DeVillbiss Air Power Company SP-100-E User Manual

DeVilbiss Air Power Company

GENERAL MANUAL FOR

Spray Guns

This product is covered by the

DeVilbiss one year limited warranty. The Warranty can be found

in this manual.

Monday thru Friday • 8:00 a.m. to 4:30 p.m. (CST)

MGGUNS-1A 3/31/97

WARRANTY

ATTACH SALES RECEIPT HERE

Retain original Sales Receipt as

proof of purchase.

If you have any questions call:

Customer Service Hotline

(Toll Free) 1-800-888-2468 Ext. 2

DeVilbiss Air Power Company • 213 Industrial Drive • Jackson, Tennessee 38301-9615

1 — Eng

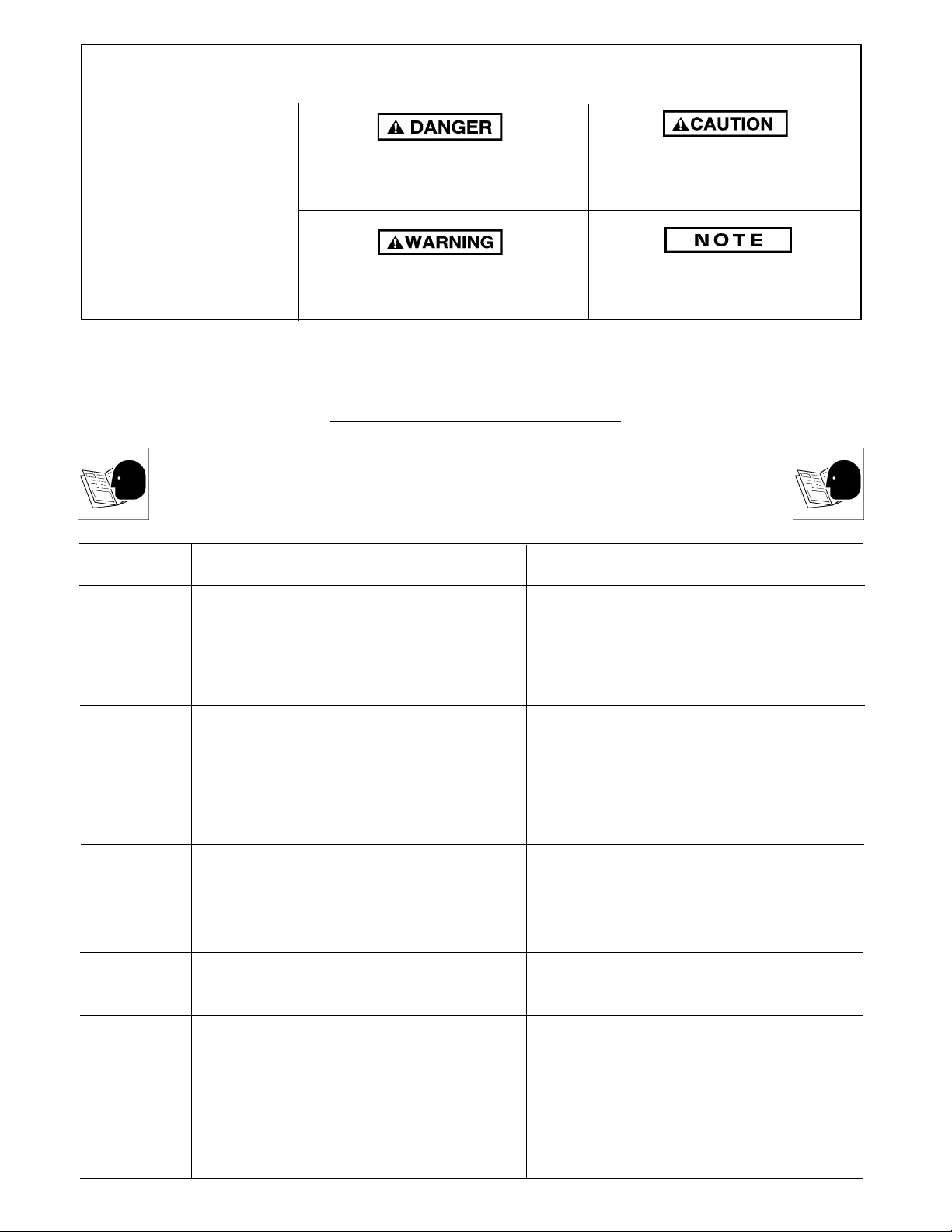

SAFETY GUIDELINES - DEFINITIONS

This manual contains information

that is important for you to know

and understand. This information

relates to protecting YOUR

SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To

help you recognize this information, we use symbols to the right.

Please read the manual and pay

attention to these sections.

IMPORTANT SAFETY INSTRUCTIONS

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT

COULD RESULT IN SERIOUS INJURY AND PROPERTY DAMAGE.

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE USING THIS EQUIPMENT.

URGENT SAFETY INFORMATION - A HAZARD

THAT WILL CAUSE SERIOUS INJURY OR LOSS

OF LIFE.

IMPORTANT SAFETY INFORMATION - A

HAZARD THAT MIGHT CAUSE SERIOUS

INJURY OR LOSS OF LIFE.

Information for preventing damage to

equipment.

Information that you should pay special

attention to.

• SAVE THESE INSTRUCTIONS •

WHAT TO

LOOK FOR WHAT COULD HAPPEN

Flammable

Spray Materials

Toxic Vapors

Compressed Air

Pressurized Parts

When paints or materials are sprayed, they are broken

into very small particles and mixed with air. This will

cause certain paints and materials to become extremely

flammable.

Some paints and coatings may be harmful if inhaled or

allowed to come into contact with skin or eyes.

Compressed air may propel dirt, metal shavings, etc.

and possibly cause an injury.

Certain parts are under pressure whenever the gun is

connected to a pressurized air line. These parts may be

propelled if the gun is disassembled.

HOW TO PREVENT IT

Never spray near open flames or pilot lights in stoves or

heaters.

Never smoke while spraying.

Provide ample ventilation when spraying indoors.

Use a mask or respirator if there is a chance of inhaling

toxic sprayed materials. Masks and respirators have

limits and will only provide protection against some

kinds and limited amounts of toxic material. Read mask

and respirator instructions carefully. Consult with a safety

expert or industrial hygienist if you are not sure about the

use of a certain mask or respirator.

Never point any nozzle or sprayer toward a person or part

of the body.

Always wear ANSI Z87 safety goggles or glases when

spraying.

Disconnect the gun from the air line, or completely

depressurize the air line whenever the gun is to be

disassembled.

Explosion

Hazard Incompatible

Materials

The solvents 1,1,1-Trichloroethane and Methylene

Chloride can chemically react with the aluminum used

in most spray equipment, and this gun and cup, to

produce an explosion hazard.

2 — Eng

Read the label or data sheet for the material you intend to

spray.

1. Do not use any type of spray coating material

containing these solvents.

2. Do not use these solvents for equipment

cleaning or flushing.

3. If in doubt as to whether a material is compatible,

contact your material supplier.

GENERAL INFORMATION

AIR CAPS

External Mix - The air and material are mixed outside

the air cap. This type of cap is best suited for quick

drying paints, such as latex, lacquers, etc.

Internal Mix - The air and material are mixed inside the

air cap. This type of cap is normally used for thick paint

where fast application is desired and where quality of

finish is less important. Internal mix must be used with

pressure feed set-up.

Fluid/Fan Adjustment- To increase volume of material, turn fluid needle adjusting screw counterclockwise. To decrease, turn clockwise. Increasing volume of

material will also increase fan pattern size when using

a fan pattern air cap.

PREPARATION FOR SPRAYING

This spray gun is shipped completely assembled, and

set-up spraying. Installation is accomplished by connecting an air line to the air inlet adapter.

This spray gun should be flushed with solvent prior to

spraying with paint.

To change air caps, turn the retaining ring counterclockwise and remove from gun.

Remove air cap and replace with different cap.

Reassemble in reverse order.

NOTE

Matched air cap and fluid tip combinations are recommended for optimum performance. The fluid tip is removed with a

1/2" socket. When assembling, be sure

the plastic baffle is in place and the tip is

not cross threaded or over tightened (160220 in.-lbs. Torque).

Be sure the surface to be sprayed is dry and free of all

dirt, grease, oil and loose paint. Mix and prepare the

paint according to the manufacturer's instructions. The

use of a viscosimeter can be very helpful. Strain the

material to be sprayed through a 60 to 90 mesh screen or

equivalent.

The fluid needle packing in this gun may be loose when

received. Tighten the packing retainer until it grabs and

holds the fluid needle , then back off the packing retainer

(approx. 1/4 turn) until the fluid needle is free to travel

into the fluid tip.

OPERATION

1. Shut off fluid flow through gun by turning fluid

needle adjusting screw clockwise as far as it will go.

Do not force.

2. Keep the air pressure as low as possible. Set pressure

to 40 psi as a starting point.

RISK OF INJURY OR EQUIPMENT DAMAGE.

DO NOT EXCEED 50 PSIG AT ANY TIME

3. Open (turn counterclockwise) air valve assembly

until the first thread is flush with the back of gun. This

is the full open position.

To use a quick disconnect, remove the air hose adapter

and install a 1/4" NPT quick disconnect adapter into the

handle of the gun body. Set air pressure at 40 psi as a

starting point and follow the safety precautions before

you begin.

4. Hold the trigger back and gradually open the fluid

needle adjusting screw until a desired pattern is

obtained.

5. Trigger the gun quickly, one second on-off. Spray a

small test pattern.

6. If the gun sprays too fast (runs or sags), lower the air

and fluid pressure. If too slow, increase pressure.

Adjust to balance pressure.

When using internal mix air cap, begin with the same air

and fluid pressure.

3 — Eng

Loading...

Loading...