DeVilbiss SleepCube nCPAP, SleepCube DV54-P, SleepCube DV53, SleepCube DV54, SleepCube DV53 PAP Service Manual

Page 1

SleepCube™ nCPAP Device

Model DV53/DV54/DV54-P

Service Manual

Page 2

2

LT-2026

EN

Table of Contents

1. General Information 3

A. Safeguards 3

B. Initial Inspection 3

C. Travel 4

D. DC Power 4

E. Setting Pressures and Features 4

F. Images: DeVilbiss DV54/DV53 PAP 4

2. Description of Normal Operation 5

3. Cleaning and Disinfecting 6

A. Routine Cleaning--Patient 6

B. Disinfecting 6

4. Maintenance 9

A. Initial Inspection—Equipment Provider 9

B. Routine Maintenance—Patient 9

C. Required 3-year Maintenance—

Equipment Provider 9

5. Testing 10

A. Pressure Accuracy Test 10

B. Keypad Test 10

C. Auto-ON / Auto-OFF Test 10

D. Backlight Test for LCD and Keypad 11

6. Alerts and Device Faults 12

A. Alerts Visible to Patients 12

B. Device Faults Visible to Patients 12

C. Reading and Clearing the Last Device Fault Code 12

7. Calibration 13

A. Manual Calibration 13

B. Calibration Errors 14

C. Auto-Calibration 14

D. Details on Tc Serial Command 14

8. Troubleshooting 15

9. Service Instructions 16

A. Cover Removal 16

B. Cover Replacement 16

C. Control PC Board Removal 16

D. Control PC Board Replacement 17

E. Power Supply Board Removal 18

F. Power Supply Board Replacement 18

G. Blower Removal 19

H. Blower Replacement 19

I. KeyPad & LCD Display Removal and Replacement 20

10. Unit Specifications 21

11. General Information- DV5HH 22

A. Safeguards 22

B. Travel 22

C. DC Power 22

D. Product Description 22

12. Description of Normal Operation (DV5HH) 23

13. Maintenance and Testing (DV5HH) 24

A. Cleaning and Disinfection 24

B. Maintenance 24

C. Testing 24

14. Troubleshooting (DV5HH) 25

15. Service Instructions (DV5HH) 26

A. Removing the DV5HH base cover 26

B. Replacing the DV5HH base cover 26

C. Removing and replacing silicone manifold 27

D. Removing and replacing the latch 27

16. Unit Specifications (DV5HH) 28

A. Ordering Non-Warranty Replacement Parts 29

B. Ordering Warranty Replacement Parts 29

C. Returning Warranty Defective Parts 29

D. Placing orders 29

17. Ordering and Returning Parts 29

18. Parts List 30

DV54/DV53 31

DV5HH 31

19. Warranties 31

Page 3

LT-2026

3

EN

1. General Information

A. Safeguards

When using electrical products, basic safety precautions

should always be followed. Read all instructions before using

this device. Important information is highlighted by the following terms.

DANGER: Urgent safety information for hazards

that will cause serious injury or death.

WARNING: Important safety information for hazards

that might cause serious injury.

CAUTION: Information for preventing damage to the

product.

NOTE: Information to which you should pay

special attention.

PLEASE READ ALL INSTRUCTIONS

BEFORE USING THIS DEVICE.

DANGER!

• ELECTRIC SHOCK HAZARD – Do not use while bathing.

• ELECTRIC SHOCK HAZARD – Do not immerse this device

into water or any other liquid.

• ELECTRIC SHOCK HAZARD – Do not attempt to open or remove the enclosure. There are no user-serviceable internal

components. If service is required, return the product to

your home care provider. Opening or tampering with the

product will void the warranty.

WARNING!

• The DeVilbiss IntelliPAP™ and SleepCube™ devices should

be used only with masks recommended by DeVilbiss, your

physician or respiratory therapist.

• To avoid rebreathing of exhaled air, do not use a CPAP

mask unless the device is turned on and providing a supply

of air. Venting in the mask should never be blocked. When

the device is turned on and providing a fresh supply of

air, exhaled air is fl ushed out of the mask vent. However,

when the device is not operating, exhaled air may be

rebreathed. Rebreathing of exhaled air for longer than

several minutes can in some circumstances lead to suffocation. This warning applies to most CPAP devices.

• The DeVilbiss IntelliPAP and SleepCube devices are not a

life support devices and may stop operating with certain

device faults or with a power failure. It is intended to be

used on spontaneously breathing individuals weighing 66

lbs/30 Kg or greater.

• To avoid electric shock, always unplug power cord from

wall outlet power source when performing cleaning.

• Use only accessories recommended by DeVilbiss.

CAUTION– Product Damage: The circular data port connector

located on the back of the IntelliPAP and the SleepCube

is used to attach accessories to the device. The connector

must only be used with accessories approved for use by

DeVilbiss. Do not attempt to attach any other device to

this connector as it may damage the CPAP or the accessory device.

CAUTION– Product Damage: Never rinse or place the device in

water. Never allow liquids to get into or around any of the

ports, switches or air fi lter; doing so will result in device

damage. If this occurs, discontinue use and remove the

power cord from the power source. Allow the device to

completely dry before use.

CAUTION– Product Damage: Do not place the IntelliPAP or

SleepCube where it can be bumped onto the fl oor or

where the power cord may create a trip hazard.

CAUTION– Product Damage: Only the DeVilbiss DV5 series

Heated Humidifi er system is recommended for use with

the IntelliPAP and SleepCube. Other humidifi er systems

may prevent the device from detecting snoring and may

cause inappropriate pressure levels in the mask.

CAUTION– Product Use: Oxygen is a prescription gas and

should only be administered under the supervision of a

physician.

B. Initial Inspection

DeVilbiss recommends equipment inspection upon delivery

❏ Power up the DV54/DV53 PAP using AC power.

❏ Test pressure accuracy using an outlet cap (DV54/

DV53D-620), a calibrated pressure gauge and the procedures listed under Pressure Accuracy Test.

❏ Test the keys on the keypad using the procedures listed

under Keypad Test.

Page 4

4

LT-2026

EN

C. Travel

The DeVilbiss DV54/DV53 PAP:

• Automatically adjusts for altitudes between sea level and

9000 ft (2750 m)

• Automatically accepts line voltages of 100-240 V, 50/60 Hz

• Needs power cord appropriate for area

o USA DV54/

DV53D-606

o Europe, except UK DV54/DV53D-607

o UK DV54/DV53D-608

o Australia DV54/DV53D-609

o Set of 3 (UK, Europe, Australia) DV54/DV53D-611

D. DC Power

The DeVilbiss DV54/DV53 PAP:

• Automatically accepts 12V DC power

• Operates on DC power only if AC power is not present

• Operates on AC power if both DC and AC power are present

• Optional 12V, 60 amp hour, deep cycle marine battery

• Optional DC to AC inverter:

minimum 200 watts @ 100/120 VAC

minimum 400 watts @ 220 VAC

• Appropriate DC power cord

o DV54/DV53D-619 DC accessory cable for DC plug-in

adapters

o DV54/DV53D-696 DC battery clamp-on adaptor for

stand-alone battery

E. Setting Pressures and Features

Use the following steps to enter Clinical/SetUp mode:

1. Apply AC power to the unit

2. Verify that LCD displays OFF

3. Press and hold the Down Arrow key and the Delay key.

4. While holding two keys, press the ON/OFF key.

5. The blower will begin operating and the LCD will display

‘Clinical Menu’.

6. Use the Left and Right Arrow keys to scroll through the

options

7. Use the Up and Down Arrow keys to select the option’s

value.

8. Press the ON/OFF key at any time to exit Clinical Mode.

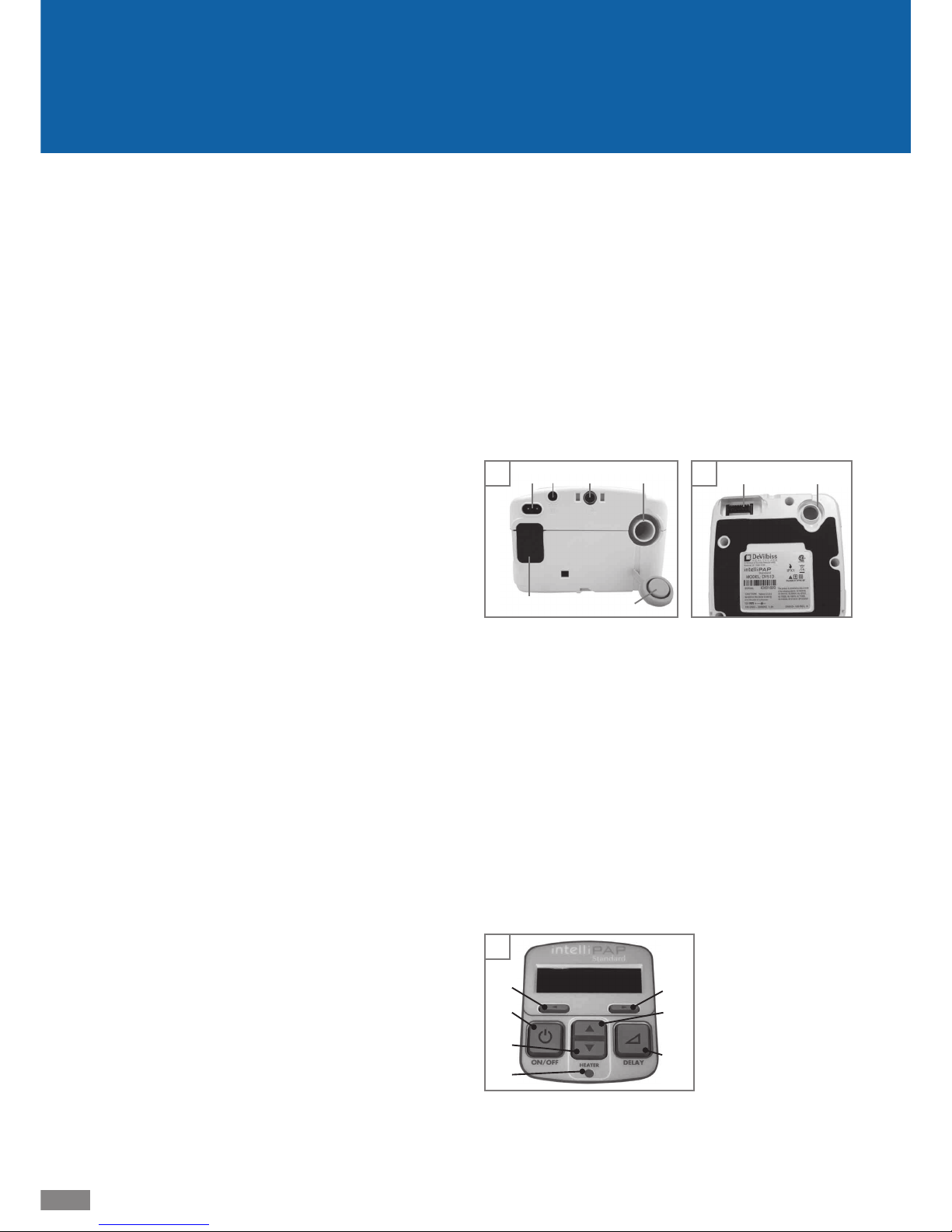

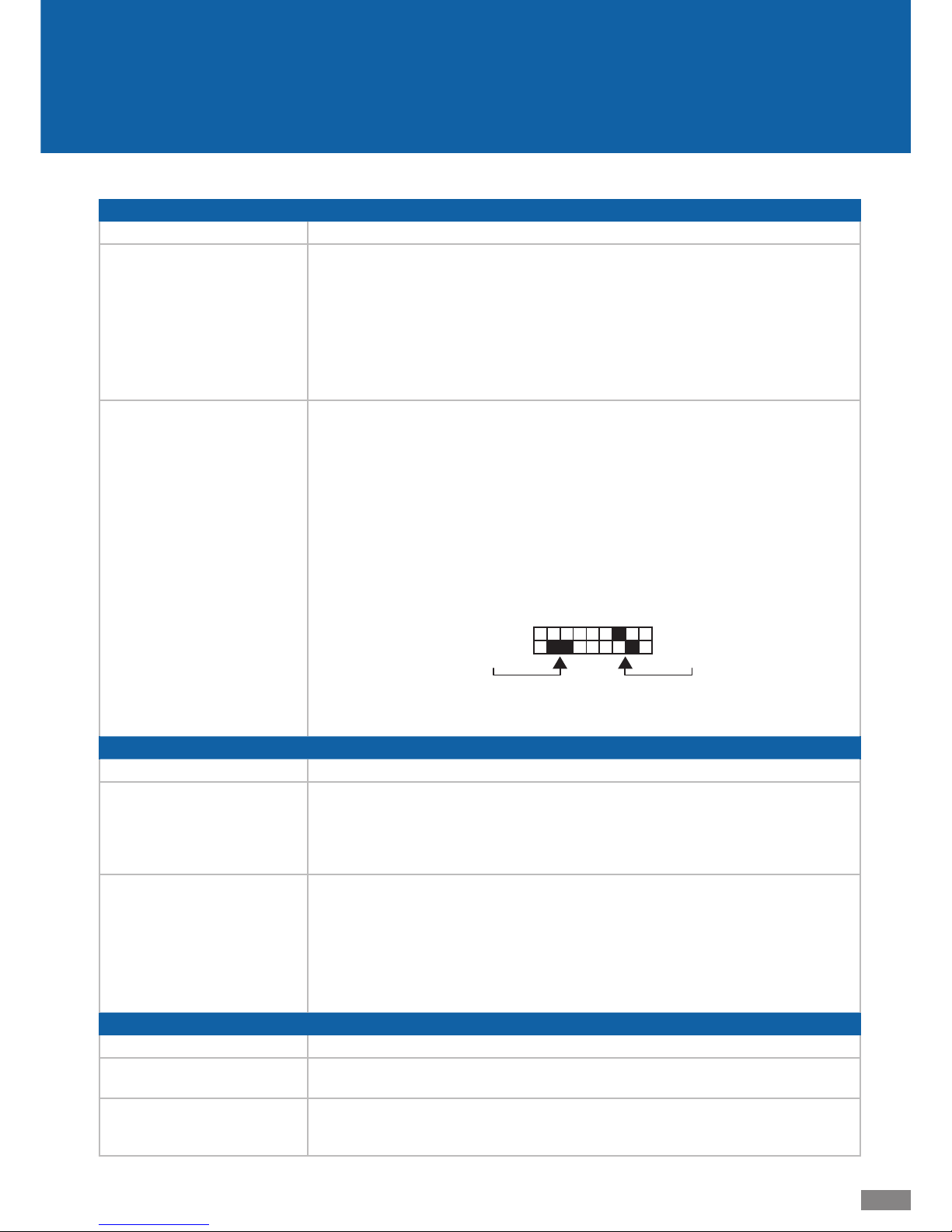

F. Images: DeVilbiss DV54/DV53 PAP

Figures A and B: DV54/DV53 Device Back and Bottom

1. Air supply port on back of device

2. Air supply port on bottom of device

(for optional humidifi er)

3. Air supply port plug

4. Heater power connector (for optional humidifi er)

5. AC power connector

6. DC power connector

7. Data por t

8. Air inlet fi lter opening

Figure C: Keypad

1. ON/OFF

2. Previous item

3. Next item

4. Delay

5. Decrease value

6. Increase value

7. Heater power LED

(for optional humidifi er)

C

5

1

2

4

6

3

7

B

2

4

A

1

3

56 7

8

Page 5

LT-2026

5

EN

2. Description of Normal Operation

An AC line cord (100-240 VAC, 50/60 Hz) or a DC line cord (12

VDC) supplies electrical power to the DV54/DV53 PAP. The

PAP converts the AC input voltage to DC voltage by means

of an internal switch mode power supply and uses the DC

voltage to power the internal electronics of the unit, such as

microcontroller, motor control circuitry, blower, LCD display,

etc. NOTE: The heated humidifi er will not operate when the

PAP uses external DC power.

The PAP produces positive pressure by spinning a reversecurved impeller with a brushless DC motor. Room air is drawn

through a fi lter into the blower, pressurized in the blower,

optionally passed through a heated humidifi er chamber, and

then discharged through a 22mm-ID, smooth-bore tube.

Pressure regulation is achieved using measured pressure as

feedback.

The DV54/DV53 PAP senses patient breathing by monitoring

changes in motor current: Breathing produces variations in

airfl ow; the airfl ow variations produce changes to the blower

load and result in variations to the motor current. A pressure

transducer triggers the auto-ON / auto-OFF functionality and

mask-OFF alerts.

Page 6

6

LT-2026

EN

A. Routine Cleaning–Patient

• Unplug the DV54/DV53 PAP and wipe enclosure with a

clean, damp cloth every few days to keep dust free. Allow

the device to dry completely before returning to power

source.

• Check the air-inlet fi lter every 10 days. Wash the dark

outer foam fi lter in a solution of warm water and mild

detergent. Rinse with water and allow the fi lter to dry

completely before returning to the device.

• Check the optional fi ne particle fi lter every 10 days and

replace if dirty or damaged.

• Clean the air supply tubing every day. Remove the tubing

from the device and mask and wash the inside of the tubing in a solution of warm water and mild detergent. Rinse

with water and allow to air dry before replacing device

and mask.

• Clean the mask and headgear according to the manufacturer’s instructions.

B. Disinfecting

CAUTION– Always work in an ESD (electro static discharge)

safe environment when assembling or disassembling

electronic components.

NOTE– DeVilbiss does not require disinfection as part of unit

maintenance. If disinfection is desired, the following procedure is recommended.

NOTE– Parts needed to perform the disinfection procedure

are NOT covered under the DV54/DV53 PAP warranty as

listed in this manual.

NOTE– Follow manufacturer’s instructions for cleaning and

disinfection solutions.

NOTE– Disinfection requires the following parts sold in Dis-

infection Kit, DV54/DV53D-682.

• Blower assembly, balanced

• Blower isolator-silicone

• Grommet-silicone

• 1/4 inch blower wrap foam

• 3 1/2 inch silicone tubing

• Air-inlet fi lter

• 5 1/2 inch silicone tubing—

discard, not needed for this model

• Tubing/Humidifi er air supply support plug

• 1/2 inch blower mount foam-round

• 1/2 inch top blower foam

• 1/8 inch inside bottom cover foam

• 5 inch silicone tubing

• Fine particle fi lter (optional)

3. Cleaning and Disinfecting

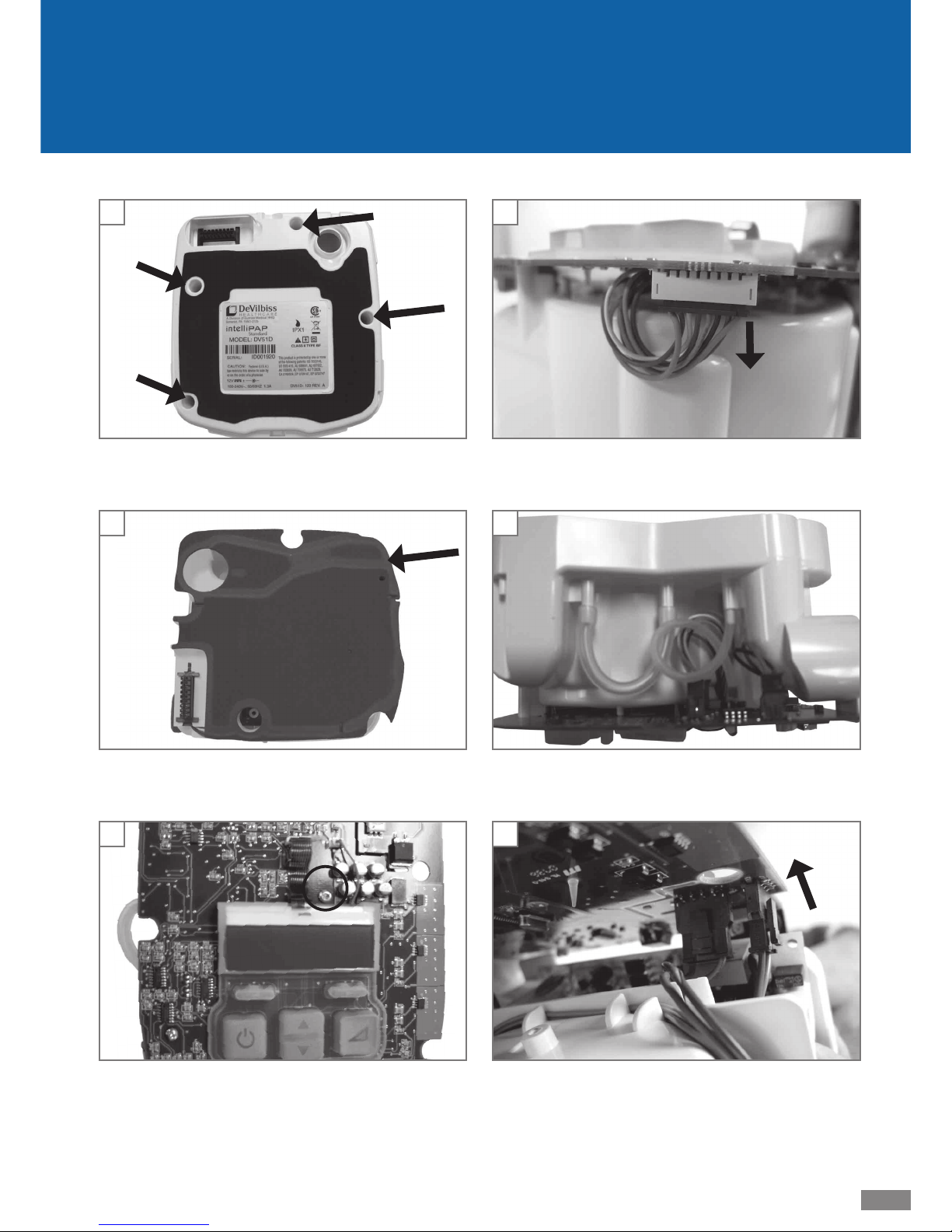

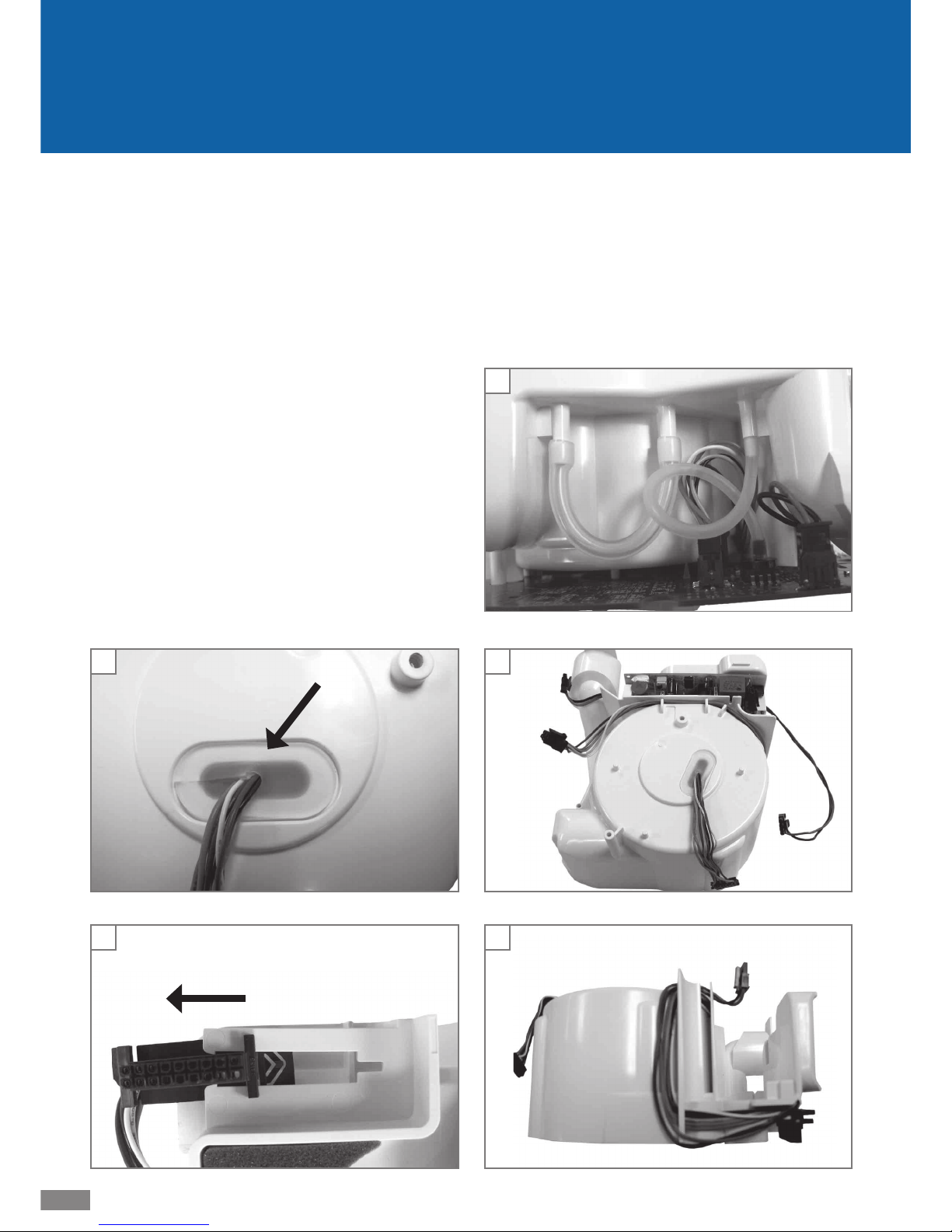

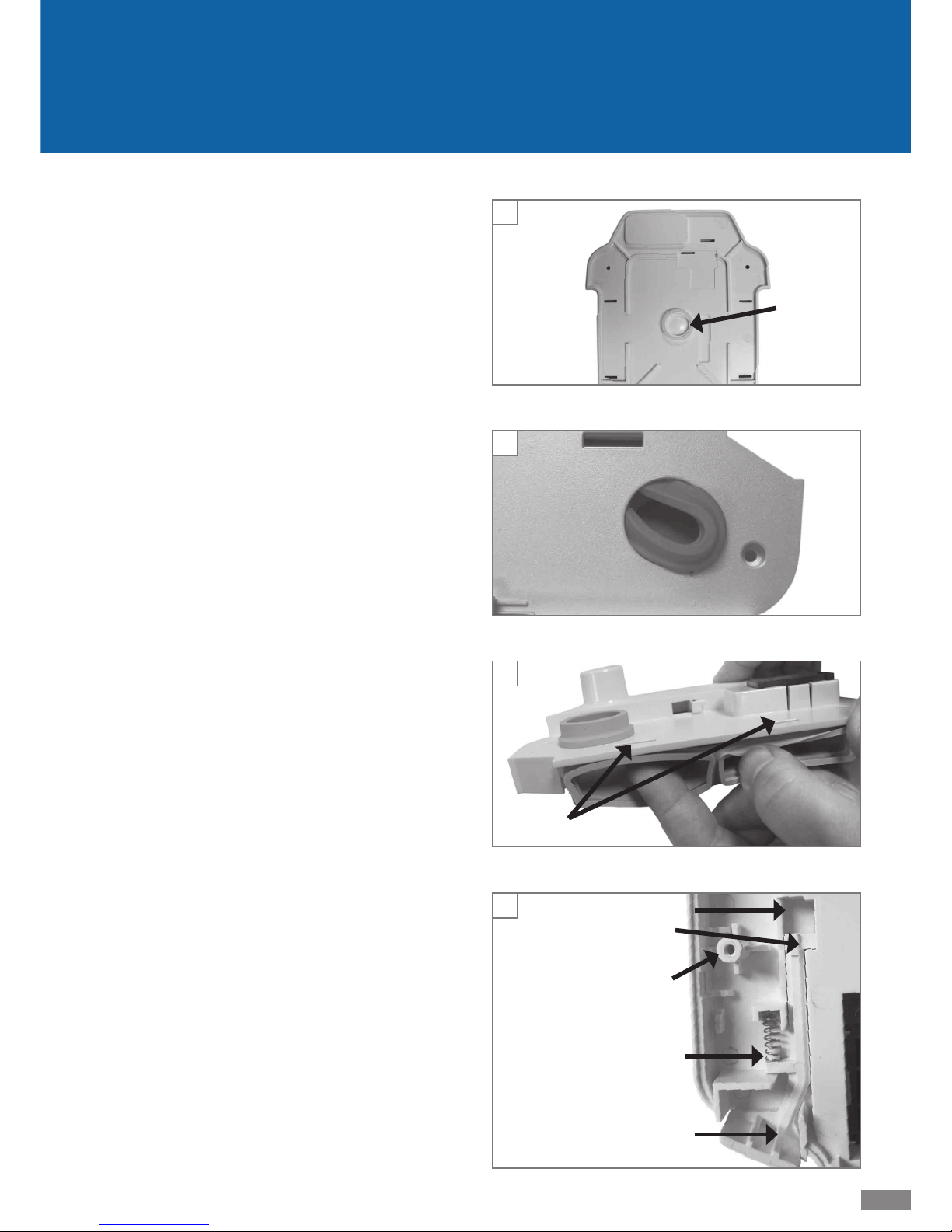

Disinfection Procedure for the DV Series PAP

1. Make certain that the device is not connected to a power

source.

2. Dispose of the mask, headgear, air supply tubing, gray air

inlet fi lter and white fi ne particle fi lter, if applicable.

3. Place the unit, top side down, onto a clean work surface.

Remove the four (4) screws from the bottom cover and

remove the bottom cover from the unit. (Fig. 1)

4. Remove the black 1/8 inch foam from inside the bottom

cover assembly and discard. This foam may stick to the

chassis of the main unit. (Fig. 2)

5. Remove the black 1/2 inch top blower foam from the

chassis assembly and discard.

6. Turn the unit top side up and remove the top cover.

7. Using a T-15 driver, remove the screw holding the PC board

to the chassis. (Fig. 3)

8. Disconnect the 8-conductor blower wire harness from the

underside of the PC board. (Fig. 4)

9. Disconnect the two (2) pieces of tubing and discard. (Fig. 5)

NOTE– Pull the tubing straight off the connectors to prevent

damaging the chassis.

10. With the ports side of the chassis toward you, tilt the

PC board and its respective wire harnesses upward, and

remove the wire connections. Lift the PC board slowly so

that you can assist any wires that may become hung up

on the chassis or power supply. (Fig. 6)

Page 7

LT-2026

7

EN

41

3

2 5

6

Page 8

8

LT-2026

EN

7

8

9

10

11

11. Remove the grommet that seals the blower’s wire harness.

(Fig. 7)

12. Remove the heater wire harness connector from the bottom of the chassis by sliding the connector outward while

pulling the top retaining tab upward slightly. (Fig. 8)

13. Remove the 1/4” blower wrap foam, the blower, and the

silicone isolator from the underside of the chassis.

14. Carefully spray, wipe or soak the air intake, fl ow path, and

blower chassis inside and outside using a 2% glutaraldehyde solution.

15. Wipe the power cord and the outside of both halves of the

PAP case with the same solution.

16. Let all components fully dry

17. Reassemble the unit using parts from the Disinfection

Kit—DV54/DV53D-682.

NOTES:

• Route the silicone tubing correctly, as shown, and ensure

that there are no kinks. (Fig. 9)

• Ensure that the silicone isolator is fully seated in the chassis and the blower.

• Ensure that the grommet is fully seated around the blower

wire harness.

• Route the wire harnesses properly, using the provided

strain reliefs on the chassis. (Fig. 10 & 11)

• Secure the power supply board within the mount clips on

the chassis before replacing the unit covers. (Fig. 10)

Page 9

LT-2026

9

EN

4. Maintenance

A. Initial Inspection—Equipment Provider

DeVilbiss recommends equipment inspection upon delivery

❏ Power up the DV54/DV53 PAP using AC power.

❏ Test pressure accuracy using an outlet cap (DV54/

DV53D-620), a calibrated pressure gauge and the procedures listed under Pressure Accuracy Test.

❏ Test the keys on the keypad using the procedures listed

under Keypad Test.

B. Routine Maintenance—Patient

❏ Wipe case with damp cloth every few days

❏ Check air-inlet fi lter every 10 days and clean as needed

❏ Clean air supply tubing daily

❏ Clean mask and headgear per manufacturer’s instructions.

C. Required three years Maintenance—

Equipment Provider

DeVilbiss requires the following maintenance from the equipment provider:

❏ Test pressure accuracy using procedures listed under Pres-

sure Accuracy Test. If the device is out of calibration, follow

corrective procedures as listed.

❏ Instruct patient on fi lter maintenance described in Instruc-

tion Guide:

Standard Filter

o Inspect fi lter every ten days

o Clean as needed

o Change every 6 months

Optional Fine Particle Filter

o Inspect fi lter every ten days

o Replace if dirty

o Change every 30 days

Page 10

10

LT-2026

EN

The following test procedures verify correct operation of the

DV54/DV53 PAP and should be performed on all repaired

units.

NOTE– Verify that the DV54/DV53 PAP contains the latest

fi rmware release before conducting maintenance or

repairs. Go to http://www.devilbisshealthcare.com/Products to download the latest fi rmware update. Download

and installation instructions are provided on the web site.

A. Pressure Accuracy Test

Additional equipment required: outlet cap (DV54/

DV53D-620), a calibrated pressure gauge (0-30 cmH2O, accuracy ±0.25 cmH2O)

1. Connect the pressure gauge to the unit outlet port.

2. Apply AC power to the unit. If the blower is running, press

the ON/OFF key on the keypad so that the blower stops

and the LCD displays ‘OFF’.

3. While pressing both the Down Arrow and Delay keys,

press the ON/OFF key to start the blower and enter clinical

mode.

4. Press the Next Item key until Set Pressure is displayed.

Use the Up and Down Arrow keys to adjust the pressure

to 12 cmH2O. Wait at least 30 seconds for the pressure to

stabilize.

5. Verify that the displayed pressure matches the pressure

measured on the gauge (pressure setting ±1.0 cmH2O).

Accuracy at other pressure settings can be checked if

needed.

6. If the pressure is out of calibration, turn the blower OFF for

approximately 1 minute to allow auto-calibration to occur.

Turn the blower back ON and allow 30 seconds for the

pressure to stabilize. If the pressure is still out of calibration, perform a full calibration using the Manual Calibration Procedure.

7. If manual calibration does not improve pressure accuracy,

there may be a problem with the fl ow path or control

board. Refer to Troubleshooting.

5. Testing

B. Keypad Test

No additional equipment required.

1. Apply AC power to the unit. If the blower is running, press

the ON/OFF key on the keypad so that the blower stops

and the LCD displays ‘OFF’.

2. While pressing both the Down Arrow and Delay keys,

press the ON/OFF key to start the blower and enter clinical

mode.

3. Press the Next Item key until Delay Time is shown on the

LCD display.

4. Note the Delay Time; then change it by pressing the Up and

Down arrow keys. Use the arrows keys to return the Delay

Time back to the original setting.

5. Use the Previous Item key to return to the Set Pressure

screen.

6. If any of the keypad keys did not function correctly during this test, replace the PC control board using Service

Instruc tions.

Page 11

LT-2026

11

EN

C. Auto-ON / Auto-OFF Test

Additional equipment required: 6 ft x 22 mm smooth bore

tubing.

1. Apply AC power to the unit. If the blower is running, press

the ON/OFF key on the keypad so that the blower stops

and the LCD displays ‘OFF’.

2. While pressing both the Down arrow and Delay keys,

press the ON/OFF key to start the blower and enter clinical

mode.

3. Press the Next Item key until Enable Menu is displayed,

then press the Down Arrow key to enter the sub-menu.

4. Press the Next Item key until the Auto-ON setting is displayed. Use the UP or DOWN arrow keys to set the value

to Enabled.

5. Press the Next Item key until the Auto-OFF setting is displayed. Use the UP or DOWN arrow keys to set the value

to Enabled.

6. Press the ON/OFF key on the keypad so that the blower

stops and OFF is displayed on the LCD.

7. Connect the 6 ft x 22 mm smooth bore tubing to the

CPAP and block the airfl ow with your hand or a plug.

8. Turn the blower ON by pressing the ON/OFF key on the

keypad.

9. Keep the airfl ow blocked for two minutes. Verify that the

blower continues running and no mask alerts appear.

10. Unblock the smooth bore tubing to open the unit’s airfl ow.

11. Verify that after approximately 10 seconds the LCD shows

‘Mask OFF’. If the mask alert did not appear, go to step 14.

12. After another 20 seconds the blower should turn OFF via

the Auto-OFF feature. Wait approximately two minutes

after the blower turns OFF. Verify that the blower does not

turn back ON without breathing present.

13. Tap the palm of your hand on and off the end of the tubing to simulate breathing and verify that the blower turns

ON via the Auto-ON feature.

14. If the Auto-OFF or Auto-ON features do not work correctly,

perform a full calibration using the Manual Calibration

Procedure.

D. Backlight Test for LCD and Keypad

No additional equipment required.

1. Apply AC power to the unit. If the blower is running, press

the ON/OFF key on the keypad so that the blower stops

and the LCD displays OFF.

2. Press the ON/OFF key and verify that the LCD and keypad

backlights are lit.

3. Wait one minute and verify that the LCD and keypad backlights reduce intensity.

4. Press any keypad key, except ON/OFF, and verify that the

LCD and keypad backlights return to full intensity.

5. If the LCD or keypad backlights did not function correctly

during this test, replace the LCD, keypad and/or PC control

board.

Page 12

12

LT-2026

EN

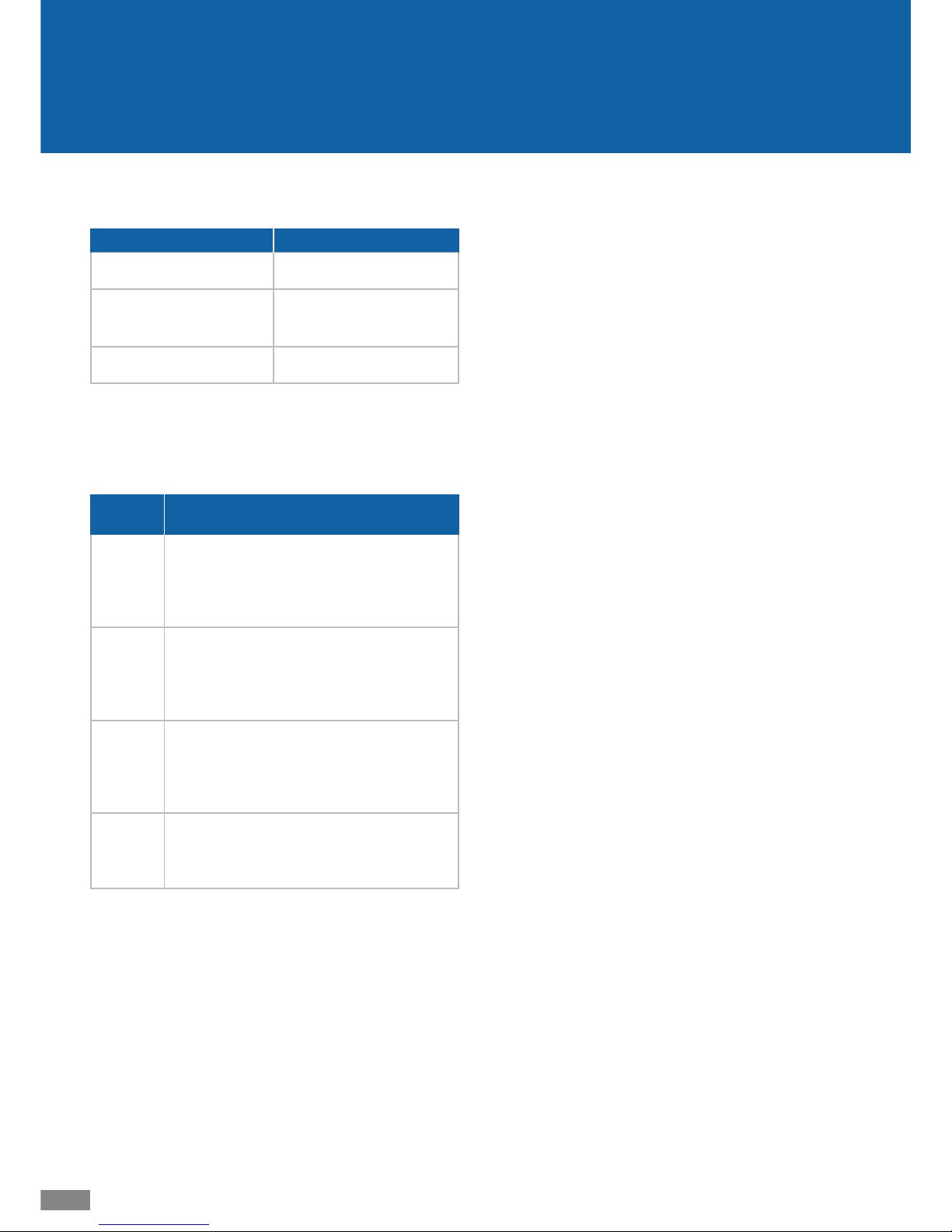

6. Alerts and Device Faults

A. Alerts Visible to Patients

Alert Description

Delay running

XX minutes left

Comfort Delay is active

Mask off. Please check

mask fi t.

High airfl ow during use

(Poor mask fi t or mask

removed)

Device Fault E0X. Call

provider.

Device error (See next table.)

B. Device Faults Visible to Patients

Only device faults classifi ed as critical are visible to the patient

on the LCD display.

These faults can be corrected by a service technician.

Device

Fault

Description

E01

Read Setting Error. Stored prescription settings are corrupted. Unit is in fail-safe state

(blower off) when this error displays. See

Troubleshooting and Service Instructions to

correct fault, or return unit for repair.

E03

Motor Error. Unit attempts to drive the motor, but the blower is not spinning (zero motor

speed). See Troubleshooting and Service

Instructions to correct fault, or return unit for

repair.

E04

Locked Rotor Error. Average motor speed is

low, while the motor current is high, for several

seconds. See Troubleshooting and Service

Instructions to correct fault, or return unit for

repair.

E07

Motor Fault Error. The motor control chip fault

output goes active low for a fi xed period of

time. See Troubleshooting and Service Instructions to correct fault, or return unit for repair.

C. Reading and Clearing the Last Device

Fault Code

NOTE– The last device fault code is stored in EEPROM to assist

in fi eld service of the unit.

Additional equipment: IBM or Compatible PC with a free serial

port, PAP to PC cable (DV54/DV53D-615), a terminal program

(Microsoft Windows HyperTerminal or equivalent).

1. Connect the DV54/DV53 PAP to the PC serial port with

PAP to PC cable.

2. Apply AC power to the unit. If the blower is running, press

the ON/OFF key on the keypad so that the blower stops

and the LCD displays ‘OFF’.

3. Use a terminal program (such as Windows HyperTerminal,

or equivalent) with COM settings 9600 baud, no parity, 8

data bits, 1 stop bit, and Flow Control set to none.

4. When connection is established with the PAP, the terminal

program will show: ‘RI;’ every 0.5 seconds. This display

indicates that the PAP is waiting for a handshake.

5. Type ‘ri’ (all commands are case sensitive) and press Enter.

The PAP should respond with the fi rmware version in the

form “V0.XX mm/dd/yyyy.” Repeat this step if necessary

to complete the handshake.

6. Request the last alert code and date by typing ‘El’ and

pressing Enter. The return value will be in the form ‘Exx

dd/mm/yyyy’. Exx is the alert code and dd/mm/yyyy is

the date the error occurred.

7. Clear the last alert code by typing ‘Ec’ and pressing Enter.

The PAP will respond with ‘OK’.

Page 13

LT-2026

13

EN

A. Manual Calibration

DeVilbiss recommends calibrating the DV54/DV53 PAP if

replacing the PC control board or when testing or troubleshooting indicate calibration is required. The manual

calibration procedure accesses a terminal program via the

unit’s communication port to calibrate the internal pressure

sensor and the motor current circuitry. Progress and confi rmation messages display on the terminal screen throughout

the procedure. If a failure occurs during calibration, the error

displays as well. See Calibration Errors below.

Additional equipment: IBM or Compatible PC with a free serial

port, PAP to PC cable (DV54/DV53D-615), a terminal program

(Microsoft Windows HyperTerminal or equivalent) and a

calibrated pressure gauge (0 to 30 cmH

2

O).

Please read all steps before beginning this process.

NOTE– Details on the Tc serial commands used in this proce-

dure are listed in Section D.

1. Use the PAP to PC cable to connect the DV54/DV53 PAP to

a PC serial port and apply AC power to the PAP.

2. Use a terminal program (such as Windows HyperTerminal,

or equivalent) with COM settings 9600 baud, no parity, 8

data bits, 1 stop bit, Flow Control set to none.

3. When connection is established with the PAP, the terminal

program will show: ‘RI;’ every 0.5 seconds. This display

indicates that the PAP is waiting for a handshake.

4. Type ‘ri’ (all DV54/DV53 commands are case sensitive)

and press ENTER. The PAP will respond with the fi rmware

version in the form ‘V0.XX dd/mm/yyyy’. Repeat this

step if necessary to complete the handshake.

5. Start the calibration process by typing ‘Tc= s’ and pressing

ENTER. The PAP will respond with

‘Calibration Started’. If the unit responds with ‘WF’,

resend the ‘Tc=s’ command.

6. The PAP will begin sending messages and prompting for

responses to complete the calibration. NOTE: If a calibration failure is encountered at any stage during the procedure, the PAP will respond with ‘Cal failed: EXX’,

where XX is a two digit error code.

a. PAP sends ‘Waiting for blower to stop spin-

ning’.

b. PAP sends ‘Cal press offset’ when spinning is

stopped.

During this stage of the procedure the PAP stops the

blower and saves the pressure sensor and motor current

offsets. After a short delay, the PAP increases the pressure

to approximately 20 cmH

2

O.

c. PAP sends ‘Set pressure to 20 cmH2O using

Tw+, Tw-, or Tw=’ ‘Send Tc=y when ready’

d. Connect the pressure gauge to the PAP outlet (the

7. Calibration

outlet should be in a deadhead or zero fl ow condition)

and, using the computer keyboard (‘Tw+’ followed by

ENTER increases the pressure and ‘Tw-’ followed by

ENTER decreases the pressure), adjust the PAP pressure

to 20 cmH2O (± 0.1 cmH2O), then type ‘Tc=y’ followed

by ENTER.

e. PAP sends ‘Reading and saving pressure hi

cal’ after confi rming that the pressure is correct.

During this stage of the procedure, the PAP calibrates

the pressure sensor by reading and saving the high

pressure calibration value.

NOTE– As an alternative to steps d and e, the current PAP

pressure gauge reading can be sent to the PAP from the

terminal. Perform the following steps for this option:

Use the ‘Tw+’, ‘ Tw-’, or ‘Tw=X’ (where X is a number

between 0 and 1023 to adjust the pressure to a value

between 15 and 30 cmH2O.

If the pressure is already within this range no adjustment

is needed.

NOTE: A more accurate calibration will be obtained, if the

value is close to 20 cmH2O.

7. Send the pressure to the PAP in the format ‘Tc=yxxxxx’,

where xxxxx is the gauge pressure in cmH2O multiplied

by 1000 (Example: 20 cmH2O is sent as ‘Tc=y20000’. )

8. After a short delay the PAP will respond with ‘cal suc-

cessful’. Calibration is now complete. Please check the

PAP pressure settings for accuracy.

Page 14

14

LT-2026

EN

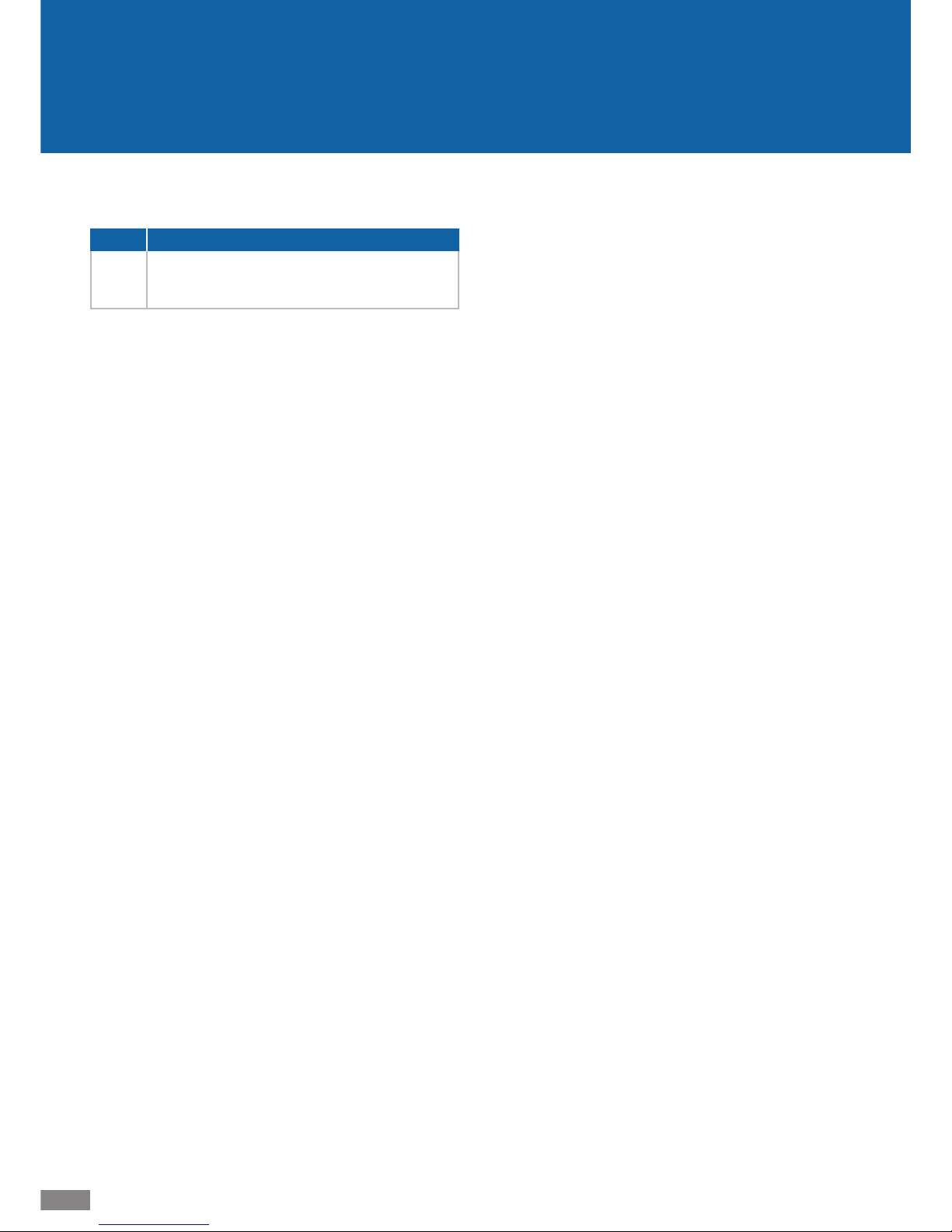

B. Calibration Errors

Code Description

E95

Calibrate Motor Stop Error. The blower did

not stop during device calibration. This error only

occurs during the calibration procedure.

C. Auto-Calibration

The DV54/DV53 PAP automatically adjusts calibration to

maintain accuracy over time and under varying operating

conditions. Each time the blower is turned OFF, the PC control

board reads and saves the offset voltages from the pressure

transducer. The PAP uses these voltages to maintain calibration accuracy as the unit is used over time.

D. Details on Tc Serial Command

Tc serial commands are used in the manual calibration procedure listed in Section A. The ‘Tc’ command on the terminal

program reads the unit’s current calibration values, starts

the calibration procedure, and handles user feedback during the calibration process. Refer to the manual calibration

procedure for details on the calibration process.

• Sending ‘Tc=s’ to the PAP starts the calibration process.

• Sending ‘Tc’ without a modifi er requests the current

calibration values. A comma-separated list of all cal values

is returned.

Comma-separated response to ‘Tc’ with no modifi er:

llll,hhhh,mmmm<cr>

o llll is the pressure low cal (sensor offset). Convert to

voltage by dividing by 1024 and multiplying by 5.

o hhhh is the pressure high cal (sensor output at 20

cmH2O). Convert to VDC by dividing by 1024 and multiplying by 5.

o mmmm is the motor current calibration (adc offset)

• Feedback is provided to the calibration task by sending

‘Tc= y’ when prompted.

Page 15

LT-2026

15

EN

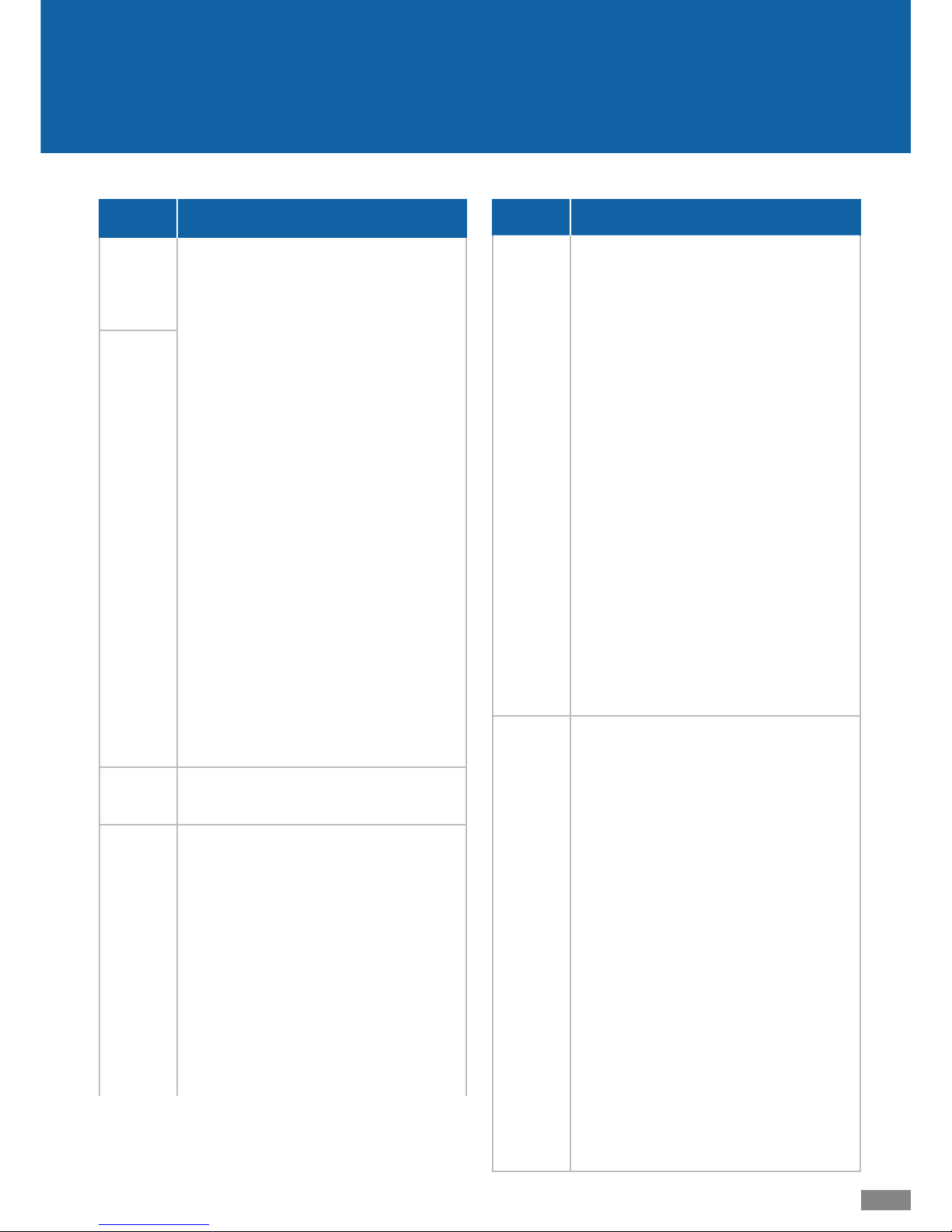

Symptom

Action (for symptoms listed at left, follow the

steps listed below)

Blower

does not

start when

powered

up

1. Remove the cover. See Service Instructions.

2. Search for disconnected wire harnesses

and reconnect, if needed.

3. Determine if fuses are open.

Without AC power to the unit, measure

the resistance across the F1 fuse with an

ohmmeter. If 0.0 to 0.5 ohms of resistance

are not present across the fuse, the fuse is

open and the power supply board should

be replaced. See Service Instructions.

Without AC power to the unit, measure

the resistances across the F2 and F3 fuses

with an ohmmeter. If 0.0 to 0.5 ohms of

resistance are not present across either

fuse, the fuse is open and the PC control

board should be replaced. See Service

Instruc tions.

4. If all fuses are closed, install a blower

known to operate properly, see Service

Instructions, and power up the unit.

If the new blower operates properly,

replace the old blower.

If the new blower does not operate prop-

erly, replace the control board. See Service

Instruc tions.

5. Replace the cover. See Service Instructions.

E03, E04,

or E07

errors

display

OR display

is blank

E01

error code

displays

Replace the control board

Blower is

loud

1. Remove the cover and control board. See

Service Instructions.

2. Inspect the assembly of the foam, blower,

and silicone isolator. See Blower Replacement instructions for correct placement.

3. Inspect the blower for visible space between the blower halves and press halves

back together, if needed.

4. If the assembly is not correct, reassemble

the components.

5. If assembly is correct, replace the blower.

See Service Instructions.

6. Replace the control board and cover. See

Service Instructions.

8. Troubleshooting

Symptom

Action (for symptoms listed at left, follow the

steps listed below)

Pressure

out of

tolerance

(Pressure ±

1.0 cmH

2

O

of setting)

1. Remove the cover. See Service Instructions.

2. Search for disconnected, occluded, or

kinked tubing on the pressure sensor or

chassis. Correct any issues.

3. Search for damage to any foam pieces

and/or tubing and replace the component, if damaged.

4. Remove the control board. See Service

Instructions.

5. Search for signs of water damage to the

blower assembly, pressure sensor and

replace the component, if damaged.

6. Inspect the blower. If a space is visible

between the top and bottom sections,

press the halves together to eliminate the

space.

7. Repeat the pressure test.

8. If the pressure remains out of tolerance,

re-calibrate the unit. See Service Instructions.

9. If the pressure remains out of tolerance,

replace the control board. See Service

Instruc tions.

10. Replace cover. See Service Instructions.

Calibration

failure–

Error code

E95

Display on

terminal

program

during

calibration.

1. Remove the cover. See Service Instructions.

2. Search for damage, and/or loose connections, on the air intake fi lter, intake

foam components, and all internal tubing

and replace or reconnect components, if

needed. Search for disconnected, occluded, or kinked tubing on the pressure sensor and chassis and reconnect or replace

tubing, if needed.

3. Remove the control board. See Service

Instruc tions.

4. Search for signs of water damage to the

blower assembly, pressure sensor and

replace, if damaged.

5. Inspect the blower. If a space is visible

between the top and bottom sections,

press the halves to eliminate the space.

6. Repeat Manual Calibration Procedure.

7. If the error codes are not resolved, replace

the control board. See Service Instructions.

8. Replace the cover. See Service Instructions.

Page 16

16

LT-2026

EN

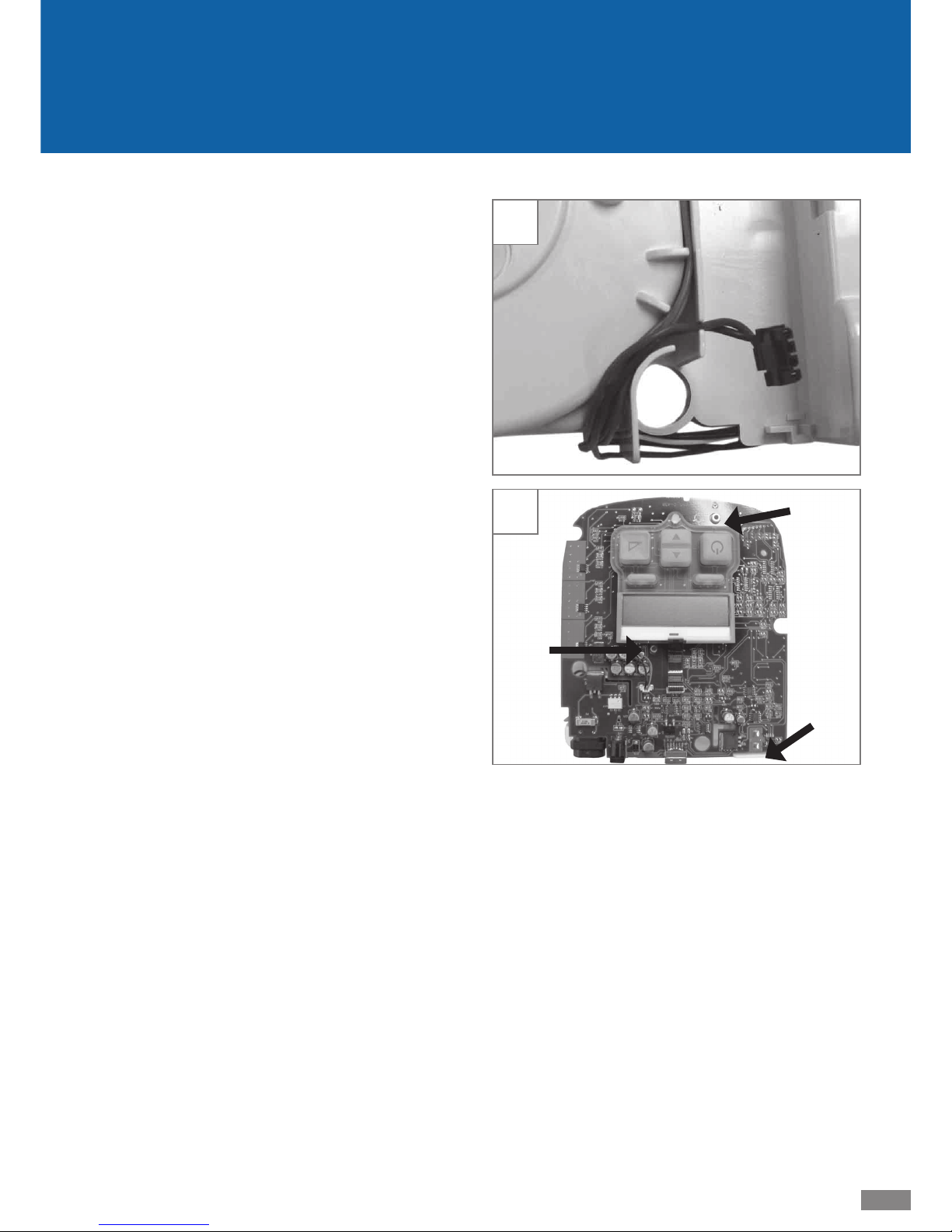

C. Control PC Board Removal

CAUTION– Failure to wear anti-static equipment during ser-

vice may damage

this device.

1. Remove the cover. See instructions above.

2. Wearing an anti-static device, lift the cover off the chassis

and place it, with the control board facing up and the

blower facing down, onto a clean fl at surface.

3. Disconnect the two pieces of tubing from the outlet port

side of the chassis.

4. Disconnect accessible wire harnesses: one behind and one

to the left of the tubing in step 3, one at the right corner

under the keypad, and one on the outside of the power

supply board.

5. Remove one T-15 screw, located near the middle of the

board beside LCD screen. Lift the board off the chassis

slowly and disconnect any remaining wire harnesses from

the control board.

6. Place control board keypad facing down onto a clean, fl at,

static-free surface, if returning to the unit.

NOTE– After performing any service on the DV54/DV53 PAP,

please test the unit to ensure proper operation and calibrate, if necessary.

A. Cover Removal

CAUTION– Failure to wear anti-static equipment during ser-

vice may damage

this device.

1. If using a DV5HH, remove the heated humidifi er and unplug the tubing/humidifi er air supply support plug from

the back of the cover and re-plug it in the outlet on the

bottom cover.

2. Position the PAP on a clean, fl at surface with the keypad

facing down.

3. Remove four T-20 screws from the bottom cover.

4. Lift the bottom cover straight up off the top cover.

NOTE– Attempting to reorient the PAP in order to lift the

top cover, instead of the bottom cover, may damage this

device.

5. Wearing an anti-static device, turn the unit over and lift

the top cover off the chassis.

B. Cover Replacement

CAUTION– Failure to wear anti-static equipment during ser-

vice may damage

this device.

1. Wearing an anti-static device, search for and connect all

loose wire harnesses.

2. Place the top cover onto the chassis, with the keypad

facing the cover and fi tting the control board around the

screw posts in the cover.

3. Connect all tubing, carefully creating the correct loops and

eliminating any kinking. (Fig. 1)

4. With the 1/8 inch inside bottom cover foam oriented

correctly and lying fl at, place the bottom cover over the

chassis and onto the top cover, fi tting the screw posts into

proper alignment with the chassis and moving any protruding wire harnesses and tubing away from the edges of

the cover.

5. Replace four T-20 screws.

9. Service Instructions

1

Page 17

LT-2026

17

EN

D. Control PC Board Replacement

CAUTION– Failure to wear anti-static equipment during ser-

vice may damage

this device.

1. See instructions above to remove the cover and the control PC board.

2. Wearing an anti-static device, verify that the silicone rattails holding the keypad and LCD display onto the control

board are pulled through the appropriate holes in the

board. See Keypad & LCD Display instructions.

3. Place the chassis on a clean fl at surface with the blower

facing down. Orient the replacement board so that the

keypad is over the rounded end of the chassis.

4. Tilt the board and connect the two wire harnesses near

the power supply board and insert the brown and blue

wires into the notch on the chassis. Tilt the board and

connect the two wire harnesses near the outlet port.

Connect the wire harness near the right corner of the

keypad. (Fig. 2)

5. Position the board (Fig. 3) so that: the hole on the board

(A), located below the ON/OFF key, is over the peg on the

chassis; the small hole (B), located near the LCD screen, is

over the screw hole on the chassis; and the cut-out (C) on

the left rear corner fi ts around the protrusion above the

air outlet port on the chassis. Move any stray tubing from

between the board and the chassis, verify that all wire harnesses are properly routed, and replace the T-15 screw on

the board.

6. Replace the cover. See instructions above.

7. Connect the CPAP to a PC serial port with cable DV54/

DV53D-615 and turn the CPAP on.

8. Use a terminal program (such as Windows HyperTerminal,

or equivalent) with COM settings 9600 baud, no parity, 8

data bits, 1 stop bit, Flow Control set to none.

9. When connection is established with the CPAP, the

terminal program will show: “RI;” every 1/2 seconds. This

display indicates that the CPAP is waiting for a handshake.

10. Type ‘ri’ and press ENTER. The CPAP should respond with

the fi rmware version in the form “V0.XX dd/mm/yyyy.”

Please note that all commands are case sensitive. Repeat

this step if necessary to complete the handshake.

11. Type ‘Mn<cr>’. The CPAP will report the model number

saved in memory, it should be “000000” if the PC board is

new.

12. Read the model number from the CPAP label on the bottom of the unit (EX: DV54SE).

13. Type ‘Mn=nnnnnn<cr>’ where nnnnnn is the 6 digit

model number read in the previous step (use a space for

the last digit if necessary to make the string 6 digits). The

CPAP should return the new six-digit model number.

14. Type ‘Sn<cr>’. The CPAP will report the serial number

2

3

A

B

C

saved in memory, it should be “00000000” if the PC board

is new.

15. Read the serial number from the CPAP label on the bottom

of the unit.

16. Type ‘Sn=nnnnnnnn<cr>’ where nnnnnnnn is the 8 digit

serial number read in the previous step. The CPAP should

return the new eight-digit serial number.

Page 18

18

LT-2026

EN

17. Read the Hour Meter (“Uh<cr>”)– a new PC board should

have 00000 hours. It is recommended that the original

hour meter value be restored if the original blower is used.

Set the hour meter by sending ‘Uh=nnnn<cr>’ where

nnnn is the hour meter reading x 10 (Ex: 100.5 hours

would be set by typing ‘Uh=1005<cr>’).

18. Read the Compliance Meter (“Up<cr>”)– a new PC board

should have 00000 hours. Clear the Compliance meter if

it is not zero by typing ‘Up=c<cr>’. The CPAP will return

000000.0 hours.

19. Check the fi rmware and hardware version information.

Read and record the following:

• BIOS rev “VB<cr>”

• Firmware rev “VF<cr>”

Check the present version of fi rmware to make sure the

board is up to date. Install new fi rmware if the board has

an old version.

20. Check for last saved error, type ‘El<cr>’. The CPAP will

respond with “Exx dd/mm/yyyy” where xx is the last

saved error code and dd/mm/yyyy is the date that the

error was detected. Clear the last error by typing ‘Ec<cr>’,

the CPAP will return “OK.” Verify that the error code is “00”

by typing ‘El<cr>’.

21. Set all device settings to their default values by typing

‘TD<cr>’. The CPAP should return “OK.”

22. Recalibrate the unit.

E. Power Supply Board Removal

CAUTION– Failure to wear anti-static equipment during ser-

vice may damage

this device.

1. See instructions above to remove the cover and the control PC board.

2. Wearing an anti-static device and with the power supply

board facing you, apply thumb pressure to top left corner

of the board while pulling the top right corner up and out

of the mount clip at its bottom.

3. Pulling the top left corner out of its mount clip, lift the

board off the chassis.

4. If returning the power supply board to the unit, place the

board onto a clean, fl at, static-free surface with its large

components facing up OR if discarding the power supply

board, remove the two wire harnesses for use with the

replacement board or purchase a new wire harness kit.

F. Power Supply Board Replacement

CAUTION– Failure to wear anti-static equipment during ser-

vice may damage

this device.

1. See instructions above to remove the cover, the control PC

board and the power supply board.

2. Wearing an anti-static device, connect the wire harnesses

from the old power supply board to the new power supply

board or use a new wire harness kit.

3. Position the chassis so that the blower faces down and the

inlet and outlet ports face you. Position the power supply

board so that the components are facing away from you

with the large brown component in the bottom left corner and the small blue component in the top right corner.

4. Place the board into the mount clips at the bottom of the

power supply board cavity and press down fi rmly on the

top corners until the board is fully mounted.

5. See instructions above to replace the control PC board and

the cover.

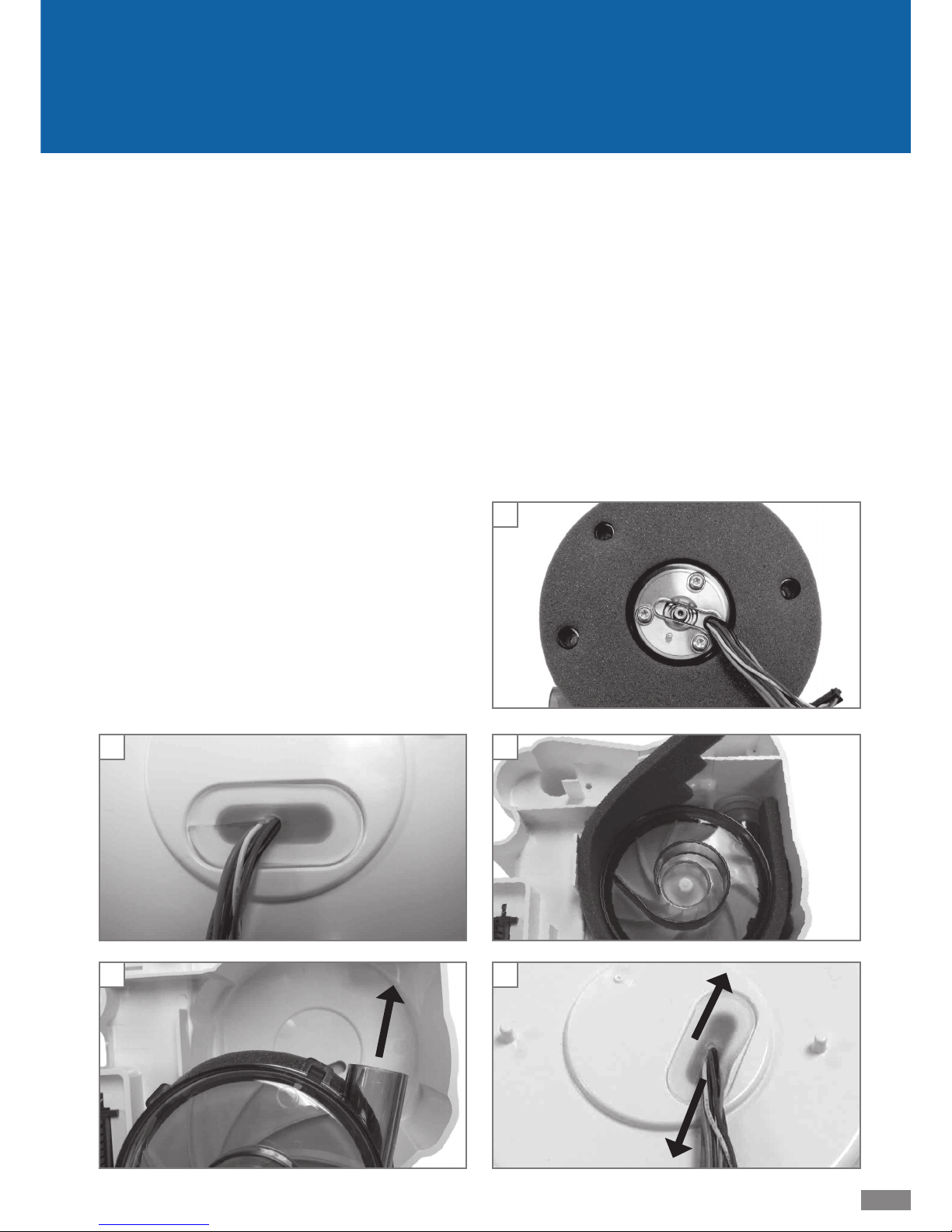

G. Blower Removal

CAUTION– Failure to wear anti-static equipment during ser-

vice may damage

this device.

1. See instructions above to remove the cover and control PC

board

2. Carefully remove the silicone grommet holding the blower

wire harness. (Fig. 4)

3. Holding the wire harness in your hand, turn the chassis

over so that the blower is facing up.

4. Remove the foam covering the blower and the foam

around the blower.

5. Reach into the blower cavity and push the silicone isolator off

the blower outlet. (Fig. 5)

6. Slowly lift blower out of the chassis and carefully pull the

wire harness through the hole in the chassis. If not returning blower to unit, remove foam from bottom of blower

and save for new blower.

Page 19

LT-2026

19

EN

6. Insert the top blower foam so that it conforms to the

edges of the blower cavity portion of the chassis.

7. Turn the chassis over so that the blower is facing down.

Gently pull any slack from the wire harness. Insert the

silicone grommet into the hole in the chassis so that the

slit in the grommet is toward the power supply board

location, all the wires are in the center hole of the grommet and the grommet fl ange is fully sealed. Route the wire

harness along the top of the chassis and down the front of

the blower cavity portion of the chassis. (Fig. 8)

8. See instructions above to replace the control PC board and

the cover.

H. Blower Replacement

CAUTION– Failure to wear anti-static equipment during ser-

vice may damage this device.

1. See instructions above to remove the cover, control PC

board and blower.

2. Insert the blower mount foam on the blower base so that

the holes in the foam align with the protrusions on the

blower and the blower wire harness is through the center

hole in the foam. (Fig. 6)

3. Turn the blower over so that the motor is facing down.

Guide the wire harness through the hole in the bottom of

the blower cavity portion of the chassis.

4. Lower the blower with its outlet port pointing at the

silicone isolator. Position the blower’s outlet port into the

top edge of the silicone isolator then tilt the outlet port

into the isolator opening without folding the isolator. Push

the outlet port into the isolator until the port is evenly

inserted into the isolator. See isolator image in Blower

Removal instructions.

5. Insert the blower wrap foam so that the single-notched

end is beside the blower outlet port. Wrap the remaining foam strip clockwise around the blower so that the

notched foam corresponds to the latches on the blower

body. Wrap the double-notched end around the blower

and over the outlet port. The top edge of the foam should

be almost fl ush with the blower. (Fig. 7)

4

6

7

Slit direction

harness direction

8

Page 20

20

LT-2026

EN

I. KeyPad & LCD Display Removal and

Replacement

CAUTION– Failure to wear anti-static equipment during ser-

vice may damage

this device.

1. See instructions above to remove cover and control PC

board.

2. Wearing an anti-static device, disconnect the two LCD

display wire harnesses. (Fig. 9)

NOTE– Do not touch the exposed contact area on the end of

the ribbon cable. Dirt and oils may damage it.

3. Gently roll the silicone frame away from the edges of the

LCD display screen (Fig. 10), lift the display off the keypad

and place it on a clean, fl at, anti-static surface, if returning

to the unit.

4. Lift the keypad off the board, gently pulling three silicone

rattails through the board.

NOTE– Do not touch the keypad contacts on the PC board.

Dirt and oils may damage them.

5. Replace the keypad by inserting the silicone rattails on the

replacement keypad through appropriate holes on the

control board and gently pulling the rattails through the

holes.

6. Insert the LCD display into the silicone frame on the

keypad and connect the wire harnesses to the appropriate

connectors on the board.

7. See instructions above to replace the control PC board and

the cover.

9

10

Page 21

LT-2026

21

EN

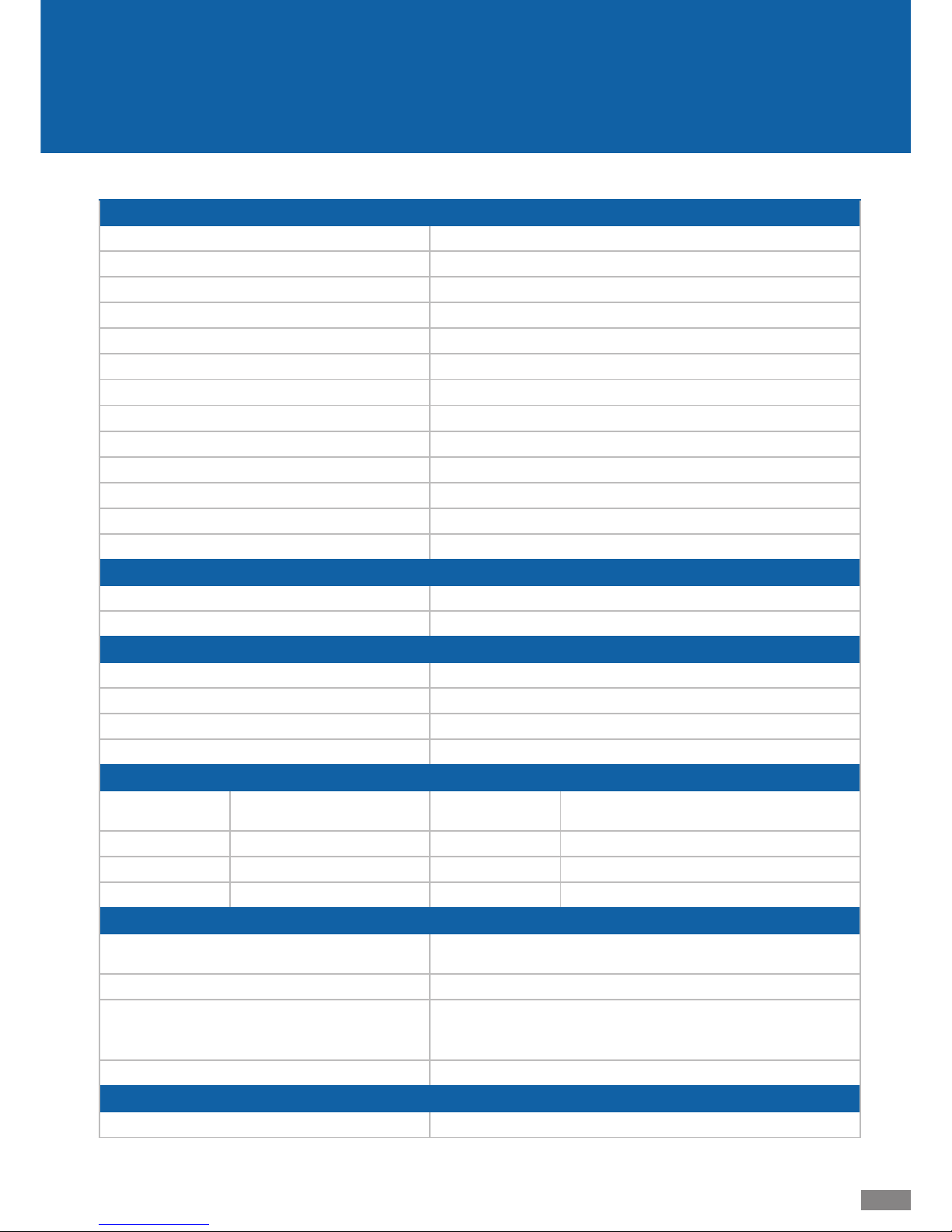

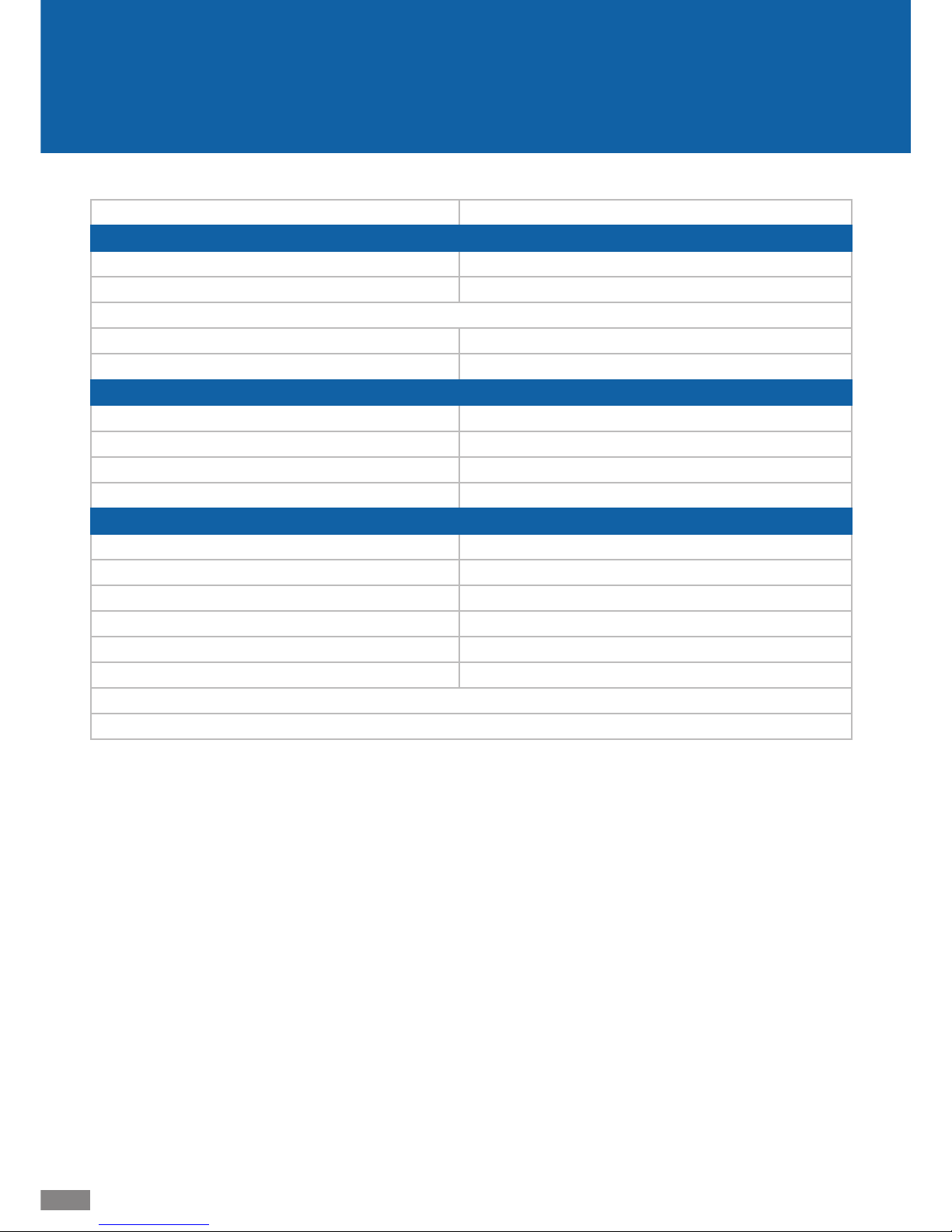

Unit Specifi cations

Size 4.2” H x 6.5” W x 6.9” D (10.7 cm x 16.5 cm x 17.5 cm)

Weight 2.7 lbs. (1.22 kg)

Electrical Requirements 100-240V~, 50/60 Hz

D.C. Operation 12 volts at 5 amps

Maximum Power Consumption 65 watts max from AC power source (PAP device only)

CPAP Pressure Range 3-20 cmH

2

O

Operating Temperature Range 41°F to 104°F (5°C to 40°C)

Operating Humidity Range 0% to 95% RH non-condensing

Operating Atmospheric Conditions Sea level to 9,000 feet

Storage & Transportation Temperature Range -40°F to 158°F (-40°C to +70°C)

Storage & Transportation Humidity Range 0% to 95% RH non-condensing

Maximum Limited Pressure 20 cmH

2

O under normal use

Sound Level 26 dBA

Filter Specifi cations

Standard Filter > 3.0 micron particles

Optional Fine Particle Filter > 0.3 micron particles

Max Flow Rates

83 L/m @ 6.5 cmH2O (1/3 max pressure)

134 L/m @ 13 cmH

2

O (2/3 max pressure)

163 L/m @ 20 cmH

2

O (max pressure)

Pressure Accuracy ± 1.0 cmH

2

O

Pressure Swings (cmH

2

O peak to peak at 500mL tidal volume, sine wave profi le)

Breaths per

minute

10 15 20

@ 6.5 cmH

2

O 0.5 0.5 0.5

@ 13 cmH

2

O 1.0 1.0 1.0

@ 20 cmH

2

O 1.0 1.0 1.0

Other Specifi cations

Equipment classifi cation with respect to protection

from electric shock

Class II

Degree of protection from electric shock Type BF Applied Part

Degree of protection against ingress of liquids IPX1

Drip Proof Equipment not suitable for use in the presence of a fl ammable anesthetic

mixture with air or with oxygen or nitrous oxide.

Mode of operation Continuous

Clinical Specifi cations for Digital Outputs

Pressure 0 to 25.5 cmH2O ± 1.0

Page 22

22

LT-2026

EN

11. General Information DV5HH

A. Safeguards

When servicing electrical products, basic safety precautions

should always be followed. Important safety information in

this manual is highlighted by the following terms.

DANGER: Urgent safety information for hazards

that will cause serious injury or death.

WARNING: Important safety information for hazards

that might cause serious injury.

CAUTION: Information for preventing damage to the

product.

NOTE: Information to which you should pay

special attention.

PLEASE READ ALL INSTRUCTIONS BEFORE

SERVICING THIS DEVICE.

DANGER!

• Electric Shock Hazard – Do not use while bathing.

• Electric Shock Hazard – Do not immerse this device into

water or any other liquid.

• Electric Shock Hazard – Do not attempt to open or remove the enclosure. There are no user-serviceable internal

components. If service is required, return the product to

your home care provider. Opening or tampering with the

product will void the warranty.

WARNING!

• Use the Heated Humidifi er system only for its intended

use as described in this manual.

• Be sure to read and understand all safety instructions

supplied with your IntelliPAP or SleepCube fl ow generator device.

• Use only accessories recommended by DeVilbiss.

• Always remove the water chamber from the humidifi er

cradle for fi lling.

• Use only tubing recommended or supplied with the fl ow

generator.

• If water has been spilled onto the cradle or it has been

submerged into water, unplug the power cord from the

power source immediately. Allow the device to completely

dry before use.

• If the device has been dropped, refer to the troubleshooting guide for instructions. Contact your homecare provider

for evaluation of the device.

• Never block the air openings of the cradle or chamber. Do

not insert any objects into any openings or tubes.

• For proper operation of the humidifi er, the device must be

placed on a fl at, level surface.

• Never place the system on a soft surface such as a bed or

couch during operation.

• This heated humidifi er is intended for single-patient

use only.

B. Travel

The DeVilbiss DV5HH humidifi er system

• Automatically accepts line voltages of 100-240 V, 50/60 Hz

• Needs power cord appropriate for area

o USA DV54/DV53D-606

o Europe, except UK DV54/

DV53D-607

o UK DV54/DV53D-608

o Australia DV54/

DV53D-609

o Set of 3 (UK, Europe, Australia) DV54/

DV53D-611

C. DC Power

The DeVilbiss DV5HH heated humidifi er system

• Will NOT operate, if the DC power is coming directly from

a 12V DC power source.

• Will operate, if the DC power coming to the PAP passes

through an inverter so that AC power is delivered to the

system.

• See DC Power information under the DV54/DV53 section

of this manual

D. Product Description

The DV5HH Standard Heated Humidifi er System is intended to

warm and add moisture to the pressurized air supplied to the

patient during the treatment of Obstructive Sleep Apnea (OSA).

The addition of heated humidifi cation to the air relieves dryness and irritation to the patient’s airway during OSA therapy.

The heated humidifi er is used in conjunction with the DV5X

series PAP devices and consists of a humidifi er chamber and

humidifi er heater.

The humidifi er chamber holds enough water for a minimum of 8 hours of operation, with the heating unit at the

maximum temperature setting at ambient conditions of

23°C and 25% R.H. with a system fl ow rate of 60 L/Min.

The chamber slides out of the unit for cleaning and fi lling,

without adjusting tubing connections. The chamber’s

halves separate for easy cleaning but, when assembled,

maintain a leak free seal to a maximum operating pressure

of 30 cmH2O.

Heat transferred from the humidifi er heater to the humidifi er chamber raises the effi ciency of the DV5HH system. The

patient controls the heater plate temperature using the up/

down arrow keypad keys on the attached PAP device to provide the appropriate level of humidifi cation depending upon

environmental conditions and individual preference.

Page 23

LT-2026

23

EN

DV5HH

The heated humidifi er connects mechanically and electrically

to a DV5X series PAP between the air stream going from the

PAP to the patient. The keypad on the PAP controls the heated

humidifi er’s output and ON/OFF functions. Before operation,

the humidifi er chamber is fi lled with water to a predefi ned

and visible water-fi ll level with the patient tubing and patient

interface attached to the outlet port on the heated humidifi er system.

During operation, the DV5X series PAP device routes AC

electrical power (100 – 240 VAC 50/60 Hz) to the heated

humidifi er’s drive circuitry, which is contained within the PAP

device. The drive circuitry directs the AC power to the heating

element on the heated humidifi er’s heater plate. A thermistor

on the heater plate provides continuous feedback back to the

control circuitry so that the temperature of the heater plate is

consistent with the setting selected via the PAP’s keypad. The

PAP’s internal switch-mode power supply routes DC electrical

power to the heater’s low-voltage circuitry.

The heated humidifi er’s heater plate transmits heat to the

chamber, and then to the water, through a heat transfer plate

located on the bottom of the humidifi er chamber. As the water is heated, its evaporation effi ciency increases. Air fl owing

into the humidifi er chamber from the PAP device is humidifi ed by the evaporation and is then transmitted to the patient

through the patient tubing and interface.

Page 24

24

LT-2026

EN

A. Cleaning and Disinfection

See the DV5HH Instruction Guide (A-DV5HH) for information

on cleaning the humidifi er chamber and heater base.

The DV5HH Standard Heated Humidifi er is single patient use

only and therefore does not require disinfection.

B. Maintenance

The DV5HH Standard Heated Humidifi er System does not

require regular maintenance.

C. Testing

Since the DV5HH device is powered and controlled by the PAP,

it is important to determine which unit is at fault when there

is an issue with humidity/heat. Use the following procedures

to determine whether the DV5HH device or the PAP device is

faulty.

1. Connect the DV5HH device to a known good PAP device.

2. After turning the system on,

• if the LCD display does NOT show “Heat:XXX” on the

bottom line, proceed to the troubleshooting section.

• if the DV5HH device does NOT produce heat, proceed

to the troubleshooting section.

3. Connect the PAP to a known good DV5HH device, if the

LCD display does NOT show “Heat:XXX” on the bottom

line, proceed to the troubleshooting section.

If you detect excessive air or water leaks in the DV5HH system, proceed to the troubleshooting section.

13. Maintenance and Testing DV5HH

Page 25

LT-2026

25

EN

14. Troubleshooting

HEATER

Symptom Action

The PAP does not recognize the

heater. (With the PAP blower

ON, the PAP display does not

indicate Heat:xxx on the bottom line.)

Connect the heater to a known good PAP device, if one is available. If PAP display still does

not recognize the heater, replace the heater.

If a known good PAP device is not available, remove the PAP from the heater and check

the thermistor for resistance. The thermistor pins are located in the connector and are the

ones closest to each other. See image below. The resistance should be 10 K ohms +/- 1%

at 25° C (77°F). If open or shorted, replace the heater. See Service instructions. Alternatively: Replace the heater plate assembly, DV5H-607. If the resistance is in the correct range,

the issue is in the PAP device. Troubleshoot as indicated below.

Heater plate does not respond

to the PAP heat setting.

(With the PAP blower ON and

the heat setting at 1 or above,

the heater plate does not get

warm.)

Connect the heater to a known good PAP device, if one is available. If the heater still does

not respond to the heat setting, replace the heater.

If a known good PAP device is not available, connect the PAP, using the serial interface

cable DV54/DV53D-615, to a PC using a terminal program (such as Windows HyperTerminal, or equivalent) with Com settings 9600 baud, no parity, 8 data stop bits, 1 stop

bit, Flow Control set to none. Turn the PAP blower ON and increase the heat setting to

10 using the PAP keypad (UP key). In the terminal program, connect to the PAP device by

typing ‘ri’ followed by ENTER; then type ‘Ht’ followed by ENTER. Repeat the ‘Ht’ – ENTER

sequence every 2-3 minutes and verify that the returned value increases. If the value increases, the system is operating normally. If the value does not increase, remove the PAP

device from heater and measure the heater resistance. The heater terminals are the ones

diagonal to each other on the connector.

heater terminals

t

hermistor terminals

The resistance should be between 180 to 220 ohms; if not replace the heater. See Service

instructions. Alternatively: Replace the heater plate assembly, DV5H-607. If the resistance

is in the correct range, the issue is in the PAP device. Troubleshoot as indicated below.

PAP

Symptom Action

The PAP does not recognize a

known good DV5HH heater.

(With the PAP blower ON, the

PAP display does not indicate

Heat:xxx on the bottom line.)

Check the wire harness on the PAP / heater connector; repair or replace, if needed. If

the wire harness and connections are correct, replace the control PC board. See Service

Instructions.

Heater plate on a known good

DV5HH heater does not respond

to the PAP heat setting.

(With the PAP blower ON and

the heat setting at 1 or above,

the heater plate does not get

warm.)

Check the wire harness on the PAP / heater connector; repair or replace, if needed. If

the wire harness and connections are correct, replace the control PC board. See Service

Instructions.

MANIFOLD and O-RING

Symptom Action

Excessive air leak Remove the humidifi er chamber. Inspect the manifold in the heater base and replace, if

torn or worn. Inspect the O-Ring in the humidifi er chamber and replace, if worn or missing.

Water leak from the humidifi er

chamber.

Remove the humidifi er chamber. Inspect the chamber for cracks in the plastic or water leaking from the heat transfer plate. If cracks or transfer plate leaks are found, replace the water

chamber. Inspect the O-Ring in the humidifi er chamber and replace, if worn or missing.

DV5HH

Page 26

26

LT-2026

EN

A. Removing the DV5HH base cover

1. Remove the humidifi er chamber from the DV5HH base.

2. Push the release button (Fig. 1) on the DV5HH base and

lift the PAP device off the heater base and set aside in a

safe place.

3. Remove two T-10 screws from the top cover of the heater

base.

4. Turn the base over so that the bottom of the unit faces up

and remove four T-10 screws.

5. Lift the bottom cover off the unit

6. Remove the fi nal T-10 screw beside the wire harness clip.

(Fig. 2)

7. Hold the heater plate onto the base and turn the unit over.

8. Gently pull the top of the unit off the chassis and carefully

tilt the top without pulling the wire harness out of the

connector.

9. Carefully release the wire harness from the harness clip.

Reposition the heater plate so that the orange side is facing the harness clip and carefully push the heater plate

through the opening. (Fig. 3)

B. Replacing the DV5HH base cover

1. Position the heater plate so that the orange side is fac-

ing the harness clip and carefully push the heater plate

through the opening in the base. See image above.

2. Hold the heater plate onto the base and carefully insert

the harness wires, two at a time, into the harness clip. See

image above.

3. Install the top of the base onto the heater chassis with the

wire harness and manifold clear of all edges and the latch

working smooth and free. Fasten top to chassis with two

T-10 screws.

4. Holding the heater plate onto the base, turn the unit over

and position heater plate into the shallow opening with

the metal side facing down and the orange plastic side

facing up. Move the harness wires between wire guides.

(Fig. 4)

5. Replace the T-10 screw beside the wire harness clip.

6. Verify that the silicone spacer is in place on the inside of

the bottom cover. (Fig. 5)

7. Install the cover onto the bottom of the unit matching the

edges. Replace the 4 remaining T-10 screws in the bottom

cover.

8. With the air supply support plug attached to the back of

the PAP device, place the front of the PAP onto the front

of the heater base against the brackets and push the back

of the PAP down so that the latch closes and the electrical

connector is tight.

9. Slide the humidifi er chamber into the heater base until it

clicks into place.

DV5HH

1

harness

clip

T-10

screw

2

3

4

Page 27

LT-2026

27

EN

DV5HH

spring post

latch control

screw post

latch retainer

short leg

8

6

rattails

7

5

C. Removing and replacing silicone

manifold

1. Remove the cover as described above.

2. Squeeze the inlet port on the silicone manifold and push

the port down into the hole in the top cover, gently releasing the manifold from all other connections. Discard the

manifold or set aside in a safe place, if returning to the

unit. (Fig. 6)

3. To replace, pinch the inlet port coupler on the replacement

silicone manifold and insert it, from the inside of the cover,

through the cover hole so that the coupler collar is fully

and evenly positioned on the outside of the cover.

4. Press the manifold body into place and insert a fi nger into

each of the rectangular openings, pressing the manifold’s

rattails through the slots in the top cover until they are

fully seated. (Fig. 7)

5. Replace the cover as described above.

D. Removing and replacing the latch

1. Remove the cover and silicone manifold as described

above.

2. Raise the latch control away from the top cover so that it

lifts the attached spring. Remove the spring from the latch

and discard or set aside in a safe place, if returning it to the

unit. (Fig. 8)

3. Still holding the latch control in a raised position, push

it into the latch retainer and rotate the latch so that the

spring post faces up. Gently push the short leg of the latch

up and through the slot in the cover. Discard faulty latch.

4. Orient the replacement latch over the bottom side of the

top cover so that short leg of the latch is over the slot near

the screw post and the spring post is facing up.

5. Insert the latch into the slot by rotating the latch stem

back toward the screw post and gently applying pressure

to the short leg until it fi ts through the slot.

6. Place one end of the spring over the spring post and insert

the other end into the channel on the cover by slightly

compressing the spring. Push the latch control several

times to ensure that the system is confi gured properly.

7. Replace the silicone manifold and cover as described

above.

Page 28

28

LT-2026

EN

Humidity Output (in the operating fl ow range) ≥10 mgH2O/L air

Chamber/Cradle Dimensions

Size 2.6” H x 6.3” W x 8.4” D (6.6 cm x16.0 cm x 21.3cm)

Weight 1.75 lbs. (0.794 Kg)

Elec trical Rating:

Electrical Supply Frequency 50/60 Hz

Power Consumption 85 Watts

Voltage and Current

DV5HH 100-240VAC, 0.95 A

Heater Plate Cutout 152°C (305°F)

Power/Temperature Control Setting of 1 (minimum) to 10 (maximum)

Heater Plate Temperature approx. 29°C to approx. 65°C (84°F to 149°F)

Operating, Transport & Storage

Operating Temperature Range 41°F to 104°F (5°C to 40°C)

Operating Humidity Range 0 to 95% R.H. non-condensing

Operating Atmospheric Pressure Range 70.0 – 106.0 kPA

Transport & Storage Temperature Range -40°F to 158°F (-40°C to +70°C)

Transport & Storage Humidity Range 0 to 95% R.H. non-condensing

Transport & Storage Atmospheric Pressure Range 50.0 – 106.0 kPA

Class II Equipment; Type BF Applied Parts; Continuous Operation

IPX1, Drip-proof vertical

16. Unit Specifications DV5HH

Page 29

LT-2026

29

EN

DV54/DV53 and DV5HH

A. Ordering Non-Warranty Replacement

Parts

Order non-warranty parts and literature from your distributor

or, if you have a DeVilbiss account, from DeVilbiss Customer

Service. To expedite the process, be prepared to provide the

following information:

B. Ordering Warranty Replacement Parts

Order warranty parts from your distributor or, if you have a

DeVilbiss account, from DeVilbiss Customer Service through

the Return Material Authorization process. To expedite the

process, be prepared to provide the above information, along

with the following:

• How and where the product was being used

• A detailed description of the problem associated with

warranty replacement item

All warranty replacement orders require the return of the

defective part to DeVilbiss.

C. Returning Warranty Defective Parts

ALL DEFECTIVE PARTS, WHICH ARE STILL UNDER WARRANTY,

MUST BE RETURNED TO THE FACTORY IN SOMERSET, PA

WITHIN 30 DAYS AFTER SHIPMENT OF THE REPLACEMENT

PARTS. AN INVOICE WILL BE ISSUED IF THE DEFECTIVE PARTS

ARE NOT RECEIVED WITHIN THIS PERIOD.

D. Placing orders

Orders may be placed by calling

• Customer Service 800-338-1988

• Warranty Parts- USA 800-338-1988

• Canada 905-660-2459

• International Department 814-443-4881

Before returning parts or units to the factory, call the DeVilbiss Healthcare Customer Service Department at 800338-1988 or 814-443-4881 to obtain a return authorization

number. Include in the package a note indicating the return

authorization number along with your company name,

address, phone number, and account number. The return

authorization number should also be written on the outside

of the package.

17. Ordering and Returning Parts

• Account and ship-to numbers

• Ship-to address

• Part numbers and/or

descriptions

• Quantity required

• Unit catalog number

• Unit serial number

Page 30

30

LT-2026

EN

DV54/DV53 PAP

Air-Inlet Filter (4/pk) DV51D-602

Optional Fine Particle Filter (4/pk) DV51D-603

Air supply tubing 7351D-616

Air supply support plug DV51D-604

Disinfection kit DV51D-682

Blower assembly, balanced DV51D-672

Blower isolator and grommet-silicone DV51D-676

Foam Repair Kit DV51D-678

Tub ing Rep air Kit DV51D -6 81

Wire harness kit DV51D-675

Outlet cap (mask/leak simulator) DV51D-620

Pressure gauge with outlet cap 8000D-607

Oxygen adapter 7353D-601

Carrying case DV51D-610

IntelliPAP case repair kit-DV54/DV53 DV54D-670

SleepCube case repair kit-DV54/DV53 DV54I-670

Blower chassis DV51D-680

Keypad DV51D-671

Control PC board-DV54/DV53 DV51D-673

Power supply board-DV5X DV51D-674

LCD repair kit-DV5X DV51D-677

Heater connection cover DV51D-605

Flow control valve DV51D-621

DV5X series serial cable DV51D-615

USB to serial adapter DV51D-691

Power

AC Power cords

o USA DV51D-606

o Europe, except U.K. DV51D-607

o U.K. DV51D-608

o Australia DV51D-609

o International AC power cord set DV51D-696

DC battery clamp-on adapters DV51D-619

DC power cord DV54/

DV53D-619

DV5HH

Heated humidifi er assembly DV5HH

Humidifi er chamber DV5C

Sealing gasket for chamber DV5C-614

Silicone manifold for heater DV5H-600

Heater latch kit w/spring DV5H-601

18. Parts List

Silicone spacer on bottom cover DV5H-602

Heater bottom cover DV5H-603

Heater top cover DV5H-604

Heater chassis DV5H-605

Case screws DV5H-606

Heater assembly DV5H-607

Chamber latch spring DV5H-601

Literature

DV54/DV53 Instruction Guide

North America A-DV54/DV53

Europe / International SE-DV54/DV53

DV54/DV53 Set up Card DV54/

DV53D-125

DV54/DV53 Instructional DVD

North America LT-2012

Europe / International LT-2015

Service Manual DV54/DV53 LT-2026

Disinfection Instruction Guide A-682

Humidifi er/Heater Instruction Guide A-DV5HH

Page 31

LT-2026

31

EN

DV54/DV53

The DeVilbiss IntelliPAP™ and SleepCube™ devices are warranted to be free from defective workmanship and material

for a period of two years from date of purchase. Any defective

part(s) will be repaired or replaced at DeVilbiss’s option if the

device has not been tampered with or used improperly during

that period. Make certain that any malfunction is not due to

inadequate cleaning or failure to follow the instructions. If repair is necessary, contact your DeVilbiss provider or DeVilbiss

Customer Service Department for instructions:

U.S.A. 800-338-1988, 814-443-4881

Canada 800-263-3390

Europe 44-138-444-6688

NOTE– This warranty does not cover providing a loaner de-

vice, compensating for costs incurred in rental while said

device is under repair, or costs for labor incurred in repairing or replacing defective part(s).

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, ARE LIMITED TO THE DURATION

OF THE EXPRESS LIMITED WARRANTY AND TO THE EXTENT

PERMITTED BY LAW. ANY AND ALL IMPLIED WARRANTIES ARE

EXCLUDED. THIS IS THE EXCLUSIVE REMEDY AND LIABILITY

FOR CONSEQUENTIAL AND INCIDENTAL DAMAGES UNDER

ANY AND ALL WARRANTIES ARE EXCLUDED TO THE EXTENT

EXCLUSION IS PERMITTED BY LAW. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, OR THE LIMITATION OR EXCLUSION OF CONSEQUENTIAL OR INCIDENTAL DAMAGES, SO THE ABOVE LIMITATION

OR EXCLUSION MAY NOT APPLY TO YOU.

This warranty gives you specifi c legal rights, and you may also

have other rights which vary from state to state.

®Registered U.S. Patent and Trademark Offi ce and other

countries.

DV5HH

The DeVilbiss Heated Humidifi er System Model DV5HH is

warranted to be free from defective workmanship and materials for a period of two years from date of purchase (except

90 days on chamber). Any defective part(s) will be repaired or

replaced at DeVilbiss’s option if the unit has not been tampered with or used improperly during that period. Make certain that any malfunction is not due to inadequate cleaning or

failure to follow the instructions. This warranty does not cover

normal wear and tear on the o-ring seal. If repair is necessary,

contact your DeVilbiss provider or DeVilbiss Customer Service

Department for instructions:

U.S.A 800-338-1988 (814-443-4881)

Canada 905-660-2459

Europe 44-138-444-6688

NOTE– This warranty does not cover providing a loaner unit,

compensating for costs incurred in rental while said unit

is under repair, or costs for labor incurred in repairing or

replacing defective part(s).

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, ARE LIMITED TO THE DURATION

OF THE EXPRESS LIMITED WARRANTY AND TO THE EXTENT

PERMITTED BY LAW. ANY AND ALL IMPLIED WARRANTIES ARE

EXCLUDED. THIS IS THE EXCLUSIVE REMEDY AND LIABILITY

FOR CONSEQUENTIAL AND INCIDENTAL DAMAGES UNDER

ANY AND ALL WARRANTIES ARE EXCLUDED TO THE EXTENT

EXCLUSION IS PERMITTED BY LAW. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, OR THE LIMITATION OR EXCLUSION OF CONSEQUENTIAL OR INCIDENTAL DAMAGES, SO THE ABOVE LIMITATION

OR EXCLUSION MAY NOT APPLY TO YOU.

This warranty gives you specifi c legal rights, and you may also

have other rights which vary from state to state

19. Warranties

0044

Page 32

32

LT-2026

EN

32

LT-2026

D

Inhaltsverzeichnis – DV54/DV53

1. Allgemeine Informationen

A. Sicherheitsvorkehrungen 33

B. Erstinspektion 33

C. Transport 34

D. Gleichstromversorgung 34

E. Einstellung von Druck und Optionen 34

F. Abbildungen: DeVilbiss DV54/DV53 CPAP 34

2. Beschreibung des Normalbetriebs 35

3. Reinigung und Desinfektion 36

A. Routinemäßige Reinigungsarbeiten – Patient 36

B. Desinfektion 36

4. Technische Überprüfung und Reinigungsarbeiten 39

A. Erstinspektion 39

B. Vom Patienten durchführbare 39

routinemäßige Wartungsarbeiten

C. Wiederkehrende Geräteüberprüfung – 39

Fachhändler

5. Prüfung 40

A. Prüfung der Druckgenauigkeit 40

B. Prüfung der Flussgenauigkeit 40

C. Prüfung des Tastenfelds 40

D. Prüfung Auto-ON / Auto-OFF 41

E. Prüfung der Hintergrundbeleuchtung für 41

LCD und Tastenfeld

6. Alarmsignale und Gerätstörungen 42

A. Für den Patienten sichtbare Warnsignale 42

B. Für den Patienten sichtbare Gerätstörungen 42

C. Lesen und löschen des letzten

Störungscodes des Geräts 42

7. Kalibrierung 43

A. Manuelle Kalibrierung 43

B. Kalibrierungsfehler 44

C. Auto-Kalibrierung 44

D. Einzelheiten des seriellen Befehls “Tc” 44

8. Fehlersuche 45

9. Service-Anleitung 46

A. Abnehmen der Abdeckung 46

B. Wiederaufsetzen der Abdeckung 46

C. Entfernen der Platine 46