Page 1

SB-E-4-205

Operation Manual:

KB-522 & KB-522-SS

Pressure Feed Cup

ISS.02

E

E

P 1 - 12

© 2010 ITW Finishing Systems and Products

Page 2

EE

Operation Manual:

KB-522 & KB-522-SS Pressure Feed Cups

Important: Read and follow all instructions and SAFETY PRECAUTIONS

before using this equipment.

The KB-522 pressure feed cup incorporates an air regulator, safety valve, pressure relief

valve, pressure gauge and a carrying handle. An additional bail handle is also supplied to

enable the user to suspend the cup from a belt or other device. Hose assemblies to

connect the spray gun to the cup are not included and should be ordered separately, see

‘Accessories’.

Corrosion resistant version also available with Stainless Steel Cup and plated Lid.

Order No.

KB-522 STD CUP

KB-522-SS STAINLESS STEEL CUP

EC Declaration of Conformity

We: ITW Finishing UK, Ringwood Rd, Bournemouth, Dorset, BH11 9LH, UK, as the

manufacturer of the

Pressure Cup models KB-522 & KB-522-SS

declare, under our sole responsibility, that the equipment to which this document relates

is in conformity with the following standards or other normative documents:

EN 13463-1:2001; and thereby conform to the protection requirements of Council

Directive 94/9/EC relating to Equipment and Protective Systems intended for use in

Potentially Explosive Atmospheres protection level II 2 G X, suitable for use in ZONE

1 hazardous areas.

© 2010 ITW Finishing Systems and Products

B. Holt, General Manager

9th February 2004

2

Page 3

SAFETY WARNINGS

EE

Fire and explosion

Solvents and coating materials can

be highly flammable or combustible

when sprayed. ALWAYS

material suppliers instructions and COSHH

sheets before using this equipment

Users must comply with all local

and national codes of practice and

insurance company requirements

governing ventilation, fire

precautions, operation and house-keeping of

working areas

FOR KB-522 ONLY:

Do not use Solvents or coating

materials containing

HALOGENATED HYDROCARBONS with this

equipment.

FOR KB-522-SS ONLY:

This equipment, as supplied, is suitable for

use with Halogenated Hydrocarbons and the

user must ensure that all other equipment in

the system is also suitable for use with these

materials. DO NOT SPRAY MATERIALS

CONTAINING THESE SOLVENTS EXCEPT

WITH EQUIPMENT SPECIFICALLY

DESIGNATED BY THE MANUFACTURER

AS BEING SUITABLE FOR SUCH USE.

Static Electricity can be generated

by fluid and/or air passing through

hoses, by the spraying process

and by cleaning non- conductive

parts with cloths. To prevent ignition sources

from static discharges, earth continuity must

be maintained to the spraygun and other

metallic equipment used. It is essential to use

conductive air and/or fluid hoses.

refer to the coating

Personal Protective

Equipment

Toxic vapours – When sprayed,

certain materials may be

poisonous, create irritation or be

otherwise harmful to health.

Always read all labels and safety

data sheets for the material before

spraying and follow any recommendations. If

In Doubt, Contact Your Material Supplier

The use of respiratory protective

equipment is recommended at all

times. The type of equipment must be

compatible with the material being sprayed.

Always wear eye protection when

spraying or cleaning the spraygun

Gloves must be worn when spraying

or cleaning the equipment

Training

Personnel should be given adequate training

in the safe use of spraying equipment.

Misuse

Never aim a spraygun at any part of the

body. Never exceed the max. recommended

safe working pressure for the equipment.

The fitting of non-recommended or non-

original spares may create hazards.

Before cleaning or maintenance, all

pressure must be isolated and relieved from

the equipment.

Never exceed the recommended safe

working pressures for any of the equipment

used.

Never drill into or modify the pressure feed

cup in any way.

Do not adjust, remove or tamper with the

safety valve. If a replacement is necessary,

only use DeVilbiss supplied spare Valves.

The materials used in the construction of the

cup are (bearing in mind the warning on

Halogenated Hydrocarbons) solvent

resistant enabling the cup to be cleaned

using gun washing machines. However, the

lid assembly must not be cleaned in a gun

washing machine as it contains parts that

will be damaged.

3

© 2010 ITW Finishing Systems and Products

Page 4

EE

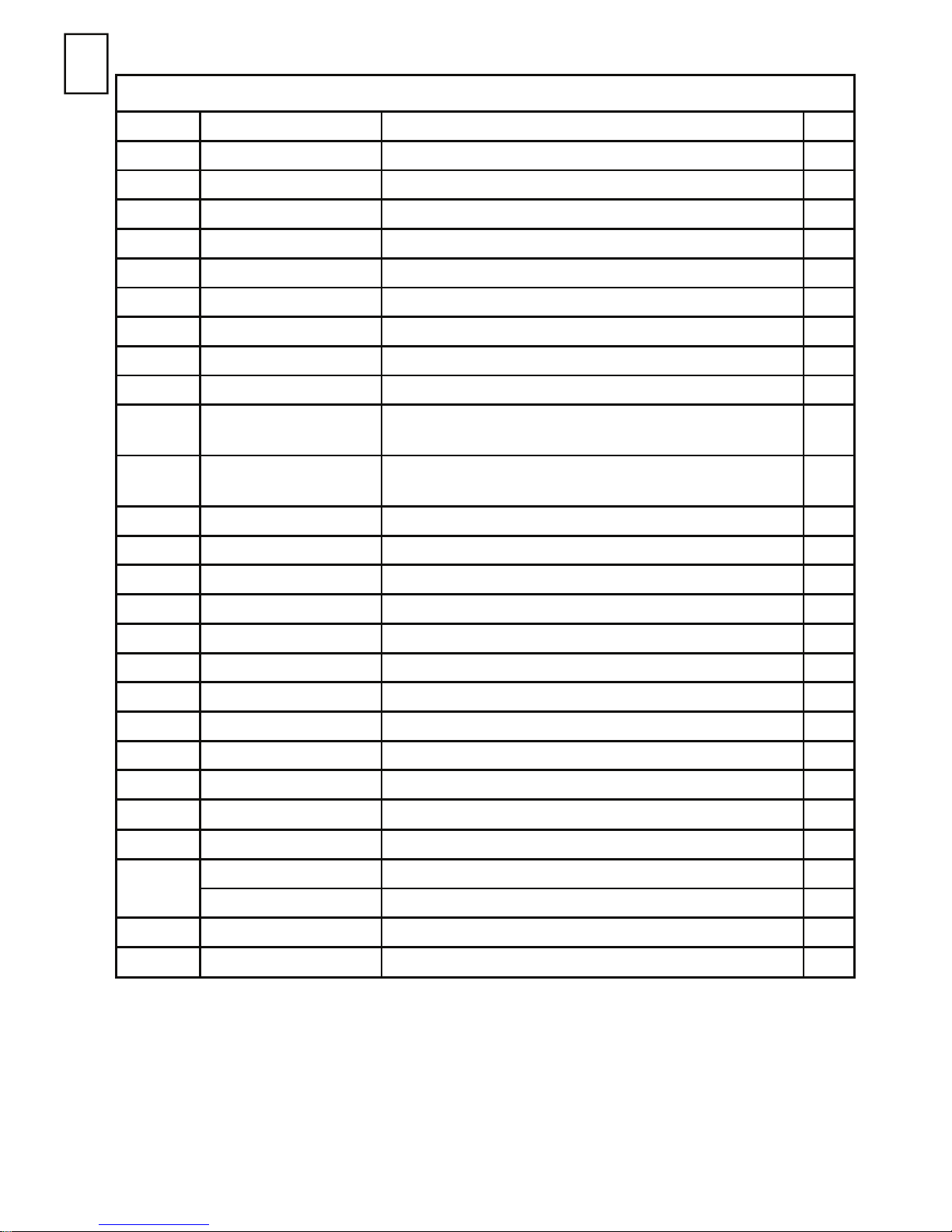

Parts List

Ref. Order No. Description Qty.

1 KB-64 Retaining Ring 1

2 KB-81-K5 Slip Rings 1

3 KB-74 Handle 1

4 SS-656-CD CD Nut 1

5 JGA-158 Connector 1/4" BSP 2

6 KB-66 Pressure Relief Valve 1

7 - Lid 1

8 GA-355 Gauge 1

9 KB-80-K5 Seal 1

10 MBD-11-K5

KB-97-K2

11 KB-422

KB-442

12 KB-432-K3 Check Valve kit of 3 1

13 KB-85-K5 Seal kit of 5 1

14 TIA-4355 Safety Valve 1

15 KB-428-1 Regulator Assembly 1

*16

*17

*18

*19

*20

21 - Spring 1

*22

23 KB-60-K6 Seal kit of 6 1

- Spring 1

- Valve 1

- Valve Seat and Seal

- Diaphragm 1

- Slip Ring 1

- Bonnet 1

Locknut (KB-522) kit of 5

Locknut -Stainless Steel (KB-522-SS) kit of 2

Cup – Aluminium (KB-522)

Cup – Stainless Steel (KB-522-SS)

1

1

1

24

KK-4997 Tube Assembly (KB-522) 1

KK-4996 Tube Assembly (KB-522-SS) 1

25 KB-444 Check Valve and Seal Assembly 1

26 KB-101-K5 Seal kit of 5 1

Note: Ref No.s marked * are supplied in repair kit Order No. KK-4887-2.

© 2010 ITW Finishing Systems and Products

4

Page 5

View showing position of internal

check valve parts

Fig 1

EE

Fig 2

5

© 2010 ITW Finishing Systems and Products

Page 6

EE

Specification

Hose connections

Air : 1/4" Universal

Fluid : 3/8" Universal

Maximum Working Pressure : 2.1 Bar (30 lbf/in2)

Maximum Air supply pressure : 8.6 Bar (125 lbf/in2)

Height : 183 mm (7 3/16")

Weight (dry) : 1.76 kg (3 lb 14 oz)

Capacity : 2 Litres

PARTS IN CONTACT WITH COATING MATERIAL:

522 522-SS

Cup : Aluminium Alloy Stainless Steel

Cup Lid : Aluminium Alloy Aluminium Alloy Nickel Plated

Lid Seal : Santoprene Santoprene

Tube : Aluminium Alloy Stainless Steel

Tube Nut : Brass Nickel Plated Stainless Steel

Check Valves : Acetal, Brass and S.S Acetal, Brass and S.S

Pressure Relief Valve : Brass Nickel Plated Brass Nickel Plated

Installation

IMPORTANT: To ensure that this equipment

reaches you in first class condition, protective

coatings, rust inhibitors, etc., have been used.

Flush all equipment through with a suitable

solvent before use to remove these agents from

the material passages.

Operation

CAUTION: The cup is under pressure.

Disconnect the air supply and release the

pressure in the cup assembly before removing

the cup from the lid assembly or disconnecting

the gun or the material hose. Never allow the cup

to lay on its side or fall over when it contains

material.

Controls (See Figure 1)

Safety Valve (14): The safety valve limits the

maximum air pressure to the cup. If the

safety valve does not work properly, over

pressurisation may occur and cause the cup

to rupture or explode. Occasionally pull the

ring on the safety valve and make sure that it

operates freely. If the valve is stuck or does

not operate smoothly it must be replaced

with a valve having the same rating. Never

attempt to adjust or dismantle the safety

valve.

Regulator (15): Controls the pressure of the

coating material in the cup. To increase the

1. Connect the coating material hose (Fig 2, A)

from the cup outlet to the gun.

2. Connect the air hose (B) from the cup outlet

to the gun.

3. Connect the air supply hose (C) to a filtered/

regulated air supply and to the cup inlet.

pressure, pull knob out, turn the knob in the

direction of the arrow shown on the knob, to

reduce pressure turn in the opposite direction.

When pressure is set push knob in to lock.

Pressure Relief Valve (6): Vents the air

pressure in the cup. To open, turn valve

counter-clockwise. CAUTION Do not

unscrew the pressure relief valve (6)

completely when relieving the pressure as it

may have sufficient air pressure to eject the

valve from the lid creating a hazard.

Pressure Gauge (8): Indicates the air

pressure in the cup. Do not attempt to

remove the cup (15), spray gun or coating

material hose if the gauge indicates pressure

in the cup.

NOTE: Regularly check that the pressure gauge

is reading correctly.

1. Mix, prepare and filter the coating material to

be sprayed according to the manufacturer’s

instructions.

© 2010 ITW Finishing Systems and Products

6

Page 7

EE

2. Adjust the spray gun controls as described in

the Operation Manual supplied with the gun.

3. Turn the regulator knob (15) to the minimum

pressure and open the pressure relief valve

(6) to vent any pressure in the cup.

4. Remove cup (11) by turning ring (1) counterclockwise and fill with the coating material,

DO NOT OVERFILL. (If using the liner Kit KK

-5051, see section on liner fitting)

5. Replace lid assembly on cup, push down

with the handle and tighten ring (1).

6. Close the pressure relief valve (6), turn on

Preventative Maintenance

CLEANING

DO NOT clean the cup lid assembly in a gun

washing machine as the safety valve (18), gauge

(6) and regulator (19) contain parts that will be

damaged.

1. Disconnect the air supply and relieve the

pressure in the cup.

2. Remove the cup (11) and empty surplus

coating material. Wipe the lid and the inside

of the cup clean.

3. Fill the cup with a small quantity of compatible solvent and refit. Connect the air supply,

and adjust the supply air pressure to 3.5 bar

(50 lbf/in2).

7. Adjust the material pressure to 0.7 bar (10

lbf/in2).

8. Test spray, adjust atomisation and material

pressures to suit required application rate.

NOTE: To reduce the material pressure turn

regulator (15) down and open the pressure relief

valve (6). Close relief valve (6), and readjust the

regulator (15).

spray the solvent until clean.

4. Disconnect the air supply and relieve the

pressure in the cup.

5. Remove the cup (11), empty the residual

solvent and dry internal surfaces.

6. Inspect that the check valve (12) and pressure relief vent holes in the lid are free from

coating material.

NOTE: The check valve cap may be unscrewed

to aid inspection and cleaning, DO NOT dismantle any further.

CONDITION CAUSE CORRECTION

Erratic regulation or

A

excess pressure in the cup

3 Safety valve (14) faulty Replace

4 Regulator Spring (21) broken or

5 Regulator diaphragm (19) damaged Replace

Insufficient pressure in the

B

cup

3 Gauge (8) reading incorrectly Replace

4 Air leakage at cup lid Tighten ring (1), replace

Service Checks

1 Regulator valve (17, 18) leak Replace

2 Gauge (8) reading incorrectly Replace

Replace

distorted

1 Check valve (12) jammed. Clean/replace.

2 Safety valve faulty. Replace

Seal (9) or Slip Ring (2)

7

© 2010 ITW Finishing Systems and Products

Page 8

EE

KK-5051 DISPOSABLE CUP LINER

The DeVilbiss Liner system creates a barrier between the coating material and the cup,

avoiding lengthy cleaning procedures and saving solvent. The liner can be used with any

coating material that is compatible with polyethylene.

Each kit consists of 20 Liners, 20 Lids and 3 Rings

Installation Instructions

Liner Kit Parts

Ring

Disposable

Lid

Liner

Insert Liner

Into Cup

Disposable Lid

Fill liner with

Coating Material

Insert Lid

Wrap Liner

Over Lid

© 2010 ITW Finishing Systems and Products

8

Page 9

EE

Place Ring

Inside Cup

Ring

Slide Fluid Tube

through opening

and assemble Lid

to cup

Disassembly/Cleaning Instructions

Disassemble Cup Lid.

Withdraw the tube slowly to allow

the paint inside the tube to drain.

Catch excess paint with rag.

9

© 2010 ITW Finishing Systems and Products

Page 10

EE

Remove Ring

Properly Dispose of Lid,

Liner and waste material.

Retrieve Ring

Pull up on Liner

© 2010 ITW Finishing Systems and Products

10

Page 11

NOTES

11

© 2010 ITW Finishing Systems and Products

Page 12

EE

Accessories

Hose Assemblies to connect cup to spraygun:

Order No. H-.6066-N Air hose 8 mm bore 1.2 m long with 1/4” connections

H-6067-N Coating material hose 6 mm bore 1.4 m long with 3/8”

connections.

Other accessories;

Order No. KB-435 Conversion Kit for 50 psi maximum working pressures version.

KK-5051 Liner Kit of 20 Liners

ITW Finishing Systems and Products

Ringwood Road,

Bournemouth,

BH11 9LH,

England.

Tel. No. (01202) 571111

Telefax No. (01202) 581940,

Website address http://www.itweuropeanfinishing.com

ITW Finishing Systems and Products is a Division of ITW Ltd. Reg. Office:

Admiral House,

St Leonard’s Road,

Windsor,

Berkshire,

SL4 3BL,

UK

Registered in England: No 559693 Vat No 619 5461 24

© 2010 ITW Finishing Systems and Products

12

August 10

Loading...

Loading...