Page 1

D28410-XE

D28411-XE

D28414-XE

D28432C-XE

1

Page 2

2

3

1

A

2

4

5

Copyright DEWALT

Page 3

4

7

9

6

10

11

8

B

C2

10

14

12

13

11

3

C1

14

12

10

11

A

14

12

10

11

B

C3

3

Page 4

15

19

17 16

D1

15

18

5

17

5

D2

E1

4

E2

Page 5

ANGLE GRINDER

D28410/D28411/D28414/D28432C

ENGLISH

Congratulations!

You have chosen a DEWALT tool. Years of

experience, thorough product development and

innovation make D

partners for professional power tool users.

E

WALT one of the most reliable

Technical data

D28410 D28411

Voltage V 230 230

Power input W 2,100 2,100

No-load speed min

Wheel diameter mm 180 230

Spindle M14 M14

Weight kg 4.7 4.7

D28414 D28432C

Voltage V 230 230

Power input W 2,200 2,600

No-load speed min

Wheel diameter mm 230 230

Spindle M14 M14

Weight kg 4.7 5.3

Fuses:

Europe 230 V tools 10 Amperes, mains

U.K. & Ireland 230 V tools 13 Amperes, in plugs

The following symbols are used throughout this

manual:

-1

8,500 6,500

-1

6,500 6,500

EC-Declaration of conformity

D28410/D28411/D28414/D28432C

DEWALT declares that these power tools have been

designed in compliance with: 98/37/EC,

89/336/EEC, 2006/95/EC, EN 60745-1,

EN 50144-2-3, EN 55014-2, EN 55014-1,

EN 61000-3-2 & EN 61000-3-3.

For more information, please contact DEWALT at the

address below, or refer to the back of the manual.

Level of sound pressure according to 86/188/EEC &

98/37/EC, measured according to EN 50144:

D28410 D28411 D28414 D28432C

(sound pressure) dB(A)* 90.5 90.0 90.0 90.0

L

pA

(acoustic power) dB(A) 99.5 98.5 98.5 98.5

L

WA

* at the operator’s ear

Take appropriate measures for the

protection of hearing.

Weighted root mean square acceleration value

according to EN 50144:

Denotes risk of personal injury, loss of

life or damage to the tool in case of

non-observance of the instructions in this

manual.

Denotes risk of electric shock.

Fire hazard.

D28410 D28411 D28414 D28432C

5.8 m/s

2

5.95 m/s2 5.9 m/s2 5.9 m/s

Director Engineering and Product Development

Horst Großmann

DEWALT, Richard-Klinger-Straße 40,

D-65510, Idstein, Germany

04/2007

2

5

Page 6

ENGLISH

Safety instructions

When using power tools, always observe the

safety regulations applicable in your country

to reduce the risk of fi re, electric shock and

personal injury.

Read all of this manual carefully before operating

the tool.

Save this manual for future reference.

General

1 Keep work area clean

Cluttered areas and benches can cause accidents.

2 Consider work area environment

Do not expose the tool to rain. Do not use the tool

in damp or wet conditions. Keep the work area

well lit (250 - 300 Lux). Do not use the tool where

there is a risk of causing fi re or explosion, e.g. in

the presence of fl ammable liquids and gases.

3 Keep children away

Do not allow children, visitors or animals to come

near the work area or to touch the tool or the

mains cable.

4 Dress properly

Do not wear loose clothing or jewellery, as these

can be caught in moving parts. Wear protective

hair covering to keep long hair out of the way.

When working outdoors, preferably wear suitable

gloves and non-slip footwear.

5 Personal protection

Always use safety glasses. Use a face or dust

mask whenever the operations may produce

dust or fl ying particles. If these particles might

be considerably hot, also wear a heat-resistant

apron. Wear ear protection at all times.

6 Guard against electric shock

Prevent body contact with earthed surfaces

(e.g. pipes, radiators, cookers and refrigerators).

When using the tool under extreme conditions

(e.g. high humidity, when metal swarf is being

produced, etc.), electric safety can be improved

by inserting an isolating transformer or a (FI)

earth-leakage circuit-breaker.

7 Do not overreach

Keep proper footing and balance at all times.

8 Stay alert

Watch what you are doing. Use common sense.

Do not operate the tool when you are tired.

9 Secure workpiece

Use clamps or a vice to hold the workpiece. It is

safer and it frees both hands to operate the tool.

10 Connect dust extraction equipment

If devices are provided for the connection of dust

extraction and collection facilities, ensure that

these are connected and properly used.

11 Remove adjusting keys and wrenches

Always check that adjusting keys and wrenches

are removed from the tool before operating

the tool.

12 Extension cables

Before use, inspect the extension cable and

replace if damaged. When using the tool

outdoors, only use extension cables intended for

outdoor use and marked accordingly.

13 Use appropriate tool

The intended use is described in this instruction

manual. Do not force small tools or attachments

to do the job of a heavy-duty tool. The tool will

do the job better and safer at the rate for which it

was intended. Do not force the tool.

Warning! The use of any accessory or

attachment or performance of any operation

with this tool other than those recommended

in this instruction manual may present a risk of

personalinjury.

14 Check for damaged parts

Before use, carefully check the tool and mains

cable for damage. Check for misalignment and

seizure of moving parts, breakage of parts,

damage to guards and switches and any other

conditions that may affect its operation. Ensure

that the tool will operate properly and perform

its intended function. Do not use the tool if any

part is damaged or defective. Do not use the tool

if the switch does not turn it on and off. Have

any damaged or defective parts replaced by an

authorised D

EWALT repair agent. Never attempt

any repairs yourself.

15 Unplug tool

Switch off and wait for the tool to come to a

complete standstill before leaving it unattended.

Unplug the tool when not in use, before

changing any parts of the tools, accessories or

attachments and before servicing.

6

Page 7

ENGLISH

16 Avoid unintentional starting

Do not carry the tool with a fi nger on the switch.

Be sure that the tool is switched off before

plugging in.

17 Do not abuse cord

Never carry the tool by its cord. Never pull the

cord to disconnect from the socket. Keep the

cord away from heat, oil and sharp edges.

18 Store idle tools

When not in use, tools must be stored in a dry place

and locked up securely, out of reach of children.

19 Maintain tools with care

Keep the tools in good condition and clean

for better and safer performance. Follow the

instructions for maintenance and changing

accessories. Keep all handles and switches dry,

clean and free from oil and grease.

20 Repairs

This tool is in accordance with the relevant

safety regulations. Have your tool repaired by an

authorised DEWALT repair agent. Repairs should

only be carried out by qualifi ed persons using

original spare parts; otherwise this may result in

considerable danger to the user.

Additional safety instructions for Australia

andNew Zealand

• This tool is not intended for use by young

children or infi rm persons without supervision.

Young children should be supervised to ensure

they do not play with this tool.

• If the supply cord is damaged, it must be

replaced by the manufacturer or an authorised

DEWALT Service Centre in order to avoid a

hazard.

Additional safety rules for grinders

• Your grinder has been designed for grinding and

cutting masonry and steel.

Do not cut or grind light metal with a

magnesium content exceeding 80%

since this type of metal is fl ammable.

in Figure A. Contravention may lead to loss of

control and unexpected injuries.

• The max. allowable speed of the grinding wheel

or cutting disc must always be equal to or greater

than the no-load speed of the tool specifi ed on

the nameplate.

• Do not cut workpieces requiring a maximum

depth of cut exceeding that of the cutting disc.

• Do not use grinding and cutting discs that do not

conform to the dimensions stated in the technical

data. Do not use any spacers to make a disc fi t

onto the spindle.

• Inspect grinding and cutting discs before each

use. Do not use chipped, cracked or otherwise

defective discs.

• If provided, ensure that blotters are used when

the disc is fi tted onto the spindle.

• Ensure that the grinding or cutting disc is

mounted correctly before use.

• Let the tool run at no-load in a safe position for

at least 30 seconds. If there is a considerable

vibration or if any other defect occurs, stop the

tool and check it to determine the cause.

• Do not operate this tool without the guard in place.

• Check that the workpiece is properly supported.

• Do not operate the tool near fl ammable liquids,

gases or dust. Sparks or hot chips from cutting

or arcing motor brushes may ignite combustible

materials.

• Do not operate the tool while standing in line with

the disc. Keep other persons away from the work

area.

• Do not use cutting discs for side grinding.

• Do not operate the spindle lock while the tool is

running.

• Beware that after switching off the tool the wheel

continues to rotate for a short period.

• Always store grinding and cutting discs in a dry

place.

Labels on tool

The following pictographs are shown on the tool:

• Only reinforced cutting-off and reinforced

depressed-centre grinding wheels are allowed.

• Use the grinding and cutting discs recommended

by the manufacturer only.

• To ensure your personal safety it is compulsory

to hold the machine with both hands as shown

Read the instruction manual before use

Wear safety glasses

7

Page 8

ENGLISH

Wear ear protection

Package contents

The package contains:

1 Angle grinder

1 Guard

1 Side handle

1 Flange set

1 Two-pin spanner

1 Instruction manual

1 Exploded drawing

• Check for damage to the tool, parts or accessories

which may have occurred during transport.

• Take the time to thoroughly read and understand

this manual prior to operation.

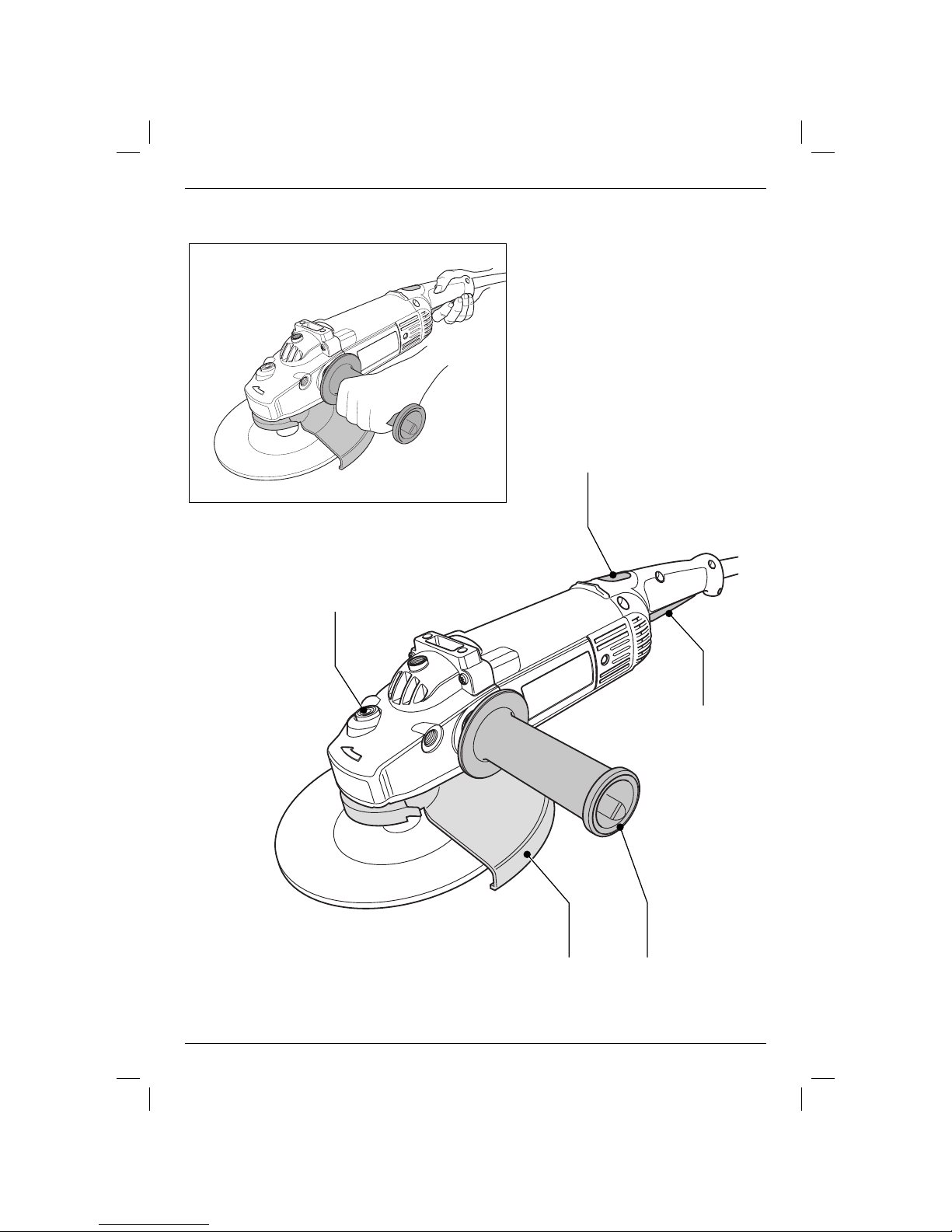

Description (fi g. A)

Your angle grinder has been designed for

professional grinding and cutting applications.

1 On/off switch

2 Locking switch/Unlocking switch (France,

Australia and New Zealand)

3 Spindle lock

4 Guard

5 Side handle

• Disconnect the plug from the supply.

• Cut off the plug and dispose of it safely; a plug

with bared copper conductors is dangerous if

engaged in a live socket outlet.

• Only fi t 13 Amperes BS1363A approved plugs

fi tted with the correctly rated fuse (1).

• The cable wire colours, or a letter, will be marked

at the connection points of most good quality

plugs. Attach the wires to their respective points

in the plug (see below). Brown is for Live (L) (2)

and Blue is for Neutral (N) (4).

• Before replacing the top cover of the mains plug

ensure that the cable restraint (3) is holding the

outer sheath of the cable fi rmly and that the two

leads are correctly fi xed at the terminal screws.

Never use a light socket.

Never connect the live (L) or neutral (N)

wires to the earth pin marked E or .

D28414/D28432C - Soft start feature

The soft start feature allows a slow speed build-up

to avoid an initial jerk when starting. This feature is

particularly useful when working in confi ned spaces.

Electrical safety

The electric motor has been designed for one

voltage only. Always check that the power supply

corresponds to the voltage on the rating plate.

Your DEWALT tool is double insulated in

accordance with EN 50144; therefore no

earth wire is required.

Mains plug replacement

(U.K. & Ireland only)

• Should your mains plug need replacing and you

are competent to do this, proceed as instructed

below. If you are in doubt, contact an authorized

DEWALT repair agent or a qualifi ed electrician.

8

Fitting a mains plug to 115 V units

(U.K. & Ireland only)

• The plug should be fi tted by a competent

person. If you are in doubt, contact an authorized

D

EWALT repair agent or a qualifi ed electrician.

The wires are coloured according to the following

code:

live = brown

neutral = blue

• Do not connect the blue or brown wire to the

earth terminal in the plug. Connect as follows:

brown to terminal marked ‘L’

blue to terminal marked ‘N’

The plug fi tted should be comply with BS EN 60309

(BS4343), 32 Amps.

Page 9

ENGLISH

Always ensure that the cable clamp is

correctly and securely fi tted to the sheath

of the cable.

Using an extension cable

If an extension cable is required, use an approved

extension cable suitable for the power input of this

tool (see technical data). The minimum conductor

size is 1.5 mm

2

.

When using a cable reel, always unwind the cable

completely.

Also refer to the following table.

Conductor size (mm2) Cable rating (Amperes)

0.75 6

1.00 10

1.50 15

2.50 20

4.00 25

Cable length (m)

7.5 15 25 30 45 60

Voltage Amperes Cable rating (Amperes)

115 0 - 2.0 6 6 6 6 6 10

2.1 - 3.4 6 6 6 6 15 15

3.5 - 5.0 6 6 10 15 20 20

5.1 - 7.0 10 10 15 20 20 25

7.1 - 12.0 15 15 20 25 25 -

12.1 - 20.0 20 20 25 - - 230 0 - 2.0 6 6 6 6 6 6

2.1 - 3.4 6 6 6 6 6 6

3.5 - 5.0 6 6 6 6 10 15

5.1 - 7.0 10 10 10 10 15 15

7.1 - 12.0 15 15 15 15 20 20

12.1 - 20.0 20 20 20 20 25 -

Assembly and adjustment

Prior to assembly and adjustment always

unplug the tool.

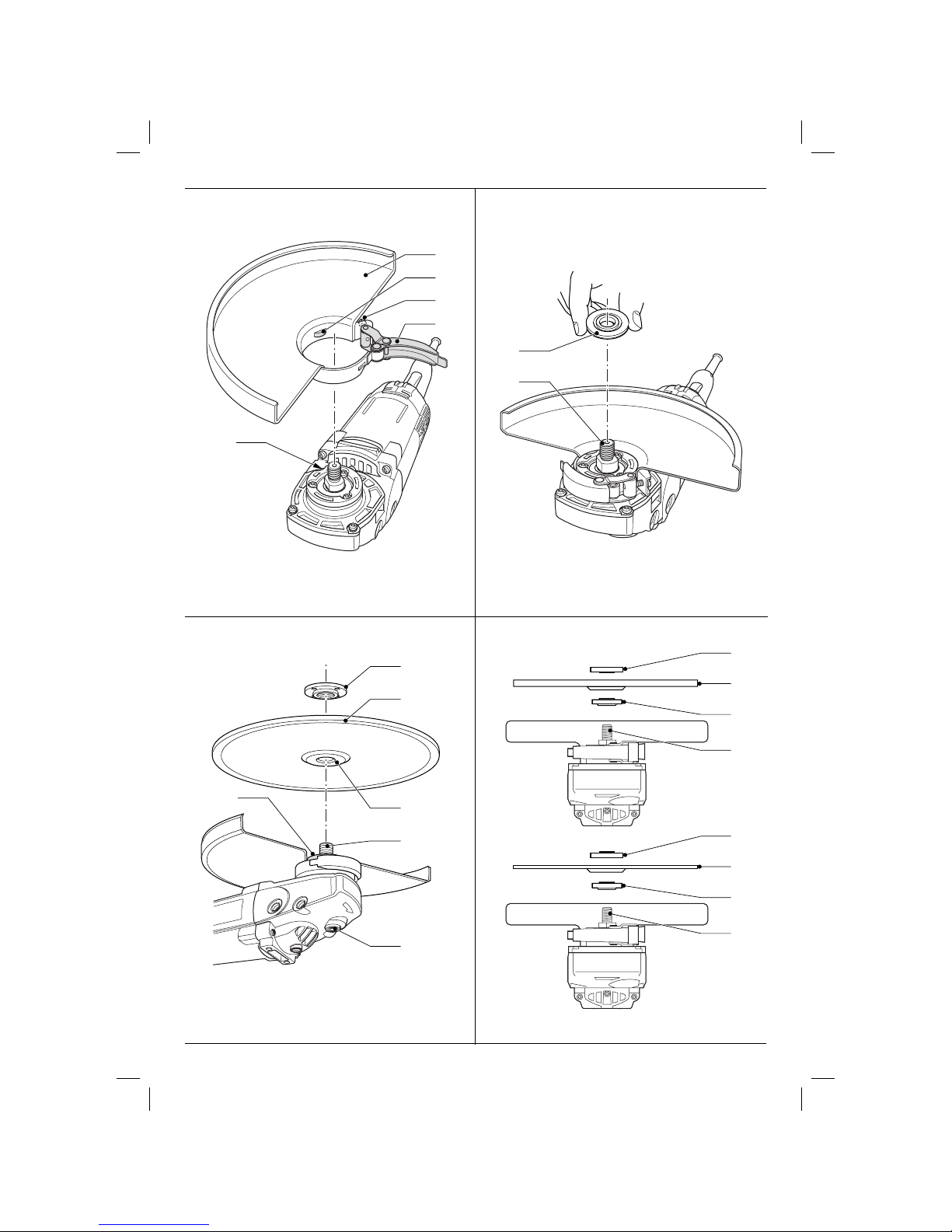

Mounting and removing the guard (fi g. B)

• Place the angle grinder on a table, spindle up.

• Release the clamping lock (6) and hold the guard

(4) over the tool as shown.

• Align the lugs (7) with the notches (8).

• Press the guard down and rotate it to the

required posiiton.

• If required, increase the clamping force by

tightening the screw (9).

• Tighten the clamping lock.

• To remove the guard, release the clamping lock.

Never use the tool without the guard in

place.

Fitting and removing a grinding or cutting disc

(fi g. C1 - C3)

• Place the tool on a table, guard up.

• Fit the inner fl ange (10) correctly onto the spindle

(11) (fi g. C1).

• Place the disc (12) on the fl ange (10) (fi g. C2).

When fi tting a disc with a raised center, make

sure that the raised centre (13) is facing the

fl ange (10).

• Screw the outer fl ange (14) onto the spindle (11)

(fi g. C3):

- the ring on the fl ange (14) must face towards

the disc when fi tting a grinding disc (A);

- the ring on the fl ange (14) must face away from

the disc when fi tting a cutting disc (B).

• Press the spindle lock (3) and rotate the spindle

(11) until it locks in position (fi g. C2)

• Tighten the fl ange (14) with the two-pin spanner

supplied.

• Release the spindle lock.

• To remove the disc, loosen the fl ange (14) with

the two-pin spanner.

Do not use a damaged disc.

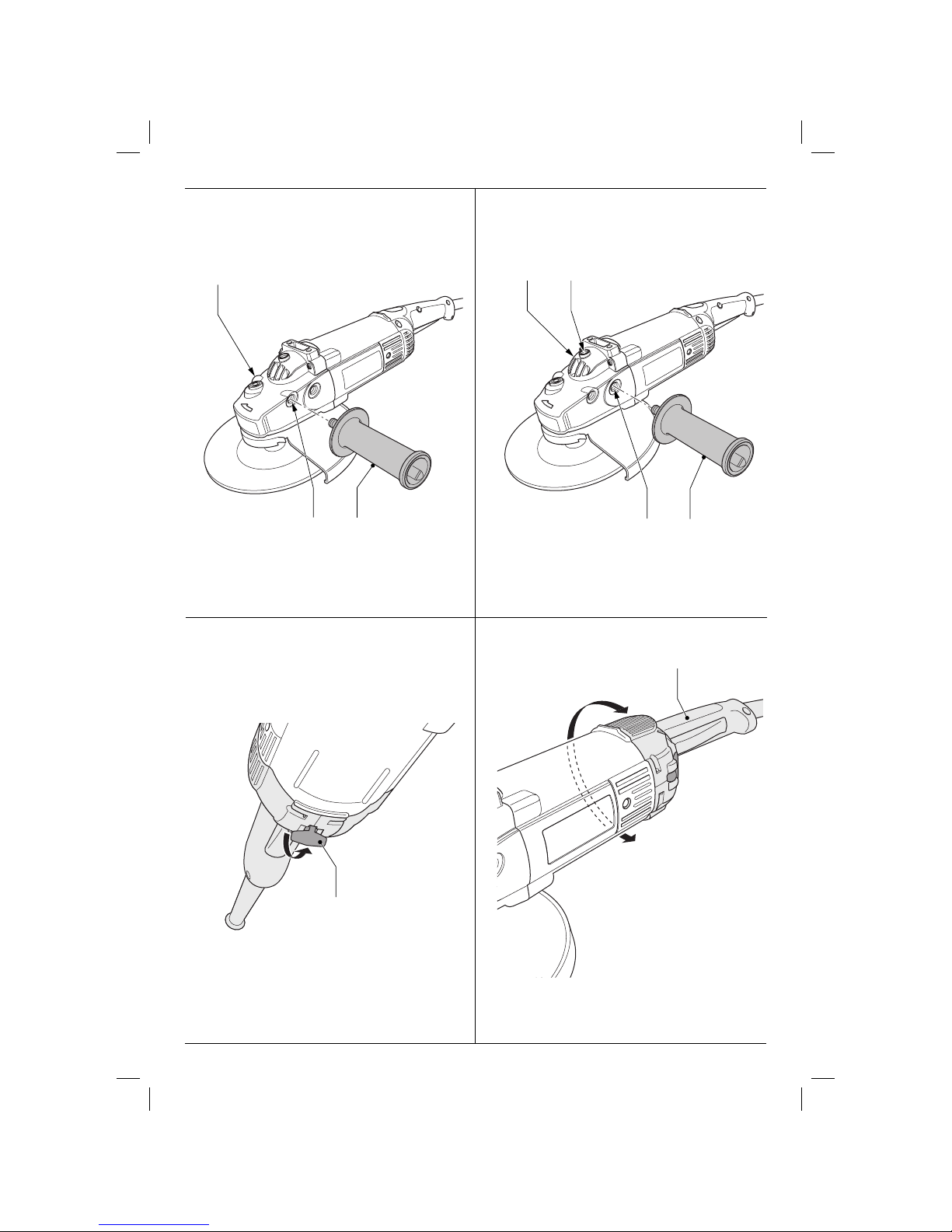

Mounting the side handle (fi g. D1 & D2)

• For grinding, screw the side handle (5) tightly into

one of the holes (15) on either side of the gear

case (fi g. D1).

• For cutting, screw the side handle (5) tightly into

the top hole (16) or into one of the holes (17) on

either side of the gear case (fi g. D2).

D28432C - Rotating the main handle (fi g. E1 & E2)

The rotary handle facilitates a more comfortable

handling in cutting applications with the side handle

mounted in the top hole.

The rotary handle has locations at 30°, 60° and 90°

both left and right.

9

Page 10

ENGLISH

• Pull the spring-loaded tab (18) to unlock the

rotary mechanism (fi g. E1). Hold the tab in the

pulled-out position.

• Rotate the handle (19) into the desired position

(fi g. E2).

• Release the tab and lock it in position.

• Check that the rotary mechanism is locked.

Do not use the tool unless the rotary

handle is in the locked postion.

Instructions for use

• Always observe the safety instructions

and applicable regulations.

• Ensure all materials to be ground or cut

are secured in place.

• Apply only a gentle pressure to the tool.

Do not exert side pressure on the disc.

• Avoid overloading. Should the tool

become hot, let it run a few minutes

under no load condition.

Prior to operation:

• Install the guard and appropriate disc or wheel.

Do not use excessively worn discs or wheels.

• Be sure the inner and outer fl ange are mounted

correctly.

• Make sure the disc or wheel rotates in the direction

of the arrows on the accessory and the tool.

Do not switch the tool on or off when

under load.

Consult your dealer for further information on the

appropriate accessories.

Maintenance

Your D EWALT Power Tool has been designed to

operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation

depends upon proper tool care and regular cleaning.

Lubrication

Your power tool requires no additional lubrication.

Cleaning

Keep the ventilation slots clear and regularly clean

the housing with a soft cloth.

Unwanted tools and the environment

Take your tool to an authorized DEWALT repair agent

where it will be disposed of in an environmentally

safe way.

DEWALT AFTER SALES SERVICE

Switching on and off (fi g. A)

The on/off switch is equipped with an unlocking

switch or a locking switch for continuous operation.

On/off switch (1) with locking switch (2)

• To run the tool, depress the locking switch (2)

and subsequently operate the on/off switch (1).

• Release the locking switch (2).

• To stop the tool, press the on/off switch again.

On/off switch (1) with unlocking switch (2)

(France, Australia and New Zealand)

• To run the tool, depress the unlocking switch (2)

and subsequently operate the on/off switch (1).

• Release the unlocking switch (2).

• To stop the tool, release the switch.

10

REPAIR AND SERVICE

All DEWALT power tools are thoroughly tested

before leaving the factory. However, if the power

tool needs repair, please contact your dealer or

take it to your nearest D

There is a Service Centre in every capital city.

For service, repair or parts call 1800 654 155

(Aust) or 02 259 1111 (NZ).

EWALT Service Centre.

Page 11

GUARANTEE

ENGLISH

THREE YEAR LIMITED WARRANTY

DEWALT will repair, without charge, any defects

due to faulty materials or workmanship for three

years from the date of purchase. Please return

the complete unit, transportation prepaid, to any

D

EWALT Service Centre, or any authorised service

station. For warranty repair information, call (AUS)

1800 654 155 or (NZ) 02 259 1111. This warranty

does not apply to:

• Accessories.

• Damage caused where repairs have

beenmade or attempted by others.

• Damage due to misuse, neglect, wear and

tear, alteration or modifi cation.

This warranty gives you specifi c legal rights and

you may have other rights under the provisions

of the Consumer Guarantee Act 1993 (New

Zealand only), Trade Practices Act 1974 and State

Legislation (Australia only).

In addition to the warranty, D

EWALT tools are

covered by our:

FREE ONE YEAR SERVICE CONTRACT

DEWALT will also maintain the tool for free at

anytime during the fi rst year of purchase. This

includes labour, parts and lubrication required to

restore the product to sound mechanical and/or

electrical condition. Normal wear parts are not

covered in this service. Carbon brushes worn

more than 50% will be replaced.

INFORMATION HOTLINE

When you need further information on a D

EWALT

product please phone:

Australia: 1800 816 900

New Zealand: 09 579 7600

NOTES

EWALT reserves the right to change or

• D

upgrade product specifi cations or standard

equipment at any time without notice.

• Standard equipment and accessories may vary

by country.

• Product specifi cations may vary by country.

• Complete product range may not be available

in all countries. See your local DEWALT dealer

for range availability.

NOTE: 3 Year warranty is not applicable to items

deemed as consumables. Radial arm saws are

covered by a one (1) year warranty only. DEWALT

reserves the right to review its warranty policy

prior to launch of any new business development

products.

30 DAY NO RISK SATISFACTION GUARANTEE

If you are dissatisfi ed with any DEWALT power tool,

laser or nailer, for any reason, simply return it to

the point of purchase with your sales receipt within

30 days for a replacement unit or a full refund.

11

Page 12

Australia Black & Decker (Australia) Pty. Ltd. Tel: 03 8720 5100

20 Fletcher Road Fax: 03 9727 5940

Mooroolbark, Victoria 3138

New Zealand Black & Decker Tel: 02 259 1111

81 Hugo Johnston Drive Fax: 09 579 8200

Penrose, Auckland, New Zealand

653602-00 5/07

Loading...

Loading...