Page 1

INSTRUCTION MANUAL

DJ-30 12” Jointer

(Model 37-360, Three Phase)

(Model 37-361, Single Phase)

PART NO. 1349482 - 02-06-04

Copyright © 2004 Delta Machinery

To learn more about DELTA MACHINERY

visit our website at: www.deltamachinery.com.

For Parts, Service, Warranty or other Assistance,

please call

1-800-223-7278 (In Canada call 1-800-463-3582).

Page 2

2

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided, may

result in property damage.

This manual contains information that is important for you to know and understand. This information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the

symbols below. Please read the manual and pay attention to these sections.

SAFETY GUIDELINES - DEFINITIONS

SOME DUST CREATED BY POWER SANDING, SAWING, GRINDING, DRILLING, AND OTHER

CONSTRUCTION ACTIVITIES contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

· lead from lead-based paints,

· crystalline silica from bricks and cement and other masonry products, and

· arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work with approved safety equipment, always wear MSHA/NIOSH

approved, properly fitting face mask or respirator when using such tools.

GENERAL SAFETY RULES

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE

USING THIS EQUIPMENT. Failure to follow all instructions listed below, may result in electric shock,

fire, and/or serious personal injury or property damage.

IMPORTANT SAFETY INSTRUCTIONS

Woodworking can be dangerous if safe and proper operating procedures are not followed. As with all machinery, there

are certain hazards involved with the operation of the product. Using the machine with respect and caution will

considerably lessen the possibility of personal injury. However, if normal safety precautions are overlooked or ignored,

personal injury to the operator may result. Safety equipment such as guards, push sticks, hold-downs, featherboards,

goggles, dust masks and hearing protection can reduce your potential for injury. But even the best guard won’t make

up for poor judgment, carelessness or inattention. Always use common sense

and exercise caution

in the workshop.

If a procedure feels dangerous, don’t try it. Figure out an alternative procedure that feels safer. REMEMBER: Your

personal safety is your responsibility. For additional information please visit our website www

.deltamachinery.com.

This machine was designed for certain applications only. Delta Machinery strongly recommends that this

machine not be modified and/or used for any application other than that for which it was designed. If you have any

questions relative to a particular application, DO NOT use the machine until you have first contacted Delta to determine

if it can or should be performed on the product.

Technical Service Manager

Delta Machinery

4825 Highway 45 North

Jackson, TN 38305

(IN CANADA: 505 SOUTHGATE DRIVE, GUELPH, ONTARIO N1H 6M7)

Page 3

3

GENERAL SAFETY RULES

1. FOR YOUR OWN SAFETY, READ THE INSTRUCTION

MANUAL BEFORE OPERATING THE MACHINE.

Learning the machine’s application, limitations, and

specific hazards will greatly minimize the possibility of

accidents and injury.

2. WEAR EYE PROTECTION. ALWAYS USE SAFETY

GLASSES. Also use face or dust mask if cutting

operation is dusty. Everyday eyeglasses are NOT safety

glasses. USE CERTIFIED SAFETY EQUIPMENT. Eye

protection equipment should comply with ANSI Z87.1

standards, hearing equipment should comply with

ANSI S3.19 standards, and dust mask protection

should comply with MSHA/NIOSH certified respirator

standards. Splinters, air-borne debris, and dust can

cause irritation, injury, and/or illness.

3. WEAR PROPER APPAREL. Do not wear loose

clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts. Nonslip

footwear is recommended. Wear protective hair

covering to contain long hair.

4. DO NOT USE THE MACHINE IN A DANGEROUS

ENVIRONMENT. The use of power tools in damp or

wet locations or in rain can cause shock or

electrocution. Keep your work area well-lit to prevent

tripping or placing arms, hands, and fingers in danger.

5. MAINTAIN ALL TOOLS AND MACHINES IN PEAK

CONDITION. Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing

accessories. Poorly maintained tools and machines can further

damage the tool or machine and/or cause injury.

6. CHECK FOR DAMAGED PARTS. Before using the

machine, check for any damaged parts. Check for

alignment of moving parts, binding of moving parts,

breakage of parts, and any other conditions that may

affect its operation. A guard or any other part that is

damaged should be properly repaired or replaced.

Damaged parts can cause further damage to the

machine and/or injury.

7. KEEP THE WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

8. KEEP CHILDREN AND VISITORS AWAY. Your shop is a

potentially dangerous environment. Children and visitors can

be injured.

9. REDUCE THE RISK OF UNINTENTIONAL STARTING.

Make sure that the switch is in the “OFF” position

before plugging in the power cord. In the event of a

power failure, move the switch to the “OFF” position.

An accidental start-up can cause injury.

10. USE THE GUARDS. Check to see that all guards are in

place, secured, and working correctly to prevent injury.

11. REMOVE ADJUSTING KEYS AND WRENCHES

BEFORE STARTING THE MACHINE. Tools, scrap

pieces, and other debris can be thrown at high speed,

causing injury.

12. USE THE RIGHT MACHINE. Don’t force a machine or

an attachment to do a job for which it was not

designed. Damage to the machine and/or injury may

result.

13. USE RECOMMENDED ACCESSORIES. The use of

accessories and attachments not recommended by

Delta may cause damage to the machine or injury to the

user.

14. USE THE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. When using

an extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersized

cord will cause a drop in line voltage, resulting in loss of

power and overheating. See the Extension Cord Chart

for the correct size depending on the cord length and

nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number, the

heavier the cord.

15. SECURE THE WORKPIECE. Use clamps or a vise to hold

the workpiece when practical. Loss of control of a

workpiece can cause injury.

16. FEED THE WORKPIECE AGAINST THE DIRECTION OF

THE ROTATION OF THE BLADE, CUTTER, OR ABRASIVE

SURFACE. Feeding it from the other direction will cause

the workpiece to be thrown out at high speed.

17. DON’T FORCE THE WORKPIECE ON THE MACHINE.

Damage to the machine and/or injury may result.

18. DON’T OVERREACH. Loss of balance can make you

fall into a working machine, causing injury.

19. NEVER STAND ON THE MACHINE. Injury could occur if the

tool tips, or if you accidentally contact the cutting tool.

20. NEVER LEAVE THE MACHINE RUNNING UNATTENDED.

TURN THE POWER OFF. Don’t leave the machine until it

comes to a complete stop. A child or visitor could be injured.

21. TURN THE MACHINE “OFF”, AND DISCONNECT THE

MACHINE FROM THE POWER SOURCE before installing

or removing accessories, before adjusting or changing

set-ups, or when making repairs. An accidental start-up

can cause injury.

22. MAKE YOUR WORKSHOP CHILDPROOF WITH

PADLOCKS, MASTER SWITCHES, OR BY

REMOVING STARTER KEYS. The accidental start-up

of a machine by a child or visitor could cause injury.

23. STAY ALERT, WATCH WHAT YOU ARE DOING, AND

USE COMMON SENSE. DO NOT USE THE

MACHINE WHEN YOU ARE TIRED OR UNDER THE

INFLUENCE OF DRUGS, ALCOHOL, OR MEDICATION. A moment of inattention while operating power

tools may result in injury.

24. THE DUST GENERATED by certain woods and wood

products can be injurious to your health. Always

operate machinery in well-ventilated areas, and provide

for proper dust removal. Use wood dust collection

systems whenever possible.

FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS INJURY.

10-27-03

Page 4

4

ADDITIONAL SAFETY RULES FOR JOINTERS

1. DO NOT OPERATE THIS MACHINE until it is

completely assembled and installed according to the

instructions. A machine incorrectly assembled can

cause serious injury.

2. OBTAIN ADVICE from your supervisor, instructor, or

another qualified person if you are not thoroughly

familiar with the operation of this machine.

Knowledge is safety.

3. FOLLOW ALL WIRING CODES and recommended

electrical connections to prevent shock or

electrocution.

4. KEEP KNIVES SHARP and free from rust and pitch.

Dull or rusted knives work harder and can cause

kickback.

5. TIGHTEN THE INFEED/OUTFEED TABLES before

starting the machine. Loss of control of the workpiece can cause serious injury.

6. PROPERLY SECURE THE BLADES IN THE CUTTERHEAD

before turning the power “ON”. Loose blades may be

thrown out at high speeds.

7. NEVER TURN THE MACHINE “ON” before clearing the

table of all objects (tools, scraps of wood, etc.). Flying

debris can cause serious injury.

8. NEVER TURN THE MACHINE “ON” with the workpiece

contacting the cutterhead. Kickback can occur.

9. AVOID AWKWARD OPERATIONS AND HAND

POSITIONS. A sudden slip could cause a hand to

move into the cutterhead.

10. KEEP ARMS, HANDS, AND FINGERS away from

the cutterhead to prevent severe injury.

11. NEVER MAKE CUTS deeper than 1/8" (3.2mm) to

prevent kickback.

12. NEVER JOINT OR PLANE A WORKPIECE that is

shorter than 10" (254mm), narrower than 3/4"

(19.0MM), or less than 1/2" (12.7mm) thick. Jointing

smaller workpieces can allow your hand to contact

the cutterhead causing severe injury.

13. USE HOLD-DOWN/PUSH BLOCKS for jointing or

planing any workpiece lower than the fence. Jointing

or planing small workpieces can result in kickback

and severe injury.

14. HOLD THE WORKPIECE FIRMLY against the table

and fence. Loss of control of the workpiece can

cause kickback and result in serious injury.

15. NEVER PERFORM “FREE-HAND” OPERATIONS. Use

the fence to position and guide the workpiece. Loss

of control of the workpiece can cause serious injury.

16. DO NOT attempt to perform an abnormal or little-

used operation without study and the use of

adequate hold-down/push blocks, jigs, fixtures,

stops, etc.

17. DO NOT FEED A WORKPIECE from the outfeed

end of the machine.The workpiece will be thrown out

of the opposite end at high speeds.

18. DO NOT ATTEMPT to back out a workpiece while

the cutters are still rotating.

18. DO NOT FEED A WORKPIECE that is warped,

contains knots, or is embedded with foreign objects

(nails, staples, etc.) to prevent kickback.

19. MAINTAIN THE PROPER RELATIONSHIP OF

INFEED AND OUTFEED TABLE SURFACES and

cutterhead knife path. Loss of control of the workpiece can cause serious injury.

20. PROPERLY SUPPORT LONG OR WIDE WORKPIECES.

Loss of control of the workpiece can cause injury.

21.

NEVER PERFORM LAYOUT, ASSEMBLY, OR SETUP WORK on the table/work area when the

machine is running. A sudden slip could cause a

hand to move into the cutterhead. Severe injury

can result.

22. TURN THE MACHINE “OFF”, disconnect the

machine from the power source, and clean the

table/work area before leaving the machine. LOCK

THE SWITCH IN THE “OFF” POSITION to prevent

unauthorized use. Someone else might accidentally

start the machine and cause injury to themselves.

23. ADDITIONAL INFORMATION regarding the safe

and proper operation of power tools (i.e. a safety

video) is available from the Power Tool Institute,

1300 Sumner Avenue, Cleveland, OH 44115-2851

(www.powertoolinstitute.com). Information is also

available from the National Safety Council, 1121

Spring Lake Drive, Itasca, IL 60143-3201. Please

refer to the American National Standards Institute

ANSI 01.1 Safety Requirements for Woodworking

Machines and the U.S. Department of Labor OSHA

1910.213 Regulations.

FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS INJURY.

SAVE THESE INSTRUCTIONS.

Refer to them often

and use them to instruct others.

04-24-03

Page 5

5

A separate electrical circuit should be used for your machines. This circuit should not be less than #12 wire and should

be protected with a 20 Amp time lag fuse. If an extension cord is used, use only 3-wire extension cords which have 3prong grounding type plugs and matching receptacle which will accept the machine’s plug. Before connecting the

machine to the power line, make sure the switch (s) is in the “OFF” position and be sure that the electric current is of

the same characteristics as indicated on the machine. All line connections should make good contact. Running on low

voltage will damage the machine.

DO NOT EXPOSE THE MACHINE TO RAIN OR OPERATE THE MACHINE IN DAMP LOCATIONS.

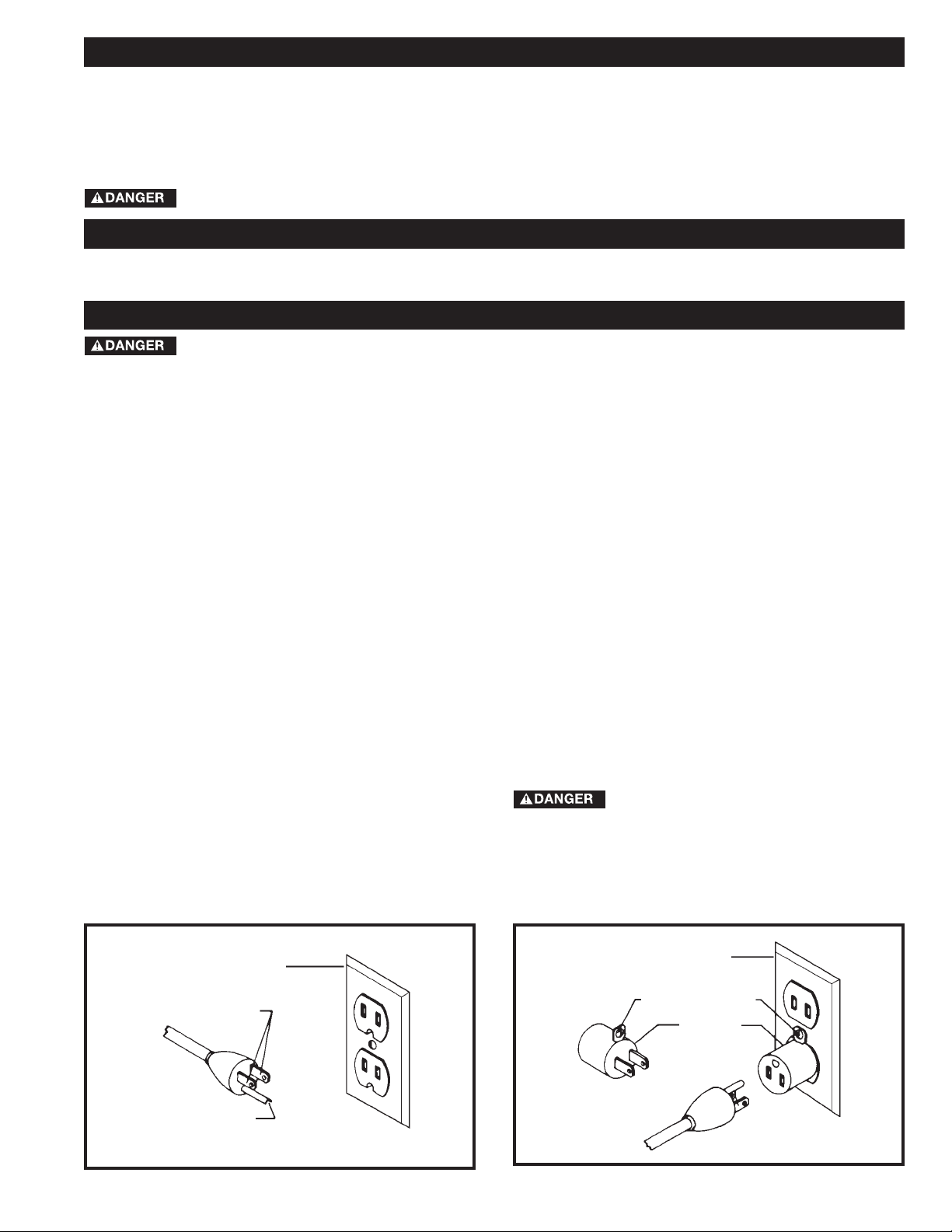

Fig. A Fig. B

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

GROUNDED OUTLET BOX

GROUNDING

MEANS

ADAPTER

2. Grounded, cord-connected machines intended for use

on a supply circuit having a nominal rating less than 150

volts:

If the machine is intended for use on a circuit that has an

outlet that looks like the one illustrated in Fig. A, the

machine will have a grounding plug that looks like the plug

illustrated in Fig. A. A temporary adapter, which looks like

the adapter illustrated in Fig. B, may be used to connect

this plug to a matching 2-conductor receptacle as shown

in Fig. B if a properly grounded outlet is not available. The

temporary adapter should be used only until a properly

grounded outlet can be installed by a qualified electrician.

The green-colored rigid ear, lug, and the like, extending

from the adapter must be connected to a permanent

ground such as a properly grounded outlet box. Whenever

the adapter is used, it must be held in place with a metal

screw.

NOTE: In Canada, the use of a temporary adapter is not

permitted by the Canadian Electric Code.

IN ALL CASES, MAKE CERTAIN THE

RECEPTACLE IN QUESTION IS PROPERLY

GROUNDED. IF YOU ARE NOT SURE HAVE A

QUALIFIED ELECTRICIAN CHECK THE RECEPTACLE.

1. All grounded, cord-connected machines:

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock. This machine is

equipped with an electric cord having an equipmentgrounding conductor and a grounding plug. The plug must

be plugged into a matching outlet that is properly installed

and grounded in accordance with all local codes and

ordinances.

Do not modify the plug provided - if it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding

conductor can result in risk of electric shock. The

conductor with insulation having an outer surface that is

green with or without yellow stripes is the equipmentgrounding conductor. If repair or replacement of the

electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if

the grounding instructions are not completely

understood, or if in doubt as to whether the machine is

properly grounded.

Use only 3-wire extension cords that have 3-prong

grounding type plugs and matching 3-conductor

receptacles that accept the machine’s plug, as shown in

Fig. A.

Repair or replace damaged or worn cord immediately.

POWER CONNECTIONS

MOTOR SPECIFICATIONS

Your machine is wired for (see SPEC PLATE VOLTAGE), 60 HZ alternating current. Before connecting the machine to

the power source, make sure the switch is in the “OFF” position.

GROUNDING INSTRUCTIONS

THIS MACHINE MUST BE GROUNDED WHILE IN USE TO PROTECT THE OPERATOR FROM

ELECTRIC SHOCK.

Page 6

6

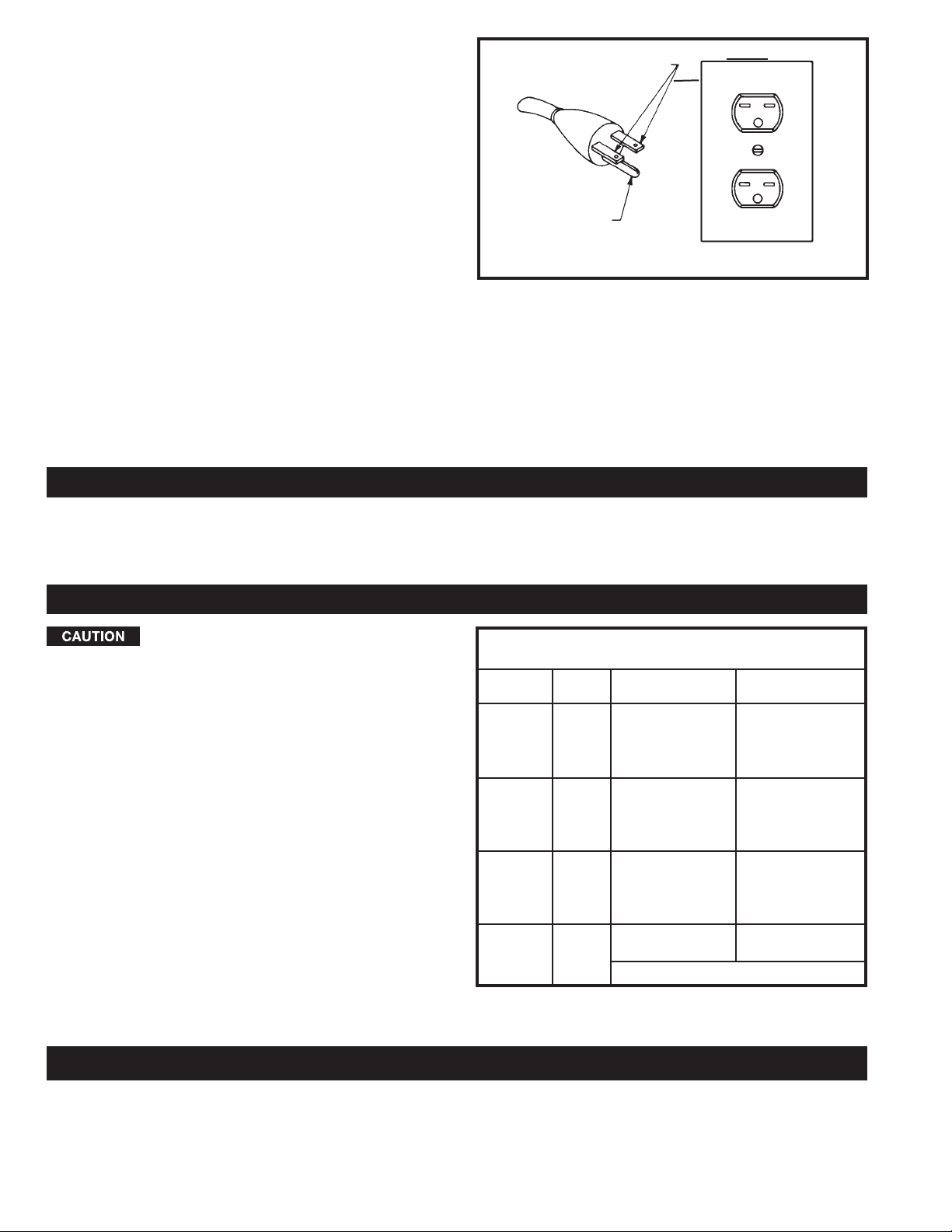

3. Grounded, cord-connected machines intended for

use on a supply circuit having a nominal rating between

150 - 250 volts, inclusive:

If the machine is intended for use on a circuit that has an

outlet that looks like the one illustrated in Fig. C, the

machine will have a grounding plug that looks like the

plug illustrated in Fig. C. Make sure the machine is

connected to an outlet having the same configuration as

the plug. No adapter is available or should be used with

this machine. If the machine must be re-connected for

use on a different type of electric circuit, the reconnection should be made by qualified service

personnel; and after re-connection, the machine should

comply with all local codes and ordinances.

4. Permanently connected machines:

If the machine is intended to be permanently connected,

the machine should be connected to a grounded metal

permanent wiring system, or to a system having an

equipment-grounding conductor.

Fig. C

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

EXTENSION CORDS

Use proper extension cords. Make sure

your extension cord is in good condition and is a 3-wire

extension cord which has a 3-prong grounding type

plug and matching receptacle which will accept the

machine’s plug. When using an extension cord, be sure

to use one heavy enough to carry the current of the

machine. An undersized cord will cause a drop in line

voltage, resulting in loss of power and overheating. Fig.

D-1 shows the correct gauge to use depending on the

cord length. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

Fig. D-2

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere Total Length Gauge of

Rating Volts of Cord in Feet Extension Cord

0-6 240

up to

50 18 AWG

0-6 240 50-100 16 AWG

0-6 240 100-200 16 AWG

0-6 240 200-300 14 AWG

6-10 240

up to

50 18 AWG

6-10 240 50-100 16 AWG

6-10 240 100-200 14 AWG

6-10 240 200-300 12 AWG

10-12 240

up to

50 16 AWG

10-12 240 50-100 16 AWG

10-12 240 100-200 14 AWG

10-12 240 200-300 12 AWG

12-16 240

up to

50 14 AWG

12-16 240 50-100 12 AWG

12-16 240

GREATER THAN 100 FEET NOT RECOMMENDED

FUNCTIONAL DESCRIPTION

Delta Model 37-360 and 37-361 (DJ-30) are 12" Precision Jointers with a cutting capacity of 12" (304mm) wide, 3/4"

deep (19mm max.) and 3/4" (19mm) rabbeting. Model 37-360 includes a three-phase 3 HP motor that is wired for 220V

(can be wired at 460V). Model 37-361 includes a single phase 3 HP motor wired for 230V. Both include a fence, threeknife cutterhead, cutterhead guard, and push blocks.

FOREWORD

THREE PHASE OPERATION

Three phase jointers are not supplied with a power cord. They must be permanently connected to the building electrical

system and grounded according to the National Electrical Code. Since they must be permanently connected to the

building electrical system, extension cords cannot be used with three phase jointers.

Page 7

7

DEFINITIONS OF JOINTING AND PLANING OPERATIONS

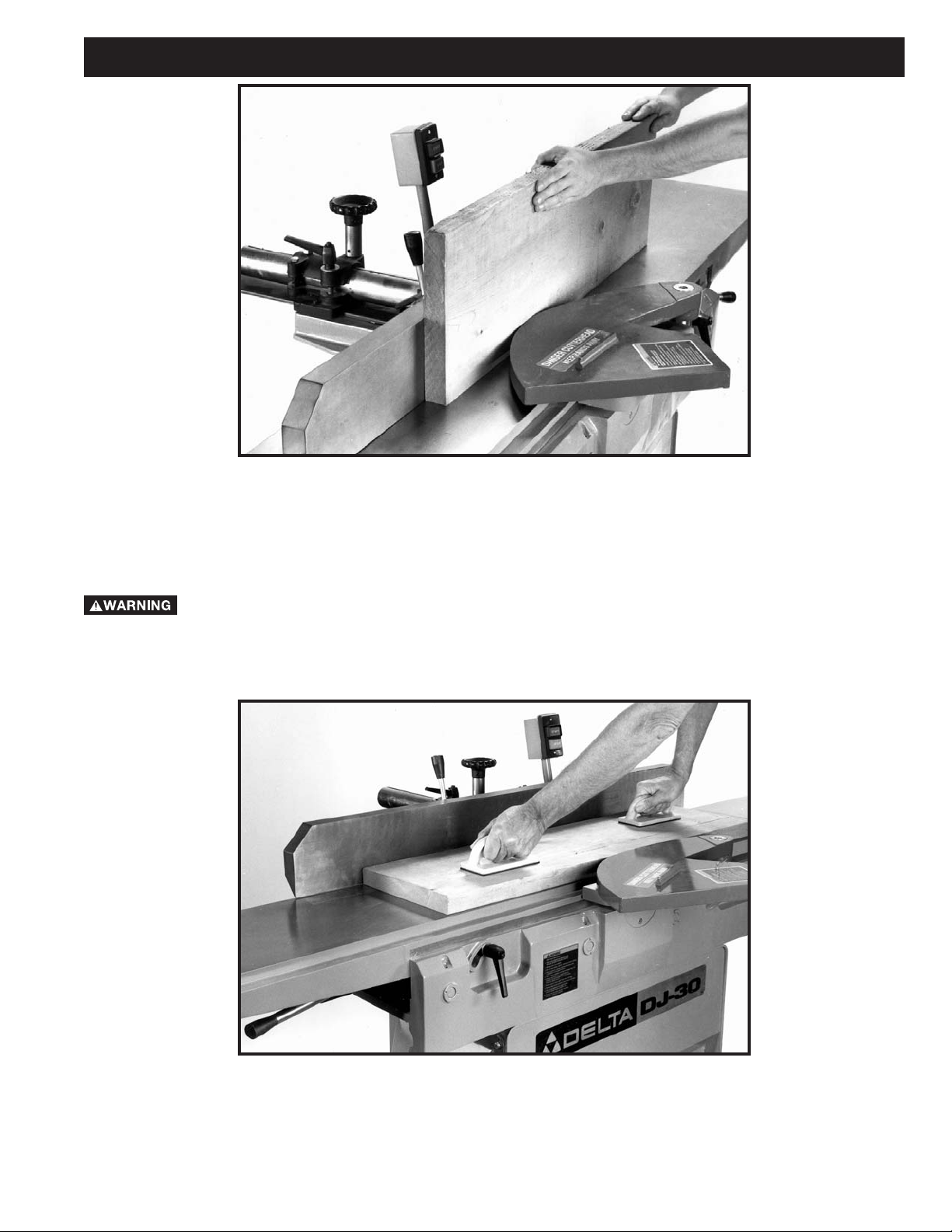

Fig. 2

Fig. 3

JOINTING OPERATIONS – Jointing cuts or edge jointing is the simplest and most common operation which can be

done on the jointer and these cuts are made to square an edge of a workpiece. The fence is square with the table and

the depth of cut is approximately 1/8 inch. The workpiece is positioned on the jointer with the narrow edge of the

workpiece on the infeed table and the major flat surface of the workpiece against the fence, as shown in Fig. 2. The

workpiece is moved from the infeed table, across the cutterhead to the outfeed table.

PLANING OPERATIONS – Planing or surfacing is identical to the jointing operation except for the position of the

workpiece. For planing, the major flat surface of the workpiece is placed on the infeed table of the jointer with the narrow

edge of the workpiece against the fence, as shown in Fig. 3. The workpiece is moved from the infeed table, across the

cutterhead to the outfeed table establishing a flat surface on the workpiece. Always use push blocks when performing

planing operations and NEVER pass your hands directly over the cutterhead.

Never pass your hands directly over the cutterhea. Use push blocks to feed the workpiece

whenever possible.

The hand over the outfeed table presses the work down so that the newly-formed surface will make perfect contact with

the table. The hand over the infeed table (usually the right hand) exerts no downward pressure, but simply advances

the work to the cutterhead. Both hands exert pressure to keep the work in contact with the fence.

Page 8

8

UNPACKING AND CLEANING

Carefully unpack the machine and all loose items from the shipping container(s). Remove the protective coating from

all unpainted surfaces. This coating may be removed with a soft cloth moistened with kerosene (do not use acetone,

gasoline or lacquer thinner for this purpose). After cleaning, cover the unpainted surfaces with a good quality household

floor paste wax.

NOTICE: THE PHOTO ON THE MANUAL COVER ILLUSTRATES THE

CURRENT PRODUCTION MODEL. ALL OTHER ILLUSTRATIONS CONTAINED

IN THE MANUAL ARE REPRESENTATIVE ONLY AND MAY NOT DEPICT THE

ACTUAL COLOR, LABELING OR ACCESSORIES AND ARE INTENDED TO

ILLUSTRATE TECHNIQUE ONLY.

REMOVING SHIPPING CRATE

1 - Dust Hood

2 - 8mm Hex wrench

3 - 12 and 14mm open end wrench

4 - 10 and 12mm open end wrench

5-5/8″ long Button Head

Screws (7)

6 - Push Blocks (2)

7 - 1-1/8″ long

Socket Head Screws (2)

8 - Flat Washers (2)

9 - Fence Assembly

10 - 4mm T-Handle wrench

(not shown)

11 - 3mm and 10mm Hex wrench

(not shown)

12 - 17mm and 19mm Open end

wrench (not shown)

Fig. 4

1

2

3

4

5

8

7

6

Your new 12″ Jointer is shipped complete in one wooden shipping crate. Remove the crate from around the machine

leaving the bottom of the machine fastened to the shipping skid at this time. Remove the fence assembly, dust hood

and all loose items from the shipping crate. Figure 4 illustrates all the loose items supplied with your machine.

Page 9

9

REMOVING MACHINE FROM SHIPPING SKID

Fig. 5

Fig. 6

Fig. 7

1. Open door (A) Fig. 5, under infeed table and remove mounting hardware that fastens infeed end of machine

to skid

2. Remove three screws (B) Fig. 6, and remove cover (C) from dust chute located under outfeed table. Remove

mounting hardware located inside cover (C) that fastens outfeed end of machine to skid and replace cover (C).

3. Remove machine

from shipping skid and

position in permanent

location.

THE

JOINTER IS VERY

HEAVY AND A

FORKLIFT OR HOIST

WITH STRAPS UNDER

THE TABLE

BRACKETS SHOULD

BE USED TO MOVE

THE MACHINE.

Figure 7 illustrates the

machine removed from

the shipping skid.

A

C

B

SELECTING FLOOR SPACE

It is important that the machine be set on a solid, level foundation. If rocking occurs, place metal shims at the corners

between the base and the floor. Lag screws or bolts may be used if desired to secure the machine to the floor using

the same holes that fastened the machine to the shipping skid.

Page 10

10

ASSEMBLY

ASSEMBLING DUST HOOD

1. Assemble the dust hood (A) Fig. 8, to the outfeed

end of the jointer base using the seven 5/8″ long button

head screws (B) as shown.

Fig. 11

Fig. 8

Fig. 9 Fig. 10

ASSEMBLING

JOINTER FENCE

1. Assemble the jointer fence assembly (A) Fig. 11, to

the machine cabinet, as shown, using the two 1-1/8″ long

screws (B) and flat washers supplied.

MOVING START-STOP

SWITCH TO THE UP POSITION

1. For shipping purposes, the start-stop switch and

switch arm (A) is shipped in the down position, as shown

in Fig. 9. Simply remove the two screws (B) Fig. 9, rotate

switch and switch arm (A) 180 degrees, as shown in

Fig. 10, and replace the two screws (B).

A

B

B

B

A

B

A

B

B

B

A

Page 11

11

SINGLE PHASE INSTALLATION

Fig. 12

A

B

Fig. 13 Fig. 14

1. Remove screw (A) Fig. 12, and terminal strip cover (B).

2. Remove plastic covering (C) Fig. 13, that snaps into

terminal strip.

3. Bring power line through access hole in bottom of

terminal strip box and connect the two power lines to

terminals (D) Fig. 14, and the green ground wire to ground

screw (E).

4. Replace plastic covering (C) Fig. 13, and terminal

strip cover removed in STEP 1.

C

E

D

IMPORTANT: The jointer cutterhead is a high inertia load which causes the motor to draw a high inrush

current during starting. The jointer must be connected to an electrical circuit protected by a properly sized

fuse or circuit breaker to handle this high inrush of current. We recommend either a 30 Amp time lag fuse, or

a 40 Amp motor start circuit breaker.

If your machine is supplied with single phase electricals, proceed as follows when connecting your machine to

an electrical power system:

Page 12

12

Fig. 16

Fig. 17

THREE PHASE INSTALLATION

If the motor on your machine is wired for 200, 230 or 460 Volts, Three Phase, proceed as follows when connecting

your machine to an electrical power system.

1. Remove screw (A) Fig. 15, and terminal strip cover

(B).

2. Remove plastic covering (C) Fig. 16, that snaps into

terminal strip.

3. Bring three phase power line through access hole in

bottom of terminal strip box and connect the three power

lines to terminals (D) Fig. 17, and the green ground wire

to ground screw (E).

C

E

D

Fig. 15

A

B

The rotation of the cutterhead must be in a

clockwise direction when viewed from the

left side of the machine; that is, the knives

must be rotating toward the infeed table

from the top. If the cutterhead rotation is

incorrect, disconnect the machine from the

power source and interchange any two of

the three incoming power lines connected to

terminals (D) Fig. 17.

Page 13

13

OPERATING CONTROLS AND ADJUSTMENTS

Fig. 18

Fig. 19

Fig. 20

Fig. 21

START-STOP SWITCH

The start-stop switch is conveniently located on a post,

behind the jointer fence, for easy accessibility. To start

the machine, simply press the start button (A) Fig. 18,

and to stop the machine, press the stop button (B).

FENCE OPERATION

1. The fence (A) Fig. 19, can be moved across the table

by loosening lock lever (B) and rotating handwheel (C).

After the fence is moved to its desired position, retighten

lock lever (B) securely. NOTE: Lock lever (B) can be repositioned by pulling out the handle and repositioning it

on the serrated nut located underneath the hub of the

handle. As the fence (A) is moved across the table, the

sliding portion of the column (D) guards the cutterhead in

back of the fence as shown.

2. To tilt the fence (A) to the right, as shown in Fig. 20,

or to the left, as shown in Fig. 21, loosen lock handle (E)

move the fence to the desired angle and tighten handle

(E) securely. NOTE: Handle (E) Figs. 20 and 21, is

spring-loaded and can be repositioned by pulling out the

handle and repositioning it on the serrated nut located

underneath the hub of the handle. Also, when tilting the

fence to the right (outward) as shown in Fig. 20, the stop

(F) Fig. 20, must be rotated to the up position as shown.

IMPORTANT: When cutting a bevel, we suggest that

whenever possible the fence (A) be tilted toward the

table, as shown in Fig. 21. The fence will then form a

V-shape with the tables, and the work is easily pressed

into the pocket while passing it across the knives.

A

B

A

C

D

B

A

F

E

E

A

Page 14

14

ADJUSTING FENCE

POSITIVE STOPS

The fence on your jointer is equipped with positive stops at

the most used fence positions of 90 degrees and 45

degrees right and left. To check and adjust the positive

stops, proceed as follows:

1. Position the fence 90 degrees to the table making sure

end of stop screw (A) is against stop (B) as shown in

Fig. 22.Then tighten lock handle (C).

2. Using a square (D) Fig. 23, check to see if the fence is

at 90 degrees to the table as shown.

3. If the fence is not at 90 degrees to the table, loosen

lock handle (C) Fig. 22, and lock nut (E). Turn stop screw

(A) until end of screw (A) contacts stop (B) when fence is

90 degrees to the table and lock handle (C) is tightened.

Fig. 22

Fig. 23

Fig. 24

Fig. 25

4. Tilt the fence inward as far as possible and using a

combination square (F) Fig. 24, check to see if the fence is

tilted inward 45 degrees to the table, as shown. If an

adjustment is necessary, loosen nuts (G) Fig. 25, and

adjust screws (H) until ends of screws (H) contact brackets

(J) when the fence is at 45 degrees to the table.

Always make certain the fence locking

handle (E) is tightened before operating machine.

C

B

A

E

D

F

J

H

G

E

J

H

G

Page 15

15

Fig. 26

Fig. 27

Fig. 28

5. Tilt the fence outward as far as possible and using a

combination square (F) Fig. 26, check to see if the fence is

tilted outward 45 degrees to the table, as shown. NOTE:

90 degree stop (B) must be rotated up in order to tilt the

fence outward. If an adjustment is necessary, loosen lock

nut (K) Fig. 27, and adjust screw (L) until head of screw (L)

contacts back of fence (M) when the fence is at 45 degrees

to the table.

Always make sure fence locking handle (E)

is tightened before operating machine.

INFEED TABLE

ADJUSTMENTS

To raise or lower the infeed table, loosen table lock handle

(A) Fig. 28, and move the table raising and lowering hand

lever (B) up or down until the table is at the desired position

and tighten table lock handle (A). NOTE: The table lock

handle (A) can be repositioned by pulling out the handle

and repositioning it on the serrated nut located under the

handle.

The depth of cut of the infeed table (position of table in

relationship with the cutting circle) can be read with the

English/Metric scale and pointer (G) Fig. 28.

Positive stops are provided on the jointer to limit the height

and depth of the infeed table. To adjust the stops, simply

loosen two locknuts (C) and (D) Fig. 29, and turn the two

adjustment screws (E) and (F) as necessary. Retighten

locknuts (C) and (D). We recommend that the height of the

infeed table be adjusted so the table at its highest point will

be 1/2mm below the highest point of the knives. This is an

important feature of your jointer which enables you to

rapidly position the infeed table for a finish or a final cut.

B

F

M

K

L

E

A

B

G

Fig. 29

E

C

D

F

Page 16

16

Fig. 30

OUTFEED TABLE

ADJUSTMENTS

For most jointing operations the outfeed table must be

exactly level with the knives at their highest point of

revolution. To move the outfeed table, loosen lock handle

(A)

Fig. 30, and move the table raising and lowering hand lever

(B) up or down until the table is level with the knives.

It may be necessary to adjust the positive stops. Loosen

the two locknuts (D) and (E) Fig. 31, and the two adjusting

screws (F) and (G) when moving the table up or down.

When the table is exactly level with the knives at the

highest point of revolution, tighten lock handle (A) Fig. 30,

and turn adjusting screw (F) Fig. 31, until it bottoms; then

tighten locknut (D). Screw (G) is also a positive stop for the

lower limit of the outfeed table. We suggest that this stop

also be tightened when the outfeed table is set level with

the knives. This will prevent the outfeed table from

accidently being lowered.

ADJUSTING BELT TENSION

The jointer is shipped with two V-belts assembled and

properly tensioned to the cutterhead and motor pulley. If

it becomes necessary to adjust belt tension, proceed as

follows:

B

A

Fig. 31

D

F

E

G

Fig. 32

Fig. 33

B

A

1. DISCONNECT THE MACHINE FROM THE POWER

SOURCE.

2. Pull outward on latch handle (A) Fig. 33, and open

hinged access door (B).

3. Fig. 31, illustrates the V-belts (C), motor pulley (D) and

cutterhead pulley (E). There should be approximately 1/2

inch deflection in the center span of the belts (C) using light

finger pressure. To adjust belt tension refer to STEP 4.

E

C

D

Page 17

Before operating jointer, check guard to

make sure it functions properly and

quickly returns to the closed position.

17

Fig. 34

Fig. 35

4. To adjust belt tension, turn nuts (F) and (G) Fig. 34, to

move motor plate (H) up or down until there is

approximately 1/2 inch deflection at the center span of the

belts, as explained in STEP 3.

ADJUSTING

SPRING TENSION OF

CUTTERHEAD GUARD

The cutterhead guard (A) Fig. 35, completely covers the

cutterhead. During operation the material being jointed or

planed pushes the guard (A) out of the way and at the

completion of the cut, the guard (A) springs back over the

cutterhead providing full coverage. If it ever becomes

necessary to adjust the spring tension of the cutterhead

guard (A), loosen two screws (B) and turn screw (C)

clockwise to increase or counterclockwise to decrease the

spring tension. Then tighten the two screws (B).

A

C

B

H

G

F

Page 18

18

The following directions will give the beginner a start on jointer operations. Use scrap pieces of lumber to check

settings and to get the feel of the operations before attempting regular work.

THE KNIVES ON THE JOINTER WILL NOT WEAR EVENLY BY FEEDING THE WOOD THROUGH THE

SAME SPOT ON THE TABLE EVERY TIME. FEED THE WOOD THROUGH THE JOINTER AT DIFFERENT SPOTS

ON THE TABLE WHEN POSSIBLE, TO HELP ELIMINATE UNEVEN WEAR OF THE KNIVES.

ALWAYS USE CUTTERHEAD GUARD AND KEEP HANDS AWAY FROM CUTTERHEAD. ALWAYS

USE PUSH BLOCKS WHENEVER POSSIBLE. NEVER MAKE JOINTING AND PLANING CUTS DEEPER THAN 1/8"

IN ONE PASS.

CUTTERHEAD ROTATION

The rotation of the cutterhead must be in a clockwise direction when viewed from the left side of the

machine; that is, the knives must be rotating toward the infeed table from the top. If the cutterhead rotation is incorrect,

disconnect the machine from the power source and proceed as follows:

Single Phase Machines – Interchange leads T5 and T8 in the motor junction box.

Three Phase Machines – Interchange any two of the three incoming power lines.

OPERATION

Fig. 36

PLACEMENT OF HANDS

DURING FEEDING

At the start of the cut, the left hand holds the work firmly

against the infeed table and fence, while the right hand

pushes the work toward the knives. After the cut is

underway, the new surface rests firmly on the outfeed table

as shown in Fig. 36. The left hand should then be moved to

the work on the outfeed table, at the same time maintaining

flat contact with the fence.The right hand presses the work

forward, and before the right hand reaches the cutter-head,

it should be moved to the work on the outfeed table.

NEVER PASS HANDS DIRECTLY OVER

THE CUTTERHEAD AND USE PUSH BLOCKS

WHENEVER POSSIBLE.

WORK

INFEED TABLE

OUT-FEED

TABLE

CUTTER

18

Page 19

19

Fig. 37

Fig. 38

Fig. 39

JOINTING AN EDGE

This is the most common operation for the jointer. Set the

guide fence square with the table. Depth of cut should be

the minimum required to obtain a straight edge. Hold the

best face of the piece firmly against the fence throughout

the feed as shown in Fig. 37.

DO NOT perform jointing operations on material shorter

than 10 inches, narrower than 3/4 inch or less than 1/2 inch

thick.

NEVER pass your hands directly over the cutterhead and

use push blocks to feed the workpiece whenever possible.

PLANING OR SURFACING

Planing or surfacing is identical to the jointing operation

except for the position of the workpiece. For planing, the

major flat surface of the workpiece is placed on the infeed

table of the jointer with the narrow edge of the workpiece

against the fence, as shown in Fig. 38. The workpiece is

moved from the infeed table, across the cutterhead to the

outfeed table establishing a flat surface on the workpiece.

Always use push blocks when performing planing

operations and NEVER pass your hands directly over the

cutterhead.

DO NOT perform planing

or surfacing operations on material shorter than 10 inches, narrower than 3/4 inch, wider

than 12 inches or less than 1/2 inch thick.

BEVELING

To cut a bevel, lock the fence at the required angle and run

the work across the knives while keeping the work firmly

against the fence and tables. Several passes may be

necessary to arrive at the desired result. When the angle is

small, there is little difference whether the fence is tilted to

the right or left. However, at greater angles approaching 45

degrees, it is increasingly difficult to hold the work properly

when the fence is tilted to the right. The advantage of the

double-tilting fence is appreciated under such conditions.

When tilted to the left, the fence forms a V-shape with the

tables, and the work is easily pressed into the pocket while

passing it across the knives as shown in Fig. 39. If the bevel

is laid out on the piece in such direction that this involves

cutting against the grain, it will be better to tilt the fence to

the right.

Page 20

20

TAPER CUTS

One of the most useful jointer operations is cutting an edge to a taper. The method can be used on a wide variety of work.

Tapered legs of furniture are a common example.

Instead of laying the piece on the infeed table, lower the forward end of the work onto the outfeed table. Do this very carefully,

as the piece will span the knives and they will take a “bite’” from the work, with a tendency to kickback unless the piece is

firmly held. Now push the work forward as in ordinary jointing. The effect is to plane off all the stock in front of the knives to

increasing depth, leaving a tapered surface.

The ridge left by the knives when starting the taper may be removed by taking a very light cut according to the regular method

for jointing, with the infeed table raised to its usual position.

Practice is required in this operation, and the beginner is advised to make trial cuts on waste material. Taper cuts over part

of the length and a number of other special operations can easily be done by the experienced craftsman.

Fig. 40

CUTTING A RABBET

When making a rabbet cut, as shown in Fig. 40, the

cutterhead guard must be removed. AFTER THE RAB-BET

CUT IS COMPLETED, BE CERTAIN GUARD IS REPLACED.

Use pushblocks whenever possible, as

shown.

1. Adjust the fence so that the distance between the end of

the knives and the fence is equal to the width of the

rabbet.

2. Lower the infeed table an amount equal to the depth of

the rabbet. If the rabbet is quite deep, it may be necessary to

cut it in two or more passes. In that event, the table

is lowered an amount equal to about half the depth of the

rabbet for the first pass, then lowered again to proper depth

to complete the cut.

Fig. 41 Fig. 42

JOINTING OR PLANING WARPED WOOD

If the wood to be jointed is dished or warped, take light cuts until the surface is flat. Avoid forcing such material down

against the table; excessive pressure will spring it while passing the knives, and it will spring back and remain curved after

the cut is completed.

DIRECTION OF GRAIN

Avoid feeding the wood into the jointer against the grain as shown in Fig. 41.The result will be chipped and splintered

edges. Feed with the grain as in Fig. 42, to obtain a smooth surface.

FRONT TABLE

FRONT TABLE

REAR

TABLE

REAR

TABLE

CUTTER

CUTTER

WRONG FEED - AGAINST THE GRAIN CORRECT FEED - WITH THE GRAIN

Page 21

21

REMOVING, REPLACING AND SETTING KNIVES

If the knives are removed from the cutterhead for replacement or regrinding, care must be used in removing, replacing

and resetting them as follows:

1. DISCONNECT THE MACHINE FROM THE POWER SOURCE.

2. Move the fence to the right until it is clear of the cutterhead.

Fig. 43

Fig. 44

Fig. 45

MAINTENANCE

3. Loosen two screws (A) Fig. 43, and remove

cutterhead guard assembly.

BE EXTREMELY CAREFUL THAT

YOUR HANDS DO NOT COME IN CONTACT WITH

THE KNIVES. WEAR PROTECTIVE GLOVES WHEN

HANDLING THE KNIVES.

4. Using wrench (C) Fig. 44, slightly loosen the six knife

locking screws (D) in each knife slot by turning the

screws (D) clockwise. This relieves stress in the

cutterhead.

5. Loosen screws (D) Fig. 44, further, and remove the

knife, knife locking bar and lifter springs located under

the knives. Remove the remaining two knives in the same

manner.

6. Before replacing the knives, make certain the knife

locking bars are thoroughly clean and free of gum and

pitch and adjust the height of the outfeed table to be

.015” above the cutterhead body as follows:

A. Using a straight edge (E) Fig. 45, and feeler

gages (F) that equal .015” adjust the height of

the outfeed table to be .015” above the

cutterhead body (G). Then lock the outfeed table

in place.

A

B

C

D

D

G

E

F

Page 22

2222

Fig. 46

Fig. 48

7. IMPORTANT: For ease in rotating the cutterhead

during the knife setting operation, pull outward on latch

(H) Fig. 46, and open hinged access door (J). This

provides access to the cutterhead pulley (K) Fig. 47, and

belt (L) allowing you to rotate the cutterhead.

After knives are adjusted, make certain the

access door (J) is in the closed and locked

position.

8. Replace the knife locking bars, lifter springs and

knives into each slot in the cutterhead.

CARE MUST BE TAKEN WHEN

INSERTING THE KNIVES

AS THE CUTTING EDGES ARE VERY SHARP. Push

the knives down as far as possible and snug up the knife

locking screws by turning them counterclockwise just

enough to hold the knives in position.

9. Construct a “U” shaped block out of hardwood similar

to the one shown at (M) Fig. 48, and place this block on

the rear table over the cutterhead, as shown. Using

wrench (C), loosen knife locking screws by turning them

clockwise. The knife (O) will lift up and contact the ends

of the gage block (M). The knives are adjusted correctly

when the cutting edge of the knife contacts the gage

block when the knife is at its highest point. When you are

certain the knife is adjusted properly, tighten the knife

locking screws by turning them counterclockwise.

10. Adjust the remaining two knives in the same manner.

MAKE CERTAIN THAT ALL KNIVES

ARE SECURELY FASTENED IN

CUTTERHEAD BEFORE TURNING ON POWER.

11. Replace cutterhead guard.

M

O

C

J

H

Fig. 47

K

L

Page 23

23

MAINTENANCE

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed

air. All plastic parts should be cleaned with a soft damp

cloth. NEVER use solvents to clean plastic parts. They could

possibly dissolve or otherwise damage the material.

Wear ANSI Z87.1 safety glasses while

using compressed air.

FAILURE TO START

Should your machine fail to start, check to make sure the

prongs on the cord plug are making good contact in the

outlet. Also, check for blown fuses or open circuit breakers

in the line.

PARTS, SERVICE OR WARRANTY ASSISTANCE

All Delta Machines and accessories are manufactured to high quality standards and are serviced by a network

of Porter-Cable • Delta Factory Service Centers and Delta Authorized Service Stations. To obtain additional

information regarding your Delta quality product or to obtain parts, service, warranty assistance, or the location

of the nearest service outlet, please call 1-800-223-7278 (In Canada call 1-800-463-3582).

A complete line of accessories is available from your Delta Supplier, Porter-Cable • Delta Factory Service Centers,

and Delta Authorized Service Stations. Please visit our Web Site

www.deltamachinery.com for a catalog or

for the name of your nearest supplier.

Since accessories other than those offered by Delta have not been tested

with this product, use of such accessories could be hazardous. For

safest operation, only

Delta recommended accessories should be used with this product.

ACCESSORIES

Two Year Limited New Product Warranty

Delta will repair or replace, at its expense and at its option, any new Delta machine, machine part, or machine accessory

which in normal use has proven to be defective in workmanship or material, provided that the customer returns the product

prepaid to a Delta factory service center or authorized service station with proof of purchase of the product within two

years and provides Delta with reasonable opportunity to verify the alleged defect by inspection. For all refurbished Delta

product, the warranty period is 180 days. Delta may require that electric motors be returned prepaid to a motor

manufacturer’s authorized station for inspection and repair or replacement. Delta will not be responsible for any asserted

defect which has resulted from normal wear, misuse, abuse or repair or alteration made or specifically authorized by

anyone other than an authorized Delta service facility or representative. Under no circumstances will Delta be liable for

incidental or consequential damages resulting from defective products. This warranty is Delta’s sole warranty and sets

forth the customer’s exclusive remedy, with respect to defective products; all other warranties, express or implied, whether

of merchantability, fitness for purpose, or otherwise, are expressly disclaimed by Delta.

LUBRICATION

Apply household floor paste wax to the machine table and

extension table or other work surface weekly.

PROTECTING CAST IRON FROM RUST

To clean and protect cast iron tables from rust, you will

need the following materials: 1 pushblock from a jointer,

1 sheet of medium Scotch-Brite™ Blending Hand Pad, 1

can of WD-40®, 1 can of degreaser, 1 can of TopCote

®

Aerosol. Apply the WD-40 and polish the table surface

with the Scotch-Brite pad using the pushblock as a

holddown. Degrease the table, then apply the TopCote

®

accordingly.

Page 24

24

The following are trademarks of PORTER-CABLE •DELTA (Las siguientes son marcas registradas de PORTER-CABLE • DELTA S.A.) (Les marques

suivantes sont des marques de fabriquant de la PORTER-CABLE

•

DELTA): Auto-Set®, BAMMER®, B.O.S.S.®, Builder’s Saw®, Contractor’s Saw®,

Contractor’s Saw II™, Delta

®

, DELTACRAFT®, DELTAGRAM™, Delta Series 2000™, DURATRONIC™, Emc²™, FLEX®, Flying Chips™, FRAME SAW®,

Grip Vac™, Homecraft

®

, INNOVATION THAT WORKS®, Jet-Lock®, JETSTREAM®, ‘kickstand®, LASERLOC®, MICRO-SET®, Micro-Set®, MIDI LATHE®,

MORTEN™, NETWORK™, OMNIJIG

®

, POCKET CUTTER®, PORTA-BAND®, PORTA-PLANE®, PORTER-CABLE®&(design), PORTER-

CABLE

®

PROFESSIONAL POWER TOOLS, PORTER-CABLE REDEFINING PERFORMANCE™, Posi-Matic®, Q-3®&(design), QUICKSAND®&(design),

QUICKSET™, QUICKSET II

®

, QUICKSET PLUS™, RIPTIDE™&(design), SAFE GUARD II®, SAFE-LOC®, Sanding Center®, SANDTRAP®&(design), SAW

BOSS

®

, Sawbuck™, Sidekick®, SPEED-BLOC®, SPEEDMATIC®, SPEEDTRONIC®, STAIR EASE®, The American Woodshop®&(design), The Lumber

Company

®

&(design), THE PROFESSIONAL EDGE®, THE PROFESSIONAL SELECT®, THIN-LINE™, TIGER®, TIGER CUB®, TIGER SAW®,

TORQBUSTER

®

, TORQ-BUSTER®, TRU-MATCH™, TWIN-LITE®, UNIGUARD®, Unifence®, UNIFEEDER™, Unihead®, Uniplane™, Unirip®, Unisaw®,

Univise

®

, Versa-Feeder®, VERSA-PLANE®, WHISPER SERIES®, WOODWORKER’S CHOICE™.

Trademarks noted with ™ and ® are registered in the United States Patent and Trademark Office and may also be registered in other countries. Las

Marcas Registradas con el signo de ™ y ® son registradas por la Oficina de Registros y Patentes de los Estados Unidos y también pueden estar

registradas en otros países.

PORTER-CABLE • DELTA SERVICE CENTERS

(CENTROS DE SERVICIO DE PORTER-CABLE

• DELTA)

Parts and Repair Service for Porter-Cable •Delta Machinery are Available at These Locations

(Obtenga Refaccion de Partes o Servicio para su Herramienta en los Siguientes Centros de Porter-Cable

•

Delta)

Authorized Service Stations are located in many large cities. Telephone 800-438-2486 or 731-541-6042 for assistance locating one.

Parts and accessories for Porter-Cable

·

Delta products should be obtained by contacting any Porter-Cable·Delta Distributor, Authorized

Service Center, or Porter-Cable·Delta Factory Service Center. If you do not have access to any of these, call 800-223-7278 and you will

be directed to the nearest Porter-Cable

·

Delta Factory Service Center. Las Estaciones de Servicio Autorizadas están ubicadas en muchas

grandes ciudades. Llame al 800-438-2486 ó al 731-541-6042 para obtener asistencia a fin de localizar una. Las piezas y los accesorios

para los productos Porter-Cable

·

Delta deben obtenerse poniéndose en contacto con cualquier distribuidor Porter-Cable·Delta, Centro

de Servicio Autorizado o Centro de Servicio de Fábrica Porter-Cable

·

Delta. Si no tiene acceso a ninguna de estas opciones, llame al

800-223-7278 y le dirigirán al Centro de Servicio de Fábrica Porter-Cable

·

Delta más cercano.

ARIZONA

Tempe 85282 (Phoenix)

2400 West Southern Avenue

Suite 105

Phone: (602) 437-1200

Fax: (602) 437-2200

CALIFORNIA

Ontario 91761 (Los Angeles)

3949A East Guasti Road

Phone: (909) 390-5555

Fax: (909) 390-5554

San Diego 92111

7638 Clairemnot Blvd.

Phone: (858) 277-9595

Fax: (858) 277-9696

San Leandro 94577 (Oakland)

3039 Teagarden Street

Phone: (510) 357-9762

Fax: (510) 357-7939

COLORADO

Arvada 80003 (Denver)

8175 Sheridan Blvd., Unit S

Phone: (303) 487-1809

Fax: (303) 487-1868

FLORIDA

Davie 33314 (Miami)

4343 South State Rd. 7 (441)

Unit #107

Phone: (954) 321-6635

Fax: (954) 321-6638

Tampa 33609

4538 W. Kennedy Boulevard

Phone: (813) 877-9585

Fax: (813) 289-7948

GEORGIA

Forest Park 30297 (Atlanta)

5442 Frontage Road,

Suite 112

Phone: (404) 608-0006

Fax: (404) 608-1123

ILLINOIS

Addison 60101 (Chicago)

400 South Rohlwing Rd.

Phone: (630) 424-8805

Fax: (630) 424-8895

Woodridge 60517 (Chicago)

2033 West 75th Street

Phone: (630) 910-9200

Fax: (630) 910-0360

MARYLAND

Elkridge 21075 (Baltimore)

7397-102 Washington Blvd.

Phone: (410) 799-9394

Fax: (410) 799-9398

MASSACHUSETTS

Franklin 02038 (Boston)

Franklin Industrial Park

101E Constitution Blvd.

Phone: (508) 520-8802

Fax: (508) 528-8089

MICHIGAN

Madison Heights 48071 (Detroit)

30475 Stephenson Highway

Phone: (248) 597-5000

Fax: (248) 597-5004

MINNESOTA

Minneapolis 55429

5522 Lakeland Avenue North

Phone: (763) 561-9080

Fax: (763) 561-0653

MISSOURI

North Kansas City 64116

1141 Swift Avenue

Phone: (816) 221-2070

Fax: (816) 221-2897

St. Louis 63119

7574 Watson Road

Phone: (314) 968-8950

Fax: (314) 968-2790

NEW YORK

Flushing 11365-1595 (N.Y.C.)

175-25 Horace Harding Expwy.

Phone: (718) 225-2040

Fax: (718) 423-9619

NORTH CAROLINA

Charlotte 28270

9129 Monroe Road, Suite 115

Phone: (704) 841-1176

Fax: (704) 708-4625

OHIO

Columbus 43214

4560 Indianola Avenue

Phone: (614) 263-0929

Fax: (614) 263-1238

Cleveland 44125

8001 Sweet Valley Drive

Unit #19

Phone: (216) 447-9030

Fax: (216) 447-3097

OREGON

Portland 97230

4916 NE 122 nd Ave.

Phone: (503) 252-0107

Fax: (503) 252-2123

PENNSYLVANIA

Willow Grove 19090

(Philadelphia)

520 North York Road

Phone: (215) 658-1430

Fax: (215) 658-1433

TEXAS

Carrollton 75006 (Dallas)

1300 Interstate 35 N, Suite 112

Phone: (972) 446-2996

Fax: (972) 446-8157

Houston 77043

4321 Sam Houston Parkway,

West

Suite 180

Phone: (713) 983-9910

Fax: (713) 983-6645

WASHINGTON

Auburn 98001(Seattle)

3320 West Valley HWY, North

Building D, Suite 111

Phone: (253) 333-8353

Fax: (253) 333-9613

Printed in U.S.A. PC-0104-149

CANADIAN PORTER-CABLE • DELTA SERVICE CENTERS

ALBERTA

Bay 6, 2520-23rd St. N.E.

Calgary, Alberta

T2E 8L2

Phone: (403) 735-6166

Fax: (403) 735-6144

BRITISH COLUMBIA

8520 Baxter Place

Burnaby, B.C.

V5A 4T8

Phone: (604) 420-0102

Fax: (604) 420-3522

MANITOBA

1699 Dublin Avenue

Winnipeg, Manitoba

R3H 0H2

Phone: (204) 633-9259

Fax: (204) 632-1976

ONTARIO

505 Southgate Drive

Guelph, Ontario

N1H 6M7

Phone: (519) 767-4132

Fax: (519) 767-4131

QUÉBEC

1515 ave.

St-Jean Baptiste, Suite 160

Québec, Québec

G2E 5E2

Phone: (418) 877-7112

Fax: (418) 877-7123

1447, Begin

St-Laurent, (Montréal),

Québec

H4R 1V8

Phone: (514) 336-8772

Fax: (514) 336-3505

Loading...

Loading...