Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contactenos.

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACION, CENTROS DE SERVICIO Y

P©LIZA DE GARANTiA. ADVERTENOIA" LEASE ESTE

INSTRUCTIVOANTES DE USAREL PRODUCTO.

E ®

D28710 Heavy-Duty 14" (355mm) Chop Saw

Scie fendeuse a service intensif de 355 mm (14") D28710

Sierra circular estacionaria de 355 mm (14 pulg.)

para trabajo pesado D28710

Page 2

F Definitions: Safety Guidelines \

The definitions below describe the level of severity for each

signal word. Please read the manual and pay attention to these

symbols.

i_,DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

i_ WARNING: Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

i_,CAUTION: Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury

which, if not avoided, may result in property damage.

\ i.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY DEWALT TOOL, CALL US TOLL FREE AT: 1-800-4-DEWALT

(1-800-433-9258).

Important Safety Instructions

_ WARNING: Read all instructions before operating

product. Failure to follow all instructions listed below

may result in electric shock, fire and/or serious injury.

SAVE THESE INSTRUCTIONS

Double Insulation

Double insulated tools are constructed throughout with two separate

layers of electrical insulation or one single layer of reinforced insulation

between you and the tool's electrical system. Tools built with this

insulation system are not intended to be grounded. As a result, your

tool is equipped with a two prong plug which permits you to use

extension cords without concern for maintaining a ground connection.

NOTE: Double insulation does not take the place of normal safety

precautions when operating this tool. The secondary insulation

system is for protection against injury resulting from a possible failure

of the primary insulation within the tool.

_CAUTION: WHEN SERVICING USE ONLY IDENTICAL

REPLACEMENT PARTS. Repair or replace damaged cords.

Polarized Plugs

Polarized plugs (one blade is wider than the other) are used on

equipment to reduce the risk of electric shock. When provided, this

plug will fit in the polarized outlet only one way. If the plug does not

fit fully in the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install the proper outlet. Do not change the plug

in any way.

• KEEP GUARDS IN PLACE and in working order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit

of checking to see that keys and adjusting wrenches are removed

from tool before turning it on.

• KEEP WORKAREA CLEAN. Cluttered areas and benches invite

injuries.

• DON'T USE IN DANGEROUS ENVIRONMENT. Don't use

power tools in damp or wet locations, or expose them to rain.

Keep work area well lighted.

• KEEP CHILDREN AWAY. All visitors should be kept at a safe

distance from work area.

• MAKE WORKSHOP KID PROOF with padlocks, master

switches, or by removing starter keys.

• DON'T FORCE TOOL. It will do the job better and safer at the

rate for which it was designed.

• USE RIGHT TOOL. Don't force tool or attachment to do ajob for

which it was not designed.

• USE PROPER EXTENSION CORD. An extension cord must

have adequate wire size (AWG or American Wire Gauge) for

safety. The smaller the gauge number of the wire, the greater the

capacity of the cable, that is 16 gauge has more capacity than

18 gauge. An undersized cord will cause a drop in line voltage

Page 3

resultinginlossofpowerandoverheating.Whenusingmorethan

oneextension to make up the total length, be sure each individual

extension contains at least the minimum wire size. The following

table shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gauge.

The smaller the gauge number, the heavier the cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet (meters)

Ampere Rating

More Not More

Than

WEAR

• APPAREL. Do not wear loose clothing,

Than

0

6

10

12

PROPER

neckties, rings, bracelets, or other jewelry which may get caught in

moving parts. Nonslip footwear is recommended. Wear protective

hair covering to contain long hair. Air vents often cover moving

parts and should also be avoided.

• ALWAYS USE SAFETY GLASSES which meet the ANSI Z87.1

requirements. Also use face or dust mask if cutting operation is

dusty. Everyday eyeglasses only have impact resistant lenses, they

are not safety glasses.

• SECURE WORK. Use clamps or a vise to hold work. It's safer

than using your hand and it frees both hands to operate tool

• DON'T OVERREACH. Keep proper footing and balance at all

times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean

for best and safest performance. Follow instructions for lubricating

and changing accessories.

• DISCONNECT TOOLS before servicing; when changing

accessories, such as blades, bits, cutters, and the like.

120V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

AWG

6

10

12

16

18 16 16 14

18 16 14 12

16 16 14 12

14 12 NotRecommended

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make

sure switch is in off position before plugging in.

• USE RECOMMENDED ACCESSORIES. Consult the instruction

manual for recommended accessories. The use of improper

accessories may cause risk of injury to persons.

• NEVER STAND ON TOOL. Serious injury could occur if the tool

is tipped or if the cutting tool is unintentionally contacted.

• CHECK DAMAGED PARTS. Before further use of the tool, a

guard or other part that is damaged should be carefully checked

to determine that it will operate properly and perform its intended

function -- check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

POWER OFF. Don't leave tool until it comes to a complete stop.

Additional Safety Rules for Chop Saw

• Always wear proper eye and respiratory protection.

• Before using, inspect the cutting wheel for cracks or flaws.

If such a crack or flaw is evident, discard the wheel. The

wheel should also be inspected whenever you think the tool

may have been dropped. Flaws may cause wheel breakage.

• When starting the tool with a new or replacement wheel

or if you are unsure of the condition of the wheel, hold the

tool in a well protected area and let H run for one minute. If

the wheel has an undetected crack or flaw, ff should burst

in less than one minute. Never start the tool with aperson inline

with the wheel This includes the operator.

• In operation, avoid bouncing the wheel or giving it rough

treatment. If this occurs, stop the tool and inspect the wheel for

cracks or flaws.

• Clean your chop saw periodically following the procedure in this

manual.

• Do not remove wheel guards or base.

Page 4

• ALWAYS USE THE VISE OR SPECIAL FIXTURE TO CLAMP

WORK SECURELY. Other aids such as spring, bar, or C-clamps

may be appropriate for certain sizes and shapes of workpiece. Use

care in selecting and placing these clamps and make a dry run

before making a cut.

• Use only 14" type 1 wheels rated at 4100 rpm orhigher.

• Allow cut off parts to cool before handling.

• Do not attempt to cut wood or plastic with this tool

• NEVER CUT MAGNESIUM WITH THIS TOOL.

• Use chop saw in a well-ventilated area.

• Turn chop saw off before removing any pieces from the base.

• DO NOT CUT ELECTRICALLY LIVE MATERIAL.

• DO NOT USE CIRCULAR SAW BLADES OR ANY OTHER

TOOTHED BLADES WITH THIS TOOL. Serious injury may

result.

• DO NOT OPERATE THIS TOOL NEAR FLAMMABLE

LIQUIDS, GASES OR DUST. Sparks or hot chips from cutting or

arcing motor brushes may ignite combustible materials.

• Do not use the side of the abrasive wheel as a deburring grinder.

This will substantially weaken the wheel creating an unsafe

condition. The wheel may come apart.

_CAUTION: Wear appropriate hearing protection during use.

Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

ACAUTION: Spark deflector will get hot. Avoid touching or

adjusting while hot. Keep cordset and materials away from spark

deflector.

AWARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to the State of California to cause cancer, birth defects, or

other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to

filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

_,WARNING: Use of this tool can generate and/or disperse dust,

which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection appropriate

for the dust exposure. Direct particles away from face and body.

For your convenience and safety, the following warnings are on your

Heavy-Duty 14" (355mm) Chop Saw:

A FOR SAFE OPERATION READ THE INSTRUCTION

MANUAL.

DO NOT USE TOOTHED BLADES.

USE ONLY REINFORCED WHEELS RATED

4100 RPM OR HIGHER.

WHEN SERVICING USE ONLY IDENTICAL

REPLACEMENT PARTS.

ALWAYS: WEAR EYE PROTECTION, USE GUARDS,

CLAMP WORK IN VISE, USE PROPER RESPIRATORY

PROTECTION.

DO NOT EXPOSE TO RAIN OR USE IN DAMP

LOCATIONS.

Page 5

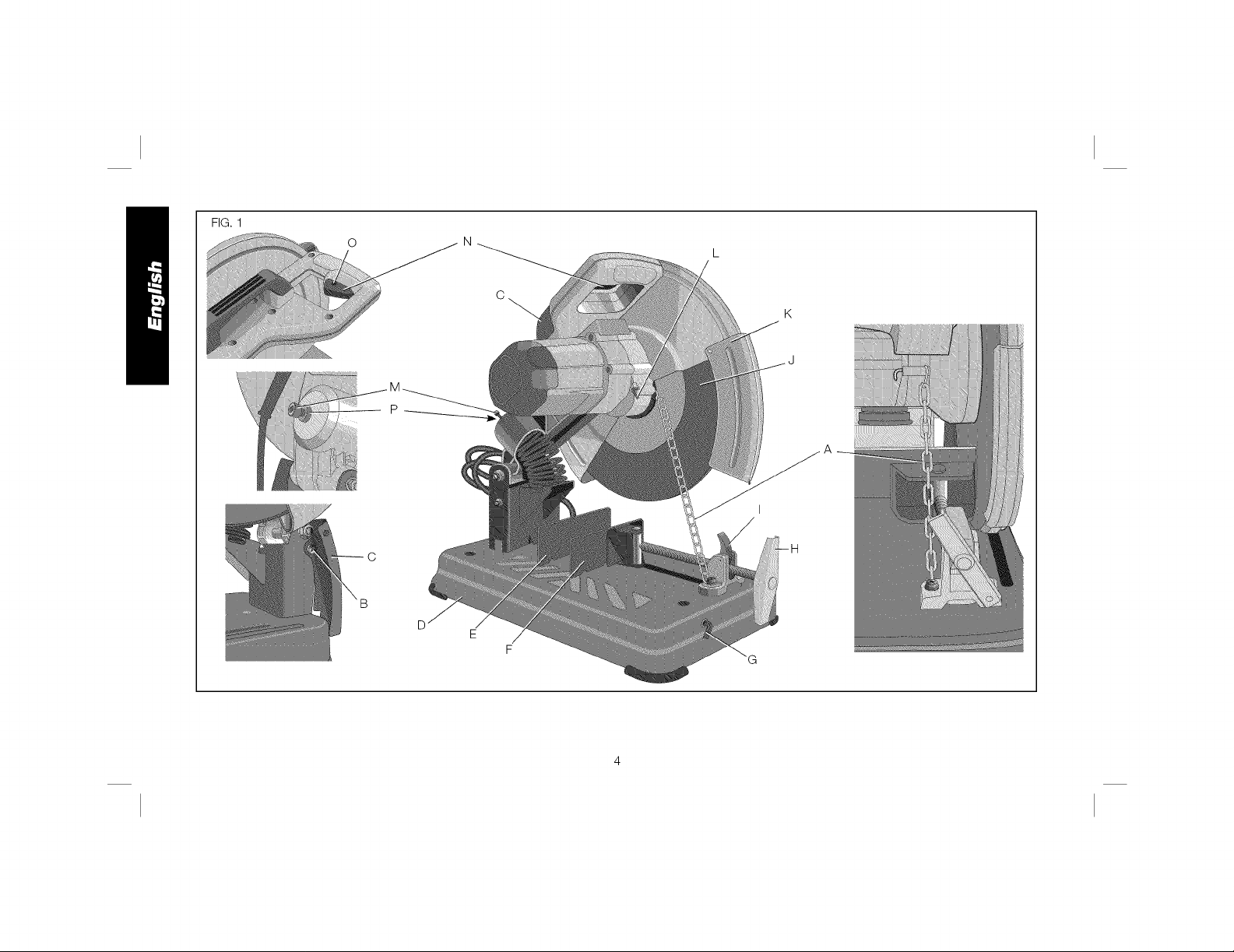

FIG. 1

Page 6

FEATURES (FIG. 1, 4)

A. Chain lock J. Wheel

B. Spark deflector screw K. Guard

C. Spark deflector L. Wheel lock lever

D. Base M. Depth stop bolt

E. Fence N. Trigger switch

F. Vise O. Padlock hole

G. 8mm hex wrench R Jam nut

H. Crank Q. Fence bolts

I. Vise lever

Power Supply

Be sure your power supply agrees with the nameplate marking.

120 volts, "60 Hz" means alternating current (normal 120 volt, 60 Hz

house current).

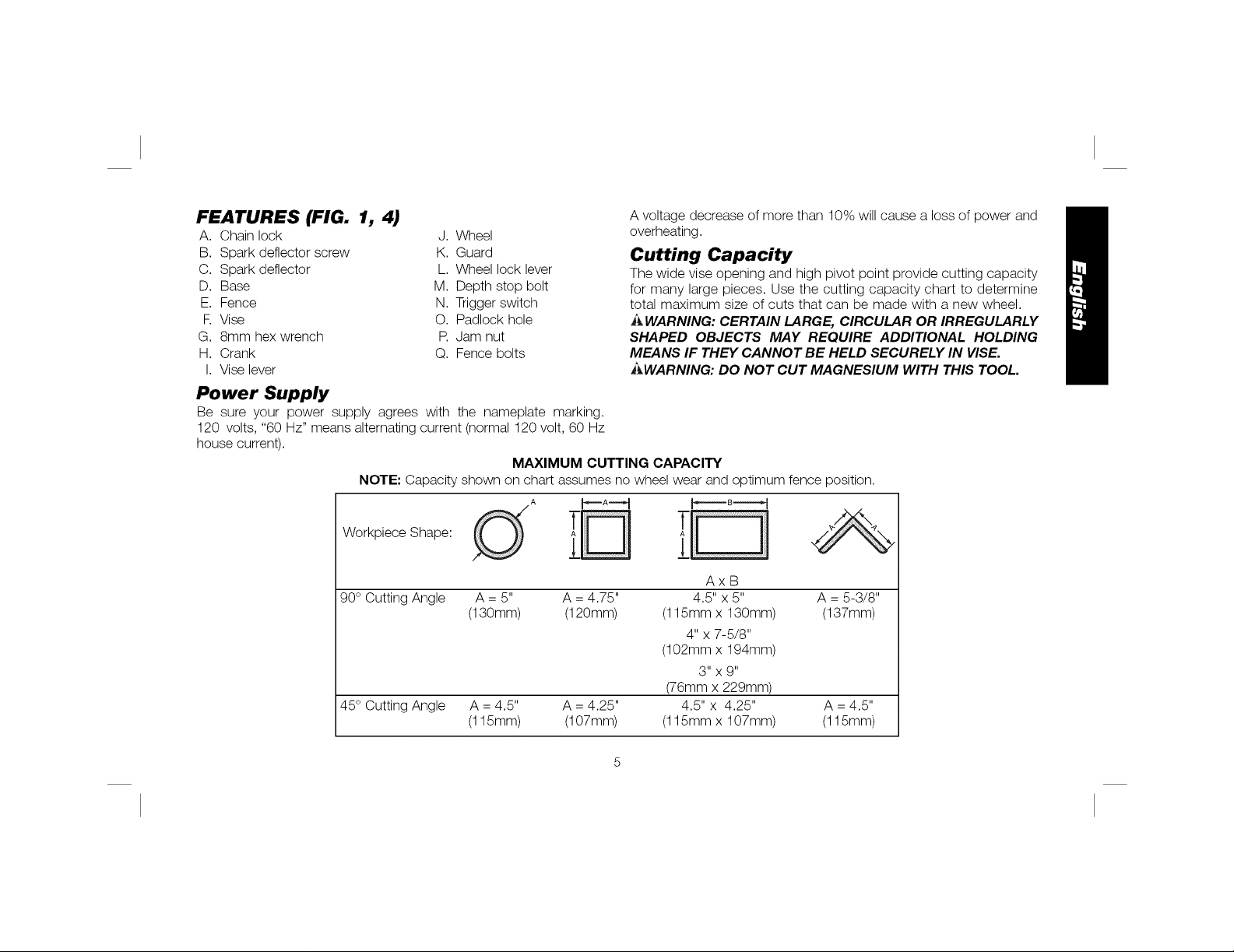

MAXIMUM CUTTING CAPACITY

NOTE: Capacity shown on chart assumes no wheel wear and optimum fence position.

Workpiece Shape: O A __

90° Cutting Angle A = 5" A = 4.75"

(130mm) (120mm)

45° Cutting Angle A = 4.5" A = 4.25" A = 4.5"

(115mm) (107mm) (115mm)

A voltage decrease of more than 10% will cause a loss of power and

overheating.

Cutting Capacity

The wide vise opening and high pivot point provide cutting capacity

for many large pieces. Use the cutting capacity chart to determine

total maximum size of cuts that can be made with a new wheel.

,_t,WARNING: CERTAIN LARGE, CIRCULAR OR IRREGULARLY

SHAPED OBJECTS MAY REQUIRE ADDITIONAL HOLDING

MEANS IF THEY CANNOT BE HELD SECURELY IN VISE.

J_,WARNING: DO NOT CUT MAGNESIUM WITH THIS TOOL.

AxB

4.5" x 5"

(115mm x 130mm

4" x 7-5/8"

(102mm x 194mm

3" x 9"

(76mm x 229mm)

4.5" x 4.25"

(115mm x 107mm

A = 5-3/8"

(137mm)

Page 7

Standard Equipment

1 14" (355mm) metal cutting abrasive wheel

1 Wheel wrench

1 Instruction manual

To Carry (Fig. 1)

Fold down unit to position where you can carry the saw. Use the chain

lock (A) to lock arm down.

Unlocking (Fig. 1)

Tounlock tool and raise head, depress motor arm slightly and unlock

the chain lock (A). Motor arm will then pivot upward.

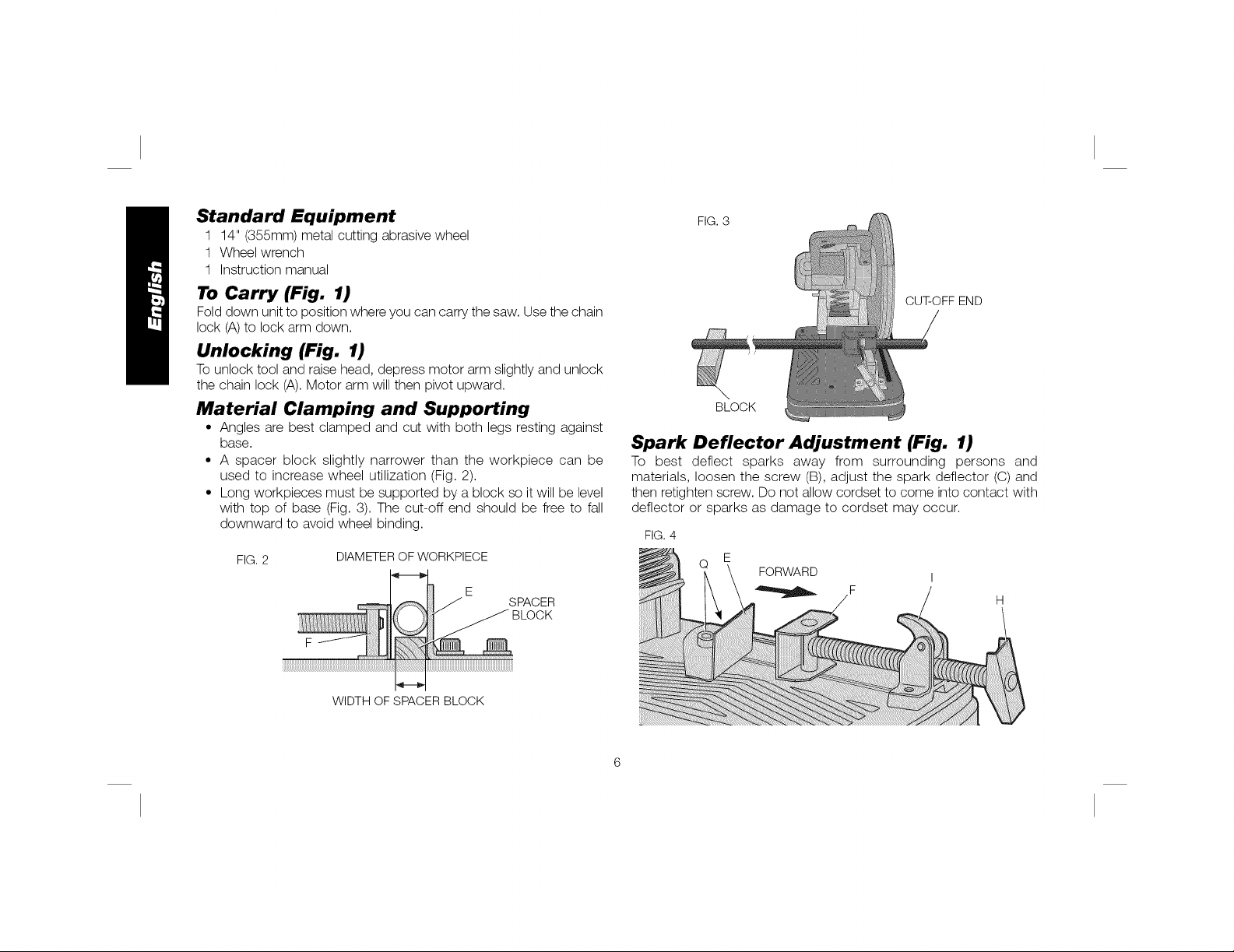

Material Clamping and Supporting

• Angles are best clamped and cut with both legs resting against

base.

• A spacer block slightly narrower than the workpiece can be

used to increase wheel utilization (Fig. 2).

• Long workpieces must be supported by a block so it will be level

with top of base (Fig. 3). The cut-off end should be free to fall

downward to avoid wheel binding.

FIG. 2

DIAMETEROFWORKPIECE

E

_¢7-_._ SPACER

LOCK

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

FIG.3

CUT-OFF END

BLOCK

Spark Deflector Adjustment (Fig. 1)

To best deflect sparks away from surrounding persons and

materials, loosen the screw (B), adjust the spark deflector (C) and

then retighten screw. Do not allow cordset to come into contact with

deflector or sparks as damage to cordset may occur.

FIG.4

FORWARD

WIDTHOFSPACERBLOCK

Page 8

Vise Operation (Fig. 4)

The vise (F) has a quick-travel feature. To release the vise when it is

clamped tightly, turn the crank (H)counterclockwise one or two times

to remove clamping pressure. Lift vise lever (I)up. Pull crank assembly

out as far as desired. Vise may be pushed forward into work without

cranking. Lower vise lever (I) then tighten vise (F) on work by using

crank (H).

Fence Operation

_WARNING: Turn off and unplug the tool before making

any adjustments or removing or installing attachments or

accessories. Be sure the trigger switch is in the OFF position.

The fence (E)can be adjusted two ways: to change desired cutting

angle and to change spacing between the fence and vise.

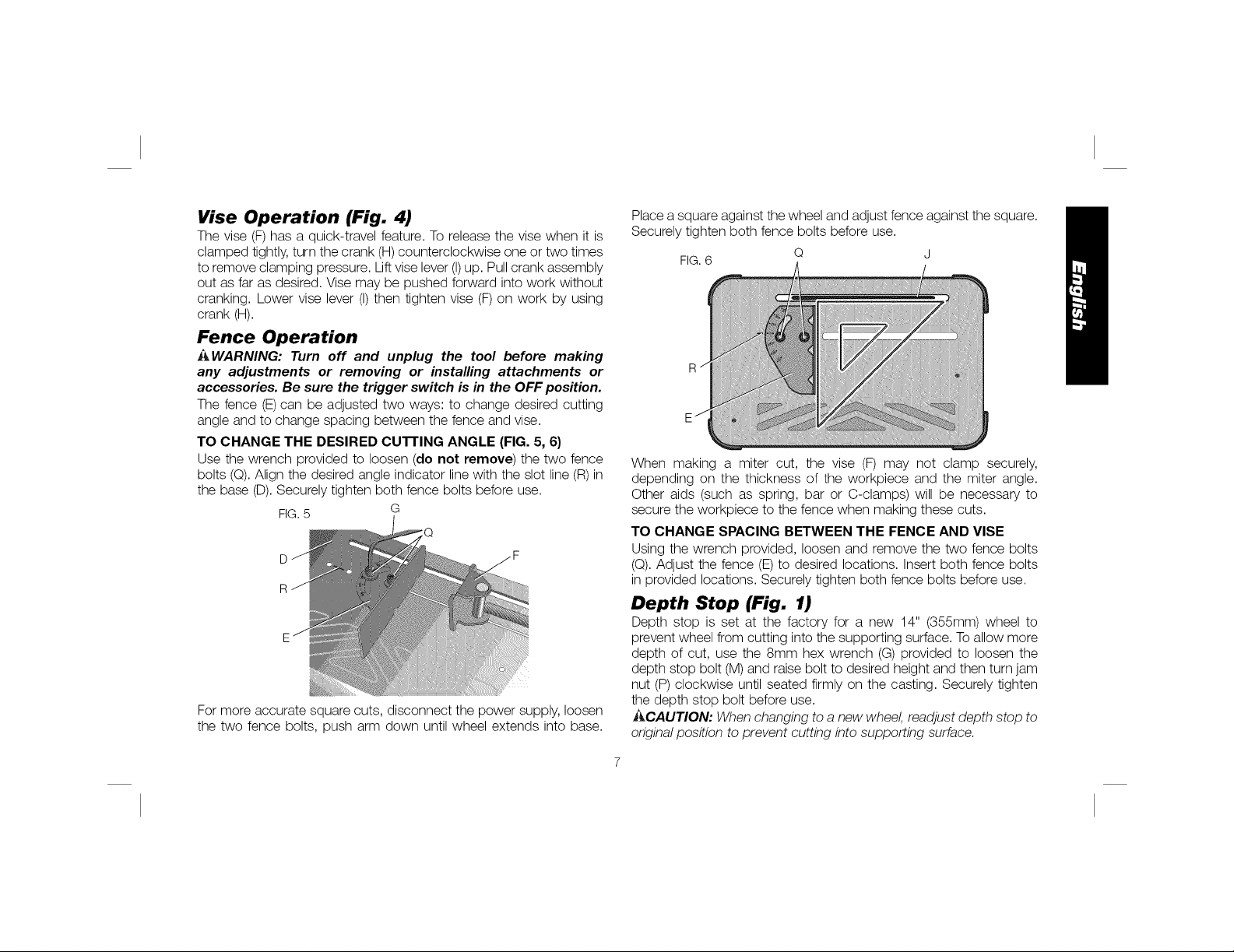

TO CHANGE THE DESIRED CU'I-I'ING ANGLE (FIG. 5, 6)

Use the wrench provided to loosen (do not remove) the two fence

bolts (Q).Align the desired angle indicator line with the slot line (R) in

the base (D). Securely tighten both fence bolts before use.

FIG.5 G

:Q

For more accurate square cuts, disconnect the power supply, loosen

the two fence bolts, push arm down until wheel extends into base.

Place a square against the wheel and adjust fence against the square.

Securely tighten both fence bolts before use.

FIG.6

When making a miter cut, the vise (F) may not clamp securely,

depending on the thickness of the workpiece and the miter angle.

Other aids (such as spring, bar or C-clamps) will be necessary to

secure the workpiece to the fence when making these cuts.

TO CHANGE SPACING BETWEEN THE FENCE AND VISE

Using the wrench provided, loosen and remove the two fence bolts

(Q). Adjust the fence (E)to desired locations. Insert both fence bolts

in provided locations. Securely tighten both fence bolts before use.

Q J

Depth Stop (Fig. 1)

Depth stop is set at the factory for a new 14" (355mm) wheel to

prevent wheel from cutting into the supporting surface. To allow more

depth of cut, use the 8mm hex wrench (G) provided to loosen the

depth stop bolt (M) and raise bolt to desired height and then turn jam

nut (P) clockwise until seated firmly on the casting. Securely tighten

the depth stop bolt before use.

_CAUTION: When changing to a new wheel, readjust depth stop to

original position to prevent cutting into supporting surface.

Page 9

Trigger Switch (Fig. 1)

To start the tool, depress the trigger switch (N). To turn the tool off,

release the trigger switch. Keep hands and material from wheel until

it has coasted to a stop.

To prevent unauthorized use of tool, install a standard padlock (not

included) into the padlock hole (O) located in the trigger.

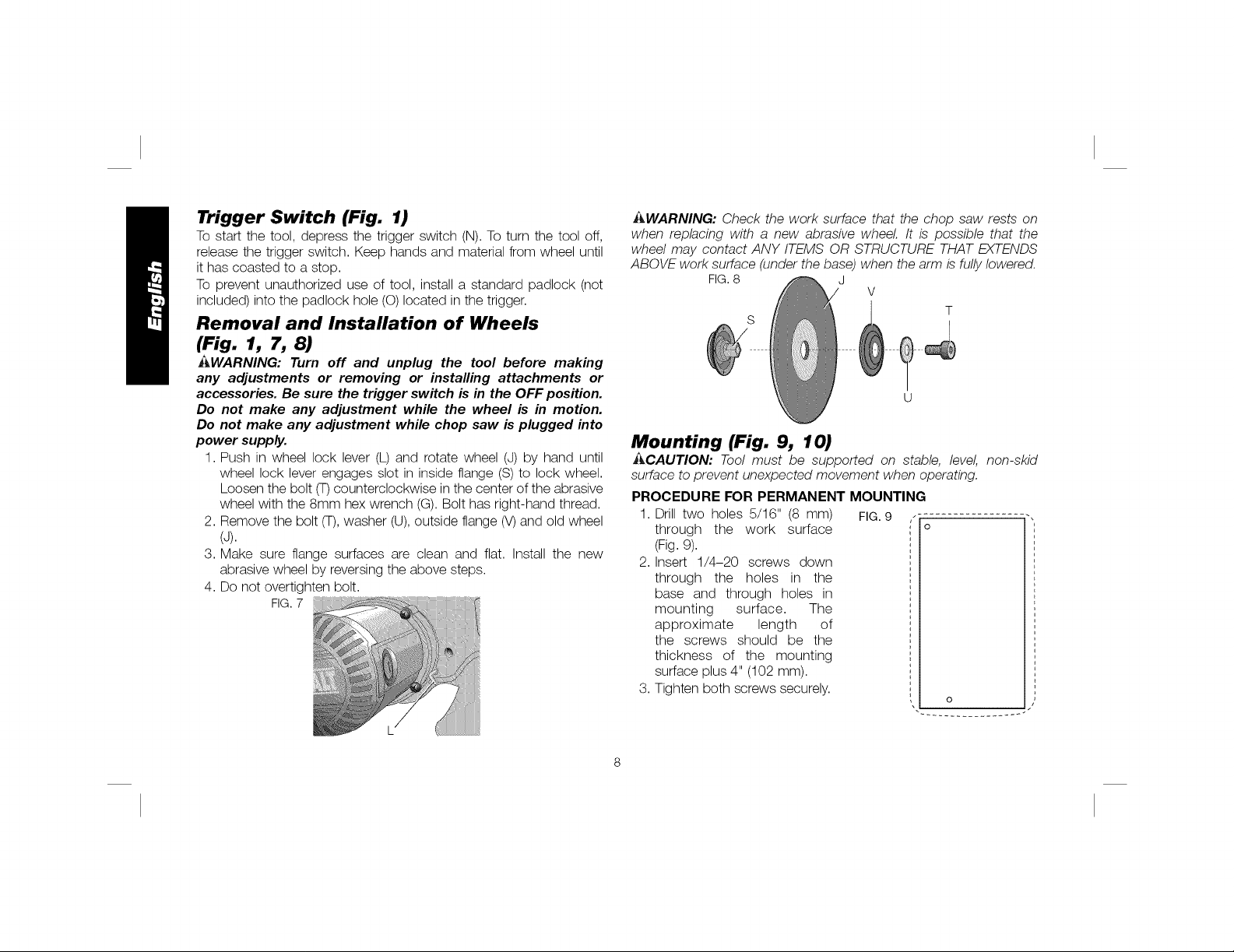

Removal and Installation of Wheels

(Fig. 1, 7, 8)

_WARNING: Turn off and unplug the tool before making

any adjustments or removing or installing attachments or

accessories. Be sure the trigger switch is in the OFF position.

Do not make any adjustment while the wheel is in motion.

Do not make any adjustment while chop saw is plugged into

power supply.

1. Push in wheel lock lever (L) and rotate wheel (J) by hand until

wheel lock lever engages slot in inside flange (S)to lock wheel.

Loosen the bolt (T)counterclockwise in the center of the abrasive

wheel with the 8mm hex wrench (G). Bolt has right-hand thread.

2. Remove the bolt (T), washer (U), outside flange (V)and old wheel

(d).

3. Make sure flange surfaces are clean and flat. Install the new

abrasive wheel by reversing the above steps.

4. Do not overtighten bolt.

FIG.7

,_WARNING: Check the work surface that the chop saw rests on

when replacing with a new abrasive wheel. It is possible that the

wheel may contact ANY ITEMS OR STRUCTURE THAT EXTENDS

ABOVE work surface (under the base) when the arm is fully lowered.

FIG.8 J

V

Mounting (Fig. 9, 10)

_CAUTION: Tool must be supported on stable, level, non-skid

surface to prevent unexpected movement when operating.

PROCEDURE FOR PERMANENT MOUNTING

1. Drill two holes 5/16" (8 mm) FIG.9 ,,................... ,

through the work surface o ,

(Fig. 9). ',

2. Insert 1/4-20 screws down ',

through the holes in the

base and through holes in

mounting surface. The

approximate length of

the screws should be the

thickness of the mounting

surface plus 4" (102 mm).

3. Tighten both screws securely.

................. /

i

i

Page 10

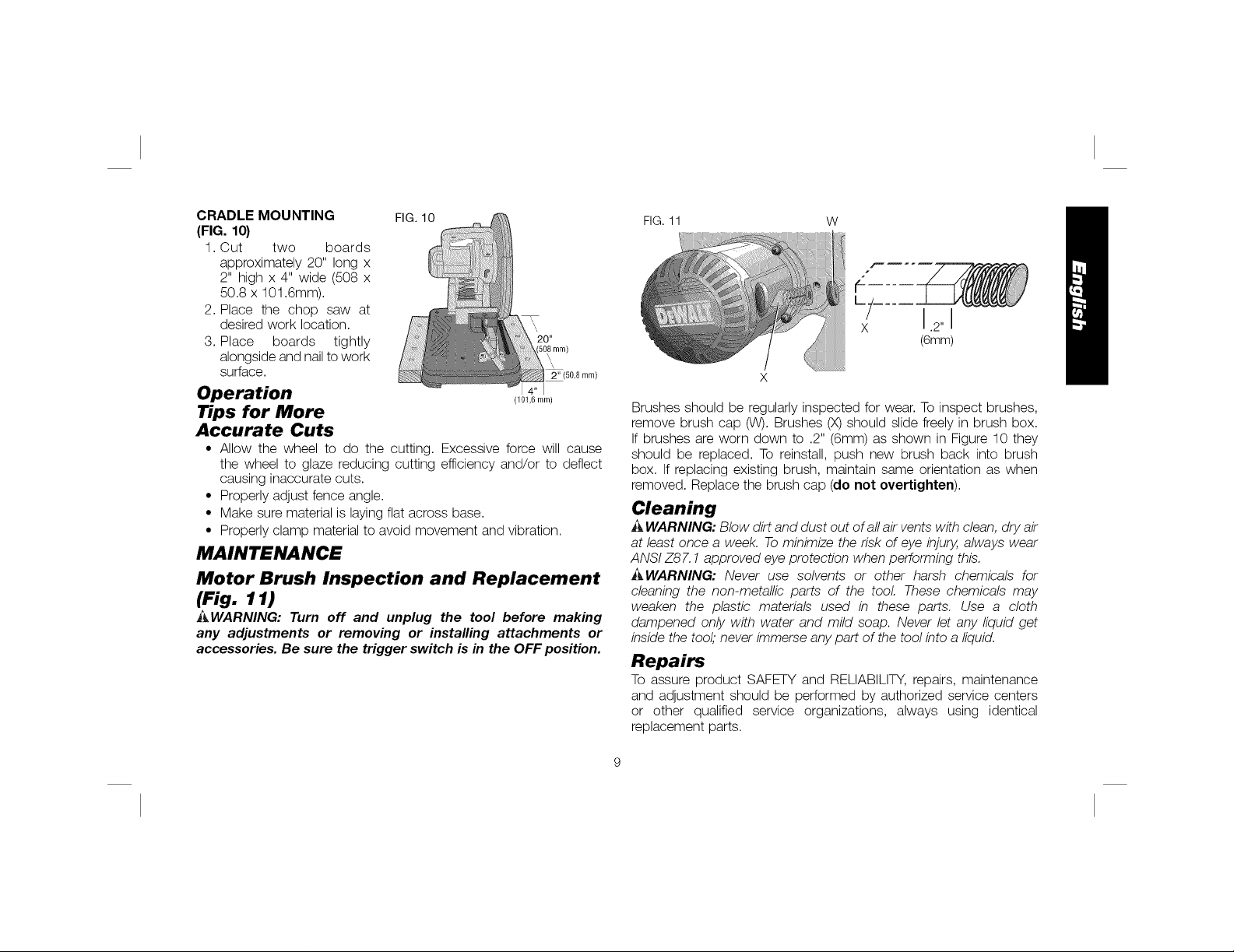

CRADLE MOUNTING

(FIG. 10)

1. Cut two boards

approximately 20" long x

2" high x 4" wide (508 x

50.8 x 101.6mm).

2. Place the chop saw at

desired work location.

3. Place boards tightly

alongside and nail to work

surface.

FIG. 10

Operation

Tips for More

Accurate Cuts

• Allow the wheel to do the cutting. Excessive force will cause

the wheel to glaze reducing cutting efficiency and/or to deflect

causing inaccurate cuts.

• Properly adjust fence angle.

• Make sure material is laying flat across base.

• Properly clamp material to avoid movement and vibration.

MAINTENANCE

Motor Brush Inspection and Replacement

(Fig. 11)

_WARNING: Turn off and unplug the tool before making

any adjustments or removing or installing attachments or

accessories. Be sure the trigger switch is in the OFF position.

FIG. 11 W

S 12I

(6mm)

Brushes should be regularly inspected for wear. To inspect brushes,

remove brush cap (W). Brushes (X)should slide freely in brush box.

If brushes are worn down to .2" (6mm) as shown in Figure 10 they

should be replaced. To reinstall, push new brush back into brush

box. If replacing existing brush, maintain same orientation as when

removed. Replace the brush cap (do not overtighten).

Cleaning

A WARNING: Blow dirt and dust out of all air vents with clean, dry air

at least once a week. To minimize the risk of eye injury, always wear

ANSI Z87.1 approved eye protection when performing this.

_WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool These chemicals may

weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get

inside the tool,"never immerse any part of the tool into a liquid.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment should be performed by authorized service centers

or other qualified service organizations, always using identical

replacement parts.

Page 11

Lubrication

Closed-type, grease-sealed ball bearings are used throughout. These

bearings have sufficient lubrication packed in them at the factory to

last the life of the chop saw.

Accessories

_WARNING: Since accessories, other than those offered by

DEWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the risk of

injury, only DEWALT recommended accessories should be used with

this product.

Use only high-strength Type 1 organic bonded wheels rated

4100 rpm or higher.

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating your local dealer or authorized service

center contact: DEWALT Industrial Tool Co., 701 East Joppa Road,

Baltimore, MD 21286 or call 1-800-4-DEWALT (1-800-433-9258).

Three Year Limited Warranty

DEWALTwill repair, without charge, any defects due to faulty materials

or workmanship for three years from the date of purchase. This

warranty does not cover part failure due to normal wear or tool

abuse. For further detail of warranty coverage and warranty repair

information, visit www.dewalt.com or call 1-800-4-DEWALT (1-800-

433-9258). This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights

which vary in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by

normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

DEWALT Power Tool, Laser, or Nailer for any reason, you can return

it within 90 days from the date of purchase with a receipt for a full

refund - no questions asked.

LATIN AMERICA: This warranty does not apply to products sold

in Latin America. For products sold in Latin America, see country

specific warranty information contained in the packaging, call the local

company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DEWALT (1-800-433-

9258) for a free replacement.

D2871014"3_., CHOPSAW

s_.

10

Page 12

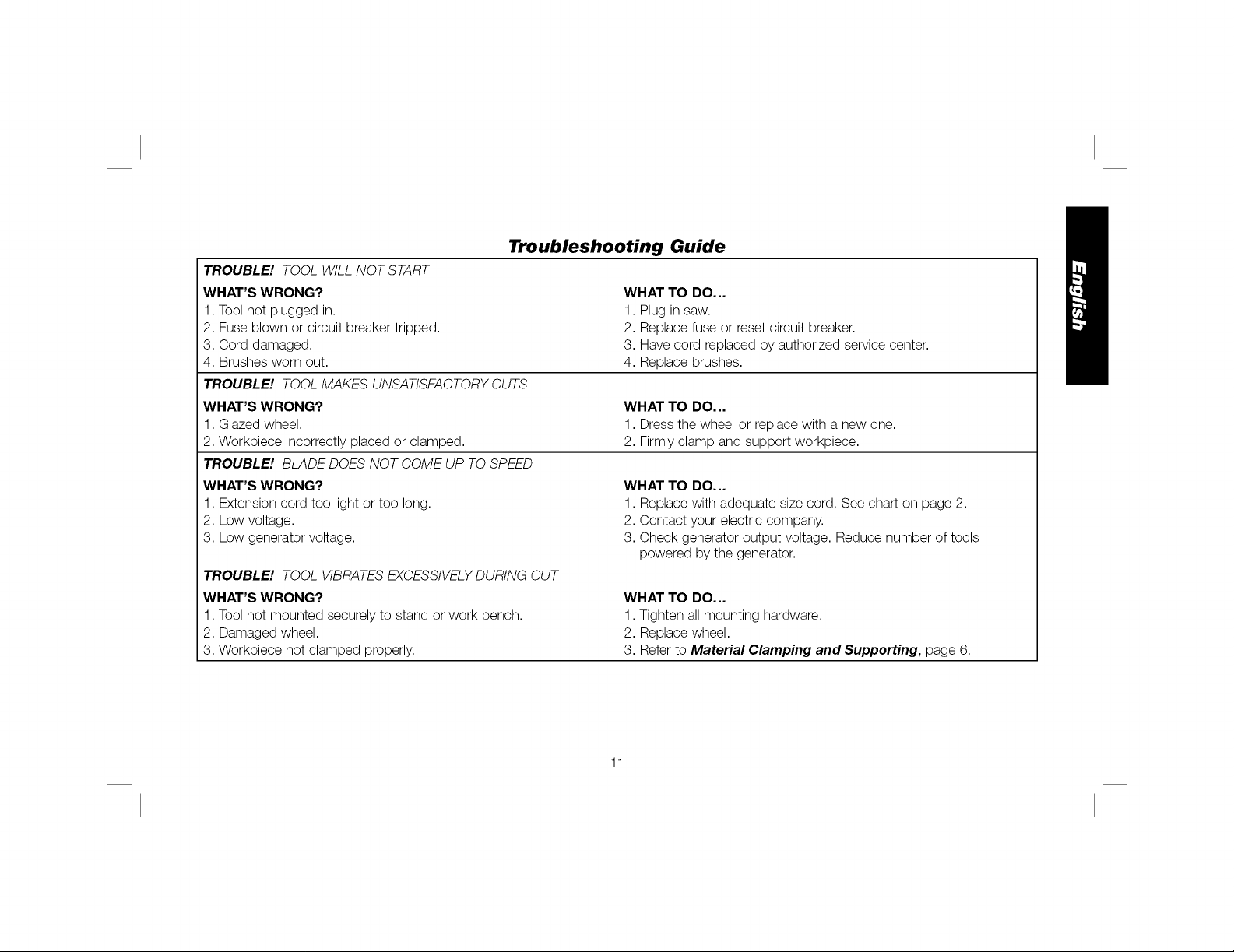

Troubleshooting Guide

TROUBLE! TOOL WILL NOT START

WHAT'S WRONG?

1. Tool not plugged in.

2. Fuse blown or circuit breaker tripped.

3. Cord damaged.

4. Brushes worn out.

TROUBLE! TOOL MAKES UNSATISFACTORY CUTS

WHAT'S WRONG?

1. Glazed wheel.

2. Workpiece incorrectly placed or clamped.

TROUBLE! BLADE DOES NOT COME UP TO SPEED

WHAT'S WRONG?

1. Extension cord too light or too long.

2. Low voltage.

3. Low generator voltage.

TROUBLE! TOOL VIBRATESEXCESSIVELY DURING CUT

WHAT'S WRONG?

1. Tool not mounted securely to stand or work bench.

2. Damaged wheel.

3. Workpiece not clamped properly.

WHAT TO DO...

1. Plug in saw.

2. Replace fuse or reset circuit breaker.

3. Have cord replaced by authorized service center.

4. Replace brushes.

WHAT TO DO...

1. Dress the wheel or replace with a new one.

2. Firmly clamp and support workpiece.

WHAT TO DO...

1. Replace with adequate size cord. See chart on page 2.

2. Contact your electric company.

3. Check generator output voltage. Reduce number of tools

powered by the generator.

WHAT TO DO...

1. Tighten all mounting hardware.

2. Replace wheel.

3. Refer to Material Clamping and Supporting, page 6.

11

Page 13

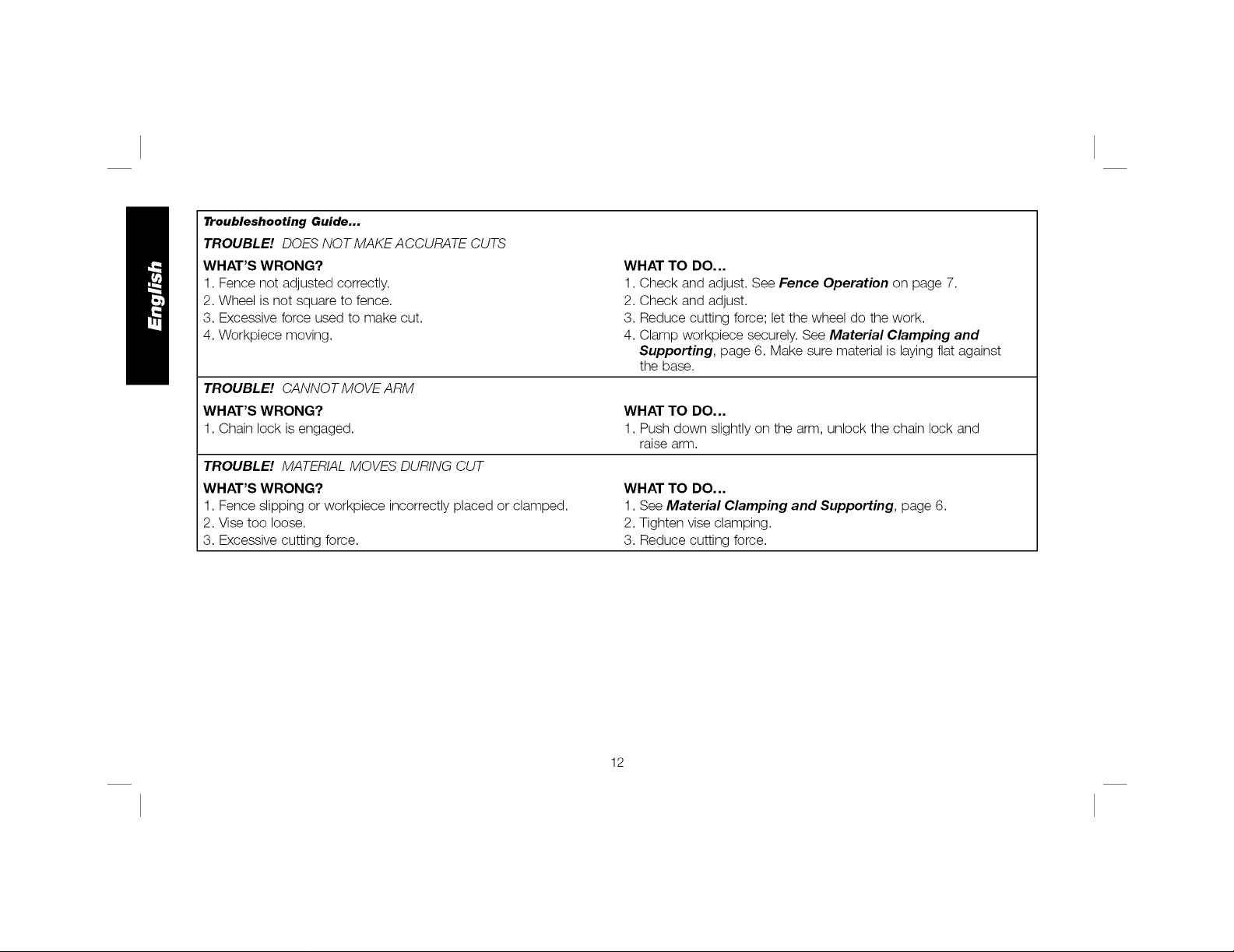

Troubleshooting Guide...

TROUBLE! DOES NOT MAKE ACCURATE CUTS

WHAT'S WRONG?

1. Fence not adjusted correctly.

2. Wheel is not square to fence.

3. Excessive force used to make cut.

4. Workpiece moving.

TROUBLE! CANNOT MOVE ARM

WHAT'S WRONG?

1. Chain lock is engaged.

TROUBLE! MATERIAL MOVES DURING CUT

WHAT'S WRONG?

1. Fence slipping or workpiece incorrectly placed or clamped.

2. Vise too loose.

3. Excessive cutting force.

WHAT TO DO...

1. Check and adjust. See Fence Operation on page 7.

2. Check and adjust.

3. Reduce cutting force; let the wheel do the work.

4. Clamp workpiece securely. See Material Clamping and

Supporting, page 6. Make sure material is laying flat against

the base.

WHAT TO DO...

1. Push down slightly on the arm, unlock the chain lock and

raise arm.

WHAT TO DO...

1. See Material Clamping and Supporting, page 6.

2. Tighten vise clamping.

3. Reduce cutting force.

12

Page 14

D_finitions : lignes directrices en

mati_re de s_curit_

Les definitions ci-dessous decrivent le niveau de danger pour

chaque mot-indicateur employe. Lire le mode d'emploi et porter

une attention particuliere a,ces symboles.

i_DANGER : indique une situation dangereuse imminente qui,

si elle n'est pas evitee, entraTnera la mort ou des blessures

graves.

_AVERTISSEMENT : indique une situation potentie//ement

dangereuse qui, si e//e n'est pas evitee, pourrait entra_ner /a

mort ou des blessures graves.

i_ATTENTION : indique une situation potentie//ement

dangereuse qui, si e//e n'est pas evitee, pourrait entra_ner des

blessures I_g_res ou modifies.

AVIS : indique une pratique ne posant aucun risque de

dommages corporels mais qui par contre, si rien n'est far

pour /'eviter, pourrait poser des risques de dommages

materiels.

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET

OUTIL OU DE TOUT AUTRE OUTIL DEWALT, COMPOSER LE

NUMFt:ROSANS FRAIS : 1-800-4-DEWALT (1-800-433-9258).

Consignes de s_curit_ importantes

AVERTISSEMENT : life toutes les directives avant

d'utiliser le produit. Negliger de suivre toutes les

directives suivantes peut entraFner des risques de

chocs electriques, d'incendie et/ou de blessures

graves.

CONSERVER CES DIRECTIVES

Double isolation

Afin de proteger I'utilisateur contre les decharges electriques, les outils

a,double isolation sont completement recouverts de deux couches

distinctes d'isolant electrique ou d'une simple epaisseur renforcee

de matiere isolante. Les outils comportant ce systeme d'isolation ne

sont pas congus pour @tremis a,la terre. L'outil est donc dote d'une

prise a,deux broches qui permet d'utiliser des rallonges sans avoir a,

se soucier de maintenir une connexion a,la terre.

REMARQUE : le fait que cet outil soit muni d'une double isolation ne

signifie pas que I'utilisateur peut cesser de respecter les consignes

de s6curite qui s'imposent. L'isolation secondaire offre une protection

contre tout dommage corporel pouvant resulter d'une defaillance

electrique possible du systeme primaire d'isolation interne.

AATTENTION : EN CAS DE REPARATION,UTILISER UNIQUEMENT

DES PIECES DE RECHANGE IDENTIQUES, Reparer ou remplacer les

cordons d'alimentation endommages,

Fiches polaris_es

Certains appareils comportent des fiches polarisees (c'est-a,-dire

qu'une lame est plus large que I'autre) afin de reduire le risque de

choc electrique. Lorsqu'elle est presente, cette fiche ne se branche

que d'une seule fagon dans une prise de courant polarisee. Si la fiche

ne s'insere pas totalement dans la prise de courant, I'inverser. Si elle

ne s'insere toujours pas dans la prise, demander a,un electricien

competent d'installer une fiche polarisee. Ne pas remplacer la fiche.

• GARDER LES DISPOSITIFS DE PROTECTION EN PLACE et

en bon etat de fonctionnement.

• RETIRER LES CLE-S DE RE-GLAGE ; prendre /'habitude de

s'assurer que les cles de reglage sont retirees de I'outil avant de le

demarrer,

13

Page 15

• GARDER L'AIREDE TRAVAIL PROPRE; les espaces de travail

et les etablis encombres sont propices aux blessures.

• NE PAS UTILISER L'OUTIL DANS UN ENVIRONNEMENT

DANGEREUX ; ne pas exposer I'outil a la pluie, ni I'utiliser clans

des endroits humides ou detrempes. Garder I'aire de travail bien

eclairee.

• TENIR LES ENFANTS A L'E-CART; s'assurer que personne ne

s'approche de I'aire de travail.

• S'ASSURER QUE L'ATELIER EST SUR POUR LES ENFANTS;

utiliser des cadenas, des interrupteurs centraux ou enlever les

commandes de demarrage.

• NE PAS FORCER L'OUTIL ; pour obtenir de meilleurs resultats

etprevenir les risques de blessure, laisser I'outil couper a la vitesse

pour laquelle il a ete conqu.

• UTILISER L'OUTIL APPROPRIE- ; ne pas forcer I'outil ou

I'accessoire, ni I'utiliser pour des travaux autres que ceux pour

lesquels ila ete conqu.

• UTILISER LES RALLONGES APPROPRIEES ; pour la

s6curit6 de I'utilisateur, utiliser une rallonge de calibre

ad_quat (AWG, American Wire Gauge [calibrage am6ricain

normalis6 des ills 61ectriques]). Plus le calibre est petit, et

plus sa capacite est grande. Un calibre 16, par exemple, a une

capacite superieure a un calibre 18. L'usage d'une rallonge de

calibre insuffisant causera une chute de tension qui entra_nera

perte de puissance et surchauffe. Si plus d'une rallonge est utilisee

pour obtenir une certaine Iongueur, s'assurer que chaque rallonge

presente au moins le calibre de filminimum. Le tableau ci-dessous

illustre les calibres a utiliser selon la Iongueur de rallonge et

I'intensite nominale indiquee sur la plaque signaletique. En cas

de doute, utiliser le calibre suivant. Plus le calibre est petit, plus la

rallonge peut supporter de courant.

Calibres minimaux des rallonges

Intensit_

(en amperes)

Sup_rieur a Inf_rieur

0 6

6 10

10 12

12 16

volts

120 V

240 V

Longueur totale de cordon

en metres (pieds)

7,6

(25)

15,2

(50)

15,2 30,5 45,7

(50) (100) (150)

30,5 61,0 91,4

(100) (200) (300)

AWG

18

18

16

14

16 16 14

16 14 12

16 14 12

12 Non recommande

• PORTER DES V£-TEMENTS APPROPRIE-S ; ne pas porter

de v_tements amples ni de gants, de cravate, de bague, de

bracelet ou d'autres b_oux, car ceux-ci peuvent rester coinces

dans les pieces mobiles. Le port de chaussures antiderapantes

est recommande. Couvrir ou attacher les cheveux longs. Se tenir

doigne des events puisque ces demiers pourraient cacher des

pioces mobiles.

• TOUJOURS UTILISER DES LUNETTES DE PROTECTION

conformes aux normes ANSI Z87.1. Utiliser aussi un masque

antipoussieres si la decoupe dolt en produire beaucoup. Les

lunettes ordinaires ne peuvent que proteger contre les impacts,

ce ne sont pas des lunettes de protection.

• ARRIMER LA PIt-CEA TRAVAILLER. Pour ce, utiliser un serre-

joint ou un etau. C'est plus sOr que de le faire manuel/ement et

cela laisse les mains libres pour utiliser I'outil.

• NE PAS EFFECTUER DE TRAVAUX HORS DE PORTEE.

Les pieds doivent rester bien ancres au sol afin de maintenir son

equilibre en tout temps.

14

Page 16

• BIEN ENTRETENIR L'OUTIL ; afin d'obtenir de mei//eurs

resultats et faire preuve de prudence, garder I'outi/ propre et bien

aiguis& Suivre /es consignes /orsqu'on /ubrifie ou qu'on remp/ace

les accessoires.

• DE-BRANOHERLESOUTILSavanttoutentretienouchangement

d'accessoires, tels lames, meches, embouts, organes de coupe

ou tout autre accessoire similaire.

• RE-DUIRE LES RISQUES DE DE-MARRAGE ACCIDENTEL ;

s'assurer que I'interrupteur est en position d'arr_t avant de

brancher I'outiL

• UTILISERLESACCESSOIRESRECOMMANDE-S;consulterle

manuel d'utilisation pour savoir quels accessoires sont appropries.

L'utilisation d'accessoires autres que ceux recommandes pourrait

entra_nerdes blessures.

• NE JAMAIS MONTER SUR UN OUTIL ; si I'outil se renverse ou

si /'organe de coupe est touche accidente/lement, ce/a pourrait

entrafner des b/essures graves.

• VE-RIFIER LES PIECES ENDOMMAGE-ES; avant de poursuivre

/es travaux, examiner attent/vement /es dispositifs de protection,

ou toute autre piece endommagee, afin de s'assurer qu'i/s

fonctionnent toujours adequatement et qu'i/s sont en mesure

d'effectuer /es travaux pour/esque/s i/s ont ete conqus. Verifier

/espieces mobiles afin de s'assurer qu'e//es sont bien a/ignees et

qu'e/les ne restent pas coincees; verifier ega/ement /es pieces et

/esassemblages afin de s'assurer qu'i/ n'y a aucun bris ni aucune

autre condition susceptible de nuire au bon fonctionnement de

/'outiL Faire reparer ou remp/acer toute piece endommagee, y

compris /es dispositifs de protection.

• NE JAMAIS LAISSER L'OUTIL FONCTIONNER SANS

SURVEILLANCE; COUPER L'ALIMENTATION et attendre que

I'outil s'arr_te completement avant de quitter les Iieux.

R_gles de sdcuritd additionnelles

relatives aux scies fendeuses

• Toujours porter des lunettes de protection et un appareil

respiratoire antipoussi_res ad_quats.

• Avant toute utilisation, v_rifier que le disque de tronqonnage

ne comporte ni fissures ni d_fauts. Dans I'affirmative,

mettre le disque au rebut. Inspecter aussi le disque chaque

lois que I'on suspecte que I'outil a far une chute. Tout defaut

pourrait provoquer la casse du disque.

• Avant de red_marrer I'outil _quip_ d'un disque neuf ou de

rechange ou si I'on n'est pas sgr de la condition du disque,

faire fonctionner I'outil pendant une minute en s'assurant

d'en #tre bien protege. Si le disque est affect_ d'une f#lure

ou d'un d_faut cache, il devrait _clater en moins d'une

minute. Ne jamais demarrer I'outil Iorsque quelqu'un se tient

directement devant le disque, y compris I'utilisateur.

• Pendant le fonctionnement, prot_ger le disque contre tout

choc ou traitement brutal Dans cette eventualit& arr_ter I'outil

et verifier que /e disque de tronqonnage ne comporte ni fissures ni

defauts.

• Nettoyer/a scie fendeuse regu/ierement en suivant/a procedure

indue darts ce manuel

• Ne jamais retirer/es proteges disque ou/a base.

• TOUJOURS UTILISER UN E-TAU OU TOUT AUTRE

DISPOSlTIF DE FIXATION POUR ARRIMER SOLIDEMENT

LA PIECE A DE-COUPER. Tout autre dispositif, te/s pinces

ressort, serre-joints a coulisse ou etaux en C, peut _tre approprie

se/on /a tai/le ou /a forme de/a piece a travai/ler. Choisir et installer

soigneusement ces dispositifs de fixation puis faire fonctionner

/'outi/ a vide avant de commencer a decouper.

• N'uti/iser que des disques de type 1 de 355 mm (14 po) conqus

pour un regime minima/de 41O0r/min.

• Laisser route piece decoupee refroidir avant route manipulation.

• Ne pas tenter de decouper bois ou p/astique avec cet outiL

15

Page 17

FIG. 1

O

16

Page 18

• NE JAMAIS DECOUPER DE MAGNESIUM AVEC CET

OUTIL.

• Utiliser la scie fendeuse dans un endroit bien ventile.

• Arr_ter la scie fendeuse avant de retirer aucune piece de sa base.

• NE DECOUPER AUCUN MATERIAU SOUS TENSION.

• NE JAMAIS UTILISER DE LAMES POUR SCIE CIRCULAIRE

AVEC CET OUTIL, NI DE LAMES DENTEES, AFIN D'EVITER

LES RISQUES DE BLESSURE GRAVE.

• NE PAS UTILISER CET OUTIL PRES DE LIQUIDES, DE

GAZ OU DE POUSSIERES INFLAMMABLES. Des etincelles

ou copeaux brOlants, ou les balais incandescents du moteur

pourraient enflammer des materiaux combustibles.

• Ne pas utiliser le c6te du disque abrasif comme une meule

ebarboir. Cela affaiblirait considerablement le disque posant ainsi

des risques a I'utilisateur. Le disque pourrait se casser.

_ATTENTION : porter un dispositif de protection personnel

anti-bruit appropri_ durant rutilisation. Sous certaines

conditions et selon la duree d'util/sation, le bruit emanant de ce

produit pourrait contribuer a la perte d'audition.

_ATTENTION : le pare-etincelles deviendra chaud. Eviter de toucher

ou de regler I'outil Iorsqu'il est chaud. Tenez le cordon amovible et le

materiel loin du pare-etincelles.

AAVERTISSEMENT : certains outils dectriques, tels que les

sableuses, les scies, les meules, les perceuses ou autres outils de

construction peuvent produire des poussieres contenant des produits

chimiques reconnus par I'etat califomien pour causer cancers,

malformations congenitales ou _tre nocifs au systeme reproductif.

Parmi ces produits chimiques, on retrouve :

• le plomb clans les peintures a base de plomb,

• la silice cristallisee dans les briques et le ciment ou autres

articles de maqonnerie, et

• I'arsenic et le chrome dans le bois ayant subi un traitement

chimique (ACC).

Le risque associe a de telles expositions varie selon la frequence

laquelle on effectue ces travaux. Pour reduire toute exposition a ces

produits : travailler dans un endroit bien aere, en utilisant le materiel de

securite approprie tel un masque antipoussieres specialement conqu

pour filtrer les particules microscopiques.

• Eviter tout contact prolong_ avec la poussi_re soulev_e par

cet outil ou autres outils _lectriques. Porter des v_tements

de protection et nettoyer les parties expos_es du corps

I'eau savonneuse. S'assurer de bien se proteger afin d'eviter

d'absorber par la bouche, les yeux ou la peau des produits

chimiques nocifs.

_AVERTISSEMENT : cet outil peut produire et repandre de

la poussiere susceptible de causer des dommages serieux et

permanents au systeme respiratoire. Toujours utiliser un appareil

respiratoire antipoussieres approprie approuve par le NIOSH ou

I'OSHA. Diriger les particules dans le sens oppose du visage et du

corps.

Pour des raisons de commodites et de securite, les etiquettes

suivantes sont apposees sur votre scie fendeuse a service intensif

de 355 mm (74")

_ POUR VOTRE SECURITE, LInE LE MANUEL DE

L'UTILISA TEUR.

NE PAS UTILISER DE LAMES DENTEES.

N'UTILISER QUE DES DISQUES RENFORCES

CON_US POUR UN REGIME MINIMAL DE

4100 R/MIN.

LORS DE L'ENTRETIEN, N'UTILISER QUE DES PIECES

DE RECHANGE IDENTIQUES.

TOUJOURS : PORTER DES LUNETTES DE

PROTECTION, UTILISER UN DISPOSITIF DE

PROTECTION, MAINTENIR LA PIECE

TRAVAILLER DANS UN ETAU,. UTILISER UN APPAREIL

RESPIRATOIRE ANTIPOUSSIERES ADEQUAT.

NE PAS EXPOSER L'OUTIL A LA PLUIE NI L'UTILISER

DANS DES ENDROITS HUMIDES.

17

Page 19

CARACTERISTIQUES (FIG. 1, 4)

A. Chatne de verrouillage J. Disque

B. Vis du deflecteur K. Protege disque

d'etincelles L. Levier de verrouillage

C. Deflecteur d'etincelles du disque

D. Base M. Boulon de butee de profondeur

E. Guide N. G_,chette

F.Etau O. Orifice de cadenas

G. Cle hexagonale de 8 mm R Contre-ecrou

H. Papillon de serrage Q. Boulons du guide

I. Levier de I'etau

Alimentation

S'assurer que le courant utilise correspond a,celui recommande sur

CAPACITIES DE COUPE MAXIMALES

REMARQUE : les capacites illustrees sur la planche presument un disque neuf et une position optimale du guide.

Forme de la A p---A----_ p-----B----_

la plaque signaletique. 120 volts, _,60 Hz ,, represente du courant

alternatif (courrant domestique normal de 120 volts et 60 Hz).

Une baisse de tension de plus de 10 % entratnerait perte de

puissance et surchauffe.

Capacit_ de coupe

L'ouverture elargie de I'etau et le point de pivotement etendu

permettent de decouper de larges pieces. Utiliser la planche de

capacite de coupe pour determiner la taille maximum de coupe

permise par un disque neuf.

AAVERTISSEMENT : CERTAINS OBJETS LARGES,

CIRCULAIRES OU DE FORME IRRE'GULIERE PEUVENT

REQUE'RIR DES MOYENS DE FIXATION ADDITIONNELS

LORSQUE L'E'TAU NE PEUT SOLIDEMENT LES MAINTENIR.

tiAVERTISSEMENT : NE PAS DE'COUPER DE MAGNESIUM

AVEC CET OUTIL.

piece a"travailler' O ]_] AT1

Angle de coupe A= 130 mm A= 120 mm 115 mm x 130 mm A= 137 mm

de 90° (5") (4,75") (4,5" x 5") (5-3/8")

k ...................................................................

AxB

102mm x 194 mm

(4"x 7-5/8")

76 mm x 229 mm

(3"x 9")

Angle de coupe A= 115mm A= 107 mm 115 mm x 107 mm A= 115mm

de 45° (4,5") (4,25") (4,5" x 4,25") (4,5")

18

Page 20

Equipement standard

1 Disque abrasif a,metaux de 355 mm (14 po)

1 Cle pour ecrous de roue

1 Manuel de I'utilisateur

Transport (fig. 1)

Repliez la scie dans sa position de transport. Utilisez la chaTne de

verrouillage (A)pour verrouiller le bras.

D_verrouillage (fig. 1)

Pour deverrouiller I'outil et redresser la t_te, appuyez legerement sur le

bras moteur puis retirez la chaTne de verrouillage (A). Le bras moteur

pivotera alors vers le haut.

Arrimage et support des mat_riaux

• Les angles sont arrimes et coupes le mieux avec les deux jambes

appuyees contre la base.

• Un bloc-espaceur legerement plus etroit que la piece _, travailler

peut _tre utilise pour augmenter la propension d'utilisation du

disque (fig. 2).

• Les pieces Iongues doivent _tre supportees par un bloc pour les

mettre de niveau avec la base (fig. 3). La partie decoupee doit

pouvoir tomber librement pour eviter de bloquer le disque.

FIG. 2

DIAMETREDELA PIECE_,TRAVAILLER

/

E BLOC-

'_d_ ]_ ESPACEUR

F

FIG. 3

FIN DE COUPE

BLOC

R_glage du d_flecteur d'_tincelles (fig. 1)

Pour proteger toute personne ou materiau environnant des etincelles,

devisser la vis (B), regler le deflecteur d'etincelles (C) puis resserrer

la vis. Ne laissez pas le cordon amovible entrer en contact avec le

pare-etincelles ou les etincelles, car le cordon amovible risque d'6tre

endommage.

Utilisation de I'_tau (fig. 4)

L'etau (F) a et6 congu pour _tre deplace rapidement. Pour relb,cher

I'etau Iorsqu'il est fermement serre, faire tourner le papillon de

serrage (H) vers la gauche un ou deux tours pour relb,cher la

pression. Relever le levier de I'etau (I).Tirer I'ensemble du papillon

de serrage jusqu'a, I'emplacement desire. Uetau peut 6tre pousse

en avant pour utilisation sans serrage. Abaisser le levier de I'etau (I)

puis resserrer I'etau (F) sur la piece a,I'aide du papillon de serrage

(m).

LARGEURDU BLOC-ESPACEUR

19

Page 21

FIG.4

AVANT

FIG. 5

D

R

G

;Q

Utilisation du guide

_AVERTISSEMENT : arr_ter et d_brancher I'outil avant tout

r_glage ou avant de retirer ou installer toute piece ou tout

accessoire. S'assurer que la g&chette est bien en position

d'Arr_t.

Le guide (E) peut prendre deux positions : pour changer I'angle de

coupe ou pour changer I'ecartement entre le guide et I'etau.

POUR CHANGER L'ANGLE DE COUPE (FIG. 5, 6)

_,I'aide de la cle fournie a, cet effet, desserrer (sans retirer) les deux

boulons du guide (Q). Aligner la ligne d'indicateur d'angle avec la

rainure (R)sur labase (D). Resserrer a,fond les deux boulons du guide

avant utilisation.

Pour un coupe d'equerre plus precis, debrancher I'appareil, devisser

les deux boulons du guide, abaisser le bras jusqu'a, ce que le disque

atteigne la base. Placer une equerre contre le disque puis ajuster le

guide contre I'equerre. Resserrer a, fond les deux boulons du guide

avant utilisation.

FIG. 6

Q

Pour faire une coupe a, onglet, suivant I'epaisseur de la piece a,

travailler et I'angle d'onglet, il se peut que I'etau (F) ne puisse pas

arrimer la piece solidement. D'autres dispositifs (tels pinces a,ressort,

serre-joints a,coulisse ou etaux en C) seront necessaires pour arrimer

la piece au guide pour effectuer ces coupes.

2O

Page 22

POUR CHANGER U#CARTEMENT ENTRE LE GUIDE

ET L'I_TAU

_, I'aide de la cle fournie a, cet effet, desserrer puis retirer les deux

boulons du guide (Q). Regler le guide (E) a, I'emplacement voulu.

Inserer les deux boulons du guide dans leurs orifices respectifs.

Resserrer a,fond les deux boulons du guide avant utilisation.

Butte de profondeur (fig. 1)

La butee de profondeur est reglee d'usine pour les disques neufs de

355 mm (14 po) pour eviter qu'ils ne coupent la surface de support.

Pour augmenter la profondeur de coupe, utiliser la cle hexagonale

de 8 mm (G) fournie a,cet effet pour desserrer le boulon de butee

de profondeur (M) et ajuster le boulon a, la hauteur desiree puis

serrer fermement le contre-ecrou (P)vers la droite contre le moulage.

Resserrer a,fond le boulon de butee de profondeur avant utilisation.

_ATTENTION : au moment de changer le disque, reajuster la butee

de profondeur a sa position initiale pour eviter que le disque ne coupe

la surface de support,

G_chette (Fig. 1)

Pour mettre I'outil en marche, appuyer sur la gb,chette (N). Pour

arr_ter I'outil, rel_,cher la gb,chette. Proteger les mains et le materiau

du disque tant qu'il n'est pas a,I'arr_t complet.

Pour prevenir toute utilisation illicite de I'outil, installer un cadenas

standard (non compris) dans I'orifice de cadenas (O) situe sur la

gb,chette.

Retrait et installation des disques

(fig. 1, 7, 8)

_AVERTISSEMENT : arr_ter et d_brancher I'outil avant tout

r_glage ou avant de retirer ou installer toute piece ou tout 2.

accessoire. S'assurer que la g_chette est bien en position

d'Arr_t. Ne faire aucun r_glage tant que le disque est en 3.

mouvement. Ne faire aucun r_glage tant que la scie fendeuse

est branch_e sur le secteur. 4.

21

FIG. 7

FIG.8 J

V

Appuyer sur le levier de verrouillage du disque (L) puis faire

tourner ledisque (J)a, la main jusqu'a, ce que le levier s'enclenche

dans la rainure de la bride interne (S) pour verrouiller le disque.

Desserrer le boulon (T)vers la gauche au centre du disque abrasif

a,I'aide de lacle hexagonale de 8 mm (G). Le boulon est filete vers

la droite.

Retirer le boulon (T), la rondelle (U), la bride externe (V)et I'ancien

disque (J).

S'assurer que les surfaces de la bride sont bien propres et lisses.

Installer le disque neuf en suivant la methode inverse.

Attention a, ne pas trop serrer le boulon.

Page 23

AAVERTISSEMENT: proteger la surface de travail sur laquelle la

scie fendeuse repose avant de remplacer le disque, IIpeut arriver que

le disque entre en contact avec des OBJETS OU STRUCTURES

AU-DELA de la surface de travail (sous la base) Iorsque le bras est

abaisse a fond,

Fixation

AATTENTION : I'outil doit _tre instal/e sur une surface stable, de

niveau et antiderapante pour prevenir tout mouvement intempestif

pendant son fonctionnement, FIG,9 ,-...................

PROC#DURE DE MONTAGE

PERMANENT

1. Percer deux trous de 8 mm (5/16

po) dans la surface de travail (fig. 9).

2. Inserer les vis 1/4 po-20 dans les

orifices de la base et les orifices

de la surface de montage. La

Iongueur approximative des vis

doit correspondre a, I'epaisseur

de la surface de montage plus

102 mm (4 po).

3. Serrer les deux vis.

FIXATION PAR BERCEAU

FIG. 10

(FIG. 10)

1. Couper deux planches

d'environ 508 mm de long x

50,8 mm de haut x 101,6 mm

de large (20 po x 2 pox 4 po ).

2. Disposer la scie fendeuse a,

I'emplacement desire.

3. Disposer les planches tout

contre chaque cOte de la scie

puis les clouer a, la surface de

travail.

o

o

20 _,

Imm)

2'_ (50,8ram)

14"I

(101,6 ram)

Conseils d'utilisation pour une d_coupe

plus precise

• Laisser le disque faire la decoupe. Toute force excessive glacera

le disque et reduira ainsi son efficacite et/ou le fera devier

provoquant des ecarts de coupe.

• Regler le guide a,I'angle adequat.

• S'assurer que le materiau est bien a,plat en travers de la base.

• Arrimer solidement le materiau pour eviter tout mouvement ou

vibration.

ENTRETIEN

Inspection et remplacement des balais

moteur (fig. 11)

/_AVERTISSEMENT : arr_ter et d_brancher I'outil avant tout

r_glage ou avant de retirer ou installer toute piece ou tout

accessoire. S'assurer que la g_chette est bien en position

d'Arr_t.

FIG. 11 W

6 mm

(0,2po)

Wrifier regulierement I'etat des balais. Pour verifier les balais, retirer

le bouchon du porte-balais (W). Les balais (X) devraient bouger

librement dans le porte-balais. Si les balais sont uses et mesurent

22

Page 24

moins de 6 mm (0,2 po) comme illustre en Figure 10, les changer.

Pour les reinstaller, inserer des balais neufs dans le porte-balais. Pour

changer des balais existants, respecter la m_me orientation. Remettre

le bouchon du porte-balais (attention _ ne pas trop serrer).

Nettoyage

i_AVERTISSEMENT : enlever les saletes et la poussiere hors des

events au moyen d'air comprime propre et sec, au moins une lois

par semaine. Pour minimiser le risque de blessure aux yeux, toujours

porter une protection oculaire conforme a la norme ANSI Z87.1 Iors

du nettoyage.

AAVERTISSEMENT : ne jamais utiliser de solvants ni d'autres

produits chimiques puissants pour nettoyer les pieces non metalliques

de I'outil. Ces produits chimiques peuvent affaiblir les materiaux

de plastique utilises dans ces pieces. Utiliser un chiffon humecte

uniquement d'eau et de savon doux. Ne jamais laisser de liquide

penetrer dans I'outil et n'immerger aucune pattie de I'outil dans un

liquide.

R_parations

Pour assurer la S¢:CURITE et la FIABILITE de ce produit, toutes

les operations d'entretien, de reparation et de reglage doivent _tre

effectuees dans un centre de service autorise ou par du personnel

qualifie ; n'utiliser que des pieces de rechange identiques.

Lubrification

L'appareil est muni de roulements a billes scelles et graisses. Ces

roulements a billes sont suffisamment lubrifiesd'usine pour la duree

de vie entiere de la scie fendeuse.

Accessoires

AAVERTISSEMENT : puisque les accessoires autres que ceux

offerts par DEWALT n'ont pas ete testes avec ce produit, leur

utilisation pourrait s'averer dangereuse. Pour reduire le risque de

blessures, utiliser exclusivement les accessoires DEWALT

recommandes avec le present produit.

N'utiliser que des disques renforces a.agglomerant organique de type

1congus pour un regime minimal de 4100 r/min.

Les accessoires recommandes pour cet outil sont vendus separement

chez les distributeurs Iocaux ou dans les centres de service autorises.

Si vous avez besoin d'aide pour Iocaliser un distributeur local ou un

centre de service autorise, veuillez contacter : DFiWALT Industrial

Tool Co., 701 East Joppa Road, Baltimore, MD 21286 ou appeler le

1-800-4-DEWALT (1-800-433-9258).

Garantie limit_e de trois ans

DEWALT reparera, sans frais, tout produit defectueux cause par un

defaut de materiel ou de fabrication pour une periode de trois ans a.

compter de la date d'achat. La presente garantie ne couvre pas les

pieces dont la defectuosite a et6 causee par une usure normale ou

I'usage abusif de I'outil. Pour obtenir de plus amples renseignements

sur les pieces ou les reparations couvertes par la presente garantie,

visiter le site www.dewalt.com ou composer le 1 800 433-9258 (1

800 4-DEWALT). Cette garantie ne s'applique pas aux accessoires

et ne vise pas les dommages causes par des reparations effectuees

par un tiers. Cette garantie confere des droits legaux particuliers a.

I'acheteur, mais celui-ci pourrait aussi beneficier d'autres droits variant

d'un etat ou d'une province a.I'autre.

En plus de la presente garantie, les outils DEWALT sont couverts par

notre :

CONTRAT D'ENTRETIEN GRATUIT D'UN AN

DEWALTentretiendra I'outil et remplacera les pieces usees au cours

d'une utilisation normale et ce, gratuitement, pendant une periode

d'un an a.compter de la date d'achat.

23

Page 25

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si I'acheteur n'est pas entierement satisfait, pour quelque raison que

ce soit, du rendement de routil electrique, du laser ou de la cloueuse

DEWALT,celui-ci peut le retourner, accompagne d'un re,u, dans les

90 jours _,compter de la date d'achat pour obtenir un remboursement

integral, sans aucun probleme,

AMI_RIQUE LATINE : cette garantie ne s'applique aux produits

vendus en Amerique latine, Pour ceux-ci, veuillez consulter les

informations relatives _, la garantie specifique presente darts

I'emballage, appeler I'entreprise locale ou consulter le site Web pour

les informations relatives _,cette garantie,

REMPLACEMENT GRATUIT DES I:!:TIQUETTES

D'AVERTISSEMENT : si les etiquettes d'avertissement deviennent

illisibles ou sont manquantes, composer le 1 800 433-9258 (1 800

4-DEiWALT)pour en obtenir le remplacement gratuit,

..................................................................................................................

24

Page 26

Guide de depannage

PROBLEME! L'OUTIL REFUSE DE DEMARRER

RAISONS

1. L'appareil n'est pas branche.

2. Un fusible a saute ou le circuit a disjoncte.

3. Le cordon est endommag&

4. Les balais sont uses.

PROBLEME! LES COUPES EFFECTUEES PAR L'OUTIL NE SONT PAS SATISFAISANTES

RAISONS

1. Disque glace.

2. Piece disposee ou arrimee incorrectement.

PROBLEME! LE DISQUE N'ARRIVE PAS A PRENDRE SA VITESSE NORMALE

RAISONS

1. Rallonge de mauvais calibre ou trop Iongue.

2. Tension trop faible.

3. Generateur de tension faible.

PROBLEME! L'OUTIL VIBRE DE FACON EXCESSIVE PENDANT LA

RAISONS

f. Uoutil n'est pas arrime solidement au support ou & I'etabli.

2. Le disque est endommag&

3. La piece n'est pas arrimee correctement.

ACTION

1. Brancher la scie.

2. Changer le fusible ou reenclencher le disjoncteur.

3. Faire remplacer le cordon par un centre de service autorise.

4. Changer les balais.

ACTION

1. Corroyer le disque ou le changer.

2. Arrimer et supporter fermement la piece.

ACTION

1. Utiliser le cordon au calibre adequat. Se reporter & la planche

en page 14.

2. Contacter votre compagnie d'electricit6.

3. Verifier le generateur de tension. Reduire le nombre d'outils

utilises avec le generateur.

COUPE

ACTION

1. Resserrer tout le dispositif de fixation.

2. Changer le disque.

3. Se reporter b,la section Arrimage et support des mat_riaux

en page 19.

25

Page 27

Guide de depannage...

PROBLEME! LES COUPES NE SONT PAS PRECISES

RAISONS

1. Le guide n'est pas regle correctement.

2. Le disque n'est pas d'equerre avec le guide.

3. Une force excessive est utilisee pour effectuer la coupe.

4. La piece a,travailler bouge.

PROBLEME! LE BRAS REFUSE DE BOUGER

RAISONS

1. La chaTnede verrouillage est en place.

PROBLEME! LE MATERIAU BOUGE PENDANT LA COUPE

RAISONS

1. Le guide glisse ou la piece est arrimee ou placee incorrectement.

2. Uetau est trop Ib,che.

3. La force utilisee est excessive.

ACTION

1. Verifier et ajuster. Se reporter a,la section Utilisation du guide

en page 20.

2. Verifier et ajustert.

3. Reduire la force utilisee et laisser le disque faire le travail.

4. Arrimer la piece solidement. Se reporter b,la section Arrimage

et support des mat_riaux en page 19. S'assurer que le

materiau est bien a,plat contre la base.

ACTION

1. Poussez legerement sur le bras, deverrouillez la chaTnede

verrouillage puis elevez le bras.

ACTION

1. Se reporter b,la section Arrimage et support des mat_riaux

en page 19.

2. Resserrer I'etau.

3. Reduire la force utilisee.

26

Page 28

Definiciones: Normas de seguridad

Las siguientes definiciones describen el nivel de gravedad de

cada palabra de sepal. Lea el manual y preste atenciOn a estos

dmbolos.

i_ PELIGRO: Indica una situacidn de peligro inminente que, si no

se evita, provocara la muerte o lesiones graves.

i_,ADVERTENCIA: Indica una situacidn de peligro potencial que,

si no se evita, podria provocar la muerte o lesiones graves.

,_,ATENCION: Indica una situacidn de peligro potencial que,

si no se evita, posiblemente provocarfa lesiones leves o

moderadas.

AVlSO: Se refiere a una practica no relacionada a lesiones

corporales que de no evitarse puede resultar en da_os a la

propiedad.

SI TIENE ALGUNA DUDA O ALGON COMENTARIO SOBRE ESTA

U OTRA HERRAMIENTA DEWALT, LLAMENOS AL NOMERO

GRATUITO: 1-800-4-DEWALT (1-800-433-9258}.

Instrucciones de seguridad importantes

_ ADVERTENCIA: Lea todas las instrucciones antes de

hacer funcionar el producto. El incumplimiento de

todas las instrucciones enumeradas a continuacidn

puede provocar una descarga electrica, un incendio o

lesiones graves.

CONSERVE ESTAS INSTRUCCIONES

Doble aislamiento

Las herramientas con aislamiento doble se construyen en todas

partes con dos capas separadas de aislamiento electrico, o una sola

capa de aislamiento reforzado, entre el operador y el sistema electrico

de la herramienta. Las herramientas fabricadas con este sistema de

aislamiento no requieren conexion a tierra. En consecuencia, esta

herramienta est6.equipada con un enchufe de dos conectores que le

permite utilizar cables prolongadores sin tener que preocuparse por

mantener la conexiOn a tierra.

NOTA: El aislamiento doble no implica que no se deban tomar

las medidas de seguridad normales al operar esta herramienta. El

sistema de aislamiento secundario supone una protecciOn contra

lesiones ocasionadas por una posible falla del aislamiento electrico

primario dentro de la herramienta.

,_,_ATENCI6N:AL REPARAR,SOLO UTILICE PIEZAS DE REPUESTO

IDENTICAS A LAS ORIGINALES. Repare o reemplace los cables

dahados.

Enchufes polarizados

Los enchufes polarizados (una pata es m6.s ancha que la otra) se

utilizan en los equipos para reducir el riesgo de descarga electrica.

J

Este enchufe se ajusta al tomacorriente polarizado de una sola

manera. Si el enchufe no se ajusta totalmente al tomacorriente,

invierta el enchufe. Si aun as[ no se ajusta bien, recurra a un

electricista calificado para que instale un tomacorriente adecuado. No

cambie el enchufe de ninguna manera.

• MANTENGA LOS PROTECTORES EN SU SITIO y en buenas

condiciones de funcionamiento.

• QUITE LAS LLAVES DE AJUSTE. Hagase el habito de

comprobar que la herramienta no tenga ninguna Ilave de ajuste

puesta antes de encenderla.

• MANTENGA LIMPIA EL AREA DE TRABAJO. Las _,reas y

mesas de trabajo desordenadas aumentan el riesgo de lesiones.

• NO UTILICE LA HERRAMIENTA EN AMBIENTES

PELIGROSOS. No utilice maquinas herramienta en lugares

hdmedos o mojados ni las exponga a Iluvia. Mantenga el area de

trabajo bien iluminada.

• MANTENGA ALEJADOS A NIhlOS. Toda visita deberfa

mantenerse a una distancia segura del area de trabajo.

27

Page 29

QUE SU TALLER SEA A PRUEBA DE NIKIOS. Para ello

utilice candados o conmutadores maestros o quite las Ilaves de

arranque.

NO FUERCE LA HERRAMIENTA. La herramienta hace el

trabajo mejor y mas seguro a la velocidad para la cual rue

disehada.

UTILICE LA HERRAMIENTA CORRECTA. No fuerce la

herramienta o el accesorio a que realice una tarea para la cual no

rue disehada.

USE EL ALARGADOR INDICADO. Los hilos del alargador

deben ser de un calibre apropiado (AWG o American Wire

Gauge) para su seguridad. Mientras menor sea el calibre del

hilo, mayor la capacidad del cable. Es decir, un hilo calibre 16

tiene mayor capacidad que uno de 18. Un cable de un calibre

insuficiente causara una cafda en la tensidn de la Ifnea dando

pot resultado una perdida de energfa y sobrecalentamiento.

Cuando se utilice mas de un alargador para completar el largo

total, asegOrese que los hilos de cada alargador tengan el calibre

mfnimo. La tabla siguiente muestra el tamaho correcto a utilizar,

dependiendo de la Iongitud del cable y del amperaje nominal de la

placa de identificacidn. Si tiene dudas sobre cual calibre usar, use

un calibre mayor. Cuanto mas pequeho sea el ndmero del calibre,

mas resistente sera el cable.

Calibre minimo para cables de alimentacibn

Voltios Largo total del cordbn en metros (pies)

Amperaje

Mas No

de mas de

0 6 16 14

6 10 14 12

10 12 14 12

12 16 No recomendado

120V 7,6(25) 15,2(50) 30,5(100) 45,7(150)

240V 15,2(50) 30,5(100) 61,0(200) 91,4(300)

AWG

18 16

18 16

16 16

14 12

• USE ROPA ADECUADA. No Ileveropa suelta, guantes, corbatas,

anillos, pulseras u otras joyas que podrfan engancharse en las

piezas mdviles. Se recomienda el uso de calzado antideslizante.

Cdbrase y recdjase el pelo si Io tiene largo. Los orificios de

ventilaci4nsueten cubrir piezas en movimiento, per Io que tambien se

deben evitar

• USE SIEMPRE GAFAS DE SEGURIDAD que cumplan con los

requisitos de ANSI Z87.1. Utilice ademas una mascara para la

cara o guardapolvo si la operacidn de corte genera demasiado

polvo. Los anteojos de uso diario sdlo tienen lentes resistentes a

golpes, no son galas de seguridad.

• AFIRME BIEN SU TRABAJO. Utilice abrazaderas o tomillos

para sujetar las piezas en las que trabaja. Es mas seguro, y asf

podra utilizar ambas manos para operar la herramienta.

• NO SE SOBREEXTIENDA. Mantengase siempre bien apoyado

y equilibrado.

• CUIDE LAS HERRAMIENTAS. Mantenga las herramientas

afiladas y limpias para un funcionamiento mejor y mas seguro.

Siga las instrucciones para lubricar y cambiar accesorios.

• DESENCHUFE LAS HERRAMIENTAS antes de reparar o

mantenerlas; cuando cambie accesorios tales como hojas,

brocas, mecanismos de corte y otros pot el estilo.

• REDUZCA EL RIESGO DE PUESTAS EN MARCHA

ACCIDENTALES. Asegdrese de que el conmutador este

apagado antes de enchufarla.

• UTILICE LOS ACCESORIOS RECOMENDADOS. Consulte

el manual de instrucciones para conocer los accesorios

recomendados. El uso de accesorios no debidos puede producir

un riesgo de lesiones corporales.

• NUNCA SE PARE SOBRE LA HERRAMIENTA. Podrfa sufrir

graves lesiones si la herramienta se cae a un lado o si se entra en

contacto no intencionado con la herramienta de corte.

• REVISE LAS PIEZAS DANADAS. Antes de continuar usando

la herramienta, se debe revisar cuidadosamente el protector

28

Page 30

ocualquierotrapiezadahadaparadeterminarquefuncionara

correctamenteyrealizaralafuncidnparalaqueruedisehada-

veriflque que las piezas mdviles esten alineadas, que no esten

atascadas, rotas, montadas una sobre otra o de otra forma que

pudiera afectar su operacidn. Cualquier protector o pieza dahada

debe repararse debidamente o cambiarse.

• JAMAS DEJE SIN SUPERVISION UNA HERRAMIENTA EN

FUNCIONAMIENTO. APAGUE LA HERRAMIENTA. No deje la

herramienta hasta que no se haya detenido completamente.

Reglas de seguridad adicionales para

sierras circulares estacionarias

• Use siempre proteccidn ocular y respiratoria apropiada.

• Antes de usarla, revise el disco de corte para verificar que

no est_ trizado o tenga fallas. Si tuviera alguna trizadura o

falla, descarte el disco. Tambi_n se debe inspeccionar el

disco siempre que piense que la herramienta pudiera haber

caMo. Las fallas pueden provocar la rotura del disco.

• Cuando arranque la herramienta con un disco nuevo o

de repuesto o si no esta seguro de la condicion del disco,

sostenga la herramienta en un lugar bien protegido y d_jela

andar per un minuto. Si el disco tiene una trizadura o fal/a

que haya pasado inadvertida, se deberfa romper en pedazos en

menos de un minuto. Nunca encienda la herramienta cuando haya

una persona alineada con el disco. Esto incluye al operador.

• Durante la operacion, evite hacer rebotar el disco o tratarlo

bruscamente. Si el/o sucediera, detenga la herramienta y revise

que el disco no tenga trizaduras o fallas.

• Limpie su sierra circular estacionaria periddicamente, siguiendo el

procedimiento de este manual

• No quite los protectores del disco o la base.

• Siempre use el tome o dispositivo de fijacion especial

para sostener bien la pieza de trabajo. Otros d/spos/t/vos

tales como abrazaderas de resorte, de barra o en C pueden

ser apropiadas para piezas de trabajo de diferentes tamahos y

formas. Tenga cuidado al seleccionar y colocar estas abrazaderas

y haga un movimiento de practica antes de hacer un corte.

• Use sdlo discos tipo 1 de 355 mm (14 pulg.) para 4100 rpm o

superiores.

• Deje que las piezas cortadas se enfrfen antes de cogerlas.

• No intente cortar madera o plastico con esta herramienta.

• NUNCA CORTE MAGNESIO CON ESTA HERRAMIENTA.

• Use la sierra circular estacionaria en un lugar bien ventilado.

• Apague la sierra circular estacionaria antes de quitar cualquier

pieza de su base.

• NO CORTE MATERIALES CARGADOS DE ELECTRICIDAD.

• NO USE HOJAS PARA SIERRAS CIRCULARES NI NINGUNA

OTRA HOJA DENTADA CON ESTA HERRAMIENTA. Pueden

producirse lesiones graves.

• NO OPERE ESTA HERRAMIENTA CERCA DE LiQUIDOS,

GASES 0 POLVOS INFLAMABLES. Las chispas o partfculas

calientes generadas del corte o las escobillas del motor podrfan

encender materiales combustibles.

• No use el lado del disco abrasivo como pulidor de rebabas. Esto

debilitara signiflcativamente el disco y creara una condicidn poco

segura. El disco podrfa desarmarse.

AATENCION: Use proteccidn auditiva apropiada durante el uso de

esta herramienta. Bajo algunas condiciones y duraciones de uso,

el ruido producido pot este producto puede contribuir a la perdida

auditiva.

i_,ATENCION: El deflector de chispas se calienta. Evite tocarlo

o ajustarlo mientras esta caliente. Mantenga cables y materiales

alejados del deflector de chispas.

•_ADVERTENCIA: Algunos tipos de polvo, como aquellos

generados pot el lijado, serruchado, pulido y taladrado electrico y

29

Page 31

otras actividades de construccidn, contienen qufmicos que el estado

de California sabe causan cancer, defectos de nacimiento y otros

dahos reproductivos. Algunos ejemplos de estos qufmicos son:

• plomo procedente de pinturas con base de plomo,

• dxido de silicio procedente de ladrillos, cemento y otros

productos de mamposterfa, y

• arsenico y cromo provenientes de maderas tratadas con

qufmicos (arseniato de cobre cromado).

El peligro derivado de la exposicidn a estos materiales varfa en

funcidn de la frecuencia con que se realice este tipo de trabajo.

Para reducir su exposicidn a estos qufmicos: trabaje en una zona

bien ventilada y Ilevando equipos de seguridad aprobados, como

mascarillas antipolvo especialmente disehadas para filtrar partfculas

microscdpicas.

• Evite el contacto prolongado con polvo generado per el

lijado, serruchado, pulido y taladrado el_ctricos y otras

actividades de construcci6n. Vista ropa protectora y lave

las areas de la piel expuestas con agua y jab6n. Si permite

que el polvo se introduzca en su boca o sus ojos, o que

quede sobre la piel, puede favorecer la absomidn de qufmicos

peligrosos.

_DVERTENCIA: La utilizacidn de esta herramienta puede

generar polvo o dispersarlo, Io que podrfa causar lesiones graves

y permanentes al sistema respiratorio, asf como otros problemas.

Siempre use proteccidn respiratoria aprobada por NIOSH (Instituto

Nacional de Seguridad y Salud en el Trabajo) u OSHA (Administracidn

de Seguridad y Salud en el Trabajo) apropiada para la exposicidn al

polvo. Dirijalas partfculas en direccidn contraria a la cara y el cuerpo.

Para su conveniencia y seguridad, su sierra circular estacionaria

para trabajo pesado de 355 mm (14 pulg.) tiene las siguientes

advertencias :

PARA OPERARLA DE UNA MANERA SEGURA, LEA EL

MANUAL DE INSTRUCCIONES.

NO UTILICE HOJAS DENTADAS.

UTILICE SOLO DISCOS REFORZADOS CALIFICADOS

PARA 4100 RPM 0 SUPERIORES.

CUANDO REALICE MANTENIMIENTO, USE S(_LO

REPUESTOS ORIGINALES.

SIEMPRE: UTILICE PROTECCION OCULAR; USE LOS

PROTECTORES DE HOJA; SUJETE LA PIEZA DE

TRABAJO CON EL TORNO; UTILICE LA

PROTECCI(_N RESPIRATORIA APROPIADA.

NO EXPONGA A LLUVIA NI USE EN LUGARES

HUMEDOS.

CARACTERiSTICAS (FIG. 1, 4)

A. Bloqueo de cadena K. Protector

B. Tornillo deflector de chispas L. Palanca de fijaciOn

C. Deflector de chispas del disco

D. Base M. Perno de tope de

E. Gu[a profundidad

F.Torno N. Conmutador tipo gatillo

G. Llave hexagonal de 8 mm O. Orificio para insertar

H. Manivela candado

I. Palanca del torno R Tuerca de obstrucciOn

J. Disco Q. Pernos para la gu[a

Alimentaci6n el_ctrica

Compruebe que su suministro electrico concuerde con el indicado

en la placa nominal. 120 voltios, "60 Hz" significa corriente alterna

(normal 120 voltios, 60 Hz de corriente domestica).

Una reducciOn de voltaje superior al 10% provocar6, perdida de

potencia y sobrecalentamiento.

3O

Page 32

FIG.1

O

31

Page 33

Capacidad de corte

La amplitud de apertura del torno y la altura del punto de pivote

proporcionan capacidad de corte para varias piezas grandes. Use la

tabla de capacidad de corte para determinar el tama_o mO,ximo total

de los cortes que se pueden realizar con un disco nuevo.

CAPACIDAD MAXIMA DE CORTE

NOTA: La capacidad indicada en la tabla supone que el disco no estO,desgastado y que la guia estO,en la posici0n Optima.

Forma de la pieza A p--A--q p------B----q

de trabajo: T

O

Angulodecorte A=130mm A=120mm 115mmx130mm A=137mm

de 90° (5") (4,75") (4,5" x 5") (5-3/8")

Angulodecorte A=115mm A=107mm 115mmx107mm A=115mm

de 45° (4,5") (4,25") (4,5" x 4.25") (4,5")

JtdIDVERTENCIA: PUEDE QUE CIERTOS OBJETOS GRANDES,

CIRCULARES 0 DE FORMAS IRREGULARES REQUIERAN

DE SOPORTE ADICIONAL SI NO PUEDEN SER SUJETOS

FIRMEMENTE EN EL TORNO.

_ADVERTENCIA: NO CORTE MAGNESIO CON ESTA

HERRAMIENTA.

]_

AxE

102 mm x 194 mm

(4"x 7-5/8" )

76 mm x 229 mm

(3"x 9")

Equipo estdndar

1 Disco abrasivo de 355 mm (14 pulg.) para cortar metales

1 Llave para el disco

1 Manual de instrucciones

Para portar (Fig. 1)

Doble hacia abajo la unidad a la posici0n donde puede transportar la

sierra. Utilice el bloqueo de cadena (A)para bloquear el brazo.

Para quitar el seguro (Fig. 1)

Para desbloquear la herramienta y levantar la cabeza, oprima el

brazo motor ligeramente y desbloquee el bloqueo de cadena (A). A

continuaci0n el brazo motriz girarO,hacia arriba.

32

Page 34

Soporte y fijacibn del material

• Podr6, sujetar y cortar 6,ngulos mejor con ambas piernas

descansando contra la base.

• Se puede utilizar un bloque espaciador ligeramente m6,s angosto

que la pieza de trabajo para aumentar la utilizaciOn de la rueda

(Fig. 2).

FIG. 2

DI_,METRO DE LA PIEZA DETRABAJO

_ E BLOQUE

_ ESPACIADOR

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

ANCHODEL BLOQUEESPACIADOR

FIG. 3

EXTREMO A

CORTAR

• Las piezas de trabajo largas deben ser soportadas por un bloque

para que esten al mismo nivel que la parte superior de la base

(Fig. 3). El extremo a cortar deber[a poder caer libremente para

evitar que el disco se atasque.

Ajuste del deflector de chispas (Fig. 1)

Para deflectar mejor las chispas de las personas y los materiales

circundantes, afloje el tornillo (B), ajuste el deflector de chispas

(C) y vuelva a ajustar el tornillo. No permita que el cable entre en

contacto con el deflector o las chispas para evitarle da_os.

Operacibn del torno (Fig. 4)

El torno (F) tiene una caracteristica que permite soltarlo r6,pidamente.

Para soltar el torno cuando est6, bien ajustado, gire la manivela (H)en

direcciOn contraria alas manillas del reloj una o dos veces para liberar

la presiOn de ajuste. Levante la palanca del torno (I).Tire de la unidad

de la manivela Io m6,sque desee. El torno puede ser empujado hacia

la pieza de trabajo sin tener que girar la manivela. Baje la palanca del

torno (I)y luego ajuste el torno (F) en la pieza de trabajo, girando la

manivela (H).

FIG. 4

HACIA

ADELANTE

BLOQUE

33

Page 35

Operaci6n de la guia

AADVERTENCIA: Apague y desenchufe la herramienta

antes de realizar ajustes o de quitarle o ponerle accesorios.

AsegE/rese que el conmutador tipo gatillo est_ APAGADO.

La gala (E) puede ser ajustada en una de dos formas: para

cambiar el 6,ngulo de corte deseado y cambiar el espacio entre la

gu[a y el torno.

PARA CAMBIAR EL

AN DE CORTE

DESEADO (FIG. 5, 6)

Use la Ilave incluida

para aflojar (sin quitar)

los dos pernos de

la gu[a (Q). Alinee la

linea de indicaciOn del

6,ngulo deseado con la

I[nea de la ranura (R)

en la base (D). Ajuste

bien ambos pernos de

la gu[a antes de usarla.

FIG. 6

FIG.5

D

R

Q

G

Q

Para realizar cortes cuadrados m6,s precisos, desenchufe la

herramienta, afloja los dos pernos de la gu[a, empuje el brazo hacia

abajo hasta que el disco se extienda dentro de la base. Coloque una

escuadra contra el disco y ajuste la gala contra la escuadra. Ajuste

bien ambos pernos de la gu[a antes de usarla.

Puede que el torno (F) no sujete bien la pieza de trabajo al realizar

cortes a inglete, dependiendo del grosor de la pieza y el 6,ngulo de

inglete. Otros dispositivos auxiliares (tales como abrazaderas de

resorte, de barra o en C) ser6,n entonces necesarios para sujetar la

pieza a la gu[a al realizar estos cortes.

PARA CAMBIAR EL ESPACIO ENTRE LA GU|A Y EL TORNO

Con la Ilave incluida, afloje y retire ambos pernos de la gala (Q),

Ajuste la guia (E) al lugar deseado, Inserte ambos pernos de la guia

en los lugares previstos, Ajuste bien ambos pernos de la guia antes

de usarla.

Tope de profundidad (Fig. 1)

El tope de profundidad viene fijado de f6,brica para un disco de 355

mm (14 pulg.) nuevo, para evitar que el disco corte la superficie de