Installation Manual

4520 South MacArthur Blvd

Oklahoma City, OK 73179

Ph. 405.680.5600 F. 405.680.9314

1

devincicaststone.com

1

Anatomy Of A Fireplace

2

Table of Contents

Shipping and Receiving Information ................................................. 4

Hearth .................................................................................................. 6

Filler Panels .......................................................................................... 10

Mantel ..................................................................................................14

Grouting ................................................................................................ 19

3

Shipping and Receiving

Receiving Shipment

The utmost care is taken at our factory to protect the integrity of our shipping crates and the fireplace

components within. In the event that the shipping container is damaged in transit you should be prepared

to capture photo documentation of the damaged container prior to signing for receipt of the shipment.

Please document-shipping damages such as forklift cuts and gouges as well as signs of the crate being

dropped on the driver’s delivery receipt and have the driver initial.

Uncrating Product

Within twenty-four (24) hours of signing for receipt of the fireplace, it must be uncrated and all contents

inspected for damage. During the uncrating process, care must be taken to protect the integrity of the

contents. Never stack the stone material upon each other without placing foam packing material

or plastic shims between them carefully. Should any damage be identified, De Vinci Cast Stone must

be notified via phone (405-680-9000) and or email (mail@devincicaststone.com) within that 24-hour

period. Such email notification must include photographic evidence of damage(s) along with photographs

of the crating and packing components. Should damages be identified, De Vinci Cast Stone will work with

the client in the most expeditious manner to bring resolution to the identified issue(s). While DeVinci will

work with the client to resolve any issues, DeVinci is not and will not accept liability except as set forth in

the terms of sale. DeVinici is not liable for any damage that results from delivery, unloading or unpacking.

DeVinci shall only be liable for damages which resulted from packing or crating.

Receipt of Shipment and Inspection of Contents

The shipping crate and contents are extremely heavy. Assure that appropriate equipment and personnel

are available to assist the shipping carrier with staging as well as breaking down its content for inspection.

DeVinci is not liable for damages that

occur because of delivery, unloading or

unpacking.

CAUTION

Here are pictures of how a typical

fireplace is packaged. When you receive

a crate and remove the top you will see

a bed of packaging foam. Under the

foam are the various pieces of stone

individually separated by foam material.

Never stack the stone material

upon each other without placing

foam packing material or

plastic shims between them

carefully.

4

They are also covered with plastic wrap to separate

the foam from the stone as well as ensure the foam

surrounds all sides of the stone inside the crate.

The crate is then shot with expanding foam to

secure all parts as one in a monolithic package.

Removing the packing foam takes some time and

requires some patience. It is advised to break out in

large chunks at a time and dispose of in a trash bag

to help keep the work area clean. Remember that

you have stone not far underneath and tools used

to cut and remove the foam can scar and chip the

underlying stone.

Inspecting Contents

De Vinci Cast Stone products are thoroughly inspected and carefully packaged for shipment. Care must be

taken during the unpacking process to assure that components do not strike one another causing chipping

or abrasion.

Whenever possible, we request that our customers continue to compile a photo journal during the

unpacking process for review by our shipping department in case of a claim.

• Carefullyremovetoppanelofpackingcrate.

• Locateandremovepackinglistforusewithinventoryingcratecontents.

• Carefullyremoveformedfoamprotectivepackagingassuringthatfireplacecomponentsdonotshift

striking one another.

CAUTION

• Removeallfireplacecomponentspositioningthemseparatelyonacleanandlevelsurface.(HEAVY)

• Inventoryallcratecontentsusingthepackinglist.

• Carefullyinspectallcontents.

• NotifyDeVinciCastStonewithintwenty-four(24)hoursofsigningforreceiptofshipmentat

Carefully remove packing crate sides as necessary during the inventory and inspection process

assuring that contents do not shift.

405-680-5600 or email mail@devincicaststone.com, should any deficiencies or damage(s) be identified.

DeVinci is not liable for any damges that occur because of delivery, unloading or upacking.

5

Installation

n preparation for the installation, assure that appropriate equipment and personnel are available to

assist during the installation process as some fireplace components are heavy and unwieldy; always wear

I

appropriate personal protective equipment.

Throughout the installation process, assure that components do not strike one another causing chipping or

abrasion by using the shims and packing foam provided or other similar material.

A very important aspect of your installation will be maintaining level. Any deviation from level throughout

the build will be magnified and can affect the aesthetics of the final product.

NOTE

De Vinci Cast Stone components may have some minor irregularities in thickness. Along with

the standard spacers provided to create proper grout spacing, additional plastic shim stock is

provided in two thicknesses that can be cut to size and added to spacers to maintain level. Assure

that the mounting surface is clean, level and capable of supporting the final product

weight.

6

Using a level to transfer the

centerline up the wall to

the intersecting point with

the final height on the wall.

Mark the line with a ‘C’.

Measure and mark the

centerline of your firebox for

reference. Measure to mark

the final height of your top

stone.

Find and lightly mark all studs

in the wall with your level, as

they will identify attaching

points during the install.

7

Hearth

Find and mark centerline of hearth.

sing a tape measure, determine the position of the hearth on the floor and mark its rough outline

in pencil. This will assist in applying the mastic more accurately later. Shim mounting surface as

U

Thin set or construction adhesive can be used as mastic during installation. If thin set is used it should be

mixed to the consistency of thick pancake batter and can be applied using a trowel or grout bag. Mastic

should be applied generously but must remain back from faces of fireplace surround at least ¾” to provide

space for grout.

necessary to gain appropriate base height and level side to side and front to back.

8

Apply a generous amount of mastic

to the mounting surface within the

outline previously drawn. Position

the hearth and compress the mastic

side-to-side, front to back until

you have achieved the appropriate

height and the centerline of the wall

is aligned with the centerline mark

of the hearth. Important: Check the

level of the hearth, as it will affect the

level of the remaining pieces.

NOTE

Wall brackets must always be located such that they will be completely covered by panels.

Drill pilot holes and attach the hearth

to the wall studs using angled wall

brackets (two places).

9

iller panels can be located at the bottom, sides and/or top of the fireplace opening. The installation depicted, uses all of these panels. Some on-site preparation is necessary prior to installation.

F

The following steps identify the preparation and installation procedures for filler panels.

Locateandmarkcenterof

bottom filler panel.

Filler Panels

Mark and drill pin placement holes in the

top of the bottom filler panel and bottom

of the side filler panels.

Pins are used to stabilize connection of

bottom to side filler panels.

10

Black spacers are normally used to provide the appropriate grout spacing but minor irregularities in level

are offset using the thin red spacer stock and the medium blue spacer stock. All panels should be dry set and

checked for level prior to permanent installation.

A grout bag can be used to apply mastic during installation of the filler panels. To prepare the grout bag,

cut the small end of the bag so that the opening is approximately 3/8” in diameter. Rinse the interior of the

bag with clean water to prevent sticking of the mastic. Fill the bag half to two-thirds full and twist top to

seal the bag. Squeeze to expel the mastic as needed.

Place two grout spacers on the hearth top adjacent to the back wall, aligning centerlines of hearth and dry

fit the bottom filler panel and apply additional shims as necessary to assure the panel is level.

Apply mastic and install

bottom filler panel.

Recheck centerline and level,

side to side and front to back,

and install wall brackets (two

places).

11

Insert mastic and stabilizer

pin in predrilled holes and

place grout spacers.

Dry fit right and left side filler

panels confirming individual

level of panels, side-to-side

and front to back, as well as

level across panels.

NOTE

Always position

shims within the

perimeter of the piece, making

certain they will never be

exposed to direct heat/flame

and that there is adequate

space for grout.

Apply mastic to both sides

of bottom filler panel, into

the predrilled hole on the

bottom of the side filler

panels, and install both side

filler panels while rechecking

all levels. Secure side filler

panels with wall brackets.

To help stabilize the piece,

apply mastic to the back of

the filler panel where it will

come in contact with the

wall.

12

Position grout spacers and

recheck for level across side

filler panels. (Add shims as

necessary to assure level)

Check that the top filler panel matches

side filler panels on both sides and check

it for level, side-to-side and front to

back. Install wall brackets (two places).

Apply mastic to top of both side filler

panels and position top filler panel.

Clean any extraneous mastic off of

installed panels. Wedges can be used

to level components front to back

during assembly.

13

rill holes (one each) in

bottom of each leg and

D

hearth for insertion of stabilizer

pins. Insert stabilizer pins,

position grout spacers and dry

fit both fireplace legs checking

for level front to back, side to

side and between legs. Using a

straight edge or string, assure

that top surface of legs is even

with the surface of filler panels

(if filler panels are used). Use

shims on grout spacers to level

legs.

matching holes in top of

Mantel

Insert mastic in hole in bottom of legs

and install legs.

Pins are used to stabilize connection of

bottom to the hearth.

14

Place grout spacers and dry

fit header checking for level

side to side and front to back

assuring that the header is

even with the top of legs.

Insert shims as necessary.

Recheck all levels and spacing

and install wall brackets on

each leg.

Apply mastic and install

header-rechecking level sideto-side and front to back.

Assure that top of header is

even with top of legs. Install

wall brackets (2 places).

15

This fireplace surround incorporates an accent shelf. In some styles, the accents, if any, are cast into the

mantel component(s).

All vertical joints and spaces between pieces of the surround (e.g. spaces between legs and header) that will

later become covered, or otherwise obstructed should be filled with mastic throughout the install. This will

reduce any chances for lateral movement.

Mark center at top front of

header and top and bottom

front of the center accent

shelf. Place grout spacers

on top of legs and header

and dry fit accent shelf

components. Use shims

as necessary to level accent

shelf components.

Apply mastic and install

accent shelf components. Use

two wall brackets on center

component, one wall bracket

on each side component, one

flat strap between center and

left component and one flat

strap between center and right

component.

16

Apply mastic and install

center mantel component

securing with wall brackets

on both sides.

Mark center on the front

bottom edge of the center

mantel component and dry fit

for level.

Predrill holes for stabilizer

pins in top of the right and

left accent shelf components

and matching holes in bottom

of the right and left mantle

components.

17

Insert mastic and stabilizer

pins in predrilled holes in

right and left accent shelves

and in predrilled holes of

bottom of right and left

mantle components. Apply

mastic to top of accent

shelves and install right and

left mantle components.

Recheck all levels and edges.

Insert stabilizer pins, place

grout spacers and dry fit right

and left mantle components.

Use shims as necessary

to level across all mantle

components

Clean up tools and mastic

containers and prepare to

grout.

18

Carefully tape both sides of areas to

be grouted.

Grouting

NOTE

When taping, set tape back

1/32” to 1/16” from opening

to provide a slight overlap.

This aids in ease of finishing

the grout lines. Added care

given to the taping process will

greatly enhance the finished

product.

CAUTION

Grout can stain floors,

walls and ceilings. Take

necessary precautions to

cover areas surrounding

the work space.

Once taping is complete,

apply drop cloths and

shielding to all surfaces

that might be stained by

grout.

19

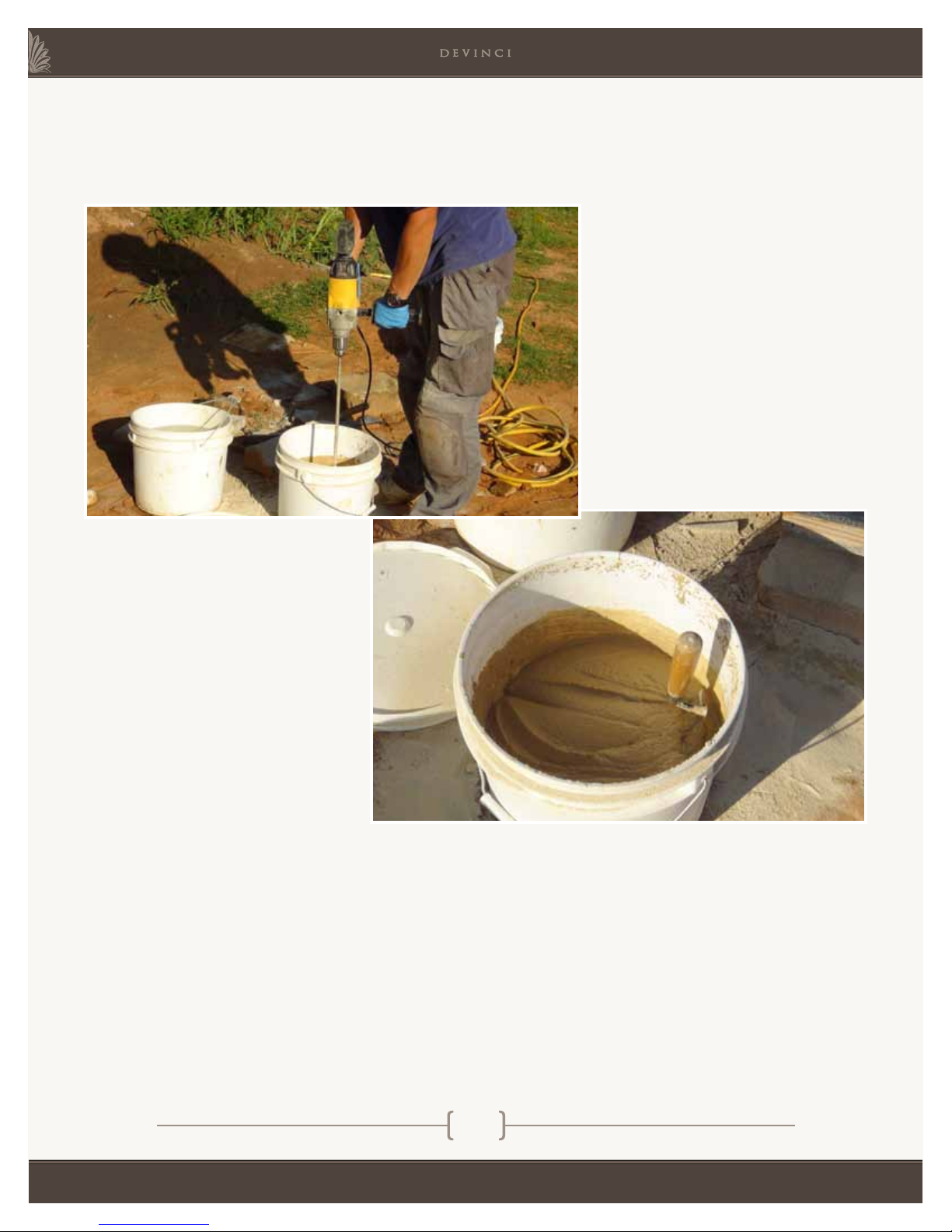

Prepare Grout

We provide a bottle of Polymer

Emulsiontobeaddedtothe

water at 8:1 ratio (8 parts water

to 1 part polymer). The additive

will help reduce shrinkage and

improve bonding properties.

Mix water into grout to

attain the desired consistency,

usually the consistency of thick

pancake batter.

grout bag should be used during the grouting process. To prepare the grout bag, cut the small end

of the bag so that the opening is approximately 3/8” in diameter. Rinse the interior of the bag with

A

the bag. The bag can be squeezed to expel the grout from the small end and the top twisted as necessary as

the contents are used. We cannot stress enough the importance of competent grouting.

clean water to prevent sticking of the grout. Fill the bag half to two-thirds full and twist top to seal

20

NOTE

It’s always good to have a

container of clean water and

sponge available for cleaning

up spatters throughout the

grouting process.

Begin grouting fireplace surround

from bottom, working up.

Fill grout joint liberally and

work first course back into joint

approximately ¼” to ½” with grout

knife or similar tool.

Apply second course of grout

leaving it standing out from the

joint.

Continue the two course

grouting method throughout.

21

Allow grout to set up until it provides resistance to slight finger pressure and grout does not transfer to

finger when touched.

Before shaving off the grout flush with the stone surface, press it into the joint with a pointing tool. The

blade of the tool should be flat and wider than the joint width and free of rust. A mastic trowel will do

perfectly. This helps reduce chances of the mortar cracking later on. The pressure applied pushes the

mortar farther into the joint and eliminates any unseen voids.

Use flat bladed tool to work

grout flush with tape. Once

flush, the joints can be tooled

smooth with a trowel or

rubbed with a piece of carpet.

A mildly damp sponge may be

used alternatively.

Remove tape, touching up minor

inconsistencies as you go with a

flat bladed tool.

22

CAUTION

Avoid cleaning the joints in a way one might do with freshly grouted tile. Too much water in

a wet sponge will expose the aggregate in the grout as well as smear the surface of the fireplace.

Mistakes will happen, but if a joint looks bad and messy it is sometimes better to clean it out,

wash the surface, and repoint it, rather than try to salvage the look with water.

A mildly damp sponge can

be used to remove minor

blemishes. Rinse sponge

frequently in clean water

container and wring out

excess water.

High grit sandpaper (120-200 grit) will help rub off minor

stains and blemishes that might have been missed during

the install. A gentle sanding can easily replace risky acid

washes. It is certainly a lot tidier.

Joints between the surround and the wall can be grouted

but hairline cracks should be expected to appear later where

the grout meets the wall. Caulking may be used to avoid

the hairline cracks.

Clean tools,

equipment

and work

area.

23

Loading...

Loading...