DeVilbiss MSV-531-46FF, MSV-531-28FX, MSV-531-33FF, MSV-531-33FX, MSV-531-46FX Service Bulletin

...

MSV-531 HIGH VOLUME LOW PRESSURE SPRAY GUN

IMPORTANT: Before using this equipment, read all Safety Precautions and

Instructions. Retain for future use.

DESCRIPTION

The MSV-531 is a slightly smaller, lighter

HVLP spray gun, capable of high production. It can be used with a wide variety of

finishing materials. All models are designed to provide maximum transfer efficiency by limiting air cap pressure to 10 psi

(complies with rules issued by SCAQMD

and other air quality authorities). The gun

is intended for use with pressure feed paint

supply only.

Note

The MSV-531 spray gun is not suitable for highly abrasive materials (i.e.

porcelain enamel, certain mica paints,

etc.). Premature fluid tip and needle

wear will occur. We recommend

carboloy fluid tips (AV-617 series) and

needles (JGA-409 series) for use with

these coatings.

Most finishing materials can be atomized

with the 28 or 33A air caps. The 28 or 33A

air caps should be used where possible as

they consume less air volume (CFM) and

have slightly better transfer efficiency than

the 46MP and 83MP air caps. However,

more difficult to atomize materials (i.e. low

VOC's) or high flow applications (over 12

oz./min.), are ideal for the 46MP (maximum

performance) air cap, fluid tip and baffle

combination. Also available is the 83MP

(maximum performer) for even higher flows

(17 oz. /min. and above), and viscosities.

Refer to the air cap chart for more information. Spray guns with a 28 or 33A nozzle

combination can be converted to 46MP or

83MP if desired.

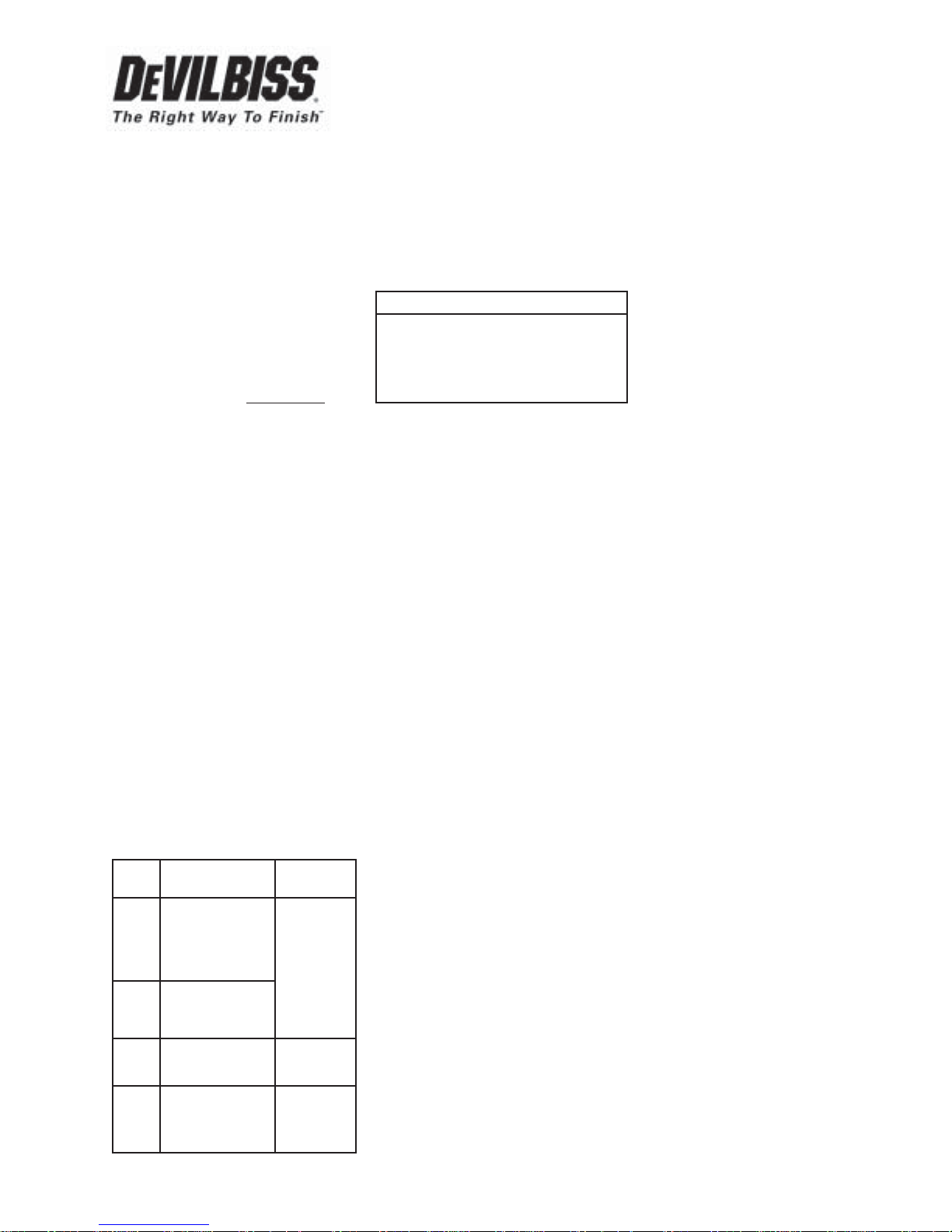

AIR CAPS - PATTERNS - APPLICATIONS

Air Cap *Typical Pattern Size Typical

No. and Shape Application

28 11" long, straight-

sized, similar to

#704 air cap. Most

common

finishing

materials

33A 9" long, tapered up to 12

ends similar to #30 oz./min.

air cap.

46MP 11" long, straight- Low VOC

sided, similar to materials, 12

#704 air cap. to 16 oz./min.

83MP 13" long, straight- Low VOC

sides, similar to materials,

#765 air cap. 17 oz./min.

and above.

*Actual pattern length dependent upon

fluid tip ID, fluid flow rate, viscosity, air

pressure, and fan pressure.

Operating Pressures:

Air: 100 PSI Maximum (see following chart)

Fluid: 150 PSI Maximum

Standard Combinations Available:

Order No. * Gun Inlet Pressure

MSV-531-28FF, FX 50 PSI

MSV-531-33FF, FX 50 PSI

MSV-531-46FF, FX 50 PSI

MSV-531-83D, E 65 PSI

•MSV-531-3-46FF, FX 50 PSI

• Models include 300 grade stainless fluid tip

with UHMW poly. needle seat and 300

stainless needle.

* Approximate pressure required to achieve

10 PSI air cap pressure.

Gun models are available with 400 grade

stainless fluid tips and 300 series stainless

needles, and are suitable for most common

coating materials. Select model combinations (see above) are available with 300 grade

stainless fluid tips and needles, and can be

used with waterborne materials or more

corrosive coatings (6.0 pH or above).

These gun models will produce approximately

10 psi cap pressure at the corresponding gun

inlet pressure, as measured at the gun inlet.

Air cap test kits (see Accessories) should be

used to insure 10 psi air cap pressure is not

exceeded.

Note

This gun may be used with chlorinated solvents; but, see additional

warnings on page 2.

INSTALLATION

Do not use more pressure than is necessary

to atomize the material being applied.

To provide optimum performance and assure compliance with all air quality regulations, an air cap test gauge kit is available

to determine actual air cap pressures being

used. See Accessories.

Connect the gun to a clean, moisture and oil

free air supply using a hose size of at least

5/16" I.D. hose. Avoid use of quick detachable connectors. Do not use 1/4" ID hose (25'

x 1/4" hose at 18 CFM has a pressure loss of

25 psi. 25' x 5/16" hose at 18 CFM has a

pressure loss of 8.1 psi).

■ Government NSN No. 4940-01-046-9919 = KK-4987-2

SERVICE BULLETIN

SB-2-243-F

Replaces SB-2-243-E

■ Repair Kit KK-4987-2

Note

Depending on hose length, larger

hose I.D. may be required. Install an

HAV-501 air gauge at the gun handle

and air cap test kit over tip. When

gun is triggered on, adjust regulated

pressure to desired setting to provide

a maximum of 10 psi at the air cap.

Do not use more pressure than is

necessary to atomize the material

being applied.

OPERATION

Adjust fluid pressure to deliver the desired

paint volume. Refer to the next paragraph

also on “Back Pressure”. Adjust air pressure

and flow to provide a uniform dispersion of

atomized paint throughout the pattern.

Excessive flow rates will result in heavy

center spray patterns. Inadequate flows may

cause the pattern to split. See Spray Gun

Guide, SB-2-001 latest revision, for details

concerning set up of spray guns.

Back Pressure - 46MP & 83MP “Maximum

Performer”

Due to the unique cone shape of the MP

fluid tips, a slight back pressure is created

against the fluid column. This will reduce

the amount of fluid output. To compensate,

increase the fluid regulator pressure slightly.

With 10 PSI cap pressure, back pressures

are approximately 3.5 PSI with the 46MP

and 2.0 PSI with the 83MP.

HVLP requires gun distances of 6-8" be

used. Excess distance will produce inferior

results. Strain material through 60 or 90

mesh screen.

PREVENTIVE MAINTENANCE

Note

If baffle (6) is removed for any

reason, replace the o-ring (5).

To prevent damage to the

o-ring during installation, apply

SSL-10 gun lube to exterior of

o-ring (5) and ID of baffle.

To clean air cap and fluid tip, brush exterior

with a stiff bristle brush. If necessary to

clean cap holes, use a broom straw or

toothpick. Never use a wire or hard instru-

ment. This may scratch or burr holes

causing a distorted spray pattern.

To clean fluid passages, remove excess material at source, then flush with a suitable

solvent using a device such as the

SolventSaver™ (see Accessories). Wipe

gun exterior with a solvent dampened cloth.

(continued on page 3)

Page 2 SB-2-243-F

This manual contains information that is improtant for you to know and understand. This information relates to USER SAFETY and

PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please pay particular attention

to these sections.

SAFETY PRECAUTIONS

Note

Important safety information - A hazard

that may cause an injury or loss of life.

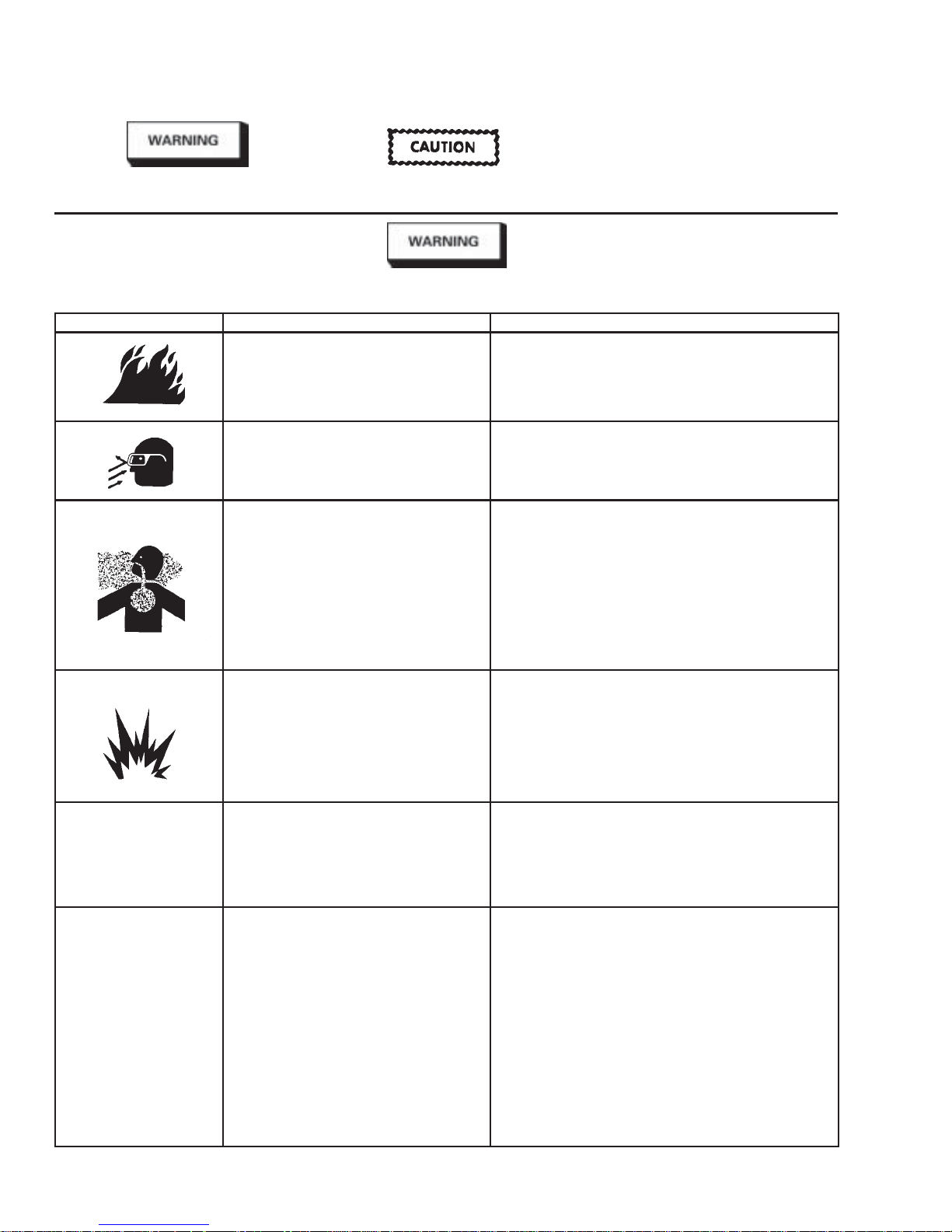

The following hazards may occur during the normal use of this equipment.

Please read the following chart before using this equipment.

HAZARD CAUSE SAFEGUARD

Fire Solvent and coatings can be highly flammable Adequate exhaust must be provided to keep

or combustible, especially when sprayed. air free of accumulations of flammable vapors.

Solvent Spray During cleaning and flushing, solvents can be Wear eye protection.

forcefully expelled from fluid and air passages.

Some solvents can cause eye injury.

Inhaling Toxic Certain materials may be harmful if inhaled, Follow the requirements of the Material Safety Data Sheet

Substances or if there is contact with skin. supplied by your coating material manufacturer.

Explosion Hazard - Halogenated hydrocarbon solvents - for Guns with stainless steel internal passageways may be used

Incompatible Materials example; methylene chloride and 1, 1, 1 - with these solvents. However, aluminum is widely used

Trichloroethane can chemically react with in other spray application equipment - such as material

aluminum. The chemical reaction caused by pumps, regulators, valves & cups. Check all equipment items

these solvents reacting with aluminum can before use and make sure they can also be used safely

become violent and lead to an equipment with these solvents. Read the label or data sheet for the

explosion. material you intend to spray. If in doubt as to whether or not

General Safety Improper operation or maintenance Operators should be given adequate training in the safe use &

of equipment. maintenance of the equipment (in accordance with the

Cumulative Trauma Use of hand tools may cause cumulative Pain, tingling, or numbness in the shoulder, forearm, wrist,

Disorders “CTD’s” trauma disorders “CTD’s”. hands or fingers, especially during the night, may be early

CTD’s, or musculoskeletal CTD’s, when using hand tools, tend to affect the early symptoms may include vague discomfort in the hand,

disorders, involve damage upper extremities. Factors which may increase loss of manual dexterity, and nonspecific pain in the arm.

to the hands, wrists, elbows, the risk of developing a CTD include: Ignoring early symptoms and continued repetitive use of the

shoulders, neck and back. arm, wrist and hand can lead to serious disability. Risk is

Carpal tunnel syndrome and 1. High frequency of the activity. reduced by avoiding or lessening factors 1-7.

tendinitis (such as tennis 2. Excessive force, such as gripping, pinching

elbow or rotator cuff or pressing with the hands and fingers.

syndrome) are examples 3. Extreme or awkward finger, wrist, or arm

of CTD’s positions.

4. Excessive duration of activity.

5. Tool vibration.

6. Repeated pressure on a body part.

7. Working in cold temperatures.

Important information that tells how to

prevent damage to equipment.

Smoking must never be allowed in the spray area.

Fire extinguishing equipment must be present in the spray area.

Adequate exhaust must be provided to keep the air free of

accumulations of toxic materials.

Use a mask or respirator whenever there is a chance of inhaling

sprayed materials. The mask must be compatible with the

material being sprayed and its concentration. Equipment must

be as prescribed by an industrial hygienist or safety expert, and

be NIOSH approved.

a coating or cleaning material is compatible, contact your

material supplier.

requirements of NFPA-33, Chapter 15). Users must comply with

all local & national codes of practice and insurance company

requirements governing ventilation, fire precautions, operation,

maintenance and housekeeping. These are OSHA Sections

1910.94 and 1910.107 and NFPA-33.

symptoms of a CTD. Do not ignore them. Should you experi

ence any such symptoms, see a physician immediately. Other

Information that you should pay special attention to.

Loading...

Loading...