Page 1

SB-E2-360-J

Operation Manual

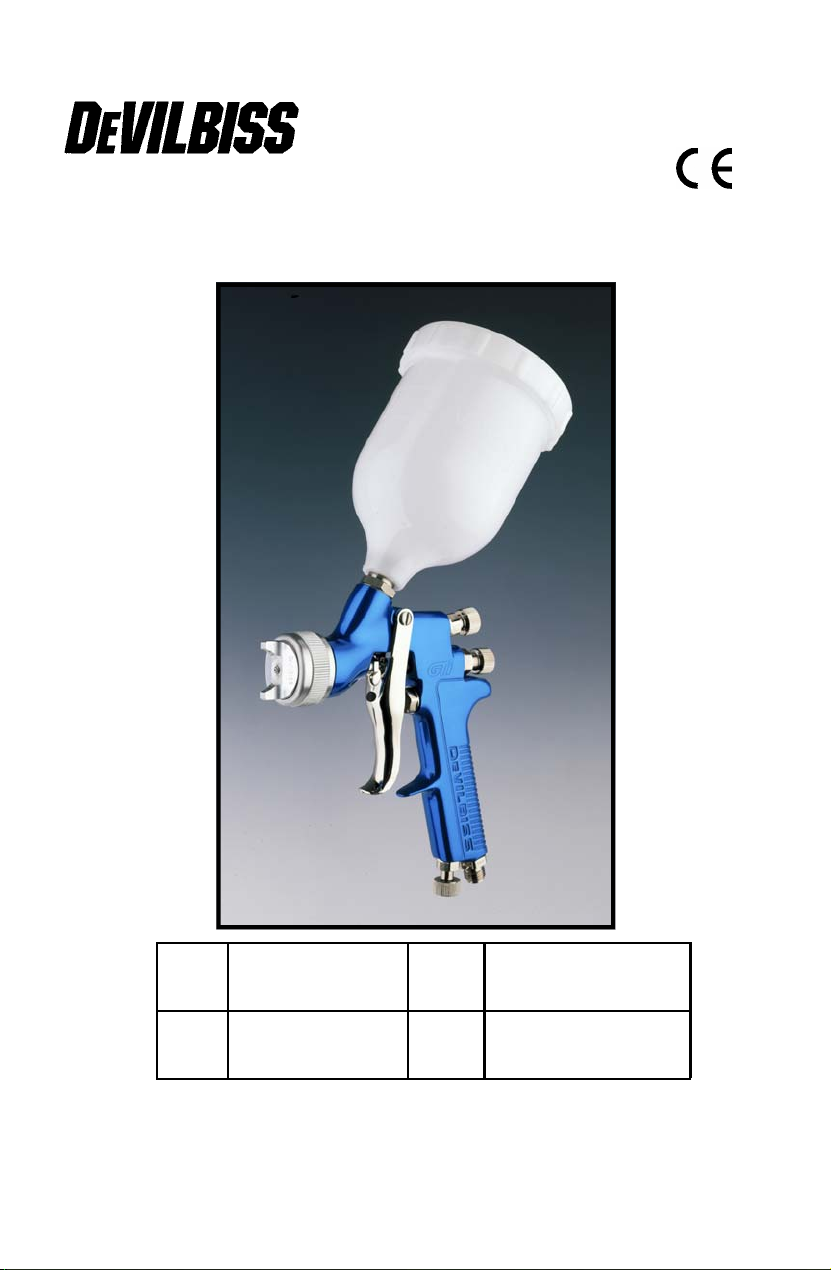

GTi – Gravity Spraygun

E

E

DK

DK

P 2 - 7

P 8 - 13

SV

SV

FIFI

1 © ITW Ltd 2000

P 14 –19

P 20 - 25

Page 2

EE

Operation Manual

GTi – Gravity Spraygun

Important

Read and follow all instructions and Safety Precautions before using this

equipment

Description

This product is suitable for use with both waterbased and solvent based

coating materials. The design uses EPA compliant atomising technology to

reduce overspray and improve coating efficiency.

Important: These guns are not designed for use with highly corrosive and/

or abrasive materials and if used with such materials it must be expected

that the need for cleaning and/or replacement of parts will be increased. If

there is any doubt regarding the suitability of a specific material contact

your local Distributor or ITW Finishing direct.

Model Part Number

Example: GTI-G110B-14

Aircap Fluid nozzle size

(14 = 1,4 mm)

Gunbody Finish

M= Multi Colour (colours may vary), B= Blue Anodised

Declaration of Conformity

We, ITW Finishing UK, Ringwood Road Bournemouth Dorset England

declare under our sole responsibility that this product is in conformity with BS

EN 292: parts 1 and 2 :1991 and BS EN 1953:1999, following the provisions

of the Machinery Directive 89/392/EEC. This product also complies with the

requirements of the EPA guidelines, PG6/34. Transfer efficiency certificates

are available on request.

B. Holt, General Manager

2 © ITW Ltd 2000

Page 3

SAFETY WARNINGS

EE

Fire and explosion

Solvents and coating materials

can be highly flammable or combustible

when sprayed. ALWAYS

coating material suppliers

instructions and COSHH sheets

before using this equipment

Users must comply with all local

and national codes of practice and

insurance company requirements

governing ventilation, fire precautions,

operation and house-keeping of working

areas

This equipment, as supplied, is

NOT

Halogenated Hydrocarbons.

Static Electricity can be generated by

fluid and/or air passing though hoses. To

prevent such a risk, earth continuity to

the spray equipment and the object

being sprayed should be maintained.

suitable for use with

refer to the

Personal Protective

Equipment

Toxic vapours – When sprayed,

certain materials may be

poisonous, create irritation or be

otherwise harmful to health.

Always read all labels and safety data

sheets for the material before spraying

and follow any recommendations. If In

Doubt, Contact Your Material Supplier

The use of respiratory protective

equipment is recommended at all

times. The type of equipment must

be compatible with the material

being sprayed

Gloves must be worn when

spraying or cleaning the

equipment

Training – Personnel should be given

adequate training in the safe use of

spraying equipment.

Misuse

Never aim a spraygun at any part of the

body

Never exceed the max. recommended

safe working pressure for the equipment

The fitting of non-recommended or nonoriginal spares may create hazards

Before cleaning or maintenance, all

pressure must be isolated and relieved

from the equipment

The product should be cleaned using a

gun washing machine. However, this

equipment should not be left inside gun

washing machines for prolonged periods

of time.

Noise Levels

The A-weighted sound level of

sprayguns may exceed 85 dB (A)

depending on the set-up being

used. Details of actual noise

levels are available on request. It is

recommended that ear protection is worn

at all times when spraying

Always wear eye protection when

spraying or cleaning the spraygun

3 © ITW Ltd 2000

Page 4

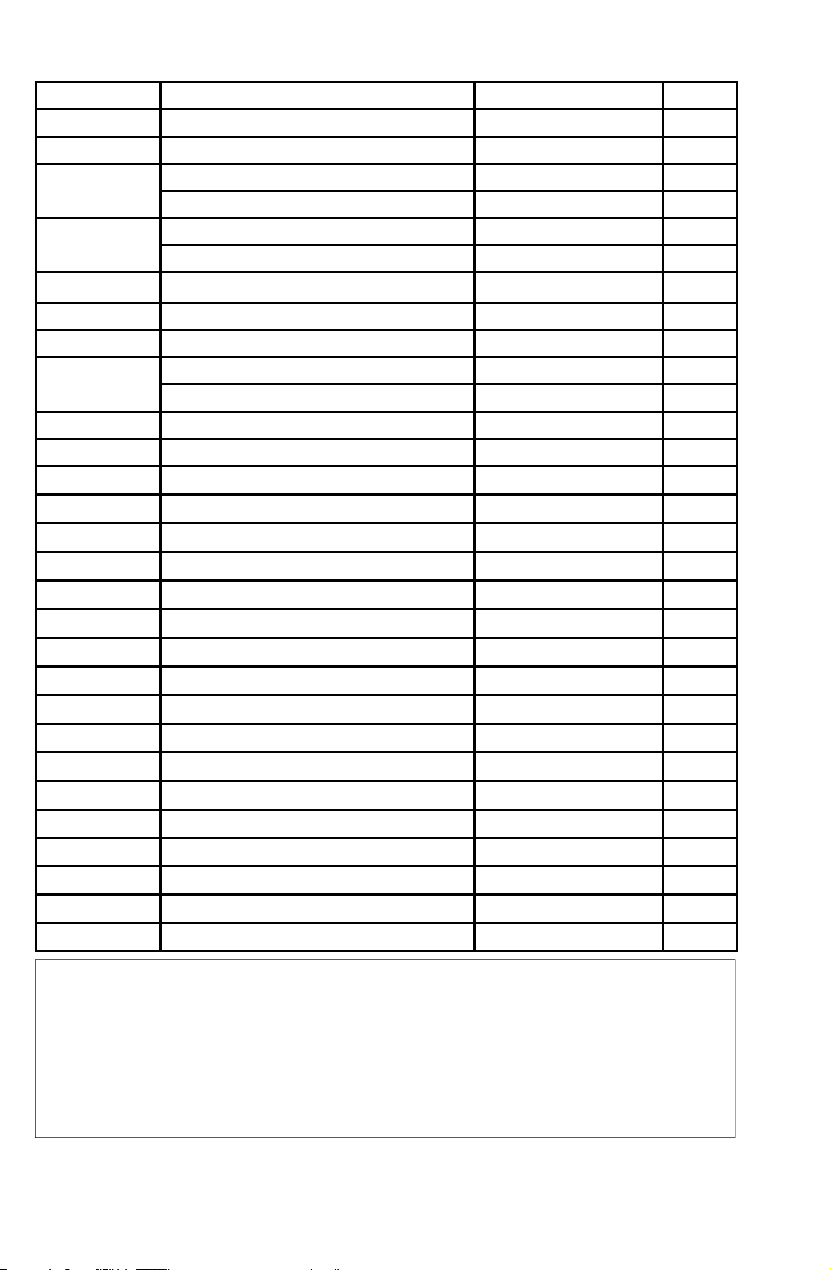

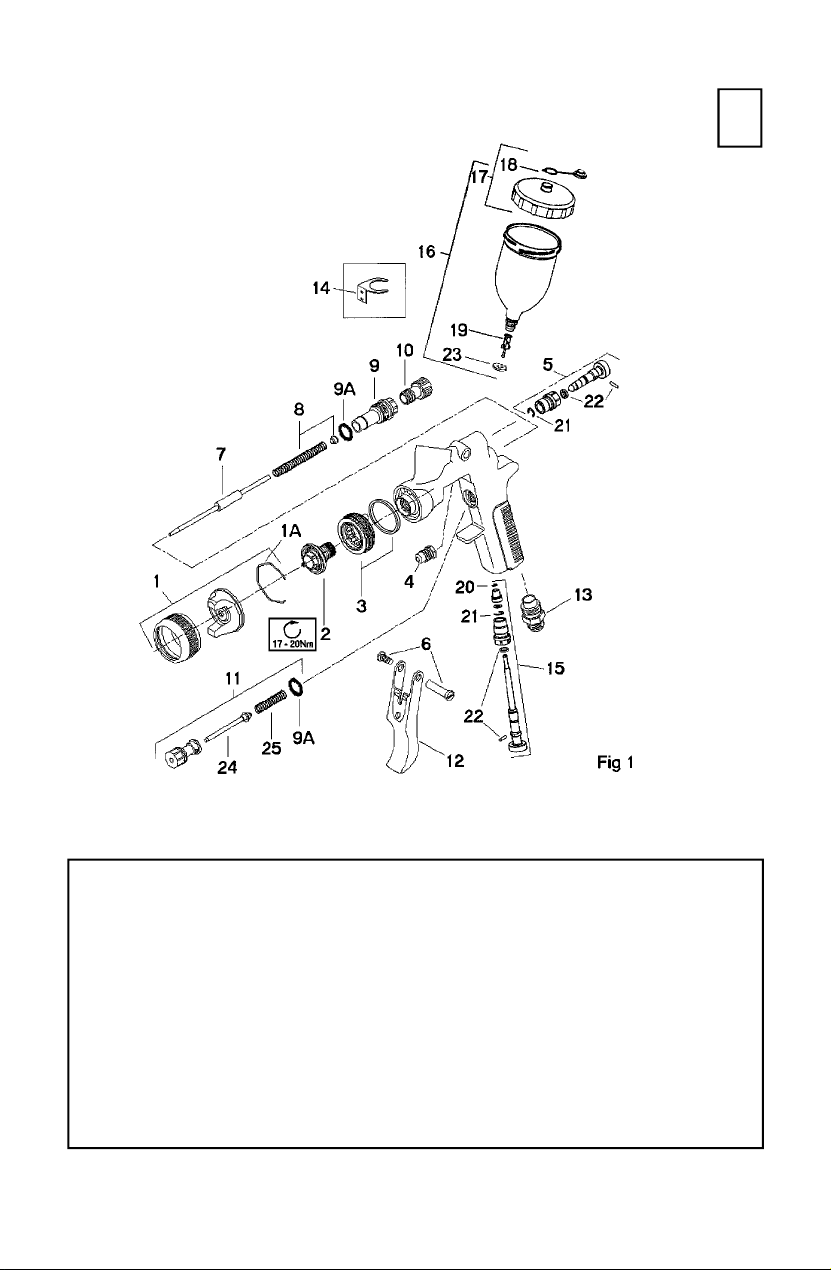

Parts List

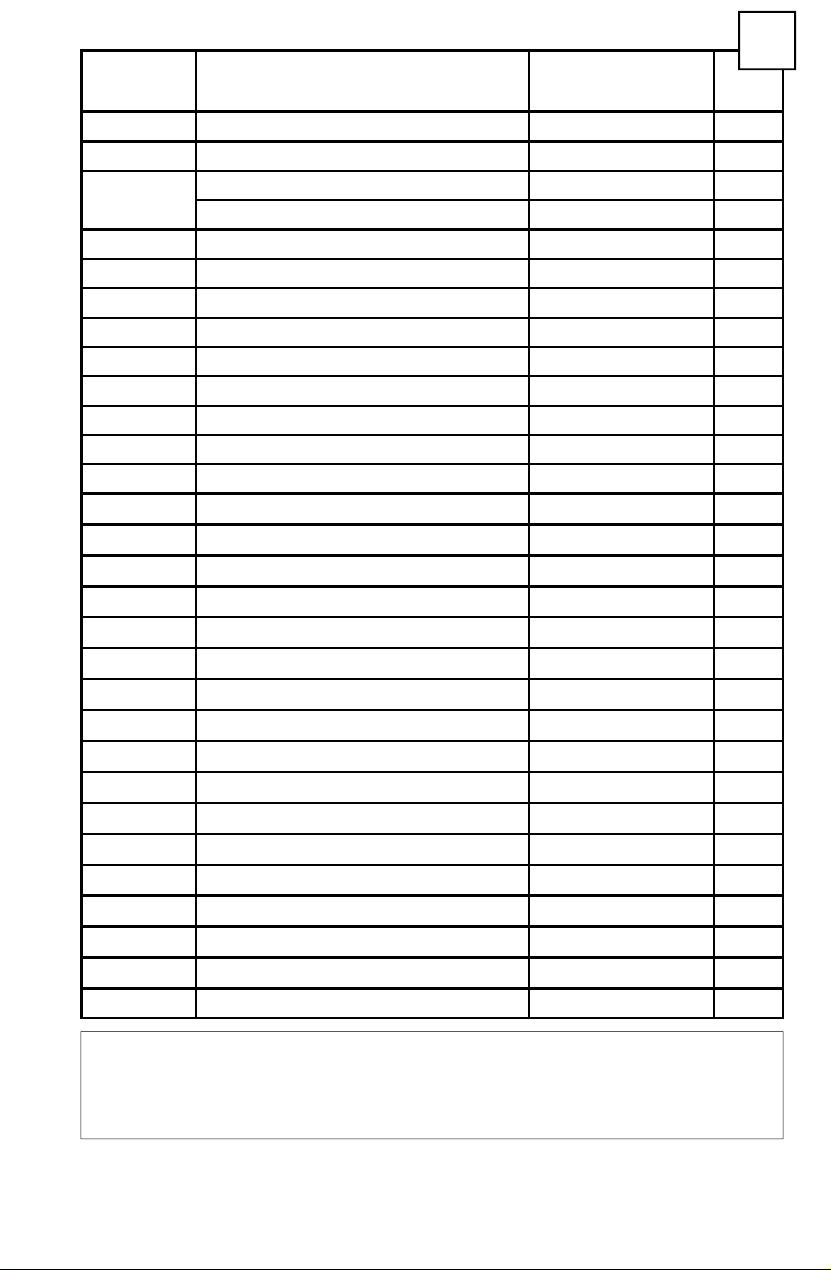

Ref. No Description Part Number Qty

*1 Air Cap/Retaining ring GTI-407-* 1

1a Spring Clip JGA-156-K5 1

+**2

3

+4 Packing GTI-439-K2 1

5 Spreader Valve GTI-404-K 1

6 Stud and Screw GTI-408-K5 1

+7

+8 Spring and Pad GTI-409-K5 1

9 Bushing GTI-402-K 1

9a Seal kit of 5 JGS-72-K5 2

10 Needle Adjusting Screw GTI-414-K 1

11 Valve Assembly JGK-449 1

12 Trigger GTI-108 1

13 Connector JGA-158 1

14 Gun Hook GFG-6 1

15 Airflow Valve GTI-415-K 1

16 1/2 Ltr Gravity Cup Kit GFC-501 1

17 Cup Lid GFC-402 1

18 Drip Check Lid kit of 5 GFC-2-K5 1

19 Filter KGP-5 1

20 Circlip 25746-007-K5 1

21 Circlip SST-8434-K5 2

22 Seal & Pin Kit ( + SST-8434-K5) GTI-428-K5 2

23 Washer GFC-17-K5 1

24 Air valve stem assembly JGS-431-1 1

25 Spring JGV-262-K5 1

Nozzle (up to 1.5 mm) GTI-213-**-K 1

Nozzle (1.6 mm to 2.2 mm) GTI-214-**-K 1

Baffle & Seal GTI-425-K 1

Baffle Seal - Kit of 5 GTI-33-K5 1

Needle (for GTI-214 Tip) GTI-420-K 1

Needle (for GTI-213 Tip) GTI-413-K 1

* - * Denotes Aircap Number - Available Aircaps No’s 105 and 110

** - ** Denotes Fluid Tip Size—Available Sizes;

GTI-213 0.85, 1.0, 1.1, 1.2, 1.3,1.4,1.5 mm

GTI-214 1.6, 1.8, 2.0 and 2.2 mm

+ - Parts included in service Kit (see accessories)

4 © ITW Ltd 2000

Page 5

EE

Specification

Air supply connection - Universal

Maximum static inlet pressure - P

Nominal gun inlet pressure with gun triggered - 2 bar (29 psi)

Gun Weight - 580 g

= 9 bar (130 psi)

1

Materials of Construction

Gun body - Anodised Aluminium

Nozzle - Stainless steel

Needle - Stainless Steel

Cup - Acetal and Stainless Steel

5 © ITW Ltd 2000

1

/4 BSP and NPS

Page 6

EE

Installation

Important: To ensure that this

equipment reaches you in first class

condition, protective coatings have

been use. Flush the equipment

through with a suitable solvent

before use.

Operation

1. Mix coating material to

manufacturers instructions

2. Turn needle adjusting screw (10)

counter-clockwise until first thread

shows

3. Turn pattern valve (5) counterclockwise to fully open

4. Adjust inlet air pressure to give 2

bar (29psi) at the gun inlet with

the gun triggered. (pressure

gauge attachment shown under

Accessories is recommended for

this)

5. Test spray. If the finish is too dry

reduce airflow by reducing inlet

pressure. If finish is too wet

reduce fluid flow by turning needle

screw (10) clockwise. If

atomisation is too coarse,

increase inlet air pressure. If too

1. Attach air hose to connector (13).

Recommended hose size 8 mm

bore.

2. Air supply should be filtered and

regulated.

fine reduce inlet pressure.

6. The pattern size can be reduced

by adjusting valve (5)

7. Hold gun perpendicular to surface

being sprayed. Arcing or tilting

may result in uneven coating.

8. The recommended spray distance

is 150-200 mm (6”-8”).

9. Spray edges first. Overlap each

stroke a minimum of 50%. Move

gun at a constant speed.

10. Always turn off air supply and

relieve pressure when gun is not

in use.

Air Flow Valve (15)

1. If the airflow valve (15) is fitted

this can be used to reduce the

inlet pressure through the gun.

Screw the Adjusting Knob in to

reduce pressure.

Preventative Maintenance

1. Turn off air supply and relieve

pressure in the airline, or if using

QD system, disconnect from

airline.

2. Empty coating material into a

suitable container and clean,

preferably in a gun wash

machine.

3. Remove air cap and clean. If any

of the holes in the cap are

blocked with coating material use

a toothpick to clean. Never use

metal wire which could damage

the cap and produce distorted

spray patterns

4. Ensure the tip of the nozzle is

clean and free from damage.

Build up of dried paint can distort

the spray pattern.

5. Lubrication – stud/screw (6),

needle (7) and air valve (11)

should be oiled each day.

6 © ITW Ltd 2000

Page 7

Replacement of Parts

EE

Nozzle (2) and Needle (7) –

Remove parts in the following order:

10, 8, 7, 1 and 2. Replace any worn

or damaged parts and re-assemble

in reverse order. Recommended

tightening torque for nozzle (2) 1720 Nm (150-180 lbf in)

Packing – Remove parts 10, 8, 7.

Unscrew cartridge (4). Fit new

cartridge finger tight. Re-assemble

parts 7, 8, and 10 and tighten

cartridge (4) with spanner sufficient

to seal but to allow free movement

of needle. Lubricate with gun oil.

Air valve – Remove parts 6 and 12.

Unscrew valve assembly. Reassemble fitting spring to valve head

Spreader valve – Caution: always

ensure that the valve is in the fully

open position by turning screw fully

counter-clockwise before fitting to

body.

Air cap / Nozzle Selection

Refer to coating material

manufacturers recommendations or

ITW Finishing UK Website:

www.itweuropeanfinishing.com

Accessories

Spanner – order SPN-5

Cleaning Brush – order 4900-5-1-K3

Service Kit – order GTi-416 add nozzle size as required (i.e. GTi-416-14)

Pressure gauge Attachment – order GA-515

Gun Mounted Regulator – order DVR-501

Lubricant - order GL-1-K10

7 © ITW Ltd 2000

Page 8

DKDK

Betjeningsvejledning

GTi – Sprøjtepistol med tyngdefødning

Vigtigt

Læs og følg vejledningen og alle sikkerhedsforholdsreglerne nøje, før du

bruger dette udstyr.

Dette produkt kan bruges både i forbindelse med vandbaseret og opløsningsmiddelbaseret sprøjtemateriale. Sprøjtepistolen bruger en forstøvningsteknik, der er i

overensstemmelse med EPAs retningslinier og mindsker overspray og gør

sprøjtebehandlingen mere effektiv.

Vigtigt: Disse pistoler kan ikke tåle at blive brugt i forbindelse med meget korrosive

og/eller slibende materialer. Hvis de bruges i forbindelse med sådanne materialer,

må det forventes, at de skal renses mere og/eller at antallet af dele, der skal

udskiftes, stiger. Hvis du er i tvivl om, hvorvidt et produkt er egnet, kan du kontakte

din lokale forhandler, eller du kan kontakte ITW Finishing direkte.

Reservedels modelnummer

Eksempel: GTI-G110B-14

Lufthætte Væskedysestørrelse

(14 = 1,4 mm)

Pistolfinish

M= Flerfarvet (farverne kan variere), B= Anodiseret blå

Overensstemmelseserklæring

Vi, ITW Finishing UK, Ringwood Road, Bournemouth, Dorset, England erklærer at

have det fulde ansvar for, at dette produkt er i overensstemmelse med BS EN 292:

del 1 og 2 :1991 og BS EN 1953:1999, og følger de gældende retningslinier i henhold

til maskindirektivet 89/392/EØF. Dette produkt overholder også kravene i henhold til

EPA-retningslinierne, PG6/34. Ved henvendelse kan man få et effektivitetscertifikat

vedrørende overførsel.

B. Holt, Administrerende direktør

8 © ITW Ltd 2000

8

Page 9

Reservedelsliste

Ref. Nr. Beskrivelse Reservedelsnummer Antal

*1 Lufthætte/omløberring GTI-407-* 1

1a Fjederholder JGA-156-K5 1

+**2

3 Luftfordelerring og taetning GTI-425-K 1

Taetning til Luftfordelerring saet med 5 GTI-33-K5 1

+4 Pakning GTI-439-K2 1

5 Sprederjustering GTI-404-K 1

6 Pindbolt og skrue GTI-408-K5 1

+7 Nål (til GTI-214-dyse) GTI-420-K 1

Nål (til GTI-213-dyse) GTI-413-K 1

+8 Fjeder og pude GTI-409-K5 1

9 Bøsning GTI-402-K 1

9a Tætnings– sæt med 5 JGS-72-K5 2

10 Nåljusterskrue GTI-414-K 1

11 Luftventil JGK-449 1

12 Aftrækker GTI-108 1

13 Luftindgangsnippel JGA-158 1

14 Pistolkrog GFG-6 1

15 Luftreguleringsventil GTI-415-K 1

16 1/2 l overkop GFC-501 1

17 Låg GFC-402 1

18 5 sæt dryplåg GFC-2-K5 1

19 Filter KGP-5 1

20 Låsering – sæt med 5 25746-007-K5 1

21 Låsering – sæt med 5 SST-8434-K5 2

22 Tætnings- og stiftsæt ( + SST-8434- GTI-428-K5 2

23 Skive GFC-17-K5 1

24 Ventil JGS-431-1 1

25 Fjeder JGV-262-K5 1

Dyse (op til 1,5 mm) GTI-213-**-K 1

Dyse (1,6 mm til 2,2 mm) GTI-214-**-K 1

DK

DK

* - ** Betegner Lufthættenummer – Fås i lufthættenumrene 105 og 110

** - ** Betegner væskespidsens størrelse – Fås i følgende størrelser;

GTI-213 0,85; 1,0; 1,1; 1,2; 1,3; 1,4; 1,5 mm

GTI-214 1,6; 1,8; 2,0 og 2,2 mm

+ - Reservedele i servicesæt (se tilbehør)

© ITW Ltd 2000

9 © ITW Ltd 2000

Page 10

DK

DK

Specifikation

Luftforsyningsforbindelse - Universal

Maksimalt statisk indgangstryk - P

Nominelt indgangstryk når pistolen er i brug - 2 bar (29 psi)

Pistolens vægt - 580 g

= 9 bar (130 psi)

1

Konstruktionsmateriale

Pistol - Anodiseret aluminium

Dyse - Rustfrit stål

Nål - Rustfrit stål

Kop - Acetal og rustfrit stål

10 © ITW Ltd 2000

1

/4 BSP og NPS

Page 11

Installation

Vigtigt: For at sikre at dette udstyr når

frem i bedste stand, har vi overfladebeskyttet materialet. Skyl udstyret

igennem med et egnet opløsningsmiddel før brug.

Betjening

1. Bland sprøjtematerialet efter

producentens vejledning.

2. Drej nåljusterskruen (10) mod uret,

indtil det første gevind bliver synlig.

3. Drej viftereguleringen (5) mod uret for

at åbne den fuldstændig.

4. Juster luftindgangstrykket til 2 bar

(29psi) ved pistolåbningen, mens du

holder aftrækkeren inde. (Det

anbefales at bruge et trykmanometer

til dette, som vist under Tilbehør).

5. Testspray. Hvis finishen er for tør,

kan man reducere luftstrømmen ved

at reducere indgangstrykket. Hvis

finishen er for våd, kan man reducere

væskestrømmen ved at dreje

nålskruen (10) med uret. Hvis

forstøvningen er for grov, kan man

øge luftindgangstrykket. Hvis

forstøvningen er for fin, skal man

reducere indgangstrykket.

6. Mønsterstørrelsen kan reduceres ved

at justere ventilen (5).

DK

DK

1. Tilslut luftslangen til

forbindelsesdelen (13). Den

anbefalede slangestørrelse har en

åbning på 8 mm.

2. Luftforsyningen skal filtreres og

reguleres.

7. Hold pistolen vinkelret på den

overflade, der sprøjtes. Hvis man

buer eller hælder den, kan det

medføre en ujævn

overfladebehandling.

8. Den tilrådelige sprøjteafstand er 150-

200 mm.

9. Spray kanterne først. Overlap hvert

strøg med minimum 50%. Bevæg

pistolen med konstant hastighed.

10. Sluk altid for luftforsyningen og

væskeforsyningen udløs trykket, når

pistolen ikke er i brug.

Luftventil (15)

1. Hvis luftventilen (15) er indstillet, kan

det hjælpe med at reducere

indgangstrykket gennem pistolen.

Skru justeringsgrebet ind for at

reducere trykket.

Forebyggende vedligeholdelse

1. Sluk for luftforsyningen og udløs

trykket i luftledningen, eller frakobl

luftledningen, hvis der anvendes et

QD-system.

2. H æ l d

overfladebehandlingsmaterialet i en

egnet beholder, og rens udstyret,

helst i en pistolrensemaskine.

3. Fjern lufthætten og rens den. Hvis

nogle af hullerne i hætten er

tilstoppet, kan man bruge en tandstik

11 © ITW Ltd 2000

til at rense dem med. Brug aldrig

ståltråd, da det kan ødelægge

hætten og forårsage et forvrænget

sprøjtemønster.

4. Kontrollér, at dysens spids er ren og

ubeskadiget. Lag på lag af tørret

maling kan forårsage et forvrænget

sprøjtemønster.

5. Smøring – pindbolt/skrue (6), nål (7)

og luftventil (11) bør smøres med

olie hver dag.

Page 12

DK

DK

Udskiftning af dele

Dyse (2) og nål (7) – Fjern delene i

følgende rækkefølge: 10, 8, 7, 1 og 2.

Udskift de slidte eller beskadigede dele,

og saml dem i omvendt rækkefølge. Det

anbefales at bruge følgende

tilspændingsmoment til dyse (2): 17-20

Nm.

Pakning – Fjern delene 10, 8, 7. Skru

indsatsen løs (4). Skru den nye indsats i

med fingerkraft. Saml delene 7, 8, og 10,

og stram indsatsen (4) med en

skruenøgle, så den er tæt, men så nålen

stadig kan bevæge sig frit. Smør med

pistololie.

Luftventil – Fjern delene 6 og 12. Skru

ventilsættet løs. Saml delene ved at

sætte fjederen sammen med

ventilhovedet.

Sprederjustering – Forsigtig: Sørg

altid for, at ventilen er i den fuldt åbne

position, ved at dreje skruen helt mod

uret, før du sætter den på.

Valg af lufthætte/dyse

Vi henviser til de anbefalinger, som

producenten af sprøjtematerialet har

givet eller til ITW Finishing UK's

Webside:

www.itweuropeanfinishing.com

Tilbehør

Skruenøgle – bestil SPN-5

Rengøringsbørste – bestil 4900-5-1-K3

Servicesæt – bestil GTi-416 tilføj den rigtige dysestørrelse (d.v.s. GTi-416-14)

Trykmanometer – bestil GA-515

Pistolmonteret regulator – bestil DVR-501

Smøremiddel – bestil GL-1-K10

12 © ITW Ltd 2000

Page 13

SIKKERHEDSADVARSLER

DK

DK

Brand og eksplosion

Opløsningsmidler og sprøjtematerialer kan være meget

brandfarlige og letantændelig, når man

sprøjter med dem. Læs altid

sprøjtematerialeleverandørens

vejledning og dokumenter med

bestemmelser om helbredsskadelige

stoffer inden brug af dette udstyr.

Brugerne skal overholde alle lokale

og nationale brugerregler samt

forsikringsselskabers krav til

ventilation, brandforanstaltninger,

betjening og rengøring af

arbejdsområder.

Dette udstyr er, som leveret, IKKE

egnet til brug i forbindelse med

halogenerede carbonhydrider.

Væske og/eller luft, der passerer

gennem slanger, kan generere statisk

elektricitet. For at forhindre en sådan

risiko bør sprøjteudstyret og genstanden,

der sprøjtes, hele tiden have

jordforbindelse.

Anvend altid beskyttelsesbriller, når du

sprøjter eller renser sprøjtemaskinen.

Brug altid handsker, når du

sprøjter eller renser udstyret.

Uddannelse – Personalet bør uddannes

tilstrækkeligt i, hvordan man bruger

sprøjteudstyret på den sikreste måde.

Forkert brug

Ret aldrig sprøjtepistolen mod en

legemsdel.

Lad aldrig udstyret overstige det højst

anbefalede sikre arbejdstryk.

Det kan være fagligt at anvende ikkeanbefalet eller uoriginale reservedele.

Før rensning eller vedligeholdelse skal al

udstyrets tryk være isoleret og udløst.

Produktet bør renses i en pistolrensemaskine. Udstyret må dog ikke

ligge i pistolrensemaskinen i længere tid

af gangen.

Personligt beskyttelsesudstyr

Giftige dampe – Visse materialer

kan være giftige, forårsage

irritation eller på anden måde

være skadelige for helbredet, når

man sprøjter med dem. Læs altid

etiketterne og materialets sikkerhedsinformationer, før sprøjtning

påbegyndes, og følg anbefalingerne.

Kontakt din materialeleverandør, hvis

du er i tvivl.

Det anbefales til enhver tid at

bruge udstyr, der forhindrer

indånding af giftige dampe.

Udstyrets type skal svare til det

materiale, der sprøjtes med.

Sprøjtepistolers A-vægtede

støjniveau kan overstige 85 dB

(A) afhængig af hvilke

arbejdsformer, der anvendes.

Ved henvendelse kan man

få detaljer for relevante støjniveauer. Det

anbefales, at man altid benytter en form

for ørebeskyttelse, når man sprøjter.

13 © ITW Ltd 2000

Støjniveau

Page 14

SVSV

Bruksanvisning

GTi – Sprutpistol med självtryck

Viktigt

Läs igenom och följ alla instruktioner och säkerhetsföreskrifter innan du använder

Den här produkten lämpar sig för användning med både vattenbaserade och

oljebaserade material. För att minska översprutning och öka

bestrykningseffektiviteten används en EPA-godkänd fördelningsteknik.

Viktigt! De här pistolerna är inte avsedda för användning med starkt frätande och/

eller nötande material. Om dessa ändå används är det viktigt att tänka på att

behovet av rengöring och/eller byte av delar då ökar. Om du är tveksam huruvida ett

visst material lämpar sig för utrustningen kan du endera kontakta din lokala

distributör eller ITW Finishing direkt.

Modell, delnummer

Exempel: GTI-G110 B- 14

Luftmunstycke Dysa, innerdimension

(14 = 1,4 mm)

Pistolhus, ytfinish

M= Flerfärg (färg kan variera), B= Blå, eloxerad

utrustningen.

Beskrivning

Överensstämmelseförklaring

Härmed förklarar vi, ITW Finishing UK, Ringwood Road, Bournemouth,

Dorset, England, som ensam ansvarig, att den här produkten

överensstämmer med standarderna BS EN 292: delar 1 och 2 :1991 samt BS

EN 1953:1999, i enlighet med bestämmelserna i maskindirektivet 89/392/

EEG. Produkten överensstämmer också med kraven i EPA:s riktlinjer,

PG6/34. Certifikat rörande överföringseffektivitet finns att få på begäran.

B. Holt, General Manager

14 © ITW Ltd 2000

Page 15

Dellista

Ref. nr Beskrivning Delnr Antal

*1 Luftmunstycke/stoppring GTI-407-* 1

1a Fjäderklämma JGA-156-K5 1

+**2

3 Fördelarplatta & tatning GTI-425-K 1

+4 Packning GTI-439-K2 1

5 Fördelarventil GTI-404-K 1

6 Bult och skruv GTI-408-K5 1

+7 Nål (till GTI-214 färgmunstycke) GTI-420-K 1

+8 Fjäder och dyna GTI-409-K5 1

9 Bussning GTI-402-K 1

9a Tætnings– sats om 5 JGS-72-K5 2

10 Justerskruv till nål GTI-414-K 1

11 Ventilsats JGK-449 1

12 Avtryckare GTI-108 1

13 Anslutning JGA-158 1

14 Pistolkrok GFG-6 1

15 Luftströmningsventil GTI-415-K 1

16 1/2 l koppsats för självtrycksmatning GFC-501 1

17 Kopplock GFC-402 1

18 Droppfångarlock, sats om 5 GFC-2-K5 1

19 Filter KGP-5 1

20 Fjäderbricka – Sats om 5 25746-007-K5 1

21 Fjäderbricka – Sats om 5 SST-8434-K5 2

22 Tätnings- och stiftsats ( + SST-8434-K5) GTI-428-K5 2

23 Packning GFC-17-K5 1

24 Ventil JGS-431-1 1

25 Fjäder JGV-262-K5 1

Dysa (upp till 1,5 mm) GTI-213-**-K 1

Dysa (1,6 mm till 2,2 mm) GTI-214-**-K 1

Fördelarplattatatning GTI-33-K5

Nål (till GTI-213 färgmunstycke) GTI-413-K

SVSV

* - ** Avser luftmunstyckesnummer – tillgängliga luftmunstycken nr 105

och 110

** - ** Avser innerdimension – tillgängliga storlekar:

GTI-213 0,85, 1,0, 1,1, 1,2, 1,3, 1,4 och 1,5 mm

GTI-214 1,6, 1,8, 2,0 och 2,2 mm

+ - Ingående delar i servicesatsen (se tillbehör)

15 © ITW Ltd 2000

Page 16

SVSV

Specifikation

Anslutning till luftintag - Universal

Maximalt statiskt inströmningstryck - P

Nominellt inströmningstryck med avtryckaren

aktiverad - 2 bar

Pistolens vikt - 580 g

= 9 bar

1

Pistolhus - Eloxerad aluminium

Dysa - Rostfritt stål

Nål - Rostfritt stål

Kopp - Acetal och rostfritt stål

Konstruktionsmaterial

16 © ITW Ltd 2000

1

/4 BSP och NPS

Page 17

Installation

SVSV

Viktigt! För att försäkra oss om att

utrustningen når dig i toppskick har

ett skyddsöverdrag använts. Spola

igenom utrustningen med lämpligt

lösningsmedel innan du använder den.

Användning

1. Blanda bestrykningsmaterialet enligt

tillverkarens instruktioner.

2. Vrid nålens justerskruv (10) motsols

tills du kan se den första gängan.

3. Vrid mönsterventilen (5) motsols för

att öppna helt.

4. Justera inströmningstrycket till att ge

2 bar vid pistolens intag med

avtryckaren aktiverad. (För detta

rekommenderas

tryckmätaraggregatet under

Tillbehör.)

5. Provspruta. Om ytan är för torr ska du

minska luftflödet genom att minska

inströmningstrycket. Om ytan är för

blöt ska du minska färgflödet genom

att vrida nålens justerskruv (10)

medsols. Om fördelningen är för grov

ska du öka inströmningstrycket. Om

den är för fin ska du minska

1. Anslut luftslangen till anslutningen

(13). Slang med en diameter om 8

mm rekommenderas.

2. Luftintaget bör filtreras och regleras.

inströmmningstrycket.

6. Mönsterstorleken kan minskas genom

att du justerar ventilen (5).

7. Håll pistolen i rät vinkel mot den yta

som sprutas. Vinkling eller lutning kan

leda till att bestrykningen blir ojämn.

8. Rekommenderat sprutavstånd är 150-

200 mm.

9. Spruta kanterna först. Spruta över

minst 50 % av varje färgdrag. Flytta

pistolen med konstant hastighet.

10. Slå alltid ifrån luftintaget och lätta på

trycket när du inte använder pistolen.

Luftströmningsventil (15)

1. Om pistolen har en luft-

strömningsventil (15) kan denna

användas till att minska

inströmningstrycket genom pistolen.

Skruva justerratten inåt för att minska

Förebyggande underhåll

1. Slå ifrån luftintaget och lätta på

trycket i luftledningen. Om du

använder snabbkopplingssystemet,

koppla bort luftledningen.

2. Töm materialet i en lämplig behållare

och rengör pistolen, helst i en

pistolrengöringsmaskin.

3. Ta bort och rengör luftmunstycket.

Om något av hålen i locket är

blockerat med färg ska du rengöra

det med en tandpetare. Använd

aldrig metalltråd som kan skada

locket och leda till förvanskade

sprutmönster.

4. Kontrollera att dysans spets är ren

och att den inte är skadad.

Ansamling av torkad färg kan

förvanska sprutmönstret.

5. Smörjning – bult/skruv (6), nål (7)

och luftventil (11) bör smörjas varje

dag.

17 © ITW Ltd 2000

Page 18

SVSV

Byte av delar

Dysa (2) och nål (7) – Ta bort delarna i

följande ordningsföljd: 10, 8, 7, 1 och 2.

Byt ut alla slitna eller skadade delar och

sätt tillbaka i omvänd ordning.

Rekommenderat åtdragningsmoment för

dysan (2) är 17-20 Nm.

Packning – Ta bort delarna 10, 8, 7.

Skruva loss patronen (4). Sätt dit den

nya patronen och dra åt för hand. Sätt

tillbaka delarna 7, 8 och 10 och dra åt

patronen (4) med skruvnyckel så pass

att det blir tätt. Se dock till att nålen kan

röra sig fritt. Smörj med vapenolja.

Luftventil – Ta bort delarna 6 och 12.

Skruva isär ventilsatsen. Montera ihop

genom att passa in fjädern på

ventilhuvudet.

Fördelarventil – Varning: kontrollera

att ventilen är helt öppen genom att

vrida skruven motsols så långt det går,

innan den monteras på huset.

Val av luftmunstycke / dysa

Se rekommendationer från materialtillverkare eller ITW Finishing UK:s

webbsida:

www.itweuropeanfinishing.com

Tillbehör

Skiftnyckel – beställningsnr SPN-5

Rengöringsborste – beställningsnr 4900-5-1-K3

Servicesats – beställningsnr GTi-416, specificera dysans storlek (t.ex. GTi-416-14)

Tryckmätaraggregat – beställningsnr GA-515

Pistolmonterat reglage – beställningsnr DVR-501

Smörjmedel – beställningsnr GL-1-K10

18 © ITW Ltd 2000

Page 19

SÄKERHETSVARNINGAR

SVSV

Brand och explosion

Lösningsmedel och bestrykningsmaterial kan vara mycket

brandfarliga och lättantändliga när de

sprutas. Läs ALLTID

materialleverantörens anvisningar

och COSHH-bladen innan du

använder utrustningen.

Användare måste följa alla lokala

och nationella föreskrifter samt

försäkringsbolagens krav rörande

ventilation, brandskydd, drift och skötsel

av arbetsområdet.

Utrustningen är i leveransskicket

lämpat för användning med

INTE

halogenkolväten.

Statisk elektricitet kan genereras av

vätskor och/eller luft som passerar

genom slangarna. För att motverka

denna risk ska sprututrustningens

förlängning jordas och det föremål som

sprutas ska underhållas.

Personlig

skyddsutrustning

Giftiga ångor – Vissa material kan

vid sprutning vara giftiga, orsaka

irritation eller på annat sätt vara skadliga

för hälsan. Läs alltid

alla etiketter och säkerhetsblad för

materialet innan sprutning. Följ alla

rekommendationer. Om du är

tveksam ska du kontakta

materialleverantören.

Du rekommenderas att alltid bära

andningsskydd. Utrustningen måste vara

kompatibel med det material som

sprutas.

Bär alltid ögonskydd vid sprutning

eller rengöring av sprutpistolen.

Handskar skall bäras vid sprutning eller

rengöring av utrustningen.

Utbildning – Personal bör ges lämplig

utbildning med avseende på säker

användning av sprututrustningen.

Missbruk

Rikta aldrig en sprutpistol mot någon del

av kroppen.

Överstig aldrig utrustningens maximala

rekommenderade säkra arbetstryck.

Montering av icke-rekommenderade

delar eller icke-originaldelar på

utrustningen kan utgöra fara.

Innan rengöring eller underhåll måste allt

tryck isoleras och släppas ut från

utrustningen.

Produkten bör rengöras med hjälp av en

pistolrengöringsmaskin. Utrustningen bör

emellertid inte lämnas inuti rengöringsmaskinen någon längre tid.

Bullernivå

Sprutpistolernas A-vägda

bullernivå kan överstiga 85 dB (A)

beroende på vilken installation som

används. Information om faktiska

bullernivåer kan fås på begäran. Vi

rekommenderar att hörselskydd alltid

bärs vid sprutning.

19 © ITW Ltd 2000

Page 20

FIFI

Käyttöohje

GTi – yläsäiliömaaliruisku

Tärkeää

Perehdy kaikkiin ohjeisiin ja varotoimiin ennen laitteen käyttöä ja noudata

niitä

Kuvaus

Tämä tuote sopii käytettäväksi sekä vesi- että liuotinpohjaisten pinnoitusaineiden

kanssa. Mallissa käytetään ympäristömääräysten mukaista sumutustekniikkaa, joka

vähentää liikasumutusta ja parantaa pinnoitustehoa.

Tärkeää: Näitä ruiskuja ei ole tarkoitettu käytettäväksi erityisen syövyttävien ja/tai

hankaavien aineiden kanssa. Jos niitä käytetään tällaisten aineiden kanssa,

puhdistuksen tarve todennäköisesti lisääntyy ja/tai osia on vaihdettava useammin.

Mikäli et ole varma jonkin aineen sopivuudesta laitteelle, ota yhteyttä paikalliseen

jälleenmyyjään tai suoraan ITW Finishingiin

Mallin osanumero

Esimerkki: GTI-G110B-14

Ilmasuutin Nestesuuttimen koko

(14 = 1,4 mm)

Ruiskun rungon pintakäsittely

M= useita eri värejä, B = sininen eloksoitu

EU:n vaatimuksenmukaisuusvakuutus

ITW Finishing UK, Ringwood Road, Bournemouth, Dorset, England vakuuttaa, että

tämä tuote on standardin EN 292, osien 1 ja 2 :1991 sekä standardin EN 1953:1999

mukainen ja täyttää konedirektiivin 89/392/ETY vaatimukset. Tuote on myös EPA:n

ohjeen PG6/34 mukainen. Todistukset siirron hyötysuhteesta toimitetaan

pyydettäessä.

B. Holt,

Johtaja

20 © ITW Ltd 2000

Page 21

Osaluettelo

Viite-numero Kuvaus Osanumero Kpl

*1 Ilmasuutin/kiinnitysrengas GTI-407-* 1

1a Jousikiinnike JGA-156-K5 1

+**2

3 Ilmanjakorengas ja tiiviste GTI-425-K 1

+4 Tiivistesarja GTI-439-K2 1

5 Viuhkansäätö (viuhka) GTI-404-K 1

6 Liipaisinpultti ja ruuvi GTI-408-K5 1

+7

+8 Jousi ja tyyny GTI-409-K5 1

9 Holkki GTI-402-K 1

10 Neulan säätöruuvi GTI-414-K 1

11 Ilmaventtiili JGK-449 1

12 Liipaisin GTI-108 1

13 Liitin JGA-158 1

14 Ruiskun pidike GFG-6 1

15 Ilmanvirtausventtiili GTI-415-K 1

16 1/2 l yläsäiliösarja GFC-501 1

17 Säiliön kansi GFC-402 1

18 Tipanestin, 5 GFC-2-K5 1

19 Suodatin KGP-5 1

20 Lukitusrengas 25746-007-K5 1

21 Lukitusrengas SST-8434-K52 1

22 Ilmaventtiilin tiivistesarja ( + SST-8434-K5) GTI-428-K5 1

23 Tiivisterengas GFC-17-K5 1

24 Venttiili JGS-431-1 1

25 Jousi JGV-262-K5 1

Suutin (1,5 mm:iin saakka) GTI-213-**-K 1

Suutin (1,6 mm – 2,2 mm) GTI-214-**-K 1

Ilmanjakorenkaan tiiviste - 5 sarja GTI-33-K5 1

Neula (GTI-214 nestesuuttimelle) GTI-420-K 1

Neula (GTI-213 nestesuuttimelle) GTI-413-K 1

FIFI

* - ** Ilmaisee ilmakannen numeron – saatavissa numerot 105 ja 110

** - ** Ilmaisee värisuuttimen koon – saatavissa seuraavat koot:

GTI-213 0,85 mm; 1,0 mm; 1,1 mm; 1,2 mm; 1,3 mm; 1,4 mm

ja 1,5 mm

GTI-214 1,6 mm; 1,8 mm; 2,0 mm ja 2,2 mm

+ - huoltosarjaan sisältyvät osat (katso lisävarusteet)

21 © ITW Ltd 2000

Page 22

Tekniset tiedot

Ilmaletkun liitäntä - Yleiskierre

Suurin staattinen tulopaine - P

= 9 bar (130 psi)

1

Nimellispaine laukaistaessa - 2 bar (29 psi)

Ruiskun paino - 580 g

Valmistusmateriaali

Ruiskun runko - eloksoitu alumiini

Suutin - ruostumaton teräs

Neula - ruostumaton teräs

Kansi - asetaali ja ruostumaton teräs

22 © ITW Ltd 2000

1

/4 " BSP ja NPS

Page 23

Asennus

FIFI

Tärkeää: Varmistaaksemme sen, että

saat laitteen ensiluokkaisessa kunnossa,

olemme käsitelleet laitteen pinnan suojaaineella. Huuhtele laite ennen käyttöä

sopivalla liuottimella.

Käyttö

1. Sekoita pinnoitusaine valmistajan

ohjeiden mukaisesti.

2. Kierrä neulansäätöruuvia (10)

vastapäivään, kunnes ensimmäinen

kierre näkyy.

3. Kierrä kuvioventtiiliä (5) vastapäivään,

kunnes se on kokonaan auki.

4. Säädä tuloilman paine siten, että se

on 2 baria (29 psi) ruiskun tuloaukolla

laukaistaessa. (Tähän tarkoitukseen

suositellaan Lisätarvikkeet-kohdassa

mainittua painemittarin liitintä.)

5. Testaa ruiskutusjälki. Jos jälki on liian

kuiva, vähennä ilmanvirtausta

alentamalla tulopainetta. Jos jälki on

liian märkä, vähennä nesteenvirtausta

kiertämällä neulan säätöruuvia (10)

myötäpäivään. Jos sumu on liian

paksua, lisää tuloilman painetta. Jos

sumu on liian hienoa, alenna

ilmanpainetta.

1. Liitä ilmaletku liittimeen (13).

Suositeltava letkun sisähalkaisija on

8 mm.

2. Ilman pitää olla suodatettua ja

säädeltyä.

6. Kuvion kokoa voidaan pienentää

säätämällä venttiiliä (5).

7. Pidä ruiskua kohtisuorassa

ruiskutettavaan pintaan nähden.

Kaarevat liikkeet tai ruiskun

kallistaminen saattavat aiheuttaa

epätasaisen jäljen.

8. Suositeltava ruiskutusetäisyys on 150

- 200 mm.

9. Ruiskuta ensin reunat. Peitä jokaisella

vedolla vähintään puolet edellisellä

vedolla maalatusta alueesta. Liikuta

ruiskua tasaisesti.

10. Katkaise ilmansyöttö ja vapauta paine

aina, kun ruiskua ei käytetä.

Ilmanvirtausventtiili (15)

1. Jos laitteessa on ilmanvirtausventtiili

(15), ilmanpainetta voidaan alentaa

kiertämällä säätövipua pienemmälle.

Ennaltaehkäisevä huolto

1. Katkaise ilmansyöttö ja vapauta

paine, tai irrota mahdollinen

pikaliitäntä.

2. Tyhjennä pinnoitusaine sopivaan

astiaan ja puhdista laite mielellään

ruiskunpesukoneessa.

3. Irrota ja puhdista ilmasuutin. Jos

pinnoitusaine on tukkinut suuttimen

reiät, puhdista ne hammastikulla. Älä

23 © ITW Ltd 2000

käytä teräslankaa, sillä se saattaa

vahingoittaa kantta ja vääristää

suihkukuviota.

4. Varmista, että neulan pää on puhdas

eikä siinä ole vaurioita. Kuivunut

maali saattaa vääristää

ruiskutuskuvion.

5. Voitelu – Öljyä pultti/ruuvi (6), neula

(7) ja ilmaventtiili (11) päivittäin.

Page 24

FIFI

Osien vaihtaminen

Suutin (2) ja neula (7) – Irrota osat

seuraavassa järjestyksessä: 10, 8, 7, 1

ja 2. Vaihda kuluneet ja vialliset osat ja

asenna osat paikalleen käänteisessä

järjestyksessä. Suuttimen (2)

suositeltava kiristystiukkuus on 17-20

Nm.

Päällyskotelo – Irrota osat 10, 8, 7.

Ruuvaa kotelo (4) irti. Asenna uusi

kotelo sormitiukkuuteen. Asenna osat 7,

8 ja 10 paikalleen ja kiristä kotelo (4)

ruuviavaimella tarpeeksi tiiviisti, mutta

kuitenkin siten, että neula pääsee

liikkumaan vapaasti. Voitele ruiskuöljyllä.

Ilmaventtiili – Irrota osat 6 ja 12.

Kierrä venttiiliyksikkö irti. Kokoa laite

ja kiinnitä jousi venttiilin päähän.

Levitysventtiili (viuhka) – Varoitus:

Varmista aina ennen venttiilin

kiinnittämistä runkoon, että venttiili on

kokonaan auki, kiertämällä ruuvia

kokonaan vastapäivään.

Ilmasuuttimen valinta

Perehdy pinnoitusaineiden valmistajien

suosituksiin tai lue ohjeet ITW Finishing

UK:

www.itweuropeanfinishing.com

Lisävarusteet

Yleisruuviavain – tilausnumero SPN-5

Puhdistusharja – tilausnumero 4900-5-1-K3

Huoltosarja – tilausnumero GTi-416, ilmoita suuttimen koko tarvittaessa (esim. GTi-

416-14)

Painemittarin liitin – tilausnumero GA-515

Kahvasäädin – tilausnumero DVR-501

Voiteluaine – tilausnumero GL-1-K10

24 © ITW Ltd 2000

Page 25

TURVAVAROITUKSIA

FIFI

Tulipalo ja räjähdys

Liuottimet ja pinnoitteet voivat olla

erittäin tulenarkoja ja syttyvät

helposti ruiskutettaessa. Perehdy AINA

pinnoitusaineen valmistajan ohjeisiin

sekä terveydelle vaarallisten aineiden

käyttöä (COSHH) koskeviin ohjeisiin

ennen laitteen käyttöä.

Käyttäjien on noudatettava kaikkia

paikallisia ja kansallisia normeja ja

vakuutusyhtiöiden vaatimuksia,

jotka koskevat tuuletusta, palovarotoimia

sekä työalueiden käyttöä, huoltoa ja

hoitoa.

Toimitettu laite EI

käytettäväksi halogenoitujen

hiilivetyjen kanssa.

Nesteen ja/tai ilman kulkiessa putkien ja

letkujen läpi voi syntyä staattista sähköä.

Riskin poistamiseksi on varmistettava

ruiskutuslaitteiden ja ruiskutuskohteen

jatkuva maadoitus.

sovi

Käyttäjän suojavarusteet

Myrkylliset kaasut –

Ruiskutettuina tietyt aineet

saattavat olla myrkyllisiä,

aiheuttaa ärsytystä tai olla

muuten haitallisia terveydelle. Lue aina

pakkausten etiketit ja turvaohjeet ennen

aineen ruiskuttamista ja noudata

suosituksia. Jos et ole varma aineen

käyttäytymisestä, ota yhteyttä aineen

valmistajaan.

laitteen puhdistuksen aikana.

Käytä käsineitä ruiskutuksen sekä

laitteen puhdistuksen aikana.

Koulutus – Henkilökunnalle on

annettava riittävä koulutus, jotta ruiskun

käyttö on turvallista.

Väärinkäyttö

Älä suuntaa ruiskua kehon osiin.

Älä ylitä laitteelle suositeltuja turvallisia

työpaineita.

Muiden kuin suositeltujen tai

alkuperäisten varaosien asentaminen

saattaa aiheuttaa vaaratilanteen.

Kaikki paineet on eristettävä ja

vapautettava laitteesta ennen puhdistustai huoltotoimia.

Laite tulee puhdistaa

ruiskunpesukoneessa. Laitetta ei saa

kuitenkaan jättää ruiskunpesukoneen

sisälle pitkäksi aikaa pesun jälkeen.

Melutasot

Ruiskujen A-painotteinen melutaso

saattaa ylittää 85 dB:iä (A)

käytettävästä kokoonpanosta

riippuen. Tietoja tarkoista

melutasoista annetaan

pyydettäessä. Ruiskutuksen aikana on

hyvä käyttää kuulosuojaimia.

Hengityssuojainten käyttö on

suositeltavaa aina ruiskutettaessa.

Käytetyn hengityssuojaimen on

sovelluttava ruiskutettavalle aineelle.

Käytä silmäsuojaimia ruiskutuksen sekä

25 © ITW Ltd 2000

Page 26

NOTES

26 © ITW Ltd 2000

Page 27

NOTES

27 © ITW Ltd 2000

Page 28

ITW Finishing Systems and Products

Ringwood Road,

Bournemouth,

BH11 9LH,

England.

Tel. No. (01202) 571111

Telefax No. (01202) 581940,

Website address http:\\www.itweuropeanfinishing.com

ITW Oberflächentechnik GmbH & Co. KG

Justus-von-Liebig-Straße 31

63128 Dietzenbach

Tel (060 74) 403-1

Telefax: (060 74) 403300

Website address http:\\www.itw-finishing.de

ITW Surfaces Et Finitions

163-171 avenue des Auréats B.P. 1453

26014 VALENCE CEDEX FRANCE

Tél. (33) 475-75-27-00

Télex 345 719F DVILBIS

Téléfax: (33) 475-75-27-99

28 © ITW Ltd 2000

November 02

Loading...

Loading...