DeVilbiss KK-5051 Service Manual

SERVICE MANUAL

EN

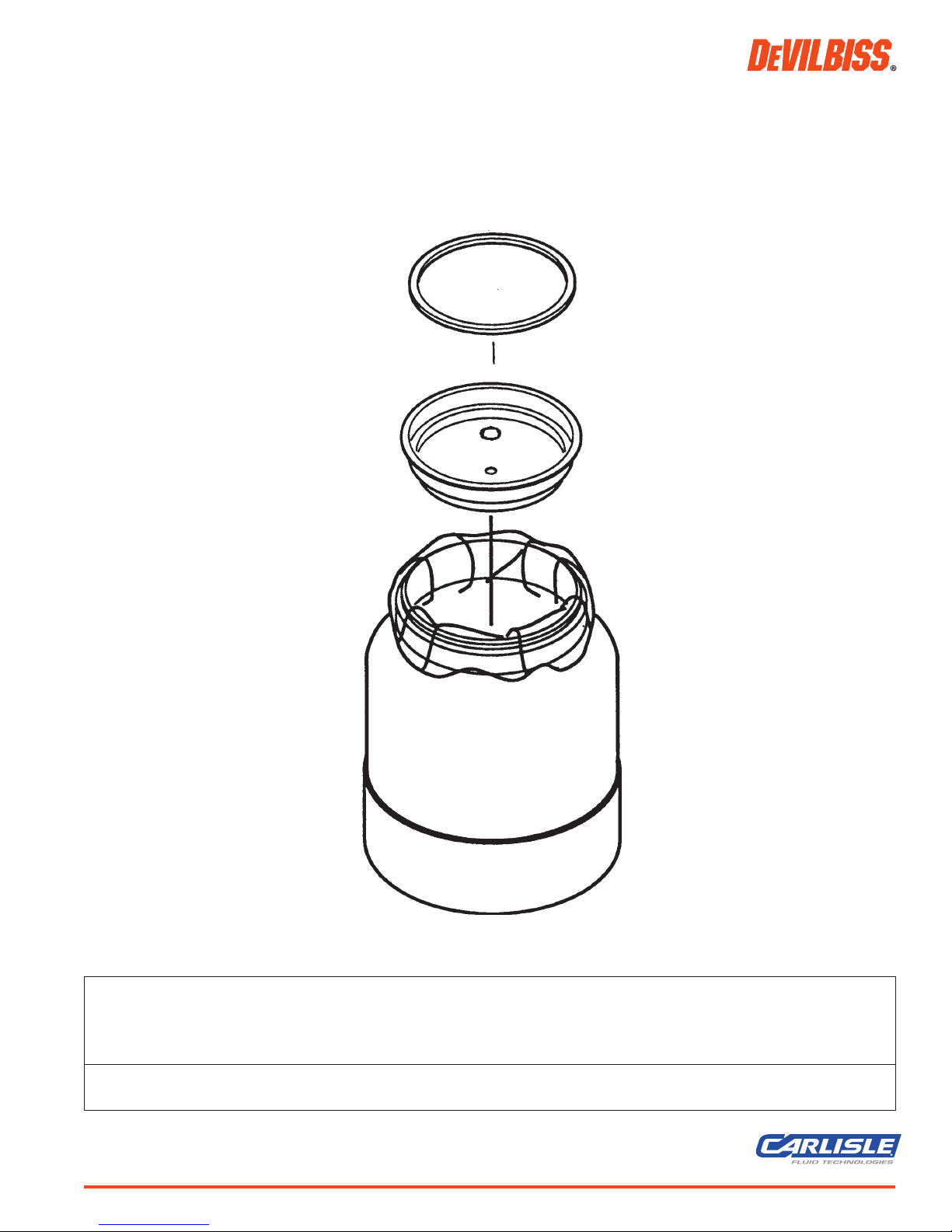

KK-5051 DISPOSABLE KB II CUP LINER

IMPORTANT! DO NOT DESTROY

It is the Customer's responsibility to have all operators and service personnel read and understand this manual.

Contact your local DeVilbiss representative for additional copies of this manual.

READ ALL INSTRUCTIONS BEFORE OPERATING THIS DEVILBISS PRODUCT.

SB-4-207-K (1/2018) 1 / 8 www.carlisleft.com

EN

IMPORTANT: Read and follow all instructions

and SAFETY PRECAUTIONS on Pages 1 and 4 before

using this equipment. Retain for future reference.

DESCRIPTION

Halogenated hydrocarbon solvents - for example:

1,1,1, - trichloroethane and methylene chloride - can

chemically react with aluminum parts and components and cause an explosion hazard. Read the label

or data sheet for the material. Do not use materials

containing these solvents with the aluminum KB555 cup. Stainless steel model KB-545-SS may be

used with halogenated solvents.

Static electricity is produced when using an equipment cleaner. Static electricity sparks may be created during the cleaning operation. A spark from

static electricity may cause fire or explosion. If the

gun or tool attached to the fluid hose line is not

grounded, it will build a static charge. To prevent

sparks from static electricity, you must ground:

KK-5051 Disposable Cup Liner Kit Includes:

20 liners

20 lids

3 rings

Ring

Lid

Liner

1. The Hose/Gun Cleaner.

2. The gun or tool attached to the fluid hose line

from the Hose/Gun Cleaner.

3. The waste container.

To ground equipment:

1. Use conductive air hose.

2. Attach one end of a ground wire to each item

listed above.

3. Attach the other end of the ground wire to a

water pipe, metal electrical conduit or any pipe

or structural member known to be grounded.

The DeVilbiss liner system is intended for use in a KB II

pressure cup. The liner creates a barrier so the coating

cannot contact the cup or lid. The liner can be used with

any material that is compatible with polyethylene. The only

wetted cup part is the fluid tube which is either stainless

steel or aluminum.

Figure 1

*KK-5052 Solvent Saver Attachment Kit Includes:

HD-410 Adapter Fitting Assembly

2' Hose Assembly

Recommended Replacement of Fluid Tube for KB II Cup:

*KK-4996 Stainless Steel

*KK-4997 Aluminum

*Order separately.

www.carlisleft.com

SB-4-207-K (1/2018)2 / 8

EN

SAFETY PRECAUTIONS

This manual contains important information that all users should know and understand before using the equipment. This information

relates to USER SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following

terms to draw your attention to certain equipment labels and portions of this Service Bulletin. Please pay special attention to any label

or information that is highlighted by one of these terms:

Note

Important information to alert you

to a situation that might cause serious injury or death if instructions

are not followed.

The following hazards may occur during the normal use of this equipment. Please read the following chart.

HAZARD CAUSE SAFEGUARDS

Fire Solvents and coatings can be 1. Adequate exhaust must be provided

highly flammable or combust- to keep the air free of accumulations

ible, especially when sprayed. of flammable vapors.

2. Smoking must never be allowed in the

spray area.

3. Fire extinguishing equipment must be

present in the spray area.

Fire - Pressure Tank Vapors from flammable liquids 1. Keep tank at least 10 feet away from

can catch fire or explode. sources of ignition. Ignition sources include

hot objects, mechanical sparks, and arcing

(non-explosion proof) electrical equipment.

Inhaling Toxic Substances Certain materials may be harmful if 1. Follow the requirements of the Safety Data

inhaled, or if there is contact with the Sheet supplied by your coating material

skin. manufacturer.

2. Adequate exhaust must be provided to keep

the air free of accumulations of toxic

materials.

3. Use a mask or respirator whenever there is

a chance of inhaling sprayed materials. The

mask must be compatible with the material

being sprayed and its concentration.

Equipment must be as prescribed by an

industrial hygienist or safety expert, and be

NIOSH approved.

Explosion, Pressure Making changes to pressure 1. Never drill into, weld, or modify tank in

Tank - Rupture tank will weaken it. any way.

2. Do not adjust, remove, or tamper with the

safety valve. If replacement is necessary,

use the same type and rating of valve.

Static Electricity Static electricity sparks may be created To prevent sparks from static electricity, you

during the cleaning operation which may must ground the Hose/Gun Cleaner, gun or tool

cause fire or explosion if not grounded attached to the fluid hose line from the equip properly. ment cleaner, and the waste container. Read

Warning on Pg. 1.

General Safety Improper operation or maintenance Operators should be given adequate training in

may create a hazard. the safe use and maintenance of the equipment

(in accordance with the requirements of NFPA 33, Chapter 15 in U.S.). Users must comply with

all local and national codes of practice and

insurance company requirements governing

ventilation, fire precautions, operation, main tenance and house keeping (in the U.S., these

are OSHA Sections 1910.94 and 1910.107, and

NFPA-33).

Important information that tells how to

prevent damage to equipment, or how

to avoid a situation that might cause

minor injury.

Information that you should pay

special attention to.

SB-4-207-K (1/2018) 3 / 8

www.carlisleft.com

Loading...

Loading...