Page 1

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW004

24 Volt 7/8” Cordless Rotary Hammer

Perceuse à percussion sans fil á 24 volt 22 mm (7/8 po)

Rotomartillos inalámbricas 24 volt 22 mm (7/8”)

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y

PÓLIZA DE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

General Safety Rules – For All Battery

Operated Tools

WARNING! Read and understand all instructions. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and dark areas invite acci-

dents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or

fumes.

• Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

• A battery operated tool with integral batteries or a separate battery pack must be

recharged only with the specified charger for the battery. A charger that may be suit-

able for one type of battery may create a risk of fire when used with another battery.

• Use battery operated tool only with the specifically designed battery pack. Use of any

other batteries may create a risk of fire.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use tool while tired or under the influence of drugs, alcohol, or medica-

tion. A moment of inattention while operating power tools may result in serious personal

injury,

• Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts. Loose clothing, jewelry, or long hair can be

caught in moving parts.

• Avoid accidental starting. Be sure switch is in the locked off position before inserting battery pack. Carrying tools with your finger on the switch or inserting the battery pack into a

tool with the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. A wrench or key that is

left attached to a rotating part of the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to a loss

of control.

• Do not force tool. Use the correct tool for your application. The correct tool will do the

job better and safer and the rate for which it is designed.

• Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled

with the switch is dangerous and must be repaired.

• Disconnect battery pack from tool or place the switch in the locked or off position

before making any adjustments, changing accessories, or storing the tool. Such pre-

ventative safety measures reduce the risk of starting the tool accidentally.

• Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the hands of untrained users.

• When battery pack is not in use, keep it away from other metal objects like: paper

clips, coins, keys, nails, screws, or other small metal objects that can make a connection from one terminal to another. Shorting the battery terminals together may cause

sparks, burns, or a fire.

• Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools,

with sharp cutting edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tools operation. If damaged, have the tool serviced before

using. Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool, may become hazardous when used on another tool.

SERVICE

• Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of electric shock or injury.

Additional Specific Safety Rules for Rotary Hammers

• Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will

make exposed metal parts of the tool “live” and shock the operator.

• Wear ear protectors when hammering for extented periods of time. Temporary hearing loss or serious ear drum damage may result from high sound levels generated by hammer drilling.

• Wear safety goggles or other eye protection. Hammering and drilling operations cause

chips to fly. Flying particles can cause permanent eye damage.

• Always use the side handle supplied with the tool. Keep a firm grip on the tool at all

times. Do not attempt to operate this tool without holding it with both hands.

• Hammer bits and tools get hot during operation. Wear gloves when touching them.

• CAUTION:DO NOT TOUCH ANY METAL PARTS OF THE TOOL when drilling or driving

into walls, floors or wherever live electrical wires may be encountered! Hold the tool only by

insulated grasping surfaces to prevent electric shock if you drill or drive into a live wire.

WARNING: Use of this tool can generate dust containing chemicals known to cause can-

cer, birth defects or other reproductive harm. Use appropriate respiratory protection.

• The label on your tool may include the following symbols.

V ........................volts A ......................amperes

Hz ......................hertz W......................watts

min......................minutes ....................alternating current

....................direct current

n

o......................no load speed

........................

Class II Construction

......................earthing terminal

......................safety alert symbol .../min................revolutions or

reciprocations

per minute

Additional Specific Safety Instructions When Using

DW0247 AC Adapter (Fig. 4)

• Double insulated tools are equipped with a polarized plug (one blade is wider than the

other.) This plug will fit in a polarized outlet only one way. If the plug does not fit fully in the

outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install a polarized outlet. Do not change the plug in any way. Double insulation eliminates the need for

the three wire grounded power cord and grounded power supply system. Applicable only to

Class II (double insulated) tools.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension cord marked “W-A” or “W.”

These cords are rated for outdoor use and reduce the risk of electric shock.

Recommended Minimum Wire Size for Extension Cords

Total Length of Cord

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Wire Size

18 AWG 18 AWG 16 AWG 16 AWG 14 AWG 14 AWG 12 AWG

• Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with your

finger on the switch or plugging in tools that have the switch on invites accidents.

• Disconnect the plug from the power source before making any adjustments, changing

accessories, or storing the tool. Such preventative safety measures reduce the risk of starting the tool accidentally.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

Battery Packs

Your tool uses a 24.0 Volt D

EWALT battery pack. When ordering replacement battery packs,

be sure to include catalog number and voltage.

CAUTION: The batteries in your battery pack are the nickel–cadmium type. Cadmium is

considered to be a toxic material by the Environmental Protection Agency. Before disposing

of damaged or worn out Nickel–Cadmium battery packs, check with your state Environmental

Protection Agency to find out about special restrictions on the disposal of these battery packs

or return them to a D

EWALT certified service center for recycling.

HOT PACK /COLD PACK DELAY

If your charger has a Hot Pack Delay feature, when it detects a battery that is hot or excessively

cold, it automatically starts a Hot Pack /Cold Pack Delay, suspending charging until the battery

has stabilized. The charger will automatically switch to the Pack Charging mode. This feature

ensures maximum battery life. The red light flashes long, then short while in the Hot Pack Delay

mode.

Using Tune-Up™ Mode

The Tune-up™ mode will equalize or balance the individual cells in the battery pack at its peak

capacity. This cycle takes up to 8 hours to complete. Battery packs should be tuned up weekly

or after 10 to 20 charge/discharge cycles or whenever the pack no longer delivers the same

amount of work.

1. To tune up your battery pack, place the battery in the charger as usual. The red light will blink

continuously indicating that the charge cycle has started.

2. The Tune-up™ Button may be pressed at any time after the charge has started. The red light

will stop blinking momentarily, blink quickly 3 times, and then resume blinking continuously.

The charger is now giving your batteries a tune-up.

3. When the charge cycle has completed, the light will stay on continuously. The pack is fully

charged and may be used at this time or left in the charger.

4. If you select Tune-up™ and then change your mind, remove the battery from the charger.

After 5 seconds, insert the battery into the charger. The normal charge cycle will commence.

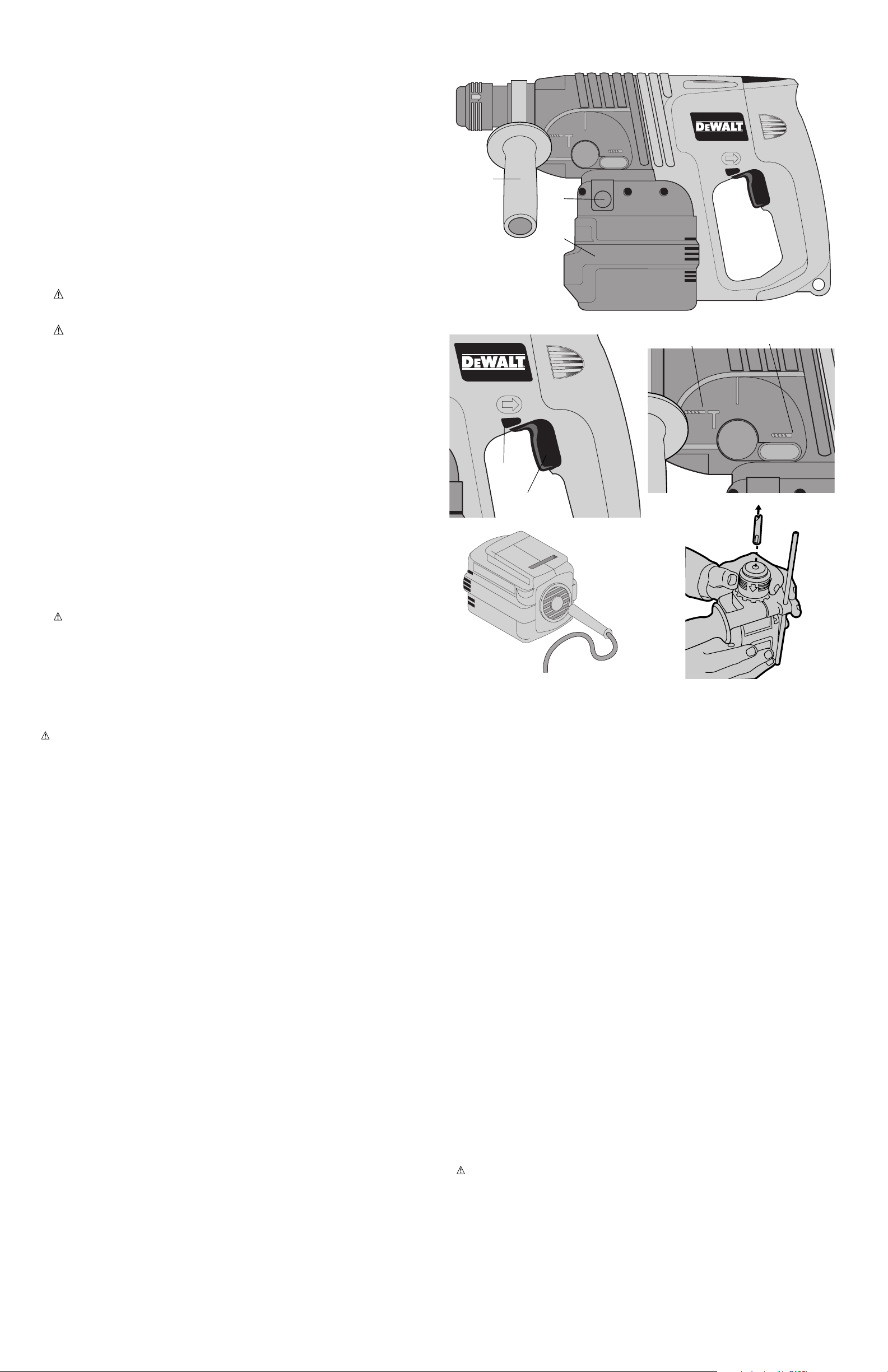

Installing and Removing the Battery Pack (Fig. 1)

NOTE: Make sure your battery pack is fully charged. To install the battery pack into the tool,

set the lock off button to disable the trigger switch, align the front of the battery with the notches inside the tool’s body and slide the battery pack firmly into place until you hear the lock

snap into place.

To remove the battery pack from the tool, depress release buttons (B) on both sides,

remove the battery pack (C). Insert it into the charger as described in the charger manual.

Important Charging Notes

1. Longest life and best performance can be obtained if the battery pack is charged when the

air temperature is between 65°F and 75°F (18°- 24°C). DO NOT charge the battery pack

in an air temperature below +40°F(+4.5°C), or above +105°F (+40.5°C). This is important

D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286

Printed in U.S.A. (DEC99-CD-1) Form No. 329869-02 DW004 Copyright © 1999

Questions? See us in the World Wide Web at www.dewalt.com

Page 2

and will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to touch while charging. This is a normal

condition, and does not indicate a problem.

3. If the battery pack does not charge properly — (1) Check current at receptacle by plugging

in a lamp or other appliance, (2) Check to see if receptacle is connected to a light switch

which turns power off when you turn out the lights. (3) Move charger and battery pack to a

location where the surrounding air temperature is approximately 65°F - 75°F (18°- 24°C).

(4) If charging problems persist, take or send the tool, battery pack and charger to your

local service center.

4. The battery pack should be recharged when it fails to produce sufficient power on jobs

which were easily done previously. DO NOT CONTINUE to use under these conditions.

Follow the charging procedure. You may also charge a partially used pack whenever you

desire with no adverse affect on the battery pack.

5. Under certain conditions, with the charger plugged into the power supply, the exposed

charging contacts inside the charger can be shorted by foreign material. Foreign materials

of a conductive nature such as, but not limited to, steel wool, aluminum foil, or any buildup

of metallic particles should be kept away from charger cavities. Always unplug the charger from the power supply when there is no battery pack in the cavity. Unplug charger before

attempting to clean.

6. Do not freeze or immerse charger in water or any other liquid.

WARNING: Don't allow any liquid to get inside charger. Electric shock may result. To

facilitate the cooling of the battery pack after use, avoid placing the charger or battery pack

in a warm environment such as in a metal shed, or an uninsulated trailer.

CAUTION: Never attempt to open the battery pack for any reason. If the plastic housing of the battery pack breaks or cracks, return to a service center for recycling.

IMPORTANT: This product is not user servicable. There are no user servicable parts inside

the charger. Servicing at an authorized service center is required to avoid damage to static

sensitive internal components.

READ ALL OF THE INSTRUCTIONS IN THE BATTERY CHARGER MANUAL BEFORE

ATTEMPTING TO CHARGE THE BATTERY PACK FOR YOUR TOOL.

Always use correct battery pack (pack supplied with tool or replacement pack exactly like it.)

Never install any other battery pack. It will ruin your tool and may create a hazardous condition.

Additional Safety Rules for Rotary Hammers

• Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will

make exposed metal parts of the tool “live” and shock the operator.

• Wear safety goggles or other eye protection. Hammering and drilling operations cause

chips to fly. Flying particles can cause permanent eye damage.

• Wear ear protectors when hammering for extented periods of time. Temporary hearing loss or serious ear drum damage may result from high sound levels generated by hammer drilling.

• Always use the side handle supplied with the tool. Keep a firm grip on the tool at all

times. Do not attempt to operate this tool without holding it with both hands.

• Do not overreach while operating the tool. Maintain a balanced working stance at all

times. When necessary, use only properly postioned, safe, platforms and scaffolding.

WORK SAFE.

• Hammer bits and tools get hot during operation. Wear gloves when touching them.

• caution:DO NOT TOUCH ANY METAL PARTS OF THE TOOL when drilling or driving

into walls, floors or wherever live electrical wires may be encountered! Hold the tool only by

insulated grasping surfaces to prevent electric shock if you drill or drive into a live wire.

Motor

Your DEWALT tool is powered by a DEWALT-built motor. Be sure your power supply agrees

with the nameplate markings.

Voltage decrease of more than 10% will cause loss of power and overheating. All D

E

WALT

tools are factory tested; if this tool does not operate, check your battery pack.

Side Handle (Fig. 1-A)

CAUTION: Always use side handle and hold rotary hammer with both hands. It clamps to

the front of the gear case as shown in Figure 1 and can be rotated 360˚ to permit right or left

hand use.

Variable Speed Switch (Fig. 2-A)

To turn the tool on, squeeze the trigger switch. To turn the tool off, release the trigger switch.

Your tool is equipped with a brake. The chuck will stop as soon as the trigger switch is fully

released.

The variable speed switch enables you to select the best speed for a particular application.

The farther you squeeze the trigger, the faster the tool will operate. Use lower speeds for starting holes without a centerpunch, drilling in metals or plastics, driving screws and drilling

ceramics. For maximum tool life, use variable speed only for starting holes or fasteners.

NOTE: Continuous use in variable speed range is not recommended. It may damage the

switch and should be avoided.

Forward/Reverse Control Button (2-B)

A forward/reverse control button determines the direction and also serves as a lock off button.

To select forward rotation, release the trigger switch and depress the forward/reverse control

button on the right side of the tool.To select reverse, depress the forward/reverse control button on the left side of the tool. The center position of the control button locks the tool in the off

position. When changing the position of the control button, be sure the trigger is released.

NOTE: The first time the tool is run after changing the direction of rotation, you may hear a

click on start up. This is normal and does not indicate a problem.

Hammer/Drill Selector (Fig. 3)

To switch the tool from the drilling mode to the hammering mode (or vice-versa) rotate the dial

on the applicable symbol shown. For straight drilling, align the dial with the drill bit symbol (B) as

shown. For hammering, align the dial with the hammer symbol (A). NOTE: The selector must be

in either drill, or hammer/drill mode at all times. There are no operable positions between the

two.

Operation

DRILLING

1. Always lock the trigger switch and remove the battery when attaching or changing bits or

accessories.

2. Use sharp drill bits only. For WOOD, use the low speed setting and twist drill bits, spade bits,

power auger bits, or hole saws. For METAL, use the low speed setting and steel twist drill bits

or hole saws. For MASONRY, such as brick, cement, cinder block, etc., use carbide-tipped

bits rated for percussion drilling.

3. Be sure the material to be drilled is anchored or clamped firmly. If drilling thin material, use a

wood “back-up” block to prevent damage to the material.

4. Always apply pressure in a straight line with the bit. Use enough pressure to keep drill biting,

but do not push hard enough to stall the motor or deflect the bit.

5. Hold tool firmly to control the twisting action of the drill.

6. IF DRILL STALLS, it is usually because it is being overloaded or improperly used.

RELEASE TRIGGER IMMEDIATELY, remove drill bit from work, and determine cause of

stalling. DO NOT CLICK TRIGGER OFF AND ON IN AN ATTEMPT TO START A STALLED

DRILL — THIS CAN DAMAGE THE DRILL.

7. To minimize stalling or breaking through the material, reduce pressure on drill and ease the

bit through the last fractional part of the hole.

8. Keep the motor running when pulling the bit back out of a drilled hole. This will help prevent

jamming.

A

B

9. With variable speed drills there is no need to center punch the point to be drilled. Use a slow

speed to start the hole and accelerate by squeezing the trigger harder when the hole is deep

enough to drill without the bit skipping out.

DRILLING IN METAL

Start drilling with slow speed and increase to full power while applying firm pressure on the tool.

A smooth even flow of metal chips indicates the proper drilling rate. Use a cutting lubricant when

drilling metals. The exceptions are cast iron and brass which should be drilled dry.

NOTE: Large (5/16” to 1/2”) holes in steel can be made easier if a pilot hole (5/32” to 3/16”)

is drilled first.

DRILLING IN WOOD

Start drilling with slow speed and increase to full power while applying firm pressure on the

tool. Holes in wood can be made with the same twist drills used for metal. These bits may

overheat unless pulled out frequently to clear chips from the flutes. Work that is apt to splinter should be backed up with a block of wood.

DRILLING IN MASONRY

When drilling in masonry, use carbide tipped bits rated for percussion drilling. Be certain that

the bit is sharp. Ensure that the hammer mode is selected. Use a constant and firm force on

the tool to drill most effectively. A smooth, even flow of dust indicates the proper drilling rate.

SDS Chuck (Fig. 5)

To insert bit, insert shank of bit about 3/4” into chuck and twist the bit until it clicks into place.

The bit will be securely held.

To release bit, pull the collar back and remove the bit.

Maintenance

CLEANING

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool;

never immerse any part of the tool into a liquid.

Self-lubricating bearings are used in the tool and periodic relubrication is not required. In the

unlikely event that service is ever needed, take your tool to an authorized service location.

Lubrication

Your tool was properly lubricated before leaving the factory. In from two to six months, depending upon

use, take or send your tool to a Service Center, or authorized service station, for a complete cleaning,

inspection and lubrication. Tools used constantly on production jobs will need relubrication more often.

Also, tools “out of service” for long periods should be relubricated before being put back to work.

Accessories

Recommended accessories for use with your tool are available at extra cost from your

distributor or local service center.

CAUTION: The use of any non-recommended accessory may be hazardous.

If you need assistance in locating any accessory, please contact Dewalt Industrial Tool Company,

P.O. Box 158, 626

Hanover Pike, Hampstead, MD 21074

or call 1-800-4 D

E

Walt (433-9258).

MAXIMUM RECOMMENDED CAPACITIES

DW004

R.P.M. 0–1,150

B.P.M 0-5800

BITS, METAL DRILLING 1/2”

WOOD, FLAT BORING 1 1/2"

A

B

A

B

FIG. 2

FIG. 3

FIG. 4

FIG. 1

C

FIG. 5

Page 3

BITS, MASONRY DRILLING 7/8" bit - Concrete, brick, block

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including brush inspection and replacement) should be performed by authorized service centers or

other qualified service organizations, always using identical replacement parts.

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from date of purchase. We will

repair, without charge, any defects due to faulty materials or workmanship. For warranty repair

information, call 1-800-4-D

EWALT. This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by others. This warranty gives you specific legal rights and you may have other rights which vary in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your D

EWALT heavy duty industri-

al tool, simply return it to the participating seller within 30 days for a full refund. Please return

the complete unit, transportation prepaid. Proof of purchase may be required.

Règles de sécurité - Outils à piles

AVERTISSEMENT! Lire et comprendre toutes les directives, car le non-respect des directives suivantes peut entraîner un choc électrique, un incendie ou des blessures graves.

CONSERVER CES DIRECTIVES

ZONE DE TRAVAIL

• Garder la zone de travail propre et bien éclairée; les établis encombrés et les endroits

sombres sont propices aux accidents.

• Ne pas utiliser les outils électriques dans une atmosphère explosive, comme à proximité de liquides, de gaz ou de poussières inflammables; le moteur peut créer des étin-

celles et enflammer les vapeurs ou les poussières environnantes.

• Tenir les enfants, les visiteurs ou toute autre personne à l’écart lorsqu’on utilise un

outil électrique; les distractions peuvent faire perdre la maîtrise de ce dernier.

MESURES DE SÉCURITÉ : ÉLECTRICITÉ

• Un outil à piles intégrées ou à bloc-piles externe doit être rechargé seulement au

moyen du chargeur approprié, car un chargeur destiné à une pile ou à un bloc-piles par-

ticulier peut entraîner un risque d’incendie lorsqu’il est utilisé avec un(e) autre.

• N’utiliser l’outil à piles qu’avec le bloc-piles désigné, car l’utilisation d’un autre type de

piles peut entraîner un risque d’incendie.

SÉCURITÉ PERSONNELLE

• Rester vigilant en tout temps et faire preuve de jugement lorsqu’on utilise un outil

électrique; ne pas utiliser l’outil lorsqu’on est fatigué ou sous l’influence de drogues, d’al-

cool ou de médicaments, car un moment d’inattention peut entraîner des blessures graves.

• Porter des vêtements appropriés; ne pas porter de vêtements amples ni de bijoux.

Couvrir ou attacher les cheveux longs. Garder les cheveux, les vêtements, les bijoux et les

gants éloignés des pièces mobiles, car ceux-ci peuvent s’y coincer.

• Éviter les démarrages accidentels; s’assurer que l’interrupteur soit verrouillé en position

arrêt avant d’insérer le bloc-piles. Ne pas transporter l’outil en laissant le doigt sur l’interrupteur ni insérer le bloc-piles lorsque l’outil est en position marche, car cela pourrait causer

un accident.

• Retirer les clés de réglage avant de démarrer l’outil; une clé laissée sur une pièce rotative peut entraîner des blessures.

• Ne pas trop étendre les bras; les pieds doivent rester ancrés fermement sur le sol afin de

maintenir son équilibre en tout temps et de mieux maîtriser l’outil dans des situations

imprévues.

• Utiliser le matériel de sécurité approprié; toujours porter des lunettes de protection.

Porter un masque anti-poussières, des chaussures antidérapantes, un casque de sécurité

ou des protecteurs auditifs lorsque la situation le requiert.

UTILISATION ET ENTRETIEN DE L’OUTIL

• Fixer et soutenir l’ouvrage sur une plate-forme stable au moyen d’un étau ou de tout

autre dispositif semblable; l’ouvrage est instable lorsqu’on le retient manuellement ou

qu’on l’appuie contre le corps, ce qui peut faire perdre la maîtrise de l’outil.

• Ne pas forcer l’outil ni l’utiliser pour des travaux autres que ceux pour lesquels il a

été conçu. Pour obtenir de meilleurs résultats et prévenir les risques de blessure, laisser

l’outil couper à la vitesse pour laquelle il a été conçu.

• Ne pas utiliser l’outil lorsque l’interrupteur marche-arrêt ne fonctionne pas; tout outil

qui ne peut être commandé au moyen de l’interrupteur est dangereux et doit être réparé.

• Débrancher le bloc-piles de l’outil ou verrouiller l’interrupteur en position arrêt avant

d’effectuer un réglage, de changer les accessoires ou de ranger l’outil; ces mesures

de sécurité préventives réduisent les risques de démarrage accidentel.

• Lorsqu’on n’utilise pas l’outil, le ranger hors de la portée des enfants ou des personnes non qualifiées; les outils sont dangereux entre les mains de personnes inexpérimen-

tées.

• Lorsqu’on n’utilise pas le bloc-piles, le ranger à l’écart des objets métalliques tels que

les trombones, les pièces de monnaie, les clés, les clous, les vis ou autres petits objets susceptibles de conduire l’électricité entre les bornes et d’occasionner ainsi des étincelles, des

brûlures ou un incendie.

• Bien entretenir l’outil; s’assurer qu’il soit toujours bien propre et aiguisé. Les outils bien

entretenus et dont les bords sont bien tranchants sont moins susceptibles de rester coincés

et sont plus faciles à maîtriser.

• Vérifier les pièces mobiles afin de s’assurer qu’elles soient bien alignées et qu’elles

ne restent pas coincées; vérifier également les pièces afin de s’assurer qu’il n’y ait aucun

bris ni aucune autre condition susceptible de nuire au bon fonctionnement de l’outil. Faire

réparer l’outil si ce dernier est endommagé avant de s’en servir à nouveau, car les accidents

sont souvent causés par des outils mal entretenus.

• N’utiliser que les accessoires recommandés par le fabricant pour le modèle concerné; un accessoire destiné à un outil particulier peut devenir dangereux lorsqu’il est util-

isé avec un autre.

ENTRETIEN

• L’outil doit être entretenu par le personnel qualifié seulement; toute maintenance effectuée par une personne non qualifiée peut entraîner des risques de blessure.

• Lors de l’entretien, n’utiliser que des pièces de rechange identiques et suivre les directives de la section «Entretien» du présent manuel afin de prévenir les risques de choc électrique ou de blessure.

Règles de sécurité additionnelles - Perceuse à percussion

• Tenir l’outil par les surfaces isolées prévues à cette fin lorsqu’il risque d’entrer en contact

avec des fils cachés ou son propre cordon, car de tels contacts peuvent mettre les pièces

métalliques de l’outil sous tension, engendrant des risques de choc électrique.

• Porter des protège-oreilles lorsqu’on effectue le martelage pour des périodes prolongées,

car les niveaux acoustiques élevés ainsi générés peuvent occasionner une perte d’audition

temporaire ou endommager sérieusement la membrane du tympan.

• Porter des lunettes de sécurité ou autre dispositif de protection oculaire car le martelage et

le perçage peuvent faire projeter des particules et entraîner des dommages irréversibles

aux yeux.

• Toujours utiliser la poignée latérale fournie avec l’outil et tenir fermement ce dernier.

Toujours le faire fonctionner en le tenant avec les deux mains.

• Les mèches de la perceuse et les outils deviennent chauds durant leur fonctionnement; on

doit porter des gants lorsqu’on les manipule.

MISE EN GARDE : NE PAS TOUCHER AUX PIÈCES MÉTALLIQUES DE L’OUTILlorsqu’on

perce un trou dans un mur ou un plancher ou qu’on y enfonce un clou ou encore lorsqu’il y

a risque d’entrer en contact avec un fil sous tension. Ne tenir l’outil qu’au moyen des surfaces

isolées prévues à cette fin afin d’éviter les chocs électriques en présence d’un tel fil.

AVERTISSEMENT : puisque cet outil peut soulever de la poussière contenant des produits

chimiques susceptibles d’entraîner le cancer, des malformations congénitales ou pouvant

être nocifs sur le plan reproductif, on recommande le port d’un appareil de protection respiratoire approprié.

• L’étiquette de l’outil peut comporter les symboles suivants.

V ......................volts A ......................ampères

Hz ....................hertz W ....................watts

min ..................minutes ....................courant alternatif

..................courant continu

n

o ....................sous vide

......................

Construction de classe II

......................borne de mise à la terre

....................symbole d´avertissement .../min ..............tours ou courses

.................... ........................à la minute

Consignes de sécurité additionnelles - Adaptateur

courant alternatif DW0247 (fig. 4)

• Les outils à double isolation sont munis d’une fiche polarisée (c’est-à-dire que l’une des

lames est plus large que l’autre), laquelle ne peut être raccordée qu’à une prise polarisée

et ce, dans un seul sens; on doit l’inverser si on est incapable de l’enfoncer complètement.

Si la fiche ne s’adapte toujours pas, on doit demander à un électricien qualifié d’installer la

prise appropriée. On ne doit jamais modifier la fiche. La double isolation élimine le besoin

d’installer un cordon d’alimentation trifilaire et un système d’alimentation électrique pourvus

d’une mise à la terre; seuls les outils de classe II (à double isolation) sont munis d’une telle

protection.

• Éviter tout contact entre le corps et les éléments mis à la terre, comme les tuyaux, les radiateurs, les cuisinières et les réfrigérateurs afin de réduire les risques de choc électrique.

• Ne pas utiliser l’outil électrique dans des endroits mouillés, ni l’exposer à la pluie; l’infiltration d’eau à l’intérieur de l’outil augmente les risques de choc électrique.

• Ne pas utiliser le cordon de manière abusive; on ne doit pas transporter l’outil en le tenant

par le cordon, ou utiliser ce dernier pour le débrancher. On doit tenir le cordon à l’écart des

sources de chaleur, de l’huile, des bords tranchants ou des pièces mobiles. Remplacer

immédiatement les cordons endommagés, car ces derniers augmentent les risques de choc

électrique.

• Lorsqu’on utilise un outil électrique à l’extérieur, on ne doit utiliser que des rallonges

conçues pour cet usage, comme celles de type W-A ou W, afin de réduire les risques de

choc électrique.

Calibre minimal recommandé des rallonges

Longueur totale de la rallonge

7,6 m 15,2 m 22,9 m 30,5 m 38,1 m 45,7 m 53,3 m

Calibre AWG

18 18 16 16 14 14 12

• Éviter les démarrages accidentels; s’assurer que l’interrupteur soit en position arrêt avant

de brancher l’outil. Ne pas transporter ce dernier en laissant le doigt sur l’interrupteur ni le

brancher lorsque l’interrupteur est en position marche, car cela pourrait causer un accident.

• Débrancher le cordon de la prise murale avant d’effectuer un réglage, de changer les accessoires ou de ranger l’outil; ces mesures de sécurité préventives réduisent les risques de

démarrage accidentel.

CONSERVER CES DIRECTIVES POUR CONSUL-

TATION ULTÉRIEURE

BLOC-PILES

L'outil fonctionne sur un bloc-piles D

EWALT de 24,0 V. Lorsqu’on commande des bloc-piles de

rechange, on doit indiquer le numéro de catalogue et la tension requise.

MISE EN GARDE : le bloc-piles contient des piles au nickel-cadmium. Le cadmium est con-

sidéré comme une substance toxique par les agences de protection de l’environnement, dont le

ministère de l’Environnement; on recommande donc de vérifier auprès de l’agence concernée

avant de mettre au rebut des bloc-piles au nickel-cadmium usés ou endommagés afin de se renseigner sur les dispositions particulières qui s’appliquent dans votre province à ce sujet, ou de

retourner les bloc-piles usés ou endommagés à un centre de service qualifié Dewalt afin qu’ils

puissent être recyclés.

DISPOSITIF DE DÉTECTION DE PILES CHAUDES OU FROIDES

Si votre chargeur est muni d’un dispositif visant à détecter les piles chaudes ou excessivement froides, le chargement sera retardé jusqu’à ce que la température de la pile se soit stabilisée; le chargeur se placera automatiquement en position de chargement. Ce dispositif sert

à maximiser la durée de vie des piles. Le voyant rouge s’allume longuement et ensuite brièvement lorsque ce dispositif est en marche.

Mode rechargement (Tune-UpMC)

Le mode rechargement (Tune-UpMC) sert à égaliser ou à équilibrer chaque cellule du bloc-piles

lors de son cycle de capacité limite; le cycle total dure 8 heures. Le bloc-piles doit être

rechargé chaque semaine, après 10 ou 20 cycles de charge / de décharge ou lorsque la

capacité du bloc-piles commence à diminuer.

1. Pour recharger le bloc-piles, placer les piles dans le chargeur de la manière habituelle. Le

voyant rouge clignotera continuellement, indiquant que le cycle de charge est amorçé.

2. On peut enfoncer le bouton Tune-UpMC à n’importe quel moment une fois la charge

amorçée. Le voyant rouge s’éteindra momentanément, clignotera trois fois brièvement

puis clignotera continuellement, indiquant que le chargeur est en mode rechargement.

3. Une fois le cycle de rechargement terminé, le voyant restera allumé, indiquant que le blocpiles est complètement rechargé; on peut alors le réutiliser ou le laisser dans le chargeur.

4. Si on sélectionne le mode de rechargement mais qu’on change d’idée par la suite, retirer

la pile du chargeur, attendre 5 secondes, puis réinsérer la pile afin d’amorcer le cycle de

charge normal.

Montage et démontage du bloc-piles (fig. 1)

REMARQUE : s’assurer que le bloc-piles soit complètement chargé. Pour l’installer dans

l’outil, régler le bouton de verrouillage en position arrêt pour couper le contact de l’interrupteur à gâchette, aligner la partie avant de la pile avec les encoches situées à l’intérieur du

corps de l’outil et glisser le bloc-piles fermement en place jusqu’à ce qu’on entende un déclic

indiquant qu’il est bien enclenché.

Pour retirer le bloc-piles de l’outil, appuyer sur les boutons de déclenchement (B) situés de

chaque côté, puis retirer le bloc-piles (C ) et l’insérer dans le chargeur selon les directives du

manuel du chargeur.

Remarques importantes concernant le chargement

1. Afin de maximiser la durée de vie du bloc-piles et d’assurer son rendement optimal, le

charger à la température ambiante, soit entre 18 et 24 °C (65 et 75 °F). Afin d’éviter d’endommager le bloc-piles, il est important de NE PAS le charger à des températures

inférieures à +4,5 °C (+40 °F) ou supérieures à +40,5 °C (105 °F).

2. Le chargeur et le bloc-piles peuvent devenir chauds au toucher lors du chargement. Ceci

est normal et n’indique pas la présence d’un problème.

3. Si le bloc-piles ne se charge pas normalement, il faut : (1) vérifier l’alimentation de la prise

en y enfichant une lampe ou un appareil, (2) s’assurer que la prise ne soit pas raccordée

à un interrupteur qui coupe le courant lorsqu’on ferme les lumières, (3) placer le chargeur

et le bloc-piles dans un endroit où la température ambiante est environ 18 à 24 °C (65 et

75 °F) ou, si le problème persiste, (4) retourner l’outil, le chargeur et le bloc-piles au centre de service de sa région.

Page 4

4. Le bloc-piles doit être rechargé lorsqu’il ne produit pas suffisamment de courant pour permettre à l’utilisateur de travailler normalement. On doit CESSER de l’utiliser dans de telles

conditions et suivre la méthode de chargement. On peut aussi charger en tout temps un

bloc-piles partiellement déchargé sans nuire à son fonctionnement.

5. Dans certaines conditions, lorsque le chargeur est enfiché, les raccords de charge à nu

situés à l’intérieur du chargeur peuvent subir un court-circuit lorsqu’ils entrent en contact

avec une matière étrangère. Les matières conductives comme la laine d’acier, la feuille

d’aluminium ou les particules métalliques, mais sans toutefois s’y limiter, doivent être tenus

à l’écart des cavités du chargeur. Toujours débrancher celui-ci lorsque le bloc-piles n’y est

pas inséré ou avant de le nettoyer.

6. Ne pas congeler ou tremper dans l’eau ou dans un liquide quelconque.

AVERTISSEMENT : ne jamais laisser de liquide s’infiltrer à l’intérieur du chargeur afin

d’éviter les risques de choc électrique. Pour faciliter le refroidissement du bloc-piles après son

utilisation, éviter de placer ce dernier ou le chargeur dans un environnement chaud comme un

cabanon en métal ou une remorque non isolée.

MISE EN GARDE : ne jamais ouvrir le bloc-piles pour quelle que raison que ce soit. Si le

compartiment en plastique se rupture ou se fissure, le retourner au centre de service afin qu’il

puisse être recyclé.

IMPORTANT : ce produit ne doit pas être entretenu par l’utilisateur; les pièces internes du

chargeur sont destinées à être entretenues par un centre de service autorisé afin d’éviter que

les composants internes à sensibilité statique ne soient endommagés.

LIRE TOUTES LES DIRECTIVES DU MANUEL DU CHARGEUR AVANT DE CHARGER

LE BLOC-PILES.

Toujours utiliser le bloc-piles approprié (celui fourni avec l’outil ou un bloc-piles de rechange

identique). Ne jamais installer un autre type de bloc-piles afin d’éviter d’endommager l’outil en

permanence et de causer une situation dangereuse.

Règles de sécurité additionnelles - Perceuse à percussion

• Tenir l’outil par les surfaces isolées prévues à cette fin lorsque l’outil risque d’entrer en contact avec des fils cachés ou son propre cordon, car de tels contacts peuvent mettre les

pièces métalliques de l’outil sous tension, engendrant des risques de choc électrique.

• Porter des lunettes de sécurité ou autre dispositif de protection oculaire car le martelage et

le perçage peuvent faire projeter des particules et entraîner des dommages irréversibles

aux yeux.

• Porter des protège-oreilles lorsqu’on effectue le martelage pour des périodes prolongées,

car les niveaux acoustiques élevés ainsi générés peuvent occasionner une perte d’audition

temporaire ou endommager sérieusement la membrane du tympan.

• Toujours utiliser la poignée latérale fournie avec l’outil et tenir fermement ce dernier.

Toujours le faire fonctionner en le tenant avec les deux mains.

• Ne pas trop étendre les bras lorsque l’outil est en marche; maintenir son équilibre en tout

temps et bien positionner les plate-formes et les échafaudages avant de débuter les

travaux, le cas échéant, afin de pouvoir TRAVAILLER EN TOUTE SÉCURITÉ.

• Les mèches de la perceuse et les outils deviennent chauds durant leur fonctionnement; on

doit porter des gants lorsqu’on les manipule.

MISE EN GARDE : NE PAS TOUCHER AUX PIÈCES MÉTALLIQUES DE L’OUTILlorsqu’on

perce un trou dans un mur ou un plancher ou qu’on y enfonce un clou ou encore lorsqu’il y a

risque d’entrer en contact avec un fil sous tension. Ne tenir l’outil qu’au moyen des surfaces

isolées prévues à cette fin afin d’éviter les chocs électriques en présence d’un tel fil.

Moteur

L’outil D

E

WALT est entraîné par un moteur fabriqué par la même entreprise; s’assurer que la

prise employée corresponde à celle de la plaque signalétique.

Une baisse de tension de plus de 10 % entraînera une perte de puissance et une surchauffe.

Les outils Dewalt sont éprouvés en usine; si l’outil ne fonctionne pas, vérifier le bloc-piles.

Poignée latérale (fig. 1-A)

MISE EN GARDE : toujours utiliser la poignée latérale et tenir la perceuse à percussion

avec les deux mains. Cette poignée est fixée sur la partie antérieure du carter d’engrenages,

tel qu’illustré à la figure 1; on peut la tourner complètement dans un sens ou dans l’autre afin

de l’utiliser à gauche ou à droite, selon le cas.

Commande de variation de vitesse (fig 2-A)

Enfoncer l’interrupteur à gâchette pour mettre l’outil en marche; le relâcher pour arrêter l’outil.

Celui-ci est muni d’un frein et le mandrin s’arrête dès que l’interrupteur est complètement

relâché.

Le variateur de vitesse permet de sélectionner la vitesse qui convient le mieux à une tâche

particulière. Plus on enfonce l’interrupteur, plus la vitesse augmente. Utiliser les plus basses

vitesses pour amorcer un trou sans pointeau, pour percer le métal, le plastique ou la

céramique ou encore pour enfoncer des vis. Pour maximiser la durée de vie de l’outil, utiliser

le variateur seulement pour amorcer des trous ou enfoncer des attaches.

REMARQUE : une utilisation sans arrêt de la commande de vitesse variable n’est pas recommandée, car cela pourrait endommager l’interrupteur; il faut donc éviter une telle pratique.

Bouton de commande marche avant ou marche arrière

(fig.-2-B )

Un bouton de commande marche avant-arrière, qui sert aussi comme bouton de verrouillage

en position arrêt, détermine la direction de marche. Pour sélectionner la position marche

avant, relâcher l’interrupteur à gâchette et enfoncer le bouton de commande situé du côté

droit de l’outil. Pour sélectionner la position marche arrière, appuyer sur le bouton situé du

côté gauche de l’outil. La position centrale du bouton sert à verrouiller l’outil en position arrêt.

On doit toujours relâcher la gâchette lorsqu’on change la position du bouton. REMARQUE :

la première fois qu’on démarre l’outil après avoir changé la direction de marche, un déclic peut

se faire entendre; ce son est normal et n’indique pas la présence d’un problème.

Sélecteur de mode martelage ou perçage (fig 3)

Pour sélectionner le mode perçage ou le mode martelage, tourner le pointeur du bouton rotatif

vers le symbole approprié. Pour utiliser l’outil en mode de perçage droit, aligner le pointeur du

bouton rotatif avec le symbole de la mèche (B), tel qu’illustré; pour le mode martelage, l’aligner avec le symbole du marteau (A). REMARQUE : le sélecteur doit toujours être placé en

mode perçage ou martelage / perçage, car il n’existe aucune position entre les deux permettant de faire fonctionner l’outil.

Fonctionnement

PERÇAGE

1. Toujours verrouiller l’interrupteur à gâchette et retirer le bloc-piles avant de fixer ou de remplacer les mèches ou les accessoires.

2. Utiliser des mèches aiguisées seulement. Pour percer le BOIS, sélectionner la basse

vitesse et utiliser une mèche hélicoïdale ou à bois, une vrille ou une scie à trous; pour le

MÉTAL, sélectionner la basse vitesse et utiliser une mèche hélicoïdale en acier ou une

scie à trous. Quant aux matériaux de MAÇONNERIE tels que la brique, le ciment, les blocs

en béton de laitier, etc., choisir des mèches à pointe carburée destinées au forage par percussion.

3. Bien fixer et soutenir l’ouvrage. Dans le cas de matériaux minces, utiliser des blocs de remplissage afin de ne pas l’endommager.

4. Appliquer une pression en ligne droite au moyen de la mèche en exerçant juste assez de

pression pour permettre à la mèche de mordre dans l’ouvrage, en évitant de caler le

moteur ou de faire dévier la mèche.

5. Saisir fermement l’outil afin de maîtriser la torsion.

6. LE CALAGE DE LA PERCEUSE découle généralement d’une surcharge ou d’une mauvaise utilisation. Lorsque cela se produit, RELÂCHER IMMÉDIATEMENT LA GÂCHETTE,

retirer la mèche de l’ouvrage et déterminer la cause du calage. NE PAS ENFONCER ET

RELÂCHER LA GÂCHETTE À PLUSIEURS REPRISES POUR ESSAYER DE

REDÉMARRER LA PERCEUSE AFIN D’ÉVITER DE L’ENDOMMAGER.

7. Réduire le calage au minimum lorsque la mèche perce l’ouvrage en réduisant la pression

et en perçant lentement la dernière section du trou.

8. Maintenir le moteur en marche lorsqu’on retire la mèche du trou percé afin d’éviter qu’elle

reste coincée.

9. Lorsqu’on utilise une perceuse à vitesse variable, il n’est pas nécessaire de marquer l’emplacement prévu du trou au moyen d’un pointeau. Faire fonctionner la perceuse à basse

vitesse pour amorcer le trou et l’augmenter lorsque le trou est suffisamment profond pour

empêcher la mèche d’en sortir.

PERÇAGE DU MÉTAL

Faire fonctionner la perceuse très lentement et augmenter la vitesse jusqu’à ce qu’on obtienne

la vitesse maximale, tout en appuyant fermement sur l’outil; la vitesse choisie est appropriée

lorsque les éclats de métaux sont projetés uniformément et régulièrement. Utiliser une huile de

coupe lorsqu’on perce des métaux, à l’exception de la fonte et du laiton, car des derniers doivent

être percés à sec.

REMARQUE : il est plus facile de percer de larges trous (c’.-à-d., de 7,94 à 12,7 mm ou de 5/16

po) dans l’acier si on perce d’abord un trou de guidage de 3,97 à 4,76 mm ou de 5/32 à 3/16

po.

PERÇAGE DU BOIS

Faire fonctionner la perceuse très lentement et augmenter la vitesse jusqu’à ce qu’on obtienne

la vitesse maximale, tout en appuyant fermement sur l’outil. On peut percer le bois au moyen

des mèches hélicoïdales qu’on utilise pour le métal. Ces mèches peuvent surchauffer si on ne

les sort pas fréquemment pour enlever les copeaux restés coincés dans les goujures. Les

ouvrages susceptibles de se fractionner doivent être calés au moyen d’un bloc de bois.

PERÇAGE DE LA MAÇONNERIE

Lorsqu’on perce la maçonnerie, utiliser des mèches à pointe carburée destinées au forage par

percussion, en s’assurant qu’elles soient bien aiguisées. Sélectionner le mode martelage et

appuyer constamment et fermement sur l’outil pour assurer un perçage efficace. La vitesse

choisie est appropriée lorsque la pousssière est soulevée uniformément et régulièrement.

Mandrin SDS (fig. 5)

Pour installer la mèche, insérer la tige de cette dernière sur environ 2 cm (3/4 po) dans le

mandrin et tourner la mèche jusqu’à ce qu’elle soit bien enclenchée.

Pour retirer la mèche, tirer le collier vers l’arrière et enlever la mèche.

Entretien

NETTOYAGE

Nettoyer l’outil seulement au moyen d’un linge humide et d’un savon doux. Ne jamais laisser de

liquide s’infiltrer à l’intérieur de l’outil; ne jamais immerger ce dernier dans quelque liquide que

ce soit.

Les roulements à l’intérieur de l’outil sont autolubrifiés, de sorte qu’une lubrication périodique

n’est pas nécessaire. Si un entretien est tout de même requis, retourner l’outil à un centre de

service autorisé.

Lubrification

Cet outil a été lubrifié en usine. Deux à six mois suivant l’achat (selon la fréquence d’utilisation),

il devra subir un entretien complet (nettoyage, inspection et lubrification) dans un centre de service autorisé. Les outils qui sont constamment utilisés doivent être lubrifiés plus fréquemment;

ceux qui ne sont pas utilisés pendant de longues périodes doivent être de nouveau lubrifiés

avant d’être réutilisés.

Accessoires

Les accessoires recommandés pour cet outil sont vendus séparément chez le distributeur ou au

centre de service de votre région.

MISE EN GARDE : l’usage d’un accessoire non recommandé peut présenter un danger.

Pour obtenir de l’aide concernant l’achat d’un accessoire, communiquer avec

D

E

WALT Industrial Tool Company,

Case postale 158, 626,

Hanover Pike, Hampstead, MD 21074, USA,

ou composer le 1 800 433-9258.

FICHE TECHNIQUE

DW004

tr / min. de 0 à 1 150

battement minute de 0 à 5 800

MÈCHES À MÉTAL 1,27 cm (5 po)

MÈCHES PLATES À BOIS 3,81 cm (1 1/2 po)

MÈCHES À MAÇONNERIE 2,22 cm (7/8 po) – béton, brique, blocs

Important

Pour assurer la SÉCURITÉ et la FIABILITÉ de ce produit, l’outil doit être réparé, entretenu et

réglé par un centre de service autorisé ou qualifié (cela comprend l’inspection et le remplacement de la brosse); seules des pièces de rechange identiques doivent être utilisées.

Garantie complète

DEWALT garantit les outils industriels à service intensif contre tout défaut de matériel ou de

fabrication pour une période d’un an à compter de la date d’achat; le produit défectueux sera

remplacé ou réparé sans frais. Pour obtenir de plus amples renseignements sur les réparations couvertes par la présente garantie, composer le 1-800-433-9258. Cette garantie ne

s’applique pas aux accessoires et ne vise pas les dommages causés par des réparations

effectuées par un tiers. Cette garantie vous confère des droits légaux particuliers, en sus des

autres droits provinciaux dont vous pourriez bénéficier.

En plus de la présente garantie, la

GARANTIE SANS RISQUE DE 30 JOURS EN CAS DE NON SATISFACTION

s’applique également aux outils D

EWALT.

Si vous n’êtes pas entièrement satisfait(e) du rendement de l’outil industriel à service intensif

D

E

WALT, il suffit de le retourner au vendeur participant dans les 30 jours pour obtenir un remboursement intégral. Retourner l’outil au complet en payant le transport à l’avance; une preuve

d’achat peut être requise.

Reglas generales de seguridad – Para todas las herramientas operadas con baterías

¡ADVERTENCIA! Lea y comprenda todas las instrucciones. No seguir las instrucciones listadas

a continuación puede resultar en un choque eléctrico, incendio y(o) lesiones personales graves.

CONSERVE ESTAS INSTRUCCIONES

ÁREA DE TRABAJO

• Conserve su área de trabajo limpia y bien iluminada. Las bancas amontonadas y las

zonas oscuras propician los accidentes.

• No opere herramientas eléctricas en atmósferas explosivas, como en presencia de

líquidos, gases o polvos inflamables. Las herramientas eléctricas producen chispas que

pueden originar la ignición de los polvos o los vapores.

• Conserve a observadores, niños y visitantes alejados mientras opera una herramien-

ta eléctrica. Las distracciones pueden ocasionar que pierda el control.

SEGURIDAD ELÉCTRICA

• Una herramienta operada con baterías integradas o por separado debe recargarse

con el cargador especificado para la batería. Un cargador que es adecuado para un tipo

de baterías puede crear riesgos de incendio cuando se emplea con otra batería.

• Utilice la herramienta únicamente con la batería específicamente diseñada para ella.

El uso de otras baterías puede crear riesgos de incendio.

SEGURIDAD PERSONAL

• Esté alerta, concéntrese en lo que está haciendo. Recurra al sentido común cuando

opere una herramienta eléctrica. No opere ninguna herramienta si se encuentra fatigado o

bajo la influencia de drogas, alcohol o medicamentos. Un momento de desatención mientras se operan herramientas eléctricas puede ocasionar lesiones graves.

• Vístase de manera adecuada. No vista ropas o artículos de joyería flojos. Cubra su cabel-

Page 5

lo si lo tiene largo. Conserve su cabello, sus ropas y guantes alejados de las piezas móviles.

Las piezas de vestir flojas, las joyas y el cabello largo pueden resultar atrapados por las

piezas móviles.

• Evite el encendido accidental. Asegúrese que el interruptor esté en posición de apagado

antes de insertar la batería. Sostener una herramienta con el dedo en el interruptor o colocar la batería sin fijarse si el interruptor está en posición de encendido propicia los accidentes.

• Retire las llaves de ajuste antes de encender la herramienta. Una llave que se deja en

una pieza giratoria puede ocasionar lesiones personales.

• No se sobreextienda. Conserve siempre los pies bien apoyados, al igual que el equilibrio.

La posición correcta de los pies y el equilibrio permiten controlar mejor la herramienta en

situaciones inesperadas.

• Utilice equipo de seguridad. Siempre utilice protección en los ojos. Se deben utilizar mas-

carillas contra polvo, zapatos antiderrapantes, casco o protectores para los oídos para tener

las condiciones apropiadas.

USO Y CUIDADOS DE LA HERRAMIENTA

• Utilice prensas u otros medios prácticos para asegurar y apoyar la pieza de trabajo

en una plataforma estable. Sujetar las piezas con la mano o contra su cuerpo es inestable

y puede originar la pérdida de control.

• No fuerce la herramienta. Utilice la herramienta apropiada para su aplicación. La herramienta apropiada hará el trabajo mejor y de manera más segura bajo las especificaciones

para las que se diseñó.

• No utilice la herramienta si el interruptor no enciende y apaga. Cualquier herramienta

que no pueda controlarse por medio del interruptor es peligrosa y debe repararse.

• Desconecte la batería de la herramienta o coloque el interruptor en posición de apagado antes de hacer cualquier ajuste, cambio de accesorios o de guardar la herramienta. Tales medidas de seguridad preventivas reducirán el riesgo de que la her-

ramienta se encienda accidentalmente.

• Guarde las herramientas fuera del alcance de los niños y de otras personas no entrenadas. Las herramientas son peligrosas en manos de personas no capacitadas.

• Cuando no use la batería consérvela alejada de otros objetos metálicos como: clips,

monedas, llaves, clavos, tornillos y otros objetos metálicos pequeños que puedan

hacer conexión de una terminal a otra. Hacer un corto entre las terminales puede causar

chispas, quemaduras o un incendio.

• Cuide sus herramientas. Conserve las herramientas de corte afiladas y limpias. Las herramientas que reciben un mantenimiento adecuado, con piezas de corte afiladas, difícilmente se atascan y son más fáciles de controlar.

• Verifique la alineación de las piezas móviles, busque fracturas en las piezas y cualesquiera otras condiciones que puedan afectar la operación de las herramientas. Si

está dañada, lleve su herramienta a servicio antes de usarla de nuevo. Muchos accidentes

se deben a herramientas con mantenimiento pobre.

• Solamente use accesorios que el fabricante recomiende para su modelo de herramienta. Los accesorios que estén diseñados para una herramienta, pueden volverse

peligrosos cuando se emplean con otra.

SERVICIO

• El servicio a las herramientas lo debe efectuar únicamente personal calificado. El servicio o mantenimiento realizado por personal no calificado puede originar riesgos de

lesiones.

• Cuando efectúe servicio a una herramienta, utilice únicamente refacciones idénticas. Siga las instrucciones de la sección de Mantenimiento de este manual. El empleo de

piezas no autorizadas o no seguir las instrucciones de mantenimiento puede originar riegos

de choque eléctrico o lesiones.

Reglas de seguridad adicionales específicas para

rotomartillos

• Sujete la herramienta de las superficies aislantes cuando efectúe una operación en

la que la herramienta de corte pueda hacer contacto con cableado oculto o con su

propio cable. El contacto con un cable “vivo” hará que las partes metálicas expuestas que-

den “vivas” y descarguen hacia el operador.

• Utilice protectores para los oídos cuando taladre por periodos prolongados. Puede

resultar con pérdida auditiva temporal o con daños graves al tambor debido a los altos niveles de ruido generados por la operación del rotomartillo.

• Utilice gafas de seguridad u otra protección para los ojos. Las operaciones de taladrado y astillado ocasionan que salgan astillas despedidas. Las partículas voladoras pueden

causar lesiones oculares permanentes.

• Siempre utilice el mango lateral que se suministra con la herramienta. Sujete la herramienta con firmeza en todo momento. No intente operar esta herramienta sin sujetarla

con ambas manos.

• No se sobreextienda al operar la herramienta. Conserve una posición de trabajo balanceada en todo momento. Cuando sea necesario, utilice plataformas de trabajo seguras

y bien posicionadas. TRABAJE SEGURO.

• Las brocas y otras piezas de corte de su rotomartillo se calientan durante la

operación. Utilice guantes cuando vaya a tocarlas.

PRECAUCIÓN: Cuando taladre en muros, suelos o cualquier otro sitio en el que puedan

encontrarse cables eléctricos vivos, ¡NO TOQUE NINGUNA PARTA METÁLICADE LA HERRAMIENTA! Sostenga el taladro por las superficies de sujeción aislantes para evitar las

descargas en caso de que taladre o atornille en un cable vivo.

ADVERTENCIA: El uso de esta herramienta puede generar polvo con contenido de pro-

ductos químicos que se sabe pueden provocar cáncer, defectos congénitos y otros daños

reproductivos. Utilice la protección respiratoria adecuada.

• La etiqueta de su herramienta puede incluir los siguientes símbolos.

V....................volts A ......................amperes

Hz..................hertz W......................watts

min ................minutos ....................corriente alterna

..............corriente directa carga

n

o......................velocidad sin

..................terminales de

......................construcción clase II

......................conexión a tierre

..................símbolo de alerta seguridad .../min................revolucione s por

...................... ..........................minuto

Instrucciones de seguridad adicionales específicas

para el adaptador DW0247 CA (Fig. 4)

• Las herramientas con doble aislamiento están equipadas con una clavija polarizada (una

pata más ancha que la otra). Esta clavija se acopla a un contacto polarizado de una sola

manera. Si la clavija no se acopla completamente a la toma, inviértala. Si aun así no

queda, haga que un electricista calificado le instale una toma polarizada. No modifique la

clavija. El doble aislamiento elimina la necesidad del cable para tierra de tres hilos y un

sistema de alimentación aterrizado. Aplicable únicamente a herramientas Clase II (con

doble aislamiento).

• Evite el contacto corporal con superficies aterrizadas como tuberías, radiadores, hornos y

refrigeradores. Existe un riesgo mayor de choque eléctrico si su cuerpo hace tierra.

• No exponga las herramientas eléctricas a la lluvia o a condiciones de humedad. El agua

en el interior de una herramienta eléctrica aumenta el riego de un choque eléctrico.

• No maltrate el cable. Nunca emplee el cable para cargar las herramientas o para

desconectar la clavija de una toma. Conserve el cable lejos de calor, aceite, bordes afilados o piezas móviles. Reemplace los cables dañados de inmediato. Los cables dañados

aumentan el riesgo de choque eléctrico.

• Cuando opere una herramienta eléctrica a la intemperie, utilice una extensión para intemperie marcada “W-A” o “W”. Estos cables están clasificados para uso a la intemperie y

reducen el riesgo de choque eléctrico.

Calibre mínimo recomendado para cables de extensión

Longitud total del cable

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Calibre del cable

18 AWG 18 AWG 16 AWG 16 AWG 14 AWG 14 AWG 12 AWG

• Evite el encendido accidental. Asegúrese que el interruptor esté en posición de apagado

antes de conectar. Cargar las herramientas con el dedo en el interruptor o conectarlas

con el interruptor en posición de encendido propicia accidentes.

• Desconecte la clavija de la toma de corriente antes de hacer cualquier ajuste, cambio de

accesorios o de guardar la herramienta. Dichas medidas de seguridad reducen el riesgo

de encender la herramienta accidentalmente.

CONSERVE ESTAS INSTRUCCIONES PARA

FUTURAS REFERENCIAS

Baterías

Su herramienta utiliza una batería DEWALT de 24.0 volts. Cuando ordene baterías de

repuesto, asegúrese de incluir el número de catálogo y el voltaje.

PRECAUCIÓN: Las baterías son de tipo níquel-cadmio. El cadmio está considerado como

material tóxico por la Agencia de Protección Ambiental (EPA). Antes de desechar baterías de

níquel-cadmio desgastadas o dañadas, verifique con la agencia de protección ambiental de su

localidad la existencia de restricciones especiales para el desecho de estas baterías, o envíela

a un centro de servicio DeWALT certificado para que la reciclen.

RETARDADOR PARA BATERÍAS CALIENTES/FRÍAS

Si el cargador cuenta con el dispositivo de retardo, cuando detecta que una batería está

excesivamente caliente o fría, se inicia un retardo en el proceso de carga, suspendiéndolo

hasta que la temperatura de la batería se haya normalizado. Después que esto suceda, el

cargador cambia automáticamente al modo de carga de baterías. Esta característica se asegura la máxima duración de sus baterías. La luz roja parpadea a intervalos largos, y lo hace

a intervalos cortos cuando está en el modo de retardo.

Uso del modo Tune-Up™

La carga en el modo Tune-Up™ nivelará o balanceará las celdas individuales de la batería a

su capacidad máxima. El ciclo del modo de refresco se lleva hasta 8 horas para completarse.

Las baterías deben recargarse en este modo cada semana o después de 10 a 20 ciclos de

carga/descarga, o siempre que la batería deje de producir la energía suficiente para el trabajo que usted acostumbre realizar.

1. Para refrescar la batería, colóquela en el cargador como los acostumbra. La luz roja

parpadeará continuamente indicando el inicio del ciclo de carga.

2. El botón Tune-Up™ puede oprimirse en cualquier momento después de que la carga se

ha iniciado. La luz roja dejará de parpadear momentáneamente, parpadeará 3 veces rápidamente, y después seguirá parpadeando de manera continua. El cargador estará en

ese momento en el modo de “refresco”.

3. Cuando se haya completado el ciclo de carga, la luz permanecerá encendida de manera

continua. La batería estará completamente cargada y podrá utilizarse ene este punto, o

podrá dejarse en el cargador.

4. Si usted selecciona el modo Tune-Up™ y después cambia de parecer, retire la batería

del cargador, e insértela de nuevo después de haber dejado pasar 5 segundos. El ciclo

normal de carga se iniciará.

Instalación y remoción de la batería (Fig. 1)

NOTA:Asegúrese de que la batería esté totalmente cargada. Para instalar la batería en la herramienta, accione el seguro del interruptor para desactivar el gatillo, alinee el frente de la

batería con las muescas que se encuentran en el interior del cuerpo de la batería y deslícela

con firmeza hasta que escuche que asiente en su posición.

Para retirar la batería de la herramienta, oprima los botones de liberación (B) a ambos lados

y retire la batería (C). Insértela en el cargador como se describe en su manual.

Notas importantes sobre la carga

1. Se puede obtener mejor rendimiento y más larga vida si la batería se carga cuando la

temperatura oscila entre 18° y 24°C (65°F - 75°). NO cargue la batería cuando la temperatura sea inferior a +4.5°C (+40°F), o superior a +40.5°C (+105°F). Esto es muy

importante y le evitará serios daños a la batería.

2. El cargador y la batería pueden sentirse calientes al tacto durante la carga. Esto es una

condición normal y no indica ningún problema.

3. Si la batería no carga apropiadamente — (1) Verifique la corriente en la toma conectando una lámpara u otro aparato eléctrico, (2) Verifique si la toma está conectada a un interruptor que corte la corriente cuando apaga las luces. (3) Lleve el cargador con la batería

a un lugar en donde la temperatura del aire que los rodee esté entre 18° y 24°C (65°F 75°F). (4) Si persisten los problemas de carga, lleve o envíe la herramienta, la batería y

el cargador a su centro de servicio local.

4. La batería debe recargarse cuando deja de producir suficiente potencia en trabajos que

se hicieron fácilmente con anterioridad. NO CONTINÚE usándola en estas condiciones.

Siga los procedimientos de carga. Usted puede cargar una batería parcialmente usada

cuando lo desee sin que ésta sufra efectos adversos.

5. Bajo ciertas condiciones, con el cargador conectado a la toma de corriente, los contactos de carga expuesto dentro del cargador pueden hacer contacto entre sí debido a algún

material externo. Los materiales externos de naturaleza conductora tales como alambre

de acero, papel aluminio o cualquier tipo de partícula metálica deben conservarse alejados de las cavidades del cargador. Desconecte siempre el cargador de la toma de corriente cuando no tenga cargando una batería. También desconéctelo antes de intentar

limpiarlo.

6. No sumerja el cargador en agua u otro líquido.

ADVERTENCIA: No permita que se introduzcan líquidos al cargador. Para facilitar el enfri-

amiento de la batería después de usarla, evite colocar el cargador o la batería en ambientes

cálidos como cobertizos metálicos o remolques sin aislamiento.

PRECAUCIÓN: Nunca intente abrir la batería por ningún motivo. Si la carcaza de plástico

de la batería se cuartea o se estrella, devuélvala a un centro de servicio para que la reciclen.

IMPORTANTE: Este producto no es susceptible de ser reparado por el usuario. No hay partes

reparables por el usuario en su interior. Se requiere el servicio en un centro de servicio autorizado para evitar daños a los componentes internos sensibles a la estática.

LEA TODAS LAS INSTRUCCIONES DEL MANUAL DEL CARGADOR DE BATERÍAS ANTES

DE INTENTAR CARGAR LA BATERÍA PARA SU HERRAMIENTA.

Utilice siempre la batería correcta (la que se suministra con su herramienta o una idéntica).

Nunca instale otra batería. Arruinará su herramienta y podrá crear una condición de peligro.

Reglas de seguridad adicionales para rotomartillos

• Sujete la herramienta de las superficies aislantes cuando efectúe una operación en la que

la herramienta de corte pueda hacer contacto con cableado oculto o con su propio cable.

El contacto con un cable “vivo” hará que las partes metálicas expuestas queden “vivas” y

descarguen hacia el operador

• Utilice gafas de seguridad u otra protección para los ojos. Las operaciones de taladrado y

astillado ocasionan que salgan astillas despedidas. Las partículas voladoras pueden

causar lesiones oculares permanentes.

• Utilice protectores para los oídos cuando taladre por periodos prolongados. Puede resultar con pérdida auditiva temporal o con daños graves al tambor debido a los altos niveles

de ruido generados por la operación del rotomartillo.

• Siempre utilice el mango lateral que se suministra con la herramienta. Sujete la herramienta con firmeza en todo momento. No intente operar esta herramienta sin sujetarla

con ambas manos.

Page 6

• No se sobreextienda al operar la herramienta. Conserve una posición de trabajo balanceada en todo momento. Cuando sea necesario, utilice plataformas de trabajo seguras

y bien posicionadas. TRABAJE SEGURO.

• Las brocas y otras piezas de corte de su rotomartillo se calientan durante la operación.

Utilice guantes cuando vaya a tocarlas.

PRECAUCIÓN: Cuando taladre en muros, suelos o cualquier otro sitio en el que puedan

encontrarse cables eléctricos vivos, ¡NO TOQUE NINGUNA PARTA METÁLICA DE LA

HERRAMIENTA! Sostenga el taladro por las superficies de sujeción aislantes para evitar

las descargas en caso de que taladre o atornille en un cable vivo.

Motor

Su herramienta DEWALT funciona gracias a un motor integrado DEWALT. Asegúrese que su

alimentación de corriente concuerde con las especificaciones de la placa de identificación.

Disminuciones en el voltaje mayores al 10% causarán pérdida de potencia y sobrecalentamiento. Todas las herramientas D

EWALT se prueban en la fábrica; si esta herramienta no

funciona, revise la batería.

Mango lateral (Fig. 1-A)

PRECAUCIÓN: Utilice siempre el mango lateral y sujete el rotomartillo con ambas manos.

El mango lateral se fija al frente de la caja de engranes como se muestra en la figura 1, y

puede girarse 360˚ para permitir el uso con cualquiera de las manos.

Interruptor de velocidad variable (Fig. 2-A)

Oprima el gatillo para encender la herramienta. Suéltelo para apagarla. Su herramienta está

equipada con un freno. El portabrocas se detendrá tan pronto como suelte el gatillo.

El interruptor para velocidad variable le permite seleccionar la mejor velocidad para una aplicación en particular. Mientras más a fondo oprima el gatillo, la herramienta funcionará a mayor

velocidad. Utilice velocidades bajas para iniciar barrenos sin marca de centro, para perforar

metales o plásticos, para atornillar y para perforar cerámica. Para obtener la máxima vida útil

de la herramienta, utilice la velocidad variable únicamente para iniciar barrenos o colocar tornillos.

NOTA: No se recomienda el uso continuo en velocidad variable. Puede dañarse el interruptor

y debe evitarse.

Botón de control de marcha adelante/reversa (2-B)

El botón de control de marcha hacia adelante/reversa determina la dirección y sirve también

como seguro. Para seleccionar la rotación hacia adelante, suelte el gatillo y oprima el botón de

control de marcha del lado derecho de la herramienta. Para seleccionar la reversa, oprima el

botón de control del lado izquierdo. La posición central del botón asegura la herramienta en

posición de apagado. Cuando cambie la posición del botón de control, asegúrese de que el

gatillo esté libre. NOTA: la primera vez que la herramienta funcione después de cambiar el sentido de rotación, puede que se escuche un chasquido. Esto es normal y no indica ningún problema.

Selector de percusión/taladro (Fig. 3)

Para cambiar la herramienta del modo de taladro al modo de percusión (o viceversa) gire la

perilla para que muestre el símbolo aplicable. Para taladrar, haga coincidir el símbolo de la

broca (B) como se muestra. Para el modo de percusión, haga coincidir el símbolo del martillo

(A). NOTA: El selector debe estar en alguna de las dos posiciones siempre. No hay posiciones de operación entre ellas.

Operación

TALADRADO

1. Siempre asegure el interruptor y retire la batería cuando instale o cambie brocas o accesorios.

2. Utilice exclusivamente brocas afiladas. Para MADERA utilice brocas helicoidales, brocas

de horquilla, brocas de poder o brocas sierra. Para METAL utilice brocas helicoidales de

alta velocidad o brocas sierra. Para MAMPOSTERÍA, ladrillo, cemento, tabiques, etc., utilice brocas con punta de carburo de tungsteno clasificadas para percusión.

3. Asegúrese que el material que va a barrenar esté firmemente anclado o asegurado. Si perforará material delgado, utilice un trozo de madera como “respaldo” para evitar dañarlo.

4. Aplique presión al taladro en línea recta con la broca. Haga suficiente presión para que la

broca siga perforando paro no tanta para que el motor se atasque o la broca se desvíe.

5. Sujete el taladro firmemente para controlar la fuerza de torsión del taladro.

6. SI EL TALADRO SE ATASCA, esto se deberá probablemente a que está sobrecargado, o

a que se usa de manera incorrecta. SUELTE EL GATILLO DE INMEDIATO y determine la

causa del atascamiento. NO APRIETE EL GATILLO PARA HACER PRUEBAS DE

ENCENDIDO Y APAGADO CUANDO LA BROCA ESTA ATORADA, ESTO PUEDE

DAÑAR EL TALADRO.

7. Para reducir el peligro de que se atasque el taladro, reduzca la presión y deje ir suavemente la broca hacia el final del barreno.

8. Conserve el motor trabajando al retirar la broca del interior del barreno, de esta manera

evitará que se atasque.

9. Con los taladros con velocidad con velocidad variable no hay necesidad de hacer una

marca de centro. Utilice una velocidad baja para comenzar el barreno y acelere al oprimir el gatillo con mayor fuerza cuando el orificio tenga la profundidad suficiente para evitar

que la broca se salga.

TALADRADO EN METAL

Inicie la perforación a baja velocidad y vaya aumentándola a la potencia completa mientras aplica presión firme en la herramienta. El flujo uniforme y suave de rebabas indica que se taladra

a la velocidad adecuada. Emplee un lubricante para corte cuando taladre en metales. Las

excepciones son hierro el colado y el latón, que deben barrenarse en seco.

NOTA: Los barrenos grandes (5/6" a 1/2") en acero se pueden hacer con mayor facilidad si se

barrena un orificio piloto (5/32" a 3/16") primero.

TALADRADO EN MADERA

Inicie la perforación a baja velocidad y vaya aumentándola a la potencia completa mientras

aplica presión firme en la herramienta. Se puede perforar madera con las mismas brocas helicoidales que se utilizan para metal. Estas deben estar afiladas y deben sacarse frecuentemente para limpiarlas de virutas. Los trabajos susceptibles de astillarse deben respaldarse

con un bloque de madera.

TALADRADO EN MAMPOSTERÍA

Cuando taladre en mampostería, utilice brocas con punta de carburo de tungsteno, clasificadas para percusión, y asegúrese que la broca tenga filo. Utilice fuerza constante y firme en

la herramienta para taladrar con mayor efectividad. El flujo uniforme de polvo indica que la

velocidad de perforación es adecuada.

Portabrocas SDS (Fig. 5)

Para insertar la broca, introduzca el vástago aproximadamente 19 mm dentro del broquero y

gire ligeramente la broca hasta que se escuche un chasquido al quedar en posición. La broca

estará sujeta con firmeza.

Para sacar la broca, tire del collarín hacia atrás y retire la broca.

Mantenimiento

LIMPIEZA

Utilice únicamente jabón suave y un trapo húmedo para limpiar la herramienta. Nunca permita

que se introduzcan líquidos en la herramienta; nunca sumerja ninguna parte de la herramienta

en ningún líquido.

Se han usado baleros autolubricantes en la herramienta y no requiere de lubricación periódica.

En el remoto caso de que llegue a requerir servicio, lleve la herramienta a un centro de servicio autorizado.

Lubricación