DeVillbiss Air Power Company Water Driver D28921, Water Driver WD1600E Operation Manual

Pressure Washer

Operation Manual

for model WD1600E

Part No. D28921 Rev. 0 3/17/03

IMPORTANT

Please make certain that the person who is to use this equipment

carefully reads and understands these instructions before operating.

Record All Information

for future reference:

Purchase Date:

Model #:

Serial #:

Questions? 1-800-888-2468

Learn more about your pressure

washer and register on line at

www

.devap.

com

2- ENG

D28921

1.0 SAFETY AND OPERATION RULES

INDEX

1.0 SAFETY AND OPERATION RULES . page 2

2.0 SAFETY FEATURES . . . . . . . . . . . . page 8

3.0 INSTALLATION . . . . . . . . . . . . . . . . page 9

3.1 HIGH PRESSURE HOSE . . . . . page 9

3.2 WATER CONNECTION . . . . . . . page 9

3.3 POWER SUPPLY

CONNECTION . . . . . . . . . . . . . page 9

4.0 OPERATING INSTRUCTIONS . . . . page 10

4.1 START-UP PROCEDURE . . . . page 10

4.2 HIGH PRESSURE/

LOW PRESSURE . . . . . . . . . . page 11

4.3 ADJUSTABLE SPRAY

NOZZLE . . . . . . . . . . . . . . . . page 12

4.4 HIGH PRESSURE/

TURBO SPRAY . . . . . . . . . . . page 12

4.5 USE OF CHEMICAL . . . . . . . . page 13

4.6 CLEANING TECHNIQUES . . . page 13

4.7 END OF OPERATION . . . . . . . page 14

5.0 USER MAINTENANCE . . . . . . . . . page 14

5.1 CONNECTIONS . . . . . . . . . . . page 14

5.2 NOZZLE . . . . . . . . . . . . . . . . . page 14

5.3 LUBRICATION . . . . . . . . . . . . page 15

5.4 WATER SCREEN . . . . . . . . . . page 15

5.5 COOLING SYSTEM . . . . . . . . page 15

6.0 MOVING AND STORAGE

INSTRUCTIONS . . . . . . . . . . . . . . page 15

6.1 AFTER EXTENDED STORAGE page 15

7.0 TROUBLESHOOTING . . . . . . . . . page 16

8.0 REPLACEMENT PARTS AND

ACCESSORIES . . . . . . . . . . . . . . page 18

9.0 TECHNICAL DATA . . . . . . . . . . . . page 18

Indicates an imminently

hazardous situation which,

if not avoided, will

result in death or

serious injury.

Indicates a potentially

hazardous situation which,

if not avoided, could result in death or

serious injury.

Indicates a potentially

hazardous situation which, if

not avoided, may

result in minor or

moderate injury.

Used without the safety alert

symbol indicates a

potentially hazardous situation which, if not

avoided, may result in pr

operty damage.

This manual contains information that is important for you to know and understand. This

information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT

PROBLEMS. To help you recognize this information, we use the symbols below. Please

read the manual and pay attention to these symbols.

Read Operation Manual. Do not operate equipment until you have

read Operation Manual for Safety, Assembly, Operation, and Mainte-

nance Instructions.

3- ENG

D28921

• Water spray directed at electrical outlets or

switches, or objects connected to an electrical

circuit, could result in a fatal electrical shock.

• Unplug any electrically operated product before

attempting to clean it. Direct spray away from

electric outlets and switches.

• This product is powered by electricity. It contains

and sprays water and other conductive liquids.

Improper operation could result in electrocution.

• The Ground Fault Circuit Interrupter (GFCI) will

not function properly unless connected to a

fully grounded electrical circuit!

• Extension cords can lead to electrical shock.

• Always connect cordset to a properly

grounded and polarized electrical circuit. Your

cordset is equipped with a Gr

ound Fault Circuit

Interrupter (GFCI) for your personal

protection.

• Do not touch plug or outlet with wet hands

• If damaged, the entire cordset assembly must be

replaced by an authorized service center. Refer

to Grounding Instructions.

• Do not use with extension cords.

RISK OF

ELECTRICAL SHOCK

DANGER

WHAT CAN HAPPEN

HOW TO PREVENT IT

• Some cleaning fluids contain substances which

could cause injury to skin, eyes, or lungs.

• Use only cleaning fluids specifically recom-

mended for high pressure washers. Follow

manufacturers recommendations. Do not use

chlorine bleach or any other corrosive

compound.

RISK OF EXPLOSION OR FIRE

DANGER

WHAT CAN HAPPEN

HOW TO PREVENT IT

Do not use acids, gasoline, kerosene, or any other

flammable materials in this product. Use only

household detergents, cleaners, and degreasers

recommended for use in Pressure Washers. Work

in a well ventilated area.

Use of acids, unapproved chemicals, or flammable

solvents with this product could cause injury or

death.

Restricting any of the pressure washer

ventilation openings will cause serious

overheating and could cause fire.

Never place objects against or on top of

pressure washer. Operate pressure washer in

an open area at least 12 inches away from any

wall or obstruction that would restrict the flow of

fresh air to the ventilation openings.

RISK TO BREATHING

DANGER

WHAT CAN HAPPEN

HOW TO PREVENT IT

4- ENG

D28921

• Your washer operates at fluid pressures and

velocities high enough to penetrate human and

animal flesh, which could result in amputation or

other serious injury. Leaks caused by loose fittings

or worn or damaged hoses can result in injection

injuries. DO NOT TREAT FLUID INJECTION AS A

SIMPLE CUT! See a physician immediately!

RISK TO FLUID INJECTION

DANGER

WHAT CAN HAPPEN

HOW TO PREVENT IT

• Injuries can result if system pressure is not

reduced before attempting maintenance or

disassembly.

• To relieve system pressure, place on/off switch in

off position, turn off water supply, and pull gun

trigger until water stops flowing.

• Use only hose and high pressure accessories

rated for pressure higher than your pressure

washer's p.s.i.

• Never place hands in front of nozzle.

• Do not direct discharge stream at persons or

animals.

• Make sure hose and fittings are tightened and in

good condition. Never hold onto the hose or

fittings during operation.

• Do not operate pressure washer with worn or a

braided hose.

• Never attach or remove wand or hose fittings

while system is pressurized.

RISK OF

CHEMICAL

BURN

DANGER

WHAT CAN HAPPEN

HOW TO PREVENT IT

• Do not use acids, gasoline, kerosene, or any

other flammable materials in this product. Use

only household detergents, cleaners and

degreasers recommended for use in pressure

washers.

• Wear protective clothing to protect eyes and

skin from contact with sprayed materials.

• Use of acids, toxic or corrosive chemicals,

poisons, insecticides, or any kind of flammable solvent with this product could result in

serious injury or death.

• Unsafe operation of your pressure washer

could lead to serious injury or death to you or

others.

• Do not use chlorine bleach or any other

corrosive compound.

• Become familiar with the operation and controls of the pressure washer.

• Keep operating area clear of all persons,

pets, and obstacles.

• Do not operate the product when fatigued or

under the influence of alcohol or drugs. Stay

alert at all times.

• Never defeat the safety features of this product.

• Never leave wand unattended while unit is

running.

• Know how to stop product and bleed

pressure quickly.

RISK OF UNSAFE OPERATION

WHAT CAN HAPPEN

HOW TO PREVENT IT

DANGER

5- ENG

D28921

• Reactive force of spray will cause gun/wand to

move, and could cause the operator to slip or

fall, or misdirect the spray. Improper control of

gun/wand can result in injuries to self and

others.

• Do not overreach or stand on an unstable

support. Grip gun/wand firmly with both

hands. Expect the gun to kick when triggered.

• The spray gun/wand is a powerful cleaning

tool that could look like a toy to a child.

• Keep children away from the pressure

washer at all times.

• Unsafe operation of your pressure washer

could lead to serious injury or death to you or

others.

• Avoid accidental starts. Move switch on unit to

"OFF" position before connecting or

disconnecting cord to electrical outlets.

• Never carry your pressure washer by the cord.

Do not pull on the cord to disconnect from the

outlet.

• To prevent damage, the cord should not be

crushed, placed next to sharp objects or near a

heat source.

• Disconnect power plug from the outlet when not

in use and prior to the detaching of the high

pressure hose.

• Never tie knots or kink the high pressure hose as

damage could result.

• Prior to starting the pressure washer in cold

weather, be sure ice has not formed in any part

of the equipment.

• To minimize the amount of water getting into the

pressure washer, the unit should be placed as far

as possible from the cleaning site during

operation.

• Pressure washer pump contains moving parts.

Contact with moving parts can cause serious

injury.

• Never operate machine with pump guard

removed.

• Do not operate machine with missing,

broken, or unauthorized parts.

• Contact with hot surfaces could result in serious burn.

• During operation, touch only the control

surfaces of the pressure washer. Keep children

away from the pressure washer at all times.

They may not be able to recognize the hazards

of this product.

RISK OF UNSAFE OPERATION

WHAT CAN HAPPEN

HOW TO PREVENT IT

RISK OF HOT

SURFACES

DANGER

WHAT CAN HAPPEN

HOW TO PREVENT IT

DANGER

6- ENG

D28921

GROUNDING INSTRUCTIONS

This product must be grounded. If it should malfunction or breakdown, grounding provides a path of

least resistance for electric current to reduce the risk of electric shock. This product is equipped with

a cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed and grounded in accordance with all local codes

and ordinances.

Improper connection of the equipment-grounding conductor can result in a

risk of electrocution. Check with a qualified electrician or service person if

you are in doubt as to whether the outlet is properly grounded. Do not modify the plug

provided with the product - if it will not fit the outlet installed by a qualified electrician. Do

not use any type of adapter with this product.

DANGER

The powerful spray from your pressure washer is capable of causing damage

to surfaces such as wood, glass, automobile paint, auto striping and trim, and

delicate objects such as flowers and shrubs. Before spraying, check the item to be cleaned to

assure yourself that it is strong enough to resist damage from the force of the spray. Avoid the

use of the concentrated spray stream except for very strong surfaces like concrete and steel.

SAVE THESE INSTRUCTIONS

• High velocity fluid spray can cause objects to

break, propelling particles at high speed.

• Light or unsecured objects can become

hazardous projectiles.

RISK OF INJURY FROM SPRAY

WHAT CAN HAPPEN

HOW TO PREVENT IT

• Always wear ANSI approved Z87 safety

glasses.Wear protective clothing to protect

against accidental spraying.

• Never point wand at, or spray people or

animals.

• Always secure trigger lock when wand is not in

service to prevent accidental operation.

• Never permanently secure trigger in pull back

(open) position.

7- ENG

D28921

PARTS DRAWING

PARTS LIST

1 Wand with Rotary Nozzle Head

2 Spray Gun

3 High-Pressure Hose

4 Holder For High-Pressure Hose

5 ON/OFF Switch

6 High-Pressure Hose Connector

7 Threaded Water Inlet

8 Wand with Variable Nozzle Head

9 Holder for Accessories

10 Screw (Chemical Solution Reservoir)

11 Electrical GFCI Plug

12 Water Plug

13 Screen Filter

14 Garden Hose Inlet Nipple with Quick Connector

15 Chemical Solution Reservoir

16 Holder for Power Cable

8- ENG

D28921

2.0 SAFETY FEATURES

The pressure washer is equipped with a stop device which will sense when the trigger on the gun

is released. It will open the power circuit to the motor and cause the pressure washer to stop.

The pressure washer is also equipped with a main power ON/OFF switch

located on the unit. It should always be moved to the off position when the

pressure washer is not being used to prevent possible injury or damage.

MOTOR OVERLOAD

The electric motor in this pressure washer is equipped with an overload protection device which

will automatically shut off the motor in the event the motor draws excessive current or overheats.

The device will automatically reset itself and resume normal operation after a short period of time.

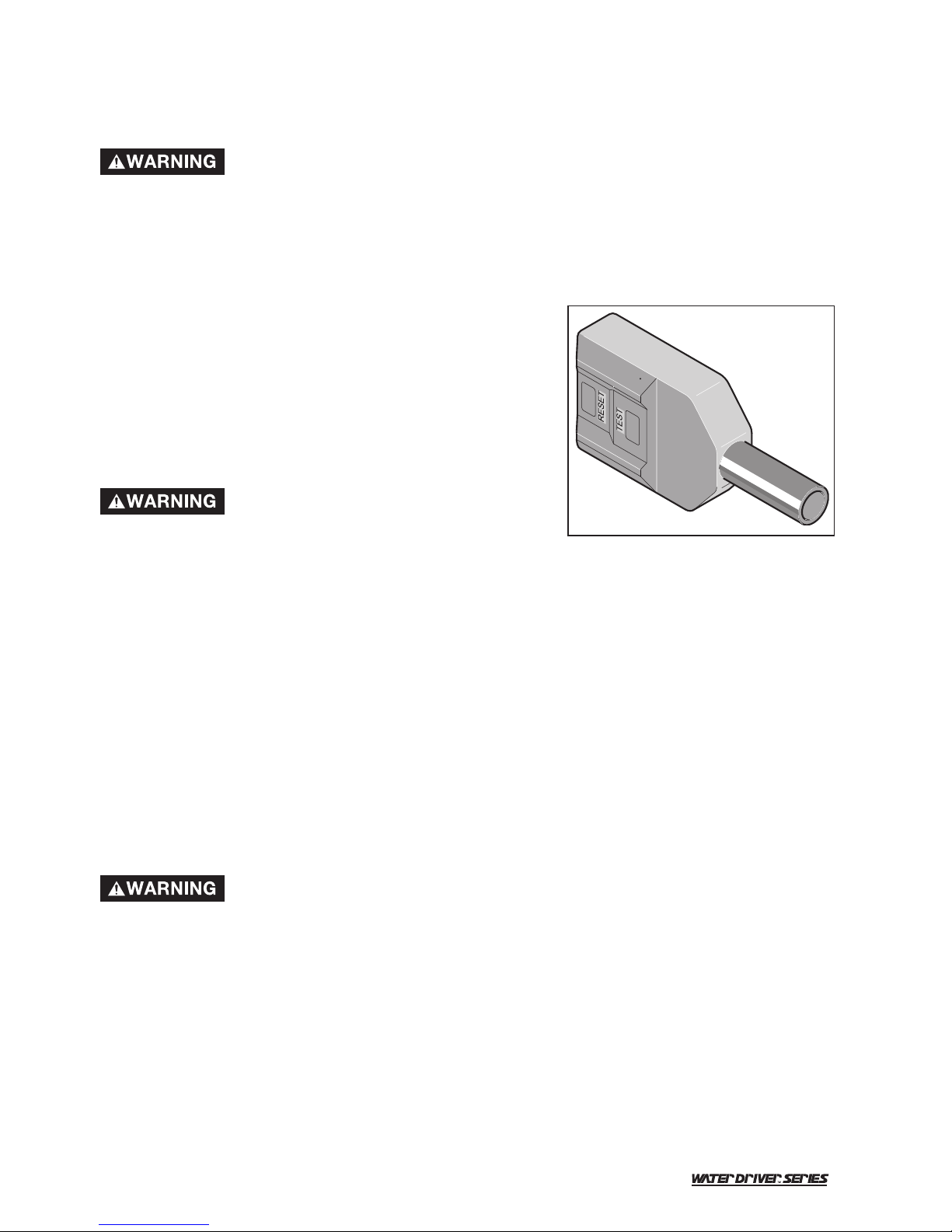

GROUND-FAULT CIRCUIT-INTERRUPTER PROTECTION

This pressure washer is provided with a ground-fault circuitinterrupter (GFCI) built into the plug of the power supply cord.

This device provides additional protection from the risk of

electric shock. Should replacement of the plug or cord

become necessary, use only identical replacement parts that

include GFCI protection.

EXTENSION CORDS

extension cords are not recommended

unless they are plugged into a groundfault circuit-interrupter found in circuit boxes or protected

receptacles.

Use only 3-wire extension cords that have 3-prong grounding-type plugs and 3-pole cord

connectors that accept the plug from the product.

Use only extension cords that are intended for outdoor use. These extension cords are identified

by a marking “Acceptable for use with outdoor appliances; store indoors while not in use”.

Use only extension cords having an electrical rating higher than the rating of the product.

Do not use damaged extension cords. Examine extension cord before using and replace if

damaged.

Do not abuse extension cord and do not yank on any cord to disconnect. Keep cord away from

heat and sharp edges. Always disconnect the extension cord from the receptacle before

disconnecting the product from the extension cord.

When using an extension cord, observe the specification below:

Cable Length Wire Gauge

Up to 50 ft. 14 AWG

50 to 100 ft. 12 AWG

To reduce the risk of electrocution, keep all connections dry and off the

ground. Do not touch plug with wet hands.

9- ENG

D28921

3.3 POWER SUPPLY CONNECTION

The pressure washer is factory-equipped with an electrical cord and a Ground Fault Circuit

Interrupter (GFCI) power plug.

This cord should only be connected to an electrical outlet installed in accordance with local safety

regulations.

NOTE: The power supply must be 120v, 60hz and a minimum 15 amp circuit.

Test GFCI before each use. DO NOT use pressure washer if test below fails.

GFCI Test Procedures:

1. Plug GFCI into power receptacle

2. Press reset button

3. Press test button.

4. Press reset button again for use.

NOTE: The GFCI must be reset each time the pressure washer is connected to an electrical outlet.

Reset by simply pushing the reset button on the GFCI power plug.

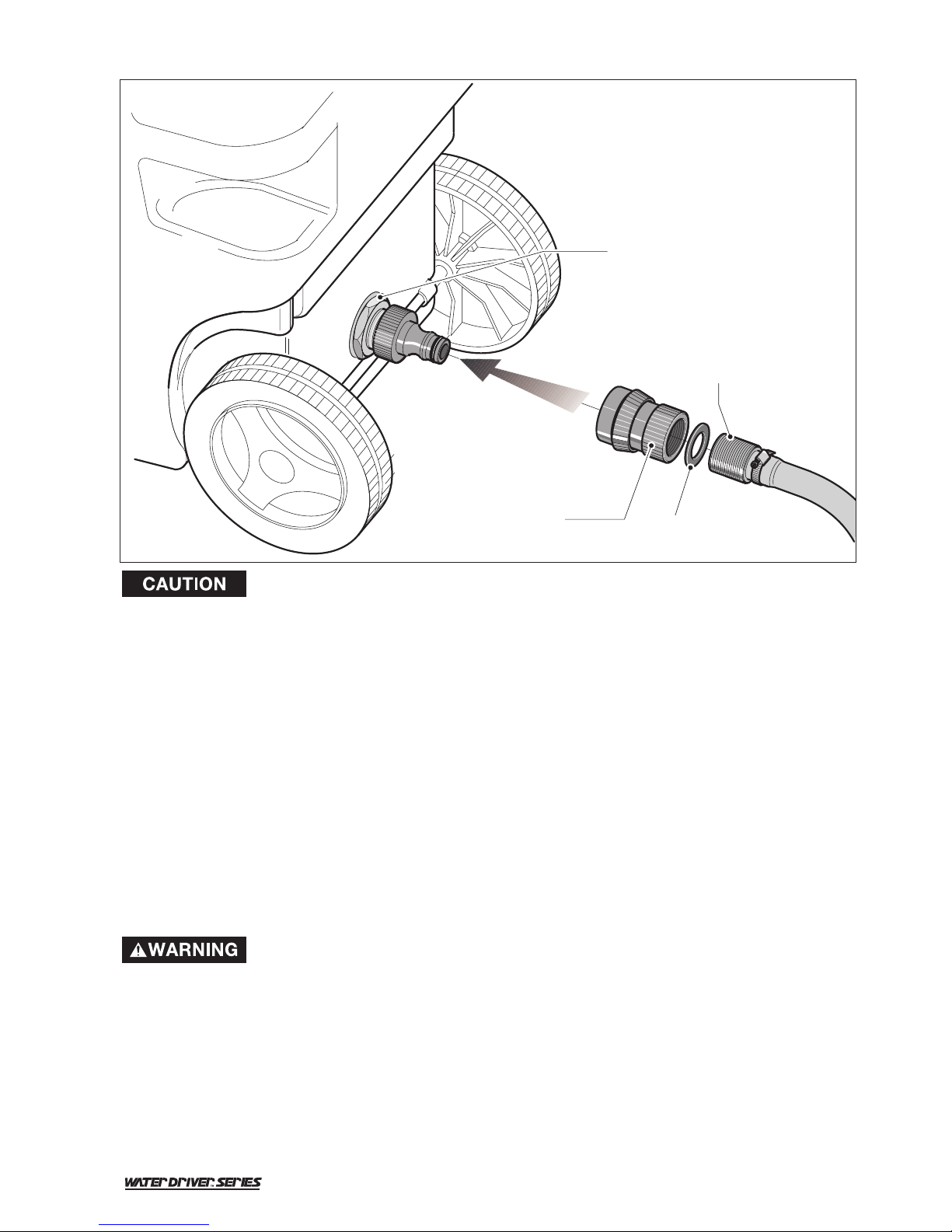

WATER CONNECTION

Proper water connection.

3.0 INSTALLATION

3.1 HIGH PRESSURE HOSE

Remove and discard the water plug (12 parts list) before attaching the high pressure hose by

carefully inserting the fitting with the o-ring into the high pressure outlet and tighten the threaded

nut by hand.

3.2 WATER CONNECTION

Before connecting, run water through the garden hose (not supplied) to flush out any foreign

matter. Attach garden hose to the pressure washer water inlet connection.

Fig. 1

Machine Inlet

Quick Connector

Garden Hose

Gasket

10- ENG

D28921

A. Connect only to properly grounded outlet. Do not remove grounding pin.

B. Inspect cord before using. Do not use if cord is damaged.

C. Keep all connections dry and off the ground.

D. Do not touch plug with wet hands.

E. The pressure washer is provided with a ground-fault circuit interrupter built into the power

plug. If replacement of the plug or cord is needed, use only identical replacement parts.

Contact Customer Service for proper replacement parts.

Extension cords are not recommended unless they are plugged into a receptacle protected by a

ground fault circuit interrupter. Any extension cord used should be 14 AWG and no longer than 50

feet to prevent excessive voltage loss. Use only extension cords intended for outdoor use. These

extension cords are identified by a marking “Acceptable for use with outdoor appliances; store

indoors when not in use”.

4.1 START-UP PROCEDURE

1. Make sure water supply is connected and turned on.

2. Make sure the unit is plugged in and the GFCI HAS BEEN RESET.

3. Release gun safety if locked.

4.0 OPERATING INSTRUCTIONS

Risk of injection or injury. Do not direct discharge stream at persons.

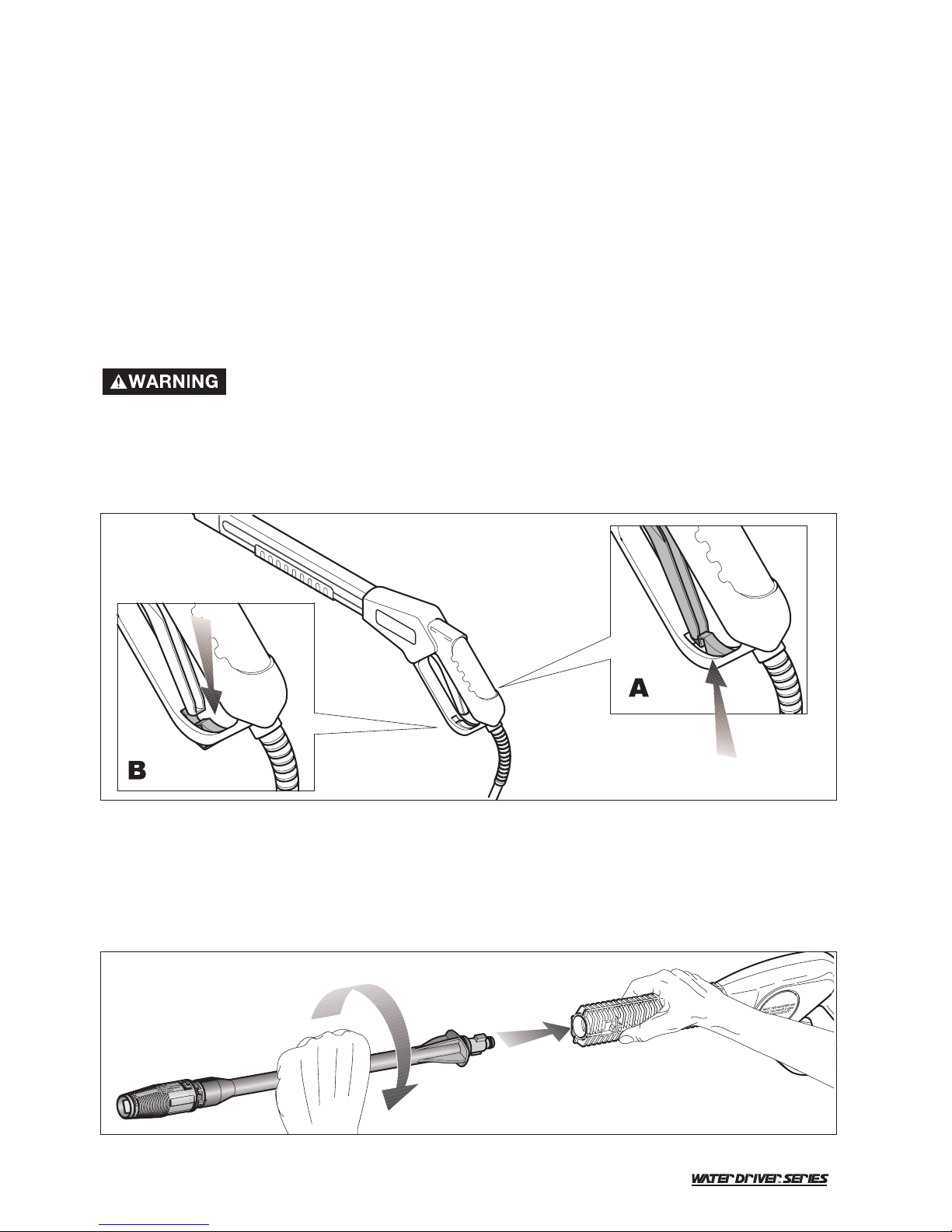

A. Safety lock “locked”

B. Safety lock “unlocked”

4. To allow air to escape from the hose, squeeze trigger on the gun until there is a steady stream

of water.

5. Remove any dirt or foreign matter from the gun outlet and the male connector of the wand.

6. Insert the requested wand into the gun’s quick connect coupling by pushing firmly and twisting

wand ¼ of a turn to lock into place.

NOTE: Make sure wand is locked.

11- ENG

D28921

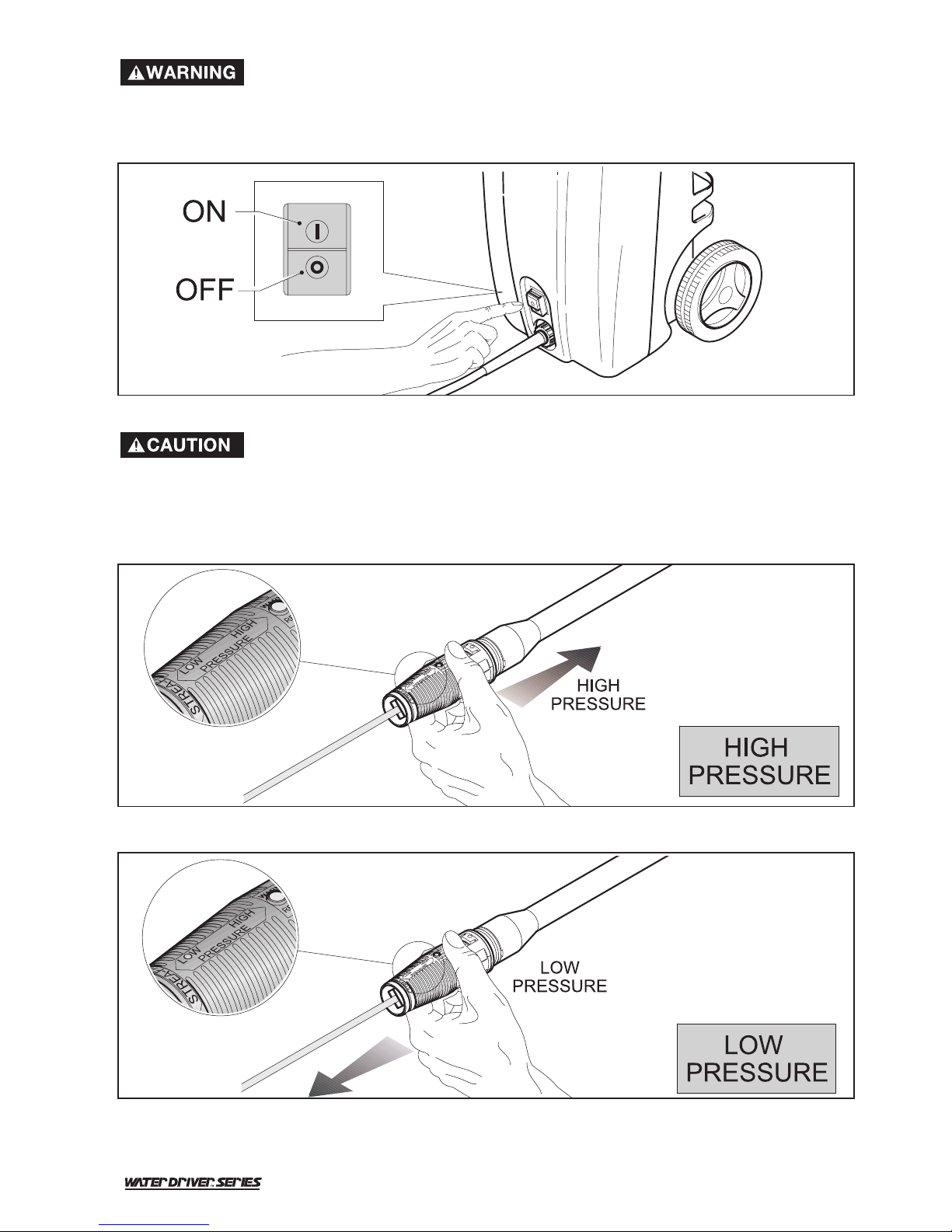

7 Squeeze trigger on the spray gun

8 Press the on/off button to start pressure washer

if the wand is not securely locked into place, it could be ejected under

high pressure when operating the gun, possibly causing injury or damage.

When low-pressure is required, grasp collar and slide collar and nozzle away from the gun.

4.2 HIGH PRESSURE/LOW PRESSURE

Do not move the nozzle to adjust pressure while the trigger is squeezed.

The high pressure nozzle position is intended for cleaning. When high pressure is required, grasp

collar and slide the collar and nozzle toward the gun.

NOTE: Make sure the collar is pulled to the extreme rear position to lock the nozzle in the high

pressure position.

12- ENG

D28921

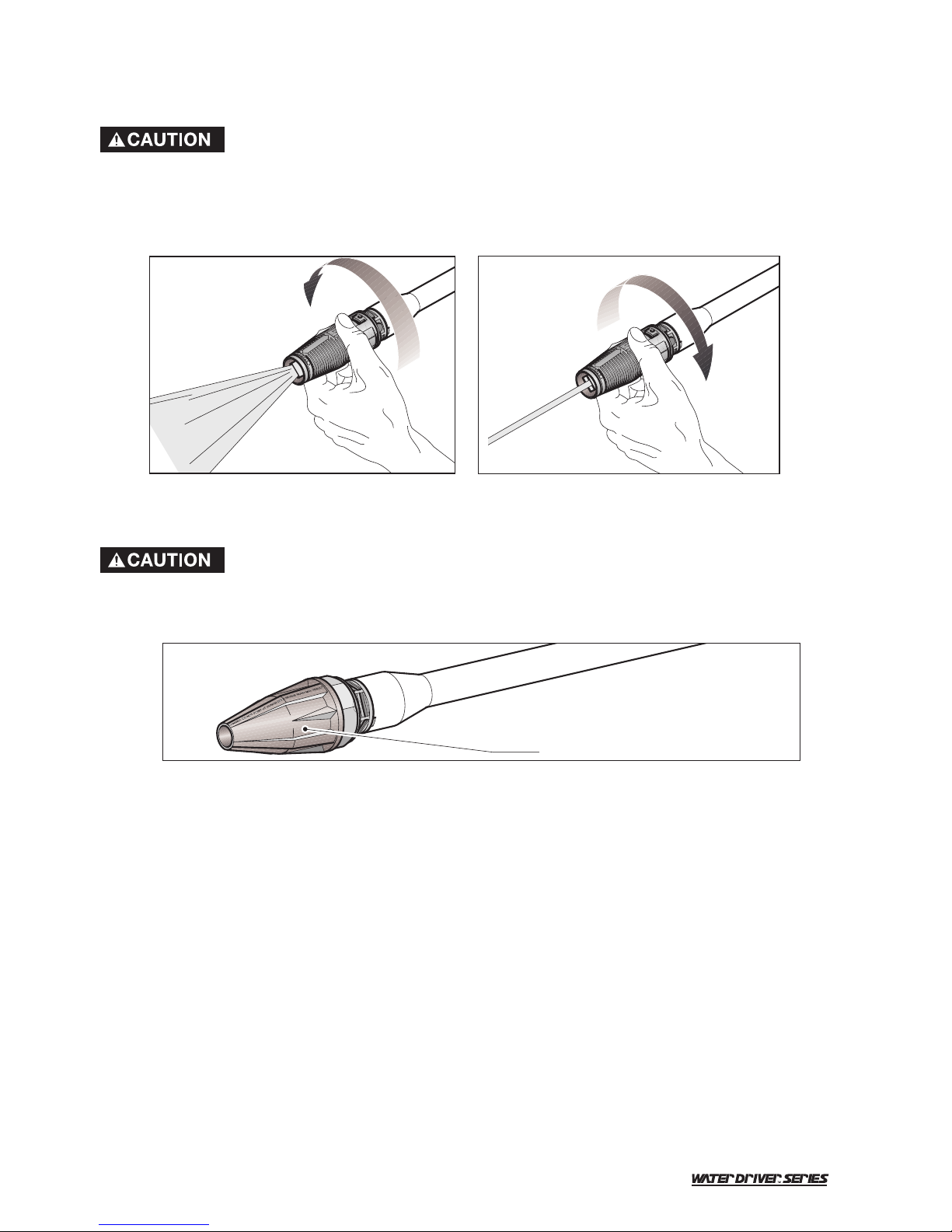

4.3 ADJUSTABLE SPRAY NOZZLE

The adjustable spray nozzle can adjust spray from fan to pencil point in both the high and low

pressure positions. The spray is adjusted by turning the nozzle.

The pencil point spray adjustment is very aggressive. We recommend that

for most cleaning applications, a twenty degree (20°) spray angle be used

to avoid damage to the surface being sprayed.

NOTE: The pressure of the spray on the surface you are cleaning increases as you move the wand

closer to the surface.

To increase angle to a fan spray, turn counterclockwise

To decrease angle to pencil point spray, turn clockwise

4.4 HIGH PRESSURE/TURBO SPRAY

Do not move the nozzle to adjust pressure.

The high pressure rotary nozzle position is intended for maximum cleaning effect. Keep the spray

lance min. 6” to 8” away from the cleaning surface at all times.

Rotary Spray

13- ENG

D28921

4.6 CLEANING TECHNIQUES

When cleaning with the pressure washer, some cleaning tasks can be solved with water alone, but

for most tasks it is advantageous to use a detergent. A detergent ensures a quick soaking of the

dirt allowing the high pressure water to penetrate and remove the dirt more effectively.

The low pressure position provides a gentle application of chemicals. This position is also

recommended to rinse a surface after wax application or for other applications which require the

low pressure of a garden hose. Low pressure is the equivalent of a garden hose set at the lowest

output to properly apply chemical. FOR CHEMICAL APPLICATION, SLIDE COLLAR ACCORDING

TO SECTION 4.2.

4.5 USE OF CLEANING CHEMICALS

only use cleaning chemicals recommended for pressure washers.

1 Insert the relevant suction tube (2) beneath the chemical solution reservoir.

2 Fill the reservoir (1) with suitable cleaning solution.

3 Insert the chemical solution reservoir into the relative compartment in the rear part of the

machine

4 Secure the chemical solution reservoir with the screw provided

5 Move the adjustable nozzle forward to the low pressure position by sliding collar toward the

nozzle. The chemical will automatically be mixed with the water and discharged through the

nozzle.

NOTE: When the adjustable nozzle is moved to the high pressure position, chemical will not be

discharged.

APPLICATION OF SOAP DEGREASER

1. Apply the solution to a DRY work surface. NOTE: WETTING THE SURFACE FIRST IS NOT

RECOMMENDED, AS IT DILUTES THE DETERGENT AND REDUCES ITS CLEANING ABILITY.

On a vertical surface, apply horizontally from side to side starting from the bottom to avoid

streaking.

2. Allow chemical to remain on the surface for a short time before rinsing

Damage may occur to painted surface if chemical is allowed to dry on the

surface. Wash and rinse a small section at a time. Avoid working on hot

surfaces or in direct sunlight.

3. Rinse with clean water under high pressure. On a vertical surface, first rinse from the bottom

up, then rinse from the top down. Hold nozzle 6 to 8 inches from the work surface at a 45°

angle using the flat spray as a peeling tool rather than a scrub brush.

NOTE: Insure that the chemical injection system is completely clean prior to switching from one

chemical to another.

14- ENG

D28921

APPLICATION OF LIQUID VEHICLE WAX

1. Immediately after cleaning, apply Pressure Washer Liquid Vehicle Wax using low pressure.

Pour wax into chemical solution reservoir.

2. Apply the wax sparingly in an even layer. Apply to wet surfaces from the bottom up for even

distribution and to avoid streaking.

3. Rinse off the surplus wax. NOTE – IF SURPLUS WAX IS NOT REMOVED, A HAZY FINISH

MAY RESULT.

4. Wipe dry to reduce water spotting.

4.7 END OF OPERATION

When you have completed use of the chemical injection system, remove tube from container,

continue to run in low pressure position and flush clean water through the chemical tank until it is

thoroughly cleaned. NOTE: Failure to clean properly will cause the injection system to become

clogged and inoperable.

l Stop the unit by pressing the ON/OFF button to the "OFF" position.

l Disconnect electrical plug.

l Turn off water and depressurize unit by squeezing trigger.

Turn off water supply and squeeze trigger to depressurize the unit. Failure

to do so could result in personal injury due to discharge of high pressure

water.

l Disconnect the high pressure discharge hose and the water inlet hose.

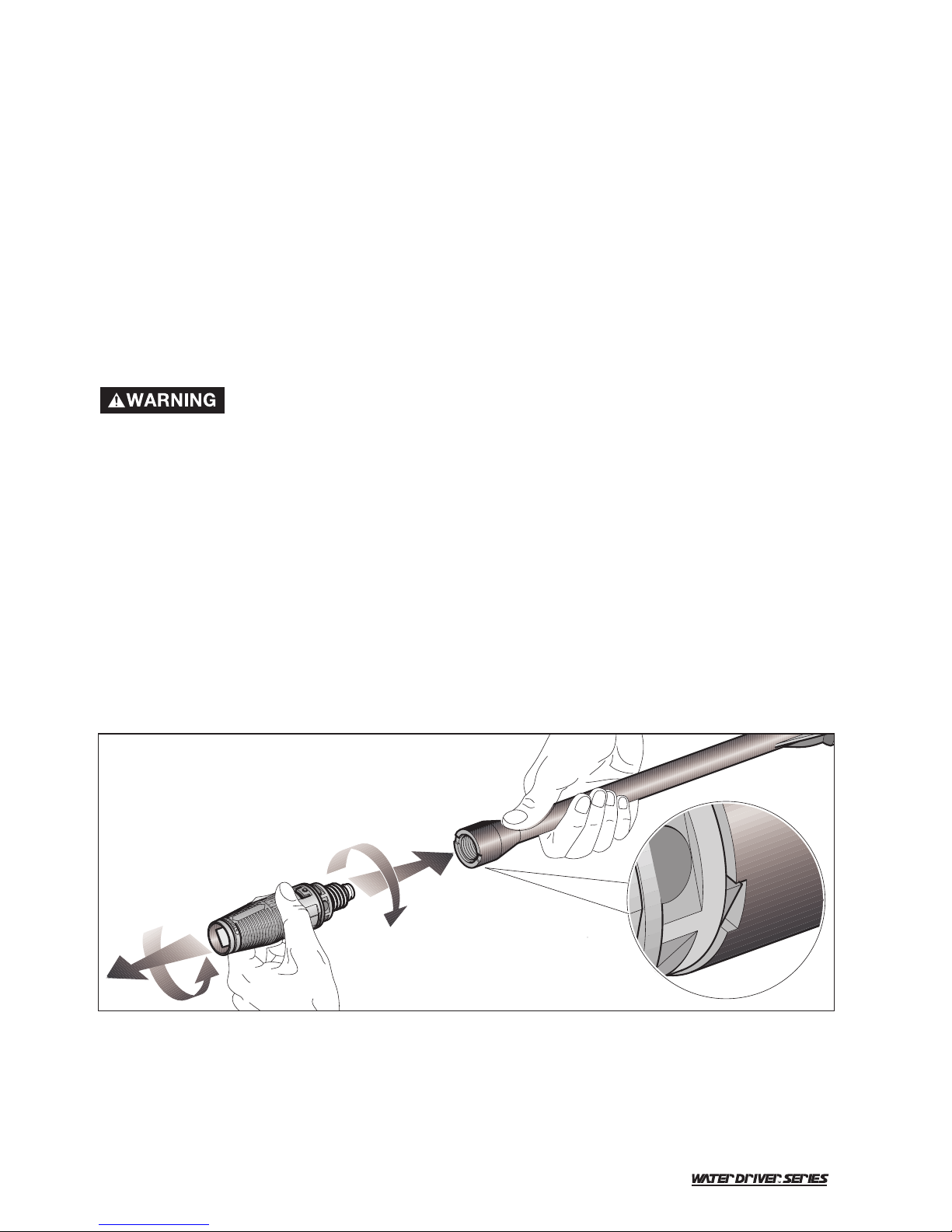

5.2 NOZZLE

The high pressure/low pressure adjustment of the nozzle should be lubricated regularly.

Clogging of the nozzle causes the pump pressure to be too high and cleaning is immediately

required.

1. Separate the nozzle from the wand

2. Clear the nozzle.

5.0 MAINTENANCE

5.1 CONNECTIONS

Connections on Pressure Washer hoses, gun and spray wand should be cleaned regularly and

lubricated to prevent leakage and damage to the o-rings.

3. Flush the nozzle backwards with water

4. Reconnect the nozzle to the wand

NOTE: Completely screw the nozzles on the wand up to the complete lock. (see picture)

Restart the pressure washer and depress the trigger on the spray gun. If the pressure is still too

high, repeat above items 1-4.

15- ENG

D28921

6.0 MOVING AND STORAGE INSTRUCTIONS

Always store your pressure washer in a location where the temperature will

not fall below 32°F. The pump in this machine is susceptible to permanent

damage if frozen. FREEZE DAMAGE IS NOT COVERED BY THE WARRANTY.

If you must store your pressure washer in a location where the temperature is below 32°F, you can

minimize the chance of damage to your machine by utilizing the following procedure:

1. Stop the pressure washer and detach supply hose and high pressure hose.

2. Squeeze the trigger of the discharge gun to drain all water from the wand and hose.

3. Restart the pressure washer and let it run briefly (about 5 seconds) until water no longer

discharges from the high pressure outlet.

6.1 AFTER EXTENDED STORAGE

Scale deposits may form in the pump when it is not used for some time.

This causes the motor to run stiff or it may not start up at all.

Remove scale deposits from the piping.

l Connect machine to water supply and rinse thoroughly with water. Do not plug unit into

electrical outlet.

To avoid electrical overloading turn the motor shaft by hand.

5.4 WATER SCREEN

The pressure washer is equipped with a water inlet screen to protect the pump.

If the screen is not kept clean, the flow of water to the pressure washer will

be restricted and the pump may be damaged.

5.3 LUBRICATION

The pressure washer is designed with a permanent lubrication system. Conventional oil check and

oil changes are not necessary.

NOTE: IN CASE OF OIL LEAKAGE, CONTACT CUSTOMER SERVICE DEPARTMENT

CONCERNING REPAIR. A SMALL AMOUNT OF OIL LEAKAGE IS NORMAL.

l To clean inner water screen, remove quick connect and remove the filter screen from the

pump inlet. (see page 4, item 13)

l Backflush screen to clean

l Replace screen and quick connect immediately to prevent any foreign matter from entering the

pump.

Do not damage the screen while removing or cleaning. Any foreign

particles entering the pump may damage the pump.

5.5 COOLING SYSTEM

The air vents, located in and around the pressure washer, must be kept clean and free of any

obstructions to ensure proper air cooling of the motor during operation.

prevent water from penetrating the vents of the pressure washer to

minimize the risk of damage to the machine and to reduce the risk of shock

to the operator.

16- ENG

D28921

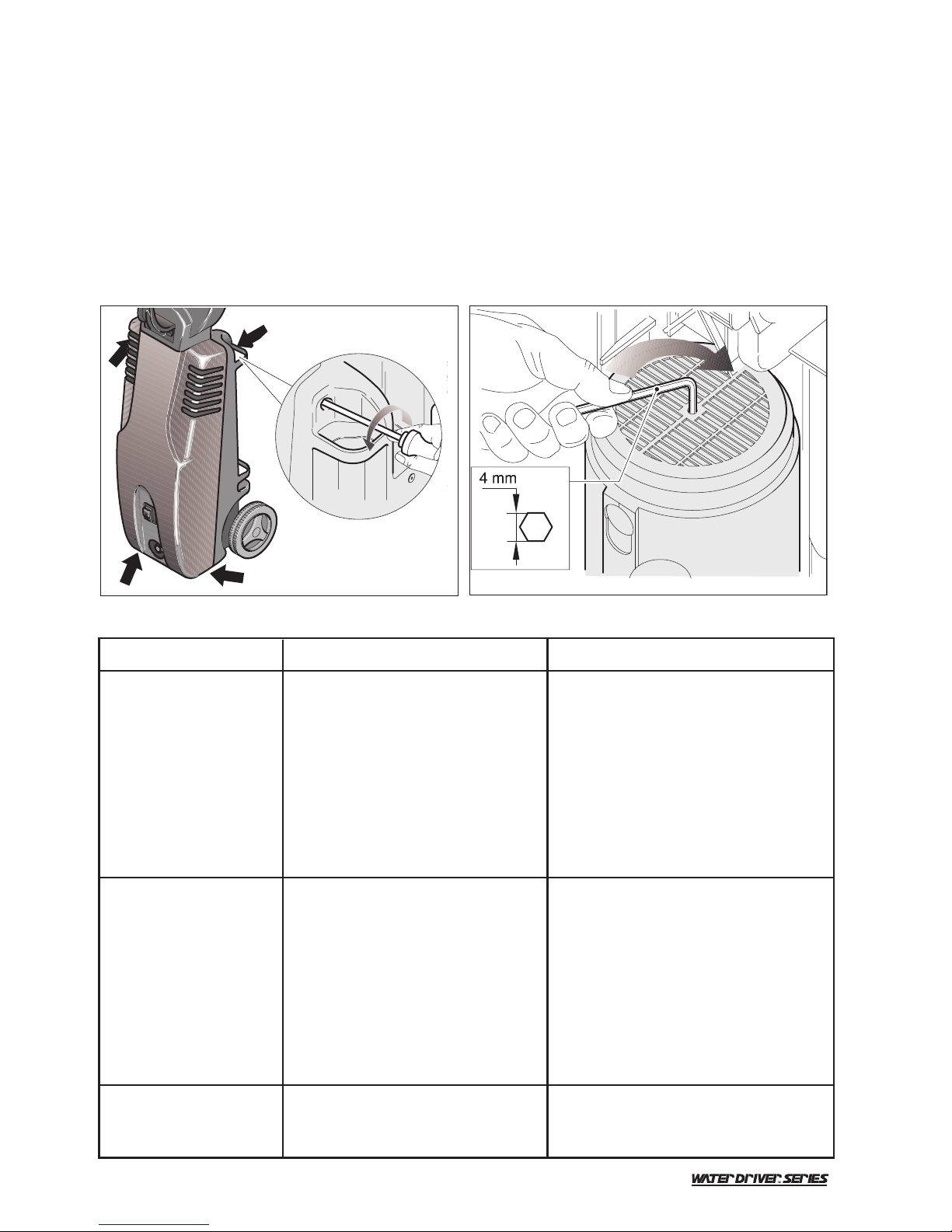

7.0 TROUBLESHOOTING

Proceed as follows:

l Disconnect unit from electrical outlet.

l Remove cover (Fig. A)

l Insert a suitable hexagon socket wrench (size 4 mm.) through the middle opening in the fan

cover and into the hexagon socket in the motor shaft.

l Turn the motor shaft clockwise by hand several times (Fig. B)

l Remove hexagon socket wrench

l Install cover

l Plug unit into electrical outlet

l Switch on machine with spray gun open.

Fig. A

Fig. b

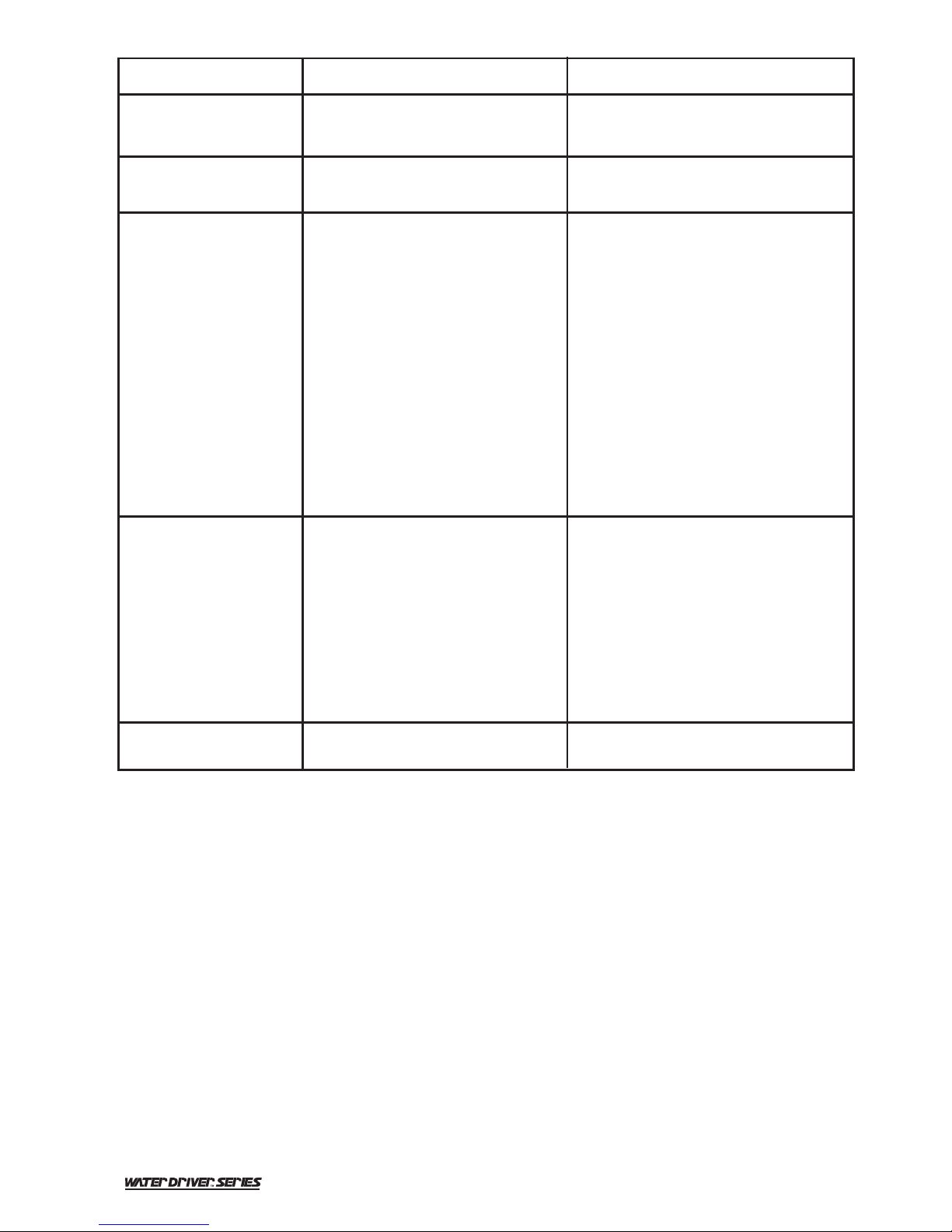

Motor will not start or

stops while operating

GFCI tripped or not reset Turn off unit. Press GFCI reset

button firmly after it has been

connected to the electrical supply

Circuit breaker tripped or fuse

blown in circuit fuse box

Disconnect all other loads on the

same circuit and reset circuit breaker

or replace fuse

Loose or disconnected plug Reconnect plug

Tripped pressure washer

circuit breaker

Allow to cool and restart unit

Circuit breaker trips or

fuse blown in fuse box

Circuit Overload Check that the circuit is rated 15

amps or greater. Disconnect all

loads on the circuit

Extension cord too long or

wire size too small

Use proper extension cord as

recommended in Operator's Manual

Nozzle partially blocked

Clean nozzle as instructed in

Section 5.2

Excessive pressure

Reduce pressure by using pressure

adjustment knob

GFCI trips repeatedly

Incorrect voltage See Section 3.3

Internal short Call Customer Service Department

PROBLEM

POSSIBLE CAUSE

CORRECTION

17- ENG

D28921

Water or oil leaking

from bottom of pump

A small amount of leakage is

normal

If excessive leaking occurs call

Customer Service Department

Bypass valve not operating

properly

Call Customer Service Department

Faucet closed

Open faucet

Unit has been stored in freezing

temperatures

Thaw out unit completely including

hose, gun, and wand

No intake of chemicals

Injection tube not securely

inserted into pressure washer

Push firmly into machine

Tube cracked or split Replace tubing

Pressure increases

when gun is closed

Motor running but

pump not building

maximum pressure or

has irregular pressure

Water inlet screen clogged

Clean screen. See section 5.4

Air in pump

Let pressure washer run with gun

open and wand removed until

steady stream of water is released.

Adjustable pressure knob not

set to maximum position

Set to maximum position. See

Section 4.2

Suction or discharge valves

clogged or worn out

Call Customer Service Department

By-pass valve not operating

effectively

Call Customer Service Department

Wrong Nozzle setting Switch nozzle to low pressure

Injection tube strainer clogged Clean strainer

Dried chemicals in injector Dissolve by running warm water

through the injection tube

Gun safety lock engaged Release safety lock

Trigger will not move

PROBLEM

POSSIBLE CAUSE

CORRECTION

Nozzle Blocked Clean Nozzle. See Section 5.2

18- ENG

D28921

9.0 TECHNICAL DATA

Pump pressure 1600 psi MAX.

Operation Pressure

Electrical requirement 120V, 13 Amps, 60 Hz

Electrical cord 35 ft.

High Pressure Hose 23 ft.

Flow Rate at 1600 psi 1.6 gpm

Minimum Amperage source 15 amp

Pressure of inlet water 20 - 100 psi

Injection rate 2 - 4%

Inlet Water Cold Tap Water

Nozzle Spray Angle

High Pressure 0 - 60°

Nozzle Spray Angle

Low Pressure 0 - 90°

Turbo Nozzle Spray 30°

Manufacturing Tolerances (+-10%) on stated performances.

8.0 REPLACEMENT PARTS AND ACCESSORIES

THE FOLLOWING LIST OF ACCESSORIES AND REPLACEMENT PARTS ARE AVAILABLE

PLEASE CONTACT CUSTOMER SERVICE FOR MORE INFORMATION 1-800-888-2468

Code

Description

D28936 Detergent Tank

D28937 Detergent Tank Cap

D28939 Handle

D28940 Hubcap

D28941 Wheel

D28942 Locknut

D28943 Hose

D28944 Suction Fliter

D28945 Gun with hose

D28946 Multi-Reg Nozzle

D28947 Rotating Nozzle

D28949 Switch

D28950 Axle

D28921 Manual

Loading...

Loading...