Page 1

Air Cap

Marking

Part Number

G(0.7)

E(1.8)

G(0.7)

E(1.8)

Basic Part Number

Fluid Tip(Size)

E :1.8mm

Air Cap No.

807MT2

Delivery adjustable

B:Fixed type

Body material

7:Stainless steel

Paint passage

9:Circulation

T2AGPV LVMP

COMPACT AUTO GUN Operation Manual

Important:Read and follow all instructions and SAFETY PRECAUTIONS before using this equipment.

DESCRIPTION

T2AGPV LVMP gun is a small, light-weight Automatic Compact gun and suitable for robots and automatic machines.

Models and application information follows.

MODELS

Example: T2AGPV - A 7 8 - 805MT2 - FX

G :0.7mm

FX :1.1mm

A:Adjustable type

6:Aluminum

805MT2

FF :1.4mm

FW :1.6mm

8:Non-Circulation

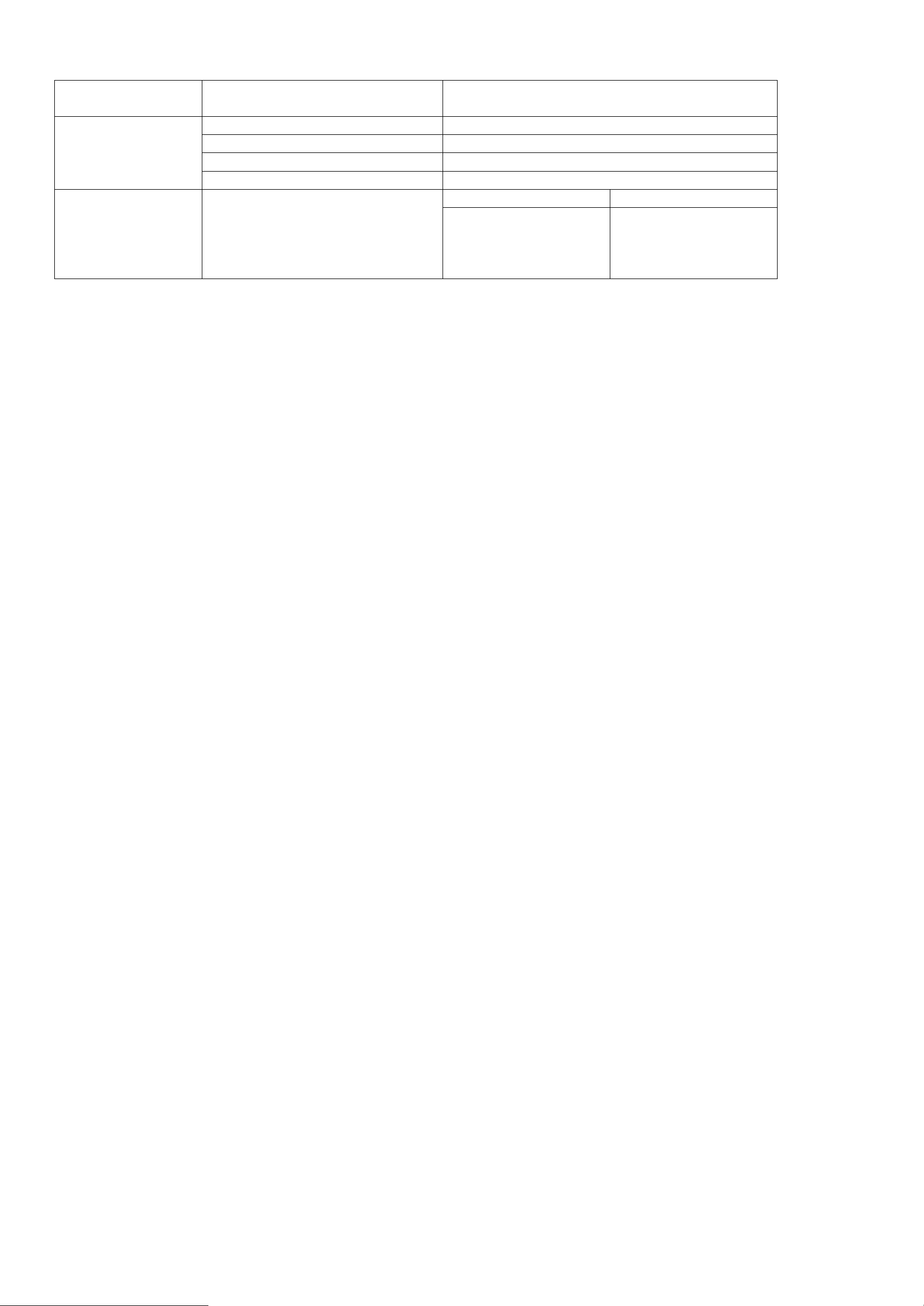

Chart 1

805MT2 AV-1239-805MT2

807MT2 AV-1239-807MT2

Fluid Tip Size (mm) Pattern Size Shape Typical Applications

FX(1.1)

FF(1.4)

FW(1.6)

FX(1.1)

FF(1.4)

FW(1.6)

220mm Blunt

280mm Taper

Most conventional materials

Waterborne

Most conventional materials

Waterborne

1

Page 2

Chart 2

G(0.7)

T2AG-440-G

FX(1.1)

T2AG-440-FX

FF(1.4)

T2AG-440-FF

E(1.8)

T2AG-440-E

FF(1.6)

Fluid Tip

Needle

T2AG-4S-G

T2AG-4S-FW

T2AG-402-FZ

T2AG-402-FZ

805MT2

807MT2

Air Cap Tip Marking (mm) Part Number (Tip & Needle Lapped Set)

805MT2

807MT2

G(0.7)

FX(1.1)

FF(1.4)

T2AG-4S-FX

T2AG-4S-FF

T2AG-402-FZ

T2AG-402-FZ

2

Page 3

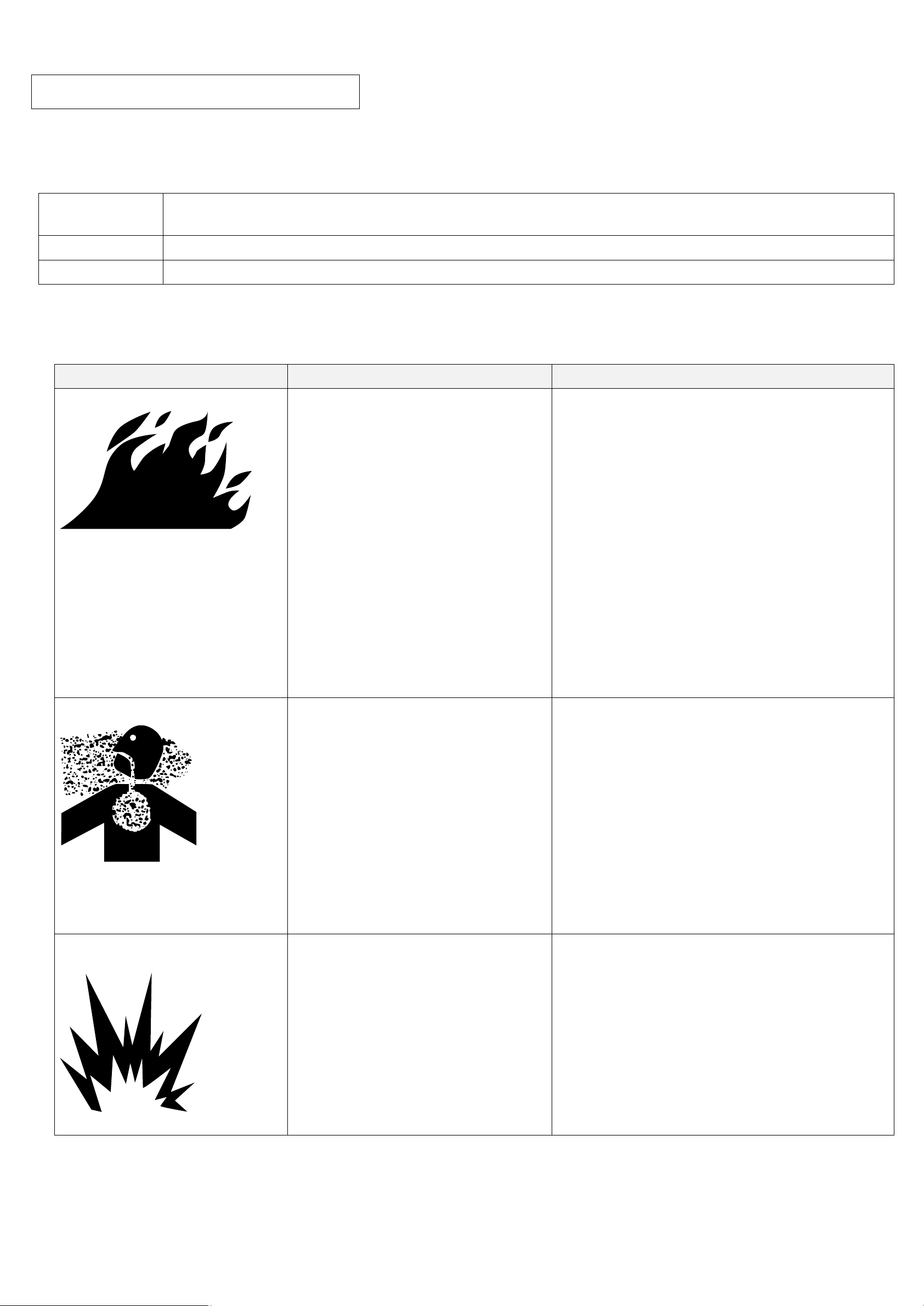

SAFETY PRECAUTIONS

Important information to alert you to a situation that might cause serious injury or loss of life if instructions

are not followed.

CAUTION

Important information that tells how to prevent damage to equipment.

NOTE

Information that you should pay special attention to.

HAZARD

CAUSE

SAFEGUARDS

Fire

Solvents and coatings can be highly

1. Adequate exhaust must be provided to keep

have flash points above 100°F (37.8°C).

Inhaling Toxic Substances

Certain materials may be harmful if

1. Follow the requirements of the Material

NIOSH approved.

Explosion Hazard –

Halogenated hydrocarbon Solvents-

equipment explosion.

The T-AGB spray gun can be used with these

This manual contains important information that ALL users should know and understand BEFORE using this equipment. This

information relates to USER SAFETY and PREVENTING EQUIPMENT PROBLEMS.

To help you recognize this information, we use the following terms to draw your attention to certain equipment labels and

portions of this manual. Pay special attention to any label or information that is highlighted by one of these terms:

WARNING

WARNING

The following hazards may occur during the normal use of this equipment. Please read the following chart.

flammable or combustible, especially

when sprayed.

the air free of accumulations of flammable

vapors.

2. Smoking must never be allowed in the spray

area.

3. Fire extinguishing equipment must be

present in the spray area.

4. Static discharges must be prevented.

Ground(earth) all conductive objects in the

spray area, such as a cleaning solvent

bucket, fire extinguisher, etc.

5. When using solvents for cleaning:

• Those used for equipment flushing must

have a flash point equal to or greater than

that of the coating.

•

Those used for general cleaning must

inhaled or if there is contact with the

skin.

Safety Data Sheet supplied by coating

material manufacturer.

2. Adequate exhaust must be provided to keep

the air free of accumulations of toxic

materials.

3. Use a mask or respirator whenever there is a

chance of inhaling sprayed materials. The

mask must be compatible with the material

being sprayed and its concentration.

Equipment must be as prescribed by an

industrial hygienist or safety expert, and be

Incompatible Materials

for example:

methylene chloride and

1,1,1,-Trichloroethane are not

chemically compatible with the

aluminum that might be used in

many system components. The

chemical reaction caused by these

solvents reacting with aluminum can

become violent and lead to an

3

solvents.

However, aluminum is widely used in other

spray application equipment – such as material

pumps, cups, regulators, valves, etc. Check all

other equipment items before use of these

solvents. Read the label or data sheet for the

material you intend to spray. If in doubt as to

where or not a coating or cleaning material is

compatible, contact your material supplier.

Page 4

HAZARD

CAUSE

SAFEGUARDS

General Safety

Improper operation or maintenance

may create a hazard.

Operators should be given adequate training in

1910.107 and NFPA-33).

Noise Levels

The continuous A-weighted sound

request.

Wear earplugs when using the spray gun.

Spraying solvent

Pressured air/fluid passage may be

Always wear eye protection when spraying or

Misuse:

The removal of waste solvents and coating materials should be carried out by an authorized local waste disposal service.

pressure level of this spray gun may

exceed 85dB(A) depending on the

air cap/nozzle set-up being used.

Sound levels are measured using an

impulse sound level meter and

analyzer, when the gun is being used

in a normal spraying application.

Details of actual noise levels

produced by the various air

cap/nozzle set-ups are available on

the safe use and maintenance of the equipment

(in accordance with the requirements of

NFPA-33, Chapter 15 in U.S.). Users must

comply with all local and national codes of

practice and insurance company requirements

governing ventilation, fire precautions, operation,

maintenance and housekeeping (in the U.S.,

these are OSHA Sections 1910.94 and

broken when cleaning or flashing

with solvent.

The solvent may be harmful if

contacted with eyes.

• All spray guns project particles at high velocity and must never be aimed t any part of body.

• Never exceed the recommended safe working pressure for any of the equipment used.

• The fitting of non-recommended or non-original accessories or spare parts may create hazardous conditions.

• Before dismantling the equipment for cleaning or maintenance, all pressures, air and material, must be isolated and

released.

Disposal of non-metallic materials must be carried out in an approved manner. Burning may generate toxic fumes.

cleaning the equipment.

4

Page 5

SPECIFICATIONS

Max. Fluid Pressure

0.69MPa (7.0kgf/cm2)

Cylinder Air Pressure

Min. 0.34MPa (3.5 kgf/cm2)

Max. 0.49MPa (5.0 kgf/cm2)

Weight

Mounting Stud

Dia. 19mm x 51mm

Fluid Tube

6x4mm

Max. Air Pressure 0.69MPa (7.0kgf/cm2)

730g (SUS / Adjustable type / Type for Non-Circulation)

336g (Aluminum/Adjustable type /

CYL Air Tube 6x4mm

CAP Air Tube 6x4mm

FAN Air Tube 6x4mm

Type for Non-Circulation)

INSTALLATION

Figure 1. Dimensions

5

Page 6

Figure 2. Installation

Mount the gun with the stud (Ø19) or tighten with Manifold (14) 8.2mm whole.

CAUTION:

The air supplied to the gun should be clean air that removed any impurities.

OPERATION

1. Mix, prepare and strain the coating material to be sprayed according to paint manufacturer’s instructions.

2. Adjust the CYL air at 0.34~0.49Mpa.

3. When the adjustable type is used, turn the Adjusting Screw counter-clockwise about 4.0 turns from fully closed position to

make it fully opened (where it lightly bumps against). Do not turn it more than that.

4. Adjust the CAP/FAN air at about 0.20Mpa.

5. Adjust fluid air at about 0.07Mpa~0.1Mpa.

6. Turn on CYL air and test spray. Adjust fluid and air pressure until desired pattern is obtained. Control fluid pressure at

source supply. Always attempt to keep CAP pressure as low as possible to minimize overspray.

WARNING

Risk of injury. Equipment and fluid may be under pressure. Pressure in the system must be relieved before beginning the

cleaning procedure and before replacing any parts. Follow the procedures in the literature provided with the system.

CLEANING

1. Please follow the instruction manual for the pressure tank or the feed pump to clean the supply equipment.

2. Supply gun with thinner from that supply equipment or another supply device.

3. Turn on CYL air and clean the fluid passages until the thinner comes out clean and clear. Quick Cleaner which supplies a

mixture of air and solvent can be used to improve cleaning efficiency and save solvent. See “ACCESSORIES” for Quick

Cleaner. Wipe gun exterior with a solvent dampened cloth.

4. When the gun is used in a paint circulation system, it may be necessary to design a system in which the paint return line

will be shut off temporarily in order to clean the forward portion of the gun.

CAUTION

Do not totally submerge gun in solvent. It is possible to damage the inside of the gun with solids.

CAUTION

The air cap can be immersed in solvent for cleaning. If orifices are clogged, use a cocktail stick or toothpick to remove

obstruction. Never use a steel wire or hard instrument. This will damage air cap and result in a distorted spray pattern.

6

Page 7

REPLACEMENT

Tools Required

Crescent Wrench

10mm or 13mm Box Wrench

Pliers (for Needle Assy)

Open Wrench

Hex Wrench

Fluid Tip (5)

1. Relieve all air and fluid pressure in system.

2. Remove Rear Body (10or11), Needle Spring (9). Pull Needle Assy (8) out from gun body with Pliers.

3. Remove Retaining Ring (1) and Air Cap (4).

4. Remove Fluid Tip (5) with 1/2 Box Wrench.

5. Reassemble in reverse order. Recommended torque of Fluid Tip (5): 16~20N・m.

Replacing Needle Assy (8), Piston Seal (7)

1. Remove Rear Body (10or11), Needle Spring (9). Pull Needle Assy (8) out from gun body with Pliers.

2. Insert the new Needle Assy and install the Spring and Rear Body.

3. Piston Seal should not be reused because it would be damaged when removed.

Replacing Needle Seal Kit (6)

1. Remove Rear Body (10or11), Needle Spring (9). Pull Needle Assy (8) out from gun body with Pliers.

2. Remove Needle Seal Kit (6) with 13mm Box Wrench or specialized tool (Optional).

3. Attach new Needle Seal Kit (6) to the gun body with the 13mm Box Wrench or specialized tool (Optional). Before doing it

please apply a little bit of vaseline to the O-ring of the Seal Kit.

4. Before inserting to the gun, apply vaseline to the Piston Seal (7) of Needle Assay (8).

5. Insert Needle Spring (9), and assemble Rear Body.

6. Pressure 0.35Mpa on CYL and check the movement of needle.

Figure 5. Gun Exploded View

7

Page 8

Item No.

Part Number

Description

Q’ty

Remarks

1

T2AG-368

Retaining Ring

1

with Cap Seat and Ring Gasket

2

T2AG-50-K5

Cap Seat

1

5 pieces

3

T2AG-55-K5

Ring Gasket

1

5 pieces

4

Refer to Chart1

Air Cap

1

5

Refer to Chart2

Fluid Tip

1

6

T2AG-10

Needle Seal Kit

1

7 T2AG-102

Piston Seal

1

8 Refer to Chart2

Needle

1

9

T2AG-106

Needle Spring

1

10

T2AG-500

Rear Body(Fixed type)

1

11

12

T2AG-140

O-Ring (Small) S4

3

2 for fluid, 1for air

13

T2AG-130

O-Ring (Big) S6

2

for air

14

T2AG-100AL

T2AG-100SS

Manifold (Aluminum)

Manifold (SUS)

1

15

--------

Hexagon Socket Bolt M6×L25

1

Commercial product

16

--------

Plug 1/8

1

Commercial product

17

T2AG-STU-64

Joint for Fluid

2

with Fluid Seal

18

EC6-R1/8A-M-R1001

Joint for Air

3

19

T2AG-TU-1-K5

Fluid Seal Kit of 5

2

T2AG-3-K

Mounting Stud Kit

Optional

T-AGPZ-34

Specialized Tool for Needle Seal Kit

Optional (Refer to Figure 5.)

T2AG-700

Rear Body(Adjustable type with scale)

Optional (Refer to Figure 5.)

T2AG-600 Rear Body(Adjustable type) 1

8

Page 9

SERVICE CHECK

Will not spray.

No pressure to gun.

Piston stops moving.

Check air and material lines.

Check CYL air pressure.

Improper spray pattern.

A. Gun not adjusted properly.

A. Re-adjust. See “Operation Section”.

Note

spray. If the pattern

. If the

pattern changes with air cap movement, the buildup is in the air cap (4).

C, D. Wrong material or material too thick.

pressure too high.

C, D Adjust material pressure or thin material.

air pressure.

Jerky or fluttering spray

1. Insufficient material in the tank or an obstruction

1. Fill tank or clear obstruction.

Air leaking from the

Damaged or worn Piston Seal (7).

Replace.

be used depending on the

extent of the damage.

Liquid spill from Fluid Tip

Clogged Needle (8) of the Fluid Tip (5)

Damaged or deformed Needle Spring (9)

Clean.

Replace.

Air or paint leaking from

body

Damaged or worn Needle Seal Kit (6)

Replace.

SSL-10

Gun Lube (60cc)

42884-214-K5

Cleaning Brush Kit of 5

Quick Cleaner(5)

HD-510

Quick Cleaner(10)

KK-5033-805MT

Air Cap Test Gauge (for AV1239-805MT2)

KK-5033-807MT

Air Cap Test Gauge (for AV1239-807MT2)

AGA-415

Universal Clamp

Normal spray pattern

©2017 Carlisle Fluid Technologies.

HP http://www.carlisleft.co.jp

DIVISION

®DEVILBISS is a registered trademark of Carlisle Fluid Technologies.

®Jupiter is a registered trademark of CFT Ransburg Japan KK.

Ransburg Japan KK

The proper combination of fluid pressure, fan and atomization air pressure,

Problem Cause Correction

and fluid tip size should result in a pattern of this shape.

A, B. Material build up on the air cap (4)or fluid

tip (5).

To determine where the material build up is, rotate the air cap (4) 180°and test

stays in the same position, the condition is caused by material build up on the fluid tip (5)

Insufficient material or atomizing air

in the line.

2. Gun material passage plugged.

3. Worn Needle Seal Kit (7).

4. Loose or damaged Fluid Tip (3).

A, B. Clean the air cap or fluid tip. See

“Preventive Maintenance”.

Increase material or reduce atomizing

2. Clean.

3. Replace or tighten.

4. Tighten or replace.

center hole of Rear Body

(5)

the 3mm hole of the gun

Damaged cylinder part of the gun body

Damaged or worn Fluid tip (5) or Needle (8)

ACCESSORIES

Part No. Description

GC-100-K48 Gun Cover Kit of (48)

Gun body may not

Replace.

HD-505-W

9

2017-08-

T2AGPV LVMP

Loading...

Loading...