Page 1

SPRAY GUN TROUBLESHOOTING AND

PREVENTIVE MAINTENANCE GUIDE

SERVICE BULLETIN

SB-2-001-F

Replaces SB-2-001-E

IMPORTANT: Before using this equipment, read all

safety precautions and instructions in this manual.

Keep for future use.

Page 2

Page 2 SB-2-001-F

SAFETY PRECAUTIONS

This manual contains information that is improtant for you to know and understand. This information relates

to USER SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we

use the following symbols. Please pay particular attention to these sections.

Note

Important safety information A hazard that may cause

serious injury or loss of life.

Important information that tells

how to prevent damage to equipment, or how to avoid a situation

that may cause minor inury.

Information that you should

pay special attention to.

The following hazards may occur during the normal use of this equipment. Please read the following chart before using this equipment.

HAZARD CAUSE SAFEGUARDS

Fire Solvent and coatings can be highly Adequate exhaust must be provided to keep air

flammable or combustible free of accumulations of flammable vapors.

especially when sprayed.

Smoking must never be allowed in the spray area.

Fire extinguishing equipment must be present

in the spray area.

Solvent Spray During cleaning and flushing, Wear eye protection.

solvents can be forcefully expelled

from fluid fluid and air passages.

Some solvents can cause eye

injury.

Inhaling Toxic Certain materials may be harmful Follow the requirements of the Material Safety

Substances if inhaled, or if there is contact Data Sheet supplied by your coating material

with the skin. manufacturer.

Adequate exhaust must be provided to keep the

air free of accumulations of toxic materials.

Use a mask or respirator whenever there is a

chance of inhaling sprayed materials. The mask

must be compatible with the material being

sprayed and its concentration. Equipment must

be as prescribed by an industrial hygienst or

safety expert, and be NIOSH approved.

Explosion Hazard Halogenated hydrocarbon solvents Guns with stainless steel internal passageways

Incompatible - for example; methylene chloride may be used with these solvents. However,

Materials and 1, 1, 1 - Trichloroethane are aluminum is widely used in other spray

not chemically compatible with application equipment - such as material pumps,

the aluminum that might be used cups and regulators, valves, etc. Check all

in many system components. The equipment items before use and make sure

chemical reaction caused by these they can also be ued safely with these solvents.

solvents reacting with aluminum Read the label or data sheet for the material

can become violent and lead to an you intend to spray. If in doubt as to whether

equipment explosion. or not a coating or cleaning material is com-

patible, contact your material supplier.

Page 3

SB-2-001-F Page 3

PRINCIPLES OF AIR SPRAY

Spray application is perhaps the simplest method of

coating where a sizeable area or volume of material

is involved or when intricate shapes and irregular

surfaces require painting. Spray will give the most

uniform film thickness making it easy to obtain a

smooth finish.

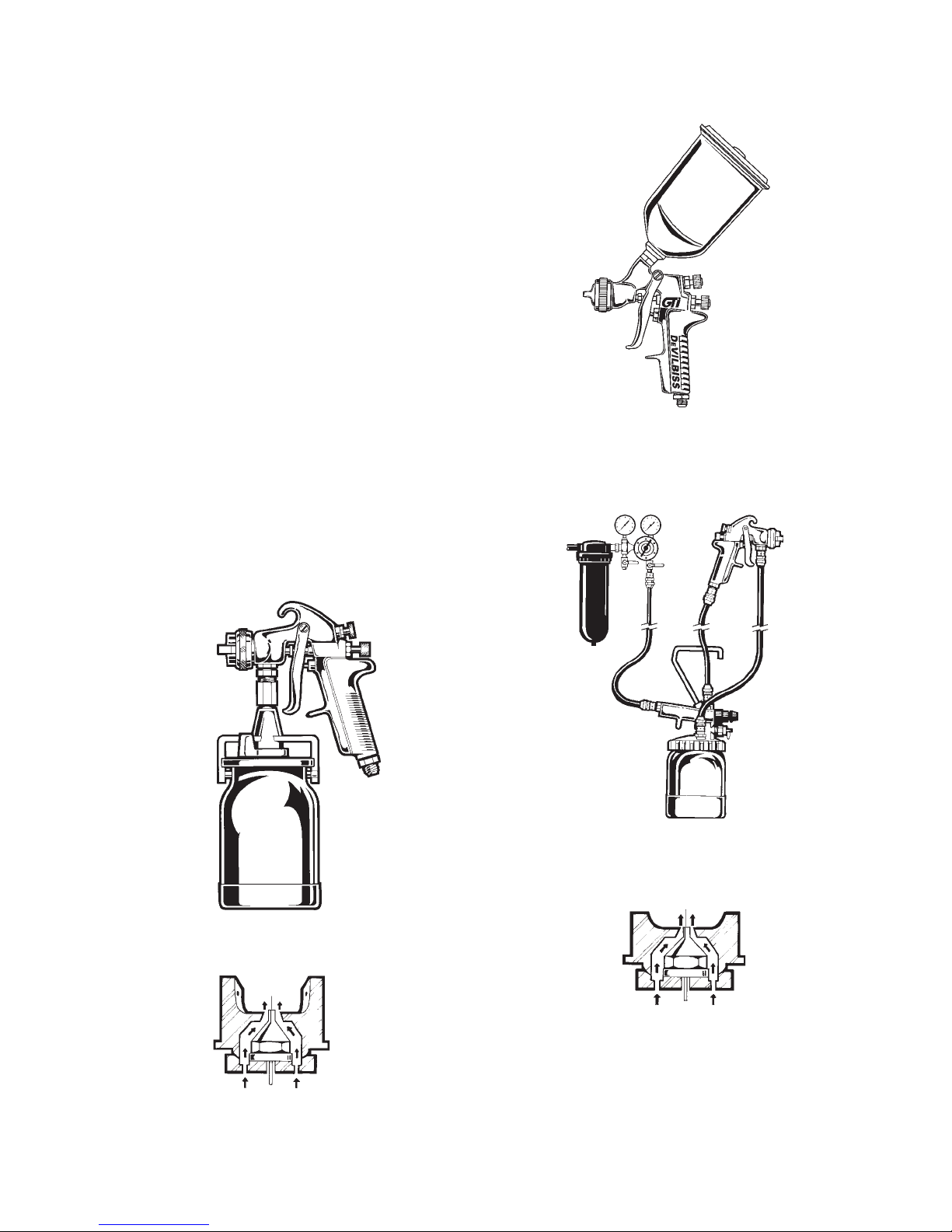

The air spray gun is a tool which uses compressed

air to atomize paint, or other sprayable material, and

to apply it to a surface. Air and material enter the

gun through separate passages, and are mixed at

the air cap in a controlled pattern. Air spray guns

may be classified in various ways. Two ways of

classifying guns are by the location of the material

container and the material feed system. Figure 1

shows a gun with a cup attached below. This is

called Suction Feed which draws material to the

gun by suction. Figure 3 is a gun with a cup attached

above. This is called Gravity Feed - the material

travels down, carried by gravity. Figure 4 shows a

material container some distance away from the

spray gun. This is Pressure Feed - the material is

fed by positive pressure. Suction feed is easily

identified by the fluid tip extending slightly beyond

the face of the air cap, as shown in Figure 2. Suction

feed guns are suited to many color changes and to

small amounts of material, such as in touchup or

lower production operations.

Figure 3 Gravity Feed Gun With Cup on Top

Gravity feed guns are ideal for small applications

such as spot repair, detail finishing or for finishing in

a limited space. They require less air than a suction

feed gun and usually have less overspray.

Figure 1 Suction Feed Gun with Attached Cup

Fluid

Tip

Figure 2 Suction Feed Air Cap

Figure 4 Typical Pressure Feed Gun With Remote

Cup

Fluid

Tip

Air Cap

Air Cap

Figure 5 Pressure Feed Air Cap

A pressure feed system is normally used when large

quantities of material are to be applied, when the

material is too heavy to be siphoned from a container

or when fast application is required.

Page 4

Page 4 SB-2-001-F

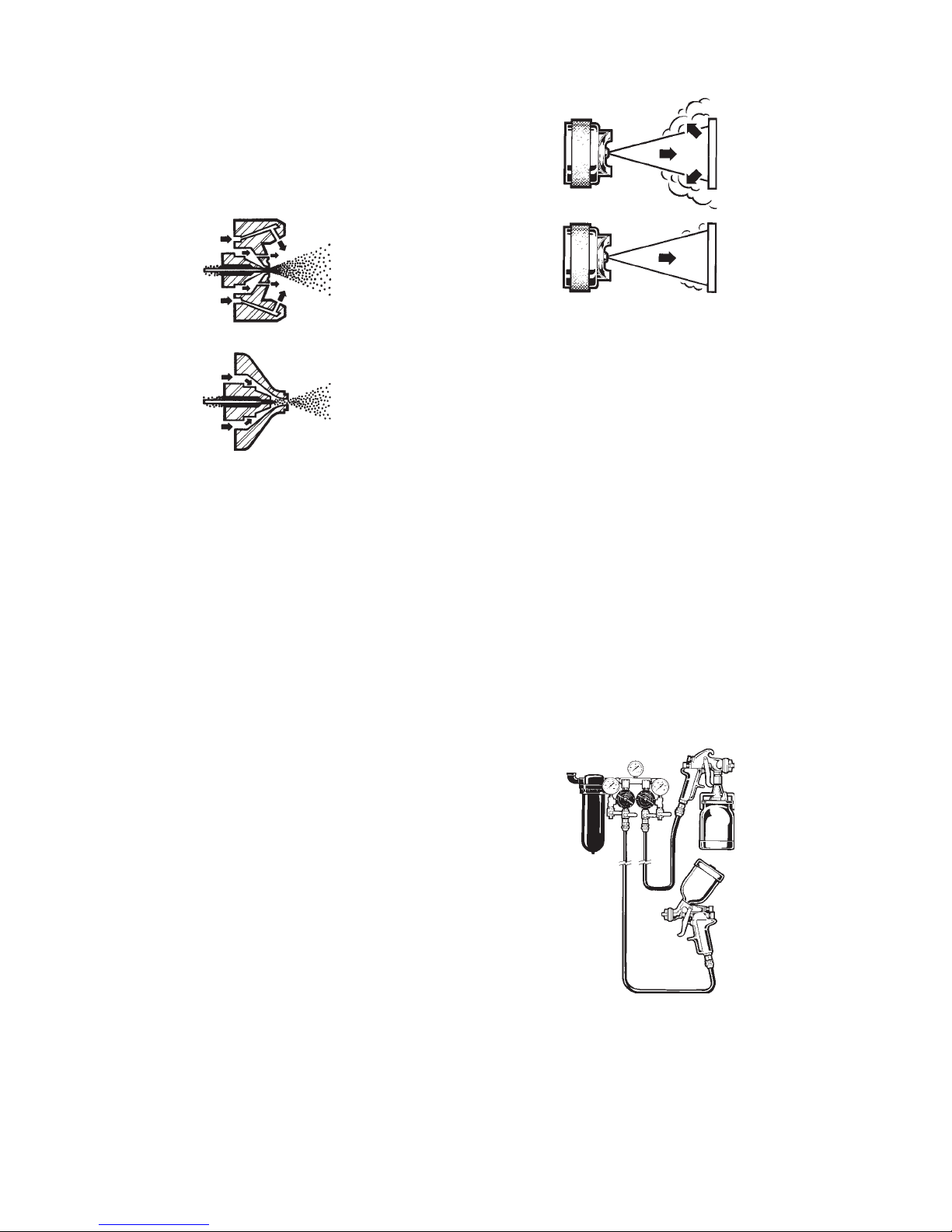

Internal and External Mix Guns

An external mix gun mixes and atomizes air and fluid

outside the air cap. It can be used for applying all

types of materials, and it is particularly desirable

when spraying fast-drying paints such as lacquer. It

is also used when a high quality finish is desired.

Figure 6 External Mix Gun

Figure 7 Internal Mix Gun

This gun mixes air and material inside the air cap,

before expelling them. It is normally used where low

air pressures and volumes are available, or where

slow-drying materials are being sprayed. A typical

example is spraying flat wall paint, or outside house

paint, with a small compressor. Internal mix guns

are rarely used for finishing when a fast-drying

material is being sprayed, or when a high quality

finish is required.

HVLP (High-Volume/Low-Pressure)

HVLP uses a high volume of air (typically between

15-22 CFM) delivered at low pressure (10 psi or

less) to atomize paint into a soft, low-velocity spray

pattern.

Conventional

HVLP

Figure 8 Air Cap Overspray, Conventional/HVLP

The HVLP spray gun resembles a standard spray gun

in shape and operation.

HVLP is growing in popularity and it has also been

judged environmentally acceptable due to its high

transfer efficiency.

HVLP can be used with low to-medium solid materials, including two-component paints, urethanes,

acrylics, epoxies, enamels, lacquers, stains, primers, etc. More recently developed HVLP air caps can

also satisfactorily atomize even high solid coatings.

OPERATION

Suction and Gravity Feed Equipment Hook-Up

Connect the air supply from the compressor outlet

to the air filter regulator inlet. Connect the air

supply hose from the regulator outlet to the air inlet

on the spray gun. After the material has been

reduced to proper consistency, thoroughly mixed

and strained into the cup, attach the gun to the cup.

As a result, far less material is lost in overspray,

bounce-back than with conventional air spray. This

is why HVLP delivers a dramatically higher transfer

efficiency (the amount of material that is actually

applied to the part) than higher pressure spray

systems.

Figure 9 Suction Feed & Gravity Feed System

Components

Spray a horizontal test pattern (air cap horns in a

vertical position). Hold the trigger open until the

paint begins to run. There should be even distribution of the paint across the full width of the pattern

(see Figure 11). Adjust with fan pattern adjustment.

Page 5

If distribution is not even, there is a problem with

either the air cap or the fluid tip. Refer to the

TROUBLESHOOTING section for examples of faulty

patterns to help diagnose the problem.

Figure 10 Horizontal Test Pattern with Even Material Distribution

If the pattern produced by the above test appears

normal, rotate the air cap back to a normal spraying

position and begin spraying (Example - a normal

pattern with a #9000 air cap will be about 9" long

when the gun is held 8" from the surface.) With the

fluid adjusting screw open to the first thread and

the air pressure set at approximately 30 psi, make

a few test passes with the gun on some clean paper.

Move the gun faster than usual when spraying the

test passes. If there are variations in particle size specks and/or large globs, the paint is not atomizing properly (See Figure 12). If the paint is not

atomizing properly, increase the air pressure slightly

and make another test pass. Continue this sequence until the paint particle size is uniform.

SB-2-001-F Page 5

To avoid hazardous bursting or equipment

damage, do not exceed the container's maximum working pressure.

Connect the fluid hose from the fluid outlet on the

tank or pump to the fluid inlet on the gun.

Open spreader adjustment valve for maximum pattern size. Open fluid adjustment screw until the first

thread is visible.

Shut off atomization air to the gun. Set the fluid

flow rate by adjusting the air pressure in the material container. Use about 6 psi for a remote cup and

about 15 psi for a 2-gallon, or larger, container.

Adjust the fluid flow in the following ways:

Remove the air cap. With atomization air off, pull

the trigger, flowing material into a clean, graduated

container for 10 seconds. Measure the amount of

material which flowed in that time and multiply

times 6 (or flow for 30 seconds and multiply time 2).

This is the fluid flow rate in ounces per minute. For

standard finishing, it should be about 14 to 16

ounces per minute. If the flow rate is less than this,

increase the air pressure in the container and repeat.

If the pattern seems starved for material and the

fluid adjusting screw is open wide (to the first

thread), the atomization air pressure may be too

high, or the material may be too heavy. Recheck the

viscosity or reduce the air pressure.

If the material is spraying too heavily and sagging,

reduce the material flow by turning in the fluid

adjusting screw (clockwise).

Figure 11 Pattern with Uneven Particle Size

Pressure Feed Components

A pressure feed system consists of a pressure feed

spray gun, pressure feed tank, cup or pump, an air

filter/regulator, appropriate air and fluid hoses and

an air compressor.

Connect the air hose from the air regulator to the air

inlet on the gun. Connect the mainline air hose to

the air inlet on the tank, cup or pump.

When the flow rate is correct, reinstall the air cap.

If fluid pressure at the tank, cup or pump exceeds 20

psi, the next larger fluid tip size should be used.

Turn the atomizaton air to about 30 psi at the gun.

Spray a fast test pattern on a clean sheet of paper

and check the consistency of the particle size.

Increase or decrease the air pressure until even

particle size is achieved.

Spray a horizontal test pattern holding the trigger

open until the material begins to run. Paint distribution across the full width of the pattern should be the

same (adjust with fan pattern adjustment). If it

cannot be adjusted, there may be a problem with

either the air cap or the fluid tip which must be

corrected. Refer to the Troubleshooting Section.

Hints for good spray technique.

Hold gun perpendicular 6" to 8" (HVLP guns) or 8"10" (suction, gravity or pressure conventional feed

guns) to surface being sprayed.

Don't tilt the gun in any direction. This will result in

uneven paint build causing runs and sags.

Trigger gun just before the edge of the surface to be

sprayed. The trigger should be held fully depressed

and the gun moved in one continuous motion, until

the other edge of the object is reached. Release the

trigger but continue the motion for a few inches until

it is reversed for the return stroke.

Page 6

Page 6 SB-2-001-F

Overlap each stroke 50%. Less than 50% will result

in streaks on the finished surface. Move the gun at

a constant speed while triggering since the material

flows at a constant rate.

Another technique of triggering is referred to as

"feathering". Feathering allows the operator to limit

fluid flow by applying only partial trigger travel.

Spray edges and corners first. This is called banding. Banding reduces overspray yet provides good

coverage on corners.

mended to replace both at the same time. Lapped

sets are available for most guns on pressure feed

combinations.

MAINTENANCE

AIR CAP - Remove the air cap from the gun and

immerse it in clean solvent. Blow it dry with compressed air.

If the small holes become clogged, soak the cap in

clean solvent. If reaming the holes is necessary, use

a toothpick, a broomstraw or some other soft

implement.

Incorrect

Correct

Figure 12 Spray Techniques

REPLACEMENT OF PARTS

Follow specific gun Service Bulletin exploded view

for replacing parts. There are areas requiring proper

sequence.

Do not clean holes with a wire, a nail or a similar

hard object. Doing so could permanently damage

the cap by enlarging the jets, resulting in a defective spray pattern.

Figure 13 Cleaning Air Cap

Suction or Pressure Feed Cleaning - A suction or

pressure feed gun with attached cup should be

cleaned as follows:

Turn off the air to the gun, loosen the cup cover and

remove the fluid tube from the paint. Holding the

tube over the cup, pull the trigger to allow the paint

to drain back into the cup.

The fan adjustment assembly should only be installed after turning the knob out. If left in, the stem

or needle could jam against the seat.

Pull trigger or remove fluid adjusting screw prior to

tip tightening. Tip and needle damage can occur.

Spray guns have some combination of plastic,

copper, leather and soft packings and gaskets. It is

recommended that these be replaced if the assembly is removed or when doing an overall repair. The

fluid needle packing must be replaced when the

packing nut bottoms out.

It is recommended to oil a new packing or needle

before assembly. Packing nuts should be tightened

just enough to seal (fluid leakage on pressure feed,

suction of air on suction feed). Too tight will bind

the needle as well as shorten life of packing. When

replacing the fluid tip or fluid needle, it is recom-

Page 7

Empty the cup and wash it with clean solvent and a

clean cloth. Clean off the outside of the tube. Fill

halfway with clean solvent and spray it through the

gun to flush out the fluid passages. Be sure to

comply with local codes regarding solvent disposal.

Then remove the air cap, clean it as previously

explained and replace it on the gun.

Wipe off the gun with a solvent soaked cloth, or if

necessary, brush the air cap and gun with a fiber

brush using clean-up liquid or thinner.

Cleaning a pressure feed gun with remote cup or

tank - Turn off air supply to cup or tank. Release

material pressure from the system by opening relief

valve. Material in hoses may be blown back. Lid

must be loose and all air pressure off. Keep gun

higher than container, loosen air cap approximately

2-3 turns, hold rag over air cap, and trigger gun until

atomizing air forces all material back into the pressure vessel.

SB-2-001-F Page 7

This device incorporates a highly efficient fluid

header, which meters a precise solvent/air mixture.

The cleaner operates with compressed air and

sends a finely atomized blast of solvent through the

fluid passages of the hose, the spray gun, etc.

This simple, easy to use cleaner speeds up equipment cleaning and saves solvent. It also reduces

VOC emissions. Be sure that both the hose cleaner

and gun are properly grounded.

Where local codes prohibit the use of a hose cleaner,

manually backflush the hose into the cup or tank

with solvent and dry with compressed air.

Clean the container and add clean solvent. Pressurize the system and run the solvent through until

clean. Atomization air should be turned off during

this procedure. Be sure to comply with local codes

regarding solvent dispersion and disposal.

Clean the air cap, fluid tip and tank. Reassemble for

future use.

A gun cleaner may be used for either type of gun.

This is an enclosed boxlike structure (vented) with

an array of cleaning nozzles inside.

Guns and cups are placed over the nozzles, the lid

is closed, the valve is energized, and the pneumatically controlled solvent sprays through the nozzles

to clean the quipment. The solvent is contained,

and must be disposed of properly.

Some states' codes require the use of a gun cleaner

and it is unlawful to discharge solvent into the

atmosphere. Another efficient method of cleaning

the hose and gun passages is with a "Gun & Hose

Cleaner" device, such as the "SolventSaver".

Note

Never soak the entire gun in cleaning solvent. This

will dry out the packings and remove lubrication.

LUBRICATION

Lubricate the fluid needle packing (A), the air valve

packing (B) the trigger bearing screw (C) and the

adjusting screw threads (D) with Spray Gun Lube,

*SSL-10, daily.

The fluid needle spring (E) should be lightly coated

with petroleum jelly.

Thoroughly clean the air cap and baffle threads (F),

and lubricate with spray gun lube, SSL-10, daily.

Lubricate each of these points after every cleaning

in a gun washer.

*A Material Safety Data Sheet is available from

DeVilbiss upon request.

C

D

A

F

D

Figure 14 Using a Hose Cleaner

E

B

Figure 15 Lubrications Points

Page 8

Page 8 SB-2-001-F

TROUBLESHOOTING

CONDITION CAUSE CORRECTION

Heavy top or bottom pattern Horn holes plugged. Clean. Ream with non-metallic

point.

Obstruction on top or bottom of Clean.

fluid tip.

Cap and/or tip seat dirty. Clean.

Heavy right or left Left or right side horn holes plugged. Clean. Ream with non-metallic

side pattern point.

Dirt on left or right side of fluid tip. Clean.

Remedies for the top-heavy, bottom-heavy, right-heavy and left-heavy patterns:

1) Determine if the obstruction is on the air cap or the fluid tip. Do this by making

a test spray pattern. Then, rotate the cap one-half turn and spray another

pattern. If the defect is inverted, obstruction is on the air cap. Clean the air cap

as previously instructed.

2) If the defect is not inverted, it is on the fluid tip. Check for a fine burr on the

edge of the fluid tip. Remove with #600 wet or dry sand paper.

3) Check for dried paint just inside the opening. Remove paint by washing with

solvent.

Heavy center pattern Fluid pressure too high for atomization Balance air and fluid pressure.

air (pressure feed)). Increase spray pattern width with

spreader adjustment valve.

Material flow exceeds air cap's capacity. Thin or lower fluid flow.

Atomizing pressure too low. Increase pressure.

Material too thick. Thin to proper consistency.

Split spray pattern Fluid adjusting knob turned in too far. Back out counterclockwise to

achieve proper pattern.

Atomization air pressure too high. Reduce at transformer.

Fluid pressure too low (pressure feed only). Increase fluid pressure.

Spreader adjusting valve set too high. Adjust.

Suction And Pressure Feed

Jerky or fluttering spray

*Loose or damaged fluid tip/seat. Tighten or replace.

Material level too low. Refill.

Container tipped too far. Hold more upright.

Obstruction in fluid passage. Backflush with solvent.

Loose or broken fluid tube or fluid Tighten or replace.

inlet nipple.

Dry or loose fluid needle packing nut. Lubricate or tighten.

*Most common problem.

Page 9

SB-2-001-F Page 9

CONDITION CAUSE CORRECTION

Jerky or fluttering spray Suction Feed Only

(continued)

Material too heavy. Thin or replace.

Container tipped too far. Hold more upright.

Air vent in cup lid clogged. Clear vent passage.

Loose, damaged or dirty lid. Tighten, replace or clean coupling

nut.

Dry or loose fluid needle packing. Lubricate or tighten packing nut.

Fluid tube resting on cup bottom. Tighten or shorten.

Damaged gasket behind fluid tip. Replace gasket.

Unable to get round spray Fan adjustment screw not seating Clean or replace.

properly.

Air cap retaining ring loose. Tighten.

Will not spray No air pressure at gun. Check air supply and air lines.

Internal mix or pressure feed air cap Change to proper suction feed air

and tip used with suction feed. cap and tip.

Fluid pressure too low with internal Increase fluid pressure at tank.

mix cap and pressure tank.

Fluid needle adjusting screw not open Open fluid needle adjusting screw.

enough.

Fluid too heavy for suction feed. Thin material or change to pressure

feed.

Starved spray pattern Inadequate material flow. Back fluid adjusting screw out to

first thread, or increase fluid

pressure at tank.

Low atomization air pressure Increase air pressure and re-

(suction feed). balance gun.

Excessive overspray Too much atomization air pressure Reduce pressure.

Gun too far from work surface. Adjust to proper distance.

Improper stroking (arcing, gun motion Move at moderate pace, parallel

too fast). to work surface.

Excessive fog Too much, or too fast-drying thinner. Remix properly.

Too much atomization air pressure. Reduce pressure.

Page 10

Page 10 SB-2-001-F

CONDITION CAUSE CORRECTION

Dry Spray Air pressure too high. Decrease air pressure.

Material not properly reduced Reduce to proper consistency.

(suction feed).

Gun tip too far from work surface. Adjust to proper distance.

Gun motion too fast. Slow down.

Gun out of adjustment Adjust.

Fluid leaking from Packing nut loose. Tighten, do not bind needle.

packing nut

Packing worn or dry Replace or lubricate.

Fluid leaking or dripping Packing nut too tight Adjust

from front of pressure

feed gun Dry packing. Lubricate.

Fluid tip or needle worn or Replace tip & needle with lapped

damaged sets.

Foreign matter in tip. Clean.

Fluid needle spring missing or Replace.

broken.

Wrong size needle or tip. Replace.

Needle bound by misaligned Tap sprayhead perimeter with a

sprayhead, (MBC guns only). wooden mallet. Retighten lock bolt.

Runs and sags Too much material flow. Adjust gun or reduce fluid pressure.

Material too thin. Mix properly or apply light coats.

Gun tilted on an angle. Hold gun at right angle to work and

adapt to proper gun technique.

Thin, sandy coarse finish Gun too far from surface. Check distance. Normally 6-8" - HVLP,

drying before it flows out 8-10" - conventional.

Too much air pressure. Reduce air pressure and check

spray pattern.

Improper thinner being used. Follow paint manufacturer's

mixing instructions.

Thick, dimpled finish Gun too close to surface. Check distance. Normally 6-8" - HVLP,

"orange peel". Too much 8-10" - conventional.

material coarsely

atomized Air pressure too low. Increase air pressure or reduce

fluid pressure.

Improper thinner being used. Follow paint manufacturer's

Material not properly mixed. Follow paint manufacturer's

Surface rough, oily, dirty. Properly clean and prepare.

mixing instructions.

mixing instructions.

Page 11

SB-2-001-F Page 11

SYSTEM SOLUTIONS FOR YOUR SPRAY FINISHING NEEDS

More than just a spray gun manufacturer, DeVilbiss

is your single source for practical solutions to all

your spray finishing challenges.

To maximize your production output, you need

consistent, reliable performance, high-quality results and a responsive service partner who knows

the industry and your business. And with DeVilbiss,

you not only get the equipment, you also get the

expertise.

Since 1888, we've advanced the science of spray

finishing by introducing innovative products and

technological developments that set the standards

for the industry. These efforts help ensure that we

can deliver the best solution for your particular spray

finishing applications.

Spray Guns

• Conventional air spray and HVLP

• Standard-size, midsize, manual and automatic

• Waterborne compatible, stainless steel passages

• Shading and touch-up guns for precision control

• Decorative guns for textured finish

• Duster guns for tough cleaning applications

• Gravity feed, suction feed, pressure feed

• MAX™ the only true ergonomic spray gun

Cups and Tanks

• Pressure, gravity and suction feed cups

• Aluminum, stainless steel and polyethylene

• ASME-certified galvanized and stainless tanks

• Tank capacities from 2 gallon to 15 gallon

• Air motor drives

Air Control

• Regulators and gauges

• Adjusting valves

• Centrifugal, coalescing, in-line and desiccant filters

Hose

• Fluid and air hose

• Ball and air-adjusting valves

• Fittings and connections

Additional Accessories

• Thread Adapters

• SolventSaver™ gun and hose cleaners

• Gun-mounted fluid strainers

• Replacement parts kits

• Air cap test kits

• Fluid regulators

Page 12

Page 12 SB-2-001-F

DeVILBISS WORLDWIDE SALES AND SERVICE LISTING - www.devilbiss.com

INDUSTRIAL FINISHING

DeVilbiss has authorized distributors throughout the world. FOR TECHNICAL ASSISTANCE OR THE DISTRIBUTOR

NEAREST YOU, CALL TOLL FREE 1-888-992-4657 (U.S.A. AND CANADA ONLY). FOR LOCAL CALLS, SEE LISTING

BELOW.

U.S./Canada Sales & Customer Service Office Address Telephone No.

GLENDALE HEIGHTS, IL 60139 195 Internationale Blvd. (630) 237-5000

Toll Free Fax No. 1-877-790-6965

AUTOMOTIVE REFINISHING

DeVilbiss has authorized distributors throughout the world. For equipment, parts and service, check the Yellow Pages

under "Automobile Body Shop Equipment and Supplies". FOR TECHNICAL ASSISTANCE, CALL TOLL FREE

1-800-445-3988 (U.S.A. ONLY). FOR LOCAL CALLS, SEE LISTING BELOW.

U.S. Customer Service Office Address Telephone No.

MAUMEE, OH 43537 1724 Indian Wood Circle (419) 891-8100

Toll Free Fax No. 1-800-445-6643

3/01 ©Copyright 2001, DeVilbiss Printed in U.S.A.

Loading...

Loading...