Page 1

D25303DH

Dust Extraction System with HEPA Filter

Système de dépoussiérage avec filtre H.E.P.A.

Sistema de extracción de polvo con Filtro HEPA

DeWALT Industrial Tool Co., 701 East Joppa Road, Towson, MD 21286

(AUG15) Part No. N451310 D25303DH Copyright © 2015 DeWALT

The following are trademarks for one or more DeWALT power tools: the yellow and black color scheme; the “D” shaped

air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps

on the surface of the tool.

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please

read the manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

NOTICE: indicates a practice not related to personal injury which, if not

avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DeWALT TOOL,

CALL US TOLL FREE AT: 1-800-4-DeWALT (1-800-433-9258)

WARNING: To reduce the risk of injury, read all of this manual carefully before operating

the attachment. Also refer to the manual of any power tool that will be used with this

attachment.

General Power Tool Safety Warnings

WARNING! Read all safety warnings and all instructions. Failure to follow the

warnings and instructions for this accessory and the power tool may result in electric

shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases or dust. Power tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a ground fault

circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric

shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energizing power tools that have

the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench

or a key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught

in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection can

reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce the risk of starting the power tool

accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could

result in a hazardous situation.

5) BATTERY TOOL USE AND CARE

a) Recharge only with the charger specified by the manufacturer. A charger that is

suitable for one type of battery pack may create a risk of fire when used with another

battery pack.

b) Use power tools only with specifically designated battery packs. Use of any other

battery packs may create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal objects like paper

clips, coins, keys, nails, screws, or other small metal objects that can make a

connection from one terminal to another. Shorting the battery terminals together may

cause burns or a fire.

d) Under abusive conditions, liquid may be ejected from the battery; avoid

contact. If contact accidentally occurs, flush with water. If liquid contacts eyes,

additionally seek medical help. Liquid ejected from the battery may cause irritation or

burns.

6) SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Additional Safety Rules

WARNING: ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT safety

glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS wear certified safety

equipment:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3).

• ANSI S12.6 (S3.19) hearing protection.

• NIOSH/OSHA respiratory protection.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with approved

safety equipment, such as those dust masks that are specially designed to filter out microscopic

particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

• Do not use without dustbox and/or filter in place.

• Do not use the appliance to pick up flammable or combustible liquids, such as gasoline, or

use in areas where flammable or combustible liquids are present.

• Do not pick up anything that is burning or smoking, such as cigarettes, matches or hot ashes.

• To avoid spontaneous combustion, empty dust box after each use.

• Do not leave dust extractor unattended when battery is installed. Remove battery

pack when not in use and before servicing.

• Do not put any objects into the openings. Do not use with any opening blocked; keep

free of dust, lint, hair and anything else that may reduce air flow.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and

permanent respiratory or other injury. Although the filter material removes 99.97% of airborne

particles 0.3 microns or greater, the dust extration system may not capture all of the dust

created by the drilling operation. Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face and body.

WARNING: Always wear proper personal hearing protection. Under some conditions

and duration of use, noise from this product may contribute to hearing loss.

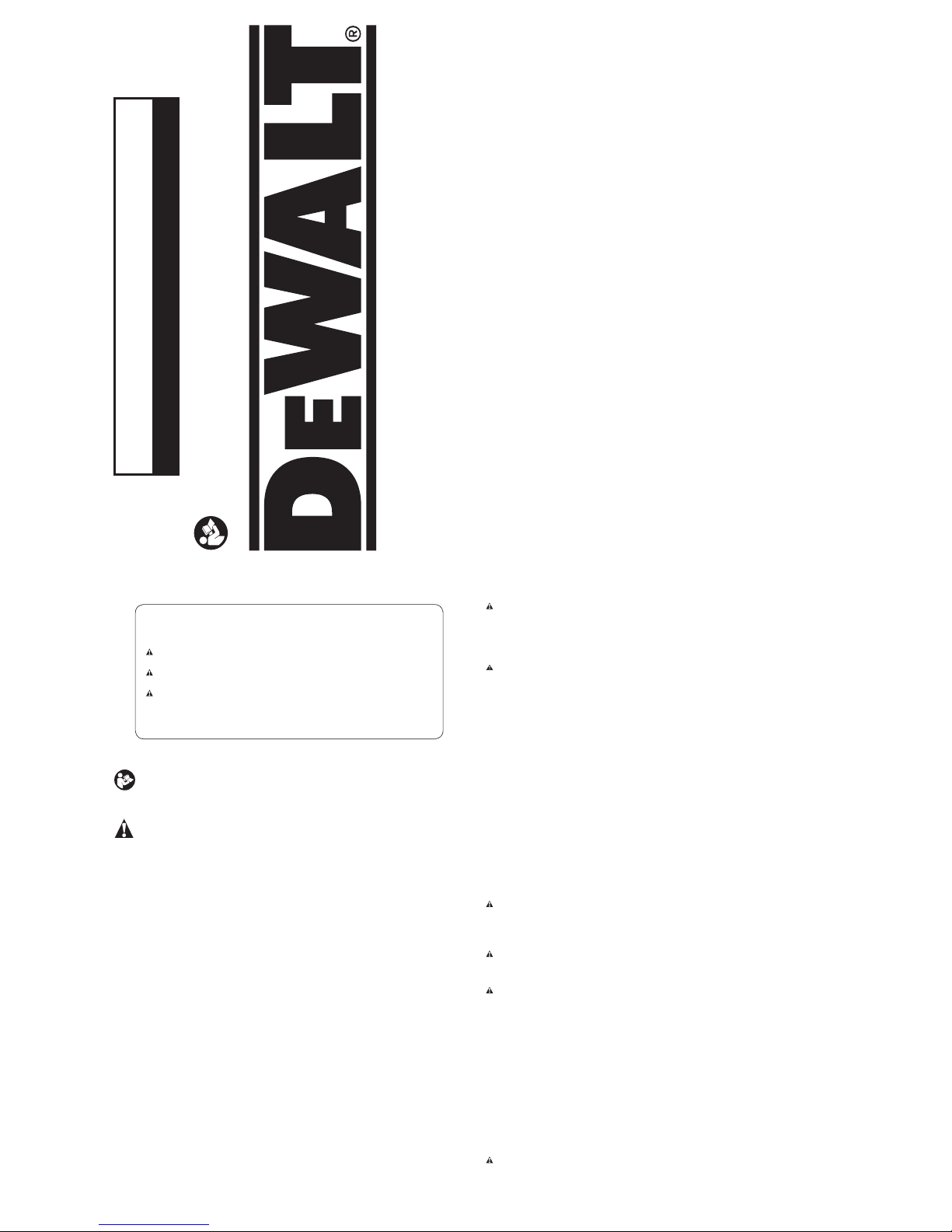

COMPONENTS (FIG. 1)

WARNING: Never modify the power tool or any part of it. Damage or personal injury could

result.

A. Dust extraction system

B. Base release buttons

C. Dust collection box

D. Dust collection box release buttons

E. Telescope

F. Depth adjustment button

G. Length adjustment button

H. Dust extraction head

I. Dust brush

J. Side handle

K. Side handle support groove

L. Side handle support locator

M. Dust extractor electrical connectors

N. Rotary hammer electrical connectors

O. Dust collection box filter assembly

P. Dust collection box filter assembly latch

INTENDED USE

Your dust extraction system D25303DH has been designed for the extraction of dust in professional

hammerdrilling in masonry or concrete, and with solid drill bits mounted to the power tool. DO NOT use for

drilling plastic, wood or metal.

This dust extraction system will fit DeWALT 20V Max cordless SDS Plus® hammers DCH253,

DCH254 (TYPE 2 only), DCH273 and DCH274.

WARNING: DO NOT use for drilling plastic, wood or metal.

Recommended power tools to be used with this attachment are available at extra cost from

your local dealer or authorized service center. If you need assistance in locating any power tool,

please contact DeWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call

1-800-4-DeWALT (1-800-433-9258) or visit our website www.dewalt.com.

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DeWALT • www.dewalt.com

INSTRUCTION MANUAL

GUIDE D’UTILISATION

MANUAL DE INSTRUCCIONES

Page 2

DO NOT use under wet conditions or in presence of flammable liquids or gases.

The dust extraction system is an attachment for use with professional power tools.

DO NOT let children come into contact with the tool. Supervision is required when inexperienced

operators use this tool.

ASSEMBLY

WARNING: ALWAYS turn off tool and disconnect the tool from the power source

before making any adjustments or removing or installing attachments or accessories.

Such preventative safety measures reduce the risk of starting the tool accidentally.

Attaching and Removing the Dust Extraction System

TO ATTACH THE DUST EXTRACTION SYSTEM (FIG. 1–3, 5)

WARNING: To reduce the risk of personal injury, ALWAYS operate the tool with the

side handle properly installed and securely tightened. Failure to do so may result in the

side handle slipping during tool operation and subsequent loss of control. Hold tool with both

hands to maximize control.

1. Remove the drill bit, side handle and the depth adjustment rod, if attached to the rotary

hammer.

2. Attach supplied side handle (J) to the hammer.

3. Ensure the base release buttons are depressed and locked in the open position before

attempting to fit the dust extraction system to the rotary hammer.

4. Insert hammer into the extractor, ensuring that both the electrical connectors and side

handle support groove and locator align. The base released buttons will click into the closed

position when hammer is properly seated in the extractor.

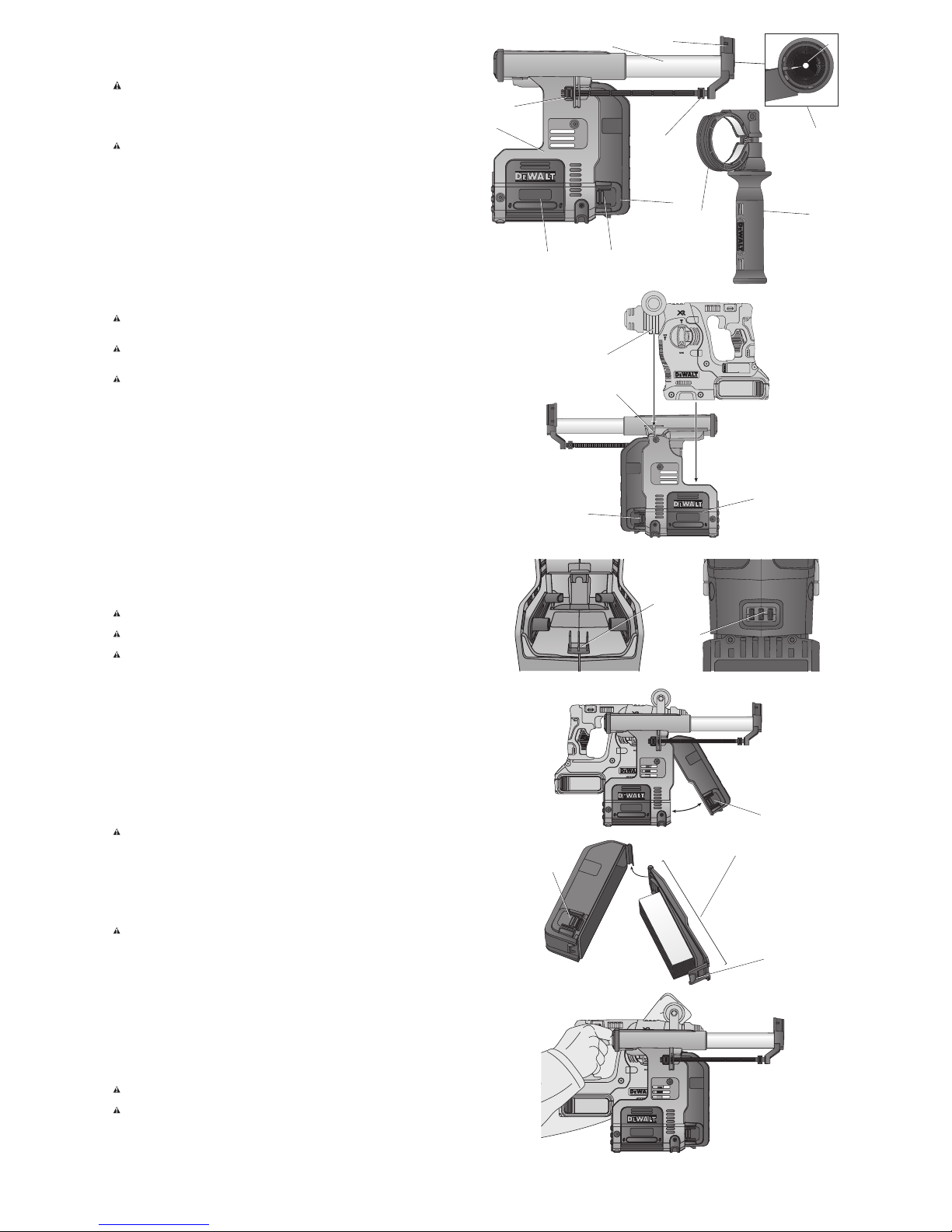

TO REMOVE THE DUST EXTRACTION SYSTEM (FIG. 2)

To remove the dust extraction system, press the two extractor base release buttons (B) and lift

the rotary hammer off the duct extraction system.

OPERATION

WARNING: ALWAYS turn off tool and disconnect the tool from the power source

before making any adjustments or removing or installing attachments or accessories.

Such preventative safety measures reduce the risk of starting the tool accidentally.

WARNING: For your own safety, read the tool instruction manual before using any accessory.

Failure to heed these warnings may result in personal injury and serious damage to the tool and

the accessory. When servicing this tool, use only identical replacement parts.

WARNING: Do not use the tool without the filter in place.

Switch

The extraction system automatically starts when the rotary hammer is turned on.

Electronic Switch-off Delay

After turning the rotary hammer off, the extraction system will run for a few seconds longer

to vacuum the remaining dust particles in the internal parts and collect the dust in the dust

collection box.

Setting the Drilling Depth (Fig. 8)

Press the depth adjustment button (F) on top of the front slider and move it to the desired drilling

depth. Release the button.

Adjusting the Drill Length (Fig. 1)

1. Insert the appropriate drill bit. The dust extractor head is designed for bits up to 5/8"

diameter.

2. Hold the dust extraction head (H) against a wall.

3. Push the tool to make the drill bit touch the surface.

4. Press the length adjustment button (G) on top of the back slider and move it to the desired

length. Release the button.

5. Gently withdraw the tool assembly from the wall, taking care that the spring-loaded

mechanism does not release.

Emptying the Dust Collection Box (Fig. 4, 5)

WARNING: ALWAYS use eye protection (CAN/CSA Z94.3). All users and bystanders

must wear eye protection that conforms to ANSI Z87.1.

WARNING: ALWAYS use proper NIOSH/OSHA/MSHA respiratory protection when

performing this procedure.

CAUTION: Do not clean with water or compressed air.

The dust collection box (C) should be emptied as soon as the performance has noticeably

decreased.

1. Press the dust collection box release buttons (D) and pull the dust collection box away

from the dust extraction system. Once the catch mechanism is clear of the dust extraction

system the upper joint will also release allowing the dust collection box to be removed

completely.

2. To empty the dust collection box (C) position it over a suitable container to catch the dust

contained within it. Lift up the assembly release latch(P) to open the dust collection box,

separating the canister from the lid. Gently tapping the dust collection box will encourage

any dust trapped within the filter to also be removed. Once the filter lid and canister are

empty reattach them, ensuring the assembly release latch (P) is securely fastened. Refer to

figure 5.

3. To reattach the dust collection box to the dust extraction system first insert the rounded

profile of the upper joint into the recess on the dust extraction system. Pivot the dust

collection box down so that the release buttons click back into place. Refer to figure 4.

MAINTENANCE

WARNING: ALWAYS turn off tool and disconnect the tool from the power source

before making any adjustments or removing or installing attachments or accessories.

Such preventative safety measures reduce the risk of starting the tool accidentally.

Your dust collector has been designed to operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation depends on proper tool care and regular

cleaning. Empty the dust extractor periodically or when the performance has noticeably

decreased.

Replacing the Dust Collection Box Filter Assembly

(fig. 4, 5)

WARNING: Wear approved eye protection and approved dust mask when performing this

procedure.

NOTE: The filter should be replaced after every 100 to 120 cycles of use.

1. Press the dust collection box release buttons (D) and pull the dust collection box away

from the dust extraction system. Once the catch mechanism is clear of the dust extraction

system the upper joint will also release allowing the dust collection box to be removed

completely.

2. Lift up the release catch(P) to open the dust collection box, separating the box from the

assembly.

3. Discard dust collection box filter assembly (O) and replace with approved DeWALT service

part.

4. Reattach the dust collection box to the dust extraction system first insert the rounded profile

of the upper joint into the recess on the dust extraction system. Pivot the dust collection box

down so that the release buttons click back into place.

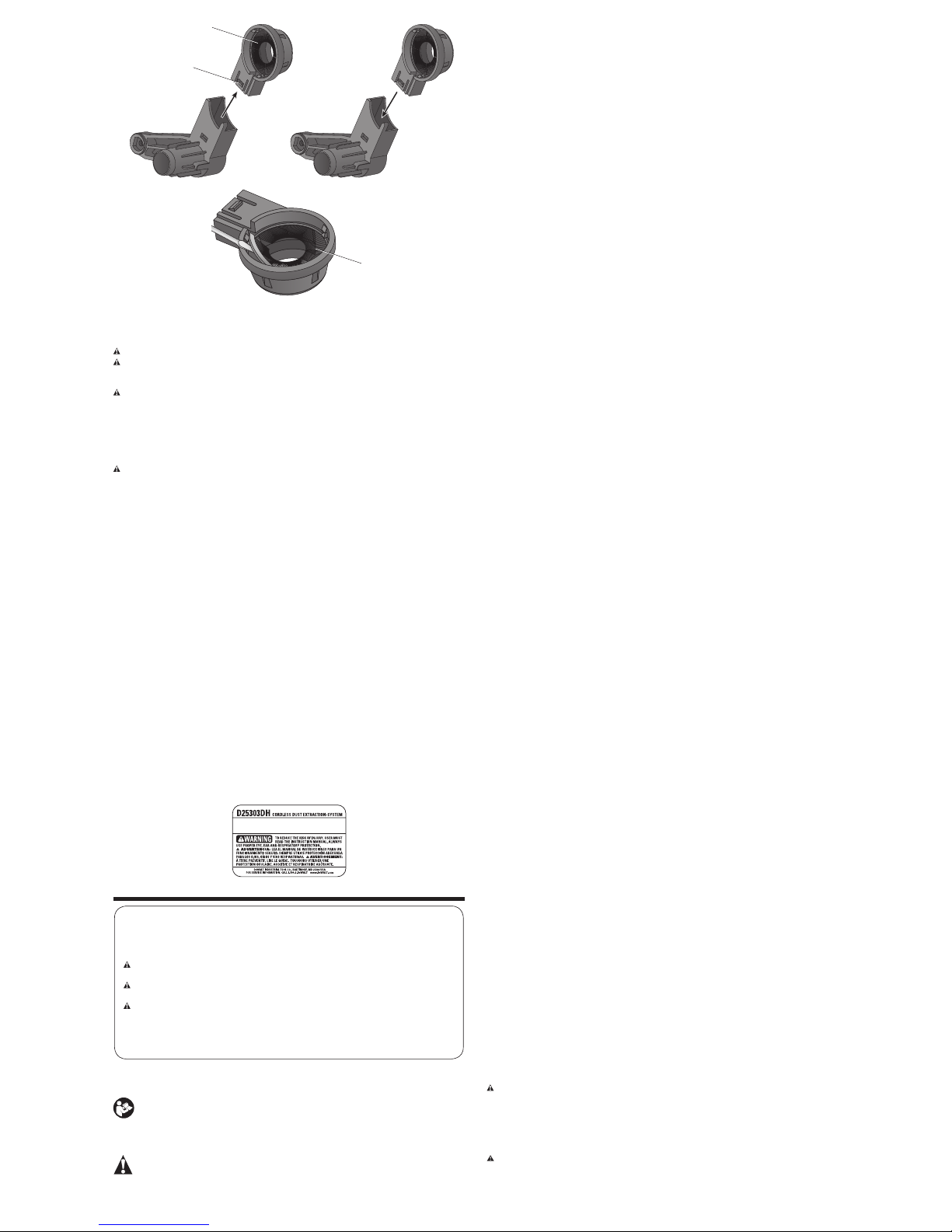

Replacing the Dust Brush (Fig. 10)

WARNING: ALWAYS use eye protection (CAN/CSA Z94.3). All users and bystanders

must wear eye protection that conforms to ANSI Z87.1.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and

permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure.

The dust brush will wear during use and will need to be replaced.

1. Push the snap-fit (S) at the back of the extraction head, and pull it out of the head holder.

2. Use a screwdriver to remove the dust brush (I) out of the extraction head.

3. Replace the dust brush with a new one.

4. Make sure that the open end of the dust brush is positioned to the centering pocket at the

extraction head.

FIG. 1

FIG. 3

FIG. 4

FIG. 5

FIG. 2

A

G

F

C

J

D

B

H

E

K

I

H

L

K

C

B

M

N

D

D

P

O

FIG. 6

Page 3

5. Push the extraction head back into the head holder. The centering pin will stick into the open

end of the dust brush and secure it in place.

Cleaning

WARNING: Do not use a brush to clean the dust collector or filter.

WARNING: Blow dirt and dust out of all air vents with clean, dry air at least once a week. To

minimize the risk of eye injury, always wear ANSI Z87.1 approved eye protection when

performing this.

WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tool. These chemicals may weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse

any part of the tool into a liquid.

During intensive use the dust collector becomes clogged with dust. Refer to Replacing The

Dust Collector Box Filter Element, under OPERATION.

Accessories

WARNING: Since accessories, other than those offered by DeWALT, have not been tested

with this product, use of such accessories with this tool could be hazardous. To reduce the risk

of injury, only DeWALT recommended accessories should be used with this product.

If you need assistance, please contact DeWALT Industrial Tool Co., 701 East Joppa

Road, Baltimore, MD 21286, call 1-800-4-DeWALT (1-800-433-9258) or visit our website

www.dewalt.com.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments should be

performed by a DeWA LT factory service center, a DeWALT authorized service center. Always use

identical replacement parts.

Three Year Limited Warranty

DeWA LT will repair, without charge, any defects due to faulty materials or workmanship for

three years from the date of purchase. This warranty does not cover part failure due to normal

wear or tool abuse. For further detail of warranty coverage and warranty repair information, visit

www.dewalt.com or call 1-800-4-DeWALT (1-800-433-9258). This warranty does not apply to

accessories or damage caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights which vary in certain

states or provinces.

In addition to the warranty, DeWALT tools are covered by our:

1 YEAR FREE SERVICE

DeWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your DeWALT Power Tool, Laser, or

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt

for a full refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, see country specific warranty information contained either in the

packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-4-DeWALT (1-800-433-9258) for a free replacement.

FIG. 7

CONSERVER TOUS LES AVERTISSEMENTS ET TOUTES

LES DIRECTIVES POUR UN USAGE ULTÉRIEUR

Le terme « outil électrique » cité dans les avertissements se rapporte à votre outil électrique à

alimentation sur secteur (avec fil) ou par piles (sans fil).

1) SÉCURITÉ DU LIEU DE TRAVAIL

a) Tenir l’aire de travail propre et bien éclairée. Les lieux encombrés ou sombres sont

propices aux accidents.

b) Ne pas faire fonctionner d’outils électriques dans un milieu déflagrant, tel qu’en

présence de liquides, de gaz ou de poussières inflammables. Les outils électriques

produisent des étincelles qui pourraient enflammer la poussière ou les vapeurs.

c) Éloigner les enfants et les personnes à proximité pendant l’utilisation d’un outil

électrique. Une distraction pourrait en faire perdre la maîtrise à l’utilisateur.

2) SÉCURITÉ EN MATIÈRE D’ÉLECTRICITÉ

a) Les fiches des outils électriques doivent correspondre à la prise. Ne jamais

modifier la fiche d’aucune façon. Ne jamais utiliser de fiche d’adaptation avec un

outil électrique mis à la terre. Le risque de choc électrique sera réduit par l’utilisation

de fiches non modifiées correspondant à la prise.

b) Éviter tout contact physique avec des surfaces mises à la terre comme des

tuyaux, des radiateurs, des cuisinières et des réfrigérateurs. Le risque de choc

électrique est plus élevé si votre corps est mis à la terre.

c) Ne pas exposer les outils électriques à la pluie ou à l’humidité. La pénétration de

l’eau dans un outil électrique augmente le risque de choc électrique.

d) Ne pas utiliser le cordon de façon abusive. Ne jamais utiliser le cordon pour

transporter, tirer ou débrancher un outil électrique. Tenir le cordon éloigné de

la chaleur, de l’huile, des bords tranchants et des pièces mobiles. Les cordons

endommagés ou enchevêtrés augmentent les risques de choc électrique.

e) Pour l’utilisation d’un outil électrique à l’extérieur, se servir d’une rallonge

convenant à cette application. L’utilisation d’une rallonge conçue pour l’extérieur

réduira les risques de choc électrique.

f) S’il est impossible d’éviter l’utilisation d’un outil électrique dans un endroit

humide, brancher l’outil dans une prise ou sur un circuit d’alimentation dotés

d’un disjoncteur de fuite à la terre (GFCI). L’utilisation de ce type de disjoncteur réduit

les risques de choc électrique.

3) SÉCURITÉ PERSONNELLE

a) Être vigilant, surveiller le travail effectué et faire preuve de jugement lorsqu’un

outil électrique est utilisé. Ne pas utiliser d’outil électrique en cas de fatigue

ou sous l’influence de drogues, d’alcool ou de médicaments. Un simple moment

d’inattention en utilisant un outil électrique peut entraîner des blessures corporelles

graves.

b) Utiliser des équipements de protection individuelle. Toujours porter une protection

oculaire. L’utilisation d’équipements de protection comme un masque antipoussière, des

chaussures antidérapantes, un casque de sécurité ou des protecteurs auditifs lorsque la

situation le requiert réduira les risques de blessures corporelles.

c) Empêcher les démarrages intempestifs. S’assurer que l’interrupteur se trouve

à la position d’arrêt avant de relier l’outil à une source d’alimentation et/ou

d’insérer un bloc-piles, de ramasser ou de transporter l’outil. Transporter un outil

électrique alors que le doigt repose sur l’interrupteur ou brancher un outil électrique dont

l’interrupteur est à la position de marche risque de provoquer un accident.

d) Retirer toute clé de réglage ou clé avant de démarrer l’outil. Une clé ou une clé de

réglage attachée à une partie pivotante de l’outil électrique peut provoquer des blessures

corporelles.

e) Ne pas trop tendre les bras. Conserver son équilibre en tout temps. Cela permet

de mieux maîtriser l’outil électrique dans les situations imprévues.

f) S’habiller de manière appropriée. Ne pas porter de vêtements amples ni de

bijoux. Garder les cheveux, les vêtements et les gants à l’écart des pièces

mobiles. Les vêtements amples, les bijoux ou les cheveux longs risquent de rester

coincés dans les pièces mobiles.

g) Si des composants sont fournis pour le raccordement de dispositifs de

dépoussiérage et de ramassage, s’assurer que ceux-ci sont bien raccordés et

utilisés. L’utilisation d’un dispositif de dépoussiérage peut réduire les dangers engendrés

par les poussières.

4) UTILISATION ET ENTRETIEN D’UN OUTIL ÉLECTRIQUE

a) Ne pas forcer un outil électrique. Utiliser l’outil électrique approprié à l’application.

L’outil électrique approprié effectuera un meilleur travail, de façon plus sûre et à la vitesse

pour laquelle il a été conçu.

b) Ne pas utiliser un outil électrique dont l’interrupteur est défectueux. Tout outil

électrique dont l’interrupteur est défectueux est dangereux et doit être réparé.

c) Débrancher la fiche de la source d’alimentation et/ou du bloc-piles de l’outil

électrique avant de faire tout réglage ou changement d’accessoire ou avant de

ranger l’outil. Ces mesures préventives réduisent les risques de démarrage accidentel

de l’outil électrique.

d) Ranger les outils électriques hors de la portée des enfants et ne permettre à

aucune personne n’étant pas familière avec un outil électrique ou son mode

d’emploi d’utiliser cet outil. Les outils électriques deviennent dangereux entre les

mains d’utilisateurs inexpérimentés.

e) Entretien des outils électriques. Vérifier si les pièces mobiles sont mal alignées

ou coincées, si des pièces sont brisées ou présentent toute autre condition

susceptible de nuire au bon fonctionnement de l’outil électrique. En cas de

dommage, faire réparer l’outil électrique avant toute nouvelle utilisation.

Beaucoup d’accidents sont causés par des outils électriques mal entretenus.

f) S’assurer que les outils de coupe sont aiguisés et propres. Les outils de coupe

bien entretenus et affûtés sont moins susceptibles de se coincer et sont plus faciles à

maîtriser.

g) Utiliser l’outil électrique, les accessoires, les forets, etc. conformément aux

présentes directives en tenant compte des conditions de travail et du travail

à effectuer. L’utilisation d’un outil électrique pour toute opération autre que celle pour

laquelle il a été conçu est dangereuse.

5) UTILISATION ET ENTRETIEN DU BLOC-PILES

a) Ne recharger l’outil qu’au moyen du chargeur précisé par le fabricant. L’utilisation

d’un chargeur qui convient à un type de bloc-piles risque de provoquer un incendie s’il

est utilisé avec un autre type de b loc-piles.

b) Utiliser les outils électriques uniquement avec les blocs-piles conçus à cet effet.

L’utilisation de tout autre bloc-piles risque de causer des blessures ou un incendie.

c) Lorsque le bloc-piles n’est pas utilisé, le tenir éloigné des objets métalliques,

notamment des trombones, de la monnaie, des clés, des clous, des vis ou

autres petits objets métalliques qui peuvent établir une connexion entre les

deux bornes. Le court-circuit des bornes du bloc-piles risque de provoquer des brûlures

ou un incendie.

d) En cas d’utilisation abusive, le liquide peut gicler hors du bloc-piles; éviter tout

contact avec ce liquide. Si un contact accidentel se produit, laver à grande

eau. Si le liquide entre en contact avec les yeux, obtenir également des soins

médicaux. Le liquide qui gicle hors du bloc-piles peut provoquer des irritations ou des

brûlures.

6) RÉPARATION

a) Faire réparer l’outil électrique par un réparateur professionnel en n’utilisant

que des pièces de rechange identiques. Cela permettra de maintenir une utilisation

sécuritaire de l’outil électrique.

Règles de sécurité additionnelles

AVERTISSEMENT : PORTER SYSTÉMATIQUEMENT DES LUNETTES DE

PROTECTION. Les lunettes courantes NE sont PAS des lunettes de protection. Utiliser aussi

un masque antipoussières si la découpe doit en produire beaucoup. Porter SYSTÉMATIQUEMENT

un équipement de sécurité homologué:

• Protection oculaire ANSI Z87.1 (CAN/CSA Z94.3);

• Protection auditive ANSI S12.6 (S3.19;

• Protection des voies respiratoires NIOSH/OSHA/MSHA.

AVERTISSEMENT : les scies, meules, ponceuses, perceuses ou autres outils de

construction peuvent produire des poussières contenant des produits chimiques reconnus par

l’État californien pour causer cancers, malformations congénitales ou être nocifs au système

reproducteur. Parmi ces produits chimiques, on retrouve:

S

I

I

Définitions: lignes directrices

en matière de sécurité

Les définitions ci-dessous décrivent le niveau de danger pour chaque mot-indicateur

employé. Lire le mode d’emploi et porter une attention particulière à ces symboles.

DANGER: indique une situation dangereuse imminente qui, si elle n’est pas évitée,

entraînera la mort ou des blessures graves

AVERTISSEMENT: indique une situation potentiellement dangereuse qui, si elle n’est

pas évitée, pourrait entraîner la mort ou des blessures graves

ATTENTION: indique une situation potentiellement dangereuse qui, si elle n’est pas

évitée, pourrait entraîner des blessures légères ou modérées.

AVIS: indique une pratique ne posant aucun risque de dommages corporels mais

qui par contre, si rien n’est fait pour l’éviter, pourrait poser des risques de dommages

matériels.

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET OUTIL OU DE TOUT AUTRE

OUTIL DeWALT, COMPOSEZ LE NUMÉRO SANS FRAIS : 1-800-4-DeWALT (1-800-433-

9258).

AVERTISSEMENT: pour réduire tout risque de dommages corporels, lire soigneusement

ce manuel avant toute utilisation de l’accessoire. Se reporter aussi au manuel de

l’utilisateur des outils électriques utilisés avec cet accessoire.

Avertissements de sécurité généraux pour les outils

électriques

AVERTISSEMENT ! Lire toutes les instructions et toutes les consignes de

sécurité. Tout manquement aux avertissements et consignes au niveau de cet accessoire

ou de l’outil électrique pose des risques de décharges électriques, d’incendie et/ou de

blessures graves.

Page 4

• Le plomb dans les peintures à base de plomb;

• La silice cristallisée dans les briques et le ciment, ou autres produits de maçonnerie; et

• L’arsenic et le chrome dans le bois ayant subi un traitement chimique.

Le risque associé à de telles expositions varie selon la fréquence à laquelle on effectue ces

travaux. Pour réduire toute exposition à ces produits: travailler dans un endroit bien aéré, en

utilisant du matériel de sécurité homologué, tel un masque antipoussières spécialement conçu

pour filtrer les particules microscopiques.

• Limiter toute exposition prolongée avec les poussières provenant du ponçage,

sciage, meulage, perçage ou toute autre activité de construction. Porter des

vêtements de protection et nettoyer à l’eau savonneuse les parties du corps

exposées. Le fait de laisser la poussière pénétrer dans la bouche, les yeux ou la peau peut

favoriser l’absorption de produits chimiques dangereux.

• Ne pas utiliser l’appareil sans le réceptacle à poussières ou le filtre.

• Ne pas utiliser l’appareil pour aspirer des liquides inflammables ou combustibles, comme

l’essence, ou l’utiliser dans des lieux abritant des liquides inflammables ou combustibles.

• Ne pas aspirer des objets incandescents, ou se consumant, comme les cigarettes, les

allumettes ou les cendres chaudes.

•Pour éviter toute combustion spontanée, vider le réceptacle à poussières après

chaque utilisation.

• Ne pas laisser l’extracteur de poussière sans supervision lorsque son bloc-piles est

connecté. Retirer le bloc-piles après utilisation et avant tout entretien.

• Ne pas insérer d’objet dans les ouvertures. Ne pas l’utiliser si les ouvertures sont

bloquées Les maintenir propres et nettes de tout cheveu, toute poussière, peluche, ou toute

autre chose pouvant en réduire la circulation d’air.

AVERTISSEMENT: L’utilisation de cet outil peut produire et/ou répandre de la poussière

susceptible de causer des dommages sérieux et permanents au système respiratoire, ou autres

dommages corporels Bien que le matériau du filtre retire entre 99,97% des particules de l’air

de 0,3 micron ou plus, il se pourra que le système d’extraction des poussières ne capture pas

l’ensemble de la poussière générée par les opérations de perçage Utiliser systématiquement un

appareil de protection des voies respiratoires homologué par NIOSH ou OSHA Diriger les

particules dans le sens opposé au visage et au corps.

AVERTISSEMENT : porter systématiquement une protection auditive individuelle

appropriée. Sous certaines conditions et suivant la durée d’utilisation, le bruit émanant de ce

produit pourrait contribuer à une perte de l’acuité auditive.

DESCRIPTION (FIG.1)

AVERTISSEMENT: ne jamais modifier l’outil électrique ni aucun de ses composants, car il

y a risques de dommages corporels ou matériels.

A. Système de dépoussiérage

B. Boutons de libération de la base

C. Réceptacle à poussières

D. Boutons de libération du réceptacle à

poussières

E. Tuyau télescopique

F. Bouton de réglage de profondeur

G. Bouton de réglage de longueur

H. Tête de dépoussiérage

I. Brosse de dépoussiérage

J. Poignée latérale

K. Rainure du support de la poignée latérale

L. Centreur du support de la poignée latérale

M. Connecteurs électriques de l’extracteur de

poussière

N. Connecteurs électriques du marteau rotatif

O. Dispositif du filtre du réceptacle à

poussières

P. Verrou du dispositif du filtre du réceptacle à

poussières

USAGE PRÉVU

Votre système de dépoussiérage D25303DH a été conçu pour extraire les poussières produites

lors du martelage-perforage professionnel de la maçonnerie ou du béton, alors que l’outil

électrique est muni d’un trépan plein. NE PAS utiliser cet outil pour percer le plastique, le bois, ou le

métal.

Ce système de dépoussiérage fonctionnera sur les marteaux DeWALT de 20 V Max, sans fil,

SDS PlusMD, modèles DCH253, DCH254 (TYPE2 seulement), DCH273 et DCH274.

AVERTISSEMENT: NE PAS utiliser cet outil pour percer le plastique, le bois, ou le métal.

Les outils électriques recommandés pour être utilisés avec cet accessoire sont vendus

séparément auprès de votre distributeur local ou dans les centres de réparation agréés. Si vous

avez besoin d’aide pour localiser ces outils électriques, veuillez contacter DeWALT Industrial Tool

Co., 701 East Joppa Road, Baltimore, MD 21286, ou appeler 1-800-4-DeWALT (1-800-433-

9258) ou vous rendre sur notre site www.dewalt.com.

NE PAS les utiliser en milieu ambiant humide ou en présence de liquides ou de gaz inflammables.

Ce système de dépoussiérage est un accessoire conçu pour être utilisé avec des outils

électriques professionnels.

NE PAS le laisser à la portée des enfants. Une supervision est nécessaire auprès de tout

utilisateur non expérimenté.

MONTAGE

AVERTISSEMENT: arrêter et débrancher SYSTÉMATIQUEMENT l’outil avant tout

réglage ou avant de retirer ou installer toute pièce ou tout accessoire. Ces mesures

préventives de sécurité réduisent les risques de démarrage accidentel de l’outil.

Installation et retrait du système de dépoussiérage

INSTALLATION DU SYSTÈME DE DÉPOUSSIÉRAGE (FIG.1 À 3, 6)

AVERTISSEMENT : pour réduire tout risque de dommages corporels, utiliser

SYSTÉMATIQUEMENT l’outil avec sa poignée latérale installée correctement et

solidement arrimée. Tout manquement à cette directive pourrait faire que la poignée latérale

glisse pendant l’utilisation de l’outil et entraîner la perte du contrôle de celui-ci. Maintenir l’outil

fermement à deux mains pour un contrôle optimal.

1. Retirez la mèche, la poignée latérale et la tige de réglage de profondeur, si rattachées au

marteau rotatif.

2. Rattachez la poignée latérale (J) fournie au marteau.

3. Assurez-vous que les boutons de libération de la base sont appuyés et verrouillés dans la

position ouverte avant d’installer le système de dépoussiérage sur le marteau rotatif.

4. Insérez le marteau dans l’extracteur, en vous assurant que les deux connecteurs électriques,

la rainure du support de la poignée latérale et le centreur sont alignés. Les boutons de

libération de la base s’encliquèteront dans la position fermée lorsque le marteau sera

correctement emboîté dans l’extracteur.

RETRAIT DU SYSTÈME DE DÉPOUSSIÉRAGE (FIG.1, 2, 4)

Pour retirer le système de dépoussiérage, appuyez sur les deux boutons de libération (B) de la

base de l’extracteur et retirez le marteau rotatif du système de dépoussiérage.

UTILISATION

AVERTISSEMENT: arrêter et débrancher SYSTÉMATIQUEMENT l’outil avant tout

réglage ou avant de retirer ou installer toute pièce ou tout accessoire. Ces mesures

préventives de sécurité réduisent les risques de démarrage accidentel de l’outil.

AVERTISSEMENT: pour votre sécurité, lire le manuel de l’utilisateur respectif à l’outil avant

l’utilisation de tout accessoire. Tout manquement à ces avertissements augmente les risques de

blessures, et les risques d’endommager sérieusement l’appareil et ses accessoires. Lors de

l’entretien de cet outil, n’utiliser que des pièces de rechange identiques.

AVERTISSEMENT: ne pas utiliser l’outil sans son filtre.

Interrupteur

Le système de dépoussiérage démarre automatiquement lorsque le marteau rotatif est mis en

marche.

Arrêt électronique à retardement

Après l’arrêt du marteau rotatif, le système de dépoussiérage continuera de fonctionner

quelques secondes pour aspirer complètement toutes les particules de poussières restant dans

les pièces internes du système pour les collecter dans le réceptacle à poussières.

Réglage de la profondeur de perçage (Fig.8)

Appuyez sur le bouton de réglage de profondeur () sur le dessus de la glissière avant et ajustezle sur la profondeur de perçage désirée. Relâchez le bouton.

Réglage de la longueur de perçage (Fig.1)

1. Insérez la mèche appropriée. La tête de l’extracteur de poussière a été conçue pour des

diamètres de mèches allant jusqu’à 5/8po.

2. Maintenez la tête de dépoussiérage (H) contre un mur.

3. Poussez sur l’outil de façon à ce que la mèche soit en contact avec la surface.

4. Appuyez sur le bouton de réglage de longueur (G) sur le dessus de la glissière arrière et

déplacez-le sur la longueur désirée. Relâchez le bouton.

5. Retirez lentement le dispositif de l’outil du mur, en prenant soin à ce que le mécanisme à

ressort ne soit pas libéré.

Vidange du réceptacle à poussières (Fig. 4, 5)

AVERTISSEMENT : porter SYSTÉMATIQUEMENT une protection oculaire (CAN/CSA

Z94.3). Tout utilisateur ou individu présent doit porter une protection oculaire homologuée ANSI

Z87.1.

AVERTISSEMENT: porter SYSTÉMATIQUEMENT une protection des voies respiratoires

NIOSH/OSHA/MSHA pour effectuer cette procédure.

MISE EN GARDE: ne pas nettoyer avec de l’eau ou de l’air comprimé.

Le réceptacle à poussières (C) devrait être vidé dès que les performances de l’appareil diminuent

sensiblement.

1. Appuyez sur les boutons de libération du réceptacle à poussières (D) puis tirez le réceptacle

hors du système de dépoussiérage. Une fois passé le mécanisme de retenue du système

de dépoussiérage, l’articulation supérieure se relâchera, laissant ainsi la possibilité de retirer

complètement le réceptacle à poussières.

2. Pour vider le réceptacle à poussières (C), placez-le au-dessus d’un réceptacle approprié

pour y vider la poussière qu’il contient. Soulevez le verrou du dispositif du filtre (P) pour

ouvrir le réceptacle à poussières, pour séparer le caisson du couvercle. Tapotez légèrement

le réceptacle à poussières pour éliminer aussi toute poussière agglomérée sur le filtre. Une

fois le couvercle du filtre et le réceptacle vidés, rattachez-les, en vous assurant que le verrou

du dispositif du filtre (P) est soigneusement verrouillé. Reportez-vous en figure5.

3. Pour rattacher le réceptacle à poussières au système de dépoussiérage, insérez d’abord

le profilé arrondi de l’articulation supérieure dans la niche du système de dépoussiérage.

Orientez le réceptacle à poussières vers le bas pour que les boutons de libération

s’encliquettent en place. Reportez-vous en figure4.

MAINTENANCE

AVERTISSEMENT: arrêter et débrancher SYSTÉMATIQUEMENT l’outil avant tout

réglage ou avant de retirer ou installer toute pièce ou tout accessoire. Ces mesures

préventives de sécurité réduisent les risques de démarrage accidentel de l’outil.

Ce système de dépoussiérage a été conçu pour fonctionner longtemps avec un minimum

d’entretien. Le fonctionnement continu et satisfaisant de l’outil dépend d’une maintenance

adéquate et d’un entretien régulier. Vider périodiquement l’extracteur de poussière ou lorsque

ses performances diminuent sensiblement.

Remplacement du dispositif du filtre du réceptacle à

poussières (Fig.4, 5)

AVERTISSEMENT: porter une protection oculaire et une protection des voies respiratoires

homologuées pour effectuer cette procédure.

REMARQUE: le filtre devrait être remplacé tous les 100 à 120 cycles d’utilisation.

1. Appuyez sur les boutons de libération du réceptacle à poussières (D) puis tirez le réceptacle

hors du système de dépoussiérage. Une fois passé le mécanisme de retenue du système

de dépoussiérage, l’articulation supérieure se relâchera, laissant ainsi la possibilité de retirer

complètement le réceptacle à poussières.

2. Soulevez le verrou du dispositif (P) pour ouvrir le réceptacle à poussières, et séparez le

caisson du dispositif.

3. Jetez le dispositif du filtre (O) du réceptacle à poussières et remplacez-le par une pièce

agréée DeWALT.

4. Pour rattacher le réceptacle à poussières au système de dépoussiérage, insérez d’abord

le profilé arrondi de l’articulation supérieure dans la niche du système de dépoussiérage.

Orientez le réceptacle à poussières vers le bas pour que les boutons de libération

s’encliquettent en place.

Remplacement de la brosse de dépoussiérage (Fig.10)

AVERTISSEMENT: porter SYSTÉMATIQUEMENT une protection oculaire (CAN/CSA

Z94.3). Tout utilisateur ou individu présent doit porter une protection oculaire homologuée ANSI

Z87.1.

AVERTISSEMENT: cet outil peut produire et/ou répandre de la poussière susceptible de

causer des dommages sérieux et permanents au système respiratoire. Utiliser systématiquement

un appareil de protection des voies respiratoires homologué par le NIOSH ou l’OSHA.

La brosse de dépoussiérage s’usera à la longue et devra être remplacée.

1. Appuyez sur le clip (S) à l’arrière de la tête de dépoussiérage, et retirez-la de son socle.

2. Utilisez un tournevis pour retirer la brosse de dépoussiérage (I) de la tête de dépoussiérage.

3. Remplacez la brosse de dépoussiérage par une nouvelle.

4. Assurez-vous que l’ouverture de la brosse de dépoussiérage est positionnée sur la poche

centrale de la tête de dépoussiérage.

5. Repoussez la tête de dépoussiérage dans son socle. Le goujon de centrage s’encastrera

dans l’ouverture de la brosse de dépoussiérage et l’arrimera en place.

Entretien

AVERTISSEMENT: ne pas utiliser de brosse pour nettoyer le système de dépoussiérage ou

le filtre.

AVERTISSEMENT: expulser tout débris ou poussière des orifices d’aération à l’aide d’un jet

d’air sec au moins une fois par semaine. Pour réduire tout risque de lésions oculaires, porter

systématiquement une protection oculaire homologuée ANSI Z87.1 pour effectuer tout

entretien.

AVERTISSEMENT: ne jamais utiliser de solvants ou tout autre produit chimique décapant

pour nettoyer les parties non métalliques de l’outil. Ces produits chimiques pourraient attaquer

les matériaux plastiques utilisés. Utiliser un chiffon humide et un savon doux. S’assurer qu’aucun

liquide ne pénètre dans l’outil; ne jamais immerger aucune partie de l’outil dans un liquide.

En cas d’utilisation intensive, le système de dépoussiérage pourra être bouché par la poussière.

Reportez-vous à la section Remplacement du dispositif du filtre du réceptacle à

poussières sous UTILISATION.

Accessoires

AVERTISSEMENT: comme les accessoires autres que ceux offerts par DeWALT n’ont pas

été testés avec ce produit, leur utilisation avec cet appareil pourrait comporter un danger. Pour

réduire tout risque de dommages corporels, seuls des accessoires DeWALT recommandés

doivent être utilisés avec cet appareil.

Pour toute assistance, veuillez contacter DeWALT Industrial Tool Co., 701 East Joppa Road,

Baltimore, MD 21286, ou appeler 1-800-4-DeWALT (1-800-433-9258) ou vous rendre sur notre

site www.dewalt.com.

Réparations

Pour assurer la SÉCURITÉ et la FIABILITÉ du produit, les réparations, l’entretien et les réglages

doivent être réalisés (cela comprend l’inspection et le remplacement du balai) par un centre de

réparation en usine DeWALT, un centre de réparation agréé DeW ALT. Toujours utiliser des pièces

de rechange identiques.

Garantie limitée trois ans

DeWALT réparera gratuitement tous les problèmes dus à des défauts de matériau ou de

fabrication pendant trois ans à compter de la date d’achat. Cette garantie ne couvre pas des

défaillances de pièce dues à une usure normale ou à une mauvaise utilisation de l’outil. Pour

plus de détails relatifs à la couverture de la garantie et aux réparations sous garantie, visiter le

site Web www.dewalt.com ou composer le 1-800-4-DeWALT (1-800-433-9258). Cette garantie

ne s’applique pas aux accessoires ni aux dommages causés par des réparations réalisées ou

tentées par des tiers. Cette garantie vous accorde des droits légaux spécifiques et il est possible

que vous ayez d’autres droits qui varient d’un État ou d’une province à l’autre.

En plus de la garantie, les outils DeWALT sont couverts par notre :

SERVICE D’ENTRETIEN GRATUIT DE 1 AN

DeWALT entretiendra l’outil et remplacera les pièces usées par une utilisation normale et ce,

gratuitement, à tout instant pendant la première année à compter de la date d’achat.

Page 5

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si vous n’êtes pas entièrement satisfait des performances de votre outil électrique, laser ou de

votre cloueuse DeWALT pour quelque raison que ce soit, vous pouvez le retourner accompagné

d’un reçu dans les 90 jours suivant la date d’achat et nous vous rembourserons entièrement –

sans poser de questions.

AMÉRIQUE LATINE : cette garantie ne s’applique pas aux produits vendus en Amérique latine.

Pour ceux-ci, veuillez consulter les informations relatives à la garantie spécifique présente dans

l’emballage, appeler l’entreprise locale ou consulter le site Web pour les informations relatives

à cette garantie.

REMPLACEMENT GRATUIT DES ÉTIQUETTES D’AVERTISSEMENT : si les étiquettes

d’avertissement deviennent illisibles ou sont manquantes, composer le 1-800-4-DeWA LT

(1-800-433-9258) pour en obtenir le remplacement gratuit.

Definiciones: Normas de Seguridad

Las siguientes definiciones describen el nivel de gravedad de cada palabra de señal. Lea el

manual y preste atención a estos símbolos.

PELIGRO: indica una situación de peligro inminente que, si no se evita, provocará la

muerte o lesiones graves.

ADVERTENCIA: indica una situación de peligro potencial que, si no se evita, podría

provocar la muerte o lesiones graves.

ATENCIÓN: indica una situación de peligro potencial que, si no se evita, posiblemente

provocaría lesiones leves o moderadas.

AVISO: se refiere a una práctica no relacionada a lesiones corporales que de no

evitarse puede resultar en daños a la propiedad.

SI TIENE ALGUNA DUDA O COMENTARIO ACERCA DE ÉSTA U OTRA HERRAMIENTA

DeWALT, LLÁMENOS AL NÚMERO GRATUITO: 1-800-4-DeWALT (1-800-433-9258).

ADVERTENCIA: Para reducir el riesgo de lesión, lea cuidadosamente la totalidad de este

manual antes de operar el aditamento. También refiérase al manual de cualquier

herramienta eléctrica que será utilizada con este aditamento.

Advertencias generales de seguridad para herramientas

eléctricas

¡ADVERTENCIA! Lea todas las advertencias de seguridad y todas las instrucciones

El incumplimiento de las advertencias e instrucciones de este accesorio y la herramienta

eléctrica podría provocar una descarga eléctrica, un incendio y/o lesiones graves.

CONSERVE TODAS LAS ADVERTENCIAS E

INSTRUCCIONES PARA FUTURAS CONSULTAS

El término “herramienta eléctrica” incluido en las advertencias hace referencia a las herramientas

eléctricas operadas con corriente (con cable eléctrico) o a las herramientas eléctricas operadas

con baterías (inalámbricas).

1) SEGURIDAD EN EL ÁREA DE TRABAJO

a) Mantenga el área de trabajo limpia y bien iluminada. Las áreas abarrotadas y

oscuras propician accidentes.

b) No opere las herramientas eléctricas en atmósferas explosivas, como ambientes

donde haya polvo, gases o líquidos inflamables. Las herramientas eléctricas originan

chispas que pueden encender el polvo o los vapores.

c) Mantenga alejados a los niños y a los espectadores de la herramienta eléctrica

en funcionamiento. Las distracciones pueden provocar la pérdida de control.

2) SEGURIDAD ELÉCTRICA

a) Los enchufes de la herramienta eléctrica deben adaptarse al tomacorriente.

Nunca modifique el enchufe de ninguna manera. No utilice ningún enchufe

adaptador con herramientas eléctricas con conexión a tierra. Los enchufes no

modificados y que se adaptan a los tomacorrientes reducirán el riesgo de descarga

eléctrica.

b) Evite el contacto corporal con superficies con descargas a tierra como, por

ejemplo, tuberías, radiadores, cocinas eléctricas y refrigeradores. Existe mayor

riesgo de descarga eléctrica si su cuerpo está puesto a tierra.

c) No exponga las herramientas eléctricas a la lluvia o a condiciones de humedad.

Si entra agua a una herramienta eléctrica, aumentará el riesgo de descarga eléctrica.

d) No maltrate el cable. Nunca utilice el cable para transportar, tirar o desenchufar

la herramienta eléctrica. Mantenga el cable alejado del calor, el aceite, los

bordes filosos y las piezas móviles. Los cables dañados o enredados aumentan el

riesgo de descarga eléctrica.

e) Al operar una herramienta eléctrica en el exterior, utilice un cable prolongador

adecuado para tal uso. Utilice un cable adecuado para uso en exteriores a fin de

reducir el riesgo de descarga eléctrica.

f) Si el uso de una herramienta eléctrica en un lugar húmedo es imposible de

evitar, utilice un suministro protegido con un interruptor de circuito por falla a

tierra (GFCI). El uso de un GFCI reduce el riesgo de descargas eléctricas.

3) SEGURIDAD PERSONAL

a) Permanezca alerta, controle lo que está haciendo y utilice el sentido común

cuando emplee una herramienta eléctrica. No utilice una herramienta eléctrica

si está cansado o bajo el efecto de drogas, alcohol o medicamentos. Un momento

de descuido mientras se opera una herramienta eléctrica puede provocar lesiones

personales graves.

b) Utilice equipos de protección personal. Siempre utilice protección para los ojos.

En las condiciones adecuadas, el uso de equipos de protección, como máscaras para

polvo, calzado de seguridad antideslizante, cascos o protección auditiva, reducirá las

lesiones personales.

c) Evite el encendido por accidente. Asegúrese de que el interruptor esté en la

posición de apagado antes de conectarlo a la fuente de energía o paquete de

baterías, o antes de levantar o transportar la herramienta. Transportar herramientas

eléctricas con el dedo apoyado en el interruptor o enchufar herramientas eléctricas con el

interruptor en la posición de encendido puede propiciar accidentes.

d) Retire la clavija de ajuste o la llave de tuercas antes de encender la herramienta

eléctrica. Una llave de tuercas o una clavija de ajuste que quede conectada a una pieza

giratoria de la herramienta eléctrica puede provocar lesiones personales.

e) No se estire. Conserve el equilibrio y párese adecuadamente en todo momento.

Esto permite un mejor control de la herramienta eléctrica en situaciones inesperadas.

f) Use la vestimenta adecuada. No use ropas holgadas ni joyas. Mantenga el

cabello, la ropa y los guantes alejados de las piezas en movimiento. Las ropas

holgadas, las joyas o el cabello largo pueden quedar atrapados en las piezas en

movimiento.

g) Si se suministran dispositivos para la conexión de accesorios con fines de

recolección y extracción de polvo, asegúrese de que estén conectados y que se

utilicen correctamente. El uso de dispositivos de recolección de polvo puede reducir

los peligros relacionados con el polvo.

4) USO Y MANTENIMIENTO DE LA HERRAMIENTA ELÉCTRICA

a) No fuerce la herramienta eléctrica. Utilice la herramienta eléctrica correcta

para el trabajo que realizará. Si se la utiliza a la velocidad para la que fue diseñada, la

herramienta eléctrica correcta permite trabajar mejor y de manera más segura.

b) No utilice la herramienta eléctrica si no puede encenderla o apagarla con

el interruptor. Toda herramienta eléctrica que no pueda ser controlada mediante el

interruptor es peligrosa y debe repararse.

c) Desconecte el enchufe de la fuente de energía o el paquete de baterías de la

herramienta eléctrica antes de realizar ajustes, cambiar accesorios o almacenar

la herramienta eléctrica. Estas medidas de seguridad preventivas reducen el riesgo de

encender la herramienta eléctrica en forma accidental.

d) Guarde la herramienta eléctrica que no esté en uso fuera del alcance de los

niños y no permita que otras personas no familiarizadas con ella o con estas

instrucciones operen la herramienta. Las herramientas eléctricas son peligrosas si

son operadas por usuarios no capacitados.

e) Realice el mantenimiento de las herramientas eléctricas. Revise que no haya

piezas en movimiento mal alineadas o trabadas, piezas rotas o cualquier otra

situación que pueda afectar el funcionamiento de la herramienta eléctrica. Si

encuentra daños, haga reparar la herramienta eléctrica antes de utilizarla. Se

producen muchos accidentes a causa de las herramientas eléctricas que carecen de un

mantenimiento adecuado.

f) Mantenga las herramientas de corte afiladas y limpias. Las herramientas de corte

con mantenimiento adecuado y con los bordes de corte afilados son menos propensas

a trabarse y son más fáciles de controlar.

g) Utilice la herramienta eléctrica, los accesorios y las brocas de la herramienta,

etc. de acuerdo con estas instrucciones y teniendo en cuenta las condiciones

de trabajo y el trabajo que debe realizarse. El uso de la herramienta eléctrica para

operaciones diferentes de aquéllas para las que fue diseñada podría originar una situación

peligrosa.

5) USO Y MANTENIMIENTO DE LA HERRAMIENTA CON BATERÍAS

a) Recargue solamente con el cargador especificado por el fabricante. Un cargador

adecuado para un tipo de paquete de baterías puede originar riesgo de incendio si se

utiliza con otro paquete de baterías.

b) Utilice herramientas eléctricas sólo con paquetes de baterías específicamente

diseñados. El uso de cualquier otro paquete de baterías puede producir riesgo de

incendio y lesiones.

c) Cuando no utilice el paquete de baterías, manténgalo lejos de otros objetos

metálicos como sujetapapeles, monedas, llaves, clavos, tornillos u otros objetos

metálicos pequeños que puedan realizar una conexión desde un terminal al

otro. Los cortocircuitos en los terminales de la batería pueden provocar quemaduras o

incendio.

d) En condiciones abusivas, el líquido puede ser expulsado de la batería. Evite su

contacto. Si entra en contacto accidentalmente, enjuague con agua. Si el líquido

entra en contacto con los ojos, busque atención médica. El líquido expulsado de la

batería puede provocar irritación o quemaduras.

6) MANTENIMIENTO

a) Solicite a una persona calificada en reparaciones que realice el mantenimiento

de su herramienta eléctrica y que sólo utilice piezas de repuesto idénticas. Esto

garantizará la seguridad de la herramienta eléctrica.

Reglas de seguridad adicionales

ADVERTENCIA: USE SIEMPRE LENTES DE SEGURIDAD. Los anteojos de diario NO

SON lentes de seguridad. Utilice además una cubrebocas o mascarilla antipolvo si la operación

de corte genera demasiado polvo. SIEMPRE lleve equipo de seguridad certificado:

• Protección ocular ANSI Z87.1 (CAN/CSA Z94.3).

• Protección auditiva ANSI S12.6 (S3.19)

• Protección respiratoria NIOSH/OSHA.

ADVERTENCIA: Algunas partículas de polvo generadas al lijar, serrar, esmerilar y taladrar

con herramientas eléctricas, así como al realizar otras actividades de construcción, contienen

químicos que el Estado de California sabe que pueden producir cáncer, defectos congénitos

u otras afecciones reproductivas. Ejemplos de estos químicos son:

• plomo de algunas pinturas en base a plomo,

• polvo de sílice proveniente de ladrillos y cemento y otros productos de albañilería, y

• arsénico y cromo provenientes de madera tratada químicamente.

Su riesgo de exposición a estos químicos varía, dependiendo de la frecuencia con la cual realiza

usted este tipo de trabajo. Para reducir su exposición a estas sustancias químicas: trabaje en

una zona bien ventilada y llevando equipos de seguridad aprobados, como mascarillas antipolvo

especialmente diseñadas para filtrar partículas microscópicas.

• Evite el contacto prolongado con polvo generado por el lijado, aserrado, pulido,

taladrado y otras actividades de construcción. Vista ropas protectoras y lave las

áreas de la piel expuestas con agua y jabón. Si permite que el polvo se introduzca en

la boca u ojos o quede sobre la piel, puede favorecer la absorción de productos químicos

peligrosos.

• No lo use sin la cámara de recolección de polvo y/o el filtro en su sitio.

• No use el aparato para recoger líquidos inflamables o combustibles, como gasolina, ni lo use

en lugares donde haya líquidos inflamables o combustibles.

• No recoja nada que se esté quemando o que esté humeando, como cigarrillos, fósforos o

cenizas calientes.

• Para evitar una combustión espontánea, vacíe la cámara de recolección de polvo

después de cada uso.

• No deje el extractor de polvo desatendido cuando la batería esté instalada.

Saque la batería cuando no esté utilizando el aparato y antes de realizar mantenimiento o

reparaciones.

• No coloque ningún objeto en las aberturas. No utilice este aparato si tiene alguna

abertura bloqueada; manténgalo sin polvo, pelusa, pelo o cualquier otra cosa que pueda

reducir el flujo de aire.

ADVERTENCIA: El uso de esta herramienta puede generar o dispersar polvo, que puede

ocasionar lesiones respiratorias graves y permanentes u otras lesiones. Aunque el material del

filtro elimina el 99.97% de partículas en el aire de 0.3 micrones o mayores, el sistema de

extracción de polvo quizás no capte todo el polvo creado por la operación de perforación. Utilice

siempre protección respiratoria aprobada por NIOSH/OSHA apropiada para la exposición al

polvo. Dirija las partículas en dirección contraria a la cara y el cuerpo.

ADVERTENCIA: Utilice siempre protección auditiva personal apropiada. Bajo algunas

condiciones y duraciones de uso, el ruido producido por este producto puede contribuir a la

pérdida auditiva.

COMPONENTES (FIG. 1)

ADVERTENCIA: Nunca modifique la herramienta eléctrica, ni tampoco ninguna de sus

piezas. Podría producir lesiones corporales.

A. Sistema de extracción de polvo

B. Botones de liberación de la base

C. Cámara de recolección de polvo

D. Botones de liberación de la cámara de

recolección de polvo

E. Telescopio

F. Botón de ajuste de profundidad

G. Botón de ajuste de longitud

H. Cabezal de extracción de polvo

I. Escobilla para polvo

J. Mango lateral

K. Ranura de apoyo para mango lateral

L. Localizador de apoyo para mango lateral

M. Conectores eléctricos del extractor de

polvo

N. Conectores eléctricos del rotomartillo

O. Unidad de filtro de la cámara de recolección

de polvo

P. Pasador de la unidad de filtro de la cámara

de recolección de polvo

USO DEBIDO

Su sistema de extracción de polvo D25303DH ha sido diseñado para la extracción de polvo en

operaciones profesionales de taladrado de percusión en mampostería o concreto, y con brocas para

taladrar sólidas montadas en la herramienta eléctrica. NO lo use para taladrar plástico, madera o metal.

Este sistema de extracción de polvo se adapta a los martillos inalámbricos de 20V Máx.

DCH253, DCH254 (sólo TIPO 2), DCH273 y DCH274 SDS Plus® de DeWALT.

ADVERTENCIA: NO la utilice para taladrar plástico, madera o metal.

Page 6

Las herramientas eléctricas a ser utilizadas con este aditamento están disponibles con un cargo

adicional en su distribuidor local o en el centro de servicio autorizado. Si necesita ayuda para

ubicar alguna herramienta eléctrica, por favor póngase en contacto con DeWALT Industrial Tool

Co., 701 East Joppa Road, Baltimore, MD 21286, llame al 1-800-4-DeWALT (1-800-433-9258)

o visite nuestro sitio web www.dewalt.com.

NO utilice la herramienta en condiciones húmedas o en la presencia de líquidos o gases

inflamables.

El sistema de extracción de polvo es un aditamento a ser utilizado con herramientas eléctricas

profesionales.

NO permita que los niños toquen la herramienta. Si el operador no tiene experiencia operando

esta herramienta, su uso deberá ser supervisado.

MONTAJE

ADVERTENCIA: SIEMPRE apague la herramienta y desconéctela de la fuente de

alimentación antes de realizar cualesquier ajustes o quitar o instalar aditamentos o

accesorios. Estas medidas de seguridad preventiva reducen el riesgo de poner en marcha la

herramienta accidentalmente.

Cómo poner y sacar el sistema de extracción de polvo

PARA ADOSAR EL SISTEMA DE EXTRACCIÓN DE POLVO (FIG. 1–3, 6)

ADVERTENCIA: Para reducir el riesgo de lesiones corporales, SIEMPRE opere la

herramienta con el mango lateral debidamente instalado y ajustado. El incumplimiento

con lo anterior podría resultar en que el mango lateral se suelte durante la operación de la

herramienta y que el operador pierda el control como consecuencia. Sostenga la herramienta

con ambas manos para maximizar control.

1. Saque la broca, el mango lateral y la barra de ajuste de profundidad, si están fijados al

rotomartillo.

2. Fije el mango lateral suministrado (J) al martillo.

3. Asegúrese de que los botones de liberación estén apretados y bloqueados en la posición

abierta antes de intentar instalar el sistema de extracción de polvo en el rotomartillo.

4. Inserte el martillo en el extractor, asegurándose de que los conectores eléctricos y la ranura

y el localizador de apoyo del mango lateral estén alineados. Los botones de liberación de la

base quedarán en posición cerrada haciendo clic cuando el martillo esté asentado bien en

el extractor.

CÓMO RETIRAR EL SISTEMA DE EXTRACCIÓN DE POLVO (FIG. 2)

Para retirar el sistema de extracción de polvo, presione los dos botones de liberación de la base

del extractor (B) y levante el rotomartillo del sistema de extracción de polvo.

FUNCIONAMIENTO

ADVERTENCIA: SIEMPRE apague la herramienta y desconéctela de la fuente de

alimentación antes de realizar cualesquier ajustes o quitar o instalar aditamentos o

accesorios. Estas medidas de seguridad preventiva reducen el riesgo de poner en marcha la

herramienta accidentalmente.

ADVERTENCIA: Para su seguridad, lea el manual de instrucciones antes de utilizar cualquier

accesorio. De no seguir estas advertencias podrían producirse lesiones corporales y graves

daños a la herramienta y al accesorio. Cuando realice el mantenimiento de esta herramienta,

utilice únicamente repuestos idénticos.

ADVERTENCIA: No use la herramienta sin el filtro en su sitio.

Interruptor

El sistema de extracción se pone en marcha automáticamente cuando se enciende el

rotomartillo.

Retraso electrónico de apagado

Después de apagar el rotomartillo, el sistema de extracción seguirá funcionando durante unos

segundos más para aspirar las partículas de polvo que hayan quedado en las piezas internas y

recolectar el polvo en la cámara de recolección de polvo.

Fijación de la profundidad del taladrado (Fig. 8)

Presione el botón de ajuste de profundidad (F) en la parte superior del deslizador frontal y

muévalo hasta la profundidad de taladrado deseada. Suelte el botón.

Ajuste de la longitud del taladrado (Fig. 1)

1. Introduzca la broca adecuada. El cabezal del extractor de polvo está diseñado para brocas

de hasta 5/8” de diámetro.

2. Sostenga el cabezal de extracción de polvo (H) contra la pared.

3. Empuje la herramienta para que la broca toque la superficie.

4. Presione el botón de ajuste de longitud (G) en la parte superior del deslizador trasero y

muévalo hasta la longitud deseada. Suelte el botón.

5. Retire con suavidad la unidad de la herramienta de la pared, procurando que el mecanismo

de resorte no se libere.

Vaciado de la cámara de recolección de polvo (Fig. 4, 5)

ADVERTENCIA: SIEMPRE utilice protección ocular (CAN/CSA Z94.3). Todos los

usuarios y personas circunstantes deben llevar protección ocular en conformidad con ANSI

Z87.1.

ADVERTENCIA: SIEMPRE lleve protección respiratoria NIOSH/OSHA/MSHA debida

cuando haga esto.

ATENCIÓN: No limpiar con agua o aire comprimido.

La cámara de recolección de polvo (C) debería vaciarse tan pronto como note que el

desempeño ha disminuido.

1. Presione los botones de liberación de la cámara de recolección de polvo(D) y sáquela del

sistema de extracción de polvo. Una vez que el mecanismo de recolección esté retirado

del sistema de extracción de polvo, la junta superior también se liberará permitiendo que la

cámara de recolección de polvo se saque por completo.

2. Para vaciar la cámara de recolección de polvo (C) colóquela por encima de un recipiente

adecuado donde verter el polvo contenido en la misma. Levante el seguro de liberación

de la unidad(P) para abrir la cámara de recolección de polvo, separando el recipiente de

la tapa. El darle golpecitos suaves a la cámara de recolección de polvo ayudará a retirar el

polvo atrapado dentro del filtro. Una vez que estén vacíos la tapa del filtro y el recipiente,

vuelva a fijarlos, asegurándose de que el seguro de liberación de la unidad (P) esté bien

fijado. Consulte la Figura 5.

3. Para volver a fijar la cámara de recolección de polvo al sistema de extracción de polvo,

inserte primero el perfil redondo de la junta superior en la hendidura del sistema de

extracción de polvo. Mueva la cámara de recolección de polvo hacia abajo para que los

botones de liberación vuelvan a colocarse en su sitio haciendo clic. Consulte la Figura 4.

MANTENIMIENTO

ADVERTENCIA: SIEMPRE apague la herramienta y desconéctela de la fuente de

alimentación antes de realizar cualesquier ajustes o quitar o instalar aditamentos o

accesorios. Estas medidas de seguridad preventiva reducen el riesgo de poner en marcha la

herramienta accidentalmente.

Su colector de polvo ha sido diseñado para operar durante un período largo de tiempo

necesitando un mínimo de mantenimiento. Su operación continuamente satisfactoria depende

del cuidado apropiado de la herramienta y regularidad de limpieza. Vacíe el extractor de polvo

periódicamente o cuando note que su desempeño ha disminuido.

Cambio de la unidad del filtro de la cámara de

recolección de polvo (fig. 4,5)

ADVERTENCIA: Cuando lleve a cabo este procedimiento póngase una protección ocular

aprobada y una mascarilla antipolvo aprobada.

NOTA: El filtro debe cambiarse cada 100 a 120 ciclos de uso.

1. Presione los botones de liberación de la cámara de recolección de polvo(D) y sáquela del

sistema de extracción de polvo. Una vez que el mecanismo de recolección esté retirado

del sistema de extracción de polvo, la junta superior también se liberará permitiendo que la

cámara de recolección de polvo se saque por completo.

2. Levante el seguro de liberación(P) para abrir la cámara de recolección de polvo, separando

la cámara de la unidad.

3. Descarte la unidad de filtro de la cámara de recolección de polvo (O) cámbiela por un

repuesto DeWALT aprobado.

4. Vuelva a fijar la cámara de recolección de polvo al sistema de extracción de polvo,

insertando primero el perfil redondo de la junta superior en la hendidura del sistema de

extracción de polvo. Mueva la cámara de recolección de polvo hacia abajo para que los

botones de liberación vuelvan a colocarse en su sitio haciendo clic.

Cambio de la escobilla para polvo (Fig. 10)

ADVERTENCIA: SIEMPRE utilice protección ocular (CAN/CSA Z94.3). Todos los

usuarios y personas circunstantes deben llevar protección ocular en conformidad con ANSI

Z87.1.

ADVERTENCIA: La utilización de esta herramienta puede generar polvo o dispersarlo, lo que

podría causar daños graves y permanentes al sistema respiratorio, así como otras lesiones.

Siempre use protección respiratoria aprobada por NIOSH (Instituto Nacional de Seguridad y

Salud en el Trabajo) u OSHA (Administración de Seguridad y Salud en el Trabajo) apropiada para

la exposición al polvo.

La escobilla para polvo se desgastará durante el uso y tendrá que ser cambiada.

1. Empuje el botón de encaje a presión (S) en la parte trasera del cabezal de extracción y

sáquelo del soporte del cabezal.

2. Use un destornillador para sacar la escobilla para polvo (I) del cabezal de extracción.

3. Cambie la escobilla para polvo por una nueva.

4. Asegúrese de que el extremo abierto de la escobilla para polvo esté colocado sobre el

orificio de centrado en el cabezal de extracción.

5. Empuje hacia atrás el cabezal de extracción dentro del soporte del cabezal. El pasador de

centrado se pegará al extremo abierto de la escobilla para polvo y la asegurará en su sitio.

Limpieza

ADVERTENCIA: No utilice un cepillo para limpiar el colector de polvo o el filtro.

ADVERTENCIA: Limpie la suciedad y el polvo de las rejillas de ventilación con aire seco y

limpio al menos una vez por semana. Para minimizar el riesgo de lesiones oculares siempre lleve

la debida protección ocular ANSI Z87.1 cuando haga esto.

ADVERTENCIA: Nunca utilice solventes u otros químicos fuertes cuando limpie las piezas

no metálicas de la herramienta. Estas sustancias químicas pueden debilitar los materiales

plásticos utilizados en estas piezas. Use un paño humedecido con agua y jabón suave. No

permita que ningún líquido se introduzca en la herramienta; no sumerja ninguna parte de la

herramienta en un líquido.

Durante el uso intensivo, el recolector de polvo se obstruye con el polvo. Consulte la

sección Cambio de la unidad de filtro de la cámara de recolección de polvo, bajo

FUNCIONAMIENTO.

Accesorios

ADVERTENCIA: Como otros accesorios fuera de los ofrecidos por DeWALT no han sido

probados con este producto, el uso de tales accesorios con esta herramienta podría ser

peligroso. Para reducir el riesgo de lesiones, sólo se deberían usar los accesorios recomendados

por DeWALT con este producto.

Si necesita ayuda, por favor póngase en contacto con DeWALT Industrial Tool Co., 701 East

Joppa Road, Baltimore, MD 21286, llame al 1-800-4-DeWALT (1-800-433-9258) o visite

nuestro sitio web www.dewalt.com.

Reparaciones

Para asegurar la SEGURIDAD y la CONFIABILIDAD del producto, las reparaciones, el

mantenimiento y los ajustes deben (inclusive inspección y cambio de carbones) ser realizados

en un centro de mantenimiento en la fábrica DeWA LT, en un centro de mantenimiento autorizado

DeWA LT. Utilice siempre piezas de repuesto idénticas.

Póliza de Garantía

IDENTIFICACIÓN DEL PRODUCTO:

Sello o firma del Distribuidor.

Nombre del producto: _______________________ Mod./Cat.: ____________________________

Marca: _______________________________ Núm. de serie: _____________________________

(Datos para ser llenados por el distribuidor)

Fecha de compra y/o entrega del producto: ___________________________________________

Nombre y domicilio del distribuidor donde se adquirió el producto:

_________________________________________________________________________________

Este producto está garantizado por un año a partir de la fecha de entrega, contra cualquier

defecto en su funcionamiento, así como en materiales y mano de obra empleados para su

fabricación. Nuestra garantía incluye la reparación o reposición del producto y/o componentes