DeVilbiss SolAiris III 30307, SolAiris III 30305, SolAiris III 303CZ, SolAiris III 303CS User manual

Page 1

Solâiris

Ш.

Oxygen

Concentrator

Service

30307,

303CZ,

and

Series

Manual

Models

30305,

303CS

LT-1691

©

1996

Rev.

DHC,

A

Inc.

Page 2

я

nf

=

©

—

=

©

©

ドー

©

©

で

pm

Table

General

introduction

Warranty

ImportantSafeguards.....................................

Safety

Theory

-Operation/Installation

SolAiris

Microprocessor-Controlled

OSD

SolAiris

Exterior

Specifications

Operating

Performing

Suggested

Maintenance

of

Information

Information

Precautions

of

Operation

Operation

Option

III

Overview

and

the

Initial

Patient

Contents

Interior

.....................

SolAiris

Inspection

Setup

and

Parts

General

Photos

III...

Warnings

Pressure-Sensing

e.

..

....

System

Patient

Patient

Diagnostic

Troubleshooting

Normal

Simplified

Troubleshooting

OSD

Component

Proper

Leak

Cabinet

Power

Flow

Pressure

Sieve

Final

Molecular

Compressor

Cooling

Four-Way

Printed

Capacitor

OSD

Ordering

Alert & Diagnostic

Alert

System

System

Operating

Troubleshooting

Troubleshooting

Testing,

Repair

Testing

Removal...

Cord...................

Meter

Regulator

Bed

Check

Check

(oxygen

Valve

Sieve

...........

Fan

Valve

Circuit

Information

Sequence...

Chart

Chart

Repair,

Procedures...

....

Valves......

........

Beds

..............

Board

sensing

device)

and

System

.

and

Parts

Replacement

List..

Page 3

General

Introduction

This

service

maintenance,

in-depth

school

manual

service,

classroom-type

information,

Information

was

created

and

training,

contact

repair

the

Service

for

DeVilbiss

procedures

DeVilbiss

Department

on

holds

qualified

the

service

SolAiris

oxygen

at

1-800-338-1988.

technicians

III

Oxygen

concentrator

to

define

Concentrator.

service

schools.

the

For

For

proper

more

service

EU

©

=

ο

=

5

Warranty

SolAiris

The

SolAiris

warranted

directly

This.equipment

as

stated

*

Valving

¢

OSD

+

All

¢

Routine

DeVilbiss’

Authorized

under

an

will

remove

container,

This

DeVilbiss,

ranty

Service Center.

this

Authorized

be

warranty

must

information

III

Limited

III

Oxygen

as

stated

from

DeVilbiss,

below

warranted

warranted

other

maintenance

obligation

Service

warranty,

Service

issued.

the

For

defective

properly

does

in

removing

be

performed

Warranty

Concentrators,

below.

or

is

warranted

from

date

of

for

for

the

components

under

Center

the

original

Center.

component

component

identify

not

cover

or

replacing

by a qualified

manufactured

This

warranty

through

shipment

the

warranted

items,

this

or

by a Return

its

by

DeVilbiss

life

of

life

of

the

such

warranty

supplying a replacement

purchaser

The claim

part(s)

part(s),

the

cost

the

extends

Providers,

to

be

free

by

DeVilbiss

the

unit.

unit

(OSD

for

three

as

filters,

is

limited

must

will

be

return(s),

properly

Authorization

of

labor

warranty

DeVilbiss

it

incurred,

and

sold

only

to

the

Buyer

Distributors,

from

to

the

models

years.

are

excluded

to

the

for

notify

evaluated

shall

package

Number,

component

provider

or

defects

original

only).

option

component

DeVilbiss

and,

be

the

responsibility

in a DeVilbiss

either

by

part(s).

and/or

by

DeVilbiss

purchasing

Agents,

in

workmanship

purchaser:

from

Warranty.

of

repairing

part(s).

at

its

if

bona

and

to

the

homecare

Service

an

Authorized

Health

as

New

at

plant

in

fide,

further

of

approved

make

shipment

under

Care,

the

equipment

equipment.

and

materials

its

plant

To

make

Somerset,

instructions

the

provider

shipping

provider

this

DeVilbiss

Inc.

are

or

an

claim

PA

or

to

prepaid.

or

war-

=

©

=

3

5

=

©

=>

NOTE—This

trator

NOTE—Replacement

be

This

warranty

*

*

*

+

+

that

warranted

This

equipment

operating

Routine

service

The

equipment

components

The

equipment

The

filters

filters

warranty

is

being

for

shall

not

is

and

service

maintenance,

personnel.

has

(i.e.,

fails

that

were

approved

by

does

repaired

components

the

unexpired

apply,

not

regenerated

and

operated

instructions.

servicing,

been

repaired

resulting

used

on

DeVilbiss.

not

obligate

with a loaner

do

not

portion

DeVilbiss

and

sieve

from

the

unit

shall

maintained

and

repair

or

altered

material).

misuse,

were

DeVilbiss

unit

carry a new

of

the

original

be

relieved

in

accordance

is

not

performed

by

the

use

abuse,

not

negligence,

authorized

to

replace

during

the

warranty

Limited

of

any

obligation

by

of

non-authorized

or

DeVilbiss

an

oxygen

time

of

and

Warranty.

with

DeVilbiss

qualified

accident;

filters

concen-

repair.

shall

or

DeVilbiss

parts

and

or

only

liability

or

quality

if:

Page 4

=

2

~

に

=

im

£

=

Г:

|

È

=

©

©

General

THERE

MERCHANTABILITY

DURATION

ANY

AND

WARRANTIES

STATES

THE

ABOVE

This

from

DeVilbiss

DeVilbiss

free

our

turned

otherwise

IS

NO

OTHER

OF

AND

ALL

LIABILITY

ARE

DO

NOT

LIMITATION

LIMITATION

warranty

state

to

state.

Labor

backs

three-year

Somerset,

to

*

Labor

(provider).

ο

Routine

PA

our

other

stipulated:

warranty

maintenance

THE

IMPLIED

gives

up

labor

Information

EXPRESS

AND

EXPRESS

FOR

CONSEQUENTIAL

EXCLUDED

ALLOW

OR

EXCLUSION

OR

you

Warranty

its

reputation

warranty

facility

authorized

is

effective

WARRANTY.

FITNESS

WARRANTIES

LIMITATIONS

EXCLUSION

specific

or

an

items,

FOR

LIMITED

TO

THE

OF

legal

for

when

Authorized

service

from

such

unexcelled

the

IMPLIED

A

PARTICULAR

WARRANTY

ARE

EXCLUDED.

AND

EXTENT

ON

HOW

CONSEQUENTIAL

MAY

NOT

rights,

centers

date

and

unit

DeVilbiss

of

as

filters,

AND

INCIDENTAL

EXCLUSION

LONG

APPLY

you

product

or

components

are

not

shipment

are

WARRANTIES,

PURPOSE,

TO

THE

THIS

IS

DAMAGES

IS

AN

IMPLIED

OR

INCIDENTAL

TO

YOU.

may

also

quality

under

Warranty

covered

from

excluded.

Center.

by

DeVilbiss

INCLUDING

ARE

LIMITED

EXTENT

THE

EXCLUSIVE

UNDER

PERMITTED

WARRANTY

have

other

and

reliability

warranty

Repairs

our

free

to

THOSE

TO

PERMITTED

REMEDY

ANY

BY

LAW.

DAMAGE,

rights

labor

original

which

by

extending

are

returned

to

units

policy

OF

THE

BY

LAW

AND

ALL

SOME

LASTS,

purchaser

SO

THE

vary

re-

unless

OR

to

a

Optional

The

Extended

manship

ment

Under

the

units

unless

A

$50

Extended

Optional

by

+

Valving

*

OSD

*

Routine

the

unit

returned

otherwise

charge

Note—International

Extended

Warranty,

and

materials

DeVilbiss

warranted

Optional

or

components

for

Warranty

Warranty

the

equipment

for

to

the

warranted

for

maintenance

Extended

under

to

our

other

stipulated.

the

Optional

(303

a

period

original

for

the

authorized

warranties

purchaser.

the

life

life

of

items,

Warranty

warranty

Extended

Extended

must

be

is

warranted

of

five

of

the

the

unit

such

service

Warranty)

selected

years,

unit.

(OSD

as

filters,

you

will

are

returned

centers

Warranty

may

vary.

at

time

by

DeVilbiss

except

models

are

excluded

receive

to

our

are

will

be

Part

of

purchase.

as

stated

only).

a

free

Somerset,

not

covered

added

#303EXTWAR

to

be

free

below,

from

Warranty.

five-year

PA

by

to

your

Under

from

defects

from

labor

warranty

facility.

our

free

invoice

the

Optional

date

Repairs

labor

at

billing.

in

of

ship-

work-

when

to

policy

Page 5

General

Important

Read

all

highlighted

WARNING—important

serious

Safeguards

instruction

by

these

injury.

Information

before

operating

terms:

safety

the

oxygen

information

concentrator.

for

hazards

Important

that

might

information

cause

is

©

O

=>

©

=

2

CAUTION—information

NOTE--information

Safety

A.

B.

C.

D.

Е

G.

H.

Precautions

Federal

Oxygen

a

minimum

use

Do

and

Do

switch;

Do

Only

filter

Electric

by a qualified

Disconnect

Extra

removed.

(U.S.A.)

promotes

person

receiving

of

five

in

rooms

not

then only a bubble-type

not

not

operate

is

care

heated

place a humidifier

connect

the

outlet

use

an

the

wet.

shock

hazard.

the

should

for

preventing

to

which

and

law

restricts

rapid

burning.

oxygen

feet

from

by

paraffin

the

oxygen

should

electrical

oxygen

DeVilbiss

power

be

be

adapter

Do

homecare

cord

taken

damage

you

should

General

this

therapy.

hot,

with

humidifier

concentrator

independent

concentrator

not

remove

from

if

it is

Warnings

device

Do

not

Do

sparking,

or

portable

an

oxygen

or

extension

cabinet.

provider.

the

wall

necessary

pay

to

sale

smoke

not

or

patient

should

to

of

with

outlet

to

the

special

by

or

when

operate

burning

gas

heaters.

unless

be

used.

an

electrical

other

appliances.

cord

with

all

filters

The

before

to

operate

product.

attention.

on

the

order

using

the

oxygen

objects

in

cabinet

attempting

the

or

prescribed

outlet

the

oxygen

place;

may

unit

of a physician.

this

unit

or

concentrator

naked

controlled

do

with

flames.

by a physician

concentrator.

not

operate

only

be

repairs

the

cabinet

when

near

within

Do

by a wall

if

the

removed

on

the

unit.

a

not

air

=

©

=

=

a

=.

に

=

I.

J.

K.

Use

L.

Theory

An

oxygen

applications.

Room

The

delivery

N

air

concentrator draws

Do

not

use

Use

only

When

come

Do

replacing

in

only

not

use

of

Operation

concentrator

is a mixture

of

the

concentrated

oils,

greases,

materials

the

contact

DeVilbiss

with

regenerated

is a device

of

78%

in

or

that

are

capacitor,

the

terminals

Health

the

Care

sieve

nitrogen,

air,

separates

oxygen

any

petroleum-based

compatible

do

not

touch

on

the

concentrator

material.

that

delivers

21%

oxygen, 1%

the

to

the

patient

with

oxygen.

the

capacitor.

replacement

highly

nitrogen

through

solvents/cleaners

terminals

concentrated

argon

from

the

or

allow

parts

、

and

other

the

oxygen,

oxygen

and

oxygen

port.

on

or

near

the

metal

gases.

objects

accessories.

for

therapeutic

and

allows

unit.

to

Page 6

=

©

uje

で

で

Pas

w

=

``

=

Ro)

pari

©

上

二

トリ

©

ο

Operation/Installation

SolAiris

The

SolAiris

filter

and

The

compressed

The

sieve

silicate.

as

it

passes

As

one bed

The

vacuum

its

pressurization

four-way

compressor.

orifice

The

beds

This

cycling

(A

typical

Oxygen

A

pressure

and

enters

adjusted

passes

Operation

III

into

beds

It is

very

through

is

being

process

and

Also

into

the

will

continue

process

cycle

leaving

regulator

the

to

the

through

uses

a

pressure-vacuum

a

double-head

air

passes

contain

is

released

bed

time

the

flow

level

the

molecular

porous

the

pressurized

removes

cycle.

during

being

to

will

at

sieve

on

meter.

prescribed

final

compressor.

through

and

has

sieve

bed.

and

the

The

nitrogen

through

each

bed

evacuated.

be

alternately

vary

in

length

3

LPM

is

approximately

beds

is

directed

the

tank

controls

The

flow

by

bacteria

system.

a

four-way

sieve

material

the

unique

:

producing

nitrogen

being

an

exhaust

pressurization,

This

pressurized

depending

through

the

meter

the

patient's

filter,

check

The

valve

ability

oxygen,

from

the

evacuated

muffler

helps

purge

oxygen

allows

physician.

valve,

air

and

which

to

sieve

located

a

small

and

on

altitude

8

seconds

a

check

pressure

the

oxygen

and

is

selectively

out

the

is

drawn

is

a

a

vacuum

material

of

amount

nitrogen

evacuated

valve

outlet

into

directed

synthetically

adsorb

the

sieve

on

the

and

at

sea

level.)

to

as

it

flow

From

the

port

the

unit

into

one

produced

nitrogen

is

drawn

that

was

bed

vacuum

of

oxygen

from

the

as

the

oxygen

the

accumulator

leaves

to

the

be

controlled

flow

meter,

to

the

through

of

two

on

the

adsorbed

passes

unit

output

patient.

through

head

flows

bed.

operates.

flow

accumulator

the

the

air

sieve

beds.

inorganic

from

the

air

other

bed.

during

the

of

the

through

tank.

and

oxygen

an

rate.

Microprocessor-Controlled

The

SolAiris

unit.

The

a

pressure

lator

tank

cycle

time

A

cycle

board

the

green

With

the

a

vacuum

accumulator

way

to

sieve

bed

the

PC

process

The

PC

condition

The

alarm

component

III

operates

cycling

transducer

by

1/16"

at

this

change

will

four-way

deactivate

board

is

board

takes

send

12

“4-way”

is

drawn

tank,

and

a

vacuum

is

not

repeated

also

or

when

system

failure.

is

controlled

mounted

diameter

point.

place

VDC

indicator

in

the

on

the

or

go

illuminated

every

activates

the

will

Pressure-Sensing

on

a

microprocessor-controlled

and

tubing

when

to

the

four-way

light

activated

the

right

PC

board

to

the

“rest”

is

drawn

time

the

the

cycle

time

also

activate

monitored

on

the

and

the

pressure

on

the

position,

sieve

bed.

removes

position

on

the

when

PC

board

alarm

has

exceeded

in

PC

board.

allows

valve

PC

When

the

left

the

voltage

senses

system

the

case

System

by

the

PC

The

transducer

the

PC

in

the

accumulator

causing

board

will

compressed

the

PC

12

VDC

from

and

compressed

sieve

bed.

is

removed

15

PSI

whenever

its

preset

of

a

power

pressure-sensing

board.

board

the

illuminate.

air

board

The

in

it

minimum

This

is

to

sense

valve

to

is

directed

senses

the

four-way.

air

is

green

from

the

oxygen

senses

failure

a

and

is

accomplished

connected

the

tank

reaches

activate.

to

15

then

“4-way”

the

valve.

low

or

or

maximum

electrical

system

the

PSI

This

directed

accumulator

to

to

the

oxygen

indicator

high

15

At

the

left

sieve

in

the

causes

to

This

pressure

limits.

or

pressure

cycling

cycle

PSI.

same

oxygen

the

pneumatic

the

by

use

accumu-

and

The

PC

time

bed

and

the

four-

right

light

on

tank.

of

Page 7

Operation

OSD

Option

The

SolAiris

of

oxygen

front

+

*

panel.

III

leaving

Normal

Low

Oxygen

with

the

the

Oxygen

(yellow

accumulator

(green

/Installation

optional

OSD

(oxygen

tank.

light) - oxygen

light) - oxygen

sensing

There

levels

levels

are

two

>85%

<85% + 2% - requires

device)

monitors

additional

+2%

the

concentration

indicator

servicing

lights

on

the

NOTE—If

sound.

SolAiris

This

service

service,

information

tenance

NOTE—DeVilbiss

oxygen

nents

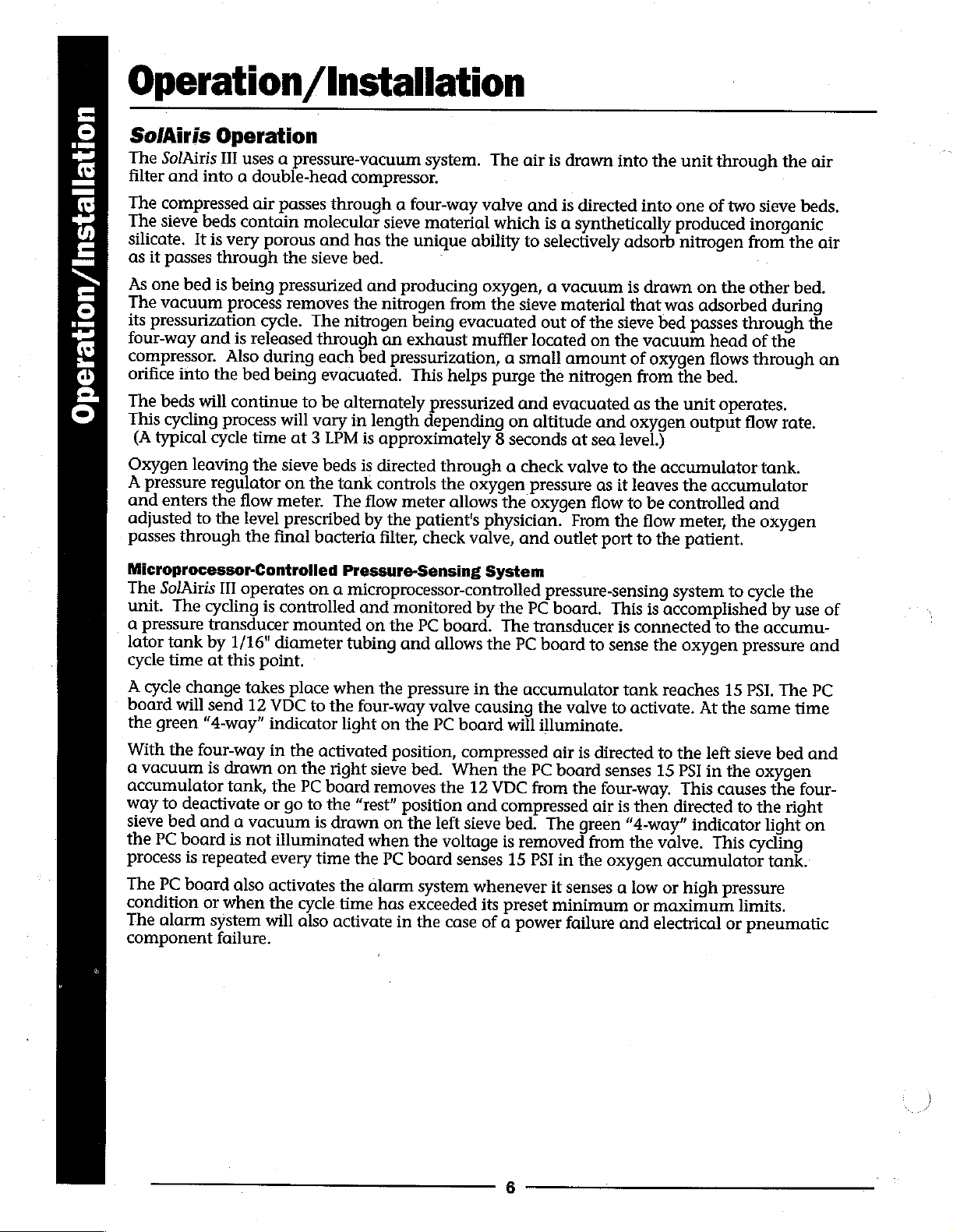

Pneumatic

III

and

on

the

may

Diagram

LEFT

SIEVE SIEVE

BED BED

PR

VALVE

CAPACITOR

the

oxygen

(On

the

303CS,

Overview

manual

safety

contained

concentrator

was

procedures

in

concentrator.

reserves

exist

than

CHECK

A

REE

5

a

πα

Mie

HEPA

FILTER

COMPRESSOR

PRESSURE

j

level

falls

this

designed

for

the

this

service

the

series.

what

VALVE

CHECK

VALVE

RIGHT

て

T

|

VAcu

below

signal

to

supply

SolAiris

manual

right

Hence,

is

described

75%,

an

will

sound

homecare

III

oxygen

before

to

slight

ACCUMULATOR|

CHECK

EXHAUST

SIENCER

attempting

alter

or

differences

herein.

|.

PRESSURE

REGULATOR}

VALVE

ーー

intermittent

if

the

oxygen

providers

concentrator.

change

FINAL

[PRESSURE

FOR

WITH

AN

FOR

OXYGEN

一

一

>

with

to

BACTERIA

UNITS

NOT

OXYGEN

SENSING

(30302.

30302}

Lo

OXYGEN

—

|

SENSINO

UNITS

EQUIPPED

SENSING

(30308,

30308)

EXHAUST

the

in

RIA

[8

EQUIPPED

audible

level

falls

the

proper

Read

and

operate

construction

FILTER

DEVICE

or

design

FLOW

METER

WITH

AN

DEVICE

一

一

THIS

APPLIES

FOLLOWING

signal

below

maintenance,

understand

perform

of

the

or

.

CHECK

TO

any

SolAiris

compo-

PATIENT

PNEUMATIC

30308

0302

303DS

TO

THE

UNITS:

DIAGRAM

will

82%.)

main-

VALVE

also

all

the

4

}ellelsul/uoleedo

©

5

Page 8

=

2

~

で

で

de

[A]

pS

a

<

©

jeď

©

>=

©

о.

©

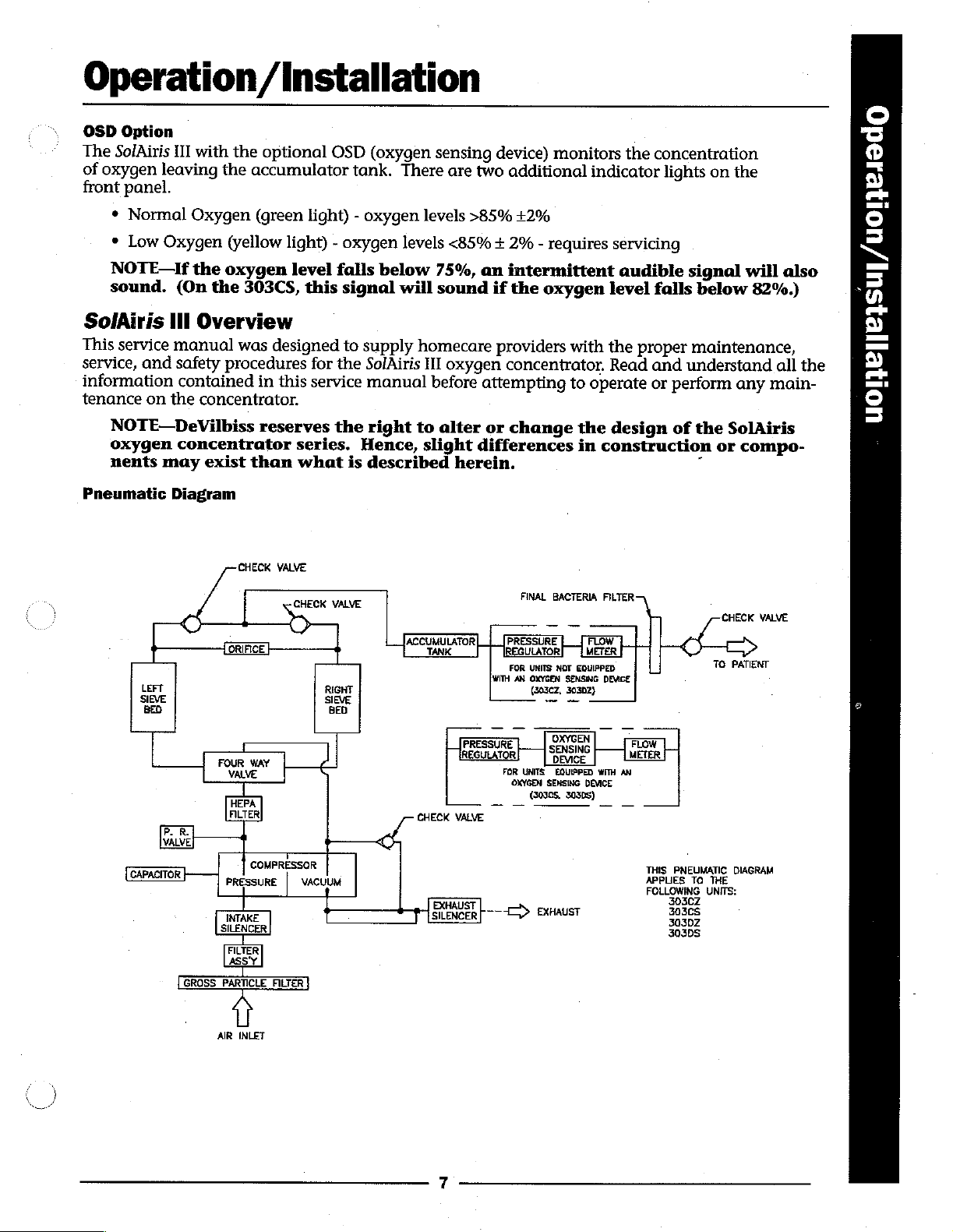

Operation

The

following

figures

will

Light

/Installation

help

familiarize

Oxygen

panel

outlet

port

you

with

Instruction

serial

the

number

label

/

exterior

and

Power

/

"TA

of

the

SolAiris

switch

Flow

meter

II]

concentrator.

EXTERIOR

|

|

| | |

FRONT

VIEW

EN

(O

Circuit

breaker

Front

cover

Bib

Figure

1

Page 9

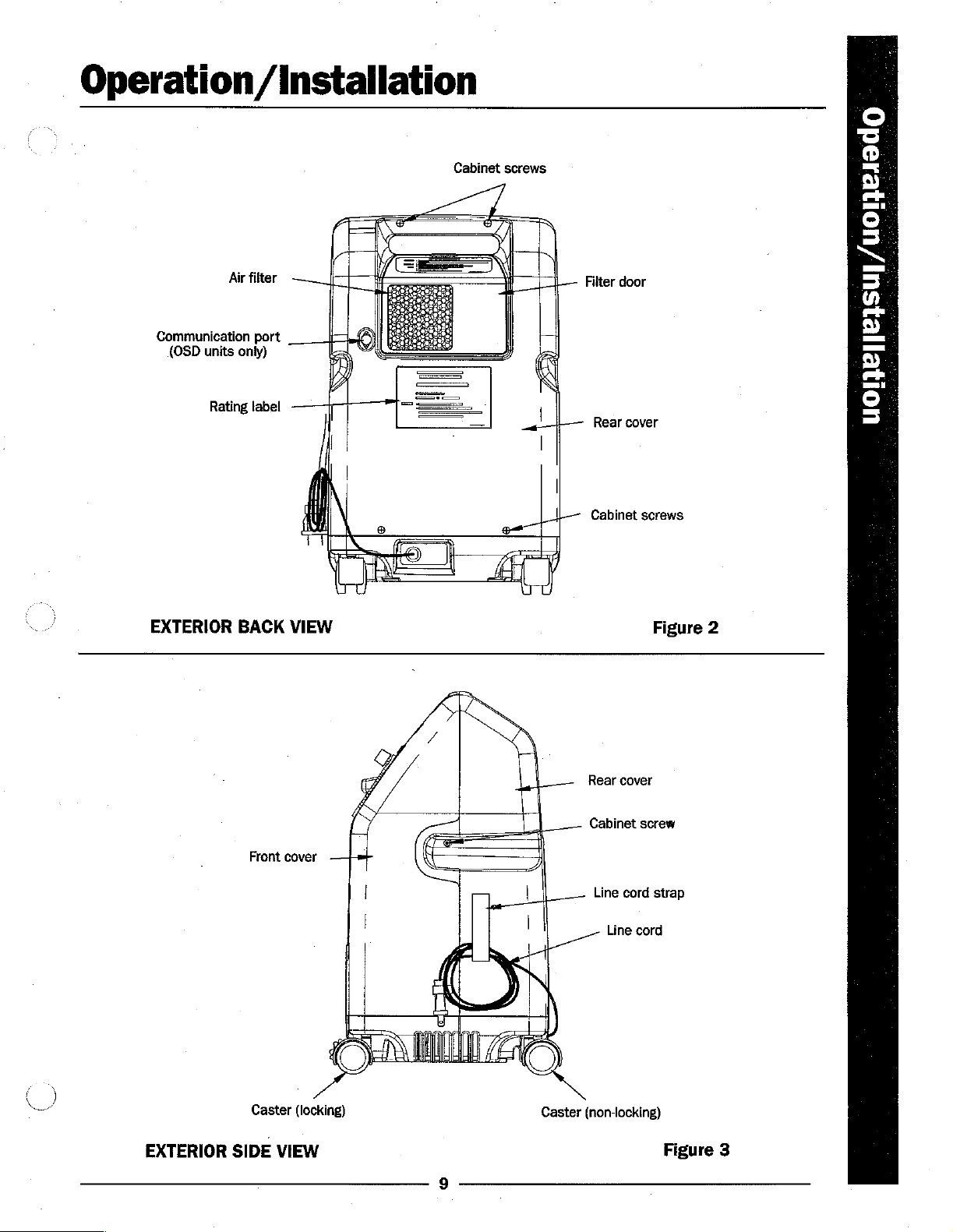

Operation

Air

filter

Communication

(OSD

units

only)

Rating

label

/Installation

Cabinet

port

|

screws

+

|

|

|

Filter

door

Rear

cover

Cabinet

screws

©

=

O.

-

=.

©

CE

に

к}

の

l

>

И

=

©

-

EXTERIOR

BACK

Front

VIEW

cover

一

|

|___

|

|

]

Rear

cover

Cabinet

Line

cord

Figure

screw

strap

2

Line

cord

+7

N

ο”

Caster

(locking)

EXTERIOR

SIDE

VIEW

Caster

(non-locking)

Figure

3

Page 10

=

©

し

で

©

~

0

=

N

=

©

—

©

=

©

©

ο

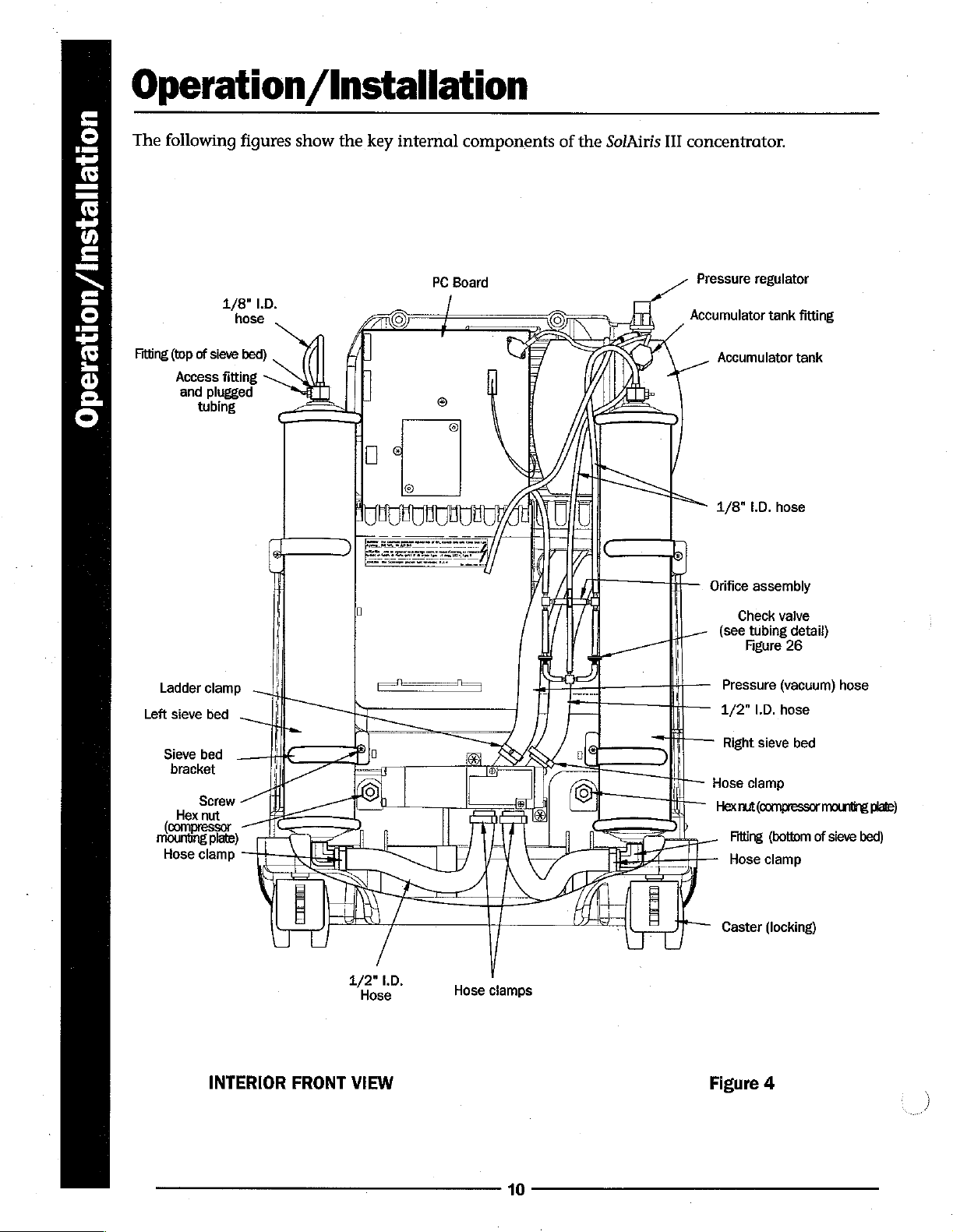

Operation

The

following

ニー』

Fitting

(top

of

sieve

Access

and

plugged

tubing

figures

1/8"

I.D.

hose

bed)

fitting

/Installation

show

the

key

internal

components

PC

Board

of

the

SolAiris

III

concentrator.

Pressure

Accumulator

Accumulator

regulator

tank

fitting

tank

Ladder

clamp — |

Left

sieve

bed — |

Sieve

bed

bracket

Screw < |

Hex

nut

(compressor.

mounting

Hose

plate)

clamp

ή

4

__—¿£

|

n

レレ

—T/C

[SX

1/8"

LD.

нове

一

Orifice

assembly

|

| — (see

|

|

[—~

a

L

Check

Pressure

1/2"

Right

Hose

Hex

nut

Fitting

Hose

Caster

valve

tubing

detail)

Figure

26

(vacuum)

1.0.

позе

sieve

bed

clamp

(compressor

(bottom

clamp

(locking)

hose

mounting

of

sieve

plate)

bed)

1/2"

Hose

INTERIOR

FRONT

VIEW

/

1D.

Hose

|

clamps

10

Figure

4

Page 11

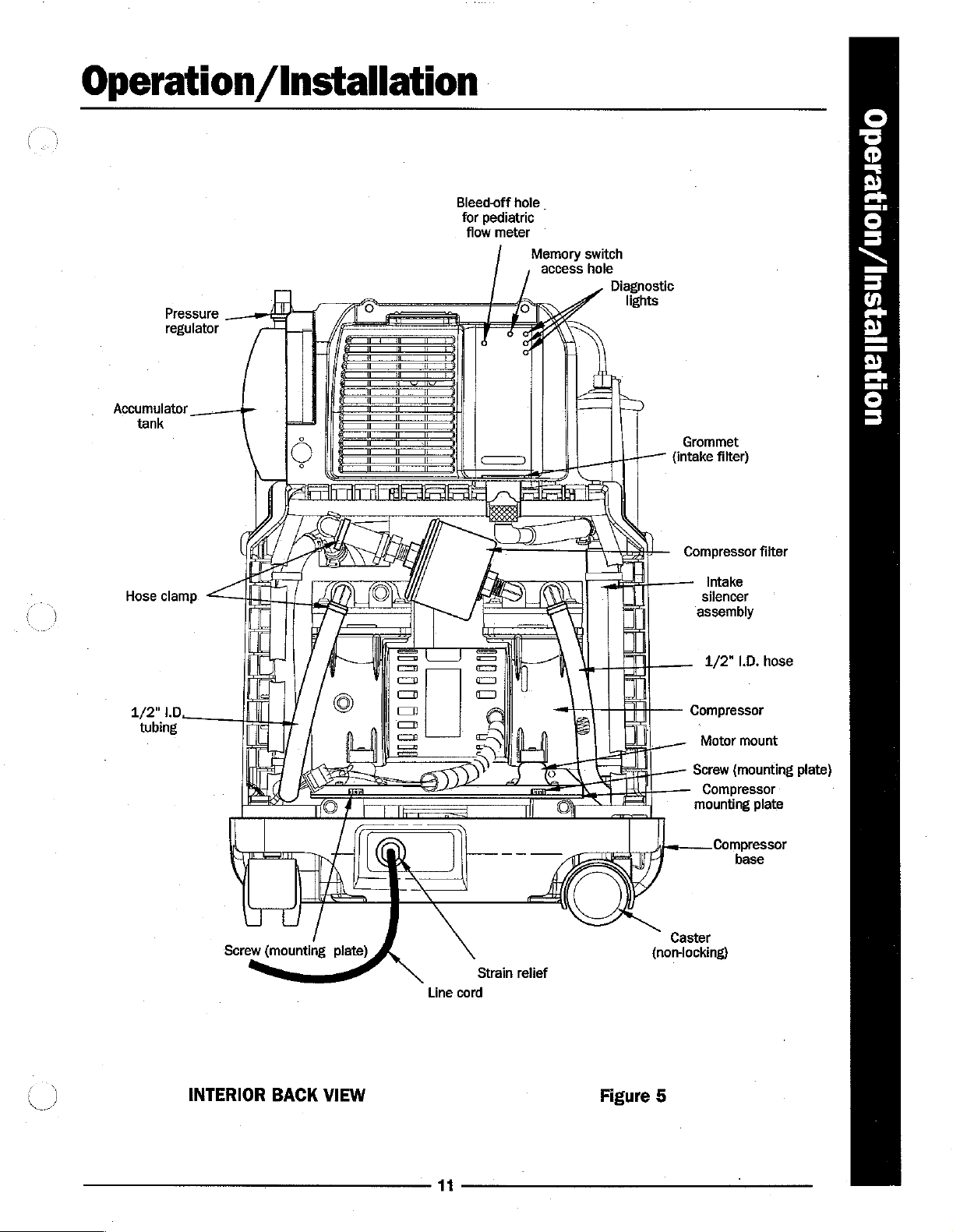

Operation

Pressure

regulator

Accumulator

tank

/Installation

Bleed-off

for

pediatric

flow

meter

hole

Memory

.

access

switch

hole

Diagnostic

lights

Grommet

{intake

filter)

©

で

©

=

W

=

©

=

=

=

mn

i

>

S

=.

©

=

y

Hose

1/2"

tubing

clamp

1.0.

Screw

(mounting

plate)

Line

Strain

cord

relief

Compressor

Intake

silencer

assembly

1/2"

Compressor

Motor

Screw

Compressor

mounting

Compressor

Caster

(nor-locking)

filter

1.D.

hose

mount

(mounting

plate

base

plate)

INTERIOR

BACK

VIEW

11

Figure

5

Page 12

=

©

--]

5

©

Pai

の

=

N

[一

©

=

6

=

©

に

O

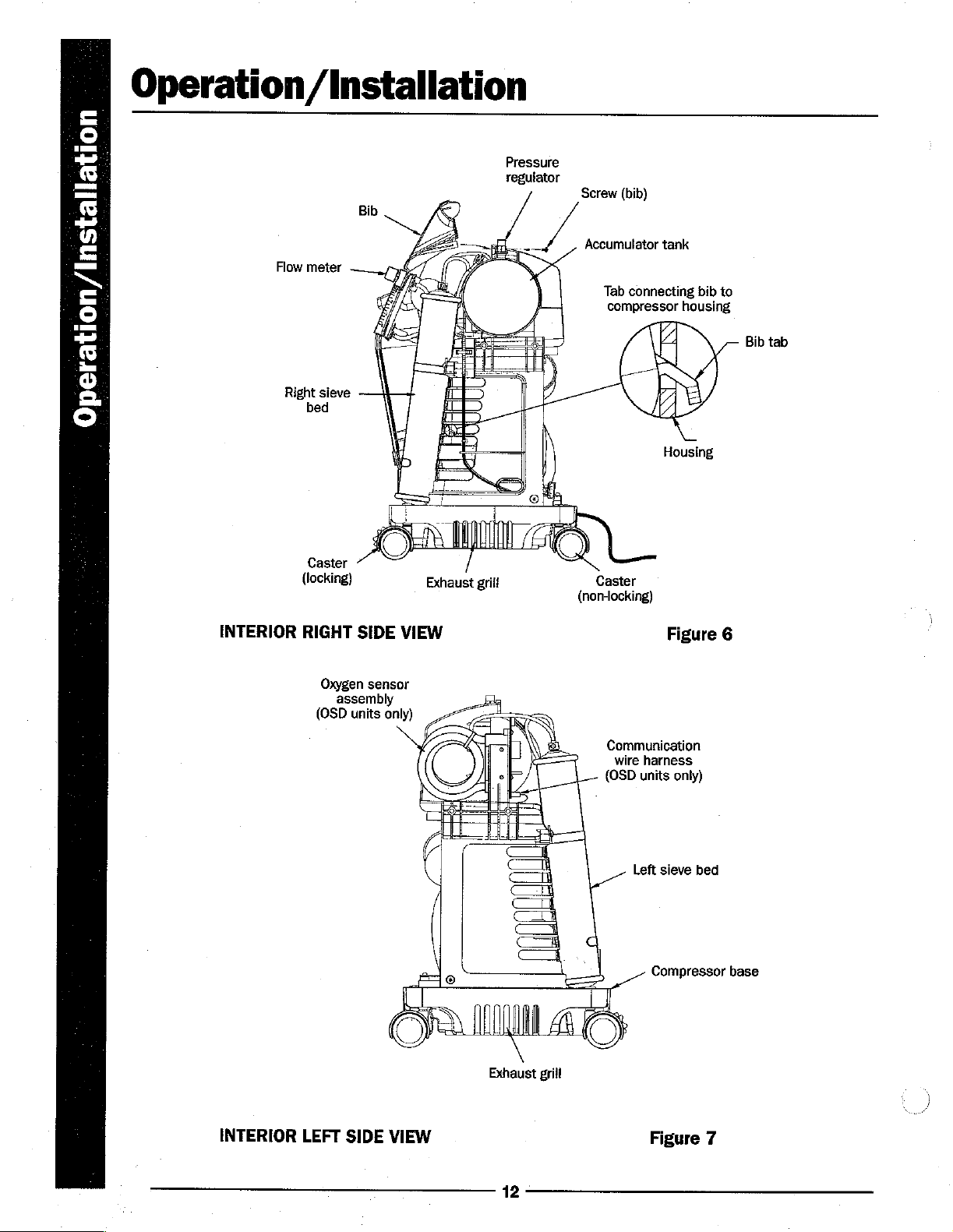

Operation

Flow

Right

/Installation

Pressure

regulator

Bib

meter

sieve

bed

Screw

(bib)

Accumulator

Tab

connecting

compressor

tank

housing

bib

to

Bib

tab

INTERIOR

Caster

(locking)

RIGHT

Oxygen

assembly

(OSD

SIDE

sensor

units

Housing

Exhaust

VIEW

only)

grili

Caster

(non-locking)

Figure

6

Communication

wire

harness

(OSD

units

only)

Left

sieve

bed

INTERIOR

LEFT

SIDE

©

VIEW

Exhaust

12

grill

-

O

Compressor

Figure

base

7

Page 13

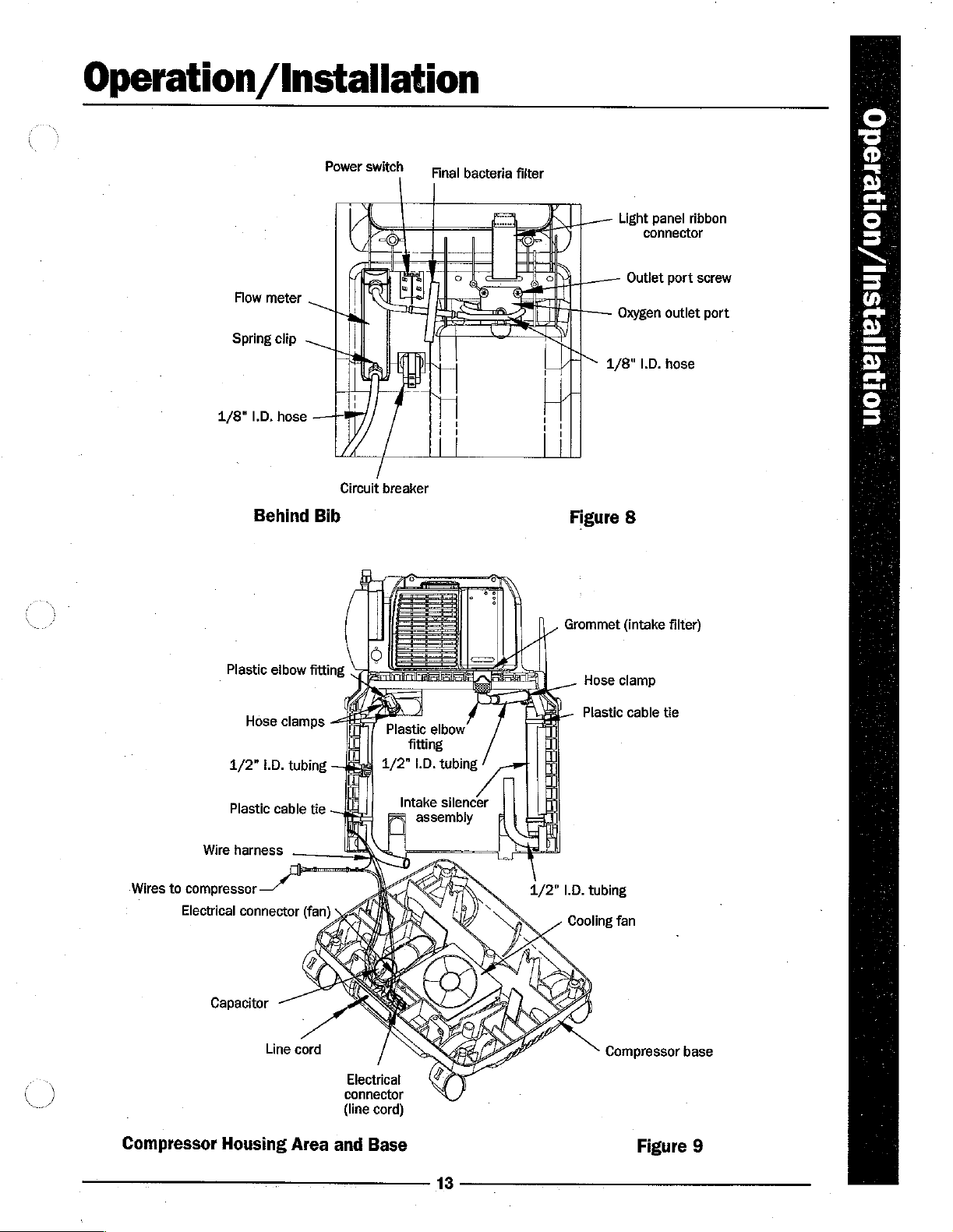

Operation/

Flow

meter

Spring

1/8"

I.D.

Installation

Power

clip

hose

Circuit

switch

breaker

Final

bacteria

filter

Light

Outlet

Oxygen

1/8"

panel

connector

1.0.

ribbon

port

screw

outlet

позе

port

o:

"S

©

|

トリ

Fu

©

—

=

=

a

ea

9

98

=

©:

5

a

ali

X

Wires

Wire

to

compressor

Electrical

Behind

Plastic

H

ose

1/2"

1.D.

Plastic

harness

connector

elbow

|

camps

tubing

cable

Bib

fitting

tie

(fan)

$

Plastic

fitting

1/2"

LD.

Intake

assembiy

elbow

tubing

silencer

x

y

1/2"

Figure

Grommet

Hose

Plastic

1.D.

tubing

Cooling

8

(intake

clamp

cable

fan

filter)

tie

ς

ーー

Ea

)

Compressor

Capacitor

Line

Housing

©

cord

み

Area

Electrical

connector

(line

cord)

and

Base

13

Compressor

Figure

base

9

Page 14

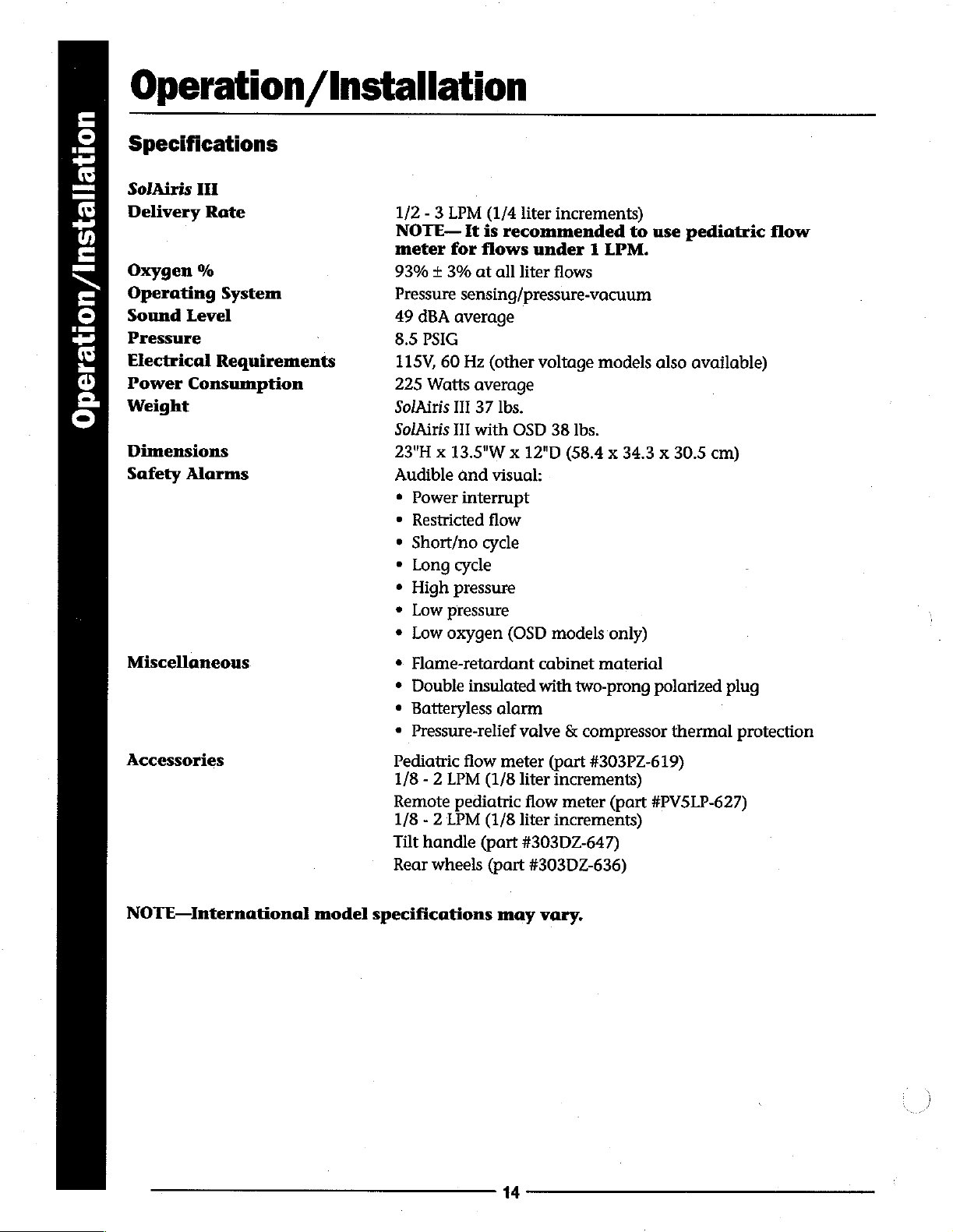

Operation/Installation

=

©

pe

Specifications

S

E:

Y

=

M

=

©

pi

σ

m

Ф

©

©

SolAiris

Delivery

Oxygen

Operating

Sound

Pressure

Electrical

Power

Weight

Dimensions

Safety

IH

Rate

%

Level

Consumption

Alarms

System

Reguirements

1/2 - 3

NOTE—

meter

93% + 3%

Pressure

49

8.5

115V,

225

SolAiris

SolAiris

23"H x 13.5"W x 12"D

Audible

©

©

*

e

*

*

*

LPM

(1/4

It is

for

flows

at

sensing/pressure-vacuum

dBA

average

PSIG

60

Hz

(other

Watts

Power

Restricted

Short/no

Long

High

Low

Low

average

III

37

III

with

and

interrupt

flow

cycle

cycle

pressure

pressure

oxygen

liter

increments)

recommended

under 1 LPM.

all

liter

flows

voltage

lbs.

OSD

38

visual:

(OSD

models

to

use

pediatric

models

lbs.

(58.4 x 34.3 x 30.5

only)

also

available)

flow

cm)

Miscellaneous

Accessories

NOTE—International

model

*

Flame-retardant

*

Double

*

Batteryless

*

Pressure-relief

Pediatric

1/8 - 2

Remote

1/8 - 2

Tilt

Rear

specifications

insulated

flow

LPM

pediatric

LPM

handle

wheels

(1/8

(1/8

(part

(part

cabinet

with

alarm

valve & compressor

meter

may

(part

liter

flow

liter

#303DZ-647)

#303DZ-636)

vary.

material

two-prong

#303PZ-619)

increments)

meter

increments)

(part

polarized

thermal

#PV5LP-627)

plug

]

protection

14

Page 15

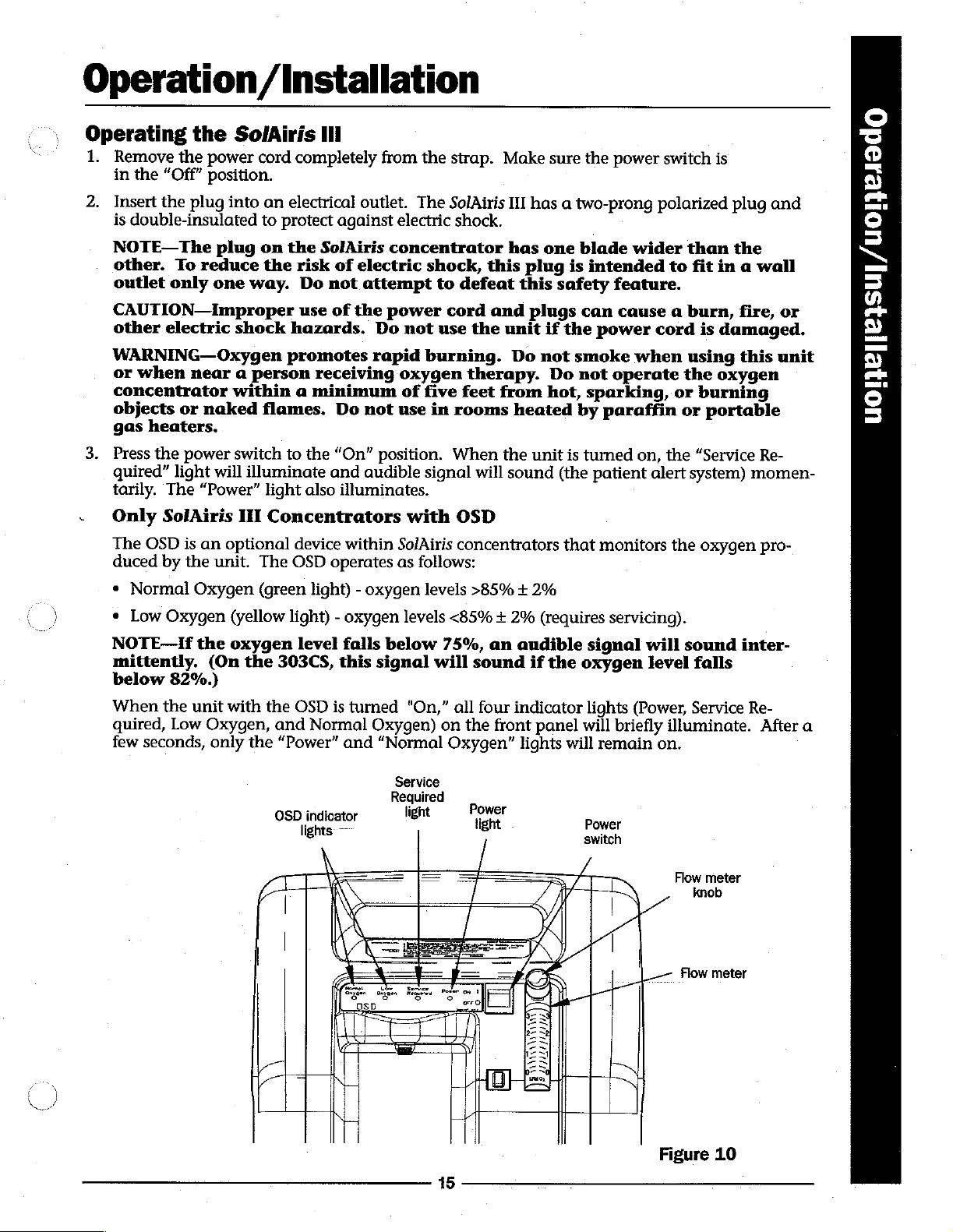

Operation

Operating

1.

Remove

in

the

2.

Insert

is

double-insulated

NOTE—The

other.

outlet

the

the

“Off”

the

plug

To

only

SoiAiris

power

position.

reduce

into

plug

one

cord

way.

/Installation

Ill

completely

an

electrical

to

protect

on

the

the

risk

Do

SolAiris

not

from

outlet.

against

concentrator

of

electric

attempt

the

strap.

The

SolAiris

electric

shock.

shock,

to

defeat

this

Make

sure

the

III

has a two-prong

has

one

blade

plug

is

intended

this

safety

power

feature.

switch

polarized

wider

to

is

than

fit

in a wall

plug

the

and

ο

で

ο

-

ad

=.

©

=

に

=

CAUTION—Improper

other

WARNING—

or

concentrator

objects

gas

Press

quired”

tarily.

Only

The

duced

+

*

NOTE—If

mittently.

below

When

quired,

few

electric

when

or

heaters.

the

power

light

The

SolAiris

OSD

by

Normal

Low

Oxygen

82%.)

the

Low

seconds,

Oxygen

near a person

naked

will

“Power”

is

an

optional

the

unit.

Oxygen

the

(On

unit

with

Oxygen,

only

use

of

the

shock

within a minimum

switch

II

(yellow

oxygen

the

hazards.

promotes

receiving

flames.

to

illuminate

light

Concentrators

The

(green

303CS,

the

and

the

“Power”

Do

the

“On”

and

also

illuminates.

device

OSD

operates

light) - oxygen

light) - oxygen

level

falls

this

OSD

is

Normal

and

within

tured

power

Do

not

rapid

oxygen

of

not

use

position.

audible

with

SolAiris

as

follows:

levels

below

signal

"On,”

Oxygen)

“Normal

cord

use the

burning.

therapy.

five

feet

in

rooms

When

signal

levels

will

OSD

concentrators

>85% + 2%

<85% + 2%

75%,

will

sound

all

four

on

the

Oxygen”

and

plugs

unit

Do

from

heated

the

sound

an

audible

if

indicator

front

lights

can

if

the

not

smoke

Do

not

hot,

sparking,

by

unit

is

turned

(the

that

(requires

signal

the

oxygen

lights

panel

will

will

cause a burn,

power

paraffin

patient

monitors

remain

cord

when

operate

on,

the

alert

the

servicing).

will

level

(Power,

briefly

illuminate.

on.

is

damaged.

using

the

oxygen

or

burning

or

portable

“Service

system)

oxygen

sound

falls

Service

fire,

or

this

unit

Re-

momen-

pro-

inter-

Re-

After

a

2

o

=.

©

=

a

Service

Required

light

s

JE

oe

indi

|

m

15

=

p

‘ower

tight

/

/

Power

switch

B

|

Figure

Flow

knob

Flow

meter

meter

10

Page 16

に

©

ドー

S.

©

pa]

ELA

=

へ

へ

=

©

rar)

©

dm

Ф

©

©

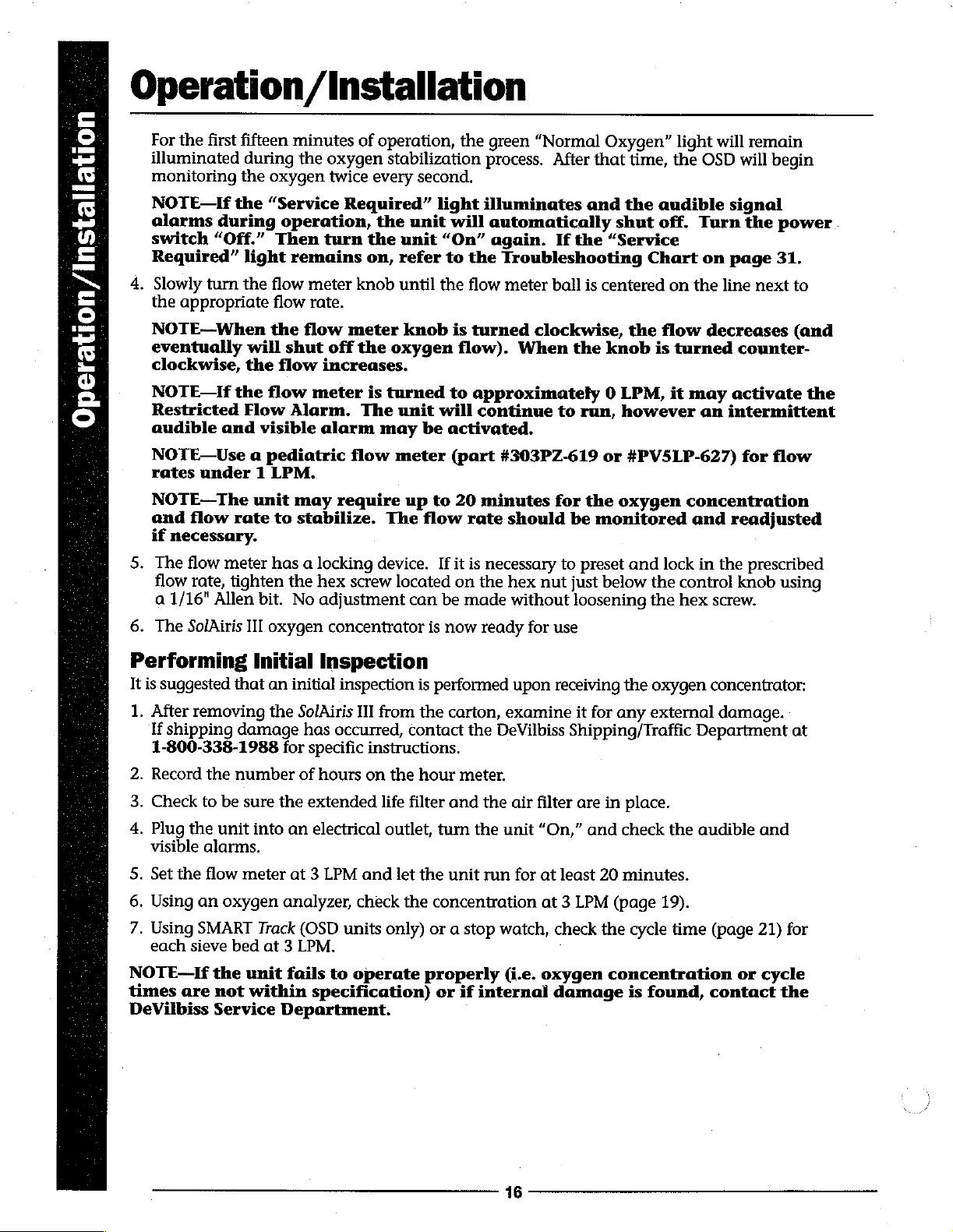

Operation/Installation

For the

illuminated

monitoring

NOTE—If

alarms

switch

Required”

4.

Slowly

the

NOTE—When

eventually

clockwise,

NOTE—If

Restricted

audible

first

fifteen

during

the

oxygen

the

“Service

during

“Off.”

light

turn

the

appropriate

the

will

the

the

flow

Flow

and

visible

minutes

the

oxygen

twice

operation,

Then

flow

flow

remains

meter

rate.

flow

shut

flow

meter

Alarm.

alarm

turn

off

increases.

of

operation,

stabilization

every

Required”

the

unit

the

unit

on,

refer

knob

until

meter

the

is

The

knob

oxygen

turned

unit

may

the

second.

light

will

“On”

to

the

the

flow

is

turned

flow).

to

approximately 0 LPM,

will

be

activated.

green

process.

illuminates

automatically

continue

“Normal

again.

Troubleshooting

meter

clockwise,

When

After

and

If

the

ball

is

the

to

run,

Oxygen”

that

time,

the

shut

“Service

Chart

centered

the

knob

however

light

the

OSD

audible

off.

Turn

on

on

the

flow

decreases

is

turned

it

may

an

will

remain

will

begin

signal

the

power

page

line

intermittent

31.

next

counter-

activate

to

(and

the

NOTE—Use

rates

NOTE—The

and

if

5.

6.

under 1 LPM.

flow

necessary.

The

flow

flow

rate,

a

1/16"

Allen

The

SolAiris

meter

Performing

It

is

suggested

1.

After

removing

If

shipping

1-800-338-1988

2.

Record

3.

Check

4.

Plug

visible

5.

Set

6.

Using

the

the

an

the

to

be

unit

alarms.

flow

oxygen

a

pediatric

unit

rate

to

has a locking

tighten

bit.

III

oxygen

the

Initial

that

an

the

damage

for

number

sure

the

into

an

meter

at 3 LPM

analyzer,

flow

may

require

stabilize.

hex

screw

No

adjustment

concentrator

Inspection

initial

inspection

SolAiris

has

specific

of

extended

HI

occurred,

hours

electrical

and

check

on

meter

The

device.

located

from

instructions.

the

life

outlet,

let

the

(part

up

to

20

flow

rate

If

it

is

on

can

be

made

is

now

is

performed

the

carton,

contact

hour

filter

the

the

meter.

and

turn

unit

concentration

#303PZ-619

minutes

should

necessary

the

hex

without

ready

the

for

upon

examine

DeVilbiss

the

air

filter

unit

run

for

or

*PV5LP-627)

for

the

oxygen

be

monitored

to

preset

nut

just

loosening

use

receiving

it

Shipping/Traffic

are

“On,”

at

least 20

at 3 LPM

below

for

in

and

any

(page

and

the

place.

check

minutes.

concentration

and

lock

in

the

the

control

the

hex

screw.

oxygen

external

19).

concentrator:

damage.

Department

the

audible

for

flow

readjusted

prescribed

knob

using

at

and

7.

Using

SMART

each

sieve

NOTE—If

times

DeVilbiss

are

Track

bed

at 3 LPM.

the

unit

not

within

Service

(OSD

units

fails

to

operate

specification)

Department.

only)

or a stop

properly

or

if

internal

watch,

(i.e.

oxygen

16

check

]

damage

the

cycle

time

concentration

is

found,

(page

21)

or

cycle

contact

for

the

Page 17

Operation

Suggested

1.

Position

his

NOTE—DO

The

outlet

2.

Locate

registers.

3.

Position

might

WARNING—

unit

or

oxygen

burning

portable

WARNING—Electric

ers

may

4.

Attach

outlet.

Patient

the

unit

or

her

time.

NOT

should

the

unit a minimum

the

unit

prevent

Oxygen

when

concentrator

near a person

objects

gas

heaters.

remove

the

appropriate

the

/Installation

Setup

near

an

connect

be

independent

at

least

proper

promotes

within a minimum

or

naked

Shock

the

cabinet.

electrical

to

an

of

six

inches

flow

flames.

Hazard.

oxygen

outlet

electrical

of

five

feet

from

from

of

air

in

and

rapid

receiving

accessories

burning.

Do

Only

in

other

walls,

oxygen

not

(oxygen

the

room

where

outlet

fireplaces,

out

of

qualified DeVilbiss

controlled

appliances.

draperies,

of

the

oxygen

Do

therapy.

five

feet

use

in

rooms

tubing

the

radiators,

or

any

concentrator.

not

smoke

Do

from

heated

or

humidifier)

patient

by a wall

heaters,

other

not

hot,

spends

objects

when

operate

sparking,

by

paraffin

homecare

to

most

switch.

and

hot-air

that

using

the

provid-

the

of

this

or

or

oxygen

ο

3

©

=

W

=

©

=

会

の

l

2

S

=

©

=

в

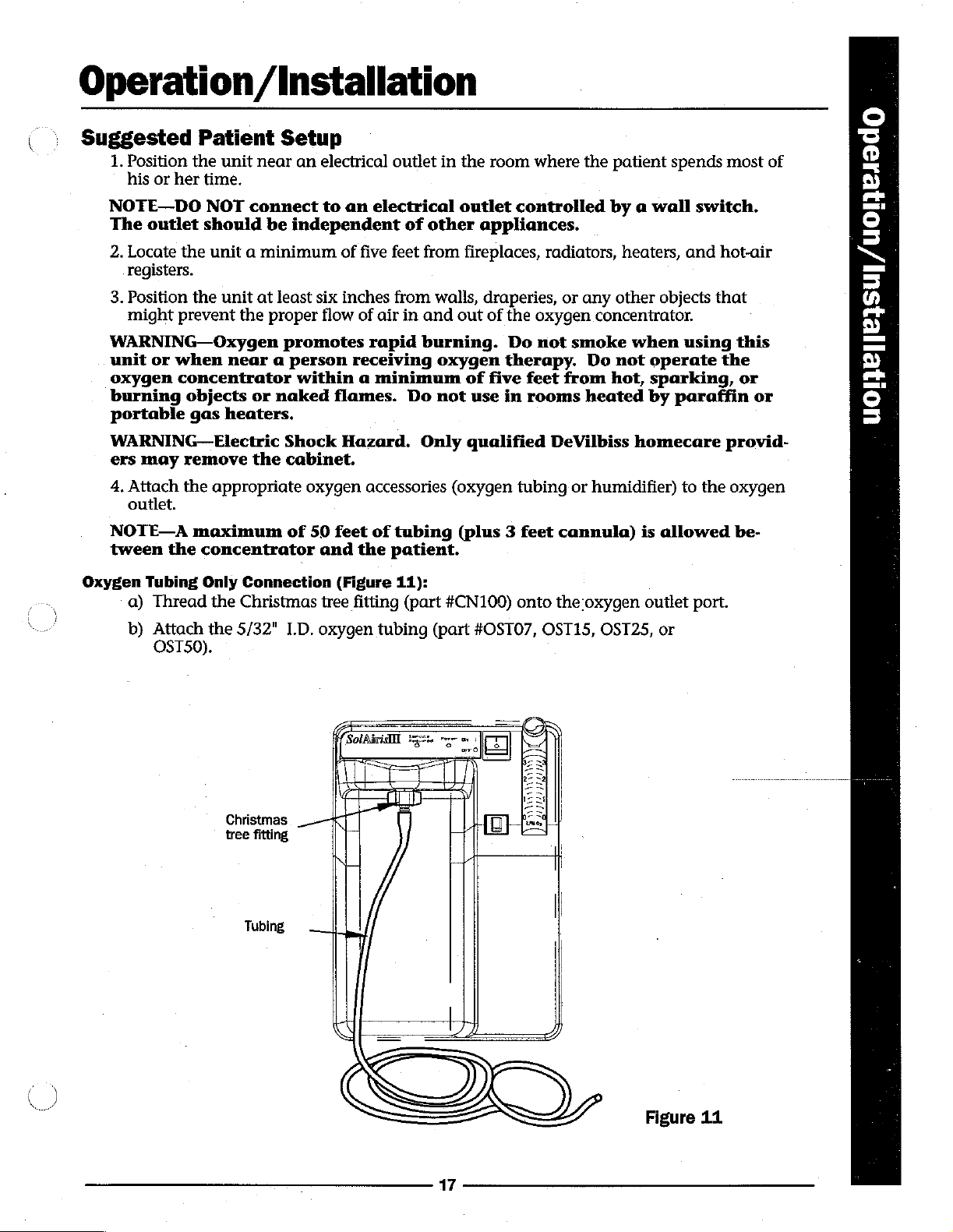

NOTE—A

tween

Oxygen

Tubing

a)

Thread

b)

Attach

OST50).

maximum

the

concentrator

Only

the

the

Christmas

tree

of

Connection

Christmas

5/32"

I.D.

fitting

Tubing

50

feet

of

tubing

and

the

patient.

(Figure

tree

oxygen

Γι

一

-|

11):

fitting

(part

tubing

(part

(plus 3 feet

#CN100)

onto

#OSTO7,

cannula)

the

oxygen

OST15,

9

ん

na

MU

мм

41111111811

En

T

8

D

is

outlet

OST25,

allowed

port.

or

be-

Figure

17

11

Page 18

<

©

ビー

S

K

Pas

の

=

N

=

©

—

©

um

©

Qi

©

Operation

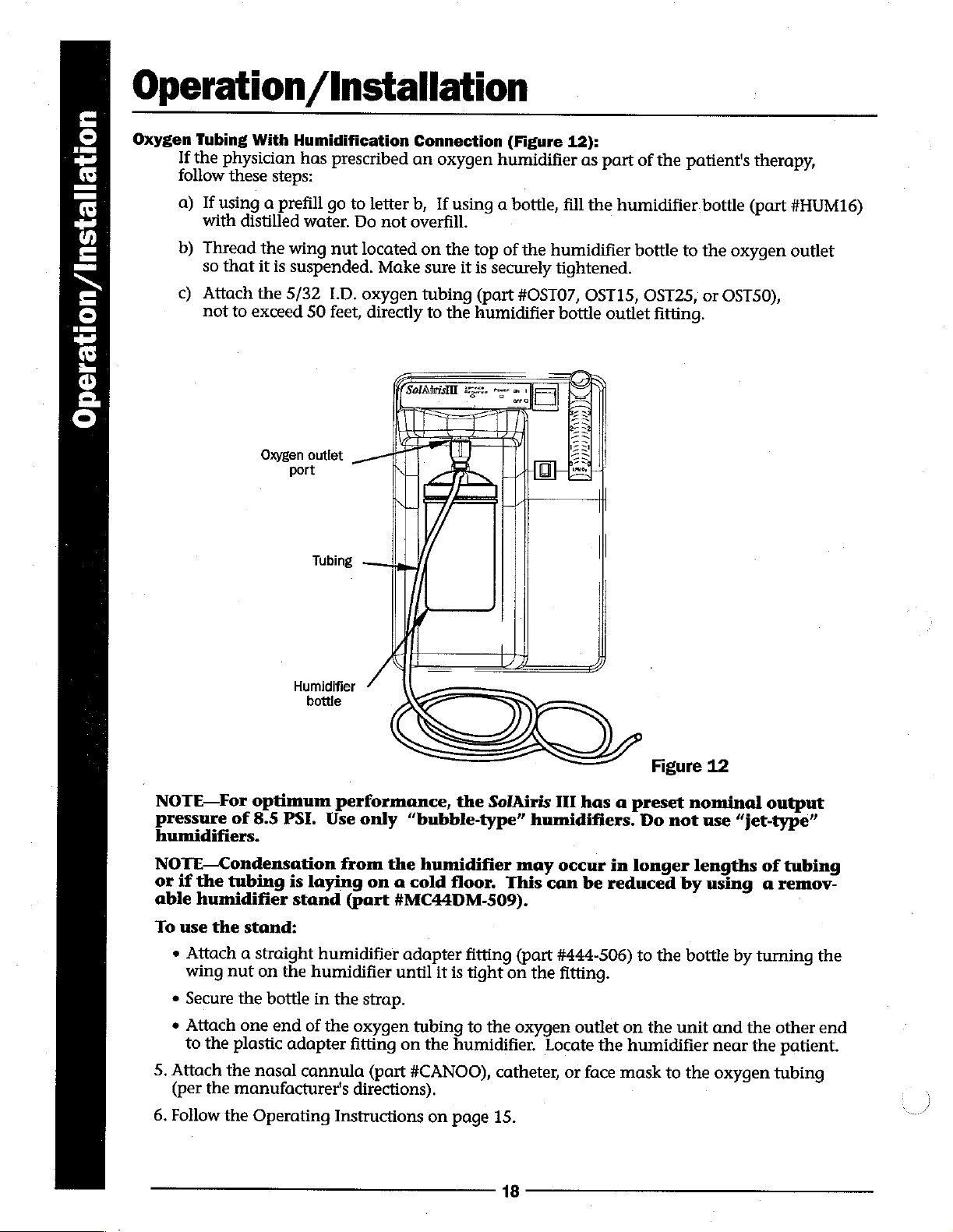

Oxygen

Tubing

If

the

physician

follow

a)

If

using

with

b)

Thread

that

so

c)

Attach

not

With

steps:

these

a

prefill

distilled

the

wing

suspended.

is

it

the

5/32

to

exceed

Oxygen

port

Humidification

has

water.

50

/Installation

prescribed

go

to

Do

nut

located

I.D.

oxygen

feet,

outlet

Connection

an

letter

b,

not

overfill.

on

sure

Make

tubing

directly

to

oxygen

If

using

the

the

(Figure

humidifier

a

bottle,

top

of

the

securely

is

it

(part

#OST07,

humidifier

12):

as

part

fill

the

humidifier.

humidifier

tightened.

OST15,

bottle

outlet

of

the

bottle

OST25,

fitting.

patient's

bottle

to

the

or

(part

oxygen

OST50),

therapy,

#HUM16)

outlet

NOTE—For

pressure

humidifiers.

NOTE—Condensation

or

if

the

able

humidifier

To

use

*

Attach a straight

wing

Secure

of

tubing

the

nut

the

optimum

8.5

PSI.

is

stand:

on

the

bottle

stand

Tubing

Humidifier

bottle

performance,

Use

only

from

laying

(part

humidifier

humidifier

in

the

“bubble-type”

the

humidifier

on a cold

#MC44DM-509).

adapter

until

it

strap.

the

SolAiris

floor.

fitting

is

tight

III

humidifiers.

may

occur

This

can

(part

#444-506)

on

the

fitting.

Figure

has a preset

Do

not

in

longer

be

reduced

to

the

12

nominal

use

lengths

by

using a remov-

bottle

output

“jet-type”

of

by

turning

tubing

the

*

Attach

to

5.

Attach

(per

6.

Follow

one

end

the

plastic

the

the

manufacturer's

the

adapter

nasal

Operating

of

the

oxygen

fitting

cannula

directions).

Instructions

on

(part

tubing

#CANOO),

to

the

humidifier.

on

page

the

oxygen

Locate

catheter,

15.

18

outlet

the

or

face

on

the

unit

humidifier

mask

to

the

and

the

near

the

oxygen

other

end

patient.

tubing

Page 19

Maintenance

|

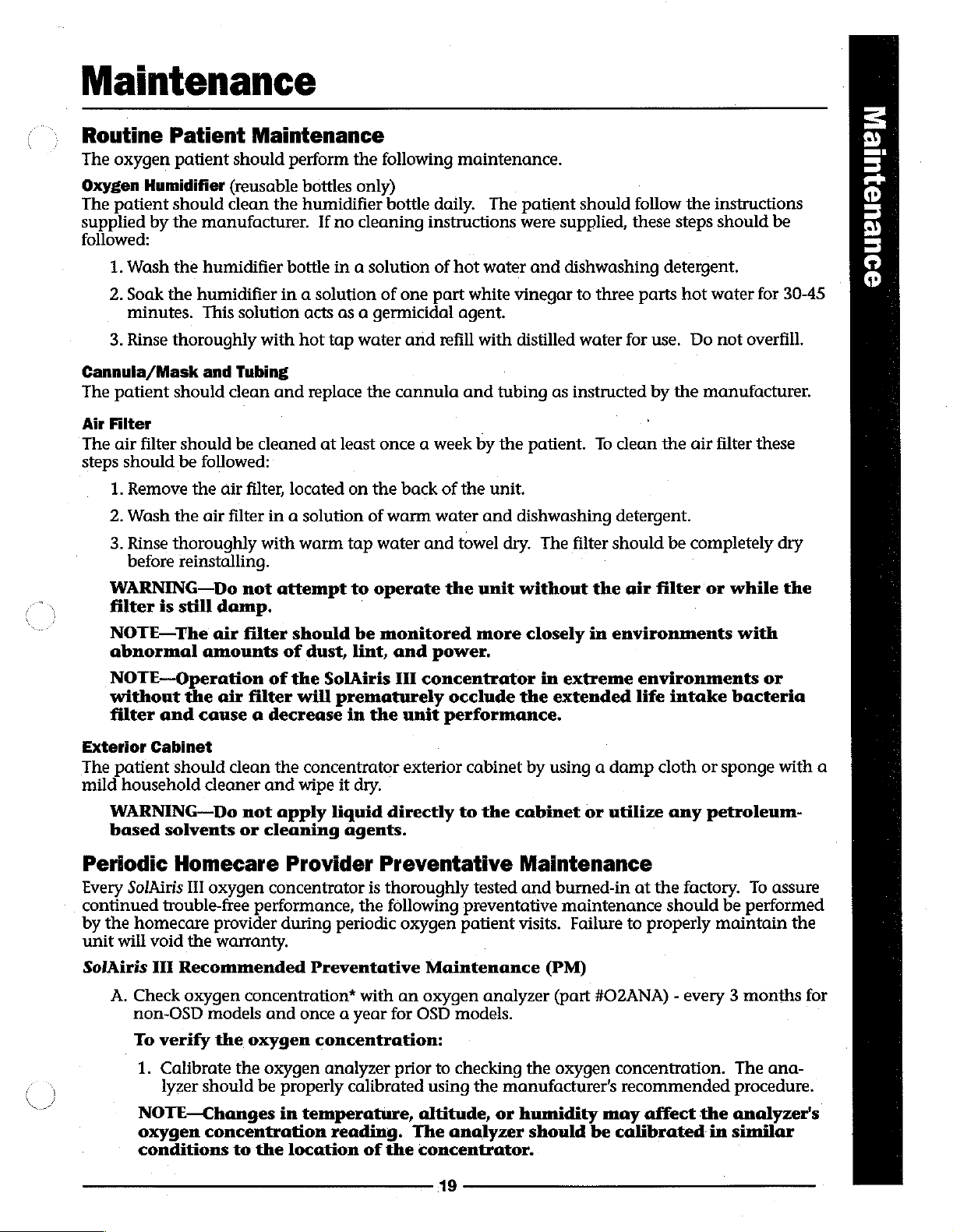

Routine

The

oxygen

Oxygen

The

patient

supplied

Patient

Humidifier

by

followed:

1.

Wash

2.

Soak

the

minutes.

3.

Rinse

Cannula/Mask

The

patient

Air

Filter

The

air

filter

steps

should

1.

Remove

2.

Wash

3.

Rinse

before

WARNING—Do

filter

is

NOTE—The

abnormal

NOTE—Operation

without

filter

and

Maintenance

patient

should

the

the

thoroughly

should

should

be

the

thoroughly

reinstalling.

still

the

should

(reusable

clean

the

manufacturer.

humidifier

humidifier

This

solution

with

and

Tubing

clean

and

be

cleaned

followed:

the

air

filter,

air

filter in a solution

with

not

attempt

damp.

air

filter

amounts

of

air

filter

cause a decrease

perform

bottles

the

only)

humidifier

If

no

cleaning

bottle

in a solution

in a solution

acts

as a germicidal

hot

tap

water

replace

located

warm

should

of

dust,

the

will

the

at

least

once a week

on

the

of

tap

water

to

operate

be

monitored

lint,

SolAiris

prematurely

in

the

following

bottle

daily.

instructions

of

of

one

part

and

refill

cannula

back

of

warm

water

and

the

and

power.

III

concentrator

occlude

unit

performance.

maintenance.

The

patient

were

hot

water

white

and

vinegar

agent.

with

distilled

and

tubing

by

the

patient.

the

unit.

and

dishwashing

towel

dry.

The

unit

without

more

closely

in

the

should

supplied,

dishwashing

to

three parts

water

for

as

instructed

To

clean

detergent.

filter

should

the

air

in

environments

extreme

extended

follow

these

the

instructions

steps

should

detergent.

hot

water

use.

Do

not

by

the

manufacturer.

the

air

filter

be

completely

filter

or

environments

life

intake

be

for

30-45

overfill.

these

dry

while

the

with

or

bacteria

te

Pettey

Exterior

Cabinet

The patient

mild

household

WARNING--Do

based

solvents

Periodic

Every

SolAiris

continued

by

the

unit

SolAiris

A.

trouble-free

homecare

will

void

III

Check

non-OSD

To

verify

1.

Calibrate

lyzer

NOTE—Changes

oxygen

conditions

should

clean

cleaner

not

or

Homecare

III

oxygen

provider

the

warranty.

Recommended

oxygen

concentration*

models

the

oxygen

the

should

concentration

to

the

concentrator

and

wipe

it

apply

cleaning

liquid

agents.

Provider

concentrator

performance,

during

and

oxygen

be

properly

in

the

location

periodic

Preventative

once a year

concentration:

analyzer

calibrated

temperature,

reading.

exterior

dry.

directly

Preventative

is

thoroughly

the

following

oxygen

Maintenance

with an

of

oxygen

for

OSD

prior

to

using

altitude,

The

the

concentrator.

cabinet

to

the

cabinet

tested

preventative

patient

analyzer

models.

checking

the

manufacturer's

or

analyzer

19

by

using a damp

or

utilize

Maintenance

and

burned-in

maintenance

visits.

humidity

Failure

(PM)

(part

the

oxygen

should

#O2ANA) - every 3 months

concentration.

may

be

calibrated

cloth

or

any

petroleum-

at

the

factory.

should

to

properly

recommended

affect

the

in

sponge

be

with

To

assure

performed

maintain

The

ana-

procedure.

analyzer's

similar

a

the

for

Page 20

=

=

=

©

©

=

=

©

G

Maintenance

2.

The

concentrator

oxygen

3.

Connect

4.

Record

B.

Check

turned

lights

C.

Change

To

change

1.

Open

2.

Pull

3.

Place

4.

Securely

NOTE—If

may

be

*

Round

Rectangular

AND

*

Intake

D.

Change

concentration.

the

analyzer

the

reading.

the

audible

“On,”

are

operating.

Extended

the

the

extended

the

current

insert

the

DeVilbiss

substituted.

Felt

Pre-Filter

Bacteria

Final

alarm

listen

Life

the

filter:

filter

door.

the

Felt

Pre-Filter

Filter

Bacteria

must

9

for

the

Intake

life

date

new

Extended

Note

(part

(part

Filter

operate

to

the

unit's

and

indicator

audible

Bacteria

filter

out

and

hours

extended

the

different

#444-503)

(part

#444-504)

(part

for

a

minimum

oxygen

lights

alarm

from

Life

#MC44D-722)

-

#PVSLD-651)

and

Filter

the

rubber

of

operation

life

filter

Intake

PM

-

change

-

change

of

20

outlet

(part

port

-

once

check

#MC44D-605)

grommet

on

the

into

the

Filter

schedules.

once

a

-

change

every

-

every

minutes

and

a

year.

to

see

if

label

grommet

is

not

month

every

six

months

two

years.

before

wait

until

When

(Figure

the

front

-

of

a

and

used,

OR

three

the

once

new

checking

the

power

panel

a

year.

13)

and

extended

close

the

the

following

months

the

display

switch

indicator

discard.

life

filter

stabilizes.

is

filter.

door.

filters

Bib

screw

Grommet

Rear

cover

Filter

door

Air

filter

Extended

life

intake

bacteria

filter

20

Figure

13

Page 21

Maintenance

To

1.

Unplug

2.

Remove

Flow

change

meter

the

the

the

final

unit

hose

bacteria

and

remove

from

each

filter:

the

end

of

cabinet

the

filter

Bib

oe

Spring

(see

(Figure

ol

clip

page

34).

14).

>

=

©

=

일

am

še

©

3.

Discard

4.

Install

E.

Recommended

hours

Track

for

normal

NOTE—Increases

decreases

various

Sea

2500

5000

F.

Change

To

change

1.

Remove

2.

Install

G.

Change

(whichever

the

the

of

operation

or a stop

cycle

in

the

altitudes

Level - approximately 8 seconds

feet - approximately

feet - approximately

Exhaust

the

tubing

Compressor

comes

filter.

new

final

Compressor

(whichever

watch)

times)

in

altitude

two

variables

are

Silencer - when

the

exhaust

hose

clamps

on

the

HEPA

first).

filter

and

if

with

as

follows:

new

Cycle

silencer

with “IN”

Time

Check - prior

comes

longer

no

and

and

silencer,

Filter - every

first).

than

leaks,

flow

will

10

11

the

(Figure

tubing

inspect

slightly

seconds

seconds

compressor

and

Final

bacteria

fitting

normal

from

Monitor

and

rate

secure

five

years

toward

will

at 3 LPM

at 3 LPM

at 3 LPM

33):

the

filter

flow

to

or

the

unit

cycle

times

change

slightly

decrease

is

rebuilt

exhaust

with hose

or

25,000

meter.

at

three

years

cycle

exist

(refer

internal

cycle

or

silencer.

components

increase

times.

replaced.

clamps.

hours

times

to

of

operation

Figure

or

12,000

(using

page

cycle

Cycle

14

SMART

27

as

needed.

times

times

and

at

To

replace

1.

Unplug

2.

Loosen

3.

Using a wrench,

4.

Discard

the

the

hose

the

compressor

unit

and

clamp

unscrew

HEPA

filter.

remove

and

remove

HEPA

the

only

the

HEPA

filter:

the

rear

hose

filter

21

cabinet

from

from

the

(refer

the

outlet

compressor

to

page

fitting

head.

34).

end

of

the

HEPA

filter.

Page 22

Maintenance

NOTE—Teflon

prior

5.

NOTE—Make

6.

Maintenance

7,

*

environment.

concentrator

frequency

which

Between

to

installation

Install

until

the

tight.

Attach

Leak

test

to

fittings

The

Preventative

(not

takes

Patient

A.

Discard

filter

B.

Wash

C.

Check

extended

must

the

the

and

operating

into

(if

or

oxygen

be

tape

or

of

new

HEPA

filter

sure

the

hose

to

the

HEPA

filter

connections

Maintenance

The

homecare

environment

to

exceed

three

consideration

Maintenance

oxygen

using

replace

tubing,

these

the

concentration.

life

intake

changed

annually).

LOX-8

HEPA

by

using

filter

outlet

end

fitting

fittings.

with

the

Schedule

provider

months

the

cannula,

filters

instead

air

filter.

bacteria

paste

should

filter.

a

wrench

marked

end

Apply

unit

running.

is

responsible

and

on

specific

humidifier

of

If

the

filter

does

be

applied

to

attach

“IN”

of

the

filter

the

leak

test

If

an

stated

above

for

determining

non-OSD

models

operating

bottle,

the

extended

unit

falls

within

not

need

to

the

the

filter

is

toward

and

solution

air

leak

reflects

compressor.

secure

(such

is

present,

a

normal,

with

determining

a

preventative

or

one

environment.

intake

life

to

be

bacteria

intake

93%

+

replaced

compressor

to

the

compressor

hose

as

Epi-Seal®

the

clean

the

condition

maintenance

year

on

filter

bacteria

3%

at

3

between

fitting

clamp.

LEAK-SEEK®)

solution

will

operating

of

OSD

models)

and

filter).

LPM,

the

patients

head

bubble.

the

interval

felt

pre-

(but

Epi-Seal®

LEAK-SEEK®

is

a

registered

trademark

of

Bonded

Products,

22

Inc.

Page 23

Patient

Patient

The

SolAiris

situations.

a

malfunction

The

diagnostic

malfunction.

The

visible

is

internally

audible

e

e

»

*

e

*

e

The

visible

tion.

After

few

seconds.

NOTE—Hf

run several

Alert

III

patient

This

system

should

lights

alarm

powered;

alarm

low/high

minimum/maximum

valve

bed

compressor

restricted

power

If

the

that

sounds,

pressure

failure

failure

flow

fail

(blinking

and

audible

unit

is

time,

the

the

minutes

Alert

System

alert

system

is

comprised

occur.

on

the

PC

located

failure

turned

concentrator

on

no

batteries

other

cycle

(blinking

visible

alarms

“On”

alarm

will

before

the

than

&

will

of

board

front

are

during

visible

produce

alarm

alarm and

will

activate

and

not

has

the

Diagnostic

detect

both

will

panel

required.

an

been

power

unit

visible

help

reads

unit

start-up, a problem

and

pulsing

for

plugged

audible

unused

component

and

audible

service

When

pulsing

approximately

fail

personnel

"Service

the

audible

in,

no

alarm

pulse

for

alarm

Required.”

indicator

audible

alarm)

and

the

an

will

failure

20

will

extended

System

as

well

as

alarms

diagnose

alarm)

visible

activate.

which

The

lights

has

occurred

minutes

sound

for

alarm

period,

signal

the

cause

audible

illuminate

such

in a no

the

will

restricted

alarm

power

first

blink

the

flow

the

patient

of

the

system

or

the

as:

situa-

10

seconds.

every

unit

must

if

IU

W

=

®

=

eb

>

©

=

=

Ro

に

トリ

ge.

=

©

の

=

o

の

by

の

=

©

3

The

printed

well

as

the

transducer

pressure

within

Most

to

the

or

the

major

unit.

circuit

alarms

indicates a malfunction,

component

preset

malfunctions

(PC)

board

by

using a pressure

failure.

minimum

and

will

is

responsible

Alarms

maximum

shut

the

for

transducer.

the

patient

will

also

cycle

unit

off

monitoring

When

alert

system

be

activated

times.

automatically,

and

the

pressure

will

if

The

alarm

preventing

controlling

sensed

activate

the

system

system

the

entire

by

the

regardless

fails

cannot

any

if

to

operate

be

further

system

pressure

it

overridden.

damage

is

as

a

23

Page 24

Е

©

цы

の

Ed

の )

о

ドー

の

©

トー

0

©

à

3

~

da

E

x

0

=

ko

=)

G

в.

Patient

Diagnostic

The

PC

board

unit

will

shut

should

page

be

43)

Oxyger

(OSD

System

has

off,

used

as

because

sensor

assembly

units

only)

and

there

Alert

three

red

these

a

troubleshooting

may

&

diagnostic

lights

be

more

PC

board

Diagnostic

lights

will

illuminate

aid

than

(Figure

in

conjunction

one

Diagnostic

(on

back

of

15).

in

a

reason

lights

PC

board)

particular

for

System

Should

with

the

a

malfunction.

a

unit

malfunction

sequence.

pressure-vacuum

The

diagnostic

occur,

gauges

the

lights

(refer

to

"4-way"

indicator

light

Figure

15

24

Page 25

Patient

Alert

&

Diagnostic

System

"|

The

diagnostic

This

gives

the

been

turned

view

To

unit:

the

1.

Turn

2.

Open

3.

Use

release

vertical

the

WARNING—Electric

when

uct

off.

the

the

the

the

light

pressing

damage.

system

service

light

unit

air filter

plastic

the

diagnostic

sequence

will

technician

sequence

“On.”

error

Memory

the

also

keep

corresponding

door.

indicator

Switch

light

access

for

the

last

Shock

memory

the

last

the

ability

tool

(part

“S”

through

holes (located

failure

Hazard.

switch;

Pediatric

bleed

diagnostic

to

view

the

the

to

#303DZ-635)

the

single

on

mode

(unless

Do

not

doing

flow

so

meter

off

light

cause

unit

access

the

PC

the

use

metal

may

Memory

access

failure

of a unit

malfunction

or

memory

cause

switch

hole

sequence

other

non-metallic

hole

located

board).

or

other

personal

Diagnostic

access

shutdown

The

has

holes

in

without

to

the

PC

board

been

conductive

injury

light

memory.

after the

opening

`

tool

to

left

of

will

cleared).

and

unit

has

press

and

the

three

display

tools

prod-

W

=

©

=

ee

2

©

=

[asi

名

2

o

ga

=

©

n

=

o

の

<

DI

©

3

ペー

=

св

=

ca

co

=

E

=

Figure

25

16

Page 26

E

©

Y

m

Y

К

Patient

After

To

viewing

clear

1.

Unplug

into

2.

Plug

the

、

the

diagnostic

unit

the

wall

unit

back

Alert

light

seguence,

light

while

still

outlet

into

running.

until

the

&

the

memory:

the

wall

Diagnostic

memory

Do

first

alarm

outlet.

may

not

sounds

This

be

turn

the

process

cleared

unit

(approximately

will

System

for

future