DeVilbiss OMX-5, OMX-6 Owner's Manual

Service Bulletin

SB-2-230-E

The

Right

Way

To

Finish"

Replaces SB-2-230-D

CE

OMX GRAVITY fEED HVLP

PAINT SPRAY

GUN

OWNER'S

MANUAL

IMPORTANT: Before

using

this

equipa

ment, read all

safety

precautions starting

on

Page 2. Other

safety

precautions are

also

noted throughout this manual. Keep

for future

use.

Record

the

gun

outfit

number

that

is

printed

on

the carton:

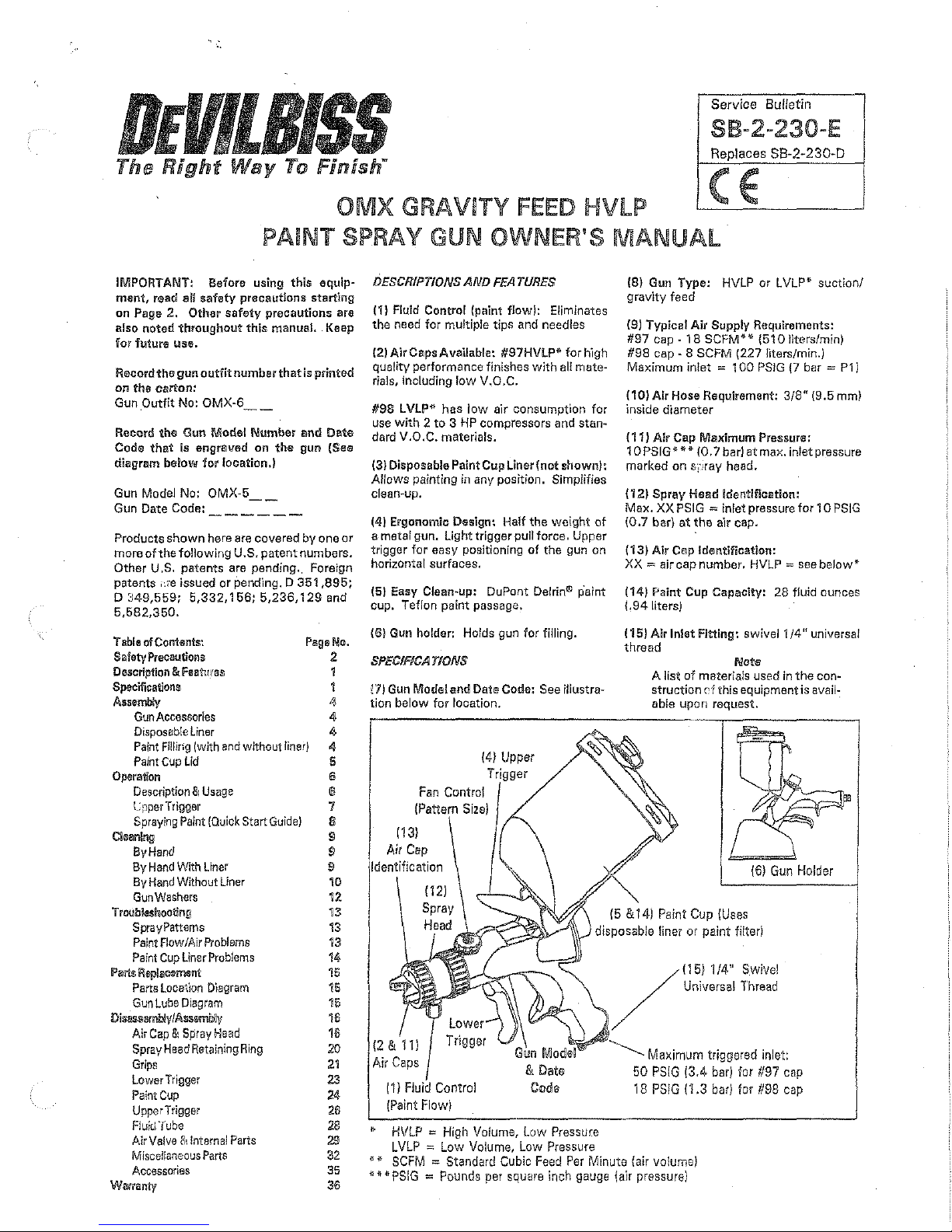

Gun

Outfit No: OMX-6

__

Record the Gun Model Number and

Date

Code

that

is engraved on

the

gun (Sea

diagram

below

for location.)

Gun

Model No: OMX-5

__

Gun

Date

Code:------

Products

shown

here are covered

by

one

or

more of

the

following U.S.

patent

numbers.

Other

U.S.

patents

are pending._ Foreign

patents

,._,-a

issued

or

Pending. D 351

,895;

0

349,559;

5,332,

156;

5,236,129

and

5,582,350.

Table

of

Contents:

Safety

Precautions

Description & Featums

Speciftcatlons

Assembly

Gun

Accessories

Disposable

Uner

PagaNo.

2

1

1

4

4

4

Paint

Filling

(with and without

liner)

Paint

Cup

Lid

4

5

6

6

7

8

9

9

9

Opera1lon

Description & Usage

LpperTrigger

Spraying Paint

(Quick

Start

Guide)

Cie1llnlng

By

Hand

By

Hand

With

Liner

By

Hand

Without

Liner

Gun

Washers

Troubleshooting

Spray

Patterns

Paint

Flow/Air

Problems

Paint

Cup

Uner

Problems

fsrts

R&placemsnt

Parts

Location

Diagram

Gun

Lube

Diagram

Oisassambly/Assembly

Air

Cap

8t

Spray

Haad

Spray

Head

Retaining

Ring

Grips

Lower

Trigger

Paint

Cup

Upper

Trigger

F!uiu

Tube

.D-.irVa!ve

8t

Internal

Parts

Misce!!aneous

Parts

Accessories

Warranty

10

12

13

13

13

14

15

15

15

16

16

20

21

23

24

26

28

23

32

35

36

DESCRIPTIONS

AND FEATURES

(1) Fluid Control (paint flow): Eliminates

the

need

for multiple

tips

and

needles

{2)

Air

Caps

Available:

#97HVlP*

for high

quality

performance

finishes

withal!

mate-

rials, including

!ow

V.O.C.

#98

LVLP*

has

low

air

consumption

for

use

with 2 to 3 HP

compressors

and

stan-

dard V.O.C.

materials.

(31

Disposable Paint Cup Liner

{not

shown):

Allows painting

in

any

position. Simplifies

clean-up.

(41

Ergonomic Design: Half

the

weight

of

a

metal

gun.

Ught

trigger

pull

force.

Upper

trigger for

easy

positioning

of

the

gun

on

horizontal

surfaces.

(5) Easy

Clean~up:

DuPont De!rin® p'aint

cup. Teflon

paint

passage,

{6)

Gun

holder: Holds gun for filling.

SPECIFICATIONS

t7l Gun Model

and

Date

Code:

See

illustra-

tion

below

for location.

{4) Upper

{131

{8) Gun

Type:

HVLP

or

LVLP*

suction/

gravity feed

{9) Typical

Air

Supply Requirements:

#97

cap

-18

SCFM**

(510liters/min)

#98

cap-

8

SCFM

(227 liters/min.)

Maximum

inlet =

100

PS!G

{7

bar

= P1)

(10)

Air

Hose Requirement:

3/8"

{9.5 mm)

inside

diameter

( 11)

Air

Cap Maximum Pressure:

1 0

PSIG

jf

* * (0. 7 bar)

at

max. inlet

pressure

marked

on

sr··.,ray

head.

{12)

Spray

Head Identification:

Max.

XX

PSIG = inlet

pressure

for 1 0 PSIG

{0.7 bar} at the

air

cap.

{13)

Air

Cap Identification:

XX=

air

cap

number.

HVLP

=see

below*

(14) Paint Cup Capacity: 28 fluid

ounces

(.94liters)

!15) Air Inlet Fitting:

swivel1/4"

universal

thread

Note

A list

of

materials

used

in

the

con~

struction

cf

this

equipment

is avail-

able

upon

request.

15

&141

Paint

Cup

{Uses

disposable

liner

or

paint

filter}

i Control

(Paint

Flow)

*

HVLP = High

Volume,

Low

Pressure

LVLP = Low

Volume,

Low

Pressure

115)

1/4" Swivel

Universal

Thread

Maximum triggered inlet:

50

PSIG

(3.4

bar)

for

#97

cap

18

PSIG

{1.3

bar)

for

#98

cap

*

lf

SCFM =

Standard

Cubic Feed Per Minute

{air

volume)

***PSIG

=Pounds

per

square

inch

gauge

\air

pressure)

Page

2 88·2·230-E

SAFETY

PRECAUTIONS

This

manual

contains

information

that

is

important

for

you

to

know

and

understand.

This information

relates

to

USER

SAFETY and

PREVENTING EQUIPMENT PROBLEMS. To help

you

recognize

this

information,

we

use

the

following

symbols.

Please pay particular

attention

to

these

sections.

WARNIN<:

Note

important

safety

information

~

A hazard

that

may

cause

serious

injury or

loss

of

life.

Important

information

that

tells

how

to

prevel'lt damage

to

equipment, or how

to

avoid a situation

that

may cause minor

lnury.

You should pay special attention to this

information.

Hazard

Fire

Inhaling

Toxic

Substances

Explosion Hazard

~

incompatible

Materials

WARNING

The following hazards

may

occur during

the

normal use

of

this

equipment.

Please

reacl

the

following chant before using this equipment.

Causa

Solvents and

coatings

can

be

highly

flammable

or

combustible

especially

when

sprayed.

Certain materials

may

be

harmful

if

inhaled,

or

if

there

is

contact

with

the

skin.

Halogenated

hydrocarbon

solvents -for

example;

methylene

chloride

and

1, 1, 1

Trich!'oroethane are

not

chemicaHy

com-

patible

w'1th

the

aluminum

that

might

be

used

in

many

system components. The

chemical reaction caused

by

these

solvents reacting

with

aluminum

can

become violent and lead

to

an

equipment

explosion.

Safeguards

Adequate

exhaust

must

be provided

to

keep air tree

of accumulations

of

flammable

vapors,

Smoking

must

never

be

allowed

in

the

spray area.

Fire extinguishing

equipment

must

be

present

in

the

spray

area.

Static

discharges

musts

be

prevented.

Ground

atl

conductive

objects

in

the

spray

area, such

as

cleaning

solvent

bucket,

fire

extinguisher,

etc.

When

us'1ng

solvents

for

cleaning:

G Those used

for

equipment

flushing

musts

have a flash

point equal

to

or

higher

than

that

of

the

cOating.

,.,

Those used

for

general cleaning

must

have flash points

above

100'

F (37.8

C).

Follow the requirements

of

the

Material

Safety

Data

Sheet supplied

by

your

coating

material manufacturer.

Adequate

exhaust

must

be

provided

to

keep

the

air

free

of

accumulations

of

toxic

materials.

Use

a mask or

respirator

whenever

there

ls a chance

of

inhaling sprayed materials.

The

mask

must

be

compat-

ible

with

the

material being

sprayed

and its concentra-

tion. Equipment

must

be

as

prescribed

by

an industrial

hygienist or

safety

expert,

and

be

NIOSH

approved.

The

OMX

HVLP

Paint Spray Gun can be used

with

these

solvents.

·However,

aluminum

is

widely

used

tn

other

spray application

equipment,

such

as

material pumps,

cups and regulators,

valves,

etc.

Check

a!!

equipment

items before

use

and

make

sure

they

can

also

be

used

safely

with

these

solvents,

Read

the

label

or

data sheet

for

the

material

you

intend

to

spray.

If

in

doubt

as

to

whether

or

not a coating

or

cleaning material is

compatible, contact

your

material supplier.

SAFETY PRECAUTIONS

(conllnuedl

Hazard

General Safety

Nolse

i£-

..

-els

-Ear

Injury

Misuse

I

Cause

Improper

operation

or

maintenance

of

equipment.

A

continuous

A-weighted

sound pressure

level

of

this

spray gun may exceed

85

dB(A) depending on

the

air cap/spray

head

setup

being used. Sound levels

are measured using an impulse sound

level

meter

and analyzer, when the

gun is being used in a normal spraying

application.

SB-2-230-E

Page

3

Safeguards

Operators

should be given adequate training in the safe

use

and maintenance

of

the

equipment

{in accordance

with

the

requirements

of

NFPA-33, Chapter

15

in U.S.).

User

must

comply

with

all local and national codes

of

practice

and insurance

company

requirements govern-

ing

ventilation,

fire precautions,

operation,

maintenance

and housekeeping. In

the

U.S., these are OSHA Sections

1910.94

and

1910.107

and NFPA-33).

Always

wear

ear

protection

when

using

the

gun.

Details

of

actual noise levels produced

by

the

various air

cap/spray

head setups are available

upon

request.

~

A!! spray guns

project

particles

at

high

velocity

and

must

never

be aimed

at

any

part

of

the

body.

e

Never

exceed

the

recommended

safe

working

pressures

for

any

of

the

equipment used.

o The

fitting

of

non~recommended

or

non-original accessories or spare

parts

may

crate hazardous conditions.

~Before

dismantling

he

equipment

for cleaning

or

maintenance all pressure, air and materials,

must

be

isolated and released.

The disposal

of

waste

materials

must

be carried out in

an

approved manner. Burning

may

generate toxic

fumes,

The removal

of

waste

solvents and

coating

materials should be carried

out

by

an

authorized

local

waste

disposal service.

Cumulative

Trauma

Dlsorders(CT!l's)

"(TO'S" ,ormulculo-

s~-a~letal

disorders,

!n·

valva damage

to

the

hands,

wriat,

elbows.,

shoulders,

neck

&back.

Carpal

tunnel

syndrome

and

tendinitis

{such

as

tennis

elbow

or

rotator

cuff syndrome)

011re

eJmmp!es

of

CTD's,

Use

of hand too!s may

ca·use

cumu!ative

trauma disorders {CTD's),

CTD'

s, when using

hand

tools, tend to affect

the upper extremities. Factors

which

may

increase the

risk of developing a

CTD

include:

1.

H'1gh

frequency of the activity,

2.

EJ(Cessiveforce,

such

as

gripping,

pinching,

or

pressing with the

hands

and

fingers.

3.

Extreme

or

awkward finger, wrist

or

arm positions.

4.

Excessive duration of the activity,

5.

Tool vibration.

6.

Repeated

pressure

on a body

part.

7.

Working

in

cold

temperature:::.

CTD' scan also

be

caused

by

such

activities

as

sewing, golf, tennis

and

bowling, to

name

a few.

Risk

is

reduced

by avoiding

or

lessening factors 1 ~ 7.

Pain,

tingling,

or

numbness in the shoulder, forearm, wrist,

hands

or

fingers, especiallydurir1!]the night, may

be

early symptoms of a

CTD.

Do

not ignore them. Should

you

experience

any

such symptoms,

see a physic;.-m

immediately.

Other early symptoms may include vague discomfort

in

the

hand,

loss of

manual

dexterity,

and

nonspecific pain

in

the

arm.

Ignoring early symptoms

and

continued repetitive

use

ot

the arm, wrist

and

hand

can

lead to serious disability,

Page

4 88·2·230-E

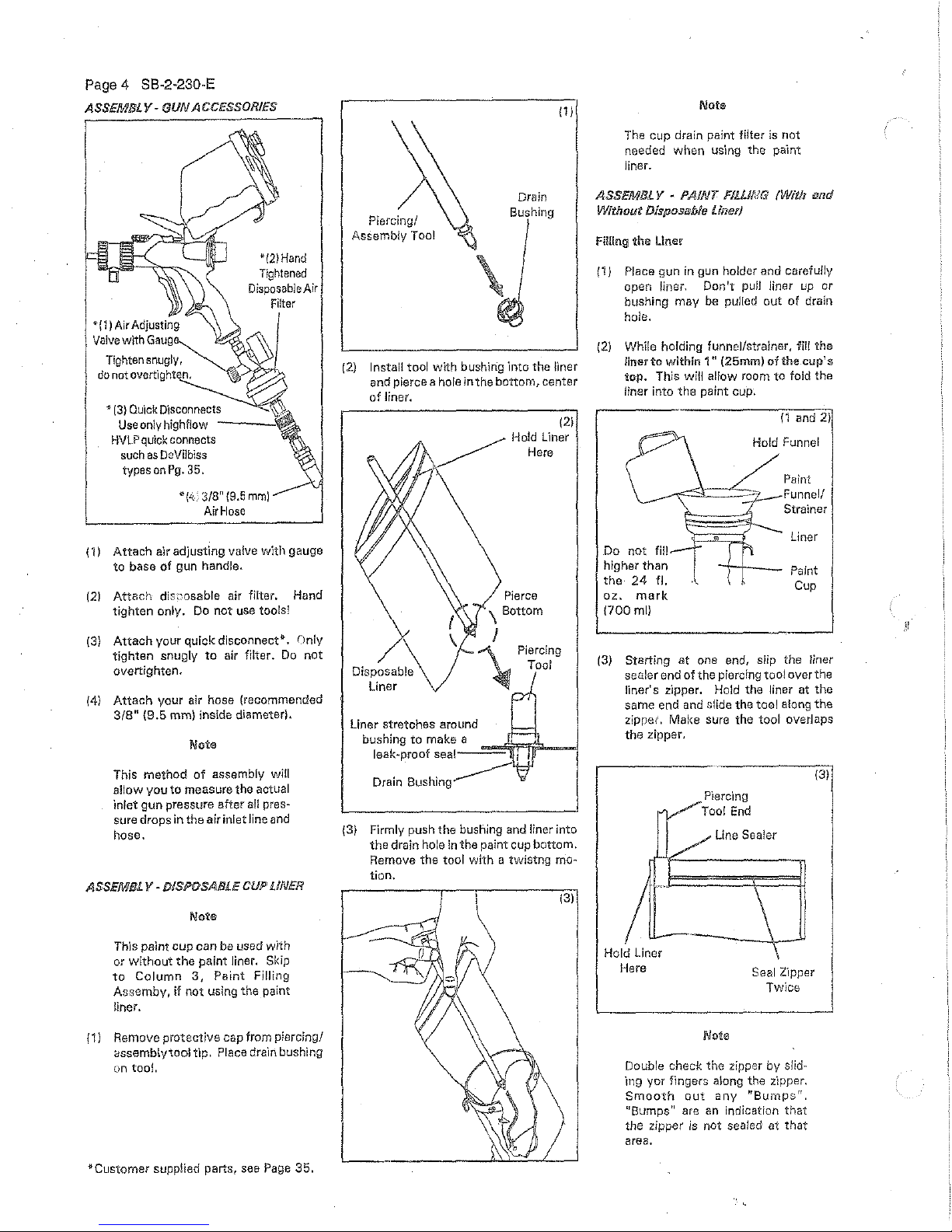

ASSEfi//BL Y •

GUN

ACCESSORIES

"(3)

Quick

Disconnects

'121Hand

Tightened

Disposable

Air

Filter

Use

only highflow ----~

HVLP

quick

connects

such

as

OsVHbiss

typesonPg. 35.

~(4.

3/8"

{9.6

mm)

Air

Hose

(1)

Attach

air adjusting valve with gauge

to

base

of

gun handle.

(2)

Attach

dis:cosabte air filter. Hand

tighten

only.

Do

not use tools!

{3)

Attach

your quick disconnect*.

rlnly

tighten

snugly

to

air filter.

Do

not

overtighten.

(4)

Attach

your air hose (recommended

3/8"

(9.5

mm) inside diameter).

Note

This

method

of

assembly will

allow

you

to

measure the actual

inlet

gun pressure

after

all pres-

sure

drops

in

the

air

inlet

line and

hose.

ASSEfi//BL

Y.

DISPOSABLE CUP LINER

Note

This paint cup can

be

used

with

or

without

the

paint liner. Skip

to

Column

3,

Paint

Filling

Assemby,

if

not

using the paint

liner.

{1)

Remove protective cap from piercing/

assemb!ytool

tip.

Place drain bushing

on too!.

*Customer supplied parts,

see

Page

35.

111

Note

The

cup drain paint filter is

not

needed when

us'1ng

the paint

liner.

Drain

ASSEfi//Bl V •

PAINT

Flllllc!G

!With

and

Piercing/

Assembly Tool

\

Bushing

(2.)

Install tool

with

bushing

into

the liner

and pierce a hole in the bottom, center

of

liner.

Disposable

Liner

(21

Hold Liner

Here

Piercing

Tool

{3) Firmly push the bushing and

liner into

the

drain hole

in

the paint cup bottom.

Remove the

tool

with a twistng

mo~

tion.

Without Disposable Liner/

filling

the

liner

{1)

Place gun in gun holder and carefully

open liner.

Don't

puJJ

liner

up

or

bushing

may be pulled

out

of

drain

hole.

{2)

While holding funnel/strainer,

fW

the

liner

to

within

1"

(25mm)

of

the cup's

top. This will allow

room

to

fold the

liner into

the

paint cup.

Do

not

fill

higher than

the

24

fl.

oz.

mark

(700mll

(1

and

21

Hold Funnel

Paint

Funnel/

Strainer

Liner

-;--+---

Paint

Cup

(3)

Starting

at

one end, slip the liner

sealer

end

of

the piercing tool over the

liner's zipper. Hold the liner at the

same end and

s!ide the tool along

the

zipper. Make sure the

tool

overlaps

the

zipper.

Hold Liner

Here

Piercing

Too!

End

Line Sealer

Seal

Z'1pper

Twice

Doub!e

checl<

the zipper

by

slid*

ing

yor

fingers

along the z'1pper.

Smooth

out

any

"Bumpsrr.

"Bumps" are

an

indication

that

the

zipper

is

not sealed at

that

area.

131

ASS/£Mfll V-

FILLING

CUP

WITHOUT UNEfl

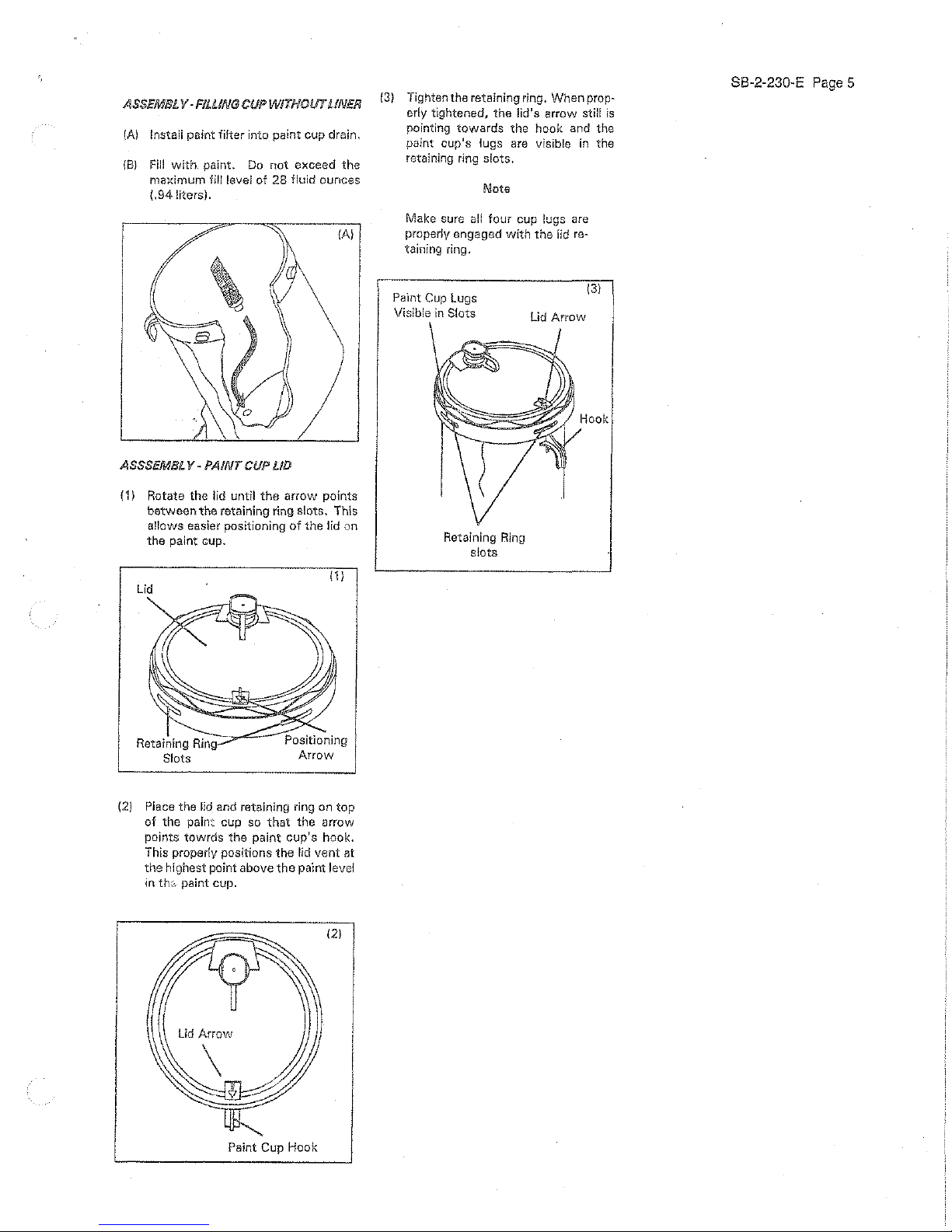

(A)

lnstalf paint

filter

into paint cup drain.

(8)

Fill

with

paint.

Do

not

exceed the

ma;dmum fill level

of

28

fluid ounces

(.941itersl.

{3)

Tighten the retaining ring. When prop-

erly tightened, the lid's arrow still

is

pointing

towards

the

hook and

the

paint cup's lugs

are

visible

in

the

retaining ring slots.

Note

Make sure

a!!

four cup lugs

are

(A)

properly engaged

with

the

lid re-

taining ring.

ASSSEMlll

ll-

PAINT

CIJP

LID

{1)

Rotate

the

lid

until

the

arrow

points

between

the

retaining ring slots. This

allows easier positioning

of

the

lid

on

the

paint cup.

(11

(2)

Place the lid and retaining ring on

top

of the pain: cup so

that

the arrow

points towrds the paint

cup's

hook.

This properly positions

the

lid

vent

at

the

highest point

above

the

paint level

in

th:-,.

paint cup.

121

Paint Cup Hook

Pa·lnt

Cup

lugs

Visible

in

Slots

Retaining

Ring

slots

131

Hook

88-2-230-E

Page

5

Page 6 88·2·230-E

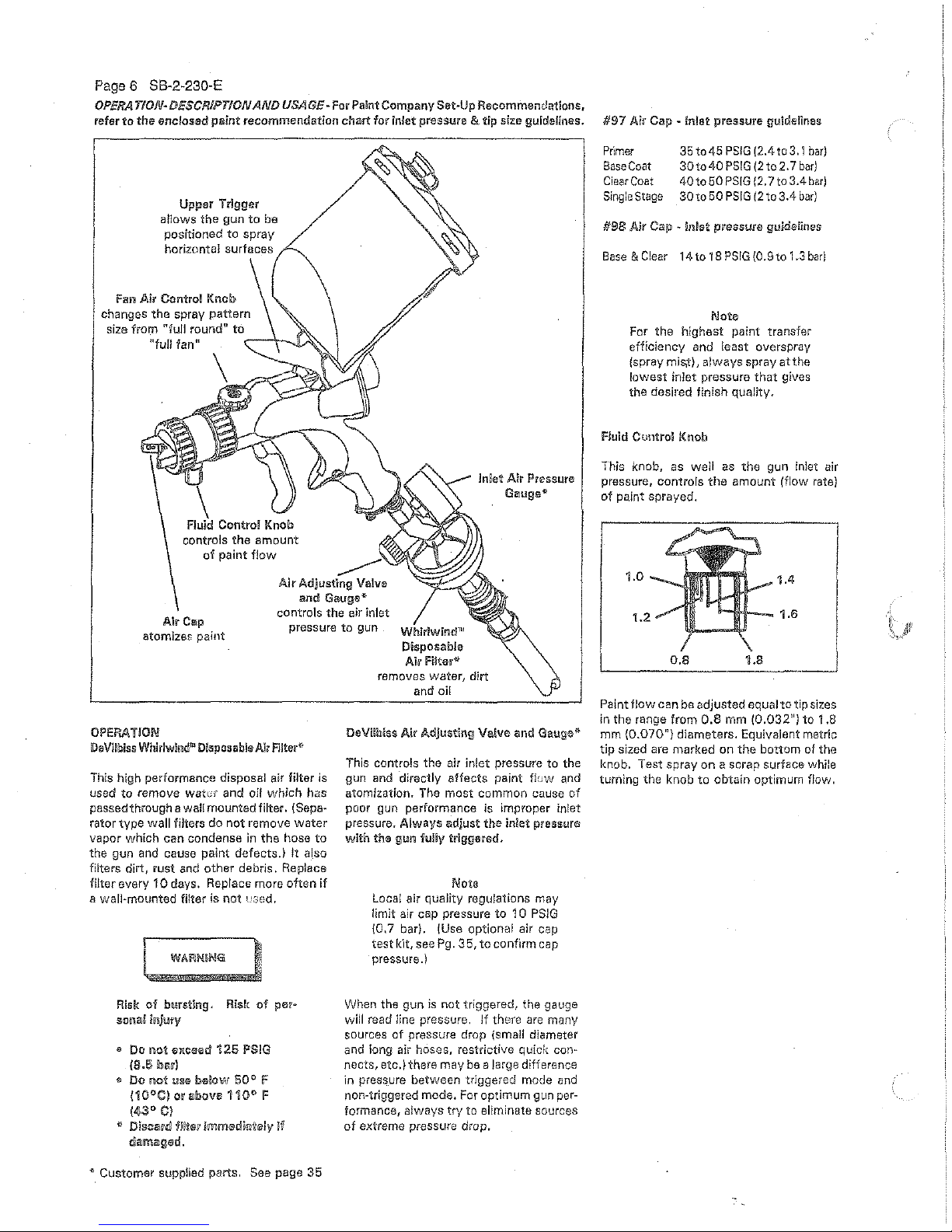

OPERATION~

DESCRIPTION

AND

USAGE~

For Paint

Company

SetAJp

Recommendations,

refer

to

the

enclosed

paint

recommendation

chart

for inlet

pressure

& tip size guidelines.

Upper

Trigger

allows

the

gun

to

be

positioned to

spray

horizontal surfaces

Fan Air Control Knob

changes the spray

pattern

size from

"full

round"

to

"full tan"

~--1.-U

\

Fluid Control Knob

controls

the

amount

of

paint

flow

-----

Inlet Air Pressure

Gaugeii

Air Adjusting Valve

and

Gauge*

controls

the

air inlet

pressure

to

gun

WhlriwintP1,1

Disposable

Air

Filtar*

OPERATIOIII

!DeVIlbiss

Whlrlwinc!l

11

Disposable

Air

FUterr'

This high performance disposal air filter is

used

to

remove

water

and oil

which

has

passed through a

waH

mounted filter. (Sepa·

rator

type

wall filters

do

not

remove

water

vapor which can condense

in

the

hose

to

the gun and cause paint defects.)

It

also

filters

dirt, rust and

other

debris. Replace

filter everv

10

days. Replace more

often

if

a wall·mounted filter is

not

used.

WARIN!N"G

Risk

of

bursting.

Risk

of

pefo

sona! inJury

Ill

Do

no~

exceed

125

PS!G

(8.5

bov)

til Do

not

us®

b®low

50

° F

(10°C)

orabov•110°

F

(43°

Ci

~

DlscB~n~

filtsc·

SmmsdiSJtely

If

damagerdl.

"'

Customer

supplied parts.

See

page

35

removes

water,

dirt

and

oil

DeVilbiss Air Adjusting Valve

and

Gauge*

This controls the air intet pressure

to

the

gun and directly

affects

paint f!uw and

atomization. The

most

common

cause of

poor gun performance is improper inlet

pressure. Always

~djus'l:

the

inlet pressure

with

the gun

fuliy

triggered.

Note

Local air quality regulations may

limit air cap pressure

to

1 0

PSJG

\0,7 bar). (Use optional air cap

test

kH,

see

Pg. 35,

to

confirm cap

pressure.)

When

the

gun

is

not

triggered,

the

gauge

will

read line pressure.

If

there

are

many

sources

of

pressure drop (small diameter

and long air hoses, restrictive quick con*

nects, etc.)

there

may

be

a large difference

in pressure between

triggered mode

and

non-triggered mode. For optimum gun per·

formance,

always

try to eliminate sources

of

extreme pressure drop.

#97

Air Cap - Inlet

pressure

guidelines

Pr'lmer

Base

Coat

Ciear

Coat

Single

Stage

35

to 45

PSIG

(2.4

to

3. I bar)

30to

40

PSIG

(2

to

2.

7

bar)

40 to

50

PSIG

12.7

to

3.4

bar)

30

to

50

PSIG

12

to

3.4

bar)

#98

Air Cap - inlet

pressure

gu!delines

Base

&Clear 14to18PSlG(0.9to1.3bar)

Note

For

the

highest paint transfer

efficiency and least overspray

(spray

mis,t),

always

spray at

the

lowest

inlet pressure

that

gives

the desired finish quality.

Fluid Cuntrol Knob

This knob,

as

well

as

the gun inlet air

pressure, controls

the

amount (flow rate)

of

paint sprayed.

1.4

1.6

0.8

1.8

Paint

flow

can

be

adjusted

equal

to

tip

sizes

in the range from

0.8

mm

(0.032")

to

1.8

mm

(0.070")

diameters.

Equivalent metric

tip

sized are

marked

on

the

bottom

of the

knob. Test spray

on

a scrap surface while

turning

the

knob

to

obtain optimum flow.

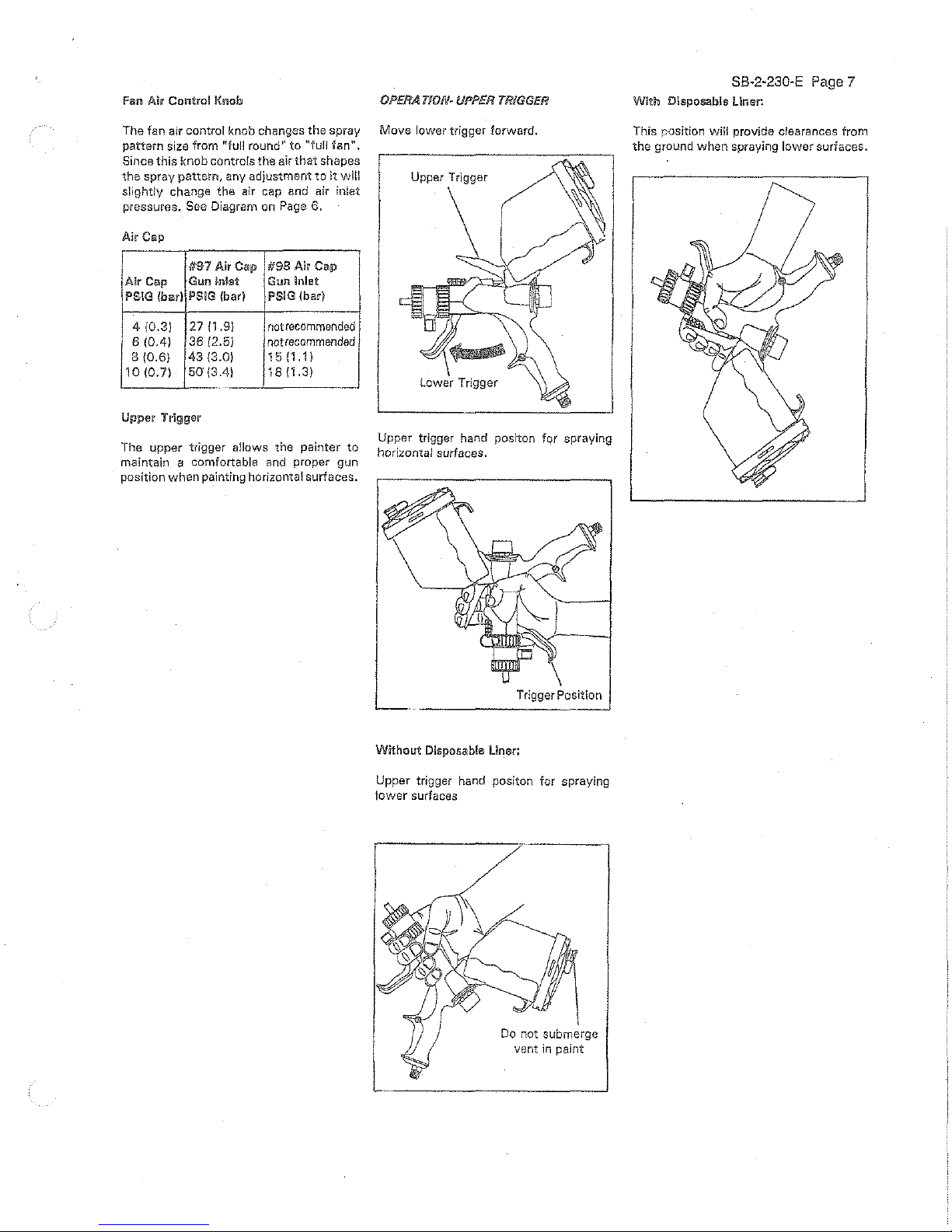

Fan l\l1 Conlrol Knob

OPERA

T/Qf/-

UPPER

TRIGGER

The fan air control knob changes

the

spray

Move

lower trigger forward.

pattern size from

"full round''

to

"full

fan",

Since

this

knob

controls

the

air

that

shapes

the

spray

pattern,

any

adjustment

to

it

will Upper Trigger

slightly change the air cap and air inlet

pressures. See Diagram on Page 6.

Air

Cap

#97

Air

Cap

#98

Air

Cap

Air Cap

Gun

inlet

Gun

lnle1t

PS!G (bar) PSIG (bar)

PSIG (ba1)

4 (0.3)

27

(1.9)

not

recommended

6

(0.4)

36

(2.5)

not

recommended

8

(0.6)

43

(3.0)

15

I 1

.1

I

10

(0.7)

50

(3.4)

18

(1.3)

Upper

Trigge~

The upper trigger allows the painter

to

maintain a comfortable and proper gun

position

when

painting horizontal surfaces.

Upper

trigger hand positon for spraying

horizontal surfaces.

Trigger Position

Without

Disposable Liner:

Upper trigger hand positon for spraying

tower surfaces

Do

not submerge

vent

in

paint

SB-2·230-E

Page

7

With Disposable Liner.

This r::osition will provide clearances

from

the

ground

when

spraying

lower

surfaces.

Page

8 SB-2-230-E

OPERATION-SPRAYING

PAIN/

(3)

Fill

Paint Cup

(5)

Purge air from disposable liner using 50

PSIG

13.4 bar).

{2)

"tighten

Air

Cap

Ring

181

Adjust spray

pattern

size.

16)Adjust Inlet

Air

Pressure

(1)

f{ead all

instructions

and safety

pre~

cautions in

the

previous sections.

Pressurized liquids. Risk

of

eye

injury, Wear eye proitecton

andl

point gun

away

from

persons.

~I

WARNING

•

'<WI·-

IS~

Flammable vapors.

Risk

offlr-:·)

or

explosion. Provide ample venti-

lation.

Toxic

Vill.POfS

!U!d

liqulc!!s.

Risk

oi

persontl'l~

injury,

Use

the

protec-

tive

equipment

spec!fled

in

the

paint's

materia!

safety

data

sheets.

121

13)

141

15)

161

171

18)

191

Cup drain

at

highest point

1.8

Setting,

Longest Line

50

PSIG

Triggered

{4}Connect

Air

Tighten air cap ring and spray

head

ring.

Install disposable liner or paint filter.

(Page

4}. Fill paint cup.

Connect

to

proper

air supply

(Page 1 ).

When using liner, purge air

to

allow

painting

in

any position.

*Adjust

gun

as

shown

in

inset {5),

* Turn cup upside

down.

* Trigger until constant paint

flow

is

observed.

* Postion gun

for

painting and

follow

Steps 6,

7,

& 8.

While triggering the gun, adjust inlet

air

pressure (page 6).

Adjust

the

paint flow (page 6).

Adjusi:

the

spray

pattern

size (Page 7).

Clean gun immediately after painting

(Page

9).

{10) Wipe gun dry.

B!owoutthepaintand

tlir passages with air.

(11) A!

ways

store the gun

with

the cup lid

and

air

cap

installed.

Note

Do

not

store

the

gun

with

paint

or

solvent in

the

cup.

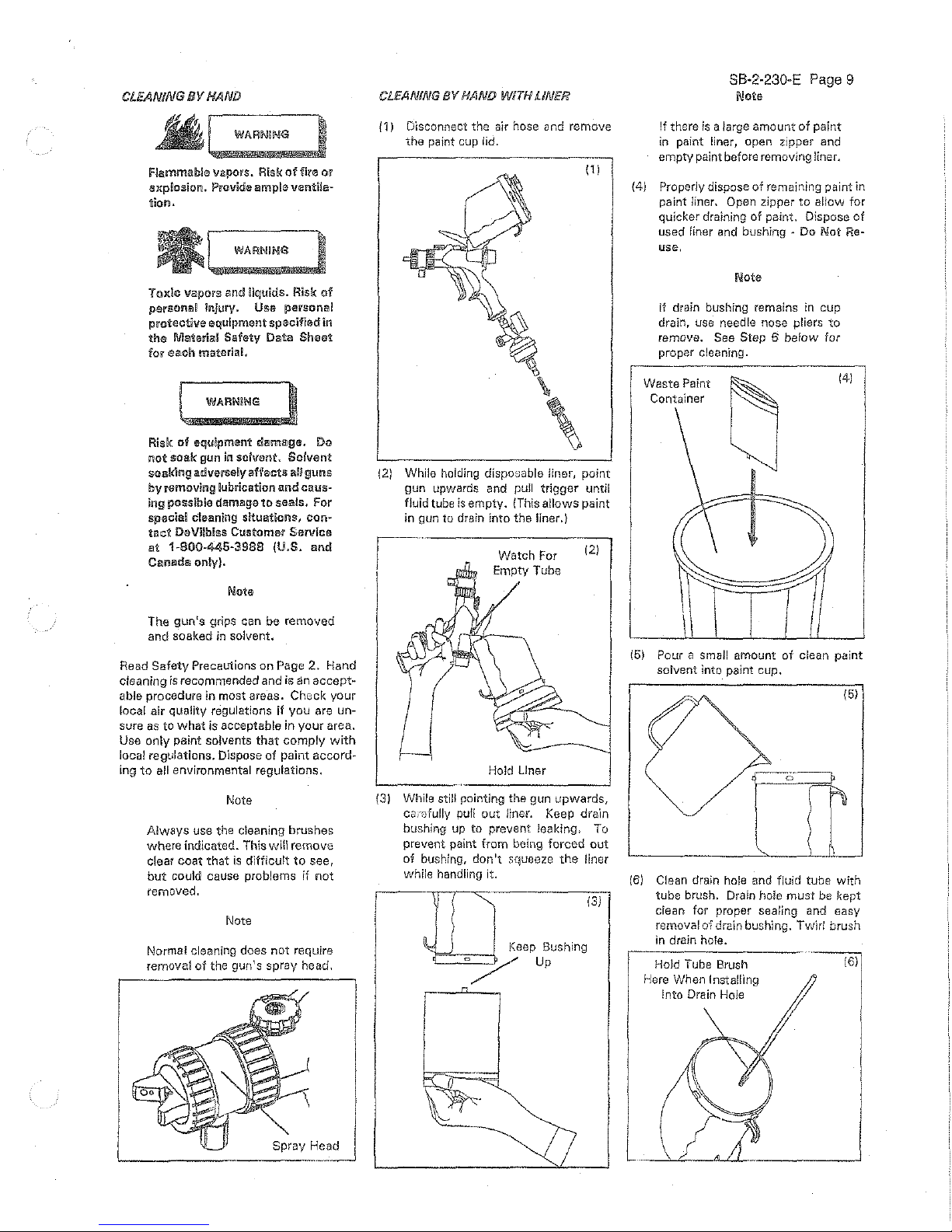

CLEANING

BY

HAND

WARNING

flammable vapors.

Risi{

of

fire or

explosion.

Provide

ample

ventila-

tion.

WARNING

Toxic vapors and liquids. Risk

of

personal injury. Use personal

protective

equipment specified

lUi

the

Msterial Safety Data

Sheet

for

each

material.

WARNiNG

Risk

og

equipment

damage.

Do

not

soak gun

in

solvent. Solvent

soaking adversely affects

all

guns

by

removing lubrication

a.nd

caws-

ing possible damage

to

seals.

For

spacial cleaning situations, con-

tact

DeVIlbiss Customer Service

a!

1-800-445-3988

(U.S.

and

Canada

only}.

Note

The

gun's

grips can be removed

and soaked

in

solvent.

Read

Safety

Precautions on Page

2.

Hand

cleaning

is

recommended and is

an

accept-

able

procedure in most areas. Check your

local air quality regulations

if

you

are un-

sure

as

to

what

is acceptable in

your

area.

Use

only

paint solvents

that

comply

with

local regulations. Dispose of paint accord-

ing

to

all

environmental regulations.

Note

Always

use the cleaning brushes

where indicated. This

will remove

clear

coat

that

is

difficult

to

see,

but

could cause problems

if

not

removed.

Note

Normal cleaning does

not

require

removal

of

the gun's spray head.

CLEANING

BV

HAND

WITH

liNER

/1) Disconnect

the

air hose and remove

the

paint cup lid.

111

\

\

(2) While holding disposable liner, point

gun upwards and

pull

trigger

until

fluid

tube is

empty.

{This

allows

paint

in gun to drain into the liner.)

Watch For

Empty Tube

Hold Llner

121

(3) While still pointing the gun

upwards,

CCL"Dfully

pull

out

liner. Keep drain

bushing up to prevent

ieaking, To

prevent paint from being forced

out

of

bushing, don1t squeeze

the

liner

while handling it.

[]

(3)

Keep Bush1ng

/Up

SB·2-230·E Page 9

Note

If there

is

a large amount

of

paint

in paint liner, open zipper and

empty paint

before removing liner.

(4) Properly dispose

of

remaining paint in

paint

liner, Open zipper

to

allow

for

quicker draining

of

paint.

Dispose

of

used liner and bushing • Do

Not

Re-

use.

Note

If

drain bushing remains in cup

drain, use needle nose

pliers

to

remove. See Step 6 below for

proper cleaning.

Waste

Paint

Container

141

(5) Pour a small amount

of

clean paint

solvent into paint cup.

(51

rrr

(6)

Clean drain hole

and

fluid tube

with

tube brush. Drain hole

must

be

){ept

clean

for proper sealing

and

easy

removal

oi drain bushing.

Twirl

brush

in drain hole.

Hold Tube Brush

Here When

Installing

Into Drain Hole

l

I

Page

1 0 88·2-230-E

CLEANING

BY

HAND WITH LINER

(con'!)

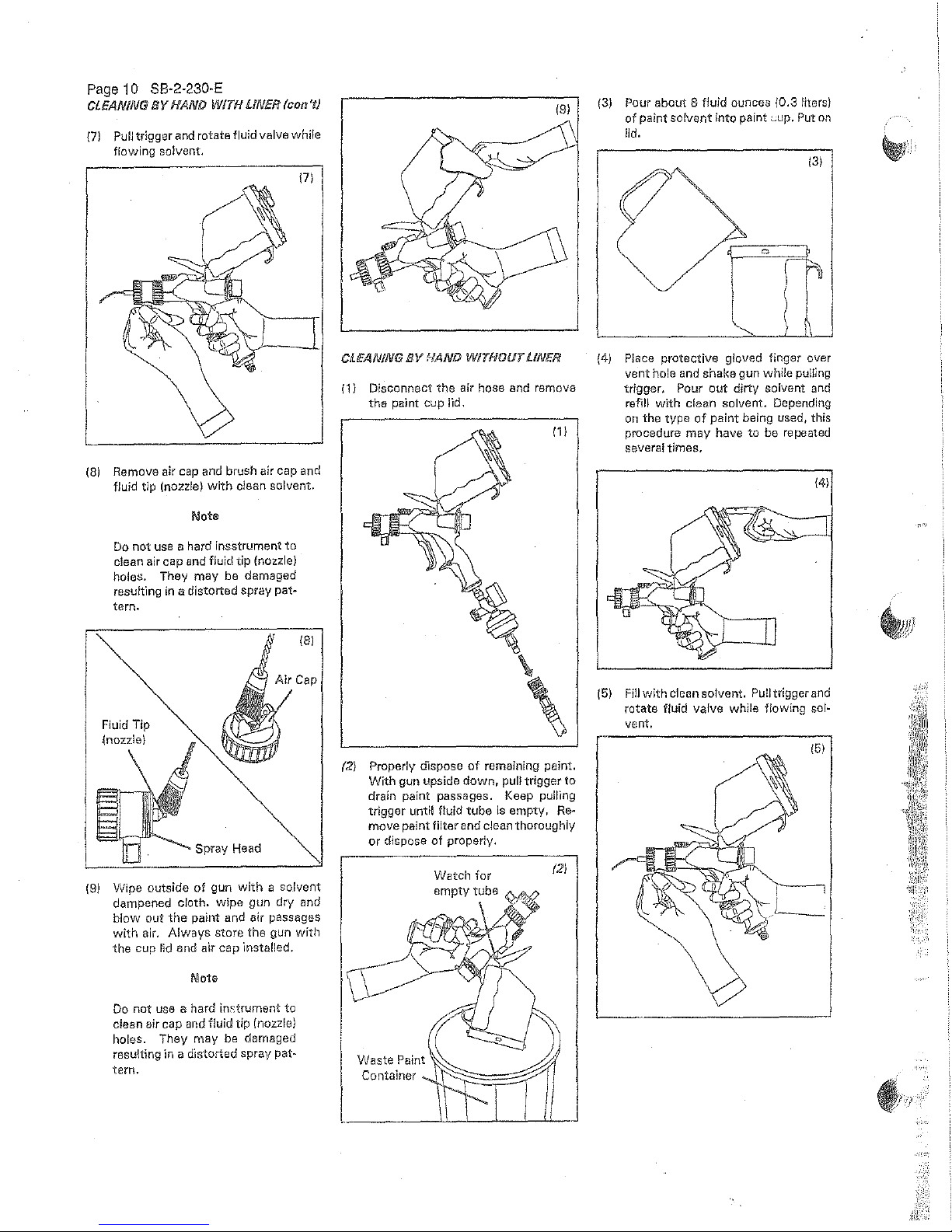

{7)

Pull trigger and rotate fluid valve while

flowing solvent.

171

(8)

Remove air cap and brush air cap and

fluid tip (nozzle)

with

dean

solvent.

Note

Do

not

use

a hard insstrument

to

clean air cap and fluid

tip

(nozzle)

holes. They

may

be damaged

resulting

in

a distorted spray

pat~

tern.

Fluid Tip

{nozzle)

Spray Head

(9)

Wipe outside

of

gun with a

solvent

dampened cloth. wipe gun dry and

blow

out

the

paint

and

air

passages

with

air.

Always

store

the

gun with

the

cup

lid

and

air

cap

instatled.

Note

Do

not

use a hard inc:trument

to

clean air cap and fluid

tip

{nozzle)

holes. They

may

be

damaged

resulting

in

a distorted spray pat-

tern.

191

CLEANING

BY

NAND W/1HOIJT LINER

(

1}

Disconnect

the

air hose and remove

the

paint cup lid.

(2) Properly dispose

of

remaining paint.

With

gun upside

down,

pull trigger

to

drain paint passages. Keep pulllng

trigger until f!uid

tube

is empty,

Re~

move paint

filter

and clean thoroughly

or

dispose

of

properly.

{3)

Pour about 8 fluid ounces (0.3 liters)

of

paint solvent into paint

wup.

Put

on

lid.

131

{4)

Place protective g!oved finger over

vent

hole and shake gun while pulling

trigger, Pour

out

dirty

solvent

and

refill with clean solvent. Depending

on

the type

of

paint

being used, this

procedure

may have to be repeated

several times.

141

(5)

Fill

with clean solvent. Pull trigger

and

rotate fluid valve while flowing solvent.

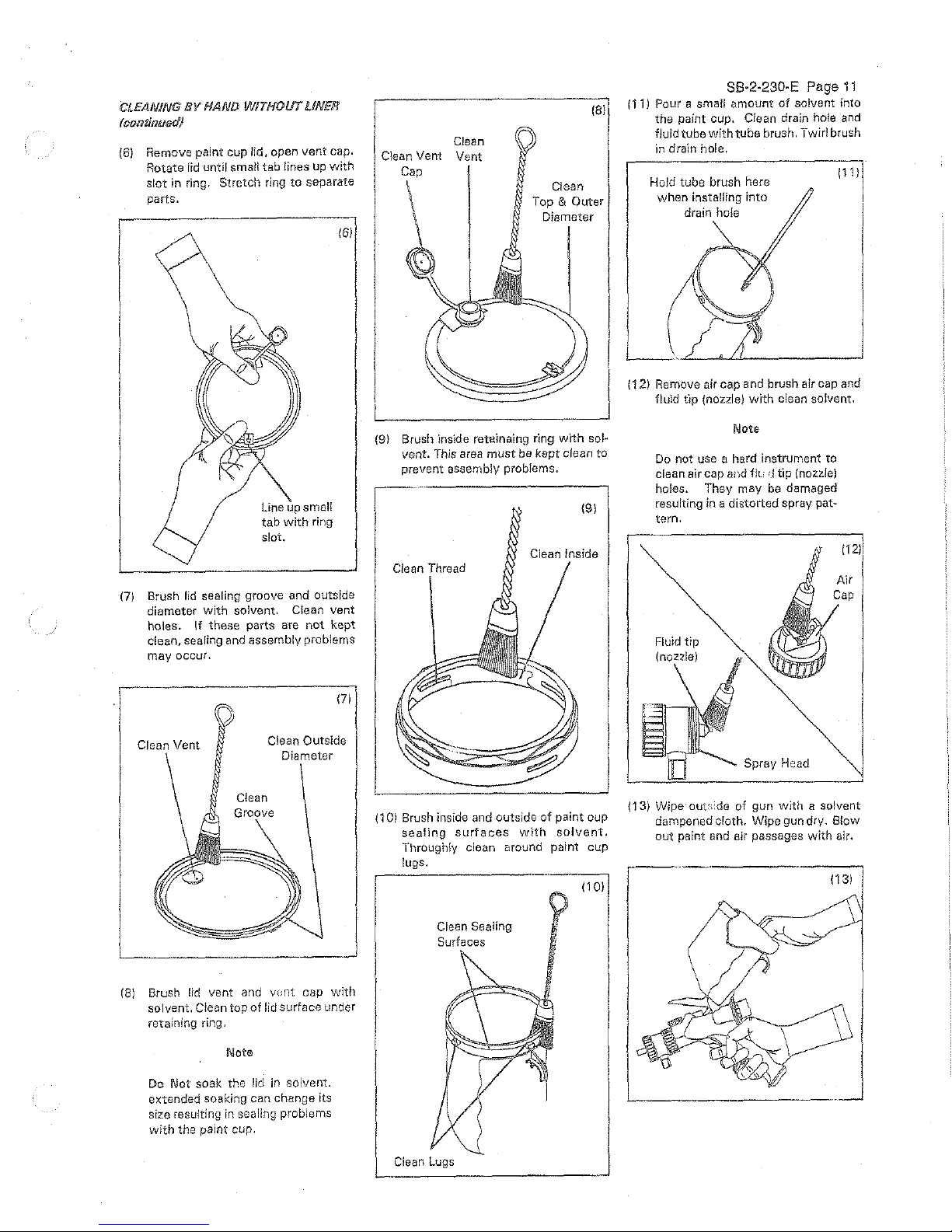

CLEANING IJY HAND

WITHOUT

LINE!/

{continued)

(6)

Remove paint cup lid, open vent cap.

Rotate lid until smatl tab lines up

with

slot

in

ring.

Stretch

ring

to

separate

parts.

Line

up

small

tab

with

ring

slot.

161

(7)

Brush

lid

sealing groove and outside

diameter

with

solvent. Clean vent

holes.

If

these

parts are not kept

clean,

searing and

assembly

problems

may occur.

171

Clean Outside

Diameter

L____

__

j

(8)

Brush

lid

vent and

vcnt

cap

with

solvent.

Clean

top

of

lid

surface

under

retaining ring.

Note

Do Not soak the lid

in

solvent.

extended

soaking

can

change

its

size resulting in sealing probiems

with the paint cup.

Clean

Clean Vent Vent

Cap

(81

C!ean

Top &

Outer

Diameter

88·2·230-E

Page

11

(11

J Pour a small amount

of

solvent into

the

paint cup. Clean drain hole

and

fluid tube

with

tube brush. Twirl brush

in drain hole.

Hold tube brush here

when installing

into

drain hole

1111

I

f

1121

Re:ove

air

cap and brush

air

cap and

fluld tlp (nozzle)

with

clean solvent.

L---------------~

(9) Brush inside retainafng ring

with

sol·

vent. This area

must

be

kept clean to

prevent assembly problems.

(91

Ciean Inside

Clean

{1

0)

Brush inside and outside

of

paint cup

sealing

surfaces

wlth

solvent.

Throughly clean around paint cup

lugs.

Clean Sealing

Surfaces

Clean

Lugs

(101

Note

Do

not use a hard instrument to

clean air cap

and

f!t.:

,_1

tip {nozzle)

holes. They may

be

damaged

resulting

in a distorted spray

pat~

tern.

Fluid

tip

Spray Head

(13)

Wipe· out:. ide of gun

with

a solvent

dampened erath. Wipe gun dry. Blow

out

paint and air passages

with

air.

1131

Loading...

Loading...