DeVilbiss KK-4456 Service Manual

SERVICE MANUAL

EN

KK-4456 FLUID REGULATOR REPAIR KIT

DESCRIPTION

The KK-4456 HGS uid regulator repair kit

is recommended for replacement of the

diaphragm and seating components when

repairing the regulator. It is designed to

be used with all HGS regulators.

DISASSEMBLY

Shut off and relieve pressure before disconnecting

hoses from uid regulator.

Pressurized parts cause

a risk of injury to personnel if disassembled under

pressure.

1. Remove all pressure from regulator.

2. Remove regulator and clean.

Note

Refer to HGS Fluid Regulator Service Bulletin SB-6-403 for general

service and cleaning procedures.

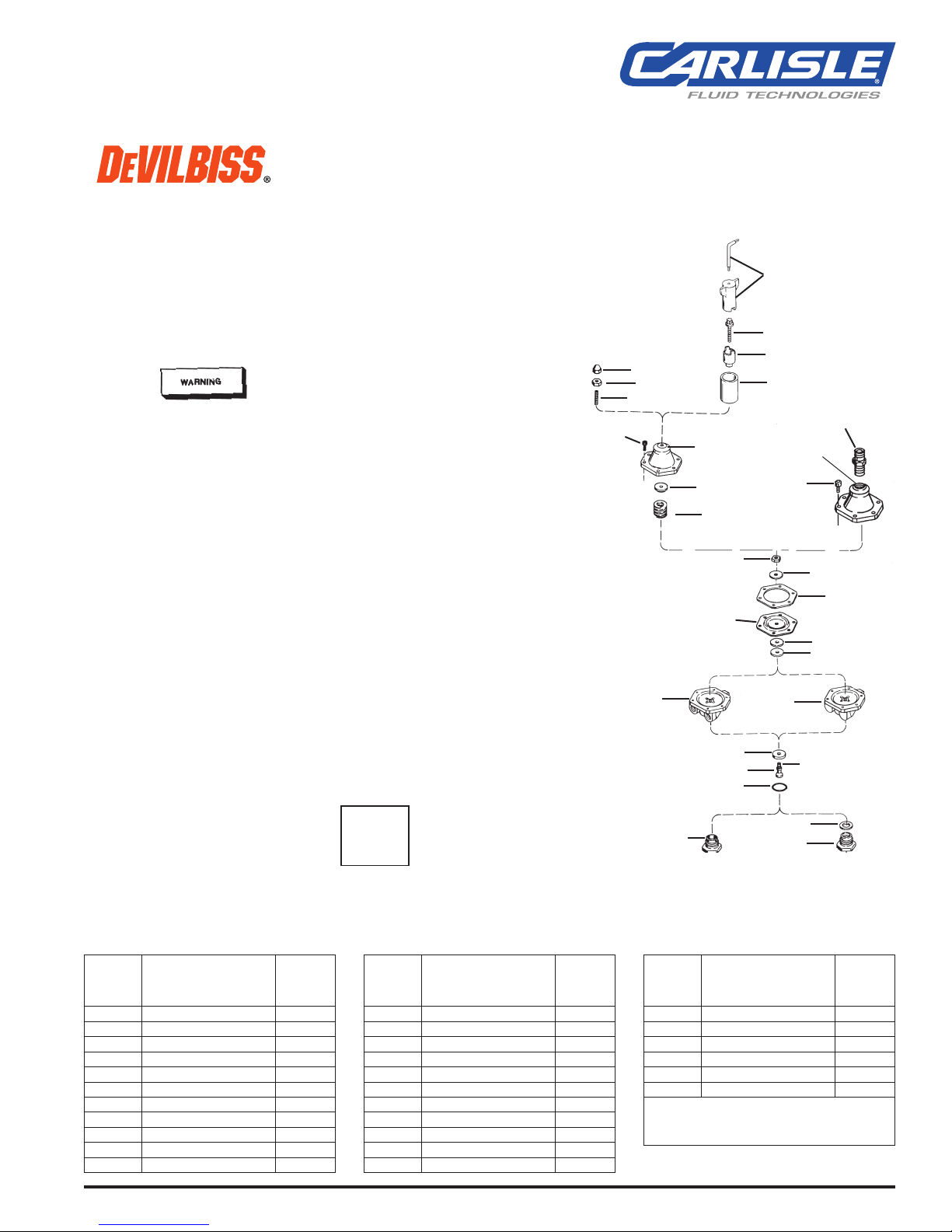

3. Remove six cap screws (8).

4. Remove bottom plug (25) circulating

regulators; or plug (27) non-circulating regulators.

5. Remove and discard O ring (24) from

plug.

6. Remove stem (23) by inserting a bladed screwdriver into slot and turning

counterclockwise while holding hex

nut (14).

7. Remove and discard upper plate (15),

gasket (16), diaphragm (17) and

PTFE washer (18) from valve stem

(23). Remove and save at washer

(19).

8. Remove and discard PTFE valve seat

(22) from body (20 or 21).

9. Clean all parts to remove any trace of

contaminates.

Ref.

No.

1 T-handle Kit •

2 Adjustment Screw 1

3 Lock 1

4 Guard 1

5 Cap Nut 1

6 Nut 1

7 Allen Set Screw 1

8 Cap Screw 6

9 Connector 1

10 Bonnet 1

11 Bonnet 1

Description

Ind.

Parts

Req'd.

ASSEMBLY

1. Insert valve seat (22) into body (20

or 21) so that the at surface of

the valve seat is ush with the at

surface of the body.

2. Insert stem (23) through seat (22) so

it extends through body (20 or 21).

3. Install flat washer (19) and PTFE

washer (18) onto valve stem (23).

Note

PTFE washer (18) must be posi-

tioned between the at washer

(19) and diaphragm (17).

4. Place diaphragm (17) onto valve stem

(23) so that threaded portion of stem

protrudes through diaphragm.

5. Apply a couple of drops of QH-130 to

threads of valve stem (23).

6. Place upper plate (15) over threads of

stem against diaphragm and secure

in place with hex nut (14). Torque to

proper torque specication.

7. Install gasket (16) and bonnet (10 or

11) and secure in place with six cap

screws (8). Torque to proper torque

specications.

8. On circulating regulators, Install O

ring (24) and plug (25); on noncurculating regulators, install O-ring

(24) and plug (27); and if equipped,

install spacer (26). Torque to proper

torque specication.

9 Reinstall uid regulator into the system.

CA PROP

65

cancer and birth defects or other

reproductive harm.

PROP 65 WARNING

WARNING: This product

contains chemicals

known to the State of

California to cause

PARTS LIST

Ref.

No.

12 Adjustment Seat 1

13 Regulator Spring 1

14* Hex Nut 1

15* Upper Plate 1

16* Gasket 1

17* Diaphragm, PTFE 1

18* Washer, PTFE 1

19 Flat Washer 1

20 Regulator Body 1

21 Regulator Body 1

22* Valve Seat, PTFE 1

Description

•T-handle must be

ordered separately.

15 lb./in.

(1.6 N-m)

Ind.

Parts

Req'd.

Tamper

Resistant

1

2

5

6

7

8

PTFE, (smooth

gray surface)

must face

wetted section

20

120 lb./in.

13.5 N-m)

Circulating Port

11

12

13

6 lb./in.

(.07 N-m)

17

25

Ref.

No.

23 Valve Stem 1

24* O-ring, PTFE 1

25 Plug 1

26 Spacer 1

27 Plug 1

* QH-130 Loctite 1

•T-handle must be ordered separately.

* These parts are included in the KK-4456

Regulator Repair Kit.

3

4

15 lb./in.

(1.6 N-m)

14

21

22

23

24

120 lb./in.

13.5 N-m)

Description

1/8”-27

9

NPT(F)

8

15

16

18

19

Apply QH-130

Loctite to threads.

26

27

1/8-27

NPT(F)

Inlet

Non-Circulating

Port

Air

Pilot

Ind.

Parts

Req'd.

SI-6-41-1-R1 (3/2018) 1 / 2 www.carlisleft.com

EN

WARRANTY POLICY

This product is covered by Carlisle Fluid Technologies’ materials and workmanship limited warranty.

The use of any parts or accessories, from a source other than Carlisle Fluid Technologies,

will void all warranties. Failure to reasonably follow any maintenance guidance provided

may invalidate any warranty.

For specic warranty information please contact Carlisle Fluid Technologies.

Carlisle Fluid Technologies is a global leader in innovative nishing technologies.

Carlisle Fluid Technologies reserves the right to modify equipment specications without prior notice.

DeVilbiss®, Ransburg®, ms®, BGK®, and Binks®

are registered trademarks of Carlisle Fluid Technologies, Inc.

©2018 Carlisle Fluid Technologies, Inc.

All rights reserved.

For technical assistance or to locate an authorized distributor,

contact one of our international sales and customer support locations.

Region Industrial/Automotive Automotive Renishing

Americas

Europe, Africa,

Middle East, India

China

Japan

Australia

Tel: 1-800-992-4657 Tel: 1-800-445-3988

Fax: 1-888-246-5732 Fax: 1-800-445-6643

Tel: +44 (0)1202 571 111

Fax: +44 (0)1202 573 488

Tel: +8621-3373 0108

Fax: +8621-3373 0308

Tel: +81 45 785 6421

Fax: +81 45 785 6517

Tel: +61 (0) 2 8525 7555

Fax: +61 (0) 2 8525 7575

For the latest information about our products, visit www.carlisleft.com

SI-6-41-1-R1 (3/2018)2 / 2www.carlisleft.com

Loading...

Loading...