Page 1

>-W

@

E

O

m

,Q

o 0

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 (MAR04 CD1)

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme;

the "D" shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the

array of lozenge-shaped humps on the surface of the tool.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258)

General Safety Rules

A ARNING! Read and understand all instructions. Failure to

WORK AREA

* Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or

fumes.

Keep bystanders, children, and visitors away while operating a power tool Distractions

can cause you to lose control.

ELECTRICAL SAFETY

, Grounded tools must be plugged into an outlet properly installed and grounded in

accordance with all codes and ordinances. Never remove the grounding prong or

modify the plug in any way. Do not use any adapter plugs. Check with a qualified

electrician if you are in doubt as to whether the outlet is properly grounded, ff the tools

should electrically malfunction or break down, grounding provides a low resistance path to

carry electricity away from the user. This tool uses grounded construction (3 prong plug) to

provide a means to transfer electrical energy safely away from the user in the event the tool

electrically malfunctions, breaks down, or the tool case becomes five. Damage to, or loss of,

one of the 3 plug blades; damage to the plug or cord, or failure to have the tool plugged into a

verified and continuously grounded electrical system, may result in electric shock, serious

injury, or death. To avoid these risks of injury, the tool must, at all times, be maintained and in

proper working order (cord, plug blades) and plugged into a continuously grounded electrical

system. (See also "Cleaning" in the Maintenance section.) Applicable only to Class I

(grounded) tools.

* Double insulated tools are equipped with a polarized plug (one blade is wider than the

other.) This plug will fit in a polarized outlet only one way. ff the plug does not fit fully in

the outlet, reverse the plug. ff it still does not fit, contact a qualified electrician to install

a polarized outlet. Do not change the plug in any way. Double insulation [] eliminates the

need for the three wire grounded power cord and grounded power supply system. Applicable

only to Class II (double insulated) tools.

* Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock ffyour body is grounded.

* Don't expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

* Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged

cords immediately. Damaged cords increase the risk of electric shock.

* When operating a power tool outside, use an outdoor extension cord marked "W-A" or

"W." These cords are rated for outdoor use and reduce the risk of electric shock. When using

an extension cord, be sure to use one heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line voltage resulting in loss of power and

overheating. The following table shows the correct size to use depending on cord length and

nameplate ampere rating, ff in doubt, use the next heavier gage. The smaller the gage

number, the heavier the cord.

W03

o%,<,

W u

n _

O3'<0

rr_

_-wo

n

OW_.I

_W

, ,_

,--W

w _- c21

a.z

w_-

c_r_ z

<

o o

>w>

F-c_F-

o o

D<D

rrUrr

n

w

oE m

0_

Nmm

CO

Form No. 623540-00 D28754 Copyright © 2003, 2004

0

follow all instructions listed below may result in electric shock,

fire and/or serious personal injury.

SAVE THES INSTRUCTIONS

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

Ampere Rating

More Not more AWG

Than Than

12 16 14 12 Not Recommended

Minimum Gage for Cord Sets

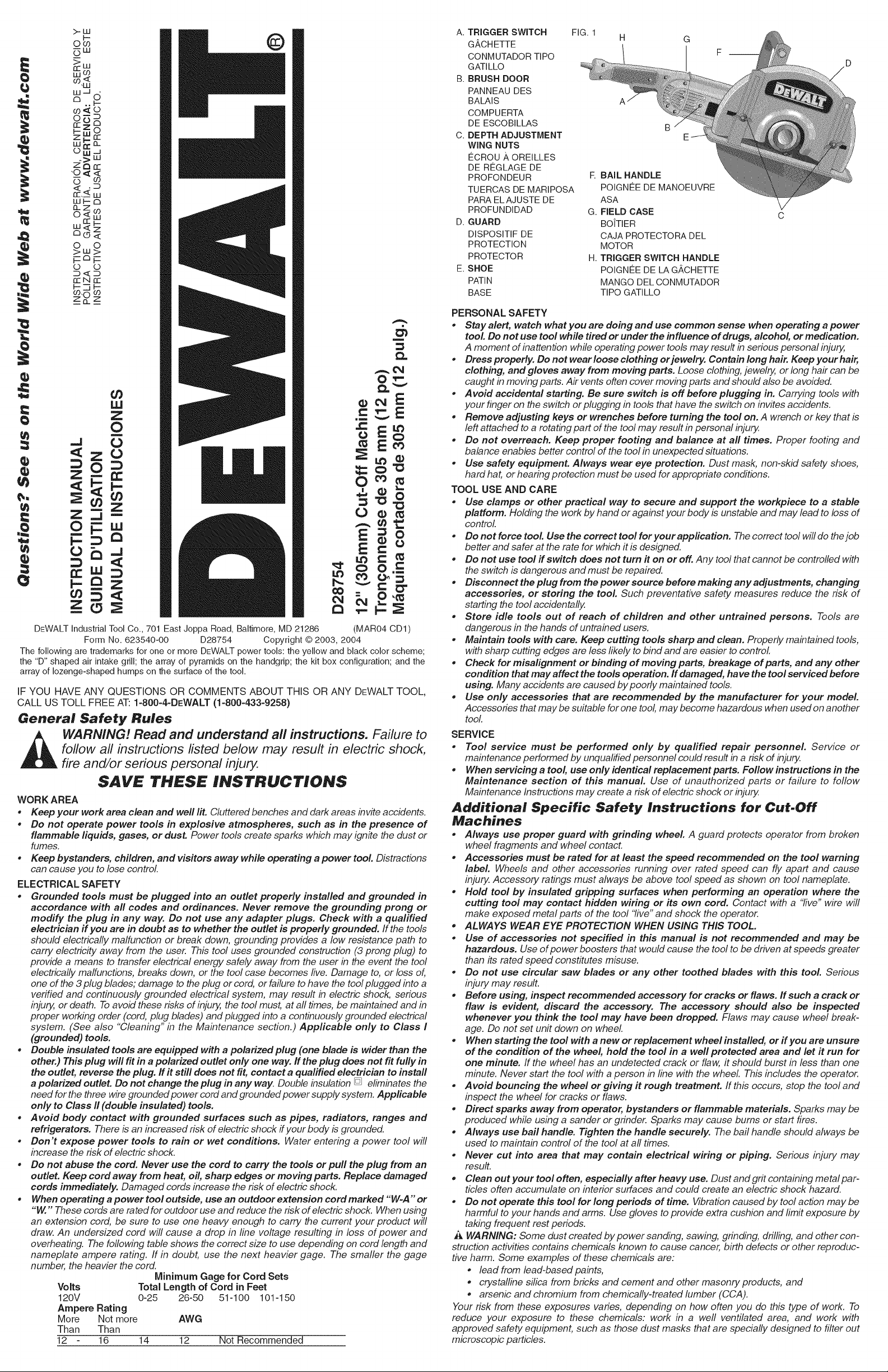

A. TRIGGER SWITCH

GACHETTE

CONMUTADOR TIPO

GATILLO

B. BRUSH DOOR

PANNEAU DES

BALAIS

COMPUERTA

DE ESCOBILLAS

C. DEPTH ADJUSTMENT

WING NUTS

ECROU A OREILLES

DE RI_GLAGE DE

PROFONDEUR

TUERCAS DE MARIPOSA

PARA ELAJUSTE DE

PROFUNDIDAD

D. GUARD

DISPOSITIF DE

PROTECTION

PROTECTOR

E. SHOE

PATIN

BASE

FIG. 1

H G

B

E BAIL HANDLE

POIGNEE DE MANOEUVRE

ASA

G. FIELD CASE

BO[TIER

CAJA PROTECTORA DEL

MOTOR

H. TRIGGER SWITCH HANDLE

POIGNEE DE LA GACHETTE

MANGO DEL CONMUTADOR

TIPO GATILLO

D

E

C

PERSONAL SAFETY

* Stay alert, watch what you are doing and use common sense when operating a power

tool Do not use tool while tired or under the influence of drugs, alcohol, or medication.

A moment of inattention while operating power tools may result in serious personal injury.

* Dress properly. Do not wear loose clothing orjewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts. Loose clothing, jewelry, or long hair can be

caught in moving parts. Air vents often cover moving parts and should also be avoided.

* Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with

your finger on the switch or plugging in tools that have the switch on invites accidents.

* Remove adjusting keys or wrenches before turning the tool on. A wrench or key that is

left attached to a rotating part of the tool may result in personal inju_

* Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enables better control of the tool in unexpected situations.

Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

* Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss of

control

* Do not force tool Use the correct tool for your application. The correct tool will do thejob

better and safer at the rate for which it is designed.

* Do not use tool ff switch does not turn # on or off. Any tool that cannot be controlled with

the switch is dangerous and must be repaired.

* Disconnect the plug from the power source before making any adjustments, changing

accessories, or storing the tool Such preventative safety measures reduce the risk of

starting the tool accidentally.

* Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

* Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools,

with sharp cutting edges are less likely to bind and are easier to control

* Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tools operation. If damaged, have the tool serviced before

using. Many accidents are caused by poorly maintained tools.

* Use only accessories that are recommended by the manufacturer for your model

Accessories that may be suitable for one tool may become hazardous when used on another

tool.

SERVICE

* Tool service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

* When servicing a tool, use only identical replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of electric shock or injury.

Additional Specific Safety Instructi_ns for Cut-Off

Machines

* Always use proper guard with grinding wheel. A guard protects operator from broken

wheel fragments and wheel contact.

* Accessories must be rated for at least the speed recommended on the tool warning

label Wheels and other accessories running over rated speed can fly apart and cause

injury. Accessory ratings must always be above tool speed as shown on tool nameplate.

* Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will

make exposed metal parts of the tool "live" and shock the operator.

, ALWAYS WEAR EYE PROTECTION WHEN USING THIS TOOL.

* Use of accessories not specified in this manual is not recommended and may be

hazardous. Use of power boosters that would cause the tool to be driven at speeds greater

than its rated speed constitutes misuse.

* Do not use circular saw blades or any other toothed blades with this tool Serious

injury may result.

* Before using, inspect recommended accessory for cracks or flaws. If such a crack or

flaw is evident, discard the accessory. The accessory should also be inspected

whenever you think the tool may have been dropped. Flaws may cause wheel break-

age. Do not set unit down on wheel

* When starting the tool with a new or replacement wheel installed, or if you are unsure

of the condition of the wheel, hold the tool in a well protected area and let it run for

one minute, ff the wheel has an undetected crack or flaw, it should burst in less than one

minute. Never start the tool with a person in line with the wheel This includes the operator.

* Avoid bouncing the wheel or giving it rough treatment. If this occurs, stop the tool and

inspect the wheel for cracks or flaws.

* Direct sparks away from operator, bystanders or flammable materials. Sparks may be

produced while using a sander or grinder. Sparks may cause bums or start fires.

* Always use ball handle. Tighten the handle securely. The bail handle should always be

used to maintain control of the tool at all times.

* Never cut into area that may contain electrical wiring or piping. Serious injury may

result.

, Clean out your tool often, especially after heavy use. Dust and grit containing metal par-

ticles often accumulate on interior surfaces and could create an electric shock hazard.

* Do not operate this tool for long periods of time. Vibration caused by tool action may be

harmful to your hands and arms. Use gloves to provide extra cushion and limit exposure by

taking frequent rest periods.

,& WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other con-

struction activities contains chemicals known to cause cancer, birth defects or other reproduc-

tive harm. Some examples of these chemicals are:

* lead from lead-based paints,

* crystalline silica from bricks and cement and other masonry products, and

* arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a weft ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

Page 2

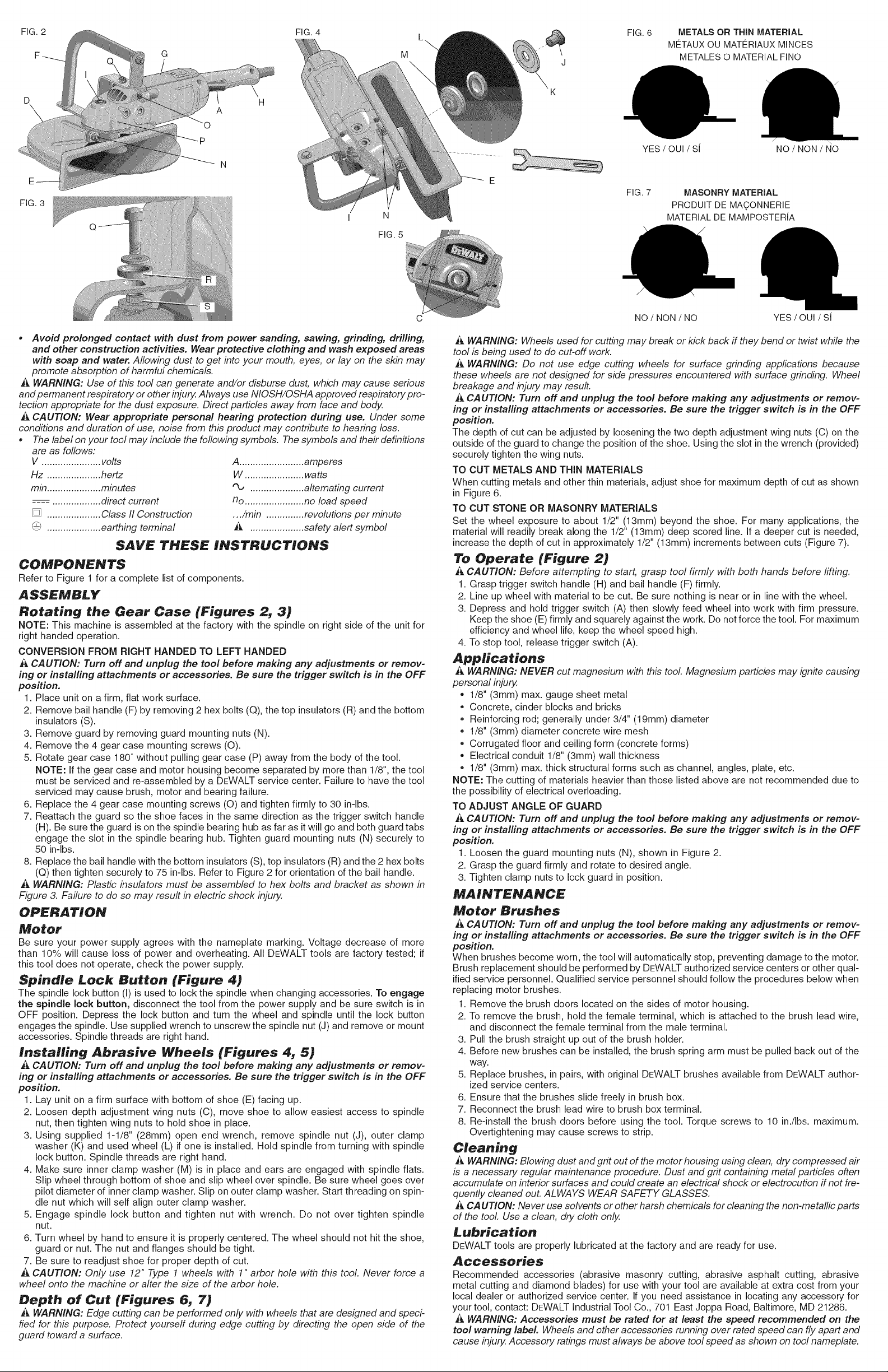

FIG. 2

FIG, 4

L\

M

A

FIG. 6

METALS OR THIN MATERIAL

M¢:TAUX OU MATERIAUX MINCES

METALES O MATERIAL FINO

FIG. 3

N

FIG, 5

* Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

A WARNING: Use of this tool can generate and/or disburse dust, which may cause serious

and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory pro-

tection appropriate for the dust exposure. Direct particles away from face and body.

_, CAUTION: Wear appropriate personal hearing protection during use. Under some

conditions and duration of use, noise from this product may contribute to hearing loss.

* The label on your tool may include the following symbols. The symbols and their definitions

are as follows:

V ...................... volts

Hz .................... hertz

min .................... minutes

.... .................. direct current

[] .................... Class II Construction

G .................... earthing terminal

A........................ amperes

W ...................... watts

'X, .................... alternating current

no ...................... no load speed

.../min .............. revolutions per minute

_t, .................... safety alert symbol

SAVE THESE INSTRUCTIONS

COMPONENTS

Refer to Figure 1 for a complete listof components.

ASSEMBLY"

Rotating the Gear Case (Figures 2, 3)

NOTE: This machine is assembled at the factory with the spindle on right side of the unit for

right handed operation.

CONVERSION FROM RIGHT HANDED TO LEFT HANDED

CAUTION: Turn off and unplug the tool before making any adjustments or remov-

ing or installing attachments or accessories. Be sure the trigger switch is in the OFF

position.

1. Place unit on a firm, flat work surface.

2. Remove bail handle (F) by removing 2 hex bolts (Q), the top insulators (R) and the bottom

insulators (S).

3. Remove guard by removing guard mounting nuts (N).

4. Remove the 4 gear case mounting screws (O).

5. Rotate gear case 180° without pulling gear case (P) away from the body of the tool.

NOTE: If the gear case and motor housing become separated by more than 1/8", the tool

must be serviced and re-assembled by a DEWALT service center. Failure to have the tool

serviced may cause brush, motor and bearing failure.

6. Replace the 4 gear case mounting screws (O) and tighten firmly to 30 in-lbs.

7. Reattach the guard so the shoe faces in the same direction as the trigger switch handle

(H). Be sure the guard is on the spindle bearing hub as far as it will go and both guard tabs

engage the slot in the spindle bearing hub. Tighten guard mounting nuts (N) securely to

50 in-lbs.

8. Replace the bail handle with the bottom insulators (S), top insulators (R) and the 2 hex bolts

(Q) then tighten securely to 75 in-lbs. Refer to Figure 2 for orientation of the bail handle.

ik WARNING: Plastic insulators must be assembled to hex bolts and bracket as shown in

Figure 3. Failure to do so may result in electric shock injury.

OPERATION

Motor

Be sure your power supply agrees with the nameplate marking. Voltage decrease of more

than 10% will cause loss of power and overheating. All DEWALT tools are factory tested; if

this tool does not operate, check the power supply.

Spindle Lock Button (Figure 4)

The spindle lock button (I) is used to lock the spindle when changing accessories. To engage

the spindle lock button, disconnect the tool from the power supply and be sure switch is in

OFF position. Depress the lock button and turn the wheel and spindle until the lock button

engages the spindle. Use supplied wrench to unscrewthe spindle nut (J) and remove or mount

accessories. Spindle threads are right hand.

Installing Abrasive Wheels (Figures 4, 5)

A CAUTION: Turn off and unplug the tool before making any adjustments or remov-

ing or installing attachments or accessories. Be sure the trigger switch is in the OFF

position.

1. Lay unit on a firm surface with bottom of shoe (E) facing up.

2. Loosen depth adjustment wing nuts (C), move shoe to allow easiest access to spindle

nut, then tighten wing nuts to hold shoe in place.

3. Using supplied 1-1/8" (28mm) open end wrench, remove spindle nut (J), outer clamp

washer (K) and used wheel (L) if one is installed. Hold spindle from turning with spindle

lock button. Spindle threads are right hand.

4. Make sure inner clamp washer (M) is in place and ears are engaged with spindle flats.

Slip wheel through bottom of shoe and slip wheel over spindle. Be sure wheel goes over

pilot diameter of inner clamp washer. Slip on outer clamp washer. Start threading on spin-

dle nut which will self align outer clamp washer.

5. Engage spindle lock button and tighten nut with wrench. Do not over tighten spindle

nut.

6. Turn wheel by hand to ensure it is properly centered. The wheel should not hit the shoe,

guard or nut. The nut and flanges should be tight.

7. Be sure to readjust shoe for proper depth of cut.

CAUTION: Only use 12" Type 1 wheels with 1" arbor hole with this tool. Never force a

wheel onto the machine or alter the size of the arbor hole.

Depth of Cut (Figures 6, 7)

_ WARNING: Edge cutting can be performed only with wheels that are designed and speci-

fied for this purpose. Protect yourself during edge cutting by directing the open side of the

guard toward a surface.

YES / OUI / Si

FIG. 7

C

A WARNING: Wheels used for cutting may break or kick back ff they bend or twist while the

tool is being used to do cut-off work.

_, WARNING: Do not use edge cutting wheels for surface grinding applications because

these wheels are not designed for side pressures encountered with surface grinding. Wheel

breakage and injury may result.

_, CAUTION: Turn off and unplug the tool before making any adjustments or remov-

ing or installing attachments or accessories. Be sure the trigger switch is in the OFF

position.

The depth of cut can be adjusted by loosening the two depth adjustment wing nuts (C) on the

outside of the guard to change the position of the shoe. Using the slot in the wrench (provided)

securely tighten the wing nuts.

TO CUT METALS AND THIN MATERIALS

When cutting metals and other thin materials, adjust shoe for maximum depth of cut as shown

in Figure 6.

TO CUT STONE OR MASONRY MATERIALS

Set the wheel exposure to about 1/2" (13ram) beyond the shoe. For many applications, the

material will readily break along the 1/2" (13mm) deep scored line. If a deeper cut is needed,

increase the depth of cut in approximately 1/2" (13mm) increments between cuts (Figure 7).

NO / NON / NO YES/OUl / Si

MASONRY MATERIAL

PRODUIT DE MA_ONNERIE

MATERIAL DE MAMPOSTERiA

NO / NON / NO

To Operate (Figure 2)

CAUTION: Before attempting to start, grasp tool firmly with both hands before lifting.

1. Grasp trigger switch handle (H) and bail handle (F) firmly.

2. Line up wheel with material to be cut. Be sure nothing is near or in line with the wheel.

3. Depress and hold trigger switch (A) then slowly feed wheel into work with firm pressure.

Keep the shoe (E) firmly and squarely against the work. Do not force the tool. For maximum

efficiency and wheel life, keep the wheel speed high.

4. To stop tool, release trigger switch (A).

Applications

_, WARNING: NEVER cut magnesium with this tool. Magnesium particles may ignite causing

personal injury.

• 1/8" (3ram) max. gauge sheet metal

• Concrete, cinder blocks and bricks

• Reinforcing rod; generally under 3/4" (19ram) diameter

• 1/8" (3mm) diameter concrete wire mesh

• Corrugated floor and ceiling form (concrete forms)

• Electrical conduit 1/8" (3mm) wall thickness

• 1/8" (3mm) max. thick structural forms such as channel, angles, plate, etc.

NOTE: The cutting of materials heavier than those listed above are not recommended due to

the possibility of electrical overloading.

TO ADJUST ANGLE OF GUARD

A CAUTION: Turn off and unplug the tool before making any adjustments or remov=

ing or installing attachments or accessories. Be sure the trigger switch is in the OFF

position.

1. Loosen the guard mounting nuts (N), shown in Figure 2.

2. Grasp the guard firmly and rotate to desired angle.

3. Tighten clamp nuts to lock guard in position.

MAINTENANCE

Motor Brushes

_&CAUTION: Turn off and unplug the tool before making any adjustments or remov=

ing or installing attachments or accessories. Be sure the trigger switch is in the OFF

position.

When brushes become worn, the tool will automatically stop, preventing damage to the motor.

Brush replacement should be performed by DEWALT authorized service centers or other qual-

ified service personnel. Qualified service personnel should follow the procedures below when

replacing motor brushes.

1. Remove the brush doors located on the sides of motor housing.

2. To remove the brush, hold the female terminal, which is attached to the brush lead wire,

and disconnect the female terminal from the male terminal.

3. Pull the brush straight up out of the brush holder.

4. Before new brushes can be installed, the brush spring arm must be pulled back out of the

way.

5. Replace brushes, in pairs, with original DEWALT brushes available from DEWALT author-

ized service centers.

6. Ensure that the brushes slide freely in brush box.

7. Reconnect the brush lead wire to brush box terminal.

8. Re-install the brush doors before using the tool. Torque screws to 10 in./Ibs, maximum.

Overtightening may cause screws to strip.

Cleaning

_, WARNING: Blowing dust and grit out of the motor housing using clean, dry compressed air

is a necessary regular maintenance procedure. Dust and grit containing metal particles often

accumulate on interior surfaces and could create an electrical shock or electrocution ff not fre-

quently cleaned out. ALWAYS WEAR SAFETY GLASSES.

_, CA UTION: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tool. Use a clean, dry cloth only.

Lubrication

DEWALT tools are properly lubricated at the factory and are ready for use.

Accessories

Recommended accessories (abrasive masonry cutting, abrasive asphalt cutting, abrasive

metal cutting and diamond blades) for use with your tool are available at extra cost from your

local dealer or authorized service center. If you need assistance in locating any accessory for

your tool, contact: DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286.

_ WARNING: Accessories must be rated for at least the speed recommended on the

tool warning label Wheels and other accessories running over rated speed can fly apart and

cause injury. Accessory ratings must always be above tool speed as shown on tool nameplate.

Page 3

WARNING:Theuseofanyotheraccessorynotrecommendedforusewiththistoolcould

behazardous.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (includ-

ing brush inspection and replacement) should be performed by authorized service centers or

other qualified service organizations, always using identical replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for

three years from the date of purchase. For warranty repair information, call 1-800-4-DEWALT.

This warranty does not apply to accessories or damage caused where repairs have been

made or attempted by others. This warranty gives you specific legal rights and you may have

other rights which vary in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

DEWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

If you are not completely satisfied with the performance of your DEWALT Power Tool, Laser,

or Nailer for any reason, you can return it within 90 days from the date of purchase with a

receipt for a full refund - no questions asked.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-4-DEWALT for a free replacement.

1 YEAR FREE SERVICE

90 DAY MONEY BACK GUARANTEE

"D28754 I,°,oolcotoFF.Ac.,.E

TYPE 1 J.=S'rED

'20VAC/DC" [] _='_,, '=mAC@US

50/60Hz 15A

no5,000/rain (RPM)

1"(25ram) ARBOR $ER.

_READ AND UNDERSTAND iNSTRUCTiON MANUAL.

ALWAYS USE PROPER GUARDS. ALWAYS USE PROPER EYE AND RESPIRATORY

PROTECTION, USE ONLY ACCESSORIES RATED AT LEAST 0500/MJN, DO NOT

USE TOOTHED BLADES.

ADVERTENCiAPA...... CIR ELRIESGO DELESIONESPERSONALES,

EL USOAMO OEBEi_A LEER Y COMPRENDER EL MANUAL DE INSTRUCCIONES,

MEMPRE SE RERERA RTIUZAR GRARRAS. S[EMPRE SE SERE LLEVAR LA PROTECCIOR

A DECUADA PAPA [A VISTA Y PARA [AS VJAS RESPJRATORIAS. SE DERERA UTJLIZAR

RNICAMENTE LOS ACCESORIOS CON CALIFICAMON MINIMA RE 5500 RPM/MIN. NO

SE DERE EMPLEAR HOJAS DENTAOAS.

AVERTISSEMENTA,TREPREVENT._,URELEDRIOE.

FOR SERVME JNFORMATIDN_-DEWALT _w.QEWAL%_m

SI VOUS AVEZ DES QUESTIONS OU VOUS VOULEZ NOUS FAIRE PART DE VOS COM-

MENTAIRES CONCERNANT CET OUTIL OU TOUT AUTRE OUTIL DEWALT, COMPOSEZ

SANS FRAIS LE : 1 800 433-9258.

R_gles de s_curit_ - g_n_ralit_s

AVERTISSEMENT! Lire, comprendre et suivre toutes les

directives precisGes ci-dessous, y compris les consignes de

securitG, afin d'eviter les risques de choc electrique,

d'incendie ou de blessure grave.

CONSERVER CES DIRECTIVES

AIRE DE TRAVAIL

* L'aire de travail dolt #tre propre et bien #clair#e. Les 6tablis encombrGs et les endroits

sombres peuvent entraTner des accidents.

* Ne pas faire fonctionner des outils #lectriques clans des atmospheres explosives,

comme en presence de liquides, de gaz et de poussi_res inflammables. Les outils

61ectriques produisent des 6tincelles qui peuvent enflammer la poussibre ou les vapeurs.

* Tenir les enfants, les visiteurs ou toute autre personne _/'#cart Iorsqu'on utilise un

outil #lectrique; les distractions peuvent faire perdre la ma_trise de ce demier.

R#GLES DE SE_CURIT# RELATIVES A, L'#LECTRIClTI_

* Les outils mis _ la terre doivent #tre branch#s clans une prise correctement install#e

et mise _ la terre tel que I'indiquent les codes et r#g/ements en vigueur. Ne jamais

retirer la broche de mise _ la terre ou modifier la prise en aucune fa_on. Ne pas utilis-

er de fiche d'adaptation. Consulter un #lectricien qualifi# s'il y a un doute en ce qui

conceme la mise _ la terre de la prise. En cas de dGfaillance 61ectrique ou de bris de

I'outil, la mise a la terre procure un chemin de faible resistance au courant afin de reduire

les risques de choc 61ectrique. Cet outil est muni d'un dispositif mis a la terre (fiche _ 3

broches) afin d'assurer la securit6 de I'utilisateur en d#rivant I'#nergie #lectrique loin de

celui-ci en cas de defaillance #lectrique ou de panne de I'outil, ou encore, de mise sous

tension du boftier. Tout dommage ou perte de I'une des 3 lames, tout dommage subi par

la fiche oule cordon, oule branchement de I'outil clans un systbme non conforme non mis

la terre de fa_on continue, augmente les risques de choc #lectrique, de blessure grave

ou de mort. Afin d'#viter tout risque de blessure, I'outil dolt #tre entretenu en tout temps,

maintenu en bon #tat de fonctionnement (cordon, lames des fiches) et branche a un sys-

teme conforme mis a la terre de fa_on continue. (Voir aussi la rubrique , Nettoyage _,clans

la section, Entretien _,.) Cette protection ne s'applique qu'aux outils de classe I (mis

la terre).

* Les outils _ double isolation sont munis d'une fiche polaris#e (c'est-b=dire que I'une

des lames est plus large que /'autre), laque/le ne peut 6tre raccord#e qu'b une prise

po/arisee et ce, clans un seul sens; on dolt I'inverser si on est incapable de/'enfon-

cer compl#tement. Si la fiche ne s'adapte toujours pas, on dolt faire appel _un #lec-

tricien qualifi# pour qu'il installe la prise appropri#e. On ne dolt jamais modifier la

fiche. La double isolation #limine le besoin d'installer un cordon d'alimentation trifilaire et

un systbme d'alimentation #lectrique pourvus d'une mise a la terre; seuls les outils de

classe II (_ double isolation) sont munis d'une te/le protection.

* E:viter tout contact entre le corps et les #l#ments mis _ la terre, comme les tuyaux,

les radiateurs, les cuisini#res et les r#frig#rateurs, afin de r#duire les risques de choc

_lectrique.

* Ne pas utiliser I'outil _lectrique dans des endroits mouill_s ni/'exposer b la p/uie;.l'in-

filtration d'eau a I'int#rieur de I'outil augmente les risques de choc #lectrique.

* Ne pas utiliser le cordon de mani#re abusive; on ne dolt pas transporter I'outil en le

tenant par le cordon, ou utiliser ce dernier pour le d#brancher. On dolt tenir le cor-

don b I'ecart des sources de chaleur, de/'huile, des bords tranchants ou des pi#ces

mobiles. Remplacer imm#diatement les cordons endommag_s, car ces demiers aug-

mentent les risques de choc #lectrique.

, Lorsqu'on utilise un outil #lectrique _/'ext#rieur, on ne dolt utiliser que des rallonges

con_ues pour cet usage, comme Relies de type W-A ou W, afin de r#duire les risques

de choc #lectrique. S'assurer que la rallonge est en mesure de porter le courant necessaire

I'outil. Une rallonge de calibre inf#rieur entrafnera une chute de tension se traduisant par

une perte de puissance et une surchauffe. Le tableau ci-dessous illustre les calibres que

I'on dolt utiliser scion la Iongueur de la rallonge et I'intensit# nominale indiquee sur la

plaque signaletique. En cas de doute, utiliser le calibre suivant. Plus le calibre est petit, plus

la rallonge peut porter de courant.

Calibres minimaux des raiionges

Tension Longueur totaie de la raiionge en m_tres

120V de0a7 de7a15 de15_30 de 30_45

Intensite (en amperes)

Plus Pas plus AWG

de de

12 16 14 12 Non recommand_

SI_CURITE PERSONNELLE

* Rester vigilant en tout temps et faire preuve de jugement Iorsqu'on utilise un outi/

_lectrique. Ne pas utiliser I'outil /orsqu'on est fatigu_ ou sous /'influence de drogues,

d'alcool ou de m_dicaments, car un moment d'inattention pourrait entra_ner des

blessures graves.

TO REDUCE THE RJSR OF INJURY, USER MOST

D_WALT INDUSTRIAL TOOL CO,, BALTIMORE, MD 21286 USA

* Porter des v_tements appropri_s. Ne pas porter des v_tements amples ou des

bijoux. Couvrir ou attacher les cheveux longs. Carder les cheveux, les v_tements,

les bijoux et les Rants _loign_s des pi_ces mobiles, car ceux-ci peuvent s'y coincer.

Se tenir _loigne des _vents puisque ces demiers pourraient camoufler des pieces mobiles.

* E:viter les d_marrages accidentels. S'assurer que I'interrupteur est en position d'ar-

r_t avant de brancher I'outil. Ne pas transporter I'outil en laissant le doigt sur I'interrup-

teur nile brancher Iorsque I'interrupteur est en position de marche, car cela pourrait causer

un accident.

* Retirer les cl_s de reglage avant de d_marrer I'outil. Une cl_ laissee sur une pibce rota-

tive pourrait entra_ner des blessures.

* Ne pas trop _tendre les bras. Les pieds doivent rester ancr_s fermement au sol afin

de maintenir son _quilibre en tout temps et de mieux ma_triser I'outil clans des situations

impr_vues.

* Utiliser le materiel de s_curit_ appropri_; toujours porter des lunettes de protection.

Porter un masque anti-poussieres, des chaussures antid_rapantes, un casque de securite

ou des protecteurs auditifs Iorsque la situation le requiert.

UTILISATION ET ENTRETIEN DE L'OUTIL

* Fixer et soutenir la piece sur une plate=forme stable au moyen d'une bride de set-

rage ou de tout autre dispositif semblable. La piece est instable Iorsqu'on la retient

manuellement ou qu'on I'appuie contre le corps, ce qui pourrait faire perdre la ma_trise de

I'outil.

* Ne pas forcer I'outil ni I'utiliser pour des travaux autres que ceux pour lesquels il a

_t_ con_u. Pour obtenir de meilleurs resultats et prevenir les risques de blessure, laisser

I'outil couper a la vitesse pour laquelle il a et_ con_u.

* Ne pas utiliser I'outil Iorsque I'interrupteur marche-arr_t ne fonctionne pas. Tout outil

qui ne peut _tre command_ au moyen de I'interrupteur est dangereux et dolt _tre r_pare.

* D_brancher I'outi/ de la source d'alimentation _lectrique avant d'effectuer un

rdglage, de changer un accessoire ou de ranger I'outil; ces mesures preventives

r_duisent les risques de d_marrage accidenteL

* Lorsqu'on n'utilise pas I'outil, le ranger hors de la pottle des enfants ou des personnes

non qualifi_es. Les outils sont dangereux entre les mains de personnes inexperiment_es.

* Bien entretenir I'outil; s'assurer qu'il est toujours bien propre et aiguis_. Les outils

bien entretenus et dont les bords sont bien tranchants sont moins susceptibles de rester

coinc_s et sont plus faciles a ma_triser.

* V_rifier/es pi_ces mobiles afin de s'assurer qu'elles sont bien align_es et qu'elles

ne restent pas coinc_es. V_rifier _galement les pi_ces afin de s'assurer qu'il n'y a

aucun bris ni aucune autre condition susceptible de nuire au bon fonctionnement

de I'outil. Faire r_parer I'outil sice demier est endommag_ avant de s'en servir

nouveau, car les accidents sont souvent causes par des outils mal entretenus.

* N'utiliser que les accessoires recommand_s par le fabricant pour le module con-

cerne. Un accessoire destine a un outil particulier peut devenir dangereux Iorsqu'il est util-

ise avec un autre.

ENTRETIEN

* L'outil dolt _tre entretenu par le personnel qualifi_ seulement; route maintenance

effectuee par une personne non qualifiee pourrait entra_ner des risques de blessure.

* Lors de I'entretien, n'utiliser que des pi_ces de rechange identiques et suivre les

directives pr_cis_es _ la section, Entretien _ du present guide afin de pr_venir les

risques de choc _lectrique ou de blessure.

Censignes de s_curit_ particuli_res relatives aux

tron_onneuses

. Utiliser toujours le dispositif de protection qui convient _ la meule afin de prot_ger

I'operateur des fragments pouvant _tre projetes par une meule brisee ou d'emp_cher tout

contact aver la meule.

. La vitesse des accessoires dolt correspondre b la vitesse minimale recommand_e

indiqu_e sur I'_tiquette d'avertissement de I'outil, car les meules et les accessoires qui

sont regl_s a une vitesse trop _levee peuvent se briser et occasionner des blessures

Iorsque des fragments de metal sont projet_s.

. Tenir I'outil par les surfaces isolees pr_vues b cette fin Iorsqu'il risque d'entrer en

contact avec des ills caches ou son propre cordon, car de tels contacts peuvent met-

tre les pibces metalliques de I'outil sous tension, engendrant des risques de choc _lec-

trique.

. TOUJOURS PORTER DES LUNETTES DE PROTECTION LORSQU'ON UTILISE CET

OUTIL.

* L'utilisation d'accessoires non sp_cifi_s clans le present guide n'est pas recom-

mand#e et peut presenter un danger. L'utilisation d'un compresseur en vue de faire fonc-

tionner I'outil a une vitesse superieure a la vitesse nominale recommandee constitue un

emploi abusff de I'outil.

* Ne jamais utiliser de lames pour scie circulaire avec cet outil, ni de lames dentees, afin

d'#viter les risques de blessure grave.

, Avant d'utiliser un accessoire recommand#, le verifier afin de s'assurer qu'il n'y a

aucun bris ni fissure. Si on y trouve de tels d#fauts, mettre /'accessoire au rebut.

/nspecter #galement /'accessoire chaque lois qu'il subit un choc, car un accessoire

defectueux risque de briser la meule. Ne pas reposer I'outil sur la meule.

* Lorsqu'on d#marre I'outil (apr#s y avoir installe une meule neuve ou de rechange)

ou qu'on doute de son #tat de fonctionnement, se tenir clans un endroit bien prot#g#

et le faire fonctionner pendant une minute, car si I'outil est fissure ou brise, il devrait

#clater en moins d'une minute. Ne jamais demarrer un outil Iorsque quelqu'un, y compris

I'operateur, se tient directement devant luL

, E:viter de faire rebondir la meule durant son fonctionnement ou de/'utiliser sans

m#nagement. Si la meule subit de tels traitements, arr#ter I'outil et inspecter cette

demibre.

* Orienter les #tincelles darts le sens oppos# de I'op#rateur ou de toute autre person-

ne se trouvant b proximitY, ainsi que des mat#riaux inflammables. Les meuleuses ou

ponceuses peuvent produire des #tincelles susceptibles de causer des brOlures ou un

incendie.

* Toujours utiliser la poign#e de manoeuvre et la fixer solidement afin de ma_triser I'outil

en tout temps.

* Ne jamais couper clans une zone pouvant camoufler des tuyaux ou des ills #lec-

triques afin d'#viter les risques de blessure grave.

* Bien nettoyer I'outil p#riodiquement, surtout apr#s/'avoir utilis# Ionguement, car la

poussibre et les particules metalliques tendent a s'accumuler sur les surfaces internes et

peuvent entrafner des risques de choc #lectrique.

* Ne pas utiliser I'outil pendant de Iongues p#riodes car les vibrations causees par ce

demier peuvent #tre endommageables aux mains et aux bras. Porter des Rants afin

d'amortir les vibrations et restreindre I'exposition du corps aux vibrations en arr#tant

fr#quemment.

AAVERTISSEMENT : Certains outils #lectriques, tels que les sableuses, les scies, les

meules, les perceuses ou certains autres outils de construction, peuvent produire de la pous-

siere contenant des produits chimiques susceptibles d'entrafner le cancer, des malformations

congenitales ou pouvant #tre nocifs pour le systeme reproductif. Parmi ces produits chim-

iques, on retrouve :

* le plomb clans les peintures a base de plomb,

* la silice cristalline clans les briques et le ciment et autres produits de ma_onnerie,

* /'arsenic et le chrome clans le bois de sciage ayant subi un traitement chimique (comme

I'ars#niate de cuivre et de chrome).

Le risque associe a de telles expositions varie selon la fr#quence avec laquelle on effectue

ces travaux. Pour reduire I'exposition _ de tels produits, il faut travailler clans un endroit bien

a#r# et utiliser le materiel de securit# approprie, tel un masque anti-poussibres specialement

con_u pour flitter les particules microscopiques.

* Eviter tout contact prolong# avec la poussi#re soulev#e par cet outil ou autres out-

ils #lectriques. Porter des v#tements de protection et nettoyer les parties expos#es

du corps b /'eau savonneuse. S'assurer de bien se prot#ger afin d'#viter d'absorber

par la bouche, les yeux ou la peau des produits chimiques nocifs.

Page 4

_AVERTISSEMENT : Cet outil peut produire et r#pandre de la poussiTre susceptible de

causer des dommages s#rieux et permanents au syst#me respiratoire. Toujours utiliser un

appareil respiratoire anti-poussi#res approuv# par le NIOSH ou I'OSHA. Diriger les particules

dans le sens oppos# du visage et du corps.

,_},MISE EN GARDE : Porter un appareil de protection personnel anti-bruit appropri#

durant I'utilisation. Sous certaines conditions et pendant toute la dur#e de I'utilisation, le bruit

#manant de ce produit pourrait contribuer a la perte d'audition.

* L'#tiquette appos#e sur I'outil peut afficher les symboles suivants, ainsi que leurs d#finitions :

V.......... volts.

Hz ........ hertz

min ......minutes

.... ....courant continu

[] ........ construction

de classe II

Q ........ bome de terre

A.................... amp#res

W................... watts

................ courant altematif

no .................. aucune option a vide

.../min ............ tours par minute

_& ................. symbole d'avertissement

CONSERVER CES DIRECTIVES

COMPOSANTS

Se reporter & la figure 1 afin d'obtenir la liste complete des composants.

ASSEMBLAGE

Rotation du carter d'engrenage (fig. 2 et 3)

REMARQUE : La broche de cet outil a 6t6 mont6e en usine du c6t6 droit en vue d'Ttre util-

is6e par un droitier.

CONVERSION EN VUE DE L'UTILISATION PAR UN GAUCHER

,& MISE EN GARDE : Arr#ter et d#brancher I'outil avant d'effectuer un r#glage ou de retirer

ou d'installer une piTce ou un accessoire. S'assurer que I'interrupteur est en position d'arr#t.

1. Placer I'outil sur une surface solide et plane.

2. Retirer la poign6e de manoeuvre (F) en enlevant les deux boulons haxagonaux (Q), ainsi

que les isolants sup6rieurs (R) et inf6rieurs (S).

3. Retirer le dispositif de protection en desserrant les 6crous de son 616ment d'assemblage

(N).

4. Retirer les quatre vis d'assemblage (O) du carter d'engrenage.

5. Faire pivoter le carter d'engrenage (P) de 180° sans le retirer du boftier de I'outil.

REMARQUE : Si le carter d'engrenage et le carter du moteur se s6parent de plus de 3,2

mm (1/8 po), rapporter I'outil & un centre de service DEWALT afin d'6tre soumis & un

entretien et assembl6 & nouveau et d'emp6cher le moteur, la brosse et le coussinet de

faire d6faut.

6. R6ins6rer les 4 vis d'assemblage du carter d'engrenage (O) et les serrer fermement

jusqu'& I'obtention d'un couple de 30 po-lb.

7. Rattacher le dispositif de protection en dirigeant le patin dans le m6me sens que la

poign6e de I'interrupteur & g_.chette (H). S'assurer que le dispositif de protection est

enclench6 & fond sur le moyeu & roulement de la broche et que ses deux languettes ren-

trent bien dans la rainure du moyeu & roulement de la broche. Resserrer fermement les

6crous de 1'616mentd'assemblage (N) en r6glant le couple & 50 po-lb.

8. R6installer la poign6e de manoeuvre, ainsi que les isolants inf6rieurs (S) et sup6rieurs (R)

et les deux boulons hexagonaux (Q); resserrer le tout fermement, en r6glant le couple

75 po-lb. Voir la figure 2 pour connaftre I'orientation appropri6e de la poign6e de manoeu-

vre.

_AVERTISSEMENT : Les isolants en plastique doivent _tre assembl#s au moyen des

boulons hexagonaux et des ferrures, tel qu'illustr# a la figure 3, afin d'#viter les risques de choc

#lectrique.

FONCTIONNEMENT

Moteur

S'assurer que le courant nominal du cordon d'alimentation correspond & celui indiqu6 sur la

plaque signal6tique. Une tension inf6rieure de plus de 10 % & celle indiqu6e pourrait entrain-

er une perte de puissance et une surchauffe. Tousles outils DEWALT sont soumis & des essais

en usine; si cet outil ne fonctionne pas, on dolt d'abord v6rifier I'intensit6 nominale du cordon

d'alimentation.

Bouton de verrouillage de la broche (fiB. 4)

Ce bouton (I) sert & verrouiller la broche Iorsqu'on change un accessoire. Pour I'actionner,

d6brancher I'outil et s'assurer que I'interrupteur est en position d'arr6t, puis enfoncer le bou-

ton en faisant tourner la meule et la broche jusqu'_ ce que cette derni_re reste bloqu6e.

D6visser 1'6crou de la broche (J) au moyen de la cl6 fournie, puis retirer ou assembler I'ac-

cessoire voulu. La broche est filet6e a droite.

Installation des meules abrasives (fig. 4 et 5)

iJ,MISE EN GARDE : Arr#ter et d_brancher I'outil avant d'effectuer un r#glage ou de

retirer ou d'installer une piece ou un accessoire. S'assurer que I'interrupteur est en

position d'arr#t.

1. D6poser I'outil sur une surface solide, en orientant la partie inf6rieure du patin (E) vers le

haut.

2. Desserrer les 6crous a oreilles de r6glage de profondeur (C), puis d6placer le patin de

mani_re &faciliter autant que possible I'acc_s & 1'6crou de la broche. Resserrer les 6crous

afin de maintenir le patin en place.

3. A,I'aide de la cl6 a fourche de 28 mm (1 1/8 po), retirer 1'Tcrou de la broche (J), la rondelle

de bride de serrage externe (K) et la meule usag6e (L), si cette derni_re est installTe.

EmpTcher la broche de tourner au moyen de son bouton de verrouillage. (La broche est

filet6e & droite).

4. S'assurer que la rondelle de bride de serrage interne (iV]) est bien en place et que les

oreilles sont bien engag6es dans les surfaces planes de la broche. Faire passer la meule

travers la partie inf6rieure du patin, par dessus la broche. S'assurer que la meule recou-

vre le diam_tre du guide de la rondelle de bride de serrage interne. Ins6rer la rondelle de

serrage externe. Commencer a visser 1'6croude la broche (celle-ci alignera automatique-

ment la rondelle de serrage externe).

5. Actionner le bouton de verrouillage de la broche, puis serrer 1'6crou au moyen de la cl6,

en 6vitant de trop serrer.

6. Tourner la meule manuellement pour s'assurer qu'elle est bien centr6e. La meule ne

devrait pas toucher nile patin, nile dispositif de protection, ni 1'6crou. Bien serrer 1'6crou

et les brides.

7. S'assurer de r6ajuster le patin & la profondeur de coupe voulue.

,_,MISE EN GARDE : Toujours utiliser une meule no 1 de 304,8 mm (12 po) munie d'un

orifice d'arbre de 25,4 mm (1 po) avec cet outil. Ne jamais forcer la meule sur la machine ou

modifier la dimension de I'orifice d'arbre.

Profondeur de coupe (fig. 6 et 7)

A AVERTISSEMENT : On ne peut couper les bords qu'au moyen de meules sp#cialement

con_ues pour ce type de coupe particulier. On dolt se prot#ger en orientant Ibuverture du dis-

positif de protection vers une surface quelconque.

_, AVERTISSEMENT : Les meules peuvent se briser ou faire des rebonds si dies sont cour-

b#es ou tordues Iorsqu'on effectue des travaux de tron_onnage.

_ AVERTISSEMENT : On do# #viter d'utiliser un coupe- bordure pour effectuer le meulage

de finition puisque ces meules ne sont pas con_ues pour subir la pression lat#rale inh#rente

ce type de travaux, ce qui risque de briser la meule et de blesser I'utilisateur.

A MISE EN GARDE : Arr#ter et d#brancher I'outil avant d'effectuer un r#glage ou de

retirer ou d'installer une pi#ce ou un accessoire. S'assurer que I'interrupteur est en

position d'arr#t.

La profondeur de coupe peut 6tre r6glTe en desserrant les deux 6crous & oreilles de r6glage

de profondeur (C) situ6s sur la partie ext6rieure du dispositif de protection en vue de modifier

la position du patin. Serrer fermement les 6crous a oreilles au moyen de la fente dans la cl6

(fournie).

COUPE DE METAUX ET DE MATERIAUX MINCES

Lors de la coupe de mat6riaux minces tels les mTtaux, on dolt r6gler le patin de mani_re &

obtenir la profondeur de coupe maximale (voir la fig. 6).

COUPE DE PIERRES OU DE PRODUCTS DE MA(_.ONNERIE

R6gler la meule de mani_re & ce qu'elle d6passe le patin sur environ 13 mm (1/2 po). Dans

plusieurs cas, le mat6riau se brisera facilement le long de la ligne entaillTe de 13 mm (1/2 po)

de profondeur. Si une coupe plus profonde est requise, on dolt augmenter la profondeur de

coupe par 6chelons d'environ 13 mm (1/2 po) (fig. 7).

FONCTIONNEMENT (fig. 2)

i_ MISE EN GARDE : Avant de d#marrer I'outil, le saish" fermement des deux mains, puis le

soulever.

1. Saisir la poign6e de I'interrupteur a g&chette (H) et la poignTe de manoeuvre (F).

2. Aligner la meule avec le mat6riau & couper, en s'assurant que rien ne se trouve dans la

ligne de coupe de la meule ni trop pros de celle-ci.

3. Appuyer sur I'interrupteur &g&chette (A) puis, sans le rel&cher, faire avancer lentement la

meule dans le matTriau en appliquant une pression ferme. Appuyer le patin (E) fermement

contre la piece, sans forcer I'outil. Pour obtenir un rendement optimal et assurer la dur6e

de vie maximale de la meule, maintenir une vitesse 61ev6e.

4. Pour arrTter I'outil, rel&cher I'interrupteur a g&chette (A).

Applications

AVERTISSEMENT : Ne JAMAIS utiliser I'outil pour couper des pieces de magn#sium, car

les particules de magn#sium peuvent s'enflammer et entraTner des risques de blessure.

• TTle mince de 3 mm (1/8 po) max.

• B6ton, blocs en b6ton de laitier et briques

• Barres d'armature, (gTnTralement inf6rieures a 19 mm ou 3/4 po de diam_tre)

• B6ton renforc6 de treillis mTtallique de 3 mm (1/8 po) de diam_tre

• Coffrages en b6ton ondul6 pour planchers et plafonds

• Conduites 61ectriques pour murs de 3 mm (1/8 po) d'6paisseur

• Charpentes de 3 mm 1/8 po) d'Tpaisseur maximale (canaux, corni_res, plaques, etc.)

REMARQUE : La coupe de mat6riaux plus 6pals que ceux 6nonc6s ci-dessus n'est pas

recommand6e en raison des risques de surcharge 61ectrique.

REGLAGE DE L'ANGLE DU D_SPOSmF DE PROTECTION

MISE EN GARDE : Arr#ter et d#brancher I'outil avant d'effectuer un r#glage ou de

retirer ou d'installer une piece ou un accessoire. S'assurer que I'interrupteur b g#chette

est en position d'arr#t.

1. Desserrer les 6crous d'assemblage (N) du dispositif de protection (fig. 2).

2. Saisir fermement le dispositif de protection et le faire pivoter jusqu'a la position voulue.

3. Serrer les 6crous de blocage afin de bien verrouiller le dispositif de protection.

ENTBETIEN

Balais de rnoteur

A MISE EN GARDE : Arr_ter et d#brancher I'outil avant d'effectuer un r_glage ou de

retirer ou d'installer une piece ou un accessoire. S'assurer que I'interrupteur b g#chette

est en position d'arr#t.

Lorsque les balais sont us6s, I'outil s'arrTte automatiquement, empTchant ainsi tout dommage

au moteur. Ces balais doivent 6tre remplacTs dans les centres de service autorisTs DEWALT

ou par du personnel qualifi6, conform6ment aux proc6dures de remplacement pr6cis6es ci-

apr_s.

1. Retirer les panneaux situ6s de chaque c6t6 du carter du moteur.

2. Pour retirer le balai, tenir la borne femelle fix6e au fil conducteur du balai, puis d6branch-

er la borne femelle de la borne m&le.

3. Tirer le balai tout droit hors du porte-balai.

4. Avant d'installer un balai neuf, dTplacer le bras & ressort du balai et le mettre & 1'Tcart.

5. Remplacer les balais jumelTs par des balais DEWALT d'origine vendus dans les centres

de service autorisTs DEWALT.

6. S'assurer que les balais glissent librement dans le boftier du balai.

7. Rebrancher le fil conducteur du balai & la borne du boftier.

8. R6installer les panneaux avant d'utiliser I'outil. Serrer les vis jusqu'& I'obtention d'un cou-

ple de 10 po/Ib maximum; un serrage excessif pourrait fausser le pas de vis.

Nettoyage

_, AVERTISSEMENT : II est n#cessaire de bien nettoyer le carter du moteur p#riodiquement

au moyen d'un systeme a air comprim# propre et sec afin d'#liminer la poussiere et les par-

ticules m#tatliques qui tendent _ s'accumuler sur les surfaces internes et peuvent entrMner

des risques de choc #lectrique ou d'#lectrocution, TOUJOURS PORTER DES LUNETTES DE

SECURITE.

_&MISE EN GARDE : Ne jamais utiliser de solvants ou d'autres produits chimiques pour net-

toyer les pi#ces non m#talliques de I'outil; ne les nettoyer qu'au moyen d'un linge propre et sec.

Lubrification

Les outils DEWALT sont lubrifi6s en usine et sont donc pr6ts & utiliser.

Accessoires

Les accessoires recommand6s pour cet outil (meules abrasives pour la coupe de ma(2onner-

ie, d'asphalte et de m6tal et meules au diamant) sont vendus s6par6ment chez les d6posi-

taires Iocaux ou dans les centres de service autoris6s. Pour obtenir plus d'information sur les

accessoires, communiquer avec DEWALT Industrial Tool Co., 701 East Joppa Road,

Baltimore, MD 21286, aux Etats-Unis.

_, AVERTISSEMENT : La vitesse des accessoires dolt correspondre b la vitesse mini-

male recommand#e indiqu#e sur I'#tiquette d'avertissement de I'outil, car les meules et

autres accessoires qui sont r#gl#s _ une vitesse trop #lev#e peuvent se d#tacher et #tre pro-

jet#s, ce qui risque d'occasionner des blessures. La vitesse nominale d'un accessoire dolt tou-

jours _tre sup#rieure a celle de I'outil indiqu#e sur la plaque signal#tique de celui-ci.

,_ AVERTISSEMENT : L'utilisation de tout autre accessoire non recommand# avec cet outil

pourrait #tre dangereux.

R_parations

Pour assurer la SECURITE et la FIABILIT¢: de ce produit, toutes les op6rations d'entretien, de

r6paration et de r6glage doivent 6tre effectu6es dans un centre de service autoris6 ou par du

personnel qualifi6 (cela comprend I'inspection et le remplacement du balai); on ne dolt utiliser

que des pi_ces de rechange identiques.

Garantie Lirnit_e de Trois Ans

DEWALT r6parera, sans frais, tout produit d6fectueux caus6 par un d6faut de mat6riel ou de

fabrication pour une p6riode de trois ans& compter de la date d'achat. Pour obtenir de plus

amples renseignements sur les r6parations couvertes par la pr6sente garantie, composer le 1

800 433-9258 (1-800-4-DEWALT). Cette garantie ne s'applique pas aux accessoires et ne vise

pas les dommages caus6s par des r6parations effectu6es par un tiers. Cette garantie conf_re

des droits 16gaux particuliers a I'acheteur, mais celui-ci pourrait aussi b6n6ficier d'autres droits

variant d'un 6tat ou d'une province a I'autre.

En plus de la pr6sente garantie, les outils DEWALT sont couverts par notre :

CONTRAT D'ENTRETIEN GRATUIT D'UN AN

DEWALT entretiendra I'outil et remplacera les pi_ces us6es au cours d'une utilisation normale

et ce, gratuitement, pendant une p6riode d'un an & compter de la date d'achat, et la

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si I'acheteur n'est pas enti_rement satisfait, pour quelque raison que ce soit, du rendement de

I'outil 61ectrique, du laser ou de la cloueuse DEWALT, celui-ci peut le retourner, accompagn6

d'un re£u, dans les 90 jours a compter de la date d'achat, pour obtenir un remboursement

int6gral, sans aucun probl_me.

REMPLACEMENT GRATUIT DE L'ET_QUETTE D'AVERTISSEMENT : En cas de perte ou

d'endommagement des 6tiquettes d'avertissement, composer le 1 800 433-9258 afin d'en

obtenir de nouvelles sans frais.

Page 5

D28754 13o5oo>c..oF,.Ac.,.E

TYPE1 = LHSTEO

,2owo,oc,,@NOM .°°Ao®os

50/60 Hz 15A

Do5,000/miD(RPM)

1" (25ram) ARBOR SEN.

TO ])EDUCE THE ])ISK OF iNJURY, USER MUST

ALWAYS USE PROPER GOAl)DR. ALWAYS USE P])OPE]) EYE AND ])ESPI])ATO])Y

P])OTECTJON. USE ONLY ACCESSORIES RATED AT LEAST 5500/MJN. DO NOT

USE TOOTHED BLADES.

ADVERTENCiAPARA OEOUCIR EL ])IERGO OE LESiO])ES PE])SOHALES,

EL USUAR O DEREi_A LEE]) Y COMPSENDER EL MANUAL DE NSTRUDC ONES,

SiEMP])E RE RESERA UTJISZAR OUARDAR. _JEMPRE RE ])ERE LLEVAR LA PROTERCiON

gOECUADA PARA LA VISTA Y PAR]) LAR ViAR RERPIRATO])IAS. RE DESERA UTJLMAR

UNJCAMENTE LOS ACCESO])IOS CON CALJFMACiDN MINIMA DE 550g RPM/MIN. NO

RE UEBE EMPLEA]) ])OJAS UENTAUAS.

AVERTISSEMENTAY.])E_])EVENtMUSELEGUIDE

D EWALT INDUSTRIAL TOOL CO., BALTIMORE, MD 212_ USA

FOR SERVICE JNFORMA_ON, CALL 1-80O-4-O_WALT www.t}_WALT.com

Instrucciones de seguridad generales

_ iADVERTENCIA! Lea y comprenda todas [as instrucciones. El

no ajustarse a [as instrucciones siguientes puede causar descarga

electrica, incendio o lesiones corporales graves.

CONSERVE ESTAS INSTRUCCiONES

AREA DE TRABAJO

* Mantenga el &rea de trabajo limpia y bien iluminada. Las mesas de trabajo desorde-

nadas y/ugares oscuros propician los accidentes.

* No opere m&quinas herramienta en atm6sferas explosivas, como en presencia de

I[quidos, gases o polvos inflamables. Las mbquinas herramienta producen chispas

que pueden originar /a ignici6n del po/vo o los vapores.

* Mientras opere m_quinas herramienta, mantenga alejados a observadores, ni_os y

visitas. Las distracciones pueden hacer que pierda e[ control.

SEGURIDAD ELi_CTRICA

* Las herramientas con conexi6n a tierra deben conectarse a una toma de corriente

debidamente instalada y con conexi6n a tierra, de acuerdo con todos los c6digos y

ordenanzas aplicables. Nunca quite la pata de conexi6n a tierra ni modifique el

enchufe en ninguna manera. No emplee ning_n adaptador para enchufes. Si tiene

alguna duda acerca de si la toma de corriente est& debidamente conectada a tierra,

consulte a un electricista cafificado. Si [as herramientas presentasen fallas eldctricas

o aver[as,/a conexi6n a tierra ofrece una v[a de baja resistencia para a/ejar/a corriente el6c-

trica del usuario. Esta herramienta uti/iza una construcci6n con conexi6n a tierra (enchufe

de tres patas) para poder transferir energ[a el6ctrica en forma segura en direcci6n contraria

a[ usuario en caso de que /a herramienta presente una fal/a el6ctrica, se aver[e o si /a her-

ramienta se cargue de corriente por a/g_n otto motivo. El dado a o perdida de una de [as

tres patas del enchufe, el dado al enchufe o al cable o el no enchufar /a herramienta a una

insta/aci6n e/6ctrica verificada y continuamente conectada a tierra puede resu/tar en descar-

ga el6ctrica, /esiones serias o muerte. Para evitar estos riesgos, /a herramienta debe, en

todo momento, set mantenida y encontrarse en buena condici6n para su funcionamiento

(cable, y patas de[ enchufe) y estar enchufada a una instalaci6n e/6ctrica continuamente

conectada a tierra. (Vet tambien bajo "Limpieza" en /a secci6n de Mantenimiento.) $61o es

aplicable a [as herramientas de Clase I (con conexi6n a tierra).

* Las herramientas con doble aislamiento est&n equipadas con un enchufe polariza-

do (una pata es m&s ancha que la otra). Este enchufe puede ser conectado a una

toma de corriente polarizada de una sola manera. Si el enchufe no puede set conec-

tado debidamente a la toma de corriente, invidrtalo. Si a_n as[ no entra,

comun[quese con un electricista cafificado para que instale una toma de corriente

polarizada. No altere el enchufe de ninguna manera. E[ dob/e aislamiento e/imina /a

necesidad de cables con tres hi/os y sistemas de suministro e/6ctrico con conexi6n a tier-

ra. $61o es aplicable a [as herramientas de Clase II (con doble aislamiento).

* Evite el contacto de[ cuerpo con superficies conectadas a tierra, tales como

tuber[as, radiadores, cocinas y refrigeradores. E[ riesgo de descarga el6ctrica aumen-

ta si su cuerpo hace conexi6n a tierra.

* No exponga [as m_quinas herramienta a la Iluvia o a condiciones de mucha humedad.

Si entra agua en una maquina herramienta, aumentara el riesgo de descarga e/ectrica.

* No maltrate el cable. Nunca agarre la herramienta pot el cable ni tire de _1para des-

enchufarla. Mantenga el cable alejado de fuentes de calor, aceite, bordes afilados o

piezas en movimiento. Cambie inmediatamente los cables da_ados. Los cables dada-

dos aumentan e[ peligro de descarga e/6ctrica.

* Cuando opere una m&quina herramienta a la intemperie, utilice un alargador marca=

do "W-A" o "W'. Estos alargadores estan c/asificados para set usados a/a intemperie y

reducen el riesgo de descarga e/_ctrica. AI usar un a/argador, aseg_rese de que tenga el

calibre necesario para Ilevar la corriente que su producto requerira. Un a/argador de un cal-

ibre insuficiente causara una ca[da en la tensi6n de la ffnea dando por resultado la perdi-

da de energ[a y sobreca/entamiento. La tab/a siguiente muestra el tamado correcto para

uti/izar dependiendo de/a Iongitud del alargador y de[ amperaje nominal de/a p/aca de

identificaci6n. En caso de duda, utilice el de mayor calibre. Cuanto mas pequedo es el

n_mero de[ calibre, mas resistente es el a/argador.

Voitios Longitud total del cable en metros

120V 0-7,6 7,6-15,2 15,2-30,5 30,5-45,8

P,mperaje

M_s No m&s AWG

de de

12 16 14 12 No recomendado

SEGURIDAD PERSONAL

* AI utilizar una m&quina herramienta, est_ atento, conc_ntrese en Io que hace y

aplique el sentido com_n. No utilice la herramienta si se encuentra fatigado o bajo

la influencia de drogas, alcohol, o f&rmacos. Mientras se uti/izan maquinas herramien-

tas, basta un instante de distracci6n para sufrir /esiones corpora/es graves.

* Lleve ropa adecuada. No uti/ice ropa suelta ni joyas. Rec6jase e[ cabe/Io largo.

Mantenga su cabel/o, ropa y guantes apartados de [as piezas en movimiento. Las

partes m6vi/es pueden atrapar prendas de vestir sue/tas, joyas y cabel/o. Las reji//as de

venti/aci6n sue/en cubrir piezas en movimiento, pot/o que tambien se deben evitar.

* Evite puestas en marcha accidentales. Aseg_rese de que el conmutador est_ apa-

gado antes de enchufar la mbquina. El transportar [as herramientas con e[ dedo sobre

e[ conmutador o enchufaflas con e[ conmutador encendido favorece los accidentes.

* Antes de poner en marcha la herramienta, retire [as [laves de ajuste. Una [[aveque se

deje en una pieza giratoria de/a herramienta puede provocar /esiones corpora/es.

* No se sobreextienda. Mant_ngase siempre bien apoyado y equilibrado. Un buen

apoyo y equi/ibrio permite contro/ar mejor /a herramienta si se produce alg_n imprevisto.

* Utilice equipo de seguridad. Lleve siempre protecci6n ocular. Se debe usar mascari/-

/a antipo/vo, ca/zado de seguridad con sue[as antideslizantes, casco o protectores audi-

tivos dependiendo de [as condiciones.

USO Y CUIDADO DE LA HERRAMIENTA

* Utilice abrazaderas u otro elemento adecuado para fijar y apoyar la pieza de trabajo

a una p/ataforma estab/e. E[ sujetar/a pieza con/a mano o contra e[ cuerpo es inestab/e

y podr[a causar una perdida de control.

* No fuerce la herramienta. Emplee la herramienta correcta para carla aplicaci6n. La

herramienta correcta hara e[ trabajo mejor y mas seguro dentro de[ tango para e[ que ha

sido disedada.

* No utilice la herramienta si e[ conmutador no la enciende y apaga. Cua/quier her-

ramienta que no pueda contro/arse con el conmutador es peligrosa y se debe reparar.

* Desconecte el enchufe de la toma de corriente antes de proceder con cua/quier

ajuste, cambiar un accesorio o guardar la herramienta. Estas medidas de seguridad

preventivas reducen e[ riesgo de poner en marcha /a herramienta accidenta/mente.

Calibre m_nimo para aiargadores

])EAD AND UNDERSTAND iNSTRUCTiON MANUAL

* Cuando no [as utilice, guarde [as herramientas fuera del alcance de ni_os o de

cua/quier persona no capacitada. Las herramientas son pe/igrosas en manos de usuar-

los no capacitados.

* Cuide [as herramientas. Conserve [as herramientas de corte afiladas y limpias. Es

menos probable que una herramienta que haya sido debidamente mantenida y que tenga

sus hordes de corte afi/ados se atasque. Ademas son mas faci/es de contro/ar.

* Compruebe que [aspiezas m6vi/es no esten desalineadas o atascadas, que no haya

ninguna pieza rota ni cualquier otra circunstancia que pudiera afectar e[ fun-

cionamiento de/a herramienta. Si la herramienta est& da_ada, h&ga/a reparar antes

de usarla. Muchos accidentes son provocados por herramientas mal cuidadas.

* Utilice Onicamente los accesorios recomendados pot el fabricante para su modelo.

Un mismo accesorio puede set adecuado para una herramienta, pero pe/igroso si se usa

en otra.

SERVIClO

* El servicio a/a herramienta s61o debe realizarlo personal de reparaci6n calificado. E[

servicio o mantenimiento realizados pot personal no cafificado puede dar como resu/tado

un riesgo de/esiones.

* AI proceder a[ mantenimiento de una herramienta, uti/ice _nicamente repuestos

origina/es. Siga [as instrucciones de la secci6n de Mantenimiento de este manual. La

uti/izaci6n de piezas no autorizadas o el no respetar [as instrucciones de mantenimiento,

puede suponer un pe/igro de descarga e/_ctrica o de/esiones.

Instrucciones de seguridad adicionales para rn_quinas

cortadoras

* Uti/ice siempre el protector apropiado con el disco de esmeril. E[ protector protege a[

operador de los fragmentos que se desprenden del disco, asf como del contacto con el disco.

* Los accesorios deben estar clasificados pot Io menos para la velocidad recomen=

dada en la etiqueta de advertencia de la herramienta. Si funcionan a velocidades supe-

riores a/a prevista, los discos y otros accesorios pueden deshacerse y provocar /esiones.

Las c/asificaciones de los accesorios deben estar siempre por encima de la velocidad de

/a herramienta, como se muestra en /a placa nominal de/a herramienta.

* Sujete la herramienta por sus empu_aduras aisladas si [[eva a cabo una operaci6n

en que la herramienta pueda tocar cables electricos ocultos o su propio cable. E[

contacto con un cable activo provocar_ que [as piezas metalicas de la herramienta se car-

guen que e[ operador reciba una descarga el_ctrica.

* SIEMPRE USE PROTECCION OCULAR CUANDO USE ESTA HERRAMIENTA.

* El uso de accesorios que no aparecen especificados en este manual no se

recomienda y podr[a set peligroso. E[ uso de amplificadores de potencia que hat[an que

/a herramienta fuera operada a ve/ocidades mayores a su ve/ocidad nominal se considera

un mal uso de esta.

* No use hojas para sierras circulares ni ning_n otto tipo de hojas con dientes con

esta herramienta. Podr[a resu/tar en lesiones graves.

* Antes de usarlos, inspeccione los accesorios recomendados en busca de cuartead-

uras y fallas. Si hay fallas o cuarteaduras evidentes, elimine el accesorio. Tambi_n

se debe inspeccionar el accesorio siempre cuando la herramienta pueda haberse

ca[do. Las fal/as pueden provocar /a rotura del disco. No co/oque /a unidad sobre e[ disco

cuando /a ponga a un [ado.

* Cuando arranque la herramienta con un disco nuevo o de repuesto instalado o si no

est& seguro de la condici6n de[ disco, sostenga la herramienta en un &rea bien pro-

tegida y d_jela que ande por un minuto. Si el disco tiene una cuarteadura o fa//a no

detectada, debiera reventar en menos de un minuto. Nunca arranque /a herramienta con

una persona situada en ffnea con e[ disco, inc/uyendo al operador.

* Evite rebotar el disco o tratarlo bruscamente. Si el/o sucediera, detenga la herramien-

ta e inspeccione el disco para ver si presenta cuarteaduras o fal/as.

* Dirija [as chispas en direcci6n opuesta al operador, observadores y materiales

inflamables. Pueden sa/tar chispas al usar lijadoras o esmeri/es. Las chispas pueden

provocar quemaduras o incendios.

* $iempre use el asa. Aj_stela firmemente. El asa deber[a set uti/izada siempre para man-

tenet el control de/a herramienta en todo momento.

* Nunca corte en un &rea que podr[a contener cables electricos o tuber[as. Podr[a

resu/tar en /esiones graves.

* Limpie su herramienta con frecuencia, especialmente despu_s de usos prolonga-

dos. El po/vo y/a areni//a que contienen part[cu/as meta/icas se acumu/an con frecuencia

en [as superficies interiores y podr[an ocasionar peligro de descarga el_ctrica.

* No opere esta herramienta durante per[odos largos de tiempo. La vibraci6n causada

por /a acci6n de/a herramienta puede set dadina para sus manos y brazos. Use guantes

para un mejor amortiguamiento y descanse con frecuencia para /imitar su exposici6n.

ADVERTENCIA: Parte del po/vo generado por el/ijado, serrado, esmeri/ado y ta/adrado

e/_ctricos, asf como al realizar otras actividades de construcci6n, contienen productos

qu[micos que pueden producir cancer, defectos de nacimiento u otras afecciones

reproductivas. Ejemplos de esas substancias qu[micas son:

* plomo procedente de pinturas a base de plomo,

* sflice crista/ina procedente de/adri//os, cemento y otros productos de mamposter[a y

* ars_nico y cromo procedentes de madera tratada qu[micamente (arseniato de cobre

cromado).

El peligro derivado de estas exposiciones que usted enfrente varfa en funcidn de la frecuen-

cia con que se realice este tipo de trabajo. Para reducir la exposicidn a esas sustancias qufmi-

cas: trabaje en una zona bien ventilada y Ilevando equipos de seguridad aprobados, como

mascarillas antipolvo especialmente disehadas para filtrar partfculas microscdpicas.

* Evite e[ contacto prolongado con el po/vo procedente de[ lijado, serrado, esmeri/a=

do y taladrado e/_ctricos, as[ como de otras actividades de construcci6n. Lleve ropa

protectora y lave con agua y jab6n [as zonas expuestas. El permitir que el polvo se

introduzca en su boca u ojos o quede sobre la pie[ puede favorecer la absorcidn de pro-

ductos qufmicos peligrosos.

_ ADVERTENCIA: El uso de esta herramienta puede generar o dispersar polvo Io cual

puede causar lesiones respiratorias serias y permanentes y otros tipos de lesidn. Siempre use

proteccidn respiratoria aprobada pot NIOSH/OSHA para la exposicidn al polvo. Dirija [as

partfculas en direccidn opuesta a su cara y cuerpo.

PRECAUCION: Utilice protecci6n auditiva apropiada durante el uso. En determinadas

condiciones y con utilizaciones prolongadas, el ruido generado pot este producto puede

favorecer la perdida de audicidn.

* La etiqueta de su herramienta puede incluir los siguientes sfmbolos. A continuacidn se indi-

can los sfmbolos y sus definiciones:

V...................... voltios

Hz .................... hercios

min .................. minutos

.... ................ corriente directa

[] .................... construccidn de

Clase II

A

.................. s[mbolo de alerta de seguridad

A .................... amperios

W .................. vatios

'%, .................. corriente altema

no .................. velocidad sin carga

.../min ............ revoluciones pot minuto

.................. terminal con conexi6n a tierra

CONSERVE ESTAS INSTRUCCIONES

COMPONENTES

Refi_rase a la Figura 1 para una lista completa de componentes.

ENSAMBLAJE

Rotacidn del c_rter (Figuras 2_ 3)

NOTA: Esta m_quina ha sido ensamblada de f_.brica con el eje en el lado derecho de la

unidad, para la operaci6n diestra.

CONVERSION DE OPERACION DIESTRA A SINIESTRA

_ PRECAUCION: Apague y desenchufe /a herramienta antes de hacer cua/quier ajuste o de

quitar o insta/ar accesorios. Aseg_rese que e[ conmutador tipo gati//o este en /a posici6n OFF

(apagada).

Page 6

1. Coloque la unidad sobre una superficie de trabajo plana y firme.

2. Para quitar el asa (F), quite los 2 pernos hexagonales (Q), los aisladores superiores (R) y

aisladores inferiores (S).

3. Para quitar el protector, quite las tuercas de montaje del protector (N).

4. Quite los 4 tornillos de montaje del carter (O).

5. Gire el carter en 180° sin tirar del carter (P) en direcci6n contraria a la caja de la her-

ramienta.

NOTA: Si el carter y la caja protectora del motor se separan en mAs de 3 mm (1/8 pulg.),

la herramienta deberA ser reparada y reensamblada en un centro de servicio DEWALT. El

no reparar la herramienta podria causar fallas en las escobillas, el motor y los rodamien-

tos.

6. Vuelva a poner los 4tornillos de montaje del carter (O) en sus sitios y ajOstelos firmemente

a 3,4 Nm (30 pulg-lb.)

7. Vuelva a conectar el protector de modo que la base quede en la misma direcci6n que el

mango del conmutador tipo gatillo (H). AsegOrese que el protector est_ Io mAs adentro

posible en el cubo del eje y que ambas lengQetas del protector enganchen en la ranura

del cubo del eje. Ajuste las tuercas de montaje del protector (N) a 5,65 Nm (50 pulg-lb.).

8. Vuelva a poner el asa en su sitio con los aisladores inferiores (S), aisladores superiores

(R) y los 2 pernos hexagonales (Q) y luego ajOstelos firmemente a 8,48 Nm (75 pulg-lb.).

Refi6rase a la figura 2 para la orientaci6n del asa.

_ ADVERTENCIA: Se deben ensamblar los pemos hexagonales y el soporte con aisladores

de plbstico, como Io muestra la Figura 3. El no hacer esto podrfa resultar en lesiones pot

descarga el6ctrica.

OPERACION

Motor

Aseg_rese que su alimentaci6n el6ctrica vaya de acuerdo con la potencia nominal.

Reducciones de voltaje de mAs de 10% causarAn una p_rdida de potencia y sobrecalen-

tamiento. Todas las herramientas DEWALT son probadas en la fAbrica; siesta herramienta no

funciona, revise la alimentaci6n el6ctrica.

Bot6n de bloqueo del eje (Figura 4)

El bot6n de bloqueo del eje (I) se utiliza para bloquear el eje cuando se cambian los acceso-

rios. Para activar el bot6n de bloqueo del eje, desenchufe la herramienta de la toma de cor-

riente y asegOrese que el conmutador est_ en la posici6n OFF(apagado). Presione el bot6n

de bloqueo y gire el disco y el eje hasta que el bot6n de bloqueo enganche con el eje. Utilice

la Ilave que viene incluida para destornillar latuerca del eje (J) y quite o instale los accesorios

deseados. El hilo del eje va en direcci6n de las manillas del reloj.

Instalati6n de discos abrasives (Figuras 4, 5)

PRECAUCION: Apague y desenchufe la herramienta antes de hacer cualquier ajuste

o de quitar o instalar accesorios. Aseg#rese que el conmutador tipo gatillo est# en

posici6n OFF (apagada).

1. Coloque la unidad sobre una superficie firme con la parte inferior de la base (E) hacia

arriba.

2. Afloje las tuercas mariposa de ajuste de profundidad (C), desplace la base para facilitar el

acceso a la tuerca del eje, luego ajuste las tuercas mariposa para fijar la base en su sitio.

3. Utilice la Ilave fija de 28 mm (1-1/8 pulg.) para quitar la tuerca del eje (J), arandela de

fijaci6n externa (K) y disco usado (L) si acaso hay uno instalado. Sujete el eje con el bot6n

de bloqueo del eje para evitar que gire. El hilo del eje va en direcci6n de las manillas del

reloj.

4. AsegOrese que la arandela de fijaci6n interna (M) est6 en su sitio y que las lengQetas

est6n sujetas entre las caras del eje. Deslice el disco por la parte inferior de la base y

col6quelo sobre el eje. AsegOrese que el disco quede encima del diAmetro del piloto de la

arandela de fijaci6n interna. Coloque la arandela de fijaci6n externa. Empiece a roscar la

tuerca del eje, la cual alinearA la arandela de fijaci6n externa.

5. Active el bot6n de bloqueo del eje y ajuste la tuerca con la Ilave. No ajuste la tuerca del

eje demasiado.

6. Gire el disco manualmente para asegurar que est6 bien centrado. El disco no deberia gol-

pear contra la base, el protector o la tuerca. La tuerca y las pestaSas deberian quedar

ajustadas.

7. AsegOrese de volver a ajustar la base para la profundidad de corte apropiada.

_, PRECAUCION: Use s61o discos Tipo 1 de 30,5 cm (12 pulg.) con orificios de 2,5 cm

(1 pulg.) para el mandril con esta herramienta. Nunca fuerce la instalacidn del disco en la

maquina ni altere el tama#o del orificio para el mandril.

Profundidad de torte (Figuras 6_ 7)

A ADVERTENCIA: El torte en bordes s61o puede rea/izarse con discos dise_ados y

especificados para este propdsito. Para su proteccidn personal dirija el lado abierto del

protector hacia una superficie cuando corte en bordes.

_&ADVERTENCIA: Los discos utilizados para el corte pueden romperse o rebotar si se

doblan o tuercen mientras la herramienta esta siendo utilizada para cortar.

_ ADVERTENCIA: No use los discos de cortar en hordes para aplicaciones de esmerilado

de superficies. Estos discos no estan dise#ados para las presiones laterales existentes en el

esmerilado de superficies. Podrfa causar que el disco se rompiese y resultar en lesiones.

A PRECAUCION: Apague y desenchufe la herramienta antes de hacer cualquier ajuste

o de quitar o instalar accesorios. Aseg_rese que el conmutador tipo gatillo est# en

posiciSn OFF.

La profundidad del corte puede set ajustada al soltar las dos tuercas mafiposa de ajuste de

profundidad (C) en la parte de afuera del protector para cambiar la posiciSn de la base. Ajuste

bien las tuercas mariposa usando la ranura en la Ilave (incluida).

PARA CORTAR METALES Y MATERIALES FINOS