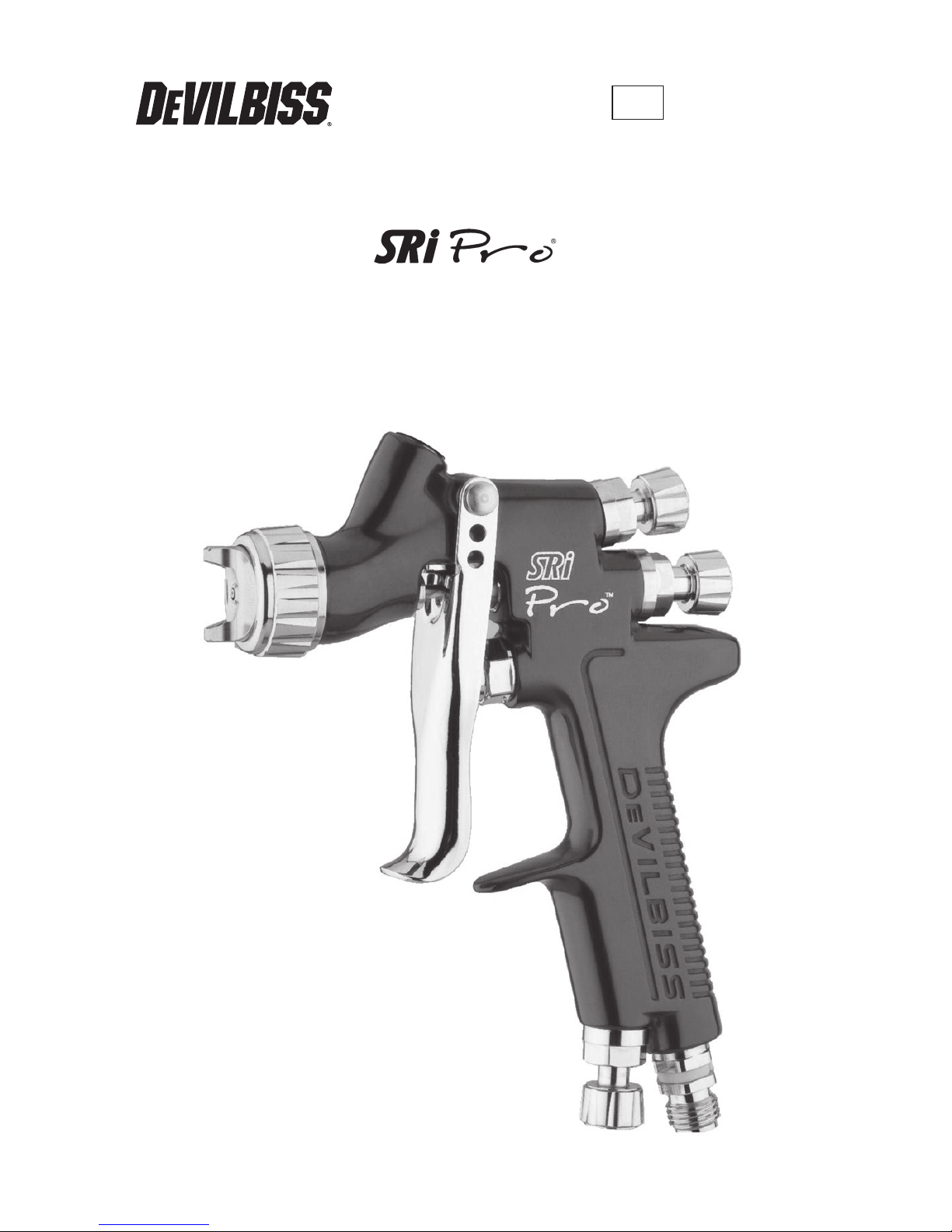

DeVilbiss SRI PRO series Technical Bulletin

Service Bulletin

SB-2-855-B

Replaces SB-2-855-A

Technical Bulletin

SRi Pro range of Gravity Spray Guns

for spot repairs and small areas

AUTOMOTIVE REFINISHING

EN

Page 2 SB-2-855-B

Table of Contents

Topic Page

EC Declaration of Conformity ................................................ 3

Operational Description .................................................... 3

Construction Features ...................................................... 4

Materials of Construction ................................................... 4

Specifications & Technical Data .............................................. 4

Safety Precautions ......................................................... 5

Parts List ................................................................. 6

Exploded Parts View ....................................................... 7

Installation, Operation, Preventive Maintenance & Cleaning, Spray Gun Lubrication .. 8

Parts Replacement/Maintenance ............................................. 9-13

A. Servicing Air Valve ................................................. 9

B. Replacing Air Valve ................................................. 10

C. Needle Packing, Spreader Valve Assembly .............................. 11

D. Replacing Separator Seal ............................................ 12

E. Chart 1 – Air Caps, Chart 2 – Fluid Nozzles & Fluid Needles ................ 13

Troubleshooting Possible Problems in Operation ............................... 14, 15

Accessories .............................................................. 16

Warranty ................................................................. 16

Page 3SB-2-855-B

EC Declaration of Conformity

We, Finishing Brands UK Ltd., Ringwood Rd, Bournemouth, Dorset, BH11 9LH, UK, as the manufacturer

of the Spray gun model SRi-PRO, declare, under our sole responsibility, that the equipment to which

this document relates is in conformity with the following standards or other normative documents:

BS EN 292-1 PARTS 1 & 2: 1991, BS EN 1953: 1999; and thereby conform to the protection

requirements of Council Directive 98/37/EEC relating to Machinery Safety Directive, and;

EN 13463-1:2001, council Directive 94/9/EC relating to Equipment and Protective Systems intended

for use in Potentially Explosive Atmospheres protection level II 2 G X. This product also complies with

the requirements of the EPA guidelines, PG6/34.

D. Smith, Vice President

1st May 2012

Operational Description

This SRi PRO Spray Gun is a professional quality gun designed with both high volume, low pressure (HVLP)

technology or Trans-Tech® technology. HVLP Technology reduces overspray and limits air cap pressure

to 0.7 bar (10 psi) (complies with rules issued by SCAQMD and other air quality authorities). Trans-Tech

technology, when tested under recommended conditions with automotive refinishing materials, has been

found to exceed 65% transfer efficiency.

IMPORTANT: These Sprayguns are suitable for use with both waterbased and solvent based coating

materials. These guns are not designed for use with highly corrosive and/or abrasive materials and if

used with such materials it must be expected that the need for cleaning and/or replacement of parts will

be increased. If there is any doubt regarding the suitability of a specific material, contact your DeVilbiss

Distributor or DeVilbiss direct.

NOTE: This gun is not to be used with halogenated hydrocarbon solvents or cleaning agents such as

1,1,1,-Trichloroethane or methylene chloride. These solvents can react with the aluminium components

used in this gun and cup. The reaction can become violent and lead to an equipment explosion.

Finishing Brands UK Ltd. reserve the right to modify equipment specification without prior notice.

Page 4 SB-2-855-B

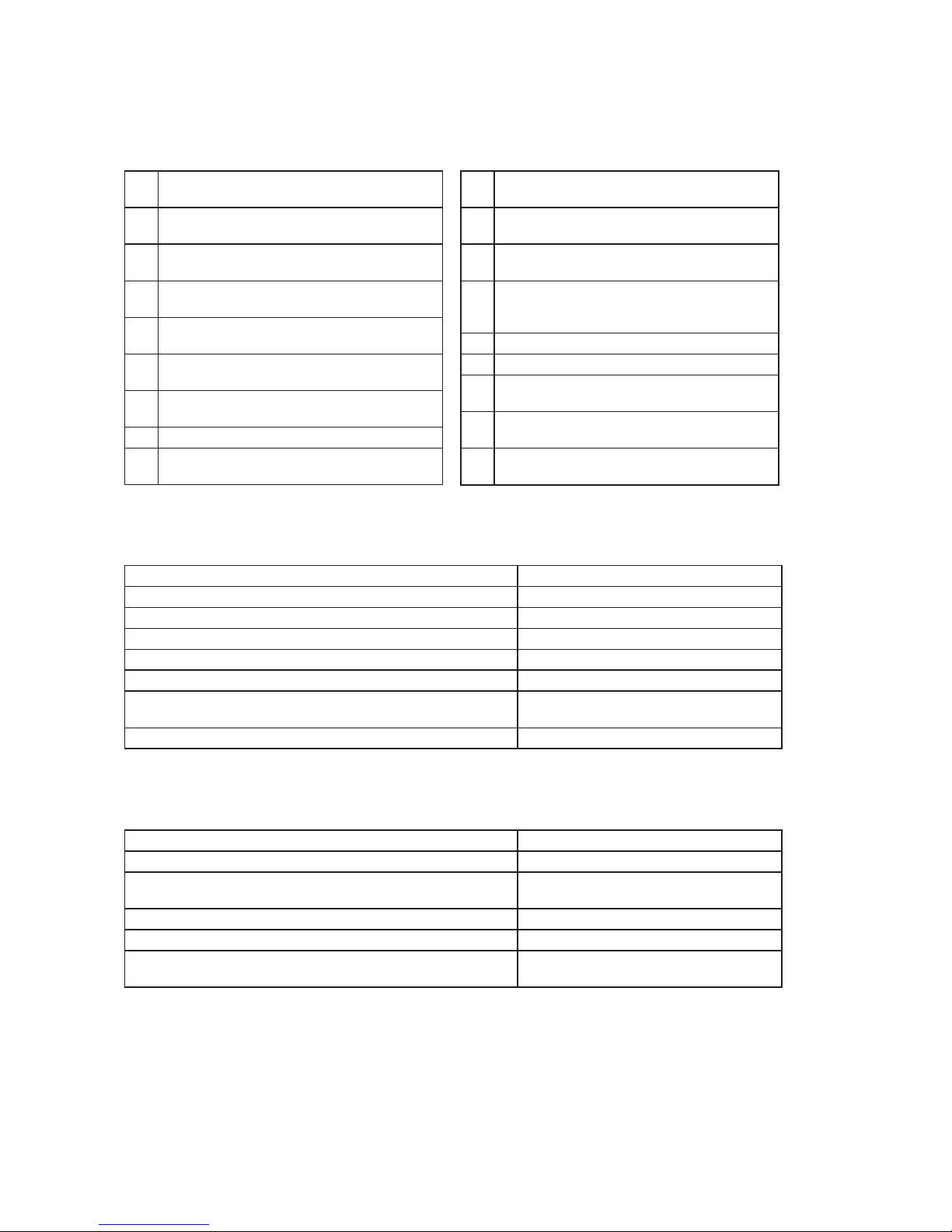

MATERIALS OF CONSTRUCTION

Gun Body Anodized aluminium

Air Cap Nickel plated brass

Fluid Nozzle, Fluid Needle, Fluid Inlet, Trigger Stud Stainless steel (303)

Springs, Clips, Screws Stainless steel (303)

Seals, Gaskets Solvent resistant

Trigger Chrome plated steel

Air Inlet, Body Bushing, Spreader Valve Body, Air Valve Nut,

Air Cap Retaining Ring, Knobs

Chrome plated brass

Air Valve Assembly Stainless steel (303), HPDE

SPECIFICATIONS & TECHNICAL DATA

Air Supply Connection Universal 1/4" BSP and 1/4" NPS male

Maximum Static Air Inlet Pressure P1 = 175 psi (12 bar)

Nominal Gun Air Inlet Pressure for HVLP (HS1) and

Trans-Tech

®

(TS1) with gun triggered

29 psi (2.0 bar)

Fluid Supply Connection 7/16 – 14 UNC

Service Temperature 32 to 104°F (0 to 40°C)

Gun Weight (gun only)

(with cup)

15.0 oz (425 g)

17.1 oz (485 g)

CONSTRUCTION FEATURES

1

Air Cap

(nickel plated brass for long durability)

2

Air Cap Retaining Ring

(allows easy rotation of air cap)

3

Fluid Nozzle

(ideal for automotive topcoat systems)

4

Fluid Needle

(grooved stem for easy removal)

5

Fluid Inlet (7/16” – 14 UNC thread) – accepts

DeVilbiss SRI cup systems

6

Air Inlet

(universal thread, accepts G 1/4 & 1/4 NPS)

7

Self Adjusting Needle Packing

(for trouble free operation)

8 Trigger (ergonomic for comfort)

9

Trigger Stud & Screw

(easy replacement design)

10

Fan Air Adjustment

(stepless regulation for fan to round spray)

11

Fluid Adjustment

(stepless regulation of fluid volume)

12

Interchangeable Color ID System

(4 colored rings supplied)

13

Anodized, forged aluminium gun body

(ergonomic, good looking & durable, easy

to clean)

14 125cc Acetal Cup (easy clean, anti-static)

15 Cup Lid with Drip Free Vent (avoid drips)

16

Air Valve (design offers low pull force & low

pressure drop)

17

Gun acceptable for waterborne and solvent

borne applications

18

Gun can be used with DeVilbiss disposable

cups

Page 5SB-2-855-B

CAUTION

Important information that tells how

to prevent damage to equipment,

or how to avoid a situation that may

cause minor injury.

NOTE

Information that you should pay special

attention to.

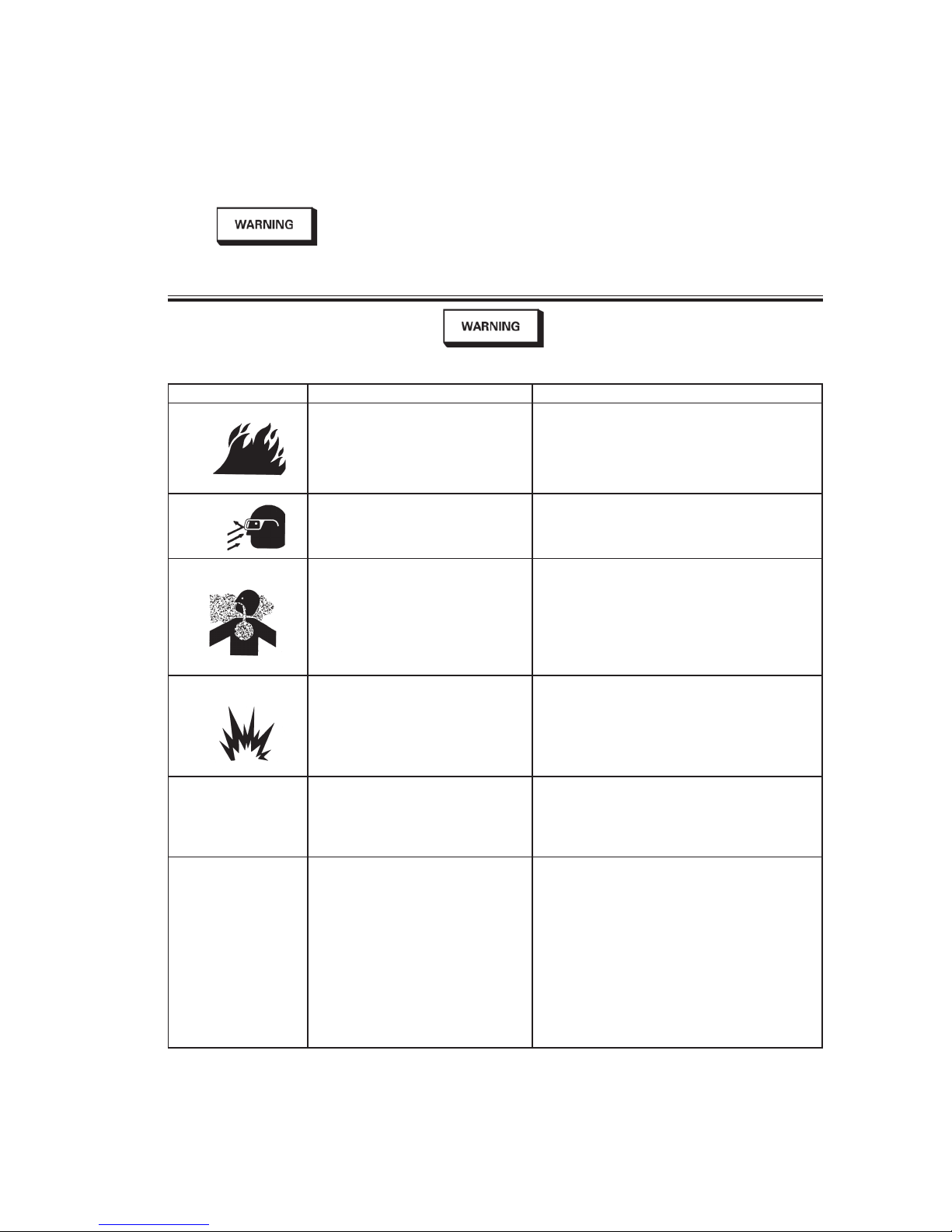

SAFETY PRECAUTIONS

This manual contains information that is important for you to know and understand. This information relates to USER SAFETY and

PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please pay particular

attention to these sections.

Important safety information – A hazard

that may cause serious injury or loss

of life.

The following hazards may occur during the normal use of this equipment.

Please read the following chart before using this equipment.

HAZARD CAUSE SAFEGUARDS

Fire

Solvent and coatings can be highly flammable or

combustible especially when sprayed.

Adequate exhaust must be provided to keep air free of

accumulations of flammable vapors.

Smoking must never be allowed in the spray area.

Fire extinguishing equipment must be present in the spray

area.

Solvent Spray

During use and while cleaning and flushing,

solvents can be forcefully expelled from fluid

and air passages. Some solvents can cause

eye injury.

Wear eye protection.

Inhaling Toxic Substances

Certain materials may be harmful if inhaled, or if

there is contact with the skin.

Follow the requirements of the Material Safety Data Sheet

supplied by your coating material manufacturer.

Adequate exhaust must be provided to keep the air free of

accumulations of toxic materials.

Use a mask or respirator whenever there is a chance of inhal

ing sprayed materials. The mask must be compatible with the

material being sprayed and its concentration. Equipment must

be as prescribed by an industrial hygienist or safety expert,

and be NIOSH approved.

Explosion Hazard Incompatible Materials

Halogenated hydrocarbon solvents

- for example; methylene chloride and 1,1,1, Trichloroethane are not chemically compatible

with the aluminum that might be used in many

system components. The chemical reaction

caused by these solvents reacting with aluminum

can become violent and lead to an equipment

explosion.

Guns with stainless steel internal passageways may be used

with these solvents. However, aluminum is widely used in

other spray application equipment - such as material pumps,

regulators, valves, and this gun and cup. Check all equip

ment items before use and make sure they can also be used

safely with these solvents. Read the label or data sheet for

the material you intend to spray. If in doubt as to whether or

not a coating or cleaning material is compatible, contact your

material supplier.

General Safety

Improper operation or maintenance of

equipment.

Operators should be given adequate training in the safe use

and maintenance of the equipment (in accordance with the

requirements of NFPA-33, Chapter 15). Users must comply

with all local and national codes of practice and insurance

company requirements governing ventilation, fire precautions,

operation, maintenance, and housekeeping. These are OSHA

Sections 1910.94 and 1910.107 and NFPA-33.

Cumulative Trauma

Disorders ("CTD's")

CTD's, or musculoskeletal

disorders, involve damage

to the hands, wrists,

elbows, shoulders, neck,

and back. Carpal tunnel

syndrome and tendonitis

(such as tennis elbow or

rotator cuff syndrome) are

examples of CTD's.

Use of hand tools may cause cumulative trauma

disorders ("CTD's").

CTD's, when using hand tools, tend to affect the

upper extremities. Factors which may increase

the risk of developing a CTD include:

1. High frequency of the activity.

2. Excessive force, such as gripping, pinching,

or pressing with the hands and fingers.

3. Extreme or awkward finger, wrist, or arm

positions.

4. Excessive duration of the activity.

5. Tool vibration.

6. Repeated pressure on a body part.

7. Working in cold temperatures.

CTD's can also be caused by such activities as

sewing, golf, tennis, and bowling, to name a few.

Pain, tingling, or numbness in the shoulder, forearm, wrist,

hands, or fingers, especially during the night, may be

early symptoms of a CTD. Do not ignore them. Should you

experience any such symptoms, see a physician immediately.

Other early symptoms may include vague discomfort in the

hand, loss of manual dexterity, and nonspecific pain in the

arm. Ignoring early symptoms and continued repetitive use of

the arm, wrist, and hand can lead to serious disability. Risk is

reduced by avoiding or lessening factors 1-7.

Page 6 SB-2-855-B

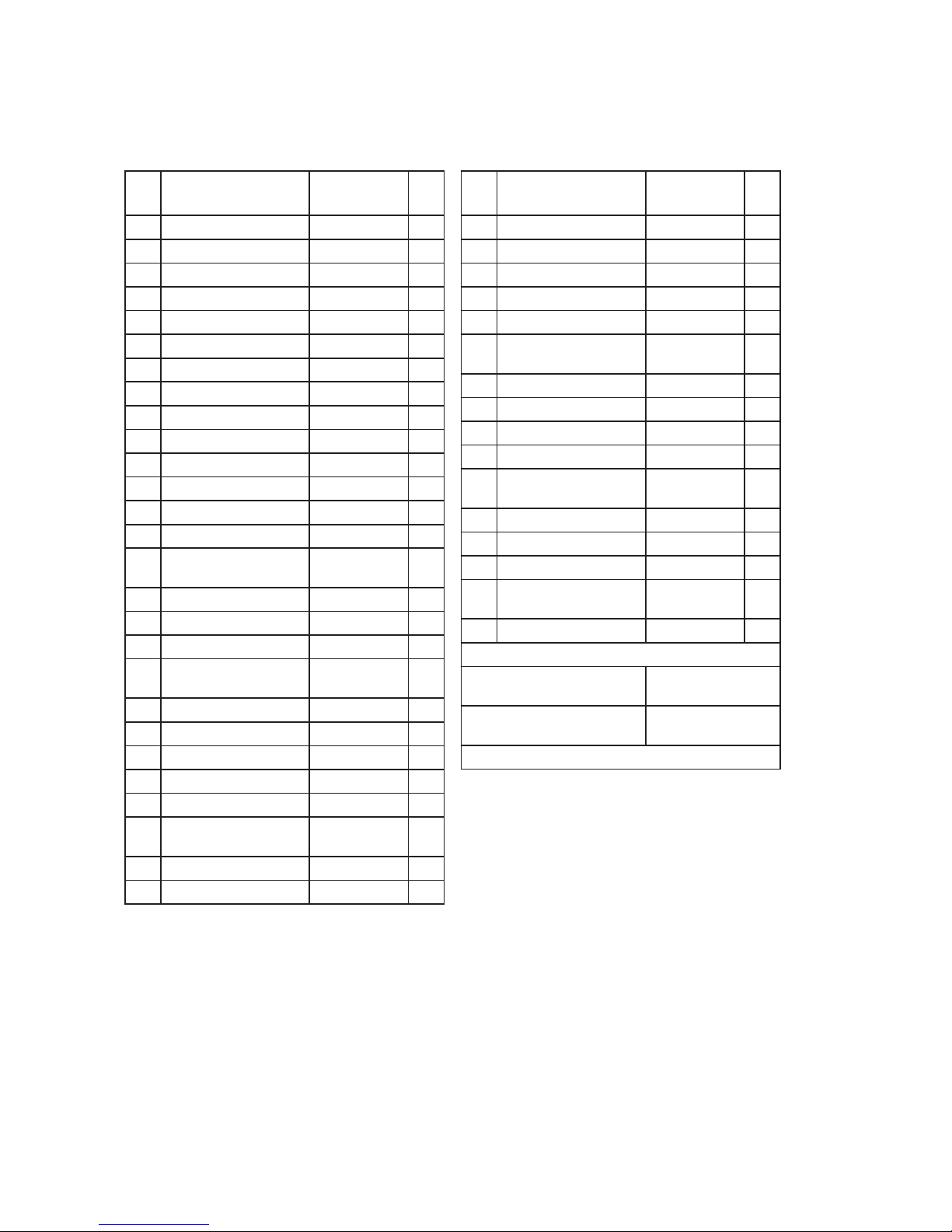

PARTS LIST

REF.

NO.

DESCRIPTION PART NO. QTY.

1 Air Cap Retaining Ring 1

2 Slip Ring 1

3 Air Cap 1

5 Retaining Ring Seal SRI-35-K5 1

6 Air Cap & Ring See chart 1, p13 1

8 Fluid Nozzle See chart 2, p13 1

9 Separator SRIPRO-2-K5 1

12* Body Bushing Seal 1

13 Body Bushing 1

14 Body Bushing & Seal 702728 1

15 Fluid Needle See chart 2, p13 1

16* Needle Spring 1

17* Needle Spring Pad 1

18 Fluid Adjusting Knob 1

19

Fluid Adjusting Knob,

Spring & Pad Kit

PRO-3-K 1

20* Retaining Clip 1

21 Spreader Valve Body 1

22* Spreader Valve Seal 2

23

Spreader Valve Adjusting

Knob

1

24* Valve Pin 1

25 Spreader Valve Assembly SRIPRO-401-K 1

26* Needle Packing 1

27* Packing Spring 1

28 Packing Nut 1

29

Packing, Spring &

Packing Nut Kit

702731 1

30 Air Valve Body 1

31 Air Valve Cage 1

REF.

NO.

DESCRIPTION PART NO. QTY.

32 Air Valve Poppet 1

33 Air Valve Spring 1

34 Air Valve Spring Pad 1

35 Air Valve Seal SN-34-K5 1

36 Air Valve Assembly 702732 1

37*

Trigger Stud Screw

(T20 Star)

1

38 Trigger 1

39* Trigger Stud 1

40 Trigger, Stud & Screw Kit SN-42-K 1

41 Air Inlet SN-40-K 1

42

Color ID Ring Kit

(4 colors)

702735 1

43 Airflow Valve PRO-404-K 1

44 Circlip 1

45 Wrench (kit of 2) SRI-50-K2 1

46

Air Valve Service Tool

(included in 702732)

1

47 Air Flow Valve Knob 1

SERVICE PARTS

Spray Gun Repair Kit

(includes items marked *)

702736

Seal & Pin Kit, kit of 5

(items 20, 22 and 24)

GTI-428-K5

For accessories, see page 16

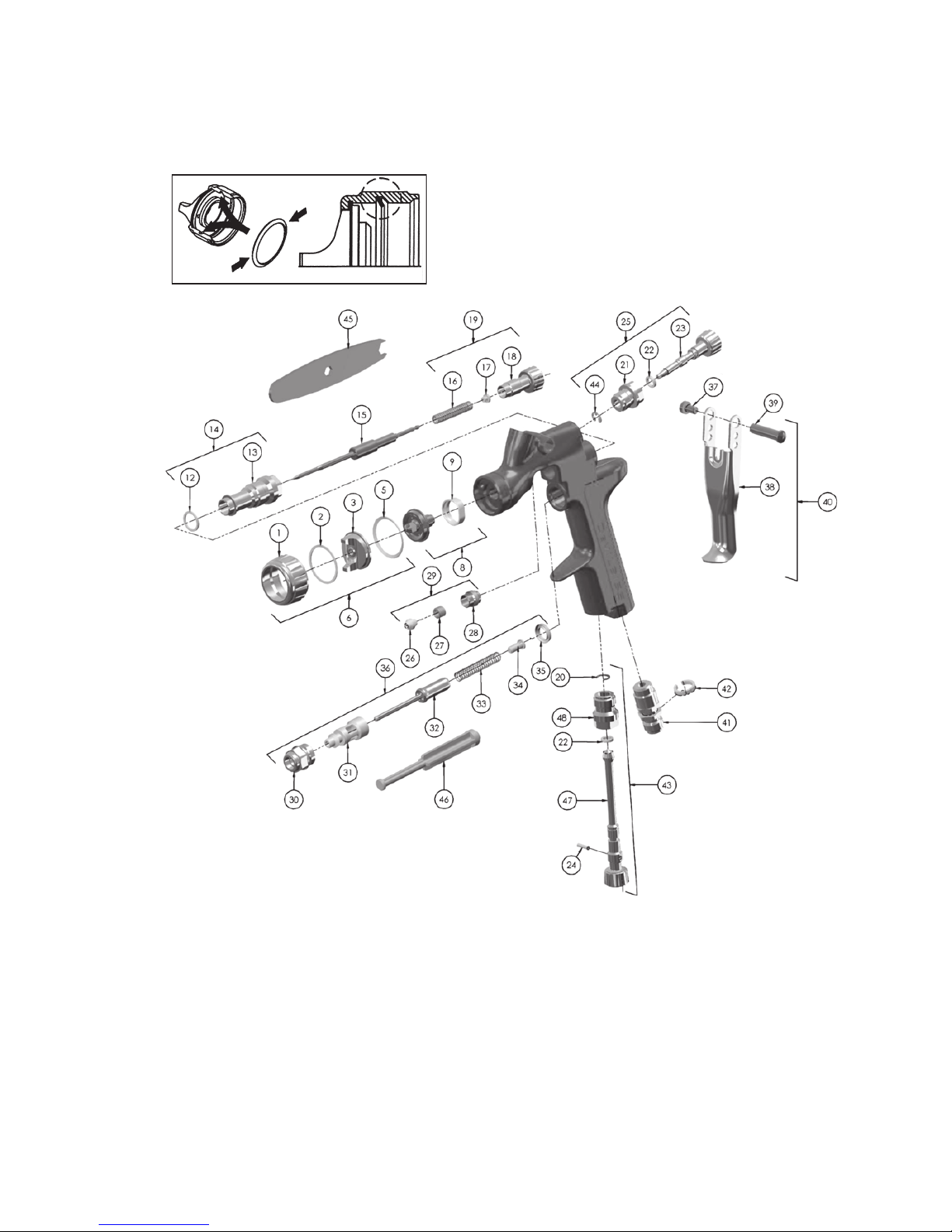

Page 7SB-2-855-B

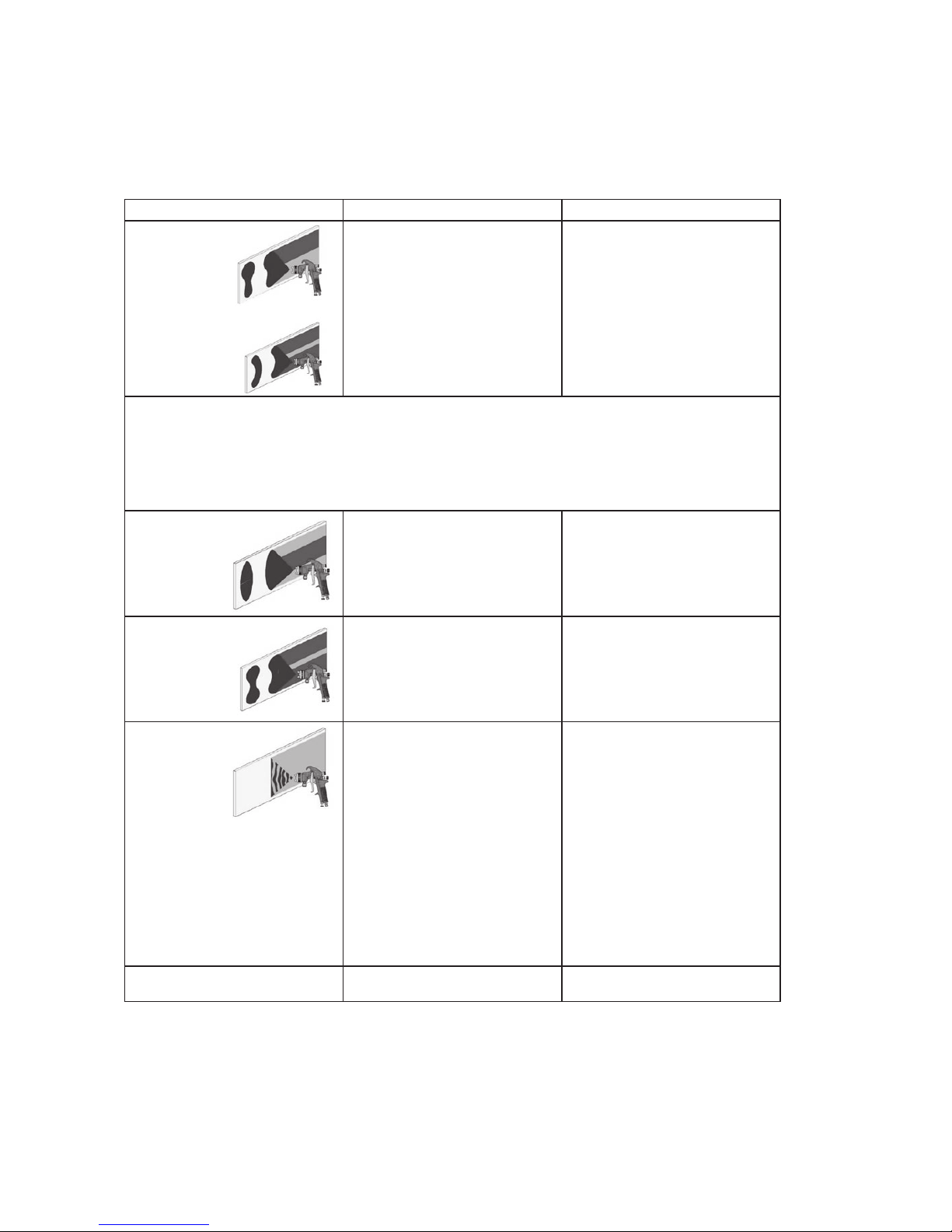

k

Fluid Nozzle

(Torque to 80-90 in-lbs)

k

A

A

B

Fig. B

Fig. A

Views showing correct

Air Cap/Retaining Ring assembly.

Page 8 SB-2-855-B

INSTALLATION

For maximum transfer efficiency,

do not use more pressure than is

necessary to atomize the material

being applied. NOTE: when using the

HS1, HVLP setup do not exceed 29.0

psi (2 bar) inlet pressure. This will

insure HVLP compliance by limiting

air cap pressure to 10 psi (0.7 bar).

1. Connect the gun to a clean,

moisture and oil free air supply

using a conductive hose.

NOTE

Install an air gauge at the

gun handle. When gun

is triggered on, adjust

regulated pressure to 29.0

psi (2.0 bar). Do not use

more pressure than is

necessary to atomize the

material being applied.

Excess pressure will create

additional overspray and

reduce transfer efficiency.

NOTE

If an air adjusting valve

is used at the gun inlet,

use DeVilbiss model HAV-

512. Some competitive

adjusting valves have

significant pressure drop

that can adversely affect

spray performance. The

DeVilbiss model HAV-512

has minimal pressure drop,

which is important for HVLP

spraying.

2. Attach the gravity feed cup to the

material inlet.

NOTE

Before using the gun, flush

it with solvent to ensure that

the fluid passages are clean.

OPERATION

1. Mix coating material to

manufacturer’s instructions.

2. Strain the material.

3. Fill the cup to no more than 1/2

inch from the top of the cup. DO

NOT OVERFILL.

4. Attach Cup Lid. Make sure that the

cup lid vent hole is clear.

5. Turn fluid adjusting knob (18)

clockwise to prevent fluid needle

movement.

6. Turn spreader valve adjusting knob

(23) counter clockwise to fully

open.

7. Adjust inlet air pressure to 29.0 psi

(2.0 bar).

8. Turn fluid adjusting knob counter

clockwise until first thread shows.

9. Test spray. If the finish is too dry,

reduce airflow by reducing air inlet

pressure.

10. If finish is too wet, reduce fluid

flow by turning fluid adjusting

knob (18) clockwise. If atomization

is too coarse, increase inlet air

pressure. If too fine, reduce inlet

pressure.

11. The pattern size can be reduced

by turning spreader valve knob

(23) clockwise.

12. Hold gun perpendicular to surface

being sprayed. Arcing or tilting

may result in uneven coating.

13. The recommended spray distance

is 3-6 in (75-150 mm).

14. Spray edges first. Overlap each

stroke a minimum of 75%. Move

gun at a constant speed.

15. Always turn off air supply and

relieve pressure when gun is not

in use.

PREVENTIVE MAINTENANCE

& CLEANING

To clean air cap and fluid nozzle,

brush exterior with a stiff bristle

brush. If necessary to clean cap holes,

use a broom straw or toothpick if

possible. If a wire or hard instrument

is used, extreme care must be used

to prevent scratching or burring of

the holes which will cause a distorted

spray pattern.

To clean fluid passages, remove

excess material from cup, then flush

with gun wash solution. Wipe the

gun exterior with a dampened cloth.

Never completely immerse in any

solvent or cleaning solutions as this

is detrimental to the lubricants and

life of the spray gun.

NOTE

When replacing the fluid

nozzle or fluid needle,

replace both at the same

time. Using worn parts

can cause fluid leakage.

See page 13, Chart 2. Also,

replace the needle packing

at this time. Torque the fluid

nozzle to 80-90 in-lbs (9-10

Nm). Do not over tighten.

CAUTION

To prevent damage to fluid

nozzle (8) or fluid needle

(15), be sure to either 1) pull

the trigger and hold while

tightening or loosening the

fluid nozzle, or 2) remove

fluid adjusting knob (18)

to relieve spring pressure

against needle collar.

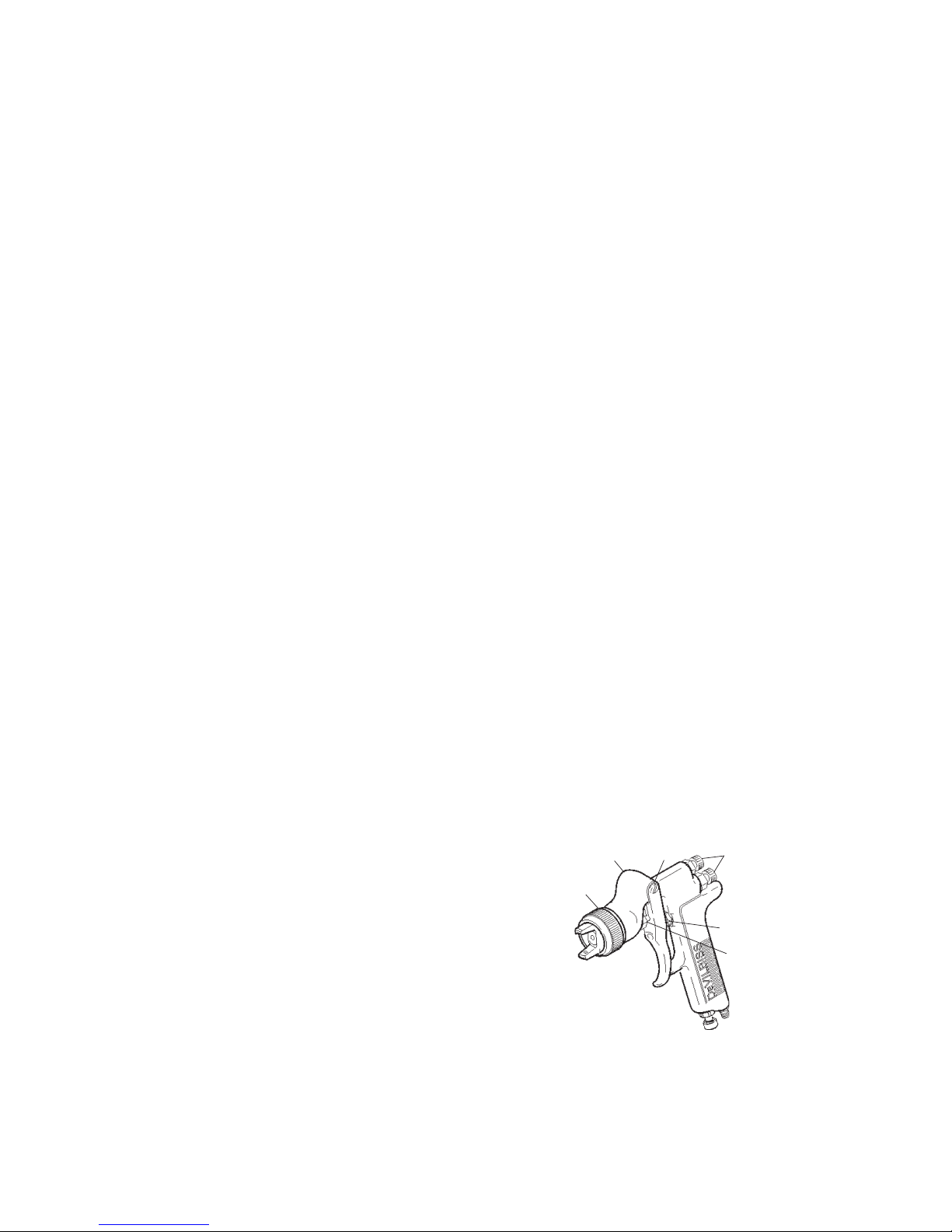

SPRAY GUN LUBRICATION

Daily, apply a drop of SSL-10 spray

gun lube at trigger bearing stud (39)

and the stem of the air valve (32). The

shank of the fluid needle (15) where

it enters the packing nut (28) should

also be oiled. Make sure the retaining

ring (1) threads are clean and free of

foreign matter. Before assembling

retaining ring to spray gun, clean

the threads thoroughly, then add two

drops of SSL-10 spray gun lube to

threads. The fluid needle spring (16)

should be coated with a very light

grease. For best results, lubricate the

points indicated, daily.

A. Trigger Points

B. Packing

C. Adjusting Valves

D. Gun/Air Cap Threads

E. Air Valve Cartridge

A

B

C

E

D

A

Page 9SB-2-855-B

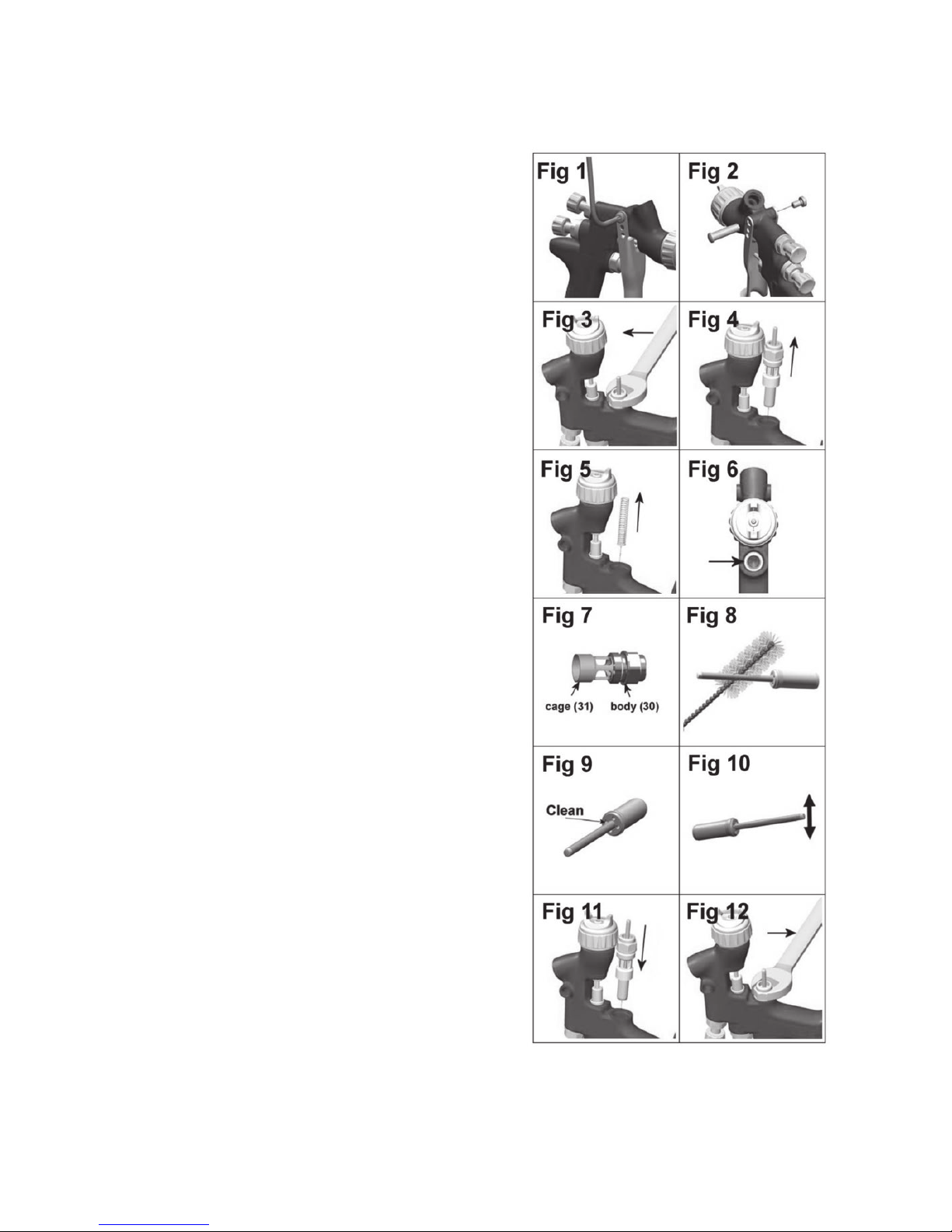

PARTS REPLACEMENT/MAINTENANCE

AIR VALVE INSTRUCTIONS

Servicing Air Valve

Reasons to service air valve:

A) Air valve not functioning correctly (may need

cleaning).

B) Routine maintenance.

C) Air leaks (advise replacement, see p10)

1. Remove trigger using a Star T20 key. (See fig 1 & 2)

2. Unscrew air valve using a (14 mm wrench. (See

fig 3)

3. Remove air valve by gripping stem. (See fig 4)

4. Remove spring with spring pad. (See fig 5)

5. DO NOT REMOVE REAR SEAL (35) FROM GUN

BODY. (See fig 6)

6. DO NOT REMOVE PLASTIC CAGE FROM AIR VALVE

BODY AS THIS MAY DAMAGE THE CAGE. (See fig 7)

7. CLEAN

a. Remove all paint build up. (See fig 8)

b. The 4 poppet holes must be clear. (See fig 9)

c. Stem must be free to float in poppet. (See fig 10)

d. Stem must slide through cage bore with slight

resistance (due to seal).

e. Rear seal must look clean and in position in the

bore. (See fig 6)

f. If any of the above cannot be rectified, replace the

air valve. (See Replacing Air Valve, p10)

8. Replace spring ensuring the end with the plastic

bearing pad goes in first. (See fig 5)

9. Insert air valve assembly into gun and carefully feed

over the spring and through the rear seal. (See fig 11)

10. Tighten air valve assembly using fingers first, and

then tighten with a 14mm wrench. (See fig 12)

11. Replace trigger. (See figs 2 & 1)

12. If there is an air leak through the gun, the air valve

may need replacing. (See Replacing Air Valve)

Page 10 SB-2-855-B

PARTS REPLACEMENT/MAINTENANCE

AIR VALVE INSTRUCTIONS

Replacing Air Valve

Reasons to replace air valve:

A) Air leak through the gun.

B) Air valve not operating correctly.

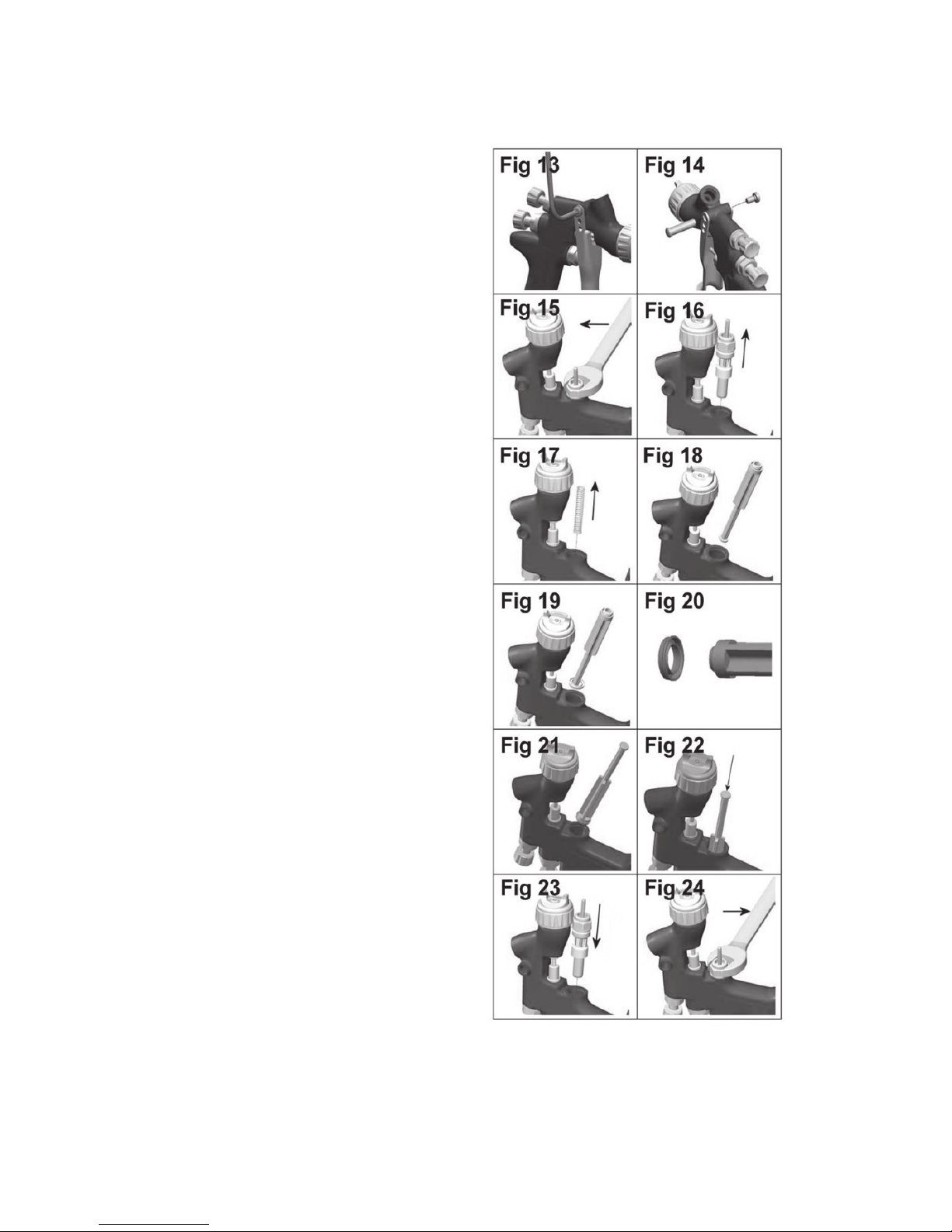

1. Remove trigger using a Star (T20) key. (See figs 13

& 14)

2. Unscrew air valve using a 14 mm wrench. (See fig 15)

3. Remove air valve by gripping the stem. (See fig 16)

4. Remove spring with spring pad. (See fig 17)

5. Hook out rear seal using Service Tool (46). (See figs

18 & 19)

6. Clean air valve bores in gun body with a brush.

7. Place new rear seal onto Service tool (46); grooves

must fit in service tool form. (See fig 20)

8. Push rear seal firmly into hole up to shoulder, using

Service tool. (See figs 21 & 22)

9. Insert new spring, ensuring the end with the plastic

bearing pad goes in first. (See fig 17)

10. Insert air valve assembly into gun and carefully feed

over the spring and through the rear seal. (See fig

23)

11. Tighten air valve assembly using fingers first, then

tighten with a 14 mm wrench. (See fig 24)

12. Replace trigger. (See figs 14 & 13)

Page 11SB-2-855-B

PARTS REPLACEMENT/MAINTENANCE

NEEDLE PACKING INSTRUCTIONS

Replacing Needle Packing

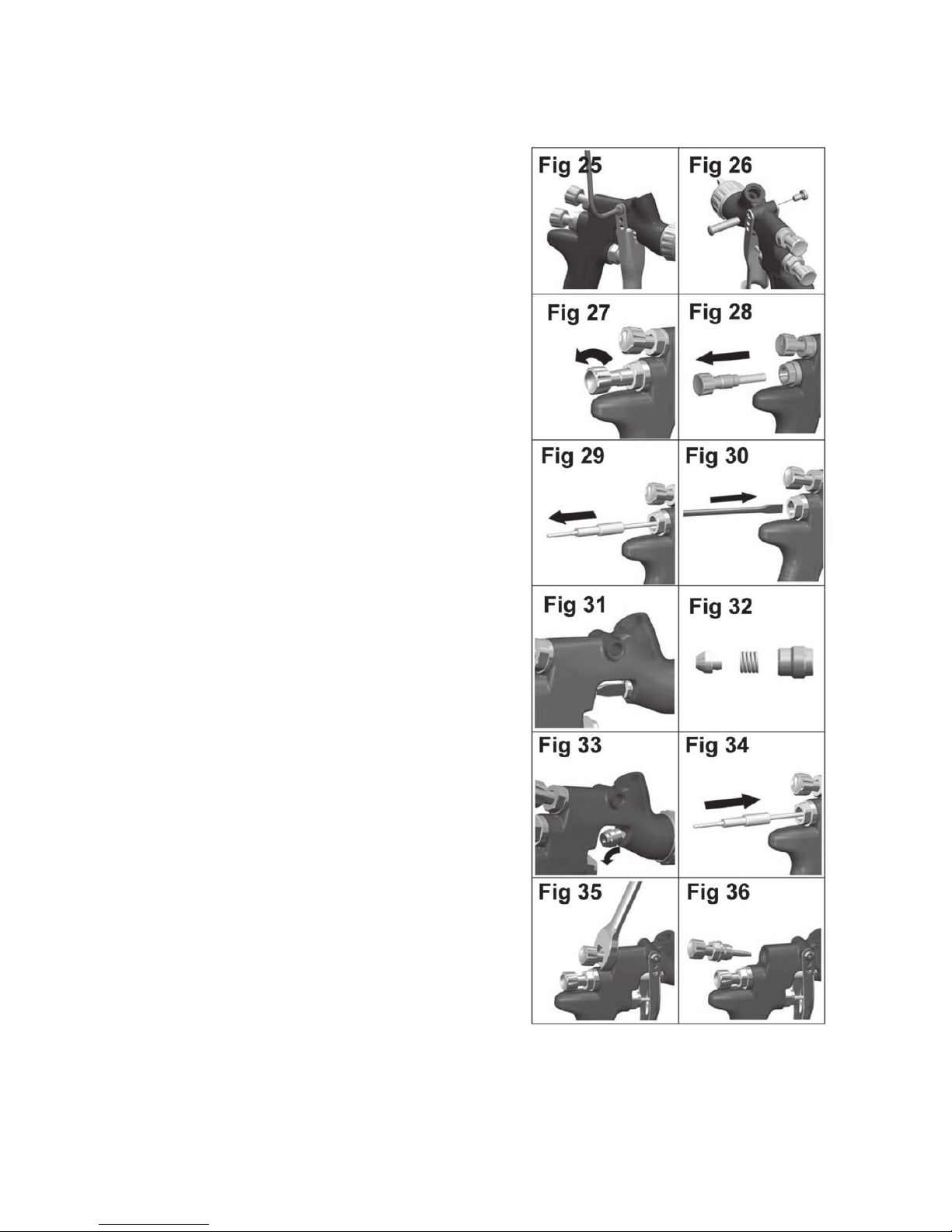

13. Remove trigger using a Star (T20) key. (See figs 25

& 26)

14. Remove fluid adjusting knob and needle spring with

spring pad from gun. (See figs 27 & 28)

15. Remove fluid needle from gun body. (See fig 29)

16. Loosen and remove packing nut using a straight

blade screwdriver. (See figs 30 & 31)

17. Discard old packing and packing spring if replacing.

Clean packing if reusing. Also clean packing spring

and nut. (See fig 32)

18. Re-assemble the packing, (See fig 32). Assemble

into gunbody by hand (see fig 33) and then tighten.

(See figs 30 and 31)

19. Insert fluid needle all the way into gun body seating

in fluid nozzle. (See fig 34)

20. Insert needle spring, spring pad, and fluid adjusting

knob. (See figs 28 & 27). Reinstall trigger. (See figs

25 & 26)

21. Trigger gun fully and screw in fluid adjusting knob

until it stops. Back it off 1/2 turn and gun will have

full needle travel.

22. Trigger gun several times to verify correct operation.

SPREADER VALVE ASSEMBLY

REPLACEMENT/MAINTENANCE

The spreader valve assembly can be replaced if

damaged. Remove using a 14 mm wrench (See figs

35 & 36). The internal seal can be replaced and is

included in the PRO Gun Rebuild Kit.

Page 12 SB-2-855-B

PARTS REPLACEMENT/MAINTENANCE

SEPARATOR SEAL INSTRUCTIONS

Replacing Separator Seal

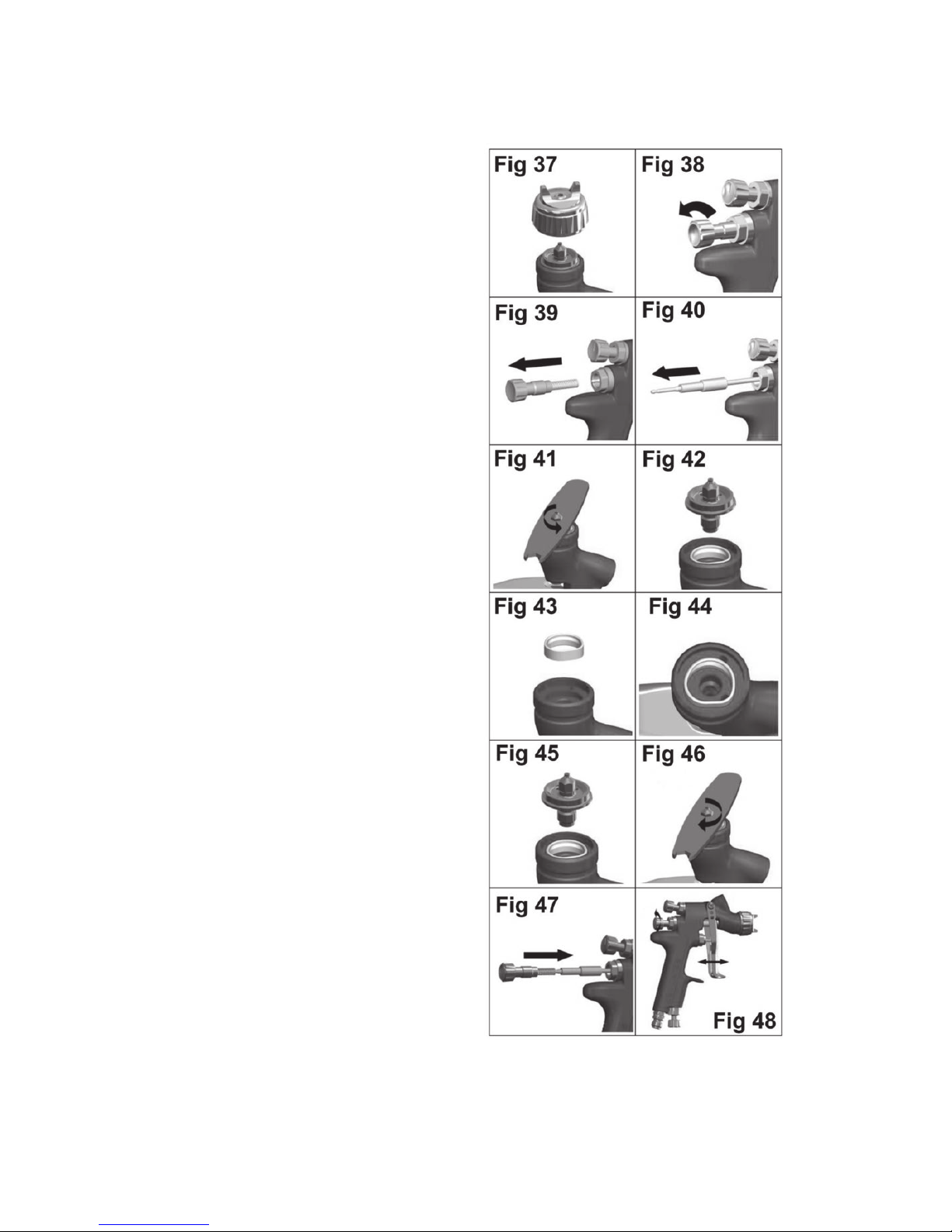

1. Remove air cap and retaining ring. (See fig 37)

2. Remove fluid adjusting knob, spring, and spring pad.

(See figs 38 & 39)

3. Remove fluid needle from gun body. (See fig 40)

4. Remove fluid nozzle using SRI-50 (6 mm) wrench.

(See figs 41, & 42)

5. Remove Separator. (See fig 43)

6. Clean front of gun if required, using a soft brush, as

well as the fluid nozzle, air cap, and retaining ring.

7. Place a new Separator Seal into the front of the gun,

making sure the flat side of the seal is aligned with

the flat in the gun. (See fig 44).

8. Fit Fluid Nozzle, Air Cap, and Retaining Ring. Torque

the Fluid Nozzle to 80-90 in-lbs (9-10 Nm). Don’t over

torque the Fluid Nozzle. (See figs 45, 46, and 37)

9. Insert Fluid Needle all the way into the Gun Body,

seating in the Fluid Nozzle. (See fig 47)

10. Reassemble Needle Spring, Spring Pad, and Fluid

adjusting Knob. (See fig 47)

11. Trigger gun fully and screw in Fluid Adjusting Knob

until it stops. Back it off 1/2 turn and gun will have

full needle travel. (See fig 48)

12. Trigger gun several times to verify correct operation.

(See fig 48)

1/2

turn

80-90 in-lbs

(9-10 Nm)

Page 13SB-2-855-B

PARTS REPLACEMENT/MAINTENANCE

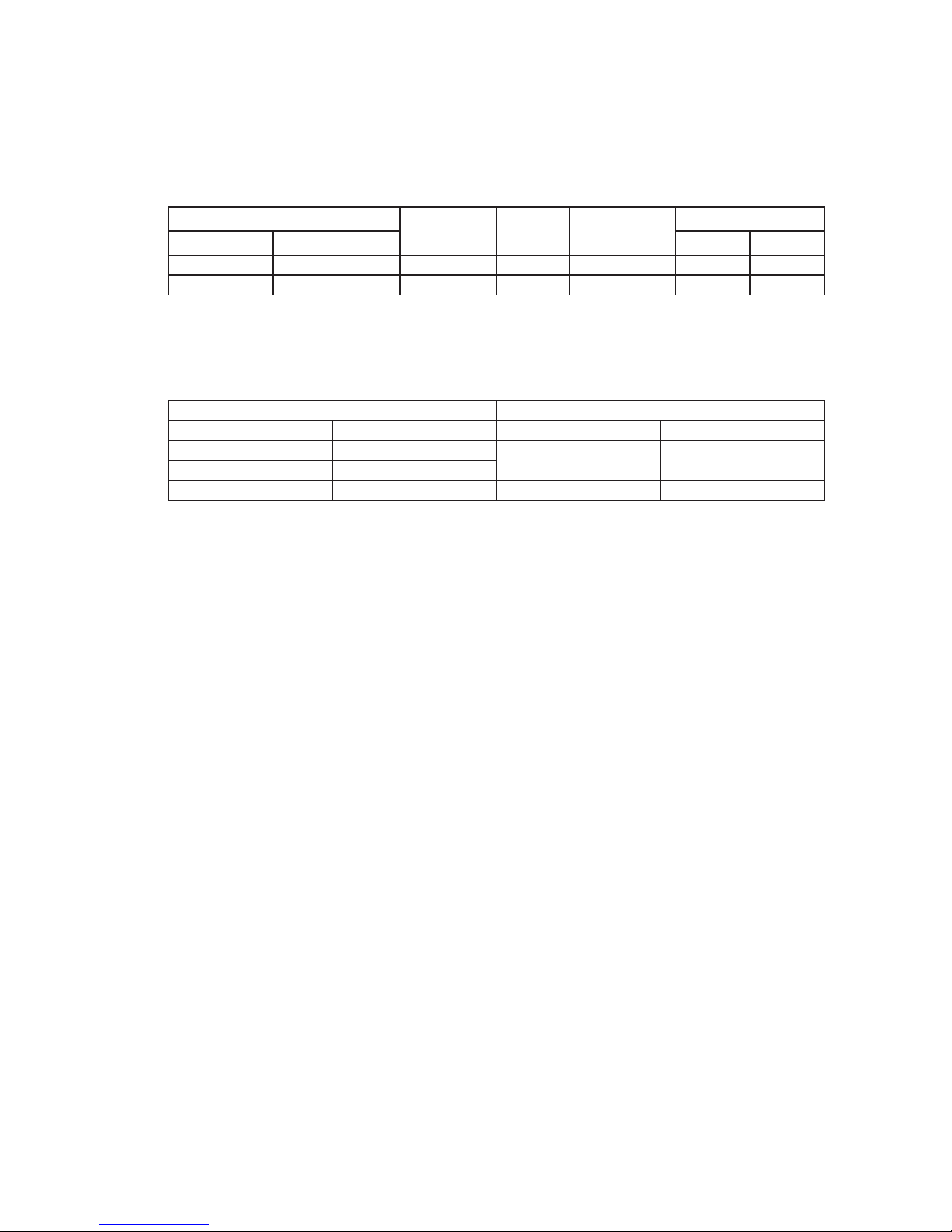

CHART 1 – AIR CAPS

AIR CAP & RING

TECHNOLOGY

MARKING

ON

AIR CAP

RECOMMENDED

INLET

PRESSURE

AIR FLOW

COMPUTER NO. PART NO. (L/min) (CFM)

803296 SRIPRO-101-HS1 HVLP HS1 29.0 psi (2.0 bar) 135 4.8

803297 SRIPRO-100-TS1 TRANS-TECH

®

TS1 29.0 psi (2.0 bar) 100 3.5

NOTE: When removing air cap from retaining ring, don’t remove the Slip Ring (2) or Retaining Ring Seal (5) from the

Retaining Ring. Damage to the parts may occur. Slip ring and Retaining Ring seal are not available as replacements.

Simply wipe parts clean and reassemble with new or clean air cap.

CHART 2 – FLUID NOZZLE RANGE & FLUID NEEDLE

FLUID NOZZLE FLUID NEEDLE

COMPUTER NO. PART NO. COMPUTER NO. PART NO.

803298* SRIPRO-200-08-K*

803302 SRIPRO-300-0810-K

803299* SRIPRO-200-10-K*

803300* SRIPRO-200-12-K* 803303 SRIPRO-300-1214-K

*Includes (1) SRIPRO-2 separator

NOTE: When replacing the fluid nozzle or fluid needle, replace both at the same time. Torque to 80-90 in-lbs (9-10 Nm).

Don’t over tighten the fluid nozzle. Use SRI-50 (6mm) wrench supplied with the gun and check with a torque wrench.

IMPORTANT NOTE: The SRI PRO and old SRI fluid nozzles and aircaps ARE NOT INTERCHANGEABLE between the

2 models. Any attempt to fit fluid nozzles or caps onto the wrong Spray Gun may cause damage to the parts or the

Spraygun body and invalidate the warranty.

Page 14 SB-2-855-B

TROUBLESHOOTING POSSIBLE PROBLEMS IN OPERATION

CONDITION CAUSE CORRECTION

Heavy top or

bottom pattern

Horn holes plugged. Clean. Ream with non-metallic point.

Obstruction on top or bottom of fluid

nozzle.

Clean.

Cap and/or nozzle seat dirty. Clean.

Left or right side horn holes plugged. Clean. Ream with non-metallic point.

Heavy right or

left side pattern

Dirt on left or right side of fluid

nozzle.

Clean.

Remedies for the top-heavy, bottom-heavy, right-heavy, and left-heavy patterns:

1. Determine if the obstruction is on the air cap or the fluid nozzle. Do this by making a test spray pattern. Then,

rotate the cap one-half turn and spray another pattern. If the defect is inverted, obstruction is on the air cap. Clean

the air cap as previously instructed. Also check for dried paint just inside the cap center hole opening; remove by

washing with solvent.

2. If the defect is not inverted, it is on the fluid nozzle. Clean nozzle. If problem persists, renew nozzle.

Heavy centre

pattern.

Spreader adjustment valve set too

low.

Turn out counter clockwise to

achieve correct pattern.

Atomizing pressure too low. Increase pressure.

Material too thick. Thin to correct consistency.

Split spray

pattern

Air pressure too high. Reduce at regulator or gun handle.

Fluid adjusting knob turned in too far.

Turn out counter clockwise to

achieve correct pattern.

Spreader adjusting valve set too

high.

Turn in clockwise to achieve correct

pattern.

Jerky or

fluttering spray

Loose or damaged fluid nozzle/seat Tighten or replace

Loose or broken cup fluid nipple Tighten or replace cup

Material level too low Refill

Container tipped too far Hold more upright

Obstruction in fluid passage Back flush with solvent

Loose fluid needle packing nut Tighten

Damaged fluid needle packing Replace

Paint bubbles in cup

Fluid nozzle not tight.

Fluid nozzle not tight. Tighten to

9-10 Nm (80-90 in-lbs).

Page 15SB-2-855-B

Fluid leaking or dripping from

cup lid

Cup lid loose. Push in or replace.

Dirty cup or lid. Clean.

Cracked cup or lid. Replace cup and lid.

Starved spray pattern

Inadequate material flow

Wind fluid adjusting knob out or

change to larger fluid nozzle size.

Blocked vent in Cup lid Clean lid and unblock vent.

Low atomization air pressure

Increase air pressure and rebalance

gun.

Excessive overspray

Air pressure to high. Reduce air pressure.

Gun too far from work surface. Adjust to correct distance.

Dry spray

Air pressure too high. Reduce air pressure.

Gun too far from work surface. Adjust to correct distance.

Gun motion too fast. Slow down.

Fluid flow too low.

Wind out needle adjusting screw or

use larger nozzle size.

Fluid leaking from packing nut

Packing worn. Replace.

Fluid leaking or dripping from

front of gun

Fluid nozzle or fluid needle worn or

damaged.

Replace fluid nozzle and fluid needle.

Foreign matter in fluid nozzle. Clean.

Fluid needle dirty or stuck in needle

packing

Clean.

Wrong size fluid needle or fluid

nozzle.

Replace fluid nozzle and fluid needle.

Fluid dripping or leaking from

bottom of cup

Cup loose on gun. Tighten.

Cup fluid inlet seat dirty. Clean.

Runs and sags

Too much material flow.

Turn fluid adjusting knob clockwise

or switch to smaller fluid nozzle and

fluid needle size.

Material too thin. Mix correctly or apply light coats.

Gun tilted on an angle, or gun

motion too slow.

Hold gun at right angle to work and

adapt to correct gun technique.

TROUBLESHOOTING POSSIBLE PROBLEMS IN OPERATION (CONTINUED)

Loading...

Loading...