Page 1

DeVILBISS

OXYGEN

CONCENTRATOR

DeVO/MC44-90

|

220

VOLT

50

Hz

SERVICE

-

We

add

1-800

Somerset,

Canada € France € Japan e U.

433-1331 e 814

PA

MANUAL

life

to

every

U.S.A.

breath.

443-4881

15501-0635

Kingdom e W.

Germany

SB-MC44

-220M

Page 2

TABLE

OF

CONTENTS

Section

Section 2 -

Section 3 -Installation

Section 4 -

Section 5 -

Section 6 -

Section 7 -

1-General

A.

B.

C.

D.

Theory

A.

B.

Maintenance

A.

B.

C.

Alarm

A.

B.

Information

Initial

Inspection

Maintaining

Warnings/Hazards

General

of

Operation

Installation

Operation

Testing

Routine

Periodic

System

Patient

Microcomputer

Troubleshooting

Service

A.

Instructions

Proper

Description

and

and Calibration

Maintenance

Maintenance

Alert

Repair

B.CabinetCovers.......................................

<.

Flow

Meter

D.

Pressure

E.

ManifoldlheckValves

F.

Molecular

G.

Four-Way

H.

Purge

|.

Compressor

J.

Pilot

К.

Manifold

L.

CapacitOr

M.CoolingFan..........................................

М.

Microcomputer

O.

Normal

Regulator

Valve

Pressure

Cycling

................................,......

.......................................

the

DeVO/MC44

............................

......................................

of

the

DeVO/MC44

...................

...............,.........,,......,.....

Operating

............................................

...............,.............................

Procedures

Procedures

.................................:.

......................

.................................

................................... 5 ㆍ

...................................

.........................

System

Control

Guide

....................................

Board

...........................

..................................

00

eee

............................,.........

Procedures

..........................................

.............................

...................................

................................

Sieve

Valve

Bed

Assemblies

......................................

........................

..........................................

..........................................

System

Assembly

een

Control

Sequence

..................................

...................................

Board

of

.........................

DeVO/MC44

...............

1

1

1

1

1

2

3

3

3

B

5

6

8

8

8

10

13

13

13

14

14

14

15

16

17

19

21

21

22

23

23

24

10/87

Section 8 -

Pneumatic

Electrical

Упк

Dealer

Block

бресИсаНоп$

Warranty

Parts

List

Diagram

Diagram

and

Wlustrations

................................

......................

for

Model

MC44

...............

0...

eee

............................

eee

K 0

K

25

38

39

40

41

Page 3

SECTION

1

GENERAL

A.

Initial

Inspection

An

Initial

inspection

DeVO/MC44

After

unpacking

any

external

during

the

DeVilbiss

dealer

The

for

concentrator

operated

Section 3 of

operate

contact

or

your

B.

Maintaining

The

DeVO/MC44

cording

the

manual.

is

required

qualified

maintain

C.

Warnings/Hazards

Oxygen

When

Person

Near

Hot,

Electrical

Removed

as

soon

damage

shipment.

international

specific

for

at

this

properly

the

DeVilbiss

dealer.

the

to

the

guidelines

Whenever

it

should

service

the

unit

Promotes

Using

The

Receiving

Sparking,

Shock

Hazard:

By A Qualified

INFORMATION

should

the

concentrator,

!f

damage

instructions.

should

least 30

manual.

or

DeVO/MC44

should

personnel.

may

Warning

Rapid

DeVO/MC44

Oxygen

Or

Warning

be

performed

as

possible

that

may

have

has

occurred,

Department

then

be

turned

minutes

internal

If

the

damage

as

International

be

routinely

set

forth

routine

be

servicing

performed

Failure

void

the

warranty.

Burning.

Therapy.

Burning

The

DeVilbiss

Do

Or

When

Objects.

Cabinet

Dealer.

on

after

receipt.

examine

occurred

contact

or

on

outlined

unit

fails

is

found

Department

serviced

in

Section 4 of

or

repair

by

to

properly

Not

Smoke

Near

Do

Not

May

Only

it

your

only

the

for

and

in

to

ac-

A

Use

Be

directs

ing

a

very

tively

concentration

Because

beds,

depressurize

allows

of

the

air

into

molecular

synthetically

porous,

sieve

produced

and

adsorbing

of

the

DeVO/MC44

it

is

able

the

the

unit

adsorbed

nitrogen

to

producing a high

process

approximately

altitude

assures

is

alternated

and

oxygen

the

patient

every

oxygen.

The

oxygen

leaving

through a check

From

here

it

passes

flow

meter,

filter

before

meter

and

adjusted

patient's

Тре

DeVO/MC44

visible

diagnostic

personnel.

power

or

pneumatic

and a second

exiting

allows

the

physician.

patient

service

This

failure,

component

to

alert

alert

low

one

of

two

cylinders

material.

This

inorganic

has

the

unique

nitrogen.

oxygen

to

other

cleanse

This

for

the

has

two

pressurize

bed

at

the

the

depressurized

while

the

pressurized

concentration

between

16

seconds

output

flow

of a continuous

the

sieve

valve

to

an

accumulator

through a pressure

high

efficiency

at

the

outlet

oxygen

the

incorporates

system

system

flow

level

system

to

system

pressure,

prescribed

as

be

will

failure.

contain-

sieve

material

silicate.

quality

of

is

It

is

selec-

produces a high

patient.

molecular

one

same

bed

time.

sieve

and

This

bed

bed

is

of

oxygen.

the

depending

rate.

The

beds

is

two

beds

cycling

supply

directed

This

on

of

tank.

regulator,

bacteria

fitting.

to

an

well

used

activate

The

be

controlled

audible

as a self-

by

and

electrical

flow

by

the

and

service

due

to

D.

General

The

DeVilbiss

is

designed

oxygen

in

the

providing

2,92%

4

liters

minute.

similar

Room

oxygen

DeVO/MC44

Description

to

for

the

home

95% + 3%

+

3%

at 3 liters

per

minute,

This

is

to

filtration.

air,

which

and

78%

by a compressor.

DeVO/MC44

through a gross

a

high

efficiency

the

compressor.

will

produce

flow

from a cooling

Leaving

HEPA

filter

clean

the

compressor,

and a four-way

of

deliver

patient

or

high

requiring

institution.

oxygen

per

and

70% + 3%

accomplished

contains

nitrogen,

particle

filter, a felt

bacteria

The

“WOB’L”

oil

free

fan.

the

the

DeVO/MC44

Oxygen

Concentrator

concentrations

oxygen

It

is

capable

concentration

minute,

approximately

80% + 3%

at S liters

by

using a process

is

drawn

The

pre-filter,

filter

before

type

compressor

air

and

is

cooled

air

passes

directional

therapy

at

21%

into

air

passes

entering

by

through

valve

of

of

1-

at

per

the

and

air

a

that

10/87

Page 4

SECTION

THEORY

The

similar

2

microcomputer

to

the

DeVO/44

OF

OPERATION

controlled

and

MC29

in

uses a pressure-depressurization

produces

efficient

are

DeVO/44

Observation

cycle

in

conjunction

the

trouble-shooting

observed

points

Variations

can

de-activating

complete

This

dependent

cycle

monitored

control board).

a

pressure

ducer

1/16”

oxygen

A

cycle

pressure

25.5

the

received

and

air

way

high

manner.

also

pneumatically

and

is

one

MC

board,

by

located

in

be

observed

cycle

is

an

approximate

and

the

transducer

is

connected

(1.6

mm)

pressure

change

in

the

PSI

(176

four-way

by

purge.

from

the

and

purge

concentrations

The

four-way

of

and

operated

MC29.

of

the

pressure-depressurization

way

to

isolate

with

the

it

can

the

installing a set

on

the

the

pressure-depressurization

in

relation

of

the

four-way

takes

on

the

liter

alarm

by

the

MC

This

is

to

diameter

in

the

takes

accumulator

KPa).

At

and

purge

pilot

valves

These

pilot

pilot

accumulator

so

they

problems.

indicator

be

of

significant

unit.

Cycle

of

gauges

manifold.

to

the

and

approximately

time

because

flow

and

system

are

board

accomplished

on

the

MC

the

accumulator

hose.

It

accumulator.

place

tank

this

point a signal

valves.

located

valves

allow

to

can

be

activated.

oxygen

lights

operation

(microcomputer

board.

constantly

only

is

on

DeVO/MC44

many

ways.

system

which

in a very

purge

similar

When

valves

to

used

located

help

when

can

to

the

cycle

activating

purge

valves.

22

seconds.

all

cycles

altitude.

controlled

by

the

use

The

trans-

tank

senses

when

approximately

is

sent

This

signal

the

four-way

compressed

enter

the

four-

is

It

the

on

be

test

and

A

are

The

and

of

by

a

the

to

is

which

the

the

purge

and

the

is

bed.

four-way

pressed

bottom.

allows

bed

from

bed

being

The

valve.

air

is

At

the

high

the

to

start

exhausted

air

and

When

directed

top.

concentrations.

air

in

the

previously

This

exhaust

can

closes.

At

the

beginning

needie

on

the

approximately

the

purge

needle

rise

until

maximum

four-way

drop

KPa).

and

bed.

hesitate

steadily

KPa).

continuous

to

depressurized

orifice.

reached,

anew

opening.

will

hesitate

maximum

accumulator

shifts

in

pressure

This

drop

releasing

When

the

slightly

and

This

low

flow

When

the

cycle

begins.

some

level

maximum

four-way

being

exhausted

out

of

the

into

same

time,

purity

When

This

its

cycle

oxygen

additional

the

pressurized

be

heard

of

the

gauge

15

PSI

will

(103

When

slightly

pressure

and

the

to

approximately

is

caused

of

purge

and

off

at

pressure

of

oxygen

bed

and

through

the

four-way

the

the

the

passes

exhaust

other

purge

to

enter

bottom

through

port

shifts,

bed

from

valve

the

pressure

at

higher

purge

each

pressurization

suddenly

KPa).

the

and

pressure

gauge

by

the

oxygen

closes,

then

pressures

valve

bed

is

exhausted.

time

increase

This

is

purge

then

continue

is

reached.

is

reached,

will

show a sudden

15

the

purge

to

the

needle

continue

closes,

the

cycle

caused

closes,

PSI

opening

the

to

approximately 2 PSI

reading

through

accumulator

from

purge

is

caused

the

pressurized

the

pressure

valves

manifold

shift

of

of

the

com-

the

opens

same

allows

and

the

purge

the

to

by

the

to

When

the

(103

other

will

drop

(13.8

by

the

is

and

The

four-way

position

PSI

tank.

this

activated

that

until

(175.8

This

takes

pressure

causing

when

KPa)

activated,

pressurization

activated,

Although

time

activated

It

is

during

the

pressurized

bed

that

During

from

into

located

purge

10/87

the

the

as

the

four-way,

position

this

is

just

pressurization a small

the

pressurized

the

depressurized

in

the

the

nitrogen

valve

will

the

right

of

oxygen

approximately

is

reached

the

left

of

the

right

left

bed

purge

valve

for

approximately

time

that

bed

is

allowed

beginning

bed

manifold.

from

remain

sieve

bed

the

is

is

it

high

in

bed

in

the

11

the

four-way

to

pressurize.

four-way

sieve

bed.

being

activated

only

remains

purity

to

its

pressurization

amount

is

constantly

bed

through

This

oxygen

the

depressurized

the

activated

builds

up

accumulator

seconds.

When

is

allows

When

pressurized.

at

the

same

in

1.0

seconds.

oxygen

flow

into

cycle.

of

oxygen

flowing

the

orifice

flow

helps

25.5

de-

Note

de-

this

from

the

bed

Page 5

SECTION

3

INSTALLATION

A.

Installation

1.

B.

Operation

1.

Position

control

lt

cycle,

a

minimum

of

trator

radiators,

NOTE:

imprinted

2)

read:

WARNING:

burning.

DeVO/MC44

receiving

near

Electrical

cabinet.

removed

With

position,

volt,

handling a minimum

Push

"ON"

illuminate,

cated

of

switch

is

guide

When

audible

the

erable

may

the

surize.

continues

shooting

The

"Service

illuminate

remain

system

With

turn

(S

the

panel

must

be

electrical

other

appliances.

should

Always

located

hot,

the

50

cycle,

the

position.

in

the

the

unit.

still

unbroken,

for

the

alarm

unit

length

sound

accumulator

If

visible

on

is

the

the

knob

Fig.

2)

AND

concentrator

is

convenient

accessible

outlet

of 7 amps

not

be

heaters,

or

observe

on

the

instruction

on

the

front

Oxygen

Do

not

smoke

or

when

oxygen

sparking,

shock

The

therapy.

or

hazard:

cabinet

by a qualified

power

plug

the

switch

line

electrical

On/Off

check

power

switch

If

the

the

connector

Replace

fails

to

illuminate,

refer

to

specific

power

has

instructions.

switch

will

sound

not

been

of

time,

for

an

extended

has

the

alarm

to

sound

guide

for

specific

alarm

on

the

Required”

when

the

until

pressure

approximately 9 PSI.

DeVO/MC44

(6

Fig.

until

the

such

to

to a 240

capable

that

is

independent

The

oxygen

located

hot

air

registers.

the

label

of

the

promotes

when

near a person

Do

burning

Do

not

may

DeVilbiss

in

cord

outlet

of 7 amps.

(1

Fig.

switch

fuse

(1

if

necessary.

and

the

troubleshooting

is

turned

momentarily.

used

for a consid-

the

audible

had

time

does

not

refer

to

the

instructions.

control

(2

Fig.

unit

is

turned

operating,

2)

on

the

ball

in

the

OPERATING

that

the

the

patient.

volt,

50

of

handling

concen-

adjacent

warnings

unit.

using

objects.

only

the

into a 240

capable

2)

does

Fig.

on

period

sound

panel

2).

within

flow

to

(4

Fig.

They

rapid

the

not

use

remove

be

dealer.

“OFF”

of

to

the

not

4)

lo-

the

back

If

the

the

fuse

on,

the

alarm

until

to

pres-

or

trouble-

says

It

will

on

and

the

slowly

meter

meter

If

is

PROCEDURES

centered

-

the

Flow

LPM.

positioned

enclosed

properly

tions

Therefore,

retained

log

Important:

pletely

tubing

because

When

trator

extended

up

oxygen

flow

period

and

If a humidifier

the

delivery

the

not

If a humidifier

a

bubble-type

humidifier

the

to

the

NOTE:

DeVO/MC44

pressure

“Set-Type”

properly

bubble-type

Included

plastic

piece

Fig.

8

inches

fitting

(203

fitting

humidifier

tightened

fitting.

oxygen

mm)

may

from

on

the

prescribed

meter

accuracy

Because

as

with

the

may

not

this

or

the

book

for

future

If

off

it

alarm”

of

the

the

DeVO/MC44

is

turned

period

to

30

minutes

concentration

rate

may

of

time

readjusted

physician,

tubing

oxygen

exceed

elastic

outlet

50

stand

strap

stand.

For

optimum

has a pre-set

of

8.5

humidifiers

at

humidifiers

with

fittings

of

tubing.

8)

for

all

humidifiers

(203

(3

Fig.

mm)

and

by

turning

counterclockwise

securely

Connect

outlet

piece

of

have

to

kinking.

line

corresponding

flow

rate.

will

of

this,

the

shown

every

correct

unit.

be

attained

green

on

oxygen

information

reference.

flow

meter

may

activate

and

turn

severely

on

(or

if

of

time),

for

the

drift

slightly

and

should

if

necessary.

has

not

been

the

5/32”

can

be

attached

fitting.

feet

(15

m).

has

been

humidifier

(4

Fig.

(5

Fig.

performance,

PSI

(58.6

this

low

the

DeVO/MC44

and a 3-inch

Use

the

mm)

tall

8)

for

humidifiers 8 inches

taller.

Attach

the

on

the

humidifier

fitting

tubing

be

with

(4

shortened

vary

slightly

ball

should

the

green

If

ball

is

concentra-

at 5 LPM.

card

should

recorded

is

turned

the

“crimped

the

unit

restricted

flow.

oxygen

not

in

use

it

may

flow

rate

to

stabilize.

during

be

monitored

prescribed

(4

mm)

directly

Tubing

prescribed,

(6

Fig.

3)

3)

securing

3)

that

is

attached

nominal

KPa),

therefore,

will

not

function

pressure.

should

straight

that

and

be

(76.2

are

the

fitting

less

the

wing

nut

until

the

humidifier

the

3-inch

Fig.

8).

The

to

prevent

with

at

5

be

card

not

set

be

in

a

com-

off

concen-

for

an

require

and

The

this

by

1.D.

to

should

place

on the

it

with

the

output

Only

used.

are

mm)

(2

than

elbow

proper

on

the

it is

to

the

(76.2

tubing

2

it

10/87

Page 6

SECTION

3

INSTALLATION

Attach

I.D.

the

cannula

not

Condensation

occur

the

oxygen

humidifier

or a suitable

exceed

in

longer

desired

delivery

50

feet

from

lengths

length

tubing

and

attach

mask.

(15 m).

the

AND

of

5/32”

(7

Fig.

either

Tubing

humidifier

of

tubing

OPERATING

(4

mm)

3)

to

a

should

may

or

with

PROCEDURES

tubing

reduced

ifier

end

outlet

plastic

The

may

laying

by

stand.

of

the

delivery

fitting

fitting

DeVO/MC44

now

be

on a cold

using

To

use

and

on

the

used.

floor.

the

removable

the

stand,

tubing

the

humidifier.

oxygen

to

other

This

can

humid-

attach

the

end

concentrator

one

oxygen

to

the

be

10/87

Page 7

SECTION

4

MAINTENANCE

Every

"burned-in“

of

assure

ous

formed

dealer.

are

A.

DeVO/MC44

the

product

continued

maintenance

on a regular

The

provided

Testing

1.

Turn

tion

trol

rate

minute.

When

used

may

gen

rate

of

gradually

specific

When

stabilized,

attached

Fig.

various

should

oxygen

under

the

decreases,

oxygen

The

outlet

the

OXYGEN

CONCEN-

TRATION

(Percent

+3)

at

the

factory

specifications

trouble-free

procedures

following

as a guideline.

and

Calibration

the

power

and

slowly

knob

(6

Fig.

is

variable

the

unit

for

an

require

concentration

may

drift

time

and

the

increase

flow

the

oxygen

an

to

2)

to

test

flow

be

calibrated

percentage

B-6).

As

percent

range

graph

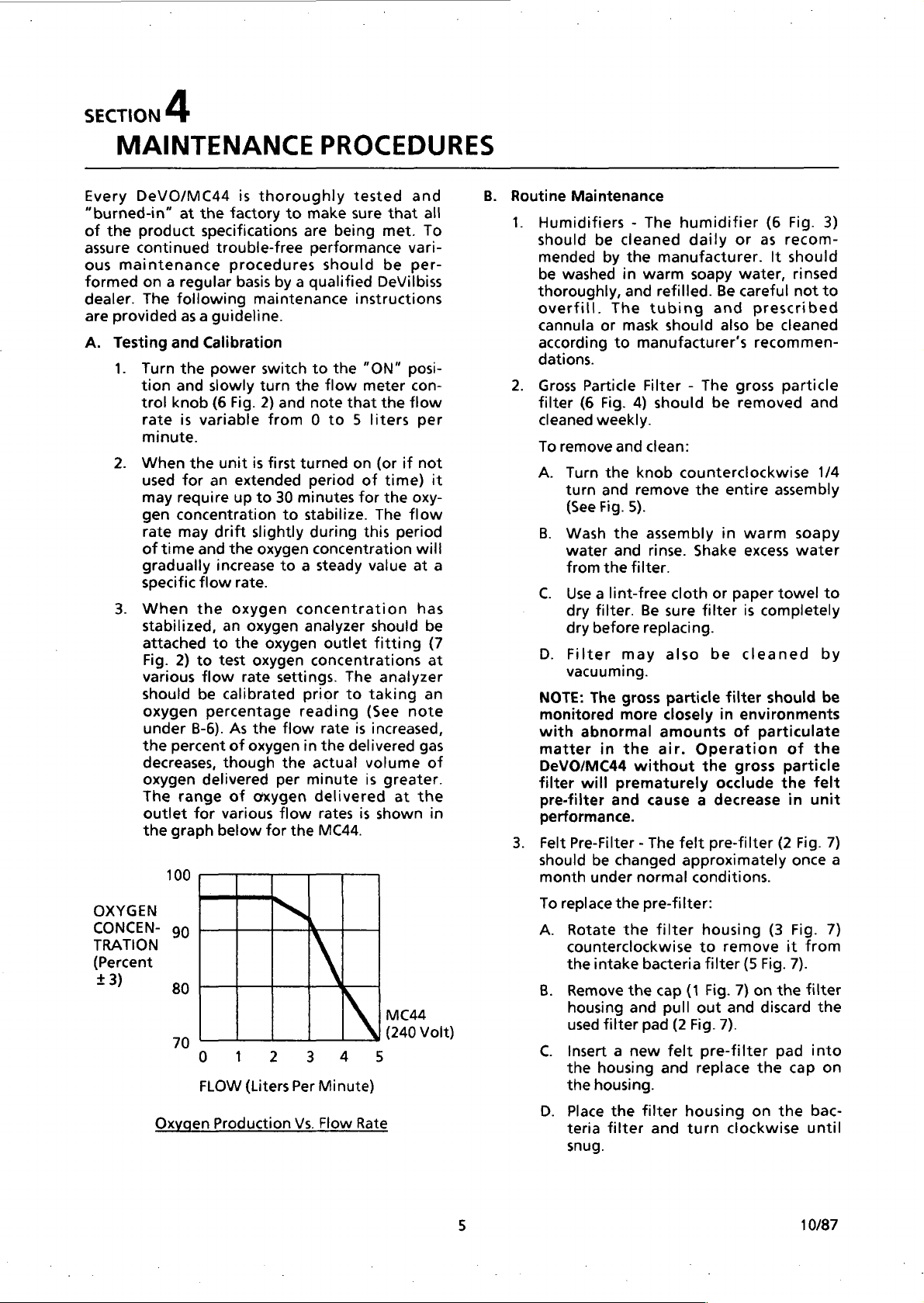

100

90

80

70

Oxygen

of

though

delivered

of

for

various

below

ο

FLOW

Production

is

thoroughly

to

basis

by a qualified

maintenance

switch

turn

2)

and

from 0 to 5 liters

is

first

extended

up

to

30

to

slightly

oxygen

to a steady

rate.

oxygen

the

oxygen

oxygen

rate

settings.

the

flow

oxygen

the

per

oxygen

flow

for

the

1

2

(Liters

PROCEDURES

tested

make

sure

are

being

performance

should

instructions

to

the

“ON”

the

flow

meter

note

that

turned

minutes

stabilize.

concentration

analyzer

prior

reading

in

Per

Vs.

on

period

during

concentration

concentrations

actual

minute

delivered

3

of

for

outlet

The

to

rate

is

the

delivered

rates

is

MC44.

4

Minute)

Flow

Rate

this

volume

and

that

met.

To

vari-

be

per-

DeVilbiss

posi-

con-

the

flow

per

(or

if

not

time)

the

oxy-

The

flow

period

will

value

at

has

should

fitting

analyzer

taking

(See

note

increased,

gas

is

greater.

at

the

shown

MC44

(240

Volt)

5

all

it

a

be

(7

at

an

of

in

B.

Routine

1.

Maintenance

Humidifiers - The

should

mended

be

thoroughly,

overfill.

cannula

according

dations.

Gross

filter

cleaned

To

A.

B.

C.

D.

NOTE:

monitored

with

matter

DeVO/MC44

filter

pre-filter

performance.

Felt

should

month

To

A.

B.

C.

D.

be

by

washed

or

Particle

(6

Fig.

weekly.

remove

Turn

turn

and

(See

Fig.

Wash

water

from

the

Use a lint-free

dry

filter.

dry

before

Filter

vacuuming.

The

abnormal

in

will

Pre-Filter - The

be

under

replace

Rotate

counterclockwise

the

intake

Remove

housing

used

filter

Insert a new

the

housing

the

housing.

Place

teria

snug.

humidifier

cleaned

the

manufacturer.

in

warm

and

refilled.

The

tubing

mask

should

to

manufacturer's

Filter - The

4)

should

and

clean:

the

knob

counterclockwise

remove

5).

the

assembly

and

rinse.

filter.

cloth

Be

sure

replacing.

may

also

gross

particle

more

closely

amounts

the

air.

without

prematurely

and

cause a decrease

felt

changed

the

the

the

and

the

filter

approximately

normal

pre-filter:

filter

bacteria

cap

(1

pull

pad

(2

felt

and

filter

housing

and

daily

turn

or

soapy

Fig.

water,

Be

careful

and

prescribed

also

gross

be

removed

the

entire

in

warm

Shake

Operation

conditions.

out

replace

excess

or

paper

filter

is

be

cleaned

filter

in

environments

of

the

gross

occlude

pre-filter

housing

to

remove

filter

(5

Fig.

7)

on

and

7).

pre-filter

on

clockwise

(6

Fig.

3)

as

recom-

It

should

rinsed

not

to

be

cleaned

recommen-

particle

and

1/4

assembly

soapy

water

towel

to

completely

by

should

particulate

(3

Fig.

discard

the

be

of

the

particle

the

felt

in

unit

(2

Fig.

once

Fig.

it

from

7).

the

filter

the

pad

into

cap

on

the

bac-

until

7)

7)

a

10/87

Page 8

SECTION

4

MAINTENANCE

С.

Intake

filter

same

and

mately

To

A.

B.

D.

Audible

system should

maintenance

checked

A.

B.

NOTE:

purchased

batteries

02

tions

accordance

procedures

NOTE:

the

calibrated

source.

changes

midity

tration

Therefore,

calibrated

the

Periodic

Bacteria

(5

time

changed

every

replace

Pull

rubber

Remove

Place

new

The

be

inserted

To

test

remove

volt

switch

alarm

replace

located

divider.

Plug

and

“ON”

momentarily.

or

sounds

battery.

Concentrations - Oxygen

should

Before

oxygen

reading

concentrator

Maintenance

Filter - The

Fig.

6)

should

the

felt

when

six

the

intake

the

bacteria

grommet

the

the

feit

bacteria

complete

into

be

pre-filter

months).

bacteria

(See

felt

pre-filter

pre-filter

filter.

filter

the

Alarm - Testing

be

included

program.

on a monthly

the

the

AC

outlet

to

the

is

not

the 9 volt

on

the

the

unit

turn

the

position.

weak

basis.

audible

line

cord

and

“ON”

heard

front

into a 220

power

The

If

the

replace

Replacement

locally

or

(Section

and

equivalent.

be

checked

with

the

4,

A).

checking

analyzer

should

using a 100%

It

should

in

temperature,

may

affect

the

in

similar

also

the

as

shown

analyzer

conditions

is

located.

PROCEDURES

intake

inspected

needed

filter

Fig.

assembly

rubber

the

alarm

turn

position.

or

battery

of

switch

alarm

alarm

batteries

should

established

concentrations,

be

altitude,

oxygen

by

bacteria

at

the

is

inspected

(approxi-

filter:

out

of

the

6).

assembly.

assembly

can

on

then

grommet.

audible

alarm

in a routine

!t

should

system,

from

the

220

the

power

if

sounds

volt

(20

the

will

is

not

weak,

Fig.

vertical

AC

outlet

to

sound

heard

the

the 9 voit

can

be

alkaline

concentra-

monthly

test

be

properly

pure

oxygen

noted

that

or

concen-

the

analyzer.

should

to

where

the

hu-

a

be

11)

be

in

be

Final

Bacteria

filter

(3

Fig.

needed

normal

To

A.

C.

D.

E.

(approximately

conditions).

replace

Loosen

top

Swing

the

and

the

Remove

each

end

Install

with

new

hose

Replace

fasteners.

Compressor

filter

(12

Fig.

before

To

A.

25,000

replace

Refer

to

compressor

cabinet

be

completely

B.

Cut

plastic

filter

in

C.

Loosen

rubber

D.

Install

new

directional

and

secure

NOTE:

directly

screws

unit

can

E.

F.

Holes

behind

and

must

be

inserted

Attach

of

filter

Replace

with

cabinet

Compressor

necessary

10,000

See

NOTE:

hour

Service

All

maintenance

listing

the

maintenance

shown

on

the

Filter - The

12)

should

final

bacteria

the

cabinet

sides

of

the

front

cover

hose

clamp

of

filter

and

bacteria

clamps.

cover

and

Filter - The

14)

should

hours

of

Service

covers.

place.

hose

hose

Instruction B to

The

removed.

cable

tie

clamps

from

HEPA

arrow

with

plastic

for

cable

left

brackets

be

removed

into

holes.

black

rubber

and

secure

cabinet

fasteners.

-

Inspect

the

internal

intervals

Instruction

routine

should

date

and

schedule

following

final

be

changed

once a year

filter:

fasteners

unit.

to

the

and

discard

filter

secure

with

compressor

be

changed

unit

operation.

filter:

back

cover

that

holds

and

remove

both

ends

filter

with

pointing

cable

tie

are

sieve

bed.

that

secure

so

that

hoses

to

with

hose

covers

and

and

components

of

unit

|.

and

be

recorded

hour

readings

like

page.

bacteria

as

under

on

the

right.

hose

from

filter.

and

secure

cabinet

HEPA

at

or

open

should

HEPA

black

of

filter.

air

flow

downward

tie.

located

Thumb

beds

to

cable

tie

each

end

clamps.

secure

change

if

at

operation.

periodic

by

in

the

one

a

10/87

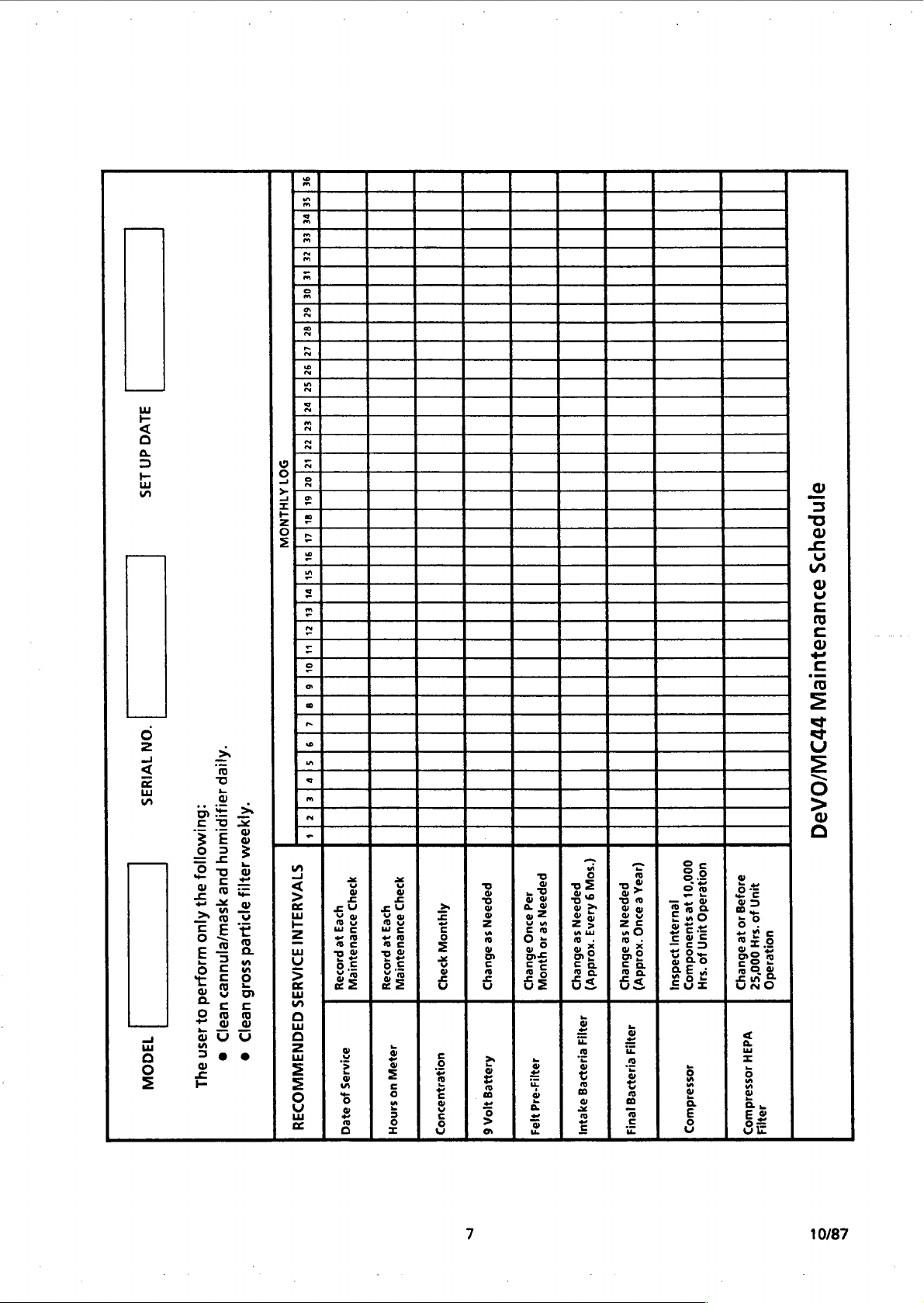

Page 9

alvd

dN

Las

"ON

1VIH

ヨ

S

“Ajlep

saipipluiny

“Apşaom

:6ulAAollol

velez|zz[izjoz|orfe

DO1A1HLNOW

le

[om]

sifurjer

za

oesforf

ee

|<]

op

spofe[z]o

ajnpayrs

SOuEu91UIBI

tt)W/OA2Q

14dOW

191J14

pue

ad

ysew/ejnuued

히

Ájuo

2!11004

wu1ojiad

55016

ues|>

46

03

히

49sn

2

@

e

au

SIVAUIINI

IDIAYIS

CIONIINNODIY

1934)

We3

4263

MULUIJUICIA

je

provou

BAJOS

40

8γεα

yay)

Ayu

as2ueuajurew

je

P1030Y

1933

YO

SANOH

uo

19340

4011613403403

papaan

og

8240

se

aBueuy

abuey>

Aisyeg

184-214

HOA

193

6

(SOW

papaan

9

A1313

se

‘xo1ddy)

abuey>

13Y14

211989

9yeyul

(ea,

papaan

e

au

se

‘xoiddy)

abuey)

19414

Cuapeg

[EU

000'01

uone1ado

¡euJa3u]

3e

$3

UUN

иэцодшо5

padsul

JO

'SIH

』Ossa』duuO

う

310498

HUN

40

10

“SAH

uone1ado

ye

95ueu

000'SZ

う

Vd3H

10sso1dw03

seua

10/87

Page 10

SECTION

5

ALARM

Most

problems

MC44

This

audible

there

problems

the

personnel

The

the

A.

are

indicated

system

is

alarms

comprised

which

is a malfunction.

are

indicated

MC

board.

These

troubleshoot

alarm

MC

Patient

1.

system

board.

Alert

Visible

located

Alarm

on

Required”

illuminated

such

as

low

compressor

flow

will

illuminate. A more

of

the

type

observing

the

MC

board.

NOTE:

come

turned

period,

The

on

on.

or

operating,

2.

guide

Audible

will

in

Section

Alarm

sound

pressure,

component

alarm

system.

the

unit

accumulator

powered

is

The

alarm

of

the

MC

alarm

control

B.

Microcomputer

The

board

cover

monitoring

as

well

transducer

When

indicates a malfunction,

be

activated

transmits

panel

microcomputer

(7

Fig.

of

the

and

as

the

(13

the

pressure

component

activated

if

the

SYSTEM

encountered

by

the

alert

by

are

problems

is

monitored

System

System - The

the

control

(2

Fig.

it

indicates a unit

pressure,

failure. A severe

also

of

problem

the

alarm

“Service

momentarily

If it

stays

comes

refer

to

6.

System - The

when

power,

failure

This

is

turned

has

had

by a 9

itself

is

board.

(3

Fig.

Control

12)

is

located

unit.

controlling

alarms

Fig.

12).

sensed

whether

failure.

system

with

patient

of

both

the

Further

alarm

lights

designed

and

panel

2).

When

valve,

cause

definitive

can

indicator

Required”

when

on

for

on

while

the

troubleshooting

there

is a low

valve,

that

alarm

will

time

volt

alkaline

located

When

the

sound

2).

Board

contro!

on

It is

responsible

the

by

using a pressure

by

the

alarm

it

is

for a pressure

Alarms

fails

to

within

this

on until

to

on

the

DeVO/

alert

system.

visible

patient

when

isolation

located

to

help

service

the

activated

visible

says

this

alarm

“Service

panel

malfunction

sieve

bed,

restriction

panel

description

be

found

lights

panel

the

unit

an

extended

the

unit

audible

or

or

other

activates

sound

pressurize.

battery.

the

backside

activated

through

board

the

this

will

operate

or

inside

entire

system

transducer

system

also

within

and

of

on

unit.

by

is

or

of

to

by

on

will

is

is

alarm

high

the

when

the

It

the

the

MC

front

for

will

or

be

the

pre-set

times.

The

DeVO/MC44

system

disconnected

the

patient

malfunction

is

still

malfunctions

minimum

cannot

or

from

because

operational.

will

automatically,

damage

The

Fig.

cycle

what

unit.

shooting

information

pressure

22)

sequence

When

indicator

sequence.

illuminate

cases,

further

the

may

malfunction.

light

causes

1.

to

the

MC

board

12)

labeled

and

high

type

of

They

aid

test

on

the

manifold.

on

a

malfunction

lights

One

when

whether

testing

exact

cause

be

more

is

given

for

the

Short

Cycle:

beds

have

minimum

been

pre-set

beds

pressurize

minimum

will

be

activated.

Possible

nation

and

will

activate

four-way

flow

may

malfunction

should

that

gauges

page

An

malfunction.

and

cycle

Cause: Severe

valve

on.

NOTE:

come

four-way

done

problem.

The

On

together

failure.

to

determine

Refer

Section 7 for

dures

for

the

and

maximum

is

designed

be

overridden.

weak

battery

being

the

For

will

alerted

visible

Also,

cause

the

unit

thus

preventing

unit.

has

four

red

indicator

short

cycle,

pressure.

be

in

conjunction

can

be

to

Refer

24.

long

These

has

occurred

used

derived

the

test

to

occurs

will

or

one

must

of

than

come

possibly

the

or

be

the

one

on

unit

shuts

two

done

problem

possible

two

lights

explanation

below

This

along

light

indicates

pressurized

maximum

on

the

time

so

MC

board.

quickly

is

reached,

cycle

cause a decreased

this

alarm. A failure

or a severe

also

cause

this

alarm

short

and

no

cycle

whether

Further

to

the

sieve

proper

beds

the

exact

Service

and

testing

cycle

so

its

alarm

example,

not

prevent

a

to a system

alarm

most

lights

to

any

cycle,

shut

system

major

off

further

lights

(8

no

indicate

in

the

as a trouble-

with

by

points

normal!

these

the

attaching

(Fig.

cycling

alarm

in a certain

lights

off.

to

determine

since

cause

of

each

with

will

In

come

on,

there

for

alarm

possible

all

the sieve

too

soon.

time

If

the sieve

that

this

bed

contami-

cycle

restriction

to

lights

it

is a bed

cause

alarm

time

of

come

must

of

A

has

the

the

of

will

or

be

the

Instructions,

testing

proce-

four-way.

a

10/87

Page 11

SECTION

5

ALARM

2.

Long

cycle

cycle

activated.

Possible

or

any

pre-set

NOTE:

by

itself

has

come

when a high

the

determine

problem.

Instructions,

testing

purge

on.

No

Cycle:

the

Possible

way

faulty

defective

of

flow

activate

SYSTEM

Cycle:

time.

time

been

on

unit.

depending

See

four-way

valve,

wiring

This

When

is

reached,

Cause: A faulty

problem

cycle

time

The

long

when

the

exceeded.

with

pressure

Further

the

Refer

Section 7 for

procedures

number 4 below:

This

light

valve

Cause:

inadequate

from

MC

board. A severe

or

contaminated

this

alarm.

light

indicates a long

the

pre-set

this

alarm

compressor,

that

causes

to

be

cycle

the

exceeded.

light

will

maximum

However,

the

high

pressure

situation

testing

Defective

must

exact

for

on

to

valve

cause

to

the

the

the

compressor

which

indicates a failure

shift

alarms

High

properly.

or

sticking

pilot

to

MC

beds

maximum

will

be

leak,

maximum

come

on

cycle

time

it

will

light

exists

be

Service

Pressure.

pressure,

board,

restriction

may

done

of

the

proper

come

four-

also

in

to

or

of

or

audible

Required”

illuminate.

The

lights

“four-way.”

Purge:

come

activated

Four-Way:

come

activated.

sieve

off,

Important:

designations

(Short

Pressure)

the

Bed,

Pressure.

DeVilbiss

either

malfunctions

same

alarm

light

MC

board

(8

Fig.

This

on

only

(approximately

This

on

only

At

bed

is

the

left

bed

Cycle,

some

following

Purge/Compressor,

These

Models

case

they

way.

will

sound

on

the

also

has

12)

labeled

These

are

green

when

green

when

the

same

being

pressurized.

is

pressurizing.

Instead

explained

Long

Cycle,

DeVO/MC44's

alarm

were

MC29

refer

and

and

control

two

green

“purge”

not

alarm

indicator

the

purge

1.0

indicator

the

four-way

time

of

in

No

light

designations:

4-way,

used

and

to

the

should

be

the

"Service

panel

indictor

lights.

light

valve

seconds).

light

valve

the

right

When

the

alarm

this

section

Cycle,

DeVO/44.

same

may

on

used

High

have

High

type

will

and

will

is

will

is

it is

the

in

of

the

NOTE:

come

way

be

the

Instructions,

testing

sieve

High

pressure

Possible

the

MC

NOTE:

lights

pressure

Further

determine

problem.

instructions,

testing

When

come

automatically

will

The

on

together

or

bed

done

to

problem.

procedures

beds.

Pressure:

situation

Cause:

activated

board

or

The

will

come

situation

testing

procedures

any

of

on

continue

short

failure.

determine

sticking

high

Refer

and

no

cycle

whether

Further

the

Refer

Section 7 for

This

Purge

position

pressure

on

the

Section 7 for

the

the

shut

to

to

for

the

light

in

the

system.

valve

due

valve.

together

exists

must

exact

to

for

the

four

red

compressor

off

but

operate.

indicates a high

lights

will

it

is a four-

testing

exact

the

the

four-way

remained

to a defective

and

when a high

in

be

cause

the

the

purge

indicator

the

must

cause

Service

proper

long

cycle

the

unit.

done

of

Service

proper

valve.

lights

will

cooling

Also,

and

the

fan

the

of

in

to

10/87

Page 12

SECTION

6

TROUBLESHOOTING

4.

5.

o.

Visible | Audible | Compressor

Alarm

1.

OFF

2.

3.

ON

ON

OFF

OFF

Symptom

、

Alarm

ON

ON

ON

OFF

OFF

On

or

OFF

OFF

OFF

ON

ON

GUIDE

Off

Other

Symptoms

On/Ott

switch

illuminated | yo

On/Off

İN

utumına

Unit

warm

o

the

U

cannot

restarted

for

several | Low

minutes

Pulsating

air

noise

Excessive

noise

Line

not

[|

or

defective

Line

termina!

Defective

Blown

Defective

ted

Loose

Defective

Defective

Upper

disconnected

Compressor

a

Occluded

an

be

Restricted

passage

Defective

Defective

Felt

filters

Compressor

disconnected

Defective

mounts

Defective

Defective

Possible

cord

power

cord

fuse

Compressor

.

and

.

line

and/or

not

Problems

not

properly

at

receptacle

disconnected

block block

On/Off

in

power

MC

board

compressor

Capacitor

lower

overheated

filters

. : :

input

voltage

cooling

compressor

intake

in

place

intake

or

loose

compressor

cooling

installed | Insert

at

switch

connector

Wire

wiring

harness | Reconnect

due

to:

or

output

air

fan

bacteria

or

defective

hose

motor

fan

line

Check

fuse,

by

Circuit

other

receptacle

Reconnect

Replace

Replace

Replace

Tighten

Replace

Replace

Replace

Remove

Check

circuit

appliances

Replace

Replace

Check

necessary

Reconnect

Replace

Replace

Replace

Suggested

99

plug

in

cord

building

or

have

qualified

electrician.

may

be

appliances

may

line

switch

fuse

MC

board

or

attach

compressor

Capacitor

wiring

filters

obstruction

line

voltage,

independent

cooling

compressor

filters

hose

or

tighten

compressor

cooling

Remed

receptacle

circuit

fully

and

be

required.

cord

wire

harness

fan

replace

fan

breaker

wiring

loaded

another

at

terminal

use

alternate

of

other

motor

house

and

y

or

replace

checked

with

if

mounts

or

10/87

10

Page 13

SECTION

6

TROUBLESHOOTING

Visible | Audible | Compressor

Alarm

6.

8.

OFF

7.

9.

10.

OFF

OFF

OFF OFF

OFF OFF

Symptom

Alarm

OFF

OFF

OFF

On

or

ON

ON

ON

ON

ON

Off

GUIDE

Other

Symptoms

Fluctuating | Occluded

flee

Littleorno

oxygen

flow

Audible

alarm

does

when

unit

_ |

isturned

Low

on

possible

increasein | Defective

cycle

Low

concentra-

tion

decrease

cycle

on } Defective

02

sn

time | Four-way

02

and

in

time

Possible

Use

of

improper

Occiuded

Occluded

and

tubing

Use

of

excessive

Defective

Air

leak

Defective

Defective

Defective

Pressure

properly

{Flow

meter

properly

Hose

disconnected

meter

Oxygen

kinked

or

Occluded

Defective 9 voit

Defective

Defective

Leaks

in

Defective

Defective

Occluded

Purge

valve

activated

Contaminated

Problem

!

humidifier

humidifier

filters

or

defective

tubing

flow

meter

in

system

compressor

reed

valve

check

valve

regulator

or

defective

not

adjusted

delivery

tubing

blocked

humidifier

battery

wire

harness

sonalert

MC

board

system

check

valves

reed

valve

compressor

valve

not

filters

stuck

position

sieve

'

not

to

in

cannula

adjusted

flow

fully

de-

beds

*

Clean

Use

only a bubble

Clean

Detach

tubing.

tained,

other

straighten

tubing

The

Ipm

meters)

(4mm)

Small

tion

may

flow

Replace

Check

fittings

Replace

Replace

Replace

|]

Adjust

regulator

Adjust

Reconnect

is

shifted | Clean

Straighten

obstruction

Clean

Replace 9 volt

Repair

Replace

Replace

Check

Replace

Replace

Replace

Replace

Refer

tions,

Purge

Replace

Suggested

99

or

replace

humidifier

or

replace

filters

cannula

check

obstructions.

if

unit

with a cannula

inside

diameter

of

any

prevent

rate.

for

or

flow

or

or

all

or

to

on

Valve

from

If

proper

flow

tubing

as

required

necessary.

is

designed

of

approximately

diameter

tubing

other

flow

obtaining

flow

meter

leaks

in

compressor

reed valve

manifold

replace

meter

hose

tubing

replace

humidifier

battery

replace

MC

board

MC

board

hoses

and

manifold

reed

valve

compressor

replace

four-way

filters

Section

7,

How

to

Trouble-shoot

sieve

beds

Remed

type

humidifier

O2

delivery

is

not

for

kinks

Clean

or

replace

to

deliver

on

50

tubing.

or

restriction

the

all

hoses

base

pressure

or

remove

wire

harness

fittings

base

Service

y

at-

or

or

5

feet

(15

5/32”

the

addi-

desired

and

valve

Instruc-

11

10/87

Page 14

SECTION

6

TROUBLESHOOTING

Visible | Audible | Compressor

Alarm

11.

12.

13.

14.

15.

ON

OFF

OFF

OFF

ON

16.

17.

ON

ON ON

NOTE:

Some

designations

Symptom

Alarm

ON ON

ON

OFF

OFF

ON

ON

On

or

Off

OFF

ON

ON

OFF

OFF

.

OFF

MC

board

alarm

stated

in

the

lights

above

Other

Symptoms

Fluctuating | System

or

no

flow KPa)

Fan

operating

Visible

alarm

does

not

illuminate

when

is

turned

Low

pilot

pressure

Fan

operating, | property

short

and

no

cycle

lights

MC

board

itluminated

Fan

operating, { exceeded

long

cycle | teak

light

on

board

illuminated | Defective

Fan

operating, | position

long

cycle

andhigh

pressure

lights

MC

board

illuminated

may

be

troubleshooting

designated

GUIDE

Possible

due

Leak

in

Defective

Four-way

Blown

fuse on

Defective

Defective

panel | Defective

unit

on

Leak

in

Defective

accumulator

Defective

Defective

compressor

Four-way

MC

on

Contaminated

Severe

to:

Crimped

Occluded

Flow

meter

too

low

Maximum

in

SY

Defective

Four-way

Purge

valve

on

Problems

Oss!

pressure

system

pilot

restriction

system

г

below 9 PSI

to:

compressor

valve

not

MC

MC

board

bulb

MC

board

pressure

check

valve

compressor

reed

valve

valve

failed

sieve

,

tubing

humidifier

turned

cycle

time

due

to:

reed

valve

compressor

valve

not

stuck

board

of

in

fully

system

in

in

to

beds

flow

off

or

was

fully

activated

Bed,

guide.

Purge/Compressor,

See

Section 5 for

explanation

(62

Check

Replace

shifted | Clean

Replace

Replace

Replace

Replace

Check

fittings

pilot

shift

due

set

shifted | Clean

Replace

Replace

Replace

Refer

Instructions,

shoot

Refer

Instructions,

Troubleshoot

Straighten

Clean

Adjust

Check

Replace

Replace

Refer

Instructions,

shoot

4-Way,

and

High

of

the

Suggested

ugg

all

hoses

compressor

or

replace

fuse

MC

bulb

MC

all

pilot

manifold

compressor

reed

to

Section

Four-Way

to

Section

or

replace

flow

all

hoses

reed

compressor

or

replace

to

Section

Purge

Pressure

various alarms.

and

four-way

board

board

pressure

valve

7,

on

How

Valve

7,

on

How

Sieve

tubing

meter

and

vaive

on

How

Valve

Remed

fittings

base

Service

Service

humidifier

four-way

7,

Service

rather

y

valve

hoses

and

to

Trouble-

to

Beds

fittings

3

valve

to

Trouble-

than

the

10/87

12

Page 15

SECTION

7

SERVICE

Proper

The

of

15)

Components

shelf

attainable.

tailed

replacing

Also,

Kit

the

ments

trator.

Service

Repair

DeVilbiss

service

and

in

information

to

(Part

necessary gauges,

to

The

(1) | 3/16”

(1)

(1)

(1)

(1)

(1)

(1) | 8"

(1)

(1) } 9/64”

(1)

(1) | 7/64”

(2)

(1) | Toolbox

(10) | Cabinet

(20) | #2

(20) | #8

(20) | #11

(20) | #12

(2)

| Pressure

(1)

In

addition

analyzer

concentration

needed

When

servicing

certain

parts

material

tape

are

is

DeVO/MC44

by

utilizing a vertical

accumulator

are

such a way

The

components

aid

service

#444-501)

properly

following

Kit.

Slotted

#1

Philips

#2

Philips

13/8”

Nut

7116”

Nut

6”

Crescent

Duckbill

5/32"

"T“

“T“

3mm

“T”

“T”

10-30

PS!

hose

Hose

Hose

Hose

Hose

Pressure

to

will

when

that

the

free

not

recommended

INSTRUCTIONS

Procedures

is

situated

as

to

service

head

head

driver

driver

wrench

pliers

Handle

Handle

Handle

Handle

Pressure

fasteners

clamp

clamp

clamp

clamp

test

test

the

be

needed

levels. A volt

voltage

the

of

compatible

section

for

troubleshooting

within

personnel, a DeVO

is

available

tools,

service

parts

screwdriver

screwdriver

screwdriver

allen

allen

allen

alien

gauge

assembly

assembly

Service

testing

DeVO/MC44

correct

oil

and

and

designed

shelf

on

the

make

which

and

the

oxygen

are

included

wrench

wrench | (444-593)

wrench | (MC29D-645)

wrench f (MC44D-710)

and

Kit,

to

check

meter

is

tools

grease

with

must

for

ease

divider

(1

provides

the

required.

are

oxygen.

be

(4

Fig.

divider

them

easily

system.

Service

contains

test

instru-

concen-

in

(444-592)

(444-591)

(444-524)

(444-537)

(MC29D-638)

(444-538)

(444-502)

(MC29D-606)

an

oxygen

the

oxygen

may

also

be

absolutely

used

or

Teflon

applied

Fig.

15).

and

de-

and

the

be

and

any

to

the

male

threads

eliminate

entering

sealant

tape.

NOTE:

components

nect

before

extra

operate

opened.

Cabinet

To

1.

2.

To

1.

2.

3.

4.

5.

To

1.

the

may

Due

the

AC

attempting

care

the

Covers

open

front

Loosen

and

on

allen

wrench

be

rotated

loosen

Carefully

to

the

trical

harness.

remove

Disconnect

(16

Fig.

ness.

Open

from

terminal

Disconnect

Fig.

11).

Remove

attached

24).

Remove

that

connects

the

flow

removed.

open

back

Loosen

back

of

allen

away

accumulator

Ensure

on

the

By

disconnecting

terminal

connect

Fig.

13)

completely.

omitting

the

possibility

oxygen

also

be

to

the

proximity

within

power

should

the

the

them.

right

front

10)

back

the

the

wrench

from

that

electrical

the

cord

repairs

be

unit

with

cover:

cabinet

sides

(See

1/4

turn

swing

to

avoid

cover

large

located

cover

block

termina!

1/16”

to

accumulator

hose

clamp

the

meter.

cover:

four

the

unit

and

the

shelf

undue

block

terminal

back

the

first

of

tape

system.

used

in

Loctite

place

of

the

DeVO/MC44,

from

the

on

the

taken

the

Either

unit

(6

if it

is

the

cabinet

fasteners

of

the

unit

Fig.

9).

Fasteners

counterclockwise

front

cover

damaging

completely:

quick-connect

in

main

and

disconnect

(6

Fig.

13).

to 9 volt

diameter

fitting

and

hose

pressure

end

of

cabinet

using a 5/32”

(1

connections.

Fig.

for

cover

then

until

Fig.

tension

the

line

13)

the

can

fasteners

pull

the

15)

and

hour

thread

particles

of

the

electrical

wall

unit.

necessary

at

using a 5/32”

(7

wiring

battery

hose

(8

regulator

hose

back

top

is

is

not

cord

the

be

to

“PST”

teflon

discon-

outlet

Also,

to

covers

the

top

should

to

Fig.

10)

the

elec-

terminal

har-

line

cord

(21

that

(2

Fig.

Fig.

10)

to

may

be

in

the

(4

mm)

cover

of

the

exposed.

placed

at

the

quick-

meter

removed

(4

is

13

10/87

Page 16

SECTION

7

SERVICE

Flow

Meter

Each

flow

meter

accuracy

repairable

DeVO/MC44

flow

check

with

care

interconnecting

diameter

ingly

back

ence

The

which

To

1.

2.

3.

4.

5.

Pressure

The

the

back

PSI

field.

pressure

suitable

or

outlet.

when

necessary,

top