Page 1

SB-E-2-533

ISS.03

Operation Manual

Advanced Conventional Suction Feed Spraygun

E

E

FF

P 2 - 11

P 12 - 21

DD

P 22 - 31

Page 2

EE

Operation Manual

Advanced Conventional

Suction Feed Spraygun

Important

Read and follow all instructions and Safety Precautions before using this

equipment

Description

The Compact Suction feed Spraygun Kit complies to ATEX regulations 94/9/EC, protection

level;

Important: These Sprayguns are suitable for use with solvent based materials. These guns

are not designed for use with highly corrosive and/or abrasive materials and if used with such

materials it must be expected that the need for cleaning and/or replacement of parts will be

increased. If there is any doubt regarding the suitability of a specific material contact your local

Distributor or ITW Finishing direct.

Example: COM-S430-16

Aircap Fluid nozzle size

(16 = 1,6 mm)

II 2 G X, Suitable for use in Zones 1 and 2

Model Part Number

EC Declaration of Conformity

We: ITW Finishing UK, Ringwood Rd, Bournemouth, Dorset, BH11 9LH, UK, as the

manufacturer of the Spraygun model Compact, declare, under our sole responsibility, that the

equipment to which this document relates is in conformity with the following standards or other

normative documents:

BS EN 292-1 PARTS 1 & 2: 1991, BS EN 1953: 1999; and thereby conform to the

protection requirements of Council Directive 98/37/EC relating to Machinery Safety Directive,

and;

EN 13463-1:2001, council Directive 94/9/EC relating to Equipment and Protective

Systems intended for use in Potentially Explosive Atmospheres protection level II 2 G X.

ITW Finishing Systems and Products reserve the right to modify equipment specification without

prior notice.

© 2005 ITW Finishing Systems and Products

B. Holt, General Manager

30th June 2003

2

Page 3

SAFETY WARNINGS

EE

Fire and explosion

Solvents and coating materials

can be highly flammable or

combustible when sprayed. ALWAYS

refer to the coating material suppliers

instructions and COSHH sheets

before using this equipment

Users must comply with all local

and national codes of practice

and insurance company

requirements governing

ventilation, fire precautions, operation

and house-keeping of working

areas

This equipment, as supplied,

is NOT

Halogenated Hydrocarbons

Static Electricity can be

generated by fluid and/or air

passing through hoses, by the spraying

process and by cleaning non- conductive

parts with cloths. To prevent ignition

sources from static discharges, earth

continuity must be maintained to the

spraygun and other metallic equipment

used. It is essential to use

conductive air and/or fluid hoses.

suitable for use with

.

Personal Protective

Equipment

Toxic vapours – When

sprayed, certain materials may

be poisonous, create irritation

or be otherwise harmful to health.

Always read all labels and safety data

sheets for the material before spraying

and follow any recommendations.

If In Doubt, Contact Your

Material Supplier

The use of respiratory protective

equipment is recommended at all times.

The type of equipment must be

compatible with the material being

sprayed.

Always wear eye protection when

spraying or cleaning the spraygun

Gloves must be worn when

spraying or cleaning the equipment

Training – Personnel should be given

adequate training in the safe use of

spraying equipment.

Misuse

Never aim a spraygun at any part of the

body

Never exceed the max. recommended

safe working pressure for the equipment

The fitting of non-recommended or nonoriginal spares may create hazards

Before cleaning or maintenance, all

pressure must be isolated and relieved

from the equipment

The product should be cleaned using a

gun washing machine. However, this

equipment should not be left inside gun

washing machines for prolonged periods

of time.

Noise Levels

The A-weighted sound level of

sprayguns may exceed 85 dB

(A) depending on the set-up being used.

Details of actual noise levels are

available on request. It is recommended

that ear protection is worn at all times

when spraying.

Operating

Spray Equipment using high pressures

may be subject to recoil forces. Under

certain circumstances, such forces could

result in repetitive strain injury to the

operator.

3

© 2005 ITW Finishing Systems and Products

Page 4

EE

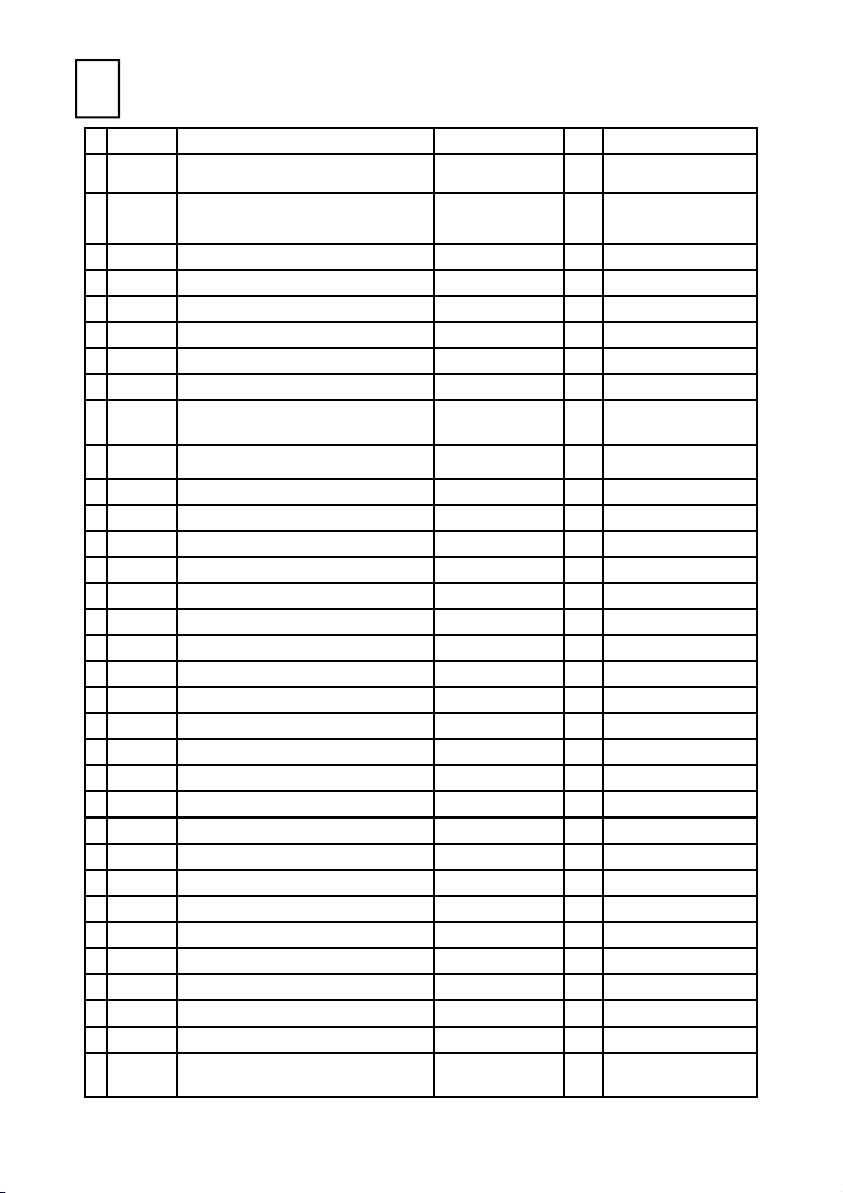

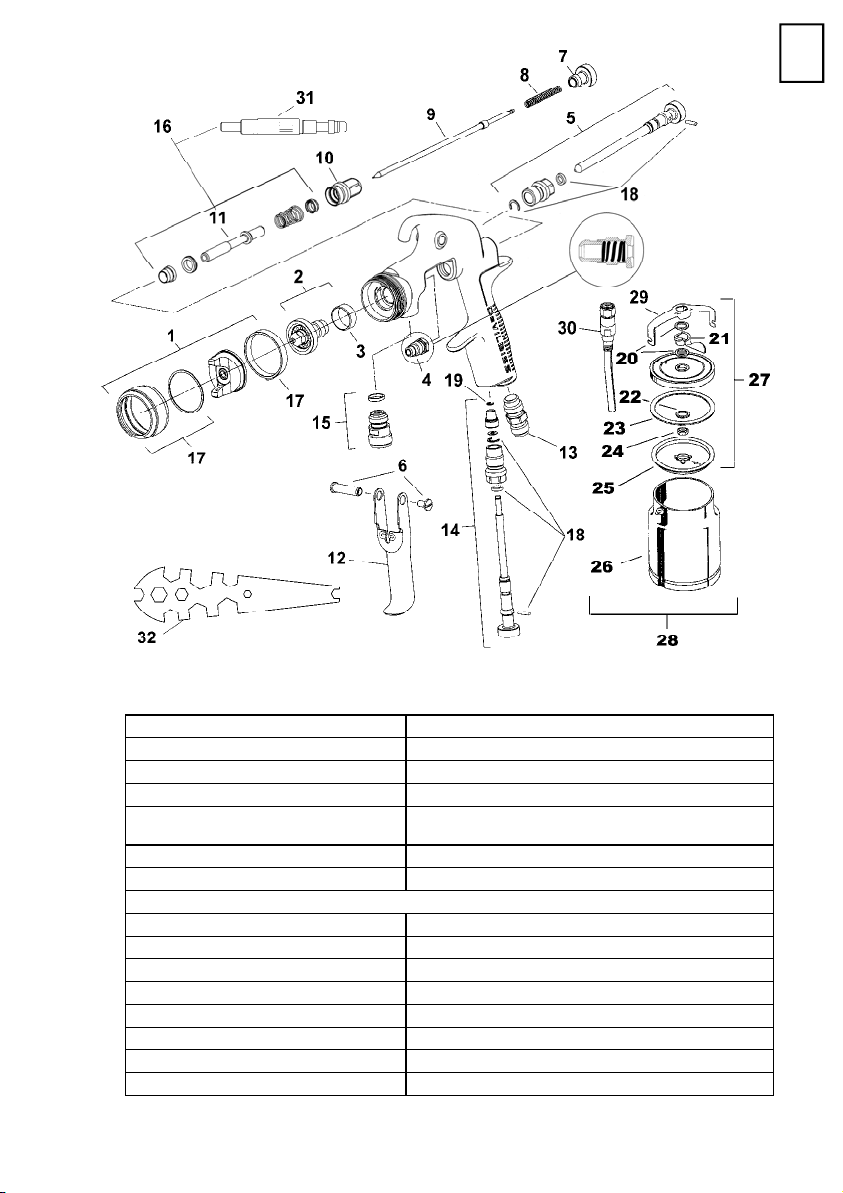

Ref. No Description Part Number Qty Options

1 Air Cap/Retaining ring SP-100-430-K 1

Parts List

+ 2 Nozzle SP-200S-**-K 1

+ 3 Separator SP-623-K5 5

+ 4 Packing GTI-445-K2 2

5 Spreader Valve SP-401-K 1

6 Stud and Screw GTI-408-K5 5

7 Needle Adjusting Screw SP-614-K 1

+ 8 Spring SP-622-K5 1

+ 9 Needle SP-300S-**-K 1

10 Airvalve housing + seal SP-612-K 1

+ 11 Spindle - 1

12 Trigger SP-617-K 1

13 Connector SP-611-K 1

14 Airflow Valve SP-402-K 1

15 Fluid Inlet Connector and seal SP-610–K 1

+ 16 Air Valve Service Kit SPK-101-K 1

17 RetainingRing and Seals SPK-102-K 1

+ 18 Spreader/ Cheater Service Kit GTI-428-K5 5

19 Circlip 25746-007-K5 5

20 Washer - kit of 5 KS-48-K5 2

21 Cam KR-445-1 1

22 Washer - kit of 5 KR-40-K5 1

23 Lid Gasket - kit of 3 KR-11-K3 1

24 Nut - kit of 5 KR-94-K5 1

25 Drip free diaphragm—kit of 5 KR-115-K5 1

26 Cup KR-466-K 1

27 Cup lid assembly KR-4001-B 1

28 Cup - KR-566-1-B 1

29 Yoke KR-77-1 1

30 Fluid Tube KR-456-B 1

+ 31 Air valve Assembly Tool 1

32 Spanner SPN-5 1

Spraygun Service Kit

(parts included marked + )

SPK-401-** 1

16,18,20,22

e.g ** =16 =1.6 mm

16,18,20,22

e.g ** =16 =1.6mm

16,18,20,22

e.g ** =16 =1.6 mm

© 2005 ITW Finishing Systems and Products

4

Page 5

EE

Patent No 2372465 (GB)

Air supply connection - Universal 1/4“ BSP and NPS

Fluid Supply Connection - Universal

Maximum static Air inlet pressure - P

Maximum static Fluid inlet pressure - P

Nominal gun Air inlet pressure -

with gun triggered

Maximum Service temperature 40°C

Gun Weight - 934 g

Gun body Aluminium

Nozzle Stainless Steel

Needle Stainless Steel

Fluid Inlet Stainless Steel / PTFE

Trigger Nickel Plated Steel

Cup Aluminium

Cup Lid Aluminium

Yoke Nickel Plated Steel

Specification

3

/8“ BSP and NPS

= 12 bar (175 psi)

1

= 15 bar (218 psi)

2

3.0 bar (44 psi)

Materials of Construction

5

© 2005 ITW Finishing Systems and Products

Page 6

EE

Important: To ensure that this equipment

reaches you in first class condition,

protective coatings have been used.

Flush the equipment through with a

suitable solvent before use.

1. Attach air hose to connector (13).

Recommended hose size 8 mm bore.

The hose must be conductive and

electrical bond from the spraygun to

earth should be checked with an

Installation

ohmeter. A resistance of less than 10

Ohms is recommended.

2. Attach the Cup Lid assembly (27) to

the Fluid Inlet connector (15).

3. Position the Yoke at right angles to the

Gun with the Cam lever (21) to the

front (see picture). Make sure the vent

hole in the lid is positioned under the

Yoke and the hole in the diaphragm

(25) is 180° to the Lid vent hole.

Operation

6

1. Mix coating material to manufacturers

instructions.

2. Fill the cup with the required amount

of material. Fill to no more than 25mm

(1“) from the top of the cup. DO NOT

OVERFILL.

3. Attach Cup to the Lid assembly.

4. Turn needle adjusting screw (7)

clockwise to prevent movement.

5. Turn spreader valve (5) counterclockwise to fully open.

6. Adjust inlet air pressure to give 3 bar

(44 psi) at the gun inlet with the gun

triggered. (pressure gauge attachment

shown under Accessories is

recommended for this).

7. Turn needle adjusting screw counter

clockwise until first thread shows.

8. Test spray. If the finish is too dry

reduce airflow by reducing air inlet

pressure or by the Airflow Valve (14).

Preventative Maintenance

1. Turn off air and relieve pressure in

the supply lines, or if using QD

system, disconnect from airline.

2. Release Cup and raise the tube out

of the material. Trigger the Gun and

allow material to drain back into the

cup. Dispose of the surplus material.

3. Clean the cup. Remove the Drip free

diaphragm and clean. Replace the

diaphragm if is split or damaged.

4. Check the breather hole in the Lid is

Screw the Adjusting Knob (14) in to

reduce pressure.

9. If finish is too wet reduce fluid flow by

turning needle screw (7) clockwise or

reducing the fluid pressure. If

atomisation is too coarse, increase

inlet air pressure. If too fine reduce

inlet pressure.

10. The pattern size can be reduced by

turning adjusting valve (5) clockwise.

11. Hold gun perpendicular to surface

being sprayed. Arcing or tilting may

result in uneven coating.

12. The recommended spray distance is

150-200 mm (6”-8”).

13. Spray edges first. Overlap each stroke

a minimum of 50%. Move gun at a

constant speed.

14. Always turn off air supply and relieve

pressure when gun is not in use.

not blocked.

5. Remove air cap (1) and clean. If any

of the holes in the cap are blocked

with coating material use a toothpick

to clean. Never use metal wire which

could damage the cap and produce

distorted spray patterns

6. Ensure the tip of the nozzle (2) is

clean and free from damage. Build up

of dried paint can distort the spray

pattern.

© 2005 ITW Finishing Systems and Products

6

Page 7

7. Lubrication – stud/screw (6), needle

(9) and air valve (11) should be oiled

each day.

Replacement of Parts

EE

Nozzle (2) and Needle (9) – Remove

parts in the following order: 7, 8, 9, 1 and

2. Replace any worn or damaged parts

and re-assemble in reverse order.

Recommended tightening torque for

nozzle (2) 9.5-12 Nm (80-100 lbf in).

Packing – Remove parts 7, 8, 9.

Unscrew cartridge (4). Fit new cartridge

finger tight. Re-assemble parts 9, 8, and

7 and tighten cartridge (4) with spanner

sufficient to seal but to allow free

movement of needle. Lubricate with gun

oil.

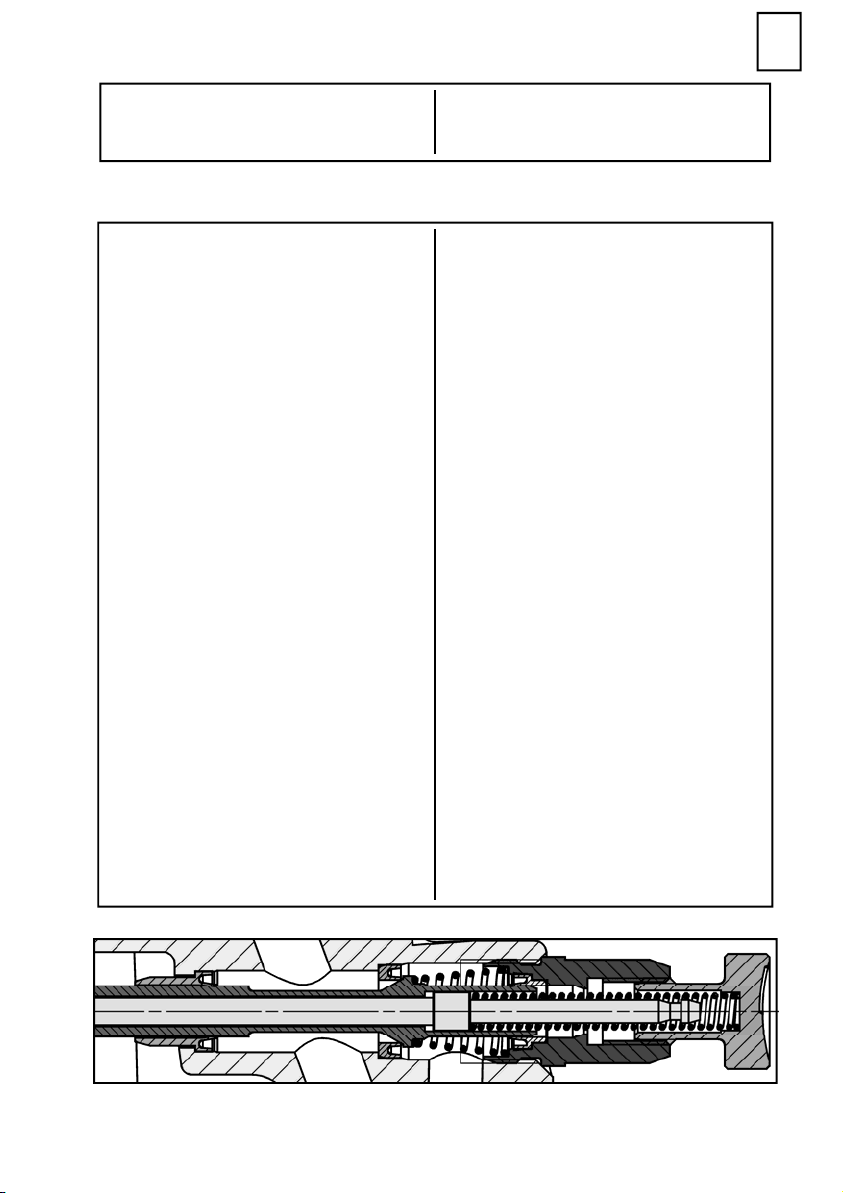

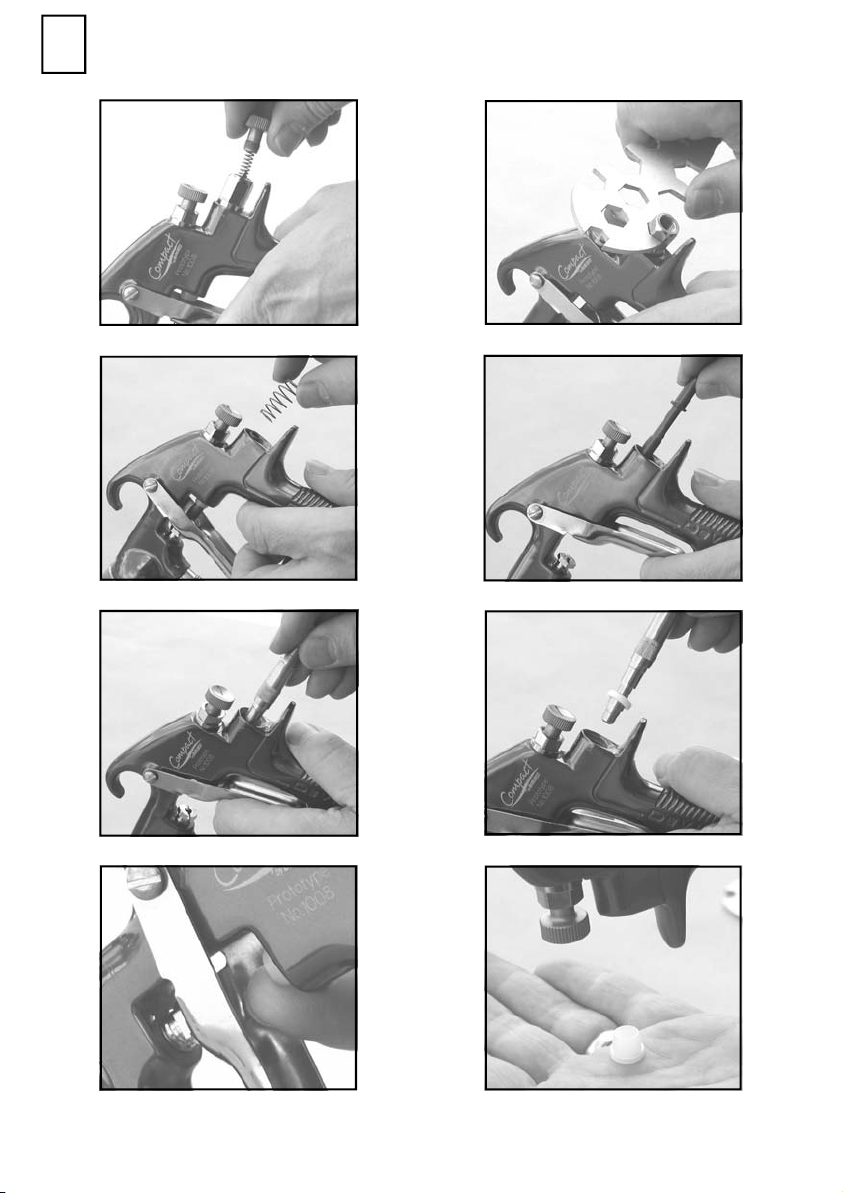

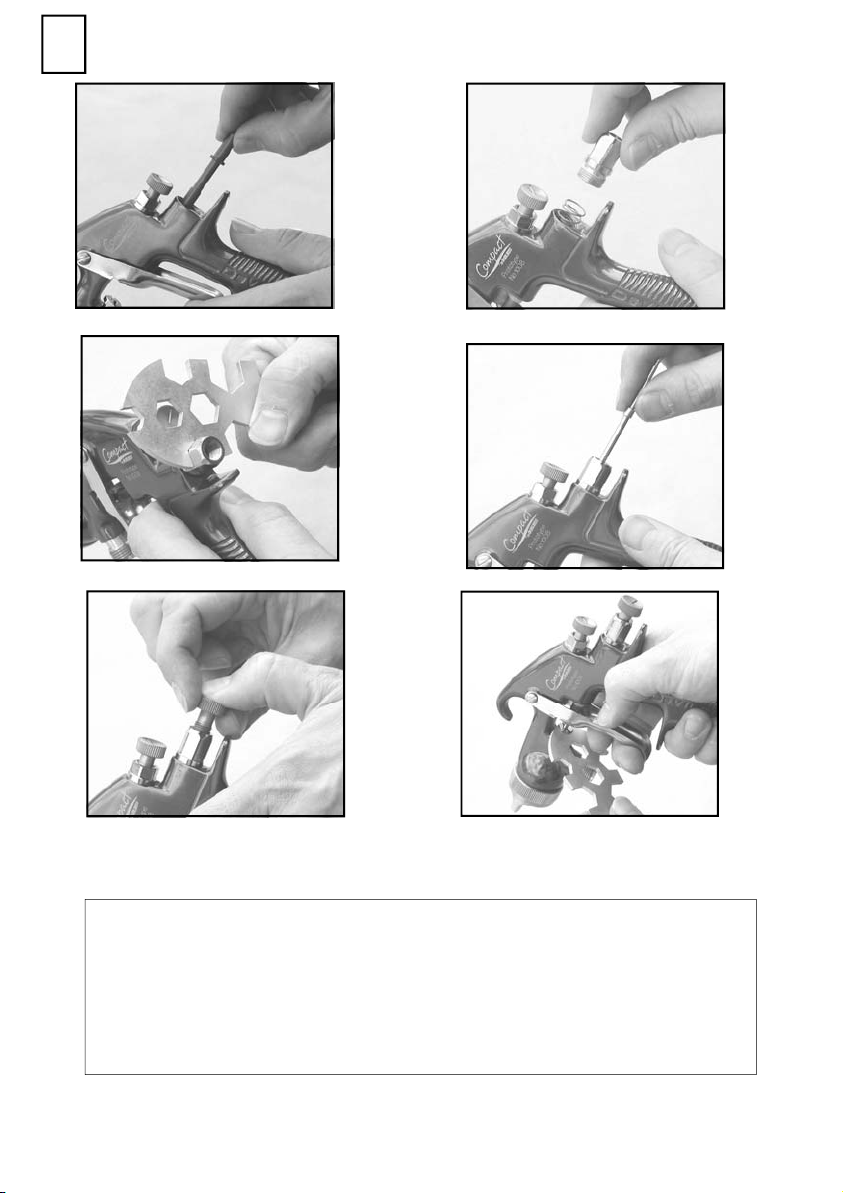

Air Valve Seal Kit (16) - (Refer to

photos 1 to 28 and fig 2).

1. Remove Adjusting Knob (7), Spring

(8), and Needle (9).

2. Loosen Housing (10).

3. Remove Housing (10) and Airvalve

Spring.

4. Remove Valve (11).

5. Using Service Tool SPN-7, engage

groove behind the Valve Seat.

6. Remove Valve Seat.

7. Push out the Front Airvalve Seal with

a finger.

8. Turn the Gun upside down and let the

Seal fall out.

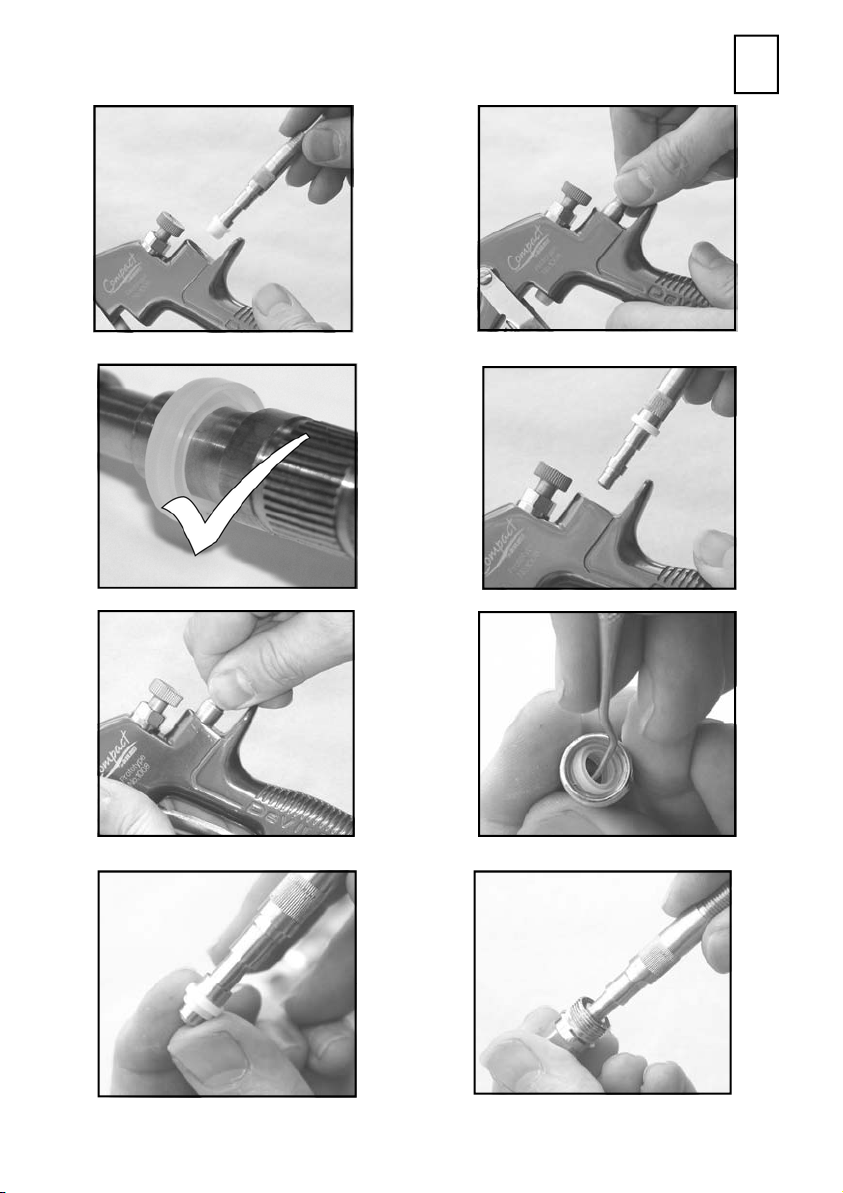

9. Fit New Front Seal to Service Tool.

10. Fit new Seal to gunbody and press

firmly to ensure Seal is engaged.

11. Fit New Valve Seat to Service Tool.

Groove must face outwards.

12. Fit Valve Seat to Gunbody.

13. Remove Rear Airvalve Seal from

housing (10) with a hooked

instrument.

14. Fit new Seal to Service Tool.

15. Fit Seal to Housing (10).

16. Replace Valve (11).

17. Replace Valve Spring and screw in

Housing (10).

18. Tighten Housing.

19. Fit Needle (9).

20. Fit Spring (8) and Knob (7).

21. Adjust Needle Packing (4) with

Spanner sufficient to seal but to allow

free movement of needle. Lubricate

with gun oil.

Spreader valve (5) – Caution: always

ensure that the valve is in the fully open

position by turning screw fully counterclockwise before fitting to body.

Air cap / Nozzle Selection

Refer to coating material manufacturers

recommendations or ITW Finishing UK

Website:

www.itweuropeanfinishing.com

FIG 2

7

© 2005 ITW Finishing Systems and Products

Page 8

EE

1 2

3 4

5 6

7 8

© 2005 ITW Finishing Systems and Products

8

Page 9

EE

9 10

11

12

14

11a

13

15

9

© 2005 ITW Finishing Systems and Products

Page 10

EE

16

18

20

17

19

21

Accessories

Spanner – order SPN-5

Cleaning Brush – order 4900-5-1-K3

Regulator/Gauge Attachment - order HAV-501-B

Pressure gauge Attachment – order GA-515

Gun Mounted Regulator – order DVR-501

Spraygun Lubricant - order GL-1-K10

© 2005 ITW Finishing Systems and Products

10

Page 11

EE

11

© 2005 ITW Finishing Systems and Products

Page 12

FF

Manuel d'utilisation

Pistolet à aspiration

classique avancé

Important

Lire attentivement toutes les instructions et suivre les Consignes de sécurité

avant d'utiliser ce matériel

Description

Le kit pistolet à aspiration Compact est conforme à la réglementation ATEX 94/9/CE, niveau de

protection

Important :

pistolets ne sont pas conçus pour l’utilisation avec des produits fortement corrosifs et/ou

abrasifs. S’ils sont utilisés avec de tels produits, ils devront être nettoyés et/ou les pièces

devront être remplacées plus souvent. S’il y a le moindre doute en ce qui concerne le

caractère approprié d’un produit spécifique, contactez votre distributeur local ou ITW

Finishing directement.

Exemple : COM-S430-16

Chapeau d'air Dimension de la buse

(16 = 1,6 mm)

II 2 G X et peut être utilisé dans les Zones 1 et 2

Ces pistolets peuvent être utilisés avec des produits à base de solvant. Ces

Numéro de référence du modèle

Déclaration de conformité CE

Nous : ITW Finishing UK, Ringwood Rd, Bournemouth, Dorset, BH11 9LH, Royaume-Uni,

en tant que fabricant du Pistolet Compact, déclarons, sous notre entière responsibilité, que le

matériel auquel ce document se rapporte est conforme aux normes suivantes ou à d'autres

documents normatifs :

BS EN 292-1 PARTIES 1& 2: 1991, BS EN 1953:1999 ; et est donc conforme aux exigences

de protection de la Directive du conseil 98/37/CEE relative à la Directive sur la sécurité des

machines et de

EN 13463-1:2001, la Directive du conseil 94/9/CE relative aux Équipements et systèmes de

protection prévus pour les atmosphères potentiellement explosives, niveau de protection

II 2 G X.

ITW Finishing Systems and Products se réserve le droit de modifier les spécifications des équipements sans préavis

© 2005 ITW Finishing Systems and Products

.

12

B. Holt, Directeur général

30/6/2003

Page 13

CONSIGNES DE SECURITE

FF

Incendie et explosion

Les solvants et produits de

revêtement peuvent être

extrêmement inflammables ou combustibles

lorsqu'ils sont pulvérisés. Se reporter

TOUJOURS

fournisseurs de produits et aux fiches

COSHH avant d'utiliser le pistolet.

ventilation, les précautions à prendre contre

l'incendie, le fonctionnement et la surveillance

des lieux de travail.

Ce pistolet, tel qu'il est fourni, n'est PAS

prévu pour les hydrocarbures halogénés.

d'inflammation avec des décharges statiques,

la continuité à la terre doit être maintenue

avec le pistolet et tout autre materiel

métallique utilisé. Il est essentiel d'utiliser des

flexibles d'air et/ou de liquide conducteurs.

aux instructions des

Les utilisateurs doivent se conformer

aux codes de pratique locaux et

nationaux et aux exigences des

compagnies d'assurance régissant la

De l'électricité statique peut être

produite par le liquide et/ou l'air qui

circule dans les flexibles, par le

processus de pulvérisation et par le

nettoyage de pièces nonconductrices avec des chiffons.

Pour éviter de créer des sources

Équipement de protection

individuel

Vapeurs toxiques – Lorsqu'ils sont

pulvérisés, certains produits peuvent

être toxiques, irritants ou

les étiquettes et les fiches signalétiques des

produits avant de les pulvériser, et respecter

les consignes de sécurité. En cas de doute,

contacter le fournisseur du produit.

pulvérisé

généralement nocifs. Toujours lire

Il est recommandé d'utiliser un

appareil de protection respiratoire à

tout moment. Le type d'appareil doit

être compatible avec le produit

.

Toujours porter une protection

oculaire pour pulvériser ou nettoyer le

pistolet.

Porter des gants pour pulvériser ou

nettoyer le pistolet.

Formation – Le personnel doit être formé à

l'utilisation sans risque apprendre du pistolet.

Mauvaise utilisation

Ne jamais diriger le pistolet vers une

quelconque partie du corps.

Ne jamais excéder la pression de service

maximale recommandée pour le pistolet.

La pose de pièces détachées nonrecommandées ou qui ne sont pas d'origine

peut être à l'origine de risques.

Avant le nettoyage ou l'entretien, isoler et

évacuer la pression du pistolet.

Nettoyer le pistolet avec une machine

spécialement conçue à cet effet. Toutefois, ne

pas laisser le pistolet à l'intérieur de la

machine pendant une période prolongée.

Niveaux sonores

Le niveau sonore pondéré A des

pistolets de pulvérisation peu

dépasser 85 dB (A) selon la

configuration utilisée. Le détail des

niveaux sonores actuels est disponible sur

demande. Le port de protecteurs d'oreilles est

recommandé à tout moment pendant la

pulvérisation.

Utilisation

Le pistolet fonctionne sous hautes pressions

susceptibles de provoquer un effort de recul.

Dans certains cas, ces forces peuvent infliger

des microtraumatismes répétés à l’utilisateur.

13

© 2005 ITW Finishing Systems and Products

Page 14

FF

Liste de pièces

Repère Description Réf Options

1 Chapeau d’air/bague de retenue

2 Buse

+

3 Séparateur

+

4 Presse-étoupe

+

5 Valve de réglage de jet

6 Goujon et vis

7 Vis de réglage d'aiguille

8 Ressort

+

9 Aiguille

+

10 Logement de soupape d'air

11 Tige

+

12 Gâchette

13 Raccord

14 Valve de débit d’air

15 Raccord d'entrée de produit et joint

16 Kit d'entretien de soupape d'air

+

17 Bague de retenue et joints

18 Kit d'entretien de valve de réglage/

+

20 Rondelle - Jeu de 5

21 Came

22 Rondelle

23 Joint de couvercle - Jeu de 3

24 Ecrou - Jeu de 5

25 Membrane antigoutte - Jeu de 5

26 Godet

27 Ensemble couvercle de godet

28 Godet

29 Chape

30 Tube à produit

+ 31

32

cheater

19 Circlip

Outil de montage de soupape d'air 1

Clé SPN-5 1

Kit d'entretien de pistolet

(pièces comprises marquées d'un +)

SP-100-430-K

SP-200S-**-K

SP-623-K5

GTI-445-K2

SP-401-K

GTI-408-K5

SP-614-K

SP-622-K5

SP-300S-**-K

SP-612-K

SP-617-K

SP-611-K

SP-402-K

SP-610–K

SPK-101-K

SPK-102-K

GTI-428-K5

25746-007-K5

KS-48-K5 2

KR-445-1 1

KR-40-K5 1

KR-11-K3 1

KR-94-K5 1

KR-115-K5 1

KR-466-K 1

KR-4001-B 1

KR-566-1-B 1

KR-77-1 1

KR-456-B 1

SPK-401-**

Qté

1

1

5

2

1

5

1

1

1

1

1

1

1

1

1

1

1

5

5

1

16,18,20,22

ex. ** =16 =1,6 mm

16,18,20,22

ex. ** =16 =1,6mm

16,18,20,22

ex. ** =16 =1,6 mm

© 2005 ITW Finishing Systems and Products

14

Page 15

Brevet N° 2372465(GB)

FF

Spécifications

Raccord d’alimentation d’air -

Raccord d'alimentation de produit -

Pression d’entrée statique d'air maximale

Pression d’entrée statique de liquide maximale -

Pression d’entrée d’air nominale de pistolet gâchette actionnée

Température de service maximale - 40°C

Poids du pistolet et du godet 934 g

Corps du pistolet Aluminium

Buse Acier inoxydable

Aiguille Acier inoxydable

Entrée de produit Acier inoxydable / PTFE

Gâchette Acier nickelé

Godet Aluminium

Couvercle de godet Aluminium

Chape Acier nickelé

Universal 1/4“ BSP and NPS

Universel

P

P

3 bar (44 psi)

Matières de construction

3

/8" BSP et NPS

= 12 bar (175 psi)

1

= 15 bar (218 psi)

2

15

© 2005 ITW Finishing Systems and Products

Page 16

FF

Installation

Important : Des revêtements protecteurs ont

été utilisés pour que ce matériel vous

parvienne en parfait état. Rincer le matériel

avec un solvant approprié avant utilisation.

1. Brancher le flexible d'air au raccord (13). Le

diamètre de flexible recommandé est de 8

mm. Le flexible doit être conducteur et la

liaison électrique du pistolet à la terre doit

être contrôlée avec un ohmmètre. Une

résistance inférieure à 10

6

Ω est

Fonctionnement

1. Mixer le produit selon les instructions du

fabricant.

2. Remplir le godet avec la quantité requise de

produit. Le niveau de produit doit s'arrêter à

25 mm ou plus du haut du godet. NE PAS

REMPLIR EXCESSIVEMENT.

3. Fixer le godet à l'ensemble couvercle.

4. Tourner la vis de réglage de l'aiguille (7)

dans le sens horaire pour interdire tout

mouvement.

5. Tourner la valve de réglage du jet (5) dans

le sens anti-horaire pour l'ouvrir

complètement.

6. Régler la pression d'entrée d'air de manière

à obtenir 3 bar (44 psi) à l'entrée du pistolet

quand la gâchette est actionnée. (le

manomètre illustré sous la rubrique

Accessoires est recommandé à cet effet).

7. Tourner la vis de réglage dans le sens antihoraire jusqu'à l'apparition du premier filet.

8. Faire un essai de pulvérisation. Si le fini est

trop sec, réduire le débit d'air en réduisant

la pression d'entrée d'air ou avec la valve de

débit d'air (14). Serrer le bouton de réglage

recommandée.

2. Fixer l'ensemble couvercle de godet (27) au

raccord d'entrée de produit (15).

3. Positionner la chape à angle droit par

rapport au pistolet, avec le levier de came

(21) à l'avant (voir illustration). Vérifier que

l'évent du couvercle se trouve sous la

chape et que l'orifice de la membrane (25)

se trouve à 180° de l'évent du couvercle.

(14) pour réduire la pression.

9. Si le fini est trop humide, tourner la vis de

réglage de l’aiguille (7) dans le sens horaire

peur diminuer le débit de produit, ou réduire

la pression du produit. Si la pulvérisation est

trop grossière, augmenter la pression

d’entrée d’air. Si elle est trop fine, réduire la

pression d’entrée.

10. La taille de la forme de pulvérisation peut

être réduite en tournant la valve de réglage

(5) dans le sens horaire.

11. Maintenir le pistolet perpendiculaire à la

surface de travail. Le revêtement risque de

ne pas être uniforme si l'on incline le pistolet

vers le haut ou le bas.

12. La distance de pulvérisation préconisée est

150-200 mm.

13. Commencer par pulvériser les bords.

Empiéter au moins de moitié sur la

pulvérisation précédente en déplaçant le

pistolet à vitesse régulière.

14. Toujours couper l’arrivée d’air et évacuer la

pression quand le pistolet est inutilisé.

Entretien préventif

1. Couper l’arrivée d’air et évacuer la pression

des conduites d’air. Si le système QD est

utilisé, le débrancher de la conduite d’air.

2. Dégager le godet et sortir le tube du produit.

Actionner la gâchette et laisser le produit

revenir dans le godet. Se débarrasser de

l'excédent de produit.

3. Nettoyer le godet. Retirer et nettoyer la

membrane antigoutte. Remplacer la

membrane si elle est fendue ou

© 2005 ITW Finishing Systems and Products

endommagée.

4. Vérifier que le trou d'évent du couvercle

n'est pas bouché.

5. Enlever et nettoyer le chapeau d’air (1). Si

les trous du chapeau sont bouchés par le

produit, les déboucher avec un cure-dent.

Ne jamais utiliser de fil métallique au risque

d’endommager le chapeau et de déformer la

pulvérisation.

16

Page 17

FF

6. Vérifier que la buse (2) est propre et en bon

état. Une accumulation de peinture sèche

risque de déformer la pulvérisation.

Remplacement de pièces

Buse (2) et aiguille (9) – Déposer les pièces

dans l'ordre suivant : 7, 8, 9, 1 et 2. Remplacer

les pièces usées ou endommagées. Pour la

repose, inverser l'ordre. Le couple de serrage

recommandé de la buse (2) est 9,5-12 Nm.

Presse-étoupe – Déposer les pièces 7, 8, et 9.

Dévisser la cartouche (4). Poser une cartouche

neuve et la visser à la main. Reposer les pièces

9, 8 et 7, puis serrer la cartouche (4) avec une

clé, suffisamment pour assurer l'étanchéité tout

en permettant à l'aiguille de bouger librement.

Lubrifier à l'huile de pistolet.

Kit joint de soupape d'air (16) – (voir les

photos 1 à 28).

1. Retirer le bouton de réglage (7), le ressort

(8) et l'aiguille (9).

2. Desserrer le logement (10).

3. Déposer le logement (10) et le ressort de la

soupape d'air.

4. Déposer la soupape (11).

5. A l'aide de l'outil d'entretien SPN-7, engager

la rainure derrière le siège de la soupape.

6. Déposer le siège de la soupape.

7. Extraire le joint avant de la soupape d'air en

le poussant du doigt.

8. Retourner le pistolet pour faire tomber le

joint.

9. Placer un joint avant neuf sur l'outil

d'entretien.

10. Poser le joint neuf sur le corps du pistolet et

appuyer fermement dessus pour bien

7. Graissage – huiler chaque jour le goujon/la

vis (6), l’aiguille (9) et la soupape d’air (11).

l'engager.

11. Placer un siège de soupape neuf sur l'outil

d'entretien.

12. Poser le siège de soupape sur le corps du

pistolet.

13. Retirer le joint de soupape d'air arrière du

logement (10) à l'aide d'un instrument

crochu.

14. Placer un joint neuf sur l'outil d'entretien.

15. Poser le joint dans le logement (10).

16. Remettre la tige (11).

17. Reposer le ressort de soupape et visser le

logement (10).

18. Serrer le logement.

19. Monter l'aiguille (9).

20. Monter le ressort (8) et le bouton (7).

21. Régler le presse-étoupe de l'aiguille (4) avec

une clé de façon à assurer l'étanchéité mais

à ne pas gêner le mouvement de l'aiguille.

Lubrifier à l’huile de pistolet.

Valve de réglage de jet (5) – Attention :

toujours s'assurer que la valve est en position

d'ouverture maximum en tournant la vis à fond

dans le sens anti-horaire avant la pose sur le

corps.

Sélection de chapeau d'air / buse

Se reporter aux recommandations du fabricant

du produit de revêtement ou visiter le site Web

d'ITW Finishing UK :

www.itweuropeanfinishing.com

FIG 2

17

© 2005 ITW Finishing Systems and Products

Page 18

FF

1 2

3 4

5 6

7 8

© 2005 ITW Finishing Systems and Products

18

Page 19

FF

9 10

11

12

14

11a

13

15

19

© 2005 ITW Finishing Systems and Products

Page 20

FF

16

18

20

17

19

21

Accessoires

Clé – N° de commande SPN-5

Brosse de nettoyage – N° de commande 4900-5-1-K3

Régulateur/manomètre – Réf. HAV-501-B

Manomètre – Réf. GA-515

Régulateur monté sur pistolet – Réf. DVR-501

Lubrifiant de pistolet – Réf. GL-1-K10

© 2005 ITW Finishing Systems and Products

20

Page 21

FF

21

© 2005 ITW Finishing Systems and Products

Page 22

DD

Betriebsanleitung

COMPACT - konventionelle

Saugbecher-Spritzpistole

Bitte lesen und befolgen Sie alle Anweisungen und Sicherheitshinweise,

Diese Spritzpistole kann sowohl mit wasserlöslichen als auch mit auf Lösungsmitteln basierenden Beschichtungsstoffen verwendet werden. Düsen und Nadeln sind aus rostfreiem Stahl.

Die COMPACT Kessel-Spritzpistole ist gemäß Richtlinie ATEX 94/9/EG, Schutzstufe II 2 G X,

zugelassen und kann in den Zonen 1 und 2 eingesetzt werden.

Wichtig: Diese Spritzpistolen sind nicht für den Einsatz mit stark korrosiven und/oder abreibenden Materialien geeignet. Bei Einsatz mit solchen Stoffen muss davon ausgegangen

werden, dass der Aufwand für die Reinigung und/oder der Bedarf an Ersatzteilen steigt. Sollte

es irgendwelche Zweifel geben, ob ein bestimmtes Material geeignet ist, wenden Sie sich bitte

an Ihren örtlichen Händler oder direkt an ITW Oberflächentechnik.

bevor Sie das Gerät in Betrieb nehmen

Wichtig

Beschreibung

Modell-Teilenummer

Beispiel: COM-S430-16

Luftkappe Größe der Farbdüse

(16 = 1,6 mm)

EG-Konformitätserklärung

Wir: ITW Finishing UK, Ringwood Rd, Bournemouth, Dorset, BH11 9LH, UK erklären

eigenverantwortlich als Hersteller des Spritzpistolenmodells COMPACT, dass das Gerät, auf

das sich dieses Dokument bezieht, die folgenden Richtlinien oder Normendokumente einhält:

BS EN 292-1 TEILE 1 & 2: 1991, BS EN 1953:1999.

Daher halten diese Geräte die Schutzanforderungen der folgenden Vorschriften ein: Richtlinie

des EU-Rates 89/37/EWG zur Maschinenrichtlinie und EN 13463-1:2001, Richtlinie des EURates 94/9/EG zu Geräte und Schutzsysteme, die für den Einsatz in potenziell explosiven

Umgebungen eingesetzt werden, Schutzstufe II 2 G X.

B. Holt, General Manager

ITW Finishing Systems and Products behält sich das Recht vor, die technischen Daten der

Geräte ohne vorherige Benachrichtigung zu ändern.

30/6/03

© 2005 ITW Finishing Systems and Products

22

Page 23

SICHERHEITSHINWEISE

DD

Feuer und Explosionen

Lösemittel und Beschichtungsstoffe

können leicht entflammbar oder brennbar

sein, wenn sie verspritzt oder versprüht werden.

Schlagen Sie IMMER die Anweisungen des

Herstellers für den Beschichtungsstoff und

die COSHH-Blätter nach, bevor Sie diese

Geräte benutzen.

Die Anwender müssen sämtliche örtlichen

und nationalen Arbeitsvorschriften und

Anforderungen der Behörden und Berufsgenossenschaften erfüllen, und zwar hinsichtlich

Belüftung, Brandbekämpfung, Betrieb und

allgemeine Praxis am Arbeitsplatz.

Diese Geräte sind in ihrem gelieferten

Zustand NICHT dazu geeignet, mit

halogenisiertem Kohlenwasserstoff

verwendet zu werden.

Beim Durchfluss von Flüssigkeiten und/

oder Luft durch Schläuche, beim Spritzlackieren und beim Reinigen von nicht-

leitenden Teilen mit Lappen können

statische Aufladungen entstehen. Die

Spritzpistole und alle eingesetzten Geräte aus

Metall müssen ständig geerdet sein, um

Zündquellen von statischen Entladungen zu

vermeiden. Es müssen auf jeden Fall leitende

Luft- und/oder Materialschläuche verwendet

werden.

Schutzausrüstung für das

Personal

Giftige Dämpfe – Bestimmte Materialien

sind giftig, können Ausschläge verursachen oder auf andere Weise gesund-

heitlich schädigend sein. Lesen Sie bitte

immer alle Schilder und Datenblätter für das

Material durch, bevor Sie mit dem Lackieren

beginnen; befolgen Sie alle Empfehlungen. Falls

Zweifel bestehen, wenden Sie sich bitte an

Ihren Materiallieferanten.

Es wird empfohlen, jederzeit Atem-

schutzgeräte zu verwenden. Die

Schutzstufe der Geräte muss dem

jeweils verarbeiteten Material entsprechen.

Augenschutz muss immer beim

Lackieren oder bei der Reinigung

getragen werden.

Handschuhe müssen immer beim

Lackieren oder bei der Reinigung

getragen werden.

Training – Das Personal muss für den gefahrlosen Einsatz der Spritzgeräte entsprechend

ausgebildet werden.

Missbrauch

Eine Spritzpistole darf auf keinen Fall auf

irgendeinen Körperteil gerichtet werden.

Der maximale, empfohlene, sichere Arbeitsdruck

für die Geräte darf niemals überschritten werden.

Der Einbau von Ersatzteilen, die nicht empfohlen

werden oder nicht original sind, könnte ein

Gefahrenrisiko darstellen.

Vor der Reinigung oder einer Wartung muss die

Druckluftversorgung abgetrennt werden; der

Restdruck muss in den Geräten abgebaut

werden.

Spritzgeräte sollten mit einer Wascheinrichtung

für Spritzgeräte gereinigt werden. Die Geräte

sollten jedoch nicht über lange Zeiträume in der

Wascheinrichtung belassen werden.

Geräuschpegel

Der A-gewichtete Geräuschpegel von

Spritzpistolen kann 85 dB (A) überschreiten, abhängig von der verwendeten Luftkappe. Einzelheiten über die

tatsächlichen Geräuschpegel sind auf

Anfrage erhältlich. Es wird empfohlen, beim

Spritzlackieren immer einen Gehörschutz zu

tragen.

Betrieb

Spritzgeräte, die mit hohem Druck arbeiten,

können Rückstöße erzeugen. In bestimmten

Situationen können diese Rückstöße Überlastungsschäden beim Bediener verursachen.

23

© 2005 ITW Finishing Systems and Products

Page 24

DD

Patentnr. 2372465(GB)

DD

Technische Daten

Lufteingang Materialeingang -

Maximaler, statischer Einlassluftdruck Maximaler, statischer Materialdruck -

Nominaler SpritzpistolenEinlassluftdruckabgezogener Pistole -

Maximale Einsatztemperatur - 40°C

Pistolengewicht inkl. Becher - 934 g

Pistolenkörper Aluminium

Düse Rostfreier Stahl

Farbnadel Rostfreier Stahl

Materialeinlass Rostfreier Stahl/PTFE

Becher Aluminium

Becherdeckel Aluminium

© 2005 ITW Finishing Systems and Products

Universal 1/4“ BSP and NPS

Universal 3/8" BSP und NPS

= 12 bar (175 psi)

P

1

= 15 bar (218 psi)

P

2

3 bar (44 psi)

Fertigungsmaterialien

24

Page 25

Stückliste

DD

Ref. Nr. Beschreibung Teilenummer Stück

1 Luftkappe 430 mit Dichtungen SP-100-430-K 1

2* Düse SP-200S-**-K 1

3* Luftverteiler (5 Stück) SP-623-K5 1

4* Farbnadelpackung (2 Stück) GTI-445-K2 1

5 Strahlregulierventil SP-401-K 1

6 Bolzen mit Schraube (5 Stück) GTI-408-K5 1

7 Farbnadelstellschraube SP-614-K 1

8* Feder SP-622-K5 1

9* Farbnadel SP-300S-**-K 1

10 Ventilgehäuse SP-612-K 1

11* Spindel - 1

12 Fingerabzug SP-617-K 1

13 Lufteinlassnippel SP-611-K 1

14 Luftfeinregulierventil SP-402-K 1

15 Farbeinlassnippel SP-610-K 1

16* Dichtungen und Feder für Luftventil SPK-101-K 1

17 Luftkappenhaltering mit Dichtungen SPK-102-K 1

18* Dichtung, Stift und Sprengring (5 Stück) GTI-428-K5 2

19 Sprengring (5 Stück) 25746-007-K5 1

20 Scheibe (5 Stück) KS-48-K5 2

21 Spannhebel KR-445-1 1

22 Scheibe KRW-40 1

23 Deckeldichtung (3 Stück) KR-11-K3 1

24 Mutter (5 Stück) KR-94-K5 1

25 Tropfschutz (5 Stück) KR-115-K5 1

26 Becher KR-466-K 1

27 Deckel, komplett KR-4001-B 1

28 Becher, komplett mit Deckel KR-566-1-B 1

29 Bügel KR-77 1

30 Ansaugrohr KR-456-B 1

31 Werkzeug für Luftventil 1

32 Pistolenschlüssel SPN-5 1

* Teile im Service Set enthalten. Bestell-Nr. SPK-401-...-K (bitte Düsengröße angeben)

** verfügbare Größen:

1.4, 1.6, 1.8, 2.0, 2.2 mm

25

© 2005 ITW Finishing Systems and Products

Page 26

DD

Inbetriebnahme

Wichtig: Um zu gewährleisten, dass Sie die

Geräte in erstklassigem Zustand erhalten,

wurden sie mit einer Schutzschicht überzogen.

Spülen Sie die Geräte vor dem Gebrauch

mit einem geeigneten Lösungsmittel durch.

1. Schließen Sie den Luftschlauch an den

Lufteingang (13) an. Ein Schlauch mit

einem Innendurchmesser von mindestens

8 mm wird empfohlen. Der Schlauch muss

elektrisch leitend sein. Prüfen Sie die

elektrische Leitfähigkeit von der Spritz-

Betrieb

1. Die Beschichtungsstoffe laut Hersteller-

angaben mischen.

2. Den Becher mit der gewünschten Material-

menge füllen. Nicht mehr als 25 mm unter

den Rand des Bechers füllen.

3. Becher am Deckel befestigen.

4. Drehen Sie die Farbnadelstellschraube (7)

im Uhrzeigersinn, um eine Bewegung der

Farbnadel zu vermeiden.

5. Drehen Sie das Strahlregulierventil (5)

gegen den Uhrzeigersinn ganz auf.

6. Stellen Sie den Einlassluftdruck so ein,

dass sich am Pistoleneinlass bei

abgezogener Pistole ein Druck von 3 bar

(44 psi) ergibt. Dazu wird der Einsatz des

Luftregulierventils mit Manometer (HAV501-B) empfohlen.

7. Drehen Sie die Farbnadelstellschraube (7)

gegen den Uhrzeigersinn, bis der erste

Gewindegang sichtbar ist.

8. Spritztest. Wenn der Auftrag zu trocken ist,

reduzieren Sie die Luftzufuhr durch Verringern des Einlassluftdrucks oder durch

Drehen des Luftfeinregulierventils (14) im

pistole zur Erde mit einem Ohmmeter. Der

Widerstand sollte unter 106 Ω liegen.

2. Den Becherdeckel (27) mit dem Materialeinlass (15) verbinden.

3. Der Bügel muss rechtwinklig zur Pistole

stehen und der Spannhebel (21) muss

nach vorne zeigen (siehe Abbildung). Das

Belüftungsloch im Deckel muss unter dem

Bügel sein. Das Loch im Tropfschutz muss

zum Luftloch im Deckel um 180° versetzt

sein.

Uhrzeigersinn.

9. Wenn der Auftrag zu nass ausfällt, reduzieren Sie die Materialzufuhr durch Drehen

der Farbnadelstellschraube (7) im Uhrzeigersinn. Wenn die Zerstäubung zu grob

erfolgt, erhöhen Sie den Einlassluftdruck. Ist

sie zu fein, reduzieren Sie den Einlassluftdruck.

10. Der Spritzstrahl kann durch Drehen des

Strahlregulierventils (5) eingestellt werden.

11. Pistole senkrecht zur zu spritzenden Fläche

führen. Ein Kippen oder Neigen kann zu

ungleichmäßigen Beschichtungsstärken

führen.

12. Der empfohlene Spritzabstand beträgt

150 - 200 mm.

13. Die Ränder zuerst spritzen. Jede Bahn um

mindestens 50 % überlappen. Die Pistole

mit gleichförmiger Geschwindigkeit bewegen.

14. Wenn die Pistole nicht verwendet wird, soll

die Luftversorgung immer abgedreht und

der Druck abgelassen werden.

Vorbeugende Wartung

1. Drehen Sie die Luftversorgung ab und

lassen Sie den Druck aus den Leitungen

ab. Wenn Sie ein Schnellwechsel-System

verwenden, hängen Sie die Luftversorgung

ab.

2. Becher lösen. Betätigen Sie den Fingerabzug und lassen das Beschichtungsmaterial

aus dem Ansaugrohr in den Becher zurückfließen.

3. Entsorgen Sie überschüssiges Material und

reinigen Sie den Becher. Nehmen Sie den

Tropfschutz ab und reinigen Sie ihn.

Wechseln Sie den Tropfschutz aus, wenn er

© 2005 ITW Finishing Systems and Products

abgenützt oder beschädigt ist.

4. Stellen Sie sicher, dass das Entlüftungsloch

im Deckel nicht verstopft ist.

5. Nehmen Sie die Luftkappe (1) ab und

reinigen Sie diese. Wenn die Löcher in der

Luftkappe mit Beschichtungsmaterial verschmutzt sind, können diese mit einem

Zahnstocher gereinigt werden. Metalldraht

darf dazu jedoch niemals verwendet

werden, da die Luftkappe dadurch beschädigt werden könnte, wodurch ein ungleichmäßiger Spritzstrahl entsteht.

26

Page 27

6. Sorgen Sie dafür, dass die Spitze der Düse

(2) sauber und nicht beschädigt ist. Ablagerungen aus getrocknetem Lack können den

Spritzstrahl ebenfalls verfälschen.

Austausch von Teilen

7. Schmierung: Bolzen/Schraube (6), Farbnadel (9) und Luftventil (11) sollten jeden

Tag eingeölt werden.

DD

Düse (2) und Farbnadel (9) – Teile in der

folgenden Reihenfolge ausbauen: 7, 8, 9, 1

und 2. Alle abgenützten und beschädigten

Teile ersetzten und in umgekehrter

Reihenfolge zusammenbauen. Empfohlenes

Drehmoment für die Düse (2) 9,5 - 12 Nm.

Farbnadelpackung (4) – Teile 7, 8 und 9

ausbauen. Farbnadelpackung (4) abschrauben. Neue Farbnadelpackung handfest

einschrauben. Teile 9, 8 und 7 einbauen und

Farbnadelpackung (4) mit dem Pistolenschlüssel ausreichend festziehen, damit sie

dicht sitzt; die Farbnadel muss sich jedoch

frei bewegen lassen.

Luftventil und Dichtungen (11/16) - siehe

Fotos 1 bis 21 und Abbildung 2.

1. Teile 7,8 und 9 ausbauen.

2. Ventilgehäuse (10) entfernen.

3. Ventilfeder herausnehmen.

4. Spindel (11) aus dem Pistolenkörper

nehmen.

5. Verwenden Sie das Werkzeug SPN-7 und

führen es in den Pistolenkörper ein.

6. Nehmen Sie nun den Ventilsitz heraus.

7. Drücken Sie die vordere Luftventildichtung mit einem Finger heraus.

8. Drehen Sie die Spritzpistole um und

lassen Sie die Dichtung herausfallen.

9. Setzen Sie eine neue Dichtung vorne auf

das Werkzeug SPN-7.

10. Drücken Sie nun die Dichtung in den

Pistolenkörper ein.

11. Setzen Sie einen neuen Ventilsitz auf das

Werkzeug.

12. Setzen Sie den Ventilsitz im Pistolenkörper ein.

13. Entfernen Sie die hintere Luftventildichtung aus dem Ventilgehäuse (10).

14. Setzen Sie eine neue Dichtung auf das

Werkzeug.

15. Setzen Sie die Dichtung in das Ventilgehäuse (10) ein.

16. Ersetzen Sie die Spindel (11).

17. Wechseln Sie die Ventilfeder aus und

schrauben Sie das Ventilgehäuse (10)

ein.

18. Ziehen Sie das Ventilgehäuse fest.

19. Setzen Sie die Farbnadel (9) ein.

20. Montieren Sie die Feder (8) und die

Farbnadelstellschraube (7).

21. Stellen Sie die Farbnadelpackung (4) mit

einem Pistolenschlüssel so ein, dass sie

abdichtet, die Farbnadel sich jedoch frei

bewegen lässt. Ölen Sie mit Pistolenöl (6-

428) ein.

Strahlregulierventil (5) – Vorsicht: Sorgen

Sie dafür, dass das Ventil immer voll geöffnet

ist, bevor es im Pistolenkörper montiert wird;

dazu drehen Sie die Schraube ganz gegen den

Uhrzeigersinn.

Luftkappen– und Düsenauswahl

Schlagen Sie die Empfehlungen vom Hersteller

für den Beschichtungsstoff nach oder schauen

Sie auf den Internetseiten von ITW

Oberflächentechnik nach:

www.itw-finishing.de

Abb. 2

27

© 2005 ITW Finishing Systems and Products

Page 28

DD

1 2

3 4

5 6

7 8

© 2005 ITW Finishing Systems and Products

28

Page 29

DD

9 10

11

12

14

11a

13

15

29

© 2005 ITW Finishing Systems and Products

Page 30

DD

16

18

20

17

19

21

© 2005 ITW Finishing Systems and Products

30

Page 31

Zubehör

Pistolenschlüssel – Bestell-Nr. SPN-5

Reinigungsbürste (3 Stück) – Bestell-Nr. 4900-5-1-K3

Service Set – Bestell-Nr. SPK-401-..-K

Filter für Lufteingang – Bestell Nr. HAF-507

Luftregulierventil mit Manometer – Bestell-Nr. HAV-501-B

Mess - und Mischbecher (50 Stück) – Bestell Nr. MC-1-K50

Viskositäts-Messbecher DIN4 (2 Stück) - Bestell-Nr. 7000-114-K2

Wartungsöl, silikonfrei (Flasche mit 75 ml) – Bestell-Nr. 6-428

Schmierfett, silikonfrei (Tube mit 50 g) – Bestell-Nr. AGMD-010

Handreinigungstücher SCRUBS (6 Eimer à 72 Tücher) - Bestell-Nr. 192218-K6

(bitte Düsengröße angeben)

DD

31

© 2005 ITW Finishing Systems and Products

Page 32

ITW Finishing Systems and Products

Ringwood Road,

Bournemouth,

BH11 9LH,

England.

Tel. No. (01202) 571111

Telefax No. (01202) 581940,

Website address http://www.itweuropeanfinishing.com

ITW Oberflächentechnik GmbH & Co. KG

Justus-von-Liebig-Straße 31

63128 Dietzenbach

Telefon: (06074) 403-1

Telefax: (06074) 403-300

Internet: http://www.itw-finishing.de

ITW Surfaces et Finitions

163-171 avenue des Auréats B.P. 1453

26014 VALENCE CEDEX FRANCE

Tél. (33) 475-75-27-00

Télex 345 719F DVILBIS

Téléfax: (33) 475-75-27-99

ITW Finishing Systems and Products is a Division of ITW Ltd. Reg. Office:

Admiral House,

St Leonard’s Road,

Windsor,

Berkshire,

SL4 3BL,

UK

Registered in England: No 559693 Vat No 619 5461 24

© 2005 ITW Finishing Systems and Products

NOV- 05

32

Loading...

Loading...