Page 1

Questions? See us on the World Wide Web at www.dewalt.com

INSTRUCTION MANUAL

GUIDE D'UTILISATION

INSTRUCTIVO DE OPERACION, CENTROS DE SERVICIO Y POLIZA

DE GARANT[A. ADVERTENCIA: LEASE ESTE INSTRUCTIVO

ANTES DE USAR EL PRODUCTO.

MANUAL DE INSTRUCCIONES

D284741D284931D28493GID284941D28494GID28499 Heavy Duty Large Angle Grinders

Grandes rectifieuses coud_es de service intensif

Esmeriladoras de _ngulo grande para trabajo pesado

D28497 Heavy Duty Large Angle Sander

Grandes ponceuse coud_es de service intensif

Lijadora angular grande para trabajo pesado

®

Page 2

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY DEWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

SAVE THESE INSTRUCTIONS!

General Safety Instructions

A WARNIN!! Read and understand allinstructions. Failure to foflow aft instructions

listed below, may result in electric shock, fire

and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

A Keep your work area clean and well lit. Cluttered benches

and dark areas invite accidents.

_ Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases, or

dust. Power tools create sparks which may ignite the dust or

fumes.

Keep bystanders, children, and visitors away while oper-

ating a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

Grounded tools must be plugged into an outlet properly

installed and grounded in accordance with all codes and

ordinances. Never remove the grounding prong or modify

the plug in any way. Do not use any adapter plugs. Check

with a qualified electrician if you are in doubt as to whether

the outlet is properly grounded, ff the tools should electrically

malfunction or break down, grounding provides a low resistance

path to carry electricity away from the user. This tool may use

grounded construction (3 prong plug) to provide a means to

transfer electrical energy safely away from the user in the event

the tool electrically malfunctions, breaks down, or the tool case

becomes live. Damage to, or loss of, one of the 3 plug blades;

damage to the plug or cord, or failure to have the tool plugged

into a verified and continuously grounded electrical system, may

result in electric shock, serious injury, or death. To avoid these

risks of inju04 the tool must, at all times, be maintained and in

proper working order (cord, plug blades) and plugged into a con-

tinuously grounded electrical system. (See also "Cleaning" in the

Maintenance section, page 15.) Applicable only to Class I

(grounded) tools.

Double insulated tools are equipped with a polarized plug

(one blade is wider than the other.) This plug will fit in a

polarized outlet only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install a polarized outlet. Do not

change the plug in any way. Double insulation _ eliminates

the need for the three wire grounded power cord and grounded

power supply system. Applicable only to Class II (double

insulated) tools.

_ Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk

of electric shock ifyour body is grounded.

_ Don't expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

_, Do not abuse the cord. Never use the cord to carry the

tools or pull the plug from an outlet. Keep cord away from

heat, oil, sharp edges or moving parts. Replace damaged

cords immediately. Damaged cords increase the risk of elec-

tric shock.

A When operating a power tool outside, use an outdoor exten-

sion cord marked "W-A" or "W." These cords are rated for out-

door use and reduce the risk of electric shock.

Page 3

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

Ampere Rating

More Not more AWG

Than Than

12 16 14 12 Not Recommended

PERSONAL SAFETY

Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use tool while

tired or under the influence of drugs, alcohol, or medica-

tion. A moment of inattention while operating power tools may

result in serious personal injurjz.

J_ Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewelry, or long hair

can be caught in moving parts. Air vents often cover moving

parts and should also be avoided.

A Avoid accidental starting. Be sure switch is off before plug-

ging in. Carrying tools with your finger on the switch or plugging

in tools that have the switch on invites accidents.

_, Remove adjusting keys or wrenches before turning the

tool on. A wrench or a key that is left attached to a rotating part

of the tool may result in personal injury.

A Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control of the

tool in unexpected situations.

_, Use safety equipment. Always wear eye protection. Dust

mask, non-skid safety shoes, hard hat, or hearing protection

must be used for appropriate conditions.

TOOL USE AND CARE

_ Use clamps or other practical way to secure and support

the workpiece to a stable platform. Holding the work by hand

or against your body is unstable and may lead to loss of control.

Do not force tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate for

which it is designed.

_ Do not use tool if switch does not turn it on or off. Any tool

that cannot be controlled with the switch is dangerous and must

be repaired.

Disconnect the plug from the power source before making

any adjustments, changing accessories, or storing the

tooL Such preventative safety measures reduce the risk of

starting the tool accidentally.

_k Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting tools sharp and

clean. Properly maintained tools, with sharp cutting edges are

less likely to bind and are easier to control

_ Check for misalignment or binding of moving parts, break-

age of parts, and any other condition that may affect the

tools operation. If damaged, have the tool serviced before

using. Many accidents are caused by poorly maintained tools.

_, Use only accessories that are recommended by the manu-

facturer for your model Accessories that may be suitable for

one tool may become hazardous when used on another tool.

SERVICE

_, Tool service must be performed only by qualified repair per-

sonneL Service or maintenance performed by unqualified per-

sonnel could result in a risk of injury

Page 4

When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this man-

ual. Use of unauthorized parts or failure to follow Maintenance

instructions may create a risk of electric shock or injury.

Specific Safety Rules for Grinders

Always use proper guard with grinding wheel. A guard pro-

tects operator from broken wheel fragments and wheel contact.

A Accessories must be rated for at least the speed recom-

mended on the tool warning label. Wheels and other acces-

sories running over rated speed can fly apart and cause injury.

Refer to the table below. Accessory ratings must always be

above tool speed as shown on tool nameplate.

NOTE: The rated no load tool speed is printed on the name plate

and embossed on the gear case.

Rated no

(no load)

Tool Speed

5000 RPM

6000 RPM

8000 RPM

A Hold tool by insulated gripping surfaces when performing

an operation where the cutting tool may contact hidden

wiring or its own cord. Contact with a "five" wire will make

exposed metal parts of the tool "live" and shock the operator.

A Before using, inspect recommended accessory for cracks

or flaws. If such a crack or flaw is evident, discard the acces-

sory. The accessory should also be inspected whenever you

think the tool may have been dropped. Flaws may cause wheel

breakage.

Minimum

Accessory

Rating

5500 RPM

6600 RPM

8500 RPM

_ When starting the tool with a new or replacement wheel, a

new or replacement wire brush installed, or if you are

unsure of the condition of the wheel, hold the tool in a well

protected area and let it run for one minute. If the wheel has

an undetected crack or flaw, it should burst in less than one

minute. If the wire brush has loose wires, they will be detected.

Never start the tool with a person in line with the wheel This

includes the operator.

_ In operation, avoid bouncing the wheel or giving # rough

treatmenL If this occurs, stop the tool and inspect the wheel for

cracks and flaws.

A Direct sparks away from operator, bystanders or flamma-

ble materials. Sparks may be produced while using a sander

or grinder. Sparks may cause bums or start fires.

A Always use side handle. Tighten the handle securely. The

side handle should always be used to maintain control of the tool

at all times.

_ Clean out your tool often, especially after heavy use. Dust

and grit containing metal particles often accumulate on interior

surfaces and could create a risk of serious injury, electric

shock or electrocution.

_, Do not operate this tool for long periods of time. Vibration

caused by tool action may be harmful to your hands and arms.

Use gloves to provide extra cushion and lim# exposure by taking

frequent rest periods.

_ WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chem-

icals known to cause cancer, birth defects, or other reproductive

harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

Page 5

• arsenic and chromium from chemically-treated lumber

(CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety equip-

ment, such as those dust masks that are specially designed to filter

out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust,

which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection appro-

priate for the dust exposure. Direct particles away from face and

body.

_CAUTION: Use extra care when grinding into a corner

because a sudden, sharp movement of the grinder may be expe-

rienced when the wheel contacts a secondary surface.

_,CAUTION: Wear appropriate personal hearing protection

during use. Under some conditions and duration of use, noise

from this product may contribute to hearing loss.

• The label on your tool may include the following symbols. The

symbols and definitions are as follows:

V ............ volts

Hz .......... hertz

min .......... minutes

.... ........direct current

[] ............Class II Construction

_, ............ safety alert symbol

A ............ amperes

W............ watts

.......... alternating current

no .......... no load speed

............earthing terminal

.../min ......revolutions

per minute

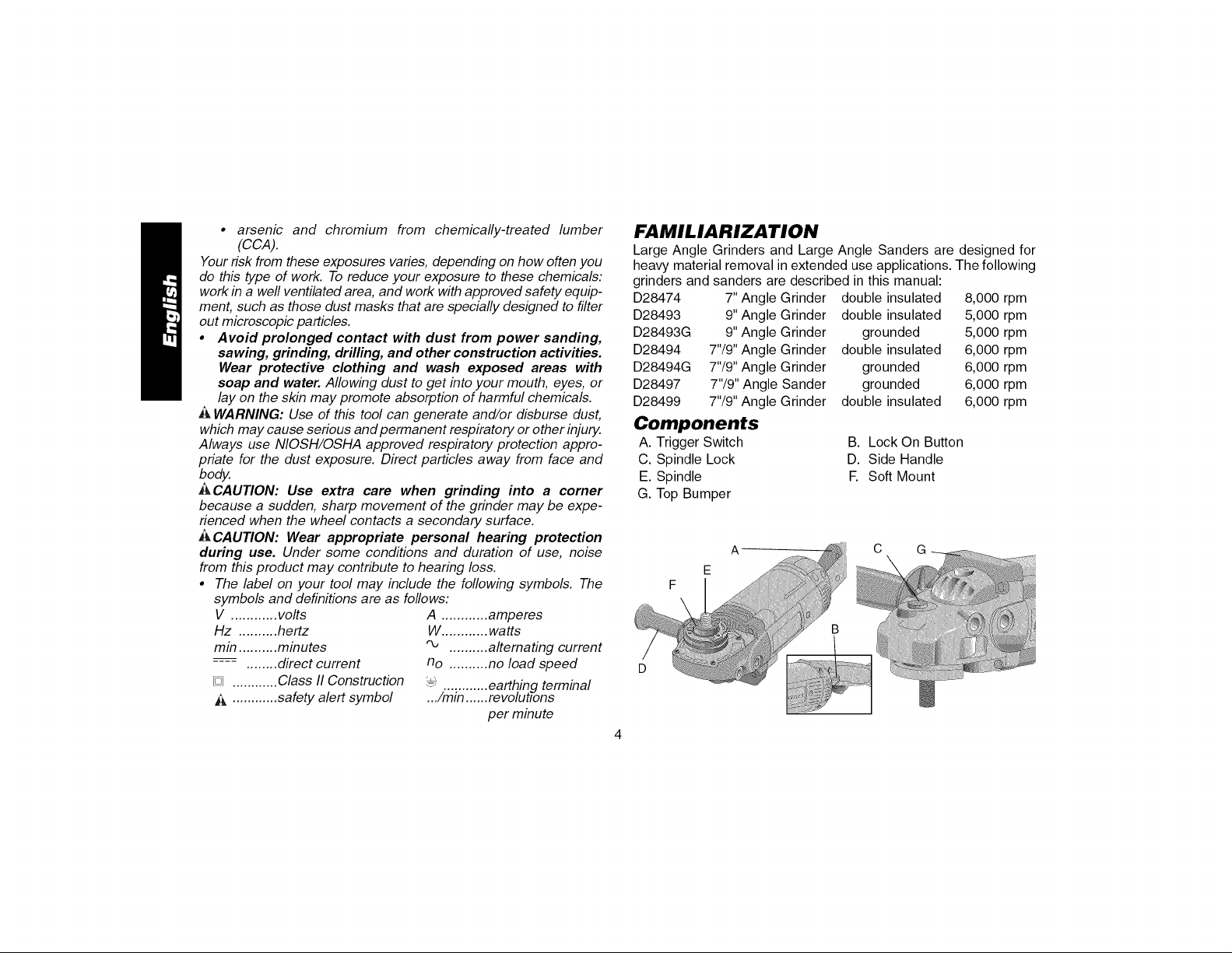

FAMILIARIZATION

Large Angle Grinders and Large Angle Sanders are designed for

heavy material removal in extended use applications. The following

grinders and sanders are described in this manual:

D28474 7"Angle Grinder double insulated

D28493 9"Angle Grinder double insulated

D28493G 9" Angle Grinder grounded

D28494 7"/9"Angle Grinder double insulated

D28494G 7"/9"Angle Grinder grounded

D28497 7"/9" Angle Sander grounded

D28499 7"/9"Angle Grinder double insulated

8,000 rpm

5,000 rpm

5,000 rpm

6,000 rpm

6,000 rpm

6,000 rpm

6,000 rpm

Components

A. Trigger Switch B. Lock On Button

C. Spindle Lock D. Side Handle

E. Spindle E Soft Mount

G. Top Bumper

A

E

D

C

Page 6

Features

SWITCH

The tool is controlled by a trigger switch (A). A lock-on button (B)

provides increased comfort in extended use applications.

ROTATING REAR HANDLE (D28499 ONLY)

The rear handle can be positioned 30°, 60°, and 90° left and right

of center position.

ROTATING GEAR CASE (D28474, D28493, D28494, D28497)

For applications in which a tool will be dedicated for uses in edge

grinding and finishing work, the gear case may be rotated 90° left

or right of its original position. See page 9 for instructions on

rotating the gear case.

MULTIPLE SIDE HANDLE POSITIONS

The side handle can be properly positioned in five locations based

on personal preference and application. The side handle must be

used at all times to maintain proper control of the tool.

TOP BUMPER

The gear case top bumper may wear with

use. The bumper can be replaced with part

number 397711-00 available at extra cost

from DEWALT authorized service centers.

Replacement should be performed by

DEWALT authorized service centers or

qualified service personnel.

SPINDLE LOCK

The spindle lock pin is provided to prevent the spindle from rotating

when installing or removing wheels. Operate the spindle lock pin

only when the tool is turned off and unplugged from the power

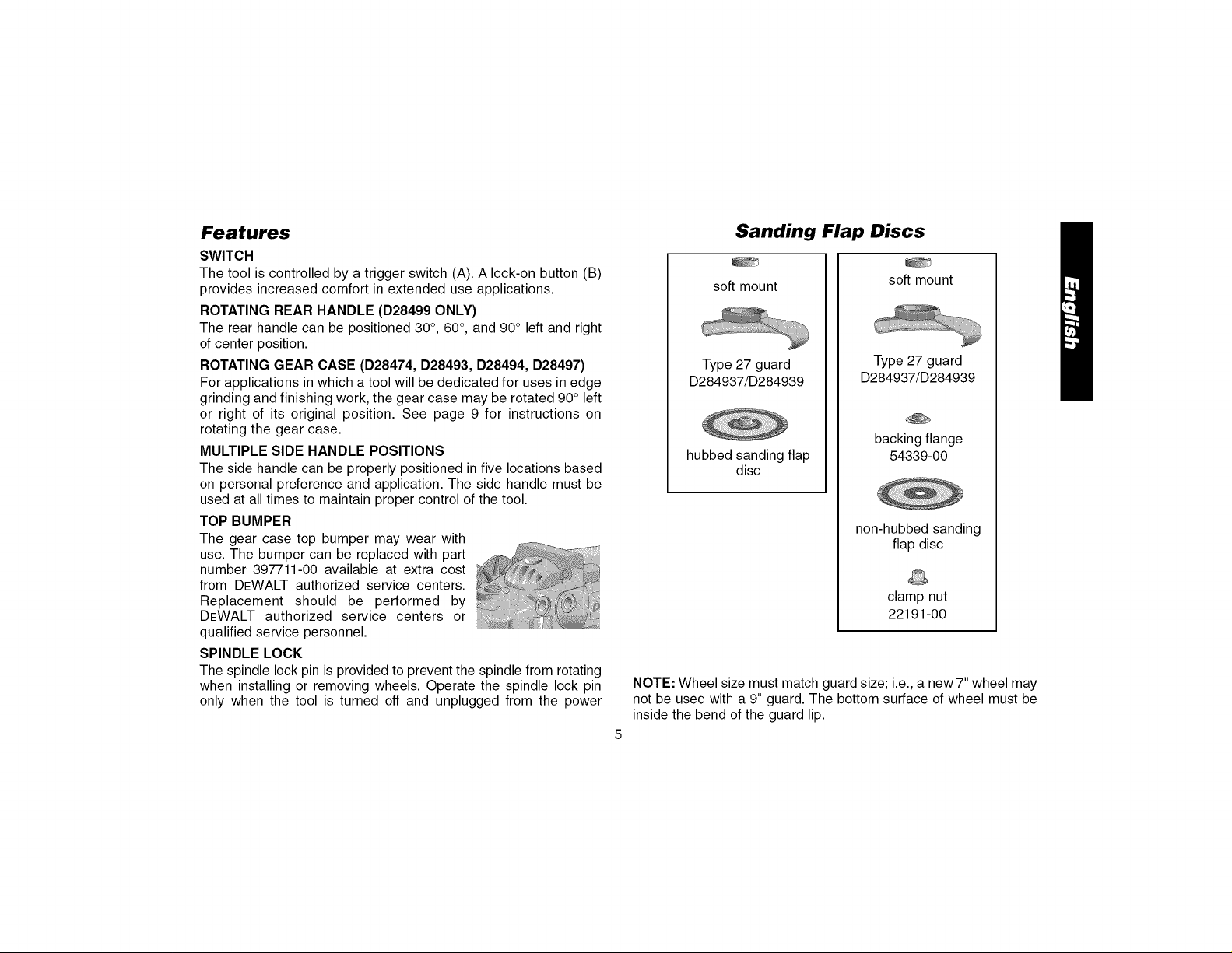

Sanding Flap Discs

soft mount

Type 27 guard

D284937/D284939

hubbed sanding flap

disc

NOTE: Wheel size must match guard size; i.e., a new 7" wheel may

not be used with a 9" guard. The bottom surface of wheel must be

inside the bend of the guard lip.

soft mount

Type 27 guard

D284937/D284939

backing flange

54339-00

non-hubbed sanding

flap disc

clamp nut

22191-00

Page 7

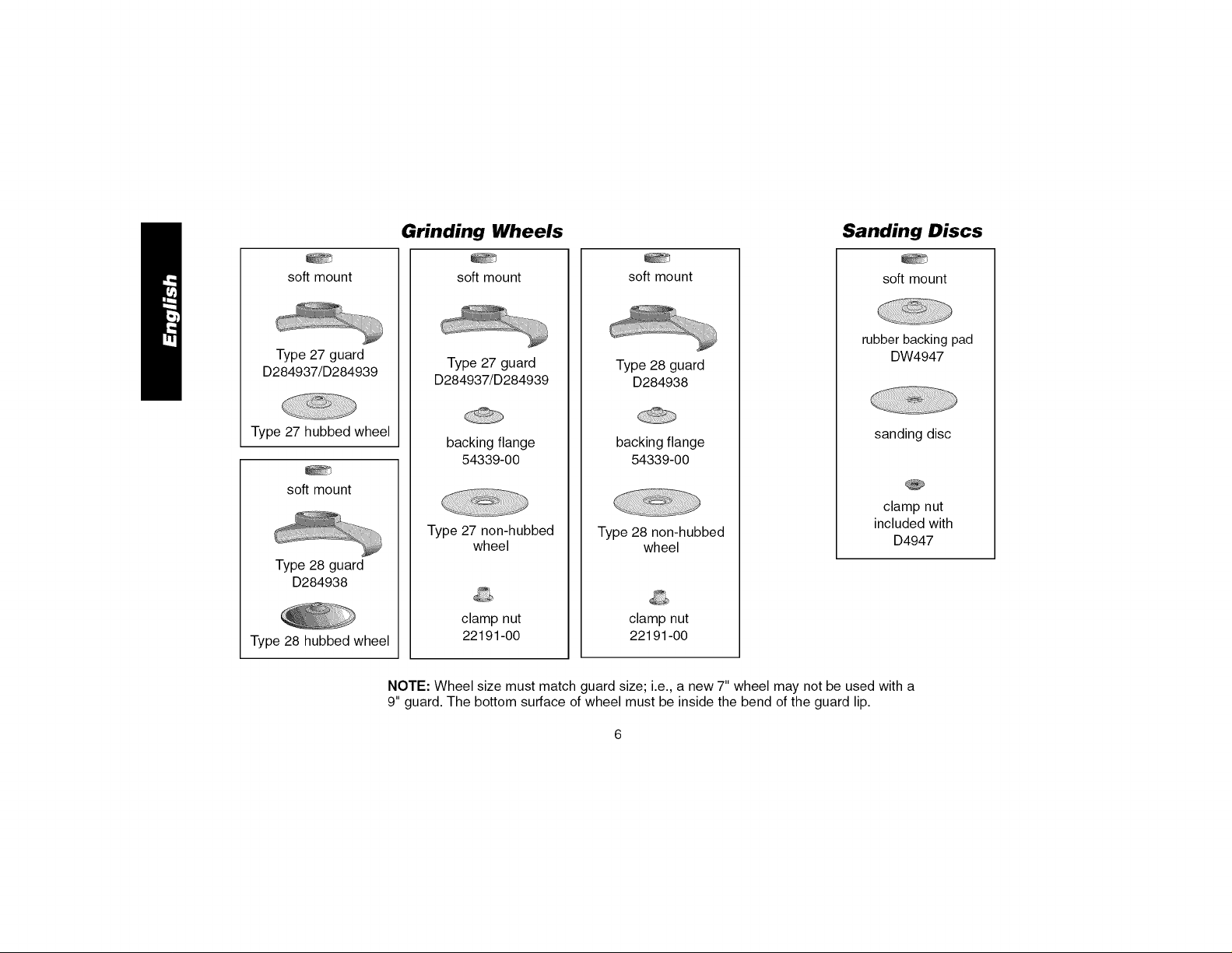

Grinding Wheels

Sanding Discs

softmount

Type27guard

D284937/D284939

Type27hubbedwheel

softmount

Type28guard

D284938

Type28hubbedwheel

NOTE: Wheel size must match guard size; i.e., a new 7" wheel may not be used with a

9" guard. The bottom surface of wheel must be inside the bend of the guard lip.

soft mount

Type 27 guard

D284937/D284939

backing flange

54339-00

Type 27 non-hubbed

wheel

clamp nut

22191-00

soft mount

Type 28 guard

D284938

backing flange

54339-00

Type 28 non-hubbed

wheel

clamp nut

22191-00

soft mount

rubber backing pad

DW4947

sanding disc

clamp nut

included with

D4947

Page 8

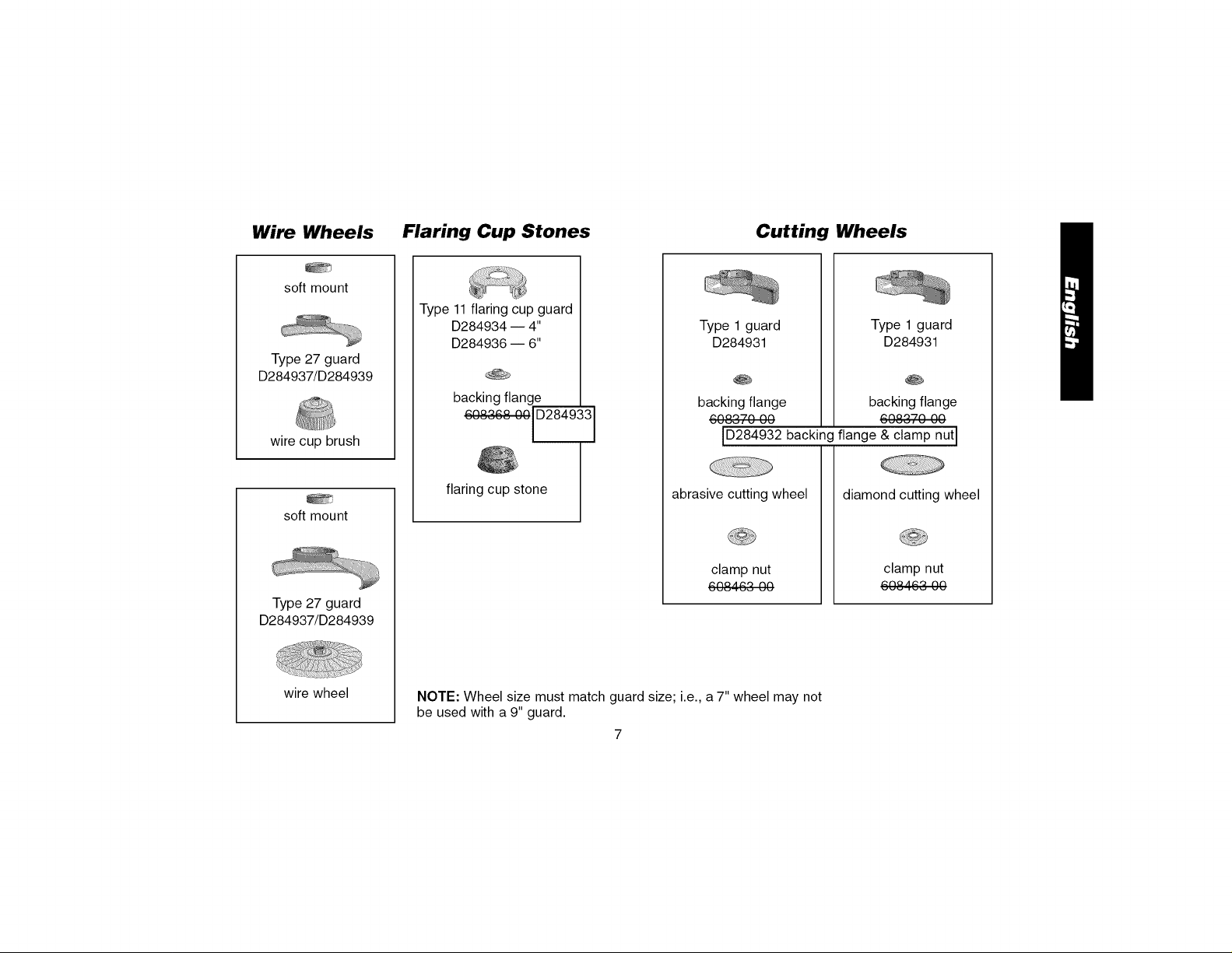

Wire Wheels

soft mount

Type 27 guard

D284937/D284939

wire cup brush

Flaring Cup Stones Cutting Wheels

Type 11flaring cup guard

D284934i4 ''

D284936--6"

backingflange

_oo_ovw_w001D2849:

31

Type 1 guard

D284931

backingflange

_nooTn nN

[D284932 backing flange & clamp nutJ

Type 1 guard

backingflange

D284931

_nooTn nN

soft mount

Type 27 guard

D284937/D284939

wire wheel

flaring cup stone

NOTE: Wheel size must match guard size; i.e., a 7" wheel may not

be used with a 9" guard.

abrasive cutting wheel

diamond cutting wheel

clamp nut

_no A_O nr_

Page 9

source.Toengagethelock,depressthespin-

dlelockbutton(C)androtatethespindleuntil C

youareunabletorotateitfurther.

ACAUTION:Never depress the spindle lock

button while the grinder b running. Never turn

on the grinder while the spindle lock button is

depressed. Damage to your tool or personal

injury may result.

SOFT MOUNT

The grinder is equipped with a soft mount, enabling easy wheel

installation and removal.

Accessories and Attachments

It is important to choose the correct guards, backing pads and

flanges to use with grinder accessories. See the chart on pages

5-7 for information on choosing the correct accessories.

ACAUTION: Accessories must be rated for at least the speed

recommended on the tool warning label Wheels and other acces-

sories running over rated speed can fly apart and cause injury.

Accessory ratings must always be above tool speed as shown on

tool nameplate.

ATTACHMENTS

Attachments designed specifically for this grinder can be

purchased through

Service centers.

D284939

D284948

D284937

D284936

D284934

D284933

D284932

DEWALT dealers and DEWALT Factory

9" Type 27 guard

9" Type 28 guard

7" Type 27 guard

6" Type 11 Flaring cup guard with flange

4" Type 11 Flaring cup guard with flange

Type 11 Flaring cup wheel backing flange

Type 1 Flange set

D284931

054339-00

22191-00

61820-01

445928-01

397711-00

7" Type 1 Guard

Grinding backing flange

Clamp nut

Wheel Wrench

Soft mount spindle protector

Top gear case bumper

ASSEMBLY AND ADJUSTMENTS

Attaching the Side Handle

To install the side handle, thread the handle into one of the five

positions listed below and tighten securely by turning clockwise.

• Two front positions: Forward handle

positions are designed for optimized bal-

ance in surface finishing applications.

• Two rear positions: Rear handle positions

are designed for optimized balance in edge

grinding applications.

• One top position: Top handle position is

designed for edge grinding applications.

NOTE: D28497 includes only three handle

positions.

Rotating the Rear Handle

Turn off and unplug tool before making any adjustments or

removing or installing accessories. Before reconnecting the

tool, depress and release the Ag_

trigger switch to ensure that the

tool is off. 60

1. Unlock the rear handle by

pulling out the Handle Release

Lever (G) as shown.

f

Page 10

2.Rotatehandleintoavailable0°,30°,60°,or90°positionleftOR

rightofcenter.

3.Pushinthehandlereleaselever.

4.Beforeturningthetoolon,ensurethatthehandleislockedinto

apositionandthehandlereleaseleverhasreturnedtotheorig-

inalpositionflushwiththetoolhousing.

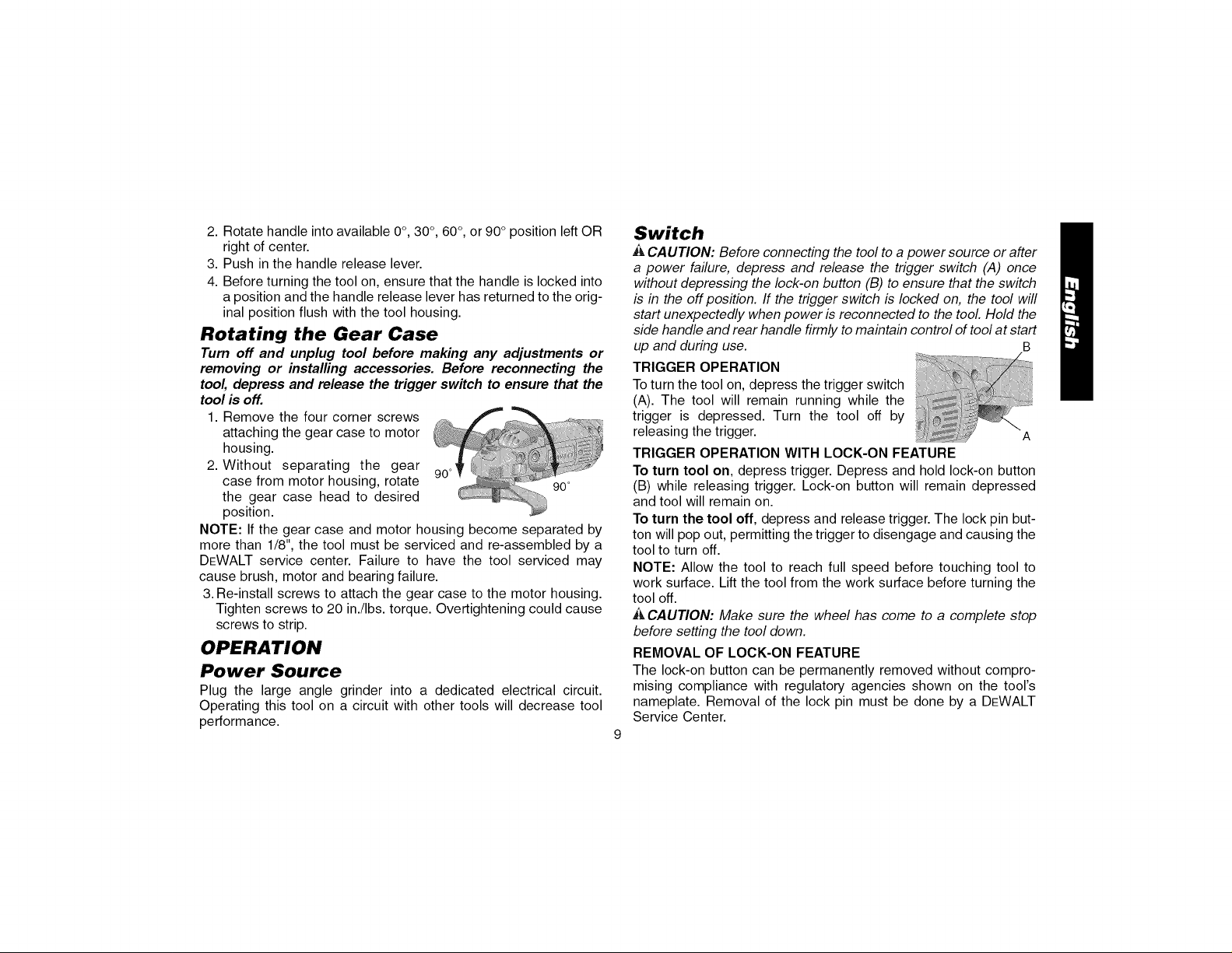

Rotating the Gear Case

Turn off and unplug tool before making any adjustments or

removing or installing accessories. Before reconnecting the

tool, depress and release the trigger switch to ensure that the

tool is off.

1. Remove the four corner screws

attaching the gear case to motor

housing.

2. Without separating the gear 90°

case from motor housing, rotate 90°

the gear case head to desired

position.

NOTE: If the gear case and motor housing become separated by

more than 1/8", the tool must be serviced and re-assembled by a

DEWALT service center. Failure to have the tool serviced may

cause brush, motor and bearing failure.

3. Re-install screws to attach the gear case to the motor housing.

Tighten screws to 20 in./Ibs, torque. Overtightening could cause

screws to strip.

OPERATION

Power Source

Plug the large angle grinder into a dedicated electrical circuit.

Operating this tool on a circuit with other tools will decrease tool

performance.

Switch

CAUTION: Before connecting the tool to apower source or after

a power failure, depress and release the trigger switch (A) once

without depressing the lock-on button (B) to ensure that the switch

is in the off position, ff the trigger switch is locked on, the tool will

start unexpectedly when power is reconnected to the tool Hold the

side handle and rear handle firmly to maintain control of tool at start

up and during use. B

TRIGGER OPERATION

To turn the tool on, depress the trigger switch

(A). The tool will remain running while the

trigger is depressed. Turn the tool off by

releasing the trigger.

TRIGGER OPERATION WITH LOCK-ON FEATURE

To turn tool on, depress trigger. Depress and hold lock-on button

(B) while releasing trigger. Lock-on button will remain depressed

and tool will remain on.

To turn the tool off, depress and release trigger. The lock pin but-

ton will pop out, permitting the trigger to disengage and causing the

tool to turn off.

NOTE: Allow the tool to reach full speed before touching tool to

work surface. Lift the tool from the work surface before turning the

tool off.

i_CAUTION: Make sure the wheel has come to a complete stop

before setting the tool down.

REMOVAL OF LOCK-ON FEATURE

The lock-on button can be permanently removed without compro-

mising compliance with regulatory agencies shown on the tool's

nameplate. Removal of the lock pin must be done by a DEWALT

Service Center.

Page 11

Mounting and Using Depressed Center

Grinding Wheels and Sanding Flap Discs

MOUNTING AND REMOVING GUARD

Turn off and unplug tool before making any adjustments or

removing or installing accessories. Before reconnecting the

tool, depress and release the trigger switch to ensure that the

tool is off.

IMPORTANT INFORMATION ABOUT GUARDS

Guards must be used with all grinding

wheels, sanding flap discs, wire brushes GRINDING

and wire wheels. The tool may be used with- WHEEL

out a guard only when sanding with conven- SURFACE

tional sanding discs. DEWALT models

D28493, D28494, D28474, D28499 are pro-

vided with a guard intended for use with

depressed center wheels (Type 27), and GUARD

hubbed grinding wheels (Type 27). The LIP

same guard is designed for use with sand-

ing flap discs, wire brushes and wire wheels.

Grinding and cutting with wheels other than Type 27 and 29 require

different accessory guards not included with the tool. Mounting

instructions for these accessory guards are included in the acces-

sory package.

_CAUTION: When using a grinding wheel with a Type 27, 28, or

29 guard, be sure that the bottom surface of the grinding wheel is

inside the the guard lip.

•& CAUTION: DEWALT model D28497 Angle Sander may only be

used for grinding by using appropriate accessory guard.

1. Open the guard latch (H), and align the lugs with slots on the

gear case cover. Position the guard facing backward, as

shown.

2. Push the guard down until the guard

lugs engage and rotate freely in the

groove on the gear case hub.

3. With the guard latch open, rotate the

guard into the desired working posi-

tion that provides maximum protec-

tion to the user as shown.

4. Close the guard latch to secure the

guard on the gear case. You should

be unable to rotate the guard by hand

when the latch is closed. Do not

operate the grinder with a loose

guard or the clamp lever in open

position.

5. To remove the guard, follow the pro-

cedure above in reverse order.

NOTE: The guard is pre-adjusted to the

diameter of the gear case hub at the fac-

tory. If, after a period of time, the guard

becomes loose, tighten the adjusting

screw (I) with clamp in the closed posi- I

tion.

CAUTION: Do not tighten the adjusting screw with the clamp

lever in open position. Undetectable damage to the guard or the

mounting hub may result.

MOUNTING AND REMOVING HUBBED WHEELS

Hubbed wheels install directly on the 5/8''i 11threaded spindle.

1. Thread the wheel on the spindle by hand, seating the wheel

against the soft mount.

2. Depress the spindle lock button and use a wrench to tighten the

hub of the wheel.

10

Page 12

3.Reversetheaboveproceduretoremovethewheel.

_CAUTION:Failure to properly seat the wheel against the soft

mount before turning the tool on may result in damage to the tool

or the wheel

MOUNTING NON-HUBBED WHEELS

Depressed center, Type 27 grinding wheels

must be used with available accessory flanges.

See the chart on pages 5-7 of this manual for

more information.

1. Install the metal backing flange (J) on spin-

dle (E) against the soft mount.

2. Place wheel against the backing flange,

centering the wheel on the backing flange

pilot.

3. While depressing the spindle lock button,

thread the clamp nut (K) on spindle, piloting

the raised hub on clamp nut in the center of

grinding wheel.

4. Tighten the clamp nut with a wrench.

5. Reverse the above procedure to remove the wheel.

SURFACE GRINDING WITH GRINDING WHEELS

1. Allow the tool to reach full speed before touching tool to work

surface.

2. Apply minimum pressure to work surface,

to allow the tool to operate at high speed.

3. Maintain a 20° to 30° angle between the

tool and work surface.

4. Continuously move the tool in a forward and back motion to

avoid creating gouges in the work surface.

5. Remove the tool from work surface before turning tool off. Allow

the tool to stop rotating before setting it down.

EDGE GRINDING WITH GRINDING WHEELS

[_CAUTION: Wheels used for cutting and edge grinding may

break or kick back if they bend or twist while the tool is being used

to do cut-off work or deep grinding. To reduce the risk of serious

injury, limit the use of these wheels with a standard Type 27 guard

to shallow cutting and notching (less than 1/2" in depth). The open

side of the guard must be positioned away from the operator. For

deeper cutting with a Type 1 wheel, use a closed, Type 1 guard.

Type 1 guards are available at extra cost from your local dealer or

authorized service center.

1. Allow the tool to reach full speed before touching the tool to the

work surface.

2. Apply minimum pressure to work surface, to allow the tool to

operate at high speed.

3. Protect yourself during edge finishing by directing the open side

of the guard away from you.

4. Move the tool continuously in a forward and back motion to

avoid creating gouges in the work surface.

5. Remove tool from work surface before turning the tool off. Allow

the tool to stop rotating before setting it down.

/_ WARNING: Do not use edge grinding wheels for surface grind-

ing applications because edge grinding wheels are not designed for

side pressures encountered with surface grinding. Wheel breakage

and injury may result.

SURFACE FINISHING WITH SANDING FLAP DISCS

1. Allow the tool to reach full speed before touching tool to work

surface.

2. Apply minimum pressure to work surface, to allow the tool to

operate at high speed.

3. Maintain a 5°to 10°angle between the tool

and work surface.

11

Page 13

4.Continuouslymovethetoolinaforwardandbackmotionto

avoidcreatinggougesintheworksurface.

5.Removethetoolfromworksurfacebeforeturningtooloff.Allow

thetooltostoprotatingbeforesettingitdown.

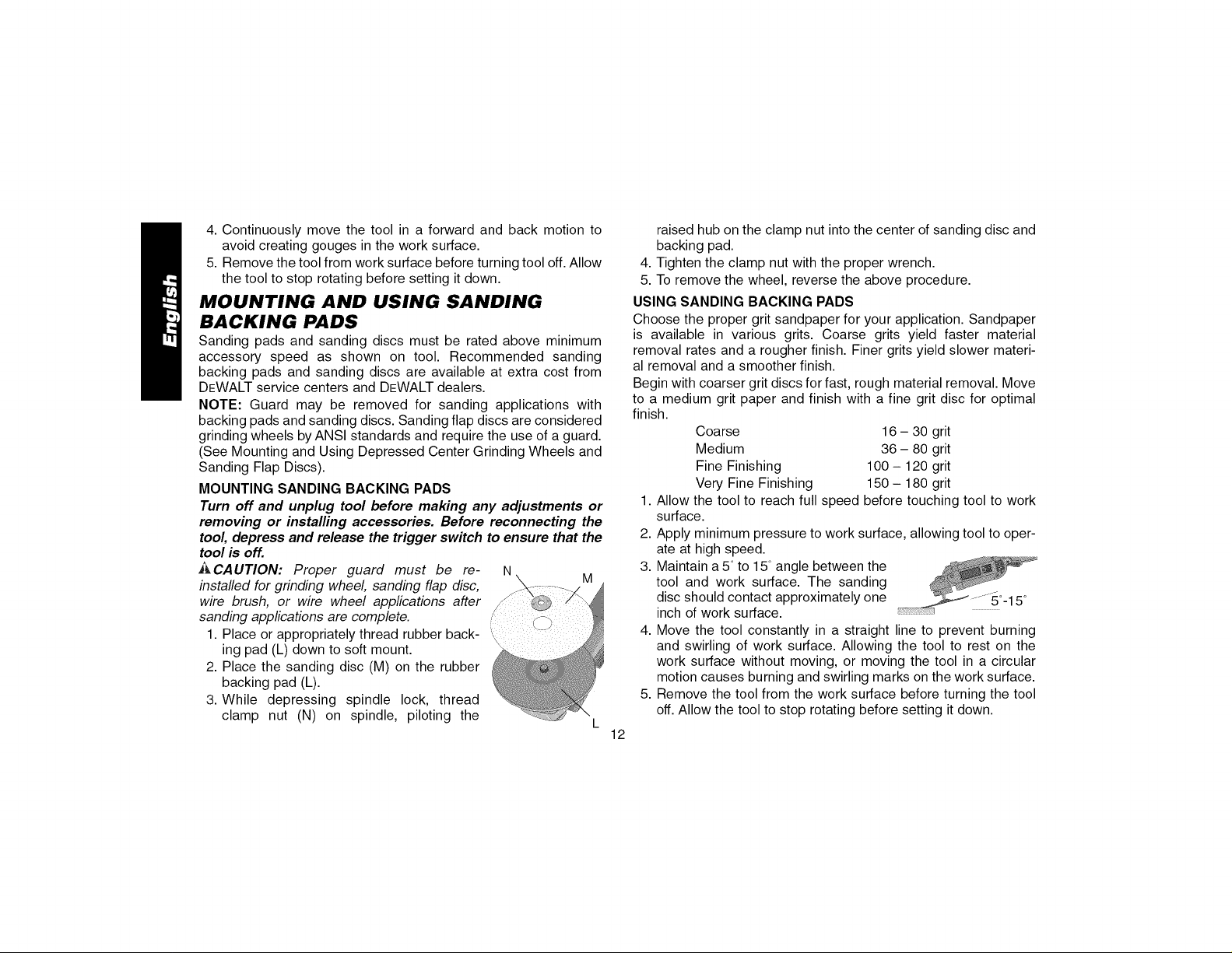

MOUNTING AND USING SANDING

BACKING PADS

Sanding pads and sanding discs must be rated above minimum

accessory speed as shown on tool. Recommended sanding

backing pads and sanding discs are available at extra cost from

DEWALT service centers and DEWALT dealers.

NOTE: Guard may be removed for sanding applications with

backing pads and sanding discs. Sanding flap discs are considered

grinding wheels by ANSI standards and require the use of a guard.

(See Mounting and Using Depressed Center Grinding Wheels and

Sanding Flap Discs).

MOUNTING SANDING BACKING PADS

Turn off and unplug tool before making any adjustments or

removing or installing accessories. Before reconnecting the

tool, depress and release the trigger switch to ensure that the

tool is off.

J_CAUTION: Proper guard must be re- N

installed for grinding wheel, sanding flap disc, M

wire brush, or wire wheel applications after

sanding applications are complete, f--_

1. Place or appropriately thread rubber back- ,_

ing pad (L) down to soft mount.

2. Place the sanding disc (M) on the rubber

backing pad (L).

3. While depressing spindle lock, thread

clamp nut (N) on spindle, piloting the

i '\ f_

raised hub on the clamp nut into the center of sanding disc and

backing pad.

4. Tighten the clamp nut with the proper wrench.

5. To remove the wheel, reverse the above procedure.

USING SANDING BACKING PADS

Choose the proper grit sandpaper for your application. Sandpaper

is available in various grits. Coarse grits yield faster material

removal rates and a rougher finish. Finer grits yield slower materi-

al removal and a smoother finish.

Begin with coarser grit discs for fast, rough material removal. Move

to a medium grit paper and finish with a fine grit disc for optimal

finish.

Coarse 16 - 30 grit

Medium 36 - 80 grit

Fine Finishing 100 - 120 grit

Very Fine Finishing 150 - 180 grit

1. Allow the tool to reach full speed before touching tool to work

surface.

2. Apply minimum pressure to work surface, allowing tool to oper-

ate at high speed.

3. Maintain a 5°to 15° angle between the

tool and work surface. The sanding

disc should contact approximately one 5°

inch of work surface.

4. Move the tool constantly in a straight line to prevent burning

and swirling of work surface. Allowing the tool to rest on the

work surface without moving, or moving the tool in a circular

motion causes burning and swirling marks on the work surface.

5. Remove the tool from the work surface before turning the tool

off. Allow the tool to stop rotating before setting it down.

12

Page 14

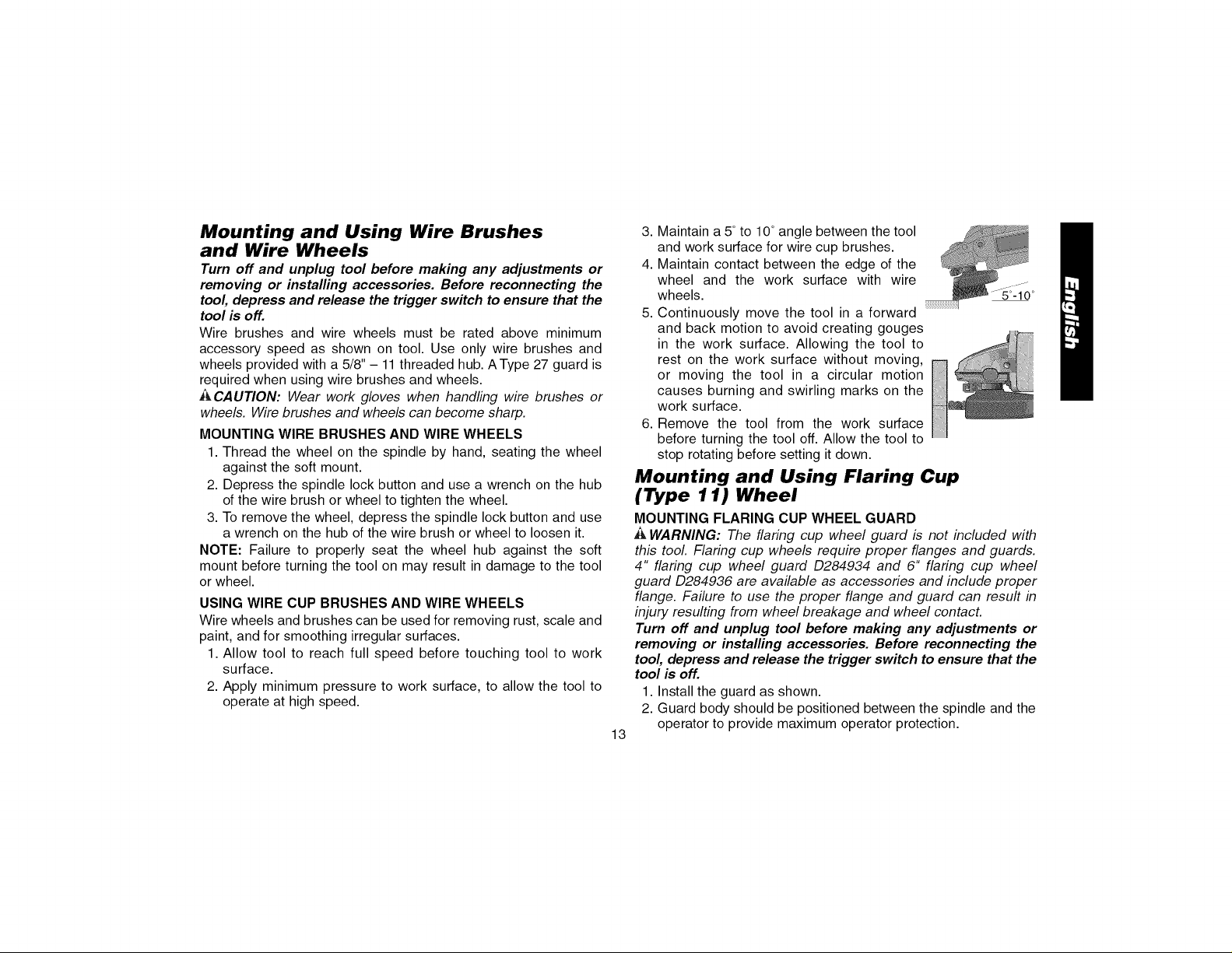

Mounting and Using Wire Brushes

and Wire Wheels

Turn off and unplug tool before making any adjustments or

removing or installing accessories. Before reconnecting the

tool, depress and release the trigger switch to ensure that the

tool is off.

Wire brushes and wire wheels must be rated above minimum

accessory speed as shown on tool. Use only wire brushes and

wheels provided with a 5/8"- 11threaded hub. AType 27 guard is

required when using wire brushes and wheels.

i_CAUTION: Wear work gloves when handling wire brushes or

wheels. Wire brushes and wheels can become sharp.

MOUNTING WIRE BRUSHES AND WIRE WHEELS

1. Thread the wheel on the spindle by hand, seating the wheel

against the soft mount.

2. Depress the spindle lock button and use a wrench on the hub

of the wire brush or wheel to tighten the wheel.

3. To remove the wheel, depress the spindle lock button and use

a wrench on the hub of the wire brush or wheel to loosen it.

NOTE: Failure to properly seat the wheel hub against the soft

mount before turning the tool on may result in damage to the tool

or wheel.

USING WIRE CUP BRUSHES AND WIRE WHEELS

Wire wheels and brushes can be used for removing rust, scale and

paint, and for smoothing irregular surfaces.

1. Allow tool to reach full speed before touching tool to work

surface.

2. Apply minimum pressure to work surface, to allow the tool to

operate at high speed.

3. Maintain a 5°to 10° angle between the tool

and work surface for wire cup brushes.

4. Maintain contact between the edge of the

wheel and the work surface with wire

wheels. °

5. Continuously move the tool in a forward

and back motion to avoid creating gouges

in the work surface. Allowing the tool to

rest on the work surface without moving,

or moving the tool in a circular motion

causes burning and swirling marks on the

work surface.

6. Remove the tool from the work surface

before turning the tool off. Allow the tool to

stop rotating before setting it down.

Mounting and Using Flaring Cup

(Type 11) Wheel

MOUNTING FLARING CUP WHEEL GUARD

•& WARNING: The flaring cup wheel guard is not included with

this tool. Flaring cup wheels require proper flanges and guards.

4" flaring cup wheel guard D284934 and 6" flaring cup wheel

guard D284936 are available as accessories and include proper

flange. Failure to use the proper flange and guard can result in

injury resulting from wheel breakage and wheel contact.

Turn off and unplug tool before making any adjustments or

removing or installing accessories. Before reconnecting the

tool, depress and release the trigger switch to ensure that the

tool is off.

1. Install the guard as shown.

2. Guard body should be positioned between the spindle and the

operator to provide maximum operator protection.

13

Page 15

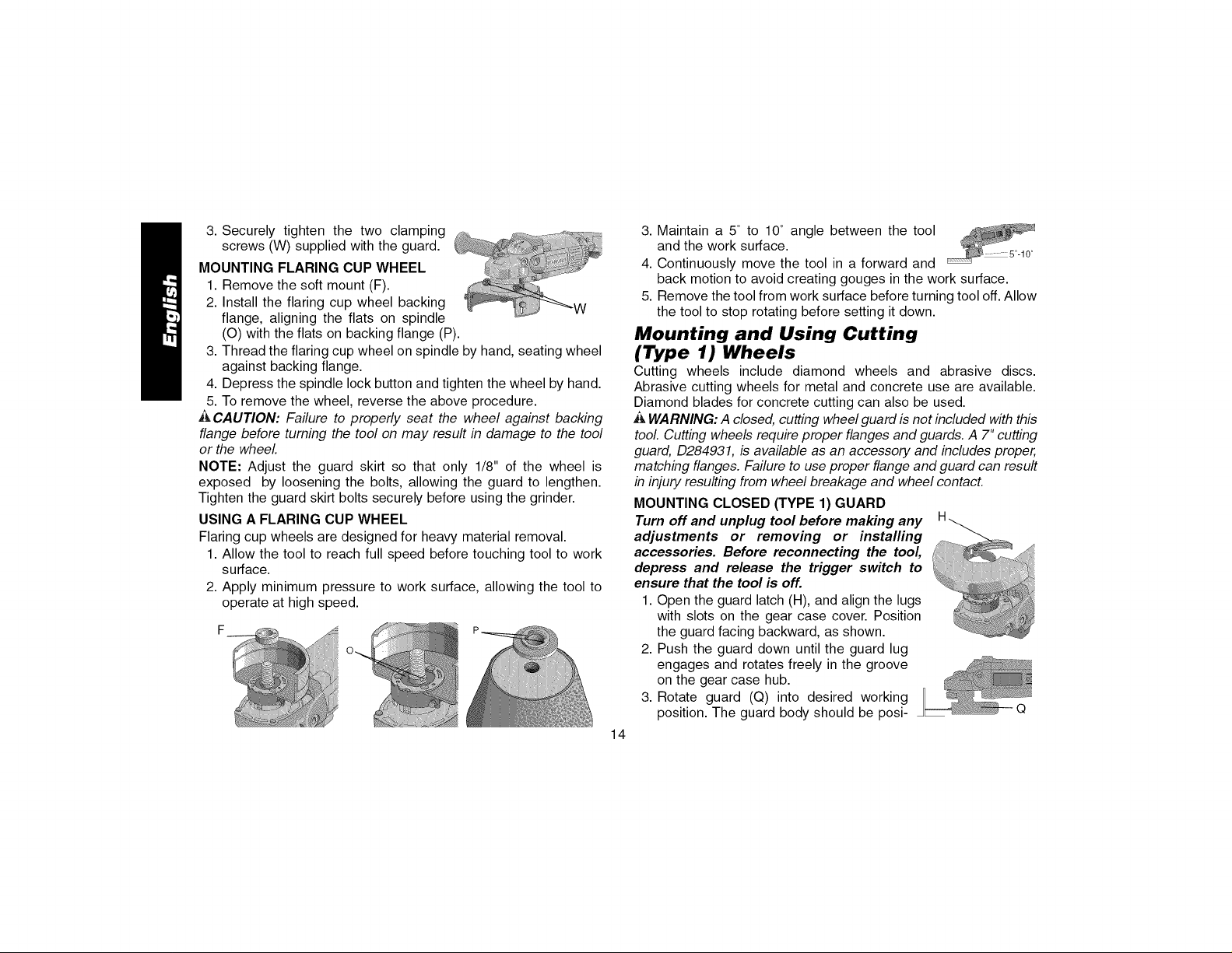

3.Securelytightenthetwoclamping.... ...........• ._-.

MOUNTINGscrews(W)FLARINGsuppliedcuPwithWHEELtheguard. _......

1.Removethesoftmount(F)

2.Installtheflaringcupwheelbacking

flange,aligningtheflatsonspindle W

(O)withtheflatsonbackingflange(P).

3.Threadtheflaringcupwheelonspindlebyhand,seatingwheel

againstbackingflange.

4.Depressthespindlelockbuttonandtightenthewheelbyhand.

5.Toremovethewheel,reversetheaboveprocedure.

_,CAUTION:Failure to properly seat the wheel against backing

flange before turning the tool on may result in damage to the tool

or the wheel

NOTE: Adjust the guard skirt so that only 1/8" of the wheel is

exposed by loosening the bolts, allowing the guard to lengthen.

Tighten the guard skirt bolts securely before using the grinder.

USING A FLARING CUP WHEEL

Flaring cup wheels are designed for heavy material removal.

1. Allow the tool to reach full speed before touching tool to work

surface.

2. Apply minimum pressure to work surface, allowing the tool to

operate at high speed.

3. Maintain a 5° to 10° angle between the tool

and the work surface.

4. Continuously move the tool in a forward and

back motion to avoid creating gouges inthe work surface.

5. Remove the tool from work surface before turning tool off. Allow

the tool to stop rotating before setting it down.

Mounting and Using Cutting

(Type 1) Wheels

Cutting wheels include diamond wheels and abrasive discs.

Abrasive cutting wheels for metal and concrete use are available.

Diamond blades for concrete cutting can also be used.

i_,WARNING: A closed, cutting wheel guard is not included with this

tool Cutting wheels require proper flanges and guards. A 7" cutting

guard, D284931, is available as an accessory and includes proper,

matching flanges. Failure to use proper flange and guard can result

in injury resulting from wheel breakage and wheel contact.

MOUNTING CLOSED (TYPE 1) GUARD

Turn off and unplug tool before making any

adjustments or removing or installing

accessories. Before reconnecting the tool,

depress and release the trigger switch to

ensure that the tool is off.

1. Open the guard latch (H), and align the lugs

with slots on the gear case cover. Position

the guard facing backward, as shown.

2. Push the guard down until the guard lug

engages and rotates freely in the groove

on the gear case hub.

3. Rotate guard (Q) into desired working

position. The guard body should be posi-

14

Q

Page 16

tionedbetweenthespindleandtheoperatortoprovidemaxi-

mumoperatorprotection.

4.Closetheguardlatchto securetheguardonthegearcase

cover.Youshouldbeunabletorotatetheguardbyhandwhen

thelatchis inclosedposition.Donotoperategrinderwitha

looseguardorclampleverinopenposition.

NOTE:Theguardispre-adjustedtothedia-

meterofthegearcasehubatthefactory.If,

aftera periodoftime,theguardbecomes

loose,tightentheadjustingscrew(I)withthe

clampleverintheclosedposition. I

CAUTION: Do not tighten adjusting screw

with clamp lever in open position. Undetectable damage to guard

or mounting hub may result.

MOUNTING CUTTING WHEELS

1. Remove Soft Mount (F).

2. Install wheel backing flange, aligning flats on spindle (O) with

flats on backing flange (R).

3. Place the wheel on the backing flange, centering the wheel on

the backing flange pilot.

R

4. Install the clamp nut, ensuring that the wheel remains centered

on the backing flange.

5. Depress the spindle lock button and tighten clamp nut with

wrench.

6. Reverse the above procedure to remove the wheel.

USING CUTTING WHEELS

A WARNING: Do not use edge grinding/cutting wheels for surface

grinding applications because these wheels are not designed for

side pressures encountered with surface grinding. Wheel breakage

and injury may result.

1. Allow tool to reach full speed before touching tool to work

surface.

2. Apply minimum pressure to work surface, allowing tool to oper-

ate at high speed.

3. Once you begin a cut, maintain the angle of the cutting wheel

to the work surface. This will keep you from bending the wheel

which could result in wheel breakage and injury.

4. Remove the tool from work surface before turning tool off. Allow

the tool to stop rotating before setting it down.

MAINTENANCE

Cleaning

i_ WARNING: Blowing dust and grit out of the motor housing using

clean, dry compressed air is a necessary regular maintenance pro-

cedure. Dust and grit containing metal particles often accumulate on

interior surfaces and could create an electrical shock or electrocu-

tion if not frequently cleaned out. ALWAYS WEAR SAFETY

GLASSES.

_CAUTION: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool Use aclean, dry rag only.

15

Page 17

Lubrication

DEWALT tools are properly lubricated at the factory and are ready

for use.

Repairs

To assure product SAFETY and RELIABILITY, repairs, mainte-

nance and adjustment should be performed by authorized service

centers or other qualified service personnel. Always use identical

replacement parts.

Motor Brushes

When brushes become worn, the tool will automatically stop, pre-

venting damage to the motor. Brush replacement should be per-

formed by DEWALT authorized service centers or other qualified

service personnel. Qualified service personnel should follow the

procedures below when replacing motor brushes.

Turn off and unplug tool before making any adjustments or

removing or installing accessories. Before reconnecting the

tool, depress and release the trigger switch to ensure that the

tool is off.

1. Remove the brush doors located on the sides of motor housing.

2. To remove the brush, hold the female terminal, which is

attached to the brush lead wire, and disconnect the female ter-

minal from the male terminal.

3. Pull the brush straight up out of the brush holder.

4. Replace brushes, in pairs, with original DEWALT brushes avail-

able from DEWALT authorized service centers.

5. Ensure that the brushes slide freely in brush box.

6. Reconnect the brush lead wire to brush box terminal.

7. Re-install the brush doors before using the tool. Torque screws

to 10 in./Ibs., maximum. Overtightening may cause screws to

strip.

Purchasing Accessories

Recommended accessories for use with your tool are available at

extra cost from you local dealer or authorized service center. Ifyou

need assistance in locating any accessory for your tool, contact:

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD

21286.

_CAUTION: Accessories must be rated for at least the speed

recommended on the tool warning label Wheels and other acces-

sories running over rated speed can fly apart and cause injuoz.

Accessory ratings must always be above tool speed as shown on

tool nameplate.

A CAUTION: The use of any other accessory not recommended

for use with this tool could be hazardous.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty mate-

rials or workmanship for three years from the date of purchase.

This warranty does not cover part failure due to normal wear or tool

abuse. For further detail of warranty coverage and warranty repair

information, visit www.dewalt.com or call 1-800-4-DEWALT (1-800-

433-9258). This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by others.

This warranty gives you specific legal rights and you may have

other rights which vary in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by

normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

16

Page 18

DEWALTPowerTool,Laser,orNailerforanyreason,youcan

returnitwithin90daysfromthedateofpurchasewithareceiptfor

afullrefund- noquestionsasked.

FREEWARNINGLABELREPLACEMENT:Ifyourwarninglabels

becomeillegibleoraremissing,call1-800-4-DEWALTforafree

replacement.Torequestreplacementlabels,youwillneedtoknow

theratedrpmofyourtool.Therpmofyourtoolisstampedintothe

toolhousing.

17

Page 19

POURTOUTRENSEIGNEMENTSUPPLI2MENTAIRESURCET

OUTILOUTOUTAUTREOUTILDEWALT,COMPOSERSANS

FRAISLENUMI2RO:

18004-DEWALT(1800433-9258)

CONSERVER CES

DIRECTIVES!

MESURES DE S_'CURIT_"-

G_'N_'RALIT_'S

_ AVERTISSEMENT! Lire et comprendre

toutes les directives, car/e non-respect

des directives suivantes pourrait entrafner

un risque de choc electrique, d'incendie ou

de blessures graves.

CONSERVER CES DIRECTIVES

ZONE DE TRAVAIL

Garder la zone de travail propre et bien eclairee; les 6tablis

encombr6s et les endroits sombres sont propices aux accidents.

Ne pas utiliser les outils electriques clans une atmosphere

explosive, comme a proximite de liquides, de gaz ou de

poussieres inflammables; le moteur peut cr6er des 6tincelles

et enflammer les vapeurs ou les poussieres environnantes.

_ Tenir les enfants, les visiteurs ou toute autre personne

I'ecart Iorsqu'on utilise un outil electrique; les distractions

peuvent faire perdre la maftrise de ce demier.

MESURES DE SI_CURITI_ - I_LECTRICITI_

Les outils mis a la terre doivent 6tre branches clans uneprise

bien installee et mise a laterre conformement a tousles codes 18

et reglements en vigueur. Ne jamais retirer la broche de terre

ni modifier la fiche. Ne pas utiliser d'adaptateur. Verifier

aupres d'un electricien qualifie en cas de doute quant a la

mise a la terre de la prise. En cas de d6fai//ance 6/ectrique ou

de bris de I'outil, la mise a la terre procure un chemin de faible

r6sistance au courant qui autrement traverserait I'utilisateur.

Pour 6viter que I'utilisateur ne soit 61ectrocut6 en cas de

d6faillance, de bris ou de conductivit6 de Ibutil, celui-ci est dot6

d'une fiche a trois broches afin d'assurer la mise a la terre, fly a

risque d'61ectrocution, de blessures graves ou de mort Iorsqu'on

utilise un outil dont une broche est endommag6e ou absente ou

dont la fiche ou le cordon est endommag6 ou qui n'est pas

branch6 dans une prise conforme mise continuellement a la

terre. Pour 6viter les risques de blessures, Ibutil do# toujours

6tre bien entretenu et en bon 6tat de marche (cordon, broches

de la fiche) et doit 6tre branch6 dans une prise mise a la terre

continuellement. (Voir 6galement la rubrique ,, Nettoyage ,

dans la section Entretien, page 34.) S'applique uniquement

aux outils de classe I (mis a la terre).

Les outils a double isolation sont pourvus d'une fiche

polarisee (une lame est plus large que I'autre). Cette fiche

ne peut #tre branchee clans une prise polarisee que clans

un seul sens. Si la fiche ne peut #tre branchee clans la

prise, inverser la fiche. Si on n'arrive pas a/a brancher, com-

muniquer avec un _lectricien qualifi_ afin qu'il installe une prise

polaris#e. Ne pas modifier la fiche. La double isolation _ #lim-

ine le besoin du systeme de rallonge d'alimentation a trois ills et

de bloc d'alimentation avec mbe a la terre. S'applique unique-

ment aux outils de classe II (a double isolation).

A

Eviter tout contact entre le corps et les elements mis a la

terre, comme les tuyaux, les radiateurs, les cuisinieres et

les refrigerateurs, afin de r_duire les risques de choc

_letrique.

Page 20

Ne pas utiliser I'outil electrique clans des endroits mouilles,

ni /'exposer a/a p/uie; /'infiltration d'eau a/'int6rieur de/'outi/

augmente les risques de choc 61ectrique.

Ne pas utiliser le cordon de maniere abusive; on ne doit pas

transporter I'outil en le tenant par le cordon, ou utiliser ce demier

pour le d6brancher. On doit tenir le cordon a 1'6cartdes sources

de chaleur, de I'huile, des bords tranchants ou des pieces

mobiles. Remplacer imm6diatement les cordons endommag6s,

car ces derniers augmentent les risques de choc 61ectrique.

Lorsqu'on utilise un outil electrique a I'exterieur, on ne dolt

utiliser que des rallonges con_ues pour cet usage, comme

celles de type ,W-A,> ou ,W,>, afin de r6duire les risques de

choc 61ectrique.

Calibre minimal des cordons de rallonge

TensionLongueur totale du cordon en meters

120V De0&7 De7&15 De 15&30 De 30&45

Intensit6 (A)

Au Au Calibre moyen de fil

moins plus

12 16 14 12 Nonrecommand6

SC'CURIT¢' PERSONNELLE

Rester vigilant en tout temps et faire preuve de jugement

Iorsqu'on utilise un outil electrique; ne pas utiliser I'outil

Iorsqu'on est fatigue ou sous I'influence de drogues,

d'alcool ou de medicaments, car un moment d'inattention

pourrait entrainer des blessures graves.

Porter des v6tements appropries; ne pas porter de

v6tements amples ni de bijoux. Couvrir ou attacher les

cheveux longs. Garder les cheveux, les v_tements, les bijoux

et les gants 61oign6s des pieces mobiles, car ceux-ci peuvent

s'y coincer. Se tenir 61oign6 des 6vents puisque ces demiers

pourraient camoufler des pieces mobiles.

Eviter les demarrages accidentels; s'assurer que

I'interrupteur est en position d'arr6t avant de brancher

I'outil. Ne pas transporter I'outil en laissant le doigt sur

I'interrupteur nile brancher Iorsque I'interrupteur est en position

de marche, car cela pourrait causer un accident.

_ Retirer les cles de reglage avant de demarrer I'outil; une cl6

laiss6e sur une piece rotative pourrait entrainer des blessures.

Ne pas trop etendre les bras; les pieds doivent rester ancr6s

fermement sur le sol afin de maintenir son 6quilibre en tout temps

et de mieux maitriser I'outil clans des situations impr6vues.

_1, Utiliser le materiel de securite approprie; toujours porter

des lunettes de protection. Porter un masque anti-poussiere,

des chaussures antid6rapantes, un casque de s6curit6 ou des

protecteurs auditifs Iorsque la situation le requiert.

UTILISATION ET ENTRETIEN DE L'OUTIL

_ Fixer et soutenir le materiau sur une plate-forme stable au

moyen d'une bride de serrage ou de tout autre dispositif

semblable; le mat6riau est instable Iorsqu'on le retient

manuellement ou qu'on I'appuie contre le corps, ce qui pourrait

faire perdre la maitrise de I'outiL

Ne pas forcer I'outil ni I'utiliser pour des travaux autres que

ceux pour lesquels il a ete con_u. Pour obtenir de meilleurs

r6sultats etpr6venir les risques de blessure, laisser I'outil couper

la vitesse pour laquelle il a 6t6 congu.

_ Ne pas utiliser I'outil Iorsque I'interrupteur marche-arr6t ne

fonctionne pas; tout outil qui ne peut 6tre command6 au

moyen de I'interrupteur est dangereux et doit 6tre r6par6.

19

Page 21

Debrancher I'outil avant d'effectuer un reglage, de changer

les accessoires ou de ranger I'outil; ces mesures de s6curit6

pr6ventives r6duisent les risques de d6marrage accidentel.

_ Lorsqu'on n'utilise pas I'outil, le ranger hors de la portee

des enfants ou des personnes non qualifiees; les outils sont

dangereux entre les mains de personnes inexp6riment6es.

_ Bien entretenir I'outil; s'assurer qu'il est toujours bien

propre et aiguise. Les outils bien entretenus et dont les bords

sont bien tranchants sont moins susceptibles de rester coinc6s

et sont plus faciles a maitriser.

Verifier les pieces mobiles afin de s'assurer qu'elles sont

bien alignees et qu'elles ne restent pas coincees; verifier

egalement les pieces afin de s'assurer qu'il n'y a ni bris ni

aucune autre condition susceptible de nuire au bon

fonctionnement de I'outil. Faire r6parer I'outil si ce demier est

endommag6 avant de s'en servir a nouveau, car les accidents

sont souvent caus6s par des outils mal entretenus.

N'utiliser que les accessoires recommandes par le fabricant

pour le modele concerne; un accessoire destin6 a un outil

particulier peut devenir dangereux Iorsqu'il est utilis6 avec un

autre.

ENTRETIEN

L'outil doff 6tre entretenu par le personnel quafifie

seulement; toute maintenance effectu6e par une personne non

qualifi6e pourrait entrainer des risques de blessure.

Lors de I'entretien, n'utiliser que des pieces de rechange

identiques et suivre les directives de la section .Entretien,>

du present guide afin de pr6venir les risques de choc 61ectrique

ou de blessure.

R_gles de s_curit_ sp_cifique

concernant les meules

Toujours utiliser le dispositif de protection qui convient a la

meule afin de prot6ger I'op6rateur des fragments pouvant _tre

projet6s par une meule bris6e.

Les accessoires doivent 6tre concus au moins pour le regime

recommande sur I'etiquette d'avertissement de I'outil. Les

meules et autres accessoires toumant a un r6gime sup6rieur a la

vitesse nominale peuvent se d6sint6grer et causer des blessures.

La vitesse nominale de I'accessoire doit toujours 6tre sup6rieure

celle de I'outil indiqu6e sur la plaque signal6tique de I'outil.

REMARQUE : la vitesse nominale a vide de I'outil est indiqu6e sur

la plaque signal6tique et le carter d'engrenages.

Vitesse nominale Vitesse minimale

&vide de I'outil des accessoires

5 000 trs/min 5 500 trs/min

6 000 trs/min 6 600 trs/min

8 000 trs/min 8 500 trs/min

A

Tenir I'outil par les surfaces isolees prevues a cette fin

Iorsqu'il risque d'entrer en contact avec des ills caches ou

son propre cordon, car de tels contacts peuvent mettre les

pieces m6talliques de I'outil sous tension, engendrant des risques

de choc 61ectrique.

A

Avant d'utiliser les accessoires recommandes, s'assurer

qu'ils ne presentent aucune fissure ou defectuosite. Si une

fissure ou d6fectuosit6 est 6vidente, mettre I'accessoire au rebut. II

faut 6galement v#rifier I'accessoire si /'onsoupgonne que I'outil a

subi une chute. Unaccessoire d#fectueux pourrait entrainer le bris

de la meule.

20

Page 22

_ Apres I'installation d'une meule neuve ou de rechange, si

I'etat de marche de la meule est douteux, ou si I'etat de

marche de la meule est douteux, faire fonctionner I'outil

pendant une minute en s'assurant d'en 6tre bien protege. Si

la meule est affect6e d'une f_lure ou d'un d6faut ind6tect6, elle

devrait 6clater en moins d'une minute. Ne jamais d6marrer Ibutil

Iorsque quelqu'un se tient directement devant la meule, y

cempris I'utilisateur.

_ Eviter de faire rebondir la meule durant son fonctionnement

ou de I'utiliser sans menagement. Si /a meu/e subit de tels

traitements, arr6ter I'outil et inspecter cette derniere.

_ Placer la ponceuse ou la meuleuse de maniere a ce que les

etincelles soient projetees du c6te oppose a I'operateur, ou

toute autre personne ou matieres inflammables; les outils

peuvent produire des 6tincelles et causer des brDlures ou un

incendie.

_ Toujours utiliser la poignee laterale et s'assurer qu'elle est

bien serree afin de bien maitriser I'outil en tout temps.

_, Faire preuve d'une grande prudence Iorsqu'on meule clans

un coin, car la meuleuse pourrait rebondir soudainement si la

meule entre en contact avec une autre surface.

_, Nettoyer periodiquement I'outil; la poussiere et la salet6

contenant des particules m6talliques tendent a s'accumuler sur

les surfaces internes et peuvent entrainer des risques de chec

61ectrique, des blessures, eu 1'61ectrecutien.

_ Ne pas utiliser cet outil pendant des periodes prolongees.

Les vibrations caus6es par I'outil peuvent poser des risques pour

les mains ou les bras. Porter des gants pour amortir les

vibrations, et pour limiter les risques faire des pauses fr6quentes.

AVERTISSEMENT : Certains outils, tels que les sableuses 61ec-

triques, les scies, les meules, les perceuses ou certains autres out-

ils de construction, peuvent soulever de la poussiere contenant des

produits chimiques susceptibles d'entrainer le cancer, des malfor-

mations cong6nitales ou pouvant 6tre nocifs pour le systeme repro-

ductif. Parmi ces produits chimiques, on retrouve:

• le plomb dans les peintures a base de plomb;

• la silice cristalline dans les briques et le ciment et autres pro-

duits de ma_onnerie;

• I'arsenic et le chrome dans le bois de sciage ayant subi un

traitement chimique (CCA).

Le risque associ6 a de telles expositions peut varier selon la

fr6quence avec laquelle on effectue ces travaux. Pour r6duire I'ex-

position a de tels produits, il faut travailler dans un endro# bien ven-

til6 et utiliser 1'6quipement de s6curit6 appropri6 tel un masque anti-

poussieres sp6cialement congu pour filtrer les particules micro-

scopiques.

• Eviter tout contactprolonge avec la poussiere soulevee par

cet outil ou autres outils electriques. Porter des v6tements

de protection et nettoyer les parties exposees du corps

avec de I'eau savonneuse. S'assurer de bien se prot6ger afin

d'6viter d'absorber par la beuche, les yeux eu la peau des pro-

duits chimiques nocifs.

AAVERTISSEMENT : Toute personne entrant la zone de travail

devrait porter un masque anti-poussieres ou un appareil respira-

teire. Le filtre doit en 6tre remplac6 quotidiennement ou chaque feis

que I'utilisateur commence a aveir des difficult#s a respirer. Se ren-

seigner aupres de son quincaillier local pour la liste des masques

anti-peussieres appreuv#s par le NIOSH/OSHA.

AMISE EN GARDE : Le meulage a I'interieur d'un angle ou

clans un coin peut creer un mouvement brusque de I'outil si la

meule ou un autre accessoire touche a une surface secondaire eu

teute autre surface, fl faut donc 6tre tres vigilant.

_MISE EN GARDE : Porter des protecteurs d'oreilles appro-

pries durant I'utilisation. Selen les conditions et la dur#e d'utili-

satien, le bruit #mis par cet eutil peut causer une perte auditive.

21

Page 23

L'6tiquettedeIbutilpeutcomporterlessymbolessuivants.Voici

lessymbolesetleursd6finitions:

V.................... volts

Hz .................. hertz

min ................ minutes

.... .............. courant continu

[] .................... Construction

de classe II

A .................. symbole

...................... d'a vertissement

FAMI LIARISA TION

Les grandes meuleuses angulaires et les grandes ponceuses

angulaires sont con£ues pour _tre utilis_es dans des travaux

importants prolong_s d'enl_vement de mat_riau. Les meuleuses et

les ponceuses suivantes sont d_crites dans le present guide :

D28474 Meuleuse angulaire de 7 po

& double isolation 8 000 trs/min

D28493 Meuleuse angulaire de 9 po

& double isolation 5 000 trs/min

D28493G Meuleuse angulaire de 9 po

mis &la terre 5 000 trs/min

D28494 Meuleuse angulaire de 7 po/9 po

& double isolation 6 000 trs/min

D28494G Meuleuse angulaire de 7 po/9 po

mis &la terre 6 000 trs/min

D28497 Ponceuse angulaire de 7 po/9 po

mis &la terre 6 000 trs/min

D28499 Meuleuse angulaire de 7 po/9 po

& double isolation 6 000 trs/min

A .......... amperes

W ........ watts

"_ ........courant alternatif

no ........SOdS vide

.......... borne de mise

............la minute

.../min ..tours ou courses

............ a la minute

A

E

F

C G

Composants

A. Interrupteur & g&chette

B. Bouton de verrouillage en position de marche

C. Bouton de verrouillage de la broche

D. Poign_e lat_rale

E. Broche

F. Bague en nylon

G. Butte sur le dessus

Caract_ristiques

INTERRUPTEUR ._,GACHETTE

L'outil est command_ par un interrupteur & g&chette (A). Le bouton

de verrouillage en position de marche (B) permet de faciliter la

t&che Iors d'usage prolong&

POIGN#E ARRI#RE TOURNANTE (D28499 SEULEMENT)

La poign_e arri_re peut _tre plac_e &30 °, & 60°, et &90° & gauche

et & droite de la position centrale.

22

Page 24

CARTERD'ENGRENAGES TOURNANT (D28474, D28493,

D28494, D28497)

Pour les applications o_ I'outil est utilis_ exclusivement dans le

meulage de bordure ou des travaux de finition, le carter d'en-

grenages peut 6tre tourn_ de 90 ° &gauche ou &droite de sa posi-

tion initiale. Cette modification doit _tre effectu_e dans un centre de

service autoris_ ou par du personnel qualifi& Voir les pages 27.

POSITIONS MULTIPLES DE LA POIGN#E LAT#RALE

La poign_e lat_rale peut 6tre plac_e dans cinq positions selon les

preferences personnelles de I'op_rateur et I'application. Toujours

utiliser la poign_e lat_rale afin de bien maftriser I'outil.

BUT#E SUR LE DESSUS

La butte sur le dessus peut s'user peu &

peu. Elle peut _tre remplac_e par le num_ro

de piece D397711-00 vendu s_par_ment

dans les centres de service autoris_s

DEWALT. Les buttes doivent _tre rem-

plac_es par les centres de service autoris_s

DEWALT ou par du personnel qualifi&

BOUTON DE VERROUILLAGE DE LA BROCHE

Le bouton de verrouillage de la broche sert & emp_cher la broche

de tourner Iors de I'installation et du retrait des meules. Arr6ter et

d_brancher I'outil avant d'utiliser le bouton de verrouillage de la

broche. Pour activer le dispositif de verrouillage, enfoncer le bou-

ton de verrouilage de la broche (C) et tourner la broche jusqu'& ce

qu'elle s'arr6te.

_MISE EN GARDE : Ne jamais appuyer sur le bouton de com-

mande de verrouillage de la broche Iorsque la meuleuse fonctionne.

Ne jamais faire fonctionner la meuleuse Iorsque la commande de

verrouillage de la broche est enfonc6e. Lbutil risque de s'endom-

mager et de blesser I'utilisateur.

Disques de pon_age a feuillets

bague en nylon

Type 27 guard : Dispositif

de protection n° 27

D284937/D284939

disque de pon£age &

feuillets avec moyeu

REMARQUE : le diam_tre de la meule doit correspondre aux

dimensions du dispositif de protection; c'est-&-dire, il n'est pas

possible d'utiliser une meule de 7 pouces avec un dispositif de

protection de 9 pouces. La surface inf_rieure de la meule doit se

trouver & I'int_rieur du bord du dispositif de protection.

23

bague en nylon

Type 27 guard = Dispositif

de protection n° 27

D284937/D284939

_p

bride de soutien

54339-00

disque de pon_age &

feuillets sans moyeu

ecrou de blocage

22191-00

Page 25

Meules

Disques de pon_age

bagueennylon

dispositifdeprotection

n°27

D284937/D284939

meuleavecmoyeu

n°27

bagueennylon

bague en nylon

dispositif de protection

n° 27

D284937/D284939

bride de soutien

54339-00

meule sans moyeu

n° 27

bague en nylon

dispositif de protection

n°28 D284938

bride de soutien

54339-00

meule sans moyeu n°

28

bague en nylon

tampon de support en

caoutchouc D4947

disque de pon£age

®

_crou de blocage

D4947

dispositifdeprotection

n°28D284938

meuleavecmoyeu

_crou de blocage

22191-00

_crou de blocage

22191-00

n°28

REMARQUE : le diam_tre de la meule doit correspondre aux dimensions du dispositif de protection; c'est-&-dire, il n'est pas

possible d'utiliser une meule de 7 pouces avec un dispositif de protection de 9 pouces. La surface inf_rieure de la meule doit

se trouver & I'int_rieur du bord du dispositif de protection.

24

Page 26

Brosses m_talliques

circulaires

bague en nylon

dispositif de protection

n° 27

D284937/D284939

brosse m_tallique en

forme de coupelle

Meules

boisseaux

coniques

dispositif de protection de

meule boisseau conique

n°l1

D284934 4 po

D284936 6 po

bride de soutien

608368-00

Meules abrasives

dispositif de protection

n°l D284931

bride de soutien

608370-00

meule abrasive

dispositif de protection

n°l D284931

bride de soutien

608370-00

MEULE AU DIAMANT

bague en nylon

dispositif de protection

n° 27

D284937/D284939

brosse m_tallique

circulaire

meule boisseau

conique

_crou de blocage

608463-00

REMARQUE : le diam_tre de la meule doit correspondre aux dimensions du dispositif de

protection; c'est-&-dire, il n'est pas possible d'utiliser une meule de 7 pouces avec un dispositif de

protection de 9 pouces.

25

_crou de blocage

608463-00

Page 27

BAGUE EN NYLON

C

La meuleuse est munie d'une bague en nylon

pour faciliter I'installation et le retralt des

meules.

Accessoires

II importe de s61ectionner les dispostifis de pro-

tection, les tampons de support et les brides

appropri6s qui seront utilis6s dans les accessoires pour la

meuleuse. Consulter le tableau aux pages 23 &25 pour obtenir de

I'information sur les accessoires appropri6s.

MISE EN GARDE : la vitesse des accesseires doit cerrespendre

la vitesse minimale recemmand6e indiqu6e sur 1'6tiquette

d'avertissement de I'outil, car les meules et les accessoires qui sent

r6gl6s a une vitesse trop 61ev6e peuvent briser et occasionner des

blessures Iorsque des fragments de m6tal sent prejet6s. La vitesse

nominale de I'accesseire doit toujours #tre sup6rieure acelle de I'outil

indiqu6e sur laplaque signal6tique de I'outil.

ACCESSOIRES

Les accessoires sp6cialement census pour cette meulese sent ven-

dus chez les d6positaires DEWALT et dans les centres de service

DEWALT.

D284939

D284948

D284937

D284936

D284934

D284933

D284932

Dispositif de protection n°27 de 9 po

Dispositif de potection no28 de 9 po

Dispositif de protection no27 de 7 po

Dispositif de protection pour meule boisseau

conique no11 de 6 po (bride fournie)

Dispositif de protection pour meule boisseau

conique no11 de 4 po (bride fournie)

Dispositif de protection pour meule boisseau

conique n° 11 (bride de soutien fournie)

Jeu de brides n° 1

D284931

054339-00

22191-00

61820-01

445928-01

397711-00

Dispositif de protection n° 1 de 7 po

Bride de soutien pour meule

12croude blocage

Cl6 pour meule

Dispositif de protection de la broche

But6e sur le dessus pour carter d'engrenages

ASSEMBLAGE ET REGLAGE

Installation de la poign_e lat_rale

Pour installer la poign_e lat6rale, I'ins6rer dans une des cinq posi-

tions indiqu6es ci-dessous et bien serrer vers la droite.

• Deux positions avant: les positions avant

de la poign6e sent con_ues pour maintenir _.,,

1'6quilibre optimal Iors des travaux de fini-

tion de surface.

arri_re de la poign6e sent con_ues pour

maintenir 1'6quilibre optimal Iors du meu-

lage des bords.

i Deux positions arriere: les positions 1

Une position sup6rieure: la position

sup6rieure de la poign6e est con£ue pour

le meulage des bords.

REMARQUE : le mod_le D28497 ne pr6sente que trois positions

de la poign6e.

Positionnement de la poign_e arri_re

Arr6ter et debrancher I'outil avant d'effectuer tout reglage ou

avant de retirer ou d'installer des accessoires. Avant de

rebrancher I'outil, enfoncer et rel&cher I'interrupteur

g&chette pour s'assurer que I'outil est arr6te.

26

Page 28

1. D6gager la poign6e arri_re en h,9o°

sortant le levier de d6gagement

(G) de la poign6e arri_re, tel

qu'illustr6.

2. Positionner la poign6e de 0°,

30°, 60°, ou 90° & gauche ou & G 30"

droite de la position centrale.

3. Enfoncer le levier de d6gagement de poign6e.

4. Avant de mettre routil en marche, s'assurer que la poign6e est

verrouill6e et que le levier de d6gagement de poign6e a repris

sa position initiale affleurant au boftier de I'outil.

f

60°

Positionnement du carter

d'engrenages

Arr6ter et debrancher I'outil avant d'effectuer tout reglage ou

avant de retirer ou d'installer des accessoires. Avant de

rebrancher I'outil, enfoncer et rel&cher I'interrupteur

g&chette pour s'assurer que I'outil est arr6te.

1. Enlever les quatre vis dans les

coins, qui fixent le carter d'en-

grenages au carter du moteur.

2. Sans s6parer le carter d'en-

grenages du carter du moteur,

positionner le carter d'en-

grenages tel que voulu.

REMARQUE : si le carter d'engrenage et le carter du moteur se

s6parent de plus de 1/8 pouce, I'outil doit _tre r6par6 et remont6

dans un centre de service DEWALT pour 6viter d'endommager les

brosses, le moteur et les roulements.

3. Poser les vis pour fixer le carter d'engrenages au carter du

moteur. Serrer les vis selon un couple de 20 pouces-livres. Ne

pas trop serrer les vis pour 6viter d'en fausser le pas.

FONC_ONNEMENT

Source d'alimentation

Brancher la grande meuleuse angulaire sur un circuit 61ectrique

sp6cialis6. L'utilisation de routil sur un circuit avec d'autres outils

r6duit le rendement de I'outil.

Interrupteur a gachette

_ MISE EN GARDE : avant de brancher I'outil sur une source

d'alimentation ou apres une panne d'61ectricit6, enfoncer et rel&cher

une fois I'interrupteur a g_chette (A) sans enfoncer le bouton de

verrouillage en position de marche (t3) pour s'assurer que

I'interrupteur est a laposition d'arr6t. Si I'interrupteur a g_chette est

la position de mise en marche, Ibutil se mettra en marche de fa_on

impr6vue Iorsque Ibutil est rebranch6. Tenir fermement la poign6e

lat6rale et la poign6e arriere pour maftriser Ibutil lots de sa mise en

marche et de son utilisation. B

UTILISATION DE L'INTERRUPTEUR ,&,

G.&CHETTE

Pour mettre I'outil en marche, enfoncer I'inter-

rupteur & g&chette (A). L'outil ne fonctionne

que si I'interrupteur est enfonc6. Pour arr6ter

I'outil, rel&cher I'interrupteur & g&chette. A

UTILISATION DE L'INTERRUPTEUR ,&,GAOHETTE AVEC LE

BOUTON DE VERROUlLLAGE EN POSITION DE MARCHE

Pour mettre I'outil en marche, enfoncer I'interrupteur & g&chette.

Enfoncer sans rel&cher le bouton de verrouillage en position de

marche (B), tout en rel&chant I'interrupteur &g&chette. Le bouton de

verrouillage en position de marche reste enfonc6 et I'outil continue

de fonctionner.

Pour arr_ter I'outil, enfoncer puis rel&cher I'interrupteur & g&chette.

Le bouton de verrouillage sort pour permettre & I'interrupteur &

g&chette de se d6gager et pour arr6ter I'outil.

27

Page 29

REMARQUE:laisserI'outilatteindresavitessemaximaleavantde

lemettreencontactaveclasurface&meuler,etlesoulevercom-

pl_tementavantdeI'arr6ter.

A MISE EN GARDE : s'assurer que la meule s'est completement

arr6t6e avant de poser I'outiL

RETRAIT DU BOUTON DE VERROUILLAGE EN POSITION

DE MARCHE

II est possible de retirer le bouton de verrouillage en position de

marche en permanence sans compromettre la conformit6 avec les

organismes de r6glementation indiqu6s sur la plaque signal6tique

de I'outil. Le bouton de verrouillage en position de marche doit _tre

retir6 dans un centre de service DEWALT.

Installation et utilisation des meules

moyeu d_port_ et des disques de

pon_age a feuillets

INSTALLATION ET RETRAIT DU DISPOSITIF DE PROTECTION

Arr6ter et debrancher I'outil avant d'effectuer tout reglage ou

avant de retirer ou d'installer des accessoires. Avant de

rebrancher I'outil, enfoncer et rel&cher I'interrupteur a g&chette

pour s'assurer que I'outil est arr6te.

RENSEIGNEMENTS IMPORTANTS SUR LES DISPOSlTIFS DE

PROTECTION

II faut installer le dispositif de protection Iors de rutilisation de

meules, de disques de pon(_age, de brosses m6talliques et de

meules m6talliques. L'outil peut _tre utilis6 sans dispositif de pro-

tection uniquement Iors de rutilisation de disques de pon(_agetradi-

tionnels. Les modules DEWALT D28493, D28494, D28474 et

D28499 sont munis d'un dispositif de protection destin6 aux meules

n° 27 & moyeu d6port6 et aux meules n° 27 avec moyeu. Ce m_me

dispositif de protection peut _tre utilis6 PARTIE

avec les disques de pon(_age & feuillets, INFC:RIEURE

les brosses m6talliques et les meules DE LA

m6talliques. Le meulage et la coupe MEULE

avec des meules autres que les meules

n° 27 et 29 n6cessitent des dispositifs de

protection diff6rents qui ne sont pas four- BORD DU

nis avec routil. Les directives de mon- DISPOSITIF

tage pour ces accessoires sont fournies DE

dans I'ensemble accessoire. PROTECTION

_ MISE EN GARDE :/ors de I'utilisation

d'une meule et d'un dispositif de protec-

tion n°27, 28, ou 29, s'assurer que la pattie inf6rieure de la meule

se trouve a I'int6rieur du bord du dispositif de protection.

MISE EN GARDE : la pon_euse angulaire DEWALT de modele

D28497 ne peut 6tre utilis6e pour le meulage qu'en installant le dis-

positif de protection appropri6.

1. Ouvrir le m6canisme de verrouillage de dispositif de protection

(H) et aligner les cosses avec les fentes

dans le boftier du carter d'engrenage.

Orienter le dispositif de protection vers

I'arri_re, tel qu'illustr6.

2. Pousser le dispositif de protection vers

le has jusqu'& ce que les cosses s'enga-

gent et tournent librement dans la rain-

ure situ6e & la base du moyeu du carter

d'engrenage.

3. Le m6canisme de verrouillage de dis-

positif de protection 6tant ouvert, d6plac-

er le dispositif de protection & la position

voulue pour prot6ger au maximum

I'op6rateur.

28

Page 30

4.Fermerlem6canismedeverrouillageafindefixersolidementle

dispositifdeprotectionaucarterd'engrenage.IInedoitpas_tre

possibledetournerledispositifdeprotectionIorsquelem6can-

ismedeverrouillageestferm6.Nepasutiliserlameuleusesile

dispositifdeprotectionn'estpasfermementserr6ousilelevi-

erdeserrageestenpositionouverte.

5.Pourretirerledispositifdeprotection,reprendreles6tapes

d6critesci-dessusenordreinverse.

REMARQUE:ledispositifdeprotection

estr6g16enusineenfonctiondudiam_tre

du moyeuducarterd'engrenages.S'il

s'av_ren6cessaire,apr_sun certain

temps,deler6glerdenouveau,mettrele

levierdeserrageenpositionferm6e,puis

serrerlavisder6glage(I). I

_J,MISE EN GARDE : ne pas serrer la vis de r6glage Iorsque le

levier de serrage est en position ouverte. Sinon, le dispositif de

protection ou le moyeu peuvent subir des dommages non d6tect6s.

INSTALLATION ET REFTRAIT DES MEULES AVEC MOYEU

Les meules avec moyeu s'installent directement sur la broche

filet6e n° 11 de 5/8 po.

1. Installer la meule sur la broche tout en I'appuyant fermement

contre la bague en nylon.

2. Enfoncer le bouton de verrouillage de la broche et serrer le

moyeu de la meule & I'aide d'une cl6.

3. Pour retirer la meule, reprendre les 6tapes d6crites ci-dessus

en ordre inverse.

MISE EN GARDE : si la meule n'est pas bien appuy6e contre la

bague en nylon avant la mise en marche de Ibutil, ce demier ou la

meule peut 6tre endommag6.

INSTALLATION DES MEULES SANS MOYEU

Les meules n° 27 & moyeu d6port6 doivent _tre utilis6es avec les

brides appropri6es fournies comme accessoire.

Consulter le tableau aux pages 23 &25 pour obtenir de I'informa-

tion.

1. Installer la bride de soutien m6tallique (J) sur

la broche (E) et contre la bague en nylon.

2. Placer la meule contre la bride de soutien,

tout en centrant la meule sur le pilote de la

bride de soutien.

3. Enfoncer le bouton de verrouillage de la

broche, installer 1'6crou de blocage (K) sur la

broche, tout en guidant le moyeu saillant sur

1'6crou de blocage au milieu de la meule.

4. Serrer 1'6crou de blocage & I'aide d'une cl6.

5. Pour retirer la meule, reprendre les 6tapes

d6crites ci-dessus en ordre inverse.

MEULAGE DE FINITION

1. Laisser I'outil atteindre sa vitesse maximale avant de le mettre

en contact avec la surface & meuler.

2. Appuyer 16g_rement sur la surface & meuler pour laisser I'outil

marcher & sa vitesse maximale.

3. Maintenir un angle d'environ 20 &30 o entre o

I'outil et la surface & meuler.

4. D6placer I'outil lentement vers ravant et

vers I'arri_re pour 6viter de rayer I'ouvrage.

5. Soulever I'outil avant de I'arr_ter. S'assurer que la meule s'est

compl_tement arr6t6e avant de poser I'outil.

MEULAGE DE BORDURE

_, MISE EN GARDE :au cours du meulage ou de la coupe de bord,

les meules peuvent 6tre endommag6es ou faire des rebonds si elles

29

Page 31

sontarqu6esousiellessubissentdestorsionsalorsqueIbutil

effectuedestravauxded6coupeoudemeulageprofond. Afin de

r6duire le risque de blessures graves, n'utiliser ces meules et le

dispositif de protection standard n ° 27 que dans la coupe peu

profonde et I'entaillage (profondeur de moins de 1/2 po). L'ouverture

du dispositif de protection ne doff pas s'orienter vers I'op6rateur. Pour