Page 1

-.

__

IEIIILBIIS

The

Right

Wey

To

Fini•h"

SERVICE

BULLETIN

SB-2-290

Major

~r

Klt

KK-4117·2

Minor~

KltKK-6034

JGP-503

CONVENTIONAL SPRAY GUN

JGPV-503

HVLP SPRAY GUN

IMPORTANT: Before uolng

this

equip- OPERATION

ment,

road oil

safety

precoutlone ond in-

ltructlons.

Keep

for future use.

DESCRIPTION

Models JGP and JGPV are lightweight,

high production spray guns. JGP models

are conventional

air

spray, and JGPV are

high volume,

low

pressure iHVLP). The

gun bodies are constructed

of

very du·

rable, solvent resistant

Verton•

(filled

ny·

Jon).

Fluid passages are constructed

of

300

grade stainless steel. Fluid tips and

needles are also

300

grade stainless, and

the fluid

tip

includes

the

"soft

seat•

UHMW

polyethylene insert, for longer service life.

Note

These guns may

be

used

with

chlorl·

nated type solvents, but refer

to

Page

2 for additional warnings.

Important: This gun miiY be ueed

with

molt

common colltlng and flnlehlng

mite-

nolo. It is doolgnad

for

UIO

With

mHdly

corrosive and non

..

abrulve

materlale.

If

used

with

other highly corrosive or abra

..

olve motoriols, It muot

be

expected

that

frequent and thorough

clunlng

wiD

be

roquirad and

tho

nocesolty

for

roplecamant

of parts

wiD

be Increased.

INSTALLATION

To avoid damage

to

gun body, do

not

overtighten air hose connection

at

•r

Inlet.

UHtwowrencheslfneceiUry.

Attach

air hose

to

1/4"

NPS

air inlet

fitting

on gun handle. The air inlet

fitting

includes

a tapered seat and is designed

for

use

with

hose connections containing a similar seat.

If

using

an

NPT

typo

fitting

without

a

tapered seat, usa

two

wrenches

to

tighten.

Do

IIIII overtighten.

Sea

CMJtlotr

above.

Attach

fluid hose

to

3/8"

NPS

fluid inlet

fitting

on gun.

Note

Protective coating and rust Inhibitors

have been used

to

keep the gun In

good condition prior

to

shipment.

Before using

the gun, flush

it

with

solvent

so

that

these materials will be

removed from fluid passages.

Strain material through

60

or

90

mesh

screen. Adjust fluid prooaure

to

deliver

the

desired paint volume. Adjust air pressure

and

flow

to

provide a uniform dispersion

of

atomized paint throughout

the

pattern.

Keep air pressure

as

low

as

poaaible

to

minimize bounce • back and overspray.

Excessive

fluid

flow

will result in heavy

center spray patterns. Inadequate flows

may causa

the

pattemtospllt.

Soo

"Trouble-

shooting•,

Page

8,

if

any problems occur.

PREVENTIVE MAINTENANCE

To clean air cap and fluid tip, brush exterior

with a stiff

bristle brush.

II

nocOIHry

to

clean cap holes, usa a broom straw

or

toothpick.

Nev•

uae a wire

or

hard

lnltnJ..

ment. This may scratch or burr holes

causing a distorted spray pattam.

To clean fluid passages, remove excaaa

material

at source, than

fiuoh

with

a suit-

able solvent using a device ouch

ao

the

SolventSavar• lsoa Acceosorlool. Wipe

gun exterior

with

a solvent dampened cloth.

Never completely Immerse in solvent

as

this is detrimental

to

the

lubricants and

packings.

Note

When replacing the fluid

tip

or fluid

needle. replace

.tm1b

at

the

same

time. Using worn parts can cause

fluid leakage.

See

Chart 2. Also,

replace the noodle packing

~t

thia

time.

Ughtly

lubricate

the

threads

of

the

fluid

tip

before reassembling.

Torque

to

20-25 ft. lbs. Do

not

overtighten

the

fluid tip.

Toprovontdo-tothefluldtlpl31

or

fluid

-•1281,

be

ouro

to

either

11

pull

the

tri-r

end

hold while

tightening

or

loounlng

tho

fluid

tip

or

21

remove fluid

-e

adjuotlng

ocrow

(211

to

rollovoopring

-sure

agolnot-

collar.

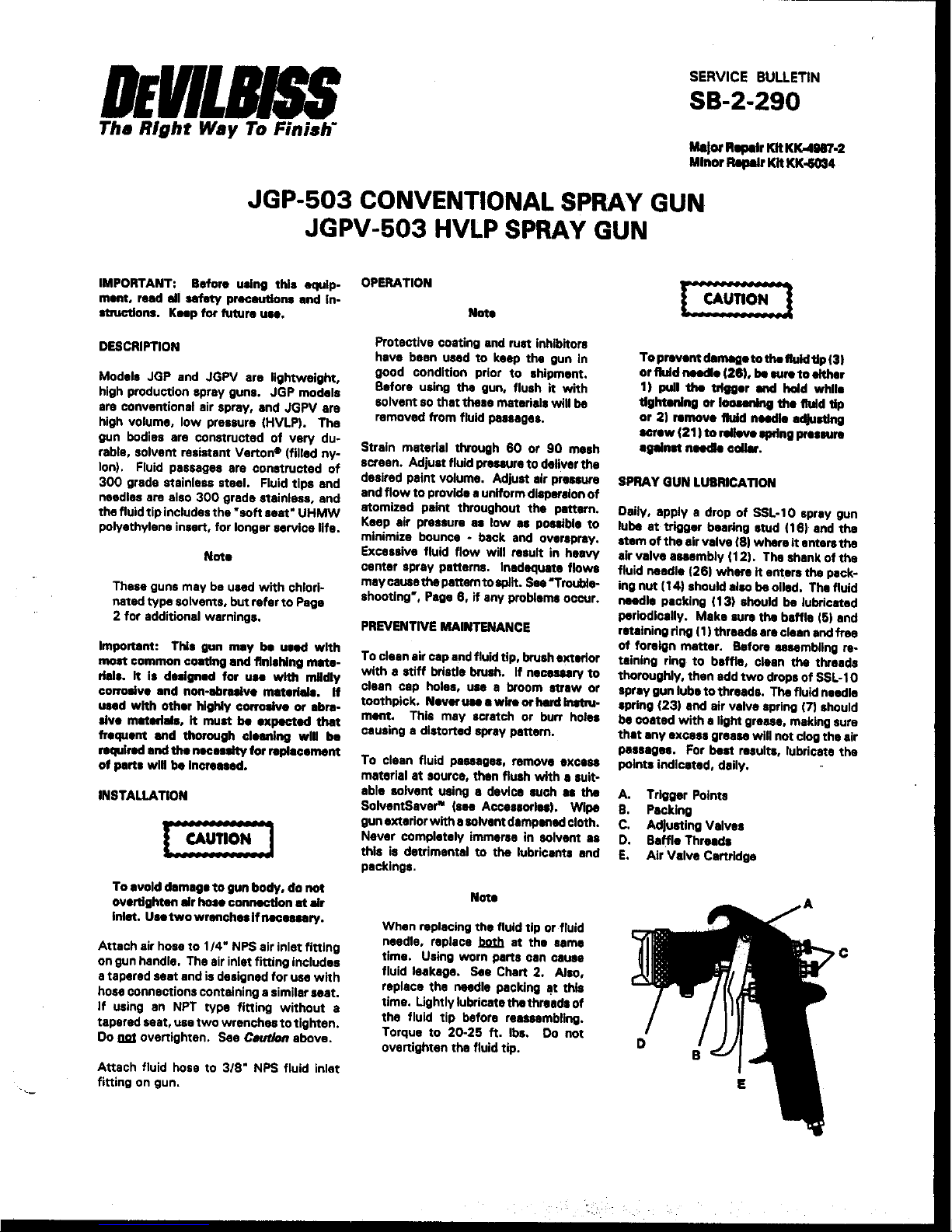

SPRAY GUN LUBRICATION

Daily, apply a drop

of

SSL-1

0 spray gun

lube

at

trigger boal'ing stud

1161

and

the

stem

of

the

air valva (8) where

it

enters the

air valve

aoHmbly

1121.

Tho shenk

of

the

fluid noodle

1261

whore ~ enters the pock-

ing

nut

1141

should aloo be oiled. Tho fluid

noodle packing i

131

should

be

lubricated

periodically. Make sura the baffle

151

ond

retaining ring

111

threads are clean and free

of

foreign matter. Before

aesembUng

re·

taining ring

to

baffle, clean

the

threads

thoroughly, than add

two

drops

of

SSL-10

spray gun lube

to

threads. The fluid noadle

spring

1231

and air valva spring

171

should

be coated

with

alight

grease, making sure

that

any excess graaae will

not

clog the air

passagee. For beat results, lubricate

the

polntalndicated, daily.

A. Trigger Points

B.

Packing

C.

Adjuoting Valves

D.

Baffle Threodo

E.

Air

Valve Cartridge

c

Page 2

Page 2 SB-2-290

This

manual

PREVENTING

attentiOn

to these sections.

contains

information that

EQUIPMENT

PROBLEMS.

SAFETY

Is

important for

To help you recognize this information, we use the following symbols. Plano pay particular

. .

you

to

PRECAUTIONS

know

and

understand.

This

information

relates

to

USER

SAFETY

and

WANIIN8

Important safety Information - A

that

may

cause

life.

The

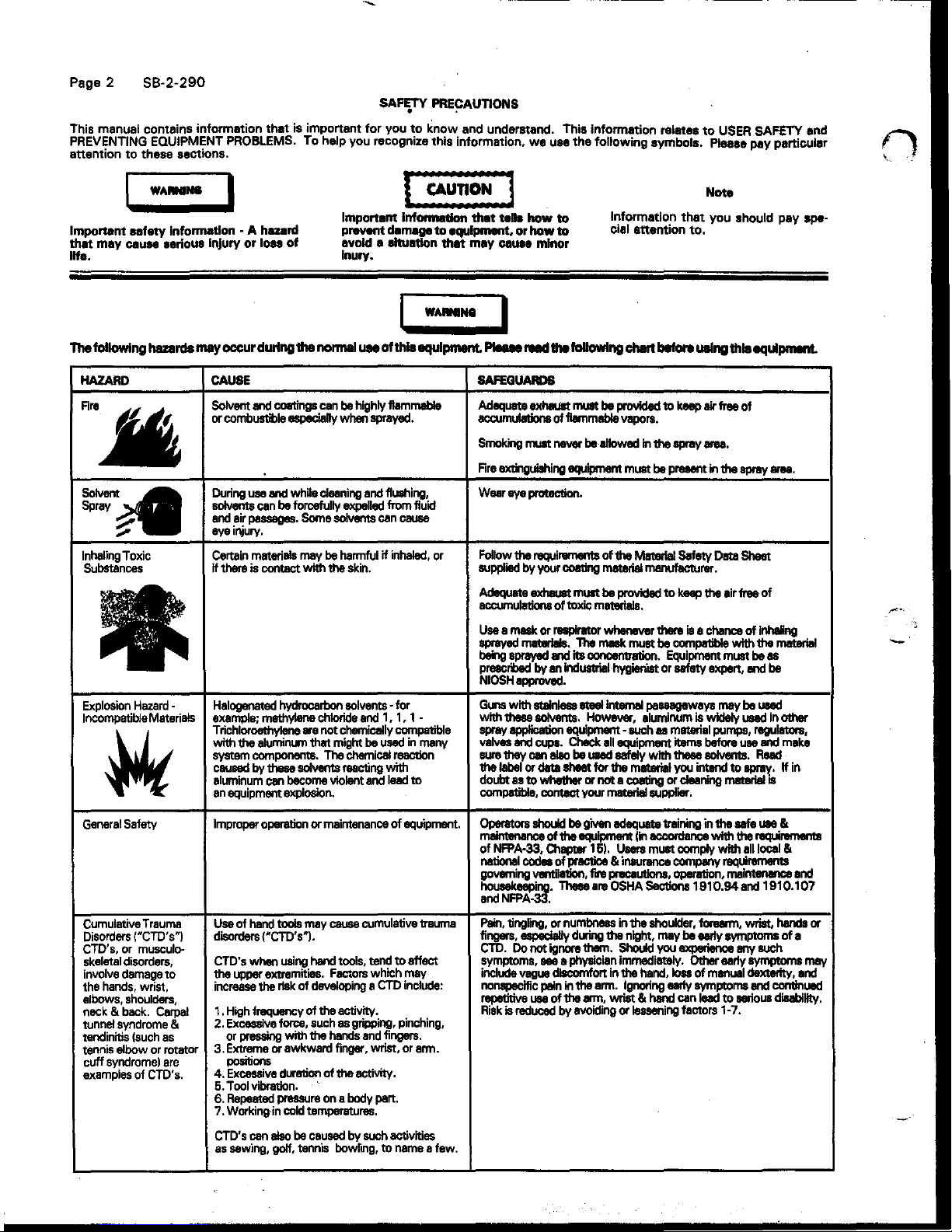

following hazards mayoccurdurlnglhe normal useofthlaequlpmant. PlouereecllltefoiiOwlng

Fire

Inhaling

serious

Toxic

Substances

Explosion

Incompatible

Hazard

Materials

-

~

I

Injury

Solvent end

or

During

solvent8

and

eye

Certain

~

Haloganatod

example;

Trichloroethylene

with the

system

cousod

aluminum

an

haurd

or

loss

combustible

use

end

con

air

passages.

injury.

materials

there

is

contact

mathylene

aluminum

oornponants.

by these

can

equipment

cootlngs

be foroefully

hydrocarbon solvants -for

explosion.

of

con

-'"fly

while

cleoning

Some

moy

with the

chloride

are

not

that might

solvent8

become

I

¥,~~~~:]

lmportom lnfonno1lon

prevent

dem-

avoid a eftulltion that may

lnury.

be

highly

and

expallod

skin.

and

be

chemical

reacting

and

flommable

flushing,

from

can

n

1, 1, 1 -

used

with

lead

when sprayed.

solvents

be

harmful

chemically

The

violent

WANIINII

fluid

cause

inhaled,

compatible

in

many

reaction

to

to

oqu""'*"· or

or

--

caue

how

how

minor

I

Adequate-

accumulations

Smoking

Weer

Follow

supplied

Adequate-

accumulations

Use

sprayed

being

NIOSH

muet

eye

protection.

the raqu;,.,._

by

your

a

maek

or

...-.

sprayed end its

preecribod by

Guns

with these sofvants,

sprey

valves

sure

the_,

doubt

compatible,

approved.

with

Sblinlea

application

and

cupa.

they

con

or

date

as

to whather

contoct your

on

also

to

to

of

flommablevopors.

never

costing

of toxic

rsopirotor

Industrial

equipment-

st.!

Information that

cial

attention to.

chart

before

muet

be provldsd to ltoap

bo

ollowod

in

the

sprey

of

the

Moterial

Sefoty

material-""·

must

bo

provldsd

to

moterials.

whenever

Tho

maek

must

000081

obalioio.

hygienist

stoellntemlil pasaageways

However,

used

for the

or

not

such

all

oqulpmam

safely

a

costing

material

Check

be

ltoap the

there

bo

cornpotlble with the

Equlpmam

or

aafety expert, end be

aluminum

os

material

items

with these

moterial

you

or

cleonlng

supplier.

Note

you

should

pay

ualngthlaoqulpmant.

air

free

of

area.

spreyareo.

Data

Sl*l

air

free

of

Ia

a

chance

of

Inhaling

bo

used

uee

to

11111'1'(·

motorial

boos

used

in-

reguletore,

end

make

Reed

ff

In

IS

must

moy

Ia

widely

pumps,

before

solvenbo.

intand

material

spe-

-

General

Safety

Cumulative

Disorders

CTD's,

skeletal

involve

the

elbows,

neck & back.

tunnalsyndrome &

tendinitis

tennis

cuff

examples

Trauma

("CTD's"l

or

musculo-

disorders,

damage

hands,

wrist,

shoulders,

(such

elbow

syndrome)

of

to

Carpal

as

or

rotator

are

CTO's.

Improper

Use

disorders

the upper extramklas. Factors which

3.

4.

of

hand

CTD's

when

increose

1.

High

flaquency

2.

Excessive

or

pressing

Extreme

positions

ExC800ivo

5.

Tool

vibration.

6.

Repeated

7.

Working·in

CTD's

con

as

sewing,

operation

tools

may

{"CTD's").

ualng

the

risk

of

force,

with the

or

awkward

duration

preeeure

cold

also

be

gotf,

tennis

or

hand

developing a CTD

of

the activity.

such

temperatures.

caused

maintenance

cause

tools,

tend

as

gripping,

hands

and

finger,

wrist,

of

the activity.

on a body

part.

by such activities

bowrmg,

to

of

equipment.

to affect

msy

include:

pinching,

fingers.

or

name

trauma

arm.

a few.

Page 3

SB-2-290

Page 3

CHART 1 AIR CAP

Conventional -JGP

HVLP-

JGPV

No.

on

cap

Part

No.

No. on cap

Port

No.

704

AV-1239-704

46MP

JGHV-1

01-46MP

766

AV-1239·

766

777

31767-777

797

AV-1239-797

CHART 2 FLUID TIP AND

NEEDLE

(300

S.S./Poly)

•Fluid

Tip

ID

No.

on

Fluid

Tip

Drdor

Port

No.

Uoo

With

Gun

ln./mm

..

•AV-1

copper gasket included

with

fluid

tip.

Do

not

use

with

these guns.

PARTS

LIST

Ref. Replacement

Individual

No. Pan No.

Deecrlptlon

Pane Required

1 MBC-368 Retaining

Ring

1

2

See

Chan 1 Air

Cap

1

3

See

Chart 2

Fluid Tip

1

• 4

JGD-14-K10 Gasket Kit (Ki t

of

1 0) (Polyethylene)

1

(not used

with

JGPV gun)

5 JGD-402-1

Baffle and Gasket K it (JGP)

1

JGPV-401-46-50 Baffle and Gasket Kit (JGPV)

•

6.

JGS-72-K10

Gasket Ki t (Kit

of

1 0) (PTFE)

2

• 7

MBD-12-K25

Spring Kit (Kit

of

25)

1

• 8

JGS-431-K25

Air Valve K it (Kit

of

25)

1

•

9.

JGS-26-K25

U Cup Seal Kit (Kit

of

25)

1

*10

JGA-15-K25 Washer Ki t (Kit

of

25)

1

*11 JGA-14-K25

Snap

Ring

Kit (Kit

of

25)

1

12

JGS-449-1 Air Valve Assembly

1

*13•

JGV-463-K3

Packing Kit (Kit

of

3)

1

14

34411-122-K10

Packing Nut Kit (Kit

of

1 0)

1

*15

---

Screw

1

16

JGS-478 Stud & Screw K it (Kit includes

1

3 studs & 5 screws)

17

JGS-477-1 Trigger, Stud & Screw Kit

1

(Kit includes 1 each)

18

JGA-497-1

Fan

Adjustment Assembly

1

*19

---

Retaining

Ring

1

*20•

SSG-8069-K25

0-Ring (Viton) (Kit

of

25)

1

21

JGS-16 Adjusting Screw

1

*22

---

Spring

Pad

(Included

1

with

# 23 and 25)

*23

MBD-19-K10

Spring Kit (Kit

of

1 0)

1

24

---

Bushing

1

25

JGA-4041 Bushing, Spring

Pad

& Knob Kit

1

26

See

Chart 2

Fluid Needle

1

27

---

Gun Body

1

#28

See

Chart 2

Fluid Tip and Needle Set (Not shown)

1

. .

* A quantrty

of

necessary part s

rs

rncluded

rn

MaJor Reparr Kit

KK-4987-2

for

complete

gun

repair .

Keep

on

hand

for

service convenience.

• A

quantity

of

necessary part s is included

in

Minor

Repair

Kit

KK-5034

for

gun repair.

#

Ref.

No.

28

includes

Ref.

Nos.

3 &

26.

AV-1

copper

gasket

also

Included

but not

used

with

JGP/JGPV

guns.

Suffixes-

K10

designates

kits of multiple

parts.

!Example)

JG0-14-K10

is

a kit of 10

gaskets.

Page 4

Page 4

SB-2-290

1

d Detail

Ref.

No.

13-

Two

i

U.S. Patent

No.

5,209

50~ece

packing

covered

by

+Tapered

edge

faces

o~

t .

owards

packing

nut.

Air

Inlet

Nipple

1/4NPS(M)

Note

Gasket not used

with

JGPV-503 HVLP

gun.

Page 5

SB-2-290

Page

5

TROUBLESHOOTING

Condition

Couse

Cornctlon

Heavy

top

or

''

Hom

holes plugged.

Clean.

Ream

with

non-metallic

poim.

bottom

pattern

Obstruction

on

top

or bottom

of

fluid

tip.

Clean.

Cap

and/or

tip

seat

dirty.

Clean.

Heavy right

or

loft side

pattern

Loft or right

side

horn

holes

plugged.

Clean.

Ream

with

non-metallic

poim.

Dirt

on

loft

or

right

side

of

fluid

tip.

Clean.

) (

Remedies

for the top-heavy,

bottom-heavy,

right·heevy

and

left·heavy patterns:

11

Determine

if the obstruction

is

on

the

air

cap or the

fluid

tip.

Do

this by

making

a

test

spray

pattern.

Then,

rotate

the

cap

OlliH1all

turn and apray another

pattern.

If

the

defect

Is

inverted,

obstruction

is

on

the

air

cap.

Clean

the

air

cap

as

previously

Instructed.

21

If

the

defect

is

not

inverted, ~ is

on

the

fluid

tip.

Check

for a

fine

burr

on

the edge

of

the

fluid

tip.

Remove

with #600 wet

or

dry

sand

paper.

3)

Check

for

dried

paint just

inside

the

opaning.

Remove

paint by

washing

with solvent.

Heavy

center

pattern

Ruid

pressure

too

high

for

atomization

Balance

air

and

fluid

pressure

.

•

air

(pressure

feed).

lncreaea

sprey

pattern

width

with

spreader

adjustment

valve.

Motorial

flow

axcaeds

air

cap's

capacity.

Thin

or

lower

fluid

flow.

Spreader

adjustment

valva

set

too low.

Adjust.

Atomizing

pressure

too

low.

Increase

pressure.

Meteriai

too thick.

Thin

to

proper

consistency.

Spl~

spray

pattern

I

Atomization

air

pressure

too

high.

Reduce

et

tranaformer or

gun.

Fluid

pressure

too

low.

1..,.._

fluid

prasaure

(increaees

gun

hondlngspeed).

Spreader

adjusting

valve

set

too

high.

Adjust.

Jerky or fluttering

spray

*Loosa

or

damaged

fluid

tip/saat.

Tighten

or

replace.

fitlllll'

Motorial

level

too low.

Re!IU.

Obstruction

in

fluid

peaeago.

Backfluah

with solvent.

Dry

orlooea

fluid

needle

packing

nut.

Lubricete

or

tighten.

Unable

to get

round

spray

Spreeder

adjustment

screw

not eesting

propeo1y.

Clean

or

replace.

Air

cap

retaining

ring

loose.

Tighten.

Will not

spray

No

air

pressure

at

gll'l.

Check

air

supply

and

air

lines.

Fluid

needle

adjusting

screw

not open

enough.

Opan

fluid

naedla

adjusting

screw.

Starved

sprey

pattern

Inadequate

meteriai

flow.

Back

fluid

adjusting

screw

out to first

thread

or

increasa

fluid

pr-.ra

et tank.

Excessiva

overspray

Too

much

atomization

air

pr-.ra

Reduce

pressure.

Gun

too far

from

work

surface.

Adjust to

proper

distance.

Improper

stroking

(arcing,

gun

motion too faa!).

Move at modorete pace,

parallel

to

work

surface.

Exceeaive

fog

Too

much,

or

too

faat-<lrying

thinner.

Remix

property.

Too

much

atomization

air

pressure.

Reduce

pressure.

Dry

Spray

Air

pressure

too

high.

Reduce

air

pressure.

Gun

tip too far from work

surface.

Adjust to

proper

distance.

Gun

motion

too fast.

Slowdown.

Gun

out

of

adjustment

Adjust.

Fluid

leaking

from

packing

nut

Packing

nut

loose.

Tighten, do not

bind

needle.

Packing

worn

or

dry

Replace

or

lubricate.

Ruid

leaking

or

dripping

from

Packing

nut too tight Adjust

front

of

prasaura

feed

gun

Dry

packing.

Lubricete.

Fluid

tip

or

needle

worn

or

damaged.

Rlaplace

tip &

needle

with

lapped

seta.

Foreign

matter

in

tip.

Clean.

Fluid

needle

spring broken.

Rlaplace.

Wrong

size

needle

or tip.

Rlaplace.

*Most

common

problem.

Page 6

Page

6

58·2·290

TROUBLESHOOTING

Condition Cause

Runs

and

sags

Thin,

sandy

drying

coarse

before

finish

it

flows out

(continued)

Too

much

Material

G1.11

tilted

too

stow.

Gun

too

Too

much

Improper

material

too thin.

on

an

far

from

air

pressure.

thinner

angle,

surface.

being

flow.

or

gun

used.

motion

Conectlon

Adjust gun

Mix

Hold

proper

Check

Aaduca

Follow paint manufacnnr'amixing instructions.

or

reduce

or

apply

fluid

light coatB.

Normally

and

property

gun at right angle to

gun technique

distance.

air,_...

pr8SSUI8.

work

approx.

check

and adapt

to

8".

spray-·

Thick, dimpled finish "orange

peel".

ACCESSORIES

P-H-5516

AdJusting Valve

Air

Cleaning Brushea

~

Enabl8l

user

to

and

rwcluce

thep.ldtallorlowprea-

...

spraying.

WR-103

control

air usage at

Wrench

~

Contains

all

hoM and

on

or

with

neceuary

nut

sizes

gun.

lip,

UNCI

Gun

Air

Improper

Material not

Surface

42884-214-KS3/8"

42884-215-K10518"

/

These brulhH are help.

lulind81ningthr9adsand

recesses

of

gun

body.

Vs-531 Low

Preaaure

Strainers

.@

The

VS-531

aunt

videla

ping loralgn

...

l.ow Pres-

Fluid

Slrainll"

final

fillet

partiCles

_.._.

pro-

fat~

too

close

to

surface.

pressure

too low.

thinner

being

properly

rough,

oily,

HD-503

SolventSaver,.

Hoee/Gun Cleaner

~

2

Qt

HoM/Gun

Ultd

to

clean N

of

hoM,

fluid

ways

of

gun & other

equipment

QMGZ

SolventSaver"'

HoeeJGun

B

2

Gallon

~anlzed

uaedto

Of

hose and

1n

18081

of

the

used.

mixad.

dirty.

Cleaner

lnalde

P.U81Qf:

paJnt

cia.-

tank

the=

matet1

pas-

gun •

Check

distance.

Too

much rnB*ial

lncreaao

air

pressure

paint manufacturer's mixing Instructions.

clean

and

SDray

liSL·10

bollte)

JGA·158-K10

Spring

Clip

Follow

Follow paint manufacturer's mixing

Property

0

Jolna

any

single

08VH-alr~

eat

version

MSA-1 retaining ring.

:r.---

--

-·

QuiCk

High

H~

NPS(F)

~

1/oi."

NPT(M)

w:-

Ill·

M ·318 or

...

DIID0111teet

HVLPGuno(~

Aow

Belland

Approved

Ring

~

~

II<"

NPT(MI

~

HC-1186

1/.i•NPT(M)

CompaltJie with all paint

mattrlaJs: contlllns no

llllconaorpetrOieumde-

tlllatet

to contaminate

point.

for

ypa

Normally

Gun

coarsely

or

reduce

prepare.

Lube

(2 oz.

approx.

8".

atomized.

fluid

AdJusting Valve

pressure.

Instructions.

HAV-5000R

HAV·5111

(HAV-!501

SHOWN)

~

HAV-600

doal

not

gage.

Uee

usage

at

~

-----

-

have

gun

to

.

pttUUre

control

air

-(818)2qt.

Food

Cup

grHter

control

presaure.

de-

over

Willi

Rogulelor

---~

Provida

gree

of

cup

fluid

JQA-4035·K5

Packing)·

place

of

(2 piece packing). hoses over work, twisting line

DeVIblu

required,

ASSISTANCE

CALLS,

U.S./Canada

MAUMEE, OH

DeVIIblu

check

the

one

of

the

FREE

1·800-445·3988

U.S.

Customer

Maumee, OH

(3

May

JGV-463·K3

lndutt~al

write

SEE

Automotive

Yellow

following

Piece

be used in

Spray Equipment • DeVilbiss has authorized distributors

or

call one

OR

THE DISRIBUTOR NEAREAT YOU, CALL TOLL

LISTING BELOW.

Sales

& Customer Service Office Address Telephone No.

43637

Pages under

Service

43537

JGA-444

combines the fluid and air hoses

gun handle preventing dragging

improving overall gun handling.

of

the

Refinishing-

DeVilbiss Distribution Canters

(U.S.A. & Canada).

Office

Fluid Tube • This

following

DeVilbiss has authorized distributors

"Automobile

IIEIIILB&

An

Company

at

Circle

WARRANTY

This

product

Warranty.

throughout

or

FREE

SEE

12198

Sales Offices nearest you.

1·8fl0.338-4448

throughout

LISTING BELOW.

tube

and

DeVilbiss Distribution Centers

1724

Indian Wood Circle

Body Shop Equipment and Supplies."

or

FOR

1724

Sales Offices nearest you.

LOCAL CALLS,

Address

Indian

Wood

is

covered

See

SB-1.000

the

the

world.

If

further

FOR

TECHNICAL ASSISTANCE,

C>Copynghl1998, OoVIIblss

by

which

wo~d.

If

further assistance is

(U.S.A. & Canada).

Toll Free Fax No.1-8fl0.33f!..0131

For equipment. parts and service.

asaistance

Ganerallnquiry

Toll Free Fax No.

Telephone

....

DeVilbiss' 1 Year

is

available

FOR

14191

is

required.

14191

upon

TECHNICAL

FOR

LOCAL

891·8200

write

CAU

No.

891·8100

1·800·446-6643

.

Printed

··

Limited

request.

or

call

TOLL

In

U.S.A.

Loading...

Loading...