Page 1

D28409

Page 2

2

B

A

D

C

FIG 1

FIG 3

FIG 2

FIG 4

H

G

E

F

Page 3

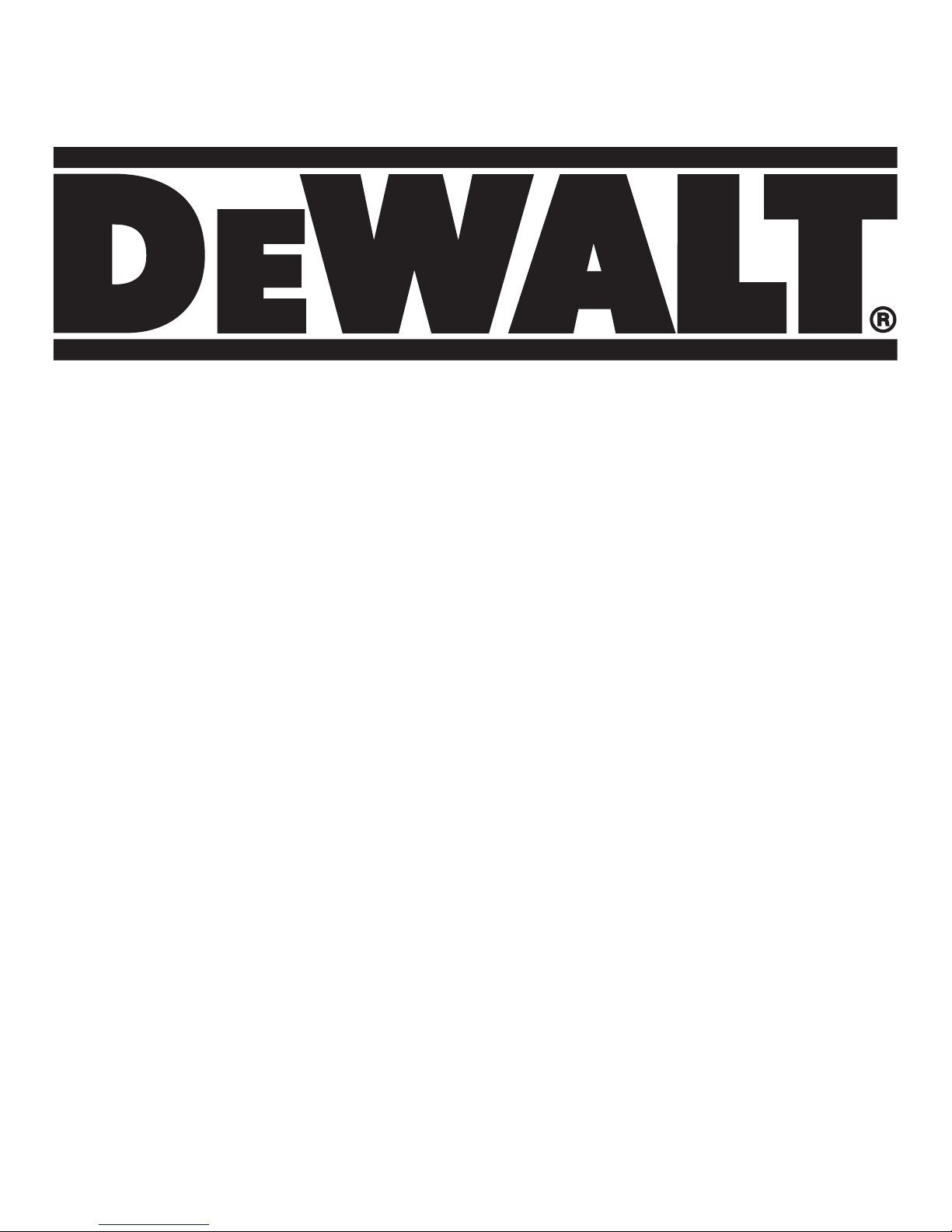

FIG 5

FIG 7

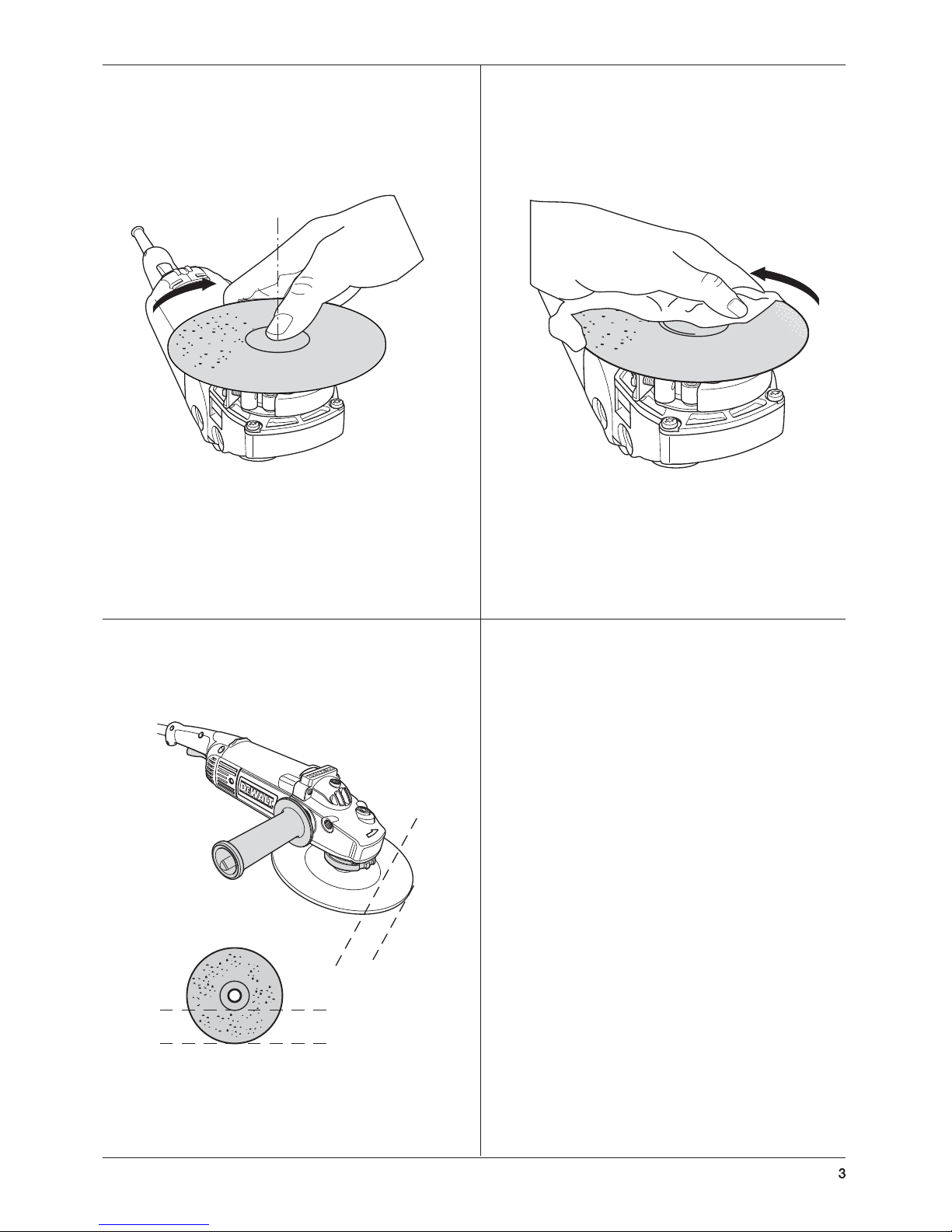

FIG 6

Page 4

4

E N G L I S H

D28409 SANDER

Congratulations!

You have chosen a DEWALT tool. Years of experience,

thorough product development and innovation make

D

EWALT one of the most reliable partners for professional

power tool users.

Technical data

Power input

No-load speed

Spindle size

Pad size

Weight

DW849

W

Min

-1

mm

Kg

2,200

5,000

M14

172

5.2

General Safety Rules

WARNING! Read all instructions. Failure to

follow all instructions listed below may result

in electric shock, fire and/or serious injury.

The term “power tool” in all of the warnings

listed below refers to your mains-operated

(corded) power tool or battery-operated

(cordless) power tool.

SAVE THESE INSTRUCTIONS

1) WORK AREA SAFETY

Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can cause you

to lose control.

2) ELECTRICAL SAFETY

Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will increase

the risk of electric shock.

Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

a)

b)

c)

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock. Replace or repair damaged

cords. Make sure your extension cord is in good

condition. Use only 3-wire extension cords that have

3-prong grounding-type plugs and 3-pole receptacles

that accept the tool’s plug.

When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock. When using an extension cord, be

sure to use one heavy enough to carry the current

your product will draw. An undersized cord will cause

a drop in line voltage resulting in loss of power and

overheating. The following table shows the correct

size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier

gauge. The smaller the gauge number, the heavier

the cord.

Using an extension cable

If an extension cable is required, use an approved

extension cable suitable for the power input of this tool (see

technical data). The minimum conductor size is 1.5 mm

2

.

When using a cable reel, always unwind the cable

completely.

Also refer to the table below.

a)

b)

c)

d)

e)

Conductor size (mm2) Cable rating (Amperes)

0.75 6

1.00 10

1.50 15

2.50 20

4.00 25

Cable length (m)

7.5 15 25 30 45 60

Voltage Amperes Cable rating (Amperes)

115 0 - 2.0 6 6 6 6 6 10

2.1 - 3.4 6 6 6 6 15 15

3.5 - 5.0 6 6 10 15 20 20

5.1 - 7.0 10 10 15 20 20 25

7.1 -12.0 15 15 20 25 25 -

12.1 -20.0 20 20 25 - - 230 0 - 2.0 6 6 6 6 6 6

2.1 - 3.4 6 6 6 6 6 6

3.5 - 5.0 6 6 6 6 10 15

5.1 - 7.0 10 10 10 10 15 15

7.1 -12.0 15 15 15 15 20 20

12.1 -20.0 20 20 20 20 25 -

Page 5

E N G L I S H

3) PERSONAL SAFETY

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication.

A moment of inattention while operating power

tools may result in serious personal injury.

Use safety equipment. Always wear eye

protection. Safety equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

Avoid accidental starting. Ensure the switch is in

the off-position before plugging in. Carrying power

tools with your finger on the switch or plugging in

power tools that have the switch on invites accidents.

Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts. Air

vents often cover moving parts and should also be

avoided.

If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used. Use of these

devices can reduce dust-related hazards.

4) POWER TOOL USE AND CARE

Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the job better and safer at the rate for

which it was designed.

Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

Disconnect the plug from the power source and/

or the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool

accidentally.

Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tools operation. If damaged, have the power tool

repaired before use. Many accidents are caused by

poorly maintained power tools.

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

Use the power tool, accessories and tool bits

etc., in accordance with these instructions and

in the manner intended for the particular type

of power tool, taking into account the working

conditions and the work to be performed. Use

of the power tool for operations different from those

intended could result in a hazardous situation.

5) SERVICE

Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

Additional Safety Instructions

Accessories must be rated for at least the speed

recommended on the tool warning label. Wheels

and other accessories running over rated speed can

fly apart and cause injury.

Hold tool by insulated gripping surfaces when

performing an operation where the cutting tool

may contact hidden wiring or its own cord.

Contact with a “live” wire will make exposed metal

parts of the tool “live” and shock the operator.

Clean your tool out periodically.

Do not operate this tool for long periods of time.

Vibration caused by the operating action of this tool

may cause permanent injury to fingers, hands, and

arms. Use gloves to provide extra cushion, take

frequent rest periods, and limit daily time of use.

WARNING: ALWAYS use eye protection.

All users and bystanders must wear eye

protection.

WARNING: Always wear proper personal

hearing protection during use. Under

some conditions and duration of use, noise

from this product may contribute to hearing

loss.

WARNING: ALWAYS use safety glasses.

Everyday eyeglasses are NOT safety

glasses. Also use face or dust mask if

cutting operation is dusty. ALWAYS WEAR

CERTIFIED SAFETY EQUIPMENT:

WARNING: Some dust created by power

sanding, sawing, grinding, drilling, and other

construction activities contains chemicals

known to cause cancer, birth defects or

other reproductive harm. Some examples of

these chemicals are:

lead from lead-based paints,

crystalline silica from bricks and cement and other

masonry products.

arsenic and chromium from chemically-treated

lumber (CCA).

5

a)

b)

c)

d)

e)

f)

g)

a)

b)

c)

d)

e)

a)

f)

g)

•

•

•

•

•

•

•

Page 6

E N G L I S H

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure

to these chemicals: work in a well ventilated area, and

work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic

particles.

Avoid prolonged contact with dust from power

sanding, sawing, grinding, drilling, and other

construction activities. Wear protective clothing and

wash exposed areas with soap and water. Allowing

dust to get into your mouth, eyes, or lay on the skin

may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate

and/or disburse dust, which may cause

serious and permanent respiratory or other

injury. Always use approved respiratory

protection appropriate for the dust exposure.

Direct particles away from face and body.

The label on your tool may include the following

symbols. The symbols and their definitions are as

follows:

V volts

A amperes

Hz hertz

W watts

min minutes

alternating current

direct current

n

0

no load speed

earthing terminal

safety alert symbol

Class II Construction (double insulated)

…/min revolutions or reciprocation per minute

BPM beats per minute

Save these instructions

DESCRIPTION

Sidle handle

Spindle lock

Lock-on button

Trigger switch

Clamp washer

Spindle

Backing pad

Sanding paper

A

B

C

D

E

F

G

H

FEATURES

Side Handle

An side handle is furnished with your tool and can be

installed on either side of the front housing. This handle

should be used at all times to maintain complete control of

the tool.

release the trigger switch once. Do not unplug the tool with

the switch in the locked on condition. Make sure the tool is

not locked on when plugging in. A locked on tool will start

immediately when plugged in.

6

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

•

•

Spindle Lock Button (Fig. 1)

WARNING: To reduce the risk of

serious personal injury, turn tool off and

disconnect tool from power source before

making any adjustments or removing/

installing attachments or accessories.

In order to prevent the spindle of the tool from rotating

while installing or removing accessories, a spindle lock

button has been provided in the gear head of the machine.

To lock the spindle, depress and hold the lock button.

NEVER DEPRESS THE SPINDLE LOCK BUTTON WITH

THE TOOL RUNNING OR COASTING.

The tool can be locked on for continuous use by squeezing

the trigger switch fully and depressing the lock button

shown in Figure 2. Hold the lock button in as you gently

release the trigger switch. The tool will continue to run. To

turn the tool off from a locked on position, squeeze and

OPERATION

WARNING: To reduce the risk of

serious personal injury, turn tool off and

disconnect tool from power source before

making any adjustments or removing/

installing attachments or accessories.

Sanding Application

ATTACHING AND REMOVING BACKING PAD

OR SANDING PAPER

(Figures 4, 5, and 6)

To attach the sanding paper, push the hub of the clamp

washer through the center of the backing pad and sanding

paper, as far as it will go, and also through the backing

pad. Engage the clamp washer threads on the tool spindle

and thread assembly clockwise, completely down on the

spindle. Hold the spindle from rotating by engaging the

spindle lock button.

To remove the backing pad and sanding, use a cloth or

glove to protect your hand. Turn the clamp washer assembly

counterclockwise

(Figure 6). Hold the spindle from rotating

by engaging the spindle lock button.

Sanding

(See Figure 7) When using an abrasive disc, hold the tool

so that an angle of 10˚ to 15˚ exists between the disc and

the work. If only the outer edge of the sanding disc is used,

a rough cut will result. If the sanding disc is pressed flat

against the work, the sanding action will be irregular and

bumpy, and the tool will be difficult to control.

MAINTENANCE

WARNING: To reduce the risk of

serious personal injury, turn tool off and

disconnect tool from power source before

making any adjustments or removing/

installing attachments or accessories.

Page 7

7

N028856

E N G L I S H

Cleaning

Blowing dust, polishing bonnet lint, and grit out of the

motor housing using compressed air is a necessary regular

maintenance procedure. Dust and grit containing metal

particles often accumulate on interior surfaces could create

an electrical shock hazard if not frequently cleaned out.

WARNING: Never use solvents or

other harsh chemicals for cleaning the

non-metallic parts of the tool. These

chemicals may weaken the plastic

materials used in these parts. Use a cloth

dampened only with water and mild soap.

Never let any liquid get inside the tool;

never immerse any part of the tool into

a liquid.

Lubrication

DEWALT tools are properly lubricated at the factory and are

ready for use. Tools should be relubricated regularly every

sixty days to six months, depending on usage. (Tools used

constantly on production or heavy-duty jobs and tools

exposed to heat may require more frequent lubrication.)

This lubrication should only be attempted by trained power

tool repairpersons such as those at D

EWALT service

centers or other authorized service locations.

Motor Brushes

Be sure tool is unplugged before inspecting brushes.

Carbon brushes should be regularly inspected for wear.

To inspect brushes, unscrew the plastic brush inspection

caps (located in the sides of the motor housing) and the

spring and brush assemblies may be withdrawn from the

tool. Keep brushes clean and sliding freely in their guides.

Carbon brushes have varying symbols stamped into them,

and if the brush is worn down to the line closest to the

spring, they must be replaced.

Accessories

Warning: Since accessories, other than

those offered by DEWALT, have not

been tested with this product, use of

such accessories with this tool could be

hazardous. To reduce the risk of injury,

only D

EWALT recommended accessories

should be used with this product.

Use only accessories having a maximum operating speed

at least as high as the highest “NO LOAD RPM” marked

on the tool’s nameplate. This precaution applies to any

accessory on any tool.

Protecting the environment

Separate collection. This product must

not be disposed of with normal household

waste.

Should you find one day that your D

EWALT product needs

replacement, or if it is of no further use to you, do not

dispose of it with household waste. Make this product

available for separate collection.

Separate collection of used products and

packaging allows materials to be recycled

and used again. Re-use of recycled materials

helps prevent environmental pollution and

reduces the demand for raw materials.

Service Information

DEWALT offers a full network of company-owned and

authorized service locations throughout Asia. All D

EWALT

Service Centers are staffed with trained personnel to

provide customers with efficient and reliable power tool

service. Wether you need technical advice, repair, or

genuine factory replacement parts, contact the D

EWALT

location nearest to you.

Notes

DEWALT’s policy is one of continuous improvement

to our products and, as such, we reserve the right to

change product specifications without prior notice.

Standard equipment and accessories may vary by

country.

Product specifications may differ by country.

Complete product range may not be available in all

countries. Contact your local D

EWALT dealers for range

availability.

-

-

-

-

Loading...

Loading...