Page 1

SI-2-25-28-R1 (7/2018)1 / 4www.carlisleft.com

Service Instruction

SI-2-25-28-G

Replaces SI-2-25-28-F

KK-4987-2 Gun Repair Kit

(for JGA, JGV, JGHV, JGP, JGPV, LMG,

MSA, MSV, & PGA GUNS)

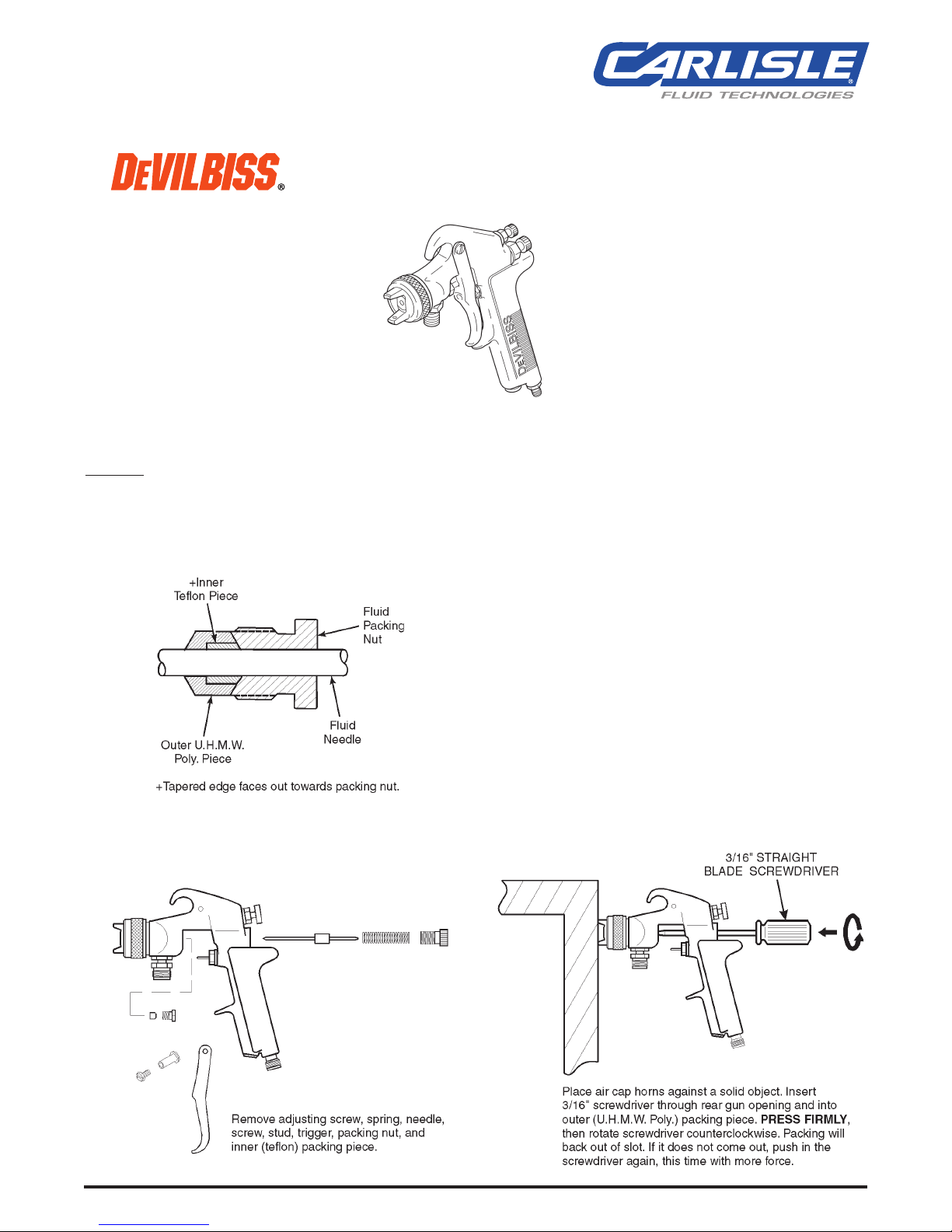

1. Remove adjusting knob, needle spring, spring pad,

and needle from gun.

2. Loosen packing nut and remove.

3. Remove old packing. See disassembly illustration

below.

4. Assemble packing nut to needle.

5. Assemble packing in order shown to needle.

6. Insert needle all the way into gun body seating in tip.

7. Install needle spring, spring pad, and adjusting knob.

8. Thread packing nut into gun body.

9. Tighten packin

g nut in equal increments - no more

than 1/6 turn at a time.

10. After each adjustment, pull needle open and observe

needle closure.

11. If needle snaps shut, continue adjusting nut until

there is evidence of needle bind or slow closing.

12. Back off packing nut 1/12 turn to the point where

needle snaps shut. Packing nut must remain tight

enough to prevent loosening by hand.

13. Pull needle several times to ve

rify needle snaps shut

and check packing nut for looseness.

NOTE 1:

JGV-463 Packing Replacement Instructions

2 piece packing covered by U.S. Patent No. 5,209,501.

Other patents pending.

PACKING REPLACEMENT

INSTRUCTIONS

PACKING REPLACEMENT INSTRUCTIONS

EN

SERVICE INSTRUCTION

KK-4987-2 GUN REPAIR KIT

(FOR JGA, JGV, JGHV, JGP, JGPV, LMG, MSA, MSV, & PGA GUNS)

Page 2

EN

SI-2-25-28-R1 (7/2018)2 / 4www.carlisleft.com

1. Remove adjusting knob, needle spring, spring pad,

and needle from gun.

2. Loosen packing nut and remove.

3. Remove old packing. See disassembly illustration

below.

4. Assemble packing nut to needle.

5. Assemble packing in order shown to needle.

6. Insert needle all the way into gun body seating in tip.

7. Install needle spring, spring pad, and adjusting knob.

8. Thread packing nut into gun body.

9. Tighten packin

g nut in equal increments - no more

than 1/6 turn at a time.

10. After each adjustment, pull needle open and observe

needle closure.

11. If needle snaps shut, continue adjusting nut until

there is evidence of needle bind or slow closing.

12. Back off packing nut 1/12 turn to the point where

needle snaps shut. Packing nut must remain tight

enough to prevent loosening by hand.

13. Pull needle several times to ve

rify needle snaps shut

and check packing nut for looseness.

NOTE 1:

JGV-463 Packing Replacement Instructions

2 piece packing covered by U.S. Patent No. 5,209,501.

Other patents pending.

PACKING REPLACEMENT

INSTRUCTIONS

NOTE 2: GTI-33 Baffle Seal Replacement

5. Install baffle on gun.

6. Install fluid tip and tighten to 20-25 ft-lbs.

NOTE

The seal is designed to be a tight fit

on the baffle. The seal should be

able to be removed using your fingers. If you are unable to remove

the seal using your fingers, insert a

small screwdriver between the outer

lip and the back of the baffle and pry

the seal off.

1. Remove fluid tip.

2. Remove b

affle.

3. Remove seal (7) from baffle.

4. Assemble seal to baffle with angled

side up as shown at right.

NOTE

The seal should be a tight fit on

the baffle. If it is a loose fit on the

baffle, assure that it is assembled with the angled side up.

ANGLED SIDE

SEAL

THICK SIDE

BAFFLE

Pry here if

necessary

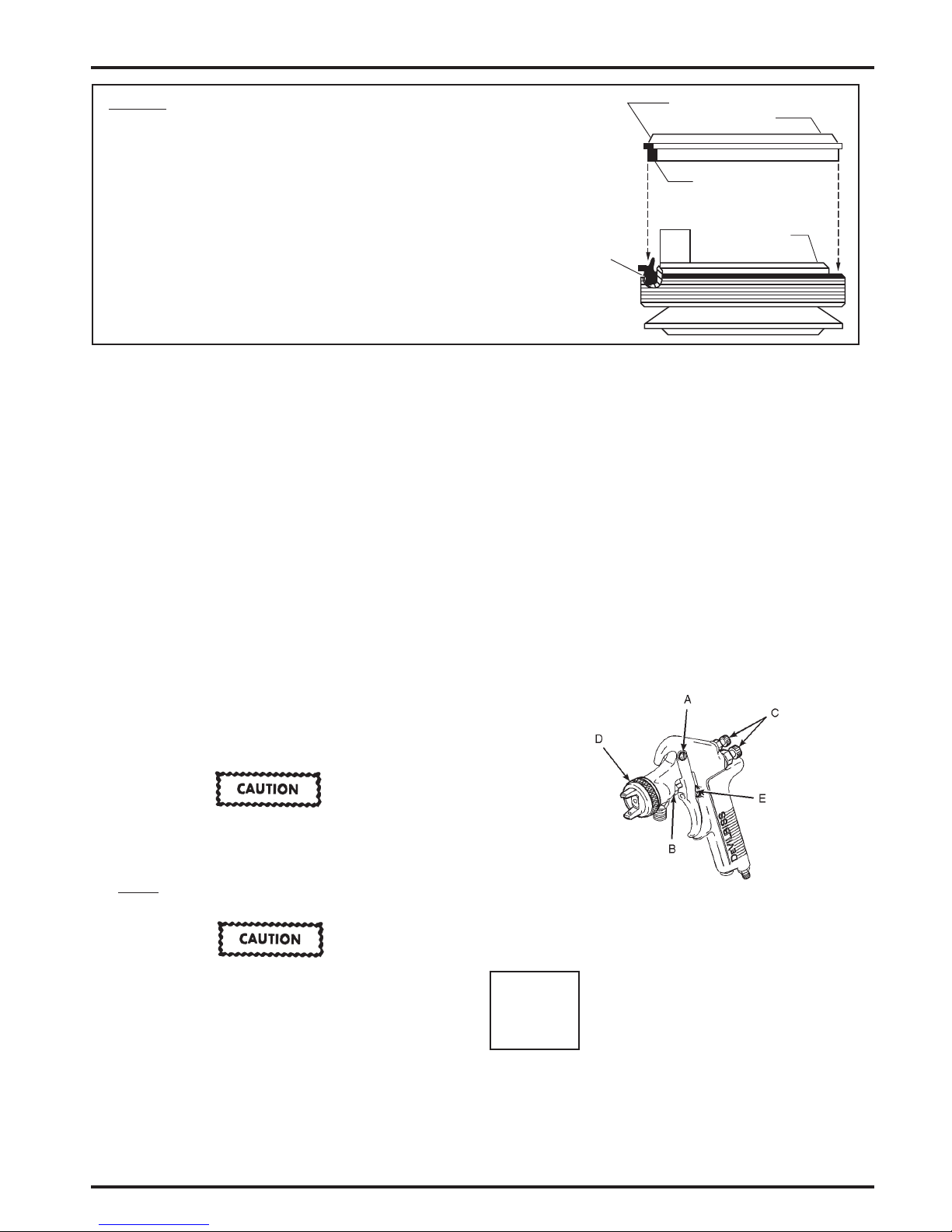

PREVENTIVE MAINTENANCE

SPRAY GUN LUBRICATION

Daily, apply a drop of gun lube at trigger stud screw (15) and

the stem of the air valve (12) where it enters the air valve

assembly. The shank of the fluid needle where it enters the

packing nut should also be lubricated. Make sure baffle

and retaining ring threads are clean and free of foreign

matter. Before assembling air cap to baffle, clean the

retaining ring and baffle threads

thoroughly, then add

two drops of spray gun lube to threads.

The fluid needle spring (4), and air valve spring (13), should

be coated with a very light grease, ensuring that any excess

grease will not clog the air passages. For best results, lubricate the points indicated daily using SSL-10 spray gun lube.

A. Trigger points

B. Packing

C. Adjusting valve

D. Baffle and retaining ring threads

E. Air valve c

artridge

FOR HVLP GUNS ONLY:

NOTE

If the baffle is removed, baffle gasket (7) and

O-ring (8) should be replaced. To prevent damage

to the O-ring during installation, apply gun lube

to exterior of O-ring and ID of baffle.

To clean air cap and fluid tip, brush exterior with a stiff bristle brush. If necessary to clean cap holes, use a broom straw

or toothpick. Never use a wire or hard instrument. Th

is

may scratch or burr holes causing a distorted spray pattern.

To clean fluid passages, remove excess material at source,

then flush with a suitable solvent using a device such as the

Solvent Saver

TM

. Wipe gun exterior with a solvent dampened

cloth. Never completely immerse in solvent as this is detrimental to the performance and gun life expectancy, as well

as destroying the lubricants and packings.

FOR GUNS WITH S.S. FLUID INSERTS ONLY:

To prevent serious gun damage, do not remove

the fluid tip if the fluid inlet adapter has been

removed. The stainless steel fluid insert can break

free (which is non-repairable). Remove the fluid tip

before

removing the fluid inlet adapter. Use a new

gasket before reinstalling the fluid inlet adapter.

To prevent damage to the fluid tip or fluid needle,

be sure to either 1) pull the trigger and hold while

tightening the fluid tip, or 2) remove fluid needle

adjusting screw to relieve spring pressure.

PROP 65 WARNING

WARNING: This product contains chemicals known

to the State of California to cause cancer and

birth defects or other reproductive harm.

CA PROP

65

Page 3

Use AV-1 copper gasket only on

model shown. Do not use with

plastic baffle or threaded baffle.

TYPICAL EXPLODED VIEW

AN EXTRA PART OF EACH HAS BEEN SUPPLIED FOR USE WITH THE OPTIONAL JGA-4005 AIR ADJUSTING VALVE.

* PLEASE SELECT THE VERSION OF BAFFLE GASKET THAT MATCHES THE BAFFLE GASKET ON YOUR GUN.

1

1

1

1

1

1

1

1

TRIGGER STUD

SCREW

15

PART DESCRIPTION

(PARTS SHOWN ACTUAL SIZE)

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

–

–

–

–

–

–

1

1

1

1

–

1

1

–

–

–

–

–

–

–

–

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

1

–

–

1

1

1

1

1

1

–

–

1

1

1

1

–

–

–

–

–

–

–

–

1

JGV-463

(See Note 1

on following

page)

SSG-8182

JGD-14

AV-1

MBD-19

JGS-72

FLUID NEEDLE

PACKING (2 PIECE)

AIR VALVE

SPRING

AIR VALVE

U-CUP SEAL

(POLYETHYLENE)

WASHER

(ALUMINUM)

SNAP RING

O-RING

(BUNA-N RUBBER)

BAFFLE GASKET

(POLYETHYLENE)

USED WITH

JGD-402-1 BAFFLE

TIP GASKET

(COPPER)

SPRING PAD

(PTFE)

NEEDLE

SPRING

GASKET

(PTFE)

O-RING

(VITON RUBBER)

14

13

12

11

10

9

8

7*

6

5

4

3

2

1

RETAINING

CLIPS

SMALL

LARGE

JGHV-530

OR

TYPE MSV

TYPE JGA

(JGA-503)

TYPE MSA

(MSA-501/503)

PGA-511

JGA-510,

JGP,

OR

MSA-510

LMG-500 LMG-501

MODEL JGV

(JGV-560,

570, 572)

JGHV-531

OR

MSV-531

JGA-502

OR

PGA-510

GUN MODELS (SEE STAMP ON SIDE OF GUN HANDLE)

QUANTITY OF PARTS REQUIRED

(REPLACE-

MENT

PART NO.

REF

NO.

( See

Caution

above)

(See Note 2

on following

page)

–

–

1

–

–

–

–

–

GTI-33

BAFFLE GASKET

(ACETAL)

USED WITH

GTI-425 BAFFLE

7*

Page 4

EN

SI-2-25-28-R1 (7/2018)4 / 4www.carlisleft.com

WARRANTY POLICY

This product is covered by Carlisle Fluid Technologies’ materials and workmanship limited warranty.

The use of any parts or accessories, from a source other than Carlisle Fluid Technologies,

will void all warranties. Failure to reasonably follow any maintenance guidance provided

may invalidate any warranty.

For specic warranty information please contact Carlisle Fluid Technologies.

For technical assistance or to locate an authorized distributor,

contact one of our international sales and customer support locations.

Region Industrial/Automotive Automotive Renishing

Americas

Tel: 1-800-992-4657 Tel: 1-800-445-3988

Fax: 1-888-246-5732 Fax: 1-800-445-6643

Europe, Africa,

Middle East, India

Tel: +44 (0)1202 571 111

Fax: +44 (0)1202 573 488

China

Tel: +8621-3373 0108

Fax: +8621-3373 0308

Japan

Tel: +81 45 785 6421

Fax: +81 45 785 6517

Australia

Tel: +61 (0) 2 8525 7555

Fax: +61 (0) 2 8525 7575

Carlisle Fluid Technologies is a global leader in innovative nishing technologies.

Carlisle Fluid Technologies reserves the right to modify equipment specications without prior notice.

DeVilbiss®, Ransburg®, ms®, BGK®, and Binks®

are registered trademarks of Carlisle Fluid Technologies, Inc.

©2018 Carlisle Fluid Technologies, Inc.

All rights reserved.

For the latest information about our products, visit www.carlisleft.com

Loading...

Loading...