก

M10

1.85

เครื่องเจียรเข้ามุม

ยินดีด้วยครับ!

D28810, D28811, D28803

ท่านได้เลือกใช้เครื่องมือจาก D

EWALT ด้วยประสบการณ์หลายปีที่ผ่านมา

ในการพัฒนาผลิตภัณฑ์และนวัตกรรมชั้นเลิศ ทำให้ DEWALT เป็นหนึ่งใน

เครื่องมือไฟฟ้าที่น่าเชื่อถือสำหรับผู้ใช้งานระดับมืออาชีพมากที่สุด

ไทย

*เครื่องรุ่น D28803 ซึ่งจำหน่ายในประเทศจีนจะไม่มีด้ามจับด้านข้าง

3

17

Page 20

4

การใช้สายไฟต่อพ่วง

หากจำเป็นต้องใช้สายพ่วง ให้ใช้เฉพาะสายพ่วงที่เหมาะสมกับกำลังไฟ

ด้านเข้าของเครื่องมือของคุณเท่านั้น (ดูข้อมูลทางด้านเทคนิค)

พื้นที่หน้าตัดของลวดตัวนำต้องมีขนาดอย่างต่ำ 1.5 ตาราง ม.ม.

เมื่อใช้สายไฟแบบตลับม้วน ให้ดึงสายไฟออกมาจนสุดทุกครั้ง และนอก

จากนั้น ให้ดูตารางด้านล่างนี้ประกอบด้วย

ขนาดตัวนำสายไฟ (mm

2

) พิกัดของสายไฟ (แอมป์)

0.75 6

1.00 10

1.50 15

2.50 20

4.00 25

ความยาวสายไฟ (ม.)

7.5 15 25 30 45 60

แรงดัน กระแสไฟ พิกัดของสายไฟ (แอมป์)

115 0 - 2.0 6 6 6 6 6 10

2.1 - 3.4 6 6 6 6 15 15

3.5 - 5.0 6 6 10 15 20 20

5.1 - 7.0 10 10 15 20 20 25

7.1 - 12.0 15 15 20 25 25 -

12.1 - 20.0 20 20 25 - - -

230 0 - 2.0 6 6 6 6 6 6

2.1 - 3.4 6 6 6 6 6 6

3.5 - 5.0 6 6 6 6 10 15

5.1 - 7.0 10 10 10 10 15 15

7.1 - 12.0 15 15 15 15 20 20

12.1 - 20.0 20 20 20 20 25 -

ความปลอดภัยส่วนบุคคล

•

มีความตื่นตัวและมีสติในสิ่งที่ทำรวมทั้งใช้วิจารณญานขณะที่กำลัง

ใช้งานเครื่องมือไฟฟ้า ห้ามใช้เครื่องมือขณะที่ร่างกายอ่อนล้าหรือ

มีอาการมึนเมาจากสารเสพติด ของมึนเมา หรือยาต่างๆ ความพลั้ง

เผลอไม่ระมัดระวังตัวแม้เพียงชั่วครู่ขณะที่กำลังใช้งานเครื่องมือไฟฟ้าอยู่

อาจก่อให้เกิดการบาดเจ็บอย่างรุนแรงได้

•

แต่งกายให้เหมาะสม อย่าสวมเสื้อผ้าที่หลวมหรือสวมใส่เครื่องประดับ

จัดเก็บผมที่ยาวให้เรียบร้อย ระมัดระวังไม่ให้ผม เสื้อผ้าหรือถุงมือ

เข้าใกล้ชิ้นส่วนที่เคลื่อนที่ได้ เสื้อผ้าที่หลวม เครื่องประดับ หรือผมที่ยาว

อาจจะถูกเกี่ยวเข้าไปในชิ้นส่วนที่เคลื่อนที่ได้ ชิ้นส่วนที่เคลื่อนที่ได้ต่างๆ

มักจะมีช่องลมครอบอยู่ ดังนั้นจึงควรหลีกเลี่ยงการเข้าใกล้ช่องลมเหล่านี้

•

หลีกเลี่ยงการเปิดเครื่องมือโดยไม่ได้ตั้งใจ ก่อนเสียบปลั๊กเครื่องมือตรวจสอบ

ให้แน่ใจว่าสวิตซ์ของเครื่องถูกปิดอยู่ การถือเครื่องมือโดยที่นิ้วมืออยู่ในบริเวณ

สวิตช์เปิดปิด หรือการเสียบปลั๊กเครื่องมือขณะที่สวิตช์เปิดอยู่ อาจก่อให้เกิดอุบัติเหตุได้

•

ถ

อดประแจสำหรับปรับตั้งต่างๆ ออกจากเครื่อง ก่อนที่จะเปิดเครื่องมือ

ประแจที่ยังค้างอยู่บริเวณชิ้นส่วนที่เคลื่อนที่ได้ของเครื่องมือ อาจก่อให้เกิดการ

บาดเจ็บได้

•

อย่าใช้งานโดยการเอื้อมไกลเกินไป ขณะใช้เครื่องมือ ควรยืนให้มั่นคง

และมีความสมดุลอยู่ตลอดเวลา เ

มื่อเกิดเหตุการณ์ไม่คาดฝัน การยืนที่มั่น

คงและสมดุลจะช่วยให้สามารถควบคุมเครื่องมือได้ดีกว่า

•

ใช้อุปกรณ์เสริมความปลอดภัย สวมอุปกรณ์ป้องกันดวงตาทุกครั้ง จะ

ต้องใช้หน้ากากป้องกันฝุ่น รองเท้านิรภัยกันลื่น หมวกนิรภัย หรืออุปกรณ์ป้อง

กันเสียง ให้ถูกต้องเหมาะสมกับสภาพการทำงานเสมอ

การใช้เครื่องมือและการดูแล

•

ใช้ปากกาหนีบจับชิ้นงาน หรือใช้วิธีที่เหมาะสมปลอดภัย เพื่อจับยึด

ชิ้นงานให้อยู่ในตำแหน่งที่มั่นคง การจับชิ้นงานด้วยมือหรือใช้ร่างกายยัน

ชิ้นงานอาจจะไม่มั่นคงและอาจก่อให้สูญเสียการควบคุมได้

•

อย่าใช้แรงฝืนเครื่องมือ ใช้เครื่องมือให้เหมาะสมกับงานที่ต้องการทำ

เครื่องมือที่เหมาะสมจะสามารถทำงานได้ดีกว่าและปลอดภัยกว่าเมื่อใช้งาน

ตามพิกัดที่ได้ถูกออกแบบมา

• ห้ามใช้เครื่องมือหากไม่สามารถเปิดหรือปิดสวิตซ์ของเครื่องมือได้

เครื่องมือใดๆ ก็ตามที่ไม่สามารถควบคุมด้วยสวิตช์ได้ อาจก่อให้เกิดอันตราย

และควรได้รับการซ่อมแซมโดยด่วน

ไทย

18

Page 21

5

หากล้อเจียรหรืออุปกรณ์เสริมใดๆ หลวม อาจจะทำให้หลุดออกจาก

เครื่องและอาจจะก่อให้เกิดการบาดเจ็บร้ายแรงได้

•

ให้ใช้งานตัวป้องกันจานเจียรเสมอ ตัวป้องกันจะทำหน้าที่ป้องกันผู้ใช้

งานจากการกระเด็นของจานเจียรที่แตกหัก และการสัมผัสถูกตัวจานเจียร

•

อุปกรณ์เสริมต่างๆ จะต้องรองรับอัตราเร็วอย่างน้อยที่สุดตามคำแนะนำ

บนป้ายเตือนของเครื่องมือ จานเจียรและอุปกรณ์เสริมที่หมุนด้วยอัตราเร็วที่

เกินกำหนดอาจหลุดและก่อให้เกิดการบาดเจ็บได้ อุปกรณ์เสริมที่ใช้จะต้องมี

พิกัดสูงกว่าความเร็วต่ำสุดของล้อเจียรดังแสดงไว้บนแผ่นป้ายของเครื่องมือ

•

ในการใช้งานซึ่งเครื่องมืออาจจะสัมผัสสายไฟที่มองไม่เห็นหรือ

สายไฟของตัวเครื่องมือเองได้ ให้ถือเครื่องมือโดยจับที่พื้นผิวที่หุ้มฉนวน

เนื่องจากการสัมผัสกับสายไฟที่มีกระแสไฟไหลอยู่อาจจะทำให้มี

ไฟฟ้าไหลผ่านชิ้นส่วนที่เป็นโลหะของเครื่องมือและช็อตผู้ใช้งานได้

• สวมอุปกรณ์ป้องกันตาทุกครั้งที่ใช้งานเครื่องมือนี้

•

อุปกรณ์เสริมที่ไม่ได้ระบุไว้ในคู่มือเล่มนี้เป็นอุปกรณ์ที่ไม่แนะนำให้ใช้งาน

และอาจก่อให้เกิดอันตรายได้ การใช้อุปกรณ์เพิ่มกำลังของเครื่องมือซึ่งช่วย

ให้เครื่องมือทำงานด้วยความเร็วที่สูงกว่าพิกัดความเร็วของเครื่องเป็นการใช้งาน

ที่ผิดวิธี

•

ห้ามใช้ใบเลื่อยวงเดือนหรือใบเลื่อยที่มีฟันเลื่อยชนิดอื่นๆ กับเครื่องมือ

นี้

เนื่องจากอาจจะก่อให้เกิดอันตรายร้ายแรงได้

•

เมื่อเริ่มเปิดเครื่องมือซึ่งเปลี่ยนล้อเจียรใหม่ หรือเมื่อมีการเปลี่ยนแปรงถ่าน

อันใหม่ ให้ถือเครื่องไว้ในที่ๆ ปลอดภัยและปล่อยให้ทำงานประมาณหนึ่งนาที

หากตัวจานเจียรมีอาการแตกหักหรือมีรอยร้าวที่ไม่สามารถมองเห็นได้

จะมีการแตกออกภายในหนึ่งนาที หากลวดในตัวแปรงถ่านหลุดออกมา

ก็จะสามารถเห็นได้ในช่วงนี้ อย่าเปิดเครื่องในขณะที่มีบุคคลอื่นอยู่ใน

ทิศทาง

ของตัวจานเจียร ซึ่งรวมถึงตัวผู้ใช้เองด้วย

.

•

ในขณะใช้งาน หลีกเลี่ยงการทำให้จานเจียรกระดอนหรือใช้งาน

จานเจียรอย่างรุนแรง หากเกิดเหตุการณ์ดังกล่าวขึ้น ให้หยุดเครื่องและ

•

ถอดปลั๊กของเครื่องมือออกก่อนที่จะทำการปรับตั้ง เปลี่ยนอุปกรณ์เสริม

หรือจัดเก็บเครื่องมือ มาตรการป้องกันดังกล่าวช่วยลดความเสี่ยงที่

เครื่องมือจะเริ่มทำงานโดยไม่ได้ตั้งใจ

.

•

จัดเก็บเครื่องมือที่ไม่ได้ใช้งานให้พ้นจากเด็กและบุคคลอื่นที่ไม่ได้รับ

การฝึกฝนในการใช้เครื่องมือนั้น

เครื่องมืออาจจะก่อให้เกิดอันตรายได้

•

เก็บรักษาและดูแลเครื่องมืออย่างดี เก็บรักษาเครื่องมือสำหรับตัดให้คม

และสะอาดอยู่เสมอ การดูแลเครื่องมือสำหรับตัดที่มีคมตัดอย่างเหมาะสม

จะช่วยให้เครื่องไม่ติดขัดและง่ายต่อการควบคุม

•

ตรวจเช็คว่าชิ้นส่วนที่เคลื่อนที่ได้มีการบิดเบี้ยวหรือติดขัด หรือมีชิ้นส่วนที่

ชำรุดหรืออยู่ในสภาพใดๆ ก็ตามที่อาจจะมีผลต่อการใช้งานของเครื่องมือ

หรือไม่ หากพบการชำรุดของเครื่องมือ จะต้องแก้ไขให้เรียบร้อยก่อนใช้

งาน อุบัติเหตุในหลายกรณีเกิดจากการไม่บำรุงรักษาเครื่องมือให้อยู่ในสภาพดี

•

ใช้เฉพาะอุปกรณ์เสริมที่ได้รับการรับรองจากผู้ผลิตให้ใช้กับเครื่องมือ

รุ่นของท่านเท่านั้น อุปกรณ์เสริมที่อาจจะเหมาะสมกับเครื่องมือรุ่นหนึ่ง อาจ

ก่อให้เกิดความเสียหายเมื่อใช้กับเครื่องมือรุ่นอื่นได้

การซ่อมแซม

•

การแก้ไขเครื่องมือจะต้องทำโดยช่างที่ชำนาญเท่านั้น การแก้ไขหรือ

ดูแลบำรุงรักษาโดยบุคคลที่ไม่ชำนาญ อาจก่อให้เกิดความเสี่ยงต่อการ

บาดเจ็บได้

•

เมื่อต้องซ่อมเครื่องมือ ให้ใช้ชิ้นส่วนอะไหล่ที่ตรงกันในการเปลี่ยนเท่านั้น

โปรดปฏิบัติตามขั้นตอนต่างๆ ที่ระบุในหัวข้อการบำรุงรักษาของคู่มือเล่มนี้

หากใช้ชิ้นส่วนที่ไม่ได้รับอนุญาตให้ใช้ หรือหากไม่ปฏิบัติตามขั้นตอนการ

บำรุงรักษา อาจทำให้เกิดไฟฟ้าช็อต หรือได้รับบาดเจ็บได้

.

ข้อแนะนำเพิ่มเติมด้านความปลอดภัย

สำหรับเครื่องเจียร

•

ตรวจสอบว่าหน้าแปลนด้านหลังของล้อเจียรมีวงแหวนยางสีเหลือง (I)

ติดตั้งอยู่หรือไม่ (ดูรูปที่ 1) หากไม่มี หรือชำรุดหรือฉีกขาด ให้ทำการ

คำเตือน:

หากวงแหวนยางสูญหายหรือเสียหาย อุปกรณ์เสริมของ

ล้อเจียรอาจจะหลวมในระหว่างการหยุดหมุนของเครื่องเมื่อถูกปิด

ไทย

เปลี่ยน โดยดูรายละเอียดการติดตั้งอย่างถูกวิธีในหน้า 9

ตรวจสอบจานเจียรว่ามีรอยแตกหรือชำรุดหรือไม่

ถ้าอยู่ในมือผู้ใช้ที่ไม่ได้รับการฝึกฝนในการใช้งาน

19

Page 22

6

•

เมื่อล้อเจียรมีการบิดตัวหรือติดกับตัวชิ้นงาน ล้อเจียรจะหยุด และตัว

มอเตอร์จะมีแรงปฏิกิริยาทำให้ตัวเครื่องถอยกลับหรือสะบัดกลับเข้าหา

ตัวผู้ใช้

•

การกระแทกกลับ (kickback) ดังกล่าวเป็นผลมาจากการใช้เครื่องมืออย่าง

ผิดวิธีและ/หรือขั้นตอนหรือสภาพการใช้งานที่ไม่ถูกต้องซึ่งสามารถหลีกเลี่ยง

ได้โดยการใช้ความระมัดระวังอย่างพอเพียงตามข้อแนะนำด้านล่างนี้:

•

จับเครื่องด้วยมือทั้งสองข้างให้แน่น และให้ลำตัวและแขนอยู่ใน

ตำแหน่งที่สามารถรองรับแรงกระแทกกลับได้ หากใช้ความระมัด

ระวังอย่างเหมาะสม ผู้ใช้จะสามารถควบคุมแรงกระแทกกลับได้

•

เมื่อมีการติดขัดของล้อเจียร หรือเมื่อเกิดการสะดุดในระหว่างใช้

งานไม่ว่าจะด้วยเหตุผลใดก็ตาม ให้ปล่อยไกสวิตช์แล้วถือเครื่อง

ให้อยู่นิ่งๆ ในวัสดุที่กำลังเจียรจนกว่าล้อเจียรจะหยุดสนิทอย่า

พยายามถอนล้อเจียรออกมาจากชิ้นงานหรือดึงเครื่องกลับมา

ในขณะที่ล้อเจียรกำลังหมุน มิเช่นนั้นอาจเกิดการกระแทกกลับได้

ตรวจสอบและทำการแก้ไขสาเหตุที่ทำให้เกิดการติดขัดของล้อเจียร

•

เมื่อเริ่มการเจียรชิ้นงานนั้นอีกครั้ง ให้วางล้อเจียรเข้าไปในชิ้นงาน

และตรวจดูไม่ให้ล้อเจียรติดเนื้อวัสดุ หากล้อเจียรติดขัดกับเนื้อวัสดุ

ล้อเจียรอาจวิ่งไปข้างหน้าหรือกระแทกกลับออกมาจากชิ้นงานเมื่อเริ่ม

การทำงานของเครื่องอีกครั้ง

•

รองรับแผ่นชิ้นงานขนาดใหญ่เพื่อลดความเสี่ยงที่ล้อเจียรจะบิด

และกระแทกกลับ แผ่นชิ้นงานขนาดใหญ่มักจะโค้งงอลงเนื่องจาก

น้ำหนักของชิ้นงานเอง การรองรับชิ้นงานจะต้องทำที่ด้านล่างของ

ชิ้นงานทั้งสองด้าน ใกล้กับแนวเจียรและใกล้กับขอบของชิ้นงาน

คำเตือน: ฝุ่นที่เกิดจากการขัด การเลื่อย การเจียร การขุด และการ

ปฏิบัติงานก่อสร้างอื่นๆ อาจมีสารเคมีที่ก่อโรคมะเร็ง การคลอดที่ผิด

ปกติ หรืออันตรายต่อระบบสืบพันธ์อื่นๆ ได้ ตัวอย่างของสารเคมีเหล่า

นี้ได้แก่:

•

ตะกั่วจากสีที่มีตะกั่วเป็นส่วนผสม

•

ผลึกซิลิกาจากอิฐและซีเมนต์รวมทั้งวัสดุก่อสร้างอื่นๆ และ

•

สารหนูและโครเมี่ยมจากไม้อบสารเคมี (CCA)

•

หลีกเลี่ยงประกายไฟไม่ให้เข้าหาตัวผู้ใช้ ผู้ที่อยู่ข้างเคียง หรือวัตถุที่ติดไฟ

อาจจะมีประกายไฟเกิดขึ้นในขณะที่ตัดหรือเจียรอยู่ ซึ่งประกายไฟดังกล่าว

อาจก่อให้เกิดไฟลุกไหม้ได้

•

ใช้ด้ามจับด้านข้างเสมอ ขันด้ามจับให้แน่น ควรใช้ด้ามจับด้านข้างนี้

ในการควบคุมการทำงานของเครื่องมือตลอดเวลา

• ห้ามใช้ตัดในบริเวณที่อาจจะมีสายไฟหรือท่อต่างๆ อยู่ เนื่องจากอาจ

จะก่อให้เกิดอันตรายร้ายแรงได้

•

ทำความสะอาดเครื่องมือบ่อยๆ โดยเฉพาะหลังจากการใช้งานหนัก

ฝุ่นและเศษโลหะต่างๆ มักจะสะสมอยู่ภายในตัวเครื่อง และอาจจะเกิด

อันตรายเนื่องจากไฟฟ้าช็อตได้

•

ห้ามใช้เครื่องมือนี้ติดต่อกันเป็นระยะเวลานานเกินไป การสั่นสะเทือน

อันเกิดจากการใช้งานเครื่องมือนี้อาจจะทำให้เกิดการบาดเจ็บอย่างถาวร

แก่นิ้วมือ มือ และแขนได้ ให้ใช้ถุงมือเพื่อลดการสั่นสะเทือน หยุดพักบ่อยๆ

และจำกัดเวลาในการใช้งานในแต่ละวันไม่ให้นานเกินไป

•

หันระบบกำจัดฝุ่นให้ออกจากตัวผู้ใช้งานและเพื่อนร่วมงาน เนื่องจาก

อาจจะก่อให้เกิดอันตรายร้ายแรงได้ (รูป 1, H)

• เครื่องมือของท่านอาจจะมีสัญลักษณ์ต่าง ๆ ดังนี้ ด้านล่างนี้เป็นสัญลักษณ์

ต่างๆ รวมทั้งคำอธิบาย:

V ..........โวลต์ A..............แอมแปร์

Hz ........เฮิรตซ์ W ............วัตต์

min ......นาที ..........ไฟกระแสสลับ

....ไฟกระแสตรง

n

o............ความเร็วขณะหมุนเปล่า

........มาตรฐานความปลอดภัย Class II

..........สัญลักษณ์เตือนด้านความปลอดภัย

........ขั้วต่อลงดิน … /min ....รอบต่อนาที

สาเหตุและการป้องกันผู้ใช้จากการกระแทกกลับ

•

การกระแทกกลับ (kickback) เป็นปฏิกิริยาที่เกิดขึ้นอย่างทันทีทันใดจาก

การบิดตัว การติด หรือการเบี้ยวของล้อเจียร แปรงถ่าน หรือจานเจียร

ซึ่งทำให้ไม่สามารถควบคุมได้และทำให้ตัวเครื่องมือสะบัดขึ้นจากชิ้นงาน

.

ไทย

เข้าหาตัวผู้ใช้งานได้

20

Page 23

7

รูป 1

ความเสี่ยงที่อาจจะเกิดจากสารเคมีเหล่านี้จะขึ้นอยู่กับความถี่ที่ท่านทำงาน

ประเภทนั้นๆ เพื่อลดความเสี่ยงในการรับสารเคมีเหล่านี้: ควรทำงานในพื้นที่

ที่มีอากาศถ่ายเทได้สะดวกและใช้เครื่องมือเพิ่มความปลอดภัยที่ผ่านการ

อนุญาตแล้ว เช่น หน้ากากป้องกันฝุ่นที่ได้ออกแบบมาเป็นพิเศษสำหรับกรอง

อนุภาคขนาดเล็กที่มองด้วยตาเปล่าไม่เห็นได้

•

หลีกเลี่ยงการสัมผัสกับฝุ่นผงที่เกิดจากการขัด การเลื่อย การเจียร

การเจาะ และกิจกรรมการก่อสร้างอื่นๆ เป็นเวลานานๆ สวมใส่ชุด

ป้องกันและล้างส่วนที่โดนสารเคมีออกด้วยน้ำและสบู่ การปล่อยให้

ฝุ่นเข้าไปในปาก ตา หรือโดนผิวหนัง อาจจะเป็นการเปิดโอกาสให้ได้รับ

สารเคมีที่เป็นอันตรายเข้าไปได้

คำเตือน: การใช้เครื่องมือนี้อาจก่อให้เกิดฝุ่นและ/หรือทำให้เกิด

การกระจายของฝุ่นซึ่งอาจก่อให้เกิดอันตรายต่อระบบทางเดินหายใจ

.

อย่างรุนแรงและเรื้อรังได้ ให้ใช้อุปกรณ์ป้องกันการหายใจที่ได้รับ

มาตรฐาน NIOSH/OSHA ทุกครั้งเพื่อป้องกันฝุ่น ปล่อยให้ฝุ่นปลิว

ไปในทิศทางที่ออกจากใบหน้าและลำตัวของผู้ใช้

ข้อควรระวัง: ใช้ความระมัดระวังเป็นพิเศษขณะทำงานอยู่ในบริเวณ

ที่เป็นมุมแคบเพราะจะเกิดการเคลื่อนไหวของเครื่องเจียรอย่างรวดเร็ว

และรุนแรง ซึ่งอาจจะเกิดขึ้นได้เมื่อตัวล้อเจียรไปสัมผัสเข้ากับผิว

อีกด้าน

ข้อควรระวัง: สวมอุปกรณ์ป้องกันเสียงที่เหมาะสมในขณะใช้งาน

ในสภาพการใช้งานบางอย่างหรือหลังจากการใช้งานที่ยาวนาน เสียง

ดังที่ออกมาจากเครื่องมืออาจก่อให้เกิดการสูญเสียการได้ยินได้

ส่วนประกอบของเครื่อง (รูป 1)

A. ปุ่มล็อกแกน

G. น็อตยึดแบบมีเกลียว

F.

หน้าแปลนหลังป้องกันการล็อกติด

B. ตัวป้องกัน

C. ล้อเจียรขนาด 100มม/125มม

H. แหวนยาง

D. สวิตช์

E. ด้ามจับด้านข้าง

คำเตือน: อย่าลืมขันสกรูทุกตัวบนตัวเครื่องให้แน่น

ไทย

G

F

D28810

D28811

D28803

H

A

C

B

D

21

Page 24

8

การติดตั้งตัวป้องกัน

การติดตั้งและการถอดตัวป้องกัน

ข้อควรระวัง: ปิดเครื่องและถอดปลั๊กเครื่องมือทุกครั้งก่อนที่จะทำ

การปรับตั้ง หรือ ถอด หรือติดตั้งอุปกรณ์เสริมใดๆ

การประกอบและการปรับตั้ง

การใส่ด้ามจับด้านข้าง

สามารถประกอบด้ามจับด้านข้าง (E) เข้าไปใน

รูคว้านเกลียวที่ด้านใดด้านหนึ่งของตัวเครื่องได้

ดังแสดงในภาพ ก่อนการใช้เครื่องมือ ให้ตรวจสอบ

ว่าได้ขันด้ามจับแน่นดีแล้ว ให้ใช้ประแจในการขัน

ด้ามจับด้านข้างเข้าไปให้แน่น

การหมุนตัวโครงเครื่อง

1. ถอดตัวป้องกันและหน้าแปลนออกจากเครื่อง

2.

3. แยกตัวโครงเครื่องออกจากโครงมอเตอร์

ไม่ให้เกิน 6.4 มม หมุนตัวโครงเครื่องให้

หันไปทางที่ต้องการ

หมายเหตุ: หากตัวโครงเครื่องแยกห่างออกจากโครงมอเตอร์เกิน 6.4 มม.

จะต้องให้ศูนย์บริการของ DEWALT ทำการซ่อมและประกอบกลับให้ หาก

ไม่ทำการซ่อมในกรณีดังกล่าวอาจทำให้แปรงถ่าน มอเตอร์ และลูกปืน

เสียหายได้

3.

ขันสกรูยึดตัวโครงเครื่องเข้ากับโครงมอเตอร์ ขันสกรูที่แรงบิด 18 นิ้วปอนด์

การขันให้แน่นเกินไปอาจจะทำให้เกลียวสกรูขาดได้

อุปกรณ์เสริม

การเลือกตัวป้องกัน แผ่นด้านหลัง และ หน้าแปลนเพื่อใช้กับอุปกรณ์เสริม

ของเครื่องเจียรที่เหมาะสมเป็นสิ่งสำคัญมาก

90˚

90˚

E

ถอดสกรูที่มุมทั้งสี่ที่ยึดตัวโครงเครื่องเข้ากับ

โครงมอเตอร์

ไทย

ข้อควรระวัง: ตรวจสอบให้แน่ใจว่าได้ใส่ตัวป้องกันไว้ถูกต้องแล้ว

ทั้งก่อนและในระหว่างการใช้เครื่องมือ

1. คลายสกรูออก ตั้งสลัก (K) ให้ตรงกับร่อง

(L) บนตัวกล่องเกียร์

2. กดตัวป้องกันลงจนกระทั่งสลักของตัวป้อง

กันลงร่องและหมุนได้อย่างอิสระในร่องบน

ศูนย์กลางของกล่องเกียร์

3. หมุนตัวป้องกัน (B) ให้ตรงกับตำแหน่งที่ต้องการจะใช้งาน

ตัวป้องกันจะต้องอยู่ระหว่างแกนหมุนกับและผู้ใช้งาน เพื่อให้สามารถ

ป้องกันผู้ใช้งานได้มากที่สุด

4.

ขันสกรูให้แน่นเพื่อยึดตัวป้องกันบนฝาครอบกล่องเกียร์โดยท่านจะ

ต้องไม่สามารถหมุนตัวป้องกันได้ด้วยมือ ห้ามใช้งานเครื่องเจียรขณะ

ที่ตัวป้องกันหลวม

5.

ขันสกรูให้แน่นเพื่อยึดตัวป้องกันบนฝาครอบกล่องเกียร์โดยท่านจะต้องไม่

สามารถหมุนตัวป้องกันได้ด้วยมือ ห้ามใช้งานเครื่องเจียรขณะที่ตัวป้องกันหลวม

การใช้งาน

ตัวป้องกันและหน้าแปลน

การเลือกตัวป้องกันและหน้าแปลนที่เหมาะสมเพื่อใช้กับอุปกรณ์เสริมของ

เครื่องเจียรเป็นสิ่งที่สำคัญมาก โปรดดูแผนผังข้อมูลในการเลือกอุปกรณ์

เสริมที่เหมาะสมได้ในหน้า 6

หมายเหตุ: ในการเจียรและตัดขอบจะต้องใช้ตัวป้องกัน type 27 ซึ่งออก

แบบมาเฉพาะ

K

L

B

ข้อควรระวัง: ปิดเครื่องและถอดปลั๊กเครื่อง

มือทุกครั้งก่อนที่จะทำการปรับตั้ง หรือ ถอด

หรือติดตั้งอุปกรณ์เสริมใดๆ

คำเตือน: ล้อเจียรขนาด 100 มม ซึ่งมีพิกัดไม่เกิน 13500 รอบต่อนาที จะไม่

สามารถใช้กับเครื่องรุ่นนี้ได้ อุปกรณ์เสริมต่างๆ จะต้องรองรับอัตราเร็วอย่างน้อย

ที่สุดตามคำแนะนำบนป้ายเตือนของเครื่องมือ จานเจียรและอุปกรณ์เสริมอื่นๆ ที่

หมุนด้วยอัตราเร็วที่เกินกำหนดอาจหลุดและก่อให้เกิดการบาดเจ็บได้ อุปกรณ์

เสริมที่มีเกลียวจะต้องมีดุมล้อขนาด M10 อุปกรณ์เสริมที่ไม่มีเกลียวจะต้องมีรูยึด

ขนาด 16มม. หากอุปกรณ์ดังกล่าวมีขนาดไม่ตรงตามที่ระบุไว้ อาจจะเป็น

อุปกรณ์ที่ออกแบบมาใช้กับเลื่อยวงเดือนเท่านั้น และจะต้องไม่นำมาใช้กับเครื่องนี้

ให้ใช้เฉพาะอุปกรณ์เสริมที่แสดงไว้ในหน้า 9-10 ของคู่มือเล่มนี้ อุปกรณ์เสริม

ที่ใช้จะต้องมีพิกัดสูงกว่าความเร็วต่ำสุดของล้อเจียรดังแสดงไว้บนแผ่นป้ายของ

เครื่องมือ

22

Page 25

9

ไทย

สวิตช์

ข้อควรระวัง: จับที่ด้ามจับด้านข้างและตัวเครื่องให้แน่นเพื่อรักษาระดับ

การควบคุมของเครื่องมือในขณะเริ่มเดินเครื่องและในระหว่างการใช้งานจน

กระทั่งเมื่อล้อหรืออุปกรณ์เสริมหยุดหมุน ต้องให้มั่นใจว่าล้อเจียรหยุดหมุน

อย่างสนิทก่อนที่จะวางเครื่องมือลง

หมายเหตุ: เพื่อลดการเลื่อนของเครื่องมือโดยไม่ได้ตั้งใจ อย่าเปิดหรือ

ปิดสวิตช์ของเครื่องมือในขณะที่มีโหลดอยู่ ปล่อยให้เครื่องเจียรเดินเครื่อง

จนถึงความเร็วเต็มที่ก่อนที่จะสัมผัสเครื่องมือกับผิวชิ้นงาน ยกเครื่องมือขึ้น

จากผิวชิ้นงานก่อนที่จะปิดเครื่องมือ ปล่อยให้เครื่องมือหยุดหมุนก่อนจะ

วางลง

การเปิดและปิดเครื่อง

การเปิดเครื่อง ทำได้โดยการโยกสวิตช์โยก (N) ไปที่

ตำแหน่ง ''1" ส่วนการปิดเครื่อง ให้โยกสวิตช์โยก (N)

ไปที่ตำแหน่ง "0"

ตัวล็อกแกน

ตัวล็อกแกน (A) มีไว้เพื่อป้องกันแกนจากการหมุนเมื่อมี

การติดตั้งหรือถอดจานเจียรออก ใช้งานตัวล็อกแกนเฉพาะเมื่อ

เครื่องมือปิดอยู่ โดยให้ถอดปลั๊กออกจาก

แหล่งจ่ายไฟ และให้เครื่องหยุดสนิทก่อน

ห้ามใช้งานตัวล็อกแกนขณะที่เครื่องกำลัง

ทำงานอยู่เนื่องจากอาจเกิดความเสียหาย

ต่อเครื่องได้ ในการล็อกแกน ให้ลดปุ่มล็อกแกน

ลงและหมุนแกนจนกระทั่งไม่สามารถหมุนต่อไป

A

A

ตัวป้องกัน Type 27

ล้อเจียรขนาด 100มม

หน้าแปลนรองหลัง

น็อตยึดแบบมีเกลียว

ล้อดุม Type 27

ตัวป้องกัน Type 27

ล้อเจียรแบบกดกลาง

Type 27

ล้อขัดแปรงลวด

แปรงถ่านแบบถ้วย

75/100มม

ล้อขัดแปรงลวด

75/100มม

ตัวป้องกัน Type 27

ตัวป้องกัน Type 27

N

คำเตือน: ล้อเจียรขนาด 100 มม ซึ่งมีพิกัดไม่เกิน 13500 รอบต่อนาทีจะไม่

สามารถใช้กับเครื่องรุ่นนี้ได้ อุปกรณ์เสริมต่างๆ จะต้องรองรับ อัตราเร็วอย่างน้อย

ที่สุดตามคำแนะนำบนป้ายเตือนของเครื่องมือ จานเจียรและอุปกรณ์เสริมอื่นๆ ที่หมุน

ด้วยอัตราเร็วที่เกินกำหนดอาจ หลุดและก่อให้เกิด การบาดเจ็บได้ อุปกรณ์เสริม

ที่มีเกลียวจะต้องมีดุมล้อ ขนาด M10 อุปกรณ์เสริมที่ไม่มีเกลียวจะต้องมีรูยึดขนาด

16มม. หากอุปกรณ์ดังกล่าวมีขนาดไม่ตรงตามที่ระบุไว้ อาจจะเป็นอุปกรณ์ที่ออก

แบบมาใช้กับเลื่อยวงเดือนเท่านั้น และจะต้องไม่นำมาใช้กับเครื่องนี้ ให้ใช้เฉพาะ

อุปกรณ์เสริมที่แสดงไว้ในหน้า 9-10 ของคู่มือเล่มนี้ อุปกรณ์เสริมที่ใช้จะต้องมี

พิกัดสูงกว่าความเร็วต่ำสุดของล้อเจียรดังแสดงไว้บนแผ่นป้ายของเครื่องมือ

ได้อีก

23

Page 26

24

ไทย

แผ่นยางรองหลัง

จานขัด

น็อตยึดแบบมีเกลียว

จานขัด

จานตัดขนาด 100มม/125มม

ตัวป้องกัน Type 27

หน้าแปลนรองหลัง

ล้อตัดเจียร

น็อตยึด

ตัวป้องกัน Type 27

หน้าแปลนรองหลัง

ล้อตัดเพชร

น็อตยึด

จานเจียรขนาด 100มม

ล้อเจียรแบบมีดุมล้อ

หน้าแปลนรองหลัง

ล้อเจียรแบบไม่มีดุมล้อ

น็อตยึดแบบมีเกลียว

ตัวป้องกัน Type 27

ตัวป้องกัน Type 27

การติดตั้งและการใช้จานเจียร

และแผ่นจานขัด

แบบกดศูนย์กลาง

การติดตั้งและการถอดจานเจียรแบบมีดุม

ข้อควรระวัง: ปิดเครื่องและถอดปลั๊กเครื่องมือทุกครั้งก่อนที่จะทำ

การปรับตั้ง หรือถอด หรือติดตั้งอุปกรณ์เสริมใดๆ ก่อนเสียบปลั๊ก

เครื่องมืออีกครั้ง ต้องกดแล้วปล่อยแป้นสวิตช์ เพื่อให้มั่นใจว่า

เครื่องมืออยู่ในสถานะปิดจริงๆ

จานเจียรแบบมีดุมจะติดตั้งโดยตรงเข้ากับแกนหมุนแบบมีเกลียว M10

เกลียวของอุปกรณ์เสริมจะต้องตรงกับเกลียวของแกนหมุน

โปรดใช้อุปกรณ์เสริมที่ถูกขนาดตามพิกัดที่ระบุไว้บนแผ่นป้าย

อย่าใช้อุปกรณ์เสริมที่ออกแบบมาสำหรับเครื่องเจียรขนาด 125มม กับ

เครื่องเจียรขนาด 100มม

Page 27

11

การเจียรผิวงานด้วยจานเจียร

1. ปล่อยให้เครื่องเจียรเดินเครื่องจนถึงความเร็วเต็มที่ก่อนที่จะสัมผัสเครื่องมือ

กับผิวชิ้นงาน

2. กดเครื่องด้วยแรงเบาๆ ไปที่ผิวของชิ้นงาน ปล่อยให้ตัวเครื่องทำงานที่

ความเร็วสูง อัตราการเจียรจะสูงสุดเมื่อเครื่องมือทำงานที่ความเร็วสูง

3. พยายามรักษามุมประมาณ 20° ถึง 30°

องศา ระหว่างตัวเครื่องกับผิวชิ้นงาน

4. เคลื่อนตัวเครื่องมือไปข้างหน้าและเคลื่อน

ถอยหลังกลับอย่างคงที่เพื่อหลีกเลี่ยง

ไม่ให้เกิดรอยเซาะบนผิวชิ้นงาน

5. ยกเครื่องมือขึ้นจากผิวชิ้นงานก่อนที่จะ

ปิดเครื่องมือ ปล่อยให้เครื่องมือหยุดหมุนก่อนจะวางลง

การเจียรขอบด้วยจานเจียร

ข้อควรระวัง: ถ้าจานเจียรถูกบิดขณะที่ใช้งานในการตัดชิ้นงานหรือเจียร

ลึกลงไปในชิ้นงาน อาจทำให้จานที่ใช้สำหรับการตัดหรือเจียรขอบนั้นแตก

ได้ เพื่อลดความเสี่ยงที่จะเกิดการบาดเจ็บอย่างรุนแรง ควรใช้งานจานเจียร

1. หน้าแปลนรองหลังจะถูกยึดติดกับเครื่องเจียรโดยใช้แหวนโอริงบน

แกนหมุน ถอดหน้าแปลนรองหลังออกโดยการดึงและหมุนหน้าแปลน

ทิศทางออกจากตัวเครื่อง

2. หมุนเกลียวของล้อเจียรบนแกนหมุนโดยใช้มือ

3. กดปุ่มล็อกแกนหมุน แล้วขันเข้ากับดุมล้อให้แน่นด้วยประแจ

4.ถ้าต้องการถอดล้อเจียรออก ให้ทำขั้นตอนด้านบนย้อนกลับ

ข้อควรระวัง: หากไม่สามารถใส่จานเจียรเข้าไปได้ก่อนที่จะเปิด:

เครื่องมืออาจจะทำให้เกิดความเสียหายกับเครื่องมือหรือจานเจียร

การติดตั้งจานแบบไม่มีดุม

ข้อควรระวัง: ปิดเครื่องและถอดปลั๊กเครื่องมือทุกครั้งก่อนที่จะทำ

การปรับตั้ง หรือถอด หรือติดตั้งอุปกรณ์เสริมใดๆ ก่อนเสียบปลั๊ก

เครื่องมืออีกครั้ง ต้องกดแล้วปล่อยสวิตช์ เพื่อให้มั่นใจว่าเครื่องมือ

อยู่ในสถานะปิดจริงๆ

จะต้องใช้จานเจียรแบบกดศูนย์กลาง type 27

กับหน้าแปลนที่ให้มา โปรดดูข้อมูลเพิ่มเติมที่

หน้า 6 ของคู่มือนี้

1. ติดแผ่นหน้าแปลนโลหะรองหลังแบบไม่มี

เกลียว (G) บนแกน (D) โดยให้ส่วนที่นูน

ขึ้นมาแนบกับที่จานเจียร ตรวจสอบให้แน่ใจ

ว่าส่วนเว้าของหน้าแปลนรองหลังจมลงไปกับแผ่นที่ราบของแกนหมุน

โดยการกดและบิดหน้าแปลนก่อนที่จะใส่จานเจียรเข้าไป

2. วางจานเจียรแนบไปกับหน้าแปลนรองหลัง

โดยวางจุดศูนย์กลางจานเจียรไว้บนส่วนที่นูน

ขึ้น (นำร่อง) ของหน้าแปลนรองหลัง

3. ขณะที่ยังกดปุ่มล็อกแกนหมุนอยู่ ให้หมุน

เกลียวน็อตยึด (G) บนแกนหมุนหาก

จานเจียรที่คุณกำลังติดตั้งมีความหนาเกิน

1/8" (3.31มม) ให้ใส่น็อตยึดแบบมีเกลียว

เข้าไปบนแกนหมุนเพื่อให้ส่วนที่นูน

สามารถเข้ากับศูนย์กลางของจานเจียร

ได้พอดี หากจานเจียรที่คุณกำลังติดตั้ง

มีความหนาไม่เกิน 1/8" (3.31มม) ให้ใส่

จานขนาด 1/4"

(6.35มม.)

น็อดยึด

น็อตยึดแบบมีเกลียวเข้าไปบนแกนหมุน

เพื่อให้ส่วนที่นูนไม่แนบเข้ากับจานเจียร

4. ขณะกดปุ่มล็อกแกนหมุน แล้วขันน็อตยึด

ให้แน่นด้วยประแจ

5. หากต้องการถอดจานเจียร กดปุ่มล็อก

แกนหมุน แล้วคลายน็อตยึดออกด้วย

ประแจ

หมายเหตุ: หากจานเจียรมีการหมุนหลังจาก

ขันน็อตยึดแน่นแล้ว ให้ตรวจสอบทิศทางของ

น็อตยึดแบบมีเกลียว หากมีการติดตั้งจานเจียร

แบบบางเข้ากับนำร่องบนน็อตยึดเข้ากับจานเจียร

จานเจียรอาจจะมีการหมุนเนื่องจากความสูง

ของนำร่องอาจจะทำให้น็อตยึดไม่แนบกับ

จานเจียร

จานขนาด 1/8"

(3.31มม.)

หน้าแปลนรองหลัง

หน้าแปลนรองหลัง

น็อตยึด

H

G

D

20°-30°

ไทย

25

Page 28

26

เหล่านี้พร้อมกับตัวป้องกันชนิดมาตรฐาน Type 27

ในการตัดและบากตื้นๆ (ลึกไม่เกิน 1/2 นิ้ว) ด้าน

เปิดของตัวป้องกันจะต้องหันออกจากตัวผู้ใช้

สำหรับการตัดลึกด้วยจานตัดชนิด Type 1 เลือก

ใช้ตัวป้องกันแบบปิดชนิด Type 1 ตัวป้องกัน

แบบ Type 1 เป็นอุปกรณ์ที่จะต้องซื้อแยก

ต่างหากจากตัวแทนจำหน่ายหรือศูนย์บริการ

ที่ได้รับการแต่งตั้ง

1.

ปล่อยให้เครื่องเจียรเดินเครื่องจนถึงความเร็ว

เต็มที่ก่อนที่จะสัมผัสเครื่องมือกับผิวชิ้นงาน

2.

กดเครื่องด้วยแรงเบาๆ ไปที่ผิวของชิ้นงาน ปล่อยให้ตัวเครื่องทำงาน

ที่ความเร็วสูง อัตราการเจียรจะสูงสุดเมื่อเครื่องมือทำงานที่ความเร็ว

3. ยืนในตำแหน่งที่ให้ด้านล่างที่เปิดของจานเจียรหันออกไปจากตัวท่าน

4. เมื่อเริ่มการตัดและมีรอยบากเกิดขึ้นในชิ้นงานแล้ว อย่าเปลี่ยนมุมใน

การตัด การเปลี่ยนมุมตัดจะทำให้จานเกิดการงอและอาจทำให้แตกหัก

ได้เพราะจานประเภทนี้ไม่ได้ถูกออกแบบมารองรับแรงกดทางด้านข้าง

ที่เกิดจากการโค้งงอ

5. ยกเครื่องมือขึ้นจากผิวชิ้นงานก่อนที่จะปิดเครื่องมือ ปล่อยให้เครื่องมือ

หยุดหมุนก่อนจะวางลง

คำเตือน: อย่าใช้จานเจียรขอบ/จายตัดในการการเจียผิวงาน

สูง

การขัดผิวชิ้นงานด้วยแผ่นจานขัด

1.ปล่อยให้เครื่องเจียรเดินเครื่องจนถึงความเร็วเต็มที่ก่อนที่จะสัมผัส

เครื่องมือกับผิวชิ้นงาน

2.กดเครื่องด้วยแรงเบาๆ ไปที่ผิวของชิ้นงาน ปล่อยให้ตัวเครื่องทำงาน

ที่ความเร็วสูง อัตราการเจียรจะสูงสุดเมื่อเครื่องมือทำงานที่ความเร็วสูง

3.พยายามรักษามุมประมาณ 5° ถึง 10° องศา

ระหว่างตัวเครื่องกับผิวชิ้นงาน

4.เคลื่อนตัวเครื่องมือไปข้างหน้าและเคลื่อน

ถอยหลังกลับอย่างคงที่เพื่อหลีกเลี่ยงไม่

ให้เกิดรอยเซาะบนผิวชิ้นงาน

5.ยกเครื่องมือขึ้นจากผิวชิ้นงานก่อนที่จะปิด

เครื่องมือ ปล่อยให้เครื่องมือหยุดหมุนก่อนจะวางลง

การใส่แผ่นรองหลังในการขัด

ข้อควรระวัง: ปิดเครื่องและถอดปลั๊กเครื่องมือทุกครั้งก่อนที่จะทำ

การปรับตั้ง หรือถอด หรือติดตั้งอุปกรณ์เสริมใดๆ ก่อนเสียบปลั๊ก

เครื่องมืออีกครั้ง ต้องกดแล้วปล่อยสวิตช์ เพื่อให้มั่นใจว่าเครื่องมืออยู่

ในสถานะปิดจริงๆ

5˚-10˚

ข้อควรระวัง: หลังจากการใช้งานเสร็จสิ้น จะต้องประกอบตัวป้องกัน

สำหรับการใช้งานจานเจียร แผ่นจานขัด แปรงถ่าน หรือล้อแปรงลวด

กลับเข้าไป

1. ใส่แผ่นรองหลังแบบมีเกลียวที่เหมาะสม

(Q) เข้าไปกับแกนหมุน

2. วางจานขัด (R) ลงไปบนแผ่นรองหลัง

3. ขณะที่ยังกดปุ่มล็อกแกนหมุนอยู่ ให้หมุน

เกลียวน็อตยึด (H) บนแกนหมุน โดยให้

ดุมล้อด้านที่นูนบนน็อตยึดอยู่กลางจานขัด

และแผ่นรองหลัง

4. ขันน็อตยึดด้วยมือให้แน่น หลังจากนั้นให้

กดปุ่มล็อกแกนพร้อมกับหมุนจานขัดจน

กระทั่งจานขัดและน็อตยึดเข้าล็อก

5. การถอดล้อออก ให้จับแผ่นรองหลังและจานขัดแล้วหมุนพร้อมกับกด

ปุ่มล็อกแกน

H

Q

R

เพราะตัวจานประเภทนี้ไม่ได้ถูกออกแบบมารองรับแรงกดทางด้าน

ข้างที่เกิดจากการเจียผิวชิ้นงาน ซึ่งอาจจะเกิดการแตกหักของจาน

เจียรหรือเกิดการบาดเจ็บได้

ไทย

Page 29

27

ไทย

การใช้แผ่นรองหลังในการขัด

ใช้กระดาษทรายให้เหมาะสมกับงานที่ต้องการทำ กระดาษทรายจะมีความ

หยาบที่แตกต่างกัน กระดาษทรายหยาบจะให้อัตราการขัดวัสดุที่ไม่ต้อง

การออกได้เร็วกว่าและให้ผิวที่หยาบกว่า กระดาษทรายละเอียดจะให้อัตรา

การขัดวัสดุที่ไม่ต้องการออกได้ช้ากว่าแต่ให้ผิวชิ้นงานที่ละเอียดกว่า

ให้เริ่มโดยการใช้กระดาษทรายหยาบเพื่อขัดส่วนของชิ้นงานที่ไม่ต้องการ

ออกย่างรวดเร็วถัดไปให้ใช้กระดาษทรายหยาบปานกลางและปิดด้วยแบบ

ละเอียดเพื่อขัดผิดอย่างละเอียด

แบบหยาบ 16 - 30 กริต

ปานกลาง 36 - 80 กริต

แบบละเอียด 100 - 120 กริต

แบบละเอียดมาก 150 - 180 กริต

1. ปล่อยให้เครื่องเจียรเดินเครื่องจนถึงความเร็วเต็มที่ก่อนที่จะสัมผัส

เครื่องมือกับผิวชิ้นงาน

2. กดเครื่องด้วยแรงเบาๆ ไปที่ผิวของชิ้นงาน ปล่อยให้ตัวเครื่องทำงาน

ที่ความเร็วสูง อัตราการเจียรจะสูงสุดเมื่อเครื่องมือทำงานที่ความเร็วสูง

3. พยายามรักษามุมประมาณ 5° ถึง 15° องศา

ระหว่างตัวเครื่องกับผิวชิ้นงาน ควรให้

จานขัดสัมผัสกับผิวชิ้นงานประมาณ 1 นิ้ว

4. เคลื่อนตัวเครื่องมือไปข้างหน้าและ

เคลื่อนถอยหลังกลับอย่างคงที่เพื่อ

หลีกเลี่ยงไม่ให้เกิดรอยเซาะบนผิวชิ้นงาน

การปล่อยให้เครื่องหยุดบนผิวชิ้นงานโดยไม่มีการเคลื่อนที่ หรือการ

เลื่อนเครื่องไปเป็นวงกลมอาจจะทำให้เกิดการไหม้และรอยวงบนผิว

5. ยกเครื่องมือขึ้นจากผิวชิ้นงานก่อนที่จะปิดเครื่องมือ ปล่อยให้เครื่องมือ

หยุดหมุนก่อนจะวางลง

การติดตั้งและการใช้งานแปรงถ่าน

และล้อขัดแปรงลวด

ขันสกรูยึดแปรงถ่านหรือล้อแปรงลวดเข้ากับเครื่องเจียรโดยตรงโดยไม่

ต้องใช้หน้าแปลน โดยให้ใช้เฉพาะแปรงถ่านหรือล้อแปรงลวดที่ให้มา

พร้อมดุมล้อ M10 แบบมีเกลียวเท่านั้น เมื่อใช้แปรงถ่านหรือล้อแปรงลวด

จะต้องใช้ตัวป้องกัน type 27

ข้อควรระวัง: ให้สวมถุงมือขณะที่จับแปรงถ่านและล้อแปรงลวด

เนื่องจากอาจจะถูกบาดจากคมของอุปกรณ์ดังกล่าว

ข้อควรระวัง: ขณะใส่ตัวป้องกันหรือขณะใช้งานอยู่ จะต้องไม่ให้แปรง

ถ่านหรือล้อแปรงลวดสัมผัสโดนตัวป้องกัน เนื่องจากอาจเกิดความเสียหาย

ต่ออุปกรณ์เสริม โดยแปรงถ่านอาจจะหักออกมาจากลูกถ้วยหรือล้อได้

การประกอบแปรงถ่านและล้อแปรงลวด

ข้อควรระวัง: ปิดเครื่องและถอดปลั๊กเครื่องมือทุกครั้งก่อนที่จะ

ทำการปรับตั้ง หรือถอด หรือติดตั้งอุปกรณ์เสริมใดๆ

ก่อนเสียบปลั๊กเครื่องมืออีกครั้ง ต้องกดแล้วปล่อยสวิตช์ เพื่อให้

มั่นใจว่าเครื่องมืออยู่ในสถานะปิดจริงๆ

1. หมุนเกลียวของล้อเจียรบนแกนหมุนโดยใช้มือ

2. กดปุ่มล็อกแกนหมุน แล้วขันเข้ากับดุมของแปรงถ่านหรือล้อแปรงลวด

ให้แน่นด้วยประแจ

3. ถ้าต้องการถอดจานตัดออก ให้ทำขั้นตอนด้านบนย้อนกลับ

ข้อควรระวัง: หากไม่สามารถใส่จานเจียรเข้าไปได้ก่อนที่จะเปิด

เครื่องมืออาจจะทำให้เกิดความเสียหายกับเครื่องมือหรือจานเจียร

การใช้งานแปรงถ่านและล้อแปรงลวด

แปรงถ่านและล้อแปรงลวดเป็นอุปกรณ์ที่ใช้ในการขัดลอกสนิม สะเก็ด

และสี รวมทั้งช่วยในการขัดผิวชิ้นงานที่ไม่สม่ำเสมอให้เรียบ

1. ปล่อยให้เครื่องเจียรเดินเครื่องจนถึงความเร็วเต็มที่ก่อนที่จะสัมผัส

เครื่องมือกับผิวชิ้นงาน

2. กดเครื่องด้วยแรงเบาๆ ไปที่ผิวของชิ้นงาน ปล่อยให้ตัวเครื่องทำงาน

ที่ความเร็วสูง อัตราการขัดลอกจะสูงสุดเมื่อเครื่องมือทำงานที่ความ

เร็วสูง

3. พยายามรักษามุมประมาณ 5° ถึง 10° องศา

ระหว่างแปรงถ่านกับผิวชิ้นงาน

4. รักษาระยะสัมผัสระหว่างขอบของจานเจียร

และผิวชิ้นงานด้วยแปรงถ่าน

5˚-10˚

5˚-15˚

ของชิ้นงานได้

Page 30

28

ไทย

5. เคลื่อนตัวเครื่องมือไปข้างหน้าและเคลื่อนถอย

หลังกลับอย่างคงที่เพื่อหลีกเลี่ยงไม่ให้เกิดรอย

เซาะบนผิวชิ้นงาน การปล่อยให้เครื่องหยุดบน

ผิวชิ้นงานโดยไม่มีการเคลื่อนที่ หรือการเลื่อน

เครื่องเป็นวงกลมอาจจะทำให้เกิดการไหม้และ

รอยวงบนผิวของชิ้นงานได้

6. ยกเครื่องมือขึ้นจากผิวชิ้นงานก่อนที่จะปิดเครื่องมือ ปล่อยให้

เครื่องมือหยุดหมุนก่อนจะวางลง

ข้อควรระวัง: ใช้ความระมัดระวังเป็นพิเศษขณะทำงานอยู่ในบริเวณขอบของ

ชิ้นงานเพราะจะเกิดการเคลื่อนไหวของเครื่องเจียรอย่างรวดเร็วและรุนแรงได้

การติดตั้งและการใช้จานตัด

จานตัดประกอบด้วยหัวตัดเพชรและจานขัด นอกจากนั้น ยังมีจานตัดแบบ

ขัดถูสำหรับใช้กับโลหะและคอนกรีตให้เลือกใช้ รวมทั้งยังมีจานตัดเพชร

สำหรับใช้ตัดคอนกรีตได้ด้วย

คำเตือน: ที่ป้องกันจานตัด 2 ด้านแบบปิดเป็นอุปกรณ์ที่ไม่ได้ให้มา

พร้อมกับเครื่องแต่เป็นอุปกรณ์ที่จำเป็นต้องใช้เมื่อต้องใช้งานจานตัด

การใช้หน้าแปลนและตัวป้องกันที่ไม่เหมาะสมอาจก่อให้เกิดการบาด

เจ็บจากการแตกหักหรือการสัมผัสจานตัดก็ได้

การติดตั้งตัวป้องกันแบบปิด

ข้อควรระวัง: ปิดเครื่องและถอดปลั๊กเครื่องมือทุกครั้งก่อนที่จะทำ

การปรับตั้ง หรือถอด หรือติดตั้งอุปกรณ์เสริมใดๆ ก่อนเสียบปลั๊ก

เครื่องมืออีกครั้ง ต้องกดแล้วปล่อยสวิตช์ เพื่อให้มั่นใจว่าเครื่องมือ

อยู่ในสถานะปิดจริงๆ

1. เปิดสลักตัวป้องกัน (J) ตั้งสลัก (K)

บนตัวป้องกันให้ตรงกับร่อง (L) บนตัว

กล่องเกียร์

2. กดตัวป้องกันลงจนกระทั่งสลักของ

ตัวป้องกันลงร่องและหมุนได้อย่าง

อิสระในร่องบนศูนย์กลางของ

กล่องเกียร์

3. หมุนตัวป้องกัน (B) ให้ตรงกับตำแหน่ง

ที่ต้องการจะใช้งาน ตัวป้องกันจะต้องอยู่ระหว่างแกนหมุนและ

ผู้ใช้งาน เพื่อให้สามารถป้องกันผู้ใช้งาน

ได้มากที่สุด

4. ปิดสลักตัวป้องกันลงเพื่อยึดตัวป้องกันบน

ฝาครอบกล่องเกียร์ เมื่อตัวสลักอยู่ใน

ตำแหน่งปิดลง ท่านจะต้องไม่สามารถ

หมุนตัวป้องกันได้ด้วยมือได้ หากยัง

สามารถหมุนได้ ให้ขันสกรูปรับตั้ง (M) ให้แน่นโดยให้ตัวล็อกใน

ตำแหน่งปิด ห้ามใช้งานเครื่องเจียรขณะที่ตัวป้องกันหลวมหรือ

ตัวยึดอยู่ในตำแหน่งเปิดอยู่

B

J

L

K

5. หากต้องการถอดตัวป้องกัน ให้เปิดสลักของตัวป้องกันออก แล้วหมุน

ตัวป้องกันจนลูกศรตรงกันและดึงตัวป้องกันขึ้น

หมายเหตุ: หากตัวป้องกันเกิดการหลวม

หลังจากใช้งานไประยะหนึ่ง ให้ขันสกรูสำหรับ

ปรับตั้ง (M) ให้แน่น โดยให้ตัวล็อกอยู่ใน

ตำแหน่งปิด

ข้อควรระวัง: อย่าขันสกรูปรับตั้งให้ตัวยึดอยู่

ในตำแหน่งเปิดอยู่เนื่องจากอาจจะเกิดความ

เสียหายต่อตัวป้องกันหรือดุมใส่จานเจียรได้

การประกอบจานตัด

ข้อควรระวัง: ปิดเครื่องและถอดปลั๊กเครื่องมือทุกครั้งก่อนที่จะทำ

การปรับตั้ง หรือถอด หรือติดตั้งอุปกรณ์เสริมใดๆ ก่อนเสียบปลั๊ก

เครื่องมืออีกครั้ง ต้องกดแล้วปล่อยสวิตช์ เพื่อให้มั่นใจว่าเครื่องมือ

อยู่ในสถานะปิดจริงๆ

M

ข้อควรระวัง: จะต้องใช้หน้าแปลนและน็อตยึด (ให้มาพร้อมเครื่อง)

ที่มีขนาดเส้นผ่าศูนย์กลางตรงกันเมื่อใช้งานจานตัด

1. ติดแผ่นหน้าแปลนรองหลังแบบไม่มีเกลียวบนแกนโดยให้ส่วนที่นูน

หันขึ้น เมื่อประกอบจานตัด ส่วนที่นูนของหน้าแปลนจะต้องแนบกับ

จานตัด

2. วางจานตัดบนหน้าแปลนรองหลัง ให้ศูนย์กลางจานตัดอยู่ตรงกับส่วน

ที่นูน (ตัวนำร่อง)

3. ติดน็อตยึดแบบมีเกลียวโดยให้ส่วนที่นูนขึ้นมาหันออกจากจานตัด

Page 31

29

ไทย

4. กดปุ่มล็อกแกนหมุน แล้วขันน็อตล็อกให้แน่นด้วยประแจ

5. หากต้องการถอดจานขัดออก ให้จับจานขัดแล้วหมุนพร้อมกับกดปุ่ม

ล็อกแกน

การใช้งานจานตัด