DeVillbiss Air Power Company AGXV-540, AGXV-541, AGXV-542, AGXV-543 User Manual

SERVICE BULLETIN

SB-2-628-K

Replaces SB-2-628-J

Repair Kit KK-4992-1

AGXV-540, AGXV-541, AGXV-542 & AGXV-543

AUTOMATIC SPRAY GUNS

IMPORTANT: Before using this equipment, read SAFETY PRECAUTIONS

starting on page 2.

DESCRIPTION

The AGXV high volume, low pressure spray gun

(spray pistol) is used on automatic and semiautomatic machines where mass production

spraying is necessary, or hand spraying is not

accurate enough. Models and application information follows. All models are designed to provide maximum transfer efficiency by limiting air

cap pressure to 10 psi (0.7 bar) (in the U.S., this

complies with rules issued by SCAQMD and

other air quality authorities). Air cap pressure

can be measured with an optional air cap test kit.

See "ACCESSORIES" on Page 8.

CHART 1 MODELS

Model No. HVLP Fluid

(Available Typical Air Cap Tip/Needle

Tip Sizes) Applications Used Construction

AGXV-540 Most common 28 or 33A 400 Gr. S/S

(E, FF, FX) finishing materials

AGXV-541 High solids (low 46MP or 400 Gr. S/S

(D, E, FF, VOC's) coatings 83MP

FX) which are difficult

AGXV-542 Waterbornes and 28 or 33A 303 Gr. S/S,

(FF, FX) other corrosive Poly.

AGXV-543 Same as AGXV- 46MP 303 Gr. S/S,

(FF, FX) 541 except for Poly.

including some

waterborne and

chlorinated.

to atomize with

HVLP, or high

flow rates.

materials (below

7pH)

more corrosive materials (below 7pH)

CHART 2 AIR CAPS – PATTERNS –

APPLICATION

Air Complete *Typical

Cap Air Cap Pattern Size Typical

No. No. and Shape Application

28 JGHV-101-28 11" (280 mm)

33A JGHV-101-33A 9" (229 mm) (360 cc)

46MP JGHV-101-46MP 11" (280 mm) Low VOC

83MP JGHV-101-83MP 13" (330 mm) Low VOC

* Actual pattern length dependent upon fluid tip (nozzle) ID,

coating material flow rate, air pressure and fan pressure.

long, straight Most comsided, similar to mon finishing

704 air cap. materials, up

to 12 oz./min.

long, tapered

ends, similar to

30 air cap.

long, straight materials, 12

sided, similar to to 16 oz./min.

704 air cap. (360 to

480 cc)

long, straight materials,

sided similar to 17 oz./min.

765 air cap. (510 cc) and

above.

Most finishing materials can be atomized with

either the 28 or 33A air caps. The 28 or 33A caps

should be used where possible as they consume less air volume (CFM) and have slightly

better transfer efficiency than the 46 MP or

83MP air caps. However, more difficult to atomize materials (i.e. low VOC's) or high flow applications over 12 oz./min. (360 cc/min.), are ideal

for the 46 MP maximum performer air cap, fluid

tip and baffle combination. Also available is the

83MP (maximum performer) for even higher

flows 17 oz./min. (510 cc/min.) and above and

higher viscosities. Refer to the air cap chart for

more information.

Note

This gun may be used with chlorinated

solvents. Aluminum is not used in fluid

passages. If using chlorinated solvents,

make sure all other fluid handling components are also compatible.

A list of materials used in the construction

of this equipment is available upon request.

SPECIFICATIONS

P1 – Maximum Inlet Pressure – 100 PSI (7 bar)

P2 – Maximum Fluid Pressure – 100 psi (7 bar)

P3 – Cylinder Air Pressure

– Min. **50 psi (3.5 bar)

– Max. 100 psi (7 bar)

Weight without mounting stud – 26 oz. (738 g)

Weight with mounting stud – 30.5 oz. (865 g)

Mounting stud diameter – 3/4" (19 mm)

Wetted Parts – 300 and 400 S/S, Teflon, Poly.

(See Chart 2 for tip/needle information)

Hose Connections –

Fluid Inlet – 3/8" NPS(M)

Cylinder Air – 1/4" NPS(M)

Atomization Air – 1/4" NPS(M)

Note

For HVLP operation (max. 10 psi, - 0.7 bar

cap pressure), do not exceed the air inlet

pressure given below.

PSI (bar) Cap No.

57 (4) 83MP

50 (3.4) 46MP

45 (3.1) 33A

38 (2.6) 28

** For installations where 50 psi (3.4 bar) cylinder air is not

available, the inner (red) piston spring can be removed

which lowers the minimum cylinder air to approximately 37 psi (2.5 bar). Refer to "OPERATION", Pg. 4

FLUID TIP (NOZZLE) ORIFICE SIZES

Inch mm

D .086" 2.2

E .070" 1.8

FF .055" 1.4

FX .042" 1.1

G 0.028 .7

PAGE 2 SB-2-628-K

SAFETY PRECAUTIONS

This manual contains important information that ALL users should know and understand BEFORE using the equipment. This

information relates to USER SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use

the following terms to draw your attention to certain equipment labels and portions of this manual. Pay special attention to any

label or information that is highlighted by one of these terms:

Important information to alert you to a situation that might cause

serious injury or loss of life if instructions are not followed.

Note

Important information that tells how to prevent

damage to equipment.

The following hazards may occur during the normal use of this equipment. Please read the following chart.

Information that you should pay special attention to.

HAZARD CAUSE SAFEGUARDS

Fire

Inhaling Toxic Substances 1. Follow the requirements of the Material Safety Data

Explosion Hazard –

Incompatible Materials

Solvents and coatings can be

highly flammable or combustible, especially when sprayed.

Certain materials may be harmful if inhaled, or if there is contact

with the skin.

Halogenated hydocarbon solvents- for example: methylene

chloride and 1,1,1,- Trichloroethane are not chemically compatible with the aluminum that might

be used in many system components. The chemical reaction

caused by these solvents reacting with aluminum can become

violent and lead to an equipment

explosion.

1. Adequate exhaust must be provided to keep the air free

of accumulations of flammable vapors.

2. Smoking must never be allowed in spray area.

3. Fire extinguishing equipment must be present in the

spray area.

4. Static discharges must be prevented. Ground (earth) all

conductive objects in the spray area, such as a cleaning

solvent bucket, fire extinguisher, etc.

5. When using solvents for cleaning:

•Those used for equipment flushing must have a flash

point equal to or greater than that of the coating.

•Those used for general cleaning must have flash points

above 100°F (37.8°C).

Sheet supplied by coating material manufacturer.

2. Adequate exhaust must be provided to keep the air free

of accumulations of toxic materials.

3. Use a mask or respirator whenever there is a chance of

inhaling sprayed materials. The mask must be compatible with the material being sprayed and its concentration. Equipment must be as prescribed by an industrial

hygienist or safety expert, and be NIOSH approved.

The AGXV spray gun (spray pistol) can be used with these

solvents. However, aluminum is widely used in other spray

application equipment – such as material pumps, cups, regulators, valves, etc. Check all other equipment items before

use and make sure they can also be used safely with these

solvents. Read the label or data sheet for the material you

intend to spray. If in doubt as to whether or not a coating or

cleaning material is compatible contact your material supplier.

General Safety Improper operation or mainte-

nance may create a hazard.

Operators should be given adequate training in the safe use

and maintenance of the equipment (in accordance with the

requirements of NFPA-33, Chapter 15 in U.S.). Users must

comply with all local and national codes of practice and

insurance company requirements governing ventilation, fire

precautions, operation, maintenance and housekeeping (in

the U.S., these are OSHA Sections 1910.94 and 1910.107 and

NFPA-33).

SAFETY PRECAUTIONS (Cont'd)

HAZARD CAUSE SAFEGUARDS

SB-2-628-K PAGE 3

Noise Levels – Ear Injury

Solvent Spray

Misuse:

• All spray guns (spray pistols) project particles at high velocity and must never be aimed at any part of the body.

• Never exceed the recommended safe working pressures for any of the equipment used.

• The fitting of non-recommended or non-original accessories or spare parts may create hazardous conditions.

• Before dismantling the equipment for cleaning or maintenance all pressure, air and materials, must be isolated and released.

The disposal of waste materials must be carried out in an approved manner. Burning may generate toxic fumes. The removal or waste

solvents and coating materials should be carried out by an authorized local waste disposal service.

A continuous A-weighted sound

pressure level of this spray gun

(spray pistol) may exceed 85

dB(A) depending on the air cap/

fluid head setup being used.

Sound levels are measured using an impulse sound level meter

and analyzer, when the gun is

being used in a normal spraying

application.

solvents can be forcefully expelled from fluid and air passages. Some solvents can cause

eye injury.

Always wear ear protection when using the gun.

Details of actual noise levels produced by the various air cap/

fluid head setups are available upon request.

Wear eye protection.During cleaning and flushing,

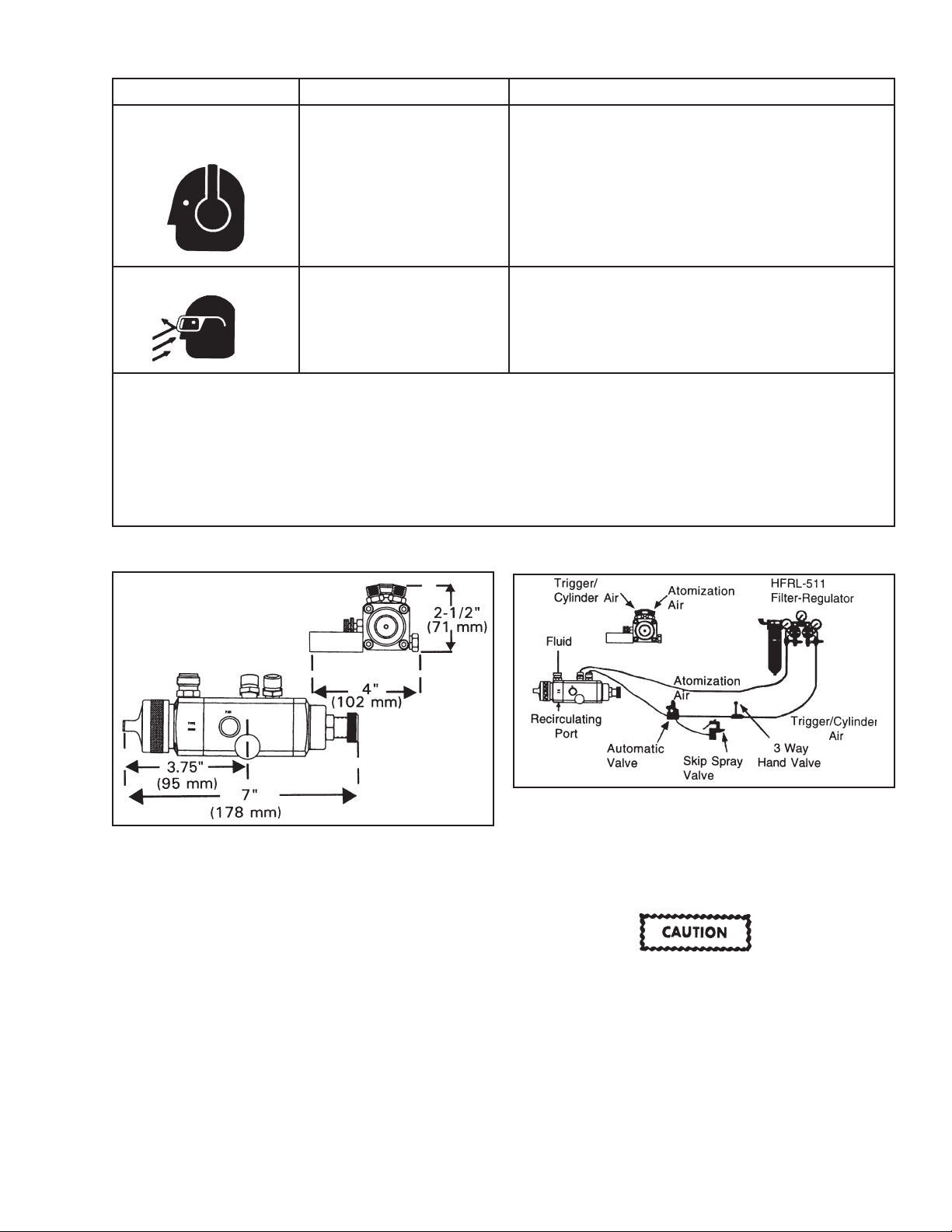

FIGURE 2 TYPICAL INSTALLATIONFIGURE 1 DIMENSIONS

INSTALLATION

Mount the gun with the stud (13) or on a 5/16" dia. rod tightening

adequately with the 1/4-28 X 1/4" set screws (Ref. 24). See "ACCESSORIES" for mounting clamps.

Note

If replacing the atomization air connection (15) with an

elbow type connection, be aware of a possible air flow

(CFM) limitation. A 1/4" (6.4 mm) I.D. 90° elbow will only

pass 20 CFM @ 40 psi (566 l/min. 2.7 bar). Some air caps

require more than 20 CFM (566 l/min.). Spray performance

could be affected.

Attach the trigger/cylinder air hose and the atomization air hose to

the connections as indicated by the markings on the gun body. The

air supply should be filtered and regulated. Attach the material

hose to the fluid inlet on the gun body. Fluid can be recirculated by

installing a fluid fitting (AGX-415) (order separately) at the recirculating port. See Caution below.

The fluid inlet and recirculating ports have a tapered

seating surface intended for use with the AGX-415 fitting. Do not substitute other fittings as fluid leakage will

occur.

Loading...

Loading...