Page 1

Questions? See us on the World Wide Web at www.dewalt.com

¿Dudas? Visítenos en Internet: www.dewalt.com

Dúvidas? Visite-nos na Internet em www.dewalt.com.br

INSTRUCTION MANUAL

MANUAL DE INSTRUCCIONES

MANUAL DE INSTRUÇÕES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR

EL PRODUCTO.

INSTRUÇÕES DE OPERAÇÃO, CENTRO DE SERVIÇOS E CERTIFICADO

DE GARANTIA. ADVERTÊNCIA: LEIA ESTAS INSTRUÇÕES ANTES DE

UTILIZAR O PRODUTO.

D28700

14" (355 mm) Chop Saw

Cortadora/Tronzadora de metales de 14" (355 mm)

Serra de Corte Rápido de 355 mm (14")

Page 2

Important Safety Instructions

WARNING! Read and understand all instructions.

Failure to follow all instructions listed below may result

in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

• KEEP GUARDS IN PLACE and in working order.

English

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed

from tool before turning it on.

• KEEP WORK AREA CLEAN. Cluttered areas and benches

invite injuries.

• DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use

power tools in damp or wet locations, or expose them to rain.

Keep work area well lighted.

• KEEP CHILDREN AWAY. All visitors should be kept at a safe

distance from work area.

• MAKE WORKSHOP KID PROOF with padlocks, master

switches, or by removing starter keys.

• DON’T FORCE TOOL. It will do the job better and safer at the

rate for which it was designed.

• USE RIGHT TOOL. Don’t force tool or attachment to do a job for

which it was not designed.

• USE PROPER EXTENSION CORD. Make sure your extension

cord is in good condition. When using and extension cord, be

sure to use one heavy enough to carry the current your product

will draw. An undersized cord will cause a drop in line voltage

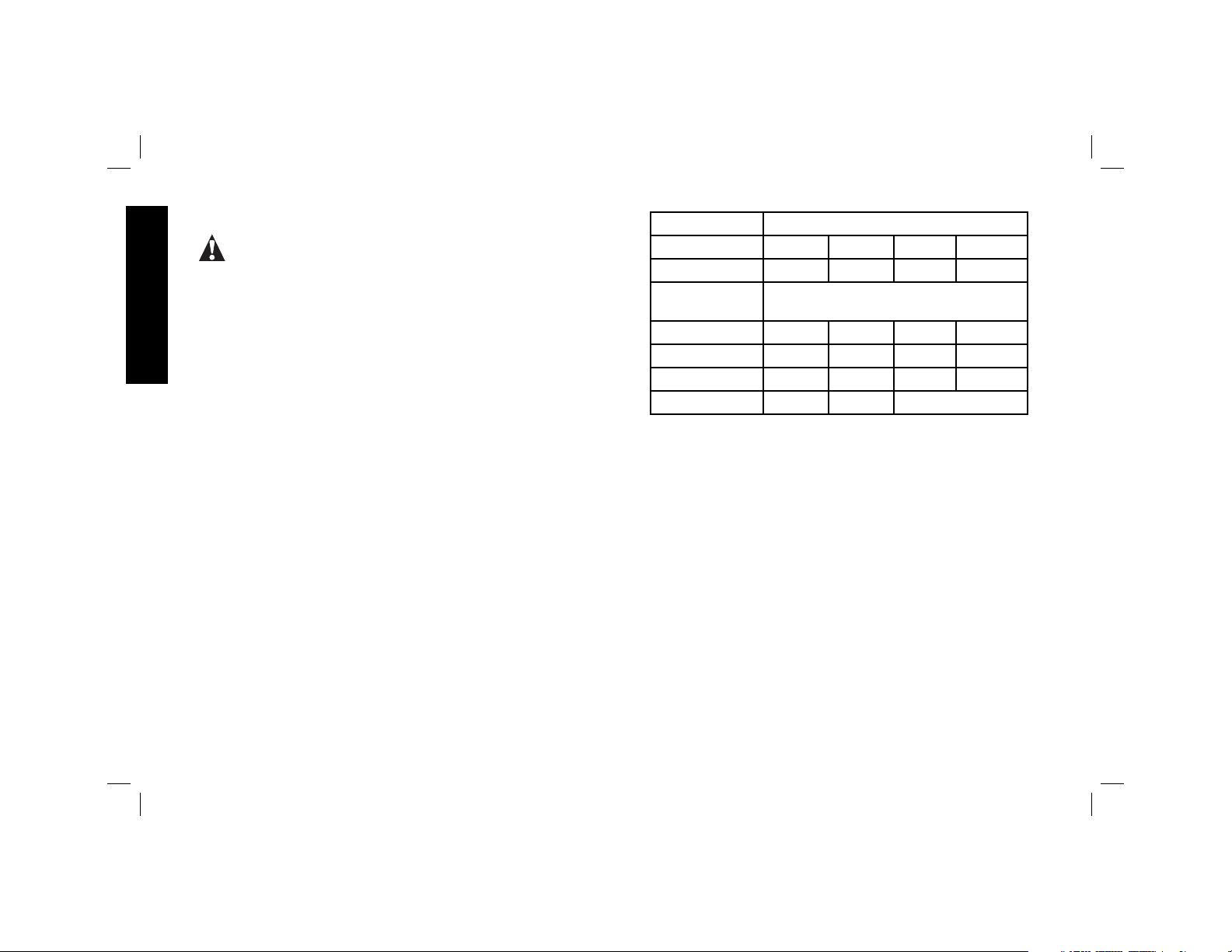

resulting in loss of power and overheating. The following table

shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gage.

The smaller the gage number, the heavier the cord.

Voltage (Volts)

120 - 127V 0 - 7 7 - 15 15 - 30 30 - 50

220 - 240V 0 - 15 15 - 30 30 - 60 60 - 100

Rated Ampere

range

0 - 6A 1.0 1.5 1.5 2.5

6 - 10A 1.0 1.5 2.5 4.0

10 - 12A 1.5 1.5 2.5 4.0

12 - 16A 2.5 4.0 Not Recommended

• WEAR PROPER APPAREL. Do not wear loose clothing,

neckties, rings, bracelets, or other jewelry which may get

caught in moving parts. Nonslip footwear is recommended.

Wear protective hair covering to contain long hair.

often cover moving parts and should also be avoided.

• ALWAYS USE SAFETY GLASSES which meet the ANSI Z87.1

requirements. Also use face or dust mask if cutting operation is

dusty. Everyday eyeglasses only have impact resistant lenses,

they are not safety glasses.

• SECURE WORK. Use clamps or a vise to hold work. It’s safer

than using your hand and it frees both hands to operate tool.

• DON’T OVERREACH. Keep proper footing and balance at all

times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for

best and safest performance. Follow instructions for lubricating

and changing accessories.

• DISCONNECT TOOLS before servicing; when changing accessories, such as blades, bits, cutters, and the like.

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make

sure switch is in off position before plugging in.

Total length of cord in meters (m)

Minimal cross-sectional area of the

cord in meters (mm

2

)

Air vents

11

Page 3

• USE RECOMMENDED ACCESSORIES. Consult the instruction

manual for recommended accessories. The use of improper

accessories may cause risk of injury to persons.

• NEVER STAND ON TOOL. Serious injury could occur if the tool

is tipped or if the cutting tool is unintentionally contacted.

• CHECK DAMAGED PARTS. Before further use of the tool,

a guard or other part that is damaged should be carefully

checked to determine that it will operate properly and perform

its intended function — check for alignment of moving parts,

binding of moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A guard or other

part that is damaged should be properly repaired or replaced.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

POWER OFF. Don’t leave tool until it comes to a complete stop.

• REPLACEMENT PARTS. When servicing use only identical

replacement parts.

• TO REDUCE THE RISK OF ELECTRIC SHOCK:

a. This equipment may have a polarized plug (one blade is

wider than the other.) This plug will fit in a polarized outlet

only one way. If the plug does not fit, contact a qualified

electrician to install the proper outlet.

b. The tool may be equipped with a 3-prong grounding type

plug. This plug is to be used in a grounded outlet only.

If the plug does not fit, contact a qualified electrician to

install the proper outlet.

c. Do not alter the plug in any way.

Additional Safety Rules for Chop Saws

• Always wear proper eye and respiratory protection.

• Before using, inspect the cutting wheel for cracks or

flaws. If such a crack or flaw is evident, discard the wheel.

The wheel should also be inspected whenever you think

the tool may have been dropped. Flaws may cause wheel

breakage.

• When starting the tool with a new or replacement wheel or

if you are unsure of the condition of the wheel, hold the tool

in a well protected area and let it run for one minute. If the

wheel has an undetected crack or flaw, it should burst in less

than one minute. Never start the tool with a person in line with

the wheel. This includes the operator.

• In operation, avoid bouncing the wheel or giving it rough

treatment. If this occurs, stop the tool and inspect the wheel for

cracks or flaws.

• Clean your chop saw periodically following the procedure in this

manual.

• Do not remove wheel guards or base.

• ALWAYS US E THE VISE OR SPECIAL FIXTURE TO CLAMP

WORK SECURELY. Other aids such as spring, bar, or

C-clamps may be appropriate for certain sizes and shapes of

workpiece. Use care in selecting and placing these clamps and

make a dry run before making a cut.

• Use only 14" type 1 wheels rated at 4100 rpm or higher.

• Allow cut off parts to cool before handling.

• Do not attempt to cut wood or plastic with this tool.

• NEVER CUT MAGNESIUM WITH THIS TOOL.

• Use chop saw in a well-ventilated area.

• Turn chop saw off before removing any pieces from the base.

• DO NOT CUT ELECTRICALLY LIVE MATERIAL.

• Do not use circular saw blades or any other toothed blades

with this tool. Serious injury may result.

• DO NOT OPERATE THIS TOOL NEAR FLAMMABLE

LIQUIDS, GASES OR DUST. Sparks or hot chips from cutting

or arcing motor brushes may ignite com bus tible materials.

• Do not use the side of the abrasive wheel as a deburring grinder.

This will substantially weaken the wheel creating an unsafe

condition. The wheel may come apart.

English

22

Page 4

CAUTION: Wear appropriate hearing protection during use.

Under some conditions and duration of use, noise from this

product may contribute to hearing loss.

CAUTION: Spark deflector will get hot. Avoid touching or adjusting

while hot. Keep cordset and materials away from spark deflector.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemi-

English

cals known to the State of California to cause cancer, birth defects,

or other reproduc tive harm. Some examples of these chemicals

are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber

(CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed

to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

WARNING: Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure. Direct particles away

from face and body.

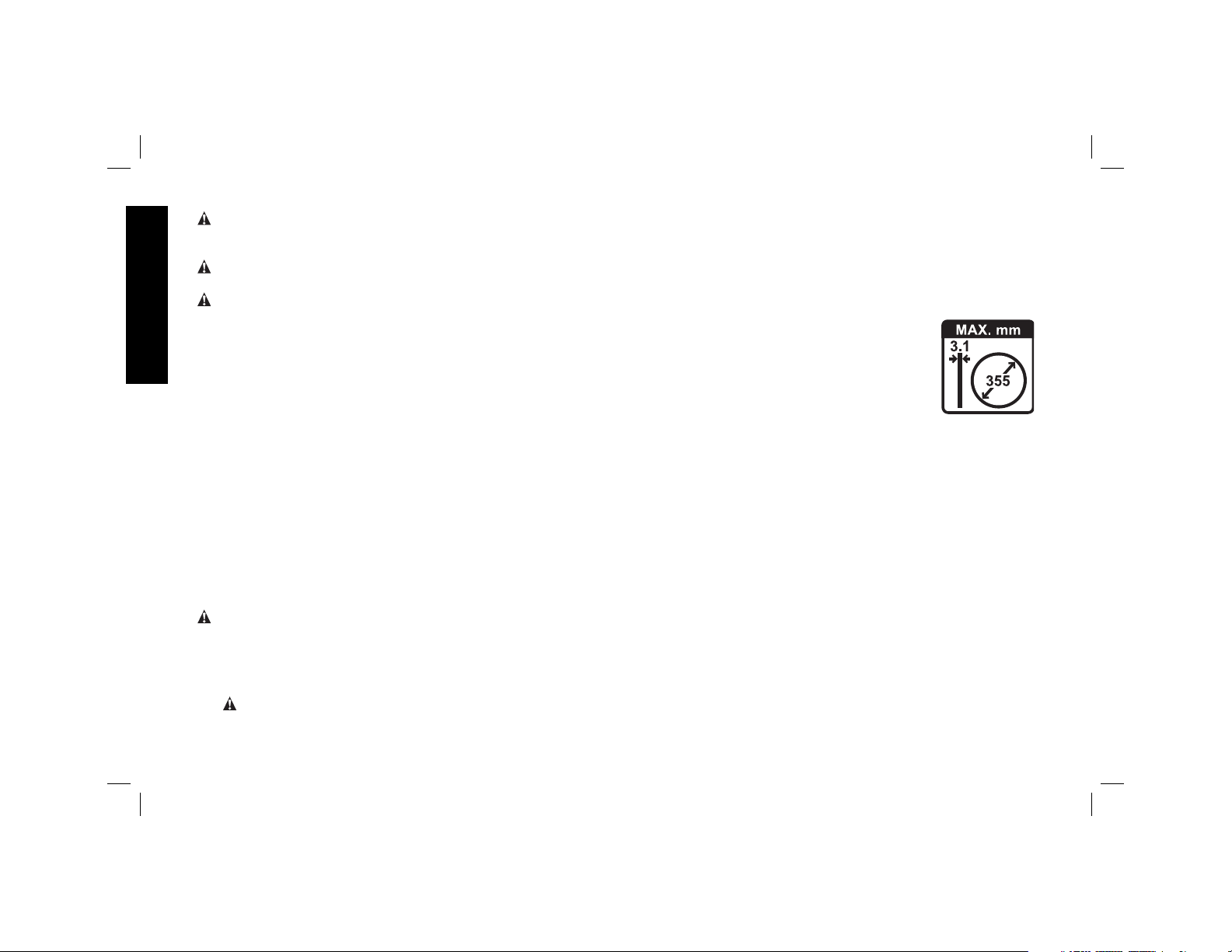

For your convenience and safety, the following warnings are on

your Heavy-Duty 14" (355 mm) Chop Saw:

FOR SAFE OPERATION READ THE INSTRUCTION

MANUAL.

DO NOT USE TOOTHED BLADES.

USE ONLY REINFORCED WHEELS RATED 4100 RPM OR

HIGHER.

WHEN SERVICING USE ONLY IDENTICAL REPLACEMENT

PARTS.

ALWAYS: WEAR EYE PROTECTION, USE GUARDS, CLAMP

WORK IN VISE, USE PROPER RESPIRATORY

PROTECTION.

DO NOT EXPOSE TO RAIN OR USE IN

DAMP LOCATIONS.

ONLY USE CHOP SAW WHEEL OF A MAX.

THICKNESS OF 3.1 mm AND A MAX.

DIAMETER OF 355 mm.

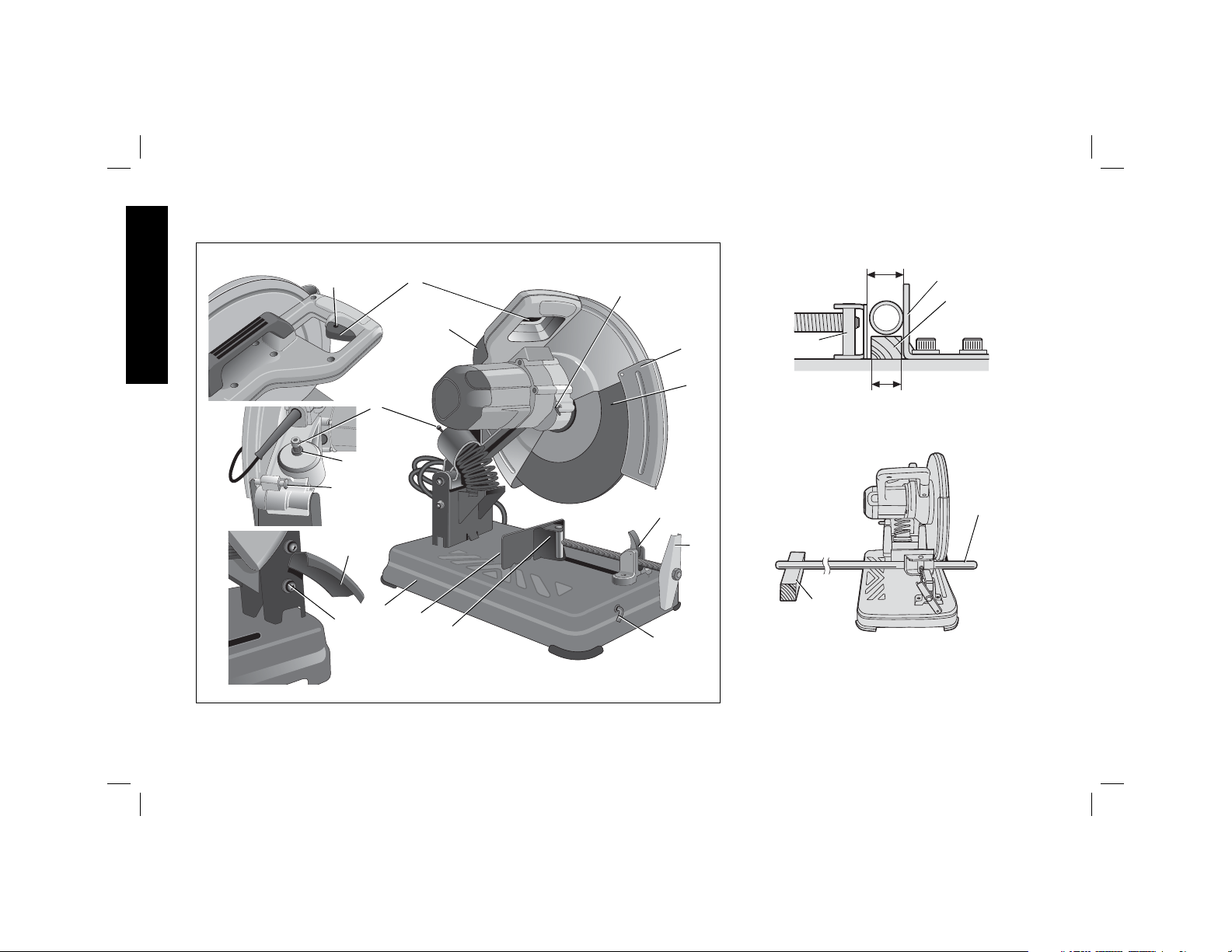

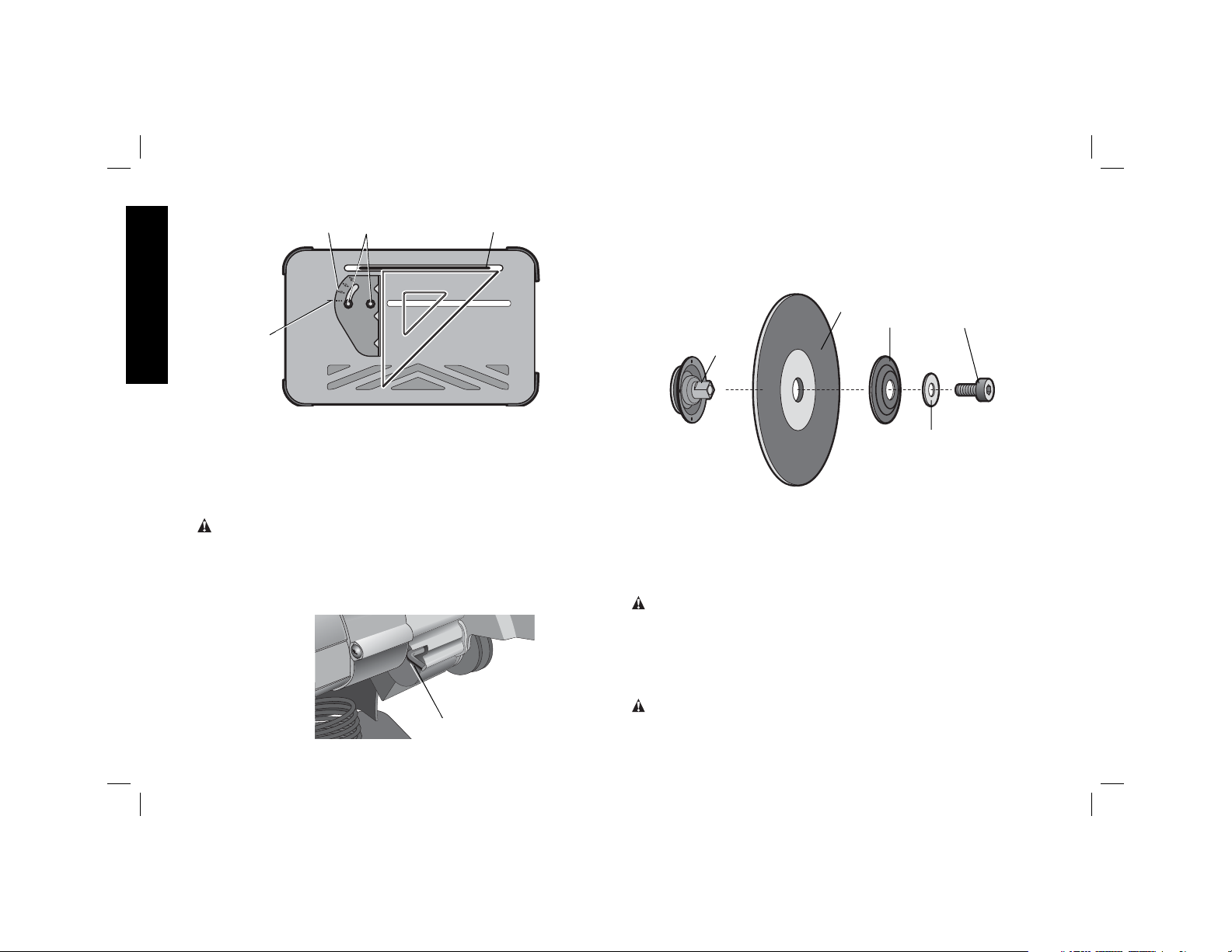

FEATURES (Fig. 1, 4)

A. Lock pin J. Wheel

B. Spark deflector screw K. Guard

C. Spark deflector L. Wheel lock lever

D. Base M. Depth stop bolt

E. Fence N. Trigger switch

F. Vise O. Padlock hole

G. 8 mm hex wrench P. Jam nut

H. Crank Q. Fence bolts

I. Vise lever

Power Supply

Be sure your power supply agrees with the nameplate marking.

A voltage decrease of more than 10% will cause a loss of power

and overheating.

Cutting Capacity

The wide vise opening and high pivot point provide cutting capacity

for many large pieces. Use the cutting capacity chart to determine

total maximum size of cuts that can be made with a new wheel.

33

Page 5

MAXIMUM CUTTING CAPACITY

NOTE: Capacity shown on chart assumes no wheel wear and optimum fence position.

Workpiece Shape:

A x B

90º Cutting Angle A = 4.5" A = 4-11/16" 4-1/2" x 5-1/8" A = 5-3/8"

(115 mm) (115 mm) (119 mm x 130 mm) (137 mm)

4" x 7-5/8"

(102 mm x 194 mm)

3" x 9"

(76 mm x 229 mm)

45º Cutting A = 3-13/16" A = 3-13/16" 4-1/2" x 3-13/16" A = 3-13/16"

Angle (98 mm) (98 mm) (115 mm x 98 mm) (98 mm)

English

CAUTION: CERTAIN LARGE, CIRCULAR OR IRREGULARLY

SHAPED OBJECTS MAY REQUIRE ADDITIONAL HOLDING

MEANS IF THEY CANNOT BE HELD SECURELY IN VISE.

CAUTION: DO NOT CUT MAGNESIUM WITH THIS TOOL.

Standard Equipment

1 14" (455 mm) Metal Cutting Abrasive Wheel

1 Wheel Wrench

1 Instruction manual

To Carry (Fig. 1)

Fold down unit to position where you can carry the saw. Push in

lock pin (A) to lock arm down.

Unlocking (Fig. 1)

To unlock tool and raise head, depress motor arm slightly and pull

lock pin (A) out. Motor arm will then pivot upward.

Spark Deflector Adjustment (Fig. 1)

To best deflect sparks away from surrounding persons and

materials, loosen the screw (B), adjust the spark deflector (C)

and then retighten screw. Do not allow cordset to come into

contact with deflector or sparks as damage to cordset may occur.

Depth Stop (Fig. 1)

Depth stop is set at the factory for a new 14" (455 mm) wheel to

prevent wheel from cutting into the supporting surface. To allow

more depth of cut, use the 8 mm hex wrench provided (G) to

loosen the depth stop bolt (M) and raise bolt to desired height and

then turn jam nut (P) clockwise until seated firmly on the casting.

Securely tighten the depth stop bolt before use.

CAUTION: When changing to a new wheel, readjust depth stop

to original position to prevent cutting into supporting surface.

44

Page 6

FIG. 1

English

FIG. 2

O

N

L

DIAMETER OF WORKPIECE

E

SPACER

C

K

F

BLOCK

J

M

P

FIG. 3

A

I

C

D

B

E

F

H

G

WIDTH OF SPACER BLOCK

CUT-OFF

END

BLOCK

55

Page 7

Trigger Switch (Fig. 1)

To start the tool, depress the trigger switch (N). To turn the tool off,

release the trigger switch. Keep hands and material from wheel until

it has coasted to a stop.

To prevent unauthorized use of tool, install a standard padlock (not

included) into the padlock hole (O) located in the trigger.

Material Clamping and Supporting

• Angles are best clamped and cut with both legs resting against

base.

• A spacer block slightly narrower than the workpiece can be

used to increase wheel utilization (Fig. 2).

• Long workpieces must be supported by a block so it will be

level with top of base (Fig. 3). The cut off end should be free to

fall downward to avoid wheel binding.

Vise Operation (Fig. 4)

The vise (F) has a quick-travel feature. To release the vise when it

is clamped tightly, turn the crank (H) counterclockwise one or two

times to remove clamping pressure. Lift vise lever (I) up. Pull crank

assembly out as far as desired. Vise may be pushed forward into

work without cranking. Lower vise lever (I) then tighten vise (F) on

work by using crank (H).

FIG. 4

E

Q

FORWARD

F

I

H

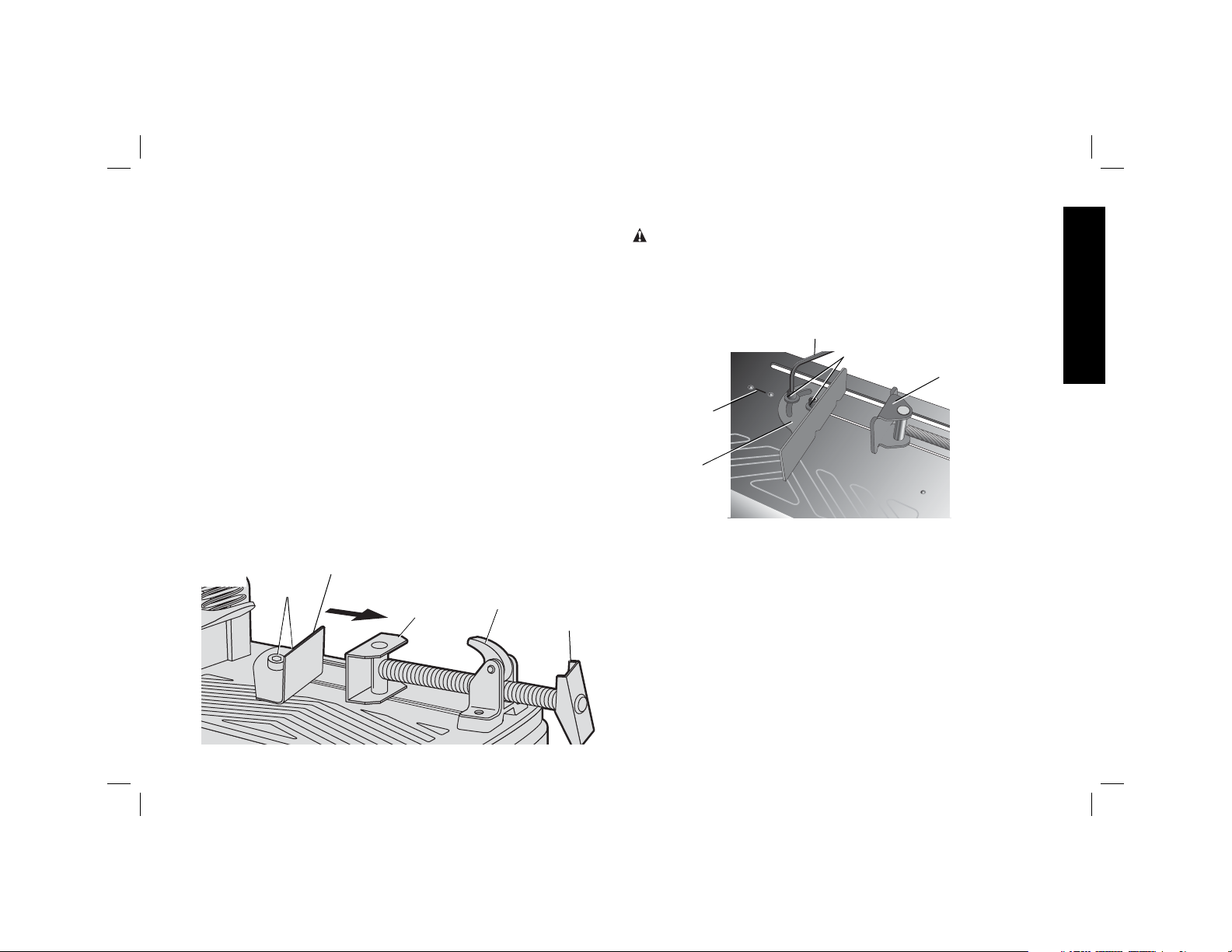

Fence Operation (Fig. 5, 6)

WARNING: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or

accessories. Be sure the trigger switch is in the OFF position.

The fence (E) can be adjusted two ways: to change desired cutting

angle and to change spacing between the fence and vise.

FIG. 5

R

E

TO CHANGE THE DESIRED CUTTING ANGLE

Use the wrench provided to loosen (do not remove) the two fence

bolts (Q). Align the desired angle indicator line with the slot line (R)

in the base (D). Securely tighten both fence bolts before use.

For more accurate square cuts, disconnect the power supply,

loosen the two fence bolts, push arm down until wheel extends into

base. Place a square against the wheel and adjust fence against

the square. Securely tighten both fence bolts before use.

When making a miter cut, the vise (F) may not clamp securely,

depending on the thickness of the workpiece and the miter angle.

Other aids (such as spring, bar or C-clamps) will be necessary to

secure the workpiece to the fence when making these cuts.

G

Q

F

English

6

6

Page 8

English

FIG. 6

R

E

Q

J

TO CHANGE SPACING BETWEEN THE FENCE AND VISE

Using the wrench provided, loosen and remove the two fence bolts

(Q). Adjust the fence (E) to desired locations. Insert both fence bolts

in provided locations. Securely tighten both fence bolts before use.

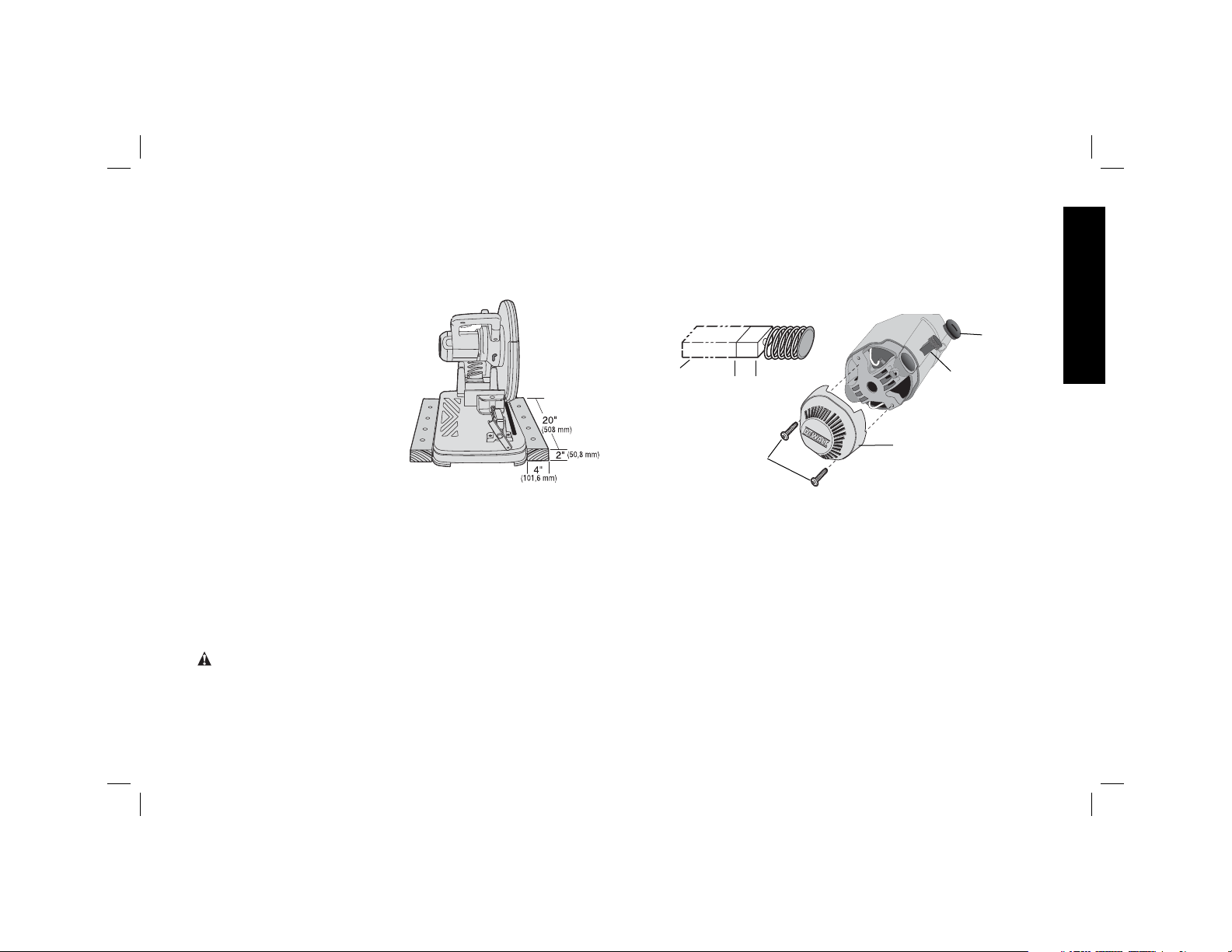

Removal and Installation of Wheels

(Fig. 7, 8)

WARNING: Turn off and unplug the tool before making

any adjustments or removing or installing attachments or

accessories. Be sure the trigger switch is in the OFF position.

Do not make any adjustment while the wheel is in motion.

Do not make any adjustment while chop saw is plugged into

power supply.

FIG. 7

L

1. Push in wheel lock lever (L) and rotate wheel (J) by hand

until wheel lock lever engages slot in inside flange (S) to lock

wheel. Loosen the bolt (T) counterclockwise in the center of the

abrasive wheel with the 8 mm hex wrench (G). Bolt has righthand thread.

FIG. 8

S

J

V

T

U

2. Remove the bolt (T), washer (U), outside flange (V) and old

wheel (J).

3. Make sure flange surfaces are clean and flat. Install the new

abrasive wheel by reversing the above steps.

4. Do not overtighten bolt.

WARNING: Check the work surface that the chop saw rests

on when replacing with a new abrasive wheel. It is possible that

the wheel may contact ANY ITEMS OR STRUCTURE THAT

EXTENDS ABOVE work surface (under the base) when the arm

is fully lowered.

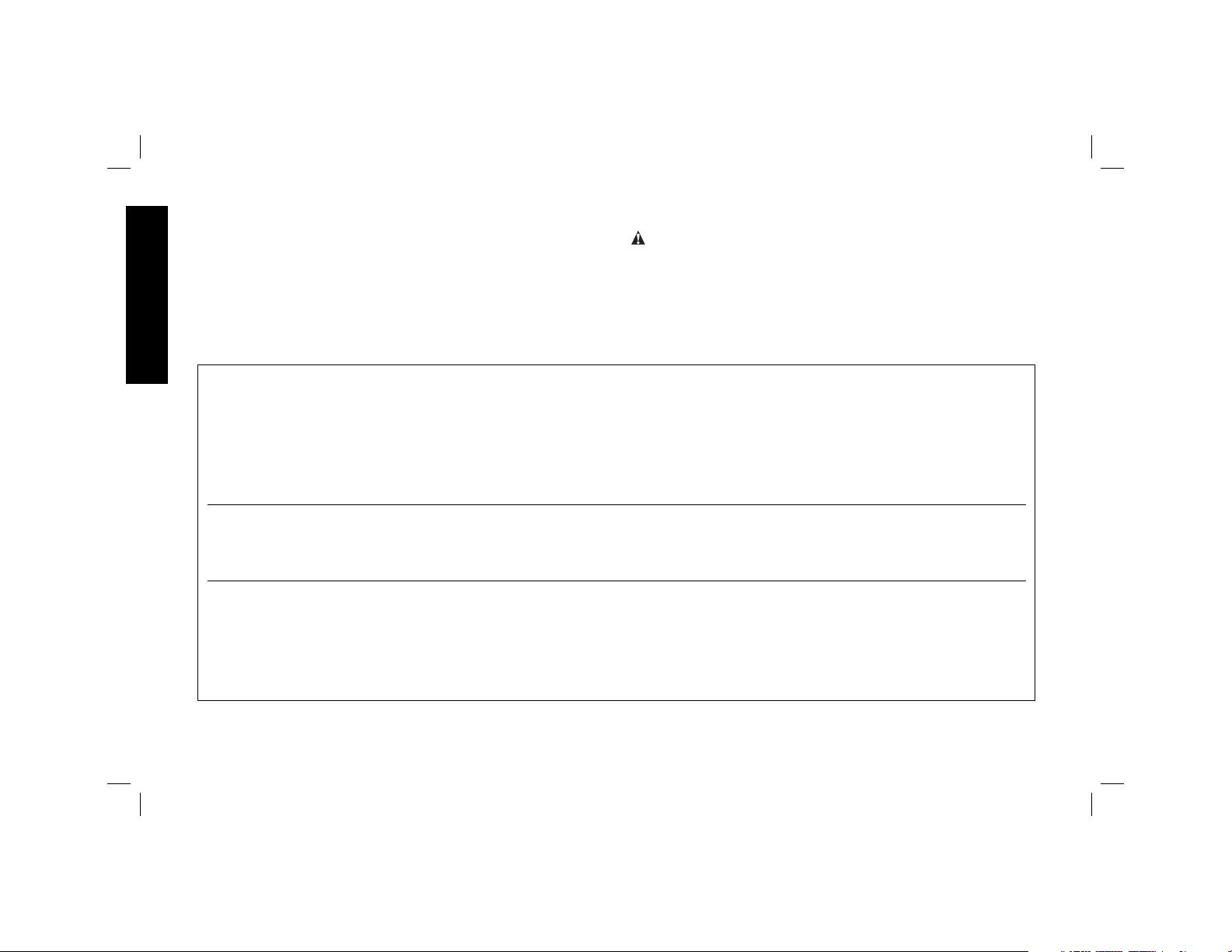

Mounting

CAUTION: Tool must be supported on stable, level, non-skid

surface to prevent unexpected movement when operating.

77

Page 9

PROCEDURE FOR PERMANENT MOUNTING

1. Mark through the holes in the base (D) and drill two holes,

5/16" (7.94 mm) diameter, through the mounting surface.

2. Use 1/4" (6.35 mm) fasteners to securely mount base to

mounting surface.

CRADLE MOUNTING (FIG. 9)

1. Cut two boards approximately

20" long x 2" high x 4" wide

(508 x 50.8 x 101.6 mm).

2. Place the chop saw at

desired work location.

3. Place boards tightly along

side and nail to work surface.

FIG. 9

Operation Tips for

More Accurate Cuts

• Allow the wheel to do the

cutting. Excessive force will

cause the wheel to glaze reducing cutting efficiency and/or to

deflect causing inaccurate cuts.

• Properly adjust fence angle.

• Make sure material is laying flat across base.

• Properly clamp material to avoid movement and vibration.

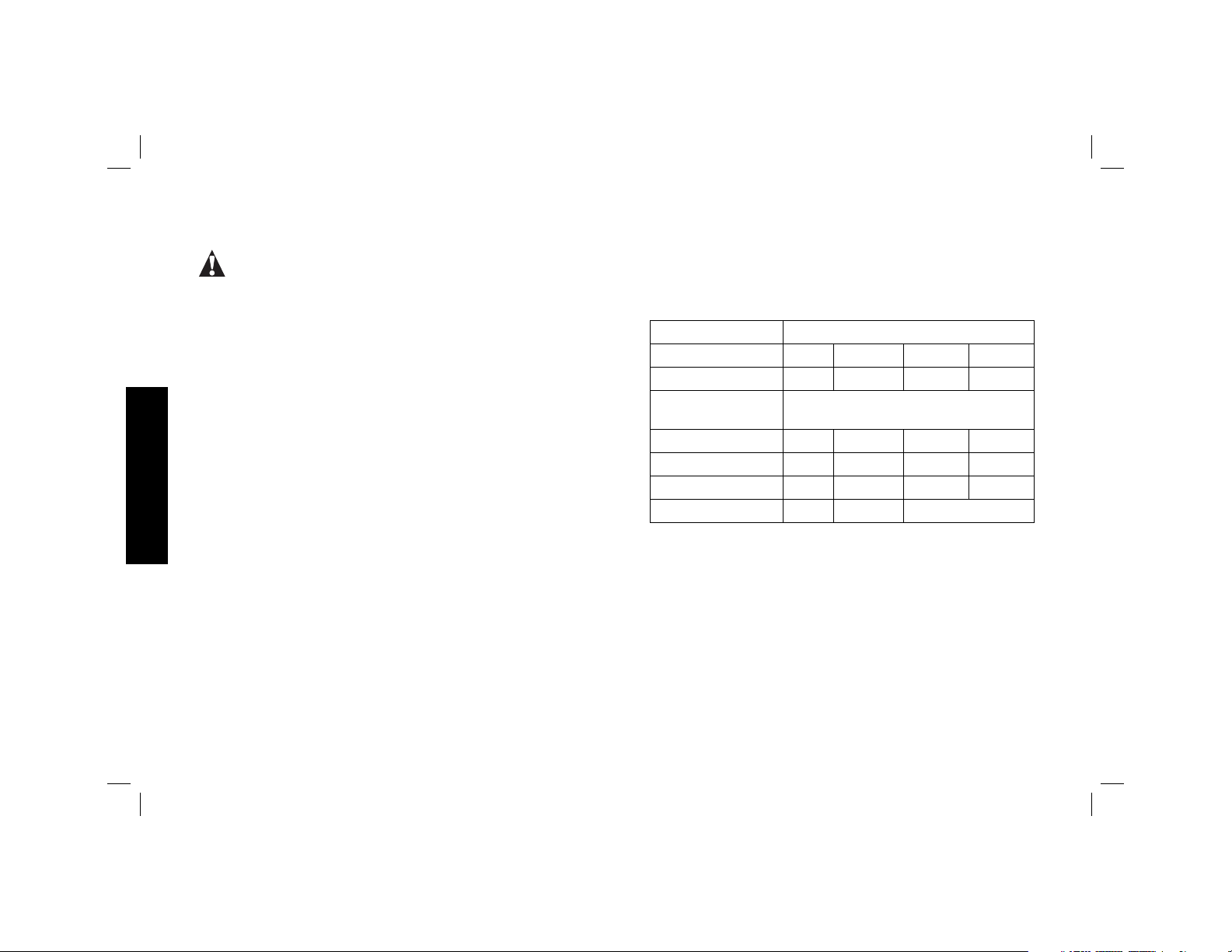

MAINTENANCE

Motor Brush Inspection and

Replacement (Fig. 10)

WARNING: Turn off and unplug the tool. Be sure the trigger

switch is in the OFF position.

Brushes should be regularly inspected for wear. To inspect

brushes, unscrew the two end cap screws (W) and remove end cap

(X). Remove brush cap (Z). Brushes (Y) should slide freely in brush

box. If brushes are worn down to .3" (8 mm) as shown in Figure 10

they should be replaced. To reinstall, push new brush back into

brush box. If replacing existing brush, maintain same orientation

as when removed. Replace the brush cap (do not overtighten).

Replace end cap and two screws. Tighten securely.

FIG. 10

Y

.3"

(8 mm)

X

W

Y

Cleaning

Blowing dust and grit out of the main housing by means of an air

hose is recommended and may be done as often as dirt is seen

collecting in and around the air vents. Always wear proper eye

and respiratory protection.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment should be performed by authorized service centers

or other qualified service organizations, always using identical

replacement parts.

NOTE: Unit may be converted to a 3-wire twist lock cord set at an

authorized service center.

English

Z

88

Page 10

Lubrication

Closed-type, grease-sealed ball bearings are used throughout.

These bearings have sufficient lubrication packed in them at the

factory to last the life of the chop saw.

English

Accessories

WARNING: The use of any other accessory not recommended

for use with this tool could be hazardous.

Use only high-strength Type 1 organic bonded wheels rated

4100 rpm or higher.

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center.

Troubleshooting Guide

TROUBLE! TOOL WILL NOT START

WHAT’S WRONG? WHAT TO DO…

1. Tool not plugged in. 1. Plug in saw.

2. Fuse blown or circuit breaker tripped. 2. Replace fuse or reset circuit breaker.

3. Cord damaged. 3. Have cord replaced by authorized service center.

4. Brushes worn out. 4. Replace brushes.

TROUBLE! TOOL MAKES UNSATISFACTORY CUTS

WHAT’S WRONG? WHAT TO DO…

1. Glazed wheel. 1. Dress the wheel or replace with a new one.

2. Workpiece incorrectly placed or clamped. 2. Firmly clamp and support workpiece.

TROUBLE! BLADE DOES NOT COME UP TO SPEED

WHAT’S WRONG? WHAT TO DO…

1. Extension cord too light or too long. 1. Replace with adequate size cord. See chart on page 1.

2. Low voltage. 2. Contact your electric company.

3. Low generator voltage. 3. Check generator output voltage. Reduce number of tools powered

by the generator.

99

Page 11

Troubleshooting Guide…

TROUBLE! TOOL VIBRATES EXCESSIVELY DURING CUT

WHAT’S WRONG? WHAT TO DO…

1. Tool not mounted securely to stand or work bench. 1. Tighten all mounting hardware. See page 8, Procedure for

Permanent Mounting.

2. Damaged wheel. 2. Replace wheel.

3. Workpiece not clamped properly. 3. Refer to Material Clamping and Supporting page 6.

TROUBLE! DOES NOT MAKE ACCURATE CUTS

WHAT’S WRONG? WHAT TO DO…

1. Fence not adjusted correctly. 1. Check and adjust. See Fence Operation on page 6.

2. Wheel is not square to fence. 2. Check and adjust.

3. Excessive force used to make cut. 3. Reduce cutting force, let the wheel do the work.

4. Work piece moving. 4. Clamp workpiece securely. See Material Clamping and

Supporting, page 6. Make sure material is laying flat against the

base.

TROUBLE! CANNOT MOVE ARM

WHAT’S WRONG? WHAT TO DO…

1. Lock down pin is engaged. 1. Push down slightly on the arm, pull down lock down pin and

raise arm.

TROUBLE! MATERIAL MOVES DURING CUT

WHAT’S WRONG? WHAT TO DO…

1. Fence slipping or workpiece incorrectly placed or clamped. 1. See Material Clamping and Supporting, page 6.

2. Vise too loose 2. Tighten vise clamping.

3. Excessive cutting force. 3. Reduce cutting force.

English

1010

Page 12

Instrucciones de seguridad

importantes

¡ADVERTENCIA! Lea todas las instrucciones hasta

comprenderlas. El incumplimiento con alguna de las

instrucciones enumeradas más abajo puede resultar en descarga

eléctrica, incendio y/o lesiones corporales serias.

CONSERVE ESTAS INSTRUCCIONES

• MANTENGA LOS PROTECTORES EN SU SITIO y en buenas

condiciones de funcionamiento.

• QUITE LAS LLAVES DE AJUSTE. Hágase el hábito de

comprobar que la herramienta no tenga ninguna llave de ajuste

puesta antes de encenderla.

• MANTENGA LIMPIA EL ÁREA DE TRABAJO. Las áreas

y mesas de trabajo desordenadas aumentan el riesgo de

lesiones.

• NO UTILICE LA HERRAMIENTA EN AMBIENTES

PELIGROSOS. No utilice máquinas herramienta en lugares

Español

húmedos o mojados ni las exponga a lluvia. Mantenga el área

de trabajo bien iluminada.

• MANTENGA ALEJADOS A NIÑOS. Toda visita debería

mantenerse a una distancia segura del área de trabajo.

• QUE SU TALLER SEA A PRUEBA DE NIÑOS. Para ello

utilice candados o conmutadores maestros o quite las llaves de

arranque.

• NO FUERCE LA HERRAMIENTA. La herramienta hace el

trabajo mejor y más seguro a la velocidad para la cual fue

diseñada.

• UTILICE LA HERRAMIENTA CORRECTA. No fuerce la

herramienta o el accesorio a que realice una tarea para la cual

no fue diseñada.

• USE EL ALARGADOR INDICADO. Cerciórese de que

su alargador esté en buenas condiciones. Cuando use un

alargador, asegúrese de que sea lo bastante resistente como

para llevar la corriente que su producto requerirá. Un alargador

de menor calibre causará una caída en el voltaje de la línea

lo que resultará en pérdida de potencia y sobrecalentamiento.

El siguiente cuadro muestra el tamaño correcto a utilizar,

dependiendo del largo del cable y del amperaje nominal. En

caso de tener dudas, utilice el de mayor calibre. Mientras menor

sea el número del calibre, mayor la capacidad del cable.

Ténsion (Volts) Longitud del cable in metros (m)

120 - 127V 0 - 7 7 - 15 15 - 30 30 - 50

220 - 240V 0 - 15 15 - 30 30 - 60 60 - 100

Corriente nominal

(Ampéres)

0 - 6A 1.0 1.5 1.5 2.5

6 - 10A 1.0 1.5 2.5 4.0

10 - 12A 1.5 1.5 2.5 4.0

12 - 16A 2.5 4.0 No recomendado

• USE ROPA ADECUADA. No lleve ropa suelta, guantes,

corbatas, anillos, pulseras u otras joyas que podrían

engancharse en las piezas móviles. Se recomienda el uso

de calzado antideslizante. Cúbrase y recójase el pelo si lo

tiene largo. Los orificios de ventilación suelen cubrir piezas

en movimiento, por lo que también se deben evitar.

• USE SIEMPRE GAFAS DE SEGURIDAD que cumplan con los

requisitos de ANSI Z87.1. Utilice además una máscara para la

cara o guardapolvo si la operación de corte genera demasiado

polvo. Los anteojos de uso diario sólo tienen lentes resistentes

a golpes, no son gafas de seguridad.

• AFIRME BIEN SU TRABAJO. Utilice abrazaderas o tornillos

para sujetar las piezas en las que trabaja. Es más seguro, y así

podrá utilizar ambas manos para operar la herramienta.

1111

Sección nominal mínima del cable

in milímetros quadrados (mm

2

)

Page 13

• NO SE SOBREEXTIENDA. Manténgase siempre bien apoyado

y equilibrado.

• CUIDE LAS HERRAMIENTAS. Mantenga las herramientas

afiladas y limpias para un funcionamiento mejor y más seguro.

Siga las instrucciones para lubricar y cambiar accesorios.

• DESENCHUFE LAS HERRAMIENTAS antes de reparar o

mantenerlas; cuando cambie accesorios tales como hojas,

brocas, mecanismos de corte y otros por el estilo.

• REDUZCA EL RIESGO DE PUESTAS EN MARCHA

ACCIDENTALES. Asegúrese de que el conmutador esté

apagado antes de enchufarla.

• UTILICE LOS ACCESORIOS RECOMENDADOS. Consulte

el manual de instrucciones para conocer los accesorios

recomendados. El uso de accesorios no debidos puede

producir un riesgo de lesiones corporales.

• NUNCA SE PARE SOBRE LA HERRAMIENTA. Podría sufrir

graves lesiones si la herramienta se cae a un lado o si se entra

en contacto no intencionado con la herramienta de corte.

• REVISE LAS PIEZAS DAÑADAS. Antes de continuar usando

la herramienta, se debe revisar cuidadosamente el protector o

cualquier otra pieza dañada para determinar que funcionará

correctamente y realizará la función para la que fue diseñada verifique que las piezas móviles estén alineadas, que no estén

atascadas, rotas, montadas una sobre otra o de otra forma

que pudiera afectar su operación. Cualquier protector o pieza

dañada debe repararse debidamente o cambiarse.

• JAMÁS DEJE SIN SUPERVISIÓN UNA HERRAMIENTA EN

FUNCIONAMIENTO. APAGUE LA HERRAMIENTA. No deje la

herramienta hasta que no se haya detenido completamente.

• REPUESTOS. Cuando realice mantenimiento, use sólo

repuestos originales.

• PARA REDUCIR EL RIESGO DE DESCARGA ELÉCTRICA:

a. Puede que este equipo tenga un enchufe polarizado (con

una para más ancha que la otra.) Este enchufe sólo puede

ser insertado en una toma de corriente polarizada de

una manera. Si el enchufe no entra, comuníquese con un

electricista calificado para que instale la toma de corriente

apropiada.

b. Puede que la herramienta venga equipada con un enchufe

con conexión a tierra de tres patas. Este enchufe sólo puede

ser utilizado en una toma de corriente con conexión a tierra.

Si el enchufe no entra, comuníquese con un electricista

calificado para que instale la toma de corriente apropiada.

c. No altere el enchufe de ninguna forma.

Reglas de seguridad adicionales para

tronzadoras de metal

• Use siempre protección ocular y respiratoria apropiada.

• Antes de usarla, revise el disco de corte para verificar que

no esté trizado o tenga fallas. Si tuviera alguna trizadura o

falla, descarte el disco. También se debe inspeccionar el

disco siempre que piense que la herramienta pudiera haber

caído. Las fallas pueden provocar la rotura del disco.

• Cuando arranque la herramienta con un disco nuevo o de

repuesto o si no está seguro de la condición del disco,

sostenga la herramienta en un lugar bien protegido y

déjela andar por un minuto. Si el disco tiene una trizadura

o falla que haya pasado inadvertida, se debería romper

en pedazos en menos de un minuto. Nunca encienda la

herramienta cuando haya una persona alineada con el disco.

Esto incluye al operador.

• Durante la operación, evite hacer rebotar el disco o tratarlo

bruscamente. Si ello sucediera, detenga la herramienta y

revise que el disco no tenga trizaduras o fallas.

• Limpie su sierra circular estacionaria periódicamente, siguiendo

el procedimiento de este manual.

• No quite los protectores del disco o la base.

• SIEMPRE USE EL TORNO O DISPOSITIVO DE FIJACIÓN

ESPECIAL PARA SOSTENER BIEN LA PIEZA DE TRABAJO.

1212

Español

Page 14

Otros dispositivos tales como abrazaderas de resorte, de barra

o en C pueden ser apropiadas para piezas de trabajo de

diferentes tamaños y formas. Tenga cuidado al seleccionar y

colocar estas abrazaderas y haga un movimiento de práctica

antes de hacer un corte.

• Use sólo discos tipo 1 de 355 mm (14 pulg.) para 4100 rpm o

superiores.

• Deje que las piezas cortadas se enfríen antes de cogerlas.

• No intente cortar madera o plástico con esta herramienta.

• NUNCA CORTE MAGNESIO CON ESTA HERRAMIENTA.

• Use la sierra circular estacionaria en un lugar bien ventilado.

• Apague la sierra circular estacionaria antes de quitar cualquier

pieza de su base.

• NO CORTE MATERIALES CARGADOS DE ELECTRICIDAD.

• No use hojas para sierras circulares ni ninguna otra hoja

dentada con esta herramienta. Pueden producirse lesiones

graves.

• NO OPERE ESTA HERRAMIENTA CERCA DE LÍQUIDOS,

Español

GASES O POLVOS INFLAMABLES. Las chispas o partículas

calientes generadas del corte o las escobillas del motor podrían

encender materiales combustibles.

• No use el lado del disco abrasivo como pulidor de rebabas. Esto

debilitará significativamente el disco y creará una condición

poco segura. El disco podría desarmarse.

ATENCIÓN: Use protección auditiva apropiada durante

el uso de esta herramienta. Bajo algunas condiciones y

duraciones de uso, el ruido producido por este producto puede

contribuir a la pérdida auditiva.

ATENCIÓN: El deflector de chispas se calienta. Evite tocarlo

o ajustarlo mientras está caliente. Mantenga cables y materiales

alejados del deflector de chispas.

ADVERTENCIA: Algunos tipos de polvo, como aquellos

generados por el lijado, serruchado, pulido y taladrado eléctrico

y otras actividades de construcción, contienen químicos que el

estado de California sabe causan cáncer, defectos de nacimiento

y otros daños reproductivos. Algunos ejemplos de estos químicos

son:

• plomo procedente de pinturas con base de plomo,

• óxido de silicio procedente de ladrillos, cemento y otros

productos de mampostería, y

• arsénico y cromo provenientes de maderas tratadas con

químicos (arseniato de cobre cromado).

El peligro derivado de la exposición a estos materiales varía en

función de la frecuencia con que se realice este tipo de trabajo.

Para reducir su exposición a estos químicos: trabaje en una

zona bien ventilada y llevando equipos de seguridad aprobados,

como mascarillas antipolvo especialmente diseñadas para filtrar

partículas microscópicas.

• Evite el contacto prolongado con polvo generado por el

lijado, serruchado, pulido y taladrado eléctricos y otras

actividades de construcción. Vista ropa protectora y lave las

áreas de la piel expuestas con agua y jabón. Si permite que el

polvo se introduzca en su boca o sus ojos, o que quede sobre la

piel, puede favorecer la absorción de químicos peligrosos.

ADVERTENCIA: Siempre use protección respiratoria aprobada

por NIOSH (Instituto Nacional de Seguridad y Salud en el Trabajo)

u OSHA (Administración de Seguridad y Salud en el Trabajo)

apropiada para la exposición al polvo. Dirija las partículas en

dirección contraria a la cara y el cuerpo.

Para su conveniencia y seguridad, su tronzadora de metales de

14 pulg. (355 mm) tiene las siguientes advertencias:

PARA OPERARLA DE UNA MANERA SEGURA, LEA EL

MANUAL DE INSTRUCCIONES.

NO UTILICE HOJAS DENTADAS.

UTILICE SÓLO DISCOS REFORZADOS CALIFICADOS

PARA 4100 RPM O SUPERIORES.

CUANDO REALICE MANTENIMIENTO, USE SÓLO

REPUESTOS ORIGINALES.

1313

Page 15

CAPACIDAD MÁXIMA DE CORTE

NOTA: La capacidad indicada en la tabla supone que el disco no está desgastado y que la guía está en la posición óptima.

Forma de la pieza

de trabajo:

Ángulo de corte A = 115 mm A = 4-11/16" 115 mm x 130 mm A = 137 mm

de 90º (4,5") (119 mm) (4-1/2" x 5-1/8") (5-3/8")

102 mm x 194 mm

(4" x 7-5/8")

76 mm x 229 mm

(3" x 9")

Ángulo de corte A = 98 mm A = 98 mm 115 mm x 98 mm A = 98 mm

de 45º (3-13/16") (3-13/16") (4-1/2” x 3-13/16") (3-13/16")

SIEMPRE: UTILICE PROTECCIÓN OCULAR; USE LOS

PROTECTORES DE HOJA; SUJETE LA PIEZA DE

TRABAJO CON EL TORNO; UTILICE LA PROTECCIÓN

RESPIRATORIA APROPIADA.

NO EXPONGA A LLUVIA NI USE EN LUGARES

HÚMEDOS.

USE ÚNICAMENTE DISCOS PARA CORTE

CON UN ESPESOR MÁXIMO DE 3.1 mm Y

DIÁMETRO DE 355 mm.

CARACTERÍSTICAS (Fig. 1, 4)

A. Clavija de fijación J. Disco

B. Tornillo deflector de chispas K. Protector

C. Deflector de chispas L. Palanca de fijación del disco

D. Base profundidad M. Perno de tope de

E. Guía N. Conmutador tipo gatillo

A x B

Español

F. Torno O. Orificio para insertar candado

G. Llave hexagonal de 8 mm P. Tuerca de obstrucción

H. Manivela Q. Pernos para la guía

I. Palanca del torno

Alimentación Eléctrica

Compruebe que su suministro eléctrico concuerde con el indicado

en la placa nominal.

Una reducción de voltaje superior al 10% provocará pérdida de

potencia y sobrecalentamiento.

Capacidad de Corte

La amplitud de apertura del torno y la altura del punto de pivote

proporcionan capacidad de corte para varias piezas grandes. Use

la tabla de capacidad de corte para determinar el tamaño máximo

total de los cortes que se pueden realizar con un disco nuevo.

14

Page 16

FIG. 1

FIG. 2

O

N

L

DIÁMETRO DE LA PIEZA

DE TRABAJO

E

BLOQUE

C

K

J

M

F

ANCHO DEL BLOQUE

ESPACIADOR

ESPACIADOR

Español

P

A

I

C

D

B

E

F

H

G

FIG. 3

EXTREMO A

CORTAR

BLOQUE

1515

Page 17

ATENCIÓN: PUEDE QUE CIERTOS OBJETOS GRANDES,

CIRCULARES O DE FORMAS IRREGULARES REQUIERAN

DE SOPORTE ADICIONAL SI NO PUEDEN SER SUJETOS

FIRMEMENTE EN EL TORNO.

ATENCIÓN: NO CORTE MAGNESIO CON ESTA

HERRAMIENTA.

Equipo Estándar

1 disco abrasivo de 355 mm (14 pulg.) para cortar metales

1 Llave para el disco

1 Manual de instrucciones

Para Portar (Fig. 1)

Doble la unidad a una posición que le permita portar la sierra.

Empuje la clavija de fijación (A) para fijar el brazo hacia abajo.

Para Quitar el Seguro (Fig. 1)

Para quitar el seguro y elevar la cabeza de la herramienta, presione

el brazo del motor ligeramente y tire de la clavija de fijación (A) para

quitarla. El brazo del motor se levantará.

Ajuste del Deflector de Chispas (Fig. 1)

Para deflectar mejor las chispas de las personas y los materiales

circundantes, afloje el tornillo (B), ajuste el deflector de chispas

(C) y vuelva a ajustar el tornillo. No permita que el cable entre en

contacto con el deflector o las chispas para evitarle daños.

Tope de Profundidad (Fig. 1)

El tope de profundidad viene fijado de fábrica para un disco de 355

mm (14 pulg.) nuevo, para evitar que el disco corte la superficie de

apoyo. Para permitir una mayor profundidad de corte, use la llave

hexagonal de 8 mm incluida (G) para aflojar el perno de tope de

profundidad (M). Luego eleve el perno a la altura deseada y gire

la tuerca de obstrucción (P) en dirección de las manillas del reloj

hasta que queden firmemente asentadas sobre la moldura. Ajuste

bien el perno de tope de profundidad antes de usarlo.

ATENCIÓN: Cuando cambie el disco por uno nuevo, vuelva

a ajustar el tope a la posición original para evitar que corte la

superficie de apoyo.

Conmutador Tipo Gatillo (Fig. 1)

Para arrancar la herramienta, presione el conmutador tipo gatillo

(N). Para apagar la herramienta, suelte el conmutador tipo gatillo.

Mantenga las manos y el material alejados del disco hasta que se

haya detenido completamente.

Para prevenir el uso no autorizado de la herramienta, instale un

candado estándar (no incluido) en el orificio para candados (O)

ubicado en el gatillo.

Soporte y Fijación del Material

• Podrá sujetar y cortar ángulos mejor con ambas piernas

descansando contra la base.

• Se puede utilizar un bloque espaciador ligeramente más

angosto que la pieza de trabajo para aumentar la utilización

de la rueda (Fig. 2).

• Las piezas de trabajo largas deben ser soportadas por un

bloque para que estén al mismo nivel que la parte superior

de la base (Fig. 3). El extremo a cortar debería poder caer

libremente para evitar que el disco se atasque.

Operación del Torno (Fig. 4)

El torno (F) tiene una característica que permite soltarlo

rápidamente. Para soltar el torno cuando está bien ajustado, gire

la manivela (H) en dirección contraria a las manillas del reloj una

o dos veces para liberar la presión de ajuste. Levante la palanca

del torno (I). Tire de la unidad de la manivela lo más que desee.

El torno puede ser empujado hacia la pieza de trabajo sin tener

que girar la manivela. Baje la palanca del torno (I) y luego ajuste el

torno (F) en la pieza de trabajo, girando la manivela (H).

Español

1616

Page 18

FIG. 4

E

Q

HACIA ADELANTE

F

I

Operación de la Guía (Fig. 5, 6)

ADVERTENCIA: Apague y desenchufe la herramienta antes

de realizar ajustes o de quitarle o ponerle accesorios.

Asegúrese que el conmutador tipo gatillo esté APAGADO.

La guía (E) puede ser ajustada en una de dos formas: para

cambiar el ángulo de corte deseado y cambiar el espacio entre la

guía y el torno.

Español

FIG. 5

R

G

Q

F

PARA CAMBIAR EL ÁNGULO DE CORTE DESEADO

Use la llave incluida para aflojar (sin quitar) los dos pernos de la

guía (Q). Alinee la línea de indicación del ángulo deseado con la

H

línea de la ranura (R) en la base (D). Ajuste bien ambos pernos de

la guía antes de usarla.

Para realizar cortes cuadrados más precisos, desenchufe la

herramienta, afloja los dos pernos de la guía, empuje el brazo hacia

abajo hasta que el disco se extienda dentro de la base. Coloque

una escuadra contra el disco y ajuste la guía contra la escuadra.

Ajuste bien ambos pernos de la guía antes de usarla.

Puede que el torno (F) no sujete bien la pieza de trabajo al realizar

cortes a inglete, dependiendo del grosor de la pieza y el ángulo de

inglete. Otros dispositivos auxiliares (tales como abrazaderas de

resorte, de barra o en C) serán entonces necesarios para sujetar

la pieza a la guía al realizar estos cortes.

FIG. 6

R

Q

E

J

E

PARA CAMBIAR EL ESPACIO ENTRE LA GUÍA Y EL TORNO

Con la llave incluida, afloje y retire ambos pernos de la guía (Q).

Ajuste la guía (L) al lugar deseado. Inserte ambos pernos de la

guía en los lugares previstos. Ajuste bien ambos pernos de la guía

antes de usarla.

1717

Page 19

Retiro e Instalación de Discos

(Fig. 7, 8)

ADVERTENCIA: Apague y desenchufe la herramienta

antes de realizar ajustes o de quitarle o ponerle accesorios.

Asegúrese que el conmutador tipo gatillo esté APAGADO. No

realice ningún ajuste mientras el disco esté en movimiento.

No realice ningún ajuste mientras la tronzadora de metales

esté enchufada a la toma de corriente.

FIG. 7

L

1. Empuje la palanca de fijación del disco (L) hacia adentro y

gire el disco (J) con la mano hasta que la palanca de fijación

del disco enganche en la ranura dentro de la pestaña (S) para

fijar el disco. Afloje el perno (T) que está en el centro del disco

abrasivo girándolo en dirección contraria a las manillas del

reloj con la llave hexagonal de 8 mm (G). El perno tiene un hilo

diestro.

FIG. 8

S

J

V

T

U

2. Retire el perno (T), la arandela (U), la pestaña exterior (V) y el

disco viejo (J).

3. Asegúrese que las superficies de la pestaña queden limpias y

planas. Instale el disco abrasivo nuevo invirtiendo los pasos de

más arriba.

4. No ajuste demasiado el perno.

ADVERTENCIA: Revise la superficie de trabajo sobre la cual

descansa la sierra cuando le cambie el disco abrasivo por uno

nuevo. Es posible que el disco entre en contacto con CUALQUIER

COSA O ESTRUCTURA QUE SE EXTIENDA por encima de la

superficie de trabajo (debajo de la base) cuando el brazo está

totalmente abajo.

Montaje

ATENCIÓN: La herramienta debe ser apoyada sobre una

superficie estable, nivelada y no deslizante para evitar el movimiento

inesperado de esta durante la operación.

PROCEDIMIENTO PARA MONTAJE PERMANENTE

1. Marque por los orificios de la base (D) y perfore dos orificios de

7,94 mm (5/16 pulg.) de diámetro en la superficie de montaje.

2. Use fijadores de 6,35 mm (1/4 pulg.) para fijar la base en forma

segura a la superficie de montaje.

MONTAJE CON SOPORTES

(FIG. 9)

1. Corte dos tablas de

aproximadamente 508 mm de

largo x 50,8 mm de alto x

101,6 mm de ancho (20 pulg.

de largo x 2 pulg. de alto x 4

pulg. de ancho).

2. Coloque la sierra circular

estacionaria en el lugar de

trabajo deseado.

FIG. 9

FIG. 9

Español

1818

Page 20

3. Coloque las tablas a ambos lados de la sierra, ajustándola

entre ellas, y clávelas a la superficie de trabajo.

Consejos de Operación Para Cortes

Más Precisos

• Deje que el disco realice el corte. Si usa demasiada fuerza, el

disco podría resbalar, reduciendo así su eficiencia de corte o

deflectar, causando cortes imprecisos.

• Ajuste debidamente el ángulo de la guía.

• Asegúrese que el material esté plano contra la base.

• Sujete bien el material con dispositivos de sujeción para evitar

que se mueva y que la sierra vibre.

MANTENIMIENTO

Inspección y Cambio de Escobillas

del Motor (Fig. 10)

ADVERTENCIA: Apague y desenchufe la herramienta.

Asegúrese que el conmutador tipo gatillo esté APAGADO.

Las escobillas deberían ser revisadas regularmente para verificar

Español

que no estén desgastadas. Para revisar las escobillas, destornille

los dos tornillos de la tapa (W) y retire la tapa (X). Retire la tapa

de las escobillas (Z). Las escobillas (Y) deberían poder deslizarse

libremente dentro de la caja. Si las escobillas están desgastadas

a 8 mm (0,3 pulg.), como aparece en la Figura 10, deberían ser

cambiadas. Para volverlas a instalar, empuje la escobilla nueva

dentro de la caja. Si va a reponer la escobilla existente, recuerde

poner la escobilla en la misma orientación que cuando fue retirada.

Reponga la tapa de las escobillas (no sobreajuste). Reponga la

tapa y los dos tornillos. Ajuste firmemente.

FIG. 10

Z

Y

8 mm

(.3")

X

W

Y

Limpieza

Se recomienda limpiar el polvo y la arenilla de la caja principal

de la herramienta con una manguera de aire, tan frecuentemente

como sea necesario limpiar tierra acumulada en las rejillas de

ventilación y alrededor de estas. Use siempre protección ocular y

respiratoria apropiada.

Reparaciones

Las reparaciones, el mantenimiento y los ajustes de este producto

deberían ser realizados por centros de servicio autorizados u

otras organizaciones de servicio calificadas, usando siempre

repuestos originales, para garantizar la SEGURIDAD y FIABILIDAD

del producto.

NOTA: La unidad puede ser convertida a una con un cable de

alimentación de 3 hilos y cierre por torsión en un centro de

servicio autorizado.

1919

Page 21

Lubricación

Se utilizaron rodamientos de grasa sellada, cerrados en toda la

herramienta. Estos rodamientos vienen con suficiente lubricación

de fábrica para durar la vida útil de la sierra circular estacionaria.

Accesorios

ADVERTENCIA: La utilización de cualquier accesorio no

recomendado para esta herramienta puede ser peligrosa.

Use sólo discos de alta resistencia tipo 1 orgánicos calificados para

4100 rpm o superiores.

Puede comprar los accesorios recomendados para su herramienta

donde su distribuidor local o en el centro de servicio autorizado. Si

necesita ayuda para ubicar su distribuidor local o centro de servicio

autorizado.

D28700

Tensión de alimentación: 120 V AC

Frecuencia de alimentación: 50-60 Hz 50-60 Hz

Potencia nominal: 2 000 W 2 200 W

Rotación sin carga: 3 800/min 3 800/min

Información Técnica

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

220 V AC

Español

2020

Page 22

Guía de resolución de problemas

¡PROBLEMA¡ LA HERRAMIENTA NO ARRANCA

¿QUÉ SUCEDE? QUÉ HACER…

1. La herramienta no está enchufada. 1. Enchufe la sierra.

2. Un fusible está quemado o el interruptor de circuito fue activado. 2. Cambie el fusible o reposicione el interruptor de circuito.

3. El cable está dañado. 3. Haga cambiar el cable en un centro de servicio autorizado.

4. Las escobillas están desgastadas. 4. Cambie las escobillas.

¡PROBLEMA¡ LA HERRAMIENTA REALIZA CORTES NO SATISFACTORIOS

¿QUÉ SUCEDE? QUÉ HACER…

1. El disco se resbala. 1. Rectifique el disco o cámbielo por uno nuevo.

2. La pieza de trabajo fue colocada o fijada incorrectamente. 2. Fije y soporte bien la pieza de trabajo.

¡PROBLEMA¡ LA HOJA NO ALCANZA LA VELOCIDAD NECESARIA

¿QUÉ SUCEDE? QUÉ HACER…

1. El alargador es de un calibre demasiado bajo o 1. Usar un cable del calibre adecuado. Ver la tabla en

es demasiado largo. la página 11.

2. Bajo voltaje. 2. Contacte a su empresa eléctrica.

3. Bajo voltaje de generador. 3. Revise el voltaje de salida del generador. Reduzca el número de

herramientas alimentadas por el generador.

Español

¡PROBLEMA¡ LA HERRAMIENTA VIBRA EXCESIVAMENTE DURANTE EL CORTE

¿QUÉ SUCEDE? QUÉ HACER…

1. La herramienta no ha sido montada bien al soporte o 1. Ajuste todos los accesorios de montaje. Vea la página 18,

la mesa de trabajo. Procedimiento para montaje permanente.

2. Disco dañado. 2. Cambie el disco.

3. La pieza de trabajo no ha sido debidamente fijada. 3. Vea Soporte y fijación del material página 16.

¡PROBLEMA¡ NO REALIZA CORTES PRECISOS

¿QUÉ SUCEDE? QUÉ HACER…

1. La guía no ha sido debidamente ajustada. 1. Revise y ajuste. Vea Operación de la guía en la página 17.

2. El disco no está cuadrado con la guía. 2. Revise y ajuste.

3. Se usó demasiada fuerza para realizar el corte. 3. Reduzca la fuerza de corte; deje que el disco haga el trabajo.

4. La pieza de trabajo se movió. 4. Fije bien la pieza de trabajo. Vea Soporte y fijación del material

página 16. Asegúrese que el material esté plano contra la base.

2121

Page 23

¡PROBLEMA¡ EL BRAZO ESTÁ FIJO

¿QUÉ SUCEDE? QUÉ HACER…

1. La clavija de fijación está enganchada. 1. Empuje el brazo ligeramente hacia abajo, tire del dispositivo de fijación

hacia abajo y eleve el brazo.

¡PROBLEMA¡ EL MATERIAL SE MUEVE DURANTE EL CORTE

¿QUÉ SUCEDE? QUÉ HACER…

1. La guía se resbala o la pieza de trabajo está mal colocada 1. Vea Soporte y fijación del material página 16.

o no debidamente soportada.

2. El torno está demasiado flojo 2. Ajuste el torno

3. Demasiada fuerza durante el corte. 3. Use menos fuerza para cortar.

Español

2222

Page 24

Instruções de segurança importantes

ATENÇÃO! Leia todas as instruções e verifique se as

entendeu completamente. O não seguimento de todas as

instruções listadas abaixo pode resultar em choque elétrico,

incêndio e/ou lesões corporais sérias.

GUARDE ESTAS INSTRUÇÕES

• MANTENHA OS DISPOSITIVOS DE SEGURANÇA

INSTALADOS em boas condições de funcionamento.

• RETIRE AS CHAVES DE AJUSTE OU PRESSÃO. Adquira o

hábito de verificar se todas as chaves, incluindo as chaves de

ajuste, foram retiradas da ferramenta antes de acioná-la.

• MANTENHA A SUA ÁREA DE TRABALHO LIMPA. As áreas

e bancadas de trabalho desorganizadas são um convite aos

acidentes.

• NÃO USE A FERRAMENTA EM AMBIENTES PERIGOSOS.

Nunca use ferramentas elétricas em áreas úmidas ou molhadas,

nem as exponha à chuva. Mantenha sua área de trabalho bem

iluminada.

• MANTENHA AS CRIANÇAS À DISTÂNCIA. Todos os

espectadores devem permanecer a uma distância segura da

área de trabalho.

• MANTENHA SUA OFICINA DE TRABALHO INACESSÍVEL

ÀS CRIANÇAS usando cadeados, interruptores-mestres ou

retirando as chaves de arranque.

• NUNCA FORCE A FERRAMENTA. A ferramenta executará o

trabalho melhor e com mais segurança quando usada de acordo

com as especificações para as quais foi projetada.

• USE A FERRAMENTA ADEQUADA. Não force uma ferramenta

nem um acessório tentando fazer um trabalho para o qual eles

não foram fabricados.

Portugêse

• USE EXTENSÕES ELÉTRICAS ADEQUADAS. Verifique

sempre se o fio de extensão está em boas condições. Sempre

que usar uma extensão, verifique se ela tem um calibre suficiente

para a corrente exigida pela sua ferramenta elétrica. Uma

extensão de menor calibre causará uma queda de voltagem

o que resultará em perda de potência e superaquecimento da

ferramenta. A tabela a seguir indica o tamanho que deve ser

usado em função do comprimento do cabo e da amperagem

nominal. Em caso de dúvida, use um fio de maior capacidade.

Quanto menor o número do calibre, maior será a capacidade do

cabo.

Tensão

(Volts)

120 - 127V 0 - 7 7 - 15 15 - 30 30 - 50

220 - 240V 0 - 15 15 - 30 30 - 60 60 - 100

Faixa de Corrente

nominal

(Ampéres)

0 - 6A 1.0 1.5 1.5 2.5

6 - 10A 1.0 1.5 2.5 4.0

10 - 12A 1.5 1.5 2.5 4.0

12 - 16A 2.5 4.0 Não Recomendado

• VISTA ROUPAS ADEQUADAS. Não use roupas folgadas,

gravatas, anéis, braceletes, pulseiras nem jóias que possam

ficar presos às partes móveis da ferramenta. Recomendamos

o uso de sapatos de segurança antiderrapantes. Utilize um

protetor para cobrir e prender seus cabelos. Muitas vezes, os

orifícios de ventilação cobrem peças móveis e, por isso, devem

ser evitados.

Comprimento do cabo de extensão

Secção minima do cabo de extensão

em milimetros quadrados (mm

em metros (m)

2

)

23

Page 25

• USE SEMPRE ÓCULOS DE PROTEÇÃO que satisfaçam à

norma ANSI Z87.1. Além disso, caso o trabalho de corte possa

criar muito pó, use sempre uma máscara facial ou máscara

contra pó. Os óculos de uso diário têm lentes resistentes ao

impacto, porém não protegem em caso de acidente.

• PRENDA A PEÇA A SER CORTADA. Use uma braçadeira

ou um torno para prender a peça a ser cortada. Desse modo,

seu trabalho será mais seguro e suas mãos estarão livres para

operar a ferramenta.

• NUNCA TENTE APANHAR ALGO QUE ESTEJA FORA DO

SEU ALCANCE. Mantenha os pés bem apoiados e fique bem

equilibrado sempre que estiver usando a ferramenta.

• MANTENHA BEM SUA FERRAMENTA. Para obter os resultados

melhores e mais seguros, mantenha suas ferramentas sempre

afiadas e limpas. Siga as instruções de lubrificação e substituição

de acessórios.

• DESCONECTE A FERRAMENTA DA CORRENTE ELÉTRICA

antes de inspecionar ou tentar identificar um problema com a

ferramenta; e antes de substituir acessórios como, por exemplo,

lâminas, discos, brocas, fresas ou outros acessórios.

• REDUZA O RISCO DE ACIONAMENTO ACIDENTAL DA

FERRAMENTA. Verifique sempre se o gatilho está desligado

(na posição “off”) antes conectar a ferramenta à corrente

elétrica.

• USE SOMENTE OS ACESSÓRIOS RECOMENDADOS PARA

SUA FERRAMENTA. Os acessórios recomendados estão

indicados no manual de instruções. O uso de acessórios

inadequados pode criar riscos de ferimentos.

• NUNCA USE A FERRAMENTA PARA APOIAR-SE NEM

SUBA NA FERRAMENTA. Ferimentos graves podem ocorrer

quando uma ferramenta de corte se desequilibra ou é acionada

acidentalmente.

• VERIFIQUE SE NENHUMA PEÇA FOI DANIFICADA. Antes

de continuar usando a ferramenta, dispositivo de proteção ou

qualquer outra peça danificada, verifique-os cuidadosamente

para certificar-se de que funcionam adequadamente e podem

executar o trabalho para o qual foram projetados. Em particular,

verifique se as peças móveis estão bem alinhadas e seguras,

se nenhuma está partida, fissurada ou montada sobre outra,

ou se não há nenhum outro problema que poderia afetar o

funcionamento da ferramenta. Os dispositivos de proteção

ou peças danificados ou quebrados devem ser corretamente

consertados ou substituídos.

• NUNCA DEIXE UMA FERRAMENTA FUNCIONANDO SEM

SUPERVISÃO. SEMPRE DESLIGUE OU DESCONECTE A

FERRAMENTA DA CORRENTE ELÉTRICA. Não vá embora

da área de trabalho antes que a ferramenta tenha parado

completamente de funcionar.

• SUBSTITUIÇÃO DE PEÇAS. Use somente peças de substituição

idênticas às peças originais.

• PARA REDUZIR O RISCO DE CHOQUE ELÉTRICO:

a. Este aparelho pode estar equipado de um plugue

polarizado (um pino é maior do que o outro). Este tipo de

plugue pode ser conectado à tomada polarizada somente

de uma maneira. Se não for possível inserir o plugue na

tomada, peça a um eletricista profissional para instalar

uma tomada apropriada.

b. Este aparelho pode estar equipado de um plugue de

três pinos com conexão à terra. Este tipo de plugue deve

ser ligado somente a uma tomada com conexão à terra.

Se não for possível inserir o plugue na tomada, peça

a um eletricista profissional para instalar uma tomada

apropriada.

c. Nunca altere o plugue de maneira nenhuma.

Portugêse

24

Page 26

Regras de Segurança Adicionais para

Serras de Corte Rápido

• Sempre use dispositivos de proteção adequados para os

olhos e para a respiração.

• Antes de utilizar a ferramenta, verifique se os discos de

corte não estão fissurados ou defeituosos. Caso note

uma fissura ou um defeito, descarte o disco. Além disso,

examine o disco sempre que suspeitar que a ferramenta

caiu ou sofreu uma pancada. Um disco defeituoso pode

quebrar-se.

• Quando puser a ferramenta para funcionar com um disco

novo ou substituído ou sempre que estiver em dúvida

sobre as condições de uso do disco, coloque a ferramenta

numa área bem protegida e a faça funcionar durante um

minuto. Caso o disco tenha uma fissura ou uma imperfeição

não detectadas, ele quebrará em menos de um minuto. Nunca

acione a ferramenta quando uma pessoa estiver diante do disco

numa linha reta, incluindo o operador da ferramenta.

• Quando a máquina estiver em funcionamento, evite que

o disco seja golpeado ou operado sem cuidado. Caso isto

ocorra, desligue a ferramenta e examine o disco para ver se não

está fissurado ou defeituoso.

• Limpe periodicamente sua serra de corte rápido de acordo com

as instruções fornecidas neste manual.

• Não retire os protetores nem a base do disco.

• USE SEMPRE O TORNO OU UM DISPOSITIVO ESPECIAL

PARA PRENDER COM SEGURANÇA A PEÇA A SER

CORTADA. Outros dispositivos como, por exemplo, tornos de

mola, de barra ou em C, podem ser adequados para prender

peças de alguns tamanhos e formas diferentes. Escolha e

Portugêse

instale estes dispositivos cuidadosamente e faça um teste de

corte antes de utilizá-los.

• Utilize somente discos de 355 mm (14"), tipo 1, de 4.100 rpm ou

mais.

• Sempre deixe que as peças cortadas esfriem antes de tocá-las

com as mãos.

• Nunca tente cortar madeira ou plástico com esta ferramenta.

• NUNCA CORTE MAGNÉSIO COM ESTA FERRAMENTA.

• Use sempre sua serra de corte rápido numa área bem

ventilada.

• Desligue a serra de corte rápido antes de retirar qualquer peça

da base.

• NUNCA CORTE NENHUM MATERIAL QUE ESTEJA

CONECTADO A UM CIRCUITO ELÉTRICO “VIVO”.

• Nunca utilize um disco de corte para serra circular nem

qualquer tipo de disco de corte dentado com esta ferramenta.

Isto pode provocar ferimentos graves.

• NÃO OPERE ESTA FERRAMENTA NA PRESENÇA DE

LÍQUIDOS, GASES OU POEIRAS INFLAMÁVEIS. O

funcionamento do motor e das escovas pode gerar faíscas ou

projetar partículas quentes e incendiar substâncias combustíveis

presentes no ambiente.

• Nunca utilize o lado do disco abrasivo como esmeril ou polidor.

Isto enfraquecerá muito o disco e tornará seu uso perigoso. O

disco poderá se desprender.

CUIDADO: Utilize proteção para os ouvidos adequada

quando estiver usando a ferramenta. Sob algumas condições e

dependendo do tempo de uso contínuo, o ruído produzido por esta

ferramenta pode contribuir para a perda da audição.

CUIDADO: O pára-faíscas se aquecerá durante o funcionamento

da ferramenta. Por isso, evite tocar ou ajustar o pára-faíscas

enquanto estiver quente. Mantenha os fios elétricos das ferramentas

e outros materiais longe do pára-faíscas.

25

Page 27

ATENÇÃO: É possível que uma parte da poeira criada por

algumas ferramentas elétricas de lixamento, serragem,

esmerilhagem, perfuração e outras atividades de construção

contenha substâncias químicas que o estado da Califórnia considera

como causadoras de câncer, defeitos congênitos ou problemas

reprodutivos. Alguns exemplos desses produtos químicos são:

• chumbo nas tintas à base de chumbo,

• sílica cristalina em tijolos, cimento e outros produtos de

alvenaria, e

• arsênio e cromo em madeiras tratadas quimicamente com

CCA (arseniato de cobre cromatado).

O risco de exposição a esses produtos varia dependendo da

freqüência de execução desse tipo de trabalho. A fim de reduzir sua

exposição a essas substâncias químicas: trabalhe em áreas bem

ventiladas e usando equipamentos de segurança aprovados como,

por exemplo, máscaras contra pó fabricadas especialmente para

impedir a passagem de partículas microscópicas.

• Evite o contato prolongado com o pó produzido por

ferramentas elétricas de lixamento, serragem, esmerilhagem,

perfuração e outras atividades de construção. Vista roupas

protetoras e lave com água e sabão as partes do corpo

expostas. Permitir que o pó entre em contato com a boca, os

olhos ou a pele pode provocar a absorção de produtos químicos

nocivos para o corpo.

ATENÇÃO: Use sempre equipamentos adequados de proteção

respiratória contra pó aprovados pelo NIOSH ou pela OSHA.

Direcione as partículas para longe do rosto e do corpo.

Para seu conforto e segurança, as seguintes advertências estão

impressas em sua serra de corte profissional 355 mm (14”):

LEIA O MANUAL DE INSTRUÇÕES PARA OPERAR COM

SEGURANÇA O APARELHO.

NÃO USE LÂMINAS DENTADAS.

UTILIZE SOMENTE DISCOS REFORÇADOS DE 4.100 RPM

OU MAIS.

USE SOMENTE PEÇAS DE SUBSTITUIÇÃO IDÊNTICAS ÀS

PEÇAS ORIGINAIS.

SEMPRE USE PROTEÇÃO PARA OS OLHOS. SEMPRE

USE OS DISPOSITIVOS DE PROTEÇÃO DO APARELHO.

SEMPRE PRENDA A PEÇA A SER CORTADA NO TORNO.

SEMPRE USE PROTEÇÃO RESPIRATÓRIA ADEQUADA.

NÃO EXPONHA O APARELHO À CHUVA

NEM O UTILIZE EM LUGARES ÚMIDOS.

USE SOMENTE DISCOS PARA SERRAS

RÁPIDAS DE UMA ESPESSURA MÁXIMA

DE 3,1 mm E UM DIÂMETRO MÁXIMO DE

355 mm.

CARACTERÍSTICAS (FIG. 1, 4)

A. Trava J. Disco

B. Parafuso do pára-faíscas K. Anteparo

C. Pára-faíscas L. Alavanca da trava do disco

D. Base M. Parafuso de profundidade

E. Guia de corte

F. Torno N. Interruptor tipo gatilho

G. Chave sextavada de 8 mm O. Orifício do cadeado

H. Manivela P. Porca baixa

I. Alavanca do torno Q. Parafusos da guia

Fonte de alimentação elétrica

Assegure-se de que o tipo de energia elétrica fornecido por sua

rede corresponde ao tipo indicado na placa do aparelho.

Uma queda de voltagem de mais de 10% causará perda potência

e superaquecimento da ferramenta.

Portugêse

26

Page 28

NOTA: A capacidade mostrada no gráfico assume que o disco de corte não

está gasto e que a guia se encontra em posição ótima.

Forma da peça a ser cortada:

CAPACIDADE DE CORTE MÁXIMA

Ângulo de corte de 90º A = 115 mm

Ângulo de corte de 45º A = 98 mm

(4,5")

(3-13/16")

Capacidade de corte

A abertura ampla do torno e o ponto elevado de giro proporcionam

uma capacidade de corte para uma grande variedade de peças

grandes. Use a tabela de capacidade de corte para determinar o

tamanho máximo dos cortes que podem ser feitos com um disco

de corte novo.

CUIDADO: ALGUNS OBJETOS GRANDES, CIRCULARES OU

DE FORMA IRREGULAR PODEM EXIGIR DISPOSITIVOS

ADICIONAIS PARA PRENDÊ-LOS CASO NÃO SEJA POSSÍVEL

PRENDÊ-LOS FIRMEMENTE NO TORNO.

CUIDADO: NUNCA USE ESTA FERRAMENTA PARA CORTAR

MAGNÉSIO.

Equipamento padrão

1 disco metálico de corte abrasivo de 355 mm (14")

Portugêse

1 chave de disco

1 manual de instruções

A = 119 mm

(4-11/16")

A = 98 mm

(3-13/16")

A x B

115 mm x 130 mm

(4-1/2" x 5-1/8")

102 mm x 194 mm

(4" x 7-5/8")

76 mm x 229 mm

(3" x 9")

115 mm x 98 mm

(4-1/2” x 3-13/16")

A = 137 mm

(5-3/8")

A = 98 mm

(3-13/16")

Como transportar o aparelho (Fig.1)

Dobre o aparelho para baixo para posicioná-lo de maneira que

você possa transportar a serra. Empurre a trava (A) para travar o

braço para baixo.

Como destravar o aparelho (Fig. 1)

Para destravar a ferramenta e levantar a cabeça, pressione

ligeiramente o braço do motor e puxe a trava (A) para fora. Então,

o braço do motor girará para cima.

Ajuste do pára-faíscas (Fig. 1)

Para melhor desviar faíscas para longe das pessoas e dos

materiais perto do aparelho, folgue o parafuso (B), ajuste o párafaíscas (C) e aperte novamente o parafuso. Nunca deixe que o fio

elétrico do aparelho entre em contato com o pára-faísca ou com

as faíscas produzidas pelo aparelho, pois isto pode causar danos

ao fio elétrico.

27

Page 29

FIG. 1

FIG. 2

O

N

L

DIÂMETRO DA PEÇA A

SER CORTADA

E

ESPAÇADOR

C

K

J

M

F

LARGURA DO ESPAÇADOR

P

A

I

C

D

B

E

F

H

G

FIG. 3

BLOCO

PEÇA

CORTADA

Portugêse

28

Page 30

Profundidade de corte (Fig. 1)

A profundidade de corte é programada na fábrica para um disco novo

de 355 mm (14") a fim de impedir que o disco corte a superfície de

suporte. Para fazer cortes mais profundos, use a chave sextavada

de 8 mm (G) para folgar o parafuso de profundidade de corte (M) e

levante o parafuso até a altura desejada. Em seguida, gire a porca

baixa (P) no sentido horário até que esteja assentada firmemente.

Aperte firmemente o parafuso de profundidade de corte antes de

usar a ferramenta.

CUIDADO: Após instalar um novo disco, reajuste a profundidade

de corte para a posição original a fim de impedir que a ferramenta

corte a superfície de suporte.

Interruptor tipo gatilho (Fig. 1)

Para acionar a ferramenta, pressione o gatilho (N). Para desligar a

ferramenta, solte o gatilho. Mantenha as mãos e o material longe

do disco até que o disco tenha parado completamente.

Para impedir o uso não autorizado do aparelho, instale um cadeado

comum (não incluído) no orifício para cadeado (O) localizado no

gatilho.

Como prender e apoiar o material

• Para melhor prender e cortar os ângulos, os dois lados devem

descansar sobre a base.

• Caso necessário, use um bloco espaçador adicional um pouco

mais estreito que a peça a ser cortada a fim de aumentar a

utilização do disco de corte (Fig. 2).

• As peças longas a serem cortadas devem ser apoiadas por

meio de um bloco de maneira que fiquem niveladas com o topo

da base (Fig. 3). O pedaço cortado deve estar solto para que

possa cair sem prender-se no disco de corte.

Portugêse

Funcionamento do torno (Fig. 4)

O torno (F) está equipado com um dispositivo de aperto rápido.

Para soltar o torno quando se encontra preso firmemente, gire

a manivela (H) em sentido anti-horário uma ou duas vezes para

diminuir a pressão do torno. Em seguida, levante a alavanca do

torno (I). Puxe a manivela para fora tanto quanto for necessário.

Inicialmente, o torno pode apertar a peça sem o auxílio da

manivela. Abaixe a alavanca do torno (I) e, em seguida, aperte a

peça com o torno (F) usando a manivela (H).

FIG. 4

Q

E

PARA FRENTE

F

I

H

Funcionamento da guia (Fig. 5, 6)

ATENÇÃO: Antes de fazer qualquer ajuste ou retirar ou

instalar qualquer acessório, desligue e desconecte o aparelho

da corrente elétrica. Assegure-se de que o gatilho esteja na

posição “off” (desligado).

A guia (E) pode ser ajustada de duas maneiras: para mudar o

ângulo de corte desejado e para mudar o espaço entre a guia e o

torno.

29

Page 31

FIG. 5

R

G

Q

F

FIG. 6

E

Q

J

E

PARA MUDAR O ÂNGULO DE CORTE DESEJADO

Use a chave fornecida para afrouxar (sem remover) os dois

parafusos da guia (Q). Alinhe a linha do indicador do ângulo

desejado com a linha (R) na base (D). Aperte firmemente os dois

parafusos da guia antes do uso.

Para fazer cortes mais precisos, desligue a ferramenta da corrente

elétrica, folgue os dois parafusos da guia, e empurre o braço para

baixo até que o disco passe além da base. Coloque um esquadro

contra o disco e ajuste a guia contra o esquadro. Aperte firmemente

os dois parafusos da guia antes do uso.

Para os cortes em ângulo, talvez o torno (F) não prenda firmemente

a peça, dependendo da espessura da peça a ser cortada e do

ângulo de corte. Para estes tipos de corte, a utilização de outros

tipos de tornos (por exemplo, de molas, de barra ou tornos em C),

pode ser necessária para prender a peça a ser cortada à guia.

R

PARA MUDAR O ESPAÇO ENTRE A GUIA E O TORNO

Usando a chave fornecida, folgue e retire o dois parafusos da

guia (Q). Ajuste a guia (E) aos lugares desejados. Insira os dois

parafusos da guia nos seus lugares respectivos. Aperte firmemente

os dois parafusos da guia antes do uso.

Como remover e instalar os discos

(Fig. 7, 8)

ATENÇÃO: Antes de fazer qualquer ajuste ou retirar ou

instalar qualquer acessório, desligue e desconecte o aparelho

da corrente elétrica. Assegure-se de que o gatilho esteja na

posição “off” (desligado). Não faça nenhum ajuste na

ferramenta enquanto o disco estiver em movimento. Não faça

nenhum ajuste enquanto a ferramenta estiver conectada à

corrente elétrica.

30

Portugêse

Page 32

FIG. 7

L

1. Empurre para dentro a alavanca da trava do disco (L) e gire o

disco (J) manualmente até que a trava da alavanca do disco

engate na linha fendida no flange interior (S) para travar o disco.

Folgue o parafuso (T) no sentido anti-horário no centro do disco

abrasivo usando a chave sextavada de 8 mm (G). O parafuso é

de rosca direita.

FIG. 8

S

J

V

T

U

2. Retire o parafuso (T), a arruela (U), o flange exterior (V) e o

disco gasto (J).

3. Assegure-se de que as superfícies dos flanges estejam limpas

Portugêse

e planas. Instale o novo disco abrasivo seguindo as etapas

acima em ordem inversa.

4. Não aperte demasiadamente o parafuso.

ATENÇÃO: Ao instalar um novo disco abrasivo, verifique a

superfície de trabalho onde se encontra a ferramenta. É possível

que o disco toque QUALQUER ELEMENTO OU ESTRUTURA

QUE PASSE ACIMA da superfície de trabalho (sob a base), quando

o braço se encontra em sua posição mais baixa.

Montagem

CUIDADO: A ferramenta deve estar suportada por uma superfície

estável, nivelada e antiderrapante a fim de impedir movimentos

inesperados quando estiver em funcionamento.

PROCEDIMENTO DE MONTAGEM PERMANENTE

1. Marque os orifícios na base (D) e faça dois orifícios de 7,94 mm

(5/16") de diâmetro através da superfície de montagem.

2. Use parafusos de 6,35 mm (1/4") para montar firmemente a

base à superfície de montagem.

MONTAGEM EM PLATAFORMA (FIG. 9)

1. Corte duas peças de

madeira de cerca de 508 mm

(comprimento) x 50,8 mm

(altura) x 101,6 mm (largura)

(20" x 2" x 4").

2. Coloque a serra na posição de

trabalho desejada.

3. Coloque as peças de madeira

firmemente nos lados da

ferramenta e pregue-as à

superfície de trabalho.

FIG. 9

31

Page 33

Sugestões para fazer cortes mais

precisos

• Permita que o disco realize o corte. O uso de força excessiva

fará com que o disco fique embotado, diminuindo assim sua

eficiência de corte e/ou se desalinhe, produzindo cortes

inexatos.

• Ajuste corretamente o ângulo da guia.

• Assegure-se de que o material esteja bem assentado sobre a

base.

• Prenda adequadamente o material para evitar movimento e

vibração.

MANUTENÇÃO

Inspeção e troca das escovas do motor

(Fig. 10)

ATENÇÃO: Desligue e desconecte a ferramenta da corrente

elétrica. Assegure-se de que o gatilho esteja na posição “off”

(desligado).

Examine com freqüência as escovas para assegurar-se de que não

estão gastas. Para isto, desenrosque os parafusos (W) da calota

e retire a calota (X). Retire a tampa das escovas (Z). As escovas

(Y) devem deslizar livremente dentro da caixa de escovas. Se as

escovas estiverem gastas a um nível inferior a 8 mm (0,3”) como

mostrado na Figura 10, elas devem ser trocadas. Para reinstalar,

empurre a nova escova para dentro da caixa de escovas. Ao

substituir uma escova existente, mantenha a mesma orientação

da escova removida. Coloque novamente a tampa das escovas no

lugar sem apertar demasiadamente. Coloque novamente a calota

e os dois parafusos no lugar. Aperte firmemente.

FIG. 10

Z

Y

8 mm

(.3")

X

W

Y

Limpeza

Recomendamos limpar o pó e os resíduos de corte que se

encontram na ferramenta usando um jato de ar sempre que

necessário para que não se acumulem nos orifícios de ventilação.

Sempre use dispositivos de proteção adequados para os olhos e

para a respiração.

Consertos

Para garantir a SEGURANÇA e CONFIABILIDADE do produto,

os consertos, manutenções e ajustes devem ser feitos por um

centro de assistência técnica autorizado ou outra organização com

mão-de-obra especializada, sempre usando peças de reposição

idênticas.

NOTA A ferramenta pode ser convertida em unidade de três

fios com trava por rotação num centro de assistência técnica

autorizado.

Lubrificação

Esta ferramenta foi fabricada com rolamentos herméticos de

lubrificação selada. Estes rolamentos têm lubrificação de fábrica

suficiente para toda a vida útil da máquina.

Portugêse

32

Page 34

Acessórios

CUIDADO: A utilização de um acessório não recomendado para

este aparelho pode ser perigosa.

Utilize somente discos para corte de aglomerante orgânico tipo 1

de alta resistência de 4.100 rpm ou mais.

Os acessórios recomendados para uso com sua ferramenta estão

disponíveis a custo adicional no seu revendedor local ou no centro

de assistência técnica autorizado.

D28700

Voltagem

Freqüência

Alimentação elétrica 2 000 W

Rotações sem carga 3 800 min

50–60 Hz

ESPECIFICAÇÕES

120 V AC 220 V AC

50-60 Hz

-1

2 200 W

3 800

min

-1

Guia de Resolução de Problemas

PROBLEMA! A FERRAMENTA NÃO QUER FUNCIONAR

CAUSA SOLUÇÃO

1. A ferramenta não está conectada à corrente elétrica. 1. Ligue a ferramenta à corrente elétrica.

2. O fusível queimou ou o disjuntor interrompeu o circuito. 2. Troque o fusível ou ligue novamente o disjuntor.

3. O fio da ferramenta foi danificado. 3. Troque o fusível ou ligue novamente o disjuntor.

4. As escovas estão gastas. 4. Troque o fusível ou ligue novamente o disjuntor.

PROBLEMA! A FERRAMENTA NÃO CORTA BEM.

CAUSA SOLUÇÃO

1. O disco está embotado. 1. Afie o disco ou troque-o por um disco novo.

2. A peça cortada foi colocada ou presa incorretamente. 2. Prenda e apóie firmemente a peça a ser cortada.

PROBLEMA! A LÂMINA NÃO ATINGE UMA VELOCIDADE SUFICIENTE

CAUSA SOLUÇÃO

1. O fio de extensão é de calibre inferior ao necessário ou é longo

demais.

2. Baixa voltagem. 2. Entre em contato com a companhia de energia elétrica.

3. Gerador de baixa voltagem. 3. Verifique a voltagem de saída do gerador. Diminua o número de

1. Substitua o fio por um fio de calibre adequado. Consulte a tabela

na página 23.

ferramentas alimentadas pelo gerador.

Portugêse

33

Page 35

PROBLEMA! A FERRAMENTA VIBRA DEMASIADAMENTE DURANTE O CORTE.

CAUSA SOLUÇÃO

1. A ferramenta não foi montada corretamente na plataforma ou na

bancada de trabalho.

2. O disco foi danificado. 2. Substitua o disco.

3. A peça a ser cortada não foi presa corretamente. 3. Consulte a seção Como prender e apoiar o material, na

PROBLEMA! A FERRAMENTA NÃO CORTA COM PRECISÃO.

CAUSA SOLUÇÃO

1. A guia não foi ajustada corretamente. 1. Faça as verificações e ajustes necessários. Consulte a seção

2. O disco não está perpendicular à guia. 2. Faça as verificações e ajustes necessários.

3. Uso de força excessiva para o corte. 3. Diminua a força de corte. Deixe o disco fazer o trabalho.

4. A peça a ser cortada se move. 4. Prenda firmemente a peça a ser cortada. Consulte a seção

PROBLEMA! NÃO É POSSÍVEL MOVER O BRAÇO.

CAUSA SOLUÇÃO

1. O pino de travamento está engatado. 1. Empurre ligeiramente o braço para baixo, puxe para baixo o pino

PROBLEMA! O MATERIAL SE MOVE DURANTE O CORTE.

CAUSA SOLUÇÃO

1. A guia está deslizando ou a peça a ser cortada foi colocada ou

presa incorretamente.

2. O torno está folgado demais. 2. Aperte o torno.

3. Uso de força excessiva para o corte. 3. Diminua a força de corte.

1. Aperte todos os parafusos de montagem do aparelho. Consulte

a página 31, Procedimento de montagem permanente.

página 29.

Funcionamento da guia, na página 29.

Como prender e apoiar o material, na página 29. Assegure-se

de que o material esteja bem assentado contra a base.

de travamento e levante o braço.