Page 1

TB-1022

Replaces TB-1022

Technical Bulletin

Professional Pressure

Feed Spraygun

Gun Repair Kit

PRO-470

ghcustserv@carlisleft.com

800.992.4657

www.devilbiss.com

Page 2

TB-1022

Table of Contents

Topic Page

EC Declaration of Conformity .................................................................................................................................3

Operational Description ............................................................................................................................................3

Construction Features, Materials of Construction, ....................................................................................4

Specications & Technical Data

Safety Precautions .......................................................................................................................................................5

Installation, Operation, Preventive Maintenance & Cleaning, .............................................................6

Spray Gun Lubrication

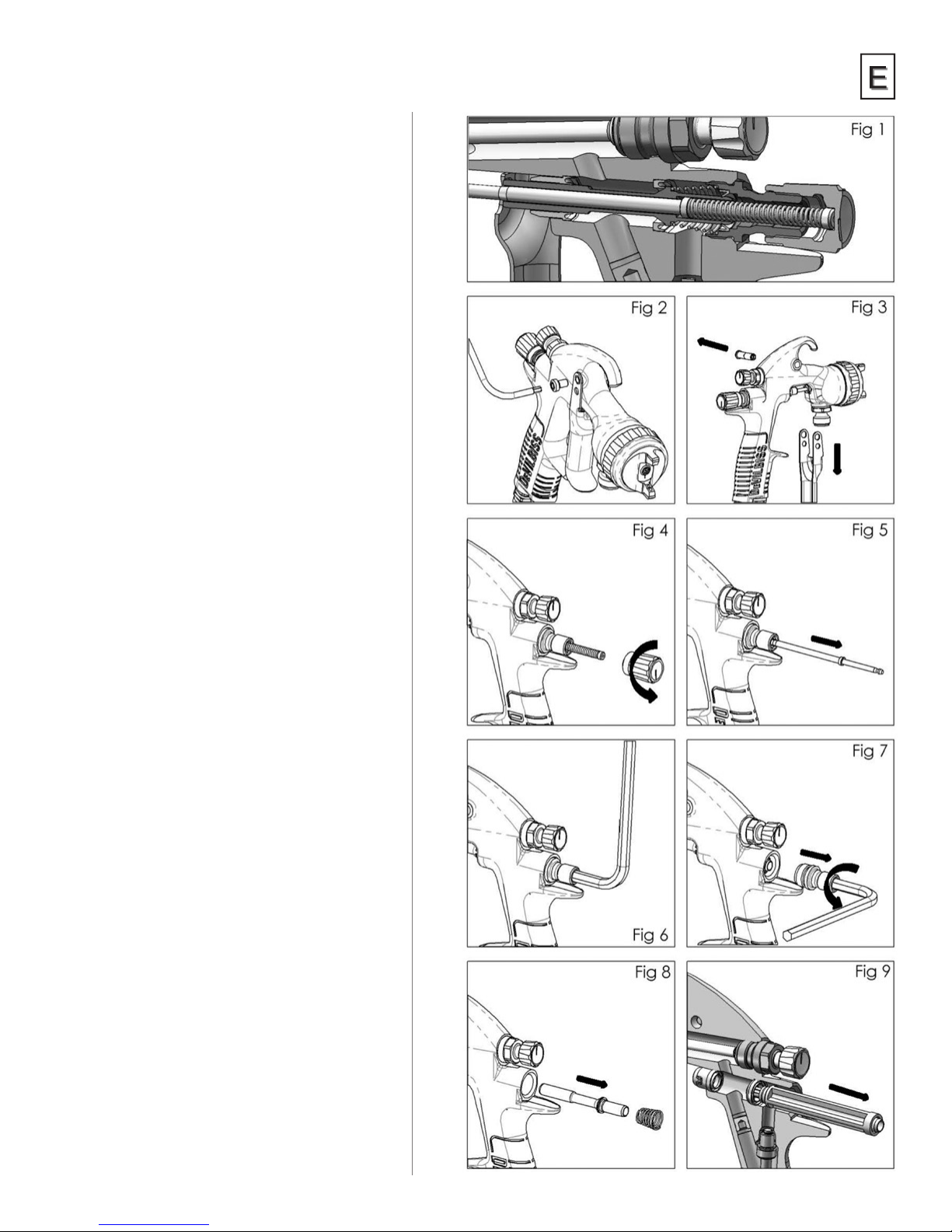

Parts Replacement/Maintenance ..............................................................................................................7–12

A. Servicing Air Valve ..............................................................................................................................7–8

B. Needle Packing, Spreader Valve Assembly, Fluid Inlet Seal ............................................. 9

C. Spray Head Seal Replacement ....................................................................................................... 10

D. Chart 1 – Air Caps ................................................................................................................................. 11

Chart 2 – Fluid Nozzles & Fluid Needles

E. Exploded View and Parts List .......................................................................................................... 12

Troubleshooting Possible Problems in Operation ............................................................................13–14

Accessories ................................................................................................................................................................... 14

Warranty .........................................................................................................................................................................15

When used with the HVLP cap, this gun can be used

anywhere—both in mandated HVLP and unregulated areas.

When used with high efciency caps and Automotive

Renishing materials, these spray guns have been found

to exceed 65% transfer efciency under recommended

conditions.

Consult your local air quality management agency with any

questions regarding HVLP or compliance requirements in

your area.

2

NOTE:

Page 3

Technical Bulletin

TEKNA Pro Lite Pressure Feed Spraygun

IMPORTANT: Read and follow all instructions and Safety Precautions before using this equipment. Keep

for future use.

EC Declaration of Conformity

We, Finishing Brands UK, Ltd., Ringwood Rd, Bournemouth, Dorset, BH11 9LH, UK, as the manufacturer of the

Spray gun model TEKNA PRO LITE, declare, under our sole responsibility, that the equipment to which this

document relates is in conformity with the following standards or other normative documents:

BS EN 12100 PARTS 1 & 2: 2010, BS EN 1953: 1998+A1:2009; and thereby conform to the

protection requirements of Council Directive 98/37/EEC relating to Machinery Safety Directive, and;

EN 13463-1:2009, council Directive 94/9/EC relating to Equipment and Protective Systems intended

for use in Potentially Explosive Atmospheres protection level II 2 G X.

This product also complies with the requirements of the EPA guidelines, PG6/34. Transfer efciency certicates

are available on request.

TB-1022

D Smith, General Manager

2nd February 2014

The TEKNA Pro Lite complies to ATEX regulations 94/9/EC, protection level II 2 G X, Suitable for use in Zones 1 and 2.

DeVilbiss Automotive Renishing reserves the right to modify equipment specication without prior notice.

Operational Description

The TEKNA Pro Lite spraygun is a lightweight professional gun designed to handle both water-based and solventbased coating materials. Both HVLP and high efciency models are available.

High volume, low pressure (HVLP) models are designed to reduce overspray and provide maximum transfer

efciency by limiting air cap pressure to 0.7 bar (10 psi) (complies with rules issued by SCAQMD and other air

quality authorities).

HVLP models will produce approximately 0.7 bar (10 psi) air cap pressure at 1.2 bar (17 psi) gun inlet pressure

with the trigger pulled. HVLP air cap #HV40 is designed for optimum basecoat and clear coat applications. An

air cap test kit is available (see Accessories) which can be utilized to set the exact air cap pressure.

High efciency models use air cap #TE20 or #TE40. These models are designed to provide optimum

atomization of virtually all waterborne or solvent-based common coating materials at increased application

rates while maintaining very high transfer efciency. High efciency models, when tested under recommended

conditions with automotive renishing materials, have been found to exceed 65% transfer efciency.

IMPORTANT: These guns are not designed for use with highly corrosive and/or abrasive materials and if

used with such materials it must be expected that the need for cleaning and/or replacement of parts will be

increased. If there is any doubt regarding the suitability of a specic material, contact your TEKNA Distributor or

TEKNA direct.

NOTE: This gun is not to be used with halogenated hydrocarbon solvents or cleaning agents such as

1,1,1,-Trichloroethane or methylene chloride. These solvents can react with the aluminium components

used in this gun and cup. The reaction can become violent and lead to an equipment explosion.

3

Page 4

TB-1022

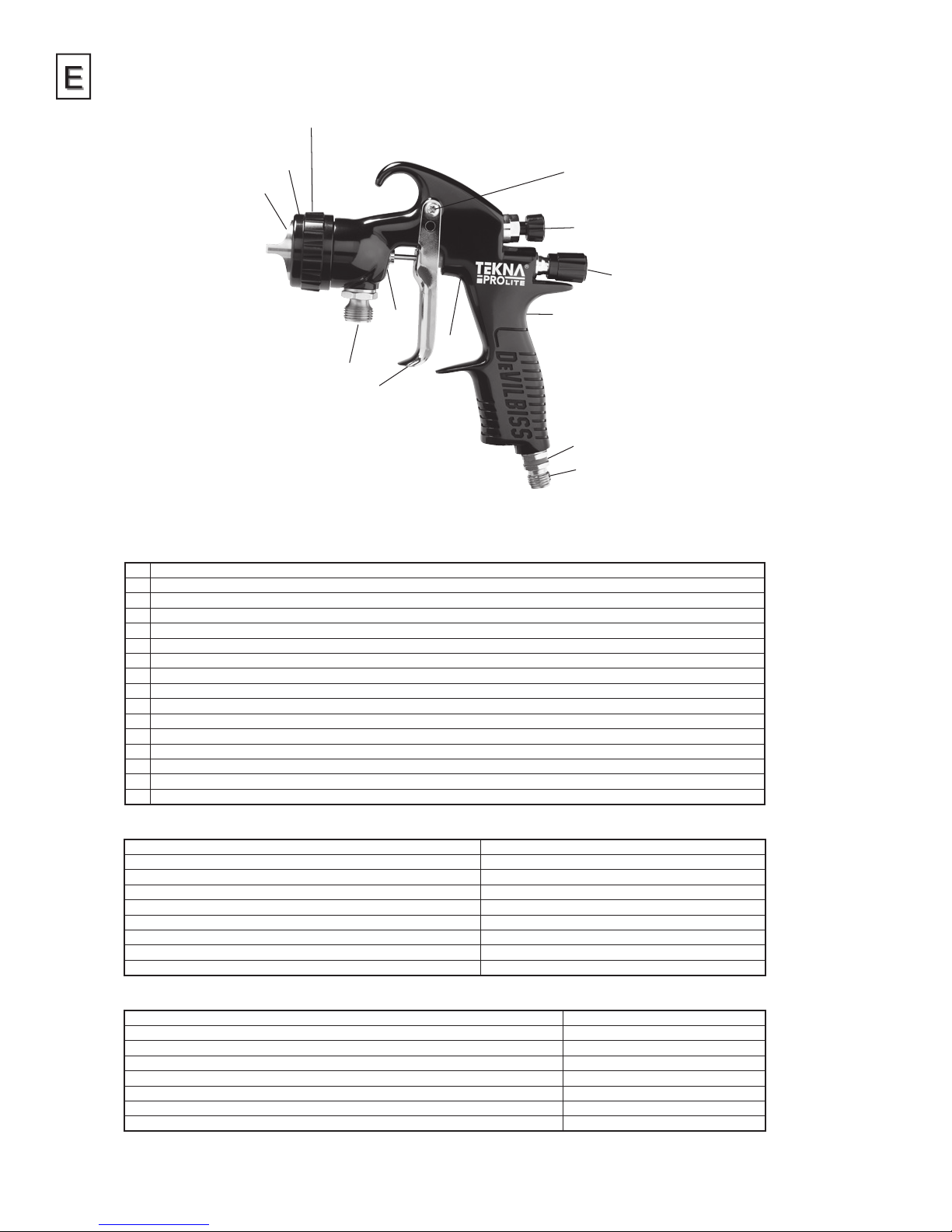

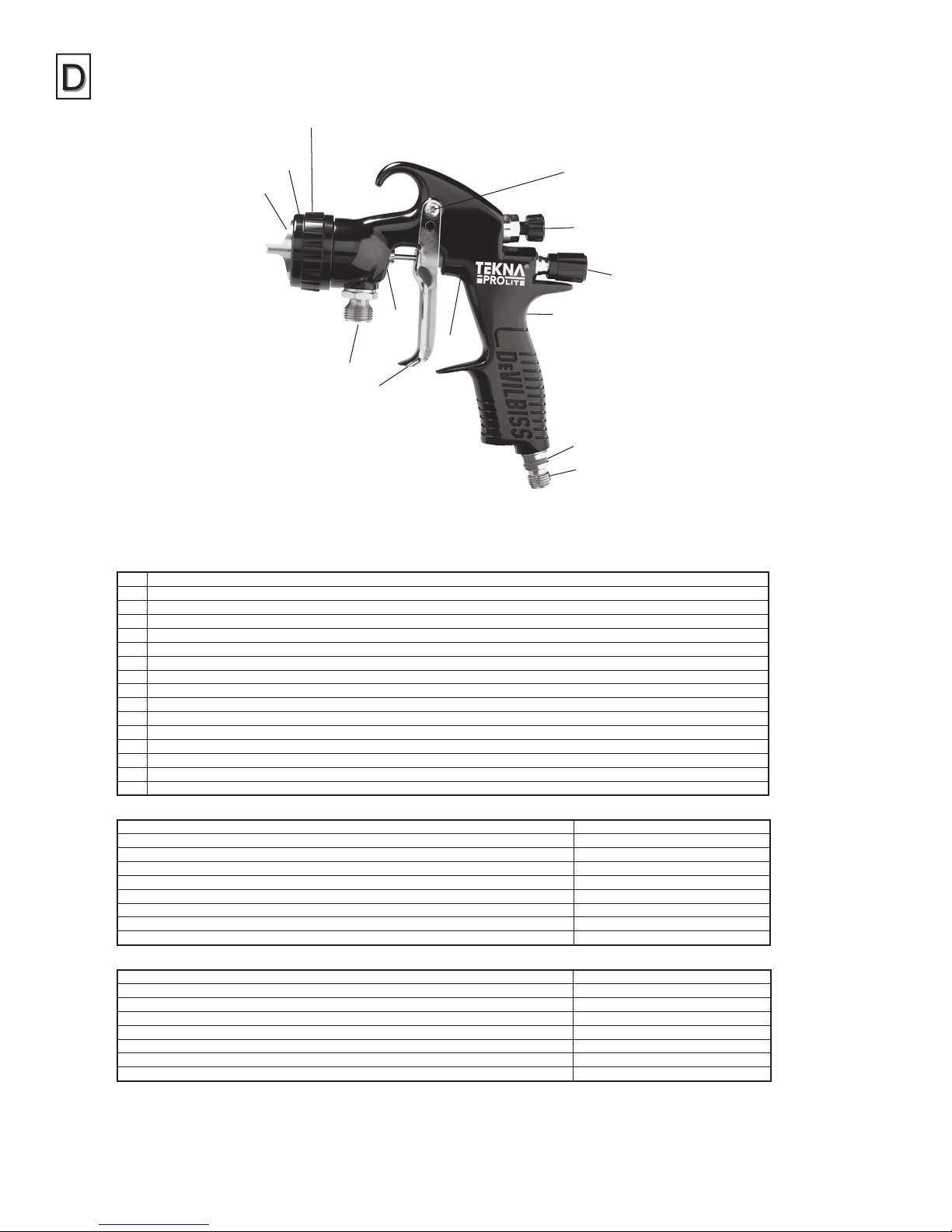

3, 4, 12

2

1

7

15

5

8

Construction Features

1 Air Cap (nickel plated brass for long durability)

2 Air Cap Retaining Ring (allows easy rotation of air cap)

3 Fluid Nozzle (not visible, ideal for automotive topcoat systems)

4 Fluid Needle (not visible)

5 Fluid Inlet (3/8 BSP thread)

6 Air Inlet (universal thread, accepts G 1/4 & 1/4 NPS)

7 Self Adjusting Needle Packing (packing not visible, for long packing life)

8 Trigger (ergonomic for comfort)

9 Trigger Stud & Screw (easy replacement design)

10 Fan Air Adjustment (stepless regulation for at to round spray)

11 Fluid Adjustment (stepless regulation of uid volume)

12 Removable Spray Head (not visible, for long gun service life)

13 Interchangeable Colour ID System (4 coloured rings supplied)

14 Forged gun body (ergonomic, good looking & durable, easy to clean)

15 Air Valve (not visible) (design offers low pull force & low pressure drop)

16 Gun acceptable for waterborne and solvent borne applications

9

10

11

14

13

6

Materials of Construction

Gun Body Anodized QuickClean®aluminium

Air Cap Nickel plated brass

Fluid Nozzle, Fluid Needle, Fluid Inlet, Trigger Stud Stainless steel

Spray Head, Air Cap Retaining Ring, Knobs, Handle Plug Anodized aluminium

Springs, Clips, Screws Stainless steel

Seals, Gaskets Solvent resistant

Trigger Chrome plated steel

Air Inlet, Body Bushing, Spreader Valve Body, Air Valve Nut Chrome plated brass

Air Valve Assembly Aluminum

Specifications & Technical Data

Air Supply Connection Universal 1/4" BSP and 1/4" NPS

Maximum Static Air Inlet Pressure P1 = 12 bar (175 psi)

Nominal Gun Air Inlet Pressure for HVLP Models – HV40 cap (with gun triggered) 1.2 bar (17 psi) (for compliance)

Nominal Gun Air Inlet Pressure for High Efciency Models – TE40 cap (with gun triggered) 2.0 – 3.5 bar (29 – 50 psi)

Air Consumption See Chart 1 on page 11

Fluid Supply Connection 3/8" BSP

Service Temperature 0 to 40°C (32 to 100°F)

Gun Weight (gun only) 500g (17.6 oz.)

4

Page 5

TB-1022

PROP 65 WARNING

WARNING: This product contains

chemicals known to the State of

California to cause cancer and birth

defects or other reproductive harm.

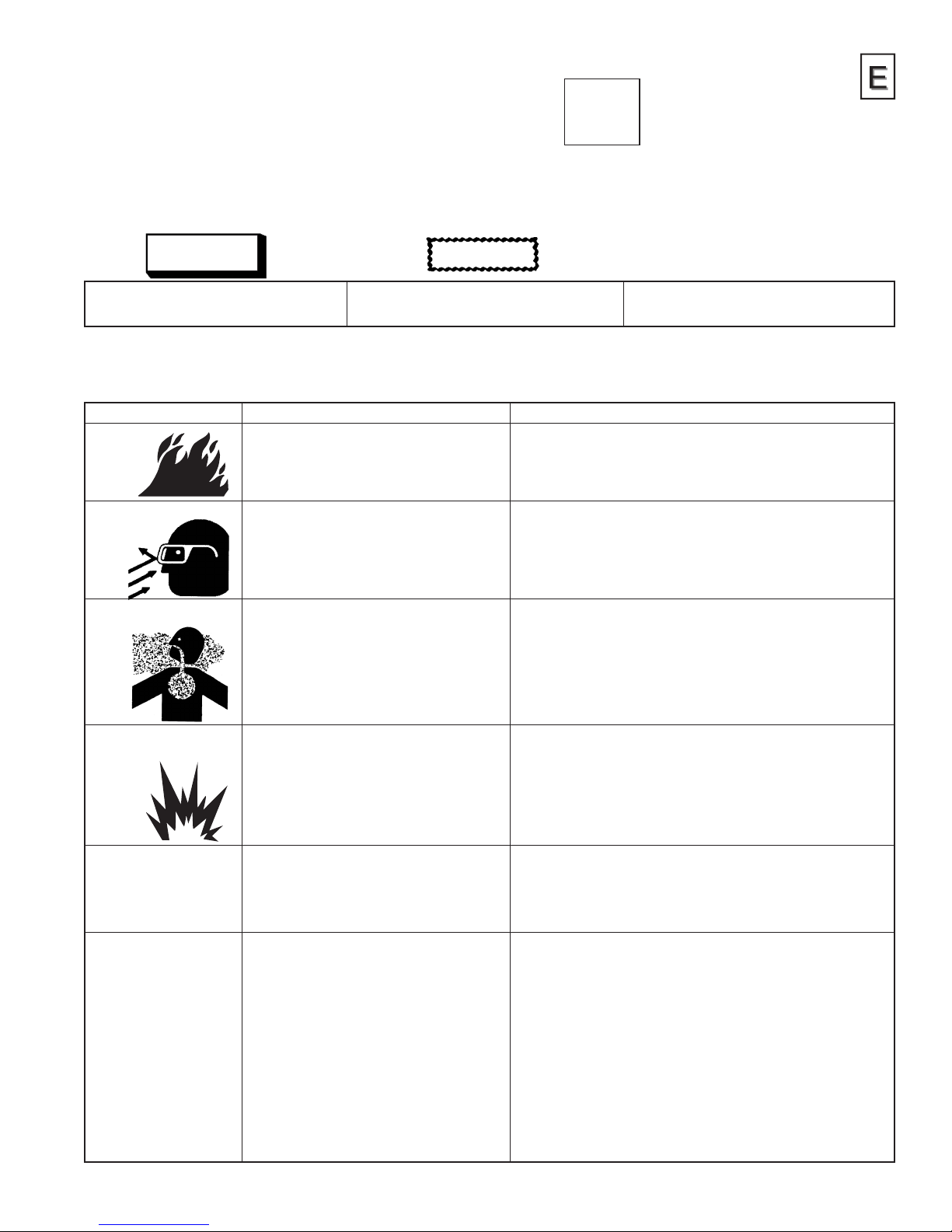

Safety Precautions

CA PROP

65

This bulletin contains information that is important for you to know and understand. This information relates to USER SAFETY and

PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please pay particular

attention to these sections.

NOTE

Important safety information – A hazard that may

cause serious injury or loss of life.

WARNING

CAUTION

Important information that tells how to prevent damage

to equipment, or how to avoid a situation that may cause

minor injury.

Information that you should pay special attention to.

The following hazards may occur during the normal use of this equipment. Please read the following chart before using

this equipment.

HAZARD CAUSE SAFEGUARDS

Fire

Solvent Spray

Solvent and coatings can be highly ammable or

combustible especially when sprayed.

During use and while cleaning and ushing, solvents

can be forcefully expelled from uid and air passages.

Some solvents can cause eye injury.

Adequate exhaust must be provided to keep air free of accumulations of

ammable vapours.

Smoking must never be allowed in the spray area.

Fire extinguishing equipment must be present in the spray area.

Wear eye protection.

Inhaling Toxic Substances

Explosion Hazard –

Incompatible Materials

General Safety

Cumulative Trauma disorders

(“CTD’s”)

CTD’s, or musculoskeletal

disorders, involve damage

to the hands, wrists, elbow,

shoulders, neck and back.

Carpal tunnel syndrome

and tendonitis (such as

tennis elbow or rotator

cuff syndrome) are examples

of CTD’s.

Certain materials may be harmful if inhaled, or if there

is contact with the skin.

Halogenated hydrocarbon solvents – for example;

methylene chloride and 1,1,1,-Trichloroethane are

not chemically compatible with the aluminium that

might be used in many system components. The

chemical reaction caused by these solvents reacting

with aluminium can become violent and lead to an

equipment explosion.

Improper operation or maintenance of equipment. Operators should be given adequate training in the safe use and maintenance of

Use of hand tools may cause cumulative trauma

disorders (“CTD’s”).

CTD’s, when using hand tools, tend to affect the upper

extremities. Factors which may increase the risk of

developing a CTD include:

1. High frequency of the activity.

2. Excessive force, such as gripping, pinching,

or pressing with the hands and ngers.

3. Extreme or awkward nger, wrist, or

arm positions.

4. Excessive duration of the activity.

5. Tool vibration.

6. Repeated pressure on a body part.

7. Working in cold temperatures.

CTD’s can also be caused by such activities as sewing,

golf, tennis, and bowling, to name a few.

Follow the requirements of the Safety Data Sheet supplied by your coating

material manufacturer.

Adequate exhaust must be provided to keep the air free of accumulations of toxic

materials.

Use a mask or respirator whenever there is a chance of inhaling sprayed

materials. The mask must be compatible with the material being sprayed and

its concentration. Equipment must be as prescribed by an industrial hygienist or

safety expert, and be NIOSH approved.

Guns with stainless steel internal passageways may be used with these solvents.

However, aluminium is widely used in other spray application equipment – such

as material pumps, regulators, valves, and cups. Check all equipment items

before use and make sure they can also be used safely with these solvents.

Read the label or data sheet for the material you intend to spray. If in doubt as to

whether or not a coating or cleaning material is compatible, contact your material

supplier.

the equipment (in accordance with the requirements of NFPA-33, Chapter 15).

Users must comply with all local and national codes of practice and insurance

company requirements governing ventilation, re precautions, operation,

maintenance, and housekeeping. These are OSHA Sections 1910.94 and

1910.107 and NFPA-33.

Pain, tingling, or numbness in the shoulder, forearm, wrist, hands, or ngers,

especially during the night, may be early symptoms of a CTD. Do not ignore

them. Should you experience any such symptoms, see a physician immediately.

Other early symptoms may include vague discomfort in the hand, loss of

manual dexterity, and nonspecic pain in the arm. Ignoring early symptoms and

continued repetitive use of the arm, wrist, and hand can lead to serious disability.

Risk is reduced by avoiding or lessening factors 1-7.

5

Page 6

TB-1022

INSTALLATION

For maximum transfer efciency, do not use more pressure than

is necessary to atomise the material being applied.

1. Connect the gun to a clean, moisture and oil free air

supply using a hose size of at least 8 mm (5/16") I.D. hose.

Do not use 6 mm I.D. hose (8 m x 6 mm hose at 510 LPM

has a pressure loss of 1.8 bar. 8 m x 8 mm hose at 510 LPM

has a pressure loss of 0.6 bar. [Do not use 1/4" I.D. hose

(25' x 1/4" hose at 18 CFM has a pressure loss of 25 psi.

25' x 5/16" hose at 18 CFM has a pressure loss of 8 psi).]

Depending on hose length, larger I.D. hose may be required.

NOTE

When gun is triggered on, adjust inlet air pressure

(for recommended pressures see Chart 1 under Parts

Replacement) at the gun inlet. (Pressure gauge shown under

Accessories is recommended for this). Do not use more

pressure than is necessary to atomise the material being

applied. Excess pressure will create additional overspray and

reduce transfer efciency.

NOTE

If quick connects are required, use only high ow quick

connects approved for HVLP use. Other types will not ow

enough air for proper gun operation.

NOTE

If an air adjusting valve is used at the gun inlet, use a DeVilbiss

air adjusting valve. Some competitive adjusting valves have

signicant pressure drop that can adversely affect spray

performance. DeVilbiss air adjusting valves have minimal

pressure drop.

2. Attach the uid supply hose to the uid inlet connector.

NOTE

Protective coating and rust inhibitors have been used

to keep the gun in good condition prior to shipment.

Before using the gun, ush it with solvents so that these

materials will be removed from uid passages.

9. If nish is too wet, reduce uid ow by turning uid adjusting

knob (28) clockwise. If atomisation is too coarse, increase inlet

air pressure. If too ne, reduce inlet pressure.

10. The pattern size can be reduced by turning spreader valve

adjusting knob (16) clockwise.

11. Hold gun perpendicular to surface being sprayed. Arcing

or tilting may result in uneven coating.

12. The recommended spray distance is 150-200 mm (6"–8").

13. Spray edges rst. Overlap each stroke a minimum of 75%. Move

gun at a constant speed.

14. Always turn off air supply and relieve pressure when gun is not

in use.

PREVENTIVE MAINTENANCE & CLEANING

To clean air cap and uid nozzle, brush exterior with a stiff bristle

brush. If necessary to clean cap holes, use a broom straw or

toothpick if possible. If a wire or hard instrument is used, extreme

care must be used to prevent scratching or burring of the holes which

will cause a distorted spray pattern.

To clean uid passages, remove uid supply hose, then ush with a

suitable solvent. Wipe gun exterior with a solvent dampened cloth.

Never completely immerse in solvent as this is detrimental to the

lubricants and packings.

NOTE

When replacing the uid nozzle or uid needle, replace both

at the same time. Using worn parts can cause uid leakage.

See page 11, Chart 2. Also, replace the needle packing at this

time. Lightly lubricate the threads of the uid nozzle before

reassembling. Torque to 18–20 Nm (13–15 ft-lbs). Do not over

tighten the uid nozzle.

CAUTION

To prevent damage to uid nozzle (8) or uid needle (24), be

sure to either 1) pull the trigger and hold while tightening or

loosening the uid nozzle, or 2) remove uid adjusting knob (28)

to relieve spring pressure against needle collar.

OPERATION

1. Mix coating material to manufacturer’s instructions and strain

material.

2. Fill the pressure cup with the required amount of material.

DO NOT OVERFILL.

3. Attach Cup Lid.

4. Turn uid adjusting knob (28) clockwise to prevent uid

needle movement.

5. Turn spreader valve adjusting knob (16) counter clockwise to

fully open.

6. Trigger gun on and adjust inlet air pressure (for

recommended gures see Chart 1 under Parts Replacement)

at the gun inlet. (Pressure gauge shown under Accessories is

recommended for this).

7. Turn uid adjusting knob (28) counter clockwise until rst

thread shows and turn on the supply air to the pressure cup.

8. Test spray. If the nish is too dry, reduce airow by reducing

air inlet pressure.

6

SPRAY GUN LUBRICATION

Daily, apply a drop of spray gun lubricant at trigger stud (40). The

shank of uid needle (24) where it enters packing nut (36) should

also be oiled. Fluid needle packing (34) should be lubricated

periodically. Make sure spray head (9) and air cap retaining ring (1)

threads are clean and free of foreign matter. Before assembling air

cap retaining ring to spray head, clean the threads thoroughly, then

add two drops of spray gun lubricant to threads. Fluid needle spring

(25) and air valve spring (21) should

be coated with a very light grease,

making sure that any excess grease

will not clog the air passages.

Points of Lubrication

A. Trigger Points

B. Packing

C. Adjusting Knobs

D. Air Cap Retaining Ring Threads

D

A

B

C

Page 7

Parts Replacement/

Maintenance

AIR VALVE INSTRUCTIONS

Servicing Air Valve

Reasons to service air valve:

A) Air valve not functioning properly

(may need cleaning).

B) Routine maintenance.

C) Air leaks.

1. Remove trigger screw (38) with Star T20 tool.

(See g 2).

2. Remove trigger stud (40) and remove trigger

(39) (See g 3).

3. Remove uid adjusting knob (28) and spring

(29). (See g 4).

4. Remove uid needle (24) (See g 5).

5. Using a 6mm hex key, remove valve housing

(27). (See Figs 6 and 7).

6. Remove spring (21) and valve spindle (20). (See

Fig 8).

7. Using service tool (44), engage groove behind

the valve seat (19) (See Fig 9).

TB-1022

7

Page 8

TB-1022

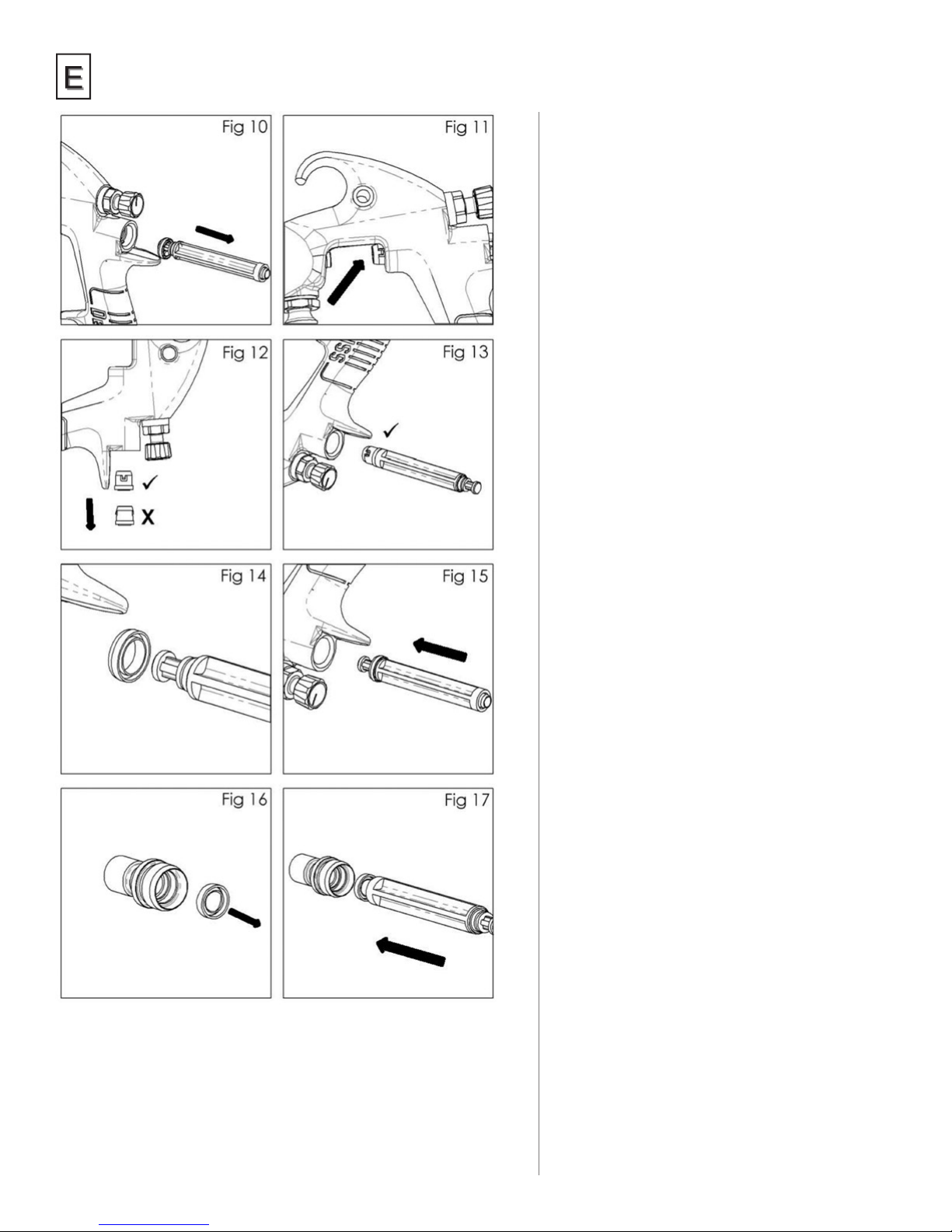

Servicing Air Valve

(continued)

8. Withdraw the valve seat (19) from the gun

body. (See g 10).

9. Push out the front airvalve seal (18) with a

nger. (See g 11).

10. Turn the gun upside down and let the seal fall

out. (See g 12).

11. Fit new front seal (18) to service tool (44). Fit

into gunbody and press rmly to ensure seal is

engaged. (See g 13).

12. Fit a new valve seat (19) to service tool (44).

Groove must face outwards. (See g 14).

13. Fit valve seat (19) to gunbody. (See g 15)

14. Remove rear airvalve seal (22) from housing

(27) with a hooked instrument.(See g 16).

15. Fit new seal(22) to service tool (44). Groove

must face outwards. Press seal (22) to housing

(27). (See g 17)

16. Reassemble remaining parts in reverse

order — valve (20), spring (21), housing (27)

and tighten with 6mm hex key, needle (24)

spring (29) and knob (28). Replace trigger

(39), tting trigger stud (40), screw in the

trigger screw (38) with Star T20 tool.

17. Trigger gun fully and screw in uid adjusting

knob (28) until it stops. Back it off 1/2 turn

and gun will have full needle travel.

18. Trigger gun several times to verify correct

operation.

8

Page 9

Parts Replacement/

Maintenance

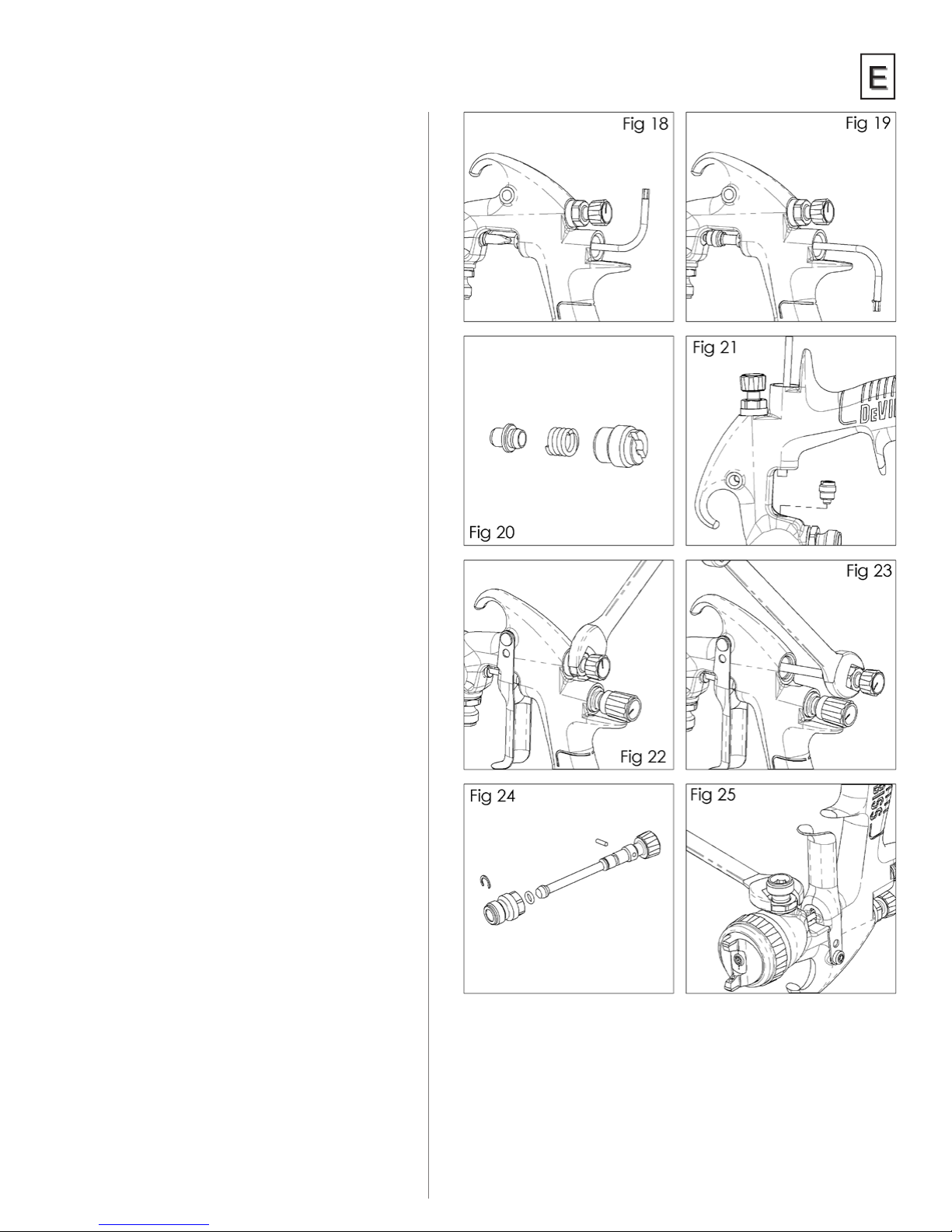

NEEDLE PACKING

REPLACEMENT INSTRUCTIONS

1. Remove trigger, uid needle, and air valve following

steps 1 to 6 on P7, servicing air valve.

2. Loosen and remove packing nut using a straight

blade screwdriver. (See gs 18 & 19)

3. Discard old packing (34) and packing spring (35)

if replacing. Clean packing if reusing. Also clean

packing spring and nut (36). (See g 20).

4. Re-assemble the packing, assemble into gunbody

by hand and then tighten. (See g 21)

5. Complete re-assembly following steps 16 to 18 on

P8.

TB-1022

SPREADER VALVE ASSEMBLY

REPLACEMENT/MAINTENANCE

The spreader valve assembly can be replaced if damaged.

Remove using a 14 mm wrench

(See gs 22 & 23). The internal seal can be replaced and

is included in the gun rebuild kit (See g 24).

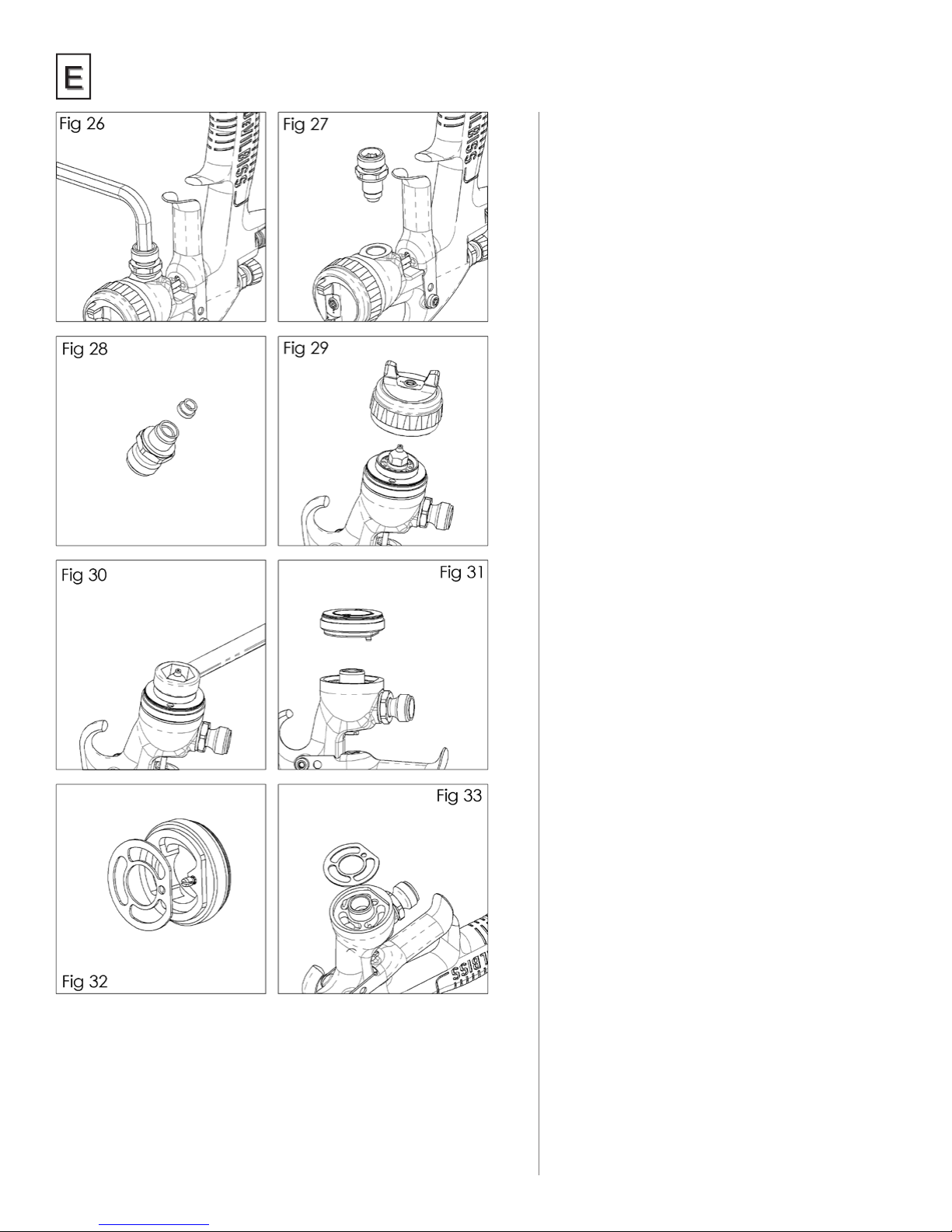

FLUID INLET SEAL

REPLACEMENT INSTRUCTIONS

1. Loosen Locknut (46) with 18mm wrench

(See Fig. 25).

2. Unscrew Fluid Inlet Adaptor (47) with 8mm hex key

(See Fig. 26).

3. Remove uid inlet adaptor (See Fig. 27).

4. Remove seal (45) and replace with new seal

(See Fig. 28).

5. Replace uid inlet adaptor (See Fig. 27)

6. Tighten with 8mm hex key to 26-28Nm (20 ft.-lbs.)

(See Fig. 26).

7. Tighten lock nut (46) with 18mm wrench

(See Fig. 25).

9

Page 10

TB-1022

Parts Replacement/

Maintenance

SPRAY HEAD SEAL

REPLACEMENT

1. Remove air cap and retaining ring (6).

(See g 29).

2. Remove uid adjusting knob (28), spring (25),

and spring pad (26). (See g 4, p7).

3. Remove uid needle (24) from gun body. (See

g 5, p7).

4. Remove uid nozzle using a 10mm wrench.

(See g 30).

5. Remove spray head (9) and seal (10)

(See g 31).

6. Remove seal (10) from spray head.

(See g 32).

7. Clean front of gun if required, using a soft

brush, as well as the uid nozzle, air cap, and

retaining ring.

8. Place a new seal (10) into the front of the gun,

making sure the at of the seal is aligned to

the at in the gun. (See g 33).

9. Fit the spray head (9), making sure the pin is

engaged into the hole in the gunbody.

(See g 31).

10. Fit uid nozzle (8), air cap and retaining Ring

(6). Torque the uid nozzle to 18–20 Nm

(13–15 ft-lbs). Do not over torque the uid

nozzle. (See gs 30, and 29)

11. Reassemble remaining parts in reverse order

— uid needle ( 24), needle spring and pad

(29), and uid adjusting knob (28).

12. Trigger gun fully and screw in uid adjusting

knob (28) until it stops. Back it off 1/2 turn

and gun will have full needle travel.

13. Trigger gun several times to verify correct

operation.

10

Page 11

Parts Replacement/Maintenance

Chart 1 – Air Caps

ORDER NO. FOR

AIR CAP

PRO-103-HV40 HVLP HV40 (1.2) / 17

PRO-103-TE20 High Efciency TE20 (1.8 – 3.5) / 26 – 50 (340 – 550) / 12 – 19.4

PRO-103-TE40 High Efciency TE40 (2.0 – 3.5) / 29 – 50 (368 – 550) / 13 – 19.4

NOTE 1: Guns with HVLP caps must not exceed 0.7 bar (10 psi) air cap pressure with

gun fully triggered. (Aproximately 17 psi gun inlet pressure.) (See accessories

for air cap test kit which is available to set the exact cap pressure.)

When used with high efciency caps and Automotive Renishing materials,

these spray guns have been found to exceed 65% transfer efciency under

recommended conditions.

TECHNOLOGY MARKING

ON AIR CAP

NOMINAL

OPERATING GUN

INLET PRESSURE

BAR/PSI

(for compliance)

AIR FLOW

LPM/SCFM

(298) / 10.5

TB-1022

NOTE 2: When removing air cap from retaining ring, don’t remove slip ring (2)

or retaining ring seal (5) from retaining ring. Damage to the parts may

occur. Slip ring and retaining ring seal are not available as replacements.

Simply wipe parts clean and reassemble with new or clean air cap.

Chart 2 – Fluid Nozzles & Fluid Needles

PART NO. ON

FLUID NOZZLE

PRO-205-10-K PRO-320-085-10K

PRO-205-12-K

PRO-205-14-K

NOTE: When replacing the uid nozzle or uid needle, replace both at the same time.

Lightly lubricate the threads of the uid nozzle before reassembling. Torque

to 18–20 Nm (13–15 ft-lbs). Don’t over tighten the uid nozzle. Use 10 mm

wrench supplied with gun.

PART NO. ON

FLUID NEEDLE

PRO-320-12-14-K

11

Page 12

TB-1022

Fluid Nozzle

Torque to 13–15 ft-lbs (18–20 Nm)

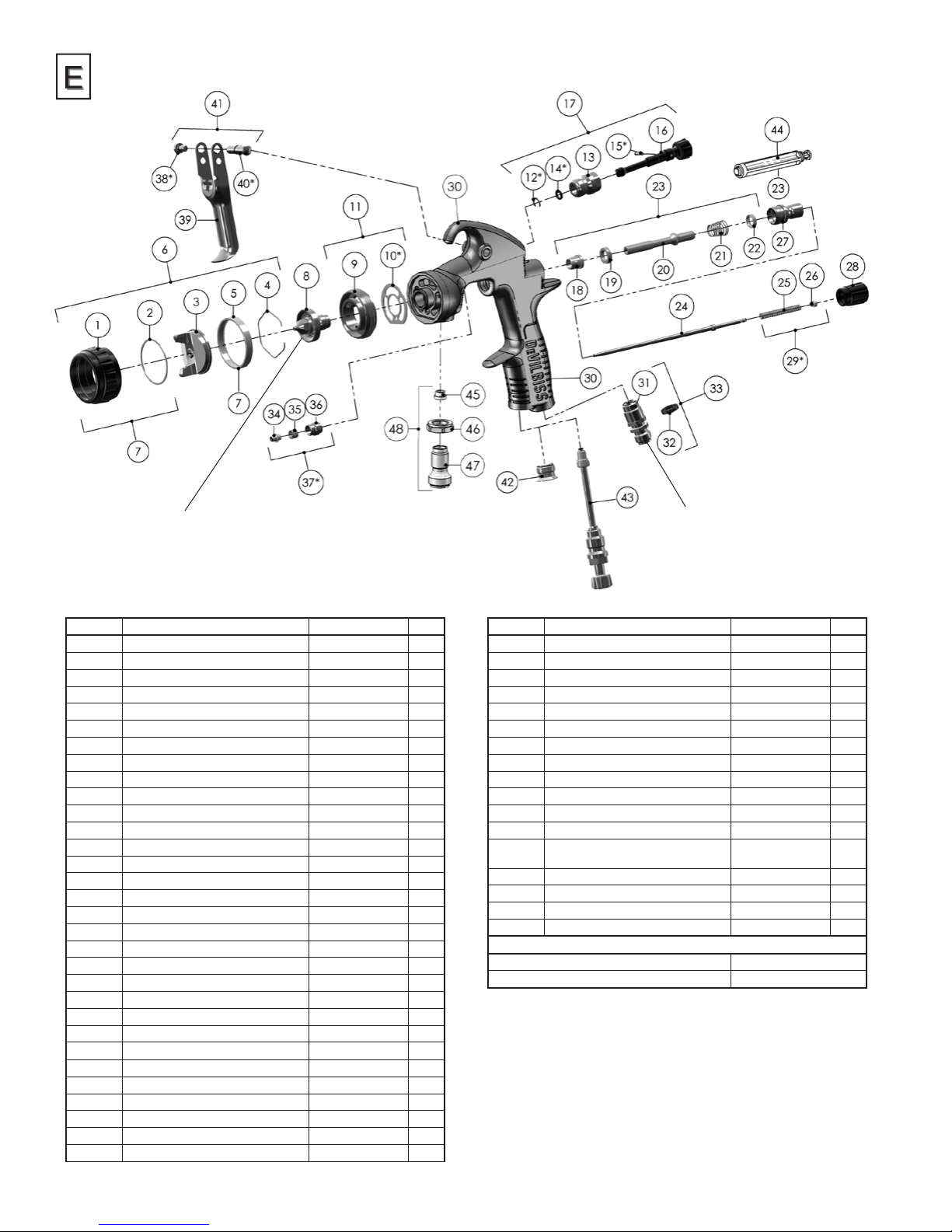

REF. NO. DESCRIPTION PART NO. QTY

1 Air Cap Retaining Ring 1

2 Slip Ring 1

3 Air Cap 1

4 Air Cap Retaining Clip JGA-156-K10 1

5 Retaining Ring Seal 1

6 Aircap & Ring See chart 1 p11 1

7 Air Cap Retaining Ring & Seals 702725 1

8 Fluid Nozzle See chart 2 p11 1

9 Spray head 1

*10 Spray head Seal 702726 1

11 Spray head kit SN-69-K 1

*12 Circlip 1

13 Valve Body 1

*14 O Ring 1

*15 Spreader Valve Pin 1

16 Spreader Valve Adjusting Knob 1

17 Spreader Valve Assembly PRO-408-BL-K 1

18 Front Valve Seal 1

19 Valve Seat 1

20 Spindle 1

21 Air Valve Spring 1

22 Rear Valve Seal 1

23 Air Valve Kit 703530 1

24 Fluid Needle See chart 2 p11 1

25 Needle Spring 1

26 Spring Pad 1

27 Housing & Seal Kit SN-66-K 1

28 Fluid Adjusting Knob SN-67-BK-K 1

*29 Needle Spring Kit PRO-472-K3 1

30 Gunbody 1

31 Air Inlet 1

Air Inlet

Torque to 15 ft-lbs (20 Nm)

Use medium strength thread sealant

(i.e. Devcon #2242 Blue or equivalent)

on threads

REF. NO. DESCRIPTION PART NO. QTY

32 Colour ID Ring Kit (4 Colours) 702735 1

33 Air Inlet Kit 702734 1

34 Needle Packing 1

35 Packing Spring 1

36 Packing Nut 1

*37 Packing, Spring and Packing Nut Kit 702731 1

*38 Trigger Screw 1

39 Trigger 1

*40 Trigger Stud 1

41 Trigger, Stud & Screw Kit SP-617-CR-K 1

42 Plug 1

43 Cheater Valve (optional) 702737 1

44 Air Valve Service Tool (only included in

the Air Valve Kit 23)

45 Seal 1

46 Lock Nut 1

47 Fluid Inlet 1

48 Fluid Inlet Kit ADV-7-K 1

SERVICE PARTS

Spray Gun repair kit (includes items marked *) PRO-470

Seal and Pin Kit, kit of 5 (items 12, 14 and 15) GTI-428-K5

12

Page 13

Troubleshooting Possible Problems in Operation

CONDITION CAUSE CORRECTION

Heavy top or

bottom pattern

Horn holes plugged.

Obstruction on top or bottom of fluid tip.

Cap and/or tip seat dirty.

Clean. Ream with non-metallic point.

Clean.

Clean.

TB-1022

Heavy right or left

side pattern

Heavy center pattern

Split spray pattern

Jerky or fluttering spray

Unable to get round spray

Will not spray

Starved spray pattern

Excessive overspray

Excessive fog

Dry spray

Fluid leaking from packing nut

Fluid leaking or dripping from

front of gun

*Most common problem.

Left or right side horn holes plugged.

Dirt on left or right side of fluid tip.

Remedies for the top-heavy, bottom-heavy, right-heavy, and left-heavy patterns:

1. Determine if the obstruction is on the air cap or the fluid tip. Do this by making a test spray

pattern. Then, rotate the cap one-half turn and spray another pattern. If the defect is inverted,

obstruction is on the air cap. Clean the air cap as previously instructed.

2. If the defect is not inverted, it is on the fluid tip. Check for a fine burr on the edge of the fluid tip.

Remove with #600 wet or dry sand paper.

3. Check for dried paint just inside the opening; remove by washing with solvent.

Fluid flow too high for atomization air.

Material flow exceeds air cap's capacity.

Spreader adjustment valve set too low.

Atomizing pressure too low.

Material too thick.

Atomization air pressure too high.

Fluid flow too low.

Spreader adjusting valve set too high.

*Loose or damaged fluid tip/seat.

Baffle seal not installed correctly.

Material level too low.

Container tipped too far.

Obstruction in fluid passage.

Dry or loose fluid needle packing nut.

Spreader adjustment screw not seating

properly.

Air cap retaining ring loose.

No air pressure at gun.

Fluid needle adjusting screw not open enough.

Fluid too heavy for suction feed.

Fluid pressure too low.

Inadequate material flow.

Low atomization air pressure.

Too much atomization air pressure.

Gun too far from work surface.

Improper stroking (arcing, gun motion

too fast).

Too much or too fast-drying thinner.

Too much atomization air pressure.

Air pressure too high.

Gun tip too far from work surface.

Gun motion too fast.

Gun out of adjustment.

Packing nut loose.

Packing worn or dry.

Packing nut too tight.

Dry packing.

Fluid tip or needle worn or damaged.

Foreign matter in tip.

Fluid needle spring broken.

Wrong size needle or tip.

Clean. Ream with non-metallic point.

Clean.

Balance air pressure and fluid flow. Increase spray

pattern width with spreader adjustment valve.

Thin or lower fluid flow.

Adjust.

Increase pressure.

Thin to proper consistency.

Reduce at transformer or gun.

Increase fluid flow (increases gun handling speed).

Adjust.

Tighten or replace.

Install per directions.

Refill.

Hold more upright.

Backflush with solvent.

Lubricate or tighten.

Clean or replace.

Tighten.

Check air supply and air lines, blow out gun air

passages.

Open fluid needle adjusting screw.

Thin material and/or change to larger tip size, or

pressure feed.

Increase fluid pressure at tank.

Back fluid adjusting screw out to first thread,

or change to larger tip size, or increase fluid

pressure at tank.

Increase air pressure and rebalance gun.

Reduce pressure.

Adjust to proper distance.

Move at moderate pace, parallel to work surface.

Remix properly.

Reduce pressure

Reduce air pressure.

Adjust to proper distance.

Slow down.

Adjust.

Tighten, do not bind needle.

Replace or lubricate.

Adjust.

Lubricate.

Replace tip and needle.

Clean.

Replace.

Replace.

13

Page 14

TB-1022

Troubleshooting Possible Problems in Operation (cont'd)

CONDITION CAUSE CORRECTION

Runs and sags

Thin, sandy coarse finish drying

before it flows out

Thick, dimpled finish

"orange peel"

Too much material flow.

Material too thin.

Gun tilted on an angle, or gun motion

too slow.

Gun too far from surface.

Too much air pressure.

Improper thinner being used.

Gun too close to surface.

Too much material coarsely atomized.

Air pressure too low.

Improper thinner being used.

Material not properly mixed.

Surface rough, oily, dirty.

Adjust gun or reduce fluid flow.

Mix properly or apply light coats.

Hold gun at right angle to work and adapt to proper

gun technique.

Check distance. Normally approximately 6–8".

Reduce air pressure and check spray pattern.

Follow paint manufacturer's mixing instructions.

Check distance. Normally approximately 6–8".

Follow paint manufacturer's mixing instructions.

Increase air pressure or reduce fluid flow.

Follow paint manufacturer's mixing instructions.

Follow paint manufacturer's mixing instructions.

Properly clean and prepare.

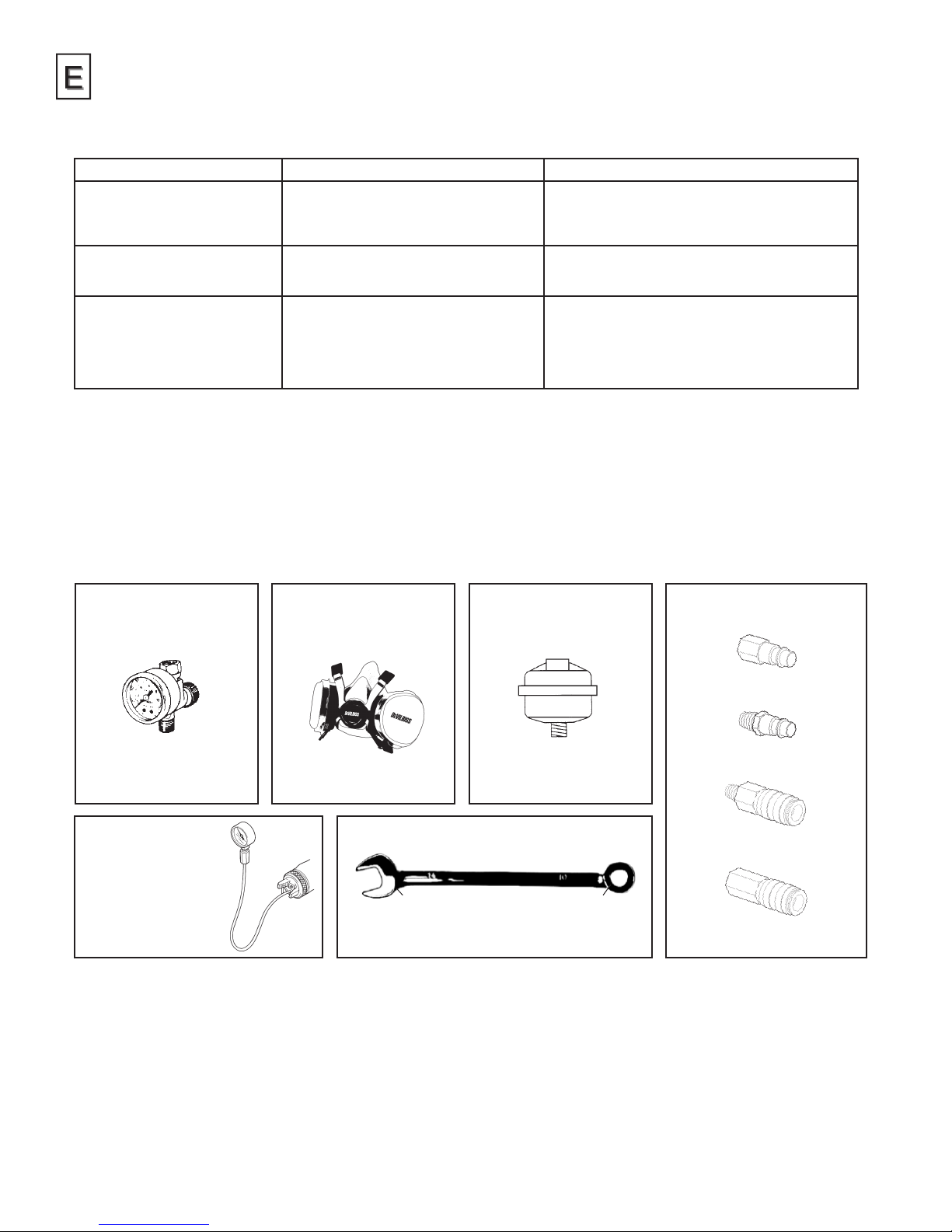

Accessories

HAV-500 OR

HAV-511

Adjusting Valve

(HAV-511 SHOWN)

HAV-500 does not have pressure gauge. Use to control air

usage at gun.

703625

HV40 Air Cap Test Kit

The purpose of this test

kit is to measure air cap

atomizing air pressure at

the center air port of the air

cap. Used to confirm code

compliance and as a daily

quality control measure.

Champion™

Disposable Respirator

803611 (Medium)

803612 (Large)

NIOSH-Certified for respiratory protection.

14 mm 10 mm

HAF-507 Whirlwind™

In-Line Air Filter

Removes water, oil, and

debris from the air line.

702740 TEKNA Wrench

For maintenance use.

Industrial Quick Connects

For HVLP Guns (Air)

HC-4419 Stem

1/4" NPT(F)

HC-1166 Stem

1/4" NPT(M)

HC-4719 Coupler

1/4" NPT(M) /NPS(M)

HC-4720 Coupler

1/4" NPT(F)

14

Page 15

WARRANTY

This product is covered by DeVilbiss' 2 Year Limited Warranty.

DeVilbiss Sales and Service: www.devilbiss.com

DeVilbiss

DeVilbiss has authorized distributors throughout the world.

For equipment, parts and service, check the Yellow Pages.

For technical assistance, see listing below.

This product is manufactured in the UK by:

Finishing Brands UK, Ltd.

Ringwood Road,

Bournemouth,

BH11 9LH, UK

Distributed exclusively in North America by:

DeVilbiss

TB-1022

3/16 ©2016 DeVilbiss. All rights reserved. Printed in U.S.A.

15

Page 16

TB-1022

WARRANTY POLICY

DeVilbiss products are covered by Finishing Brands two year materials and workmanship limited warranty. The use of any parts or

accessories, from a source other than Finishing Brands, will void all warranties. For specic warranty information please contact the closest

Finishing Brands location listed below.

Finishing Brands reserves the right to modify equipment specifications without prior notice. DeVilbiss®, Ransburg®, BGK®, and

Binks® are registered trademarks of Carlisle Fluid Technologies, Inc., dba Finishing Brands. ©2016 Carlisle Fluid Technologies, Inc.,

dba Finishing Brands. All rights reserved.

DeVilbiss is a Carlisle Fluid Technologies Company, a global leader in innovative spray nishing

technologies. For technical assistance or to locate an authorized distributor, contact one of our

sales and customer support locations below.

USA/Canada

www.devilbiss.com

ghcustserv@carlisleft.com

Toll Free Tel: 1-800-992-4657

Toll Free Fax: 1-877-790-6965

© 2016 DeVilbiss. All rights reserved. 3/16

Page 17

TB-1022

Ersetzt TB-1022

Technisches

Bulletin

Fließbecher-Spritzpistole

für Druck

Reparturset

für Spritzpistole

PRO-470

ghcustserv@carlisleft.com

800.992.4657

www.devilbiss.com

Page 18

TB-1022

Inhaltsverzeichnis

Thema Seite

EG-Konformitätserklärung ......................................................................................................................................3

Funktionsbeschreibung ............................................................................................................................................3

Konstruktionsmerkmale und -werkstoffe .......................................................................................................4

Technische Daten und Spezikationen

Sicherheitsmaßnahmen .......................................................................................................................................... 5

Installation, Betrieb, vorbeugende Wartung und Reinigung .................................................................6

Spritzpistolenschmierung

Teileaustausch/Wartung ................................................................................................................................ 7–12

A) Luftventil warten ................................................................................................................................ 7–8

B) Nadeldichtung, Strahlregulierventil, Fluideinlass Dichtung .............................................. 9

C) Sprühkopf-Dichtungsersatz ............................................................................................................ 10

D) Tabelle 1 – Luftkappen .......................................................................................................................11

Tabelle 2 – Flüssigkeitsdüsen und -nadeln

E) Explosionsdarstellung und Teileliste .......................................................................................... 12

Fehlersuche bei möglichen Betriebsproblemen ..............................................................................13–14

Zubehör ....................................................................................................................................................................... 14

Garantie .........................................................................................................................................................................15

Bei Verwendung mit der HVLP-Kappe kann diese Spritzpistole in

allen Pichtzonen eingesetzt werden—in vorgeschriebenen HVLPPichtzonen sowie nicht regulierten Bereichen.

Wenn mit hohem Wirkungsgrad Kappen und "Automotive

Renishing" Materialien sind diese Pistolen wurde festgestellt,

dass 65% Transferefzienz unter den empfohlenen Bedingungen

überschreiten.

Wenden Sie sich an Ihre behörde zur Überwachung

der Luftqualität vor Ort, wenn Sie Fragen zu HVLP oder

Konformitätsanforderungen in Ihrer Pichtzone haben.

2

HINWEIS:

Page 19

Technisches Bulletin

Fließbecher-Spritzpistole für Druck

WICHTIG: Bitte lesen und befolgen Sie alle Anweisungen und Sicherheitsvorschriften vor Verwendung

dieser Ausrüstung. Bitte zur späteren Bezugnahme aufbewahren.

EG-Konformitätserklärung

Finishing Brands UK, Ltd., Ringwood Rd, Bournemouth, Dorset, BH11 9LH, UK, ist der Hersteller der Spritzpistole,

Modell TEKNA PRO LITE, und erklärt hiermit als Alleinverantwortlicher, dass die Ausrüstung, auf die sich dieses

Dokument bezieht, den nachfolgend aufgeführten Normen oder anderen wesentlichen Dokumenten gerecht wird:

BS EN 12100 TEILE 1 & 2: 2010, BS EN 1953: 1998+A1:2009; und somit den Schutzanforderungen der

Richtlinie 98/37/EEC bezüglich der Maschinensicherheitsrichtlinie und

EN 13463-1:2009, Richtlinie 94/9/EC für Geräte und Schutzsysteme zur bestimmungsgemäßen

Verwendung in explosionsgefährdeten Bereichen Stufe II 2 G X entspricht.

Dieses Produkt entspricht auch den Anforderungen der EPA-Richtlinie PG6/34. Auf Anforderung können auch die

Übertragungsratenzertikate vorgelegt werden.

TB-1022

D Smith, General Manager

2. Februar 2014

Die TEKNA Pro Lite-Fließbecher-Spritzpistolenausrüstung entspricht der Explosionsschutzrichtlinie (ATEX)

94/9/EG, Schutzgrad II 2 G X, geeignet für Zone 1 und 2.

DeVilbiss Automotive Renishing behält sich das Recht vor, Änderungen ohne vorherige Mitteilung vorzunehmen.

Funktionsbeschreibung

Bei der TEKNA Pro Lite-Spritzpistole handelt es sich um eine leichte, gewerbliche Pistole zum Umgang mit auf Wasser basierenden

und lösungsmittelhaltigen Anstrichstoffen. Sowohl HVLP- als auch Hochleistungsmodelle stehen zur Wahl. Mit den HVLP-Modellen

(High Volume, Low Pressure = Hohes Volumen, Niederdruck) wird Overspray reduziertund maximale Übertragungsleistung

erbracht, indem der Luftkappendruck auf 0,7 bar (10 psi) begrenzt wird (erfüllt die von SCAQMD und anderen

Luftqualitätsbehörden erlassenen Regeln).

Bei gezogenem Abzugshebel produzieren HVLP-Modelle einen Luftkappendruck von ca. 0,7 bar (10 psi) bei einem

Pistoleneingangsdruck von 1,2 bar (17 psi). Die HVLP-Luftkappe #HV40 ist für optimalen Grundlackauftrag und optimalen

Klarlackauftrag konzipiert. Es gibt eine Luftkappen-Prüfset verfügbar (siehe Zubehör), mit denen der exakte Luftkappendruck

eingestellt werden kann.

Hochleistungsmodelle verwenden die Luftkappe #TE20 oder #TE40. Diese Modelle bieten optimale Zerstäubung praktisch

aller üblichen, auf Wasser basierenden oder lösungsmittelhaltigen Anstrichstoffe bei erhöhten Aufwandmengen und sehr

hoher, konstanter Übertragungsleistung. Tests unter den empfohlenen Bedingungen mit Autolacken haben ergeben, dass

Hochleistungsmodelle 65% Übertragungsleistung überschreiten.

WICHTIG: Diese Spritzpistolen eignen sich nicht für den Einsatz von stark korrosiven und/oder abreibenden Materialien. Bei

Einsatz solcher Stoffe muss davon ausgegangen werden, dass der Aufwand für die Reinigung bzw. der Bedarf an Ersatzteilen

zunimmt. Wenn Sie nicht genau wissen, ob ein bestimmtes Material geeignet ist, wenden Sie sich bitte an Ihren örtlichen TEKNA-

Händler oder direkt an TEKNA selbst.

HINWEIS: Diese Spritzpistole ist nicht für den Einsatz mit halogeniertem Kohlenwasserstoff oder Reinigungsmitteln

wie Methylendichlorid und 1,1,1,-Trichloräthan geeignet. Solche Lösungsmittel können mit den in dieser Spritzpistole

und dem Becher verwendeten Aluminiumteilen reagieren. Die entstehende Reaktion kann sehr stark sein und zu einer

Explosion des Geräts führen.

3

Page 20

TB-1022

3, 4, 12

2

9

1

10

11

7

14

15

5

8

13

6

Baumerkmale

1 Luftkappe (Messing, vernickelt, daher lange Lebensdauer)

2 Haltering, Luftkappe (gewährleistet einfache Drehung der Luftkappe)

3 Flüssigkeitsdüse (nicht sichtbar, ideal für Auto-Decklacksysteme)

4 Farbnadel (nicht sichtbar)

5 Materialeinlass (3/8 BSP Gewinde)

6 Lufteinlass (Universalgewinde, für G 1/4 & 1/4 NPS geeignet)

7 Selbstregulierende Nadeldichtung (Dichtungspackung nicht sichtbar, optimal lange Lebensdauer)

8 Fingerabzug (ergonomisch konstruiert, daher äußerst bequem zu handhaben)

9 Bolzen mit Schraube (sehr einfach auszutauschen)

10 Gebläselufteinstellung (stufenlose Regelung für Rundumspray)

11 Flüssigkeitseinstellung (stufenlose Regelung des Flüssigkeitsvolumens)

12 Entfernbarer Sprühkopf (nicht sichtbar, zur Erzielung einer langen Spritzpistoleneinsatzdauer)

13 Austauschbares Farb-ID-System (4 Farbringe werden mitgeliefert)

14 Pistolengehäuse (ergonomisch konstruiert, gutes Design, dauerhaft, leicht zu reinigen)

15 Luftventil (niedrige Zugkraft und geringer Druckabfall dank des vorzüglichen Designs)

16 Spritzpistole für wasserlösliche und auf Lösungsmittel basierende Einsätze geeignet

Werkstoffe

Spritzpistolengehäuse Aluminium, eloxiert QuickClean®

Luftkappe Messing, vernickelt

Flüssigkeitsdüse, Farbnadel, Materialeinlass, Fingerabzugsbolzen Edelstahl

Sprühkopf, Luftkappenhaltering, Knöpfe, Griffschraube Aluminium, eloxiert

Federn, Klammern, Schrauben Edelstahl

Dichtungen Lösungsmittelbeständig

Fingerabzug Stahl, verchromt

Lufteinlass, Gehäusebuchse, Regulierventilgehäuse, Luftventilmutter Messing, verchromt

Luftlter Aluminium

Technische Daten und Spezifikationen

Druckluftanschluss Universal 1/4” BSP und 1/4” NPS

Statischer Einlassluftdruck, max. P1 = 12 bar (175 psi)

Nominaler Lufteinlassdruck der Spritzpistole für HVLP-Modelle, HV40-Spritzpistolengehäuse (bei abgezogener Spritzpistole)

Nominaler Lufteinlassdruck der Spritzpistole für Hochleistungsmodelle, TE40-Spritzpistolengehäuse (bei abgezogener Spritzpistole)

Luftverbrauch Siehe Tabelle 1 auf Seite 11

Flüssigkeitsanschluss 3/8” BSP

Betriebstemperaturbereich 0 bis 40°C (32 bis 100°F)

Pistolengewicht (nur Pistole) 500 g (17.6 Unzen)

1,2 bar (17 psi) (für Konformität)

2,0 – 3,5 bar (29 – 50 psi)

4

Page 21

TB-1022

PROP 65 WARNUNG

WARNUNG: Dieses Produkt enthält Chemikalien,

die im Bundesstaat Kalifornien Krebs und

Geburtsschäden oder andere reproduktive

Schäden verursachen.

Sicherheitsmaßnahmen

CA PROP

65

Dieses Bulletin umfasst Informationen, die Sie lesen und verstehen müssen. Die aufgeführten Informationen beziehen sich auf

BETRIEBSSICHERHEIT und VERMEIDUNG VON AUSRÜSTUNGSPROBLEMEN. Zum besseren Verständnis dieser Informationen verwenden wir

die folgenden Symbole: Bitte lesen Sie sich diese Abschnitte mit größter Sorgfalt durch.

WARNUNG

Wichtige Sicherheitsinformationen für mögliche

Gefahren, die zu schweren Verletzungen oder sogar Tod

führen können.

VORSICHT

Wichtige Informationen, die Ihnen erklären, wie man Schäden an der

Ausrüstung oder Situationen vermeiden kann, die zu leichten Verletzungen

führen würden.

HINWEIS

Informationen, die Sie genauer

beachten sollten.

Während des normalen Einsatzes dieser Ausrüstung können die nachfolgend beschriebenen Gefahren auftreten. Bitte lesen Sie vor

Einsatz dieser Ausrüstung die nachfolgende Tabelle durch.

GEFAHR URSACHE SICHERHEITSMASSNAHMEN

Feuer

Lösungsmittelspray

Lösungsmittel und Lacke können sehr leicht entammbar

oder brennbar sein, vor allen Dingen beim Sprühen.

Beim Einsatz und Reinigen sowie Spülen können

Lösungsmittel plötzlich aus Flüssigkeits- und Luftleitungen

ausgestoßen werden. Einige Lösungsmittel können zu

Augenverletzungen führen.

Um die Luft frei von Ansammlungen entzündbarer Dämpfe zu halten,

muss der Bereich immer gut entlüftet werden.

Rauchen ist im Sprühbereich immer verboten.

Feuerlöschanlagen müssen immer im Sprühbereich vorgesehen

werden.

Schutzbrille tragen.

Einatmen von Giftstoffen

Explosionsgefahr nicht kompatible Stoffe

Allgemeine Sicherheit

Kumulative traumatische

Erkrankungen (CTDs)

Kumulative traumatische

Erkrankungen (CTDs - Cumulative

Trauma Disorders) oder MuskelSkelett-Beschwerden einschl.

Beschwerden an Händen,

Handgelenken, Ellbogen,

Schultern, Nacken und Rücken.

Karpaltunnelsyndrom (KTS) und

Sehnenscheidenentzündungen

(wie Tennisarm oder

Rotatorenmanschettensyndrom)

sind Beispiele

von CTDs.

Bestimmte Stoffe sind schädlich, wenn sie eingeatmet

werden oder in Kontakt mit der Haut kommen.

Halogenisierte Kohlenwasserstoff-Lösungsmittel – zum

Beispiel: Methylendichlorid und 1,1,1,-Trichloräthan sind

nicht chemisch kompatibel mit Aluminium, das in vielen

Systemteilen Einsatz ndet. Die chemische Reaktion, die

erzeugt wird, wenn diese Lösungsmittel mit Aluminium

reagieren, kann sehr stark sein und zu einer Explosion der

Ausrüstung führen.

Falscher Betrieb oder falsche Wartung der Ausrüstung Das Bedienungspersonal muss gründlich für den sicheren Einsatz und

Die Verwendung von Handwerkzeugen kann CTDs

(kumulative traumatische Erkrankungen) verursachen.

CTD wirkt sich bei Verwendung von Handwerkzeugen

auf die oberen Extremitäten aus. Die folgenden Faktoren

können das Risiko von CTDs erhöhen:

1. Große Häugkeit dieser Tätigkeit.

2. Übermäßiger Krafteinsatz wie Greifen, Klemmen oder

Drücken mit Händen und Fingern.

3. Extreme oder ungewöhnliche Finger-, Handgelenk- oder

Armbewegungen.

4. Überlange Dauer dieser Tätigkeit.

5. Vibration des Werkzeugs.

6. Wiederholter Druck auf ein Körperteil.

7. Arbeiten bei niedrigen Temperaturen.

CTDs können außerdem durch Aktivitäten wie Nähen, Golf,

Tennis, Bowling und viele andere mehr verursacht werden.

Befolgen Sie alle Empfehlungen des Sicherheitsdatenblattes (SDS),

die vom Lackhersteller zur Verfügung gestellt wird.

Um die Luft frei von Ansammlungen von Giftstoffen zu halten, muss der

Bereich immer gut entlüftet werden.

Wenn die Möglichkeit besteht, dass Sprühmaterial eingeatmet wird, müssen

Sie eine Maske oder einen anderen Atemschutz tragen. Die Maske muss

mit dem gesprühten Material und seiner Konzentration kompatibel sein. Die

entsprechenden Ausrüstungen müssen von Sicherheitsexperten genehmigt

sein und NIOSH oder gleichwertig entsprechen.

Für solche Lösungsmittel können Spritzpistolen mit internen

Leitungen aus Edelstahl verwendet werden. Aluminium wird jedoch

häug in anderen Sprühausrüstungen verwendet – zum Beispiel

Materialpumpen, Regler, Ventile usw. Prüfen Sie alle Anlagenteile vor

dem Einsatz und stellen Sie sicher, dass sie mit diesen Lösungsmitteln

verwendet werden können. Lesen Sie das Etikett oder Datenblatt

für das Material, das gesprüht werden soll. Wenn Sie Zweifel haben,

ob ein Lack oder Reinigungsmittel kompatibel ist, fragen Sie das

Lieferunternehmen des betreffenden Materials.

die vorschriftsmäßige Wartung der Ausrüstung ausgebildet werden

(gemäß NFPA-33, Kapitel 15, oder gleichwertig). Benutzer müssen

alle Vorschriften geltender lokaler und nationaler Bestimmungen

sowie Erfordernisse seitens Versicherungen bezüglich Entlüftung,

Feuerschutz, Betrieb, Wartung und Instandhalten einhalten. Dabei sind

alle Bestimmungen wie OSHA, Abschnitt 1910.94 und 1910.107 sowie

NFPA-33 und ähnliche Vorschriften zu beachten.

Schmerzen, Kribbeln oder Taubheit in Schulter, Vorderarm, Handgelenk,

Händen oder Fingern, vor allen Dingen nachts, können erste Anzeichen

einer CTD sein. Lassen Sie diese Symptome nicht unbeachtet. Wenn

Sie solche Symptome feststellen, suchen Sie bitte sofort einen Arzt auf.

Andere frühe Symptome sind leichte Beschwerden in der Hand, ein

Abnehmen der Fingerfertigkeit sowie nicht spezische Schmerzen im

Arm. Ein Ignorieren früher Warnzeichen und lang anhaltende monotone

Verwendung von Arm, Handgelenk und Hand können zu ernsten

Beschwerden führen. Das Risiko wird verringert, indem Sie die Faktoren

1 bis 7 ausschalten oder herabsetzen.

5

Page 22

TB-1022

AUFSTELLUNG

Zur Erzielung des optimalen Auftragswirkungsgrads verwenden Sie

niemals mehr Druck, als zum Zerstäuben des verwendeten Materials

erforderlich ist.

1. Schließen Sie die Spritzpistole an einer sauberen feuchtigkeitsund ölfreien Druckluftversorgung an. Verwenden Sie dazu eine

Schlauchgröße von mindestens 8 mm Innendurchmesser. Verwenden

Sie niemals einen Schlauch mit 6 mm Innendurchmesser. (Ein 8 m x 6

mm Schlauch zeigt bei 510 l/min einen Druckverlust von 1,8 bar.) Ein

8 m x 8 mm Schlauch zeigt bei 510 l/min einen Druckverlust von 0,6

bar. [Verwenden Sie keinen Schlauch mit 1/4” Innendurchmesser. (Ein

25’ x 1/4” Schlauch zeigt bei 18 CFM einen Druckverlust von 25 psi.)

Ein 25’ x 5/16” Schlauch zeigt bei 18 CFM einen Druckverlust von 8

psi.)] Je nach Schlauchlänge kann es vorkommen, dass ein Schlauch

mit größerem Innendurchmesser notwendig ist.

HINWEIS

Bei abgezogener Pistole den Lufteinlassdruck (empfohlene

Druckwerte können in Tabelle 1 unter Teileaustausch nachgelesen

werden) am Pistoleneinlass einstellen. (der unter Zubehör gezeigte

Luftdruckmesser wird dafür empfohlen). Nicht mehr Druck als

notwendig zum Aufsprühen des Materials aufwenden.

Übermäßiger druck schafft zusätzliches Übersprühen und reduziert

die Übertragungsleistunge.

HINWEIS

Wenn Sie Schnellkupplungen verwenden wollen, muss es sich um

Schnellkupplungen mit hohem Durchuss handeln, die für den Einsatz

mit HVLP-Ausrüstungen zugelassen sind. Andere Typen lassen nicht

genug Luft für einen vorschriftsmäßigen Pistolenbetrieb durch.

HINWEIS

Wenn ein Luftdruckeinstellungsventil am Pistoleneinlass

verwendet wird, sollten Sie das Modell DeVilbiss verwenden. Einige

Einstellungsventile anderer Hersteller verursachen großen Druckabfall,

der sich negative auf die Zerstäubungsleistung auswirken kann. Das

Modell DeVilbiss weist einen minimalen Druckabfall auf.

2. Befestigen der Fluidzuführschlauch dem Fluideinlassanschluss.

HINWEIS

Vor dem Versand wird die Spritzpistole mit einer Schutzschicht und

Rostschutz behandelt. Spülen Sie die Spritzpistole vor dem ersten

Gebrauch mit Lösungsmittel aus, sodass die Schutzstoffe aus den

Flüssigkeitskanälen entfernt werden.

BETRIEB

1. Mischen Sie das Beschichtungsmaterial gemäß Anweisungen des

Herstellers und ltern Sie es.

2. Füllen Sie den Druck Becher mit der erforderlichen Menge an Material.

NICHT ÜBERFÜLLEN.

3. Bringen Sie den Becherdeckel an.

4. Drehen Sie den Flüssigkeitseinstellknopf (28) nach rechts, um eine

Farbnadelbewegung zu verhindern.

5. Drehen Sie den Einstellknopf der Strahlregulierventils (16) zum

vollständigen Öffnen nach links.

6. Betätigen Sie die Pistole und stellen Sie am Pistoleneingang den

Eingangsluftdruck ein (für empfohlene Zahlen sie Diagramm 1

unter Ersatz von Teilen). (Hierfür empehlt sich der unter Zubehör

dargestellte Druckmesser).

7. Schalten Farbnadelstellrad (28) nach links, bis der erste Gewindegang

sichtbar Uhrzeigersinn und schalten Sie die Luftzufuhr für den

Druckbehälter.

8. Führen Sie einen Probesprühvorgang durch. Wenn der Auftrag

zu trocken ist, verringern Sie die Luftzufuhr, indem Sie den

Lufteinlassdruck herabsetzen.

9. Wenn der Auftrag zu nass ausfällt, verringern Sie die Materialzufuhr,

indem Sie den Flüssigkeitseinstellknopf (28) nach rechts drehen.

Wenn die Zerstäubung zu grob ist, erhöhen Sie den Einlassluftdruck.

Ist sie zu fein, verringern Sie den Einlassluftdruck.

10. Der Spritzstrahl kann durch Drehen des Einstellknopfs für das

Strahlregulierventil (16) nach rechts verringert werden.

11. Halten Sie die Spritzpistole senkrecht zur Oberäche, auf die

Sie sprühen. Ein Kippen oder Neigen kann zu ungleichmäßigen

Beschichtungsstärken führen.

12. Der empfohlene Spritzabstand beträgt 150 bis 200 mm.

13. Sprühen Sie zuerst die Ränder. Lassen Sie jede Bahn um mindestens

75 % überlappen. Bewegen Sie die Spritzpistole mit

gleichförmiger Geschwindigkeit.

14. Wenn die Spritzpistole nicht verwendet wird, müssen Sie immer

die Druckluftversorgung abstellen und den Druck ablassen.

VORBEUGENDE WARTUNG UND REINIGUNG

Die Luftkappe und Flüssigkeitsdüse werden zum Reinigen mit

einer steifen Borstenbürste außen abgebürstet. Zum Reinigen der

Luftkappenlöcher verwenden Sie eine Besenborste oder einen

Zahnstocher. Wenn Sie einen Draht oder ein anderes hartes Instrument

verwenden, müssen Sie mit großer Sorgfalt darauf achten, dass die

Löcher nicht zerkratzt oder vergratet werden. Dadurch kann das Sprühbild

beeinträchtigt werden.

Um Fluiddurchgänge reinigen, entfernen Fluidzuführschlauch, dann mit

einem geeigneten Lösungsmittel zu spülen. Wischen Sie die Spritzpistole

außen mit einem Lappen ab, der mit Lösungsmittel befeuchtet wurde.

Niemals ganz in Lösungsmittel eintauchen. Das kann Schmiermittel und

Dichtungen beeinträchtigen.

HINWEIS

Flüssigkeitsdüsen oder Farbnadeln müssen immer beide zur gleichen

Zeit ausgetauscht werden. Verschlissene Teile können zu Lecks führen.

Siehe auch Seite 11, Tabelle 2. Tauschen Sie auch gleichzeitig die

Nadeldichtung aus. Vor dem Zusammenbau werden die Gewinde der

Flüssigkeitsdüse leicht geschmiert. Mit einem Drehmoment von 18 bis

20 Nm anziehen. Ziehen Sie die Flüssigkeitsdüse nicht zu fest an.

Um Schäden an der Flüssigkeitsdüse (8) oder der Farbnadel (24)

zu verhindern, stellen Sie sicher, dass Sie 1. den Abzug betätigt halten,

während Sie die Flüssigkeitsdüse anziehen oder lockern, oder 2. den

Flüssigkeitseinstellknopf (28) entfernen, um den Federdruck gegen die

Nadelmanschette zu entlasten.

SPRITZPISTOLENSCHMIERUNG

Tragen Sie täglich einen Tropfen Spritzpistolenschmiermittel am

Fingerabzugsbolzen (40). Außerdem muss der Schaft der Farbnadel (24)

am Eingang zur Dichtungsmutter (36) geölt werden. Die Farbnadeldichtung

(34) muss regelmäßig geschmiert werden. Stellen Sie sicher, dass der

Sprühkopf (9) und das Gewinde des Luftkappenhalterings (1) sauber und

frei von Fremdkörpern sind. Vor dem Einbau des Luftkappenhalterings

am Sprühkopf müssen die Gewinde gründlich gereinigt werden. Geben

Sie dann zwei Tropfen Spritzpistolenschmiermittel auf die Gewinde.

Die Farbnadelfeder (25) und die

Luftventilfeder (21) müssen mit einem

sehr leichten Fett beschichtet werden.

Stellen Sie sicher, dass überschüssiges

Fett nicht die Luftkanäle verstopft.

Schmierstellen

A) Stellen am Abzug

B) Dichtung

C) Einstellknöpfe

D) Gewinde, Luftkappenhaltering

D

A

B

C

6

Page 23

Teileaustausch/

Wartung

LUFTVENTILANWEISUNGEN

Arbeiten am Luftventil

Gründe für Arbeiten am Luftventil:

A) Luftventil funktioniert nicht richtig (muss

möglicherweise gereinigt werden).

B) Routinewartungsarbeiten.

C) Luft tritt aus.

1. Entfernen Sie die Fingerabzugschraube (38) mit

einem Star T20 Schraubendreher. (Siehe Abb.

2).

2. Entfernen Sie den Fingerabzugbolzen(40) und

den Fingerabzug (39). (Siehe Abb. 3).

3. Entfernen Sie den Flüssigkeitsstellknopf (28)

und die Feder (29). (Siehe Abb. 4).

4. Entfernen Sie die Farbnadel (24). (Siehe Abb. 5).

5. Entfernen Sie das Ventilgehäuse (27) mit einem

6 mm-Sechskantschlüssel. (Siehe Abb. 6 und 7).

6. Entfernen Sie die Feder (21) und die

Ventilspindel (20). (Siehe Abb. 8).

7. Haken Sie in die Nut hinter dem Ventilsitz (19)

mit dem Wartungswerkzeug (44) ein. (Siehe

Abb. 9).

TB-1022

7

Page 24

TB-1022

Arbeiten am Luftventil

(Fortsetzung)

8. Bauen Sie den Ventilsitz(19) aus dem

Pistolengehäuse aus. (Siehe Abb. 10).

9. Drücken Sie die vordere Luftventildichtung

(18) mit einem Finger heraus. (Siehe Abb. 11).

10. Drehen Sie die Spritzpistole um, damit die

Dichtung herausfallen kann. (Siehe Abb. 12).

11. Setzen Sie die neue vordere Dichtung (18) auf

das Wartungswerkzeug (44). Setzen Sie diese

in das Pistolengehäuse ein und drücken Sie

fest, bis die Dichtung einrastet. (Siehe Abb. 13).

12. Setzen Sie den neuen Ventilsitz (19) auf das

Wartungswerkzeug (44). Die Nut muss nach

außen zeigen. (Siehe Abb. 14).

13. Setzen Sie die hintere Dichtung (19) auf das

Spritzpistolengehäuse. (Siehe Abb. 15).

14. Entfernen Sie die Dichtung des hinteren

Luftventils (22) mit einem hakenförmigen

Instrument aus dem Gehäuse (27). (Siehe

Abb. 16).

15. Setzen Sie die neue Dichtung (22) auf das

Wartungswerkzeug (44). Die Die Nut muss

nach außen zeigen. Drücken Sie die Dichtung

(22) in das Gehäuse (27). (Siehe Abb. 17).

16. Bauen Sie die restlichen Teile in umgekehrter

Reihenfolge wieder ein — Ventil (20), Feder

(21), Gehäuse (27) und ziehen Sie diese mit

einem 6mm-Sechskantschlüssel fest, Nadel

(24) Feder (29) und Knopf (28). Setzen Sie

den Abzug wieder ein(39), setzen Sie den

Abzugbolzen auf (40) und ziehen Sie die

Abzugschraube (38) mit einem Star T20Schraubendreher fest.

17. Ziehen Sie den Abzug der Pistole und

schrauben Sie den Flüssigkeitsstellknopf ein

(28), bis dieser festsitzt. Drehen Sie um eine

½ Drehung zurück, damit die Spritzpistole die

volle Nadelbewegung hat.

18. Betätigen Sie die Spritzpistole mehrere

Male, um sicherzustellen, dass sie

vorschriftsmäßig funktioniert.

8

Page 25

Teileaustausch/

Wartung

ANWEISUNGEN FÜR DEN

AUSTAUSCH DER NADELDICHTUNG

1. Entfernen Sie den Abzug, die Farbnadel und das

Luftventil nach Anweisung der Schritte 1 bis 6 auf S.

7 (Arbeiten am Luftventil).

2. Lockern und entfernen Sie die Dichtungsmutter mit

einem achen Schraubendreher. (Siehe Abb. 18 & 19).

3. Entsorgen Sie die alte Dichtung (34) und

Dichtungsfeder (35) beim Austauschen. Bei

Wiederverwendung muss die Dichtung gereinigt

werden. Reinigen Sie außerdem die Feder und die

Mutter (36). (Siehe Abb. 20).

4. Bauen Sie die Dichtung wieder von Hand in das

Spritzpistolengehäuse ein und ziehen Sie diese fest.

(Siehe Abb. 21).

5. Gehen Sie wie unter den Schritten 16 bis 18 auf S.

8 beschrieben vor.

TB-1022

AUSTAUSCH UND WARTUNG DES

STRAHLREGULIERVENTILS

Wenn das Strahlregulierventil beschädigt ist, kann es

ausgetauscht werden. Bauen Sie es mit einem 14 mmSchlüssel aus. (Siehe Abb. 22 & 23). Die Innendichtung

kann ausgetauscht werden. Die Teile nden Sie im

Spritzpistolen-Reparatursatz. (Siehe Abb. 24).

Fluideinlaß SEAL Anweisungen

zum Austausch

1. Kontermutter (46) mit 18mm-Schlüssel

(Siehe Abb. 25).

2. Abschrauben Flüssigkeitsansaugadapter (47) mit 8mm

Inbusschlüssel (Siehe Abb. 26).

3. Entfernen Fluideinlaß Adapter (siehe Abb. 27).

4. Entfernen Dichtung (45) und mit neuer Dichtung

ersetzen (Siehe Abb. 28).

5. Replace Fluideinlaß Adapter (siehe Abb. 27)

6. Ziehen mit 8mm Inbusschlüssel bis

26-28 Nm (20 ft.-lbs.) (Siehe Abb. 26).

7. Kontermutter (46) mit 18mm-Schlüssel (Siehe Abb. 25).

9

Page 26

TB-1022

Teileaustausch/

Wartung

AUSTAUSCH DER

LUFTABSCHEIDERDICHTUNG

1. Entfernen Sie die Luftkappe und den Haltering

(6). (Siehe Abb. 29).

2. Entfernen Sie den Flüssigkeitsstellknopf (28),

die Feder (25) und das Federlagersegment

(26). (Siehe Abb. 4, S7).

3. Entfernen Sie die Farbnadel (24) aus dem

Spritzpistolengehäuse. (Siehe Abb. 5, S7).

4. Entfernen Sie die Flüssigkeitsdüse mit einem

10 mm-Schlüssel. (Siehe Abb. 30).

5. Entfernen Sie den Sprühkopf (9) und die

Dichtung (10). (Siehe Abb. 31).

6. Entfernen Sie die Dichtung (10) vom

Sprühkopf. (Siehe Abb. 32).

7. Reinigen Sie ggf. den vorderen Teil der

Spritzpistole, die Flüssigkeitsdüse, die

Luftkappe und den Haltering mit einer

weichen Bürste.

8. Bringen Sie eine neue Dichtung (10) vorne an

der Spritzpistole an und versichern Sie sich,

dass der ache Teil auf der Dichtung mit dem

achen Teil der Spritzpistole ausgerichtet ist.

(Siehe Abb. 33).

9. Setzen Sie den Sprühkopf (9) auf und

vergewissern Sie sich, dass der Passstift in

das Loch auf dem Spritzpistolengehäuse

passt. (Siehe Abb. 31).

10. Setzen Sie die Flüssigkeitsdüse (8), die

Luftkappe und den Haltering (6) auf. Drehen

Sie die Flüssigkeitsdüse mit 18–20 Nm

(13–15 ft-lbs) fest. Die Flüssigkeitsdüse nicht

zu sehr festziehen. (Siehe Abb. 30 und 29).

11. Die restlichen Teile in umgekehrter

Reihenfolge wieder einbauen — Farbnadel

(24), Nadelfeder und Federlagersegment (29)

und Flüssigkeitsstellknopf (28).

12. Ziehen Sie den Abzug der PIstole und

schrauben Sie den Flüssigkeitsstellknopf ein

(28), bis dieser festsitzt. Drehen Sie um eine

½ Drehung zurück, damit die Spritzpistole die

volle Nadelbewegung hat.

13. Betätigen Sie die Spritzpistole mehrere

Male, um sicherzustellen, dass sie

vorschriftsmäßig funktioniert.

10

Page 27

Teileaustausch/Wartung

Tabelle 1- Luftkappen

BESTELLNR. FÜR

LUFTKAPPE

PRO-103-HV40 HVLP HV40 (1.2) / 17

PRO-103-TE20 Hochleistung TE20 (1.8 – 3.5) / 26 – 50 (340 – 550) / 12 – 19.4

PRO-103-TE40 Hochleistung TE40 (2.0 – 3.5) / 29 – 50 (368 – 550) / 13 – 19.4

HINWEIS 1: Spritzpistolen mit HVLP-Kappen dürfen nicht 0,7 bar (10 psi)

Luftkappendruck bei voll gezogener Pistole überschreiten. (Ungefähr 17

psi Pistoleneinlassdruck.) (Siehe Zubehör für Luftkappen-Testsatz, der

verfügbar ist, um den exakten Kappendruck einzustellen.)

Wenn mit hohem Wirkungsgrad Kappen und "Automotive Renishing"

Materialien sind diese Pistolen wurde festgestellt, dass 65%

Transferefzienz unter den empfohlenen Bedingungen überschreiten.

TECHNOLOGIE MARKING

AUF KAPPE

EINLASSDRUCK

NOMINAL BAR/PSI

(für Konformität)

LUFTSTROM

L/MIN

ODER SCFM

(298) / 10.5

TB-1022

HINWEIS 2: Beim Ausbau der Luftkappe vom Haltering dürfen der Distanzring (2) oder

die Halteringdichtung (5) nicht vom Haltering abgenommen werden. Dabei

könnten Teile beschädigt werden. Der Distanzring und die Halteringdichtung

sind nicht als Ersatzteile erhältlich. Wischen Sie die Teile einfach sauber

und verwenden Sie sie mit einer neuen oder gereinigten Luftkappe.

Tabelle 2 – Flüssigkeitsdüse & Farbnadeln

NR. AUF DER

FLÜSSIGKEITSDÜSE

PRO-205-10-K PRO-320-085-10K

PRO-205-12-K

PRO-205-14-K

HINWEIS: Flüssigkeitsdüsen und Farbnadeln müssen immer zur gleichen Zeit

NR. AUF DER

FARBNADEL

PRO-320-12-14-K

ausgetauscht werden. Vor dem Zusammenbau werden die Gewinde der

Flüssigkeitsdüse leicht geschmiert. Ziehen Sie die Flüssigkeitsdüse mit 18–20

Nm (13–15 ft-lbs) fest. Nicht zu sehr festziehen. Den im Lieferumfang der

Spritzpistole gelieferten 10 mm-Schlüssel verwenden.

11

Page 28

TB-1022

Flüssigkeitsdüse

Mit 18–20 Nm (13–15 ft-lbs) festziehen.

BEZ. NR. BESCHREIBUNG TEILE-NR. ANZ.

1 Luftkappenhaltering 1

2 Distanzring 1

3 Luftkappe 1

4 Luftkappenhaltering JGA-156-K10 1

5 Halteringdichtung 1

6 Luftkappe & Ring

7 Luftkappenhaltering & Dichtungen 702725 1

8 Flüssigkeitsdüse

9 Sprühkopf 1

*10 Sprühkopfdichtung 702726 1

11 Sprühkopf-Satz SN-69-K 1

*12 Sicherungsring 1

13 Ventilgehäuse 1

*14 O-Ring 1

*15 Strahlregulierventil-Passstift 1

16 Strahlregulierventil-Stellknopf 1

17 Strahlregulierventilsystem PRO-408-BL-K 1

18 Vorderer Ventilsitz 1

19 Ventilsitz 1

20 Spindel 1

21 Luftventilfeder 1

22 Hinterer Ventilsitz 1

23 Luftventilsatz 703530 1

24 Farbnadel

25 Nadelfeder 1

26 Federlager 1

27 Gehäuse- und Dichtungs-Satz SN-66-K 1

28 Flüssigkeitsstellknopf SN-67-BK-K 1

*29 Nadelfeder-Satz PRO-472-K3 1

30 Spritzpistolengehäuse 1

31 Lufteinlass 1

Siehe Tabelle 1, S. 11

Siehe Tabelle 2, S. 11

Siehe Tabelle 2, S. 11

1

1

1

Lufteinlass

Mit 20 Nm (15 ft-lbs) festziehen.

Verwenden Sie auf den Gewinden

einen mittelstarken Gewindeklebstoff

(zum Beispiel Devcon Nr. 2242 Blue

oder ähnlich).

BEZ. NR. BESCHREIBUNG TEILE-NR. ANZ.

32 Farb-ID-Ringsatz (4 Farben) 702735 1

33 Lufteinlass-Satz 702734 1

34 Nadeldichtung 1

35 Dichtungsfeder 1

36 Dichtungsmutter 1

*37

*38 Abzugschraube 1

*40 Abzugbolzen 1

SERVICETEILE

Spritzpistolen-Reparatursatz (enthält die Teile, die

mit einem * markiert sind)

Dichtungs- und Passstift-Satz, Satz mit 5 Teilen

(Teile 12, 14 und 15)

Dichtung, Feder und Dichtungsmutter-Satz

39 Abzug 1

41 Abzug-, Abzugbolzen- & Schrauben-

Satz

42 Stopfen 1

43 Cheater-Ventil (optional) 702737 1

44 Luftfeder-Wartungswerkzeug (nur im

Luftventil-Satz 23 enthalten)

45 Dichtung 1

46 Kontermutter 1

47 Fluideinlaß 1

48 Fluideinlaß Kit ADV-7-K 1

702731 1

SP-617-CR-K 1

PRO-470

GTI-428-K5

12

Page 29

Fehlersuche bei möglichen Betriebsproblemen

ZUSTAND URSACHE FEHLERBEHEBUNG

Spritzbild oben

oder unten zu stark

Spritzbild stark

gekrümmt

Starker Auftrag in der

Mitte des Spritzbildes

Verstopfte Bohrungen.

Verstopfung an der Düse oben oder unten.

Verschmutzung der Kappe und/oder

Düsenpassung.

Verstopfung der Bohrungen links oder rechts.

Schmutz an der linken oder rechten Seite der

Düse.

Abhilfen bei einem Spritzbild, das oben und unten zu stark ist oder einem zu sehr gekrümmten

Spritzbild:

1. Bestimmen Sie, ob die Verstopfung an der Luftkappe oder der Düse vorliegt. Testen Sie das

Spritzbild. Drehen Sie dann die Kappe um eine halbe Drehung und sprühen Sie ein weiteres

Spritzbild. Falls der Defekt umgekehrt wurde, liegt die Verstopfung an der Luftkappe vor. Reinigen

Sie die Luftkappen wie zuvor angegeben.

2. Falls der Defekt nicht umgekehrt wurde, liegt die Verstopfung an der Düse vor. Prüfen Sie die

Düsenkante auf feinen Bohrgrat. Mit Nass- oder Trocken-Sandpapier Nr. 600 entfernen.

3. Prüfen Sie auf getrockneten Lack in der Öffnung; entfernen Sie diesen mit Lösungsmittel.

Lackmenge für Zerstäuber zu groß.

Reinigen. Ausfräsen mit Nichtmetall-Spitze.

Reinigen.

Reinigen.

Reinigen. Ausfräsen mit Nichtmetall-Spitze.

Reinigen

Luftdruck und Flüssigkeitsmenge ausgleichen.

Spritzbild mit Strahlregulierventil einstellen.

TB-1022

Spritzbild gespalten

Stoßweiser oder flatternder

Spritzstrahl

Runder Spritzstrahl nicht

möglich

Kein Spritzstrahl

Mangelhaftes Spritzbild

Übermäßiges Übersprühen

Übermäßiger Sprühnebel

Trockensprühung

Flüssigkeitsleck an

Packungsmutter

*Häufigstes Problem.

Die Lackmenge überschreitet das Fassungsver-

mögen der Luftkappe.

Strahlregulierventil zu niedrig eingestellt.

Zerstäuberdruck zu niedrig.

Material zu dickflüssig.

Sprühdruck zu hoch.

Lackmenge zu gering.

Strahlregulierventil zu hoch eingestellt.

*Flüssigkeitsdüse/-Packung lose oder beschädigt.

Blendensitz nicht richtig installiert. Lackmenge zu

gering.

Behälter zu weit gekippt. Verstopfung in der Flüs-

sigkeitsleitung.

Nadelpackungsmutter trocken oder lose.

Strahlregulierer-Stellschraube sitzt nicht richtig.

Luftkappen-Haltering zu lose.

Kein Luftdruck in der Spritzpistole.

Flüssigkeitsnadel-Stellschraube nicht offen genug.

Flüssigkeit zu schwer für Ansaugung.

Flüssigkeitsdruck zu niedrig

Nicht genügend Lack.

Geringer Sprühdruck.

Sprühdruck zu hoch.

Spritzpistole zu weit von Oberfläche entfernt.

Unsachgemäßer Hub (Wölbung, Bewegung der

Spritzpistole zu schnell).

Verdünnermenge zu hoch oder Verdünner

trocknet zu schnell.

Sprühdruck zu hoch

Luftdruck zu hoch.

Düse zu weit von Oberfläche entfernt.

Bewegung der Spritzpistole zu schnell.

Spritzpistole nicht richtig eingestellt.

Packungsmutter zu lose.

Packungsverschleiß oder trockene Packung.

Flüssigkeit verdünnen oder weniger Flüssigkeit

zuführen. Einstellen.

Druck erhöhen.

Auf die richtige Konsistenz verdünnen.

Am Transformator oder der Spritzpistole reduzieren.

Lackmenge erhöhen (Fördermenge der Spritzpistole

erhöhen).

Einstellen.

Festziehen und auswechseln.

Nach Anweisung installieren.

Wieder auffüllen.

Gerader halten.

Mit Lösungsmittel rückspülen.

Schmieren oder festziehen.

Reinigen oder auswechseln.

Festziehen.

Luftzufuhr und Luftleitungen prüfen; Luftleitungen

der Spritzpistole ausblasen.

Flüssigkeitsnadel-Stellschraube öffnen.

Material verdünnen und/oder eine größere Düse

wählen oder Druckzufuhr.

Flüssigkeitsdruck am Tank erhöhen.

Flüssigkeits-Stellschraube zum ersten Gewinde

schrauben, eine größere Düse verwenden oder

den Flüssigkeitsdruck am Tank erhöhen.

Luftdruck erhöhen und die Spritzpistole wieder ins

Gleichgewicht bringen.

Druck reduzieren.

Entfernung richtig einstellen.

Langsamer und parallel zur Arbeitsoberfläche

spritzen

Richtig mischen.

Druck reduzieren.

Luftdruck reduzieren.

Entfernung richtig einstellen.

Spritzpistole langsamer verwenden.

Einstellen.

Nadel festziehen, nicht klemmen.

Auswechseln oder schmieren

13

Page 30

TB-1022

Fehlersuche bei möglichen Betriebsproblemen (Forsetzung)

ZUSTAND URSACHE FEHLERBEHEBUNG

Flüssigkeit leckt oder tropft am

vorderen Teil der Spritzpistole

Auslaufen und Ablaufen

Dünne, sandig-raue Lackschicht,

die zu schnell trocknet

Dicke, ungleichmäßige

Oberfläche, wie eine

„Orangenschale“

Packungsmutter sitzt zu fest.

Packung trocken.

Düse oder Nadel verschlissen oder beschädigt.

Fremdkörper in Spitze.

Düsenfeder gebrochen.

Falsche Nadelgröße oder –spitze

Lackmenge zu hoch.

Material zu dünnflüssig.

Spritzpistole im falschen Winkel oder zu

langsame Verwendung.

Spritzpistole zu weit von Oberfläche entfernt.

Luftdruck zu hoch.

Falscher Verdünner wurde verwendet.

Spritzpistole zu nahe an Oberfläche.

Zu viel Material wird grob versprüht.

Luftdruck zu niedrig.

Falscher Verdünner wurde verwendet.

Material wurde nicht richtig gemischt.

Oberfläche rau, ölig, schmutzig

Einstellen.

Schmieren.

Spitze oder Nadel auswechseln.

Reinigen.

Auswechseln.

Auswechseln

Spritzpistole einstellen oder Lackmenge reduzieren.

Richtig mischen oder dünne Schichten auftragen.

Spritzpistole im richtigen Winkel halten und richtig

verwenden.

Entfernung prüfen. Normale Entfernung liegt bei

15 - 20 cm.

Luftdruck reduzieren und Spritzbild prüfen.

Mischanweisungen des Lackherstellers einhalten

Entfernung prüfen. Normale Entfernung liegt bei

15 - 20 cm.

Mischanweisungen des Lackherstellers einhalten.

Luftdruck erhöhen oder Lackmenge reduzieren.

Mischanweisungen des Lackherstellers einhalten.

Mischanweisungen des Lackherstellers einhalten.

Richtig reinigen und vorbereiten.

Zubehör

HAV-500 OR

HAV-511 Regelventil

(HAV-511

DARGESTELLT)

HAV-500 hat keine Druckmessvorrichtung. Zur Kontrolle der

Luftmenge an der Pistole.

703625 HV40

Luftkappen-Testsatz

Mit diesem Testsatz wird der

Zerstäubungsluftdruck in der

Mitte der Luftkappe gemessen.

Damit können die Einhaltung von

Auflagen bestätigt und tägliche

Qualitätskontrollmaßnahmen

durchgeführt werden.

Champion™

Einweg-Atemschutzmasken

803611 (mittlerer Größe)

803612 (Großformat)

NIOSH-zertifiziert zum

Atemschutz.

702740 TEKNA-Schlüssel

14 mm 10 mm

Zu Wartungszwecken.

HAF-507 Whirlwind™

Inline-Luftfilter

Entfernt Wasser, Öl und

Verschmutzung aus der

Luftleitung.

Industrial-Anschlüsse für

HVLP-Spritzpistolen (Luft)

HC-4419 Schaft

¼ Zoll NPT(F)

HC-1166 Schaft

¼ Zoll NPT(M)

HC-4719 Verbindungsstück

¼ Zoll NPT(M)/NPS(M)

HC-4720 Verbindungsstück

¼ Zoll NPT(F)

14

Page 31

GARANTIE

Dieses Produkt wird von DeVilbiss mit einer zweijährigen beschränkten Garantie geliefert.

DeVilbiss Verkauf und Service: www.devilbiss.com

DeVilbiss

DeVilbiss verfügt über Vertragshändler weltweit.

Einzelheiten zu Ausrüstungsteilen, Ersatzteilen und Service finden Sie in

den Gelben Seiten.

Technische Hilfe – siehe nachstehende Auflistung.

Dieses Produkt wird in Großbritannien hergestellt von:

Finishing Brands UK, Ltd.

Ringwood Road,

Bournemouth,

BH11 9LH, UK

Exklusivvertrieb in Nordamerika durch:

DeVilbiss

TB-1022

3/16 ©2016 DeVilbiss. Alle Rechte vorbehalten. Printed in U.S.A.

15

Page 32

TB-1022

WARRANTY POLICY

Finishing Brands erteilt für DeVilbiss-Produkte eine beschränkte Garantie von zwei Jahren für Material und Verarbeitung. Bei der Verwendung

von Teilen oder Zubehör von einem anderen Hersteller als Finishing Brands erlöschen alle Garantien. Spezische Garantieinformationen