Page 1

SERVICE MANUAL

Repair Kit KK-4058-1

MBC - ZINC SPRAY GUN

MBC-ZINC-W (FOR WATERBASED INORGANIC ZINC)

MBC-ZINC-S (FOR SOLVENTBORNE ORGANIC ZINC)

EN

IMPORTANT: Before using this

equipment, read all safety precautions and

instructions. Keep for future reference.

DESCRIPTION

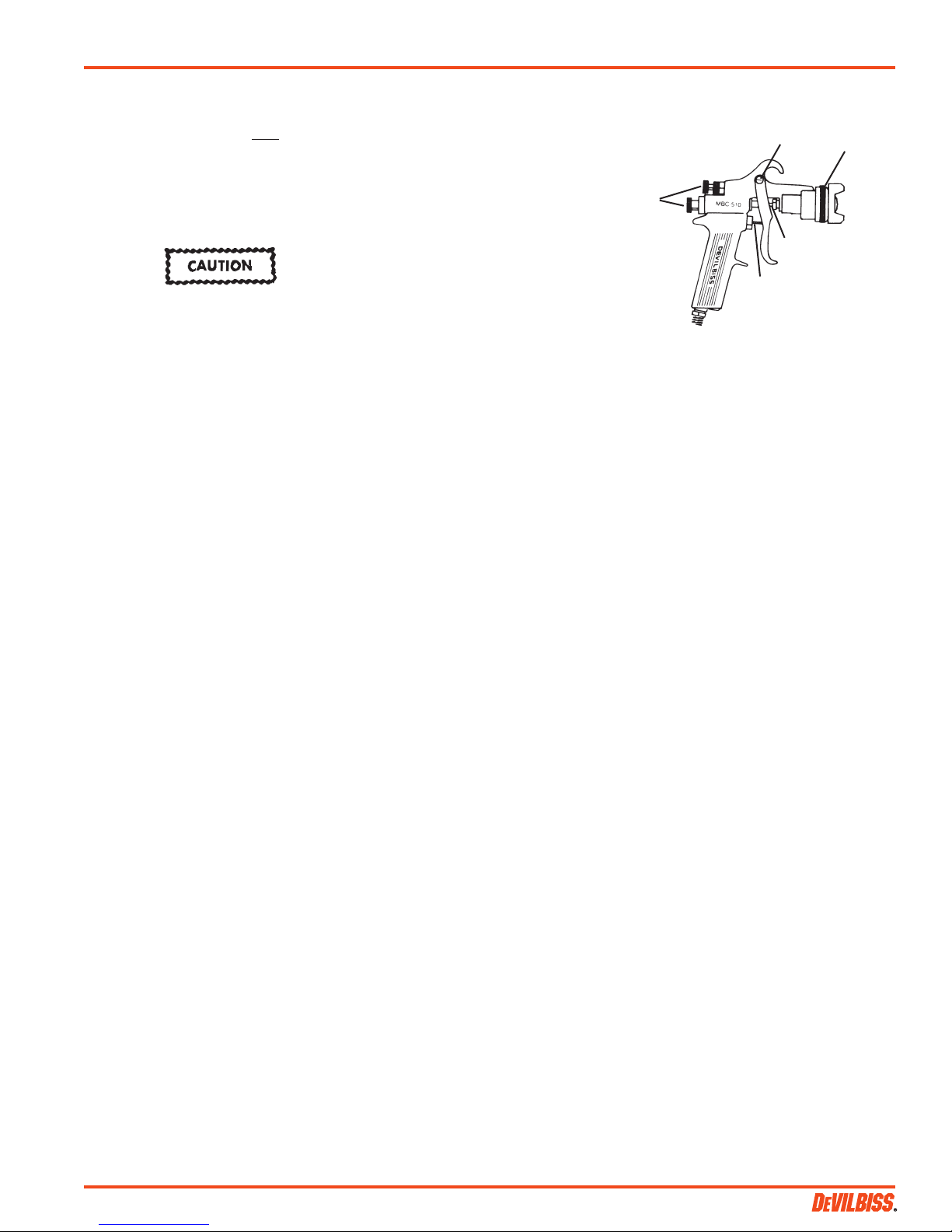

The MBC-ZINC-W spray gun is intended

for use with the new waterborne, zinc rich

protective coatings. MBC-ZINC-S is used

for solvent based zinc coatings.

The MBC-ZINC-W has all the features

of the standard MBC-510 and consists

of spray gun body and removable

sprayhead. MBC-ZINC-W differs in the

following components.

Leather packings

Heavy duty needle spring

Acetal copolymer construction air cap

Fluid tip with composition insert

The MBC-ZINC-S is set up for solvent

based ZINC and has the same features as

the MBC-510. The MBC-ZINC-S includes:

Leather Packings

Heavy Duty Needle Spring

MB-4039-64HD Air Cap

Standard Fluid tip and needle

These components have proven

very effective in handling the unique

characteristics of waterborne zinc rich

coatings. By using these components,

the user will insure the longest and most

reliable operation before major repair is

required.

HANDLING OF ZINC COATING

Some zinc rich formulations can require

up to 20 lbs. of dry zinc per gallon of

liquid. Care must be taken when adding

the zinc to insure complete suspension

into the liquid. Mechanical agitation

must be used when mixing, and during

application, to prevent agglomeration and

settling of the zinc particles. These larger

clumps will interfere with needle seating

and cause premature wear and leakage to

the tip or needle.

Zinc rich formulations have limited pot

life. Once the zinc is added, the liquid

slurry begins to increase in viscosity.

Material should be used within 3-4 hours

after mixing. If material is applied outof-doors, viscosity will increase faster

as a result of heat buildup caused by

environmental conditions.

Zinc solution – Follow manufacturers

directions for mixing zinc powder into

solution. Make sure adequate mechanical

mixing is observed during and after zinc

is mixed into liquid.

These instructions are found on both

container label and Technical Data Sheets.

In addition to specific recommendations

on handling the zinc, suppliers also have

recommendations concerning operating

pressures, air and fluid hose length

and size.

GUN OPERATION

The MBC-ZINC guns are supplied with

a D (.086”) size fluid tip. Extensive field

testing of the various zinc formulations

conclude that the use of smaller tip sizes

require elevated fluid pressures, which in

turn, increase the tendency of needle seat

interference. These higher fluid pressures

also cause the liquid material to pack out

when the gun is triggered off. Lower fluid

pressures help minimize both conditions.

After first mixing, a fluid pressure of

approximately 15 psi should provide

satisfactory flow rates for normal

production speeds. A reduction in flow

output will be experienced as the viscosity

increases and fluid pressures will have

to be increased. Under most application

conditions, atomizing air in the range of

50 psi will be satisfactory.

Packing operation – The packing set

consists of 3, pre-lubricated leather

packings. Packing tension on needle is

factory set. Lubricate packings twice daily

by adding a few drops of •SSL-10 gun lube

to the needle shaft. Retain proper packing

tension to allow smooth needle travel.

This will insure minimal needle shaft and

packing wear.

CLEANING

The fluid hose interior and gun fluid

passages should be cleaned immediately

after each zinc batch is used. Exterior

metal surfaces of the gun body and

head should be wiped clean before

any accumulation is allowed to dry.

Waterborne zinc in its dried state will be

extremely difficult to remove from any

metal surface.

The DeVilbiss air cap GTI-1-100L, is

constructed of Acetal copolymer. The

zinc will not adhere to its surface. If

zinc is allowed to dry, the film can be

simply removed with a fiber brush or by

soaking the cap in water. When the cap

is removed, always wipe off the fluid tip

exterior surfaces to prevent any zinc build

up from drying.

PREVENTIVE MAINTENANCE

The MBC-ZINC spray gun is designed

to provide the user trouble free service

applying this unique protective coat ing,

with only minimal care and maintenance.

There are certain steps the user can take

to insure trouble-free service.

1.Never immerse or soak the entire spray

gun in any liquid. These liquids are

generally contaminated and can foul

interior components and passages.

Immer sion over long periods can also

dilute and remove lubricants necessary

for smooth operation. Lubri cate gun

components daily as indicated.

2. Mix dry zinc into solution using a

mechanical agitator. Maintain agitation

during application.

3. Mix only the amount to be used in 4

hours or less.

4. Refrain from using excessive fluid

pressures. A range of 15-30 psi should

be satisfactory during the 4 hour

period of application.

5. Avoid longer than 25 ft. lengths of fluid

and air supply hoses to the gun. Air

hoses should be 5/16” I.D. minimum.

6. Do not allow zinc to dry on any interior,

metal fluid passage in the gun or hose

fittings. An appropriate cleaning agent

should be used to purge the system as

soon as a batch is used up.

7. Use a cleaning brush (see Accessories)

to clean the air cap. Do not use a wire

brush. Also avoid using metal objects

such as drill bits to clean air hole jets.

SB-2-303-F (1/2016) 1 / 8

•Safety Data Sheet available upon request.

Page 2

EN

SAFETY PRECAUTIONS

This manual contains information that is improtant for you to know and understand. This information relates to USER SAFETY and

PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please pay particular

attention to these sections.

Note

Important information that tells how

Important safety information - A hazard

that may cause serious injury or loss

of life.

The following hazards may occur during the normal use of this equipment. Please read the following chart before using this equipment.

HAZARD CAUSE SAFEGUARDS

Fire Solvent and coatings can be highly flammable Adequate exhaust must be provided to keep air free of

or combustible especially when sprayed. accumulations of flammable vapors.

Smoking must never be allowed in the spray area.

Fire extinguishing equipment must be present in the spray area.

Solvent During use and while cleaning and flushing, Wear eye protection.

Spray solvents can be forcefully expelled from fluid

and air passages. Some solvents can cause

eye injury.

Inhaling Toxic Certain materials may be harmful if inhaled, or Follow the requirements of the Safety Data Sheet

Substances if there is contact with the skin. supplied by your coating material manufacturer.

Adequate exhaust must be provided to keep the air free of

accumulations of toxic materials.

Use a mask or respirator whenever there is a chance of inhaling

sprayed materials. The mask must be compatible with the material

being sprayed and its concentration. Equipment must be as

prescribed by an industrial hygienist or safety expert, and be

NIOSH approved.

Explosion Hazard - Halogenated hydrocarbon solvents - for The MBC-510 can be used with these solvents.

Materials example; methylene chloride and 1, 1, 1 - However, aluminum is widely used in other spray application

Trichloroethylene are not chemically compatible equipment - such as material pumps, regulators, valves and cups.

with the aluminum that might be used in many Check all equipment items before use and make sure they can

system components. The chemical reaction also be used safely with these solvents. Read the label or

caused by these solvents reacting with data sheet for the material you intend to spray. If in doubt as to

aluminum can become violent and lead to whether or not a coating or cleaning material is compatible, contact

an equipment explosion. your material supplier.

General Safety Improper operation or maintenance of equipment. Operators should be given adequate training in the safe use &

maintenance of the equipment (in accordance with the requirements

of NFPA-33, Chapter 15). Users must comply with all local &

national codes of practice & insurance company requirements

governing ventilation, fire precautions, operation, maintenance and

housekeeping. These are OSHA Sections 1910.94 and 1910.107

and NFPA-33.

Cumulative Trauma Use of hand tools may cause cumulative trauma Pain, tingling, or numbness in the shoulder, forearm, wrist, hands or

Disorders (“CTD’s”) disorders (“CTD’s”). fingers, especially during the night, may be early symptoms of a CTD’s, or

musculo- CTD. Do not ignore them. Should you experience any such

skeletal disorders, CTD’s when using hand tools, tend to affect symptoms, see a physician immediately. Other early symptoms may

involve damage to the upper extremities. Factors which may include vague discomfort in the hand, loss of manual dexterity, and

the hands, wrist, increase the risk of developing a CTD include: nonspecific pain in the arm. Ignoring early symptoms and continued

elbows, shoulders, repetitive use of the arm, wrist & hand can lead to serious disability.

neck and back. Carpal 1. High frequency of the activity. Risk is reduced by avoiding or lessening factors 1-7.

tunnel syndrome and 2. Excessive force, such as gripping, pinching,

tendinitis (such as or pressing with the hands and fingers.

tennis elbow or rotator 3. Extreme or awkward finger, wrist, or arm.

cuff syndrome) are positions.

examples of CTD’s. 4. Excessive duration of the activity.

5. Tool vibration.

6. Repeated pressure on a body part.

7. Working in cold temperatures.

CTD’s can also be caused by such activities

as sewing, golf, tennis bowling, to name a few.

to prevent damage to equipment, or

how to avoid a situation that may cause

minor inury.

CA PROP

65

Information that you should pay

special attention to.

PROP 65 WARNING

WARNING: This product contains chemicals

known to the State of California to cause cancer

and birth defects or other reproductive harm.

SB-2-303-F (1/2016)2 / 8

Page 3

EN

Note

When replacing the fluid tip or

fluid needle, replace both at the

same time. Using worn parts can

cause fluid leakage. Also, replace

the needle packings at this time.

Lightly lubricate the threads of

the fluid tip before reassembling.

Torque to 20 - 25 ft. lbs.

To prevent damage to the fluid tip

(3) or fluid needle (3B), be sure to

either 1 ) pull the trigger and hold

while tightening or loosening

the fluid tip or 2) remove fluid

needle adjusting screw (27) to

relieve spring pressure against

needle collar.

TROUBLESHOOTING

Leakage from the tip can be caused by

sluggish needle travel, improperly mixed

zinc solution, or worn tip and/or needle.

If leakage occurs during application, clean

the gun and hoses out and remove fluid

tip. Inspect the interior seating surfaces.

If large particles appear to be imbeded

into the tip seat, scrape the surfaces with

a blunt object. Then, attempt to remove

agglomerates from the balance of solution

by straining.

In order to insure proper operation,

replace these parts when tip leakage

occurs due to wear:

AV-4915-D Fluid Tip

MBC-496-DEX Fluid Needle

AV-1-K5 Gasket

(Zinc waterborne gun)

AV-2115-D Fluid Tip

MBC-496-DEX Fluid Needle

AV-1-K5 Gasket

(Zinc solvent-based gun)

MB-135-K9

pre-lubricated leather packings (3)

(both guns)

SPRAY GUN LUBRICATION

Daily, apply two drops of •SSL-10 spray gun

lube (see Accessories) at trigger bearing

stud (29) and the stem of the air valve (19)

where it enters the air valve assembly.

The shank of the fluid needle (3B) where

it enters the packing nut (7) should also

be oiled. The fluid needle packing (3A)

should be kept soft and pliable by periodic

lubrication. Make sure the sprayhead (6)

and retaining ring (1) threads are clean and

free of foreign material. Before assembling

retaining ring to sprayhead, clean the

threads thoroughly, then add two drops of

SSL-10 spray gun lube to threads. The fluid

needle spring (26) and air valve spring (20)

should be coated with a very light grease,

making sure that any excess grease will

not clog the air passages. For best results,

lubricate the points indicated, daily.

A. Trigger Points

B. Packing

C. Adjusting Valves

D. Threads

C

A

B

A

D

Fluid Tip – If large imbedded clumps

cannot be removed, or if the tip seating

surface is worn, it will be necessary to

replace the tip and needle. Satisfactory

operation depends on the unique DeVilbiss

tip design, smooth needle shaft, and

lubricated and properly adjusted packings.

• Safety Data Sheet available from

DeVilbiss upon request.

SB-2-303-F (1/2016) 3 / 8

Page 4

EN

PARTS LIST

Ref. Replacement Individual

No. Part No. Description Parts Req

1 MBC-368 Retaining Ring 1

2 GTI-1-100L Air Cap, Acetal copolymer (waterborne) 1

2A MB-4039-64HD Air Cap, (solvent-based) 1

3 AV-4915-D Fluid Tip (waterborne) 1

AV-2115-D Fluid Tip (solvent-based) 1

3A MB-135-K9 Leather Packings (Kit of 9) 3

3B MBC-496-DEX Needle 1

4 AV-1-K5 Gasket Kit (Kit of 5) 1

5 MBC-1225 Baffle 1

6 P-MBC-402 Sprayhead Body 1

7 MB-19-K5 Packing Nut (Kit of 5) 1

8 MBC-1226-K10 Gasket Kit (Kit of 10) 1

9 MBC-67 Locking Bolt 1

10 MBC-498-1 Fan Adjustment Valve 1

11 --- Washer 1

12 --- Packing 1

13 --- Packing Nut 1

14 --- Knob 1

15 --- Screw 1

16 JGA-14-K25 Snap Ring (Kit of 25) 1

17 JGA-15-K25 Washer (Kit of 25) 1

18 JGS-26-K25 U-cup (Kit of 25) 1

19 JGS-431-K25 Air Valve (Kit of 25) 1

20 MBD-12-K25 Spring (Kit of 25) 1

21 JGS-72-K10 Gasket (Kit of 10) 1

22 JGS-449-1 Air Valve Assembly 1

23 CV-5-K5 Gasket Kit (Kit of 5) 1

24 --- Cylinder 1

25 MBC-33 Plunger

26 MBC-70-K2 Spring (Kit of 2) 1

27 MBC-39 Screw 1

28 MBC-4247 Cylinder Assy. 1

29 --- Trigger Bearing Stud 1

30 --- Screw 1

31 JGS-478 Stud & Screw Kit 1

(3 studs, 5 screws in kit)

32 JGS-477-1 Trigger, Stud & Screw Kit 1

(kit includes 1 each)

33 P-MB-51 Air Inlet Adapter 1/4” NPS 1

For Gun Repair order the following:

KK-4058-1 Repair Kit

MB-135-K9 Leather Packings

MBC-70-K2 Springs

SB-2-303-F (1/2016)4 / 8

Page 5

# 2A

EN

Torque to

150 inch lbs.

16

17

18

#1

19

#2

14

10

3B

15

27

23

6

#3A

Torque to

140 inch lbs.

9

Torque to

300 inch lbs.

24

3

#

8

20

21

4

Torque to

20-25 ft. lbs.

5

•33

25

11

7

12

13

#26

28

30

31

29

32

SB-2-303-F (1/2016) 5 / 8

22

• Use medium strength thread sealant (i.e. Loctite 242 value, or equal) on threads.

# These components have proven very effective in handling characteristics of zinc

rich coatings.

Page 6

EN

TROUBLESHOOTING

CONDITION CAUSE CORRECTION

Heavy top or Horn holes plugged. Clean. Ream with non-metallic point.

bottom pattern Obstruction on top or bottom of fluid tip. Clean.

Cap and/or tip seat dirty. Clean.

Heavy right or left side pattern Left or right side horn holes plugged. Clean. Ream with non-metallic point.

Dirt on left or right side of fluid tip. Clean.

Remedies for the top-heavy, bottom-heavy, right-heavy and left-heavy patterns:

1) Determine if the obstruction is on the air cap or the fluid tip. Do this by making a test spray

pattern. Then, rotate the cap one-half turn and spray another pattern. If the defect is inverted,

obstruction is on the air cap. Clean the air cap as previously instructed.

2) If the defect is not inverted, it is on the fluid tip. Check for a fine burr on the edge of the

fluid tip. Remove with #600 wet or dry sand paper.

3) Check for dried paint just inside the opening. Remove paint by washing with solvent.

Heavy center pattern Too much material. Reduce fluid flow on suction guns. Reduce

fluid pressure on pressure feed guns .

Material too thick. Thin to proper consistency.

Split spray pattern Not enough material. Reduce air pressure or increase fluid flow by

turning fluid needle adjusting screw counter

clockwise on suction feed, increase fluid

pressure on pressure feed guns.

Jerky or fluttering spray *Loose or damaged fluid tip/seat. Tighten or replace.

Insufficient fluid in cup or pressure tank. Fill cup or tank.

Gun (with cup) tipped at excessive angle. Do not tip excessively or rotate fluid tube.

Obstructed fluid passage or hose. Clean.

Loose or cracked fluid tube in cup or tank. Tighten or replace.

Too heavy fluid for suction feed. Dry or Change to pressure feed.

worn packing (14) or loose packing nut (15). Lubricate or replace. Tighten.

Unable to get round spray Fan adjustment screw not seating properly. Clean or replace.

Air cap retaining ring loose. Tighten.

Will not spray No air pressure at gun. Check air supply and air lines.

Internal mix or pressure feed air cap and tip Change to proper suction feed air

used with suction feed. cap and tip.

Fluid pressure too low with internal mix cap Increase fluid pressure at tank.

and pressure tank.

Fluid needle adjusting screw not open enough. Open fluid needle adjusting screw.

Fluid too heavy for suction feed. Thin material or change to pressure feed.

Fluid leaking from packing nut Packing nut loose. Tighten, do not bind needle.

Packing worn or dry Replace or lubricate.

Dripping from fluid tip Dry packing. Lubricate. See “Preventive Maintenance”.

Sluggish needle. Lubricate. See “Preventive Maintenance”.

Tight packing nut. Adjust. See “ Preventive Maintenance”.

Sprayhead misaligned, causing needle to bind. Tap all around sprayhead with wooden

mallet and retighten locking bolt.

*Most common problem.

SB-2-303-F (1/2016)6 / 8

Page 7

ACCESSORIES

WR-103 Wrench

42884-214-K5 3/8”

42884-215-K10 5/8”

Cleaning Brushes

HD-503

SolventSaver™

Hose/Gun

Cleaner

183GZ-5200

Hose/Gun Cleaner

SolventSaver™

HAF-507

Whirlwind™

In-Line Air Filter

EN

Spray Gun Lube

SSL-10 (2 oz.

bottle)

Contains all necessary

tip, hose and nut sizes

used on or with gun.

HAV-500 OR

HAV-501

These brushes are helpful

in cleaning threads and

recesses of gun body.

P-H-5516 Air

Adjusting Valve

Adjusting Valve

(HAV-501 SHOWN)

HAV-500 does not have

pressure gage. Use to

control air usage at gun.

Quick Disconnect Approved for

HVLP Guns (Air)

High Flow Ball and Ring Type

HC-4419 1/4”

NPS(F)

HC-4720

1/4” NPT(F)

Removes water, oil, and

debris from the air line.

HC-4719

1/4” NPT(M)

HC-1166

1/4” NPT(M)

2 Qt. & 2-1/2 Gal hose/

gun cleaner used to clean

the inside of hose, fluid

passageways of gun &

other paint equipment.

KB-555 (Aluminum) &

KB-545-SS (S/S)

2 qt. Pressure Feed Cup

With Regulator

Provides greater

degree of control

over cup fluid

pressure.

HARG-510

Air Regulator

Use to maintain nearly

constant outlet pressure

despite changes in

inlet pressure and

downstream flow.

2 gallon galvanized tank

used to clean the inside

of hose and material

passages of the gun.

KK-5060 Air Cap

Cleaning Kit

Consists of: 2 brushes,

1 wire pick. Helps

keep air cap clean and

performing properly.

Compatible with all paint

materials: contains no

Removes water, oil, and

debris from the air line.

This tube combines the fluid and air hoses at gun

handle preventing dragging hoses over work, twisting

line and improving overall gun handling.

JGA-444 Fluid Tube

silicone or petroleum

distillates to contaminate

paint. MSDA sheet

available upon request.

TLC-576 Aluminum Cup

(Non-stick Lined) &

TSC-591Stainless Steel Cup

1 Qt. pressure feed cups.

3/8” NPS (F), cam lock lid.

Requires KK-4980 air

regulator kit.

192212 Professional Spray Gun

Cleaning Kit

Contains six precision tools designed to effectively

clean all DeVilbiss, Binks, Finishline and other

brand spray guns.

29-3100 Scrubs®

Hand Cleaner Towels

Scrubs® are a premoistened hand cleaner

towel for painters.

No water is needed.

Millennium 3000

Twin Cartridge

Paint Spray Respirator

NIOSH-Certified, for

respiratory protection

in atmospheres not

immediately dangerous

to life.

SB-2-303-F (1/2016) 7 / 8

Page 8

EN

WARRANTY POLICY

DeVilbiss products are covered by Finishing Brands one year materials and workmanship limited warranty.

The use of any parts or accessories, from a source other than Finishing Brands, will void all warranties.

For specic warranty information please contact the closest Finishing Brands location listed below.

Finishing Brands reserves the right to modify equipment specications without prior notice.

DeVilbiss®, Ransburg®, BGK®, and Binks® are registered trademarks of Carlisle Fluid Technologies, Inc.,

dba Finishing Brands. ©2016 Carlisle Fluid Technologies, Inc., dba Finishing Brands. All rights reserved.

DeVilbiss is part of Finishing Brands, a global leader in innovative spray nishing

technologies. For technical assistance or to locate an authorized distributor,

contact one of our international sales and customer support locations below.

USA/Canada

www.devilbiss.com

info@carlisleft.com

Tel: 1-800-992-4657

Fax: 1-888-246-5732

United Kingdom

www.nishingbrands.eu

info@carlisleft.eu

Tel: +44 (0)1202 571 111

Fax: +44 (0)1202 573 488

China

www.nishingbrands.com.cn

mkt@carlisleft.com.cn

Tel: +8621-3373 0108

Fax: +8621-3373 0308

Mexico

www.carlisleft.com.mx

ventas@carlisleft.com.mx

Tel: 011 52 55 5321 2300

Fax: 011 52 55 5310 4790

France

www.nishingbrands.eu

info@carlisleft.eu

Tel: +33(0)475 75 27 00

Fax: +33(0)475 75 27 59

Japan

www.ransburg.co.jp

overseas-sales@carlisleft.co.jp

Tel: 081 45 785 6421

Fax: 081 45 785 6517

Brazil

www.devilbiss.com.br

vendas@carlisleft.com.br

Tel: +55 11 5641 2776

Fax: 55 11 5641 1256

Germany

www.nishingbrands.eu

info@carlisleft.eu

Tel: +49 (0) 6074 403 1

Fax: +49 (0) 6074 403 281

Australia

www.nishingbrands.com.au

sales@carlisleft.com.au

Tel: +61 (0) 2 8525 7555

Fax: +61 (0) 2 8525 7500

SB-2-303-F (1/2016)8 / 8

Loading...

Loading...