Page 1

SERVICE MANUAL

Repair Kit KK-5007

■

TLC-555 & TGC-545

DRIP FREE SUCTION CUPS

Important: Before using this equipment, read all safety

precautions and instructions. Keep for future use.

Figure 1

DESCRIPTION

Models: ■ TLC-555 – One quart capacity,

Non-stick coating lined cup

TGC-545 – One quart capacity

OPERATION

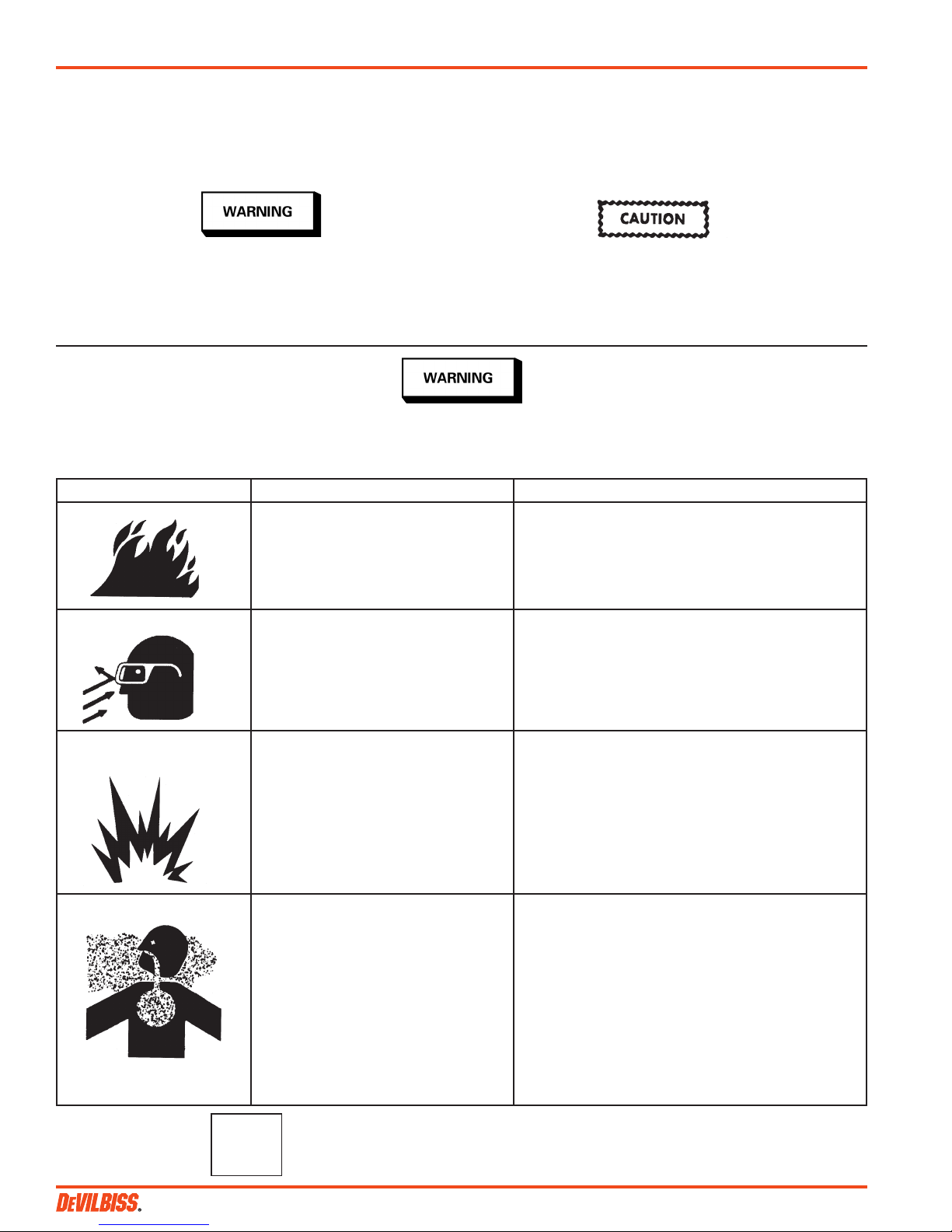

Open Vent Mode "O"- To operate in the open vent mode, rotate the

valve with a screwdriver or coin so that the hole in the valve slot is

aligned with the "O" on the lid. See Figure 2.

If the valve slot hole should plug while operating in the "O" vent

mode, use a pointed tool such as a nail or drill bit to probe through

the valve slot hole to clear away the obstruction.

Lid Top Lid Underside

Gasket

Channel

Channel

Vent Hole

Gasket shown

partially removed

Channel

Vent Hole

(Do Not Probe)

D/F

O

Valve slot

hole can be

probed to clean.

Valve in Open Position

Figure 2 – Open Vent Mode

Drip Free Mode "D/F" – To operate in the drip free mode, rotate the

valve with a screwdriver or coin so that the hole in the valve slot is

aligned with the "D/F" on the lid. See Fig. 3

These drip free suction cups have a unique, two position valve which

permits selection of either a drip free spraying mode or a conventional

open vent mode.

In the drip free position, air is directed through the vent in the lid

to a channel beneath the lid gasket before entering the cup at the

valve. This allows the cup to be tilted when full without dripping

paint through the vent. The cup can also be inverted while spraying

without leaking.

The open position isolates the channel and opens a direct vent into

the cup.

The position of the valve is indicated by alignment of the hole in the

valve slot with the marks cast on the lid. These positions are identified

as "O" for vent open and "D/F" for Drip Free.

Note

Non-stick Coating Lined Cup - Only use a wooden or plastic

paddle or mixer for mixing material in the cup (7). A metal

paddle or mixer can scratch the non-stick coating.

Note

For Non-stick Coating Lined Paint Cups, variation in the color

of the non-stick coating is normal. This variation is the result

of the normal production process used with this type of coating. We have selected this particular grade of non-stick coating

because it provides the best overall performance and maximum

durability possible.

Do not probe through the channel vent hole at any time. Do

not probe through the valve slot hole while the valve is in the

"D/F" position. These holes are sealed by a gasket and gasket

damage could result. See Figs. 2 & 3.

Valve Movement – Do not forcibly rotate the valve. If it will not move

freely, soak in solvent or remove the lid assembly from the cup and

press down on the top of the valve until it breaks free. The valve

has free travel vertically of about 1/8". This can be used to push out

the gasket.

Lid Top

Channel

Vent Hole

(Do Not Probe)

D/F

Valve slot

hole sealed (Do Not Probe)

O

Valve in Drip Free

Lid Underside

Gasket shown

partially removed.

Position

Figure 3 - Drip Free Model

Government NSN # 4940-01-208-8876 = TLC-555

SB-4-391-V (6/2016) 1 / 6

Page 2

SAFETY PRECAUTIONS

This manual contains important information that ALL users should know and understand BEFORE using the equipment. This information

relates to USER SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following terms

to draw your attention to certain equipment labels and portions of this manual. Pay special attention to any label or information that is

highlighted by one of these terms:

Important information to alert you to a situation

that might cause injury or loss of life.

Note

Information that you should pay special attention to.

The following hazards may occur during the normal use of this equipment.

Please read the following chart.

HAZARD SAFEGUARDS

Fire

Solvent Spray

CAUSE

Solvents and coatings can be highly

flammable or combustible, especially

when sprayed.

During cleaning and flushing, solvents

can be forcefully expelled from fluid

and air passages. Some solvents can

cause eye injury or irritation.

Important information that tells how to prevent

damage to equipment

Do not spray near open flames, pilot lights in stoves

or heaters, or other heat sources.

Adequate ventilation must always be provided.

Industrial applications must comply with OSHA

requirements.

Wear eye protection.

Explosion Hazard Incompatible Materials

Inhaling Toxic Substances Certain materials may be harmful if

Chlorinated solvents, such as 1, 1, 1

- Trichloroethane and Methylene Chloride (sometimes called methyl chloride)

can chemically react with the aluminum used in most spray equipment,

and these cups, to produce an explosion hazard. The TLC-555, TGC-545 and

TGC-536 are aluminum.

inhaled, or if there is contact with the

skin.

CA PROP

65

PROP 65 WARNING

WARNING: This product contains chemicals known to the State of California to

cause cancer and birth defects or other reproductive harm.

1. Read the label or data sheet for the material you

intend to spray.

2. Do not use any type of spray coating material

containing these solvents.

3. Do not use these solvents for equipment cleaning

or flushing.

4. If in doubt as to whether a material is compatible,

contact your material supplier.

Follow the requirements of the Safety Data Sheet

supplied by your coating material manufacturer.

Adequate exhaust must be provided to keep the air

free of accumulations of toxic materials.

Use a mask or respirator whenever there is a chance

of inhaling sprayed materials. The mask must be

compatible with the material being sprayed and its

concentration. Equipment must be as prescribed by

an industrial hygienist or safety expert, and be NIOSH

approved.

SB-4-391-V (6/2016)2 / 6

Page 3

INSTALLATION

Cleaning Procedures:

1. Position yoke at right angle to gun body with vent hole in lid

toward rear and lever of cam (3) toward front of gun.

2. Fasten cup lid assembly to gun by attaching nut (2), see Fig. 4,

to fluid inlet nipple on gun. Tighten nut with wrench only until

snug.

3. Strain material to be sprayed through a 60-90 mesh screen before

pouring into cup.

4. Engage pins on cup into yoke and tighten yoke by moving lever

of cam clockwise.

MAINTENANCE

Lid Repair/Replacement:

1. To replace a damaged part, use a 5/16" hex wrench to loosen

and remove adapter (1), nut (2), yoke & cam (3). Lid and tube

assembly are now loose for replacement.

2. Replace damaged parts on the lid and tube assembly. The cam

lever should be located on opposite side of lid from valve (4).

3. Apply sealant (Loctite #262) to the first two full threads of adapter

(1). Insert threaded end of adapter into open end of nut (2).

4. Install adapter (1) and nut (2) in top of lid and tube assembly.

Use a 5/16" hex wrench to tighten firmly (10-12 foot pounds).

Valve and Lid Gasket Replacement:

1. To remove a damaged valve (4) or lid gasket (5), press on top of

valve until it breaks free. The valve pushes the lid gasket from the

seat. The lid gasket may now be removed from the lid. Continue

pressing hard on the valve to remove it from the lid.

2. Install replacement valve (4) through bottom of lid so that the

valve tab is toward center of lid. Snap in place. If necessary, use

a plastic mallet or screwdriver handle to tap the valve in place.

Press the lid gasket firmly in the lid using the end of a crescent

wrench. Insert the side with the black marks first.

CLEANING

Note

Always clean the cam lever (3) surfaces with clean solvent and

a brush. This will keep the cam lever functioning properly. Do

not lubricate the cam.

1. Empty paint from cup and add small amount of clean solvent. The

amount required will vary with different coatings and solvents.

2. Shake cup to wash down inside surfaces. Then spray solvent at

low air pressure (15-20 psi) to flush out fluid passages.

3. Pour out solvent and add same amount of clean solvent.

4a. Again, shake cup. Loosen air cap. Hold a folded cloth over front

of gun and invert cup over solvent receptacle. Trigger with short

bursts to back flush vent channel. With valve in D/F position,

solvent will be expelled with force from the channel vent hole

in lid.

Alternative to Step 4a.

4b. Shut off air to gun. With valve in D/F position, invert cup over

solvent receptable. Trigger gun. Allow solvent to drip out channel vent hole in lid for several seconds, or until clean solvent is

seen.

• Do not probe through the channel vent hole at any time. Do

not probe through the valve slot hole while the valve is in

the D/F position. These holes are sealed by gasket (5) and

gasket damage could occur.

• Do not use abrasives such as a wire brush or steel wool to

clean the inside of the non-stick coating lined cup (7). Damage

to the non-stick surface could result.

IMMERSION

Since all materials in the cup are highly solvent resistant, the cup

assembly may be immersed for cleaning. Immersion should not

exceed 24 hours. The use of paint strippers should be avoided because strippers will affect the aluminum as well as other non-metallic

components. If the lid gasket has become swollen from prolonged

exposure to solvents, it will return to its original size without loss of

properties when allowed to dry.

General: For routine cleaning, it is not necessary to remove the lid

gasket. It is not necessary or desirable to remove the valve for any

cleaning procedure. The valve can be depressed from the outside

to assist in removal of the gasket for gasket replacement or when

cleaning dried paint from the channel. The valve should not be forced

past the shoulder which retains it in the lid except for replacement.

Air Pressure: Always clean with reduced air pressure. An air pressure

no greater than 15 to 20 psi will allow quick and thorough cleaning

of the cup and gun and at the same time will:

1. Minimize the amount of solvent atomized into the air.

2. Prevent possibility of damage to cup from excessive back pressure.

3. Reduce the force with which solvent is expelled from the vent.

SB-4-391-V (6/2016) 3 / 6

Page 4

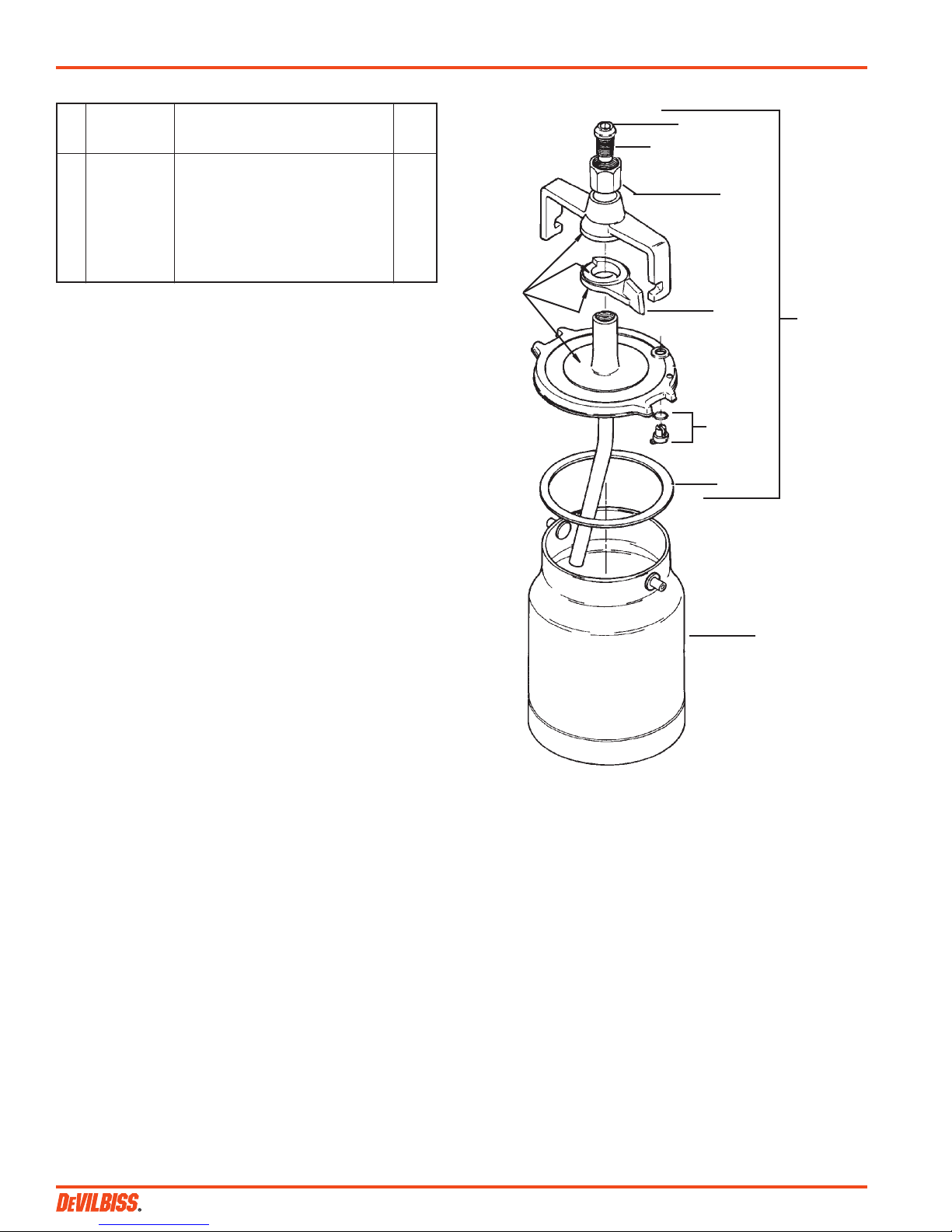

Parts List

Ind.

Ref. Replacement Parts

No. Part No. Description Req.

1* Adapter, 1/2" NPS (M) 1

2* Nut, 3/8" NPS (F) 1

3* Cam 1

4* TGC-407-1-K3 Drip Free Valve & Gasket (Kit of 3) 1

5* TGC-9-K5 **Tri Seal® Lid Gasket (Kit of 5) 1

6 TGC-404 Lid Assembly (Quart) 1

7 KR-428-2 Suction Cup Assy. (Quart) 1

TLC-401 Suction Cup Assy. (Non-stick, Quart)

* KK-5007 Repair Kit includes Ref. Nos. 1-5. Repair kit contains enough

parts to repair one complete assembly.

Suffix -K3 designates a kit of multiple parts. Example: TGC-407-1-K3 is a

kit of 3 drip free valves.

** Registered Trademark of Tri-Seal International.

Figure 4

Yoke

Keep

these

surfaces

clean.

1

Apply sealant to

first two threads

(Loctite #262).

2

3

4

5

6

7

SB-4-391-V (6/2016)4 / 6

Page 5

NOTES

SB-4-391-V (6/2016) 5 / 6

Page 6

WARRANTY POLICY

DeVilbiss products are covered by Carlisle Fluid Technologies one year materials and workmanship limited warranty.

The use of any parts or accessories, from a source other than Carlisle Fluid Technologies, will void all warranties.

For specic warranty information please contact the closest Carlisle Fluid Technologies location listed below.

Carlisle Fluid Technologies reserves the right to modify equipment specications without prior notice.

DeVilbiss®, Ransburg®, MS®, BGK®, and Binks® are registered trademarks of

Carlisle Fluid Technologies, Inc. ©2016 Carlisle Fluid Technologies, Inc. All rights reserved.

DeVilbiss is part of Carlisle Fluid Technologies, a global leader in innovative

nishing technologies. For technical assistance or to locate an authorized distributor,

contact one of our international sales and customer support locations.

USA/Canada

info@carlisleft.com

Tel: 1-888-992-4657

Fax: 1-888-246-5732

United Kingdom

info@carlisleft.eu

Tel: +44 (0)1202 571 111

Fax: +44 (0)1202 573 488

China

mkt@carlisleft.com.cn

Tel: +8621-3373 0108

Fax: +8621-3373 0308

For the latest information about our products, visit www.carlisleft.com.

Mexico

ventas@carlisleft.com.mx

Tel: 011 52 55 5321 2300

Fax: 011 52 55 5310 4790

France

info@carlisleft.eu

Tel: +33(0)475 75 27 00

Fax: +33(0)475 75 27 59

Japan

overseas-sales@carlisleft.co.jp

Tel: 081 45 785 6421

Fax: 081 45 785 6517

Brazil

vendas@carlisleft.com.br

Tel: +55 11 5641 2776

Fax: 55 11 5641 1256

Germany

info@carlisleft.eu

Tel: +49 (0) 6074 403 1

Fax: +49 (0) 6074 403 281

Australia

sales@carlisleft.com.au

Tel: +61 (0) 2 8525 7555

Fax: +61 (0) 2 8525 7575

DeVilbiss Automotive Renishing is part of Carlisle Fluid Technologies,

a global leader in innovative nishing technologies. For technical assistance

or to locate an authorized distributor, contact one of our international sales

and customer support locations.

USA/Canada

www.autorenishdevilbiss.com

askus@carlisleft.com

Toll Free Tel: 1-800-445-3988

Toll Free Fax: 1-800-445-6643

Mexico

www.autorenishdevilbiss.com.mx

Toll Free Tel: 1-888-835-6232 USA

SB-4-391-V (6/2016)6 / 6

Page 7

MANUAL DE SERVICIO

Kit de reparación KK-5007

■

TLC-555 Y TGC-545

TAZAS DE SUCCIÓN LIBRES DE GOTEO

Importante: Antes de usar este equipo, lea todas las precauciones de seguridad y las instrucciones. Guárdelo para

futuro uso.

Figura 1

DESCRIPCIÓN

Modelos: ■ TLC-555 – Capacidad de un cuarto de galón,

Taza revestida con revestimiento antiadherente

TGC-545 – Capacidad de un cuarto de galón

Estas tazas de succión libres de goteo tienen una válvula exclusiva con

dos posiciones que permite la selección de un modo de atomización

libre de goteo o un modo convencional con ventilación abierta.

En la posición libre de goteo, el aire es dirigido a través del orificio de

ventilación en la tapa hacia un canal debajo del empaque de la tapa

antes de entrar en la taza por la válvula. Esto permite inclinar la taza

cuando se encuentra llena sin derramar pintura a través del orificio de

ventilación. También se puede invertir la taza al atomizar sin escapes.

La posición abierta aísla el canal y abre un orificio de ventilación

directo hacia la taza.

La posición de la válvula se indica por la alineación del orificio en

la ranura de la válvula con las marcas fundidas en la tapa. Estas

posiciones se identifican como "O" para ventilación abierta y "D/F"

para Libre de goteo.

Nota

Taza con revestimiento antiadherente - Use únicamente una

paleta o un mezclador de madera o de plástico para mezclar

materiales en la taza (7). Una paleta o mezclador de metal

puede rayar el revestimiento de revestimiento antiadherente.

Nota

En las Tazas de Pintura con Revestimiento de Antiadherente,

es normal la variación del color en el revestimiento de

antiadherente. Esta variación es el resultado del proceso

de producción normal con este tipo de recubrimiento.

Hemos seleccionado esta clase particular de revestimiento

antiadherente porque proporciona el mejor desempeñ o global

y la máxima durabilidad posible.

OPERACIÓN

Modo con orificio de ventilación abierto "O"- Para funcionar en el modo

con orificio de ventilación abierto, gire la válvula con un desarmador

o con una moneda de manera que el orificio en la ranura de la válvula

quede alineado con el "O" en la tapa. Ver Figura 2.

Si se obstruye el orificio en la ranura de la válvula mientras se

funciona en el modo con orificio de ventilación abierto "O", use una

herramienta puntiaguda como un clavo o una broca de barrena para

penetrar a través del orificio en la ranura de la válvula para despejar

la obstrucción.

Parte superior de la tapa Parte inferior de la tapa

Empaque

Canal

Orificio de

ventilación

del canal

El empaque

se muestra parcialmente quitado

Orificio de ventilación

del canal

(No introduzca

nada)

D/F

O

Se puede penetrar el orificio

en la ranura de

la válvula para

limpiar.

Válvula en posición

Abierta

Figura 2 – Modo con orificio de ventilación abierto

Modo libre de goteo "D/F" – Para funcionar en el modo libre de goteo,

gire la válvula con un desarmador o con una moneda de manera que

el orificio en la ranura de la válvula quede alineado con el "D/F" en

la tapa. Ver Fig. 3

PRECAUCIÓN

Nunca introduzca nada a través del orificio de ventilación del

canal. No introduzca nada a través del orificio en la ranura

de la válvula mientras la válvula se encuentre en la posición

"D/F". Estos orificios son sellados por un empaque y el empaque

puede dañarse. Ver las figuras 2 y 3.

Movimiento de la válvula – No gire la válvula forzándola. Si no se

desplaza con libertad, vierta disolvente o quite la unidad de la tapa de

la taza y presione la parte superior de la válvula hasta que se desplace.

La válvula tiene un desplazamiento libre vertical de aproximadamente

1/8”. Esto se puede utilizar para sacar el empaque.

Parte superior de la tapa

O

D/F

Orificio de ventilación

del canal

(No introduzca

nada)

Orificio en la

ranura de la

válvula sellado (No introduzca

nada)

Válvula en posición

Libre de goteo

Parte inferior de la tapa

El empaque

se muestra parcialmente quitado

Figura 3 - Modelo libre de goteo

Gobierno NSN # 4940-01-208-8876 = TLC-555

SB-4-391-V (6/2016) ES-1 / 5

Page 8

PRECAUCIONES DE SEGURIDAD

Este manual contiene información importante que TODOS los usuarios deben conocer y comprender ANTES de utilizar el equipo. Esta

información se relaciona con la SEGURIDAD DEL USUARIO y CÓMO EVITAR PROBLEMAS CON LOS EQUIPOS. Para ayudarle a reconocer

esta información, utilizamos los siguientes términos para llamar su atención a ciertas etiquetas de los equipos y partes de este manual.

Preste atención especial a cualquier etiqueta o información que se destaque con uno de estos términos:

ADVERTENCIA

Información importante para alertarlo acerca

de una situación que pueda ocasionar lesión o

pérdida de la vida.

Nota

Información a la que debe prestar atención especial.

ADVERTENCIA

Durante el uso normal de este equipo pueden ocurrir las siguientes situaciones de peligro.

Sírvase leer la siguiente tabla.

PELIGRO MEDIDAS PREVENTIVAS

Incendio

Atomizar solventes

CAUSA

Los solventes y recubrimientos

pueden ser altamente inflamables o

combustibles, especialmente cuando

se atomizan.

Durante la limpieza y purga, los

solventes pueden expulsarse con

fuerza de los pasajes de fluido y aire.

Algunos solventes pueden causar

lesiones o irritación en los ojos.

Información importante que indica cómo prevenir

daño al equipo

No atomice cerca de llamas descubiertas, luces piloto

en cocinas o calentadores u otras fuentes de calor.

Siempre debe haber ventilación adecuada. Las

aplicaciones industriales deben cumplir con los

requisitos de OSHA.

Use gafas de protección.

PRECAUCIÓN

Peligro de explosión –

Materiales incompatibles

Inhalación de sustancias tóxicas Ciertos materiales pueden ser dañi-

Los solventes clorados, tales como 1, 1,

1 – Tricloroetano y cloruro de metileno

(denominado algunas veces cloruro

de metilo) pueden generar reacciones

químicas con el aluminio utilizado en la

mayoría de los equipos pulverizadores

y estas tazas, ocasionando peligro

de explosión. TLC-555, TGC-545 y

TGC-536 son aluminio.

nos si se inhalan o si tienen contacto

con la piel.

PROP

65

DE CA

ADVERTENCIA PROP 65

ADVERTENCIA: Este producto contiene sustancias químicas que según información

en poder del estado de California producen cáncer, defectos de nacimiento y otros

daños al sistema reproductor.

1. Lea la etiqueta u hoja de seguridad para el material que piensa atomizar.

2. No use ningún tipo de material de recubrimiento

atomizado que contenga estos solventes.

3. No use estos solventes para limpieza o purga del

equipo.

4. Si tiene dudas acerca de si un material es compatible, póngase en contacto con su proveedor de

materiales.

Siga los requisitos de la Hoja de datos de seguridad

(SDS) suministrada por el fabricante del material de

recubrimiento.

Debe proveerse de un escape adecuado para mantener el aire libre de acumulaciones de vapores tóxicos.

Use una máscara o respirador siempre que haya

riesgo de inhalar materiales atomizados. La máscara

debe ser compatible con el material que se atomiza

y su concentración. El equipo debe ser como el recomendado por un higienista industrial o experto en

seguridad y aprobado por NIOSH.

SB-4-391-V (6/2016)ES-2 / 5

Page 9

INSTALACIÓN

Procedimientos de limpieza:

1. Coloque la varilla de unión en ángulo recto respecto del cuerpo

de la pistola con el orificio de ventilación en la tapa orientado

hacia la parte trasera y la palanca de la leva (3) hacia la parte

delantera de la pistola.

2. Sujete la unidad de la tapa de la taza a la pistola fijando la tuerca

(2), ver Fig. 4, a la boquilla de entrada de fluido en la pistola.

Apriete la tuerca con la llave únicamente hasta dejarla bien

ajustada.

3. Filtre el material que va a ser atomizado a través de un tamiz de

malla 60-90 antes de verterlo en la taza.

4. Enganche las clavijas de la taza en la varilla de unión y apriete

la varilla de unión moviendo la palanca de la leva en sentido

horario.

MANTENIMIENTO

Reparación/Reemplazo de la tapa:

1. Para reemplazar una pieza dañada, use una llave hexagonal de

5/16" para aflojar y quitar el adaptador (1), la tuerca (2), la varilla

de unión y la leva (3). La unidad de la tapa y el tubo está ahora

floja para reemplazarse.

2. Reemplace las piezas dañadas en la unidad de la tapa y el tubo.

La palanca de la leva debe estar ubicada en el lado opuesto de

la tapa desde la válvula (4).

3. Aplique sellador (Loctite #262) a las primeras dos roscas completas

del adaptador (1). Inserte el extreme roscado del adaptador en

el extremo abierto de la tuerca (2).

4. Instale el adaptador (1) y la tuerca (2) en la parte superior de la

unidad de la tapa y el tubo. Use una llave hexagonal de 5/16"

para apretar con firmeza (10-12 libras pies).

Reemplazo de la válvula y el empaque de la tapa:

1. Para quitar una válvula (4) o el empaque de la tapa (5) dañados,

presione la parte superior de la válvula hasta que se suelte. La

válvula empuja el empaque de la tapa de su encaje. El empaque de

la tapa se puede separar ahora de la tapa. Continúe presionando

con firmeza la válvula para separarla de la tapa.

2. Instale la válvula de reemplazo (4) a través de la parte inferior de

la tapa de manera que la lengüeta de la válvula quede hacia el

centro de la tapa. Encájela en su lugar. Si fuese necesario, use el

mango de un martillo plástico o desarmador para dar golpes a

la válvula hasta que quede en su lugar. Presione con firmeza el

empaque en la tapa utilizando el extremo de una llave ajustable.

Inserte primero el lado con las marcas negras.

1. Vacíe la pintura de la taza y agregue una cantidad pequeña de

solvente limpio. La cantidad necesaria varía según los diferentes

recubrimientos y solventes.

2. Agite la taza para limpiar las superficies interiores. Luego atomice

el solvente con una presión del aire baja (15-20 psi) para purgar

los pasajes de fluido.

3. Vierta el solvente y agregue la misma cantidad de solvente limpio.

4a. Vuelva a agitar la taza. Afloje el casquillo de aire. Sostenga un

paño doblado sobre la parte delantera de la pistola e invierta

la taza sobre el receptáculo del solvente. Accione con ráfagas

pequeñas para retropurgar el canal de ventilación. Con la válvula

en la posición D/F, el solvente será expulsado con fuerza del

orificio de ventilación del canal en la tapa.

Alternativa al Paso 4a.

4b. Interrumpa la entrada de aire en la pistola. Con la válvula en la

posición D/F, invierta la taza sobre el receptáculo del solvente.

Accione la pistola. Deje que el solvente se escurra por el orificio

de ventilación del canal en la tapa por unos segundos o hasta

que se vea el solvente limpio.

PRECAUCIÓN

• No introduzca nada a través el orificio de ventilación del canal

en ningún momento. No introduzca nada a través del orificio

en la ranura de la válvula mientras la válvula se encuentra en

la posición D/F. Estos orificios está sellados por un empaque

(5) y éste podría dañarse.

• No use abrasivos como un cepillo de alambre o virutas finas

de acero para limpiar el interior de la taza con revestimiento

antiadherente (7). Esto puede dañar la superficie de

revestimiento antiadherente.

INMERSIÓN

Debido a que todos los materiales en la taza son altamente resistentes

a los solventes, la unidad de la taza puede sumergirse para su limpieza.

La inmersión no puede sobrepasar las 24 horas. Se debe evitar el uso

de quitapinturas debido a que afectan el aluminio así como otros

componentes no metálicos. Si el empaque de la tapa se expande

debido a la prolongada exposición a los solventes, recuperará su

tamaño original sin pérdida de sus propiedades cuando se deja secar.

LIMPIEZA

Limpie siempre las superficies de la palanca de la leva (3)

con solvente limpio y un cepillo. Esto mantendrá la palanca

funcionando debidamente. No lubrique la leva.

General: Para limpieza de rutina, no es necesario quitar el empaque

de la tapa. No es necesario ni deseable quitar la válvula para cualquier

procedimiento de limpieza. Se puede oprimir la válvula desde fuera

como ayuda para quitar el empaque para reemplazarlo o cuando se

limpia pintura seca del canal. No se debe forzar la válvula más allá del

soporte saliente que la retiene en la tapa excepto para su reemplazo.

Presión del aire: Limpie siempre con presión del aire reducida. Una

presión del aire no superior a entre 15 y 20 psi permitirá la limpieza

rápida y completa de la taza y la pistola y al mismo tiempo:

1. Minimizará la cantidad de solvente atomizado en el aire.

2. Prevendrá la posibilidad de daño a la taza debido al exceso de

contrapresión.

3. Reducirá la fuerza con la cual el solvente es expulsado del orificio

de ventilación.

Nota

SB-4-391-V (6/2016) ES-3 / 5

Page 10

Lista de piezas

No.

de No. de

Ref. repuestos Descripción

Núm. de

piezas

requeridas

1* Adaptador, 1/2" NPS (M) 1

2* Tuerca, 3/8" NPS (F) 1

3* Leva 1

4* TGC-407-1-K3 Válvula libre de goteo y empaque

(Kit de 3) 1

5* TGC-9-K5 **Empaque de la tapa**Tri Seal®

(Kit de 5) 1

6 TGC-404 Unidad de la tapa (cuarto de galón) 1

7 KR-428-2 Unidad de la taza de succión.

(Cuarto de galón) 1

TLC-401 Unidad de la taza de succión.

(Revestimiento antiadherente, cuarto de galón)

* El Kit de reparación * KK-5007 incluye Núm. de Ref. 1-5. El kit de repara-

ción contiene suficientes piezas para reparar una unidad completa.

El sufijo -K3 designa un kit de piezas múltiples. Ejemplo: TGC-407-1-K3 es

un kit de 3 válvulas libres de goteo.

** Marca registrada de Tri-Seal International.

Figura 4

Varilla de

unión

Mantenga

estas

superficies

limpias.

1

Aplique sellador a las

dos primeras roscas

(Loctite #262).

2

3

4

5

6

7

SB-4-391-V (6/2016)ES-4 / 5

Page 11

POLÍTICA DE GARANTÍAS

Los productos DeVilbiss están cubiertos por la garantía limitada de materiales y mano de obra por un año

de Carlisle Fluid Technologies. El uso de cualquier pieza o accesorio de una fuente que no sea Carlisle Fluid

Technologies, anulará todas las garantías. Para obtener información especíca sobre la garantía, favor ponerse

en contacto con el local de Carlisle Fluid Technologies más cercano a usted entre los listados a continuación.

Carlisle Fluid Technologies se reserva el derecho de modicar las especicaciones del equipo sin previo aviso.

DeVilbiss®, Ransburg®, MS®, BGK®, y Binks® son marcas registradas de Carlisle Fluid Technologies, Inc.

©2016 Carlisle Fluid Technologies, Inc. Reservados todos los derechos.

DeVilbiss es parte de Carlisle Fluid Technologies, un líder global en tecnologías de

acabados innovadores. Para asistencia técnica o para localizar un distribuidor autorizado,

póngase en contacto con uno de nuestros centros internacionales de ventas y apoyo al

cliente listados.

EE.UU/Canadá

info@carlisleft.com

Teléfono: 1-888-992-4657

Fax: 1-888-246-5732

Reino Unido

info@carlisleft.eu

Teléfono: +44 (0)1202 571 111

Fax: +44 (0)1202 573 488

China

mkt@carlisleft.com.cn

Teléfono: +8621-3373 0108

Fax: +8621-3373 0308

Para obtener la última información sobre nuestros productos, visite www.carlisleft.com.

DeVilbiss Automotive Renishing es parte de Carlisle Fluid Technologies, un líder

global en tecnologías de acabados innovadores. Para asistencia técnica o para

localizar un distribuidor autorizado, póngase en contacto con uno de nuestros

centros internacionales de ventas y apoyo al cliente listados.

México

ventas@carlisleft.com.mx

Teléfono: 011 52 55 5321 2300

Fax: 011 52 55 5310 4790

Francia

info@carlisleft.eu

Teléfono: +33(0)475 75 27 00

Fax: +33(0)475 75 27 59

Japón

overseas-sales@carlisleft.co.jp

Teléfono: 081 45 785 6421

Fax: 081 45 785 6517

Brasil

vendas@carlisleft.com.br

Teléfono: +55 11 5641 2776

Fax: 55 11 5641 1256

Alemania

info@carlisleft.eu

Teléfono: +49 (0) 6074 403 1

Fax: +49 (0) 6074 403 281

Australia

sales@carlisleft.com.au

Teléfono: +61 (0) 2 8525 7555

Fax: +61 (0) 2 8525 7575

EE.UU/Canadá

www.autorenishdevilbiss.com

askus@carlisleft.com

Tel gratuito: 1-800-445-3988

Fax gratuito: 1-800-445-6643

SB-4-391-V (6/2016) ES-5 / 5

México

www.autorenishdevilbiss.com.mx

Tel gratuito: 1-888-835-6232 USA

Page 12

MANUEL DE SERVICE

Trousse de réparation KK-5007

■

TLC-555 ET TGC-545

RÉSERVOIRS À SUCCION À L’ÉPREUVE DES FUITES

Important : Prendre connaissance de toutes les consignes de

sécurité et des directives avant d’utiliser ce matériel. Conserver

pour utilisation future.

Figure 1

DESCRIPTION

Modèles : ■ TLC-555 : capacité de 950 ml (1 pinte)

Réservoir à doublure de revêtement anti-adhésif

TGC-545 : capacité de 946 ml (1 pinte)

Ces réservoirs à l’épreuve des fuites sont munis d’une soupape unique,

à deux positions, qui permet de choisir un mode de pulvérisation sans

fuite ou un mode conventionnel à évent ouvert.

Dans la position sans fuite, l’air est dirigé à travers l’évent du couvercle

vers un sillon sous l’anneau d’étanchéité du couvercle avant de

pénétrer dans le réservoir, au niveau de la soupape. Cela permet

de pencher le réservoir lorsqu’il est plein sans que la peinture ne

dégoutte à travers l’évent. Le réservoir peut également ètre renversé

en pulvérisant, sans fuir.

La position ouverte isole le sillon et ouvre un évent direct vers le

réservoir.

La position de la soupape est indiquée en alignant l’orifice de la fente

de la soupape avec les marques qui se trouvent sur le couvercle. Ces

positions sont identifiées par « O » pour l’évent ouvert et par « D/F

» pour le mode sans fuite.

Remarque

Réservoir en revêtement anti-adhésif : Utiliser uniquement une

spatule ou un mélangeur en bois ou en plastique pour remuer

le produit dans le réservoir en revêtement anti-adhésif (7).

L’utilisation d’une spatule ou d’un mélangeur en métal peut

égratigner le revètement de revêtement anti-adhésif.

Remarque

La couleur du revètement en revêtement anti-adhésif peut

varier dans les différents réservoirs recouverts de revêtement

anti-adhésif. Ces différences sont la conséquence du processus

normal de production utilisé pour ce type de revètement. Nous

avons choisi cette qualité de revètement de revêtement antiadhésif, car elle fournit le meilleur rendement général et la plus

grande durabilité possible.

FONCTIONNEMENT

Mode à évent ouvert « O » : Pour travailler en mode à évent ouvert,

faire pivoter la soupape à l’aide d’un tournevis ou d’une pièce de

monnaie de manière à ce que l’orifice de la fente de la soupape soit

aligné avec le « O » qui se trouve sur le couvercle. Voir figure 2.

Si l’orifice de la fente de la soupape se bouche lors du fonctionnement

en mode d’évent ouvert, utiliser un outil pointu comme un clou ou un

foret pour pénétrer dans l’orifice de la fente de la soupape et déloger

ce qui l’obstrue.

Dessus du couvercle Dessous du couvercle

Anneau

d’étanchéité

Sillon

Trou

d’évent

du sillon

Anneau d’étanchéité

montré partiellement

retiré

Trou d’évent

du sillon :

(ne pas y insérer

d’objet.)

D/F

O

On peut insérer

un objet dans

l’orifice de la

fente de la soupape pour

le dégager.

Soupape en

position ouverte

Figure 2 : mode à évent ouvert

Mode sans fuite « D/F » : Pour travailler en mode sans fuite, faire

pivoter la soupape à l’aide d’un tournevis ou d’une pièce de monnaie

de manière à ce que l’orifice de la fente de la soupape soit aligné avec

le « D/F » qui se trouve sur le couvercle. Voir figure 3.

AVERTISSEMENT

Ne jamais insérer d’objet dans le trou d’évent du sillon. Ne pas

insérer d’objet dans l’orifice de la fente de la soupape alors

que la soupape est en position « D/F ». Ces ouvertures sont

scellées par un anneau d’étanchéité et l’insertion d’un objet

risque de l’endommager. Voir figures 2 et 3.

Mouvement de la soupape : Ne pas tourner la soupape de force. Si

elle ne tourne pas librement, faire tremper dans du solvant ou retirer

le module du couvercle du réservoir et appuyer sur le sommet de la

soupape jusqu’à ce qu’elle soit libérée. La soupape peut bouger librement d’environ 3 mm (1/8 po) à la verticale. Cela permet de pousser

l’anneau d’étanchéité pour le dégager.

Dessus du couvercle

Orifice de la

fente de la

soupape :

(ne pas y insérer

d’objet.)

Soupape en posi-

D/F

Trou d’évent

du sillon :

(ne pas y insérer

d’objet.)

O

tion sans fuite

Figure 3 : modèle sans fuite

DSN gouvernemental n° 4940-01-208-8876 = TLC-555

Dessous du couvercle

Anneau d’étanchéité

montré partiellement

retiré

SB-4-391-V (6/2016)FR-1 / 5

Page 13

CONSIGNES DE SÉCURITÉ

Ce manuel renferme des renseignements importants que TOUS les utilisateurs doivent connaître et comprendre AVANT d’utiliser ce matériel.

Cette information se rapporte à la SÉCURITÉ DE L’UTILISATEUR et à la PRÉVENTION DES PROBLÈMES DE FONCTIONNEMENT DU MATÉRIEL.

Pour aider les utilisateurs à se retrouver dans cette information, nous avons recours aux termes suivants pour attirer l’attention sur certaines

étiquettes du matériel et des sections du manuel. Porter une attention particulière à toute étiquette ou information qui est soulignée par

l’un de ces termes :

MISE EN GARDE

Information importante pour attirer l’attention

sur une situation pouvant occasionner des blessures graves ou même la mort.

Information à laquelle il faut porter une attention particulière.

Information importante servant à prévenir les

dommages au matériel

Remarque

AVERTISSEMENT

MISE EN GARDE

Les dangers suivants peuvent se produire durant l’usage normal de cet appareil.

Lire attentivement le tableau suivant.

DANGER MESURES DE PROTECTION

Feu

Pulvérisation de solvants

CAUSE

Les solvants et les revètements

peuvent ètre hautement inflammables

ou combustibles, surtout lorsqu’ils sont

vaporisés.

Durant le nettoyage et le rinçage du

matériel, des solvants peuvent ètre

évacués sous pression des conduites

d’air et de liquide. Certains solvants

peuvent occasionner des blessures ou

de l’irritation aux yeux.

Ne pas vaporiser près de flammes, veilleuses des

cuisinières et appareils de chauffage, ou autres

sources de chaleur.

Il est essentiel de toujours fournir une ventilation

adéquate. Toutes les utilisations industrielles doivent

respecter les normes de l’OSHA.

Porter des lunettes de protection.

Risque d’explosion :

matériaux incompatibles

Inhalation de substances toxiques

Les solvants chlorés, par exemple :

le trichloroéthane 1-1-1 et le

dichlorométhane (parfois appelés

chlorométhane), peuvent causer une

réaction chimique avec l’aluminium

contenu dans la plupart des pistolets

pulvérisateurs, et leurs réservoirs, et

provoquer un risque d’explosion. Les

modèles TLC-555, TGC-545 et TGC-536

sont faits d’aluminium.

Certains produits peuvent ètre nocifs

lorsqu’inhalés, ou s’ils entrent en

contact avec la peau.

CA PROP

65

PROPOSITION 65 AVERTISSEMENT

AVERTISSEMENT: Ce produit contient des produits chimiques connus de l’état de

Californie pour causer des malformations congénitales ou d’autres cancers et

troubles de la reproduction.

1. Lire l’étiquette ou la fiche technique du produit à

pulvériser.

2. N’utiliser aucun type de matériaux de revètement

contenant ces solvants.

3. Ne pas utiliser ces solvants pour nettoyer et rincer

le matériel.

4. En cas de doute à savoir si un produit est

compatible avec le matériel, communiquer avec le

fournisseur du matériel.

Suivre les recommandations de sécurité de la fiche

technique fournie par le fabricant du produit de

revètement à pulvériser.

Un système d’évacuation adéquat doit ètre prévu afin

d’éviter l’accumulation de vapeurs toxiques.

Utiliser un masque ou un respirateur lorsqu’il existe

un risque d’inhaler les produits pulvérisés. Le

masque doit ètre compatible avec le produit utilisé et

sa concentration. Le matériel de protection doit ètre

recommandé par un expert en santé et sécurité au

travail et approuvé par NIOSH.

SB-4-391-V (6/2016) FR-2 / 5

Page 14

INSTALLATION

Méthodes de nettoyage :

1. Placer l’étrier à angle droit par rapport au corps du pistolet, avec

le trou d'évent du couvercle vers l’arrière et le levier de came (3)

vers l’avant du pistolet.

2. Installer le module du couvercle du réservoir au pistolet en

fixant l’écrou (voir l’élément nº 2 de la figure 4), au mamelon

d’admission du liquide sur le pistolet. Resserrer l’écrou avec une

clé, sans forcer.

3. Filtrer le produit à pulvériser à travers un tamis 60 ou 90 avant

de le verser dans le réservoir.

4. Engager les goupilles du réservoir dans l’étrier et resserrer en

déplaçant le levier de came dans le sens des aiguilles d’une

montre.

ENTRETIEN

Réparation/remplacement du couvercle :

1. Pour remplacer toute pièce endommagée, utiliser une clé

hexagonale 5/16 po pour desserrer et retirer l’adaptateur (1),

l’écrou (2), l’étrier et la came (3). Les pièces du module couvercle

et du tube sont maintenant libres et peuvent ètre remplacés.

2. Remplacer les pièces endommagées du module du couvercle et

du tube. Le levier de came doit ètre situé du côté du couvercle

opposé à la soupape (4).

3. Appliquer un agent d'étanchement (Loctite nº 262) aux deux

premiers filets de l’adaptateur (1). Insérer l’extrémité filetée de

l’adaptateur dans l’extrémité ouverte de l’écrou (2).

4. Installer l’adaptateur (1) et l’écrou (2) au sommet du module du

couvercle et du tube. Utiliser une clé hexagonale 5/16 po pour

bien resserrer l’écrou (15 à 18 kg/m [10-12 pi/lb]).

Remplacement de la soupape et de l’anneau d’étanchéité du

couvercle :

1. Pour retirer une soupape (4) ou un couvercle de soupape (5)

endommagé, appuyer sur le sommet de la soupape jusqu’à ce

qu’elle soit libérée. La soupape pousse l’anneau d’étanchéité

du couvercle hors de son assise. Il est maintenant possible de

retirer l’anneau du couvercle. Continuer à appuyer fermement

sur la soupape pour la libérer du couvercle.

2. Installer la soupape de rechange (4) à travers le bas du couvercle

de manière à ce que la languette de la soupape soit dirigée

vers le centre du couvercle. Enclencher en place. Si nécessaire,

utiliser un maillet de plastique ou la poignée d’un tournevis pour

enfoncer la soupape en place. Appuyer fermement sur l’anneau

d’étanchéité du couvercle pour le faire pénétrer en place à l’aide

de l’extrémité d’une clé à molette. Insérer d’abord le côté portant

les marques noires.

1. Vider la peinture du réservoir et verser une petite quantité de

solvant propre à l’intérieur. La quantité nécessaire variera en

fonction du type de revètement et de solvant.

2. Agiter le réservoir afin de bien laver les surfaces intérieures.

Vaporiser ensuite le solvant avec une pression d’air réduite 103

à 134 kPa (15 à 20 psi) pour expulser le liquide des conduits.

3. Jeter le solvant et remplacer par une quantité égale de solvant

propre.

4a. Agiter de nouveau le réservoir. Desserrer l’anneau déflecteur.

Tenir un linge plié devant le pistolet et retourner le réservoir sur

le contenant de solvant. Appuyer à petits coups sur la gâchette

pour que solvant circule à l’envers dans le conduit de l’évent.

En mettant la soupape en position D/F, le solvant sera expulsé

avec force du trou d’évent du sillon dans le couvercle.

Solution de rechange à l’étape 4a.

4b. Couper l'alimentation en air du pistolet. En mettant la soupape

en position D/F position, retourner le réservoir sur le réservoir

de solvant. Appuyer sur la gâchette. Laisser le solvant dégoutter

du trou d’évent du sillon dans le couvercle pendant plusieurs

secondes, ou jusqu’à ce que du solvant propre s’écoule.

AVERTISSEMENT

• Ne jamais insérer d’objet dans le trou d’évent du sillon. Ne

pas insérer d’objet dans l’orifice de la fente de la soupape

alors que la soupape est en position D/F. Ces ouvertures sont

scellées par un anneau d’étanchéité (5) et l’insertion d’un

objet risque de l’endommager.

• Ne pas utiliser d’abrasif comme une brosse métallique ou

de la laine d’acier pour nettoyer l’intérieur du réservoir en

revêtement anti-adhésif (7). La surface de revêtement antiadhésif pourrait être endommagée.

IMMERSION

Étant donné que tous les matériaux composant le réservoir sont très

résistants aux solvants, le module du réservoir peut ètre immergé pour

le nettoyage. L’immersion de doit pas dépasser 24 heures. L’utilisation

de décapant à peinture est à éviter, car ces produits peuvent réagir

avec aluminium ainsi qu’avec d’autres composants non métalliques.

Si l’anneau d’étanchéité du couvercle gonfle suite à une exposition

prolongée aux solvants, il reprendra sa taille originale sans perdre

ses propretés une fois asséché.

NETTOYAGE

Remarque

Toujours nettoyer les surfaces du levier de came (3) avec

du solvant propre et une brosse. Cela assurera son bon

fonctionnement. Ne pas lubrifier la came.

Général : Pour un nettoyage de routine, il n’est pas nécessaire de

retirer l’anneau d’étanchéité du réservoir. Il n’est pas nécessaire ni

souhaitable de retirer la soupape pour effectuer le nettoyage. Il est

possible d’abaisser la soupape de l’extérieur afin de contribuer au retrait

de l’anneau d’étanchéité, pour le remplacer, ou déloger la peinture

séchée du sillon. La soupape ne doit pas ètre poussée plus loin que

l’épaulement qui la retient dans le couvercle, sauf pour la remplacer.

Pression d’air : Toujours réduire la pression d’air pour effectuer le

nettoyage. Une pression d’air ne dépassant pas 103 à 134 kPa (15 à

20 psi) permettra un nettoyage rapide et profond du réservoir et du

pistolet tout en assurant de :

1. réduire la quantité de solvant pulvérisé dans l’air;

2. prévenir les risques que la contre-pression excessive

n’endommage le réservoir;

3. réduire la force avec laquelle le solvant est expulsé de l’évent.

SB-4-391-V (6/2016)FR-3 / 5

Page 15

Liste des pièces

N°

de N° de pièce

réf. détachée Description

Nb de

pièces

nécessaire

1* Adaptateur, 1/2 po NPS (M) 1

2* Écrou, 3/8 NPS (F) 1

3* Came 1

4* TGC-407-1-K3 Soupape et anneau d’étanchéité sans

fuite (ensemble de 3) 1

5* TGC-9-K5 **Anneau d’étanchéité de couvercle

Tri Seal® (ensemble de 5) 1

6 TGC-404 Module du couvercle (946 ml

[1 pinte]) 1

7 KR-428-2 Module de réservoir à succion

(946 ml [1 pinte]) 1

TLC-401 Module de réservoir à succion

(Revêtement anti-adhésif, 946 ml [1 pinte])

* La trousse de réparation KK-5007 contient les numéros de réf. 1 à 5. La

trousse de réparation contient suffisamment de pièces pour réparer un

module complet.

Le suffixe K3 désigne un ensemble comprenant plusieurs pièces. Par

exemple : L’ensemble TGC-407-1-K3 comprend 3 soupapes sans fuite.

** Marque de commerce enregistrée de Tri-Seal International.

Figure 4

Garder

ces

surfaces

propres.

Étrier

1

Appliquer un agent

d'étanchement (Loctite n° 262) aux deux

premiers filets.

2

3

4

5

6

7

SB-4-391-V (6/2016) FR-4 / 5

Page 16

CONDITIONS DE GARANTIE

Les produits DeVilbiss sont couverts contre les vices de matériel et de fabrication par une garantie limitée d’un

an de Carlisle Fluid Technologies. L’utilisation de toutes pièces ou accessoires issus d’une source autre que

Carlisle Fluid Technologies, annulera toutes les garanties. Pour des informations précises sur la garantie, veuillez

contacter le site de Carlisle Fluid Technologies le plus proche, que vous trouverez sur la liste ci-dessous.

Carlisle Fluid Technologies se reserve le droit de modier sans préavis les spécications de l’équipement.

DeVilbiss®, Ransburg®, MS®, BGK®, et Binks® sont des marques de commerce déposées de

Carlisle Fluid Technologies, Inc. ©2016 Carlisle Fluid Technologies, Inc. Tous droits réservés.

DeVilbiss fait partie de Carlisle Fluid Technologies, un leader mondial dans le domaine des

technologies innovatrices de nition. Pour toute assistance technique ou pour localiser un

distributeur agréé, veuillez contacter l’un de nos bureaux de ventes internationaux et de

soutien client.

USA/Canada

info@carlisleft.com

Tél: 1-888-992-4657

Fax: 1-888-246-5732

Royaume-Uni

info@carlisleft.eu

Tél: +44 (0)1202 571 111

Fax: +44 (0)1202 573 488

Chine

mkt@carlisleft.com.cn

Tél: +8621-3373 0108

Fax: +8621-3373 0308

Pour obtenir les dernières informations sur nos produits, visitez www.carlisleft.com.

Mexique

ventas@carlisleft.com.mx

Tél: 011 52 55 5321 2300

Fax: 011 52 55 5310 4790

France

info@carlisleft.eu

Tél: +33(0)475 75 27 00

Fax: +33(0)475 75 27 59

Japon

overseas-sales@carlisleft.co.jp

Tél: 081 45 785 6421

Fax: 081 45 785 6517

Brésil

vendas@carlisleft.com.br

Tél: +55 11 5641 2776

Fax: 55 11 5641 1256

Allemagne

info@carlisleft.eu

Tél: +49 (0) 6074 403 1

Fax: +49 (0) 6074 403 281

Australie

sales@carlisleft.com.au

Tél: +61 (0) 2 8525 7555

Fax: +61 (0) 2 8525 7575

DeVilbiss Automotive Renishing fait partie de Carlisle Fluid Technologies, un leader

mondial dans le domaine des technologies innovatrices de nition. Pour toute

assistance technique ou pour localiser un distributeur agréé, veuillez contacter l’un

de nos bureaux de ventes internationaux et de soutien client.

USA/Canada

www.autorenishdevilbiss.com

askus@carlisleft.com

Tél sans frais: 1-800-445-3988

Fax sans frais: 1-800-445-6643

Mexique

www.autorenishdevilbiss.com.mx

Tél sans frais: 1-888-835-6232 USA

SB-4-391-V (6/2016)FR-5 / 5

Loading...

Loading...