DeVilbiss KK-5058-2 Service Manual

SERVICE MANUAL

EN

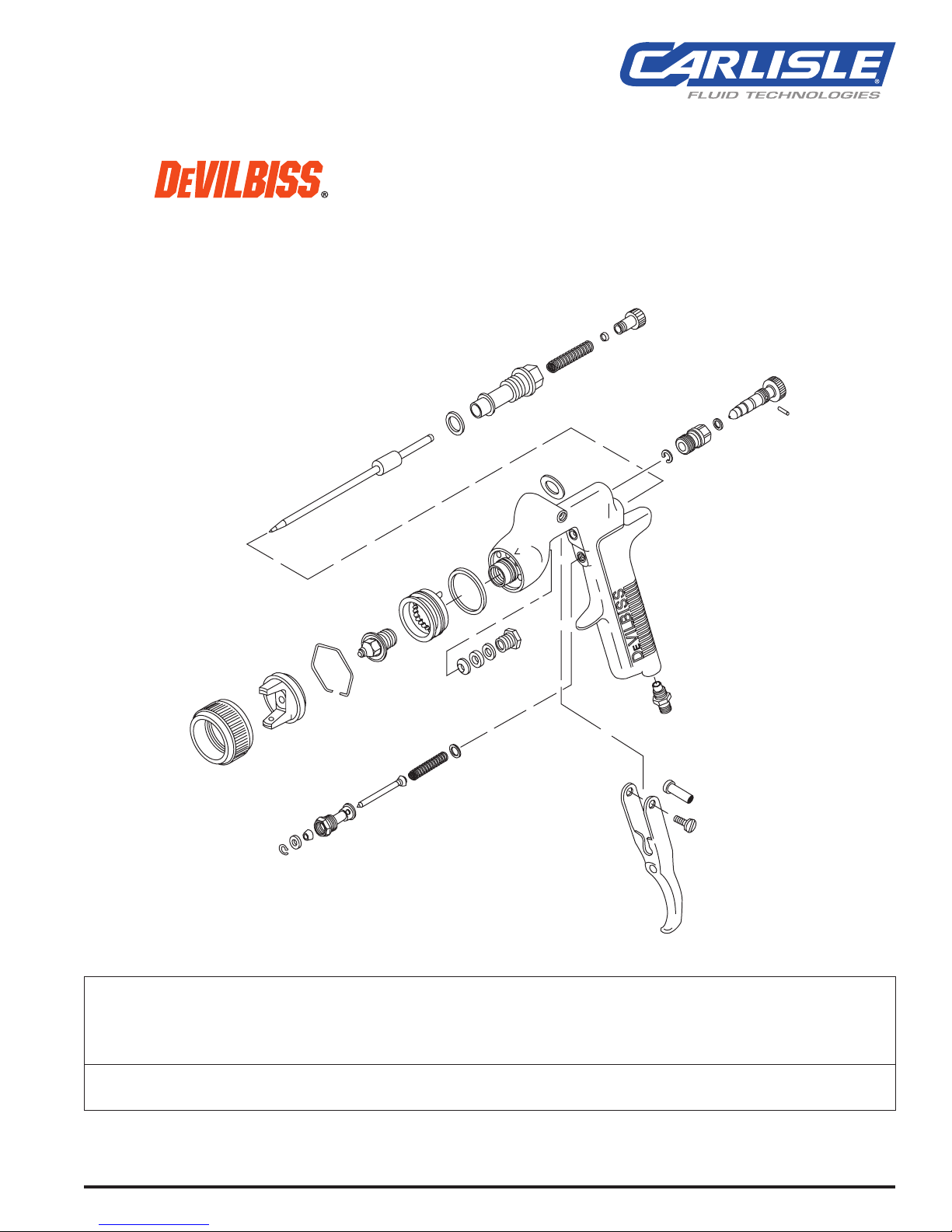

KK-5058-2 GUN REPAIR KIT

"WATERBORNE COMPATIBLE"

This repair kit can be used on all GTI guns, all EXL guns,

all PLUS guns and all PRI guns.

IMPORTANT! DO NOT DESTROY

It is the Customer's responsibility to have all operators and service personnel read and understand this manual.

Contact your local DeVilbiss representative for additional copies of this manual.

READ ALL INSTRUCTIONS BEFORE OPERATING THIS DEVILBISS PRODUCT.

SI-2-25-33-R1 (6/2018) 1 / 4 www.carlisleft.com

EN

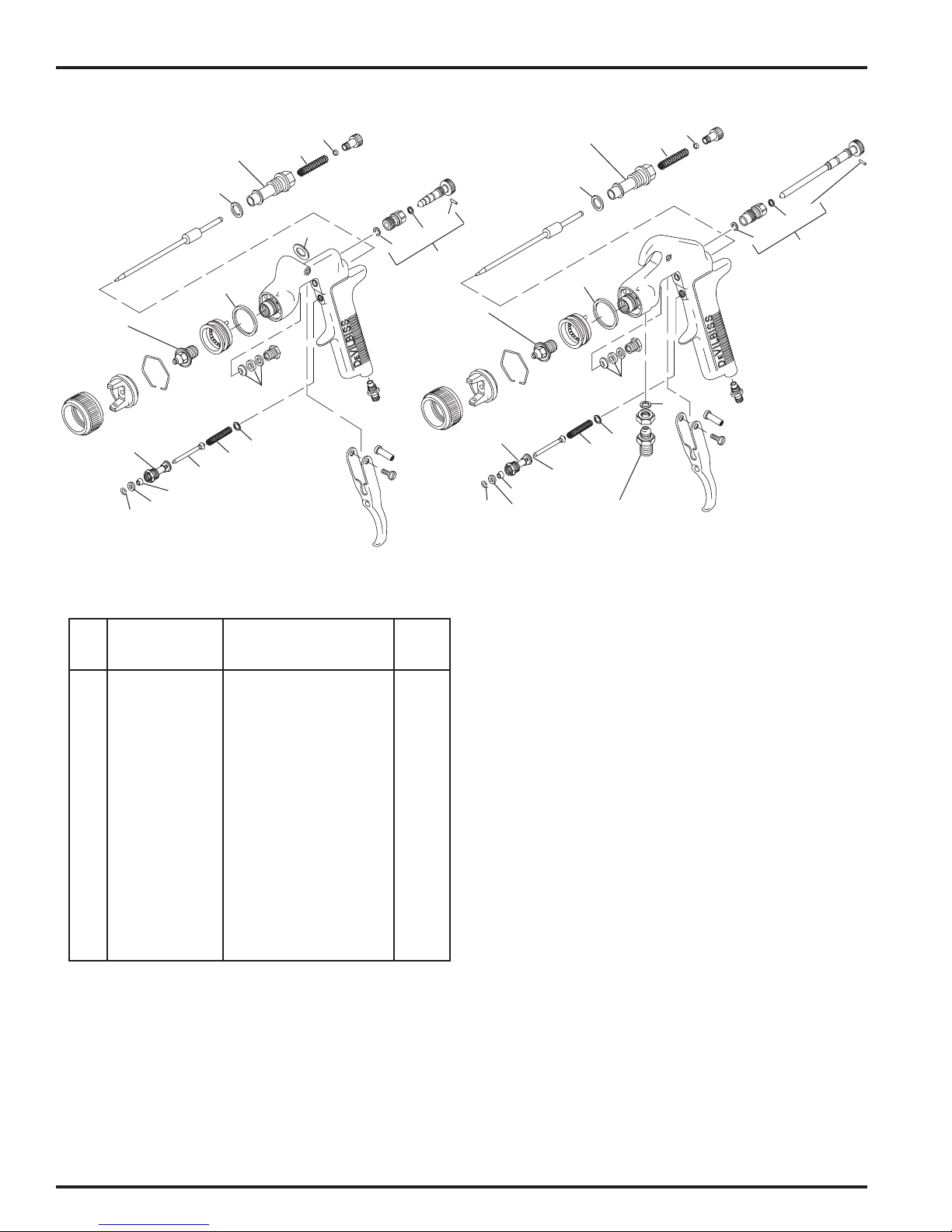

Gravity Feed Spray Guns Suction and Pressure Feed Spray Guns

4

See note below

3

2

11

5

Fluid Tip

(Torque to

15-20 ft. lbs.)

1

See note below

7

2

6

8

9

10

NOTE: If the color of these parts is blue or black,

then the parts marked with a "*" below are not

required and should not be used.

13

12

14

15

Fluid Tip

(Torque to

15-20 ft. lbs.)

See note

below.

10

See note below

2

5

1

2

6

7

8

9

Fluid Inlet Adapter

(Torque to 20-25 ft. lbs.)

Use medium strength thread

sealant (i.e. Devcon #2242 blue

or equal) on threads.

4

3

14

13

12

15

16

PARTS LIST

Qty. of

Ref. Replacement Parts in

No. Part No. Description Kit

1 JGA-4035-K5 Packing 1

*2 JGS-72-K10 Gasket Kit (PTFE) 2

3 --- Fluid Needle Spring 1

4 --- Spring Pad 1

■5 GTI-33-K5 Baffle Seal 1

6 --- Air Valve Spring 1

7 --- Air Valve 1

*8 --- U Cup Seal 1

*9 --- Washer 1

*10 --- Snap Ring 1

11 KGP-13-K5 Cup Gasket 1

(Gravity Guns Only)

12 --- Retaining Clip 1

13 --- Seal 1

14 --- Pin 1

15 GTI-428-K5 Clip, Seal & Pin Kit (5 ea.) 1

16 --- Fluid Inlet Gasket (PTFE) 1

(Suction and Pressure

Feed Guns Only)

Suffixes -K5, -K10 designates kits of multiple parts.

Example: JGA-4035-K5 is a kit of 5 packings.

■ Some gun models do not require a baffle seal. If white seal is present, order GTI-33-K5.

PREVENTIVE MAINTENANCE

To clean air cap and fluid tip, brush exterior with a stiff bristle

brush. If necessary to clean cap holes, use a broom straw or toothpick if possible. If a wire or hard instrument is used, extreme care

must be used to prevent scratching or burring of the holes which

will cause a distorted spray pattern.

To clean fluid passages, remove excess material from cup, then

flush with a suitable solvent. Wipe gun exterior with a solvent

dampened cloth. Never completely immerse in solvent as this is

detrimental to the lubricants and packings.

FLUID INLET GASKET (16) REPLACEMENT INSTRUCTIONS

1. Remove fluid inlet adapter with appropriate wrench.

2. Clean Loctite from gun body inlet threads and seal area.

3. Place gasket (16) squarely onto the fluid inlet adapter and push

it down until it is flat against the shoulder.

4. Use medium strength thread sealant (i.e. Devcon #2242 blue,

or equal) on threads before installing fluid inlet adapter.

5. Torque fluid inlet adapter to 20-25 ft. lbs. and tighten locknut.

SI-2-25-33-R1 (6/2018)2 / 4www.carlisleft.com

Loading...

Loading...