Page 1

D25112(K)

D25113K

®

D25114K

D25213K

1

Page 2

English 6

Ⱥড় 13

༹ዐ࿔ 20

ݏ༹ዐ࿔ 27

34

Copyright DEWALT

2

Page 3

13

5

4

679

11

10

A

D25213K

D25113K

54

679

1

11

10

8

4

D25112(K) D25114K

3

2

3

Page 4

B1

4 5

4 5

6

7

12

B2

D

4

C

10

911

E

Page 5

3

3

F1

G

F2

13

8

8

6

H

5

Page 6

ENGLISH

HEAVY DUTY ROTARY HAMMER DEILL

D25112(K)/D25113K/D25114K/D25213K

Congratulations!

You have chosen a DEWALT tool. Years of experience, thorough product development and innovation make

EWALT one of the most reliable partners for professional power tool users.

D

Technical data

Voltage V 220 220 220 220

Power input W 800 800 800 800

No-load speed min-10-1,1500-1,1500-1,1500-1,150

Load speed min-10-8300-8300-8300-830

Impact energy

hammer drilling J 3.1 3.1 3.1 3.1

chiselling J - 3.4 3.4 3.4

Maximum drilling range in

steel/wood/concrete mm 13/30/26 13/30/26 13/30/26 13/30/26

Chisel positions - 51 51 51

Core drilling capacity in soft brick mm 68 68 68 68

Tool holder SDS-plus

Collar diameter mm 54 54 54 54

Weight kg 2.55 2.6 2.6 2.75

The following symbols are used throughout this

manual:

Denotes risk of personal injury, loss of life

or damage to the tool in case of nonobservance of the instructions in this

manual.

Denotes risk of electric shock.

D25112(K) D25113K D25114K D25213K

®

SDS-plus

®

SDS-plus

®

SDS-plus

EC-Declaration of conformity

D25112(K)/D25113K/D25114K/D25213K

EWALT declares that these power tools have been

D

designed in compliance with: 98/37/EEC,

89/336/EEC, 73/23/EEC, EN 50144, EN 55014-2,

EN 55014-1, EN 61000-3-2 & EN 61000-3-3.

For more information, please contact D

address below, or refer to the back of the manual.

EWALT at the

®

Fire hazard.

6

Level of sound pressure according to 86/188/EEC &

98/37/EEC, measured according to EN 50144:

Page 7

ENGLISH

LpA(sound pressure) dB(A)* 90.5 90.5

LWA(acoustic power) dB(A) 99 99

LpA(sound pressure) dB(A)* 90.5

LWA(acoustic power) dB(A) 99

* at the operator’s ear

D25112(K) D25113K

D25114K

Take appropriate measures for the

protection of hearing.

Weighted root mean square acceleration value

according to EN 50144:

D25112(K) D25113K D25114K D25213K

9.2 m/s

2

9.2 m/s

2

9.2 m/s

2

9.2 m/s

2

Director Engineering and Product Development

Horst Großmann

DEWALT, Richard-Klinger-Straße 11

D-65510, Idstein, Germany

Safety instructions

When using power tools, always observe the

safety regulatio ns a pplicab le in y our c ountry to

reduce the risk of fire, electric shock and

pers onal injury.

Read all of this manual carefully before operating

the tool.

S ave this manual for future referenc e.

General

1 K eep work area clean

Cluttered areas and benches can cause accidents.

2 C onsider work area environment

Do not expose the tool to rain. Do not use the

tool in damp or wet conditions. Keep the work

area well lit (250 - 300 Lux). Do not use the tool

where there is a risk of causing fire or explosion,

e.g. in the presence of flammable liquids and

gases.

3Keepchildrenaway

Do not allow children, visitors or animals to come

near the work area or to touch the tool or the

mains cable.

4Dressproperly

Do not wear loose clothing or jewellery, as these

can be caught in moving parts. Wear protective

hair covering to keep long hair out of the way.

When working outdoors, preferably wear suitable

gloves and non-slip footwear.

5Personalprotection

Always use safety glasses. Use a face or dust

mask whenever the operations may produce

dust or flying particles. If these particles might be

considerably hot, also wear a heat-resistant

apron. Wear ear protection at all times.

6 Gua rd agains t electric shock

Prevent body contact with earthed surfaces

(e.g. pipes, radiators, cookers and refrigerators).

When using the tool under extreme conditions

(e.g. high humidity, when metal swarf is being

produced, etc.), electric safety can be improved

by inserting an isolating transformer or a (FI)

earth-leakage circuit-breaker.

7 Do not overreac h

Keep proper footing and balance at all times.

8Stayalert

Watch what you are doing. Use common sense.

Do not operate the tool when you are tired.

9Secureworkpiece

Use clamps or a vice to hold the workpiece. It is

safer and it frees both hands to operate the tool.

10 C onnec t dus t ex trac tion eq uipment

If devices are provided for the connection of dust

extraction and collection facilities, ensure that

these are connected and properly used.

11 Remove adjusting keys and wrenches

Always check that adjusting keys and wrenches

are removed from the tool before operating the

tool.

12 E xte nsion ca bles

Before use, inspect the extension cable and

replace if damaged. When using the tool

outdoors, only use extension cables intended for

outdoor use and marked accordingly.

13 Us e appropriate tool

The intended use is described in this instruction

manual. Do not force small tools or attachments

to do the job of a heavy-duty tool.

7

Page 8

ENGLISH

The tool will do the job better and safer at the rate

for which it was intended. Do not force the tool.

Warning! The use of any accessory or attachment

or performance of any operation with this tool

other than those recommended in this instruction

manual may present a risk of personal injury.

14 Check for damaged parts

Before use, carefully check the tool and mains

cable for damage. Check for misalignment and

seizure of moving parts, breakage of parts,

damage to guards and switches and any other

conditions that may affect its operation. Ensure

that the tool will operate properly and perform its

intended function. Do not use the tool if any part

is damaged or defective. Do not use the tool if

the switch does not turn it on and off. Have any

damaged or defective parts replaced by an

authorised D

EWALT repair agent. Never attempt

any repairs yourself.

15 Unplug tool

Switch off and wait for the tool to come to a

complete standstill before leaving it unattended.

Unplug the tool when not in use, before changing

any parts of the tools, accessories or

attachments and before servicing.

16 Avoid unintentional starting

Do not carry the tool with a finger on the switch.

Be sure that the tool is switched off before

plugging in.

17 Do not abuse cord

Never carry the tool by its cord. Never pull the

cord to disconnect from the socket. Keep the

cord away from heat, oil and sharp edges.

18 Store idle tools

When not in use, tools must be stored in a dry place

and locked up securely, out of reach of children.

19 Maintain tools with care

Keep the tools in good condition and clean for

better and safer performance. Follow the

instructions for maintenance and changing

accessories. Keep all handles and switches dry,

clean and free from oil and grease.

20 Repairs

This tool is in accordance with the relevant safety

regulations. Have your tool repaired by an

authorised D

EWALT repair agent. Repairs should

only be carried out by qualified persons using

original spare parts; otherwise this may result in

considerable danger to the user.

8

Package contents

The package contains:

1 Heavy duty rotary hammer drill

1 Side handle

1 Depth adjustment rod

1 Kitbox (K-models only)

1 Keyless chuck (D25114K)

1 Instruction manual

1 Exploded drawing

• Check for damage to the tool, parts or

accessories which may have occurred during

transport.

• Take the time to thoroughly read and understand

this manual prior to operation.

Your heavy duty rotary hammer drill D25112(K)/

D25113K/D25114K/D25213K has been

designed for professional rotary and hammer drilling,

screwdriving and light chipping, chiselling, demolition

applications and for carbide tipped core drilling.

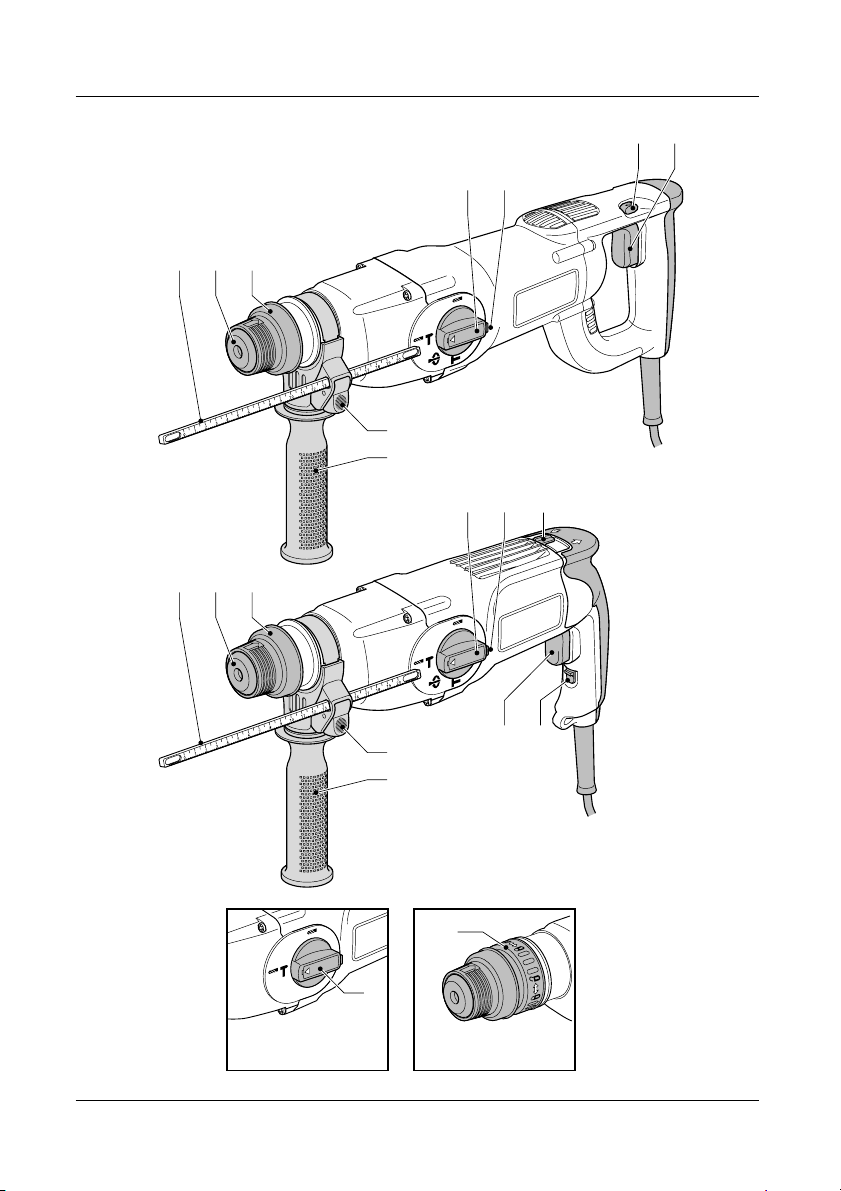

1 Variable speed switch

2 Lock-on button

(D25112(K)/D25113K/D25114K)

3 Forward/reverse slider

4 Mode selector

5 Safety lock

6 Tool holder

7 Dust cover

8 Locking collar (D25114K)

9 Depth adjustment rod

10 Side handle

11 Depth stop clamp

Torque limiting clutch

All rotary hammer drills are equipped with a torque

limiting clutch that reduces the maximum torque

reaction transmitted to the operator in case of

jamming of a drill bit. This feature also prevents the

gearing and electric motor from stalling. The torque

limiting clutch has been factory-set and cannot be

adjusted.

Electrical safety

The electric motor has been designed for one

voltage only. Always check that the power supply

corresponds to the voltage on the rating plate.

Page 9

ENGLISH

Your DEWALT tool is double insulated in

accordance with EN 50144; therefore no

earth wire is required.

Using an extension cable

If an extension cable is required, use an approved

extension cable suitable for the power input of this

tool (see technical data). The minimum conductor

size is 1.5 mm

2

.

When using a cable reel, always unwind the cable

completely.

Also refer to the table below.

Conductor size (mm2) Cable rating (Amperes)

0.75 6

1.00 10

1.50 15

2.50 20

4.00 25

7.5 15 25 30 45 60

Voltage Amperes Cable rating (Amperes)

115 0-2.0 6 6 6 6 6 1

2.1 - 3.4 6 6 6 6 15 15

3.5 - 5.0 6 6 10 15 20 20

5.1 - 7.0 10 10 15 20 20 25

7.1 - 12.0 15 15 20 25 25 -

12.1 - 20.0 20 20 25 - - -

230 0 - 2.0 6 6 6 6 6 6

2.1 - 3.4 6 6 6 6 6 6

3.5 - 5.0 6 6 6 6 10 15

5.1 - 7.0 10 10 10 10 15 15

7.1 - 12.0 15 15 15 15 20 20

12.1 - 20.0 20 20 20 20 25 -

Cable length (m)

Assembly and adjustment

Prior to assembly and adjustment always

unplug the tool.

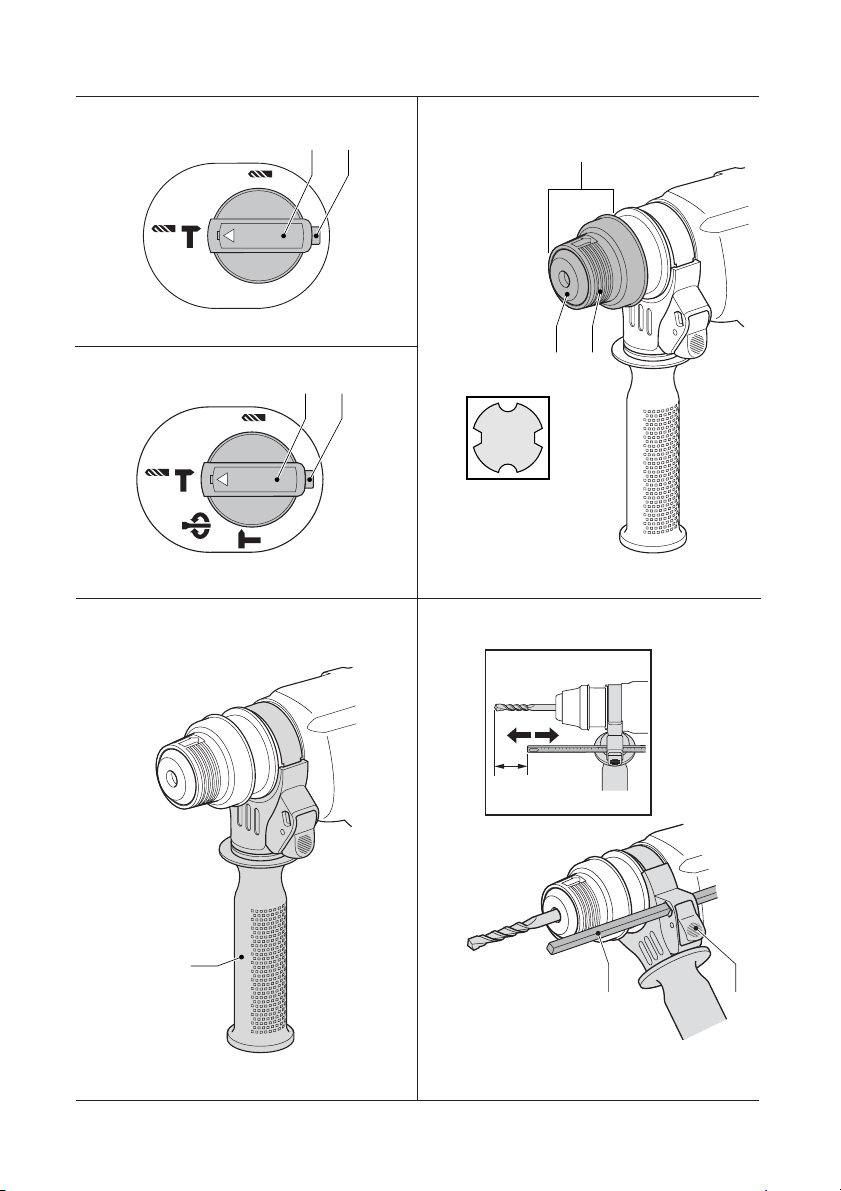

Selecting the operating mode (fig. B1 & B2)

D25112(K) (fig. B1)

The tool can be used in the following operating modes:

Rotary drilling: for screwdriving and for

drilling into steel, wood and plastics

Hammer drilling: for concrete and

masonry drilling operations.

D25113K/D25114K/D25213K (fig. B2)

The tool can be used in the following operating modes:

Rotary drilling: for screwdriving and for

drilling into steel, wood and plastics

Hammer drilling: for concrete and

masonry drilling operations.

Hammering only: for light chipping,

chiselling and demolition applications.

In this mode the tool can also be used as

a lever to free a jammed drill bit.

0

Bit rotation: non-working position used

only to rotate a flat chisel into the desired

position.

• To select the operating mode, press the safety

lock (5) and rotate the mode selector switch (4)

until it points to the symbol of the required mode.

• Release the safety lock and check that the mode

selector switch is locked in place.

Do not select the operating mode when

the tool is running.

Indexing the chisel position

The chisel can be indexed and locked into 51

different positions.

• Rotate the mode selector switch (4) until it points

to the “bit rotation” position.

• Rotate the chisel in the desired position.

• Set the mode selector switch (4) to the

“hammering only” position.

• Twist the chisel until it locks in position.

®

Inserting and removing SDS-plus

(fig. C)

This tool uses SDS-plus

accessories

®

accessories (refer to the

inset in fig. B for a cross-section of an SDS-plus

shank).

®

bit

9

Page 10

ENGLISH

We recommend to use professional accessories only.

• Clean and grease the bit shank.

• Insert the bit shank into the tool holder (6).

• Push the bit down and turn it slightly until it fits

into the slots.

• Pull on the bit to check if it is properly locked.

The hammering function requires the bit to be

able to move axially several centimetres when

locked in the tool holder.

• To remove a bit pull back the tool holder locking

sleeve (12) and pull out the bit.

Fitting the side handle (fig. D)

The side handle (10) can be fitted to suit both

RH- and LH-users.

Always use the tool with the side handle

properly assembled.

• Loosen the side handle.

• For RH-users, slide the side handle clamp over the

collar behind the tool holder, handle at the left.

• For LH-users, slide the side handle clamp over

the collar behind the tool holder, handle at the

right.

• Rotate the side handle to the desired position

and tighten the handle.

Setting the drilling depth (fig. E)

• Insert the required drill bit as described above.

• Press the depth stop clamp (11) and keep it

depressed.

• Fit the depth adjustment rod (9) through the hole

in the depth stop clamp.

• Adjust the drilling depth as shown.

• Release the depth stop clamp.

Forward/reverse slider (fig. F1 & F2)

D25112(K)/D25113K/D25114K (fig. F1)

• Push the forward/reverse slider (3) to the RH-side

for forward (RH) rotation. See arrows on tool.

• Push the forward/reverse slider (3) to the LH-side

for reverse (LH) rotation.

D25213K (fig. F2)

• Push the forward/reverse slider (3) to the LH-side

for forward (RH) rotation. See arrows on tool.

• Push the forward/reverse slider (3) to the RH-side

for reverse (LH) rotation.

Always wait until the motor has come to

a complete standstill before changing the

direction of rotation.

D25112(K)/D25113K/D25213K Fitting the chuck adapter & chuck

• Screw the chuck onto the threaded end of the

chuck adapter.

• Insert the connected chuck and adapter in the

tool as though it were a standard SDS-plus

• To remove the chuck, proceed as for removing a

standard SDS-plus

®

bit.

®

bit.

Never use standard chucks in the

hammer drilling mode.

D25114K - R eplacing the tool holder with

the c huck (fig. G )

• Turn the locking collar (8) into the unlocking

position and pull the tool holder (6) off.

• Push the chuck (13) onto the spindle and turn the

locking collar into the locking position.

• To replace the chuck with the tool holder,

first remove the chuck the same way as the tool

holder was removed. Then place the tool holder

the same way as the chuck was placed.

Never use standard chucks in the

hammer drilling mode.

R eplacing the dust c over (fig. C )

The dust cover (7) prevents dust ingress into the

mechanism. Replace a worn dust cover immediately.

• Pull back the tool holder locking sleeve (12) and

pull the dust cover (7) off.

• Fit the new dust cover.

• Release the tool holder locking sleeve.

Instructions for use

• Always observe the safety instructions

and applicable regulations.

10

Page 11

ENGLISH

Be aware of the location of pipework and wiring.

Apply only a gentle pressure to the tool (approx. 5 kg).

Excessive force does not speed up drilling but

decreases tool performance and may shorten tool

life.

Do not drill or drive too deep to prevent damage to

the dust cover.

Always hold the tool firmly with both hands and

ensure a secure stance (fig. H). Always operate the

tool with the side handle properly mounted.

Switching on and off (fig. A)

D25112(K)/D25113K/D25114K

• To run the tool, press the variable speed switch

(1). The pressure exerted on the variable speed

switch determines the tool speed.

• For continuous operation, press and hold down

the variable speed switch, press the lock-on

button (2) and release the switch.

• To stop the tool, release the switch.

• To stop the tool in continuous operation, press

the switch briefly and release it. Always switch off

the tool when work is finished and before

unplugging.

D25213K

• To run the tool, press the variable speed switch

(1). The pressure exerted on the variable speed

switch determines the tool speed.

• To stop the tool, release the switch.

• To lock the tool in off position, move the forward/

reverse slider (3) to the central position.

Hammer drilling (fig. A)

Drilling with a core bit

• Set the mode selector (3) to the “hammer drilling”

position.

• Adjust the side handle (9) as required.

• Insert the appropriate core bit.

• Assemble the centerdrill into the core bit.

• Place the centerdrill on the spot and press the

variable speed switch (1). Drill until the core

penetrates into the concrete approx. 1 cm.

• Stop drilling and remove the centerdrill. Place the

core bit back into the hole and continue drilling.

• When drilling through a structure thicker than the

depth of the core bit, break away the round

cylinder of concrete or core inside the bit at

regular intervals. To avoid unwanted breaking

away of concrete around the hole, first drill a hole

the diameter of the centerdrill completely through

the structure. Then drill the cored hole halfway

from each side.

• Always switch off the tool when work is finished

and before unplugging.

Rotary drilling (fig. A)

• Set the mode selector switch (4) to the “rotary

drilling” position.

• Depending on your tool, follow either of the

following instructions:

- Fit the chuck adapter/chuck assembly

(D25112(K)/D25113K/D25213K).

- Replace the tool holder with the chuck

(D25114K).

• Proceed as described for hammer drilling.

Never use standard chucks in the

hammer drilling mode.

Drilling with a solid bit

• Set the mode selector switch (4) to the

“hammer drilling” position.

• Insert the appropriate drill bit. For best results

use high quality carbide-tipped bits.

• Adjust the side handle (9) as required.

• If necessary, set the drilling depth.

• Mark the spot where the hole is to be drilled.

• Place the drill bit on the spot and switch on the

tool.

• Always switch off the tool when work is finished

and before unplugging.

Screwdriving (fig. A)

• Set the mode selector switch (4) to the “rotary

drilling” position.

• Select the direction of rotation.

• Depending on your tool, follow either of the

following instructions:

- Insert the special SDS-plus

®

screwdriving

adaptor for use with hexagonal screwdriver bits

(D25112(K)/D25113K/D25213K).

- Replace the tool holder with the chuck

(D25114K).

11

Page 12

ENGLISH

• Insert the appropriate screwdriver bit.

When driving slotted head screws always use

bits with a finder sleeve.

• Gently press the variable speed switch (1) to

prevent damage to the screw head. In reverse

(LH) rotation the tool speed is automatically

reduced for easy screw removal.

• When the screw is flush with the workpiece,

release the variable speed switch to prevent the

screw head from penetrating into the workpiece.

D25113K/D25114K/D25213K - Chipping and

chiselling (fig. A)

• Set the mode selector switch (4) to the

“hammering only” position.

• Insert the appropriate chisel and rotate it by hand

to lock it into one of 51 positions.

• Adjust the side handle (9) as required.

• Switch on the tool and start working.

• Always switch off the tool when work is finished

and before unplugging.

• Do not use this tool to mix or pump

easily combustible or explosive fluids

(benzine, alcohol, etc.).

• Do not mix or stir inflammable liquids

labelled accordingly.

Lubrication

Your power tool requires no additional lubrication.

Accessories and attachments used must be

regularly lubricated around the SDS-plus

®

fitment.

Cleaning

Keep the ventilation slots clear and regularly clean

the housing with a soft cloth.

Unwanted tools and the environment

Take your tool to an authorized DEWALT repair

agent where it will be disposed of in an

environmentally safe way.

®

Various types of SDS-plus

drill bits and chisels are

available as an option.

Consult your dealer for further information on the

appropriate accessories.

Maintenance

Your DEWALT power tool has been designed to

operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation

depends upon proper tool care and regular cleaning.

• This machine is not user-serviceable. Take the

tool to an authorised D

approximately 40 hours of use. If problems occur

before this time contact an authorised D

repair agent.

• The tool will automatically switch off when the

carbon brushes are worn.

12

EWALT repair agent after

EWALT

Loading...

Loading...